Page 1

Installation, Operation and Maintenance Manual

for

Thermal Air Flow Measurement Transmitter

Version 1.4X & 1.5X

®

1

Page 2

TABLE OF CONTENTS

SECTION 1 – GENERAL INFORMATION

1.1 DESCRIPTION .................................................................................................................................4

1.2 THEORY OF OPERATION ................................................................................................................4

SECTION 2 – PERFORMANCE SPECIFICATIONS

2.1 ACCURACY ......................................................................................................................................5

2.2 RANGE ............................................................................................................................................5

2.3 PROBE ASSEMBLY .........................................................................................................................5

2.4 TRANSMITTER ................................................................................................................................5

2.5 POWER ............................................................................................................................................5

SECTION 3 – FEATURES

3.1 OPERATOR MENU ...........................................................................................................................5

3.2 DATA DISPLAY .................................................................................................................................5

3.3 LARGE OPERATION RANGE ...........................................................................................................5

3.4 ENCLOSURE ...................................................................................................................................5

3.5 MULTIPLE OPERATING POWER SELECTIONS .............................................................................5

SECTION 4 – INSTALLATION

4.1 RECEIVING AND INSPECTION .......................................................................................................6

4.2 LOCATION ........................................................................................................................................6

4.3 MOUNTING ......................................................................................................................................6

4.4 PROCESS CONNECTIONS .............................................................................................................7

4.5 POWER/SIGNAL CONNECTIONS ............................................................................................... 7-8

4.6 DISPLAY CONTRAST ADJUSTMENT .............................................................................................8

SECTION 5 – OPERATION

5.1 INTRODUCTION ..............................................................................................................................9

5.2 START-UP .........................................................................................................................................9

5.3 NORMAL OPERATION .....................................................................................................................9

5.4 CONFIGURATION ............................................................................................................................9

5.5 PUSHBUTTON DEFINITION ..........................................................................................................10

5.6 CONFIGURATION PROGRAMMING ....................................................................................... 10-12

5.7 OPERATOR PASSWORD SELECTION ..........................................................................................12

5.8 FLOW CONFIGURATION ......................................................................................................... 13-14

5.9 DISPLAY CONFIGURATION .................................................................................................... 14-15

5.10 OUTPUT 2 PARAMETER SELECTION ..........................................................................................16

5.11 LOW PASS FILTER ........................................................................................................................17

5.12 OUTPUT SIGNAL TYPE SELECTION ............................................................................................17

5.13 TRANSMITTER OUTPUT CALIBRATION ................................................................................ 18-19

5.14 K-FACTOR CONFIGURATION ................................................................................................. 20-21

5.15 MENU INACTIVITY TIMEOUT SELECTION ...................................................................................21

5.16 NETWORK CONFIGURATION .......................................................................................................22

5.17 FLOW ALARM CONFIGURATION ........................................................................................... 22-23

5.18 TEMPERATURE ALARM CONFIGURATION ........................................................................... 23-24

2

Page 3

TABLE OF CONTENTS

SECTION 6 – SUPERVISOR MENU

6.1 INTRODUCTION ............................................................................................................................25

6.2 SUPERVISOR PASSWORD SELECTION ......................................................................................26

6.3 SENSOR MANAGEMENT ........................................................................................................ 27-28

6.4 DIAGNOSTIC DISPLAY SELECTION ............................................................................................. 29

6.5 DIAGNOSTIC ALERT DETERMINATION ................................................................................. 29-30

6.6 POWER CYCLE SENSOR NETWORK ...........................................................................................31

SECTION 7 – MAINTENANCE

7.1 CLEANLINESS ...............................................................................................................................31

7.2 MECHANICAL ................................................................................................................................31

7.3 ELECTRICAL ..................................................................................................................................31

SECTION 8 – TROUBLESHOOTING ..................................................................................................32

APPENDIX A ................................................................................................................................... 33-35

Technical Support:

E-mail: dampers@greenheck.com or

Phone: 1-800-717-6540

3

Page 4

1 – GENERAL INFORMATION

1.1 – DESCRIPTION

The Vari-Green® Thermal Air Flow Transmitter is used in conjunction with Vari-Green Probe(s). One Transmitter can

receive up to 32 individual flow sensors measuring a single ducted airflow or fan.

The Transmitter’s microprocessor averages flow and temperature signals from all sensors and outputs an analog

signal and local display of these averages. The Transmitter serves as the interface for all configuration and

diagnostic functions.

1.2 – THEORY OF OPERATION

The Vari-Green utilizes thermal dispersion technology

to measure airflow. As air moves across the surface of

an elevated temperature sensor, heat is transferred from

the sensor to the airflow in a mathematically defined

relationship between heat transfer rate and airflow

velocity.

Each Vari-Green sensing node utilizes a pair of precision

matched thermistors. One functions as a reference

sensor measuring the ambient air temperature at the

sensing node location, and the other thermistor is heated

to a preset temperature differential (∆T) above the

ambient air temperature. Airflow velocity is determined

using the measured ambient air temperature, the known

heat transfer characteristics of the heated thermistor,

and the power consumed to maintain the ∆T between

the two thermistors.

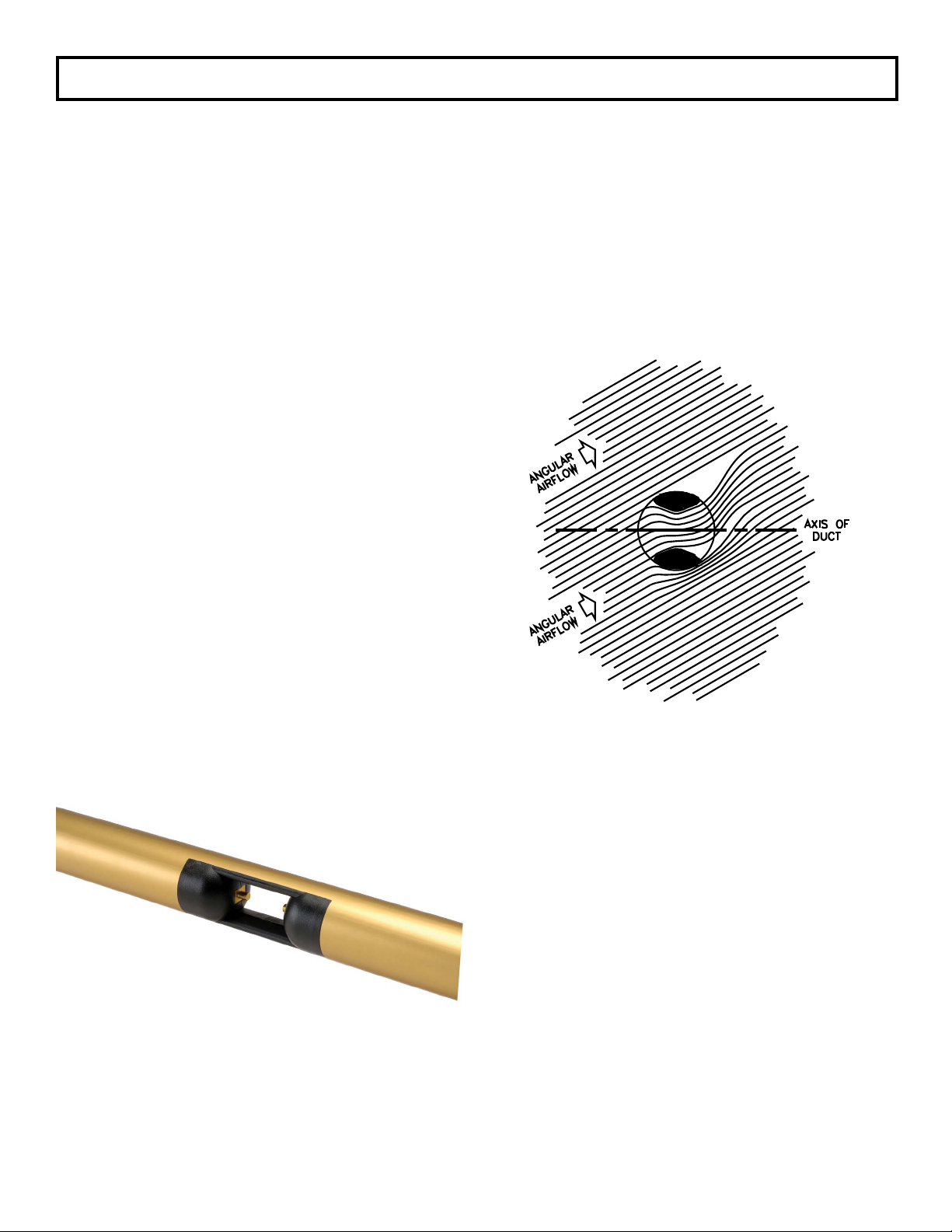

Using a combination of Computational Fluid Dynamics

(CFD) modeling and extensive full-scale wind tunnel

verification, the aerodynamically optimized cross section

of the sensing node aperture prevents error inducing

turbulence typical of sharp edged sensing tubes.

Using a combination of Computational Fluid Dynamics

(CFD) modeling and extensive full-scale wind tunnel

verification, the aerodynamically optimized cross section

of the sensing node aperture prevents error inducing

turbulence typical of sharp edged sensing tubes.

The aperture’s injection molded shape has been

engineered to minimize the angular flow effects

naturally present in any duct. The flared aperture

captures a representative sample of the ducted

airflow, while the contoured leading edges prevent the

creation of vortices. The center cross section of the

aperture functions in the same manner as a venturi. It

stabilizes and flattens the velocity profile at the point of

measurement ensuring the airflow maintains full contact

with the sensing thermistors. The flow conditioning

characteristic of the aperture compensates for turbulent

airflow with pitch and/or yaw angles up to ±30 degrees

and produces an accuracy of ±2% of reading for each

Vari-Green sensor.

4

Page 5

2 – PERFORMANCE SPECIFICATIONS

2.1 – ACCURACY

Sensor Accuracy.

Velocity: ±2% of Reading

Temperature: ±0.1ºF

Overall System Accuracy.

Flow: ±2-3% of Actual Flow

Temperature: ±0.1ºF of Air Temperature

2.2 – RANGE

Velocity Calibration Range.

Low Range (0 to 5,000 FPM)

High Range (0 to 10,000 FPM)

Custom Range (consult Factory)

2.3 – PROBE ASSEMBLY

Mounting.

4 in. x 4 in. aluminum plate with four 0.25 in. holes for

fasteners and neoprene gasket.

Length.

8 in. up to 120 in.

Sensors Per Probe.

Maximum of 16

Connection.

Probe to Probe via RJ-45 cable for signal and power.

Probe to Transmitter via shielded cable with RJ-45

connection. 10 foot length standard with optional 50

foot and 100 foot lengths.

Temperature Limits.

–20ºF to 180ºF Storage

–20ºF to 140ºF Operating

Humidity Limits.

0 to 95% RH, non-condensing.

2.4 – TRANSMITTER

Display.

3 line, backlit graphical display. Flow on Line 1 is

double height and width for improved visibility. Lines

2 and 3 are standard size and are user selectable.

Output.

Dual analog outputs (0-5VDC, 0-10VDC, 4-20mA)

user selectable and configurable.

Configuration.

Via cover mounted membrane keypad

Filter.

Analog outputs filtered via user selectable digital low

pass filter.

Temperature Limits.

–20ºF to 180ºF Storage

–20ºF to 140ºF Operating

Humidity Limits.

0 to 95% RH, non-condensing

2.5 – POWER

Power Supply.

24VAC or 24VDC.

Power Consumption.

16 to 90VA dependent on number of sensor nodes (1 to

32 maximum)

Circuit Protection.

Power input is isolated, fused, and reverse polarity

protected. Earth Ground must be connected to the

terminal labeled "G".

3 – FEATURES

3.1 – OPERATOR MENU

The microprocessor program contains a Operator menu

system for selecting parameters.

Four pushbuttons UP, DN, ENT, and ESC allow the

operator access to the menu for setting configuration

modes and values. Refer to the Configuration

Programming (Section 5.6) instructions for operation

details.

