Page 1

®

Vari-Green Constant Volume Controller

for AMS & AMD Damper Series

Installation, Operation and Maintenance Manual

Please read and save these instructions for future reference. Read carefully before attempting to assemble, install,

operate or maintain the product described. Protect yourself and others by observing all safety information. Failure to

comply with instructions could result in personal injury and/or property damage!

These instructions apply to Greenheck’s Vari-Green Constant Volume damper controller. The controller accepts

an analog output from a factory supplied pressure transducer on a Greenheck AMS airflow measuring station

or AMD airflow measuring damper to calculate the realtime volumetric airflow rate (cfm) going through the unit.

Using PID logic the controller then controls the damper’s actuator to achieve a target cfm setpoint. The cfm

setpoint can be established either remotely via an analog input to the controller or locally using touch sensitive

buttons on the cover of the controller.

Table of Contents

General Operation of the Controller .............2

• Setting the Flow Setpoint ...................... 2

• Airflow Output Signal ............................. 2

Document number 479830

Constant Volume

Varigreen Damper

Controller

Controller Display and Interface Buttons ...2-3

Controller Configuration ............................3-6

• Factory Configuration .........................3-4

• Field Configuration ..............................4-6

• Manual Control ......................................6

• Factory Defaults ....................................6

Diagnostic LED ............................................. 7

Wiring of Controller ...................................7-8

Receiving

Upon receiving the control, check to ensure all items are

accounted for by referencing the delivery receipt or packing

list. Inspect each crate or carton for shipping damage

before accepting delivery. Alert the carrier of any damage

detected. The customer will make notification of damage

(or shortage of items) on the delivery receipt and all copies

of the bill of lading which is countersigned by the delivering

carrier. If damaged, immediately contact your Greenheck

Representative. Any physical damage to the unit after

acceptance is not the responsibility of Greenheck Fan

Corporation.

Unpacking

Verify that all required parts and the correct quantity of

each item have been received. If any items are missing,

report shortages to your local representative to arrange for

obtaining missing parts.

Storage

Controls are protected against damage during shipment. If

the control cannot be installed and operated immediately,

precautions need to be taken to prevent deterioration of

the control during storage. The user assumes responsibility

of the control and any accessories while in storage. The

manufacturer will not be responsible for damage during

storage. These suggestions are provided solely as a

convenience to the user.

Indoor

The ideal environment for the storage of controls is indoors,

above grade, in a low humidity atmosphere which is

sealed to prevent the entry of blowing dust, rain or snow.

Temperatures should be evenly maintained between 30° to

110°F (-1° to 43°C). Wide temperature swings may cause

condensation and “sweating” of metal parts. All accessories

must be stored indoors in a clean, dry atmosphere.

Removing from Storage

As controls are removed from storage to be installed in their

final location, they should be protected and maintained in a

similar fashion until the control goes into operation.

1

Page 2

General Operation of the Controller

The Vari-Green Constant Volume Controller has two operating modes. The controller is factory set to its Flow Control

Mode. In Flow Control Mode the controller will modulate the position of the damper to achieve a target airflow setpoint. The

controller can also be put into Position Control Mode. In Position Control Mode the controller treats the setpoint as a target

damper blade position.

In addition to the two operating modes the controller has a parameter called Setpoint Location that can be configured to

either Remote or Local. The controller ships from the factory with the Setpoint Location set to Remote. In Remote mode the

controller uses a voltage sent to one of its analog inputs to establish the setpoint (see the Setting the Flow Setpoint section

below). When the Setpoint Location is in Local mode the interface on the front cover of the controller is used to establish the

setpoint and the voltage sent to the analog input is ignored.

See the Field Configuration section of this document to learn how to change the Control Mode and Setpoint Location. The

following section assumes that the controller is in the factory default Flow Control and Remote Setpoint Location modes.

