Page 1

4-Wire Photoelectric Duct

Smoke Detector

The InnovairFlex™ Series are the only duct smoke

detectors flexible enough to fit configurations from

square to rectangular and everything in between.

Features

Photoelectric, integrated low-flow technology•

Air velocity rating from 100 ft/min to 4,000 ft/min (0.5 m/s to 20.32 •

m/sec)

Versatile mounting options: square or rectangular configuration•

Plug-in sensor offers superb false alarm immunity and the latest •

sensor technology

Broad ranges for operating temperature (–4°F to 158°F) and •

humidity (0% to 95% non-condensing)

Patented sampling tube installs from front or back of the detector •

with no tools required

Increased wiring space with a newly added ¾-inch conduit •

knockout

One easy-access Test/Reset button and improved LED status•

Patented interconnect feature for multi-fan shutdown •

New high contrast terminal designations•

Built-in short circuit protection from operator wiring errors •

Field selectable settings for configuring the detector•

Two DPDT Form-C relay contacts•

24 VAC/DC or 120 VAC •

Backward compatibility with existing Innovair products, including •

remote accessories

Agency Listings

The InnovairFlex D4120 4-wire photoelectric duct smoke

detector features a pivoting housing that ts both square and

rectangular footprints and mounts to round or rectangular ductwork.

This unit senses smoke in the most challenging conditions, operating

in airow speeds of 100 to 4,000 feet per minute, temperatures

of –4°F to 158°F, and a humidity range of 0 to 95 percent (noncondensing). A plug-in sensor head oers improved false alarm

immunity and simple installation, testing, and maintenance. An

improved cover design isolates the sensor head from the low-ow

feature for simple maintenance.

The InnovairFlex housing provides ample wiring space, a ¾-inch

conduit knockout, and built-in short circuit protection to prevent

damage to sensitive components during installation. High contrast

terminal designations make wiring easy. With its 2:1 sensor-to-power

capability, the power board of the D4120 may be used to monitor

a second sensor, D4S, simultaneously (i.e., supply and return side).

As many as 50 InnovairFlex detectors can be interconnected. When

one unit senses smoke, all interconnected detectors will switch

their relays; only the detector sensing smoke will go into alarm, thus

pinpointing the re source.

An easy-access Test/Reset button makes it possible to test the unit

with the cover on. Three DIP switches can be used to congure eld

selectable settings: cover tamper delay, number of sensors to be

controlled, and shut down on trouble option. Each power board

has two LEDs that can be used to indicate the status of connected

sensors, and a quick reference imprinted on the cover explains the

LED status indications (Standby, Maintenance, Trouble, and Alarm).

The InnovairFlex duct smoke detector can be customized to meet

local codes and specications without additional wiring. The new

InnovairFlex product line is compatible with all previous Innovair

models, including remote test accessories.

WARNING: Duct smoke detectors are NOT a substitute for open

area smoke detectors; NOT a substitute for early warning detection;

NOT a replacement for a building’s regular re detection system.

Refer to NFPA 72 and 90A for additional information.

Page 2

InnovairFlex™ Duct Smoke Detector Specifications

Architectural/Engineering Specifications

The air duct smoke detector shall be a System Sensor InnovairFlex™ D4120 Photoelectric Duct Smoke Detector. The detector housing shall be UL listed per UL

268A specically for use in air handling systems. The exible housing of the duct smoke detector ts multiple footprints from square to rectangular. The detector

shall operate at air velocities of 100 feet per minute to 4000 feet per minute (0.5 to 20.32 meters/second). The unit shall be capable of controlling up to 50 air

handling systems when interconnected with other detectors. The detector shall be capable of providing a trouble signal in the event that the front cover is

removed. It shall be capable of local testing via magnetic switch, test button on the cover, or remote testing using the SSK451 Multi-Signaling Accessory or the

RTS451KEY Remote Test Station. Terminal connections shall be of the strip and clamp method suitable for 12–18 AWG wiring.

