Page 1

Centrifugal Cabinet Fans

Model BDF

Belt Drive Duct Fan

July

2007

Page 2

BDF

Belt Drive Duct Fans

Greenheck’s Belt Drive Duct Fans, Model BDF, provide the industry’s best performance and durability. Model

BDF is carefully engineered for efficiency and reliability in supply, exhaust, and return air applications. The BDF

is designed specifically for low sound levels in ducted applications.

Performance ranges from 400 to 17,000 cfm (• 680 to 28,883 m3/h)

with static pressure up to 3.0 in. wg (745 Pa).

Available in seven sizes ranging from 80 to 200.•

Each fan size has been tested in our AMCA Accredited •

Laboratory, and all models are licensed to bear the AMCA air

performance seal. Performance as cataloged is assured.

Removable access panels provide easy •

access for service.

Rugged drive frame configuration.•

Vibration isolation, assures long life and •

quiet operation.

UL Listed.•

Greenheck subjects these products to •

extensive life testing, assuring the fans will

provide many years of reliable performance.

Greenheck Fan Corporation certifies that the model

BDF fans shown herein are licensed to bear the

AMCA Seal. The ratings shown are based on tests

and procedures performed in accordance with

AMCA Publication 211 and Publication 311 and

comply with the requirements of AMCA Certified

Ratings Program. The certified ratings for model BDF

are shown on pages 5 to 11.

Quick Delivery and Quick Build Programs

Greenheck’s QB (Quick Build) program provides custom built to order

products that ship in one, three, five, or ten days. This allows the flexibility of

knowing that your fan can be made to order and shipped in as little as one

day. All BDF sizes are available in three, five or ten days through our Quick

Build program.

Many products are available from our Quick Delivery (QD) program. The

QD program provides same day shipment of Greenheck product from our

strategically located warehouses throughout the world. These stock products

can be ordered over the internet by visiting www.greenheck.com/quick

Leading Edge Technical Support

BDF model is listed for electrical

(UL 705) with TEFC motor only.

File no. E40001.

When product and IOM (Installation, Operation and Maintenance Manual)

information is needed, our products are supported by the industry’s best product

literature, electronic media, and Computer Aided Product Selection (CAPS)

program. You’ll also find this information on our website at www.greenheck.com

Our national and international representative organization provides personal

service and expertise. To locate your nearest Greenheck representative, call

2

715-359-6171 or visit our website at www.greenheck.com

Page 3

Standard Construction Features

F

C

G

B

2

(51)

