Greenheck ALL PRODUCTS BROCHURE

Welcome to Greenheck.

As one of Greenheck’s employees, I

want to assure you that our organization

is deeply committed to being easy to do

business with, anywhere in the world. As

an industry-leading manufacturer, our focus

is to build value in air ... by offering the

widest range of reliable air movement

and control products and to exceed

your expectations for on-time delivery,

easy installation, performance and

operating efficiency. We also pledge

to address the industry’s most complex

challenges and your future needs by

introducing innovative new product

solutions you can depend on.

Chairman of the Board,

Chief Executive Officer

Our Mission: To be the market leader in the development,

manufacture and worldwide sale of quality air moving and control

equipment with total commitment to the customer.

Our Vision: Greenheck will be a company that exceeds customer

expectations and that others strive to emulate. We will be the worldwide

leader in providing timely, flexible and cost-effective solutions focused on

the movement, cleaning, tempering, and control of air.

2

B U I L D I N G V A L U E I N A I R

Building value in air — from the beginning.

Today, we’re the world’s largest manufacturer of commercial, institutional and industrial

air movement and control equipment.

Greenheck’s worldwide leadership in providing

cost-effective, value-added solutions for air movement

and control challenges evolved from rather humble

beginnings. Bernie and Bob Greenheck weren’t sure

what lay ahead when they opened their small sheet

metal shop in Schofield, Wisconsin USA in 1947. But

they were determined that no product would ever

leave their shop, unless it met the most stringent

quality standards—their own. At first, the company

manufactured a variety of sheet metal products. In

1956, Greenheck engineers developed a highly efficient

power roof ventilator. This product and the innovative

ventilation solutions that followed ultimately enabled

us to expand our distribution throughout the world.

Today, quality Greenheck products are efficiently

moving air in commercial buildings, institutions and

factories throughout North America, Latin America,

the Middle East, and Asia.

The first factory.

1947

Bernie and Bob Greenheck

1956

Customer driven employees.

Every Greenheck product is still designed and built with pride of ownership.

Greenheck employees continue to share an

extraordinary commitment to meeting our customers’

needs. We know our future success depends on the

value we bring to the market: reliable, top-quality

products and exceptional service. At our headquarters

in Schofield, Wisconsin USA, and at additional plants

Manufacturing

Rocklin, CA

Schofield, WI

Frankfort, KY

Charlotte, NC

Kunshan, China

Saltillo, Mexico

National Distribution

Schofield, WI

Rocklin, CA

Dallas, TX

Miami, FL

Greensboro, NC

International Distribution

China

Mexico

in Frankfort, Kentucky; Rocklin, California; Charlotte,

North Carolina and Kunshan, China, you’ll find

hardworking and experienced employees designing,

manufacturing and delivering the most dependable air

movement and control equipment available.