Setting the Flow Setpoint

The controller accepts an analog input (configurable for

either 0-10 or 2-10 VDC) that is proportional to a target

volumetric airflow rate (cfm). The voltage corresponding to

the setpoint can be determined using the following formulas:

0 - 10 VDC setpoint

C = Q /(V

2 - 10 VDC setpoint

C = Q /(V

Formula 1

Where:

C = Flow Setpoint (VDC)

Q = Desired Airflow (cfm)

V

= Maximum Velocity as specified at the time the unit

max

was ordered (fpm)

A = Face Area of the Damper (ft2)

max

* A) * 8 + 2

max

* A) * 10

Airflow Output Signal

The controller outputs an analog signal (configurable for

either 0-10 or 2-10 VDC) that is proportional to the real-time

airflow rate (cfm) going through the AMD/AMS. The cfm

corresponding to the voltage output can be determined

using the following formulas:

0 - 10 VDC setpoint

Q = (C * V

max

* A) /10

2 - 10 VDC setpoint

Q = ((C - 2) * V

max

* A) /8

Formula 2

Where:

C = Voltage Output Signal (VDC)

Q = Real-time Airflow (cfm)

V max = Maximum Velocity as specified at the time the unit

was ordered (fpm)

A = Face Area of the Damper (ft2)

Controller Display and Interface

Buttons

There are four touch sensitive buttons on the controller’s

cover that are used to interface with the controller: Back,

Enter, Up and Down (see Figure 2).

