Page 1

Fiberglass Centrifugal Fans

Model BCSW-FRP

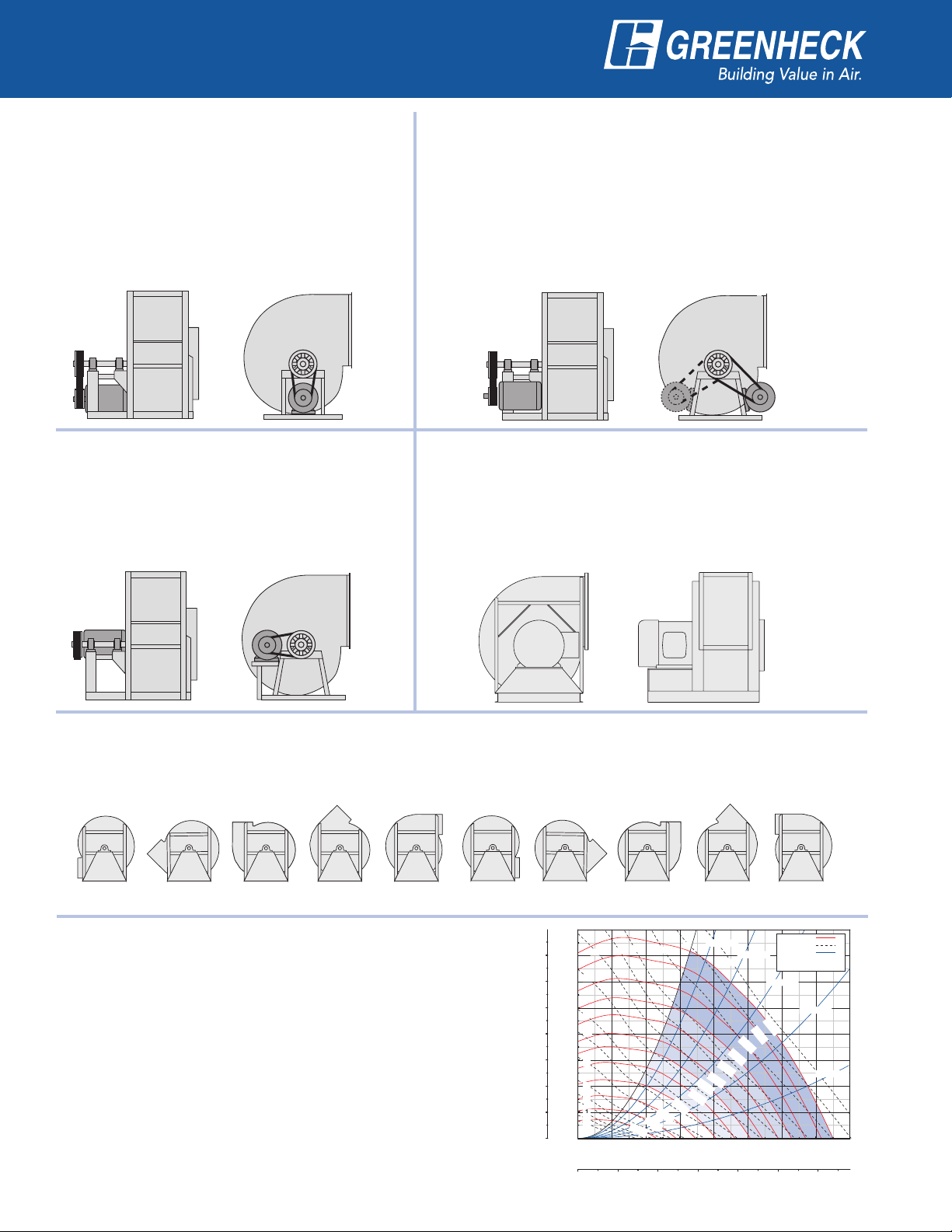

• Belt and Direct Drive • Backward-Curved Wheels

June

2010

Page 2

Model BCSW-FRP

Greenheck’s model BCSW-FRP backward-curved centrifugal fans

are designed to provide reliable and efficient operation for corrosive

applications. Our products are manufactured using hand lay-up

and chop spray fiberglass construction techniques. Every fiberglass

component complies with the ASTM C582 and ASTM D4167

specifications for fiberglass laminates and blowers.

• Fiberglass Reinforced Plastic (FRP) available in sizes 6-73

• Both belt and direct drive arrangements

• Backward-curved single width wheel

• Concentric mount bearings with the industry’s highest

cataloged bearing life

• Each BCSW-FRP fan complies with ASTM D4167 and

ASTM C582 through the use of a protective layer of “C”

veil as standard.

• Coated steel drive frame

• AMCA Spark A Resistant

• AMCA Licensed Air Performance Certified Rating for

sizes 15-73. Sizes 6, 8 and 10 are not AMCA Licensed.

• Capacities range from 300 to 150,000 cfm

(510 to 255,000 m³/hr)

®®

Greenheck Fan Corporation certifies that the

model BSCW-FRP sizes 15-73 fans shown herein

are licensed to bear the AMCA seal. Sizes 6, 8,

and 10 are not certified. The ratings shown are

based on tests and procedures performed in

accordance with AMCA Publication 211 and

comply with the requirements of the AMCA

Certified Ratings Program.

BCSW-FRP Model Number Code:

36 - BCSW - FRP - 4 - CCW - III - BH

Fan Size

6-73

Model

Backward-Curved Single Width

Fiberglass Reinforced Plastic

Arrangement

4, 9, 9H, 10

Leading Edge Support

All Greenheck products are supported by the industry’s best product literature,

electronic media, and Computer Aided Product Selection (CAPS) program. You’ll

also find extensive product and Installation, Operation and Maintenance Manuals

(IOM) information on the internet.

And of course, you can always count on the personal service and expertise

of our national and international representative organization. To locate your

nearest Greenheck representative, call 715-359-6171 or visit our web site at

www.greenheck.com

Rotation

CW, CCW

Discharge Position

Class

I, II, III, IV

2

Page 3

Typical Applications

®

Greenheck BCSW-FRP centrifugal fans are the fan of choice for use in highly corrosive environments. A few of

typical applications are detailed below.

Wastewater Treatment

Wastewater treatment plants produce some of the most

corrosive gases that flow through any duct system including

hydrogen sulfide, methane, ammonia, chlorine, and many

others. In addition to the wastewater components, a number

of corrosive chemicals are added to the wastewater at

different stages of the process.

Wastewater treatment plant ventilation is split into two

categories: general ventilation and odor control. Model

BCSW-FRP fans are mainly used in the odor control portion of

the ventilation system. Hydrogen sulfide is the most common

gas produced by the wastewater. It is highly explosive, so an

explosion proof motor should be used, and the fan should be

statically grounded by carbon gelling the interior surface of

the fan housing.

Other Industries:

• Chemical Process

• Pharmaceutical

• Fertilizer

Semiconductor Manufacturing

There are many toxic and corrosive materials used in the

semiconductor fabrication process. A variety of acids are

utilized to clean the metals before the chips are assembled.

Different acids and corrosive gases are also used in various

other stages of the manufacturing process. The most common

of these include hydrochloric acid (HCl), hydrofluoric acid (HF),

phosphoric acid (H3PO4), and ammonia (NH3).

It is important that all systems in a semiconductor

manufacturing facility run continuously, without fail. The

hazardous chemicals and acids used pose a health hazard for

employees if not vented properly.

FRP fans can last decades without needing to be replaced,

and with minimal maintenance requirements, limiting the

duration of ventilation downtime.

Other Applications:

• Roasters

• Precipitators

• Plant Ventilation

• Pulp and Paper

• Metal and Metal Finishing

• Fiber Optics/Glass

• Food and Agricultural

• Mining/Minerals Processing

• Digesters

• Reagant Preparation

• Clean Rooms

• Scrubbers for Pollution Control

• Pickling and Galvanizing Lines

3

Page 4

Corrosion Resistance

Corrosion Resistance

• No steel parts exposed to the airstream.

• Resin specially formulated for resistance to corrosive

chemicals.

• Nexus Veil (a synthetic cloth) layering is optional for the

most severe applications, such as hydrogen fluoride and

strong oxidizers.

• Ultraviolet (UV) resistant top coat — all surfaces exposed

to UV rays are stabilized against ultraviolet degradation,

suitable for outdoor installation.

Interior

“C” Veil or Nexus

One oz. material

Two oz. chopped

strand material

Chopped

strand material

Chopped

strand material

Two oz. chopped

strand material

“C” Glass Veil

UV Inhibitor Top Coat

ExteriorStandard Lamination Sequence

Corrosion Resistance and Temperature Rating

®

BCSW-FRP

Chemical

Aluminum

Stainless 316

Temperature

Resistance

°F (°C)

Carbon Steel

Chemical

Aluminum

Stainless 316

Carbon Steel

Resistance: G = Good F = Fair NR = Not Recommended Resistance: G = Good F = Fair NR = Not Recommended

Acetic Acid (10%) - Fumes G G F 210° (99°) Hydrobromic Acid (25%) NR NR NR 200° (93°)

Ethyl Alcohol G G G 150° (66°) Hydrochloric Acid (15%) NR NR NR 210° (99°)

Aluminum Chloride NR G NR 210° (99°) Hypochlorous Acid NR NR NR 90° (32°)

Aluminum Fluoride F NR G 90° (32°) Hydrofluosilicic Acid (10%) NR NR - 150° (66°)

Ammonium Chloride NR F NR 210° (99°) Hydrofluoric Acid (10%) NR NR NR 100° (38°)

Ammonium Sulphate NR G F 210° (99°) Hydrogen Peroxide (30%) G G NR 100° (38°)

Barium Chloride NR G F 210° (99°) Lactic Acid F G NR 210° (99°)

Barium Hydroxide NR G F 150° (66°) Lithium Chloride NR NR - 210° (99°)

Bromine, Wet Gas NR NR NR 90° (32°) Magnesium Chloride NR G F 210° (99°)

Calcium Oxide

NR F - 170° (77°) Phosphoric Acid (10%) NR F NR 210° (99°)

(Caustic Lime)

Carbon Dioxide (Dry) F G NR 210° (99°) Picric Acid NR F NR 100° (38°)

Chlorine Gas (Dry) F F NR 180° (82°) Potassium Carbonate

NR NR - 180° (82°)

(Potash)

Chlorine Gas (Moist) NR NR NR 180° (82°) Potassium Chloride NR NR F 210° (99°)

Chlorine Water NR NR NR 180° (82°) Potassium Hydroxide

NR NR G 150° (66°)

(Caustic Potash)

Chromic Acid (5%) F G NR 100° (38°) Potassium Sulfate NR F F 210° (99°)

Citric Acid F G NR 210° (99°) Salt Spray F G NR 210° (99°)

Copper Chloride NR NR NR 210° (99°) Sodium Carbonate NR NR NR 180° (82°)

Copper Cyanide NR G NR 210° (99°) Sodium Chloride NR F NR 210° (99°)

Copper Nitrate NR G NR 210° (99°) Sodium Hydroxide

NR NR F 150° (66°)

(Caustic Soda)

Copper Sulphate NR G NR 210° (99°) Stearic F G NR 210° (99°)

Ferric Chloride NR NR NR 180° (82°) Sulfuric Acid (25%) NR NR NR 200° (93°)

Ferric Sulphate NR F NR 210° (99°) Sulfurous Acid (10%) F G NR 100° (38°)

Ferrous Sulphate G G NR 210° (99°) Tannic Acid NR F NR 210° (99°)

Fluoboric Acid NR F NR 180° (82°) Tartaric F G NR 210° (99°)

Formic Acid (10%) F G NR 180° (82°) Water, Fresh F G NR 220° (104°)

BCSW-FRP fans are rated good for the maximum allowable temperature for each chemical. NOTE: Maximum allowable

airstream temperature for BCSW-FRP fans currently offered is 180°F (82°C).

