Page 1

1

A

A

s

CM

e

)

●●●●●

●

●●●●●●●●●●●●●

●

Torq

]

●●●●●●●●●●●

●

]

●●●

]

●

●

Ang

●●●●●●●●●●●●●●●●●

y

C

●●●●●●●●●●●●●

●

C

●

●

C

On/O

●

t

●●●●●

)

●●●

●

Multi-F

y

●●●

●

0

m

●

0 to 20V Phasecu

●

S

®

●

eedbac

one

●●●●●

●

C

●●●●●

V

)

●●●●●

R

●●●●●

Adj

ds

●

●

)

●●●●●●●

●

seconds

●●●

Cable

●●●●●●●●●

●●●

p

●●●●●

●

●●●

●●●●●●●

A

●

●●●●●●●●●●●●●●●●●

t

A

M Series Direct Coupled Actuato

r

Versatile and Powerful

*

AMB(X)24-3

AMX24-3-T

AMB24-3-T N4(H)

AMX120-3

AMB(X)24-SR

AMB24-SR-T N4(H)

AMX120-SR

AMB(X)24-MFT

AMCX24-MFT

(p. 229)

AMX24-MFT95

AMX24-PC

AMQB(X)24-1

AMQB(X)24-MFT

AMX24-LON

AMB24-3-S

AMX24-SR-T

AMX24-MFT-T N4(H)

●

Minimum 180 in-lb torque in a compact package.

For damper areas up to 45 sq. ft*, Q Series- 35 sq. ft

ll Actuator

have BD

AM Series - At A Glanc

Basic Product (B

Flexible Product

ue 180 in-lb [20 Nm

160 in-lb [16 Nm

140 in-lb [16 Nm

le of Rotation 95 degrees

Power Suppl

24 VAC/D

100 to 240 VA

ontrol Input

ff

On/Off, Floating Poin

2 to 10 VDC (4 to 20mA

unction Technolog

to 135 Oh

t

LonWORK

F

kN

2 to 10 VD

ariable (0 to 10 VDC

unning Time 95 seconds

. 7 to 20 secon

Adj. 95 to 300 seconds (150

150

Wiring Plenum Rated

Appliance Rated Cable

Terminal Stri

Conduit Fitting

uxiliary Switch Built-In

Add-On

Installation and Operation… (page 269).

●

40024 - 05/10 - Subject to change. © Belimo Aircontrols (USA), Inc.

●

*Based on 4 in-lb/f

2

damper torque loading. Parallel blade. No edge seals.

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

21

Page 2

212

●

.

●

C

●

J

C

.

●

●

.

●

y

●

.

●

.

●

S

●

A

r

T

e

●

.

y.

●

.

bili

L

.

A

A CLOS

ER L

OOK…

j

g

(

)

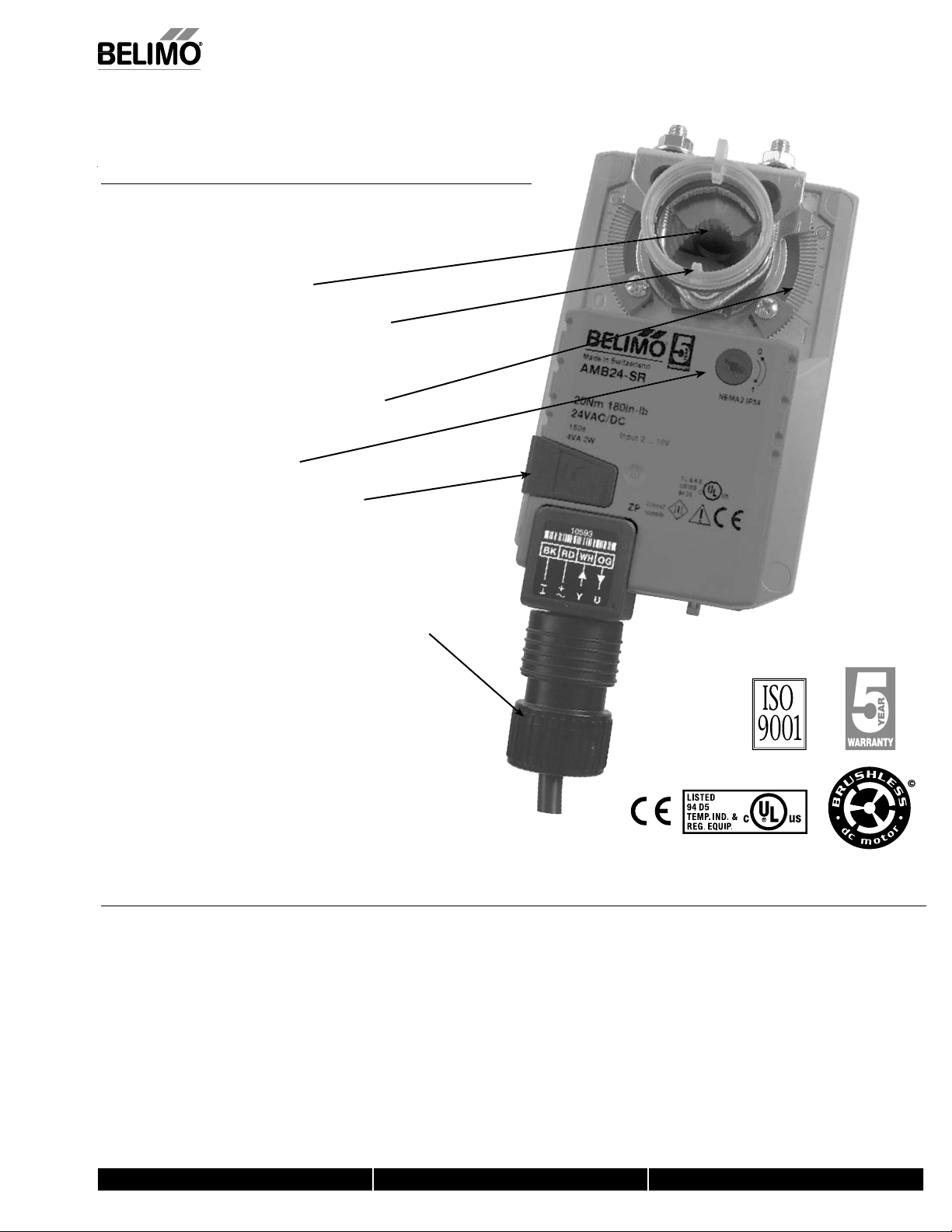

Brushless DC Motor for Added Accuracy and Controllability

ut Labor Costs with Simple Direct Coupling.

Self-Centers on 1/2",3/4", and 1.05"

ackshafts with Standard Clamp.

●

heck Damper Position with Clear Position Indicator

Don’t Worry about Actuator Burn-Out; Belimo is Overload Proof

throughout Rotation.

●

Enjoy Added Flexibility with Easy Mechanical Stops

to Adjust Angle of Rotation.

Need to Change Control Direction?

Do it easily with a Simple Switch

M Series Direct Coupled Actuato

Easily Accessible Manual Override Button helps

ou Pre-Tension Damper Blades.

Fully Adjustable Built-In Auxiliary Switch (AMB24-3-S)

Auxiliary Switch and Feedback Potentiometer Add-Ons Mount

Directly on Clamp, Includes Conduit Connector

tandard 3ft Plenum Rated Cable and Conduit Connector Provided

on Basic Models.

Added Flexibility to Select Clamp, Electrical Connection, and

Running Time to fit your Specific Application with Belimo’s New

Flexible Line of Actuators.

, Inc.

USA

e. © Belimo Aircontrols

ect to chan

he Belimo Differenc

ustomer Commitment

Extensive product range. Application assistance.

40024 - 05/10 - Sub

Same-day shipments. Free technical support. Five year warrant

Low Installation and Life-Cycle Cost

Easy installation. Accuracy and repeata

ow power consumption. No maintenance.

ty.

●

Long Service Life

Components tested before assembly. Every product tested before shipment.

30+ years direct coupled actuator design.

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

Page 3

3

AMB(X)

24-3(-S)(-T

)

V

pply

z

n

)

T

g

)

n

e

S)

r

)

n

l

t

600

n

Torque

]

n

ibl

h

n

)

e

n

Auxiliary

h

)

C

e

d

y

)

e

]

S

g

l

Ag

†

/CS

acc

08/EEC and 2006/95/EC

el

)

g

ee

d

Weig

3

S

on

)

)

†

T

.

n

s

n

g

.

g

tuat

,

d

lding

.

s

g

.

A

.

2

On/Off, Floating Point, Non-Spring Return, 24

Technical Data AMB(X)24-3(-S)(-T)

ower su

ower consumptio

ransformer sizin

lectrical connectio

verload protectio

ontro

nput impedance

Angle of rotatio

Direction of rotatio

osition indicatio

anual overrid

switc

-S models

unning tim

umidit

Ambient temperatur

torage temperature -40°F to 176°F [-40°C to 80°C]

ousin

ousing materia

ency listings

ise lev

Servicin

uality standar

ht 2.2 lbs [1000 Kg] AMB24-

24 VAC ± 20% 50/60 H

24 VDC ± 10%

2.5 W (0.5 W

5.5 VA (Class 2 power source

3 ft, 18 GA plenum rated cabl

3 ft, 18 GA appliance rated cable (1/2” conduit connecto

protected NEMA 2 (IP54

electronic throughout 0 to 95° rotation

on/off, floating poin

Ω

max. 95°, adjust. with mechanical stop

180 in-lb [20 Nm

revers

e with switc

reflective visual indicator (snap-on

external push butto

1 x SPDT, 3A (0.5A) @ 250 VA

adj. 0 to 100%, UL approved

95 seconds, constant independent of loa

5 to 95% RH non condensing (EN 60730-1

-22°F to 122°F [-30°C to 50°C

NEMA 2, IP54, UL enclosure type 2

L94-5VA

cULus acc. to UL 60730-1A/-2-14,

AN

A E60730-1:02,

E

. to 2004/1

<45dB(A

maintenance fr

ISO 9001

2.4 lbs [1050 Kg] AMB24-3-

orque min. 180 in-lb for control of damper surfaces up to 45 sq ft

Applicatio

For on/off and floating point control of dampers in HVAC systems. Actuator sizing

hould be done in accordance with the damper manufacturer’s specifications.

The actuator is mounted directly to a damper shaft up to 1.05” in diameter by means

of its universal clamp, self-centered default. A crank arm and several mounting

rackets are available for applications where the actuator cannot be direct coupled to

the damper shaft.

