Page 1

PART # 453284

Fan

Filter Box

Mixing Box

C

B

A

D

®

READ AND SAVE THESE INSTRUCTIONS

Model BCF Belt Drive

Centrifugal Cabinet Fans

Installation, Operation, and Maintenance Manual

Upon receiving unit, check for any

damage that may have occurred during

transit and report it immediately to

the shipper. Also, check to see that all

accessory items are accounted for.

Typical Installation

WARNING: Always disconnect, lock

and tag power source before installing

or servicing. Failure to disconnect

power source can result in fire, shock,

serious injury or death.

Please read and save these instructions

for future reference. Read carefully

before attempting to assemble, install,

operate or maintain the unit. Failure

to comply with instruction could result

in personal injury and/or property

damage!

Move fan to the desired location and

determine the position of the access

door. Provide adequate door opening

clearance for servicing the motor and

blower assembly. Attach the fan to a

suitable framework as specified. Use

of optional hanging or base vibration

isolators are recommended. Optional

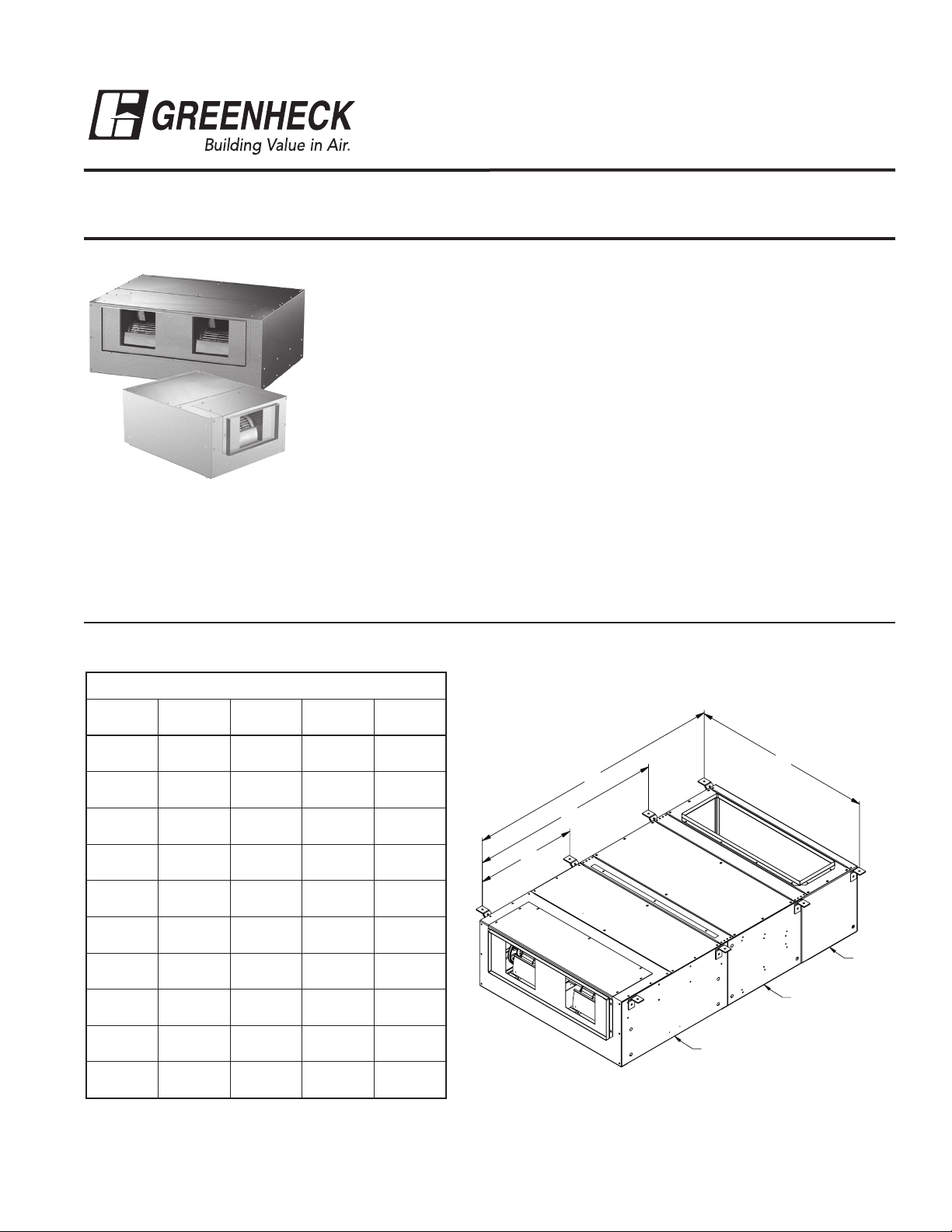

Mounting Dimensions

Hanging or Base Mounts

BCF

Size

106

107

108

110

112

206

207

208

210

212

All dimensions are in inches (mm).