Also contained in the Operator menu is an output

calibration feature. The calibration method is completely

digital and contains no analog potentiometer

adjustments which are susceptible to drift. Non-volatile

memory is used for storing all setup parameters and

calibration values, and will remain unchanged after set,

even when power to the unit is off.

3.2 – DATA DISPLAY

The Vari-Green Thermal Air Flow Transmitter utilizes a

high visibility backlit graphical LCD. 3/4" x 2-1/2" display

with three lines of process data, selectable for U.S. or

S.I. units. Also used for configuration interface.

3.3 – LARGE OPERATION RANGE

The Vari-Green Thermal Air Flow System can maintain

accurate and linear output of flows from 0 to 5,000 FPM

(Low Range) and 0 to 10,000 FPM (High Range). Consult

factory for custom range.

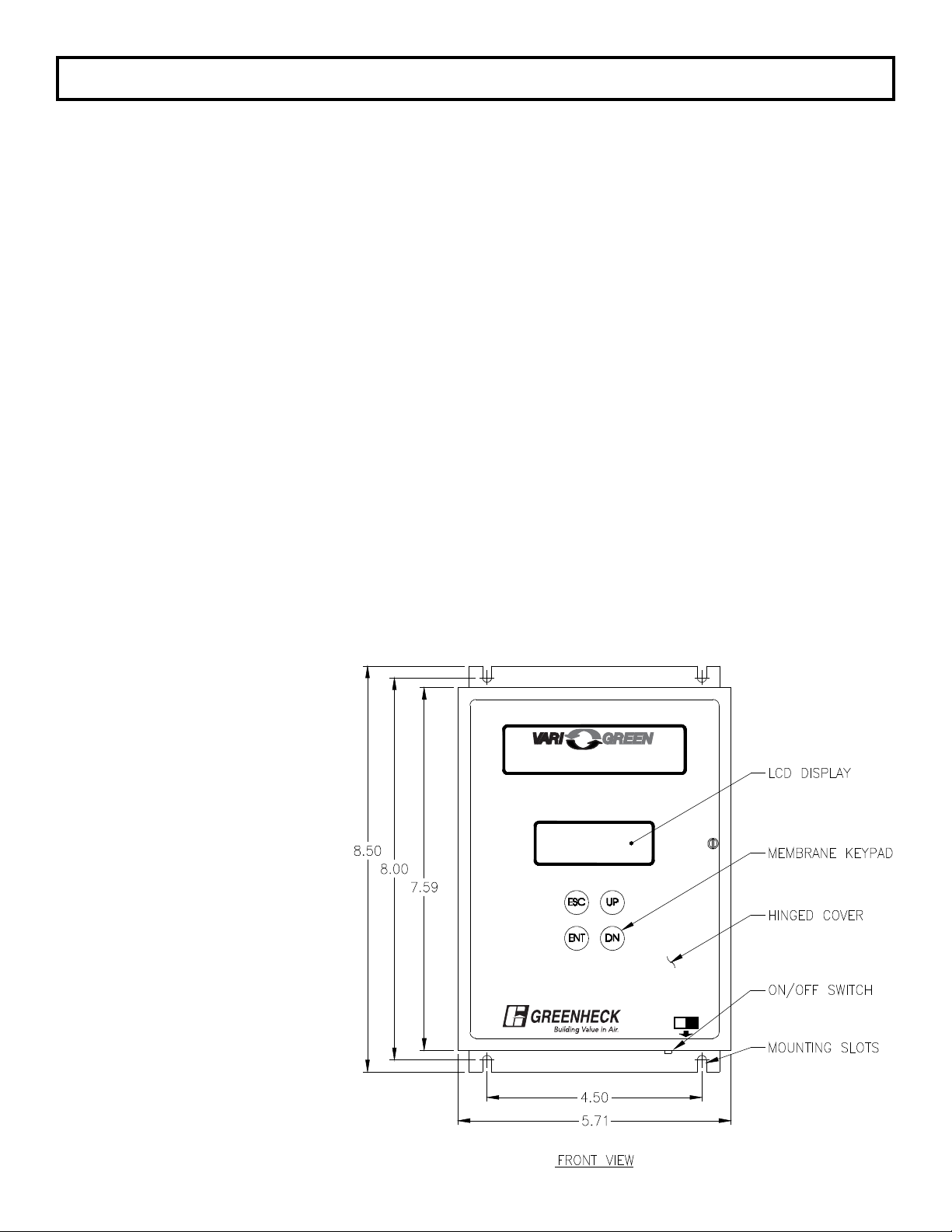

3.4 – ENCLOSURE

The Vari-Green Thermal Air Flow Transmitter is housed

in an aluminum NEMA 1 enclosure with hinged front

cover for access to power and signal terminals for field

connection.

3.5 – MULTIPLE OPERATING POWER

SELECTIONS

The Vari-Green Thermal Air Flow Transmitter can be

powered by either 24VAC or 24VDC.

5

Page 6

4 – INSTALLATION

4.1 – RECEIVING AND INSPECTION

• Carefully remove the Vari-Green Probe(s) or Station,

and Transmitter from the shipping container and

inspect for any damage. If any damage has occurred

in transit, contact freight carrier.

• Review the Factory Set-Up Information Sheet provided

separately and verify the W.O. # and Serial # match

those on the Vari-Green. Verify that the configuration

recorded on the Factory Set-Up Information Sheet

is correct for your application. If not, contact the

Greenheck dampers at 1-800-717-6540 for further

guidance.

Note: The Vari-Green has been configured to customer

provided parameters (see "Factory Setup Information

Sheet" provided separately), and requires no field

calibration/verification prior to installation.

4.2 – LOCATION

• The standard version of the Vari-Green Transmitter is

a NEMA 1 enclosure suitable for most clean indoor

locations. If additional protection is required, mount

the Transmitter in an enclosure with adequate NEMA

rating.

• The ambient temperature of the selected mounting

location must be between -20ºF to 140ºF.

Consideration should be given to units exposed to

direct sunlight.

• The selected mounting location should be rigid and

free of vibration.

4.3 – MOUNTING

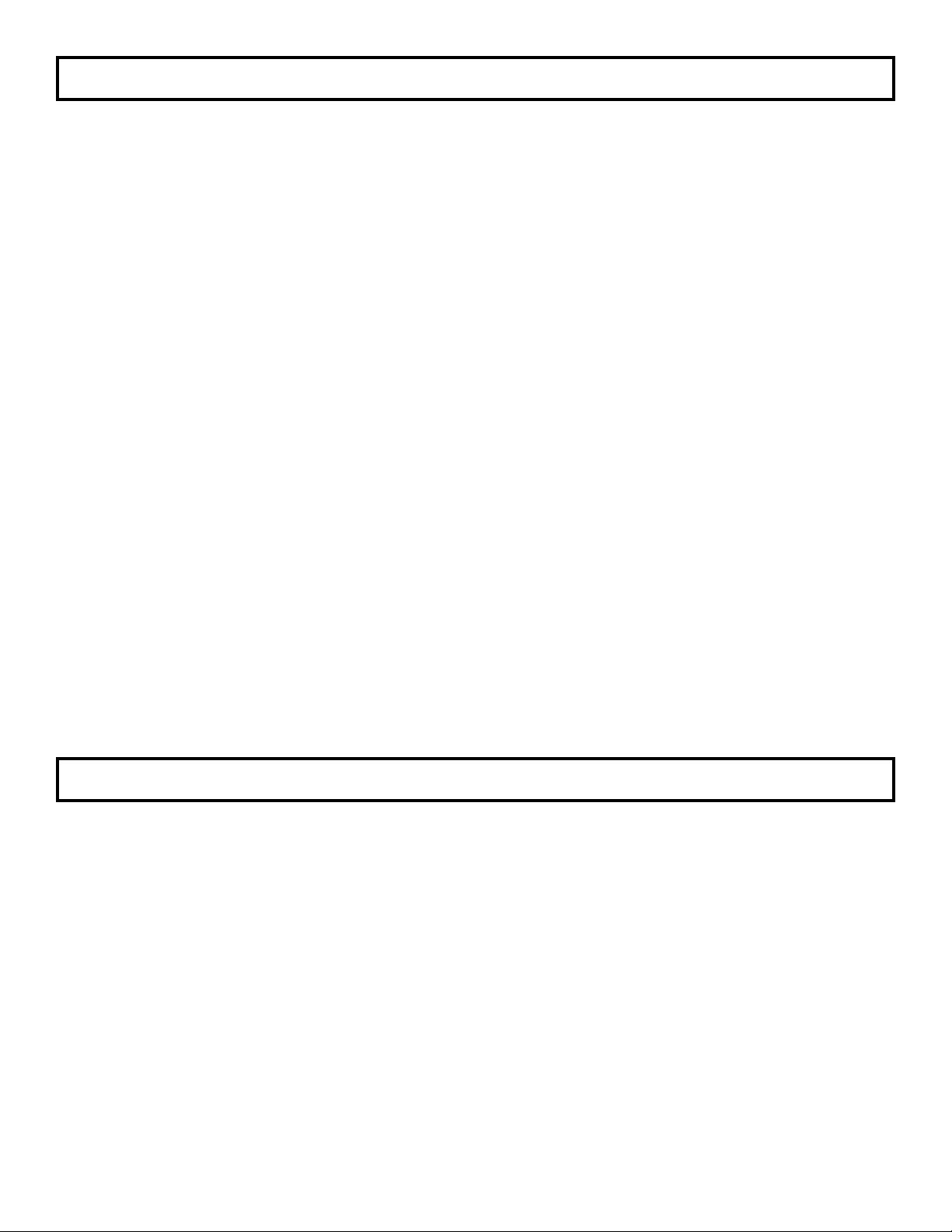

Probes. See separate Installation Instructions for the

installation/mounting of Vari-Green Probes and Stations.

Transmitter. This section may be skipped if the

Transmitter was ordered factory mounted to the station.

– Tools Required: electric drill; #25 (0.1495”) bit;

screwdriver or nutdriver; and four #8-32 self-tapping

machine screws.

– The Vari-Green can be mounted in any position

provided it is secured using all four mounting holes.

– Reasonable consideration should be given to

clearances for electrical connections.

– Once a suitable location is found, use the unit as a

template to mark the centers of the four mounting

holes.

– Drill four pilot holes at the marked locations. With the

unit in position, install the four #8-32 screws.

®

Thermal Air Flow Transmitter

®

OFF ON

Figure 4.1

6

Page 7

4.4 – PROCESS CONNECTIONS

See separate Installation Instructions provided with the Vari-Green Probes or Station for information on connecting

cables from the Probes or Station to the Transmitter.

If the Vari-Green have been purchased with a factory mounted transmitter, all connector cabling has already been

installed.