Physical Specifications

Size: (Rectangular Dimensions)

(Square Dimensions)

Weight: 2.5 lbs (1.14 kg)

Operating Temperature Range: D4120 & D4S: –4° to 158°F (–20° to 70°C); D4P120: –40° to 158°F (–40° to 70°C)

Storage Temperature Range: D4120 & D4S: –22° to 158°F (–30° to 70°C); D4P120: –40° to 158°F (–40° to 70°C)

Operating Humidity Range: 0% to 95% relative humidity non-condensing

Air Duct Velocity: 100 to 4000 ft/min (0.5 to 20.32 m/sec)

Electrical Ratings

Power supply voltage: 20–29 VDC 24 VAC 50–60 Hz 120 VAC 50–60 Hz

Input capacitance: 270 µF max. 270 µF max. N/A

Reset voltage: 3.0 VDC min. 2.0 VAC min. 10 VAC min.

Reset time: (with RTS451) .03 to 0.3 sec. .03 to 0.3 sec. .03 to 0.3 sec.

Reset time: (by power down) 0.6 sec. max. 0.6 sec. max. 0.6 sec. max.

Power up time: 35 sec. max. 35 sec. max. 35 sec. max.

Alarm response time: 15 sec. 15 sec. 15 sec.

Sensitivity Test: See detector label See detector label See detector label

Current Requirements: (Using No Accessories)

Max. standby current: 21 mA @ 24VDC 65 mA RMS @ 24VAC 60Hz 20 mA RMS @ 120VAC 60Hz

Max. alarm current: 65 mA @ 24VDC 135 mA RMS @ 24VAC 60Hz 35 mA RMS @ 120VAC 60Hz

Contact Ratings

Alarm initiation contacts: (SPST) 2.0A @ 30 VDC (resistive)

Alarm auxiliary contacts: (DPDT) 10A @ 30 VDC (resistive); 10A @ 250 VAC (resistive); ½ HP @ 240 VAC ; ¼ HP @ 120 VAC

Note: Alarm auxiliary contacts shall not be connected to initiating circuits of control panels. Use the alarm initiation contact for this purpose.

Supervisory contacts: (SPDT) 2.0A @ 30 VDC (resistive); 2.0A @ 125 VAC (resistive)

Accessory Current Loads at 24 VDC

Device Standby Trouble Alarm

APA151/APA451 12.5 mA n/a 30 mA Max.

MHR/MHW 0 mA n/a 29 mA Max.

RA100Z 0 mA n/a 12 mA Max.

RTS151/RTS151KEY 0 mA/12 mA n/a 12 mA Max.

RTS2/RTS2-AOS 3.0mA max 16 mA Max. with strobe: 55 mA max; without strobe 30 mA max

Note: Any combination of accessories may be used such that the given accessory loads are: 110 mA or less at the Aux output, and 50 mA or less at the Alarm output