NOTE: Only four (4) hanging or base mounts required per unit.

NOTE: Fan can NOT be mounted vertically.

A B C D

19½

(493)

25

(635)

29

(737)

29½

(749)

38

(965)

19½

(493)

25

(635)

29

(737)

29½

(749)

38

(965)

42½

(1080)

47¾

(1213)

523/8

(1330)

561/8

(1426)

647/8

(1648)

42½

(1080)

47¾

(1213)

523/8

(1330)

561/8

(1426)

647/8

(1648)

52½

(1334)

60¾

(1543)

(1753)

(1905)

87¾

(2229)

52½

(1334)

60¾

(1543)

(1753)

(1905)

87¾

(2229)

69

75

69

75

24¼

(616)

27¼

(692)

30¼

(768)

36¼

(921)

40½

(1029)

38¼

(972)

42¼

(1073)

48¼

(1226)

52¼

(1327)

62¼

(1581)

hanging isolators can be sized to

support the weight of the fan only

or the fan with filter/mixing boxes.

Separate support should be used for

ductwork.

The motor voltage and amperage rating

must be checked for compatibility with

the electrical supply. Supply wiring may

be routed through knockouts which

are provided on each side of the fan

housing. Provide adequate wiring to

permit the access door to open for

servicing. Wiring should be secured

inside the fan to prevent interference

with the drive components.

Inlet and discharge collars are provided

for duct connection. The inlet panel is

removable for attaching optional filter

and mixing box accessories.

Fig. 1 - Mounting Dimensions

Page 2

1 in.

(25 mm)

G

I

H

E

F

L

Fan

Optional Side Acess Door

35/8 in. (92 mm)

Fan

Filter Box

Mixing Box

H

L

L

J

E

F

I

K

Dimensional Data

®

Rotation

Airflow

Fasteners (2)

Fasteners (2)

Deflection =

Belt Span

62.5 (in.)

Belt Span

(in.)

(in.)

CORRECT

WRONG

WRONG

WRONG

WRONG

WRONG

®

®

Fig. 2 - BCF Unit Dimensions Fig. 3 - BCF with Filter and Mixing Box Unit Dimensions

BCF

Size

106

107

108

110

112

206

207

208

210

212

E F G H I

23¼

(591)20(508)

29

(737)23(584)

32

(813)26(660)

36

(914)32(813)

42

(1067)36(914)

23¼

(591)34(864)

29

(737)38(965)

32

(813)44(1118)

36

(914)48(1219)

42

(1067)58(1473)

-

5/8

(16)

5/8

(16)

5/8

(16)

5/8

(16)

5/8

(16)

5/8

(16)

5/8

(16)

5/8

(16)

5/8

(16)

All dimensions are in inches (mm).

12

(305)6(152)

15

(381)8(203)

18

(457)

24

(610)

28

(711)

10

(254)

12

(305)

14

(356)

26

(660)6(152)

30

(762)8(203)

36

(914)

40

(1016)

50

(1270)

10

(254)

12

(305)

14

(356)

Slide-Out Sloped Slide-Out Qty. Sloped Qty.

(152)

(152)

(152)

(178)

(178)

(152)

(152)

(152)

(178)

(178)

J Filter Size

6

6

6

7

7

6

6

6

7

7

22

(559)

23

(584)

24

(610)

25

(635)

27

(686)

22

(559)

23

(584)

24

(610)

25

(635)

27

(686)

19½ x 10¼

(495 x 260)

7

22

/8 x 12¼

(581 x 311)

7

25

/8 x 15½

(657 x 394)

7

31

/8 x 18½

(810 x 470)

7

35

/8 x 223/8

(911 x 568)

7

33

/8 x 10¼

(860 x 260)

7

37

/8 x 12¼

(962 x 311)

7

43

/8 x 15½

(1114 x 394)

7

47

/8 x 18½

(1216 x 470)

7

57

/8 x 22½

(1470 x 572)

1

1

1

1

1

1

1

1

1

1

16 x 20

(406 x 508)

16 x 20

(406 x 508)

16 x 20

(406 x 508)

20 x 20

(508 x 508)

16 x 20

(406 x 508)

20 x 20

(508 x 508)

