Page 1

®

478799 AMD-xx-TD Series

Installation, Operation, and Maintenance Instructions

This manual is the property of the owner, and is required for future maintenance. Please leave it with the

owner when the job is complete.

Safety Warning:

Improper installation, adjustment, alteration, service or maintenance can cause property damage, injury or

death. Read the installation, operating, and maintenance instructions thoroughly before installing or servicing

this equipment.

Receiving and Handling

Upon receiving dampers, check for both obvious and hidden damage. If damage is found, record all

necessary information on the bill of lading and file a claim with the final carrier. Check to be sure that all parts

of the shipment, including accessories, are accounted for.

Dampers must be kept dry and clean. Indoor storage and protection from dirt, dust and the weather is highly

recommended. Do not store at temperatures in excess of 100°F (37ºC).

Due to continuing research, Greenheck reserves the right to change specifications without notice.

Pre-Installation Guidelines

The basic intent of a proper installation is to secure

the AMD-xx-TD series damper into the opening

in such a manner as to prevent distortion and

disruption of damper operation. The following items

will aid in completing the damper installation in a

timely and effective manner.

1. Check your schedule for proper damper locations

within the building. Visually inspect the damper

for damage.

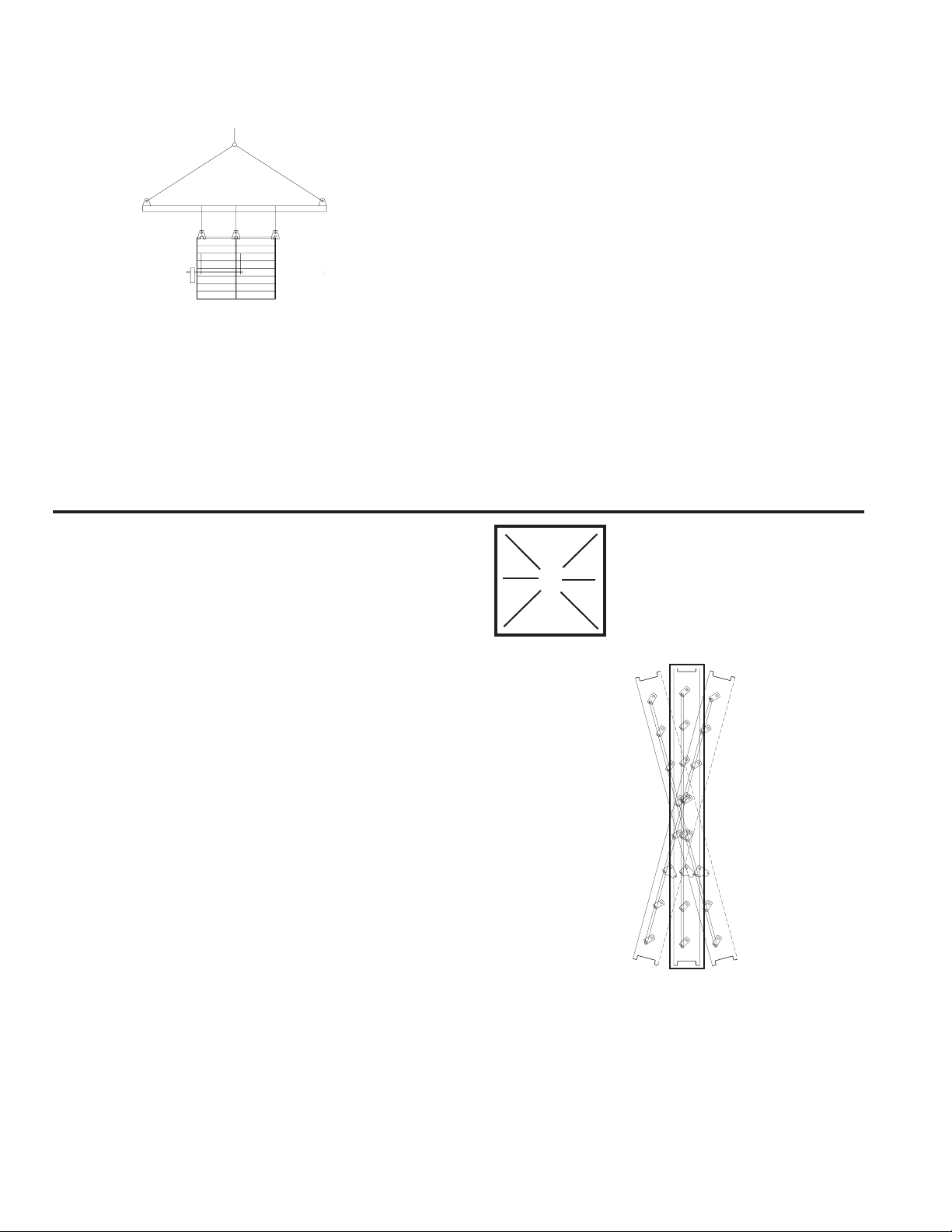

2. When you lift or handle the damper use the sleeve

or frame. Do not lift damper using blades, linkage,

actuators, probes, or jackshafting. When you

handle multiple section assemblies, use sufficient

support to evenly lift at each section mullion (see

drawing). Do not drag, step on, apply excessive

bending, twisting, or racking.

3. Do not install screws in damper frame that will

interfere with unexposed blade linkage and prevent

damper blades from opening and/or closing.

Page 2

Pre-Installation Guidelines cont...

4. Damper must be installed into duct or opening

square and free of twist or other misalignment.

Spreader Bar

Attachments

Multi section dampers

Damper must not be squeezed or stretched into

duct or opening. Out of square, racked, twisted

or misaligned installations can cause excessive

leakage and/or torque requirements to exceed

damper/actuator design.

5. Damper, actuator, and transmitter must be kept

clean, dry and protected from dirt, dust and other

foreign materials prior to and after installation.

Examples of such foreign materials include but

are not limited to:

a) Mortar dust

b) Drywall dust

c) Firesafing materials

d) Wall texture

e) Paint overspray