Operatio

The actuator is not provided with and does not require any limit switches, but is

electronically protected a

actuator will prevent lateral movement

The AM... series provides 95° of rotation and a visual indicator indicates position of the

actuator. When reaching the damper or actuator end position, the actuator

automatically stops. The

or cover.

ac

The AM...24-3… actuators use a sensorless brushless DC motor

y an Application Specific Integrated Circuit (ASIC). The ASIC monitors and controls

the actuator’s rotation and provides a digital rotation sensing (DRS) function to prevent

amage to the actuator in a stall condition. Power consumption is reduced in ho

mode

The AM...24-3-S version is provided with 1 built-in auxiliary switch. This SPDT switch

s provided for safety interfacing or signaling, for example, for fan start-up. The

witching function is adjustable 0 to 95°. The auxiliary switch is double insulated so

an electrical

round connection is not necessary

dd-on auxiliary switches or feedback potentiometers are easily fastened directly onto

the actuator body for signaling and switching functions

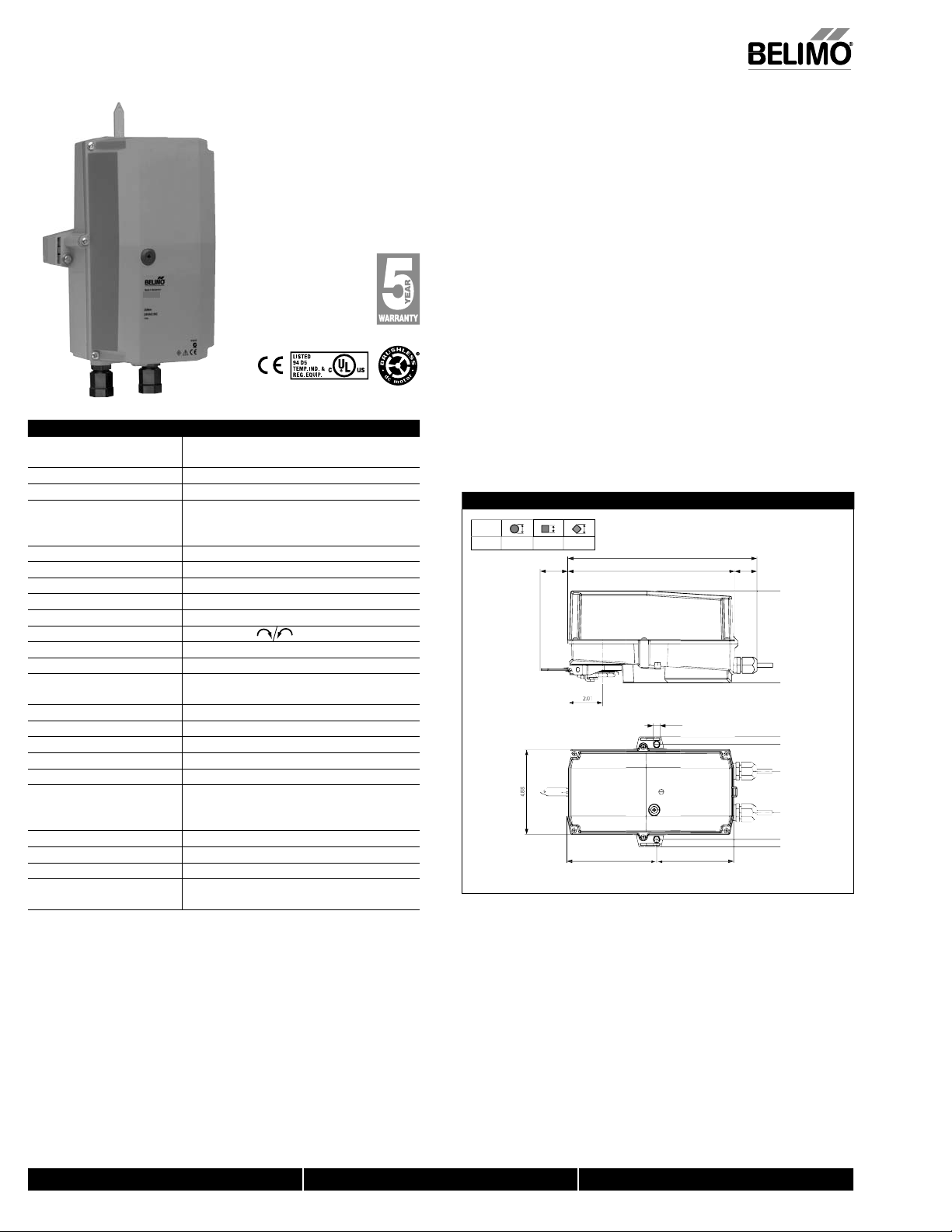

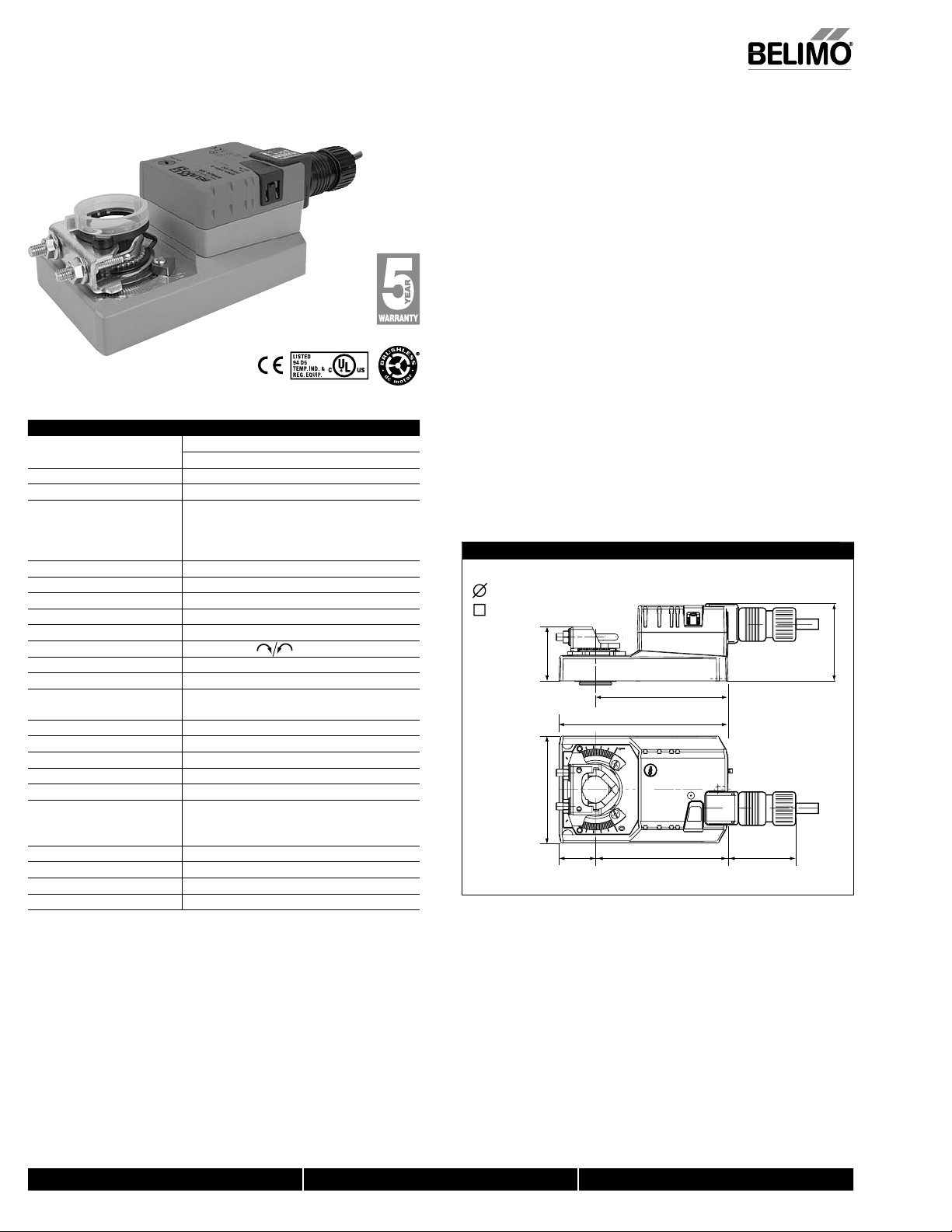

Dimensions (Inches [mm])

1/2” to 1.05” [12.7 to 26.67]

2/5” to 1.05” [10 to 26.67]

ainst overload. The anti-rotation strap supplied with the

ears can be manually disengaged with a button on the

2.2” [56]

3.46” [88]

1.18”

[30]

4.06” [103]

5.47” [139]

4.3” [109]

To center of

mounting slot.

2” [50.8]

which is controlled

2.49” [63.4]

12

AMB(X)24-3-T

lectrical connecti

screw terminal (for 26 to 14 GA wire

unprotected (NEMA 1/IP20

Rated Impulse Voltage 800V, Type of action 1, (1.B for -S version), Control Pollution Degree 3.

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

21

40024 - 05/10 - Subject to change. © Belimo Aircontrols (USA), Inc.

Page 4

214

A

MB(X)24-3(-S)(-T

)

/Off

V

1

03

4

t

AV

s

2

g

g

T

6

A

)

h

A

NOTE:

.

w

a

a

c

c

w

S

.

.

,

:

.

e

.

Live Electrical Components!