4

BCSW-FRP

Temperature

Resistance

°F (°C)

Page 5

Construction Features

and Benefits

Housings

BCSW-FRP housings are constructed from corrosion-resistant,

fire retardant polyester resin systems. Each BCSW-FRP fan

complies with ASTM D4167 and ASTM C582 through the use of

a protective layer of “C” veil as standard. The standard housing

lamination sequence is shown on page 4.

All hardware in contact with the airstream is made of stainless

steel and will be encapsulated in fire retardant polyester to

eliminate all sources of corrosion and ensure all components

have the same extended service life as the fan itself.

Fan shafts are made of coated carbon steel for fans where the

shaft to wheel connection is made outside of the airstream. For

shaft to wheel connections made in the airstream, 316 stainless

steel is used.

The fan bases are constructed from heavy-gauge steel with a

vinyl coating as standard. Epoxy coatings are also available

for more severely corrosive environments. Arrangement 10

is standard for smaller fans up to size 25; Arrangement 9 is

standard for sizes 30 thru 73.

®

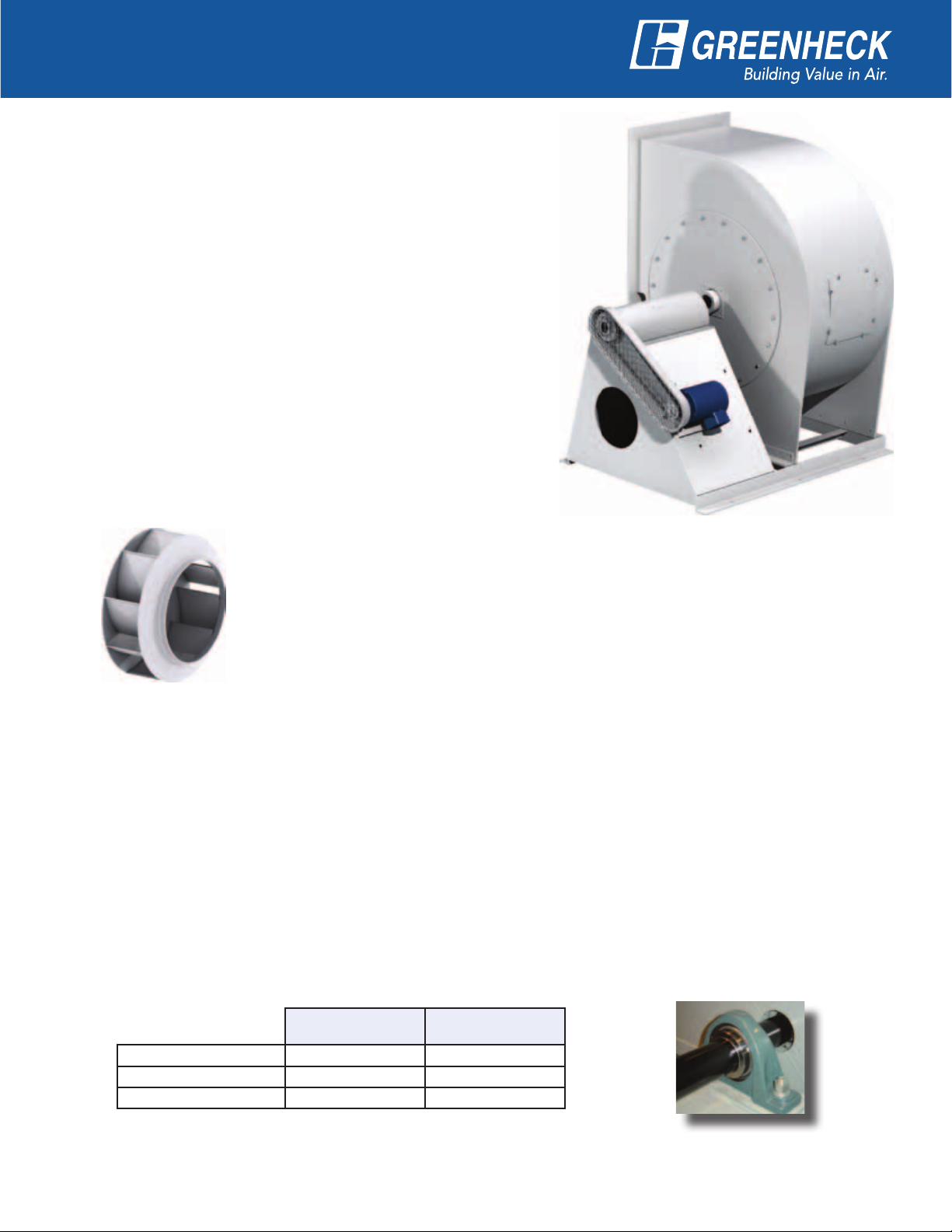

Wheels

Greenheck BCSW-FRP centrifugal

fans have non-overloading

backward curved blades. Every

wheel is laid up by hand. The

blades are strapped to the

backplate rather than just glued

to ensure a stronger wheel. The

backplate and hub are made of

steel and encapsulated in FRP. The minimum peak

static efficiency for every wheel is 65%. Every wheel is

statically and dynamically balanced twice; the wheel is

balanced by itself prior to assembly and then again in

the housing. The balancing is conducted in accordance

with AMCA 204-06 with a vibration limit of 0.05 in./sec.

velocity for direct drive and 0.078 in./sec. velocity for

belt drive.

Weatherhoods

BCSW-FRP weatherhoods protect the motor and

drive components from rain, moisture, dust, dirt.

They are standard on all arrangement 10 fans and

optional on arrangement 4.

Belt Guards

BCSW-FRP belt guards are required on all

arrangement 9 and 9H fans and are designed for

easy access to the belts and pulleys. BCSW-FRP

shaft guards are required on all arrangement 9,

and 9H fans and are designed to cover the shaft

and bearings. All guards can be made to meet

OSHA guidelines.

Premium Bearings

The FRP products are manufactured with “Air Handling Quality” self aligning ball and roller bearings. Our

standard bearings use concentric lock collars (no set screws) which ensure smooth operation and provide

superior grip force between the bearing collar and fan shaft. All bearings are selected for a basic rating fatigue

life of L(10) in excess of 80,000 hours. For more critical applications, Greenheck offers bearings with a minimum

L(10) life in excess of 200,000 hours. Our bearings include zerk fittings for relubrication.

L(10) Life

Industry Standard 40,000 hrs. 200,000 hrs.

Greenheck Standard 80,000 hrs. 400,000 hrs.

Greenheck Upgrade 200,000 hrs. 1,000,000 hrs.

L(10) life implies 90% reliability or 10% failure rate after the stated hours.

L(50) life implies 50% reliability or 50% failure rate after the stated hours.

Equal to L(50) or

Average Life

5

Page 6

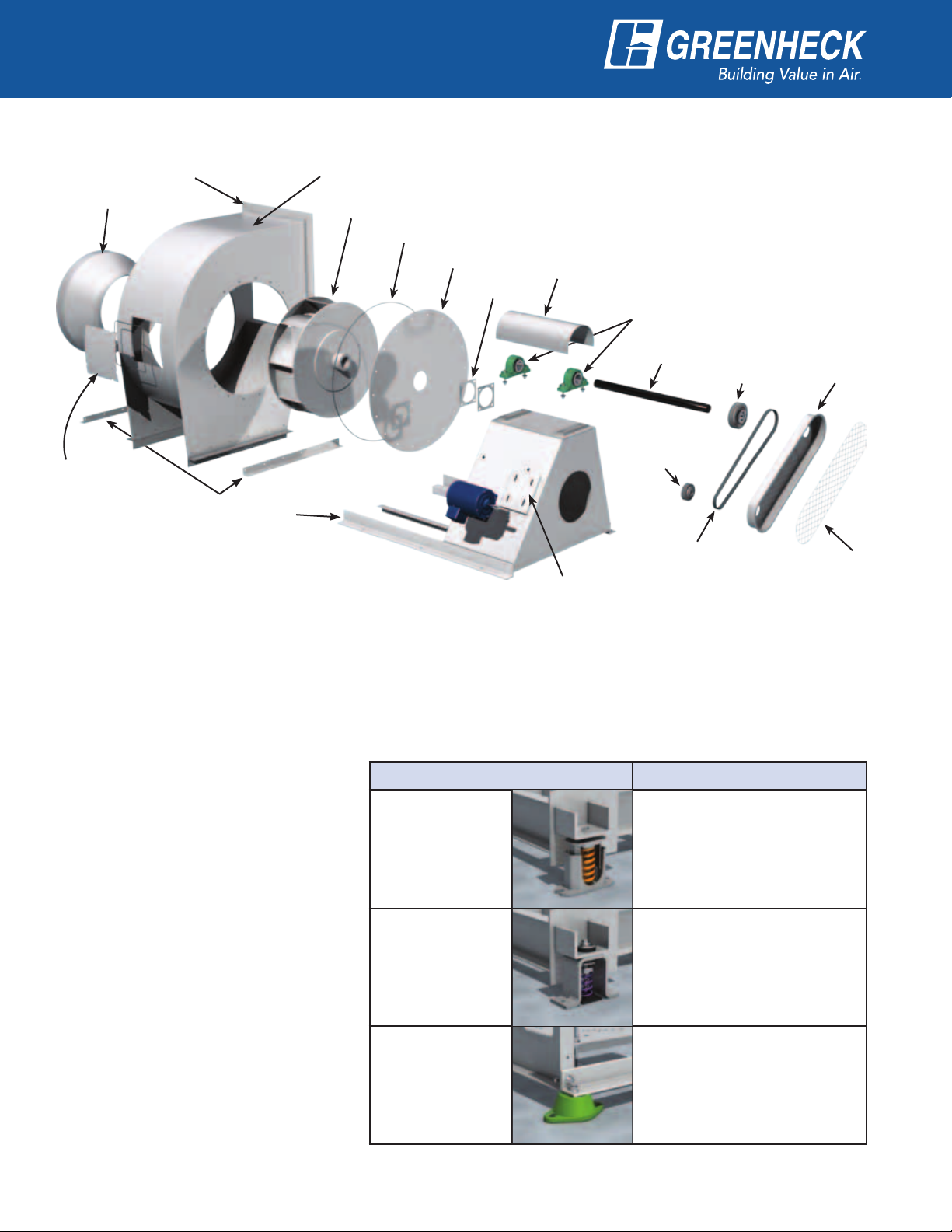

BCSW-FRP

®

Inlet Cone

Access Door

with Gasket

Outlet Flange

Base/Housing

Foot Angle (4)

Housing

Wheel

Gasket

Backplate

Shaft Seal

Shaft Guard

Bearings

Shaft

Motor

Pulley

Adjustable Motor

Slide Base

Belt

Shaft

Pulley

Belt

Guard

Belt Guard

Cover

Vibration Isolators and

Structural Bases

Greenheck offers a complete package

of vibration isolators to reduce

transmitted vibrations.

Vibration isolator options include

neoprene, housed spring and

restrained spring isolators. Housed and

restrained springs are only available on

sizes 30-73.

6

Isolator Type Application

Housed Spring

Restrained

Spring

Rubber-in-Shear

Permits radial and axial

vibration dampening

where less motion can be

tolerated.

Used where large weight

changes or high wind loads

occur. Upward vertical

movement is prevented by

mechanical restraints.

Neoprene isolators highly

effective for relatively small

fans with RPMs of 1800

and over.

Page 7

Accessories

®

Inlet and Outlet Flanges

A slip fit connection on the inlet and an unpunched

flange on the outlet are standard on all BCSW-FRP

sizes and arrangements. An unpunched flange is also

an option for the inlet.