K*

D

E

H

Fan

Access

Panel

Filter Box

Access

Panel

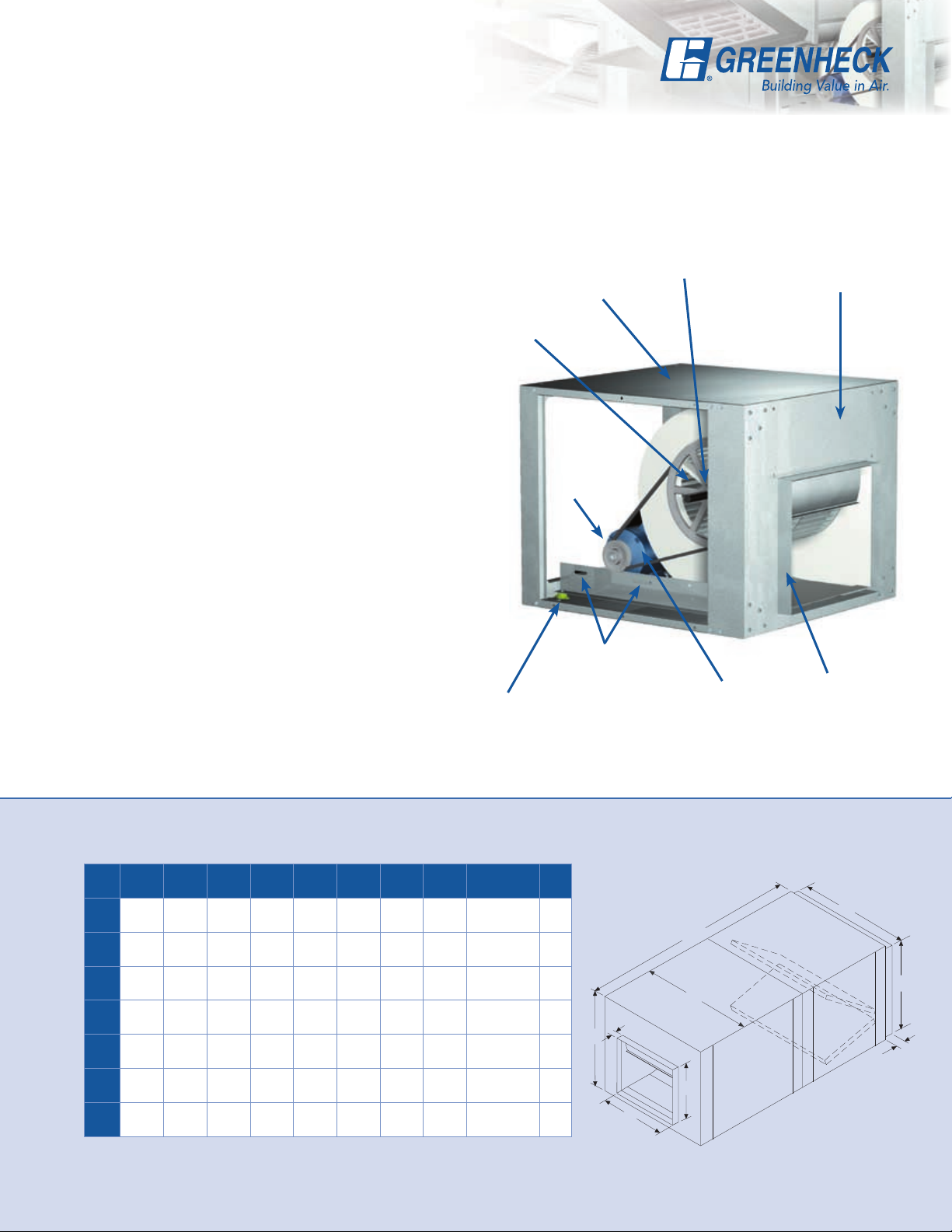

Vibration Isolation - Internal isolators support the

entire drive assembly, wheel, and scroll to provide

long life and quiet operation.

Housing - The fan cabinet is constructed of

galvanized steel for corrosion resistance and

maintenance free operation.

Access Panels - Two side panels are removable for

inspection or servicing. Removal of either side panel,

gives easy access to all the fans internal parts.

Bearings - Permanently sealed, pillow block ball

bearings are selected for a minimum L10 life in excess

of 100,000 hours (L50 average life of 500,000 hours)

at maximum catalogued operating conditions.

Duct Collars - Inlet and outlet duct collars are

provided for easy duct connections.

Motor - Ball bearing motors are carefully matched to

the fan load and receive the cooling benefits of being

in the airstream for increased motor life.

Wheel - Forward curved, centrifugal, galvanized

steel wheel is utilized to generate high efficiency

and minimal sound. Each wheel is statically and

dynamically balanced for long life and quiet operation.

Multi Discharge Positions - Where space between

duct and ceiling is a premium, bottom horizontal and

top horizontal discharge positions are available for

easy installation.

Nameplate - Permanent stamped aluminum

nameplate for model and serial identification.

Bearings

Housing

Nameplate

Wheel

Drive

Assembly

Drive Frame - Heavy duty frame supports motor,

scroll, and wheel to provide long life and durability.

Drive Assembly - Belts, pulleys and keys are sized for

a minimum of 150% of driven horsepower. Machined

cast iron pulleys are factory set to the required RPM

Vibration Isolation

Drive Frame

Motor

Duct Collars

and adjustable for final system balancing. Belts are

static free and oil resistant.

Filter Box Dimensions

BDF

*K B C D E F G H Filter Size Qty.

Size

3

1

7

3

11

3

7

1

1

1

1

1

/2

1

1

1

/2

1

1

/2

16 x 20

(406 x 508)

20 x 25

(508 x 635)

20 x 20

(508 x 508)

12 x 25

(533 x 635)

16 x 20

(406 x 508)

20 x 25

(508 x 635)

16 x 25

(406 x 635)

2

2

2

4

8

6

12

3

49

/4

18

/2

15

/8

15

/16

12

/16

9

/4

8

80

(1264)

90

(1394)

100

(1318)

120

(1614)

150

(1576)

180

(1915)

200

(2165)

*K is length of fan and filter box combined. All dimensions in inches (mm).

63

62

54

51

75

85

(470)

(403)

(386)

(322)

(248)

7

1

3

1

/8

21

/4

18

/4

(476)

20

(527)

22

(578)

27

(705)

31

(606)

39

3

/4

3

/4

3

/4

3

/4

3

/4

18

(464)

19

(502)

24

(613)

28

(727)

37

(953)

48

(1222)

(540)

7

3

/8

22

/4

(578)

9

1

/16

27

/4

(692)

1

5

/16

32

/8

(829)

3

3

/8

41

/4

(1060)

1

1

/4

49

/4

(1251)

(1010)

7

/4

15

/8

12

(403)

(311)

3

7

/4

17

/8

(454)

19

(505)

23

(604)

27

(708)

36

(914)

13

(349)

7

16

/8

(406)

7

/8

19

(486)

7

/8

22

(572)

23

(587)

1

/8

5

/8

1

/2

1

/8

/8

10

11

13

16

18

25

(25)

1

/2

(25)

7

/8

(25)

3

/8

(38)

3

/8

(25)

7

/8

(38)

1

/4

(38)

(225)

1

/4

(267)

3

/4

(302)

(340)

1

/8

(416)

1

/2

(479)

1

/8

(641)

Page 4

Options & Accessories

C

C

A

A

C

Access

Panel

Access

Panel

Filter Box

A

Sloped Filter Boxes - The double-vee configuration

constructed of galvanized steel. Filters are available

in 1 or 2-inch pleated

disposable media or

permanent washable

aluminum mesh. Side

access panels are

standard for easy

maintenance.

Multi Discharge

Positions - BDF fans have been designed for

horizontal mounting and are standard with bottom

horizontal discharge. Optional top horizontal

discharge is also available.

Insulated Housing - For noise reduction and

condensation control, the interior of fan housing and

filter box can be lined with a fiberglass duct liner.

