Page 1

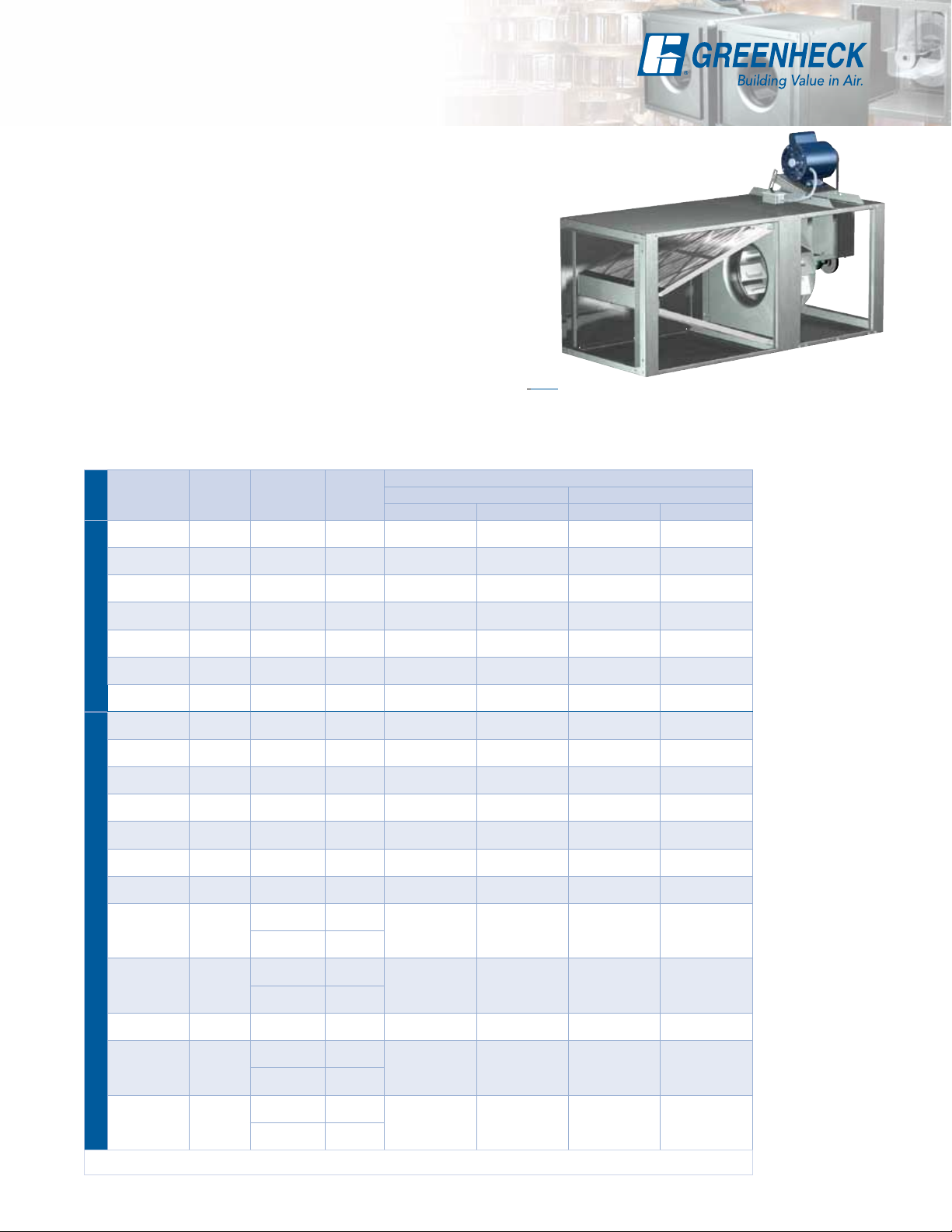

Centrifugal Inline Fans

Models SQ and BSQ

Direct and Belt Drive

VARI GREEN

Motor

April

2010

Page 2

Models SQ and BSQ

Centrifugal Square Inline Duct Fans

Greenheck’s model SQ and BSQ centrifugal inline

fans feature a unique combination of installation

flexibility, rugged construction, ease of service, high

efficiency and low sound levels. These compact

inline fans are the ideal selection for indoor clean

air applications including intake, exhaust, return

or make-up air systems where space is a prime

consideration. The need for costly square-to-round

transition pieces is eliminated reducing installation

costs. The square housing design, compact size

and straight-thru airflow also give the system

designer the flexibility to mount SQ and BSQ fans

in any configuration - horizontal, vertical or at

any angle.

Greenheck Fan Corporation certifies the model SQ and BSQ

fans shown herein are licensed to bear the AMCA Seal. The

ratings shown are based on tests and procedures performed

in accordance with AMCA Publication 211 and Publication

311 and comply with the requirements of the AMCA Certified

Ratings Program. The certified ratings for models SQ and BSQ

are shown on pages 14 to 44.

*UL is optional and must be

specified. SQ and BSQ models are

listed for electrical (UL/cUL 705)

File no. E40001

Table of Contents

Standard Construction Features . . . . . . . . .4-5

Options and Accessories . . . . . . . . . . . . . . . . 6

Vari-Green Motor. . . . . . . . . . . . . . . . . . . . . . . 7

Discharge Configurations . . . . . . . . . . . . . . .8-9

Mounting Options . . . . . . . . . . . . . . . . . . . . . 10

Isolators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Filter Options . . . . . . . . . . . . . . . . . . . . . . . . . 12

• Broadest performance in the industry, up to

4 in. wg (1,000 Pa) and 28,000 cfm (47,000 m

3

/hr).

• Performance as cataloged is assured. All

fan sizes are tested in our AMCA Accredited

Laboratory, and all models are licensed to bear

the AMCA sound and air performance seals.

• UL Listed for electrical

• These Greenheck products are subjected to

extensive life testing to assure the fans will

provide many years of reliable performance

Over the years Greenheck has listened to your

needs and input to remain the industry leader.

• Each fan is tested at the factory prior to shipping.

The test includes vibration check, adjusting RPM

and maximum amp draw test.

• Each fan displays a permanently stamped metal

nameplate with complete model number, mark

and unique serial number for future identification.

• Packages are tested in accordance with ISTA

(International Safe Transit Association) standards

and procedures.

Turn to our inline fans to meet your requirements

for applications in office buildings, schools and

hospitals to name a few.

Typical Installation . . . . . . . . . . . . . . . . . . . . 13

Model Number Code . . . . . . . . . . . . . . . . . . . 13

Direct Drive . . . . . . . . . . . . . . . . . . . . . . . . 14-22

Belt Drive . . . . . . . . . . . . . . . . . . . . . . . . . .23-44

Specificatons. . . . . . . . . . . . . . . . . . . . . . .45-46

Centrifugal Inline Guide . . . . . . . . . . . . . . . . 47

Quick Delivery . . . . . . . . . . . . . . . . . . . . . . . . 48

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

2

Page 3

The Greenheck Standard

Leading

Edge

Technical

Support

When product and

IOM (Installation, Operation and Maintenance Manual)

information is needed, our products are supported

by the industry’s best product literature, electronic

media and Computer Aided Product Selection (CAPS)

program. You’ll also find this information on our

web site at www.greenheck.com

Our national and international representative

organizations provide personal service and

expertise. To locate your nearest Greenheck

representative, call 715-359-6171 or visit our

web site at www.greenheck.com

Outstanding

Customer Service

Your local Greenheck representative has a wealth

of industry and product knowledge to answer your

questions. Our representatives receive the latest

product information and can have orders processed

directly to our factory. With our direct order

processing system, we can ship orders as fast as

the next day. With Greenheck’s experienced staff,

we can answer questions

and provide solutions.

Greenheck’s Quick Delivery

Program provides many

options to help you meet

your project’s schedule.

Stocking warehouses and

distribution centers around

the world ensure sameday pickup and same-day

shipment for orders in by

2 p.m. (CST). Hundreds of custom products can be

manufactured through Quick Build in just days.

Please refer to chart on back cover for model size

and availability for QD and QB programs. The

Greenheck Stock & Quick Build Catalog is a great

resource for specific options and accessories

available with QD and QB fans.

LEED

Greenheck is driving the fan industry in the

Green Building and LEED charge. As one of the

first manufacturers in the air movement industry

to join the United States Green Building Council

in 2005, we have been actively researching how

our products can be applied. This commitment

to the green movement continues with product

development that qualifies within the LEED rating

system—it’s prerequisites and credits.

The Vari-Green motor is

equipped to play a large role in

the green building movement,

specifically Prerequisite Two;

Minimum Energy Performance

and Credit One; Optimize

Energy Performance.

See page 7 for more information.

World Class Manufacturing

Greenheck’s skilled production workers use cost-effective machines and

unique dies, designed and built by our own engineers to add innovative

features and greater strength to our centrifugal inline fans. Our advanced

manufacturing processes and quality control procedures always ensure the

highest product quality. And just to be sure you get the peace-of-mind you

expect when you specify Greenheck, our assembly inspectors test run and

monitor every fan before it leaves the factory. Results of these tests are kept

in permanent records for future reference.

3

Page 4

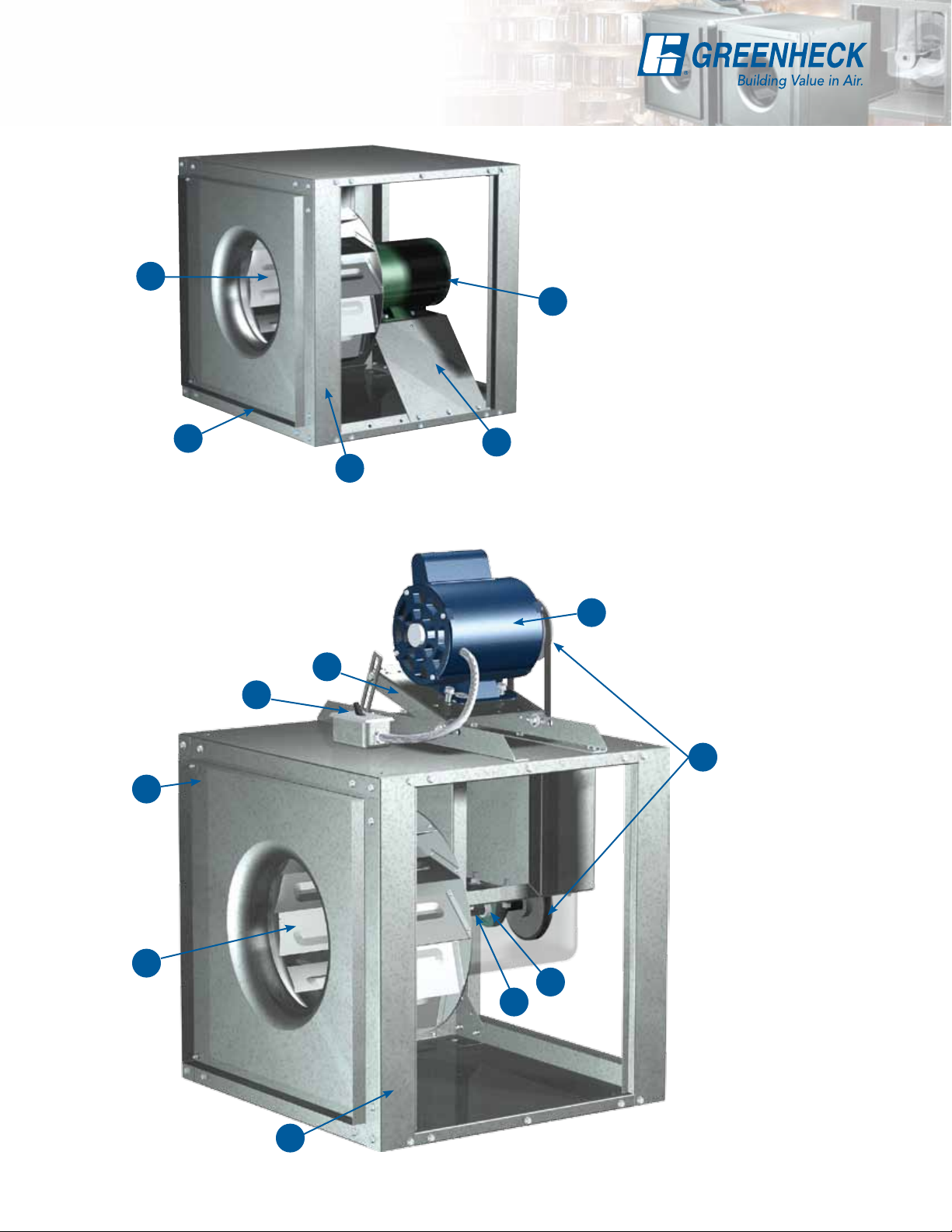

Standard Construction Features

3

Model SQ Direct Drive

5

4

1

2

Model BSQ Belt Drive

5

2

9

7

4

3

6

8

1

4

Page 5

Standard Construction Features

1 Cabinet Construction

The fan housing is constructed of rigid

structural members and formed galvanized

steel panels. (Aluminum construction is

optional in all SQ sizes 60-160 and in

BSQ sizes 70-300.)

2 Drive Frame

Constructed from heavy gauge steel.

3 Wheel

An aluminum, backward inclined, nonoverloading centrifugal wheel is utilized to

deliver maximum efficiency. Each wheel is

statically and dynamically balanced.

4 Duct Collars

Inlet and discharge duct collars are provided

for easy duct connection. The square design

provides a larger discharge area than tubular

centrifugal, and vane axial fans; outlet

velocities are reduced for quieter operation.

5 Motor

Permanently lubricated, sealed ball

bearing motors are selected to provide

years of trouble-free operation with

minimal maintenance.

7 Drive Assembly

Drives are sized for a minimum of 150 percent

of driven horsepower. Machined cast iron

pulleys are factory set to the required RPM

and adjustable for final system balancing.

Belts are static free and oil resistant. Belt

adjustment is accomplished by loosening

fasteners, sliding the motor plate and

retightening fasteners.

8 Fan Shaft

Precisely sized, ground and polished so

the first critical speed is at least 25 percent

over the maximum operating speed. Close

tolerances where the shaft makes contact

with bearings result in longer bearing life.

9 Disconnect Switch

NEMA-1 disconnect switch is factory mounted

and wiring is provided from the motor as

standard. All wiring and electrical components

comply with the National Electric Codes

and materials are UL Listed. Other NEMA

enclosure disconnect switches are optional.

Access Panels (not shown on images)

The cabinet construction features two side

access panels. These panels permit easy

access to all internal components.

6 Bearings

100 percent factory tested bearings are

designed specifically for air handling

applications with a minimum L10 life in excess

of 100,000 hours (L50 average life in excess of

500,000 hours).

5

Page 6

Options and Accessories

Aluminum Construction

Aluminum construction is available for all direct

drive sizes 60-160 and belt drive sizes 70-300.

Some drive frame components may still be of

galvanized construction to maintain

structural integrity.