-

.

ol

l

h

j

g

(

)

n

, Floating Point, Non-Spring Return, 24

Accessories

K-SA Reversible Clamp

ZG-100 Universal Mounting Bracket

ZG-10

ZG-1

ZG-10

Z-SMA AM/SM to AM Retrofit Mounting Bracke

ZG-NMA Crank arm Adaptor Kit

8-25 Universal Shaft Extension

ZG-JSA (-1, 2,3)Jackshaft Adaptors for Hollow Jackshaft

ZS-T Terminal Cover for NEMA

ZS-100 Weather Shield - Steel

ZS-150 Weather Shield - Polycarbonate

ZS-260 Explosion Proof Housin

ZS-300 (-1) (-5)NEMA 4X Housin

ool-0

PS-100 Actuator Power Supply Simulator

S1A, S2

P370 Shaft Mount Auxiliary Switc

…

When using AM...24-3… actuators, only use accessories listed on this page

Universal Mounting Bracket

Universal Mounting Bracket

Universal Mounting Bracket

8 mm & 10 mm Wrench

Auxiliary Switch (es

eedback Potentiometers

Typical Specification

Floating point, on/off control damper actuators shall be electronic direct-coupled type,

hich require no crank arm and linkage and be capable of direct mounting to a shaft

up to 1.05” diameter. Actuators shall have brushless DC motor technology and be

protected from overload at all angles of rotation. Actuators shall have reversing switch

nd manual override on the cover. If required, actuators shall be provided with one

djustable SPDT auxiliary switch. Actuators with auxiliary switches must be

onstructed to meet the requirements for double insulation so an electrical ground is

not required to meet agency listings. If required, actuators will be provided with a

screw terminal strip for electrical connections (AMX24-3-T). Run time shall be

onstant and independent of torque. Actuators shall be cULus listed, have a 5-year

arranty, and be manufactured under ISO 9001 International Quality Control

tandards. Actuators shall be as manufactured by Belimo

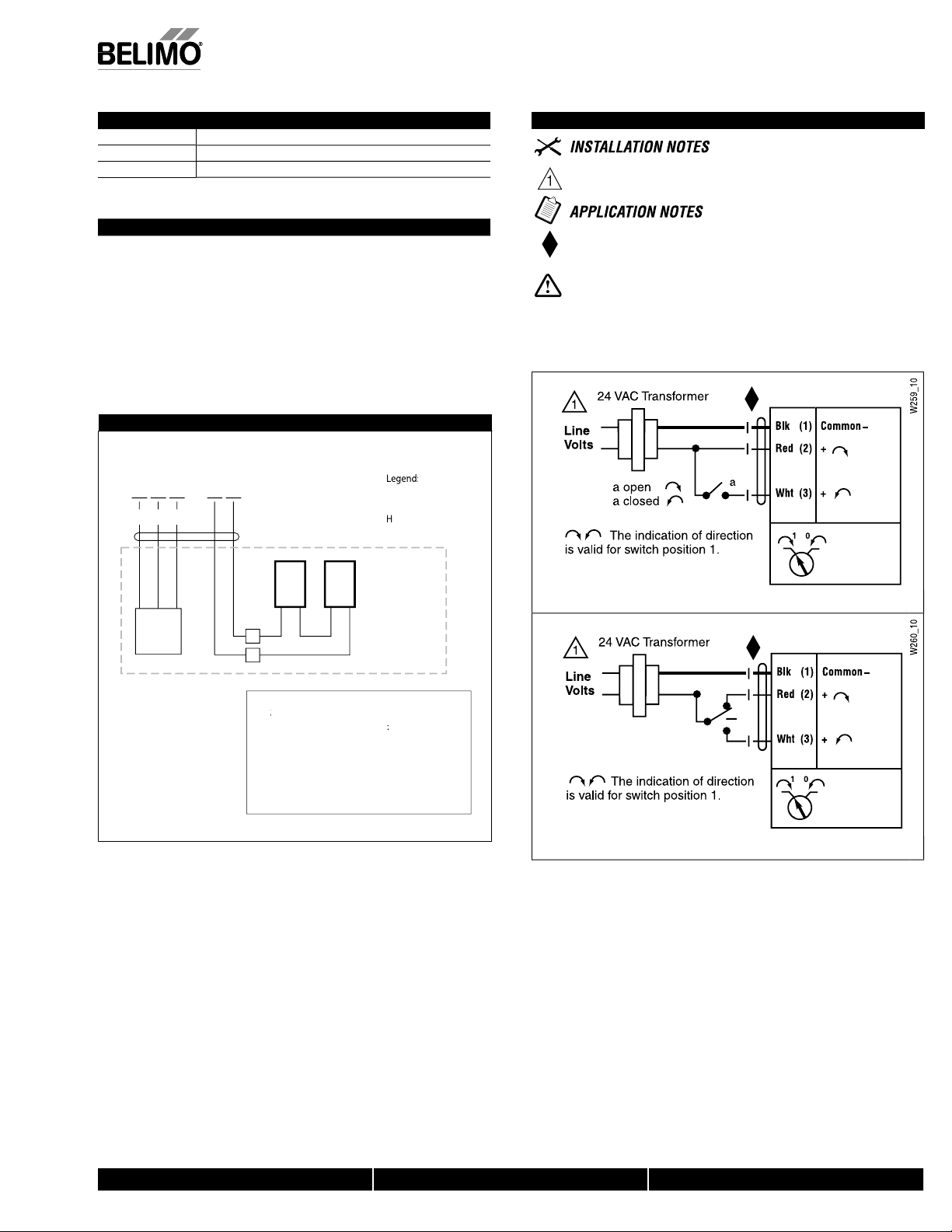

Wiring Diagrams

Provide overload protection and disconnect as required

Actuators may also be powered by 24 VDC.

For end position indication, interlock control, fan startup, etc.

AMB24-3-S incorporates one built-in auxiliary switches

1 x SPDT, 3A (0.5A) @250 VAC, UL Approved, adjustable 0 to 95

Meets cULus or UL and CSA Standard requirements without th

need of an electrical ground connection

During installation, testing, servicing and troubleshooting of this product, it may be

necessary to work with live electrical components. Have a qualifi ed licensed electrician or other

individual who has been properly trained in handling live electrical components perform these

tasks. Failure to follow all electrical safety precautions when exposed to live electrical compo

nents could result in death or serious injury

W259_08

On/Off contr

, Inc.

USA

e. © Belimo Aircontrols

ect to chan

W260_08

loating Point or On/Off contro

40024 - 05/10 - Sub

W258_08

Auxiliary Switc

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

Page 5

5

AMB

24-3-T N4,

AMB

H

V

y

z

n

T

g

n

])

n

l

t

0

Ω

n

T

e

]

on

h

n

r

e

n

e

idi

(EN

)

e

g

]

g

7

l

g

†

,

l

)

g

ee

d

Weigh

]

Kg] with h

.

n

s

T

.

n

Th

p

.

T

tuat

T

c

c

.

.

9

0.52

0.2

5.154.

/

QE

...

/M/

...

/QE/

QE

...

/

M

24-3-T N4

EMA 4X, On/Off, Floating Point Control, Non-Spring Return, Direct Coupled, 24

Torque min. 160 in-lb for control of damper surfaces up to 40 sq ft

Applicatio

For on/off and floating point control of dampers in HVAC systems. Actuator sizing

hould be done in accordance with the damper manufacturer’s specifications.

he actuator is mounted directly to a damper shaft up to ¾” in diameter by means of

ts universal clamp, self-centered default

eratio

e actuator is not provided with and does not require any limit switches, but is

electronically protected against overload. The anti-rotation strap supplied with the

actuator will

he AMB24-3-T N4 provides 95° of rotation and a visual indicator indicates position of

the actuator. When reaching the damper or actuator end position, the actuator

automatically stops. The gears can be manually disengaged with a button on the

ac

he AMB24-3-T N4 actuator uses a sensorless brushless DC motor, which is

ontrolled by an Application Specific Integrated Circuit (ASIC). The ASIC monitors and

ontrols the actuator’s rotation and provides a digital rotation sensing (DRS) function to

Technical Data AMB24-3-T N4, AMB24-3-T N4H

ower suppl

ower consumptio

ransformer sizin

lectrical connectio

verload protectio

ontro

nput impedance 60

Angle of rotatio

orqu

Direction of rotati

osition indicatio

anual overrid

unning tim

um

ty 5 to 95% RH non condensing

Ambient temperatur

e temperature -40°F to 176°F [-40°C to 80°C

Stora

ousin

ousing materia

ency listings

A

oise leve

Servicin

uality standar

t 3.3 lbs [1.5 Kg

24 VAC ± 20% 50/60 H

24 VDC ± 10%

2.5 W (0.5 W) / heater 23 W

5.5 VA (Class 2 power source) / heater 20.5 VA

screw terminal (for 26 to 14 GA wire [heater 15

GA wire

1/2” conduit connector

electronic throughout 0 to 95° rotation

on/off, floating poin

max. 95°, adjust. with mechanical stop

160 in-lb [16 Nm

reversible wit

switch

pointe

external push butto

95 seconds

constant independent of load

60730-1

-22°F to 122°F [-30°C to 50°C]

UL Type 4X, NEMA 4X, IP66/6

L94-5VA

ccULus acc. to UL 60730-1A/-2-14,

CAN/CSA E60730-1, CSA C22.2 No. 24-93

CE acc. to 89/336/EEC

<45dB(A

maintenance fr

ISO 9001

3.7 lbs [1.6

eater

revent damage to the actuator in a stall condition. Power consumption is reduced in

olding mode

Add-on auxiliary switches or feedback potentiometers are easily fastened directly onto

the actuator body for signaling and switching functions

Dimensions (Inches)

AM..N4

revent lateral movement

or cover.

.56 1.1

1

41

21

40024 - 05/10 - Subject to change. © Belimo Aircontrols (USA), Inc.

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

Page 6

216

A

EMA 4X, On

/Off

V

A

)

eedbac

s

.

w

a

c

c

.

g

.

e

.

!

fi

.

AMB24-3-T N4

On/Off

l

AMB24-3-T N4

l

3

actua

to

T

osta

t

g

oteThe f

ollo

k

en int

o account

ex

t

e

g

:

•

All

w

e

ar

be

av

oided.

•

her

e necessar

y

use cables

su

cient

actuat

o

.

j

g

(

)

MB24-3-T N4, AMB24-3-T N4H

, Floating Point Control, Non-Spring Return, Direct Coupled, 24

Accessories

PS-100 Actuator Power Supply Simulator

S1A, S2

P…A F

NOTE: When using AMB24-3… actuators, only use accessories listed on this page

Auxiliary Switch (es

k Potentiometer

Typical Specification

Floating point, on/off control damper actuators shall be electronic direct-coupled type,

hich require no crank arm and linkage and be capable of direct mounting to a shaft

up to ¾” diameter. Actuators shall have brushless DC motor technology and be

protected from overload at all angles of rotation. Actuators shall have reversing switch

nd manual override on the cover. If required, actuators needing auxiliary switches,

an be provided as an add-on accessory. Actuators with auxiliary switches must be

onstructed to meet the requirements for double insulation so an electrical ground is

not required to meet agency listings. Run time shall be constant and independent of

torque. Actuators shall be cULus listed, have a 5-year warranty, and be manufactured

under ISO 9001 International Quality Control Standards. Actuators shall be as

manufactured by Belimo

Wiring Diagrams

w

th actuator types ..-

N

1L2L3

NL

=

(°C) = Therm

= Heatin

Wiring Diagrams

rovide overload protection and disconnect as required

eets cULus or UL and CSA requirements without th

eed of an electrical ground connection

ARNINGLive Electrical Components

During installation, testing, servicing and troubleshooting of this product, it

may be necessary to work with live electrical components. Have a quali

electrician or other individual who has been properly trained in handling live electrical

components perform these tasks. Failure to follow all electrical safety precautions

when exposed to live electrical components could result in death or serious injury

ed licensed

HT

rnal wirin

en the cables or wires that

,

with

contro

, Inc.