Companion Flanges

Punched companion flanges are available for both the

inlet and outlet for all sizes.

Discharge Transitions

Integral discharge transitions are available when a

transition from rectangular discharge to round duct is

needed. Integral transitions are available up to size44.

For sizes 48 to 73, a separate bolt-on transition is

available.

Access Doors

Bolted or hinged (quick opening) access doors

are available to provide access for inspection and

cleaning. Raised access doors are also available for

use with the integral acoustical insulation.

Shaft Seals

The standard seal is a Teflon® plate. Stuffing box

type seals or mechanical seals are available for more

severe requirements.

Extended Life Bearing

Extended life bearings are selected for a basic fatigue

life L(10) rating per ABMA Standards in excess of

200,000 hours at the maximum RPM for each pressure

class. L(10) is the life associated with 90% statistical

reliability of a bearing.

Extended Lubrication Lines

Flexible rubber tubing extending from the bearings to

grease fittings at a convenient location on the drive

frame are available for all FRP fans. Stainless steel

extended lubrication lines are also available for highly

corrosive applications.

Disconnect Switches

Greenheck offers a wide variety of NEMA rated

disconnect switches. Switches are shipped loose for

field installation.

Drain Connection

A FRP coupling drain connection is located at the

bottom of the fan housing to drain any water or other

liquids that may accumulate within the fan.

Drive Frame Coatings

There are three types of coatings available for the

fan drive frame: Types A, B, and C. Type A is a

hand brushed enamel finish for the least corrosive

applications. Type B is a sandblasted and epoxy

coating for slightly more corrosive applications. Type

C is a sandblasted and double epoxy coating for the

most severely corrosive applications.

Stainless Steel Shafts

Stainless steel shafts are available for highly corrosive

applications.

Integral Acoustical Insulation

Integral acoustical insulation is built into the fan by

encasing 2 inches of insulation in fiberglass. This

integral insulation allows for normal access to fan

components while lowering the sound levels.

Carbon Gel

Every FRP surface in contact with airstream is

graphite-impregnated to eliminate static buildup

within the fan. A grounding lug is located externally.

Used when explosive gases are in the airstream.

Nexus Veil

Nexus Veil is a type of synthetic cloth used to obtain

a longer service life in aggressive environments.

Necessary for hydrogen fluoride service and in

environments containing strong oxidizers.

7

Page 8

Configurations

Z

W

Fan

Isolation Base

XY

Motor position and fan rotation is

determined from drive side

Z

Y

X

W

FAN

BCSWFRP-36

®

Arrangement 10* — Belt Drive

Sizes 6-25

• Compact design providing space savings.

• Bearings are located out of the airstream.

• Motor is mounted beneath the drive frame.

• Includes easy-to-remove weatherhood.

Arrangement 9H — Belt Drive

Sizes 30-73

• Bearings are located out of the airstream.

• Motor is mounted horizontally on the drive frame

for easy accessibility.

• Belt guard and shaft guard included.

Arrangement 9 — Belt Drive

Sizes 30-73

• Easy access to motors mounted on drive frame.

• Bearings are located out of the airstream.

• Standard motor position is on the left side of the drive frame

for CW rotation and on the right side for CCW rotation.

• Belt guard and shaft guard is included.

Arrangement 4 — Direct Drive

Sizes 6-44

• Available with wheel and housing modifications for

specific performance.

• Provides compact design with low maintenance.

Discharge Positions and Rotatable Housings

All BCSW-FRP centrifugal fans are available with clockwise (CW) or counterclockwise (CCW) rotation in five

standard discharge positions. Rotatable housings are standard on fan sizes 25 and less; arrangements 10 and 4.

Class of Construction

Fan Class refers to a construction level designed to

handle a given fan outlet velocity and pressure. As the fan

performance requirements increase, the fan construction

(material gauge, shaft diameter, motor size) must also

increase to physically handle the new work load.

Centrifugal products are available in Class I, II, III, or IV, with

Class I being the lightest construction and Class IV having

the heaviest construction and performance capacity.

A typical fan curve is shown with shaded class limits.

8

CW THCW BH CW TAUCW UBCW BAU CCW THCCW BH CCW TAUCCW UBCCW BAU

16

30

40

25

35

30

25

20

15

Static Pressure (Pa x 100)

10

5

0

20

14

15

12

10

10

7½

8

6

5

3

Static Pressure (in. wg)

4

2

1½

1

2

S

¾

T

½

O

N

O

D

0

0 5 10 15 20 25 30 35 40

0 10 20 30 40 50 60

S

Y

S

S

I

H

T

F

O

T

F

E

L

E

H

T

O

T

T

C

E

750

L

E

625

500

50% WOV

50

60

E

V

R

U

C

M

E

T

1360

1275

1175

1099

1000

879

Volume (cfm x 1000)

Volume (m /hr x 1000)

3

60% WOV

1550

1450

Constant RPM

Constant HP

% WOV

Density 0.075 lb/ft

Density 1.2 kg/m

70% WOV

1625

80% WOV

3

3

90% WOV

Page 9

BCSW-FRP 6

FRP-6

Class I Maximum rpm 2992

Class II Maximum rpm 3820

Class III Maximum rpm 4615

Class IV Maximum rpm 5100

Minimum Starting HP 1/4 hp

Outlet Area 0.186 ft

Tip Speed rpm x 1.57

Maximum BHP (rpm / 2807)

Approximate Weight (LMD) 125 lbs.

CFM OV

1 2 3 4 5 6 8 10 12

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

300 1612

400 2150

500 2688

600 3225

700 3763

800 4301

900 4838

1000 5376

1100 5913

1200 6451

1300 6989

1400 7526

1500 8064

1600 8602

RPM % WOV

1683

2448

1395 0.11

1587 0.18 1930 0.30

1819 0.28 2106 0.41 2381 0.56

2062 0.40 2323 0.56 2557 0.73 2789 0.91 3001 1.10

2312 0.57 2556 0.76 2765 0.95 2966 1.14 3169 1.35 3355 1.57

2568 0.78 2797 1.00 2996 1.22 3174 1.43 3347 1.65 3530 1.89 3860 2.38

2833 1.05 3043 1.29 3233 1.55 3404 1.78 3562 2.02 3709 2.26 4034 2.80 4313 3.34 4588 3.91

3101 1.37 3295 1.64 3474 1.92 3639 2.20 3791 2.46 3933 2.73 4212 3.28 4486 3.86 4745 4.47

3373 1.77 3551 2.06 3721 2.37 3879 2.68 4026 2.98 4163 3.27 4418 3.85 4662 4.45 4918 5.10

3647 2.23 3813 2.55 3972 2.88 4123 3.22 4265 3.56 4398 3.88 4645 4.51 4856 5.11

3923 2.78 4079 3.12 4228 3.48 4371 3.84 4507 4.20 4637 4.57 4877 5.26 5079 5.90

4200 3.41 4347 3.78 4486 4.15 4623 4.54 4754 4.93 4879 5.33

4479 4.14 4618 4.54 4750 4.93 4879 5.34 5004 5.76

4759 4.97 4891 5.39 5017 5.81

Inlet Sound Power, L

1 2 3 4 5 6 7 8 L

100 73 80 80 77 76 71 64 55 80

85 73 80 81 73 72 69 63 54 78

70 75 80 78 69 70 69 63 54 78

50 75 79 78 67 68 69 63 54 75

100 79 85 88 88 85 82 76 68 90

85 78 85 89 89 81 79 75 67 89

70 81 86 87 86 77 78 75 67 87

50 81 86 87 86 75 78 75 67 87

[dB ref 10

Wi

25

60

3 5 7½

20

40

2

3

20

Static Pressure (Pa x 100)

0

2

15

1½

1

10

¾

½

Static Pressure (in. wg)

1

5

/3

¼

N

O

D

0

0 2 4 6 8 10 12 14 16 18

T

T

C

E

L

E

S

T

O

1500

O

H

T

2000

T

F

O

T

F

E

L

E

2500

H

S

I

2992

E

V

R

U

C

M

E

T

S

Y

S

4350

4085

3820

3400

60% WOV

5100

4850

4615

Constant RPM

Constant HP

60

% WOV

Density 0.075 lb/ft

Density 1.2 kg/m

70% WOV

3

3

80% WOV

90% WOV

Volume (cfm x 100)

0 1 2 3

Volume (m /hr x 1000)

3

STATIC PRESSURE (inches wg)

-12

watts]

RPM % WOV

A

Wi

Inlet Sound Power, L

1 2 3 4 5 6 7 8 L

[dB ref 10

Wi

100 87 89 95 96 93 92 87 80 99

3468

85 86 88 95 97 89 88 85 79 97

70 89 90 96 94 85 85 85 79 95

50 89 90 95 94 83 84 85 79 94

100 95 95 100 104 104 101 98 92 108

5100

85 94 94 100 105 105 97 95 91 108

70 97 97 102 103 102 93 94 91 106

50 97 97 101 103 102 91 93 91 105

-12

watts]

A

Wi

The AMCA Certified Ratings Seal does not apply to model BCSW-FRP size 6.

9®9

Page 10

BCSW-FRP 8

BCSWFRP-8

Class I Maximum rpm 2244

Class II Maximum rpm 2865

Class III Maximum rpm 3462

Class IV Maximum rpm 3820

Minimum Starting HP 1/4 hp

Outlet Area 0.333 ft

Tip Speed rpm x 2.09

Maximum BHP (rpm / 1750)

Approximate Weight (LMD) 155 lbs.

25

60

5 15 2010

20

40

2

3

20

Static Pressure (Pa x 100)

0

3

15

2

10

1½

1

Static Pressure (in. wg)

¾

5

½

1

/3

¼

0

0 5 10 15 20 25 30 35

7½

60% WOV

E

V

R

U

C

M

E

T

S

Y

S

S

I

H

T

F

O

T

F

E

L

E

H

T

O

T

T

C

E

1900

L

E

S

T

1500

O

N

1000

O

D

2244

2600

2865

3150

3462

3650

3820

Constant RPM

Constant HP

% WOV

Density 0.075 lb/ft

Density 1.2 kg/m

70% WOV

80% WOV

90% WOV

3

3

Volume (cfm x 100)

0 1 2 4 5

Volume (m /hr x 1000)

3

3

STATIC PRESSURE (inches wg)

CFM OV

1 2 3 4 5 6 8 10 12

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

500 1501 1021 0.19

700 2102 1180 0.31 1440 0.52

900 2702 1376 0.50 1588 0.74 1795 1.02

1100 3303 1581 0.76 1774 1.06 1943 1.36 2117 1.69 2273 2.04

1300 3903 1794 1.12 1973 1.48 2127 1.82 2267 2.17 2418 2.56 2558 2.96 2815 3.79

1500 4504 2013 1.58 2178 2.00 2324 2.41 2455 2.81 2576 3.20 2706 3.64 2952 4.55 3172 5.48

1700 5105 2238 2.17 2388 2.64 2526 3.12 2652 3.58 2767 4.02 2876 4.47 3100 5.45 3310 6.46 3509 7.51

1900 5705 2466 2.91 2603 3.42 2733 3.95 2853 4.49 2964 4.99 3068 5.49 3261 6.50 3457 7.58 3651 8.72

2100 6306 2697 3.81 2823 4.36 2944 4.94 3058 5.53 3165 6.12 3266 6.68 3452 7.79 3613 8.86 3798 10.08

2300 6906 2929 4.88 3047 5.49 3159 6.11 3267 6.75 3370 7.40 3467 8.05 3647 9.26 3802 10.42

2500 7507 3163 6.15 3274 6.81 3377 7.47 3480 8.16 3578 8.86 3671 9.56

2700 8108 3399 7.62 3502 8.34 3600 9.05 3695 9.78 3789 10.53

2900 8708 3635 9.33 3733 10.10

-12

RPM % WOV

Inlet Sound Power, L

[dB ref 10

Wi

1 2 3 4 5 6 7 8 L

watts]

Wi

100 78 82 83 76 71 64 57 51 79

1261

85 76 79 79 69 63 57 53 49 74

70 77 79 79 69 62 56 51 46 73

50 76 75 74 67 61 55 50 45 70

100 83 88 91 87 82 76 69 63 88

1834

85 81 87 87 81 75 69 63 59 83

70 83 87 87 79 75 67 62 57 83

50 83 85 82 77 73 67 61 56 80

The AMCA Certified Ratings Seal does not apply to model BCSW-FRP size 8.