4.5 – POWER/SIGNAL CONNECTIONS

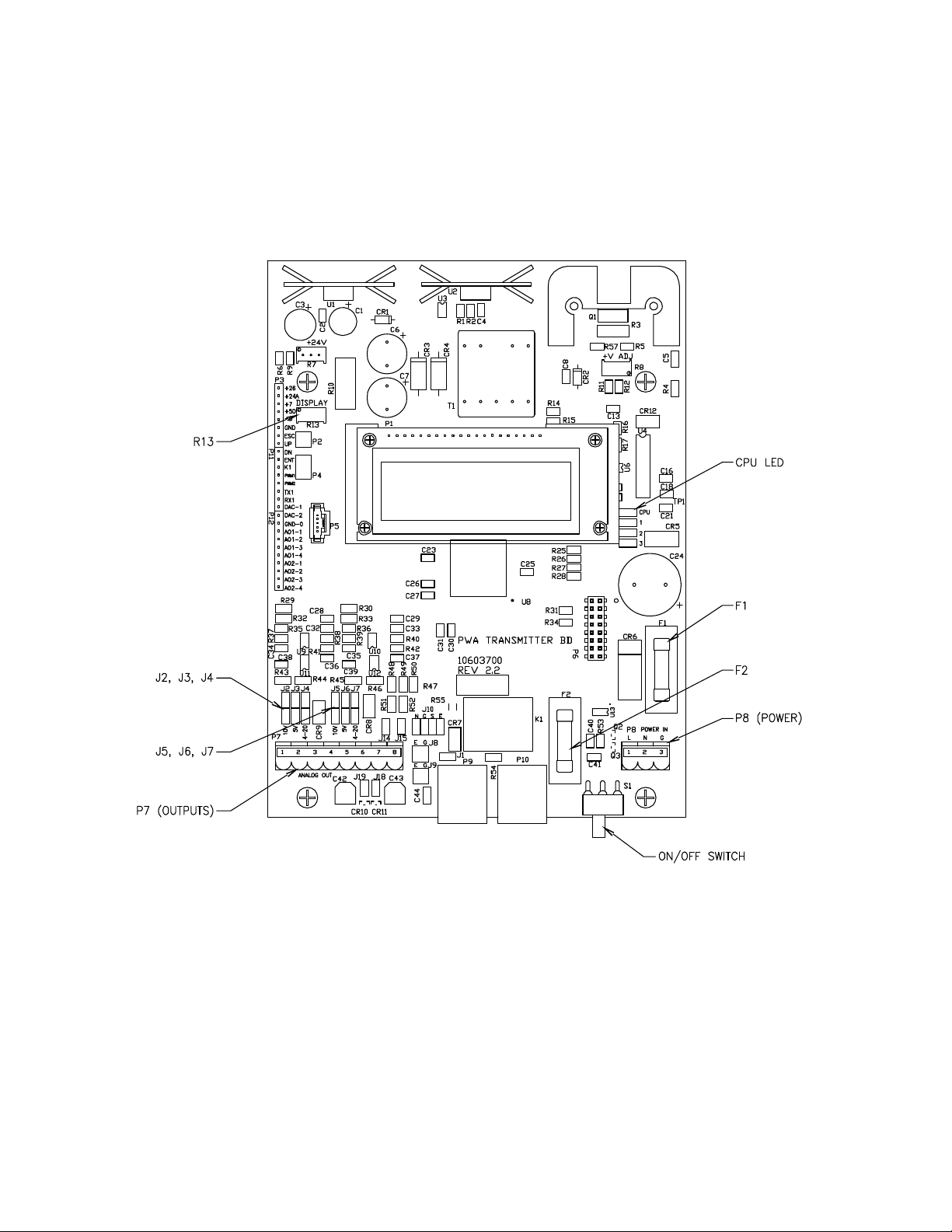

Power wiring is done at terminal strip P8, and signal wiring is done at terminal strip P7. Both P7 and P8 are located

in the lower portion of the transmitter and are accessible by opening the front cover. See Figure 4.2 for location of

P7 and P8. Two conduit openings are provided in the bottom of the transmitter for the power and signal wiring.

Figure 4.2

WIRING.

It is recommended that power wiring be 14 awg to 18

awg, and signal wiring should be 14 awg to 22 awg.

14 awg is the maximum wire gauge that the terminals

can accommodate. No more than two wires should be

connected to any one terminal. To aid in the wiring of

both power and signal wires, P7 and P8 are removable

by pulling the terminal strip straight up and off the circuit

board. Once wiring has been completed, replace the

terminal strip by aligning with receptacle and pressing

firmly.

POWER 24 VAC/DC (Terminals L, N and G, P8).

Power required by the Vari-Green must be connected

to the two terminals labeled L(+) and N(–). Earth ground

must be connected to the terminal labeled G. Power

Supply must be 20-28VAC or 20-40VDC.

OUTPUT #1 (Terminals 1(+) and 2(-), P7).

This output represents the measured airflow and is

sourced (powered) by the Vari-Green. Output can be

configured for 0-5VDC, 0-10VDC, or 4-20mADC. Review

Factory Set-Up Information Sheet for your configuration.

If output is to be 0-5VDC: Position both jumpers on

J3. See Figure 4.2.

If output is to be 0-10VDC: Position both jumpers on

J2. See Figure 4.2.

If output is to be 4-20mADC: Position both jumpers on

J4. See Figure 4.2.

In addition to positioning the jumpers for the desired

output type, the corresponding output type must be

selected in the Operator Menu (see Section 5.12).

7

Page 8

4.5 – POWER/SIGNAL CONNECTIONS (con’t)

OUTPUT #2 (Terminals 3(+) and 4(-), P7).

This output can represent the measured flow (0 - Design

Full Range) or temperature (0 to 140ºF / -18 to 60ºC) and

is sourced (powered) by the Vari-Green. Output can be

configured for 0-5VDC, 0-10VDC, or 4-20mADC. Review

Factory Set-Up Information Sheet for your configuration.

If output is to be 0-5VDC: Position both jumpers on

J6. See Figure 4.2.

If output is to be 0-10VDC: Position both jumpers on

J5. See Figure 4.2.

If output is to be 4-20mADC: Position both jumpers on

J7. See Figure 4.2.

In addition to positioning the jumpers for the desired

output type, the corresponding output type must be

selected in the Operator Menu (see Section 5.12).

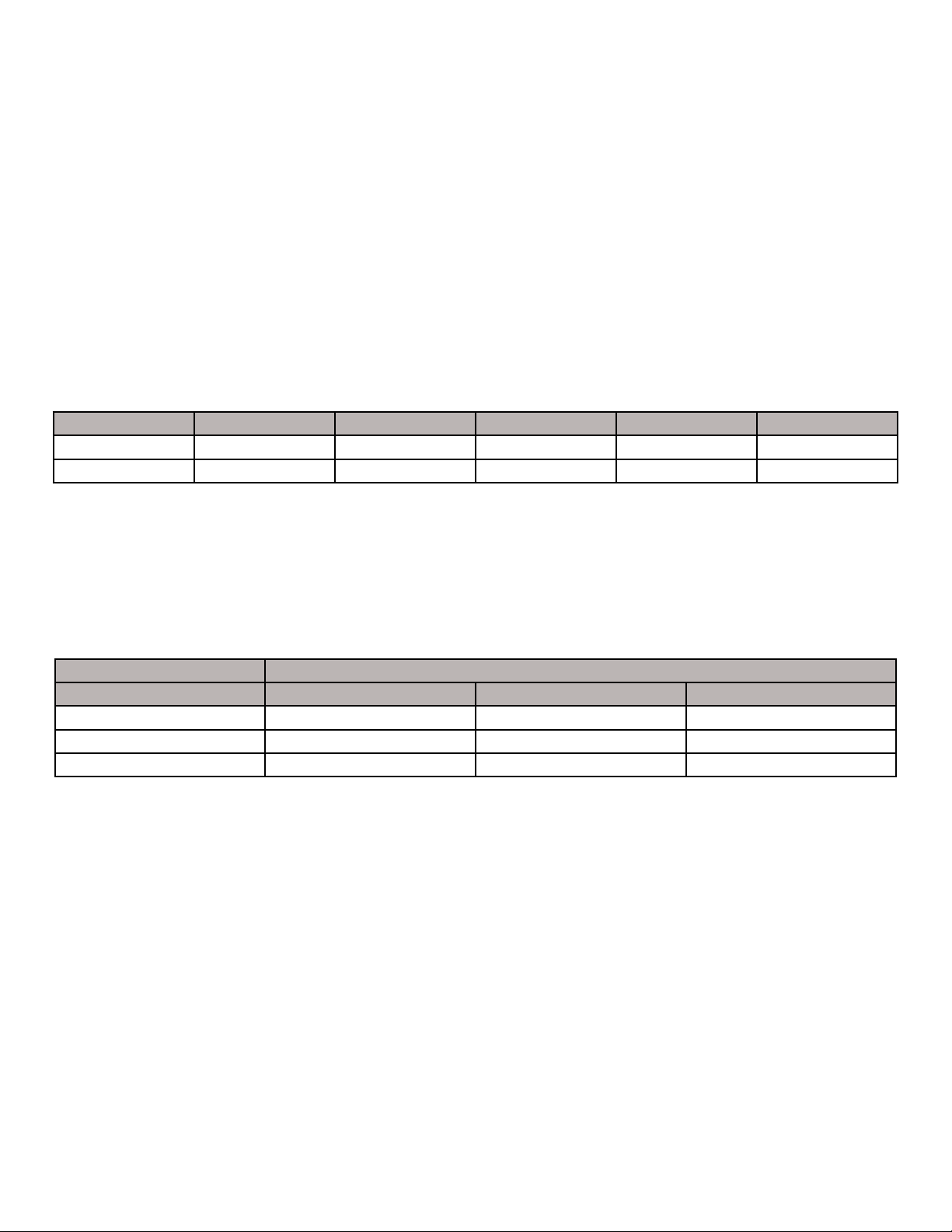

SNVT SNVT Index Measurement Units Type Category Type Size

SNVT_flow_f 53 Flow Volume Liters/Sec Floating Point 4 bytes

SNVT_temp_p 105 Temperature °C x 100 Signed Long 2 bytes

For BACnet, connections are as follows:

Terminal 5 – Net A or Net +

Terminal 6 – Net B or Net Terminal 7 – Network Ground

For BACnet objects, see Appendix A.

Set the S1 Termination switches on the BACnet module as follows:

Network Connection (Terminals 5, 6 & 7, P7).

This serial output is available with optional LonWorks or

BACnet (Version 1.5X only) communication.

For LonWorks, connections are as follows:

Terminal 5 – LonWorks B

Terminal 6 – LonWorks A

Terminal 7 – Ground

Two output variables are provided, flow volume and

temperature.

S1 Switch Position

Termination Type 1 2 3

No Termination OFF OFF OFF

End of Line ON OFF OFF

Fail-safe Bias ON ON ON

Note: The Fail-safe Bias termination includes End of Line termination.

4.6 – DISPLAY CONTRAST ADJUSTMENT

To compensate for different ambient lighting conditions and viewing angles, the Vari-Green display's contrast can

be adjusted for optimum visibility. Contrast is adjusted using potentiometer R13. Turn R13 clockwise to increase

contrast (darken characters relative to background) or counterclockwise to decrease contrast.

8

Page 9

5 – OPERATION

5.1 – INTRODUCTION

The Vari-Green has been configured at the factory to

customer specified parameters. Review this information

and verify that the Vari-Green set-up is correct for

your application. If any problems or discrepancies are

detected, contact Greenheck Dampers at 1-800-7176540 prior to proceeding.