6. Damper should be sufficiently covered as to

prevent overspray if wall texturing or spray

painting will be performed within 5 feet (1.5m)

of the damper. Excessive dirt or foreign material

deposits on the damper can cause excessive

leakage and/or torque requirements and

inaccurate airflow measurement to exceed

damper/actuator design.

7. ACCESS: Suitable access (actuators maintenance,

etc.) must be provided for damper inspection

and servicing. Where it is not possible to achieve

sufficient size access, it will be necessary to

install a removable section of duct.

Installation- Failure to follow instructions will void all warranties

1. Ensure the AMD-xx-TD series damper is

mounted with measurement probes upstream

of the damper.

2. Your duct opening or opening square should

measure 1/4 inch (6mm) larger than damper

dimension and should be straight and level.

3. Use shims between damper frame and

duct opening or opening space to prevent

distortion of frame by fasteners holding it

in place. Brace at every horizontal mullion

and vertically brace at every 8 feet (2.4m) of

damper width for strength. Dampers in high

velocity (2000 fpm [610m per second]) may

require more bracing.

Note: Greenheck dampers are specifically

designed and engineered for structural

integrity based on model and conditions.

Attachment, framing, mating flanges,

and anchoring of damper assemblies

into openings, ductwork, or walls is the

responsibility of the installer. Design

calculations for these retaining and

supporting members should be determined

by field engineers for that particular

installation.

4. Individual damper sections, as well as

entire multiple section assemblies must be

completely square and free from racking,

twisting, or bending. Measure diagonally from

upper corners to opposite lower corners of

each section.

5. Damper blades, axles, and linkage must

operate without binding. Before system

operation, you can cycle dampers after

2

A

C

E

installation to assure proper operation. On

multiple section assemblies all sections

should open and close simultaneously.

6. AMD-xx-TD series more than one section

high will be shipped separately in individual

sleeves. Using the provided RJ-45 cable

connect the bottom probe on the top section

to the top probe on the bottom section. The

bottom section has the transmitter mounted

to it.

B

Do not twist

D

AF = BE

AB = CD

F

or bow. Mount

damper plumb

in the opening.

Page 3

Electrical Guidelines

Electrical and/or pneumatic connections to damper actuators should be made in accordance with wiring and

piping diagrams developed in compliance with applicable codes, ordinances and regulations.

SAFETY CAUTION !