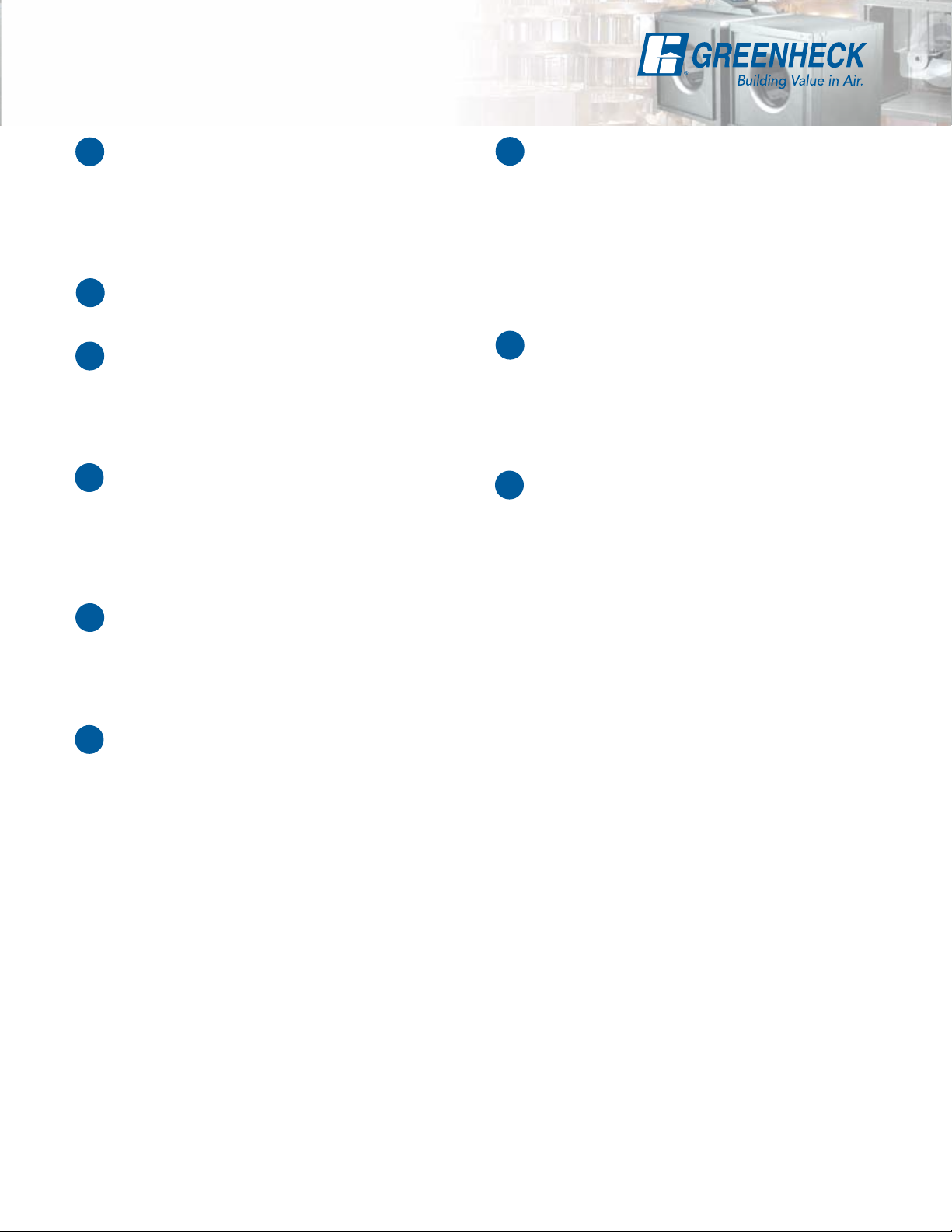

Speed Controllers

Available for use with

shaded pole and

permanent split capacitor

(PSC) motors on model

SQ fans. They provide

an economical means of

system balancing with direct drive fans.

Inlet and Outlet Guards

Inlet and outlet guards provide protection for nonducted applications. Guards are fabricated of

welded wire on a galvanized steel frame. They are

easily removed for maintenance and inspection.

Belt Drive Motor Cover and Belt Guard

For belt driven fans, combination motor cover

and belt guards constructed of galvanized steel

are available for protection of motors, drives and

personnel. Standard on units specified with UL.

Coatings

Wide variety of coatings

and colors are available.

Decorative coatings

are available in sixteen

standard colors.

Protective coatings are

available in a choice of

five electrostatic applied

powders providing an

available selection for

most environments.

All Greenheck coatings and resistance charts can

be found in the performance coatings catalog.

Inlet Vane Dampers

Variable inlet vane dampers (model IVDE) are

available for models SQ and BSQ sizes 140-420

and are factory assembled to the fan. They can be

specified for either manual or automatic operation

(controls furnished by others). These dampers

are constructed of heavy gauge steel and feature

uniform blade movement for positive control.

Companion inlet rings for round duct connections

are also available.

Direct Drive Motor Cover

Formed, galvanized steel motor covers are

available to isolate direct drive motors from the

airstream. When motor covers are furnished, vents

to the exterior of the fan are provided to ensure

sufficient motor cooling.

Backdraft Dampers

Gravity or motorized

parallel blade dampers

(model WD-330) are

available for duct

mounting. These

dampers feature sturdy

galvanized frames with

prepunched mounting

holes, aluminum blades

with felt edges, and a balanced design for minimal

resistance to airflow.

Control Dampers

Square, opposed blade volume control dampers

(model VCD) are available for duct mounting. These

dampers feature sturdy galvanized frames with

prepunched mounting holes, steel blades with vinyl

seals, and flexible metal jamb seals. A balanced

design results in minimal resistance to airflow.

Insulated Housing

For noise reduction and condensation control,

the interior of the fan housing can be lined with

a 1-inch fiberglass duct liner. The optional motor

cover can also be insulated.

The table depicts the radiated sound reduction

that can be obtained in each octave band for the

insulated housing and motor cover together.

Approximate Radiated Sound Attenuation (dB)

Octave Band 1 2 3 4 5 6 7 8

Sizes 60 - 130 -2 -7 -4 -4 -6 -13 -13 -9

Sizes 140 - 420 -3 -2 -5 -4 -5 -5 -7 -8

Wiring Pigtail

Allows direct hook-up to the power supply

eliminating field wiring at the fan.

6

Page 7

Vari-Green Motor

Electrically Commutated,

Controllable, Efficient

Start saving now—with

the new, low-cost, easy

to control, electronicallycommutated motor that

offers high reliability

and low maintenance.

VARI GREEN

technology, controllability and energy-efficiency into

a low maintenance package that is changing the

way the industry designs, specifies and operates air

movement equipment.

Motor

The Greenheck VariGreen (VG) motor blends

Reliability

With industry leading technology comes a new

standard in motor reliability

• No shaft grounding required regardless of

the turndown

• Bearing life is greater since the motor runs cooler

the further it is turned down

• No voltage or current spikes as in VFD

controlled motors

Electronic Commutation

Electronic commutation uses electronic circuitry to

control the motor’s functions:

• Solid state circuitry controls the output of power

and the speed of rotation

• Internal circuitry converts 115 volt single phase

AC power to DC voltage for increased efficiencies

and full controllability of speed

1

2

3

Speed Control Options

Motor is available with one of these control options:

1. Motor mounted dial

2. Control wire inputs (0-10V)

3. Remote dial (available with 0-10V motor).

Motor and Fan Sizes

VG Motors come in three fractional horsepowers;

1/4, 1/2, 3/4 and are available in both 50 and

60 Hz power on models G, CUE, CW, and SQ.

Consult factory for other motor sizes available.

Better than a PSC

• Potentiometer dial pre-mounted on motor for

speed control

• 80% usable turndown vs. 30% with PSC motor

• No speed controller to wire

• 20%-70% energy savings

• Full speed range for better adjustment

More Efficient than Belts

• Potentiometer dial pre-mounted on motor for

speed control

• No belt and pulley losses

• Higher efficiency motor

• 40% energy savings

• Lower up-front

cost

• No maintenance

required

Easier than

VFDs

• 0-10 volt control

wires preinstalled in motor

• No VFD to buy or

install

• 30% energy savings

• Lower up-front cost

• Eliminates stray current and carrier frequencies

Model SQ with

Vari-Green motor

Specifications

• Motor enclosures: Open type

• Motor to be a DC electronic commutation

type motor (ECM) specifically designed for fan

applications. AC induction type motors are not

acceptable. Examples of unacceptable motors

are: Shaded Pole, Permanent Split Capacitor

(PSC), Split Phase, Capacitor Start and 3 phase

induction type motors.

• Motors are permanently lubricated, heavy duty

ball bearing type to match with the fan load and

pre-wired to the specific voltage and phase

• Internal motor circuitry to convert AC power

supplied to the fan to DC power to operate the

motor.

• Motor shall be speed controllable down to 20%

of full speed (80% turndown). Speed shall be

controlled by either a potentiometer dial mounted

at the motor or by a 0-10 VDC signal

• Motor shall be a minimum of 85% efficient at

all speeds

7

Page 8

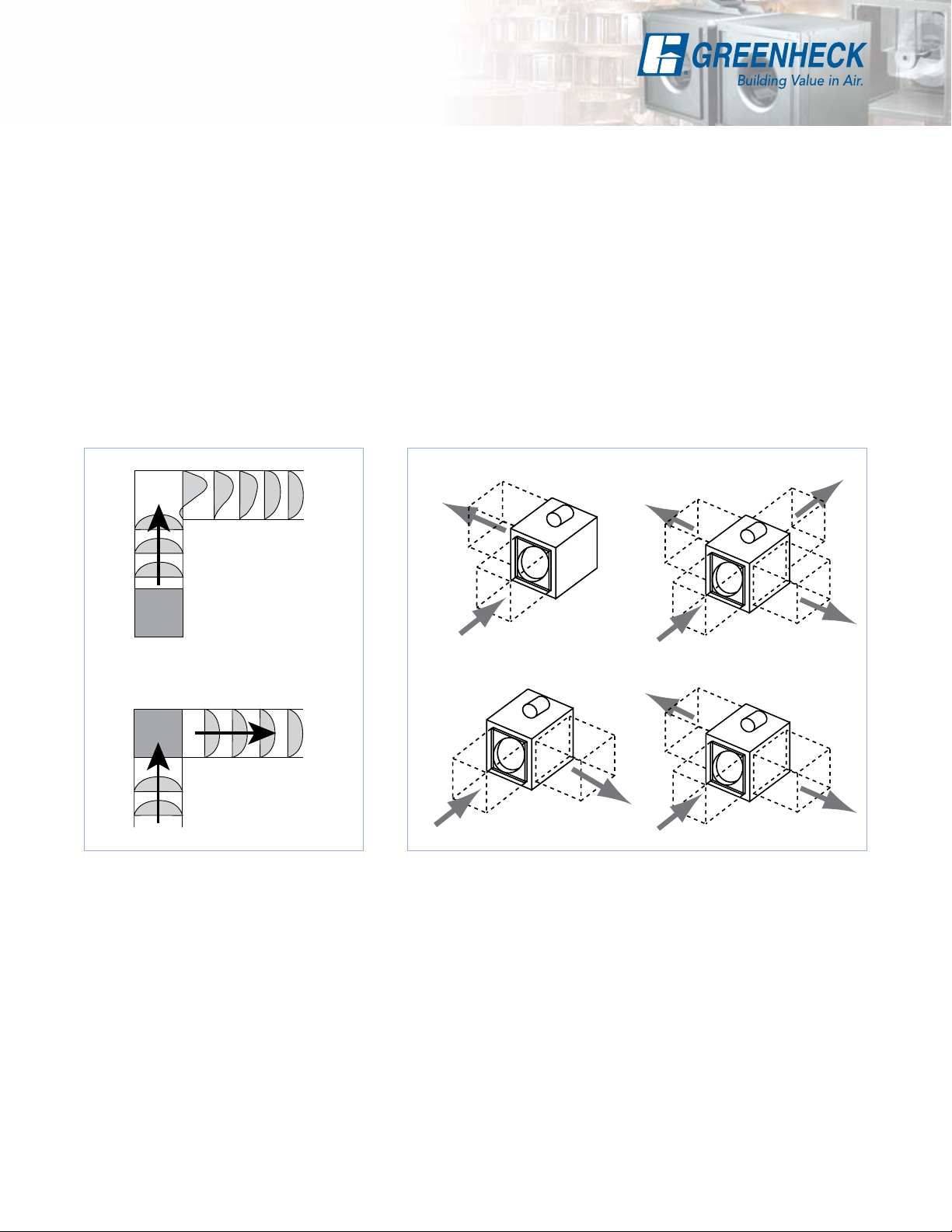

Discharge Configurations

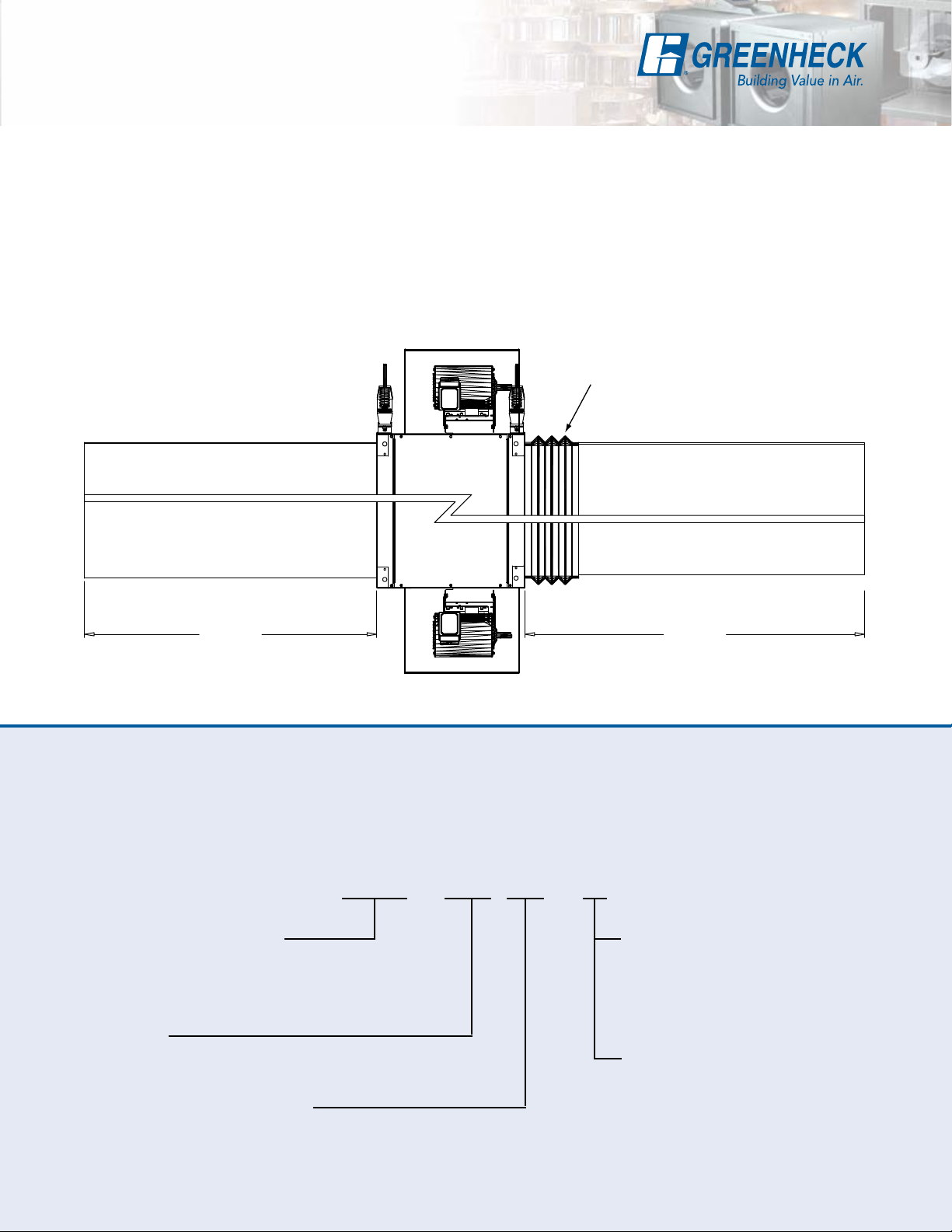

The side discharge option helps to reduce system

effect. It will increase performance and reduce

installation labor. The most notable is reducing

system effects. Note the figure 1 example, it shows

the air being discharged into the corner. It will take

several duct lengths before the airflow becomes

laminar or smooth again after making the turn.