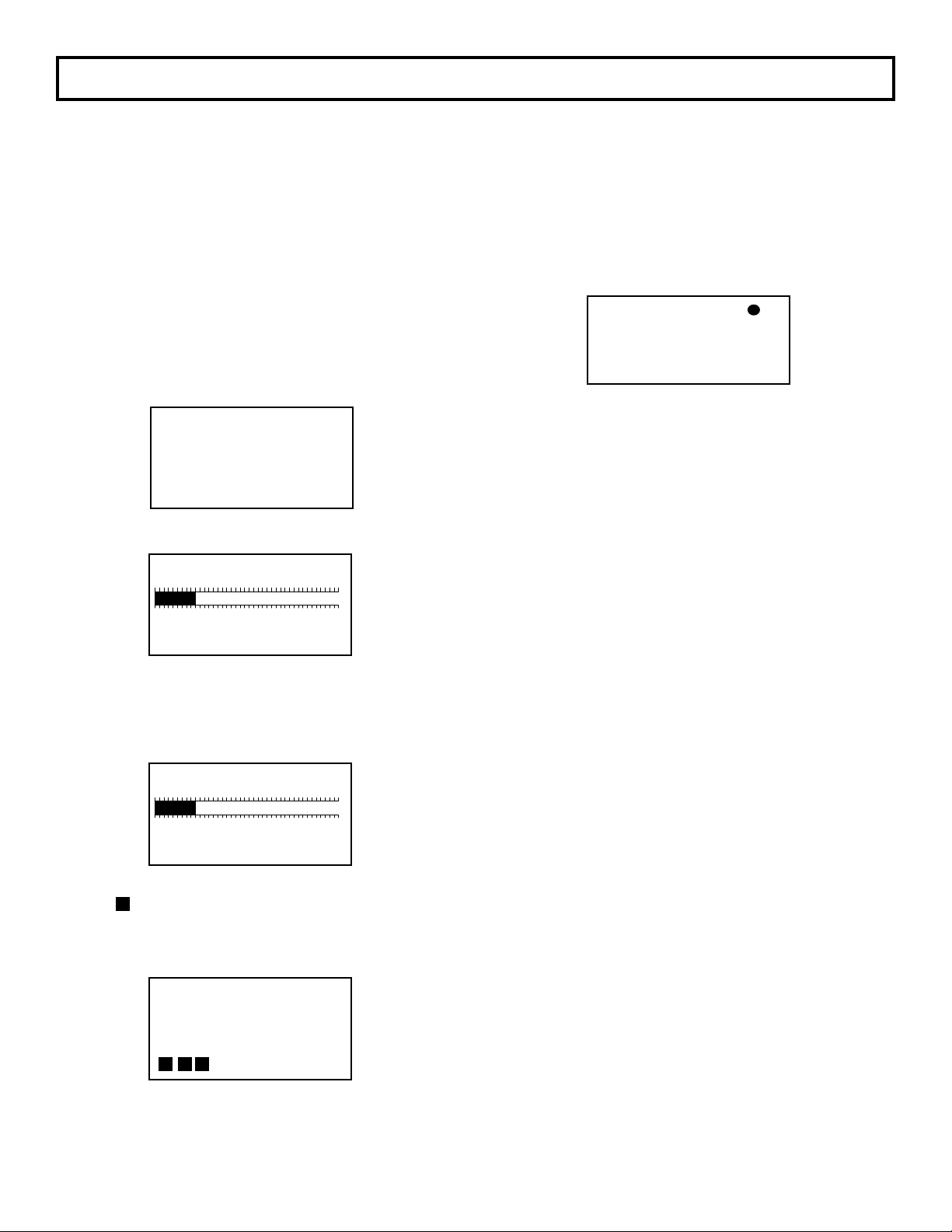

5.2 – START-UP

1. After Installation has been verified in accordance with

Section 4, turn power switch located at the lower front

side to the ON position (see Figure 4.1).

2. Display will briefly indicate:

Followed by:

The number of active sensors will be represented by

Vari-Green

- - - - - - - - - - - - - - - - - - Thanks for Choosing

Greenheck

the bar graph and listed below. There are 8 active

sensors in this example.

1 8 16 24 32

Sensors Found: 8

Total Sensors: 8

After 5 seconds, display will indicate:

The number of enabled sensors will be represented

by the bar graph and listed below. There are 8 active

sensors in this example.

1 8 16 24 32

After 20 seconds, the display will return to Normal

display mode, and the dot in the upper right of the

display indicating CPU Activated will blink rapidly (4

times per second). This is Normal operation mode

and no further user interface is required. If, however,

user would like to verify configuration or change user

selectable parameters, continue to Section 5.4 entitled

“CONFIGURATION”.

0 ACFM

VELO 0 AFPM

TEMP 68.0°F

Normal display mode

* Dot flashes 4 times a second, indicating that

CPU is active. If ALERT flashes instead of Dot, see

section for Diagnostics.

*

5.3 - NORMAL OPERATION

Under Normal operation, the Vari-Green transmitter will

continuously display flow and velocity, or temperature.

5.4 - CONFIGURATION

The Vari-Green onboard microprocessor controls

Configuration: Operating parameter selection; input/

output activation and scaling, and display scaling.

The customer can verify configuration and change

certain parameters (within defined ranges) by

entering the Vari-Green Configuration mode. This is

accomplished using the four membrane pushbuttons

located on the Vari-Green cover. See Figure 4.1 for

location of pushbuttons.

Enabled Sensors: 8

Total Sensors: 8

After 5 seconds, display will indicate:

with the progressing from left to right.

Vari-Green

- - - - - - - - - - - - - - - - - - - Sensor Warming Up

®

9

Page 10

5.5 – PUSHBUTTON DEFINITION

The four pushbuttons used to interface with the Vari-Green are as follows: UP DN ENT ESC

In addition to use during Configuration programming, pushbuttons can be used for certain functions when in the

Normal operation mode. The following list describes the pushbutton function when in the Normal operation mode

and in the User Setup (programming).

When in Normal Operation Mode.

ENT then ESC then UP then ENT Activates the Operator menu.

ENT then ESC then DN then ENT Activates the Supervisor menu.

ENT Activates Password selection menu.

ENT then UP then DN then ENT Displays ID, ESID, and WO#. Press UP and software version and maximum

velocity will be displayed. Press ESC and the display will go back to the

Normal operation mode.

When in User Setup.

UP or DN Use to scroll to the desired Main Menu item.

Use to scroll to the value or mode within a parameter.

ENT Enters user into specific selection sub-menu from Main Menu Selection.

Displays current setting of selected Parameter. Enters the selected value or

setting into memory.

ESC Use as an escape key to exit back to Main Menu selection to avoid scrolling

to Return to MAIN MENU

The following pushbutton combinations can be used to more quickly set user selected values (i.e. Process Min and

Max Values, etc.).

UP* + ESC Increases the second column digit.

DN* + ESC Decreases the second column digit.

UP* + DN Increases the third column digit. XXXXX

DN* + UP Decreases the third column digit.

UP* + ESC + DN Increases the fourth column digit.

DN* + ESC + UP Decreases the fourth column digit.

*Must be pressed and held before other button(s) are pressed.

Note: Pushbuttons are momentary type and should be quickly pressed and released to initiate desired change,

unless otherwise instructed to press and hold.

2nd Column

3rd Column

4th Column

5.6 – CONFIGURATION PROGRAMMING

1. With power ON and initialization complete (see Section 5.2), press ENT then ESC then UP then ENT to activate

the Operator menu. The display will indicate:

ENTER PASSWORD FOR

OPERATOR MENU

XXXX

Note: If Operator Menu password has been bypassed (see Section 5.7), the display will indicate as shown in Step 3

below.

2. Using UP and ENT, scroll to the numeric password for the Operator Menu. From the Factory, password is set for

1,111.

3. Once password is displayed, press ENT and display will indicate:

4. Press ENT and display will indicate:

By using UP and DN, the user can scroll through the following selections:

10

OPERATOR MENU

OPERATOR PASSWORD

Page 11

Main Menu Selection Description

between VELOCITY,

between VELOCITY,

Operator Password Selection Allows for the selection of password for the Operator Menu, and the

bypassing of the password

Flow Configuration Allows for the configuration of process variable such as: Duct size

and shape, process type, process maximum/units, and percent

lockdown

Display Configuration Allows the selection of parameter to be displayed on Lines 2 & 3,

and display filter

Output 2 Parameter Selection Allows the selection Output 2 parameter

Low Pass Filter Selection Selects amount of filtering applied to the output and to the display

Output Signal Type Selection Allows the selection of signal type for Output 1 and 2

Transmitter Output Calibration Allows for the zeroing and spanning of transmitter analog Outputs

1 and 2

K-factor Configuration Turns K-factor ON or OFF and allows for the calculation or selection

of exponent and gain values

Menu Inactivity Timeout Selection Allows for the selection a time after which the unit returns to

normal operation if no activity in the Operator Menu

Network Configuration Turns the Network ON or OFF, and allows BACnet configuration

Flow Alarm Configuration

(available only with BACnet Network Option)

Temperature Alarm Configuration

(available only with BACnet Network Option)

Operator Menu Exit Returns display to Normal operation

Turns each alarm ON or OFF, select High and Low Setpoints,

Deadband selection and Alarm Delay

Turns each alarm ON or OFF, select High and Low Setpoints,

Deadband selection, and Alarm Delay

5. Once the desired selection is displayed, press ENT to enter its sub-menu.

Once the desired Selection is displayed, its sub-menu can be entered by pressing ENT.

At any time while in the Operator Menu, User can return to Normal operation mode by pressing ESC or scrolling to:

OPERATOR MENU

and pressing ENT.

EXIT

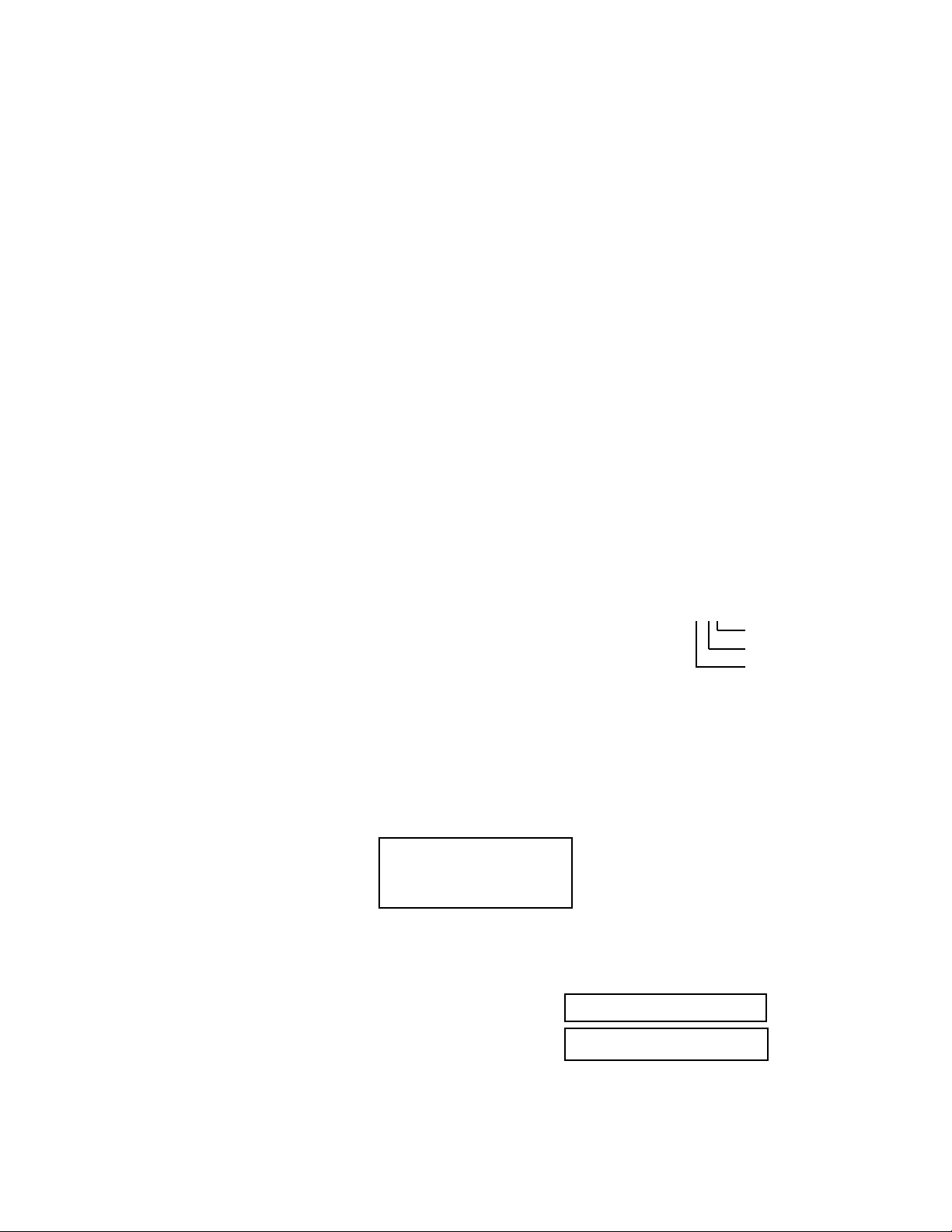

To better understand the process of Configuration Programming, arrows with pushbutton designation have been

included on the following flow chart of Display Configuration. This will aid in the navigation of the Configuration

Programming Process.