USA

(°C)

M

1

2

N

wing points must be ta

with independent,

contact bet

e introduced and the heating element isto

W

mbers of wires, e.g. so that the heating and the

r can be supplied separately with votage

Heater wirin

e. © Belimo Aircontrols

ect to chan

40024 - 05/10 - Sub

loating Point or On/Off contro

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

Page 7

7

AMX120-3

On/Off, Floating Point, Non-Spring Return, 100 to 240 VAC

pply

)

n

)

T

g

)

n

r

)

]

n

l

t

n

Torque

]

n

ibl

h

n

e

n

e

y

)

e

]

S

C]

g

l

A

†

C

l

)

S

g

ee

d

Weig

†

3

.

n

p

n

g

.

g

tuat

y

d

lding

.

.

2

Technical Data AMX120-3

ower su

ower consumptio

ransformer sizin

lectrical connectio

verload protectio

ontro

nput impedance 600

Angle of rotatio

Direction of rotatio

osition indicatio

anual overrid

unning tim

umidit

Ambient temperatur

torage temperature -40°F to 176°F [-40°C to 80°

ousin

ousing materia

gency listings

oise leve

ervicin

uality standar

ht 2.2 lbs [1.0 Kg]

Rated Impulse Voltage 4kV, Type of action 1, Control Pollution Degree

100 to 240 VAC, 50/60 Hz (nominal

85 to 265 VAC, 50/60 Hz (tolerance)

3 W (0.6 W

7 VA (Class 2 power source

18 GA appliance rated cable

1/2” conduit connecto

protected NEMA 2 (IP54

3 ft [1m] 10 ft [3m] 16 ft [5m

electronic throughout 0 to 95° rotation

on/off, floating poin

max. 95°, adjust. with mechanical stop

180 in-lb [20 Nm

revers

e with switc

reflective visual indicator (snap-on)

external push butto

300 seconds 150 seconds 95 seconds

constant independent of load

5 to 95% RH non condensing (EN 60730-1

-22°F to 122°F [-30°C to 50°C

NEMA 2/IP54

NEMA 2, IP54, UL enclosure type 2

cULus acc. to UL 60730-1A/-2-14,

CAN/CSA E60730-1:02,

E acc. to 2004/108/EEC and 2006/95/E

<45dB(A

maintenance fr

ISO 9001

Torque min. 180 in-lb for control of damper surfaces up to 45 sq ft

Applicatio

or on/off and floating point control of dampers in HVAC systems. Actuator sizing

should be done in accordance with the damper manufacturer’s specifications.

The actuator is mounted directly to a damper shaft up to 1.05” in diameter by means

of its universal clamp, self-centered default. A crank arm and several mounting

brackets are available for applications where the actuator cannot be direct coupled to

the dam

er shaft.

Operatio

The actuator is not provided with and does not require any limit switches, but is

electronically protected a

actuator will prevent lateral movement

The AMX series provides 95° of rotation and a visual indicator indicates position of the

actuator. When reaching the damper or actuator end position, the actuator

automatically stops. The

or cover.

ac

The AMX120-3 actuators use a sensorless brushless DC motor, which is controlled b

an Application Specific Integrated Circuit (ASIC). The ASIC monitors and controls the

actuator’s rotation and provides a digital rotation sensing (DRS) function to prevent

amage to the actuator in a stall condition. Power consumption is reduced in ho

mode

Add-on auxiliary switches or feedback potentiometers are easily fastened directly onto

the actuator body for signaling and switching functions

Dimensions (Inches [mm])

1/2” to 1.05” [12.7 to 26.67]

2/5” to 1.05” [10 to 26.67]

ainst overload. The anti-rotation strap supplied with the

ears can be manually disengaged with a button on the

2.2” [56]

3.46” [88]

1.18”

[30]

4.06” [103]

5.47” [139]

4.3” [109]

To center of

mounting slot.

2” [50.8]

2.49” [63.4]

D12

21

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

40024 - 05/10 - Subject to change. © Belimo Aircontrols (USA), Inc.

Page 8

218

A

n

/Off

C

1

03

4

t

AV

s

g

Tool-06

8

S

A

)

h

NOTE:

AMX

w

a

f

.

.

!

e

.

Live Electrical Components!

.

On/Off

j

g

(

)

, Floating Point, Non-Spring Return, 100 to 240 VA

MX120-3

Accessories

K-SA Reversible Clamp

ZG-100 Universal Mounting Bracket

ZG-10

ZG-1

ZG-10

Z-SMA AM/SM to AM Retrofit Mounting Bracke

ZG-NMA Crank arm Adaptor Kit

8-25 Universal Shaft Extension

ZG-JSA (-1, 2,3)Jackshaft Adaptors for Hollow Jackshaft

ZS-100 Weather Shield - Steel

ZS-150 Weather Shield - Polycarbonate

ZS-260 Explosion Proof Housing

ZS-300 (-1) (-5)NEMA 4X Housin

PS-100 Actuator Power Supply Simulator

1A, S2

P370 Shaft Mount Auxiliary Switc

P…A Feedback Potentiometers

When using

Universal Mounting Bracket

Universal Mounting Bracket

Universal Mounting Bracket

mm & 10 mm Wrench

Auxiliary Switch (es

120-3 actuators, only use accessories listed on this page.

Typical Specification

Floating point, on/off control damper actuators shall be electronic direct-coupled type,

hich require no crank arm and linkage and be capable of direct mounting to a shaft

up to 1.05” diameter. Actuators shall have brushless DC motor technology and be

protected from overload at all angles of rotation. Actuators shall have reversing switch

nd manual override on the cover. Run time shall be constant and independent o

torque. Actuators shall be cULus listed, have a 5-year warranty, and be manufactured

under ISO 9001 International Quality Control Standards. Actuators shall be as

manufactured by Belimo

Wiring Diagrams

rovide overload protection and disconnect as required

AUTION

2

Actuators may be connected in parallel.

ower consumption and input impedance must be observed.

Meets cULus or UL and CSA Standard requirements without th

eed of an electrical ground connection

During installation, testing, servicing and troubleshooting of this product, it may be

ecessary to work with live electrical components. Have a qualifi ed licensed electrician or other

ndividual who has been properly trained in handling live electrical components perform these

tasks. Failure to follow all electrical safety precautions when exposed to live electrical compo-

ents could result in death or serious injury

quipment Damage

control

, Inc.

USA

e. © Belimo Aircontrols

ect to chan

Floating Point or On/Off control

40024 - 05/10 - Sub

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

Page 9

9

AMB(X)

24-SR(-T)

.

n

p

.

li

.

n

g

ill p

.

h

(X)

d

g

.

.

2

y

z

n

W)

T

g

)

n

e

r

)

]

n

A

Ω

)

n

Torque

]

n

s

ch

:

)

)

n

)

ide

n

e

p

)

Ambi

e

S

C]

g

l

g

†

/CS

acc

08/EEC and 2006/95/EC

l

dB(A)

S

g

ee

d

Weig

g]

n

)

†

.

Proportional, Non-Spring Return, 24 V, for 2 to 10 VDC or 4 to 20 mA

Technical Data AMB(X)24-SR(-T)

ower suppl

ower consumptio

ransformer sizin

lectrical connectio

verload protectio

perating range Y 2 to 10 VDC, 4 to 20 m

nput impedance 100 kΩ (0.1 mA), 500

eedback output U 2 to 10 VDC (max 0.5 mA

Angle of rotatio

Direction of rotatio

osition indicatio

anual overr

unning tim

umidity 5 to 95% RH non condensing (EN 60730-1

ent temperatur

torage temperature -40°F to 176°F [-40°C to 80°

ousin

ousing materia

ency listings

A

oise leve

ervicin

uality standar

ht 2.2 lbs [1000 K

AMB(X)24-SR-T

ectrical connectio

Rated Impulse Voltage 800V, Type of action 1, Control Pollution Degree 3

24 VAC ± 20% 50/60 H

24 VDC ± 10%

2.5 W (0.4

5 VA (Class 2 power source

18 GA plenum rated cabl

1/2” conduit connecto

protected NEMA 2 (IP54

3 ft [1m] 10 ft [3m] 16 ft [5m

electronic throughout 0 to 95° rotation

max. 95°, adjust. with mechanical stop

180 in-lb [20 Nm

reversible with

wit

actuator will move

=CCW with decreasing control signal (10 to 2V

=CW with decreasing control signal (10 to 2V

reflective visual indicator (snap-on

external push butto

300 seconds 150 seconds 95 seconds

constant inde

endent of load

-22°F to 122°F [-30°C to 50°C]

NEMA 2, IP54, UL enclosure type 2

UL94-5VA

cULus acc. to UL 60730-1A/-2-14,

AN

A E60730-1:02,

E

. to 2004/1

<45

maintenance fr

ISO 9001

screw terminal (for 26 to 14 GA wire)

unprotected (NEMA 1/IP20

Torque min. 180 in-lb for control of damper surfaces up to 45 sq ft

Applicatio

or proportional modulation of dampers in HVAC systems. Actuator sizing should be

done in accordance with the damper manufacturer’s specifications.

The actuator is mounted directly to a damper shaft up to 1.05” in diameter by means

of its universal clamp, 1/2” self-centered default. A crank arm and several mounting

brackets are available for applications where the actuator cannot be direct coupled to

the dam

er shaft

The actuator operates in response to a 2 to 10 VDC, or with the addition of a

500

resistor, a 4 to 20 mA control input from an electronic controller or positioner.

A 2 to 10 VDC feedback signal is provided for position indication or master-slave

app

cations

Operatio

The actuator is not provided with and does not require any limit switches, but is

electronically protected a

actuator w

revent lateral movement

The AMB(X) series provides 95° of rotation and a visual indicator indicates position of

e actuator. When reaching the damper or actuator end position, the actuator

t

automatically stops. The gears can be manually disengaged with a button on the

actuator cover.

The AMB

24-SR… actuators use a sensorless brushless DC motor, which is

controlled by an Application Specific Integrated Circuit (ASIC). The ASIC monitors and

controls the actuator’s rotation and provides a digital rotation sensing (DRS) function to

prevent

amage to the actuator in a stall condition. Power consumption is reduced in

mode

holdin

Add-on auxiliary switches or feedback potentiometers are easily fastened directly onto

the actuator body for signaling and switching functions

Dimensions (Inches [mm])

1/2” to 1.05” [12.7 to 26.67]

2/5” to 1.05” [10 to 26.67]

ainst overload. The anti-rotation strap supplied with the

2.2” [56]

4.06” [103]

5.47” [139]

3.46” [88]

1.18”

[30]

4.3” [109]

To center of

mounting slot.

2” [50.8]

2.49” [63.4]

12

40024 - 05/10 - Subject to change. © Belimo Aircontrols (USA), Inc.