Verify power requirements before wiring

actuator. Greenheck is not responsible for

any damage to, or failure of the unit caused

by incorrect field wiring.

Connect electrical connection to terminal strip as shown in drawings on pages 4 and 5.

Electrical input may be needed for

this equipment. This work should be

performed by a qualified electrician.

SAFETY DANGER !

Setup and Operation for AMD-xx-TD Series Damper

All AMD-xx-TD’s are supplied with a Vari-Green®

airflow rate transmitter that is factory wired to one or

more Vari-Green airflow measurement probe(s). The

transmitter has been configured at the factory with

customer supplied parameters. For normal applications

the transmitter’s configuration should not need to be

modified in the field. However, if field configuration is

necessary please reference the Vari-Green transmitter

Installation, Operation, and Maintenance Manual

available at www.greenheck.com.

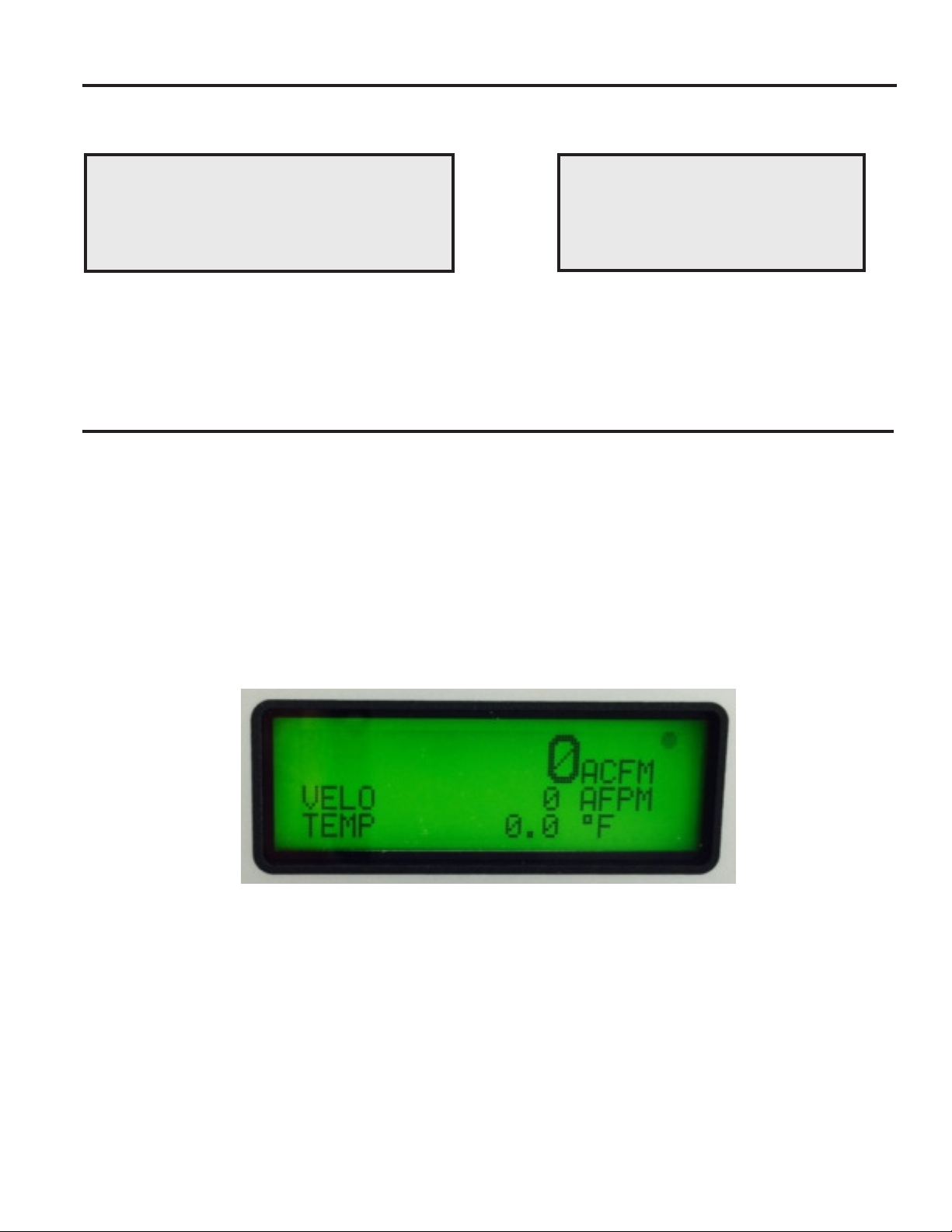

Once electrical power is applied, the transmitter

will go through a standard start-up sequence

during which it will identify and enable each airflow

sensor. This will take approximately 30 seconds.