The duct liner can be utilized to reduce radiated

noise from fan housings. It is recommended for

applications when fans are placed in acoustically

sensitive locations. The duct liner also reduces the

noise radiation from the inlet and outlet of the fan.

The accompanying table depicts the reduction that

can be obtained in each octave band.

Approximate (%) Sound Attenuation

Octave

Band

*Lined

Housing

*Lined Housing shows the reduction that can be obtained in each

octave band.

1 2 3 4 5 6 7 8 Sones

-3 -2 -3 -3 -5 -5 -5 -4 13%

Vibration Isolators - Base and hanging isolator kits

are available with either neoprene or spring isolators.

Kits range in size to support either the weight of

Bottom Horizontal (Standard)

Disconnect Switches - A

wide selection of NEMA rated

switches are available for

positive electrical shutoff and

safety. This includes general,

dust-tight, rainproof, and

corrosion-resistant.

Wiring Pigtail - Allows direct hook-up to the power

Top Horizontal (Optional)

the fan alone or the weight of the fan with filter and

mixing box combinations. Kits are for horizontal

mounting and include mounting brackets and

hardware. Knockouts are provided in the fan cabinet

for ease of installation. (Hanging rods supplied by

others.)

Hanging

Spring

supply externally eliminating field wiring at the fan.

Coatings - A wide variety of protective or decorative

coatings are available. Consult Greenheck’s

Performance Coatings for Commercial & Industrial

Fans brochure and our Product Application Guide

FA/110/04R, Performance Coatings for Ventilation

Products for in-depth information.

Typical Installations

All BDF fans have been designed to be

mounted horizontally. For ease of installation,

knockouts are provided at each location where

mounting brackets are shown. Universally

adjustable brackets are available to mount the

fan in hanging or base mounted positions.

In order to assure proper fan performance,

caution must be exercised in fan placement

and connection. Obstructions, transitions,

poorly designed elbows, etc., can cause

reduced performance, excessive noise, and

increase mechanical stress. For performance

to be as published, the system must provide

uniform and stable airflow into the fan.

4

4

Standing

Spring

Hanging Neoprene

BDF Size A C

80

90

100

120

150

180

200

All dimensions in inches (mm).

Neoprene

3

/4

20

(527)

3

21

/4

(552)

3

23

/4

(603)

1

30

/2

(775)

32

(813)

3

37

/8

(949)

3

47

/8

(1203)

11

22

/16

(576)

5

25

/8

(651)

1

27

/8

(689)

5

31

/8

(803)

35

(889)

44

(1118)

1

51

/2

(1308)

Page 5

D

o

n

o

t

s

e

l

e

c

t

t

o

t

h

e

l

e

f

t

o

f

t

h

i

s

s

y

s

t

e

m

c

u

r

v

e

BDF-80 — Belt Drive

3

/16 (386)

231/4 (591)

15

2

181/2 (470)

157/8

(51)

5

3

/

8

(137)

12

(322)

11

/16

(403)

7

8

/8

(226)

3

/4 (248)

9

1

4

/4 (108)

1 (25)

Damper Size (Outlet Side) = 93/4 x 87/8 (248 x 225)

Housing Thickness = 20 ga.

^Approximate Unit Weight = 70 lb. (32 kg)

All dimensions in inches (millimeters).

^Weight shown is largest cataloged Open Drip Proof motor.

Model

Number

Fan

CFM

0.125 0.25 0.375 0.5 0.625 0.75 1 1.25 1.5 1.75

Static Pressure in Inches wg

BDF-80 300 RPM 511

BHP 0.01

Sones 4.6

400 RPM 546 717

BHP 0.02 0.03

AVERAGE OUTLET VELOCITY = CFM/0.654

MAXIMUM RPM = 1885

TIP SPEED = RPM x 2.356

MAXIMUM MOTOR FRAME SIZE = 56

Sones 4.4 4.7

500 RPM 610 745 881

BHP 0.03 0.04 0.05

Sones 4.2 5.0 6.1

600 RPM 691 791 908 1022 1126

BHP 0.05 0.06 0.08 0.09 0.11

Sones 4.9 5.6 6.6 7.2 7.9

700 RPM 772 857 949 1051 1149 1244

BHP 0.08 0.09 0.11 0.12 0.13 0.15

Sones 5.8 6.4 7.1 7.6 8.4 9.5

800 RPM 855 937 1006 1092 1181 1269 1435

BHP 0.11 0.13 0.14 0.16 0.17 0.19 0.23

Sones 6.7 7.4 7.7 8.1 9.0 10.1 12.3

900 RPM 939 1019 1084 1148 1224 1301 1457 1605 1738

BHP 0.16 0.18 0.19 0.21 0.23 0.24 0.27 0.33 0.38

Sones 7.7 8.3 8.6 9.0 9.7 10.8 12.9 15.2 15.5

1000 RPM 1024 1100 1165 1220 1280 1348 1490 1628 1762 1884

BHP 0.21 0.23 0.25 0.27 0.28 0.31 0.34 0.38 0.44 0.50

Sones 9.0 9.4 9.7 10.0 10.8 11.7 13.7 15.5 15.8 16.2

1100 RPM 1111 1183 1246 1300 1350 1405 1526 1660 1784

BHP 0.28 0.30 0.32 0.34 0.36 0.38 0.42 0.46 0.50

Sones 10.3 10.8 11.1 11.4 12.0 12.6 14.6 15.9 16.2

1200 RPM 1198 1266 1327 1382 1430 1475 1582

1300 RPM 1287 1351 1409

Performance certified is for installation type D: Ducted inlet, Ducted outlet. Power rating (bhp/kW) does not include transmission losses. Performance ratings do

not include the effects of appurtenances (accessories).