B U I L D I N G V A L U E I N A I R

3

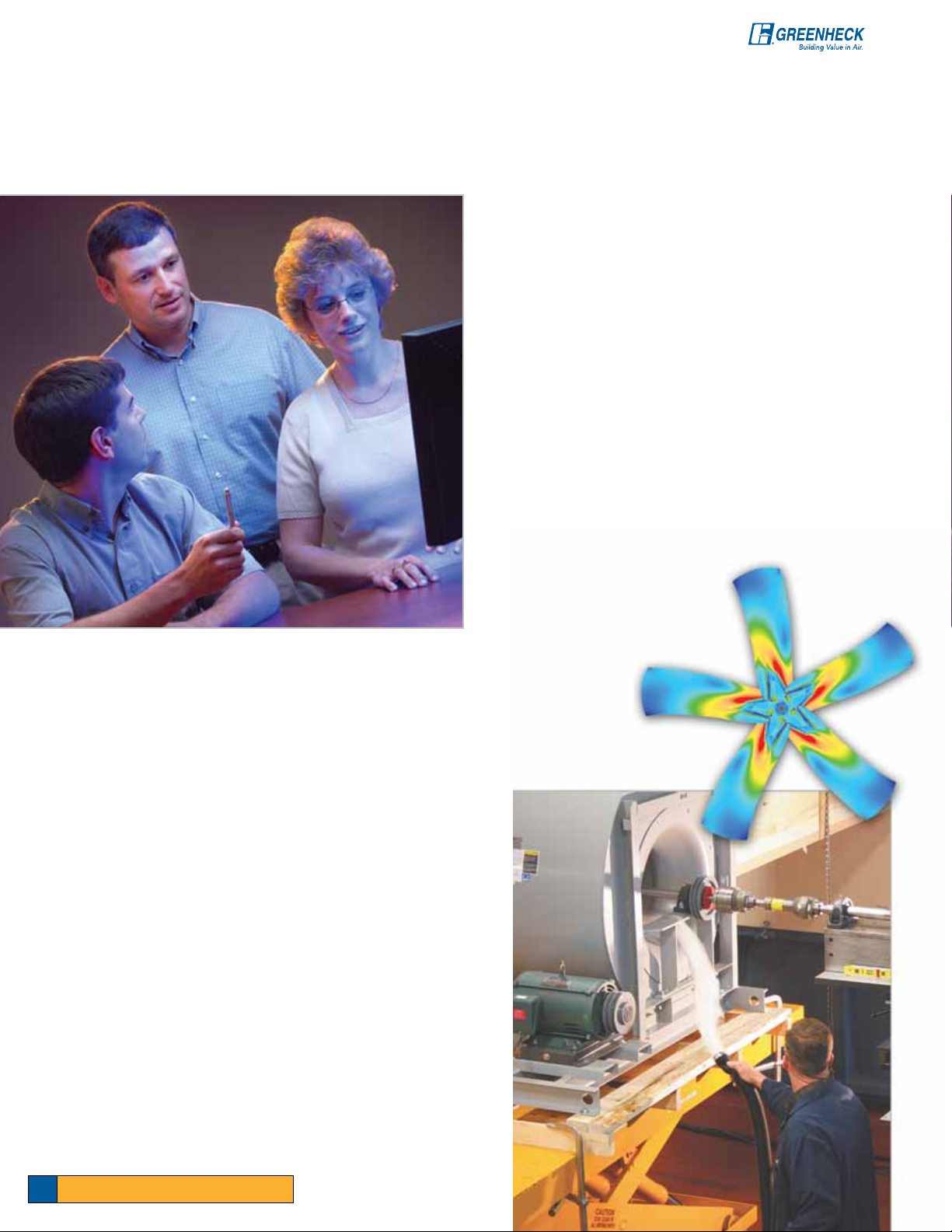

We don’t “value engineer” — we engineer value.

Our innovative engineers continuously explore more cost-effective, value-added product solutions.

Our engineers continuously develop and introduce

new product solutions based on the input they

receive from more than 300 Greenheck manufacturer

representatives around the world who listen carefully

to what you need. State-of-the-art computer modeling

and extensive prototype testing ensure that our

newest products offer more efficient performance and

easy, lower-cost installation. Whether it’s developing

compact, quieter fans with the lowest industry sound

levels, kitchen exhaust systems that trap more grease,

the most advanced energy recovery ventilators

available, or more effective laboratory exhaust

systems, Greenheck engineers always have one goal in

mind: deliver value that exceeds your expectations.

Finite element analysis

image showing blade

stress distribution

Every product we make is

thoroughly tested to ensure top

performance and unequaled reliability.

Because we test our products so extensively,

Greenheck offers more products with certifications

from AMCA, UL, ETL, CSA and AHRI than any other

manufacturer. Our real-life testing procedures measure

aerodynamic performance, sound levels, structural

integrity, mechanical operation, environmental impact,

temperatures, vibration levels and more. We also

offer two on-site third-party registered air chambers

and a registered sound-testing facility. In addition,

Greenheck tests new Life Safety Damper products in

our on-site UL Certified testing lab. We can also test

louver and damper performance on-site with extensive

dynamic water tests and missile impact tests.

Bearings, pulleys and motors must also meet the

industry’s highest standards for reliability and

endurance.

4

B U I L D I N G V A L U E I N A I R

Your single source.

We have the world’s most comprehensive line of top-quality

air movement and control products.

No other manufacturer offers you as many options

for air movement and control as Greenheck.

Specifying engineers and contractors can rely on us

for products that stand at the forefront of technology

and performance. To maintain your trust, we assign

a knowledgeable product manager, a talented group

of engineers and an experienced customer service

team to each of our product areas:

• Roof Mounted Fans & Gravity Ventilators

• Inline, Ceiling & Sidewall Fans

• Utility, Centrifugal & Radial Blowers

• Laboratory Exhaust Systems

• Kitchen Ventilation Systems

Energy Recovery Ventilators

• Make-Up Air

• Indoor Air Handlers

• Fan Coils & Coils

• Dampers

• Louvers

When you specify Greenheck, you’re specifying quality.