In figure 2, the fan is placed in the corner using a

side discharge. In this configuration the air flow

pattern at discharge is smooth and supports a more

predictable system. Remember the duct length

on the discharge side, should be approximately

two to three wheel diameters to achieve catalog

performance.

Left Discharge

Discharge Configuration

Fan performance will change with different

discharge positions. Catalog data is based on an

inline discharge. Right side discharge will give

you 108% of cataloged performance and left side

will give you 109% of cataloged performance.

Use figure 3 to locate the orientation to fit your

application. Figures 4 and 5 on the facing page

illustrate the proper side discharge definitions.

Refer to the CAPS program or consult factory for

performance modifications.

Left, Right & Inline Discharge

Fan

Fan

Figure 1

Figure 2

Right Discharge

Figure 3

Left & Right Discharge

8

Page 9

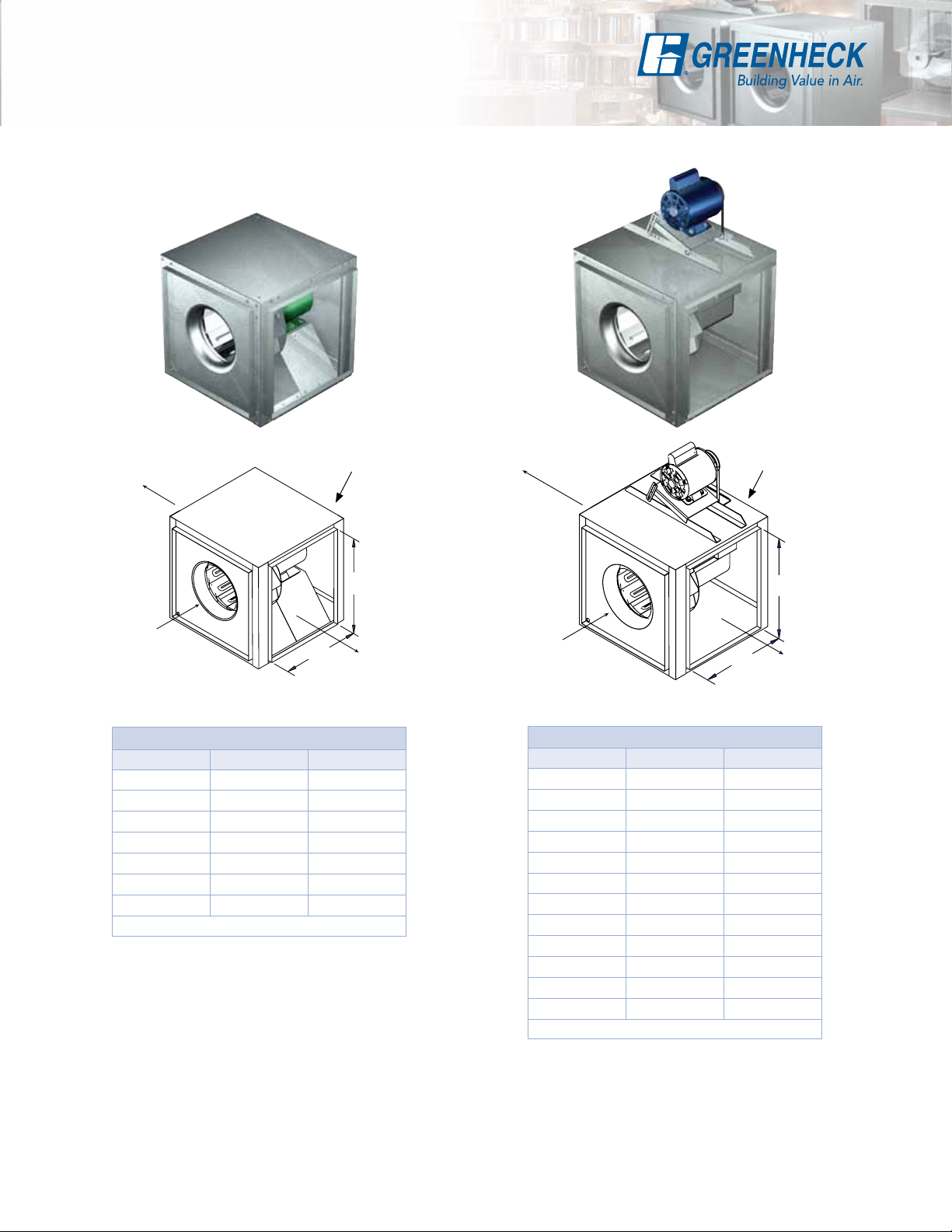

Side Discharge

Left Side

Discharge

Figure 4

SQ Side Discharge

Access Door

Inline

Discharge

Height

Left Side

Discharge

Figure 5

BSQ Side Discharge

Access Door

Height

Inline

Discharge

Inlet

Width

SQ Side Discharge Duct Openings

Unit Size Width Height

60-75 9

80-95 127⁄8 (327) 117⁄8 (302)

100 137⁄8 (352) 137⁄8 (352)

120 157⁄8 (403) 157⁄8 (403)

130 177⁄8 (454) 177⁄8 (454)

140 197⁄8 (505) 197⁄8 (505)

160 227⁄8 (581) 227⁄8 (581)

All dimensions in inches (millimeters).

7

⁄8 (251) 87⁄8 (225)

Right Side

Discharge

Inlet

BSQ Side Discharge Duct Openings

Unit Size Width Height

70-80-90 11

100 137⁄8 (352) 137⁄8 (352)

120 157⁄8 (403) 157⁄8 (403)

130-130HP 177⁄8 (454) 177⁄8 (454)

140-140HP 197⁄8 (505) 197⁄8 (505)

160-160HP 227⁄8 (581) 227⁄8 (581)

180-180HP 237⁄8 (606) 237⁄8 (606)

200-200HP 277⁄8 (708) 277⁄8 (708)

240-240HP 287⁄8 (733) 347⁄8 (886)

300-300HP 317⁄8 (810) 417⁄8 (1064)

360-360HP 327⁄8 (835) 377⁄8 (962)

420 347⁄8 (886) 437⁄8 (1114)

All dimensions in inches (millimeters).

7

⁄8 (302) 117⁄8 (302)

Width

Right Side

Discharge

9

Page 10

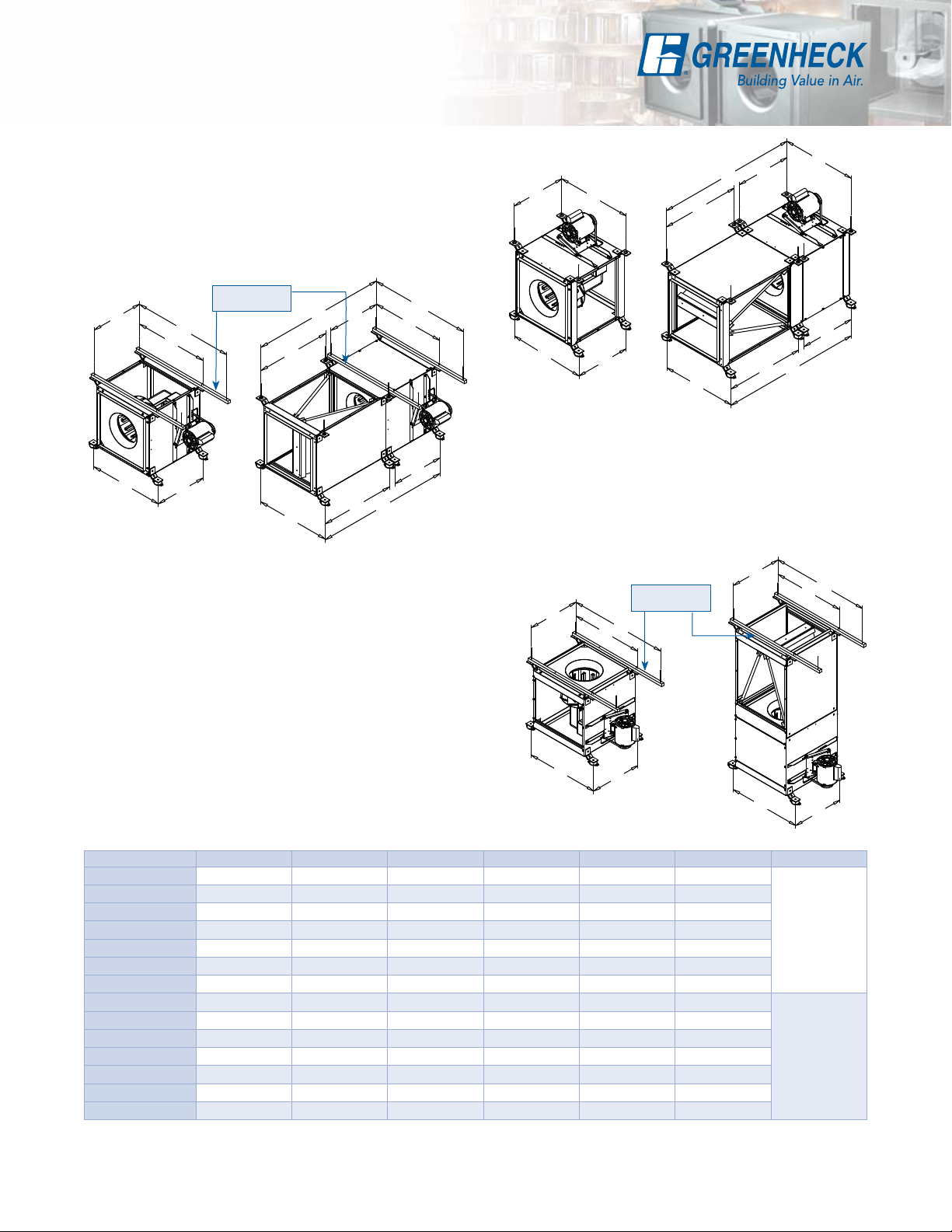

Horizontal and Vertical

Mounting Options

All SQ and BSQ fan models can be mounted

horizontally, vertically or at an angle. For ease of

installation, knockouts are provided at each location

where mounting brackets are shown in figures 6, 7

and 8. Optional brackets are universally adjustable

to mount in any of these locations.

NOTE: Hanging

A

rails by others

E

A

G

B

F

G

B

A

B

A

F

E

B

Figure 6

Horizontal Hanging or Base Mount

With either a hanging or base mount the motor

may be located on either side. The base mount

allows top access panels only.

E

A

A

C

F

C

A

C

A

F

E

C

Figure 7

Horizontal Hanging or Base Mount

With a hanging mount, the motor may be located

on either top or bottom. The base mount allows

top motor location only. Both options provide

access panels on two sides.

D

NOTE: Hanging

B

rails by others

G

D

G

B

Figure 8

Vertical Hanging or Base Mount

Mounting brackets are turned

90° for vertical mounting. Access

panels are located on the two sides

adjacent to the motor.

Model A B C D E F G

SQ 60-75 10

SQ 80-95 131⁄4 (337) 20 (508) 183⁄4 (476) 117⁄8 (302) 43 (1092) 273⁄8 (695)

BSQ 70-90 185⁄8 (473) 201⁄8 (511) 183⁄4 (476) 117⁄8 (302) 485⁄16 (1227) 273⁄8 (695)

SQ-BSQ 100 185⁄8 (473) 221⁄8 (562) 203⁄4 (527) 137⁄8 (352) 447⁄8 (1140) 24 (610)

SQ-BSQ 120 185⁄8 (473) 24 (610) 223⁄4 (578) 16 (406) 493⁄8 (1254) 281⁄8 (714)

SQ-BSQ 130 185⁄8 (473) 261⁄8 (664) 243⁄4 (629) 177⁄8 (454) 44 (1118) 23 (584)

SQ-BSQ 140 195⁄8 (498) 281⁄8 (714) 263⁄4 (679) 197⁄8 (505) 501⁄16 (1272) 28 (711)

SQ-BSQ 160 231⁄2 (597) 31 (787) 293⁄4 (756) 227⁄8 (581) 495⁄8 (1260) 235⁄8 (600)

BSQ 180 251⁄2 (648) 331⁄2 (851) 299⁄16 (751) 223⁄4 (578) 529⁄16 (1335) 241⁄2 (622)

BSQ 200 291⁄8 (740) 37 (940) 333⁄4 (857) 263⁄4 (679) 643⁄16 (1630) 321⁄4 (819)

BSQ 240 315⁄8 (803) 441⁄4 (1124) 403⁄4 (1035) 337⁄8 (860) 661⁄2 (1689) 321⁄8 (816)

BSQ 300 35 (889) 51 (1295) 473⁄4 (1213) 407⁄8 (1038) 691⁄8 (1756) 313⁄8 (797)

BSQ 360 383⁄4 (974) 571⁄4 (1454) 531⁄2 (1359) 463⁄4 (1187) 76 (1930) 3411⁄16 (881)

BSQ 420 471⁄8 (1197) 63 (1600) 597⁄8 (1521) 597⁄8 (1521) 901⁄2 (2299) 401⁄2 (1029)

All dimensions in inches (millimeters).

5

⁄8 (270) 17 (432) 153⁄4 (400) 87⁄8 (225) 193⁄4 (502) 7 (178)

B

D

B

D

Hanging

rails not

included.

Supplied by

others.

Hanging

rails not

included.

Supplied by

others.