Once the start-up sequence has been completed

the transmitter's display will show the measured

volumetric airflow rate, velocity, and ambient air

temperature (see below). Under normal operation a

dot in the upper right corner of the display will blink

rapidly (4 times per second).

You can order AMD-xx-TD’s with or without a factory supplied controller. When a factory supplied controller

is ordered, the controller can be configured for either analog operation or operation via a BACnet MS/TP

connection. Setup and operation for these different options are described on the following pages.

3

Page 4

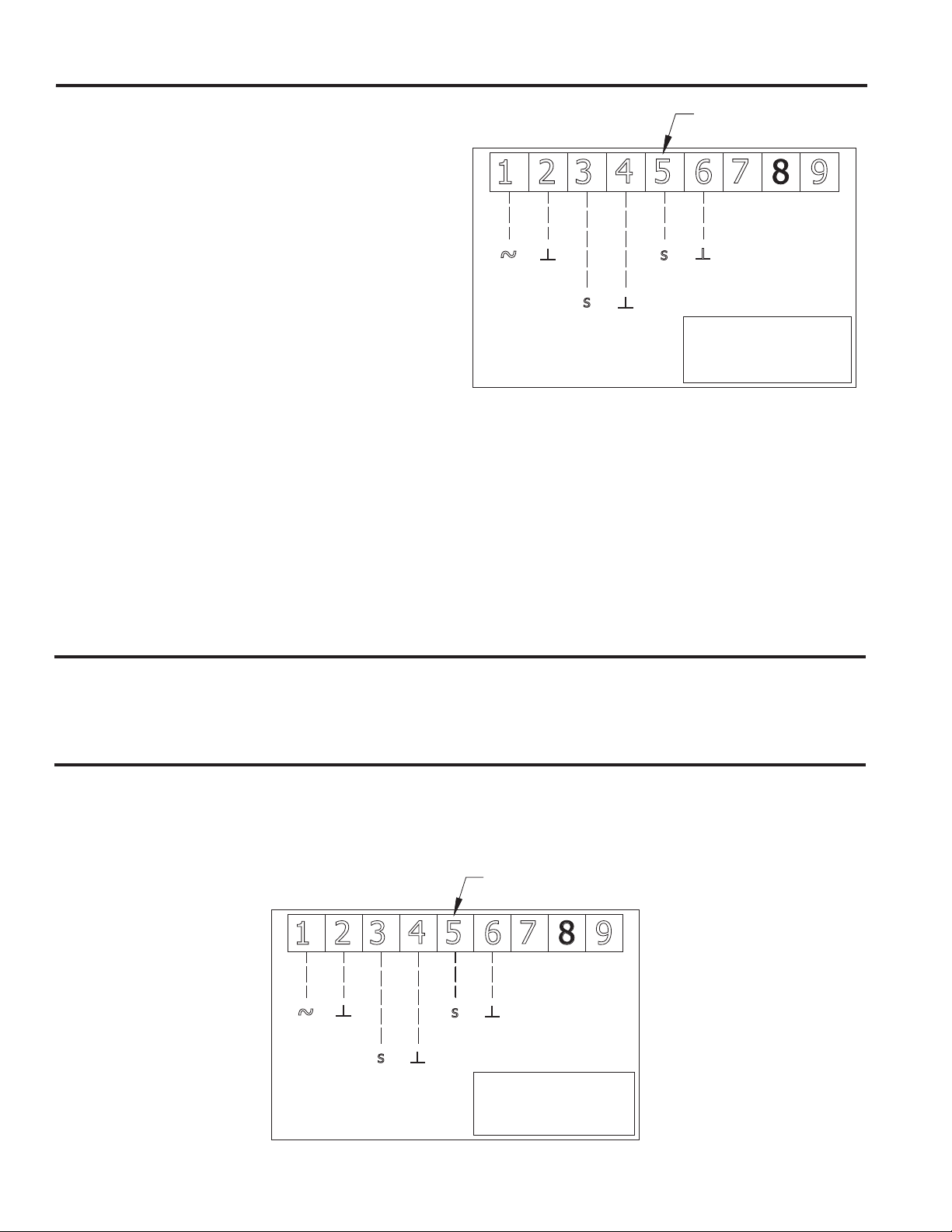

AMD-xx-TD Series Dampers without a Factory Supplied Controller

Units ordered without a factory supplied controller

are supplied with a standard modulating actuator.