10®10

A

RPM % WOV

100 90 93 97 99 92 87 80 73 99

2598

85 88 92 95 95 85 79 73 68 94

70 90 92 95 95 85 78 72 67 94

50 90 92 91 90 82 77 71 66 90

100 98 99 104 107 103 98 93 85 108

3820

85 96 97 102 103 97 91 85 79 108

70 98 99 102 103 95 92 83 78 103

50 98 98 101 98 93 89 83 77 99

-12

Inlet Sound Power, L

[dB ref 10

Wi

watts]

1 2 3 4 5 6 7 8 L

A

Wi

Page 11

BCSW-FRP 10

BCSWFRP-10

Class I Maximum rpm 2081

Class II Maximum rpm 2657

Class III Maximum rpm 3211

Class IV Maximum rpm 3560

Minimum Starting HP 1/4 hp

Outlet Area 0.515 ft

Tip Speed rpm x 2.62

Maximum BHP (rpm / 1569)

Approximate Weight (LMD) 185 lbs.

25

60

5

10

7½

15

50% WOV

20

3

40

15

2

3

20

Static Pressure (Pa x 100)

0

2

1½

10

1

¾

Static Pressure (in. wg)

½

5

1

/3

¼

N

O

D

0

0 1 2 3 4 5

E

H

T

O

T

T

C

E

L

E

S

T

O

1250

E

V

R

U

C

M

E

T

S

Y

S

S

I

H

T

F

O

T

F

E

L

2081

1750

1500

2350

2657

2850

3025

3560

3400

3211

20

60% WOV

Constant RPM

Constant HP

% WOV

Density 0.075 lb/ft

Density 1.2 kg/m

70% WOV

3

3

80% WOV

90% WOV

Volume (cfm x 1000)

0 2 4 6 8

Volume (m /hr x 1000)

3

STATIC PRESSURE (inches wg)

CFM OV

1 2 3 4 5 6 8 10 12

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

1200 2330 1201 0.45 1420 0.70 1612 0.97 1785 1.25 1948 1.54 2098 1.85 2378 2.48

1450 2815 1354 0.65 1555 0.95 1729 1.26 1889 1.59 2040 1.92 2179 2.26 2443 2.98 2676 3.71 2901 4.48

1700 3300 1514 0.92 1701 1.27 1862 1.62 2010 1.99 2145 2.37 2282 2.75 2526 3.55 2751 4.36 2960 5.20

1950 3786 1680 1.26 1852 1.65 2005 2.06 2144 2.47 2273 2.89 2393 3.32 2628 4.20 2837 5.09 3039 6.02

2200 4271 1849 1.70 2010 2.13 2154 2.58 2285 3.04 2407 3.51 2524 3.98 2736 4.94 2939 5.92 3131 6.92

2450 4757 2022 2.22 2172 2.71 2306 3.20 2433 3.71 2549 4.22 2659 4.74 2866 5.79 3045 6.83 3234 7.93

2700 5242 2198 2.85 2337 3.40 2465 3.94 2584 4.48 2696 5.04 2802 5.61 3000 6.76 3173 7.87 3340 9.04

2950 5728 2375 3.60 2505 4.21 2627 4.79 2739 5.38 2847 5.98 2949 6.60 3138 7.84 3305 9.04 3468 10.29

3200 6213 2554 4.48 2676 5.14 2791 5.78 2899 6.42 3001 7.06 3099 7.71 3283 9.05 3439 10.33

3450 6699 2735 5.50 2849 6.21 2958 6.91 3062 7.60 3159 8.28 3253 8.97 3431 10.40

3700 7184 2916 6.67 3025 7.43 3127 8.20 3226 8.93 3320 9.66 3410 10.40

3950 7669 3098 8.00 3201 8.82 3298 9.64 3393 10.43 3484 11.21

4200 8155 3281 9.50 3379 10.37 3472 11.24

4450 8640 3465 11.20 3558 12.10

RPM % WOV

100 79 84 81 77 72 64 58 52 79

1175

85 78 80 76 70 64 58 53 49 73

70 79 80 74 70 63 57 52 47 72

50 78 75 72 67 62 56 51 46 69

100 85 89 93 87 82 77 69 63 89

1709

85 83 88 89 81 75 69 64 60 84

70 85 88 89 80 76 67 62 57 84

50 84 86 84 78 73 67 61 56 81

-12

Inlet Sound Power, L

[dB ref 10

Wi

watts]

1 2 3 4 5 6 7 8 L

RPM % WOV

A

Wi

Inlet Sound Power, L

1 2 3 4 5 6 7 8 L

[dB ref 10

Wi

100 91 95 99 100 93 88 80 74 100

2421

85 89 93 96 96 86 80 74 69 95

70 91 94 96 96 86 79 73 68 95

50 91 93 92 91 83 78 72 67 91

100 100 100 105 109 104 99 93 86 109

3560

85 98 98 104 105 98 92 86 80 105

70 100 100 104 105 96 92 84 79 104

50 100 100 102 100 94 90 84 78 101

-12

watts]

Wi

A

The AMCA Certified Ratings Seal does not apply to model BCSW-FRP size 10.

11®11

Page 12

BCSW-FRP 15

BCSWFRP-15

30

25

20

15

10

14

2674

10

2875

60% WOV

3450

3310

3075

70% WOV

3550

3

12

5

7½

10

E

F

O

T

1550

V

R

U

C

M

E

T

S

Y

S

S

I

H

T

2450

2139

1850

2

8

1½

6

1

¾

4

Static Pressure (in. wg)

½

1

/3

5

0

¼

2

0

0 1 2 3 4 5 6

S

T

O

N

O

D

F

E

L

E

H

T

O

T

T

C

E

L

E

1250

Class I Maximum rpm 2139

Class II Maximum rpm 2674

Class III Maximum rpm 3310

Class IV Maximum rpm 3550

Minimum Starting HP 1/4 hp

Outlet Area 1.29 ft

Tip Speed rpm x 3.93

Maximum BHP (rpm / 1789)

Approximate Weight (LMD) 195 lbs.

2

3

Static Pressure (Pa x 100)

Volume (cfm x 1000)

0 2 4 6 8 10

STATIC PRESSURE (inches wg)

CFM OV

1 2 3 4 5 6 8 10 12

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

697 1098 0.21

900

1200 930 1203 0.30 1536 0.57

1500 1162 1345 0.41 1619 0.72 1887 1.07

1800 1395 1495 0.55 1750 0.92 1972 1.30 2198 1.71 2415 2.20

2100 1627 1653 0.72 1892 1.15 2095 1.58 2284 2.02 2482 2.50 2664 3.00

2400 1860 1820 0.93 2040 1.41 2234 1.92 2407 2.40 2568 2.90 2747 3.44 3072 4.59

2700 2093 1991 1.19 2194 1.71 2380 2.27 2546 2.85 2699 3.38 2841 3.93 3152 5.15 3427 6.41

3000 2325 2164 1.51 2355 2.07 2529 2.67 2690 3.30 2837 3.94 2977 4.54 3239 5.78 3507 7.11

3300 2558 2342 1.88 2521 2.49 2683 3.14 2838 3.81 2981 4.51 3114 5.21 3362 6.53

3600 2790 2522 2.31 2690 2.98 2843 3.67 2990 4.38 3129 5.12 3258 5.89 3499 7.38

3900 3023 2704 2.81 2862 3.54 3009 4.27 3144 5.03 3279 5.82 3406 6.62

4200 3255 2888 3.39 3036 4.17 3176 4.95 3307 5.76 3433 6.58

4500 3488 3073 4.04 3212 4.89 3347 5.72 3472 6.57

4800

3720 3259 4.79 3391 5.68 3519 6.57

Constant RPM

Constant HP

% WOV

Density 0.075 lb/ft

Density 1.2 kg/m

80% WOV

3

3

90% WOV

RPM % WOV

100 72 74 76 78 70 62 58 53 77

1172

85 70 73 74 75 68 61 57 53 75

70 70 73 73 69 65 62 59 56 72

50 74 73 73 67 63 62 61 61 71

100 80 80 82 85 86 72 68 64 88

1704

85 79 78 82 83 82 71 68 64 85

70 79 78 81 80 75 71 68 65 81

50 82 82 81 80 72 71 70 69 81

-12

Inlet Sound Power, L

[dB ref 10

Wi

watts]

1 2 3 4 5 6 7 8 L

RPM % WOV

A

Wi

Inlet Sound Power, L

1 2 3 4 5 6 7 8 L

[dB ref 10

Wi

100 88 88 89 90 93 86 78 73 95

2414

85 86 86 88 89 90 84 77 73 93

70 86 86 87 88 85 81 77 74 90

50 89 89 89 89 83 79 78 77 90

100 96 96 96 98 100 102 88 84 105

3550

85 95 95 94 97 99 99 87 84 103

70 95 95 94 97 97 91 87 85 99

50 97 97 98 97 96 88 87 86 100

-12

watts]

Performance certified is for installation type B: Free inlet, Ducted outlet. Power ratings (Bhp) do not include transmission losses. Performance ratings do not

include the effects of appurtenances (accessories).

The AMCA Certified Ratings Seal applies to air performance ratings only.

12®12

A

Wi

Page 13

BCSW-FRP 18

BCSWFRP-18

Class I Maximum rpm 1758

Class II Maximum rpm 2198

Class III Maximum rpm 2721

Class IV Maximum rpm 3250

Minimum Starting HP 1/4 hp

Outlet Area 1.92 ft

Tip Speed rpm x 4.78

Maximum BHP (rpm / 1291)

Approximate Weight (LMD) 225 lbs.