Operator Menu

Display Configuration

DN

UP

ENT

ESC

ESC

ENT or ESC

Display Filter

Selection

DN

Line 2 Parameter

Selection

DN

Line 3 Parameter

Selection

DN

Return to

MAIN MENU

UP

UP

UP

ENT

ENT or ESC

ENT

ENT or ESC

ENT

ENT or ESC

Line 2 Parameter

Line 2 Parameter

TEMPERATURE

Display Filter

0 (None)

VELOCITY

UP or DN will scroll

between 0 and 5

UP or DN wil scroll

TEMPERATURE, &

CUSTOM TEXT

UP or DN wil scroll

TEMPERATURE, &

CUSTOM TEXT

Output 2 Parameter

Selection

This example of navigation is similar for all Operator Menu selections.

11

Page 12

Note: All selections that are available for further configuration programming will have an “arrow” symbol

displayed in the right side of the display field. Those that are not available for further configuration

programming will not have the “arrow” symbol displayed and will display Not Installed beneath the selection

description. Example:

Network option is

not installed

The remainder of this Section details steps to verify or change Configuration Programming of all Operator Menu

Selections.

5.7 – OPERATOR PASSWORD SELECTION

Allows the selection of an Operator Menu password and the option of bypassing the password.

Operator Menu

- OPERATOR MENU EXT

Operator Password Select

- Flow Configuration

Password Menu

- Password Selection

- Bypass Password? Selection

- Return to MAIN MENU

Default selection shown

Password

1, 111

Bypass Password?

NO

Return to

MAIN MENU

Available selections

0 to 9,999

NO or YES

Note: The Operator Password menu can be accessed directly following start-up (power ON) by pressing:

UP then DN then UP then ESC.

1. While in Operator Menu, use UP or DN to scroll to:

Operator Password

Selection

2. Press ENT to enter Operator password menu. Display will indicate:

Password

Selection

3. Press ENT and display will indicate current password.

Note: From the Factory, password is set for 1,111

4. Use UP or DN to change password. Once desired password is displayed, press ENT. New password will be

stored in memory and display will return to previous menu (see Step 2).

Caution: If password is changed, write it down, and retain in case it is forgotten.

Note: If user desires not to change password and return to password menu, press ESC. Unit will remain

programmed as it was originally.

5. Use UP to select Bypass Password if desired.

6. Follow Steps 3 and 4 to make changes.

CAUTION: If YES is selected, this will eliminate the need to enter any password when accessing the Operator Menu.

7. To return to Main Menu, select Return to MAIN MENU in the Operator Password Selection menu, and press ENT.

12

Page 13

5.8 – FLOW CONFIGURATION

Operator Menu

Dimensional Units

U.S.

Temperature Units

°F

Duct Shape

RECTANGULAR

Duct Height

XX.XX in.

Duct Width

XX.XX in.

Duct Diameter

XX.XX in.

Duct Area

XX.XX Sq. Ft.

Actual or Standard

ACTUAL

Maximum Full Range is based

This Operator Menu selection is where all application specific data is entered to configure the Vari-Green for a

unique application. Typical data includes: Units of Measure, Duct Type and Size, Flow Type, Units and Conditions,

and Output Lockdown.

Note: The factory has entered data in this section based on customer supplied information. Data can be reviewed

and verified by scrolling through the individual menu items or reviewing the Factory Set-Up Information

sheet provided separately. Review this information BEFORE making any changes as it can have a

significant effect on the operation of the Vari-Green.

Flow Configuration MenuOperator Menu

Default slection shown

- Operator Password Selection

Flow Configuration

- Display Configuration

- Dimensional Units Selection

- Temperature Units Selection

- Duct Shape Selection

- Duct Height Selection ¹

- Duct Width Selection ¹

- Duct Diameter Selection ²

- Duct Area Selection ³

- Actual or Standard Selection

- Site Elevation Selection

- Volume Units Selection

- Design Full Range Selection

- Output Lockdown Selection

- Return to MAIN MENU

¹ Available only if RECT ANGULAR or OVAL is

selected as Shape

² Available only if ROUND is selected as Shape.

³ Available only if OTHER is selected as Shape.

U.S or METRIC

°F or °C

RECTANGULAR, ROUND,

OVAL, FAN INLET-SINGLE,

FAN INLET-DOUBLE, or

OTHER

0.00 to 300.00 in.

0 to 10,000 mm

0.00 to 300.00 in.

0 to 10,000 mm

0.00 to 300.00 in.

0 to 10,000 mm

0.00 to 325.00 Sq.Ft.

0 to 35,500 Sq. M.

Actual or

Standard

Design Full Range

XX,XXX ACFM

1. While in Operator Menu, use UP or DN to scroll to:

2. Press ENT to enter Flow Configuration menu. Display will indicate:

3. Press ENT and display will indicate current setting of Units (U.S. or METRIC).

Maximum Full Range

XX,XXX ACFM

Output Lockdown

Site Elevation

0 Feet

Volume Units

ACFM

4

200 AFPM

Return to

MAIN MENU

0 to 15,000 Feet

0 to 4,572 M.

See UNITS list for

available

selections

Design value

adjustable up to

maximum value.

0 to 5000 AFPM

4

on the duct area.

Flow

Configuration

Dimensional Units

Selection

13

Page 14

4. Use UP or DN to change setting. Once desired setting is displayed, press ENT, new setting will be stored in

memory and display will return to Flow Configuration menu as in Step 2.

Note: If user desires not to change the setting and return to the Flow Configuration menu, press ESC. Unit will

remain programmed as it was originally.

5. Use UP or DN to select remaining parameters to be changed within the Flow Configuration menu.

6. Follow Step 4 to make any changes to parameters.

See the following Units List for the available selections for the appropriate Flow Type.

Units List for Volume

Unit of Measurement Display

Actual cubic feet per minute ACFM

Actual cubic feet per hour ACFH

Actual liters per second Al/s

Actual liters per minute Al/m

Actual cubic meters per hour Am3/h

Standard cubic feet per minute SCFM

Standard cubic feet per hour SCFH

Standard liters per second Sl/s

Standard liters per minute Sl/m

Standard cubic meters per hour Sm3/h

7. To return to the Main Menu, select Return to MAIN MENU in the Flow Configuration menu and press ENT.

5.9 – DISPLAY CONFIGURATION

Allows selection of display parameter for lines 2 and 3. Also, the level of filtering, 0 through 5 (5 is the maximum) can

be selected by User.

Operator Menu

- Flow Configuration

Display Configuration

- Output 2 Parameter Selection

Display Configuration Menu

- Display Filter Selection

- Line 2 Parameter Selection

- Line 2 Custom Text Selection

- Line 3 Parameter Selection

- Line 3 Custom Text Selection

- Return to MAIN MENU

1

Available only if Parameter is

CUSTOM TEXT.

Default selection shown

Display Filter

1

1

0 (None)

Line 2 Parameter

TEMPERATURE

Line 2 Custom Text

Line 3 Parameter

VELOCITY

Available selections

0 (None) to

5 (Maximum)

TEMPERATURE,

CUSTOM TEXT,

or VELOCITY

See ASCII

Character Chart for

Selection

TEMPERATURE,

CUSTOM TEXT,

or VELOCITY

14

Line 3 Custom Text

Return to

MAIN MENU

See ASCII

Character Chart for

Selection

Page 15

5.9 – DISPLAY CONFIGURATION (con’t)

1. While in Operator Menu, use UP or DN to scroll to:

Display

Configuration

2. Press ENT to enter Display Configuration menu. Display will indicate:

Display Filter

Selection

3. Press ENT and display will indicate current setting of the filter [0 (None), 1 (Minimum), 2, 3, 4, or 5 (Maximum)].

4. Use UP or DN to change setting. Once desired setting is displayed, press ENT, new setting will be stored in

memory and display will return to Display Configuration menu as in Step 2.

Note: If user desires not to change the setting and return to the Display Configuration menu, press ESC. Unit will

remain programmed as it was originally.

5. Use UP and display will indicate:

Line 2 Parameter

Selection

6. Press ENT and display will indicate current parameter selected to display on Line 2 (VELOCITY, TEMPERATURE,

or CUSTOM TEXT).

7. Use UP or DN to scroll to desired parameter. Press ENT, and parameter will be stored in memory and display will

indicate as in Step 5.

Note: If user desires not to change the setting and return to the Setup menu, press ESC. Unit will remain

programmed as it was originally.

8. If CUSTOM TEXT was selected and ENT pressed in Step 7, proceed to Step 13. For other parameters, continue

with Step 9.

9. Press UP and display will indicate:

Line 3 Parameter

Selection

10. Repeat Steps 6 through 8 for Line 3. The only differences being the change of Line # in the display.

11. After Line 3 has been set, Step 9 will yield a display:

Return to

MAIN MENU

12. Press ENT to return to Main Menu.

13. If Custom Text was selected and ENT pressed in Step 7 (or for Line 3), press UP and display will indicate:

Line 2 Custom Text

Selection

14. Press ENT and display will indicate:

Line 2 Custom Text

Cursor indicates position to be set.

There are 20 positions available to

hold custom text.

15. Use UP or DN to scroll through available characters (see ASCII Chart at the end of this Section for available

characters).

16. When desired character is displayed, press ENT, character will be stored and cursor will advance one position to

the right.

17. Repeat Steps 15 and 16 for all 20 positions. When position 20 is entered, user will be exited back to display as in

Step 13.

15

Page 16

In “Set Custom Text” mode, the pushbuttons can be used in the following combinations to facilitate programming.

ESC + UP Moves position cursor to the right, one position at a time.

ESC + DN Moves position cursor to the left, one position at a time.

ESC + ENT Exits “Set Custom Text”. Does not enter any changes to the display since the last time ENT was

pressed.

UP + DN Jumps up five characters at a time, to the desired character.

DN + UP Jumps down five characters at a time, to the desired character.

ASCII Character Chart

! * 3 < E N W ` i r {

+ 4 = F O X a j s l

″

#

$ - 6 ? H Q Z c l u

% . 7 @ I R [ d m v

& / 8 A J S

'

( 1 : C L U

5 > G P Y b k t }

'

e n w

¥

0 9 B K T ] f o x

g p y

^

↑

↓

) 2 ; D M V - h q z

5.10 – Output 2 Parameter Selection

Allows the selection of which process variables Output 2 represents.

Process variables available for output are: Flow, Temperature, or None.

If Flow is selected, output will represent 0 to Design Full Range (see Section 5.8).

Operator Menu

- Display Configuration

Output 2 Parameter Select

- Low Pass Filter Selection

Default selection shown

Output 2 Parameter

TEMPERATURE

Available selections

FLOW, NONE

TEMPERATURE

If Temperature is selected, output will represent 0º to 140ºF (-18ºC to 60ºC).

1. While in Operator Menu, use UP or DN to scroll to:

Line 3 Parameter

Selection

2. Press ENT and display will indicate current setting of Output #2 (Flow, Temperature or None).

3. Use UP or DN to change setting. Once desired setting is displayed, press ENT. New setting will be stored in

memory and display will return as in Step 1.

Note: If user desires not to change the setting and return to Output 2 Parameter menu, press ESC. Unit will

remain programmed as it was originally.

16

Page 17

5.11 – Low Pass Filter

Allows selection of level of Process filtering applied to the output. Levels are 0 to 10, with 0 representing no filtering

and 10 representing maximum filtering. Display Filter is an additional filter selection applied only to the display.

This filtering affects all subsequent outputs and displays.

Operator Menu

- Output 2 Parameter Selection

Low Pass Filter Selection

- Output Signal Type Selection

Default selection shown

Low Pass Filter

1 (Minimum)

Available selections

0 (None) to

10 (Maximum)

1. While in Operator Menu, use UP or DN to scroll to:

Low Pass Filter

Selection

2. Press ENT and display will indicate current setting of Process filter; (0 (none) to 10

(maximum).

3. Use UP or DN to change setting. Once desired setting is displayed, press ENT. New setting will be stored in

memory and display will return as in Step 1.