Our engineers design and build many of our

machines and dies to accommodate the unique

value-added features you’ll find in our products.

In addition, state-of-the-art, numerically controlled

manufacturing systems and a highly efficient,

experienced production staff help Greenheck meet

the most challenging delivery requirements in the

industry. To keep up with the worldwide demand

for our products, we operate and maintain 1.5 million

square feet of manufacturing and office space.

B U I L D I N G V A L U E I N A I R

5

The value

of Greenheck

customer service.

We want to be the easiest company

you’ll ever do business with.

Giving you the level of customer service that

distinguishes us from our competitors has always

been a hallmark at Greenheck. Greenheck makes it

easy for you to access all the technical information

you’ll need to specify and select our products. You

can go to our Web site at greenheck.com, navigate

our comprehensive product and technical literature

or request CAPS — our innovative Computer-Aided

Product Selection Program. In addition, we offer

Internet-based seminars. And of course, you’re

always welcome to take a plant tour and visit one

of our spectacular Greenheck Product Centers in

Schofield, WI, Rocklin, CA and Kunshan, China.

Most products can be

shipped in less than 24 hours.

Distribution centers around the world ensure that

Greenheck products are readily available.

Today, even our most complex ventilation systems

and largest products can be built in less than ten

days, and many products can be built and shipped

the next day. Greenheck also provides an efficient

Quick Delivery in-stock program that ships products

to your jobsite in less than 24 hours. In fact, most

orders received before noon can be shipped the

same day! Stocking warehouses at our manufacturer’s

representatives are backed up by strategically located

Greenheck distribution centers around the world.

Greenheck Product Center

Schofield, Wisconsin USA

B U I L D I N G V A L U E I N A I R

6

6

B U I L D I N G V A L U E I N A I R

Our Products.

Engineered and manufactured for top performance — and value.

Roof Mounted Fans

8

Gravity Ventilators

12

Inline, Ceiling &

Sidewall Exhaust

Fans

13

Utility, Centrifugal &

Radial Blowers

19

Energy Recovery

Ventilators

29

Make-Up Air

32

Indoor Air Handlers &

Fan Coils & Custom

Coils

36

Dampers

38

Laboratory Exhaust

Systems

23

Kitchen Ventilation

Systems

25

Louvers

45

B U I L D I N G V A L U E I N A I R

B U I L D I N G V A L U E I N A I R

7

7

Roof Mounted Fans and

Gravity Ventilators

Greenheck offers the world’s widest selection of top quality fans

and ventilators for commercial, institutional and industrial buildings.

This selection offers you a vast variety of products to ensure you

can always find the right fan to meet your precise performance

requirements. Discover the value of a Greenheck fan with the

world’s best-selling centrifugal roof upblast and exhaust fans with

one-piece, leakproof construction. Take advantage of our reputation

for quality and reliability by experiencing one of our many Greenheck

fan and ventilator products.

Centrifugal Roof Exhaust Fans

The centrifugal roof exhaust fans include both direct and belt-driven fans with backward-inclined centrifugal

wheels. The fans feature double-studded isolators for true vibration isolation. The fans are a downblast

configuration and are suitable for roof mounted applications exhausting relatively clean air.

Models G/GB

Model G/GB housing is available with a spun aluminum style. The Vari-Green,

high-efficiency motor is available on model G direct drive fans. Capacities range

from 50 to 45,000cfm (85 to 76,455 m3/hr) and 3.25 in. wg (806Pa). Third-party

certified (Florida Products and Miami-Dade Approved) for high wind and AMCA

Licensed for Sound and Air Performance.

Catalog: Centrifugal Downblast Exhaust — G and GB

Models LD/LB

Model LD/LB housing style is a low silhouette with “rib-lock” construction. Capacities

range from 100 to 37,500 cfm (170 to 63,713 m3/hr) and 2in.wg (496 Pa). Thirdparty certified (Florida Products and Miami-Dade Approved) for high wind and AMCA

Licensed for Sound and Air Performance.

Catalog: Centrifugal Roof Exhaust Fans — Series L (LD/LB)

Models LDP/LBP

Model LDP/LBP housing style is a louvered penthouse design (severe duty louvered

enclosure) which features extruded aluminum louvers. Capacities range from 100 to

37,500cfm (170 to 63,713 m3/hr) and 2 in. wg (496 Pa). Third-party certified (Florida

Products and Miami-Dade Approved) for high wind and AMCA Licensed for Sound and

Air Performance.