The sound ratings shown are loudness values in fan sones at 5 ft. (1.5m) from the test inlet duct in a hemispherical free field calculated per AMCA Standard 301.

Values shown are for installation type D: ducted inlet, ducted outlet. Ratings do not include the effects of duct end connection.

BHP 0.36 0.38 0.40 0.43 0.45 0.47 0.51

Sones 11.9 12.5 12.7 12.7 13.2 13.8 15.7

BHP 0.45 0.48 0.50

Sones 13.5 14.0 13.9

5

Page 6

D

o

n

o

t

s

e

l

e

c

t

t

o

t

h

e

l

e

f

t

o

f

t

h

is

s

ys

t

e

m

c

u

r

v

e

BDF-90 — Belt Drive

1

/4 (464)

241/4 (616)

18

2

211/4 (540)

(51)

6

3

/

4

3

18

/4

(171)

15

(403)

7

/8

(476)

7

/8

8

12

1

/4 (311)

(226)

1

/2 (114)

4

1 (25)

Damper Size (Outlet Side) = 121/4 x 101/2 (311 x 267)

Housing Thickness = 20 ga.

^Approximate Unit Weight = 91 lb. (41 kg)

All dimensions in inches (millimeters).

^Weight shown is largest cataloged Open Drip Proof motor.

Model

Number

Fan

CFM

0.125 0.25 0.375 0.5 0.625 0.75 1 1.25 1.5 1.75

Static Pressure in Inches wg

BDF-90 800 RPM 465 584 689

BHP 0.05 0.07 0.09

Sones 3.9 4.1 5.5

970 RPM 514 619 713 802

BHP 0.08 0.10 0.12 0.15

AVERAGE OUTLET VELOCITY = CFM/0.899

MAXIMUM RPM = 1506

TIP SPEED = RPM x 2.602

MAXIMUM MOTOR FRAME SIZE = 143T

Sones 4.5 5.0 6.4 8.2

1140 RPM 569 660 748 827 905 975

BHP 0.11 0.14 0.17 0.20 0.23 0.26

Sones 5.2 6.0 7.5 8.8 9.6 10.7

1310 RPM 626 708 787 863 932 1000 1125

BHP 0.16 0.19 0.23 0.26 0.29 0.33 0.40

Sones 6.6 7.3 8.9 9.4 10.2 11.2 13.5

1480 RPM 684 761 830 901 968 1030 1150 1260

BHP 0.22 0.25 0.29 0.33 0.37 0.41 0.49 0.57

Sones 8.0 8.9 9.6 10.2 10.9 11.8 13.9 15.9

1650 RPM 744 817 881 943 1006 1066 1178 1285 1385

BHP 0.30 0.34 0.38 0.42 0.46 0.50 0.59 0.68 0.77

Sones 9.6 10.1 10.5 11.1 11.8 12.6 14.5 16.5 16.9

1820 RPM 805 874 934 991 1048 1106 1213 1312 1409 1501

BHP 0.39 0.44 0.47 0.52 0.57 0.61 0.71 0.80 0.90 1.00

Sones 11.3 11.2 11.5 12.2 12.8 13.6 15.3 17.0 17.4 17.5

1990 RPM 872 932 990 1044 1095 1147 1250 1347 1436

BHP 0.51 0.56 0.60 0.64 0.69 0.74 0.84 0.95 1.04

Sones 12.4 12.5 12.8 13.4 14.1 14.7 16.2 17.6 18.0

2160 RPM 940 991 1047 1098 1147 1193 1291

BHP 0.64 0.69 0.74 0.78 0.83 0.89 1.00

Sones 13.8 14.0 14.3 14.8 15.4 16.0 17.3

2330 RPM 1008 1051 1105 1154 1200

BHP 0.80 0.85 0.91 0.95 1.00

Sones 15.4 15.7 16.0 16.3 16.8

2500 RPM 1077 1112

Performance certified is for installation type D: Ducted inlet, Ducted outlet. Power rating (bhp/kW) does not include transmission losses. Performance ratings do

not include the effects of appurtenances (accessories).

The sound ratings shown are loudness values in fan sones at 5 ft. (1.5m) from the test inlet duct in a hemispherical free field calculated per AMCA Standard 301.

6

Values shown are for installation type D: ducted inlet, ducted outlet. Ratings do not include the effects of duct end connection.

BHP 0.98 1.02

Sones 17.3 17.4

Page 7

D

o

n

o

t

s

e

l

e

c

t

t

o

t

h

e

l

e

f

t

o

f

t

h

i

s

s

y

s

t

e

m

c

u

r

v

e

BDF-100 — Belt Drive

3

/4 (502)

261/4 (667)

19

2

223/4 (578)

(51)

7

3

/

8

3

20

/4

(187)

17

(454)

7

/8

(527)

7

11

/8

(302)

13

3

/4 (349)

1

4

/2 (114)

1 (25)

Damper Size (Outlet Side) = 133/4 x 117/8 (349 x 302)

Housing Thickness = 20 ga.