14.38 in (37 cm) Length; 5 in (12.74 cm) Width; 2.5 in (6.36 cm) Depth

7.75 in (19.7 cm) Length; 9 in (22.9 cm) Width; 2.5 in (6.35 cm) Depth

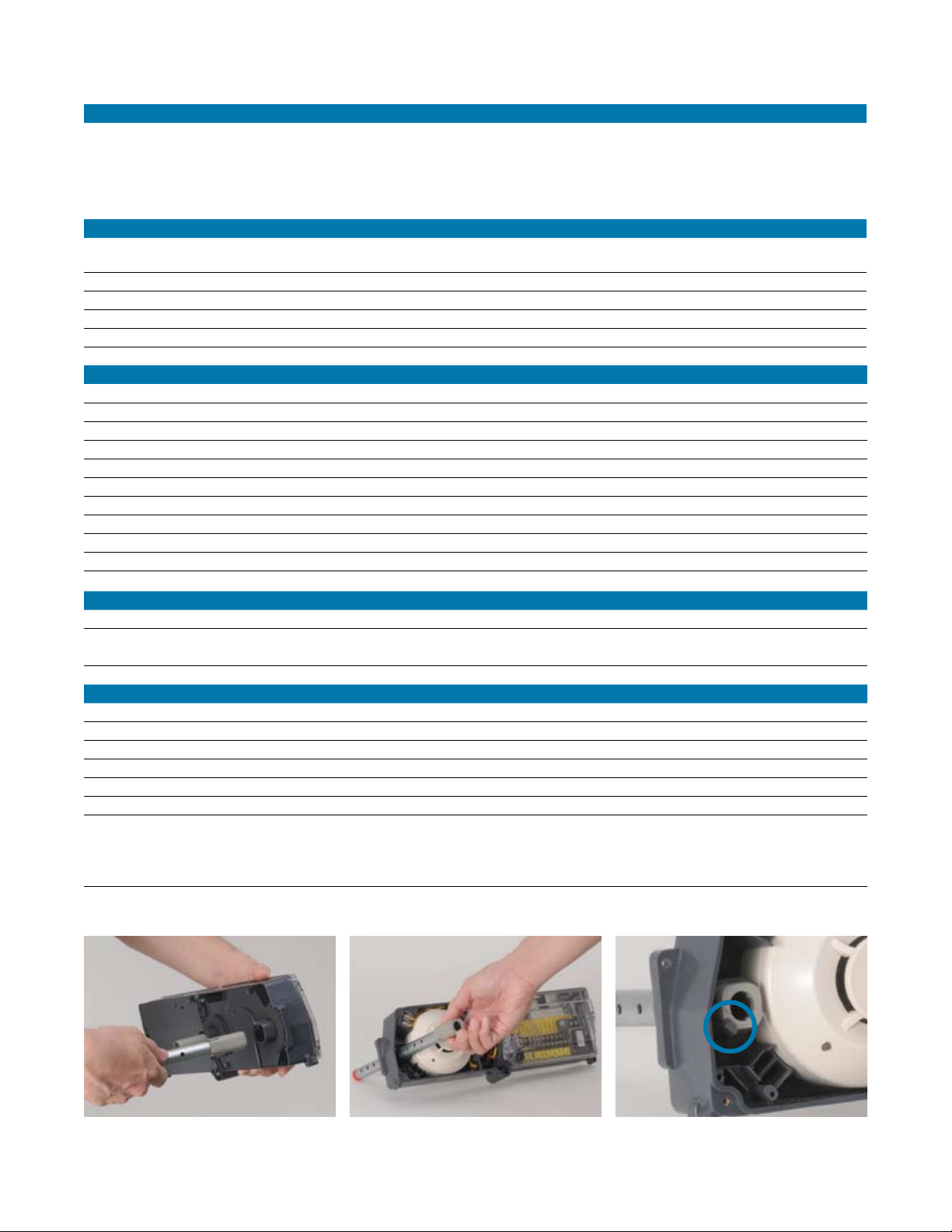

Installing the InnovairFlex Sampling Tube

The InnovairFlex sampling tube may be installed from the front or back of the detector. The tube locks securely into place and can be removed by releasing

the front or rear locking tab (front locking tab shown below right).

A05-0419-001

Page 3

Wiring for 4-wire Duct Smoke Detector and Accessories

24VAC/DC

9 10

AUXILIARY CONTACTS

FOR FAN SHUTDOWN, ETC. (NOTE 2)

16

617

8187

N.O.

C.

N.C.

N.O.

C.

N.C.

16

617

8 18 7

N.O.

C.

N.C.

N.O.

C.

N.C.

SUPERVISORY CONTACTS

(NOTE 3)

24V

9 10

AUXILIARY CONTACTS

FOR FAN SHUTDOWN, ETC. (NOTE 2)

SUPERVISORY CONTACTS

(NOTE 3)

SUP C. SUP N.O.

SUP N.O.

SUP C.

5

4

ALARM

INITIATION

CONTACTS

(NOTE 4)

5

4

ALARM

INITIATION

CONTACTS

(NOTE 4)

ALARM

INITIATION

LOOP

UL/FM LISTED

4-WIRE

CONTROL PANEL

+

120

VAC

120

VAC

OR

OR

AUX A

AUX B

AUX A

AUX B

ALARM C.ALARM C.

ALARM N.O.

ALARM N.O.