Catalog: Centrifugal Roof Exhaust Fans —Series L (LDP/LBP)

R O O F M O U N T E D A N D G R A V I T Y

8

Models NYD/NYB

Model NYD/NYB fans feature tamper-resistant housings while also allowing

ease of access for service. Capacities range from 200 to 8,000 cfm (340 to

13,592 m3/hr) and 1in.wg (248 Pa). AMCA Licensed Air Performance.

Catalog: Centrifugal Roof Exhaust Fans — NYD and NYB

Centrifugal Upblast and Sidewall Exhaust Fans

The centrifugal roof upblast and sidewall exhaust fans include both direct and belt-driven fans with

backward-inclined centrifugal wheels. The motors on the fans are out of the airstream. The fans are suitable

for applications ranging from storage rooms and fume hood exhaust, to kitchen grease exhaust and

smokecontrol.

Models CUE/CUBE - Roof Mounted

Models CW/CWB - Sidewall Mounted

Model CUE/CUBE spun aluminum fans are specifically designed for roof mounted

applications and are Third-party certified (Florida Products and Miami-Dade Approved)

for high wind. Models CW/CWB are designed for sidewall mounted applications.

Contaminated or grease-laden exhaust air is discharged directly upward, away from

the roof surface or discharged out and away from building walls. The fans feature a one

piece windband continuously welded to the curb cap and double-studded isolators for true

vibration isolation. The Vari-Green high-efficiency motor is available on model CUE and CW

direct drive fans. Capacities range from 70 to 30,000 cfm (119 to 50,970 m3/hr) and 5 in. wg

(1,240 Pa). AMCA Licensed for Sound and Air Performance.

Catalog: Centrifugal Upblast & Sidewall Exhaust — CUE/CUBE, CW/CWB

Model USGF

Model USGF (Ultimate Steel Grease Fan) is the ideal fan for heavy grease

exhaust applications where high amounts of grease are used like charbroilers,

solid fuel cooking, and oriental cooking. Constructed of steel, the model USGF

includes a nonstick coated steel wheel, steel windband, steel curb cap, and

steel motor compartment. Standard features include UL 762, a heat baffle,

clean-out port, dual belt and pulley system, and a mounted and wired NEMA-3R

disconnect switch. The unit is powder coated for protection. Capacities range

from 350 to 7,000 cfm (595 to 11,893 m3/hr) and 3.25 in. wg (806 Pa). Thirdparty certified (Florida Products and Miami-Dade Approved) for high wind and

AMCA Licensed for Sound and Air Performance.

Catalog: Centrifugal Upblast & Sidewall Exhaust — USGF

Model S-CUBE

Model S-CUBE is a spun aluminum fan specifically designed for emergency

smoke control systems. This fan is UL Listed for 500ºF/260ºC for 4 hours and

1,000ºF/538ºC for 15 minutes. Capacities range from 200 to 30,000 cfm

(340 to 50,970m3/hr) and 2.75 in. wg (682 Pa). Available in upblast configuration

only. Third-party certified (Florida Products and Miami-Dade Approved) for high

wind and AMCA Licensed for Sound and Air Performance.

Catalog: Centrifugal Upblast & Sidewall Exhaust — S-CUBE

R O O F M O U N T E D A N D G R A V I T Y

9

Propeller Tube Axial Fans

For low to medium pressure applications, tube axial fans include both direct and belt-driven fans with

cast aluminum or fabricated steel blades. Propeller tube axial inline fans have a straight through airflow,

compact size and the flexibility to be mounted in any configuration—horizontal, vertical, or any angle.

These fans are designed for reliable air movement in ducted commercial and industrial applications. The

roof upblast configuration is designed to discharge contaminants up and away from the building in most

applications. Where indicated below, models are available in both configurations.

Roof Upblast: Models RDU/RBU/RBUMO

Model RBUMO has its motor mounted out of the airstream and is suitable

for high temperature emergency smoke removal (500

or 1000ºF/538ºC for 15 minutes) and is available with UL Power

Ventilators for Smoke Control Systems

blades, and the RDU has cast aluminum blades. Capacities range from

2,800 to 64,500 cfm

AMCA Licensed for Sound and Air Performance.