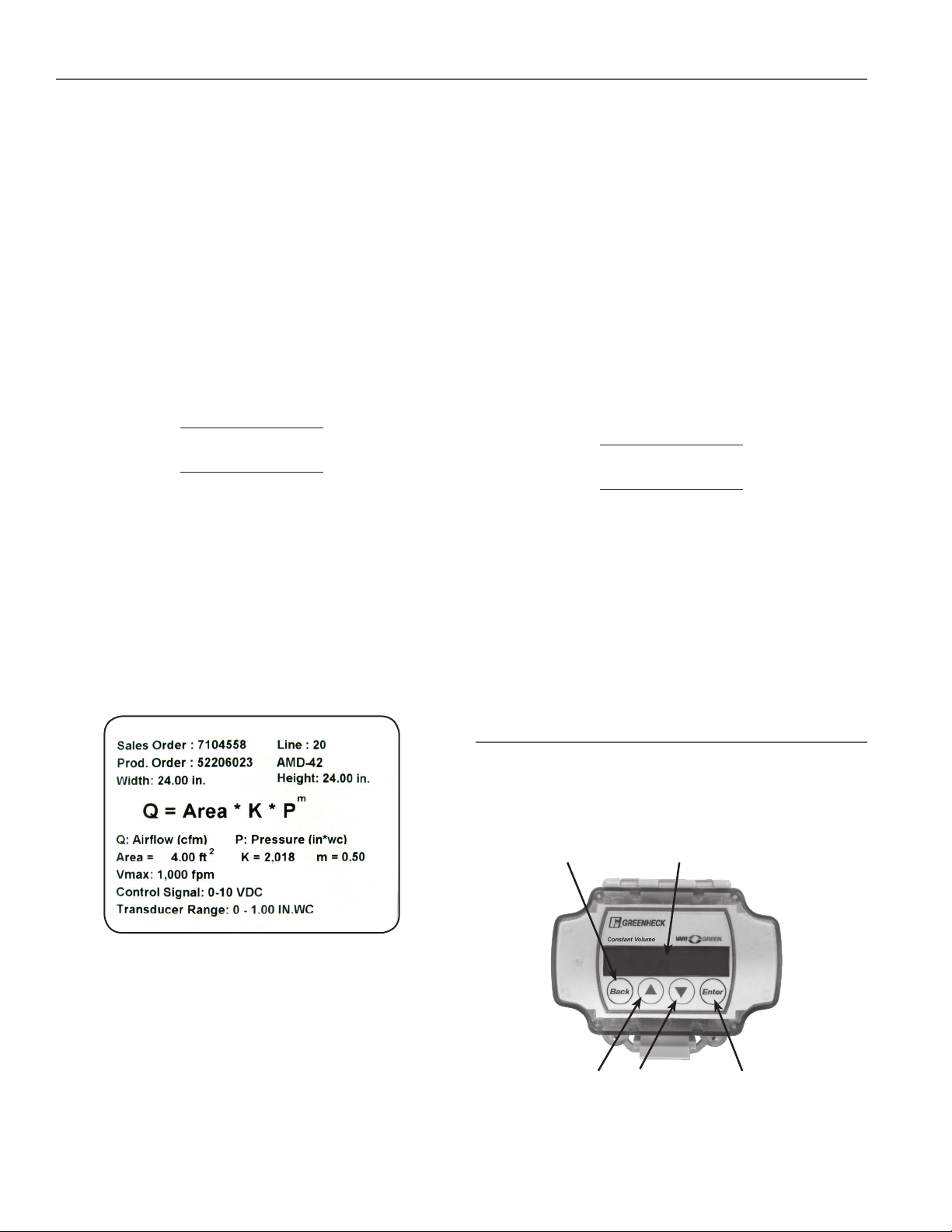

Figure 1 - Label affixed to AMS/AMD that

lists the V

Example: The BMS desires 2,000 cfm through a

24 in. x 24 in. AMD-42 that was ordered with a maximum

velocity of 1,000 fpm. Find the voltage setpoint that

corresponds to 2,000 cfm:

C = 2,000 / (1,000 * 4) * 10 = 5 VDC (0-10 VDC)

C = 2,000 / (1,000 * 4) * 8 +2 = 6 VDC (2-10 VDC)

2

and damper area.

max

DisplayBack Button

Up Arrow

Figure 2 - Outside of the controller's cover

Down Arrow Enter Button

Page 3

Controller Display and Interface Buttons cont...

The controller also has a two line backlit LCD display. By

using the up and down arrows the display can be toggled

through three sets of data:

XXXXX CFM

Setpt XXXXX CFM

• Top Screen: Real-Time CFM and CFM Setpoint

• Middle Screen: Real-Time Velocity (fpm) and Velocity

Setpoint

XXXX FPM

Setpt XXXX FPM

• Bottom Screen: Real-Time Differential Pressure

Measurement and Actuator Position

X.XX in WC

Act XX.X% Open

Figure 3 - Run Mode display screens

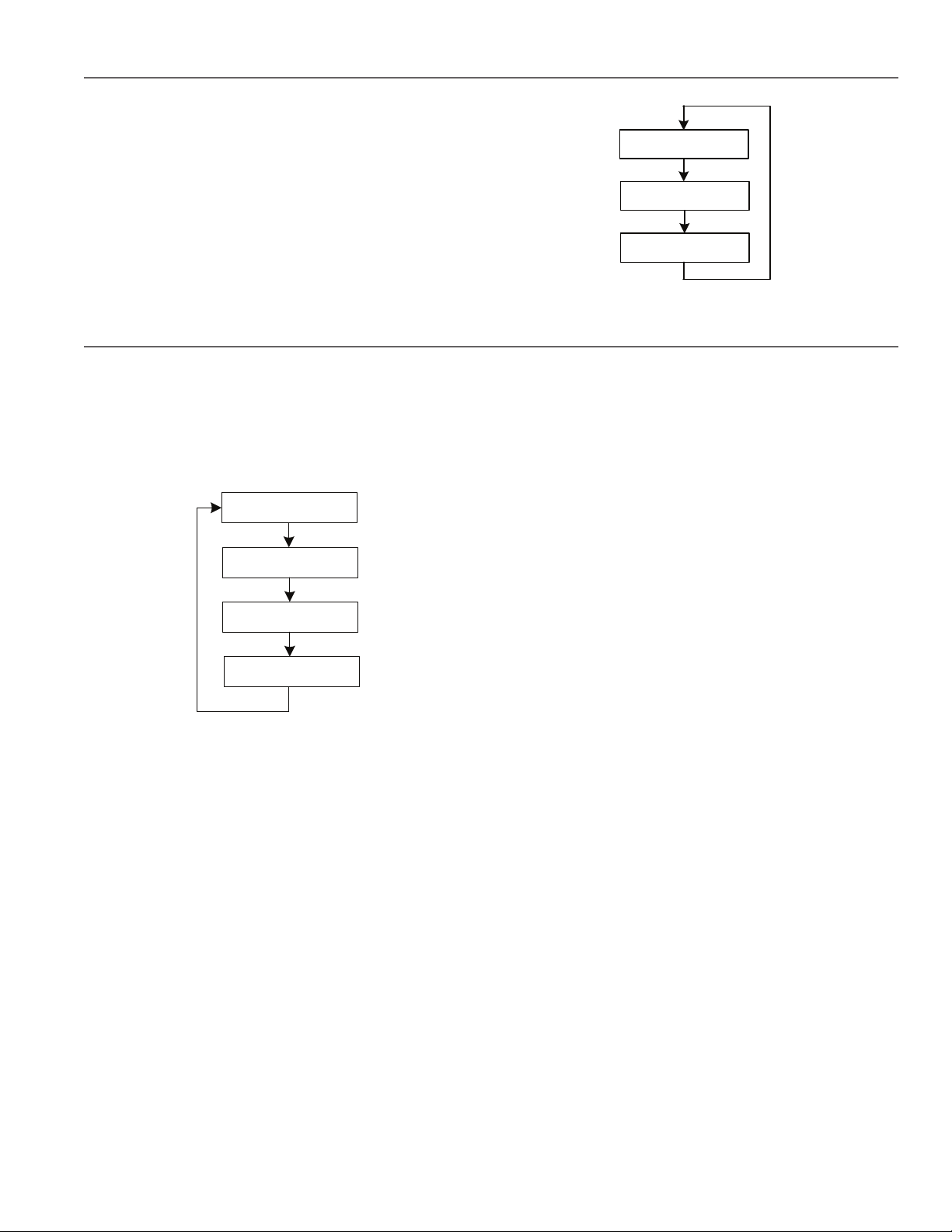

Controller Configuration

The Vari-Green Constant Volume Controller is shipped in “Run Mode”. When calculating the airflow rate going through the

AMS/AMD and to control the damper (on AMD models) the controller should be left in run mode. In most cases the controller

should not need to be taken out of run mode. However, a variety of parameters can be adjusted in the field as needed by

opening the controller’s cover and moving the toggle switch into the PROG position (see Figure 2).

When in program mode the display can be toggled through a “Top Level Menu” by using the up and down arrows on the

controller’s cover (see Figure 4). The desired menu item can be accessed by pressing the “Enter” button.

Factory Config

Enter to Select

Field Config

Enter to Select

Manual Control

Enter to Select

Factory Defaults

Enter to Select

Figure 4 - Top level menu in Program Mode.

Factory Configuration

The controller comes from the factory configured with the

physical parameters of the AMD/AMS it was ordered with.

These parameters include:

• Flow Measurement Device – should always be left as

“Diff Pressure”

• The unit’s K & M Values – damper specific constants

used to calculate airflow. These values are set at the

factory and can also be found on the label affixed to

the AMD/AMS (see Figure 1)

• Maximum Pressure – this parameter represents

the top-end of the AMD/AMS pressure transducer

range. The selectable values are: 0.25” wc, 0.5” wc,

1.0” wc, 2.0” wc, 2.5” wc, 3.0” wc, and 5.0” wc. The

maximum pressure is also a configurable value on the

pressure transducer (see the transducer instructions).

The top-end of the controller’s pressure range and

the transducer’s pressure range must match for the

controller to operate properly. They are set at the

factory to the same values.

• Damper Area - the face area of the AMD/AMS

(ft2)

• Maximum Velocity – this parameter represents

the velocity corresponding to a 10 VDC remote

setpoint. This parameter is set by the factory to the

value selected at the time the unit was ordered.

The selectable values are: 500 fpm, 1000 fpm, 1500

fpm, 2000 fpm, 2500 fpm, 3000 fpm, 3500 fpm and

4000 fpm. To achieve optimal accuracy the lowest

value that meets the application should be selected.

Changing the maximum velocity value will affect

the flow setpoint and flow output calculations. See

formulas 1 and 2 on page 2.

• Minimum Velocity – this is the minimum velocity

the unit is designed to accurately measure airflow

and control the damper at. To avoid “hunting” the

controller will treat setpoints below the minimum

velocity as a setpoint of zero. The controller is set to a

value of 300 fpm at the factory.

While the parameters in the factory configuration menu

don’t normally require adjustment, they can be changed by

putting the controller into Program Mode (see above) and

then pressing enter on the “Factory Config” option in the top

level menu. The factory configuration menu structure, see

Figure 5, can be navigated by using the up and down arrows

on the controller’s cover. When the parameter you wish to

adjust is shown in the display press the "Enter" button to

enter the edit mode. The parameter can then be adjusted

by using the up and down arrows (parameter will blink

on display when in edit mode). Once the desired value is

selected press "Enter" again to leave edit mode. Once all of

the parameters have been adjusted press the "Back" button

on the controller to return to the top level menu or return the

slider switch inside the controller to run mode.