10

Page 11

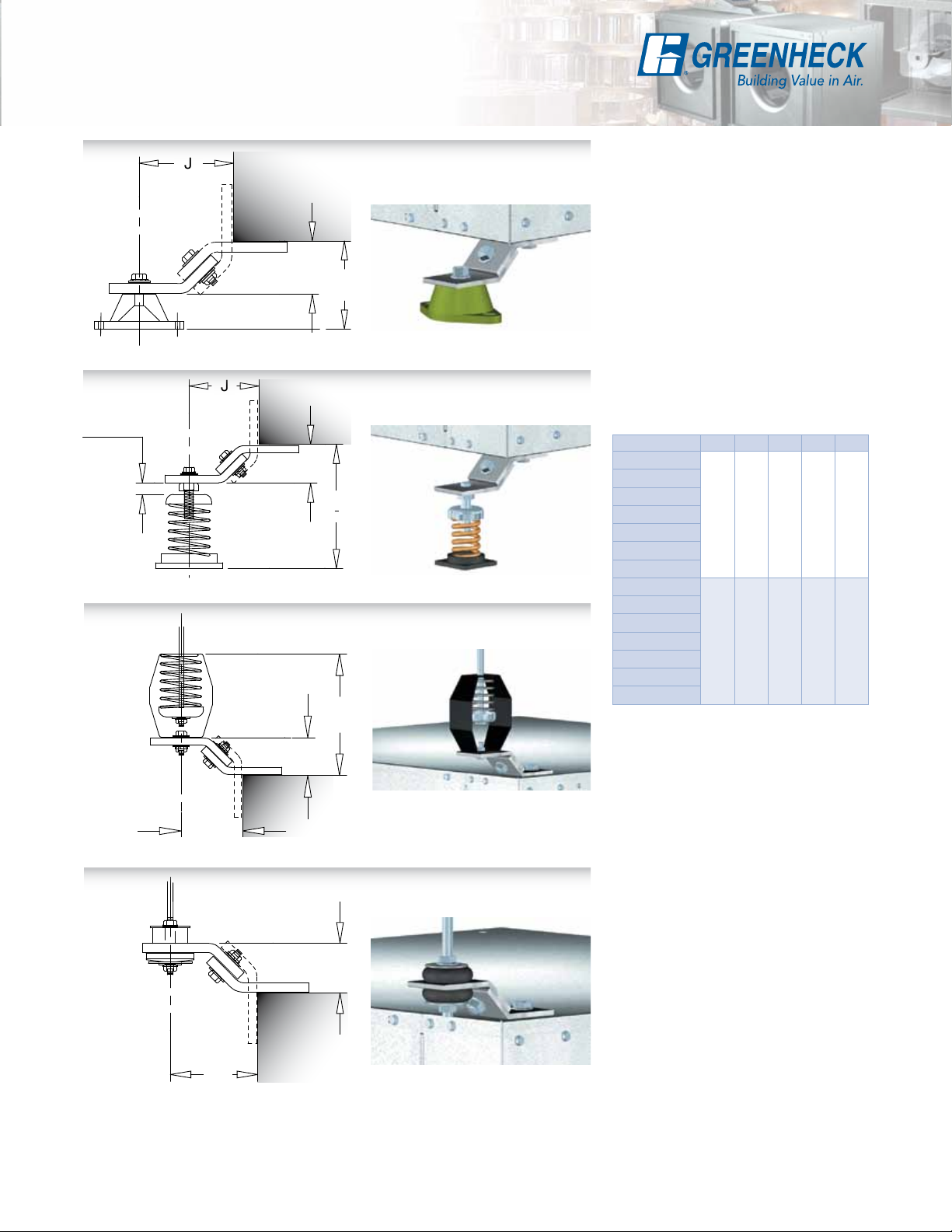

Base Mount or Hanging Isolators

5

⁄8 inch (16 mm)

nominal

J

Standing Neoprene Isolator

Complete isolation kits are

available with either neoprene or

spring isolators and are sized to

match the weight of the specified

fan size. The hanging isolator

support brackets are designed to

H

L

permit mounting of the fan with

the motor located on top, bottom

or side. The base isolator support

brackets are designed to permit

mounting of the fan with the motor

located on top or either side.

J

Standing Spring Isolator

H

I

Hanging Spring Isolator

K

Note: Hanging rods to be supplied

by others.

Model H I J K L

SQ 60-75

SQ 80-95

BSQ 70-90

SQ-BSQ 100

SQ-BSQ 120

SQ-BSQ 130

SQ-BSQ 140

SQ-BSQ 160

BSQ 180

BSQ 200

BSQ 240

BSQ 300

BSQ 360

BSQ 420

All dimensions in inches (millimeters).

1

(35)

1

(35)

3

3

⁄8

(140)2 (51)

⁄8

(140)2 (51)

51⁄2

51⁄2

63⁄4

(171)

63⁄4

(171)

25⁄16

(59)

25⁄8

(67)

H

J

Hanging Neoprene Isolator

H

J

11

Page 12

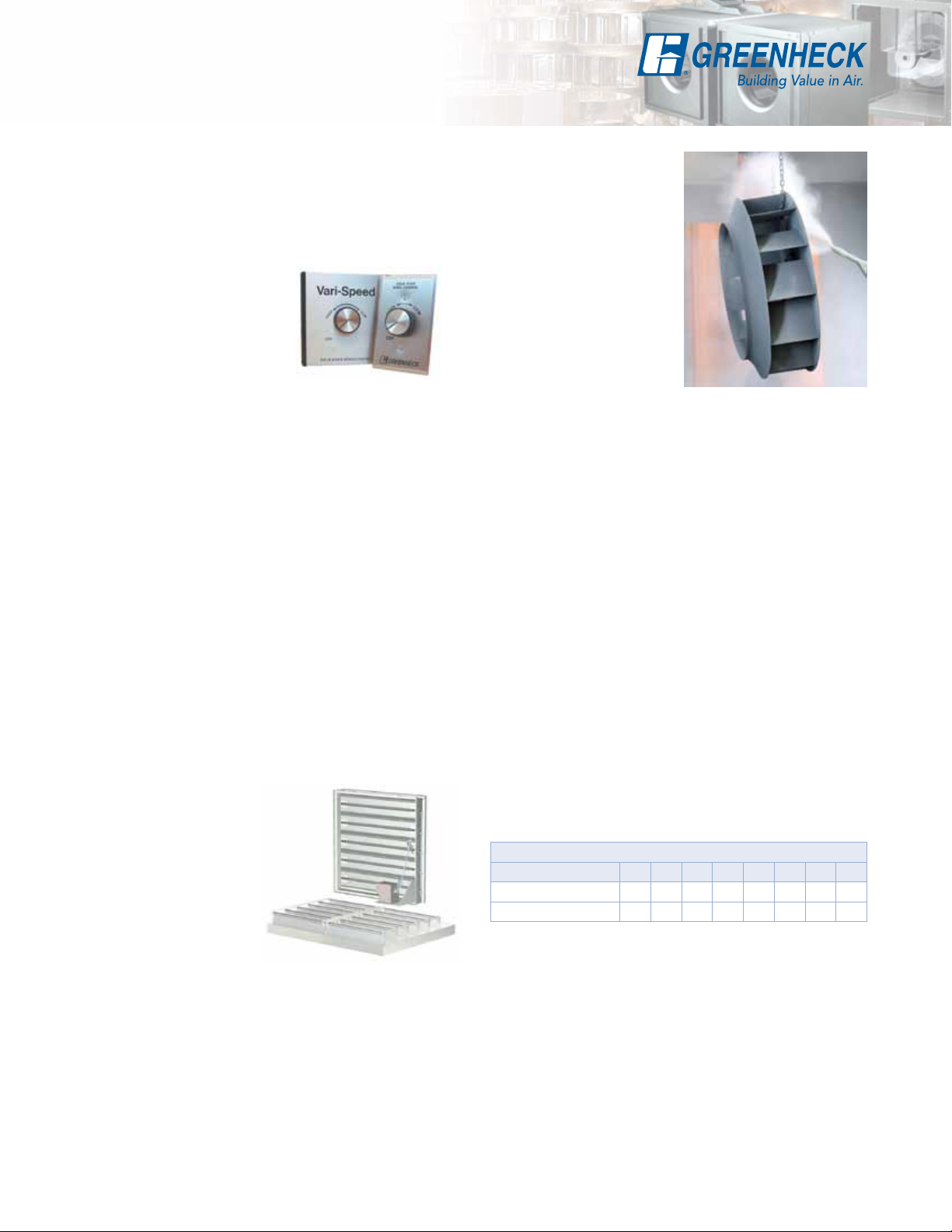

Filter Options

The filter box is designed to provide a compact and convenient clean

air solution. Factory assembled as a single unit, this fan eliminates the

costly process of designing, fabricating and installing special remote

filter box assemblies. Both the fan and filter section feature

removable access panels on both sides to remove and replace

filters, making fan maintenance simple and fast.

Model Selection Procedure

1. Calculate system pressure drop and cfm requirements

(not including filters).

2. Make a preliminary model size selection.

3. Calculate a filter pressure drop (P) for the preliminary

model size selected in step 2 using the equation: P = F x (

To determine the filter factor (F) refer to chart below.

•

4. Add the filter pressure drop (P) to the system pressure drop and make a revised model size selection.

cfm

10,000

2

)

12

Fan

Size

Model

60 - 75

80 - 95

100

120

130

Model SQ

140

160

70 - 80 - 90

100

120

130 - 130HP

140 - 140HP

160 - 160HP

180 - 180HP

200 - 200HP

Model BS Q

240 - 240HP

300 - 300HP

360 - 360HP

420

Note: 24-inch side clearance is recommended for accessing and removing filters.

All dimensions in inches (millimeters) and weight in pounds (kilograms).

Filter Box

Weight

40

(18)

74

(34)

88

(40)

114

(52)

120

(54)

174

(79)

246

(112)

117

(53)

120

(54)

144

(79)

140

(64)

181

(82)

294

(133)

344

(156)

441

(200)

573

(260)

759

(344)

957

(434)

1185

(538)

Filter Size

10 x 12

(254 x 305)

14 x 25

(356 x 635)

16 x 20

(406 x 508)

16 x 25

(406 x 635)

20 x 20

(508 x 508)

20 x 25

(508 x 635)

20 x 20

(508 x 508)

14 x 25

(356 x 635)

16 x 20

(406 x 508)

16 x 25

(406 x 635)

20 x 20

(508 x 508)

20 x 25

(508 x 635)

20 x 20

(508 x 508)

20 x 25

(508 x 635)

12 x 25

(305 x 635)

16 x 25

(406 x 635)

20 x 25

(508 x 635)

16 x 25

(406 x 635)

20 x 25

(508 x 635)

16 x 25

(406 x 635)

20 x 25

(508 x 635)

16 x 25

(406 x 635)

20 x 25

(508 x 635)

Filter

Quantity

Aluminum Paper Filters Aluminum Paper Filters

1 186 318.06 251.1 303.18

1 21.8 37.28 29.43 35.53

2 8.72 14.91 11.77 14.21

2 5.58 9.54 7.53 9.10

2 5.58 9.54 7.53 9.10

2 3.57 6.11 4.82 5.82

4 2.09 3.57 2.82 3.41

1 21.8 37.28 29.43 35.53

2 8.72 14.91 11.77 14.21

2 5.58 9.54 7.53 9.10

2 5.58 9.54 7.53 9.10

2 3.57 6.11 4.82 5.82

4 2.09 3.57 2.82 3.41

4 1.34 2.29 1.81 2.18

3

0.77 1.32 1.04 1.26

3

4

0.41 0.70 0.55 0.67

4

8 0.33 0.56 0.45 0.54

10

0.15 0.26 0.20 0.25

5

5

0.13 0.22 0.18 0.21

10

Filter Factor (F)

1 inch (25) 2 inch (51)

Page 13

Typical Installation

Models SQ/BSQ ducted inline fans are designed

for the exhaust, supply or recirculation of air in a

building. Typical installation requires ductwork on

the inlet and outlet side of the fan. A minimum of

three duct diameters is required on the inlet and

outlet of the fan to minimize system effect losses.

See the diagram below for a typical installation.

Installations can include flexible duct connections

(by others) on either the inlet or outlet side of the fan

or both. The motor is rigidly mounted and can be

oriented in any direction (top, bottom, side).

The model BSQ ducted inline fan must be installed

with the motor accessible for maintenance and

inspection.

External isolators are recommended, hanging

(shown below) or base mounted.

Installation must meet all local governing codes

and the NEC.

Flexible duct (by others)

3 Wheel

Diameters

3 Wheel

Diameters

Model Number Code

The model number system is designed to completely identify the fan. The correct code letters must be

specified to designate belt or direct drive. The remainder of the model number is determined by the size

and performance selected from the following pages.

BSQ - 300 HP - 75

MODEL CONFIGURATION

BSQ - Belt Drive Inline Exhaust

SQ - Direct Drive Inline Exhaust

FAN SIZE

60 through 420

PRESSURE LEVEL (Belt Drive Only)

HP - High Pressure Wheel

MOTOR HP

6 = 1/6 7 = 3/4 30 = 3

4 = 1/4 10 = 1 50 = 5

3 = 1/3 15 = 11⁄2 75 = 71⁄2

5 = 1/2 20 = 2 100 = 10

MOTOR RPM

A = 1725 D = 1550

B = 1140 E = 1050

C = 860 G = 1300

(Belt Drive only)

(Direct Drive only)

13

Page 14

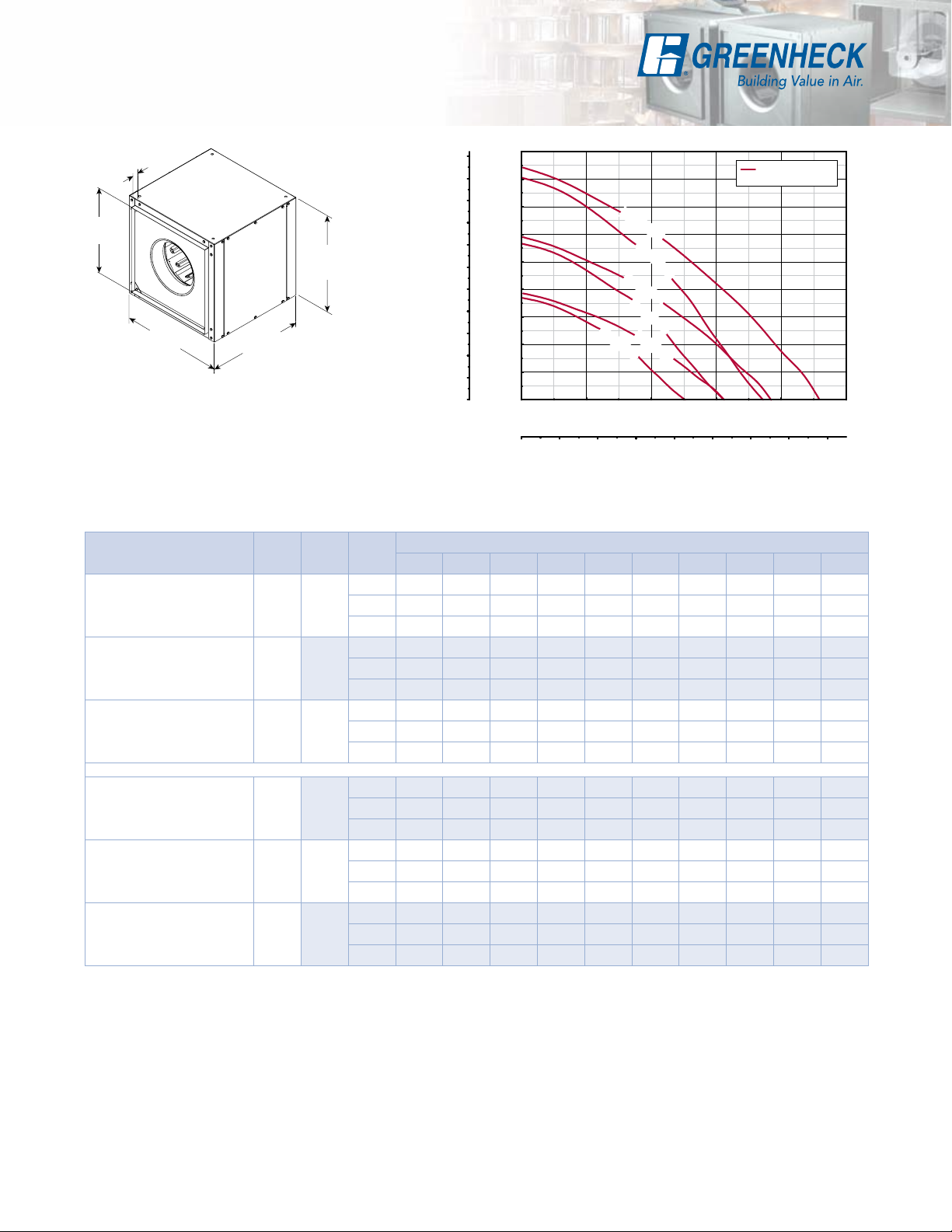

SQ 60-65 - Direct Drive

1

(25)

87⁄8

(225)

12

(305)

12

(305)

13

(330)

Damper size = 9 x 9 (229 x 229)

Unit weight** = 26 (12)

Housing thickness = 20 ga

Outlet velocity = 1.828 x cfm

Dimensions shown in inches (millimeters) and weight is

shown in pounds (kilograms).