21

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

Page 10

220

A

MB(X)24-SR(-T)

SA

0

t

t

03

t

t

A

A

t

A

AV

5

n

s

T

2

0

l

0

e

0

g

g

6

S

A

A

)

0

S

A

s

NEMA

g

SG

g

0

0

e

A

n

S

le

0

r

.

h

t

g

s

s

f

.

.

!

.

o

.

Live Electrical Components!

f

.

_

8

_

4 to

ol

j

g

(

)

Proportional, Non-Spring Return, 24 V, for 2 to 10 VDC or 4 to 20 mA

Accessories

ZG-10

ZG-101 Universal Mounting Bracke

ZG-1

ZG-104 Universal Mounting Bracke

Z-SM

ZG-NM

8-2

ZG-JSA (-1, 2, 3)Jackshaft Adaptors for Hollow Jackshaft

ZSZS-10

ZS-15

ZS-26

ZS-300 (-1) (-5)NEMA 4X Housin

Tool-0

1A, S2

37

…

SGA24

F24 Min positioners for flush panel mountin

TA-25

RM-10

ADS-100

ZG-R01 Resistor for 4 to 20 mA Conversio

V24 U

ZG-X4

NOTE: When using AMB(X)24-SR… actuators, only use accessories listed on this page

Reversible Clamp

niversal Mounting Bracke

Universal Mounting Bracke

M/SM to AM Retrofit Mounting Bracke

rank arm Adaptor Kit

Universal Shaft Extensio

Terminal Cover NEMA

Weather Shield - Stee

Weather Shield - Polycarbonat

Explosion Proof Housin

8 mm & 10 mm Wrench

uxiliary Switch (es

haft Mount Auxiliary Switch

Feedback Potentiometer

n positioners in

4 housin

Pulse Width Modulation Interface

Input Rescaling Modul

nalog to Digital Switch

attery Back-Up Modu

Transforme

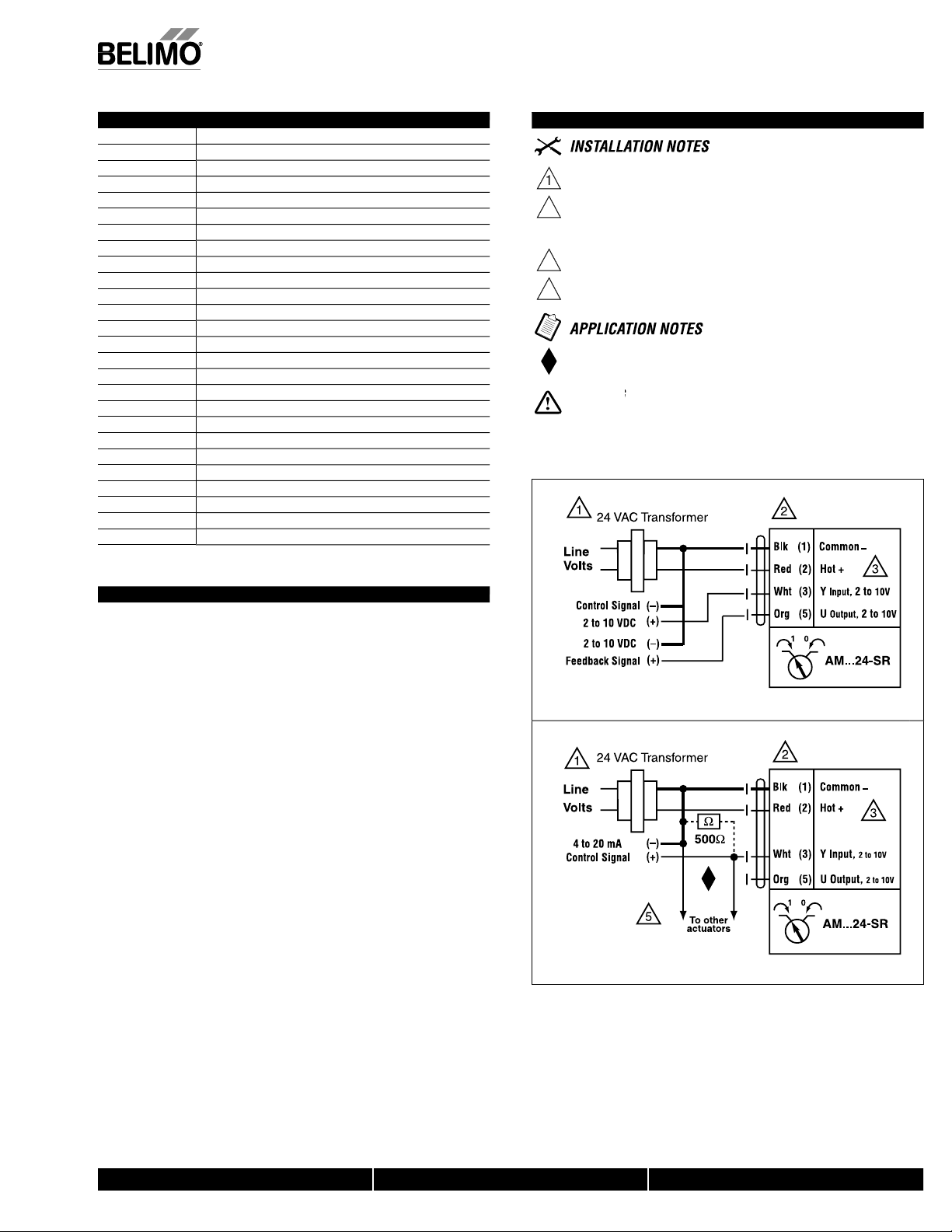

Wiring Diagrams

rovide overload protection and disconnect as required

AUTION

2

Actuators may be connected in parallel.

ower consumption and input impedance must be observed.

Actuators may also be powered by 24 VDC.

nly connect common to neg. (–) leg of control circuits

The ZG-R01 500

2 to 10 VDC, up to 2 actuators may be connected in parallel

During installation, testing, servicing and troubleshooting of this product, it may be

ecessary to work with live electrical components. Have a qualifi ed licensed electrician or other

ndividual who has been properly trained in handling live electrical components perform these

tasks. Failure to

ents could result in death or serious injury

quipment Damage

resistor converts the 4 to 20 mA control signal t

ollow all electrical safety precautions when exposed to live electrical compo-

0

W257

Typical Specification

roportional control damper actuators shall be electronic direct-coupled type, whic

require no crank arm and linkage and be capable of direct mounting to a shaft up to

1.05” diameter. Actuators must provide proportional damper control in response to a 2

o 10 VDC or, with the addition of a 500 Ωresistor, a 4 to 20 mA control input from an

electronic controller or positioner. Actuators shall have brushless DC motor technology

and be protected from overload at all angles of rotation. Actuators shall have reversin

witch and manual override on the cover. If required, actuator will be provided with

, Inc.

crew terminal strip for electrical connections (AMX24-SR-T). Run time shall be

USA

constant and independent of torque. A 2 to 10 VDC feedback signal shall be provided

or position indication. Actuators shall be cULus listed, have a 5-year warranty, and be

anufactured under ISO 9001 International Quality Control Standards. Actuators shall

be as manufactured by Belimo

e. © Belimo Aircontrols

ect to chan

40024 - 05/10 - Sub

2 to 10 VDC control

08

W257

20 mA contr

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

Page 11

1

A

MB24-SR-T N4, AMB24-SR-T N4H

z

n

T

g

A

on

])

r

n

A

0

Ω

)

n

T

e

n

h

s

n

r

de

n

e

d

y

)

Ambi

e

g

7

l

g

†

,

,

C

el

)

S

g

ee

d

Weig

g]

†

.

T

.

n

T

T

0

a

.

n

Th

el

a

.

T

o

a

actuat

T

c

c

.

A

t

.561.10

8

AM..N4

QE

...

/M/

...

/QE/

QE

...

NEMA 4X, Proportional Control, Non-Spring Return, Direct Coupled, 24V, for 2 to 10 VDC and 4 to 20 mA

orque min. 160 in-lb for control of damper surfaces up to 40 sq ft

Applicatio

or proportional modulation of dampers in HVAC systems. Actuator sizing should be

done in accordance with the damper manufacturer’s specifications.

he actuator is mounted directly to a damper shaft up to ¾” in diameter by means of

ts universal clamp.

he actuator operates in response to a 2 to 10 VDC, or with the addition of a 50

esistor, a 4 to 20 mA control input from an electronic controller or positioner. A 2 to

0 VDC feedback signal is provided for position indication or master-slave

pplications

peratio

e actuator is not provided with and does not require any limit switches, but is

ectronically protected against overload. The anti-rotation strap supplied with the

ctuator will prevent lateral movement

he AMB24-SR-T N4 provides 95° of rotation and a visual indicator indicates position

f the actuator. When reaching the damper or actuator end position, the actuator

utomatically stops. The gears can be manually disengaged with a button on the

Technical Data AMB24-SR-T N4, AMB24-SR-T N4H

ower supply 24 VAC ± 20% 50/60 H

ower consumptio

ransformer sizin

lectrical connecti

verload protectio

perating range Y 2 to 10 VDC, 4 to 20 m

nput impedance 100 kΩ (0.1 mA), 50

eedback output U 2 to 10 VDC (max 0.5 mA

Angle of rotatio

orqu

Direction of rotatio

osition indicatio

nual overri

unning tim

umidit

ent temperatur

Storage temperature -40°F to 176°F [-40°C to 80°C]

ousin

ousing materia

ency listings

A

ise lev

ervicin

uality standar

ht 3.3 lbs [1.5 K

Rated Impulse Voltage 800V, Type of action 1, Control Pollution Degree 3

24 VDC ± 10%

2.5 W (0.4 W) / heater 23 W

5 VA (Class 2 power source) / heater 20 V

screw terminal (for 26 to 14 GA wire [heater 15

GA wire

1/2” conduit connecto

electronic throughout 0 to 95° rotation

max. 95°, adjust. with mechanical stop

160 in-lb [16 Nm]

reversible wit

witch

pointe

external push butto

95 seconds, constant independent of loa

5 to 95% RH non condensing (EN 60730-1

-22°F to 122°F [-30°C to 50°C]

UL type 4X, NEMA 4X, IP66/6

L94-5VA

cULus acc. to UL 60730-1A/-2-14

CAN/CSA E60730-1, CSA C22.2 No. 24-93

E acc. to 89/336/EE

<45dB(A

maintenance fr

ISO 9001

3.7 lbs [1.6 Kg] with heater

or cover.

he AMBX24-SR-T N4 actuator uses a sensorless brushless DC motor, which is

ontrolled by an Application Specific Integrated Circuit (ASIC). The ASIC monitors and

ontrols the actuator’s rotation and provides a digital rotation sensing (DRS) function to

revent damage to the actuator in a stall condition. Power consumption is reduced in

olding mode

dd-on auxiliary switches or feedback potentiometers are easily fastened directly onto

he actuator body for signaling and switching functions.