16 x 20

(406 x 508)

16 x 20

(406 x 508)

20 x 20

(508 x 508)

20 x 25

(508 x 635)

1

1

2

2

4

1

2

4

4

4

K L

2½

(64)

2½

(64)

3

(76)

3½

(89)

4½

(114)

2½

(64)

2½

(64)

3

(76)

3½

(89)

4½

(114)

11

(279)

13

(330)

16

(406)

19

(483)

23

(584)

11

(279)

13

(330)

16

(406)

19

(483)

23

(584)

Weight Information

BCF

Size

106

107

108

110

112

206

207

208

210

212

All weights are in lb. (kg)

*Unit weight is cataloged with the largest Open Proof Motor available.

2

*Unit

(36)

100

(45)

120

(54)

265

(120)

340

(157)

145

(66)

207

(84)

220

(100)

345

(156)

515

(234)

80

Filter Box Mixing Box

Slide-Out Sloped Without Damper With Damper

9

(229)

10

(254)

12

(305)

20

(508)

28

(711)

12

(305)

14

(356)

17

(432)

26

(660)

38

(965)

(610)

(660)

(991)

(1626)

(2184)

(889)

(914)

(1270)

(2007)

(3023)

24

26

39

64

86

35

36

50

79

119

14

(356)

17

(432)

23

(584)

40

(1016)

64

(1626)

19

(483)

23

(584)

31

(787)

51

(1295)

86

(2184)

29

(737)

36

(914)

45

(1143)

69

(1753)

100

(2540)

42

(1067)

52

(1321)

67

(1702)

93

(2362)

142

(3607)

Page 3

Pre-Starting Checks

Rotation

Airflow

Fasteners (2)

Fasteners (2)

Deflection =

Belt Span

62.5 (in.)

Belt Span

(in.)

(in.)

CORRECT

WRONG

WRONG

WRONG

WRONG

WRONG

®

®

WARNING: Disconnect and secure

to the “OFF” position all electrical

power to the fan prior to inspection or

servicing. Failure to comply with this

safety precaution could result in serious

injury or death.

Check all fasteners for tightness. The

blower wheel should rotate freely and

not rub on the fan panel venturi. Turn

the fan on momentarily to check for

unusual vibration or noise. Do not

run the fan more than a few seconds

without being connected to the system

for which it was designed. Motor

overloading and burnout may result

from lack of system static pressure.

Direction of wheel rotation is critical.

Reversed rotation will result in poor air

performance, motor overloading and

possible burnout. Check wheel rotation

by momentarily energizing the unit.

Rotation is always in the same direction

as airflow at the outlet. See Fig. 4.

Belt tension should be checked after

the first 24 hours of operation, after

100 hours of operation and periodically

thereafter. Premature belt failures are

frequently caused by improper belt

tension (either too tight or loose) or

misaligned pulleys. The proper tension

for operating a V-belt is the lowest

tension at which the belts will not slip.

Belt tension can be adjusted by

loosening the four fasteners on the

drive frame (pointed out in Fig. 5) and

sliding the motor base away from the

blower housing.

Fig. 5 - Drive Frame Fasteners

Belt tension should be adjusted to allow

1/64 inch (0.4 mm) of belt deflection

per inch of belt span. For example, a

16 inch (406 mm) belt span should have

16/64 inch (6.4 mm) or 1/4 inch (6.4 mm)

of deflection using moderate thumb

pressure at mid-point between pulleys,

see Fig. 6. Overtightening will cause

excessive bearing wear and noise.

Too little tension will cause slippage at

startup and uneven wear.

Fig. 6 - Belt Tension

It is very important that the pulleys

remain in proper alignment after

adjustments are made. Misalignment

of pulleys will result in premature belt

wear, noise, vibration and power loss.

See Fig. 7.

Fig. 7 - Pulley Alignment

Fig. 4 - Wheel Rotation

Maintenance

WARNING: Before servicing or cleaning

the unit, switch power off at service

panel and lock service disconnecting

means to prevent power from being

switched on accidentally. When the

service disconnecting means cannot

be locked, securely fasten a prominent

warning device, such as a tag, to the

service panel.

Once the fan has been put into

operation, a periodic maintenance

program should be set up to preserve

the reliability and performance of

the fan. Items to be included in this

program are:

BELTS, BEARINGS, MOTOR,

FASTENERS, and WHEEL(S).