The Vari-Green transmitter and actuator are wired to

a factory supplied terminal block. Figure 1 shows the

field wiring side of the terminal block.

The 0-10 VDC analog output at terminals 3 and

4 comes from the Vari-Green transmitter and is

proportional to the velocity going through the

AMD-xx-TD. A 10 VDC signal represents the

maximum velocity that was selected at the time the

unit was ordered. The selected maximum velocity

and the area of the AMD-xx-TD are listed on a label

adjacent to the terminal block. An example of how

you can determine the velocity and/or cfm going

through the unit is shown below.

Figure 1

Example 1: Determine the CFM from a 24 in.

x 24 in. AMD-xx-TD (area of 4 ft2) with a selected

maximum velocity of 2,000 fpm and a voltage reading

across terminals 3 and 4 of 3.5 VDC.

Measured Velocity = Max Velocity * (Measured Voltage / 10)

Measured Velocity = 2,000 * (3.5 / 10)

Measured Velocity = 700 fpm

and

Measured CFM = Measured Velocity * Area

Measured CFM = 700 fpm * 4 ft2

Measured CFM = 2,800 cfm

Factory Installed

Terminal Block

2 3

1

~

24VAC

0-10VDC Output

Proportional to

On multiple section high dampers, the

*** ***

actuators on the sections without the

terminal block will need to be field wired

4 5

S

Control

Signal to

Actuator

S

Flow

into Terminals 1, 2, & 5

7

6

AMD-XX-TD w/o Factory

Supplied Controller

8

9

AMD-xx-TD’s Ordered with a Factory Supplied Controller

When you order a factory supplied controller, it comes with a Greenheck exclusive VAFB24-BAC-GTD actuator

which has the controller integrated inside of it. The actuator/controller is configured by the factory at the time

the unit is ordered for either analog or BACnet operation. This selection is made by setting the Setpoint Source

datapoint to Local AI or BACnet. A complete list of the all the BACnet datapoints is listed in Table 1 (page 7).

AMD-xx-TD Series Dampers with an Analog Factory Supplied Controller

Figure 2 shows field wiring for an AMD-xx-TD ordered with a factory supplied controller configured for analog

operation.

Factory Installed

Terminal Block

1

~

24VAC

Figure 2

S

4 5

Flow

2 3

0-10 VDC Output

Proportional to

S

0-10VDC

Input

Setpoint

7

6

AMD-XX-TD w/Analog

Factory Supplied

Controller

8

9

4

Page 5

The controller is designed to modulate the AMD-xxTD series damper such that it maintains a desired

cfm setpoint. The setpoint is supplied via a 0-10 VDC

analog input (terminals 5 and 6) that is proportional to

that setpoint. The Vari-Green transmitter will output

a 0-10 VDC signal (terminals 3 and 4) proportional

to the actual cfm being measured by the unit. For

both the desired cfm setpoint and the cfm output, a

voltage reading of 10 VDC represents the maximum

velocity that was selected at the time the product

was ordered. The selected maximum velocity and the

area of the AMD-xx-TD are listed on a label adjacent

to the terminal block. Example 2 shows how to

determine the voltage corresponding to the desired

cfm setpoint.

Example 2:

Determine the voltage setpoint that should be sent

to terminals 5 & 6 to achieve a flow of 4,800 CFM

on a 24 in. x 24 in. AMD-xx-TD (area of 4 ft2) with a

selected maximum velocity of 2,000 fpm.