14

14

3

3

FIRST DETECTOR IN THE LOOP

POWER INPUTS (NOTE 1) POWER INPUTS (NOTE 1)

LAST DETECTOR IN THE LOOP

EOL RESISTOR

SPECIFIED BY

PANEL

MANUFACTURER

NOTE 1: 24V Power Inputs accept a non-polarized 24VDC or 24VAC 50-60Hz.

120VAC Power Inputs accept only 120VAC 50-60Hz. Connect power

source to appropriate terminals of each detector. See specications

for additional power supply information.

NOTE 2: Auxiliary contacts shown in standby position. Contacts switch

during alarm as indicated by arrows. Auxiliary contacts are not to

NOTE 3: Supervisory contacts shown in standby position. Open contacts

indicate a trouble condition to the panel. See specications for

contact ratings.

NOTE 4: Alarm Initiation contacts shown in standby position. Closed

contacts indicate an alarm condition to the panel. See specications

for contact ratings.

be used for connection to the control panel. See specications for

contact ratings.

*Please refer to the corresponding installation manual for accessory wiring diagrams.

Important Notes on 2:1 Sensor-to-Power Capability

• 2:1 sensor-to-power capability is not available for all InnovairFlex models. The feature is only available on the D4120 4-wire conventional models.

• 2:1 sensor-to-power capability can be enabled using one D4120 and one D4S, or two D4S and one D4P120.

Important Interconnect Notes

• When using the interconnect feature, all interconnected units must be powered using the same independent supply.

• Polarity must be maintained throughout the interconnect wiring. Connect the INT+ terminal on unit 1 to the INT+ terminal on unit 2 and so on. Similarly,

connect the INT/AUX– terminal on unit 1 to the INT/AUX- terminal on unit 2 and so on.

• Up to 50 D4120 units, 50 D4P120 units, or 50 units of combination may be interconnected.

• Up to 10 DH100ACDC units may be interconnected. Please note that each of the 9 DH100ACDC units interconnected may be replaced by three D4P120

units. Therefore, when using the interconnect feature a single DH100ACDC can drive either 9 DH100ACDCs or 27 D4120 units.

* NOTE: Alarm can be reset only at the initiating device and not at the devices interconnected.

A05-0419-001

Page 4

Accessories

System Sensor provides system exibility with a variety of accessories, including two remote test stations and several dierent means of

visible and audible system annunciation. As with our duct smoke detectors, all duct smoke detector accessories are UL listed.

RTS151 UL S4011

RA100Z UL S2522

RTS151KEY UL S2522

MHW UL S4011 MHR UL S4011

APA151 UL S4011

RTS2-AOS UL S2522

Ordering Information

Part No. Description

D4120 4-wire photoelectric low-ow duct smoke detector

Accessories

D4S 4-wire photoelectric sensor component only MHR Mini Horn, Red

D4P120 4-wire photoelectric power board component only,

24 VAC/DC, 120 VAC

2D51 4-wire conventional photoelectric sensor head P48-21-00 End cap for metal sampling tubes

DST1 Metal sampling tube duct width up to 1ft (0.3m) RA100Z Remote annunciator alarm LED

DST1.5 Metal sampling tube duct widths 1 ft to 2 ft (0.3 to 0.6 m) RTS151 Remote test station

DST3 Metal sampling tube duct widths 2 ft to 4 ft (0.6 to 1.2 m) RTS151KEY Remote test station with key lock

DST5 Metal sampling tube duct widths 4 ft to 8 ft (1.2 to 2.4 m) RTS2 - AOS Multi-signaling accessory

DST10 Metal sampling tube duct widths 8 ft to 12 ft (2.4 to 3.7 m)

APA151 Remote annunciator with piezo alarm

DH400 OE-1 Weatherproof enclosure

ETX Metal exhaust tube duct width 1ft (0.3m)

M02-04-00 Test magnet

MHW Mini Horn, White

AOS

3825 Ohio Avenue • St. Charles, IL 60174

Phone: 800-SENSOR2 • Fax: 630-377-6495

Product specications subject to change without notice. Visit systemsensor.com for

current product information, including the latest version of this data sheet.

©2009 System Sensor.

A05-0419-001 • 6/09 • #2172

Loading...

Loading...