^Approximate Unit Weight = 106 lb. (48 kg)

All dimensions in inches (millimeters).

^Weight shown is largest cataloged Open Drip Proof motor.

Model

Number

Fan

CFM

0.125 0.25 0.375 0.5 0.625 0.75 1 1.25 1.5 1.75

Static Pressure in Inches wg

BDF-100 800 RPM 380 501

BHP 0.04 0.06

Sones 3.6 4.8

1000 RPM 413 521 615

BHP 0.06 0.09 0.12

AVERAGE OUTLET VELOCITY = CFM/1.05

MAXIMUM RPM = 1315

TIP SPEED = RPM x 2.913

MAXIMUM MOTOR FRAME SIZE = 143T

Sones 4.0 5.0 5.9

1200 RPM 453 548 635 715 785

BHP 0.09 0.13 0.16 0.19 0.23

Sones 4.8 5.4 6.2 6.8 7.3

1400 RPM 498 581 660 735 804 869

BHP 0.14 0.17 0.21 0.25 0.29 0.33

Sones 6.0 6.1 6.7 7.4 7.9 8.6

1600 RPM 548 620 691 760 825 887 1002 1104

BHP 0.19 0.24 0.27 0.32 0.37 0.41 0.50 0.58

Sones 7.6 7.4 7.4 8.1 8.7 9.7 10.9 12.5

1800 RPM 605 662 728 791 851 909 1020 1121 1212

BHP 0.27 0.31 0.36 0.40 0.45 0.50 0.60 0.70 0.79

Sones 9.7 8.6 8.5 8.9 9.8 10.6 11.7 13.3 14.1

2000 RPM 666 710 768 826 882 937 1041 1139 1231 1314

BHP 0.37 0.40 0.45 0.50 0.55 0.61 0.72 0.83 0.94 1.05

Sones 10.9 9.9 9.7 10.2 11.2 11.6 12.6 13.9 14.9 15.9

2200 RPM 728 760 810 864 917 968 1065 1160

BHP 0.49 0.51 0.56 0.63 0.68 0.73 0.86 0.98

Sones 12.2 11.4 11.1 11.7 12.3 12.6 13.5 14.7

2400 RPM 789 812 857 906 954 1002 1096

BHP 0.63 0.65 0.69 0.76 0.83 0.88 1.01

Sones 13.6 13.1 12.9 13.3 13.5 13.8 14.6

2600 RPM 851 872 907 948 995

BHP 0.80 0.82 0.85 0.91 0.99

Sones 15.1 14.7 14.7 14.6 14.9

2800 RPM 914 933 957

Performance certified is for installation type D: Ducted inlet, Ducted outlet. Power rating (bhp/kW) does not include transmission losses. Performance ratings do

not include the effects of appurtenances (accessories).

The sound ratings shown are loudness values in fan sones at 5 ft. (1.5m) from the test inlet duct in a hemispherical free field calculated per AMCA Standard 301.

Values shown are for installation type D: ducted inlet, ducted outlet. Ratings do not include the effects of duct end connection.

BHP 0.99 1.01 1.04

Sones 16.6 16.4 16.3

7

Page 8

D

o

n

o

t

s

e

l

e

c

t

t

o

t

h

e

l

e

f

t

o

f

t

h

i

s

s

y

st

e

m

c

u

r

v

e

BDF-120 — Belt Drive

1

/8 (613)

33 (838)

24

2

271/4 (692)

(51)

7

7

/

8

3

/4

22

(200)

19

(505)

7

/8

(578)

3

13

/8

(340)

16 (406)

5

/8 (143)

5

1 (25)

Damper Size (Outlet Side) = 16 x 133/8 (406 x 340)

Housing Thickness = 20 ga.

^Approximate Unit Weight = 142 lb. (64 kg)

All dimensions in inches (millimeters).

^Weight shown is largest cataloged Open Drip Proof motor.