**Weight shown is largest cataloged Open Drip Proof motor.

Model Number

Motor HPFan

RPM

SQ-60-E 1/140 1050

SQ-60-G 1/80 1300

SQ-60-D 1/40 1550

110

100

Static Pressure Pa

0.45

RPM

0.40

90

0.35

80

0.30

70

0.25

60

50

0.20

40

0.15

30

Static Pressure in. wg

0.10

20

0.05

10

0.00

0

0 50 100 150 200 250

SQ-65-D

SQ-65-G

SQ-60-E

SQ-60-D

SQ-60-G

SQ-65-E

Density 0.075 lb/ft

3

cfm

0 50 100 150 200 250 300 350 400

3

/hr

m

CFM / Static Pressure in Inches wg

0.000 0.050 0.100 0.125 0.150 0.200 0.250 0.300 0.350 0.375

CFM 126 101 78 63 42

BHP 0.005 0.006 0.007 0.007 0.006

Sones 1.7 1.7 1.8 1.8 1.9

CFM 156 135 117 109 99 72 37

BHP 0.01 0.011 0.012 0.012 0.013 0.013 0.012

Sones 2.5 2.5 2.5 2.5 2.5 2.5 2.5

CFM 186 168 153 145 138 122 105 78 47 31

BHP 0.017 0.018 0.019 0.02 0.020 0.022 0.022 0.021 0.020 0.019

Sones 4.0 4.0 4.0 4.0 4.0 4.0 4.0 4.1 4.1 4.1

CFM 154 129 98 79 56

SQ-65-E 1/100 1050

BHP 0.007 0.008 0.009 0.009 0.008

Sones 2.1 2.0 2.0 1.9 1.9

CFM 191 171 149 137 123 92 52

SQ-65-G 1/50 1300

BHP 0.013 0.014 0.016 0.016 0.017 0.016 0.015

Sones 2.9 2.9 2.9 2.9 2.9 2.8 2.8

CFM 228 213 194 184 175 153 128 101 66 46

SQ-65-D 1/30 1550

BHP 0.022 0.023 0.026 0.026 0.027 0.028 0.028 0.027 0.025 0.023

Sones 4.2 4.1 4.1 4.0 4.0 3.9 3.8 3.7 3.6 3.5

Performance certified is for installation type B: Free inlet, Ducted outlet. Performance ratings do not include the effects of appurtenances (accessories).

The sound ratings shown are loudness values in fan sones at 1.5 m (5 feet) in a hemispherical free field calculated per AMCA Standard 301.

Values shown are for installation type B: free inlet hemispherical fan sone levels.

14

Page 15

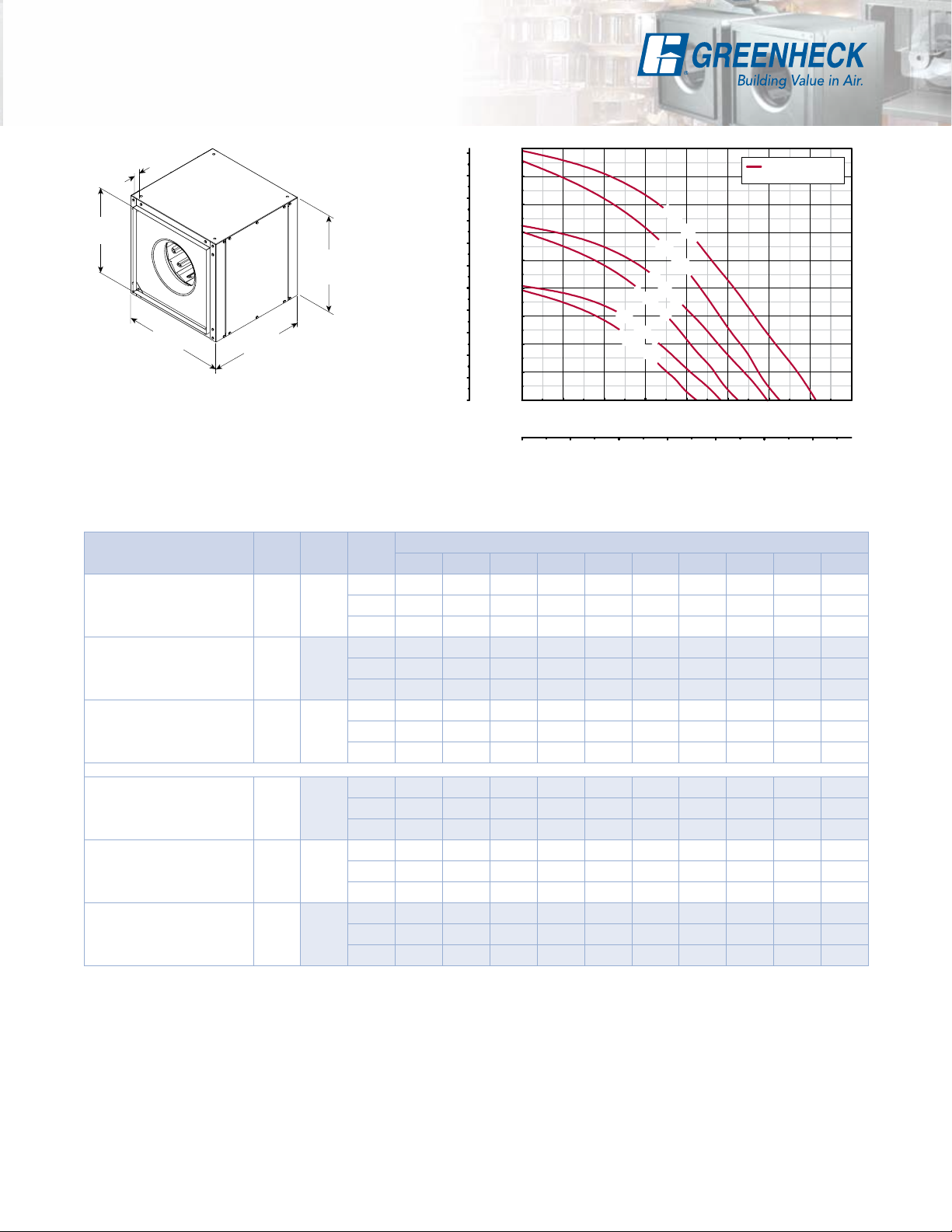

SQ 70-75 - Direct Drive

1

(25)

87⁄8

(225)

12

(305)

12

(305)

13

(330)

Damper size = 9 x 9 (229 x 229)

Unit weight** = 26 (12)

Housing thickness = 20 ga

Outlet velocity = 1.828 x cfm

Dimensions shown in inches (millimeters) and weight is

shown in pounds (kilograms).

**Weight shown is largest cataloged Open Drip Proof motor.

Model Number

Motor HPFan

RPM

SQ-70-E 1/100 1050

SQ-70-G 1/50 1300

SQ-70-D 1/30 1550

90

80

70

60

50

40

30

20

10

0

0.45

RPM

0.40

0.35

0.30

0.25

0.20

0.15

Static Pressure in. wg

0.10

0.05

0.00

0 50 100 150 200 250 300 350 400

SQ-75-D

SQ-70-D

SQ-75-G

SQ-70-G

SQ-75-E

SQ-70-E

Density 0.075 lb/ft

110

100

Static Pressure Pa

cfm

0 100 200 300 400 500 600

3

/hr

m

CFM / Static Pressure in Inches wg

0.000 0.100 0.125 0.150 0.200 0.250 0.300 0.350 0.375 0.400

CFM 212 140 118 86

BHP 0.008 0.009 0.009 0.009

Sones 2.7 1.7 1.5 1.5

CFM 262 204 190 176 139 77

BHP 0.015 0.018 0.018 0.018 0.017 0.015

Sones 4.1 3.4 3.3 3.1 2.9 2.5

CFM 313 265 252 240 216 189 155 99 67

BHP 0.026 0.029 0.030 0.030 0.030 0.030 0.029 0.026 0.025

Sones 5.6 5.2 5.1 5.1 4.9 4.7 4.5 4.2 4.0

3

CFM 241 167 146 123

SQ-75-E 1/100 1050

BHP 0.010 0.011 0.011 0.010

Sones 3.6 2.9 2.8 2.6

CFM 298 239 224 209 176 133

SQ-75-G 1/50 1300

BHP 0.019 0.021 0.021 0.021 0.020 0.019

Sones 4.1 3.7 3.7 3.7 3.6 3.5

CFM 356 306 294 281 256 229 201 164 137 99

SQ-75-D 1/30 1550

BHP 0.032 0.034 0.035 0.035 0.035 0.035 0.034 0.033 0.032 0.029

Sones 6.1 5.5 5.4 5.3 5.1 4.9 4.9 4.8 4.8 4.8

Performance certified is for installation type B: Free inlet, Ducted outlet. Performance ratings do not include the effects of appurtenances (accessories).

The sound ratings shown are loudness values in fan sones at 1.5 m (5 feet) in a hemispherical free field calculated per AMCA Standard 301.

Values shown are for installation type B: free inlet hemispherical fan sone levels.

15

Page 16

SQ 80-85 - Direct Drive

1

(25)

117⁄8

(302)

15

(381)

15

(381)

16

(406)

Damper size = 12 x 12 (305 x 305)

Unit weight** = 41 (19)

Housing thickness = 20 ga

Outlet velocity = 1.021 x cfm

Dimensions shown in inches (millimeters) and weight is

shown in pounds (kilograms).

**Weight shown is largest cataloged Open Drip Proof motor.

Model Number

Motor HPFan

RPM

SQ-80-E 1/40 1050

SQ-80-G 1/20 1300

SQ-80-D 1/12 1550

Static Pressure Pa

160

140

120

100

0.7

0.6

0.5

SQ-80-G

SQ-80-E

SQ-80-D

SQ-85-D

SQ-85-G

SQ-85-E

0.4

80

60

40

20

0

0.3

0.2

Static Pressure in. wg

0.1

0.0

0 100 200 300 400 500 600

RPM

Density 0.075 lb/ft

3

cfm

0 200 400 600 800 1000

3

m

/hr

CFM / Static Pressure in Inches wg

0.00 0.100 0.125 0.200 0.250 0.300 0.375 0.400 0.450 0.500

CFM 306 241 225 166 104

BHP 0.011 0.014 0.015 0.017 0.016

Sones 3.8 3.7 3.6 3.8 4.1

CFM 378 324 312 273 244 210 140

BHP 0.021 0.025 0.026 0.029 0.032 0.032 0.031

Sones 5.4 5.4 5.4 5.4 5.4 5.4 5.5

CFM 451 405 394 363 342 318 280 266 238 201

BHP 0.035 0.039 0.041 0.045 0.047 0.051 0.055 0.055 0.055 0.055

Sones 7.3 7.3 7.3 7.3 7.2 7.3 7.3 7.4 7.5 7.6

CFM 357 291 272 206 142

SQ-85-E 1/40 1050

BHP 0.012 0.016 0.017 0.018 0.017

Sones 4.0 3.9 3.9 3.9 4.0

CFM 442 391 377 331 298 260 185

SQ-85-G 1/20 1300

BHP 0.024 0.028 0.028 0.032 0.033 0.034 0.033

Sones 5.5 5.3 5.3 5.3 5.3 5.4 5.4

CFM 528 485 474 439 413 386 343 327 294 254

SQ-85-D 1/12 1550

BHP 0.040 0.045 0.046 0.049 0.052 0.054 0.056 0.057 0.057 0.057

Sones 7.6 7.4 7.4 7.4 7.4 7.4 7.4 7.5 7.5 7.6

Performance certified is for installation type B: Free inlet, Ducted outlet. Performance ratings do not include the effects of appurtenances (accessories).

The sound ratings shown are loudness values in fan sones at 1.5 m (5 feet) in a hemispherical free field calculated per AMCA Standard 301.

Values shown are for installation type B: free inlet hemispherical fan sone levels.

16

Page 17

SQ 90-95 - Direct Drive

1

(25)

117⁄8

(302)

15

(381)

15

(381)

16

(406)

Damper size = 12 x 12 (305 x 305)

Unit weight** = 41 (19)

Housing thickness = 20 ga

Outlet velocity = 1.021 x cfm

Dimensions shown in inches (millimeters) and weight is

shown in pounds (kilograms).