Catalog: Propeller Upblast Roof Fans — RDU/RBU/RBUMO

(4,757 to 109,586 m3/hr)

. The RBU/RBUMO has steel

Roof Upblast: Model TAUB-L/H

Model TAUB-L/H has its motor mounted out of the airstream and is

suitable for high temperature emergency UL smoke removal. Typical

applications include clean air, industrial processes, and high-temperature

exhaust. The TAUB-L/H has steel blades. Capacities range from 4,000 to

66,800 cfm (6,796 to 113,494 m3/hr) and 1 in. wg (248 Pa). For higher

pressure capabilities use roof mounted option on model TBI-FS. AMCA

Licensed for Sound and Air Performance.

ºF/260ºC for 4 hours

and 1 in. wg (248 Pa).

Catalog: Tube Axial Upblast Roof Exhauster — TAUB

Roof Upblast: Models TAUD/TAUB-CA

Models TAUD/TAUB-CA have cast aluminum blades. Typical applications

include clean air, fume exhaust, and spark resistant construction.

Capacities range from 2,400 to 74,000 cfm (4,078 to 125,727 m3/hr) and

1.25 in. wg (310 Pa). For higher pressure capabilities use roof mounted

option on models TDI/TBI-CA or AX. AMCA Licensed Air Performance.

Catalog: Tube Axial Roof Upblast — TAUD & TAUB-CA

Centrifugal Supply Fans

The centrifugal roof supply fans include filtered and non-filtered belt-driven units. These fans are suitable

for non-tempered kitchen make-up air or building supply air.

Model SAF

Model SAF filtered roof supply fan features a belt-driven, double-width,

forward-curved, galvanized blower for low-cost, low sound, and high

performance applications. Capacities range from 850 to 14,000 cfm

(1,444 to 23,786 m3/hr) and 3.5 in. wg (868 Pa). AMCA Licensed for

Sound and Air Performance.

Catalog: Centrifugal Roof Supply Fans — SAF

R O O F M O U N T E D A N D G R A V I T Y

10

Models KSFB and KSFD

Models KSFB and KSFD economically supply untempered make-up air

where needed. Kitchen make-up air applications are common and an

extended weatherhood option provides a 10 foot separation between

intake and exhaust fan discharge. Capacities range from 800 to

10,500cfm (1,359 to 17,840 m3/hr) and 2 in. wg (496 Pa).

Catalog: Untempered Make-Up Air for Kitchen Systems — KSFB and KSFD

Models RSF/RSFP

Model RSF/RSFP fans feature forward-curved wheels designed for high

efficiency and low sound. Housing styles include a straight-sided hood

(RSF) or a louvered penthouse which features extruded aluminum louvers

(RSFP). Capacities range from 700 to 14,500 cfm (1,189 to 24,636m3/

hr) and 2 in. wg (496 Pa). Third-party certified (Florida Products and MiamiDade Approved) for high wind and AMCA Licensed for Air Performance.

Catalog: Forward-Curved Centrifugal Roof Supply Fan — RSF & RSFP

Models LSF

Model LSF features a double-width centrifugal blower with a backward-inclined wheel

to efficiently supply filtered air. The aluminum louvered penthouse is available with

a standard machine finish or multiple decorative coatings for aesthetics. Capacities

range from 800 to 37,000cfm (1,359 to 62,863 m3/hr) and 5.5 in. wg (1,364 Pa).

Catalog: Louvered Roof Supply Fans — LSF

Hooded Propeller Exhaust and Supply Fans

The hooded roof propeller fans include both direct and belt-driven fans with fabricated steel, fabricated

aluminum, or cast aluminum blades. These fans are suitable for clean air applications, including exhaust,

supply, or filtered supply. Typical applications are factories and warehouses.

Models R2/RC3/RB/RBC

Model R2/RC3/RB/RBC hooded roof propeller fans are available with a wide

variety of accessories including tall bases, dampers and guards. Capacities

range from 700 to 86,500 cfm (1,189 to 146,964 m3/hr) and 1.5in. wg

(372 Pa). Third-party certified (Florida Products and Miami-Dade Approved)

for high wind and AMCA Licensed for Sound and Air Performance.

Catalog: Hooded Roof Propeller Fans — Exhaust, Supply and Reversible

Models RPDR/RPBR

Models RPDR/RPBR are compatible with ducted and non-ducted systems

and offers the ability to exhaust or supply air on demand. Performance is

equivalent in both the exhaust and supply modes. Capacities range from

2,000 to 70,500 cfm (3,398 to 119,780 m3/hr) and 1 in. wg (248 Pa).