Note: If user desires not to change the setting and return to Output 2 Parameter menu, press ESC. Unit will

remain programmed as it was originally.

5.12 – Output Signal Type Selection

User can select signal type for Output 1 and 2.

The output types selected below must correspond to the types selected via jumpers J3 through J7 (see Section 4.5).

Operator Menu

- Low Pass Filter Selection

Output Signal Type Select

- Transmitter Output Calibration

Output Signal Menu

- Output 1 Signal Type Selection

- Output 2 Signal Type Selection

- Return to MAIN MENU

1. While in Main Menu, use UP or DN to scroll to:

Default selection shown

Output 1 Signal Type

4-20 mA

Output 2 Signal Type

4-20 mA

Return to

MAIN MENU

Available selections

4-20 mA,

0-10 Vdc, 0-5 Vdc

4-20 mA,

0-10 Vdc, 0-5 Vdc

Output Signal Type

Selection

2. Press ENT to enter Output Signal Type menu. Display will indicate:

Output Signal Type

Selection

3. Press ENT and display will indicate current signal type (4-20mA).

4. Use UP or DN to change signal type. Once desired signal type is displayed, press ENT. New signal type will be

stored in memory and display will return to Output Signal Type Selection menu as in Step 2.

Note: If user desired not to change the signal type and return to Output Signal Type Selection menu, press ESC.

Unit will remain programmed as it was originally.

5. Use UP or DN to select remaining parameters to be changed.

6. Follow Step 4 to make any changes to parameters.

7. To return to Main Menu, select Return to MAIN MENU in Output Signal Type Selection menu and press ENT.

17

Page 18

5.13 – Transmitter Output Calibration

Allows for the calibration of the Vari-Green analog outputs.

Operator Menu

- Output Signal type Selection

Transmitter Output Calib.

- K-Factor Configuration

Output Calibration Menu

- Output 1 Zero Selection

- Output 1 Span Selection

- Output 2 Zero Selection

- Output 2 Span Selection

- Return to MAIN MENU

See Calibration

Instructions

Note: Unit is supplied Factory calibrated.

This section can be accomplished with the Vari-Green mounted in its operating location or at a test bench in a calibration

lab.

Required Equipment.

1. Digital Multimeter

Preparation.

1. Turn Power switch OFF on the Vari-Green (see Figure 4.1).

2. Open cover of the Vari-Green.

3. Remove all wires connected to terminals 1 through 4 (see Figure 4.2).

4. Turn Power switch ON.

1. While in Operator Menu, use UP or DN to scroll to:

Transmitter Output

Calibration

2. Press ENT to enter Display Configuration menu. Display will indicate:

Output 1 Zero

Selection

Type is 4-20 mA

3. Press ENT. Display will indicate:

Output 1 Zero

Perform Calibration

4. Connect a DMM set for type and scale of Transmitter Output 1 (as indicated on display)

Type is 4-20 mA

across terminals 1 and 2 on the Vari-Green (see Figure 4.2).

Note: If the output is 4-20mA, a load resistance should be in series with the DMM. This can be accomplished by

connecting the actual process load or a resistor of similar value to the actual process load.

DMM should be reading a minimum value; 0.00 ± 0.01 volts or 4.00 ± 0.01mA.

5. If DMM is reading out of tolerance, use UP or DN to adjust the Vari-Green output for an acceptable DMM reading.

Depending on DMM’s selected range, the UP or DN button may need to be pressed and held for a period of time

before any change occurs in the DMM’s display. To speed up changes in output, pushbutton combinations can be

used. The following chart lists these combinations along with the associated change in output type.

18

Page 19

Pushbutton

Combination

UP only +0.001mA +0.3mV +0.6mV

DN only -0.001mA -0.3mV -0.6mV

UP* + ESC +0.01mA +0.003V +0.006V

DN* + ESC -0.01mA -0.003V -0.006V

UP* + DN +0.1 mA +0.03V +0.06V

DN* + UP -0.1mA -0.03V -0.06V

UP* + ESC* and DN +1.0mA +0.3V +0.6V

DN* + ESC* and UP -1.0mA -0.3V -0.6V

*Must be pressed and held before other button(s) are pressed.

6. Once an acceptable zero reading is obtained, press ENT and then UP and display will indicate:

4-20mA

Output Type

0-5VDC

0-10VDC

Output 1 Span

Selection

Type is 4-20 mA

7. Press ENT. Display will indicate:

8. With DMM still connected as in Step 4, reading should be at maximum value; 10.00 ± 0.01 volts, 5.00 ± 0.01 volts,

or 20.00 ± 0.1mA.

9. If DMM is reading out of tolerance, use UP or DN to adjust the Vari-Green’s output for an acceptable DMM

reading.

10. Once an acceptable span reading is obtained, press ENT and then UP and display will indicate:

11. Repeat Steps 3 through 10 for Transmitter Output 2. For Transmitter Output 2, connect DMM across terminals 3

and 4.

12. Press UP and display indicates:

Output 1 Span

Selection

Type is 4-20 mA

Output 1 Zero

Selection

Type is 4-20 mA

Return to

MAIN MENU

19

Page 20

5.14 – K-Factor Configuration

Operator Menu

K-Factor Off/On

OFF

Calculate K-Factor?

NO

Numbr of Data Points

One Point

Measured Point 1

1,000 ACFM

Measured Point 2

5,000 ACFM

Measured Point 3

9,000 ACFM

Reference Point 1

1,000 ACFM

Reference Point 2

5,000 ACFM

Caution

In the majority of applications, the use of a K-Factor is neither required nor desirable.

Before using the K-Factor feature, contact the factory (see Section 8) to review

the application and obtain assistance in determining the K-Factor exponent and gain values.

Turns K-factor function ON or OFF, calculate a K-Factor exponent and gain from measured data, or select a K-Factor

exponent value and K-Factor gain value.

Note: If K-Factor is ON, Process displays will have an asterisk (KFon) to the right of the flow value.

Flow Configuration MenuOperator Menu

Default slection shown

- Transmitter Output Calibration

K-Factor Configuration

- Menu Inactivity Timeout Select

- K - Factor Off/On Selection

- Calculate K-Factor? Selection

- Numbr of Data Points Selection

- Measured Point 1 Selection ¹

- Measured Point 2 Seleciton ¹

- Measured Point 3 Selection 1,²

- Reference Point 1 Selection

- Reference Point 2 Selection

- Reference Point 3 Selection

- Perform Calculation Selection

- K-Factor Exponent Selection

- K-Factor Gain Selection

- Return to MAIN MENU

¹ Available only if YES is selected in Calculate K-Factor?

² Depends on the number of Data Points selected

³ Available only if NO is selected in Calculate K-Factor?

1

,2

1

1,2

1,2

1

3

3

Reference Point 3

9,000 ACFM

EXPO: 1.0000

GAIN: 1.000

K-Factor Exponent

1.0000

K-Factor Gain

1.000

Return to

MAIN MENU

OFF or ON

NO or YES

One Point

Two Points

Three Points

Uses Process Units

& Format Selected

in Process Config.

Uses Process Units

& Format Selected

in Process Config.

Uses Process Units

& Format Selected

in Process Config.

Uses Process Units

& Format Selected

in Process Config.

Uses Process Units

& Format Selected

in Process Config.

Uses Process Units

& Format Selected

in Process Config.

Calulated from data

entered above

0.5000 to 2.0000*

0.0001 increments

0.000 to 32.750*

0.0001 increments

*Available Range depends on

operating span versus natural

span.

20

Page 21

5.14 – K-Factor Configuration (con’t)

1. While in Operator Menu, use UP or DN to scroll to:

K-Factor

Configuration

2. Press ENT to enter K-Factor Configuration menu. Display will indicate:

K-Factor Off/On

Selection

3. Press ENT and display will indicate current setting of K-Factor (OFF or ON).

4. Use UP or DN to change setting. Once desired setting is displayed, press ENT. New setting will be stored in

memory and display will return to K-Factor Configuration menu as in Step 2.

Note: If user desires not to change the setting and return to K-Factor Configuration menu, press ESC. Unit will

remain programmed as it was originally.

5. Use UP or DN to select remaining parameters to be changed.

6. Follow Step 4 to make any changes to parameters.

7. To return to Main Menu, select Return to MAIN MENU in parameter menu and press ENT.

5.15 – Menu Inactivity Timeout Selection

Allows user to select a time (minutes) after which the unit returns to Normal operation if no activity in the Operator Menu.

Operator Menu

- K-Factor Configuration

Menu Inactivity Timeout Select

- Network Selection

Output Calibration Menu

Menu Inactivity

2 Minutes

OFF to 30 minutes,

1 minute increments

1. While in Main Menu, use UP or DN to scroll to:

Menu Inactivity

Timeout Selection

2. Press ENT and display will indicate current timeout value (1 to 30 minutes or OFF).

3. Use UP or DN to change timeout value. Once desired value is displayed, press ENT. New setting will be stored in

memory and display will return to Main Menu.

Note: If user desires not to change the setting and return to Main Menu, press ESC. Unit will remain programmed

as it was originally.

21

Page 22

5.16 – Network Configuration

Allows user to turn network ON or OFF, and configure parameters based on Network type. BACnet available only with

version 1.5X.

Operator Menu

Network Configuration Menu

1

Default slection shown

- Menu Inactivity Timeout Select

Network Configuration

- Flow Alarm Configuration

- Network ON/OFF Selection

- BACnet Instance ID Selection

- BACnet Instance ID Selection

- BACnet MaxMasters Selection

- BACnet Baud RateSeleciton

- Return to MAIN MENU

¹ Available only with Network option

² Available only with BACnet

2

2

2

2

1. While in Main Menu, use UP or DN to scroll to:

2. Press ENT to enter Network Configuration menu. Display will indicate:

Network Off/On

OFF

BACnet Instance ID

0

BACnet Address

1

BACnet Max Masters

1

Bacnet Baud Rate

9600

Return to

MAIN MENU

OFF or ON

0 to 4,194,303

1 to 127

1 to 127

9600, 19200,

38400, or 76800

Network

Configuration

Network Off/On

Selection

3. Press ENT and display will indicate current setting of Network (OFF or ON).

4. Use UP or DN to change setting. Once desired setting is displayed, press ENT and new setting will be stored in

memory and display will return to Network Configuration menu as in Step 2.

Note: If user desires not to change the setting and return to Network Configuration menu, press ESC. Unit will

remain programmed as it was originally.

5. Use UP or DN to select remaining parameters to be changed.

6. Follow Step 4 to make any changes to parameters.

7. To return to Main Menu, select Return to MAIN MENU in Network Configuration menu and press ENT.

5.17 – Flow Alarm Configuration

Available only with BACnet Network option.

User can turn each Alarm ON or OFF, select type of alarm and set the following values:

Alarm 1 Setpoint (this is Low, Low1, or High1 depending on Alarm Type): Selected value of flow below (for Low and

Low1) or above (for High 1) which an alarm condition will exist.

Alarm 2 Setpoint (this is High, Low2, or High2, depending on Alarm Type): Selected value of flow below (for Low2) or

above (for High and High2) which an alarm condition will exist.

Alarm Deadband: Value that transmitter signal has to reach above (for Low, Low1, or Low2) or below (for High, High1,

or High2) before an activated alarm will reset. Value is selected in same units as transmitter span.

Alarm Delay: Time between an alarm condition existing and alarm activation. Adjustable between 0.0 and 10.0 minutes

in 0.1 minute increments.

22

Page 23

5.17 – Flow Alarm Configuration (cont.)

Operator Menu

- Network Configuration

Flow Alarm Configuration

- Temperature Alarm Config

Flow Alarm Configuration Menu

- Alarm 1 Off/On Selection

- Alarm 2 Off/On Selection

- Alarm 1 Setpoint Selection

- Alarm 2 Setpoint Selection

- Alarm 1 Dead Band Selection

- Alarm 2 Dead Band Selection

- Alarm Delay Selection

- Return to MAIN MENU

¹ Available only with BAC net.