**Weight shown is largest cataloged Open Drip Proof motor.

Model Number

Motor HPFan

RPM

SQ-90-E 1/50 1050

SQ-90-G 1/25 1300

SQ-90-D 1/10 1550

0.8

Static Pressure Pa

180

160

140

120

100

80

60

40

20

0

0.7

0.6

0.5

0.4

0.3

Static Pressure in. wg

0.2

0.1

0.0

0 100 200 300 400 500 600 700 800 900 1000

SQ-90-D

SQ-90-G

SQ-90-E

SQ-95-D

SQ-95-G

SQ-95-E

cfm

0 200 400 600 800 1000 1200 1400 1600

3

/hr

m

CFM / Static Pressure in Inches wg

0 0.125 0.2 0.25 0.3 0.375 0.4 0.5 0.6 0.625

CFM 500 369 271 188

BHP 0.016 0.020 0.021 0.020

Sones 4.0 3.9 4.0 4.1

CFM 619 519 449 397 343 245 207

BHP 0.030 0.036 0.039 0.040 0.040 0.038 0.037

Sones 5.4 5.4 5.4 5.5 5.5 5.6 5.6

CFM 738 654 602 564 522 457 435 334

BHP 0.051 0.059 0.062 0.064 0.067 0.068 0.068 0.067

Sones 7.6 7.5 7.5 7.4 7.4 7.4 7.4 7.4

RPM

Density 0.075 lb/ft

3

CFM 623 475 365 274

SQ-95-E 1/30 1050

BHP 0.028 0.031 0.031 0.030

Sones 4.9 4.5 4.4 4.5

CFM 771 659 579 522 461 352 311

SQ-95-G 1/15 1300

BHP 0.053 0.057 0.058 0.059 0.059 0.057 0.056

Sones 7.6 6.7 6.5 6.4 6.4 6.4 6.4

CFM 919 829 765 720 677 603 579 461 324 276

SQ-95-D 1/8 1550

BHP 0.090 0.094 0.097 0.097 0.100 0.100 0.100 0.099 0.094 0.091

Sones 9.6 9.3 8.9 8.7 8.4 8.1 8.0 7.6 7.2 7.1

Performance certified is for installation type B: Free inlet, Ducted outlet. Performance ratings do not include the effects of appurtenances (accessories).

The sound ratings shown are loudness values in fan sones at 1.5 m (5 feet) in a hemispherical free field calculated per AMCA Standard 301.

Values shown are for installation type B: free inlet hemispherical fan sone levels.

17

Page 18

SQ 100 - Direct Drive

1

(25)

137⁄8

(352)

17

(432)

17

(432)

21

(533)

Damper size = 14 x 14 (356 x 356)

Unit weight** = 56 (25)

Housing thickness = 20 ga

Outlet velocity = 0.748 x cfm

Dimensions shown in inches (millimeters) and weight is

shown in pounds (kilograms).

**Weight shown is largest cataloged Open Drip Proof motor.

Model Number

Motor HPFan

RPM

SQ-100-C 1/8 860

SQ-100-B 1/6 1140

SQ-100-A 1/4 1725

1.2

RPM

Density 0.075 lb/ft

1725

3

Static Pressure Pa

250

200

150

100

E

V

R

1.0

0.8

0.6

0.4

Static Pressure in. wg

50

0.2

0.0

0

0 200 400 600 800 1000 1200 1400 1600

S

T

O

N

O

D

E

L

E

H

T

O

T

T

C

E

L

E

860

U

C

M

E

T

S

Y

S

S

I

H

T

F

O

T

F

1140

cfm

0 500 1000 1500 2000 2500

3

m

/hr

CFM / Static Pressure in Inches wg

0.000 0.100 0.125 0.250 0.300 0.375 0.500 0.625 0.750 1.000

CFM 725 637 611

BHP 0.027 0.030 0.030

Sones 4.7 3.8 3.7

CFM 961 898 881 785 738 657

BHP 0.064 0.067 0.068 0.071 0.071 0.070

Sones 7.4 6.6 6.5 6.1 5.9 5.6

CFM 1454 1412 1402 1349 1326 1292 1227 1156 1077 830

BHP 0.220 0.230 0.230 0.230 0.240 0.240 0.240 0.250 0.250 0.220

Sones 13.1 12.6 12.4 11.9 11.7 11.5 11.1 10.7 10.4 9.6

Performance certified is for installation type B: Free inlet, Ducted outlet. Performance ratings do not include the effects of appurtenances (accessories).

The sound ratings shown are loudness values in fan sones at 1.5 m (5 feet) in a hemispherical free field calculated per AMCA Standard 301.

Values shown are for installation type B: free inlet hemispherical fan sone levels.

18

Page 19

m3/hr

SQ 120 - Direct Drive

1

(25)

157⁄8

(403)

19

(483)

19

(483)

Damper size = 16 x 16

21

(533)

(406 x 406)

Unit weight** = 67 (30)

Housing thickness = 20 ga

Outlet velocity = 0.571 x cfm

Dimensions shown in inches (millimeters) and weight is

shown in pounds (kilograms).

**Weight shown is largest cataloged Open Drip Proof motor.

Model Number

Motor HPFan

RPM

SQ-120-C 1/8 860

SQ-120-B 1/6 1140

SQ-120-A 1/2 1725

Static Pressure Pa

400

350

300

250

200

150

100

1.8

1.6

1.4

1.2

1.0

E

L

0.8

0.6

Static Pressure in. wg

0.4

O

50

0.2

0.0

0

0 400 800 1200 1600 2000

N

O

D

E

H

T

O

T

T

C

E

L

E

S

860

T

E

V

R

U

C

M

E

T

S

Y

S

S

I

H

T

F

O

T

F

1140

RPM

Density 0.075 lb/ft

1725

3

cfm

0 500 1000 1500 2000 2500 3000

CFM / Static Pressure in Inches wg

0.000 0.125 0.250 0.375 0.500 0.625 0.750 1.000 1.250 1.375

CFM 971 843 704

BHP 0.051 0.055 0.059

Sones 4.4 4.1 3.3

CFM 1287 1189 1094 992 873 692

BHP 0.120 0.120 0.130 0.140 0.140 0.130

Sones 7.4 7.2 7.0 6.3 5.9 5.8

CFM 1948 1883 1818 1754 1692 1628 1562 1416 1239 1128

BHP 0.410 0.420 0.420 0.440 0.450 0.460 0.460 0.480 0.480 0.470

Sones 14.7 14.1 13.8 13.6 13.5 13.4 13.2 12.6 11.9 11.7

Performance certified is for installation type B: Free inlet, Ducted outlet. Performance ratings do not include the effects of appurtenances (accessories).

The sound ratings shown are loudness values in fan sones at 1.5 m (5 feet) in a hemispherical free field calculated per AMCA Standard 301.

Values shown are for installation type B: free inlet hemispherical fan sone levels.

19

Page 20

SQ 130 - Direct Drive

m3/hr

1

(25)

177⁄8

(454)

21

(533)

21

(533)

21

(533)

Damper size = 18 x 18 (457 x 457)

Unit weight** = 77 (35)

Housing thickness = 20 ga

Outlet velocity = 0.451 x cfm

Dimensions shown in inches (millimeters) and weight is

shown in pounds (kilograms).

**Weight shown is largest cataloged Open Drip Proof motor.

Model Number

Motor HPFan

RPM

SQ-130-C 1/8 860

SQ-130-B 1/4 1140

SQ-130-A 3/4 1725

1.8

RPM

Density 0.075 lb/ft

1725

3

Static Pressure Pa

400

350

300

250

200

150

100

E

1.6

1.4

1.2

1.0

T

0.8

0.6

Static Pressure in. wg

0.4

50

0.2

0.0

0

0 500 1000 1500 2000 2500

E

S

T

O

N

O

D

F

E

L

E

H

T

O

T

T

C

E

L

860

V

R

U

C

M

E

T

S

Y

S

S

I

H

T

F

O

1140

cfm

0 500 1000 1500 2000 2500 3000 3500 4000

CFM / Static Pressure in Inches wg

0.00 0.125 0.250 0.375 0.500 0.625 0.750 1.000 1.250 1.375

CFM 1180 1048 890

BHP 0.067 0.075 0.078

Sones 6.2 5.2 4.5

CFM 1564 1471 1366 1248 1104 865

BHP 0.16 0.17 0.18 0.18 0.18 0.17

Sones 9.4 8.3 7.4 6.8 6.5 6.4

CFM 2368 2307 2247 2174 2105 2038 1961 1791 1559 1409

BHP 0.54 0.56 0.57 0.59 0.60 0.62 0.62 0.63 0.61 0.59

Sones 17.4 17.6 17.1 17.1 16.6 16.4 15.9 15.7 15.6 15.6

Performance certified is for installation type B: Free inlet, Ducted outlet. Performance ratings do not include the effects of appurtenances (accessories).

The sound ratings shown are loudness values in fan sones at 1.5 m (5 feet) in a hemispherical free field calculated per AMCA Standard 301.

Values shown are for installation type B: free inlet hemispherical fan sone levels.

20

Page 21

SQ 140 - Direct Drive

1

(25)

197⁄8

(505)

23

(584)

23

(584)

22

(559)

Damper size = 20 x 20 (508 x 508)

Unit weight** = 104 (47)

Housing thickness = 18 ga

Outlet velocity = 0.364 x cfm

Dimensions shown in inches (millimeters) and weight is

shown in pounds (kilograms).

**Weight shown is largest cataloged Open Drip Proof motor.

Model Number

Motor HPFan

RPM

SQ-140-C 1/8 860

SQ-140-B 1/3 1140

SQ-140-A 1 1725

0

2.1

E

V

1.8

1.5

1.2

0.9

0.6

Static Pressure in. wg

0.3

0.0

0 500 1000 1500 2000 2500 3000 3500

T

O

N

O

D

E

H

T

O

T

T

C

E

L

E

S

R

U

C

M

E

T

S

Y

S

S

I

H

T

F

O

T

F

E

L

1140

860

RPM

Density 0.075 lb/ft

1725

3

500

400

300

200

Static Pressure Pa

100

cfm

0 1000 2000 3000 4000 5000

3

m

/hr

CFM / Static Pressure in Inches wg

0.000 0.250 0.375 0.500 0.625 0.750 1.000 1.375 1.500 1.75

CFM 1637 1316 1033

BHP 0.12 0.13 0.13

Sones 7.0 6.2 5.9

CFM 2170 1942 1818 1666 1446 1121

BHP 0.27 0.29 0.30 0.30 0.30 0.27

Sones 10.8 10.1 10.0 9.8 9.6 9.4

CFM 3283 3139 3065 2985 2905 2825 2645 2268 2085 1624

BHP 0.93 0.97 0.98 1.00 1.01 1.03 1.03 1.03 1.01 0.93

Sones 20 19.3 19.0 18.7 18.6 18.4 18.2 17.2 16.7 15.9

Performance certified is for installation type B: Free inlet, Ducted outlet. Performance ratings do not include the effects of appurtenances (accessories).

The sound ratings shown are loudness values in fan sones at 1.5 m (5 feet) in a hemispherical free field calculated per AMCA Standard 301.

Values shown are for installation type B: free inlet hemispherical fan sone levels.

21

Page 22

SQ 160 - Direct Drive

1

(25)

227⁄8

(581)

26

(660)

26

(660)

Damper size = 23 x 23

26

(660)

(584 x 584)

Unit weight** = 160 (73)

Housing thickness = 18 ga

Outlet velocity = 0.275 x cfm

Dimensions shown in inches (millimeters) and weight is

shown in pounds (kilograms).

**Weight shown is largest cataloged Open Drip Proof motor.

Model Number

Motor HPFan

RPM

SQ-160-C 1/4 860

SQ-160-B 1/2 1140

SQ-160-A 2 1725

Static Pressure Pa

600

500

400

300

200

100

0

2.8

2.4

2.0

1.6

1.2

O

0.8

Static Pressure in. wg

0.4

D

0.0

0 1000 2000 3000 4000 5000 6000

T

T

C

E

L

E

S

T

O

N

O

E

V

R

U

C

M

E

T

S

Y

S

S

I

H

T

F

O

T

F

E

L

E

H

T

1140

860

1725

RPM

Density 0.075 lb/ft

3

cfm

0 2 4 6 8 10

3

/hr X 1000

m

CFM / Static Pressure in Inches wg

0.000 0.250 0.500 0.750 1.000 1.250 1.500 1.750 1.875 2.000

CFM 2506 2147 1605

BHP 0.20 0.23 0.24

Sones 8.8 7.2 6.5

CFM 3322 3061 2773 2388 1808

BHP 0.47 0.51 0.54 0.56 0.51

Sones 14.0 12.8 11.9 11.4 10.8

CFM 5027 4856 4683 4504 4312 4094 3845 3575 3414 3236

BHP 1.64 1.69 1.74 1.80 1.85 1.89 1.93 1.95 1.94 1.91

Sones 26 25 24 24 24 24 24 24 24 24

Performance certified is for installation type B: Free inlet, Ducted outlet. Performance ratings do not include the effects of appurtenances (accessories).

The sound ratings shown are loudness values in fan sones at 1.5 m (5 feet) in a hemispherical free field calculated per AMCA Standard 301.

Values shown are for installation type B: free inlet hemispherical fan sone levels.

22

Page 23

BSQ 70 - Belt Drive

m3/hr

*151⁄2

(394)

1 (25)

117⁄8

(302)

15

(381)

Damper size = 12 x 12 (305 x 305)

Unit weight** = 76 (34)

Housing thickness = 20 ga

Model Number

*14

(356)

21

(533)

Motor HPFan

600

*121⁄2

(318)

15

(381)

Dimensions shown in inches (millimeters) and weight is shown in pounds (kilograms).

*Motor cover is optional. Size may be greater depending on motor.

**Weight shown is largest cataloged Open Drip Proof motor.

Static Pressure Pa

400

200

2.5

1/3 hp

2.0

1/4 hp

1.5

1.0

Static Pressure in. wg

0.5

T

O

N

O

D

0.0

0

0 100 200 300 400 500 600

0 200 400 600 800 1000

E

V

1/2 hp

R

U

C

M

E

T

S

Y

S

S

I

H

T

F

O

T

F

E

L

E

H

T

O

T

T

C

E

L

E

S

790

1810

1470

1130

CFM / Static Pressure in Inches wg

RPM

1050

Sones 8.0 7.5

1313

0.125 0.250 0.500 0.625 0.750 1.000 1.250 1.500 1.750 2.000

CFM 184 129

BHP 0.039 0.037

MAX Bhp AT A GIVEN RPM = (rpm/3084)

TIP SPEED (ft/min) = rpm x 2.928

CFM 251 211 117

BHP 0.077 0.076 0.068

MAX NEMA MOTOR FRAME SIZE = 145T

OUTLET VELOCITY (ft/min) = 1.0212 x cfm

Density 0.075 lb/ft

2486

2150

cfm

MAXIMUM RPM = 2486

Sones 11.0 10.4 9.2

CFM 284 249 169 122

1445

BHP 0.103 0.102 0.097 0.09

Sones 12.8 12.3 10.7 10.3

CFM 314 284 213 175 131

BSQ-70-4 1/4

1577

BHP 0.13 0.13 0.13 0.12 0.12

Sones 14.9 14.6 12.7 11.9 11.4

CFM 345 318 254 220 184 97

1709

BHP 0.17 0.17 0.17 0.16 0.16 0.14

Sones 16.1 15.9 14.5 13.9 13.3 12.4

CFM 375 351 293 262 231 159

1840

BHP 0.21 0.21 0.21 0.21 0.20 0.19

Sones 17.3 17.0 16.4 16.0 15.4 14.5

CFM 405 384 331 302 273 212 142

1972

BHP 0.26 0.26 0.26 0.25 0.25 0.24 0.22

Sones 19.2 19.1 18.6 18.2 17.9 17.7 16.5

CFM 428 408 360 332 305 249 184 103

2072

BSQ-70-3 1/3

2172

BHP 0.30 0.30 0.30 0.30 0.29 0.29 0.27 0.24

Sones 20 20 19.9 19.5 19.1 18.5 18.2 16.8

CFM 450 431 387 361 335 282 224 161

BHP 0.34 0.35 0.35 0.34 0.34 0.33 0.32 0.30

Sones 21 21 21 21 20 19.7 19.2 18.8

CFM 486 467 428 406 381 332 283 225 166

2329

BSQ-70-5 1/2

2486

BHP 0.43 0.43 0.43 0.43 0.42 0.42 0.41 0.39 0.36

Sones 23 23 23 23 23 22 21 20 21

CFM 521 504 468 447 426 380 334 287 232 176

BHP 0.52 0.52 0.52 0.52 0.52 0.51 0.50 0.49 0.47 0.44

Sones 25 25 25 25 25 24 23 22 22 23

Performance certified is for installation type B: Free inlet, Ducted outlet. Performance ratings do not include the effects of appurtenances (accessories).