Maximum CFM = 4 ft2 * 2,000 fpm = 8,000 cfm

Voltage Setpoint = 10 * (Desired CFM Setpoint /

Maximum CFM)

Voltage Setpoint = 10 *(4,800 / 8,000) = 6.0 VDC

See example 1 on how to convert the transmitter

voltage output (terminals 3 & 4) to cfm.

AMD-xx-TD Series Dampers with a BACnet Enabled Factory Supplied Controller

Figure 3 shows field wiring for an AMD-TD ordered with a factory supplied controller configured for a BACnet

MS/TP connection.

Factory Installed

Terminal Block

2 3

1

~

24VAC

Figure 3

This controller is designed to modulate the AMDxx-TD series damper such that it maintains a

desired cfm setpoint. The setpoint is established

by the BACnetSetpoint datapoint. Table 1 lists all

of the BACnet datapoints. The BACnetSetpoint is a

percentage of the MaxCFMSetpoint datapoint, which

is set at the factory based on the maximum velocity

which is selected at the time the unit is ordered.

4 5

Example 3: Determine the BACnet setpoint for a

24 in. x 24 in. AMD with a maximum velocity of 2,000

fpm and a target flow of 6,000 cfm.

MaxCFMSetpoint = 8,000 cfm (4 ft2 x 2,000 fpm)

BACnetSetpoint = (Target CFM / Maximum CFM)

BACnetSetpoint = (6,000 / 8,000) = 75%

With a BACnetSetpoint of 75% the actuator/controller

will position the damper to allow 6,000 cfm through it.

Position Control Mode

Example 3 applies when the actuator/controller is

in its factory default operating mode called “Flow

Control Mode”. However, for certain applications

it may be desirable to operate the AMD-TD as

7

6

Factory

Installed

Jumper

+ -

BACnet

MS/TP

AMD-XX-TD w/BACnet

MS/TP Factory

Supplied Controller

a standard modulating damper. This can be

accomplished by changing the DamperMode BACnet

data point (see Table 1) from CurrentAirflow to

DamperPosition. In “Position Control Mode” a

BACnetSetpoint of 75% will drive the damper 75%

open instead of finding a position that supplies 75%

of the maximum airflow.

8

9

Safety Override of the BACnet Setpoint

If your application requires the ability to locally

close the damper, the factory installed jumper wire

should be removed and replaced with a normally

closed “safety switch”. When the safety switch is

closed the damper will track the BACnetSetpoint as

if the jumper wire was left in place. When the safety

switch is open the actuator will power the damper

closed. Interlocking the damper with a fan such that

the damper closes when the fan shuts down is an

example of when the safety switch feature may be

utilized.

5

Page 6

Setting the Actuator/Controller's BACnet Configuration

The actuator’s BACnet configuration including the

device instance, MAC address, and baud rate can be

accessed through its Ethernet port.

Connecting to the Actuator

1. Using an Ethernet cable, connect the CAT 5

Ethernet port on your computer to the CAT 5 port

on your actuator.

2. Go into your computer’s Control Panel and access

the Local Area Connection

Windows 7 or 8

• Access the Network and Internet settings

then the Network Sharing Center

• Click on Change adapter settings then right

click on the Local Area Connection and

select Properties

Windows XP

• Open Network Connections

• Right click on the Local Area Connection

and select Properties

Access IP Address Settings

1. Select Internet Protocol

Windows 7 or 8

Select Internet Protocol Version 4 (TCP/IPv4)

the click on Properties

Windows XP

Select Internet Protocol (TCP/IP) the select

Properties

2. Change the IP Address to the value shown below.

Then hit the Tab key and the Subnet mask will

populate. Then click OK.

Access the Actuator

1. Open Internet Explorer and enter the following

address: http://192.168.0.10:8080/index.html

2. Enter "amdsetup" as the User Name and "gfcamd"

as the password.

Entering the BACnet Settings

1. Click on BACnet/MP settings.

2. Select MS/TP as Protocol

3. Configure the desired baud rate and MAC address

4. Choose unique Instance ID

5. Enter desired Device Name (optional)

6. Click Submit button

6

Page 7

BACnet Data Point List

Table 1 lists and describes all of the BACnet data points associated with the controller inside the actuator of

BACnet enabled AMD-TD series dampers.