To access the fan motor, drives and

blower simply remove the fasteners

attaching the bottom access door

and remove door carefully. Hinged

access doors are provided on fan

models 106, 107, 206, and 207. Provide

support for hinged access doors before

removing fasteners. The door supports

weight of the motor, blower, and drive

components. Bolted access doors

are provided on fan models 108, 110,

112, 208, 210, and 212. Bolted access

doors do not support weight of any

components.

BELTS

Belts tend to stretch after a period

of time. They should be checked

periodically for wear and tightness.

When replacing belts, use the same

type as supplied with the unit. Loosen

the sliding motor plate to allow removal

of the belt by hand. Do not force belts

on or off. This may cause cords to

break, leading to premature belt failure.

Once installed, adjust belts as shown in

“Pre-Starting Checks”, Fig. 6 and Fig. 7.

MOTOR

Motor maintenance is generally limited

to cleaning and lubrication (where

applicable). Cleaning should be limited

to exterior surfaces only. Removing

dust and grease build-up on motor

housing assures proper motor cooling.

Use a brush or vacuum to remove dust.

Motors should never be sprayed with

water or solvents.

Greasing of the motor is only intended

when fittings are provided. Many

motors are permanently lubricated and

should not be lubricated further.

Motors supplied with grease fittings

should be greased in accordance with

manufacturer’s recommendations.

Use caution not to over lubricate. Oil

spillage collects dust and dirt which

may obstruct motor cooling openings.

Where motor temperatures do not

exceed 104ºF (40ºC), the grease should

3

Page 4

WRONG

be replaced after 2,000 hours of

®

running times as a general rule.

WHEEL(S)

Wheels should be inspected for

dust and dirt accumulation at each

maintenance interval. Left unchecked,

dirt may cause wheel imbalance and

cause vibration. Keeping the wheel(s)

clean helps maintain a smooth and

quiet running fan.

FASTENERS

Any fan vibration has a tendency to

loosen mechanical fasteners. A periodic

inspection should include checking all

fasteners and set screws for tightness

prior to restarting the unit.

Troubleshooting

WARNING: Disconnect and secure to the “OFF” position all electrical power to the fan prior to inspection or

servicing. Failure to comply with this safety precaution could result in serious injury or death.

PROBLEM CAUSE CORRECTIVE ACTION

REDUCED AIRFLOW

EXCESSIVE NOISE

System resistance is too high. Check dampers for proper operation. Remove

obstructions in ductwork. Clean dirty filters. Check

for adequate supply air.

Unit running backwards. Correct. Adjust as described in “Pre-Starting

Checks”, Fig. 4.

Excessive dirt on wheel. Clean wheel.

Loose belt or pulleys. Refer to Fig. 6 and adjust tension.

Mechanical looseness. Check all fasteners and set screws for tightness.

Check the ductwork for rattles.

Wheel unbalanced. Check for dirt build-up and clean wheel if required.

Bad bearings. Replace bearings.

Incorrect belt tension. Adjust belts as described in “Pre-Starting Checks”,

Fig. 6.

Foreign objects in blower. Remove objects, check for damage or unbalance.

Defective motor. Replace motor.

4

Page 5

Fan

Filter Box

Mixing Box

C

B

A

D

®

Parts List

MOTOR

MOTOR PULLEY

BELT

SHAFT PULLEY

SHAFT

BEARINGS

DOOR

BLOWER

MOTOR BASE

DR. FRAME ANGLES

VIBRATION ISOLATORS (4)

CABINET

BEARING SUPPORTS

MOTOR

MOTOR PULLEY

SHAFT PULLEY

BELT

SHAFT

BEARINGS

BLOWER

MOTOR BASE

BEARING SUPPORTS

DOOR

DR. FRAME MOUNTS

VIBRATION ISOLATORS (8)

CABINET

®

BCF Sizes 106 thru 112

•

Fig. 8 - Replacement Parts Single Blower

BCF Sizes 206 thru 212

•

Fig. 9 - Replacement Parts Double Blower

5

Page 6

Fan

Filter Box

Mixing Box

C

B

A

D

®

WARRANTY

Greenheck warrants this equipment to be free from defects in material and workmanship for a period of one year from

the date of purchase. Any units or parts which prove to be defective during the warranty period will be replaced at our

option when returned to our factory, transportation prepaid. Motors are warranted by the motor manufacturer for a

period of one year. Should motors furnished by Greenheck prove defective during this period, they should be returned

to the nearest authorized motor service station. Greenheck will not be responsible for any removal or installation costs.

As a result of our commitment to continuous improvement, Greenheck reserves the right to change specifications

without notice.

IOM BCF Rev. 2 April 2007

Copyright © 2007 Greenheck Fan Corp.

Loading...

Loading...