1

Default selection shown

Alarm 1 Off/On

OFF

Alarm 2 Off/On

OFF

Alarm 1, Low Setpt

250 [units]

Alarm 2, High Setpt

250 [units]

Alarm 1 Dead Band

50 [units]

Alarm 2 Dead Band

50 [units]

Alarm Delay

0.0 Min.

Return to

MAIN MENU

Available selections

OFF or ON

OFF or ON

Depends on Flow

Units

Depends on Flow

Units

Depends on Flow

Units

Depends on Flow

Units

0.0 to 10.0 Min.

in 0.1 increments

1. While in Main Menu, use UP or DN to scroll to:

Flow Alarm

Configuration

2. Press ENT to enter Alarm Configuration menu. Display will indicate:

Alarm 1 Off/On

Selection

3. Press ENT and display will indicate current setting of Alarm 1 (OFF or ON).

4. Use UP or DN to change setting. Once desired setting is displayed, press ENT. New setting will be stored in memory

and display will return to Alarm Configuration menu as in Step 2.

Note: If user desires not to change the setting and return to Alarm Configuration menu, press ESC. Unit will remain

programmed as it was originally.

5. Use UP or DN to select remaining parameters to be changed.

6. Follow Step 4 to make any changes to parameters.

7. To return to Main Menu, select Return to MAIN MENU in Alarm Configuration menu and press ENT.

5.18 – Temperature Alarm Configuration

Available only with BACnet Network option.

User can turn each Alarm ON or OFF, select type of alarm and set the following values:

Alarm 1 Setpoint (this is Low, Low1, or High1 depending on Alarm Type): Selected value of temperature below (for

Low and Low1) or above (for High 1) which an alarm condition will exist.

Alarm 2 Setpoint (this is High, Low2, or High2, depending on Alarm Type): Selected value of temperature below (for

Low2) or above (for High and High2) which an alarm condition will exist.

Alarm Deadband: Value that transmitter signal has to reach above (for Low, Low1, or Low2) or below (for High, High1,

or High2) before an activated alarm will reset. Value is selected in same units as transmitter span.

Alarm Delay: Time between an alarm condition existing and alarm activation. Adjustable between 0.0 and 10.0 minutes

in 0.1 minute increments.

23

Page 24

Operator Menu

Temp Alarm Configuration Menu

1

Default selection shown

Available selections

- Flow Alarm Configuration

Temperature Alarm Config

- OPERATOR MENU EXIT

- Alarm 1 Off/On Selection

- Alarm 2 Off/On Selection

- Alarm 1 Setpoint Selection

- Alarm 2 Setpoint Selection

- Alarm 1 Dead Band Selection

- Alarm 2 Dead Band Selection

- Alarm Delay Selection

- Return to MAIN MENU

¹ Available only with BAC net.

Alarm 1 Off/On

OFF

Alarm 2 Off/On

OFF

Alarm 1, Low Setpt

250 [units]

Alarm 2, High Setpt

250 [units]

Alarm 1 Dead Band

50 [units]

Alarm 2 Dead Band

50 [units]

Alarm Delay

0.0 Min.

Return to

MAIN MENU

OFF or ON

OFF or ON

Depends on Temp

Units

Depends on Temp

Units

Depends on Temp

Units

Depends on Temp

Units

0.0 to 10.0 Min.

in 0.1 increments

1. While in Main Menu, use UP or DN to scroll to:

Flow Alarm

Configuration

2. Press ENT to enter Alarm Configuration menu. Display will indicate:

Alarm 1 Off/On

Selection

3. Press ENT and display will indicate current setting of Alarm 1 (OFF or ON).

4. Use UP or DN to change setting. Once desired setting is displayed, press ENT. New setting will be stored in memory

and display will return to Alarm Configuration menu as in Step 2.

Note: If user desires not to change the setting and return to Alarm Configuration menu, press ESC. Unit will remain

programmed as it was originally.

5. Use UP or DN to select remaining parameters to be changed.

6. Follow Step 4 to make any changes to parameters.

7. To return to Main Menu, select Return to MAIN MENU in Alarm Configuration menu and press ENT.

24

Page 25

6 - Supervisor Menu

6.1 – Introduction

The Supervisor menu allows individual sensors to be enabled or disabled, scan all sensors for status, and perform

diagnostics on any alert conditions.

1. To enter the Supervisor Menu, press ENT then ESC then DN then ENT at the same time.

The display will indicate:

Note: If Supervisor Menu password has been bypassed, display will indicate as shown in Step 3 below.

2. Using UP or DN scroll to the numeric password for the Supervisor Menu. From the Factory, password is set to

2,222.

3. Once password is displayed, press ENT, and the display will indicate:

ENTER PASSWORD FOR

SUPERVISOR MENU

XXXXX

SUPERVISOR MENU

4. Press ENT, and the display will indicate:

By using UP or DN, supervisor can scroll through the following selections.

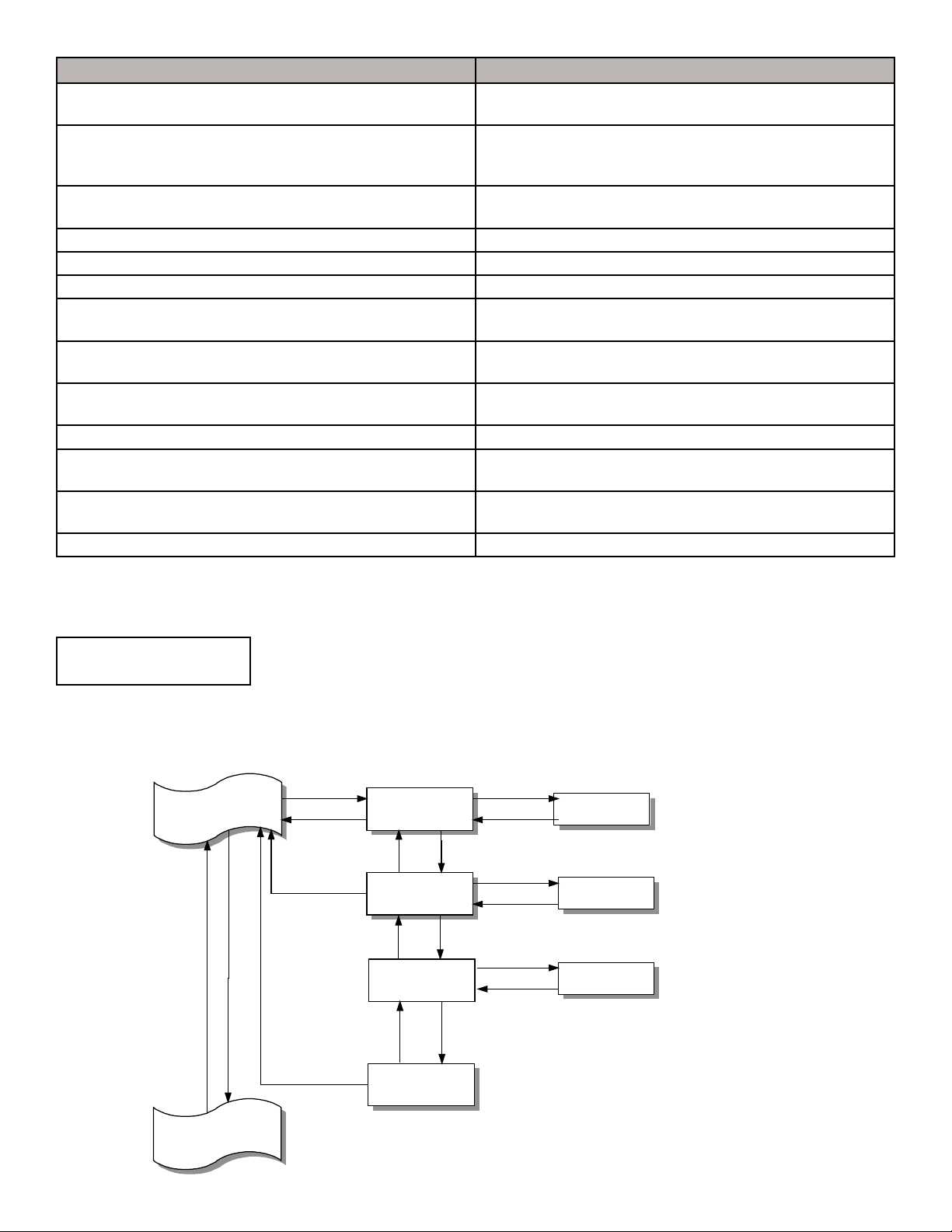

MENU SELECTION DESCRIPTION

Supervisor Password Selection Allows for the selection of password for the Supervisor menu, and

the option to bypass the password.

Sensor Management Allows for the scanning of the sensor network for active and/or

enabled sensors. Also allows for the enabling/disabling of individual

sensors.

Diagnostic Display Selection Displays each sensor’s current reading of velocity and temperature

Diagnostic ALERT Determination Displays any sensor or average that currently has an ALERT

condition and the ALERT code.

Power Cycle Sensor Network Allows for the cycling of power to the sensors.

Supervisor Menu Exit Returns display to Normal operation.

Once the desired selection is displayed, press ENT to enter its sub-menu.

SUPERVISOR PASSWORD

SELECTION

25

Page 26

6.2 – Supervisor Password Selection

Allows the selection of a Supervisor Menu password, and the option of bypassing the password.

Operator Menu

- SUPERVISOR MENU EXIT

Supervisor Password Select

- Sensor Management

Password Menu

- Password Selection

- Bypass Password? Selection

- Return to MAIN MENU

1. While in Supervisor Menu, use UP or DN to scroll to:

2. Press ENT to enter Supervisor password menu. Display will indicate:

3. Press ENT and display will indicate current password.

Note: From the Factory, password is set for 1,111

Default selection shown

Password

2,222

Bypass Password?

NO

Return to

MAIN MENU

Available selections

0-9,999

NO or YES

SUPERVISOR PASSWORD

SELECTION

PASSWORD

SELECTION

4. Use UP or DN to change password. Once desired password is displayed, press ENT. New password will be

stored in memory and display will return to previous menu (see Step 2).

Caution: If password is changed, write it down, and retain in case it is forgotten.

Note: If user desires not to change password and return to password menu, press ESC. Unit will remain

programmed as it was originally.

5. Use UP to select Bypass Password if desired.

6. Follow Steps 3 and 4 to make changes.

7. To return to Main Menu, select Return to MAIN MENU in the Supervisor Password Selection menu, and press

ENT.

26

Page 27

6.3 – Sensor Management

Operator Menu

- Supervisor Password Select

Sensor Management

- Diagnostic Display Selection

Sensor Management Menu

- Scan Network for Sensors

- Display Enabled Sensors

- Enable Sensor Selection

- Disable Sensor Selection

- Ping Sensor Selection

- Return to MAIN MENU

Default slection shown

1 8 16 24 32

Sensors Found: 6

Xmitter Total: 1

1 8 16 24 32

Enabled Sensors : 6

Xmitter Total: 1

Enable Sensor: 1

1 8 16 24 32

Enabled Sensors : 6

Disable Sensor: 1

1 8 16 24 32

Enabled Sensors : 6

Ping Sensor

SENSOR FOUND

Return to

MAIN MENU

1. While in Operator Menu, use UP or DN to scroll to:

2. Press ENT to enter Sensor Management menu. Display will indicate:

Available selections:

1

1 to 32

1

1 to 32

SENSOR FOUND

1

or

SENSOR NOT FOUND

1 to 321, EXIT

Sensor

Management

Scan Network

for Sensors

3. Press ENT to enter Sensor Management menu. Display will indicate:

*The number of Active Sensors is unique to each application.

1 8 16 24 32

Sensors Found: 8

Total Sensors: 8

4. Press ESC or ENT to return to previous menu (Step 2).

5. Press UP. Display will indicate:

Display Enabled

Sensors

6. Press ENT. Display will indicate:

1 8 16 24 32

Sensors Found: 8

Total Sensors: 8

Display will indicate all enables sensors on the bar graph by darkened area under their respective #, and total

number of enabled sensors will be displayed at the bottom.