Dimensions (Inches [mm])

/

4.

9

40024 - 05/10 - Subject to change. © Belimo Aircontrols (USA), Inc.

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

22

Page 12

222

A

MX24-SR-T N4, AMX24-SR-T N4H

S

A

A

s

SG

g

SG

g

50

odulatio

face

0

le

00

A

on

S

e

0

r

h

g

s

A

A

.

g

!

3

.

0

Ω

o

.

!

-

t

comp

w

.

AMB24-SR-T N4

AMB24-SR-T N4

4

l

actua

to

T (°C)

osta

t

g

te

The f

ollo

k

en int

o account

ex

t

e

g

:

tact betw

een the cables o

r

es that

ar

e

to

be avoided.•Where necessar

y

use cables

su

cientnumbers o

actuat

o

t

el

.

F

T

j

g

(

)

EMA 4X, Proportional Control, Non-Spring Return, Direct Coupled, 24V, for 2 to 10 VDC and 4 to 20 mA

Accessories

1A, S2

…

A24 Min positioners for surface mountin

F24 Min positioners for flush panel mountin

TA-2

-10

ADS-1

ZG-R01 Resistor for 4 to 20 mA Conversi

SV24 U

ZG-X4

uxiliary Switch (es)

Feedback Potentiometer

Pulse Width M

nput Rescaling Modu

nalog to Digital Switch

Battery Back-Up Modul

Transforme

n Inter

Typical Specification

roportional control damper actuators shall be electronic direct-coupled type, whic

require no crank arm and linkage and be capable of direct mounting to a shaft up to

¾” diameter. Actuators must provide proportional damper control in response to a 2 to

10 VDC or, with the addition of a 500 Ω resistor, a 4 to 20 mA control input from an

electronic controller or positioner. Actuators shall have brushless DC motor technology

and be protected from overload at all angles of rotation. Actuators shall have reversin

witch and manual override on the cover. Run time shall be constant and independent

of torque. A 2 to 10 VDC feedback signal shall be provided for position indication.

ctuators shall be cULus listed, have a 5-year warranty, and be manufactured under

SO 9001 International Quality Control Standards. Actuators shall be as manufactured

by Belimo

Wiring Diagram

ith actuator types ..-SR or M

T

N

1L23512

NL

egend:

=

= Therm

= Heatin

Wiring Diagram

rovide overload protection and disconnect as required.

AUTION

2

Actuators may be connected in parallel.

quipment damage

ower consumption and input impedance must be observed.

Actuators may also be powered by 24 VDC.

nly connect common to neg. (–) leg of control circuits

The ZG-R01 50

esistor converts the 4 to 20 mA control signal t

2 to 10 VDC, up to 2 actuators may be connected in parallel

ARNINGive Electrical Components

uring installation, testing, servicing and troubleshooting of this product, it may be

ecessary to work with live electrical components. Have a qualified licensed elec

rician or other individual who has been properly trained in handling live electrical

onents perform these tasks. Failure to follow all electrical safety precautions

hen exposed to live electrical components could result in death or serious injury

T

,

H

2 to 10 VDC control

rnal wirin

r wi

with

y with votage

, Inc.

USA

e. © Belimo Aircontrols

ect to chan

(°C)

M

1

2

wing points must be ta

with independent,

• All con

introduced and the heating element is

f wires, e.g. so that the heating and the

r can be supplied separa

Heater wirin

40024 - 05/10 - Sub

to 20 mA contro

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

Page 13

3

A

MX120-

SR

A

)

n

)

T

g

)

n

r

)

]

n

A

Ω

)

n

T

e

]

n

ibl

h

h

:

)

)

on

de

n

e

)

e

]

S

g

l

Ag

†

,

C

el

)

S

g

ee

d

900

W

†

.

.

n

p

.

li

.

n

g

ill p

.

Wh

S

d

lding

.

.

2

Proportional, Non-Spring Return, 100 to 240 VAC, for 2 to 10 VDC or 4 to 20 m

Torque min. 180 in-lb for control of damper surfaces up to 45 sq ft

Applicatio

or proportional modulation of dampers in HVAC systems. Actuator sizing should be

done in accordance with the damper manufacturer’s specifications.

The actuator is mounted directly to a damper shaft up to 1.05” in diameter by means

of its universal clamp, 1/2” self-centered default. A crank arm and several mounting

brackets are available for applications where the actuator cannot be direct coupled to

the dam

The actuator operates in response to a 2 to 10 VDC, or with the addition of a

500

A 2 to 10 VDC feedback signal is provided for position indication or master-slave

app

cations

Operatio

The actuator is not provided with and does not require any limit switches, but is

electronically protected a

actuator w

The AMX series provides 95° of rotation and a visual indicator indicates position of the

actuator.

automatically stops. The gears can be manually disengaged with a button on the

actuator cover.

The AMX120-SR actuators use a sensorless brushless DC motor, which is controlled

by an Application

Technical Data AMX120-SR

ower supply 100 to 240 VAC, 50/60 Hz (nominal

85 to 265 VAC, 50/60 Hz (tolerance)

ower consumptio

ransformer sizin

lectrical connectio

verload protectio

perating range Y 2 to 10 VDC, 4 to 20 m

nput impedance 100 kΩ (0.1 mA), 500

eedback output U 2 to 10 VDC (max 0.5 mA

Angle of rotatio

orqu

Direction of rotatio

ition indicati

nual overri

unning tim

umidity 5 to 95% RH non condensing (EN 60730-1

Ambient temperatur

torage temperature -40°F to 176°F [-40°C to 80°C]

ousin

ousing materia

ency listings

ise lev

ervicin

uality standar

eight 2.2 lbs [1.0 Kg]

Rated Impulse Voltage 4kV, Type of action 1, Control Pollution Degree 3

4 W (1 W

7.5 VA (Class 2 power source

18 GA appliance rated cable

1/2” conduit connecto

protected NEMA 2 (IP54

3 ft [1m] 10 ft [3m] 16 ft [5m

electronic throughout 0 to 95° rotation

max. 95°, adjust. with mechanical stop

180 in-lb [20 Nm

revers

e wit

actuator will move

=CCW with decreasing control signal (10 to 2V

=CW with decreasing control signal (10 to 2V

reflective visual indicator (snap-on)

external push butto

300 seconds 150 seconds 95 seconds

constant independent of load

-22°F to 122°F [-30°C to 50°C

2, IP54, UL enclosure type 2

L94-5VA

cULus acc. to UL 60730-1A/-2-14,

CAN/CSA E60730-1:02

E acc. to 2004/108/EEC and 2006/95/E

<45dB(A

maintenance fr

ISO

1

switc

actuator’s rotation and provides a digital rotation sensing (DRS) function to prevent

amage to the actuator in a stall condition. Power consumption is reduced in ho

mode

Add-on auxiliary switches or feedback potentiometers are easily fastened directly onto

the actuator body for signaling and switching functions

Dimensions (Inches [mm])

er shaft

resistor, a 4 to 20 mA control input from an electronic controller or positioner.

ainst overload. The anti-rotation strap supplied with the

revent lateral movement

en reaching the damper or actuator end position, the actuator

pecific Integrated Circuit (ASIC). The ASIC monitors and controls the

143_

40024 - 05/10 - Subject to change. © Belimo Aircontrols (USA), Inc.

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

22

Page 14

224

A

MX120-

SR

A

1

03

4

t

AV

s

g

Tool-06

8

A

)

S

h

g

4

g

50

odulatio

ace

0

A

1

r

NOTE:

a

g

o

A

A

.

.

!

.

e

.

o

.

Live Electrical Components!

.

_

l

j

g

(

)

roportional, Non-Spring Return, 100 to 240 VAC, for 2 to 10 VDC or 4 to 20 m

Accessories

K-SA Reversible Clamp

ZG-100

ZG-10

ZG-1

ZG-10

Z-SMA AM/SM to AM Retrofit Mounting Bracke

ZG-NMA Crank arm Adaptor Kit

8-25 Universal Shaft Extension

ZG-JSA (-1, 2, 3)Jackshaft Adaptors for Hollow Jackshaft

ZS-100 Weather Shield - Steel

ZS-150 Weather Shield - Polycarbonate

ZS-260 Explosion Proof Housing

ZS-300 (-1) (-5)NEMA 4X Housin

S1A, S2

370

P…A Feedback Potentiometers

SGA24 Min positioners in NEMA 4 housin

SGF2

PTA-2

IRM-10

DS-100 Analog to Digital Switch

ZG-R0

NSV24 US

ZG-X40 Transforme

When using AMX120-SR actuators, only use accessories listed on this page.

niversal Mounting Bracket

Universal Mounting Bracket

Universal Mounting Bracket

Universal Mounting Bracket

mm & 10 mm Wrench

Auxiliary Switch (es

haft Mount Auxiliary Switc

Min positioners for flush panel mountin

Pulse Width M

Input Rescaling Module

Resistor for 4 to 20 mA Conversion

attery Back-Up Module

n Interf

Wiring Diagram

rovide overload protection and disconnect as required

AUTION

2

Actuators may be connected in parallel.

ower consumption and input impedance must be observed.

Only connect common to neg. (–) leg of control circuits

Meets cULus or UL and CSA Standard requirements without th

eed of an electrical ground connection

The ZG-R01 500

2 to 10 VDC, up to 2 actuators may be connected in parallel

During installation, testing, servicing and troubleshooting of this product, it may be

ecessary to work with live electrical components. Have a qualifi ed licensed electrician or other

ndividual who has been properly trained in handling live electrical components perform these

tasks. Failure to follow all electrical safety precautions when exposed to live electrical compo-

ents could result in death or serious injury

quipment Damage

resistor converts the 4 to 20 mA control signal t

08

W374

Typical Specification

roportional control damper actuators shall be electronic direct-coupled type, which

require no crank arm and linkage and be capable of direct mounting to a shaft up to

.05” diameter. Actuators must provide proportional damper control in response to a 2

to 10 VDC or, with the addition of a 500Ω resistor, a 4 to 20 mA control input from an

electronic controller or positioner. Actuators shall have brushless DC motor technology

nd be protected from overload at all angles of rotation. Actuators shall have reversin

switch and manual override on the cover. Run time shall be constant and independent

f torque. A 2 to 10 VDC feedback signal shall be provided for position indication.