Model

Number

Fan

CFM

0.125 0.25 0.375 0.5 0.625 0.75 1 1.25 1.5 1.75

Static Pressure in Inches wg

BDF-120 1000 RPM 313 420

BHP 0.05 0.08

Sones 3.0 4.2

1300 RPM 338 437 518 593

BHP 0.07 0.11 0.15 0.20

AVERAGE OUTLET VELOCITY = CFM/1.45

MAXIMUM RPM = 1119

TIP SPEED = RPM x 3.436

MAXIMUM MOTOR FRAME SIZE = 182T

Sones 3.3 5.1 5.6 5.6

1600 RPM 370 456 535 604 666 726

BHP 0.12 0.16 0.21 0.26 0.31 0.37

Sones 4.3 6.3 6.2 6.3 7.1 8.4

1900 RPM 408 483 554 621 680 737 839

BHP 0.18 0.23 0.28 0.34 0.39 0.45 0.58

Sones 5.8 7.0 7.0 7.1 8.0 9.2 12.5

2200 RPM 451 515 580 640 699 753 851 939

BHP 0.26 0.31 0.37 0.43 0.50 0.56 0.70 0.84

Sones 7.7 7.9 8.0 8.1 8.9 10.0 12.9 13.2

2500 RPM 504 554 608 666 719 771 866 953 1033 1110

BHP 0.37 0.42 0.48 0.55 0.62 0.69 0.84 1.00 1.16 1.33

Sones 9.4 9.6 9.0 9.2 9.9 11.0 13.3 13.6 13.9 14.1

2800 RPM 561 592 645 694 745 793 885 969 1047

BHP 0.53 0.55 0.62 0.70 0.77 0.85 1.02 1.18 1.35

Sones 11.0 11.9 10.6 10.2 11.0 12.0 13.8 14.2 14.5

3100 RPM 619 635 683 727 773 819 904 988

BHP 0.71 0.72 0.79 0.87 0.95 1.04 1.20 1.41

Sones 13.2 13.2 12.5 11.7 12.1 13.2 14.3 14.8

3400 RPM 677 689 721 766 804 847 930

BHP 0.94 0.94 0.99 1.07 1.16 1.26 1.44

Sones 14.7 14.8 14.1 13.6 13.7 14.3 15.1

3700 RPM 737 744 761 803 844 877

BHP 1.21 1.21 1.22 1.32 1.41 1.50

Sones 16.6 16.6 16.7 15.3 15.6 15.7

4000 RPM 796 802 814

Performance certified is for installation type D: Ducted inlet, Ducted outlet. Power rating (bhp/kW) does not include transmission losses. Performance ratings do

not include the effects of appurtenances (accessories).

The sound ratings shown are loudness values in fan sones at 5 ft. (1.5m) from the test inlet duct in a hemispherical free field calculated per AMCA Standard 301.

8

Values shown are for installation type D: ducted inlet, ducted outlet. Ratings do not include the effects of duct end connection.

BHP 1.52 1.53 1.54

Sones 18.6 18.6 18.8

Page 9

BDF-150 — Belt Drive

5

/8 (727)

343/4 (883)

28

2

325/8 (829)

(51)

9

7

/

8

3

27

/4

(251)

23

(607)

7

/8

(705)

3

16

/8

19

1

/8 (486)

(416)

3

6

/4 (171)

1

1

/2 (38)

Damper Size (Outlet Side) = 191/8 x 163/8 (486 x 416)

Housing Thickness = 20 ga.

^Approximate Unit Weight = 221 lb. (100 kg)

All dimensions in inches (millimeters).

^Weight shown is largest cataloged Open Drip Proof motor.

Model

Number

Fan

CFM

0.125 0.25 0.5 0.75 1 1.25 1.5 1.75 2 2.25

Static Pressure in Inches wg

BDF-150 2500 RPM 374 406 517

BHP 0.27 0.29 0.42

Sones 6.6 7.0 9.0

2830 RPM 411 444 527 622

BHP 0.37 0.41 0.53 0.68

AVERAGE OUTLET VELOCITY = CFM/2.05

MAXIMUM RPM = 1071

TIP SPEED = RPM x 3.927

MAXIMUM MOTOR FRAME SIZE = 184T

Sones 8.0 8.6 9.6 13.1

3160 RPM 449 483 544 637 714

BHP 0.50 0.56 0.65 0.82 1.00

Sones 9.6 9.7 10.5 13.5 16.0

3490 RPM 488 523 569 646 728 799

BHP 0.65 0.73 0.80 0.98 1.17 1.37

Sones 11.0 11.2 11.6 13.6 16.5 19.1

3820 RPM 528 561 607 662 741 810 875

BHP 0.84 0.93 1.03 1.16 1.37 1.58 1.80

Sones 12.6 13.0 13.2 14.3 17.0 19.3 20

4150 RPM 570 598 645 685 749 826 886 945

BHP 1.07 1.16 1.29 1.37 1.58 1.81 2.04 2.29

Sones 14.5 14.8 15.0 15.6 17.4 19.6 20 21

4480 RPM 611 637 685 720 770 833 902 957 1010 1071

BHP 1.33 1.42 1.59 1.67 1.84 2.08 2.32 2.57 2.83 3.15

Sones 16.3 16.5 17.1 17.5 18.3 19.9 21 22 22 23

4810 RPM 653 675 724 758 792 847 911 973

BHP 1.63 1.73 1.93 2.03 2.13 2.38 2.64 2.89

Sones 18.0 18.2 19.1 19.9 20 20 21 22

5140 RPM 695 715 763 797 827 869 919

BHP 1.97 2.07 2.32 2.44 2.53 2.72 2.97

Sones 19.8 20 21 22 22 21 22

5470 RPM 737 756 801 836 866 893

BHP 2.36 2.47 2.72 2.89 3.00 3.10

Sones 22 22 23 24 24 23

5800 RPM 780 797

BHP 2.80 2.91

Sones 24 24

Performance certified is for installation type D: Ducted inlet, Ducted outlet. Power rating (bhp/kW) does not include transmission losses. Performance ratings do

not include the effects of appurtenances (accessories).

The sound ratings shown are loudness values in fan sones at 5 ft. (1.5m) from the test inlet duct in a hemispherical free field calculated per AMCA Standard 301.

Values shown are for installation type D: ducted inlet, ducted outlet. Ratings do not include the effects of duct end connection.