16

10

35

14

30

12

25

10

2

3

20

8

15

6

Static Pressure (Pa x 100)

Static Pressure (in. wg)

10

4

5

2

0

0

7½

5

3

2

1½

1

¾

½

1

/3

¼

N

O

D

E

H

T

O

T

T

C

E

L

E

S

T

O

1000

0 2 4 6 8 10

F

E

L

1250

15

E

V

R

U

C

M

E

T

S

Y

S

S

I

H

T

F

O

T

2000

1758

1500

2198

2375

20

60% WOV

2721

2550

3075

2900

3250

Constant RPM

Constant HP

% WOV

Density 0.075 lb/ft

Density 1.2 kg/m

70% WOV

80% WOV

Volume (cfm x 1000)

0 2 4 6 8 10 12 14 16

Volume (m /hr x 1000)

3

STATIC PRESSURE (inches wg)

CFM OV

1 2 3 4 5 6 8 10 12

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

1650 859 957 0.40 1253 0.81

2200 1145 1100 0.60 1327 1.06 1548 1.57

2750 1432 1253 0.86 1460 1.43 1635 1.99 1820 2.62 1992 3.31

3300 1718 1418 1.19 1607 1.86 1771 2.55 1916 3.22 2070 3.95 2218 4.72 2505 6.49

3850 2005 1589 1.63 1761 2.38 1916 3.18 2055 3.98 2182 4.76 2306 5.57 2568 7.34 2807 9.28

4400 2291 1766 2.19 1923 3.02 2068 3.90 2200 4.82 2322 5.75 2437 6.63 2655 8.47 2878 10.44 3087 12.52

4950 2578 1946 2.87 2092 3.79 2224 4.75 2351 5.76 2468 6.80 2577 7.87 2780 9.84 2965 11.86 3170 14.09

5500 2864 2131 3.70 2265 4.72 2389 5.76 2506 6.85 2619 7.97 2724 9.12 2920 11.44 3089 13.56

6050 3151 2317 4.68 2442 5.81 2559 6.94 2667 8.10 2774 9.31 2876 10.54 3065 13.10 3227 15.51

6600 3437 2505 5.85 2620 7.08 2731 8.30 2835 9.55 2933 10.83 3031 12.15 3214 14.87

7150 3723 2694 7.20 2803 8.54 2907 9.86 3006 11.20 3099 12.56 3189 13.95

7700 4010 2885 8.77 2987 10.20 3084 11.64 3179 13.06

8250 4296 3076 10.60 3173 12.10

3

3

90% WOV

RPM % WOV

100 76 78 80 82 72 65 61 56 81

1073

85 74 77 78 79 71 65 61 57 79

70 74 77 77 72 68 65 62 59 75

50 78 77 76 70 67 66 65 65 75

100 84 84 86 89 88 76 72 67 91

1560

85 83 83 86 87 85 75 71 67 88

70 83 82 85 84 78 75 72 69 85

50 86 86 85 83 76 75 74 73 85

-12

Inlet Sound Power, L

[dB ref 10

Wi

watts]

1 2 3 4 5 6 7 8 L

RPM % WOV

A

Wi

Inlet Sound Power, L

1 2 3 4 5 6 7 8 L

[dB ref 10

Wi

100 92 91 94 96 98 88 81 77 100

2210

85 90 90 93 94 94 87 81 77 97

70 90 90 92 92 88 84 81 78 94

50 93 93 93 92 86 83 82 81 93

100 101 100 100 102 105 105 92 88 109

3250

85 99 99 98 102 103 101 91 88 107

70 99 99 98 101 100 94 91 88 104

50 102 102 102 101 99 92 91 90 103

-12

watts]

Performance certified is for installation type B: Free inlet, Ducted outlet. Power ratings (Bhp) do not include transmission losses. Performance ratings do not

include the effects of appurtenances (accessories).

The AMCA Certified Ratings Seal applies to air performance ratings only.

A

Wi

13®13

Page 14

BCSW-FRP 22

BCSWFRP-22

Class I Maximum rpm 1442

Class II Maximum rpm 1803

Class III Maximum rpm 2232

Class IV Maximum rpm 2550

Minimum Starting HP 1/2 hp

Outlet Area 2.84 ft

Tip Speed rpm x 5.83

Maximum BHP (rpm / 929)

Approximate Weight (LMD) 300 lbs.

16

10

35

14

30

25

2

3

20

15

10

Static Pressure (Pa x 100)

5

0

7½

12

10

5

8

3

6

2

1½

Static Pressure (in. wg)

4

1

¾

2

½

1

/3

¼

O

D

0

0 2 4 6 8 10 12 14

15 20

I

H

T

F

O

T

F

E

L

E

H

T

O

T

T

C

E

L

E

S

T

O

N

750

975

1200

25

50% WOV

60% WOV

E

V

R

U

C

M

E

T

S

Y

S

S

1803

1625

1442

1950

2100

2232

2350

2450

70% WOV

2550

Constant RPM

Constant HP

% WOV

Density 0.075 lb/ft

Density 1.2 kg/m

80% WOV

3

3

90% WOV

Volume (cfm x 1000)

0 2 4 6 8 10 12 14 18 20 22

Volume (m /hr x 1000)

3

16

STATIC PRESSURE (inches wg)

CFM OV

1 2 3 4 5 6 8 10 12

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

2450 862 785 0.60 1027 1.21

3200 1126 892 0.87 1082 1.54 1267 2.30

3950 1390 1006 1.20 1178 2.02 1328 2.85 1480 3.76 1628 4.82

4700 1654 1128 1.63 1287 2.59 1424 3.56 1546 4.53 1680 5.61 1801 6.71

5450 1919 1256 2.19 1402 3.26 1531 4.41 1647 5.52 1752 6.63 1867 7.84 2082 10.38

6200 2183 1388 2.89 1520 4.07 1644 5.33 1754 6.65 1856 7.91 1951 9.16 2148 11.87 2333 14.72 2519 18.01

6950 2447 1522 3.74 1646 5.04 1760 6.40 1866 7.84 1964 9.32 2056 10.75 2224 13.56 2398 16.58

7700 2711 1659 4.75 1775 6.18 1880 7.66 1981 9.20 2076 10.80 2164 12.45 2328 15.59 2471 18.65

8450 2975 1799 5.96 1906 7.53 2006 9.12 2099 10.77 2190 12.48 2276 14.24 2434 17.87

9200 3239 1939 7.37 2039 9.09 2134 10.80 2222 12.56 2307 14.37 2391 16.25 2544 20.11

9950 3503 2081 9.01 2174 10.88 2265 12.71 2349 14.59 2428 16.51 2508 18.49

10700 3767 2224 10.90 2312 12.90 2397 14.90 2478 16.90

11450 4031 2367 13.10 2451 15.20 2530 17.30

12200 4295 2511 15.50

RPM % WOV

100 76 79 81 82 69 65 60 56 81

842

85 75 78 79 79 68 64 60 56 78

70 75 77 77 71 68 65 62 59 75

50 79 78 76 69 68 66 66 65 75

100 85 86 87 90 84 75 71 66 90

1224

85 83 85 86 88 82 75 71 66 88

70 83 84 85 82 78 75 72 69 84

50 87 86 86 81 76 75 74 74 84

-12

Inlet Sound Power, L

[dB ref 10

Wi

watts]

1 2 3 4 5 6 7 8 L

RPM % WOV

A

Wi

Inlet Sound Power, L

1 2 3 4 5 6 7 8 L

[dB ref 10

Wi

100 93 92 95 97 98 85 81 76 100

1734

85 91 91 94 95 95 84 80 76 98

70 91 90 93 93 87 84 81 78 94

50 94 94 94 92 84 84 82 81 93

100 101 101 102 103 106 100 91 87 108

2550

85 99 99 100 102 104 98 91 87 107

70 99 99 100 101 99 94 91 88 103

50 102 102 102 102 97 92 91 90 103

-12

watts]

A

Wi

Performance certified is for installation type B: Free inlet, Ducted outlet. Power ratings (Bhp) do not include transmission losses. Performance ratings do not

include the effects of appurtenances (accessories).

The AMCA Certified Ratings Seal applies to air performance ratings only.

14®14

Page 15

BCSW-FRP 25

BCSWFRP-25

Class I Maximum rpm 1258

Class II Maximum rpm 1573

Class III Maximum rpm 1947

Class IV Maximum rpm 2350

Minimum Starting HP 1 hp

Outlet Area 3.72 ft

Tip Speed rpm x 6.68

Maximum BHP (rpm / 740)

Approximate Weight (LMD) 410 lbs.

16

30

35

14

10

30

12

25

2

3

20

15

Static Pressure (Pa x 100)

10

5

0

7½

10

5

8

6

2

Static Pressure (in. wg)

4

1½

1

¾

2

½

1

¼

0

0 2 4 6 8 10 12 14 16 18

15

3

C

E

L

E

S

T

/3

O

N

O

D

25

20

E

V

R

U

C

M

E

T

S

Y

S

S

I

H

T

F

O

T

F

E

L

E

H

T

O

T

T

925

750

1075

1258

1400

1573

1700

40

60% WOV

1947

1850

2075

70% WOV

2350

2225

Constant RPM

Constant HP

% WOV

Density 0.075 lb/ft

Density 1.2 kg/m

80% WOV

Volume (cfm x 1000)

0 5 10 15 20 25 30

Volume (m /hr x 1000)

3

STATIC PRESSURE (inches wg)

CFM OV

1 2 3 4 5 6 8 10 12

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

3650 981 725 0.93 912 1.74

4750 1276 833 1.37 987 2.35 1133 3.40 1273 4.60

5850 1572 948 1.94 1091 3.16 1211 4.34 1330 5.61 1447 6.96 1561 8.48

6950 1868 1072 2.71 1202 4.08 1315 5.56 1417 6.95 1511 8.39 1617 9.97 1808 13.29

8050 2163 1200 3.70 1316 5.23 1425 6.87 1521 8.60 1611 10.21 1693 11.84 1868 15.39 2032 19.13 2197 23.51

9150 2459 1331 4.94 1439 6.64 1538 8.44 1630 10.33 1715 12.29 1796 14.16 1942 17.86 2095 21.86 2243 26.06

10250 2755 1465 6.45 1565 8.35 1655 10.31 1743 12.36 1825 14.48 1901 16.66 2044 20.87 2170 24.96 2306 29.40

11350 3051 1601 8.27 1693 10.38 1779 12.51 1858 14.72 1937 17.00 2011 19.35 2148 24.21 2271 28.67

12450 3346 1738 10.40 1823 12.80 1904 15.10 1980 17.40 2052 19.90 2124 22.40 2257 27.60

13550 3642 1877 13.00 1956 15.50 2032 18.00 2104 20.60 2172 23.20 2239 25.80

14650 3938 2016 16.00 2090 18.70 2162 21.40 2231 24.10 2296 26.90

15750 4233 2156 19.40 2226 22.30 2293 25.30

16850 4529 2297 23.30

3

3

90% WOV

RPM % WOV

100 79 81 84 83 71 66 62 57 82

776

85 78 81 82 80 70 66 62 58 80

70 77 80 79 73 70 67 64 61 77

50 81 80 78 71 70 69 68 67 77

100 87 90 91 93 84 77 73 68 92

1128

85 85 89 90 90 83 76 73 68 90

70 85 88 88 84 80 77 74 71 87

50 89 89 88 82 79 77 77 76 87

-12

Inlet Sound Power, L

[dB ref 10

Wi

watts]

1 2 3 4 5 6 7 8 L

RPM % WOV

A

Wi

Inlet Sound Power, L

1 2 3 4 5 6 7 8 L

[dB ref 10

Wi

100 95 95 97 100 99 86 82 78 102

1598

85 93 93 96 98 96 86 82 78 99

70 93 93 95 95 89 86 83 80 96

50 96 97 96 94 87 86 84 84 96

100 104 103 106 107 109 101 93 89 111

2350

85 102 101 105 105 106 99 93 89 108

70 102 101 104 104 100 96 93 90 106

50 105 105 104 104 98 95 94 93 105

-12

watts]

Performance certified is for installation type B: Free inlet, Ducted outlet. Power ratings (Bhp) do not include transmission losses. Performance ratings do not

include the effects of appurtenances (accessories).

The AMCA Certified Ratings Seal applies to air performance ratings only.

A

Wi

15®15

Page 16

BCSW-FRP 30

BCSWFRP-30

Class I Maximum rpm 1070

Class II Maximum rpm 1337

Class III Maximum rpm 1655

Class IV Maximum rpm 1975

Minimum Starting HP 1 hp

Outlet Area 4.85 ft

Tip Speed rpm x 7.85

Maximum BHP (rpm / 588)

Approximate Weight (LMD) 600 lbs.