Name Type # Access Description

Greenheck AMD-TD AI 1 C Displays the application version

AirflowSetpoint AI 2 C Displays the real-time setpoint in cfm

CurrentAirflow AI 3 C Displays the real-time volumetric airflow rate in cfm

AirVelocity AI 4 C Displays the real-time air velocity in fpm

DamperPosition AI 5 C Displays the real-time damper position as a percentage (0% - fully

closed; 100% fully open)

MaxCFMSetpoint AI 6 C Displays the maximum volumetric airflow rate in cfm. This value

is a function of the value selected for "Maximum FPM". (Max CFM

Setpoint = Damper Area * Maximum FPM).

DamperArea AV 1 C Represents the nominal damper face area in square feet. Set by the

factory.

MinimumFPMSetpoint AV 2 C Represents the minimum allowable velocity setpoint in fpm. If the

actuator receives a setpoint below the "Minimum FPM Setpoint" the

setpoint will be set to zero. The factory default value is 100 fpm.

BACnetSetpoint AV 3 C When the Setpoint Source is set to BACnet this variable establishes

the unit's setpoint. When the Damper Mode is set to Flow the BACnet

Setpoint is a percentage of the MaxCFM Setpoint. When the Damper

Mode is set to Position the BACnet Setpoint is the percentage the

damper is open. When the Setpoint Source is set not set to BACnet

this variable has no impact on controlling the damper.

SafetyStatus BI 1 C Represents the status of the safety circuit. Inactive = Open/Failure;

Active = Closed/OK

MaximumFPM MV 1 C Represents the maximum setpoint velocity in fpm. The value this

variable is set to corresponds to a 10 VDC input to the actuator. This

value is set at the factory based on maximum velocity that was

selected at the time the unit was ordered. 1 = 500 fpm; = 1000 fpm;

3 = 1500 fpm; 4 = 2000 fpm; 5 = 2500 fpm; 6 = 3000 fpm; 7 = 3500

fpm; 8 = 4000 fpm

DamperMode MV 2 C Establishes the mode of operation for the actuator. When in flow

control mode the actuator will view the setpoint as a target cfm to

maintain. When in position control mode the actuator will view the

setpoint percentage as a position to drive to (0% fully closed, 100%

fully open). Whether the actuator is in Flow or Position control mode

the source of the setpoint will be determined by the Setpoint Source

variable. 1 = Flow; 2 = Position

SetpointSource MV 3 C When set to BACnet the actuator uses the BACnet variable as the

setpoint. When set to Local AI it uses the actuator's second analog

input (S2) as the setpoint. When set to Zth the actuator uses a

handheld Zth module to establish the setpoint. 1 = BACnet; 2 = Local

AI; 3 = ZTH

AI - Analog Input

AO - Analog Output

AV - Analog Value

BI - Binary Input

BO - Binary Output

BV - Binary Value

MI - Multi-State Input

MO - Multi-State Output

MV - Multi-State Value

R - ReadOnly

W - Writable

C - Commandable

(Contains Priority Array)

7

Page 8

Protocol Implementation Conformation Statement - PICS

General Information

Date: 11. April 2014

Vendor Name: BELIMO Automation AG

Vendor ID: 423

Product Name: AFB24-OP GTD

Product Model Number: N/A

Applications Software Version: 1.34.0

Firmware Revision: 1.0.3

BACnet Protocol Revision: 1.6

Product Description:

The device is an air damper control actuator with the added benefit of a built-in programmable controller.

Free programming environment allows handling of a wide range of HVAC control applications. MP-Bus master

capabilities allow this device to monitor and control up to 15 additional slave devices that contain Belimo

MP-Bus technology, affording significant expandability. BACnet server functionality allows easy integration in

standard building automation systems. The commissioning of the device (BACnet Device Address, IP Address

settings, MS/TP Address …) is done via the integrated web-server.