3

Page 4

Return

Flow Measure Dev

Thermal Disp

Flow Measure Dev

Diff Pressure

AMD “K” Value

2000

AMD “M” Value

0.5

Maximum Pressure

1.00 in WC

Damper Area

4.00 ft^2

Maximum Velocity

2,000 FPM

Minimum Velocity

300 FPM

Figure 5 - Factory Configuration Menu Structure

Field Configuration

The controller comes from the factory with the parameters

in the field configuration menu (see Figure 6) set to the most

commonly used values. The field configuration menu can

be accessed from the top level menu (see Figure 4).These

parameters include:

• Units of Measure – the controller comes with imperial

units selected. The controller can be configured to

display in metric units.

• Actuator Setpoint – this parameter sets the type of

analog output signal the controller will use to control

the damper’s actuator. The default selection is 2-10

VDC, but the controller can be configured to send a

0-10 VDC signal to the actuator.

• Velocity Output – this parameter sets the type of

analog signal the controller uses to output the airflow

rate. The default selection is 0-10 VDC, but the

controller can be configured to output a 2-10 VDC

signal.

• Control Mode – this parameter determines how the

controller treats the setpoint. The default selection

is Flow Control mode. In Flow Control mode the

controller treats the setpoint as the desired airflow

(cfm). See the section on Setting the Flow Setpoint.

The controller can also be put into Position Control

mode. In this mode the controller treats the setpoint

as the desired position of the actuator.

• Setpoint Location – this parameter determines where

the controller gets its setpoint from. The default

setpoint location is Remote. In Remote setpoint

location mode the controller uses the signal from its

analog input as the target setpoint. See the section

on Setting the Flow Setpoint. The controller can also

be put into Local setpoint location mode. In Local

setpoint location mode the controller will ask for a

Flow or Damper Position setpoint (depending on the

selected control mode) to be entered using the up

and down arrows on the controller’s cover when in the

Field Configuration Menu (see the Field Configuration

menu structure). When the controller’s toggle switch is

moved back into run mode it will control the damper

to the entered setpoint instead of the value sent to

the analog input. Local setpoint mode should be used

when the desired flow or position setpoint is constant.

• Setpoint Input - this parameter sets the type of analog

signal that will be sent to the controller as the remote

setpoint. The default selection is 0-10 VDC, but the

controller can be configured to accept a 2-10 VDC

signal.

• Field Correction – this parameter can be used to

adjust the airflow calculation of the controller. The

default value is 1.0. Changing this value will adjust the

calculated flow proportionally. For example, setting

the Field Correction factor to 0.95 will reduce the

calculated flow values by 5%. Setting it to 1.05 will

increase the calculated flow by 5%.

• Air Density Correction – this parameter adjusts the

airflow calculation to account for changes in the dry

bulb temperature of the air being measured and/or the

elevation above sea level of the jobsite. The default

value is 1.00, which corresponds to an air temperature

of 70° F and an elevation of 0 ft. Table 1 shows the Air

Density Correction as a function of air temperature

and elevation

• Response Time – this parameter determines how

the controller responds to changes in the setpoint or

system conditions. The controller has three available

response times. It comes from the factory set to

the fastest response time. If, because of system

conditions, the controller is “hunting” without settling

on a point one of the slower response times should be

selected. The Medium response time should be tried

first. If the controller is still not settling on a point the

Slow setting should be used.

4

Page 5

Field Configuration cont....

• Control Deadband – this parameter determines the

range of acceptable values around the setpoint that

the controller will attempt to achieve. The factory

default Control Deadband is 25 fpm. As an example,

with a 25 fpm deadband and a setpoint of 1,000 fpm

the controller will adjust the damper’s position until the

real-time velocity is between 975 fpm and 1,025 fpm

(note that fpm can be converted to cfm by multiplying

by the AMD/AMS area). Larger deadbands will make it

easier for the controller to reach an acceptable point,

but may result in the realtime flow being further from

the setpoint.

• Override Out – the controller has a voltage free non-

grounded contact that can be used to override the

normal operation of the controller. When the contact is

Units of Measure

Imperial

Actuator Setpnt

0 to 10 VDC

open the controller functions normally. However, if the

contact is closed the controller will drive the actuator

to an override position. The override position is set to

100% open from the factory, but may be adjusted to

any position between 0 and 100%.