Third-party certified (Florida Products and Miami-Dade Approved) for high wind.

Catalog: Hooded Roof Propeller Fans — Exhaust, Supply and Reversible

Models AE/AS

Model AE/AS axial roof exhaust and supply fans are designed for low

volume, low pressure applications where a spun aluminum hood is

desired. Capacities range from 150 to 6,000 cfm (255 to 10,194 m3/hr)

and 1 in. wg (248 Pa). AMCA Licensed for Sound and Air Performance.

Catalog: Propeller Hooded Roof Fans — Series A (AE/AS)

R O O F M O U N T E D A N D G R A V I T Y

11

Recirculating Roof Fans

The propeller recirculating roof fans include direct driven fans with and without filters. These fans have cast

aluminum blades and are available with optional control centers. Suitable for clean air applications, such as

factories and warehouses.

Models ESRMD/ERD

Model ESRMD, also called the four-way fan, offers the flexibility to meet

changing needs brought on by production processes or seasonal shifts by

exhausting, supplying, recirculating, or mixing air as required. Performance

is equivalent in all four modes of operation. Capacities range from 2,800

to 43,000 cfm (4,757 to 73,057 m3/hr) and 0.375 in. wg (93 Pa).

Catalog: Recirculating Roof Fans — ESRMD, ESRMDF and ERD

Gravity Ventilators

The gravity intake and relief ventilators are non-powered and work on pressure differential between the

inside and outside of the building.

Model GRS

Model GRS is an aluminum ventilator designed to be used as an intake

(model GRSI) or relief unit (model GRSR) on natural gravity systems. The

GRS appearance blends with other Greenheck products, and with its low

silhouette, avoids the problem of detracting from architectural aesthetics.

Catalog: Gravity Ventilators — GRSI/GRSR

Models FGI/FGR

Models FGI (intake) and FGR (relief) have a low silhouette Fabra Hood design.

The Fabra Hood design is superior in appearance, load bearing strength,

weather resistance, and dimensional flexibility. Third-party certified (Florida

Products and Miami-Dade Approved) for high wind.

Catalog: Gravity Ventilators — FGI/FGR

Models WIH/WRH

Model WIH (intake) and WRH (relief) units feature a stormproof aluminum

louver with mitered corners. The louver design affords lower pressure

drops while maintaining low hood heights. The all-aluminum construction

assures lasting durability and appearance. The removable hood is lined

with insulation to prevent condensation.

Catalog: Gravity Ventilators — WIH/WRH

Model RGU

Model RGU gravity upblast ventilators are designed for use as a

weatherproof outlet on vertical, high velocity exhaust systems.

Catalog: Propeller Upblast Roof Fans — RDU/RBU/RBUMO

Gravity Ventilators — RGU

R O O F M O U N T E D A N D G R A V I T Y

12

Inline, Ceiling and

Sidewall Exhaust

Greenheck’s inline, ceiling, and sidewall exhaust products are

suitable for a wide range of commercial and industrial applications.

Ceiling and cabinet fans are easily mounted in or above ceilings

for efficient and quiet supply or exhaust applications. Sidewall fans

are wall mounted exhaust units suitable for clean or fume-laden air

exhaust. Tubular centrifugal, axial and mixed flow inline products

provide higher performance capacity than ceiling and sidewall fans.

They are typically horizontally or vertically mounted in duct systems,

but can be wall mounted, as well as roof mounted.

Ceiling, Cabinet and Inline Fans

Ceiling and cabinet fans include both direct and belt-driven fans. The fans have forward-curved wheels

for low sound and high efficiency. They are suitable for clean air applications such as bathrooms, storage

rooms, or offices.

Centrifugal inline fans include both direct and belt-driven fans with backward-inclined centrifugal wheels.

Models feature rugged construction, high-efficiency, and low sound levels. Centrifugal inline fans are ideal

for clean air applications, including intake, exhaust, return, or make-up air. They have straight through

airflow with compact size and have the flexibility to be mounted in any configuration—horizontal, vertical,

or at any angle.

Model SP

Model SP is a direct drive ceiling exhaust fan designed for clean air applications

where low sound levels are required. Many options and accessories are available

such as lights, motion detectors, ceiling radiation dampers and speed controls.

These fans may be easily converted from horizontal to a vertical discharge.