, Inc.

ctuators shall be cULus listed, have a 5-year warranty, and be manufactured under

ISO 9001 International Quality Control Standards. Actuators shall be as manufactured

USA

by Belimo

2 to 10 VDC or 4 to 20 mA contro

e. © Belimo Aircontrols

ect to chan

40024 - 05/10 - Sub

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

Page 15

5

50/60 Hz

n

T

g

)

n

e

r

)

]

n

)

)

Ω

)

x

f

n

y

e

Torque

]

on

s

ch

n

)

de

n

e

(

)

idity

(EN

)

Ambi

e

C]

]

g

l

g

†

C

el

)

g

ee

d

900

Weigh

kg]

†

.

AMB(X)

24-

MFT

®

.

n

p

.

C

so

e.

n

l

p

.

f

(X)

g

g

g

.

.

1.18" [30]

]

03]

]

]

6

88]

9

63

2

8]

3

Proportional, Non-Spring Return, 24 V, Multi-Function Technology

Technical Data AMB(X)24-MFT

ower supply 24 VAC ± 20%

ower consumptio

ransformer sizin

lectrical connectio

verload protectio

perating range Y 2 to 10 VDC, 4 to 20 mA (default

nput impedance 100 kΩ (0.1 mA), 500

eedback output U 2 to 10 VDC, 0.5 mA ma

rotatio

Angle o

Direction of rotati

osition indicatio

nual overri

unning tim

um

ent temperatur

Storage temperature -40°F to 176°F [-40°C to 80°C

ousin

ousing materia

ency listings

A

ise lev

Servicin

uality standar

t 2.6 lbs [1.2

Rated Impulse Voltage 800V, Type of action 1, Control Pollution Degree 3

24 VDC ± 10%

3.5 W (1.3 W)

6 VA (Class 2 power source

18 GA plenum rated cabl

1/2” conduit connecto

protected NEMA 2 (IP54

3 ft [1m] 10 ft [3m] 16 ft [5m

electronic throughout 0 to 95° rotation

variable (VDC, PWM, floating point, on/off

1500 W (PWM, floating point, on/off

VDC variable

max. 95°, adjustable with mechanical stop

electronicall

variabl

180 in-lb [20 Nm

reversible with

wit

reflective visual indicator (snap-on

external push butto

150 seconds (default)

variable

90 to 350 seconds

5 to 95% RH non condensing

60730-1

-22°F to 122°F [-30°C to 50°

NEMA 2, IP54, UL enclosure type 2

L94-5VA

cULus acc. to UL 60730-1A/-2-14,

CAN/CSA E60730-1:02,

E acc. to 2004/108/EEC and 2006/95/E

<45dB(A

maintenance fr

ISO

1

Torque min. 180 in-lb for control of damper surfaces up to 45 sq ft

Applicatio

or proportional modulation of dampers in HVAC systems. Actuator sizing should be

done in accordance with the damper manufacturer’s specifications.

The actuator is mounted directly to a damper shaft up to 1.05” in diameter by means

of its universal clamp, 1/2” self-centered default. A crank arm and several mounting

brackets are available for applications where the actuator cannot be direct coupled to

the dam

er shaft

The default parameters for 2 to 10 VDC applications of the …MFT actuator are

assigned during manufacturing. If necessary, custom versions of the actuators can be

ordered. The parameters can be changed by two means: pre-set and custom

configurations from Belimo or on-site configurations using the Belimo P

-Tool

ftwar

Operatio

The actuator is not provided with and does not require any limit switches, but is

ectronically protected against overload. The anti-rotation strap supplied with the

e

actuator will

The AMB(X) series provides 95° of rotation and a visual indicator indicates position o

the actuator. When reaching the damper or actuator end position, the actuator

automatically stops. The gears can be manually disengaged with a button on the

actuator cover.

The AMB

Application Specific Integrated Circuit (ASIC). The ASIC monitors and controls the

actuator’s rotation and provides a di

dama

mode

Add-on auxiliary switches or feedback potentiometers are easily fastened directly onto

the actuator body for signaling and switching functions

Dimensions (Inches [mm])

revent lateral movement

24-MFT actuators use a brushless DC motor, which is controlled by an

ital rotation sensing (DRS) function to prevent

e to the actuator in a stall condition. Power consumption is reduced in holdin

1/2” to 1.05” [12.7 to 26.67]

2/5” to 1.05” [10 to 26.67]

.4]

" [

.4

4.06" [1

4.3" [109

5.2" [131

" [

.4

8.3" [211

" [50.

D14

40024 - 05/10 - Subject to change. © Belimo Aircontrols (USA), Inc.

22

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

Page 16

226

SA

0

t

t

03

t

t

A

A

t

A

AV

5

n

s

0

l

0

e

0

g

06

8

A

A

0

S

s

g

00

A

n

S

e

0

r

AMB(X)

MFT

.

t

s

.

d.

!

A

shaf

eedback cannot be used

.

T

)

.

8

osures

acs.

.

9

.

The ZG-R01 500

.

Live Electrical Components!

fi

g

-

.

8

V

A

On/Off control

8

l

A

MB(X)24-MFT

®

j

g

(

)

roportional, Non-Spring Return, 24 V, Multi-Function Technology

Accessories

ZG-10

ZG-101 Universal Mounting Bracke

ZG-1

ZG-104 Universal Mounting Bracke

Z-SM

ZG-AM

8-2

ZG-JSA (-1, 2, 3)Jackshaft Adaptors for Hollow Jackshaft

ZS-10

ZS-15

ZS-26

ZS-300 (-1) (-5)NEMA 4X Housin

ToolS1A, S2

37

…

SGA24 Min positioners in NEMA 4 housing

SGF24 Min positioners for flush panel mountin

ADS-1

ZG-R01 Resistor for 4 to 20 mA Conversio

SV24 U

ZG-X4

NOTE: When using

Reversible Clamp

niversal Mounting Bracke

Universal Mounting Bracke

M/SM to AM Retrofit Mounting Bracke

rank arm Adaptor Kit

Universal Shaft Extensio

Weather Shield - Stee

Weather Shield - Polycarbonat

Explosion Proof Housing

mm & 10 mm Wrench

uxiliary Switch (es)

haft Mount Auxiliary Switch

Feedback Potentiometer

nalog to Digital Switch

Battery Back-Up Modul

Transforme

24-

… actuators, only use accessories listed on this page

Typical Specification

roportional control damper actuators shall be electronic direct-coupled type, which

require no crank arm and linkage and be capable of direct mounting to a shaft up to

1.05” diameter. Actuators must provide proportional damper control in response to a 2

o 10 VDC or, with the addition of a 500 Ωresistor, a 4 to 20 mA control input from an

electronic controller or positioner. Actuators shall have brushless DC motor technology

and be protected from overload at all angles of rotation. Actuators shall have reversing

witch and manual override on the cover. Run time shall be constant and independent

of torque. Actuators shall be cULus listed, have a 5-year warranty, and be

anufactured under ISO 9001 International Quality Control Standards. Actuators shall

be as manufactured by Belimo

, Inc.

USA

Wiring Diagrams

During installation, testing, servicing and troubleshooting of this product, it may be

necessary to work with live electrical components. Have a quali

individual who has been properly trained in handlin

tasks. Failure to follow all electrical safety precautions when exposed to live electrical compo

nents could result in death or serious injury

live electrical components perform these

ed licensed electrician or other

DC/4-20 m

W399_0

W399_08

W399_08

rovide overload protection and disconnect as require

e. © Belimo Aircontrols

ect to chan

AUTION Equipment Damage

ctuators may be connected in parallel if not mechanically mounted to the same

Actuators may also be powered by 24 VDC.

he actuator internal common reference is not compatible.

Control signal may be pulsed from either the Hot (source

or the Common (sink) 24 VAC line

40024 - 05/10 - Sub

ntact cl

A & B should both be closed for triac source and open for triac sink

or triac sink the common connection from the actuator

ust be connected to the hot connection of the controller

t. Power consumption and input impedance must be observed.

ition f

with Triac sink controller

A & B also can be tri

resistor may be used

loating Point contro

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

W399_0

Page 17

7

AMX

24-

MFT-T N

AMX

MFT-T N4H

®

y

z

0%

n

T

g

A

on

])

n

)

)

0

Ω

00

Ω

)

x

g

n

y

e

T

e

]

n

h

h

n

r

ide

n

e

)

)

y

)

e

]

]

g

7

l

Ag

†

,

C

el

dB(A)

S

g

d

900

Weigh

kg]

†

.

.

n

.

so

e.

n

Th

p

.

actuator cove

g

.

.

.561.101.5

2.0

5.15

4.41

4

/

QE

...

/M/

...

/QE/

QE

...

/

M

4,

24-

NEMA 4X, Proportional Control, Non-Spring Return, Direct Coupled, 24V, Multi-Function Technology

Torque min. 160 in-lb for control of damper surfaces up to 40 sq ft

Applicatio

or proportional modulation of dampers in HVAC systems. Actuator sizing should be

done in accordance with the damper manufacturer’s specifications.

The actuator is mounted directly to a damper shaft up to ¾” in diameter by means of

its universal clamp

The default parameters for 2 to 10 VDC applications of the …MFT actuator are

assigned during manufacturing. If necessary, custom versions of the actuators can be

ordered. The parameters can be changed by two means: pre-set and custom

configurations from Belimo or on-site configurations using the Belimo PC-Tool

ftwar

Operatio

e actuator is not provided with and does not require any limit switches, but is

electronically protected against overload. The anti-rotation strap supplied with the

Technical Data AMX24-MFT-T N4, AMX24-MFT-T N4H

ower suppl

ower consumptio

ransformer sizin

lectrical connecti

verload protectio

perating range Y 2 to 10 VDC, 4 to 20 mA (default

nput impedance 100 kΩ (0.1 mA), 50

eedback output U 2 to 10 VDC, 0.5 mA ma

le of rotatio

An

orqu

Direction of rotatio

osition indicatio

anual overr

unning tim

umidit

Ambient temperatur

Storage temperature -40°F to 176°F [-40°C to 80°C

ousin

ousing materia

ency listings

lev

ervicin

uality standar

t 3.7 lbs [1.6

Rated Impulse Voltage 800V, Type of action 1, Control Pollution Degree 3

24 VAC ± 20% 50/60 H

24 VDC ± 1

3.5 W (1.25 W) / heater 24 W

6 VA (Class 2 power source) / heater 21 V

screw terminal (for 26 to 14 GA wire [heater 15

GA wire

1/2” conduit connector

electronic throughout 0 to 95° rotation

variable (VDC, PWM, floating point, on/off

5

PWM, floating point, on/off

VDC variable

max. 95°, adjustable with mechanical stop

electronicall

variabl

160 in-lb [16 Nm

reversible wit

switc

pointe

external push butto

150 seconds (default

variable (90 to 300 secondss

5 to 95% RH non condensing (EN 60730-1

-22°F to 122°F [-30°C to 50°C

UL type 4X, NEMA 4X, IP66/6

L94-5VA

cULus acc. to UL 60730-1A/-2-14,

CAN/CSA E60730-1, CSA C22.2 No. 24-93

E acc. to 89/336/EE

<45

maintenance free

ISO

1

4.1 lbs [1.8 kg] with heater

actuator will

The AMX24-MFT-T N4 provides 95° of rotation and a visual indicator indicates position

of the actuator. When reaching the damper or actuator end position, the actuator

automatically stops. The gears can be manually disengaged with a button on the

The AMX24-MFT-T N4 actuator uses a brushless DC motor, which is controlled by an

Application Specific Integrated Circuit (ASIC). The ASIC monitors and controls the

actuator’s rotation and provides a digital rotation sensing (DRS) function to prevent

damage to the actuator in a stall condition. Power consumption is reduced in holdin

mode

Add-on auxiliary switches or feedback potentiometers are easily fastened directly onto

the actuator body for signaling and switching functions

Dimensions (Inches)

AM..N

revent lateral movement

r.