Power rating (Bhp) does not include transmission losses.

The sound ratings shown are loudness values in fan sones at 1.5 m (5 feet) in a hemispherical free field calculated per AMCA Standard 301.

Values shown are for installation type B: free inlet hemispherical fan sone levels.

RPM

HP

3

3

23

Page 24

BSQ 80 - Belt Drive

*151⁄2

(394)

1 (25)

117⁄8

(302)

15

(381)

Damper size = 12 x 12 (305 x 305)

Unit weight** = 79 (36)

Housing thickness = 20 ga

Model Number

*14

(356)

21

(533)

Dimensions shown in inches (millimeters) and weight is shown in pounds (kilograms).

*Motor cover is optional. Size may be greater depending on motor.

**Weight shown is largest cataloged Open Drip Proof motor.

Motor HPFan

*121⁄2

(318)

15

(381)

RPM

CFM 372 298

1050

BHP 0.049 0.049

Sones 8.0 7.6

CFM 445 386 206

1207

BHP 0.073 0.075 0.065

Static Pressure Pa

700

600

500

400

300

200

100

0

3.0

1/3 hp

1/4 hp

N

O

D

1/2 hp

T

T

C

E

L

E

S

T

O

2.5

2.0

1.5

1.0

Static Pressure in. wg

0.5

0.0

0 200 400 600 800 1000 1200

L

E

H

T

O

790

F

O

T

F

E

1160

E

3/4 hp

V

R

U

C

M

E

T

S

Y

S

S

I

H

T

2270

1900

1530

cfm

0 500 1000 1500 2000

3

m

/hr

CFM / Static Pressure in Inches wg

0.125 0.250 0.500 0.750 1.000 1.250 1.500 1.750 2.000 2.500

MAX Bhp AT A GIVEN RPM = (rpm/2866)

MAXIMUM RPM = 2645

TIP SPEED (ft/min) = rpm x 2.928

MAX NEMA MOTOR FRAME SIZE = 145T

OUTLET VELOCITY (ft/min) = 1.0212 x cfm

Sones 9.7 9.1 8.2

CFM 585 542 442 301

BSQ-80-4 1/4

1520

BHP 0.15 0.15 0.15 0.14

Sones 13.9 13.5 11.8 10.8

CFM 652 615 530 426 254

1676

BHP 0.19 0.20 0.20 0.20 0.17

Sones 15.9 15.6 14.1 12.9 11.5

CFM 720 687 613 524 424

1833

BHP 0.25 0.26 0.26 0.26 0.25

Sones 17.2 16.9 16.3 15.3 14.3

CFM 760 728 660 579 486 346

1926

BSQ-80-3 1/3

2018

BHP 0.29 0.30 0.30 0.30 0.30 0.27

Sones 18.4 18.3 17.8 17.1 16.9 13.9

CFM 799 769 704 630 545 452 269

BHP 0.34 0.34 0.35 0.35 0.34 0.34 0.28

Sones 19.6 19.5 19.2 18.4 18.1 16.7 13.5

CFM 861 833 774 708 633 550 442

2164

BSQ-80-5 1/2

2310

BHP 0.41 0.42 0.43 0.43 0.43 0.42 0.40

Sones 21 21 21 20 19.6 19.2 17.6

CFM 924 897 842 784 716 643 563 445

BHP 0.50 0.51 0.52 0.52 0.52 0.52 0.51 0.48

Sones 23 23 22 23 21 21 20 19.9

CFM 995 969 919 865 807 743 671 597 486

2478

BSQ-80-7 3/4

2645

BHP 0.62 0.63 0.63 0.64 0.65 0.65 0.64 0.63 0.59

Sones 25 25 24 25 24 23 22 22 23

CFM 1065 1041 995 945 894 835 773 705 635 395

BHP 0.75 0.76 0.77 0.78 0.79 0.79 0.78 0.77 0.77 0.65

Sones 28 28 27 27 27 26 25 24 24 35

Performance certified is for installation type B: Free inlet, Ducted outlet. Performance ratings do not include the effects of appurtenances (accessories).

Power rating (Bhp) does not include transmission losses.

The sound ratings shown are loudness values in fan sones at 1.5 m (5 feet) in a hemispherical free field calculated per AMCA Standard 301.

Values shown are for installation type B: free inlet hemispherical fan sone levels.

24

2645

RPM

HP

Density 0.075 lb/ft

3

3

Page 25

BSQ 90 - Belt Drive

*151⁄2

(394)

1 (25)

117⁄8

(302)

15

(381)

Damper size = 12 x 12 (305 x 305)

Unit weight** = 84 (38)

Housing thickness = 20 ga

Model Number

BSQ-90-4 1/4

*14

(356)

21

(533)

Motor HPFan

3.0

700

600

*121⁄2

(318)

15

(381)

Dimensions shown in inches (millimeters) and weight is shown in pounds (kilograms).

*Motor cover is optional. Size may be greater depending on motor.

**Weight shown is largest cataloged Open Drip Proof motor.

Static Pressure Pa

500

400

300

200

100

2.5

2.0

1.5

1.0

Static Pressure in. wg

0.5

0.0

0

1/2 hp

1/3 hp

1/4 hp

H

T

O

T

T

C

E

L

E

S

T

O

790

N

O

D

0 200 400 600 800 1000 1200 1400 1600 1800

0 500 1000 1500 2000 2500 3000

3/4 hp

F

O

T

F

E

L

E

1170

S

I

H

T

M

E

T

S

Y

S

1550

U

C

E

1 hp

V

R

CFM / Static Pressure in Inches wg

RPM

1050

Sones 8.0 7.6

1211

0.125 0.250 0.500 0.750 1.000 1.500 1.750 2.000 2.250 2.500

CFM 547 443

BHP 0.061 0.061

MAX Bhp AT A GIVEN RPM = (rpm/2649)

TIP SPEED (ft/min) = rpm x 2.928

CFM 655 574 333

BHP 0.092 0.095 0.084

MAX NEMA MOTOR FRAME SIZE = 145T

OUTLET VELOCITY (ft/min) = 1.0212 x cfm

Sones 9.8 9.1 8.3

CFM 864 806 667 477

1533

BHP 0.18 0.19 0.19 0.18

Density 0.075 lb/ft

2691

2310

1930

cfm

3

m

/hr

MAXIMUM RPM = 2691

Sones 14.2 13.8 12.1 11.0

CFM 965 914 798 654 437

1694

BHP 0.25 0.25 0.26 0.25 0.22

Sones 16.0 15.8 14.4 13.1 12.3

CFM 1019 971 863 734 562

1780

BSQ-90-3 1/3

1866

BHP 0.29 0.29 0.30 0.30 0.28

Sones 16.7 16.5 15.6 14.4 13.7

CFM 1072 1028 926 808 657

BHP 0.33 0.33 0.35 0.35 0.33

Sones 17.5 17.3 16.9 15.9 15.4

CFM 1239 1202 1118 1024 917 638

BSQ-90-5 1/2 2136

BHP 0.49 0.50 0.51 0.52 0.52 0.47

Sones 21 21 21 19.9 19.2 18.4

CFM 1334 1300 1223 1138 1045 811 668

2291

BSQ-90-7 3/4

2445

BHP 0.61 0.61 0.62 0.64 0.65 0.61 0.58

Sones 23 23 22 22 21 20 20

CFM 1429 1396 1326 1249 1167 976 844 707

BHP 0.73 0.74 0.75 0.77 0.79 0.77 0.73 0.70

Sones 25 25 24 25 23 22 22 23

CFM 1504 1473 1407 1336 1258 1082 977 851 704

2568

BSQ-90-10 1

2691

BHP 0.85 0.86 0.87 0.89 0.90 0.90 0.88 0.84 0.80

Sones 26 26 26 26 26 24 22 24 25

CFM 1579 1549 1488 1420 1347 1186 1097 987 866 713

BHP 0.98 0.98 1.00 1.02 1.03 1.05 1.03 1.00 0.96 0.91

Sones 28 28 27 28 28 26 25 24 26 29

Performance certified is for installation type B: Free inlet, Ducted outlet. Performance ratings do not include the effects of appurtenances (accessories).

Power rating (Bhp) does not include transmission losses.

The sound ratings shown are loudness values in fan sones at 1.5 m (5 feet) in a hemispherical free field calculated per AMCA Standard 301.

Values shown are for installation type B: free inlet hemispherical fan sone levels.

RPM

HP

3

3

25

Page 26

BSQ 100 - Belt Drive

*151⁄2

(394)

1 (25)

137⁄8

(352)

17

(432)

Damper size = 14 x 14 (357 x 357)

Unit weight** = 91 (41)

Housing thickness = 20 ga

Model Number

BSQ-100-4 1/4

*14

(356)

21

(533)

Dimensions shown in inches (millimeters) and weight is shown in pounds (kilograms).

*Motor cover is optional. Size may be greater depending on motor.

**Weight shown is largest cataloged Open Drip Proof motor.

Motor HPFan

RPM

1050

1330

1469

3.0

700

0

2.5

2.0

1.5

1.0

Static Pressure in. wg

0.5

0.0

*121⁄2

(318)

17

(432)

Static Pressure Pa

600

500

400

300

200

100

0.125 0.250 0.500 0.625 0.750 1.000 1.250 1.500 1.750 2.000

CFM 774 671

BHP 0.072 0.073

Sones 7.9 7.6

CFM 1024 953 770

BHP 0.14 0.15 0.15

Sones 11.3 10.6 9.4

CFM 1145 1080 931 837

BHP 0.19 0.20 0.20 0.20

1 hp

3/4 hp

E

1/2 hp

1/3 hp

1/4 hp

T

F

E

L

E

H

T

O

T

T

1500

C

E

L

E

1145

S

T

O

790

N

O

D

0 500 1000 1500 2000 2500

V

R

U

C

M

E

T

S

Y

S

S

I

H

T

F

O

2210

1855

cfm

0 1000 2000 3000 4000

3

m

/hr

CFM / Static Pressure in Inches wg

MAX Bhp AT A GIVEN RPM = (rpm/2517)

MAXIMUM RPM = 2556

TIP SPEED (ft/min) = rpm x 2.928

MAX NEMA MOTOR FRAME SIZE = 145T

OUTLET VELOCITY (ft/min) = 0.7617 x cfm

Sones 13.2 12.6 11.0 10.5

CFM 1265 1207 1088 1003 917

1609

BHP 0.25 0.25 0.26 0.26 0.26

Sones 15.4 15.0 13.4 12.4 11.8

CFM 1405 1352 1247 1187 1110 939

BSQ-100-3 1/3 1772

BHP 0.33 0.34 0.35 0.35 0.35 0.35

Sones 16.6 16.4 15.5 14.8 14.3 13.1

CFM 1515 1465 1366 1320 1255 1115

1901

BSQ-100-5 1/2

2029

BHP 0.40 0.41 0.43 0.43 0.43 0.43

Sones 18.0 17.8 17.4 17.1 16.6 16.2

CFM 1623 1577 1484 1439 1396 1262 1119

BHP 0.49 0.50 0.52 0.52 0.52 0.52 0.52

Sones 19.8 19.6 19.4 19.0 18.6 18.2 17.2

CFM 1747 1704 1617 1574 1533 1428 1305 1163

2176

BSQ-100-7 3/4

2323

BHP 0.60 0.61 0.63 0.64 0.65 0.65 0.65 0.65

Sones 21 21 21 21 20 19.8 19.3 18.5

CFM 1871 1830 1749 1708 1668 1591 1472 1358 1197

BHP 0.73 0.74 0.76 0.78 0.79 0.79 0.79 0.79 0.78

Sones 23 23 23 23 23 22 21 20 21

CFM 1969 1930 1853 1815 1776 1703 1605 1494 1377 1184

2440

BSQ-100-10 1

2556

BHP 0.84 0.86 0.88 0.89 0.90 0.91 0.91 0.91 0.91 0.88

Sones 25 25 24 24 25 23 23 22 22 23

CFM 2066 2029 1956 1919 1882 1810 1734 1626 1522 1402

BHP 0.97 0.98 1.01 1.02 1.03 1.05 1.05 1.05 1.05 1.05

Sones 26 26 25 26 26 25 25 24 22 24

Performance certified is for installation type B: Free inlet, Ducted outlet. Performance ratings do not include the effects of appurtenances (accessories).

Power rating (Bhp) does not include transmission losses.

The sound ratings shown are loudness values in fan sones at 1.5 m (5 feet) in a hemispherical free field calculated per AMCA Standard 301.

Values shown are for installation type B: free inlet hemispherical fan sone levels.

26

RPM

HP

Density 0.075 lb/ft

2556

3

3

Page 27

BSQ 120 - Belt Drive

*177⁄8

(454)

1 (25)

157⁄8

(403)

19

(483)

Damper size = 16 x 16 (406 x 406)

Unit weight** = 97 (44)

Housing thickness = 20 ga

Model Number

BSQ-120-4 1/4

*16

(406)

21

(533)

Motor HPFan

RPM

1000

1367

*121⁄2

(318)

19

(483)

Static Pressure Pa

900

800

700

600

500

400

300

200

100

4.0

3.5

3.0

2.5

1/3 hp

2.0

1.5

Static Pressure in. wg

1.0

0.5

0

0.0

0 500 1000 1500 2000 2500 3000

1/4 hp

1 hp

3/4 hp

1/2 hp

N

O

D

O

790

T

1 1/2 hp

E

V

R

U

C

M

E

T

S

Y

S

S

I

H

T

F

O

T

F

E

L

E

H

T

O

T

T

C

E

L

E

S

1130

1810

1470

cfm

0 500 1000 1500 2000 2500 3000 3500 4000 4500 5000

Dimensions shown in inches (millimeters) and weight is shown in pounds (kilograms).

*Motor cover is optional. Size may be greater depending on motor.