• Sensor Filter – this parameter establishes the amount

of averaging the controller performs on the pressure

reading before it updates the airflow calculation. The

factory default setting is 3 seconds. The value should

not be adjusted below 3 seconds and should only be

increased above 3 seconds if turbulence such as wind

gusts result in sporadic airflow measurement readings.

If the sensor filter is increased above 3 seconds one of

the slower response time settings will likely need to be

used to avoid the actuator hunting for the setpoint.

Units of Measure

Metric

Actuator Setpnt

2 to 10 VDC

Setpoint Input

0 to 10 VDC

Setpoint

Location: Remote

Setpoint Input

2 to 10 VDC

Response Time

Fast

Velocity Output

0 to 10 VDC

Control Mode

Flow

Setpoint

Location: Local

Flow Setpoint

XXXX CFM

Field Correction

1.00

Air Density Corr

1.00

Response Time

Medium

Control Deadband

20 FPM

Velocity Output

2 to 10 VDC

Control Mode

Position

Setpoint

Location: Local

Damp Pos Setpnt

XX%

Response Time

Slow

Setpoint Input

0 to 10 VDC

Setpoint

Location: Remote

Setpoint Input

2 to 10 VDC

Override Out %

100%

Sensor Filter

0 Seconds

Return

Figure 6- Field Configuration Menu Structure

5

Page 6

Duct Air

Temp

°F

(Deg. C)

-40 (-40) 0.79 0.81 0.82 0.84 0.85 0.87 0.88 0.9 0.92 0.93 0.95 0.97 0.99

-20 (-29) 0.83 0.85 0.86 0.88 0.89 0.91 0.93 0.94 0.96 0.98 0.99 1.02 1.04

0 (-18) 0.87 0.88 0.9 0.92 0.93 0.95 0.97 0.99 1 1.02 1.04 1.06 1.08

20 (-7) 0.91 0.92 0.94 0.96 0.97 0.99 1.01 1.03 1.05 1.07 1.08 1.11 1.13

40 (4) 0.94 0.96 0.98 1 1.01 1.03 1.05 1.07 1.09 1.11 1.13 1.16 1.18

70 (21) 1 1.02 1.04 1.06 1.08 1.1 1.12 1.14 1.16 1.18 1.2 1.22 1.25

80 (27) 1.02 1.04 1.06 1.08 1.1 1.12 1.14 1.16 1.18 1.2 1.22 1.25 1.27

100 (38) 1.06 1.08 1.1 1.12 1.14 1.16 1.18 1.2 1.22 1.25 1.27 1.29 1.32

120 (49) 1.09 1.11 1.13 1.16 1.18 1.2 1.22 1.24 1.27 1.29 1.31 1.34 1.37

140 (60) 1.13 1.15 1.17 1.2 1.22 1.24 1.26 1.29 1.31 1.34 1.36 1.39 1.41

160 (71) 1.17 1.19 1.21 1.24 1.26 1.28 1.31 1.33 1.35 1.38 1.4 1.43 1.46

180 (82) 1.21 1.23 1.25 1.28 1.3 1.32 1.35 1.37 1.4 1.42 1.45 1.48 1.51

200 (93) 1.25 1.27 1.29 1.32 1.34 1.36 1.39 1.42 1.44 1.47 1.49 1.53 1.55

0 500 1000 1500 2000 2500 3000 3500 4000 4500 5000 5500 6000

(0) (152.4) (304.8) (457.2) (609.6) (762) (914.4) (1066.8) (1219.2) (1371.6) (1524) (1676.4) (1828.8)

Air Density Correction Factors

Elevation Dimensions in feet and (meters)

Table 1 - Air Density Correction Factor

Manual Control

Manual Control mode allows the user to directly change the percent the damper is open by using the up and down arrows

on the controller’s cover. This can be done by entering the top level menu, scrolling down to Manual Control, and pressing

"Enter". You can leave Manual Control mode at any time by pressing the "Back" button or by putting the slider switch inside

the controller back into the run position.