16

50% WOV

E

700

30

25

E

V

R

U

C

M

E

T

S

Y

S

S

I

H

T

F

O

T

F

E

L

1200

1070

900

1337

1450

60% WOV

1655

1550

40

1775

70% WOV

1875

35

14

30

25

2

3

20

15

Static Pressure (Pa x 100)

10

5

0

10

12

7½

10

8

5

6

3

2

Static Pressure (in. wg)

4

1½

1

¾

2

½

1

/3

¼

O

D

0

0 5 10 15 20 25 30

20

15

H

T

O

T

T

C

E

L

E

S

T

O

N

500

1975

50

Constant RPM

Constant HP

% WOV

Density 0.075 lb/ft

Density 1.2 kg/m

80% WOV

3

3

90% WOV

Volume (cfm x 1000)

0 5 10 15 20 25 30 35 40 45 50

Volume (m /hr x 1000)

3

STATIC PRESSURE (inches wg)

CFM OV

1 2 3 4 5 6 8 10 12

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

3000 618 525 0.61

4550 938 578 0.91 749 1.82

6100 1257 652 1.36 805 2.43 931 3.60 1052 4.94

7650 1577 741 1.94 874 3.25 993 4.59 1099 6.02 1195 7.53 1293 9.23

9200 1896 840 2.70 954 4.23 1062 5.82 1162 7.42 1255 9.11 1339 10.86 1501 14.66

10750 2216 944 3.69 1043 5.43 1140 7.25 1232 9.10 1320 10.96 1402 12.88 1552 16.92 1683 21.10 1820 25.84

12300 2536 1052 4.94 1142 6.88 1227 8.92 1310 11.02 1391 13.14 1469 15.25 1614 19.62 1740 24.09 1858 28.80

13850 2855 1164 6.50 1244 8.64 1321 10.88 1397 13.19 1470 15.56 1541 17.97 1681 22.71 1802 27.47 1919 32.56

15400 3175 1278 8.39 1348 10.73 1421 13.17 1487 15.70 1557 18.28 1623 20.91 1752 26.22 1868 31.30

16950 3494 1392 10.70 1456 13.20 1523 15.80 1586 18.60 1646 21.40 1710 24.20 1828 30.00 1938 35.60

18500 3814 1508 13.30 1568 16.10 1626 18.90 1687 21.90 1745 24.90 1799 27.90 1914 34.10

20050 4134 1624 16.50 1680 19.40 1733 22.50 1790 25.60 1845 28.80 1897 32.10

21600 4453 1741 20.10 1794 23.30 1844 26.50 1894 29.80 1947 33.20

23150 4773 1859 24.30 1908 27.60 1956 31.10

RPM % WOV

100 83 91 80 79 72 63 58 53 81

652

85 80 89 77 75 67 60 56 52 78

70 78 87 74 71 63 57 55 53 75

50 75 83 71 68 64 57 56 55 72

100 94 99 94 87 84 76 68 64 91

948

85 92 97 92 84 80 72 66 62 88

70 91 95 89 80 76 69 64 62 85

50 85 91 86 77 75 69 64 64 83

-12

Inlet Sound Power, L

[dB ref 10

Wi

watts]

1 2 3 4 5 6 7 8 L

RPM % WOV

A

Wi

Inlet Sound Power, L

1 2 3 4 5 6 7 8 L

[dB ref 10

Wi

100 104 99 106 96 95 88 79 74 101

1343

85 102 96 105 93 91 83 76 72 99

70 101 94 103 90 86 80 73 71 96

50 94 91 98 87 84 80 73 72 92

100 112 110 115 111 103 101 93 85 112

1975

85 111 108 113 108 100 96 88 82 109

70 110 107 111 106 96 92 85 80 107

50 103 101 107 102 93 91 85 80 103

-12

watts]

Wi

A

Performance certified is for installation type B: Free inlet, Ducted outlet. Power ratings (Bhp) do not include transmission losses. Performance ratings do not

include the effects of appurtenances (accessories).

The AMCA Certified Ratings Seal applies to air performance ratings only.

16®16

Page 17

BCSW-FRP 36

BCSWFRP-36

Class I Maximum rpm 879

Class II Maximum rpm 1099

Class III Maximum rpm 1360

Class IV Maximum rpm 1625

Minimum Starting HP 1 hp

Outlet Area 7.12 ft

Tip Speed rpm x 9.42

Maximum BHP (rpm / 425)

Approximate Weight (LMD) 950 lbs.

16

50% WOV

35

30

25

2

3

20

15

Static Pressure (Pa x 100)

10

5

0

20

14

15

12

10

10

7½

8

6

5

3

Static Pressure (in. wg)

4

2

1½

1

2

0

0 5 10 15 20 25 30 35 40

S

¾

T

½

O

N

O

D

F

O

T

F

E

L

E

H

T

O

T

T

C

E

L

E

625

500

30

25

50

40

E

V

R

U

C

M

E

T

S

Y

S

S

I

H

T

1099

1000

879

750

1175

60

1275

60% WOV

1450

1360

1550

Constant RPM

Constant HP

% WOV

Density 0.075 lb/ft

Density 1.2 kg/m

70% WOV

1625

80% WOV

Volume (cfm x 1000)

0 10 20 30 40 50 60

Volume (m /hr x 1000)

3

STATIC PRESSURE (inches wg)

CFM OV

1 2 3 4 5 6 8 10 12

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

6950 976 480 1.40 618 2.75

9250 1299 543 2.09 666 3.69 769 5.45 868 7.44

11550 1622 617 2.97 724 4.94 820 6.92 907 9.09 985 11.35 1065 13.87

13850 1945 699 4.13 791 6.43 879 8.80 960 11.17 1035 13.70 1105 16.33 1236 21.98 1360 28.2

16150 2268 785 5.64 866 8.24 944 10.97 1019 13.74 1090 16.49 1156 19.33 1280 25.40 1386 31.63 1500 38.71

18450 2591 875 7.54 947 10.44 1016 13.49 1084 16.63 1149 19.81 1214 22.92 1331 29.39 1436 36.15 1533 43.23

20750 2914 967 9.90 1032 13.09 1094 16.45 1156 19.90 1216 23.44 1272 27.06 1387 34.07 1486 41.15 1583 48.79

23050 3237 1061 12.80 1117 16.30 1177 19.90 1231 23.70 1288 27.50 1342 31.50 1446 39.40 1541 46.90

25350 3560 1155 16.20 1207 20.00 1261 23.90 1313 28.00 1362 32.20 1414 36.40 1510 45.10 1600 53.40

27650 3883 1251 20.30 1299 24.40 1347 28.60 1397 33.00 1443 37.40 1488 42.00 1581 51.30

29950 4206 1346 25.00 1392 29.40 1435 33.90 1481 38.60 1526 43.40 1569 48.20

32250 4529 1443 30.50 1486 35.20 1527 40.00 1567 45.00 1610 50.00

34550 4852 1540 36.70 1580 41.80 1619 46.90

36500 5126 1623 43.3

RPM % WOV

100 92 90 81 79 71 63 58 54 81

536

85 91 88 78 75 66 60 56 53 78

70 89 85 74 70 63 58 56 54 74

50 84 81 71 69 64 58 57 56 72

100 94 100 92 89 84 75 69 64 91

780

85 92 99 90 85 79 71 67 63 88

70 90 97 87 81 75 69 65 63 86

50 86 92 84 79 75 69 66 65 83

-12

Inlet Sound Power, L

[dB ref 10

Wi

watts]

1 2 3 4 5 6 7 8 L

RPM % WOV

A

Wi

Inlet Sound Power, L

1 2 3 4 5 6 7 8 L

[dB ref 10

Wi

100 105 108 106 96 95 88 79 74 102

1105

85 103 106 104 93 91 82 76 72 99

70 102 104 102 90 86 79 74 72 96

50 95 100 98 87 85 80 74 73 93

100 114 110 116 109 105 100 92 85 112

1625

85 112 108 115 107 101 96 88 83 110

70 111 106 113 104 97 92 85 81 107

50 104 102 108 100 95 91 85 82 103

-12

watts]

3

3

90% WOV

A

Wi

Performance certified is for installation type B: Free inlet, Ducted outlet. Power ratings (Bhp) do not include transmission losses. Performance ratings do not

include the effects of appurtenances (accessories).

The AMCA Certified Ratings Seal applies to air performance ratings only.

17®17

Page 18

BCSW-FRP 44

BCSWFRP-44

FRP-6

Class I Maximum rpm 721

Class II Maximum rpm 901

Class III Maximum rpm 1116

Class IV Maximum rpm 1330

Minimum Starting HP 1-1/2 hp

Outlet Area 10.61 ft

Tip Speed rpm x 11.0

Maximum BHP (rpm / 306)

Approximate Weight (LMD) 1250 lbs.

16

35

30

25

2

3

20

15

Static Pressure (Pa x 100)

10

5

0

30

14

25

12

20

10

15

8

10

7½

6

5

Static Pressure (in. wg)

4

3

2

1½

1

½

L

E

S

T

O

N

O

250

D

2

0

0 10 20 30 40 50 60

T

F

O

T

F

E

L

E

H

T

O

T

T

C

E

550

400

50

40

75

60

E

V

R

U

C

M

E

T

S

Y

S

S

I

H

800

721

50% WOV

975

901

100

60% WOV

1190

1116

1050

70% WOV

1330

1275

Constant RPM

Constant HP

% WOV

Density 0.075 lb/ft

Density 1.2 kg/m

Volume (cfm x 1000)

0 10 20 30 40 50 60 70 80 90 100

Volume (m /hr x 1000)

3

STATIC PRESSURE (inches wg)

CFM OV

1 2 3 4 5 6 8 10 12 14

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

9500 895 383 1.89 502 3.84

13000 1225 433 2.86 537 5.16 624 7.69 707 10.62

16500 1555 493 4.13 584 6.95 665 9.86 736 12.98 803 16.32 869 20.01

20000 1885 562 5.81 639 9.15 713 12.59 780 16.08 842 19.77 900 23.59 1010 31.95

23500 2214 633 8.01 700 11.83 766 15.81 829 19.85 887 23.91 943 28.13 1044 36.98 1136 46.33 1228 56.75

27000 2544 708 10.80 769 15.10 826 19.60 882 24.20 937 28.80 989 33.40 1087 43.10 1174 53.10 1254 63.40

30500 2874 786 14.30 839 19.00 891 24.00 942 29.10 991 34.30 1039 39.60 1133 50.00 1217 60.70 1296 71.90

34000 3204 864 18.60 911 23.80 960 29.20 1005 34.80 1052 40.40 1096 46.20 1183 58.00 1263 69.40

37500 3534 943 23.80 986 29.40 1031 35.20 1074 41.30 1114 47.50 1156 53.70 1236 66.60 1312 79.10

41000 3864 1023 29.90 1063 36.00 1103 42.30 1143 48.80 1182 55.40 1218 62.20 1295 76.00

44500 4194 1104 37.10 1141 43.70 1177 50.40 1215 57.30 1252 64.40 1287 71.60

48000 4524 1185 45.40 1220 52.50 1254 59.60 1287 67.00 1322 74.50

51500 4853 1266 55.00 1299 62.50

80% WOV

3

3

90% WOV

RPM % WOV

100 94 88 82 79 70 63 59 54 80

439

85 92 86 79 74 66 61 57 53 77

70 90 83 75 70 63 59 57 55 74

50 86 79 73 69 64 60 59 58 72

100 94 102 91 91 84 74 69 65 92

638

85 91 100 88 87 78 71 67 63 89

70 89 99 85 82 75 69 66 64 86

50 86 94 82 80 75 68 67 67 83

-12

Inlet Sound Power, L

[dB ref 10

Wi

watts]

1 2 3 4 5 6 7 8 L

RPM % WOV

A

Wi

Inlet Sound Power, L

1 2 3 4 5 6 7 8 L

[dB ref 10

Wi

100 105 110 104 98 95 86 79 75 102

904

85 102 108 102 95 90 82 77 73 99

70 101 106 99 91 86 79 75 73 96

50 96 102 96 88 85 80 75 75 93

100 116 110 118 107 107 100 90 85 113

1330

85 114 108 116 105 103 95 87 83 110

70 113 106 115 101 98 91 85 82 108

50 106 103 110 98 96 92 85 83 104

-12

watts]

Performance certified is for installation type B: Free inlet, Ducted outlet. Power ratings (Bhp) do not include transmission losses. Performance ratings do not

include the effects of appurtenances (accessories).