**Weight shown is largest cataloged Open Drip Proof motor.

3

/hr

m

CFM / Static Pressure in Inches wg

0.125 0.375 0.750 1.000 1.250 1.500 2.000 2.250 2.500 2.750

CFM 1026 783

BHP 0.096 0.102

Sones 7.7 7.5

CFM 1471 1311 1020

BHP 0.24 0.25 0.26

MAX Bhp AT A GIVEN RPM = (rpm/2144)

MAXIMUM RPM = 2490

TIP SPEED (ft/min) = rpm x 3.436

MAX NEMA MOTOR FRAME SIZE = 145T

OUTLET VELOCITY (ft/min) = 0.5805 x cfm

Density 0.075 lb/ft

2490

2150

Sones 10.9 10.5 10.0

CFM 1555 1403 1145

1437

BSQ-120-3 1/3

1506

BHP 0.28 0.29 0.30

Sones 11.7 11.3 10.4

CFM 1636 1492 1252 1027

BHP 0.32 0.33 0.35 0.34

Sones 12.5 12.1 11.1 10.2

CFM 1764 1631 1418 1245

1615

BSQ-120-5 1/2

1724

BHP 0.39 0.41 0.43 0.43

Sones 13.8 13.6 12.4 11.8

CFM 1892 1767 1571 1423 1241

BHP 0.47 0.49 0.52 0.52 0.52

Sones 15.2 15.3 13.8 13.6 12.4

CFM 2183 2075 1908 1791 1663 1518

BSQ-120-7 3/4 1974

BHP 0.71 0.73 0.76 0.78 0.78 0.78

Sones 19.0 18.9 17.6 16.9 16.4 15.7

CFM 2298 2195 2037 1928 1813 1683 1293

2073

BSQ-120-10 1

2172

BHP 0.82 0.84 0.88 0.89 0.91 0.91 0.86

Sones 21 21 19.0 18.6 17.9 17.5 15.2

CFM 2413 2314 2164 2062 1953 1836 1553

BHP 0.94 0.97 1.00 1.02 1.04 1.05 1.03

Sones 23 23 21 21 19.7 19.0 17.5

CFM 2594 2503 2363 2268 2171 2069 1841 1695 1477

BHP 1.16 1.19 1.22 1.25 1.27 1.28 1.29 1.28 1.23

Sones 26 26 24 23 23 22 21 19.9 18.8

CFM 2779 2694 2563 2475 2387 2294 2093 1984 1852 1682

BHP 1.41 1.44 1.49 1.51 1.54 1.55 1.58 1.58 1.57 1.53

BSQ-120-15 1

2329

1

⁄2

2490

Sones 31 30 27 26 27 26 24 23 23 22

Performance certified is for installation type B: Free inlet, Ducted outlet. Performance ratings do not include the effects of appurtenances (accessories).

Power rating (Bhp) does not include transmission losses.

The sound ratings shown are loudness values in fan sones at 1.5 m (5 feet) in a hemispherical free field calculated per AMCA Standard 301.

Values shown are for installation type B: free inlet hemispherical fan sone levels.

RPM

HP

3

3

27

Page 28

BSQ 130 - Belt Drive

*177⁄8

(454)

1 (25)

177⁄8

(454)

21

(533)

Damper size = 18 x 18 (457 x 457)

Unit weight** = 97 (44)

Housing thickness = 20 ga

Model Number

BSQ-130-4 1/4

*16

(406)

21

(533)

Dimensions shown in inches (millimeters) and weight is shown in pounds (kilograms).

*Motor cover is optional. Size may be greater depending on motor.

**Weight shown is largest cataloged Open Drip Proof motor.

Motor HPFan

*121⁄2

(318)

21

(533)

RPM

CFM 1084 911

BHP 0.086 0.087

900

Sones 7.7 7.7

CFM 1275 1151 709

1031

BHP 0.13 0.13 0.12

Static Pressure Pa

700

600

500

400

300

200

100

3.0

3/4 hp

2.5

1/2 hp

2.0

1/3 hp

1.5

1.0

Static Pressure in. wg

0.5

0.0

0

1/4 hp

O

N

O

D

0 500 1000 1500 2000 2500 3000 3500

F

E

L

E

H

T

O

T

T

C

E

L

E

S

T

790

1 hp

T

F

O

T

1105

S

Y

S

S

I

H

1420

M

E

T

E

V

R

U

C

1 1/2 hp

1735

cfm

0 1000 2000 3000 4000 5000

3

m

/hr

CFM / Static Pressure in Inches wg

0.125 0.250 0.500 0.750 1.000 1.250 1.500 1.750 2.000 2.500

MAX Bhp AT A GIVEN RPM = (rpm/2022)

MAXIMUM RPM = 2355

TIP SPEED (ft/min) = rpm x 3.435

MAX NEMA MOTOR FRAME SIZE = 145T

OUTLET VELOCITY (ft/min) = 0.4571 x cfm

Sones 8.8 8.7 8.5

CFM 1652 1563 1328 958

1293

BHP 0.24 0.25 0.26 0.24

Sones 11.8 11.6 11.2 10.6

CFM 1838 1754 1568 1299

BSQ-130-3 1/3 1424

BHP 0.32 0.33 0.35 0.34

Sones 13.6 13.3 12.8 12.4

CFM 1984 1902 1743 1515 1204

1527

BSQ-130-5 1/2

1630

BHP 0.40 0.41 0.43 0.42 0.40

Sones 14.8 14.5 13.9 13.3 12.6

CFM 2126 2050 1908 1714 1468 1121

BHP 0.48 0.49 0.52 0.52 0.51 0.47

Sones 15.9 15.6 15.0 14.3 13.6 12.7

CFM 2448 2389 2266 2128 1949 1740 1462

BSQ-130-7 3/4 1866

BHP 0.72 0.73 0.76 0.78 0.78 0.76 0.73

Sones 19.9 19.5 18.8 18.2 17.2 15.9 14.7

CFM 2576 2523 2403 2279 2120 1934 1714 1419

1960

BSQ-130-10 1

2053

BHP 0.83 0.84 0.87 0.90 0.91 0.89 0.87 0.83

Sones 21 21 19.9 19.3 18.4 17.3 16.7 16.2

CFM 2702 2655 2537 2426 2286 2117 1926 1686 1319

BHP 0.95 0.96 1.00 1.03 1.05 1.03 1.02 0.99 0.89

Sones 23 22 21 20 19.8 18.7 18.0 17.9 18.5

CFM 2905 2864 2751 2653 2533 2390 2227 2045 1823

HP 1.17 1.18 1.22 1.25 1.28 1.28 1.27 1.26 1.22

Sones 26 25 24 22 22 21 20 19.9 21

CFM 3112 3074 2971 2877 2777 2659 2514 2359 2189 1732

BHP 1.43 1.44 1.48 1.52 1.55 1.58 1.57 1.55 1.54 1.44

BSQ-130-15 1

2202

1

⁄2

2355

Sones 30 28 28 25 24 23 22 22 22 27

Performance certified is for installation type B: Free inlet, Ducted outlet. Performance ratings do not include the effects of appurtenances (accessories).

Power rating (Bhp) does not include transmission losses.

The sound ratings shown are loudness values in fan sones at 1.5 m (5 feet) in a hemispherical free field calculated per AMCA Standard 301.

Values shown are for installation type B: free inlet hemispherical fan sone levels.

28

2355

2050

RPM

HP

Density 0.075 lb/ft

3

3

Page 29

BSQ 130HP - Belt Drive

*177⁄8

(454)

1 (25)

177⁄8

(454)

21

(533)

Damper size = 18 x 18 (457 x 457)

Unit weight** = 97 (44)

Housing thickness = 20 ga

Model Number

BSQ-130HP-4 1/4

*16

(406)

21

(533)

Motor HPFan

0

4.5

4.0

3/4 hp

1/3 hp

N

O

1 hp

H

T

O

T

T

C

E

L

E

S

T

O

790

3.5

3.0

1/2 hp

2.5

1/4 hp

2.0

1.5

Static Pressure in. wg

1.0

0.5

D

0.0

0 500 1000 1500 2000 2500

0 500 1000 1500 2000 2500 3000 3500 4000

L

E

F

O

T

F

E

1190

S

I

H

T

C

M

E

T

S

Y

S

1590

E

V

R

U

1 1/2 hp

1100

1000

900

Static Pressure Pa

800

700

600

500

400

300

200

100

*121⁄2

(318)

21

(533)

Dimensions shown in inches (millimeters) and weight is shown in pounds (kilograms).

*Motor cover is optional. Size may be greater depending on motor.

**Weight shown is largest cataloged Open Drip Proof motor.

CFM / Static Pressure in Inches wg

RPM

1300

Sones 11.2 10.5

1520

0.500 0.750 1.000 1.250 1.500 1.750 2.000 2.500 3.000 3.500

CFM 784 549

BHP 0.16 0.15

MAX Bhp AT A GIVEN RPM = (rpm/2377)

TIP SPEED (ft/min) = rpm x 3.435

CFM 1014 884 670

BHP 0.25 0.26 0.25

MAX NEMA MOTOR FRAME SIZE = 145T

OUTLET VELOCITY (ft/min) = 0.4571 x cfm

Density 0.075 lb/ft

2770

2390

1990

cfm

3

/hr

m

MAXIMUM RPM = 2770

RPM

HP

Sones 11.4 11.2 10.8

CFM 1161 1048 930 700

BSQ-130HP-3 1/3 1674

BHP 0.33 0.34 0.35 0.33

Sones 12.4 12.5 12.0 11.5

CFM 1273 1176 1063 930 691

1795

BSQ-130HP-5 1/2

1916

BHP 0.40 0.41 0.42 0.42 0.4

Sones 13.3 13.4 13.1 12.6 11.7

CFM 1380 1294 1192 1091 925 680

BHP 0.48 0.50 0.50 0.52 0.51 0.48

Sones 14.6 14.3 14.2 13.9 13.0 11.9

CFM 1501 1426 1339 1239 1146 971 756

2055

BSQ-130HP-7 3/4

2194

BHP 0.59 0.60 0.62 0.62 0.65 0.62 0.59

Sones 16.9 15.9 15.4 15.3 14.9 13.8 12.6

CFM 1621 1555 1477 1388 1297 1203 1033

BHP 0.71 0.73 0.75 0.76 0.77 0.78 0.76

Sones 19.2 18.4 17.1 17.0 17.2 16.5 15.1

CFM 1715 1653 1582 1504 1414 1331 1229 865

2304

BSQ-130HP-10 1

2414

BHP 0.81 0.84 0.86 0.87 0.87 0.90 0.90 0.84

Sones 21 20 19.0 18.2 18.6 18.4 17.6 14.5

CFM 1808 1749 1685 1614 1532 1448 1369 1080

BHP 0.93 0.95 0.98 1.00 1.01 1.01 1.04 1.00

Sones 22 22 21 19.0 19.5 19.7 19.2 16.8

CFM 1956 1901 1846 1781 1714 1635 1557 1392 1076

BHP 1.14 1.17 1.19 1.22 1.24 1.24 1.25 1.28 1.21

Sones 24 25 24 22 21 22 22 20 17.7

CFM 2108 2056 2005 1950 1888 1825 1750 1608 1421 1110

BHP 1.39 1.42 1.44 1.47 1.5 1.52 1.52 1.56 1.54 1.48

BSQ-130HP-15 1

2589

1

⁄2

2770

Sones 27 28 27 26 25 24 24 23 22 19.2

Performance certified is for installation type B: Free inlet, Ducted outlet. Performance ratings do not include the effects of appurtenances (accessories).

Power rating (Bhp) does not include transmission losses.

The sound ratings shown are loudness values in fan sones at 1.5 m (5 feet) in a hemispherical free field calculated per AMCA Standard 301.

Values shown are for installation type B: free inlet hemispherical fan sone levels.

3

3

29

Page 30

BSQ 140 - Belt Drive

*177⁄8

(454)

1 (25)

197⁄8

(505)

23

(584)

Damper size = 20 x 20 (508 x 508)

Unit weight** = 111 (50)

Housing thickness = 18 ga

Model Number

BSQ-140-4 1/4

*16

(406)

22

(559)

Dimensions shown in inches (millimeters) and weight is shown in pounds (kilograms).

*Motor cover is optional. Size may be greater depending on motor.

**Weight shown is largest cataloged Open Drip Proof motor.

Motor HPFan

RPM

800

1076

800

700

Static Pressure Pa

600

500

400

300

200

100

0

*121⁄2

(318)

23

(584)

0.125 0.250 0.500 0.750 1.000 1.500 1.750 2.000 2.500 2.750

CFM 1362 1185

BHP 0.10 0.11

Sones 6.3 6.7

CFM 1927 1810 1538

BHP 0.24 0.25 0.26

3.5

3.0

2.5

2.0

1.5

1.0

Static Pressure in. wg

0.5

0.0

0 500 1000 1500 2000 2500 3000 3500 4000 4500

1/2 hp

1/3 hp

O

D

1/4 hp

T

O

N

1 hp

3/4 hp

C

E

L

E

S

T

T

O

H

T

790

1 1/2 hp

S

I

H

T

F

O

T

F

E

L

E

1065

2 hp

M

E

T

S

Y

S

1340

E

V

R

U

C

1890

1615

cfm

0 1000 2000 3000 4000 5000 6000 7000

3

/hr

m

CFM / Static Pressure in Inches wg

MAX Bhp AT A GIVEN RPM = (rpm/1682)

MAXIMUM RPM = 2153

TIP SPEED (ft/min) = rpm x 3.812

MAX NEMA MOTOR FRAME SIZE = 145T

OUTLET VELOCITY (ft/min) = 0.3692 x cfm

Sones 10.7 10.7 10.2

CFM 2142 2039 1807 1463

BSQ-140-3 1/3 1185

BHP 0.32 0.33 0.35 0.34

Sones 12.1 11.9 12.0 10.6

CFM 2311 2217 2006 1741 1199

1271

BSQ-140-5 1/2

1356

BHP 0.39 0.41 0.43 0.43 0.39

Sones 13.3 13.0 13.1 13.0 12.7

CFM 2476 2392 2197 1979 1636

BHP 0.48 0.49 0.51 0.52 0.51

Sones 14.2 13.9 13.8 13.8 13.8

CFM 2858 2787 2626 2449 2253 1447

BSQ-140-7 3/4 1553

BHP 0.71 0.73 0.75 0.78 0.79 0.70

Sones 16.2 16.0 16.0 15.6 15.3 13.9

CFM 3008 2941 2790 2625 2446 1865

1631

BSQ-140-10 1

1709

BHP 0.82 0.84 0.86 0.89 0.91 0.87

Sones 17.1 16.9 16.9 16.6 16.1 14.8

CFM 3159 3094 2953 2798 2635 2177 1752

BHP 0.95 0.96 0.99 1.02 1.05 1.03 0.97

Sones 18.2 18.0 17.9 17.7 17.2 16.1 15.1

CFM 3633 3576 3461 3330 3193 2894 2705 2457

BSQ-140-15 1

1

⁄2 1956

BHP 1.41 1.43 1.47 1.49 1.53 1.57 1.57 1.55

Sones 24 23 24 24 23 22 21 20

CFM 3822 3769 3662 3537 3410 3136 2982 2777 2168

2055

BSQ-140-20 2

2153

BHP 1.63 1.66 1.70 1.73 1.75 1.82 1.82 1.81 1.70

Sones 27 26 28 27 26 25 24 23 21

CFM 4009 3958 3856 3741 3622 3365 3225 3078 2627 2260