Capacities range from 25 to 1,600 cfm (42 to 2,718 m3/hr) and 1 in. wg

(248 Pa). AMCA Licensed for Sound and Air Performance. Energy Star

Certified models include: SP-A, 50, 70, 90, 200, 250, 290 and 410;

SP-B, 50, 70, 80 and 90.

Catalog: Centrifugal Ceiling and Cabinet Exhaust Fans — SP and CSP

Model CSP

Model CSP is a direct drive inline exhaust fan designed for clean air

applications where low sound levels are required. These fans may be

easily converted from horizontal to vertical discharge. Capacities range

from 70 to 3,800 cfm (119 to 6,456 m3/hr) and 1 in. wg (248 Pa). AMCA

Licensed for Air Performance.

Catalog: Centrifugal Ceiling and Cabinet Exhaust Fans — SP and CSP

I N L I N E , C E I L I N G A N D S I D E W A L L

13

Model BCF

Model BCF is a belt drive inline low profile cabinet fan. It is designed for

efficiency and reliability in supply, exhaust, and ducted return applications.

Horizontal mounting with either top horizontal or upblast discharge allows

the BCF to be applied in a wide range of applications. Capacities range

from 200 to 6,000 cfm (340 to 10,194 m3/hr) and 1.5 in. wg (372 Pa).

AMCA Licensed for Air Performance.

Catalog: Centrifugal Cabinet Fans — BCF

Model BDF

Model BDF is a belt drive duct fan designed for efficiency and reliability in

supply, exhaust, or return air applications. Capacities range from 300 to

15,000 cfm (510 to 25,485 m3/hr) and 3 in. wg (744 Pa). AMCA Licensed

for Sound and Air Performance.

Catalog: Centrifugal Cabinet Fans — BDF

Models SQ/BSQ

Models SQ/BSQ have a square housing design for indoor applications.

Easy access for inspection and service is provided by removable side

panels. Fans can be configured to discharge air 90º from the inlet for tight

space constraints. The Vari-Green, high-efficiency motor, is available on

model SQ direct drive fans. Capacities range from 50 to 27,000 cfm (85

to 45,873m

Air Performance.

3

/hr) and 4 in. wg (992 Pa). AMCA Licensed for Sound and

Catalog: Centrifugal Inline Fans — SQ and BSQ

Tubular Centrifugal Fans

Greenheck tubular centrifugal fans, models TCB and TCF, have been designed for commercial and

industrial inline or roof upblast applications that demand quiet, efficient and reliable air movement. Tubular

centrifugal fans can be mounted in any position from horizontal to vertical providing for installations in the

smallest possible space.

Model TCB

Model TCB uses a backward-inclined centrifugal wheel for high

efficiencies and low sound levels when used in medium pressure ducted

systems. All TCB inline fans are belt-driven with the motor out of the

airstream. Fan construction includes the roof upblast model TCBRU and

roof supply model TCBRS. Capacities range from 360 to 24,000 cfm (612

to 40,776m3/hr) and 4.5 in. wg (1,116 Pa). Model TCB is AMCA Licensed

for Sound and Air Performance.

Catalog: Tubular Centrifugal Fans — TCB/TCBRU/TCBRS

Model TCF

Model TCF uses an airfoil centrifugal wheel for high efficiencies and low

sound levels in high-pressure ducted commercial or industrial systems.

Welded steel straightening vanes help to further increase the efficiency

while straightening the airflow as it passes through the housing. Air

handling quality bearings with L

(equivalent to an average life of 400,000 hours). Capacities range from

1,600 to 127,000 cfm (2,718 to 215,774m3/hr) and 8.5 in. wg (2,108 Pa).

AMCA Licensed for Air Performance.

life in excess of 80,000 hours

(10)

Catalog: Tubular Centrifugal Fans — TCF

I N L I N E , C E I L I N G A N D S I D E W A L L

14

Model TCBRS

Model TCBRS features aluminum backward-inclined wheels for quiet

and efficient supply airflow. Greenheck’s Fabra Hood housing on this

model provides a strong, weathertight cover, and is available with filters.

Capacities range from 360 to 24,000 cfm (612 to 40,776 m3/hr) and

4in.wg (992 Pa). AMCA Licensed for Air Performance.

Catalog: Tubular Centrifugal Fans — TCB/TCBRU/TCBRS

Model TCBRU

Model TCBRU is a belt drive upblast roof exhaust fan. It features a

tapered outlet which creates high outlet velocities to carry contaminated

exhaust away from nearby make-up air units. Capacities range from 360

to 24,000cfm (612 to 40,776 m3/hr) and 4.5 in. wg (1,116 Pa). AMCA

Licensed for Air Performance.