The AMCA Certified Ratings Seal applies to air performance ratings only.

18®18

A

Wi

Page 19

BCSW-FRP 48

BCSWFRP-48

Class I Maximum rpm 662

Class II Maximum rpm 827

Class III Maximum rpm 1024

Class IV Maximum rpm 1190

Minimum Starting HP 1-1/2 hp

Outlet Area 12.6 ft

Tip Speed rpm x 12.57

Maximum BHP (rpm / 264)

Approximate Weight (LMD) 1700 lbs.

16

35

30

25

2

3

20

15

Static Pressure (Pa x 100)

Static Pressure (in. wg)

10

5

0

40 50 60

14

30

12

25

20

10

15

8

10

6

7½

4

5

3

2

2

1½

1

½

D

0

0 10 20 30 40 50 60 70

T

C

E

L

E

S

T

O

N

O

250

75

C

M

E

T

S

Y

S

S

I

H

T

F

O

T

F

E

L

E

H

T

O

T

525

375

50% WOV

60% WOV

900

975

1024

100

1075

E

V

R

U

827

750

662

1125

Constant RPM

Constant HP

% WOV

Density 0.075 lb/ft

Density 1.2 kg/m

70% WOV

1190

80% WOV

Volume (cfm x 1000)

0 20 40 60 80 100

Volume (m /hr x 1000)

3

STATIC PRESSURE (inches wg)

CFM OV

1 2 3 4 5 6 8 10 12

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

11000 873 349 2.18 459 4.48

15000 1190 391 3.27 488 5.93 570 8.92 646 12.35

19000 1507 444 4.66 530 7.92 604 11.31 670 14.93 734 18.92 794 23.24

23000 1825 504 6.50 576 10.37 646 14.32 708 18.38 766 22.67 818 27.12 923 37.04

27000 2142 566 8.89 630 13.29 691 17.93 751 22.55 805 27.24 856 32.16 949 42.45 1038 53.68 1123 65.86

31000 2460 632 11.90 689 16.80 744 22.00 795 27.40 848 32.70 896 38.00 987 49.20 1068 60.90 1144 73.10

35000 2777 700 15.70 751 21.10 799 26.80 848 32.70 894 38.80 940 44.80 1027 56.90 1106 69.40 1179 82.50

39000 3095 769 20.30 814 26.30 860 32.50 902 38.90 946 45.50 988 52.30 1070 65.70 1145 79.00

43000 3412 838 25.90 879 32.30 921 39.10 962 46.00 1000 53.20 1040 60.40 1114 75.40

47000 3730 909 32.40 947 39.40 985 46.70 1023 54.10 1059 61.80 1094 69.60 1166 85.60

51000 4047 980 40.10 1015 47.60 1049 55.40 1085 63.40 1120 71.50 1152 79.90

55000 4365 1051 49.00 1084 57.10 1116 65.30 1148 73.80 1182 82.50

59000 4682 1123 59.20 1154 67.80 1184 76.60

3

3

90% WOV

RPM % WOV

100 94 86 83 78 69 63 58 54 80

393

85 93 84 79 73 65 60 57 53 76

70 91 81 75 69 63 59 57 55 73

50 86 78 72 69 63 60 59 58 72

100 102 101 91 90 82 73 69 64 91

571

85 101 99 88 86 77 70 67 63 88

70 99 97 84 81 74 68 66 64 85

50 94 93 82 79 75 68 67 67 83

-12

Inlet Sound Power, L

[dB ref 10

Wi

watts]

1 2 3 4 5 6 7 8 L

RPM % WOV

A

Wi

Inlet Sound Power, L

1 2 3 4 5 6 7 8 L

[dB ref 10

Wi

100 104 110 102 98 94 85 79 74 101

809

85 101 108 100 95 89 81 76 73 98

70 100 106 97 91 85 78 75 73 95

50 95 102 94 88 85 79 75 75 92

100 116 118 117 107 106 99 89 85 113

1190

85 114 117 116 104 102 93 87 83 111

70 113 115 114 100 97 90 84 82 108

50 106 110 109 98 96 91 84 83 104

-12

watts]

Performance certified is for installation type B: Free inlet, Ducted outlet. Power ratings (Bhp) do not include transmission losses. Performance ratings do not

include the effects of appurtenances (accessories).

The AMCA Certified Ratings Seal applies to air performance ratings only.

A

Wi

19®19

Page 20

BCSW-FRP 54

BCSWFRP-54

FRP-6

®

Class I Maximum rpm 592

Class II Maximum rpm 740

Class III Maximum rpm 916

Class IV Maximum rpm 1092

Minimum Starting HP 2 hp

Outlet Area 15.77 ft

Tip Speed rpm x 14.2

Maximum BHP (rpm / 220)

Approximate Weight (LMD) 2600 lbs.

16

35

14

40 50 60

30

12

30

25

2

3

20

15

Static Pressure (Pa x 100)

10

5

0

25

10

20

8

15

6

10

7½

4

Static Pressure (in. wg)

5

3

2

2

1

D

0

0 10 20 30 40 50 60 70 80 90

T

T

C

E

L

E

S

T

O

N

O

250

O

350

100

50% WOV

800

60% WOV

125

975

916

850

75

E

V

R

U

C

M

E

T

S

Y

S

S

I

H

T

F

O

T

F

E

L

E

H

T

475

592

740

650

1025

70% WOV

150

1092

Constant RPM

Constant HP

% WOV

Density 0.075 lb/ft

Density 1.2 kg/m

80% WOV

90% WOV

3

3

Volume (cfm x 1000)

0 20 40 60 80 100 120 140

Volume (m /hr x 1000)

3

STATIC PRESSURE (inches wg)

CFM OV

1 2 3 4 5 6 8 10 12

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

14000 887 314 2.73 411 5.41

19000 1204 352 4.16 439 7.28 510 10.35

24000 1521 399 5.92 475 10.03 543 13.99 600 17.54 657 22.06 711 27.98

29000 1838 453 8.25 517 13.11 579 18.09 635 23.04 687 27.34 733 31.64 826 43.84

34000 2155 509 11.30 565 16.80 620 22.60 673 28.40 722 34.40 768 39.70 850 49.70 929 62.40 1006 79.20

39000 2473 567 15.10 618 21.30 667 27.80 713 34.50 760 41.20 804 47.90 885 60.50 957 72.00 1024 83.70

44000 2790 628 19.90 673 26.70 716 33.90 760 41.20 801 48.80 842 56.40 920 71.60 992 85.60 1056 98.60

49000 3107 690 25.70 730 33.10 771 40.90 808 49.00 848 57.30 885 65.70 958 82.50 1027 99.50

54000 3424 752 32.70 788 40.80 826 49.20 862 57.90 896 66.90 932 76.00 998 94.70 1065 112.90

59000 3741 815 40.90 849 49.70 882 58.80 917 68.10 949 77.80 980 87.60 1044 107.50

64000 4058 878 50.60 910 60.00 940 69.70 972 79.70 1003 90.00 1032 100.50 1092 121.80

69000 4375 942 61.80 972 71.90 1000 82.20 1029 92.90 1058 103.80 1087 114.90

74000 4692 1006 74.60 1034 85.40 1061 96.40 1086 107.70

RPM % WOV

100 96 86 84 78 69 64 59 55 80

360

85 94 84 81 73 66 61 58 54 77

70 92 81 76 70 63 60 58 56 74

50 88 78 74 70 63 61 60 59 73

100 104 101 92 90 83 74 70 65 92

524

85 102 99 89 86 78 72 68 64 89

70 100 97 85 82 75 70 67 65 86

50 96 93 83 80 75 70 69 68 83

-12

Inlet Sound Power, L

[dB ref 10

Wi

watts]

1 2 3 4 5 6 7 8 L

RPM % WOV

A

Wi

Inlet Sound Power, L

1 2 3 4 5 6 7 8 L

[dB ref 10

Wi

100 105 111 103 100 94 85 80 75 102

743

85 102 110 100 96 89 82 77 74 99

70 100 108 97 92 86 79 76 74 96

50 97 103 94 90 86 79 77 76 93

100 116 120 117 108 107 99 90 86 113

1092

85 114 118 116 105 103 94 88 84 111

70 113 116 113 102 98 91 86 83 108

50 107 112 109 99 97 92 86 85 105

-12

watts]

Performance certified is for installation type B: Free inlet, Ducted outlet. Power ratings (Bhp) do not include transmission losses. Performance ratings do not

include the effects of appurtenances (accessories).

The AMCA Certified Ratings Seal applies to air performance ratings only.

2020

A

Wi

Page 21

BCSW-FRP 60

BCSWFRP-60

Class I Maximum rpm 535

Class II Maximum rpm 668

Class III Maximum rpm 828

Class IV Maximum rpm 925

Minimum Starting HP 2 hp

Outlet Area 19.22 ft

Tip Speed rpm x 15.71

Maximum BHP (rpm / 186)

Approximate Weight (LMD) 3000 lbs.

14

60

30

12

25

10

20

2

8

15

6

50

40

30

25

20

15

3

10

Static Pressure (Pa x 100)

5

0

10

4

7½

Static Pressure (in. wg)

5

3

2

2

1

O

D

0

0 20 40 60 80 100

H

T

O

T

T

C

E

L

E

S

T

O

N

250

100

75

E

V

R

U

C

M

E

T

S

Y

S

S

I

H

T

F

O

T

F

E

L

E

535

450

350

125

50% WOV

668

600

150

60% WOV

775

725

828

70% WOV

925

875

Constant RPM

Constant HP

% WOV

Density 0.075 lb/ft

Density 1.2 kg/m

80% WOV

90% WOV

Volume (cfm x 1000)

0 20 40 60 80 100 120 140 160

Volume (m /hr x 1000)

3

STATIC PRESSURE (inches wg)

CFM OV

1 2 3 4 5 6 8 10 12

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

17000 884 283 3.38 371 6.91

23000 1196 317 5.01 395 9.09 461 13.68

29000 1508 358 7.10 428 12.07 488 17.25 541 22.80 593 28.90 642 35.50

35000 1821 406 9.84 465 15.72 521 21.74 571 27.94 618 34.49 660 41.27 745 56.45

41000 2133 455 13.40 507 20.10 556 27.10 605 34.10 648 41.30 690 48.80 765 64.50 839 81.70 908 100.40

47000 2445 507 17.90 553 25.30 598 33.20 640 41.30 683 49.30 722 57.50 795 74.50 862 92.40 924 111.30

53000 2757 560 23.40 602 31.70 641 40.40 681 49.20 719 58.40 757 67.50 827 85.80 892 105.10

59000 3069 615 30.20 652 39.20 689 48.70 724 58.40 760 68.40 794 78.60 861 98.80 923 119.30

65000 3381 670 38.40 703 48.10 738 58.30 771 68.90 803 79.70 835 90.70 895 113.20

71000 3694 726 48.00 757 58.60 788 69.50 819 80.80 848 92.50 878 104.30

77000 4006 782 59.20 811 70.60 839 82.30 868 94.40 897 106.80 923 119.50

83000 4318 839 72.20 866 84.40 892 96.90 918 109.80

89000 4630 895 87.10 921 100.10

3

3

RPM % WOV

100 95 84 83 76 67 62 58 53 79

305

85 94 81 80 71 64 60 56 53 76

70 92 77 75 67 61 59 57 55 72

50 87 75 73 68 61 60 60 59 71

100 103 97 92 88 80 73 68 64 90

444

85 102 95 88 84 76 70 66 63 86

70 100 93 84 79 73 69 66 64 83

50 95 89 82 79 73 69 68 67 82

-12

Inlet Sound Power, L

[dB ref 10

Wi

watts]

1 2 3 4 5 6 7 8 L

RPM % WOV

A

Wi

Inlet Sound Power, L

1 2 3 4 5 6 7 8 L

[dB ref 10

Wi

100 103 111 99 99 92 82 78 73 101

629

85 100 109 96 96 87 80 76 72 98

70 98 107 93 91 83 77 75 73 95

50 95 103 90 89 84 77 76 75 92

100 114 119 114 108 105 96 89 84 111

925

85 112 118 112 104 100 92 86 83 109

70 111 116 109 100 96 89 85 82 106

50 106 111 106 98 95 89 85 84 103

-12

watts]

Performance certified is for installation type B: Free inlet, Ducted outlet. Power ratings (Bhp) do not include transmission losses. Performance ratings do not

include the effects of appurtenances (accessories).