9

Page 10

D

o

n

ot

s

e

l

e

c

t

t

o

t

h

e

l

e

f

t

o

f

t

h

i

s

s

y

s

t

e

m

c

u

r

v

e

BDF-180 — Belt Drive

1

/2 (953)

401/4 (1022)

37

2

413/4 (1060)

(51)

10

1

/

2

3

/4

31

(267)

27

(708)

7

/8

(806)

7

/8

18

1

/2 (572)

22

Damper Size (Outlet Side) = 22

(480)

5

/8 (245)

9

1

/2 x 187/8 (572 x 479)

1

1

/2 (38)

Housing Thickness = 20 ga.

^Approximate Unit Weight = 304 lb. (138 kg)

All dimensions in inches (millimeters).

^Weight shown is largest cataloged Open Drip Proof motor.

Model

Number

Fan

CFM

0.25 0.5 0.75 1 1.25 1.5 1.75 2 2.25 2.5

Static Pressure in Inches wg

BDF-180 4000 RPM 353 448 529

BHP 0.48 0.68 0.91

Sones 7.6 12.1 14.6

4540 RPM 375 463 540 610 673

BHP 0.63 0.86 1.10 1.36 1.62

AVERAGE OUTLET VELOCITY = CFM/2.86

MAXIMUM RPM = 958

TIP SPEED = RPM x 4.843

MAXIMUM MOTOR FRAME SIZE = 215T

Sones 8.9 13.6 15.2 16.1 17.0

5080 RPM 400 479 553 621 682 738

BHP 0.82 1.08 1.34 1.62 1.91 2.19

Sones 10.8 14.9 15.8 16.8 17.4 15.5

5620 RPM 426 498 568 632 693 748 799

BHP 1.05 1.34 1.62 1.90 2.22 2.55 2.85

Sones 13.0 15.9 16.6 17.6 17.8 16.3 15.9

6160 RPM 453 519 585 647 704 759 810 857 903

BHP 1.31 1.63 1.94 2.26 2.56 2.93 3.28 3.62 3.98

Sones 15.7 17.0 17.5 18.5 18.3 17.2 16.8 17.3 18.4

6700 RPM 480 544 603 662 718 770 821 868 912 954

BHP 1.62 1.98 2.32 2.65 3.00 3.33 3.73 4.11 4.49 4.85

Sones 17.9 18.1 18.6 19.5 18.9 18.2 17.8 18.5 19.4 21

7240 RPM 510 568 623 680 733 784 832 879 923

BHP 2.00 2.37 2.73 3.11 3.47 3.84 4.19 4.63 5.05

Sones 18.9 19.3 19.8 20 19.9 19.3 18.9 19.6 20

7780 RPM 540 594 647 698 749 799 846 890

BHP 2.44 2.81 3.22 3.61 3.99 4.40 4.79 5.17

Sones 20 20 21 21 21 20 20 21

8320 RPM 570 621 671 717 768 814

BHP 2.95 3.31 3.75 4.17 4.60 5.00

Sones 21 22 23 23 22 22

8860 RPM 601 648 696 741 786

BHP 3.51 3.86 4.35 4.80 5.25

Sones 23 24 24 24 24

9400 RPM 632 675 722

Performance certified is for installation type D: Ducted inlet, Ducted outlet. Power rating (bhp/kW) does not include transmission losses. Performance ratings do

not include the effects of appurtenances (accessories).

The sound ratings shown are loudness values in fan sones at 5 ft. (1.5m) from the test inlet duct in a hemispherical free field calculated per AMCA Standard 301.

10

Values shown are for installation type D: ducted inlet, ducted outlet. Ratings do not include the effects of duct end connection.

BHP 4.15 4.48 5.00

Sones 24 25 26

Page 11

D

o

n

o

t

s

e

l

e

c

t

t

o

t

h

e

l

e

f

t

o

f

t

h

i

s

s

y

s

t

e

m

c

u

r

v

e

BDF-200 — Belt Drive

1

/8 (1146)

501/4 (1276)

45

2

491/4 (1251)

(51)

12

1

/

2

3

39

/4

(318)

36

(914)

(1010)

1

25

/4

23

1

/8 (588)

(641)

1

1

/2 (38)

13 (330)

Damper Size = 23

1

/8 x 251/4 (587 x 638)

Housing Thickness = 20 ga.

^Approximate Unit Weight = 560 lb. (254 kg)

All dimensions in inches (millimeters).

^Weight shown is largest cataloged Open Drip Proof motor.