Catalog: Tubular Centrifugal Fans — TCB/TCBRU/TCBRS

Mixed Flow Fans

Mixed flow fans are an excellent choice for inline ventilation applications. This fan design combines the

best axial and centrifugal properties: high fan efficiency, low sound levels, and a smooth, steep fan curve

for stable fan selections. Mixed flow fans can be mounted in any position from horizontal to vertical and

their compact design allows for installations in space limited areas.

Models QEI/QEID

Models QEI/QEID include the universal mounting system for motor

position changes in the field. Fans have slip-fit collars for quick and easy

connection to ductwork. Typical applications include ventilation of office

buildings, concert halls, parking garages, educational facilities, libraries,

and dormitories. Air handling quality bearings with L

80,000 hours (equivalent to an average life of 400,000 hours) (QEI) and

vibration test of complete assembly at the factory prior to shipment.

Capacities range from 500 to 115,000 cfm (850 to 195,386 m3/hr)

and 8.5in. wg (2,108 Pa). AMCA Licensed for Sound (inlet and outlet)

and Air Performance.

Catalog: Mixed Flow Fans — QEI (belt drive)/QEID (direct drive)

life in excess of

(10)

I N L I N E , C E I L I N G A N D S I D E W A L L

15

Tube and Vane Axial Fans

Axial inline fans are designed for ducted indoor or outdoor applications. They are available in both direct

drive and belt drive and with cast aluminum or fabricated steel propellers.

Inline or Roof Upblast: Models TDI/TBI-CA

Models TDI/TBI-CA axial fans feature a cast aluminum hub and airfoil

blades. The universal mounting system allows for vertical or horizontal

installations. Typical applications include clean air, fume exhaust, and

spark-resistant construction. Capacities range from 800 to 95,000 cfm

(1,359 to 161,406m3/hr) and 3.25 in. wg (806 Pa). AMCA Licensed

for Air Performance.

Catalogs: Tube Axial Inline Fans — TDI &TBI-CA Level 3

Medium Pressure Axial Fans — TBI-CA Level 4 & 5

Inline or Roof Upblast: Models TBI-FS

Model TBI-FS has a fabricated steel hub and airfoil blades. It is suitable for

continuous high temperature (400ºF/204ºC max.) for inline configurations,

(500ºF/260ºC max.) for roof upblast configuration and is available with UL

Power Ventilators for Smoke Control Systems. The universal mounting

system accommodates any vertical or horizontal installation configuration.

Typical applications involve clean air, industrial processes, and hightemperature exhaust. Capacities range from 3,300 to 76,000 cfm (5,607

to 129,124 m3/hr) for inline configurations [5,500 to 74,000 cfm (9,345 to

125,727 m3/hr) for roof upblast configurations] and 3.5 in. wg (868 Pa).

Bolt-on straightening vanes are available for increasedefficiency. AMCA

Licensed for Sound and Air Performance.

Catalog: Medium Pressure Axial Fans — TBI-FS Levels 3, 4 & 5

Inline or Roof Upblast: Model AX

Model AX features a cast aluminum hub and airfoil blades which have

a manually adjustable blade pitch. The universal mounting system

allows for vertical or horizontal installations. Typical applications include

clean air and are available with UL Power Ventilators for Smoke Control

Systems and UL 705. Bolt-on straightening vanes (AX-V) are available for

increased efficiency. Capacities range from 500 to 150,000 cfm

(850 to 254,852 m3/hr) and 5.5 in. wg (1,364 Pa). AMCA Licensed

for Air Performance.

Catalog: High Performance Axial Fans — AX

Model VAB

Model VAB belt drive vane axial fans accommodate for final system balancing

and have a manually adjustable blade pitch. These fans are an excellent

choice for variable air volume HVAC systems, clean rooms, parking garage

exhaust, and tunnel ventilation. For sound critical applications, belt drive vane

axial fans are available with Greenheck’s sound trap housing. UL/cUL 705 for

electrical is available. A complete vibration test of all fans are performed prior

to shipment. Capacities range from 2,000 to 125,000 cfm (3,398 to 212,376

m3/hr) and 9 in. wg (2,232 Pa). AMCA Licensed for Air Performance.

Catalog: Vane Axial Fans — VAB and VAD

I N L I N E , C E I L I N G A N D S I D E W A L L

16

Loading...

Loading...