The AMCA Certified Ratings Seal applies to air performance ratings only.

A

Wi

21®21

Page 22

BCSW-FRP 73

BCSWFRP-73

®23®

Class I Maximum rpm 440

Class II Maximum rpm 550

Class III Maximum rpm 680

Class IV Maximum rpm 820

Minimum Starting HP 3 hp

Outlet Area 28.48 ft

Tip Speed rpm x 19.12

Maximum BHP (rpm / 134)

Approximate Weight 4500 lbs.

16

100

35

30

25

2

3

20

15

Static Pressure (Pa x 100)

10

5

0

75

14

60

12

50

10

40

8

30

25

6

20

15

Static Pressure (in. wg)

4

10

7½

5

2

3

2

N

O

1

D

0

0 20 40 60 80 100 120 140 160

L

E

H

T

O

T

T

C

E

L

E

S

T

250

300

O

200

150125

M

E

T

S

Y

S

S

I

H

T

F

O

T

F

E

375

50% WOV

60% WOV

E

V

R

U

C

725

680

650

600

550

500

440

250

775

Constant RPM

Constant HP

% WOV

Density 0.075 lb/ft

Density 1.2 kg/m

70% WOV

820

80% WOV

90% WOV

3

3

Volume (cfm x 1000)

0 50 100 150 200 250

Volume (m /hr x 1000)

3

STATIC PRESSURE (inches wg)

CFM OV

1 2 3 4 5 6 8 10 12

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

27000 948 237 5.43 308 10.78

37000 1299 271 8.35 333 14.79 384 21.81 434 29.76

47000 1650 312 12.20 364 20.30 412 28.40 456 37.10 494 46.20 534 56.20

57000 2001 357 17.50 402 26.90 445 36.70 485 46.50 522 56.70 557 67.40 621 89.90 684 115.40

67000 2352 404 24.40 443 35.10 481 46.30 517 58.00 553 69.40 585 81.10 646 105.80 701 131.70 756 160.00

77000 2703 453 33.20 488 45.20 521 57.90 554 70.80 585 84.30 617 97.30 675 124.10 729 152.40 778 181.70

87000 3054 504 44.30 534 57.60 565 71.50 594 86.00 623 100.60 651 115.70 707 145.50 757 175.80 806 207.40

97000 3405 555 57.90 582 72.50 610 87.70 637 103.50 663 119.60 690 135.90 739 169.60 789 202.60

107000 3757 607 74.40 632 90.30 657 106.80 682 123.70 706 141.20 729 159.00 777 195.20

117000 4108 659 93.90 682 111.20 704 128.90 728 147.20 750 165.90 772 185.00 816 224.00

127000 4459 711 117.00 733 135.00 753 154.00 774 174.00 796 194.00 817 214.00

137000 4810 763 143.00 784 163.00 803 184.00

147000 5161 816 174.00

RPM % WOV

100 96 87 85 78 69 65 60 56 81

271

85 94 84 81 73 66 63 59 55 77

70 92 80 77 70 64 62 60 58 74

50 88 78 75 70 64 64 63 62 74

100 107 99 95 90 81 75 71 66 92

394

85 105 96 92 85 78 73 69 65 89

70 103 94 87 82 75 72 69 67 86

50 99 90 85 81 75 72 71 70 84

-12

Inlet Sound Power, L

[dB ref 10

Wi

watts]

1 2 3 4 5 6 7 8 L

RPM % WOV

A

Wi

Inlet Sound Power, L

1 2 3 4 5 6 7 8 L

[dB ref 10

Wi

100 114 112 103 101 94 85 81 76 103

558

85 113 110 100 97 89 82 79 75 100

70 111 108 96 93 86 80 78 76 97

50 106 104 93 91 86 80 79 78 94

100 117 123 115 111 107 98 91 87 114

820

85 114 121 113 108 102 94 89 85 111

70 113 119 110 103 98 91 88 85 108

50 108 115 107 101 98 91 88 87 105

-12

watts]

Performance certified is for installation type B: Free inlet, Ducted outlet. Power ratings (Bhp) do not include transmission losses. Performance ratings do not

include the effects of appurtenances (accessories).

The AMCA Certified Ratings Seal applies to air performance ratings only.

22®22

A

Wi

Page 23

Dimensions

B

E

D

A

A

G

C

F

B

A

D

E

C

F

G

A

Arrangement 4

Arrangement 9

B

E

D

A

G

C

F

Arrangement 4

B

E

D

A

TH

B

A

D

BAU

B

A

D

BH

B

A

D

UB

A

B

D

TAU

B

A

D

G

C

F

Arrangement 4

Arrangement 9

B

A

TAU

D

B

A

BAU

D

B

A

TH

D

B

A

BH

D

B

A

D

E

C

F

G

UB

A

B

D

Arrangement 4

Arrangement 9

B

E

D

A

TH

B

A

D

BAU

B

A

D

BH

B

A

D

UB

A

B

D

TAU

B

A

D

G

C

F

Arrangement 4

Arrangement 4

Arrangement 10 — Belt Drive

Sizes 6-25

B

B

B

B

B

A

D

TH

B

E

A

D

C

F

G

Fan

Size

6

8

10

15

18

22

25

Class

TH BH UB TAU BAU

281⁄4 255⁄8 28 323⁄8 27 183⁄4 18 171⁄8 221⁄2 28 18 51⁄2 47⁄8 6

313⁄8 283⁄16 29 351⁄4 285⁄16 223⁄8 233⁄8 223⁄8 281⁄8 2913⁄16 18 73⁄8 61⁄2 8

383⁄4 35 36 43 351⁄16 243⁄4 26 241⁄2 307⁄8 353⁄8 24 91⁄8 81⁄8 10

I, II,

III, IV

33 295⁄8 293⁄8 361⁄2 281⁄2 243⁄4 261⁄2 241⁄2 303⁄4 351⁄2 24 153⁄4 113⁄4 14

411⁄2 375⁄8 373⁄8 457⁄8 363⁄4 29 311⁄8 291⁄2 365⁄16 413⁄4 24 185⁄8 137⁄8 18

459⁄16 405⁄8 405⁄16 51 395⁄16 351⁄4 373⁄8 351⁄2 443⁄8 4413⁄16 24 225⁄8 167⁄8 20

523⁄4 471⁄8 465⁄8 581⁄2 451⁄2 403⁄8 431⁄2 407⁄8 51 517⁄16 28 26 195⁄8 24

A

D

BH

UB

A B

A

D

TH

UB TAU BAU

BH

TAU

A

D

BAU

C D E F G

A

D

Arrangement 9 & 9H — Belt Drive

TAU

B

A

D

BAU

B

A

D

C D E F G

Sizes 30-73

B

E

A

D

C

F

G

Fan

Size

30

36

44

48

54

60

73

B

A

D

TH

Class

I, II,

III, IV

B

A

D

BH

A B

TH BH UB TAU BAU

593⁄4 59 53 671⁄2 569⁄16 471⁄2 51 48 60 53 31 301⁄2 223⁄4 30

713⁄4 71 633⁄4 801⁄2 691⁄16 515⁄8 611⁄4 58 72 611⁄2 37 371⁄8 275⁄8 36

863⁄8 85 769⁄16 967⁄8 827⁄16 611⁄4 75 701⁄2 89 70 44 451⁄4 333⁄4 42

947⁄8 881⁄8 851⁄2 1081⁄2 853⁄8 621⁄8 821⁄2 77 96 751⁄2 50 493⁄8 363⁄4 48

104 100 953⁄4 121 973⁄8 711⁄2 913⁄4 86 108 81 56 551⁄4 411⁄8 54

1131⁄2 1123⁄4 1057⁄8 134 1091⁄16 80 1015⁄8 951⁄2 119 86 62 61 453⁄8 60

1341⁄2 1321⁄2 1257⁄16 159 1293⁄16 903⁄8 1231⁄2 118 147 106 72 741⁄4 551⁄4 72

UB

B

A

D

TH

UB TAU BAU

BH

Arrangement 4 — Direct Drive

Sizes 6-44

A

D

B

E

C

F

G

Fan

Size

6

8

10

15

18

22

25

30

36

44

TH

B

B

BH

TH BH UB TAU BAU

D

Class

A

301⁄4 295⁄8 28 333⁄4 27 183⁄4 201⁄8 171⁄4 251⁄4 25 18 51⁄2 47⁄8 6

333⁄8 295⁄8 29 365⁄8 285⁄16 223⁄8 251⁄2 227⁄8 293⁄4 2613⁄16 18 73⁄8 61⁄2 8

403⁄4 295⁄8 36 445⁄16 351⁄16 243⁄4 281⁄8 221⁄2 321⁄4 313⁄8 24 91⁄8 81⁄8 10

33 295⁄8 293⁄8 361⁄2 281⁄2 243⁄4 291⁄4 241⁄2 303⁄4 351⁄2 18 153⁄4 113⁄4 14

I, II,

411⁄2 375⁄8 373⁄8 457⁄8 363⁄4 29 337⁄8 291⁄2 365⁄16 413⁄4 24 185⁄8 137⁄8 18

451⁄2 405⁄8 405⁄16 51 391⁄3 351⁄4 401⁄8 351⁄2 443⁄8 4413⁄16 24 225⁄8 167⁄8 20

III, IV

523⁄4 471⁄8 465⁄8 581⁄2 451⁄2 403⁄8 461⁄2 407⁄8 51 517⁄16 28 26 195⁄8 24

593⁄4 59 53 56 5611⁄16 471⁄16 537⁄16 48 60 53 36 301⁄2 223⁄4 30

713⁄4 71 633⁄4 801⁄2 691⁄16 573⁄8 641⁄4 58 72 611⁄2 44 371⁄8 275⁄8 36

863⁄8 85 769⁄16 967⁄8 827⁄16 693⁄4 773⁄4 701⁄2 89 70 52 451⁄4 333⁄4 42

B

A

D

UB

A B

D

TH

BH

A

UB TAU BAU

B

D

TAU

B

A

BAU

C D E F G

A

D

Page 24

Specifications

Model BCSW-FRP

Supply, exhaust, or return air fans shall be a

single width, single inlet type fan, in clockwise

or counterclockwise rotation as specified.

The housing shall be constructed of fire

resistant vinyl ester resins and conform to

PS 12-96 FRP construction standards. All

interior surfaces of the fan which are exposed

to the airstream shall contain a layer of “C”

grade glass veil and shall be resin rich. The

exterior FRP surfaces of the housing shall be

resin rich and stabilized against ultraviolet

degradation and enhanced with “C” grade veil.

The housing shall have a slip fit connection on