7. Press ESC to return to previous menu (see Step 5).

8. Press UP and display will indicate:

Enable Sensor

Selection

*

27

Page 28

9. Press ENT. Display will indicate:

This display will indicate which sensors are enabled.

Only enabled sensors will be indicated on bar graphn by darkened area under their respective #, and total number of

enabled sensors will be displayed at the bottom.

If any active sensors have been previously disabled, they can be enabled by scrolling (using UP and DN), to their #,

and pressing ENT.

10. Press ESC to return to previous menu (see Step 8).

11. Press UP and display will indicate:

Enable Sensor: 1

1 8 16 24 32

Enabled Sensors: 8

Disable Sensor

Selection

12. Press ENT. Display will indicate:

13. To disable a sensor, use UP and DN to scroll to that sensor’s # and press ENT. Display will respond by removing

the darkened area under the sensor’s # on the bar graph and reducing the number of enabled sensors by 1.

14. When done disabling sensors, press ESC and display will return to previous menu (see Step 11).

15. Press UP. Display will indicate:

16. Press ENT. Display will indicate:

17. Use UP and DN to scroll to desired sensor.

18. Once desired sensor # is displayed, press ENT and display will indicate either:

Ping Sensor

1

SENSOR FOUND

Ping Sensor

1

SENSOR NOT FOUND

Disable Sensor: 1

1 8 16 24 32

Enabled Sensors: 8

Ping Sensor

Selection

Ping Sensor

1

19. Use UP and DN to scroll to all desired sensors, and press ENT to view results.

20. Either scroll to exit (after #32) or press ESC to return to previous menu (see Step 15).

21. Press UP and display will indicate.

22. Press ENT and display will return to Main Menu.

28

Return to

MAIN MENU

Page 29

6.4 – Diagnostic Display Selection

Supervisor Menu

- Sensor Management

Diagnostic Display Selection

- Diagnostic ALERT Determin

Diagnostic Display

Diagnostic Display

Sensor Number: 1

VELO XXX SFPM

TEMP XX.X°F

Velocity & temperature units depend

on selections made in Flow

Configuration in Operator Menu.

1. While in Main menu, use UP and DN to scroll:

2. Press ENT. Display will indicate:

3. Use UP and DN to scroll through all enabled sensors.

4. When done, press ESC and siplay will return to previous menu (see Step 1).

6.5 – Diagnostic Alert Determination

Supervisor Menu

- Diagnostic Display Selection

Display ALERT Determination

- Power Cycle Sensor Network

Diagnostic ALERT Menu

- ALERT for Sensors

- ALERT for Averages

- Turn Off/On ALERT

for Missing Sensors

- Return to MAIN MENU

ALERT for Sensors

NO ALERT EXISTS

ALERT for Averages

NO ALERT EXISTS

Available selections:

1

1 to 32

1

Depends on # of

sensors installed.

Diagnostic Display

Selection

Diagnostic Display

Sensor Number: 1

VELO XXX SFPM

TEMP XX.X°F

See table below for

Sensor ALERT

code & definition

See table below for

Averages ALERT

code & definition

Turn Off/On

ALERT ON

Return to

MAIN MENU

1. While in Main Menu, use UP or DN to scroll to:

2. Press ENT. Display will indicate:

3. Press ENT. Display will indicate:

or if an ALERT does exist, display will indicate:

Definitions of individual sensor ALERT codes are found at the end of this Section.

ON or OFF

Diagnostic ALERT

Determination

ALERT for Sensors

ALERT for Sensors

NO ALERT EXISTS

Sensor Number: 1

ALERT CODE: 1

Sensor has not

responded

29

Page 30

4. Use UP or DN to scroll through all sensors that have an alert.

Note: Only sensors with an existing alert will be displayed with its alert code.

5. When done, press ESC and display will return to previous menu (see Step 2).

6. Press UP. Display will indicate:

ALERT for Averages

7. Press ENT. Display will indicate:

or if an ALERT does exist, display will indicate:

Definitions fo individual averages ALERT codes are found at the end of this Section.

8. Use UP or DN to scroll through all average alerts.

9. When done, press ESC and display will return to previous menu (see Step 6).

10. Press UP. Display will indicate:

11. Press ENT. Display will indicate current setting (ON or OFF).

12. Use UP or DN to change setting if desired, press ENT.

13. Press UP. Display will indicate:

14. Press ENT and display will return to Main Menu.

ALERT for Averages

NO ALERT EXISTS

Averages Signal

ALERT CODE: 4

Average Velocity is out

of device range

Turns Off/On ALERT

for Missing Sensors

Return to

MAIN MENU

Sensor Alert Code Definition

1 Sensor has not responded

2 Sensor response address incorrect

3 Sensor response command incorrect

4 Sensor signals are out of range

Sensor Alert Code Definition

4 Average Velocity is our of device range

5 Average Volume is out of design range

6 Avg. Velo. & Volu. are out of range

7 Average Temperature out of device range

8 Avg. Velo. & Temp. are out of range

9 Avg. Volu. & Temp. are out of range

10 Velo, Volu, & Temp are out of range

30

Page 31

6.6 – Power Cycle Sensor Network

Supervisor Menu

- Diagnostic ALERT Determination

Power Cycle Sensor Network

- SUPERVISOR MENU EXT

Power Cycle Display

Power Cycle

Are you sure?

NO

Available selections:

YES or NO

1. While in Main Menu, use UP or DN to scroll to:

2. Press ENT. Display will indicate:

3. Use UP or DN to scroll to YES if it is desired to cycle Power.

4. With YES displayed, press ENT and Transmitter will cycle power and scan active sensors and enabled sensors,

similar to when power is first turned on (see Section 5.2).

5. Press ESC to return to previous menu ( see Step 1).

7 - Maintenance

The Vari-green is a solid state device having few mechanical parts requiring special periodic maintenance. The

following maintenance steps are not requirements, but guidelines for establishing a maintenance program for your

specific installation.

Operating experience should be used to set frequency of specific types of maintenance.

7.1 – Cleaniness

- Verify condensation (or other sources of liquids) are not present inside the Vari-green.

7.2 - Mechanical

- Verify CABLE connections between probes and transmitter are secure.

- Verify mounting hardware is secure.

7.3 – Electrical

Periodically inspect all wiring to the Vari-green for good connections and absence of corrosion.

31

Page 32

8 - Troubleshooting

Personnel should be familar with the operation of the Vari-green (see Section 5) before performing any

troubleshooting.

Problem Solution

Dispaly blank; with backlight and

outputs

Display blank; no backlight with

outputs

Display blank with backlight and no

outputs

Display blank without backlight and

no outputs

Normal Operation with Extremely

Low or High Flow displayed

- Check the display’s ribbon cable for proper seating in transmitter dicuit board

- Bad display or transmitter board

- Check the display’s ribbon cable for proper seating in transmitter circuit board

- Defective display

- Defective display

- Defective transmitter board

- Check the CPU LED flashing on transmitter board (located to the right of the display on the

transmitter board. Figure 4.2)

- Check for proper supply voltage at P8 terminals 1 & @ (see Figure 4.2, Page 6)

- Check F1 fuse

- Defective transmitter board

- Check the CPU LED flashing on transmitter board (located to the right of the display on the

transmitter board. Figure 4.2)

- Check F2 fuse

- Verify upon powering up transmitter that all sensore are “Found” and “Enabled (section 5.2)

- Verify Factory Set Up data is correct in Operator Menu under “Flow Configuration” (section 5.8)

- Enter Supervisor Menu (Section 6), “Diagnostic Display Selection” (Section 6.4). Scroll through

all sensors, log data, and contact the Factory.

Display reading “0” flow with NO

“Alert” message

Display reading “0” flow with “Alert”

message

If after the following the Troubleshooting steps the Vari-green continues to operate improperly, contact the Factory for further assistance

(see Section 10).

- Ensure Flow is above lockdown (see Section 5.8)

- Check cable connections

- Indicated there is a fault with one or more sensors

- Perform “Diagnostic Alert Determination: in the “Supervisor Menu; determine if “Sensor” or

“Average” alert (Section 6.5)

- Perform “Diagnostic Display Selection” in the Supervisor Menu; determine which sensor has a

failure (Section 6.4)

32

Page 33

Appendix A

BACnet Standardized Device Profile (Annex L)

BACnet Operator Workstation (B-OWS)

BACnet Building Controller (B-BC)

BACnet Advanced Application Controller (B-AAC)

X BACnet BACnet Applicatioon Specific Controller (B-ASC)

BACnet Smart Sensor (B-SS)

BACnet Smart Actuator (B-SA)

List of all BACnet Interoperability Building Blocks supported (see Annex K in BACnet Addendum 135d)

- DS-RP-B ............Read Property

- DS-WP-B ...........Write Property

- DM - DDB-B ......Dynamic Device Binding

- DM-DOB-B ........Dynamic Object Binding

- DM-DCC-B ........Device Communication Control

- DM-RPM-B ........Read Property Multiple

- DM-RD-B ...........Reinitialize Device

Which of the following device binding methods does the property support? (check one or more)

Send Who-is, receive I-Am (BIBB DM-DDB-A)

X Receive Who-is, send I-Am (BIBB DM-DDB-B)

Send Who-Has, receive I-Have (BIBB DM-DOB-A)

X Receive Who-Has, send I-Have (BIBB DM-DOB-B)

Manual configuration of recipient device’s network number and MAC address

None of the above

Analog Input Object Type

No Dynamically creatable using BACnet’s CreateObject Service?

No Dynamically deletable useing BACnet’s DeleteObject Service?

List of “Required” Properties Supported

X PROP_OBJECT_IDENTIFIER

X PROP_OBJECT_NAME

X PROP_OBJECT_TYPE

X PROP_PRESENT_VALUE

X PROP_STATUS_FLAGS

X PROP_EVENT_STATE

X PROP_OUT_OF_SERVICE

X PROP_UNITS

List of “Optional” Properties Supported

X PROP_DESCRIPTION

The Greenheck BACnet stack supports the optional property “PROP_DESCRIPTION”. This is used to indicate the

type of information in the object. For example, for an Vari-green system, the description will indicate as “AF0” for

average flow, or “AT0” for average temperature. If the object belongs to a sensor in the system, it will be indicated

as “STn” or “SFn”, where n is the sensor address. The Greenheck Device which supports BACnet will determine

the amount of AI objects available. For an Vari-green system, the amount of AI objects is determined by the total

number of sensors in the system x 2 with an additional 2 AI objects for system average flow and system average

33

Page 34

temperature. So an Vari-green system with 8 sensors will have a total of 18 AI objects. These are for average Flow

and average DP. This object does not support intrinsic reporting, so the event state is always “NORMAL”.

Usage of the Status Field.

– Each object supports status bits IN_ALARM, FAULT, and OUT_OF_SERVICE.

– OVERRIDDEN is not supported as it makes no sense to override a value with no reasonable substitute.

– The OOS property indicates the physical input to the object is not in service. In the case of an ElectraFLO system,

this will be set by the transmitter if someone intentionally removes the sensor from the network. If the transmitter

determines there is a problem with any sensor in question, the OOS bit is set along with the FAULT bit. If the OOS

property is set, data from the physical device will not be used in any calculation.

– IN_ALARM is set for values which exceed the predetermined values set in the transmitter memory. Sensor analog

objects will not typically have this flag set. This will be done at the transmitter level indicating the average flow or

temperature are out of range.

None List of all properties that are writable where not otherwise required by this standard

None List of proprietary properties

None List of any property value range restrictions

List of non-dynamic object identifiers and their meaning in this device

- Analog Input AFO ...................... Total System Flow (always present)

- Analog Input AT1/DP1 .............. Total System Temperature

- Analog Input SF1 ...................... Sensor 1 Flow (guaranteed to be present)

- Analog Input ST1 ...................... Sensor 1 Temperature (guaranteed to be present)

- Analog Input SF2 ...................... Analog Inputs 2-32 are only present if there is more than 1 sensor in system