Factory Defaults

For trouble shooting purposes, it may be desirable to reset the controller’s parameters back to the factory defaults. This can

be done by entering the top level menu, scrolling down to “Factory Defaults” and pressing enter. You will see an option to

“Resort Factory Defaults”. Select Yes and then select Yes again when asked “Are You Sure?”. Once this is done you will need

to go through each parameter in both the factory and field configuration menus and select the appropriate value.

6

Page 7

Diagnostic LED

Wiring the Controller

The controller has a multicolor LED that is used to

distinguish between operating modes and to indicate

trouble conditions.

• Solid Green – Flow Control with Remote Setpoint

(Control Mode = Flow; Setpoint Source = Remote;

Request Velocity >= Minimum Velocity)

• Blinking Green – Flow Control with Local Setpoint

(Control Mode = Flow; Setpoint Source = Local;

Request Velocity >= Minimum Velocity)

• Solid Blue – Position Control with Remote Setpoint

(Control Mode = Position Setpoint Source = Remote;

Request Velocity >= Minimum Velocity)

• Blinking Blue – Position Control with Local Setpoint

(Control Mode = Position Setpoint Source = Local;

Request Velocity >= Minimum Velocity)

• Solid Purple – Parameter Editing or Manual Mode

• Solid Pink – Override activated

• Blinking Yellow – Low Velocity Setpoint. The LED will

blink yellow when the requested velocity is greater

than 20 fpm, but less than the minimum velocity

parameter. This indicates that the user is sending

a velocity request, but that it is under the defined

minimum velocity.

• Blinking Red – No Velocity Setpoint. When in Remote

Setpoint Source mode regardless of the control mode,

if the velocity request is less than 20 fpm the LED

should blink red.

The basic wiring of the controller is shown below in Figure

7. The controller’s three terminal blocks can be accessed by

opening the cover of the enclosure.

Powering the Controller

The controller is powered by applying electrical power to the

“Power In” terminal block. The controller can run off of 24

VAC +/- 20% 50/60 Hz or 24 VDC +/- 10%

Connecting the Pressure Transducer

The second terminal block is labeled “Remote Sensor” and

is used to connect to the pressure transducer. The three

terminals from the Remote Sensor block connect directly to

the pressure transducer as shown in Figure 6. The controller

supplies the transducer with its power and reads the

pressure signal.

Connecting the Damper Actuator

The actuator can be powered either by the same power

supply as the controller, as shown in Figure 7, or by running

a separate power supply to terminals 4 and 5 of the factory

supplied terminal block on the AMD/AMS. In addition, the

“Control Out” from the controller (terminal 7) must be run to

terminal 6 on the damper’s terminal block.

Connecting the Flow (or position) Setpoint Signal

Connect the 0-10 VDC or 2-10 VDC flow (or position)

setpoint to the controller terminals 1 and 3. The controller’s

terminal 1, labeled Remote Setpoint, is the positive terminal

and the controller’s terminal 3 is the common terminal.

Connecting to the Flow Output Signal

Connecting to controller terminals 6 and 3 allows the

user to read the 0-10 VDC or 2-10 VDC flow output that

is proportional to the cfm measured by the AMD/AMS. To

convert the voltage signal to cfm see the section above on

Airflow Output Signal.

Override Mode

The functionality of the override feature is described above

in the Field Configuration section of this document. The

override feature can be activated by closing the contacts

of an external relay across terminals 2 and 3 (or by simply

putting a jumper wire across them).

7

Page 8

Vari-Green Constant Volume Controller Wiring Diagram

Remote Transducer

Wiring Connector

Control Wiring

Connector

PROG/RUN

Switch

Power Wiring

Connector

All wiring above terminal block done at factory

when the actuator is externally mounted. When

the actuator is internally mounted the actuator

must be wired to the terminal block in the field.

Figure 7 - Basic Wiring of Vari-Green Constant Pressure Controller

Our Commitment

As a result of our commitment to continuous improvement, Greenheck reserves the right to change specifications without

notice.

Specific Greenheck product warrantees can be located on greenheck.com within the product area tabs and listed in the

Library under Warrantees.

®

Phone: (715) 359-6171 • Fax: (715) 355-2399 • E-mail: gfcinfo@greenheck.com • Website: www.greenheck.com

479830 • BAPI Controller for AMD & AMS, Rev. 1, April 2015 Copyright 2015 © Greenheck Fan Corporation

Loading...

Loading...