2

.8

9

40024 - 05/10 - Subject to change. © Belimo Aircontrols (USA), Inc.

22

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

Page 18

228

00Weather Shield

eel

A

A

)

s

g

g

A

n

S

e

0

r

p

C

g

s

ufactured by Be

o.

manufactured by Belimo.

.

!

A

3

A

.

T

)

.

.

A

.

.

T

Live Electrical Components!

-

g

NEMA 4X, Proportional Control, Non-Spring Return, Direct Coupled, 24V, Multi-Function Technology

®

8

ol

l

g

F

T

:

actua

to

T (°C)

osta

t

te

The f

ollo

k

en int

o account

h

ex

t

e

g

:

All contact betw

een the cables o

that

ar

beavoided. Wher

e necessar

use cables

su

cient

actuat

o

.

j

g

(

)

Accessories

ZS-1

S1A, S2

…

uxiliary Switch (es

eedback Potentiometer

SGA24 Min positioners for surface mountin

SGF24 Min positioners for flush panel mountin

ADS-100

nalog to Digital Switch

ZG-R01 Resistor for 4 to 20 mA Conversio

SV24 U

ZG-X4

Battery Back-Up Modul

Transforme

Typical Specification

roportional control damper actuators shall be electronic direct-coupled type, which

require no crank arm and linkage and be capable of direct mounting to a shaft up to

¾” diameter. Actuators must

or, with the addition of a 500 Ω

10 VD

electronic controller or positioner. Actuators shall have brushless DC motor technolo

and be protected from overload at all angles of rotation. Actuators shall have reversing

witch and manual override on the cover. Run time shall be constant and independent

of torque. Actuators shall be cULus listed, have a 5-year warranty, and be

anufactured under ISO 9001 International Quality Control Standards. Actuators shall

as man

as

lim

Wiring Diagrams

- St

rovide proportional damper control in response to a 2 to

esistor, a 4 to 20 mA control input from an

AMX24-MFT-T N4, AMX24-MFT-T N4H

399_0

W399_08

y

On/Off contr

rovide overload protection and disconnect as required

AUTIONEquipment damage

2

ctuators may be connected in parallel if not mechanically mounted to the

W399_08

same shaft. Power consumption and input impedance must be observed.

ctuators may also be powered by 24 VDC.

osition feedback cannot be used with Triac sink controller

he actuator internal common reference is not compatible.

ontrol signal may be pulsed from either the Hot (source

or the Common (sink) 24 VAC line

ontact closures A & B also can be triacs

& B should both be closed for triac source and open for triac sink

, Inc.

USA

r triac sink the common connection from the actuator

t be connected to the hot connection of the controller

loating Point contro

ith actuator types ..-SR or M

T

N

1L23512

NL

e. © Belimo Aircontrols

he ZG-R01 500Ωresistor may be used.

During installation, testing, servicing and troubleshooting of this prod

uct, it may be necessary to work with live electrical components. Have a qualifi ed

licensed electrician or other individual who has been properly trained in handlin

live electrical components perform these tasks. Failure to follow all electrical safety

ect to chan

precautions when exposed to live electrical components could result in death or

serious injury.

40024 - 05/10 - Sub

M

wing points must be ta

independent,

wit

•

e introduced and the heating element isto

T

(°C)

1

2

egend

=

= Therm

= Heating

H

rnal wirin

r wires

VDC/4-20 mA

numbers of wires, e.g. so that the heating and the

y,

r can be supplied separately with votage

eater wirin

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

with

Page 19

9

AMC

X24-MF

T

®

pply

z

0%

n

)

T

g

)

n

e

r

)

]

n

)

)

Ω

)

U

x

e

n

e

Torque

]

n

h

on

)

ide

n

e

)

)

)

e

]

]

g

l

†

acc

08/EEC and 2006/95/EC

l

dB(A)

S

g

ee

d

W

.

n

.

p

.

C

so

e.

n

l

p

.

.

g

g

g

.

s

1.18" [30]

]

03]

]

]

6

88]

9

63

2

8]

3

Proportional, Non-Spring Return, 24 V, Multi-Function Technology

Technical Data AMCX24-MFT

ower su

ower consumptio

ransformer sizin

lectrical connectio

verload protectio

perating range Y 2 to 10 VDC, 4 to 20 mA (default

nput impedance 100 kΩ (0.1 mA), 500

eedback output

Angle of rotatio

Direction of rotatio

ition indicati

anual overr

unning tim

umidity 5 to 95% RH non condensing (EN 60730-1

Ambient temperatur

Storage temperature -40°F to 176°F [-40°C to 80°C

ousin

ousing materia

Agency listings

oise leve

ervicin

uality standar

eight 2.6 lbs [1.2 kg]

24 VAC ± 20% 50/60 H

24 VDC ± 1

4 W (1.25 W

6 VA (Class 2 power source

18 GA plenum rated cabl

1/2” conduit connecto

protected NEMA 2 (IP54

3 ft [1m] 10 ft [3m] 16 ft [5m

electronic throughout 0 to 95° rotation

variable (VDC, PWM, floating point, on/off

1500 W (PWM, floating point, on/off

2 to 10 VDC, 0.5 mA ma

VDC variabl

max. 95°, adjustable with mechanical stop

electronically variabl

180 in-lb [20 Nm

reversible with switc

reflective visual indicator (snap-on

external push butto

35 seconds (default

variable (35 to 120 seconds

-22°F to 122°F [-30°C to 50°C

NEMA 2, IP54, UL enclosure type 2

UL94-5VA

cULus acc. to UL 60730-1A/-2-14,

CAN/CSA E60730-1:02,

E

. to 2004/1

<45

maintenance fr

ISO 9001

Torque min. 180 in-lb for control of damper surfaces up to 45 sq ft

Applicatio

or proportional modulation of dampers in HVAC systems. Actuator sizing should be

done in accordance with the damper manufacturer’s specifications

The actuator is mounted directly to a damper shaft up to 1.05” in diameter by means

of its universal clamp, 1/2” self-centered default. A crank arm and several mounting

brackets are available for applications where the actuator cannot be direct coupled to

the dam

er shaft

The default parameters for 2 to 10 VDC applications of the …MFT actuator are

assigned during manufacturing. If necessary, custom versions of the actuators can be

ordered. The parameters can be changed by two means: pre-set and custom

configurations from Belimo or on-site configurations using the Belimo P

-Tool

ftwar

Operatio

The actuator is not provided with and does not require any limit switches, but is

ectronically protected against overload. The anti-rotation strap supplied with the

e

actuator will

The AMX series provides 95° of rotation and a visual indicator indicates position of the

actuator. When reaching the damper or actuator end position, the actuator

automatically stops. The gears can be manually disengaged with a button on the

actuator cover

The AMCX24-MFT actuators use a brushless DC motor, which is controlled by an

Application Specific Integrated Circuit (ASIC). The ASIC monitors and controls the

actuator’s rotation and provides a di

dama

mode

Add-on auxiliary switches or feedback potentiometers are easily fastened directly onto

the actuator body for signaling and switching function

Dimensions (Inches [mm])

revent lateral movement

ital rotation sensing (DRS) function to prevent

e to the actuator in a stall condition. Power consumption is reduced in holdin

1/2” to 1.05” [12.7 to 26.67]

2/5” to 1.05” [10 to 26.67]

.4]

" [

.4

4.06" [1

4.3" [109

5.2" [131

" [

.4

8.3" [211

" [50.

D14

40024 - 05/10 - Subject to change. © Belimo Aircontrols (USA), Inc.

22

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

Page 20

230

AMC

X24-MF

T

®

SA

Z

0

t

Z

t

ZG-103

t

ZG

t

Z-SMA

ZG

A

t

AV

5

n

Z

s

ZS

0

l

Z

0

ZS

0

Z

g

06

8

)

0

S

h

s

g

g

00

h

Z

n

e

Z

0

r

.

t

t

f

t

-

t

.

d.

!

A

ctuators may be connected in parallel if not mechanically mounted to the same

shaf

A

eedback cannot be used

T

)

8

.

A

.

9

or

.

500

.

Live Electrical Components!

fi

g

-

.

8

V

A

8

On/Off control

8

l

j

g

(

)

roportional, Non-Spring Return, 24 V, Multi-Function Technology

Accessories

G-10

G-101 Universal Mounting Bracke

-104 Universal Mounting Bracke

-AM

8-2

G-JSA (-1, 2, 3)Jackshaft Adaptors for Hollow Jackshaft

-10

S-15

-26

S-300 (-1) (-5)NEMA 4X Housin

ToolS1A, S2A Auxiliary Switch(es

37

…A Feedback Potentiometer

SGA24 Min positioners in NEMA 4 housin

SGF24 Min positioners for flush panel mountin

ADS-1

G-R01 Resistor for 4 to 20 mA Conversio

SV24 US Battery Back-Up Modul

G-X4

ote: When using AMCX24-MFT… actuators, only use accessories listed on this page

Reversible Clamp

niversal Mounting Bracke

Universal Mounting Bracke

AM/SM to AM Retrofit Mounting Bracket

Crank arm Adaptor Ki

Universal Shaft Extensio

Weather Shield - Stee

Weather Shield - Polycarbonate

Explosion Proof Housing

mm & 10 mm Wrench

haft Mount Auxiliary Switc

Analog to Digital Switc

Transforme

Typical Specification

roportional control damper actuators shall be electronic direct coupled type, which

require no crank arm and linkage and be capable of direct mounting to a shaft up

o 1.05” diameter. Actuators must provide proportional damper control in response

o a 2 to 10 VDC or, with the addition of a 500Ω resistor, a 4 to 20 mA control input