BACnet Standard Device Profile: BACnet Application Specific Controller (B-ASC)

BACnet Interoperability Building Blocks supported:

Data Sharing - ReadProperty-B (DS-RP-B)

Data Sharing - ReadPropertyMultiple-B (DS-RPM-B)

Data Sharing - WriteProperty-B (DS-WP-B)

Device Management - DynamicDeviceBinding-B (DM-DDB-B)

Device Management - DynamicObjectBinding-B (DM-DOB-B)

Device Management - DeviceCommunicationControl-B (DM-DCC-B)

Segmentation Capability: No

Data Link Layer Options: BACnet IP, (Annex J)

BACnet IP, (Annex J), Foreign Device

MS/TP master,

baud rates: 9'600, 19'200, 38'400, 76'800, 115'200

Device Address Binding: No static device binding supported

Networking Options: None

Character Sets Supported: ANSI X3.4

Standard Objects

The device provides datapoints for common operation as well as datapoints for parameterization using the following object

types:

• Analog Input

• Analog Output

• Analog Value

• Binary Input

• Binary Output

• Binary Value

• Device

• Multi-State Input

• Multi-state Output

• Multi-state Value

8

Page 9

Object Processing

Object Type Optional Properties Writeable Properties

Analog Input Description

Analog Output Description Present_Value

Analog Value Description Present_Value

Binary Input Description

Binary Output Description

Binary Value Description

Device Description

Multistate Input Description

Multistate Value Description

Multistate Output Description

1)

Only if object is commandable.

2)

Only if MS/TP is the selected data link layer type

Active_Text

Inactive Text

Active_Text

Inactive_Text

Relinquish_Default

Priority_Array

Active_Text

Inactive_Text

Relinquish_Default

Priority_Array

Location

State_Text

State_Text

Relinquish_Default

Priority_Array

State_Text

Relinquish_Default

Priority_Array

1)

1)

1)

1)

Present_Value

1)

Present_Value

1)

Object_Identifier

Object_Name

Location

APDU_Timeout

Number_Of_APDU_Retries

Max_Master

Max_Info_Frames

Present_Value

1)

Present_Value

1)

2)

2)

• The properties Object_Name and Location of the Device Object support up to 255 characters (all other

character strings are read-only).

• The device does not support the CreateObject and DeleteObject service.

Service Processing

• The device supports DeviceCommunicationControl service. No password is required.

9

Page 10

Optimal Placement for AMD-TD Damper Series

Fans

2X

Centrifugal Fan Discharge

Centrifugal Fan Inlet

3X

Vane Axial Fan Discharge

3/4X

1X

Elbows

1/2X

90° Vaned Elbow

1X

Vane Axial Fan Inlet

1/2X

1.5X

90°Elbow Without Vanes

1/2X

10

Round Sweep Elbow

Page 11

Optimal Placement for AMD-TD Damper Series

Takeoffs

1X

Branch Takeoff B1

Transitions

1.5X

Branch Takeoff 2

Bellmouth Inlets

α

α

1/2X

Transition 1

α

α

1/2X

Transition 3

11

Page 12

Damper Maintenance

Greenheck's dampers are designed to be trouble free and hassle free under normal operation. Dampers are

to be installed square and straight so as to prevent binding during operation. The following annual damper

maintenance suggestions will help to insure proper damper operation and increase the life expectancy of the

damper.

Foreign Matter Over the course of time, dirt and grime may collect on damper surfaces. The

damper surfaces should be cleaned to prevent hindrance to airflow.

Moving Parts Make sure that parts such as linkage, bearings, blades, etc. that are intended

to move freely, can do so. Lubricating these components can prevent possible

rusting and unnecessary friction increase. Use only a moli-spray oil or similar

graphite based oil as regular lubricating oil will attract dirt.

Bearings: Synthetic, oil impregnated, and ball bearings (without grease fittings)

do not require lubrication. Ball bearings with grease fittings require only minimal

grease.

Closure Remove foreign materials that may be interfering with blade closure or effective

sealing of the blades with each other or with the frame.

Operation While operating the damper through its full cycle, check to see that the blades

open and close properly. If there is a problem, check for loose linkage, especially

at the actuator. Tighten the linkage where required.

Our Commitment

As a result of our commitment to continuous improvement, Greenheck reserves the right to change specifications without

notice.

Specific Greenheck product warranties can be located on greenheck.com within the product area tabs and listed in the

Library under Warranties.

®

Phone: (715) 359-6171 • Fax: (715) 355-2399 • E-mail: gfcinfo@greenheck.com • Website: www.greenheck.com

478799 • AMS & AMD, Rev. 1, March 2014 Copyright 2014 © Greenheck Fan Corporation

Loading...

Loading...