Model

Number

Fan

CFM

0.25 0.5 0.75 1 1.5 1.75 2 2.5 2.75 3

Static Pressure in Inches wg

BDF-200 5000 RPM 310 394 464

BHP 0.57 0.84 1.09

Sones 12.5 12.6 12.3

6000 RPM 340 413 480 538

BHP 0.88 1.16 1.49 1.77

AVERAGE OUTLET VELOCITY = CFM/3.87

MAXIMUM RPM = 997

TIP SPEED = RPM x 5.318

MAXIMUM MOTOR FRAME SIZE = 256T

Sones 13.1 13.2 13.3 14.0

7000 RPM 374 437 498 556 656 705

BHP 1.28 1.59 1.93 2.33 3.04 3.50

Sones 14.4 14.0 14.4 15.1 16.8 18.3

8000 RPM 411 465 521 574 671 712 757

BHP 1.80 2.17 2.53 2.92 3.82 4.16 4.63

Sones 15.9 14.8 15.7 16.4 18.0 19.2 21

9000 RPM 449 498 546 596 689 731 770 846 885

BHP 2.45 2.87 3.26 3.70 4.65 5.15 5.63 6.52 7.11

Sones 17.6 17.0 17.3 18.0 19.4 20 21 22 22

10000 RPM 489 533 576 620 707 749 788 860 892 928

BHP 3.26 3.71 4.19 4.60 5.56 6.15 6.71 7.77 8.15 8.71

Sones 19.6 19.4 19.3 19.9 21 22 23 24 24 24

11000 RPM 529 569 610 647 730 768 806 878 911 943

BHP 4.24 4.72 5.26 5.75 6.77 7.27 7.88 9.13 9.73 10.29

Sones 22 22 22 22 23 24 24 25 26 26

12000 RPM 571 607 644 680 754 791 827 896 929 961

BHP 5.42 5.94 6.49 7.06 8.10 8.70 9.27 10.56 11.25 11.92

Sones 25 25 25 25 26 26 27 28 28 28

13000 RPM 613 646 679 714 779 815 850 915 947 979

BHP 6.81 7.34 7.91 8.56 9.70 10.27 10.93 12.14 12.87 13.63

Sones 28 28 28 28 29 29 29 30 31 31

14000 RPM 655 686 717 748 810 840 874 938 968 997

BHP 8.42 8.97 9.59 10.25 11.57 12.14 12.74 14.14 14.79 15.44

Sones 31 31 31 32 31 32 32 33 34 35

15000 RPM 697 726 756 783 843 871 899

Performance certified is for installation type D: Ducted inlet, Ducted outlet. Power rating (bhp/kW) does not include transmission losses. Performance ratings do

not include the effects of appurtenances (accessories).

The sound ratings shown are loudness values in fan sones at 5 ft. (1.5m) from the test inlet duct in a hemispherical free field calculated per AMCA Standard 301.

Values shown are for installation type D: ducted inlet, ducted outlet. Ratings do not include the effects of duct end connection.

BHP 10.30 10.80 11.50 12.20 13.60 14.30 14.90

Sones 35 35 35 35 35 35 35

11

Page 12

Specifications

Duct mounted supply, exhaust, or return

air fans shall be of the centrifugal, belt

driven, inline type. The fan housing

shall be of the rectangular design and

constructed of heavy gauge galvanized

steel, and shall include rectangular duct

mounting collars on the inlet and outlet.

Removable panels shall be provided on

each side of the fan cabinet, and shall

be of sufficient size to permit access

for service to all of the fans internal

components without further dismantling

of the cabinet.

The fan wheel shall be of the galvanized

steel, forward curved, centrifugal

type. Wheels shall be statically and

dynamically balanced.

Motors shall be of the heavy duty type

with permanently lubricated and sealed

ball bearings. The wheel shaft shall be

ground and polished steel mounted

in permanently sealed bearings.

The bearings shall be selected for a

minimum L10 life in excess of 100,000

hours (L50 average life of 500,000 hours)

at maximum cataloged RPM. Drives

shall be sized for a minimum of 150%

of the driven horsepower. Pulleys shall

be of the machined cast type, keyed

and securely attached to the wheel and

motor shafts. The motor pulley shall be

adjustable for final system balancing.

Heavy gauge galvanized steel mounting

rails shall support the drive assembly,

motor, wheel, and scroll.

Fans shall have true internal vibration

isolation (no metal to metal contact) of

the drive assembly, motor, wheel, and

scroll.

All fans shall be tested in an AMCA

Accredited Laboratory and shall be

certified to bear the AMCA Certified

Ratings Seal for sound and air

performance.

Fans shall be Greenheck Model BDF,

manufactured by Greenheck Fan

Corporation in Schofield, Wisconsin.

Building Value in Air

Greenheck delivers value

to mechanical engineers by

helping them solve virtually

any air quality challenges

their clients face with a

comprehensive selection of

top quality, innovative airrelated equipment. We offer

extra value to contractors

by providing easy-to-install,

competitively priced, reliable

products that arrive on time.

And building owners and

occupants value the energy

efficiency, low maintenance

and quiet dependable operation

they experience long after the

construction project ends.

Our Warranty

Greenheck warrants this equipment to be free from defects in material and workmanship for a period

of one year from the purchase date. Any units or parts which prove defective during the warranty

period will be replaced at our option when returned to our factory, transportation prepaid. Motors are

warranted by the motor manufacturer for a period of one year. Should motors furnished by Greenheck

prove defective during this period, they should be returned to the nearest authorized motor service

station. Greenheck will not be responsible for any removal or installation costs.

As a result of our commitment to continuous improvement, Greenheck reserves the right to change

specifications without notice.

Prepared to Support

Green Building Efforts

P.O. Box 410 • Schofield, WI 54476-0410 • Phone (715) 359-6171 • greenheck.com

Catalog BDF Rev. 4 July 2007 RG

Copyright © 2007 Greenheck Fan Corp.

Loading...

Loading...