Page 1

AFB24, AFB24-S, AFX24, AFX24-S

On/Off, Spring Return, 24 V

Technical Data AFB24, AFB24-S, AFX24, AFX24-S

Power supply 24 VAC ± 20% 50/60 Hz

Power consumption running

Transformer sizing 7.5 VA (class 2 power source)

Electrical connection

AFB24... 3 ft, 18 GA appliance cable, 1/2" conduit

AFX24...

Overload protection electronic throughout 0 to 95° rotation

Control on/off

Torque 180 in-lb [10 Nm] minimum

Direction of rotation spring reversible with CW/CCW mounting

Mechanical angle of rotation 95° (adjustable with mechanical end stop, 35° to

Running time

Position indication visual indicator, 0° to 95°

Manual override 5 mm hex crank (³⁄₁₆" Allen), supplied

Humidity max. 95% RH non-condensing

Ambient temperature -22°F to 122°F [-30°C to 50°C]

Storage temperature -40°F to 176°F [-40°C to 80°C]

Housing Nema 2, IP54, Enclosure Type2

Housing material zinc coated metal and plastic casing

Agency listings

† cULus acc. to UL60730-1A/-2-14,

Noise level <50dB(A) motor @ 75 seconds

Servicing maintenance free

Quality standard ISO 9001

Weight 4.6 lbs (2.1 kg); 4.9 lbs (2.25 kg) with switches

† Rated Impulse Voltage 800V, Type of action 1.AA (1.AA.B for -S version), Control Pollution Degree 3.

AFB24-S, AFX24-S

Auxiliary switches 2 x SPDT 3A (0.5A) @ 250 VAC, UL approved

24 VDC +20% / -10%

5 W

holding

2.5 W

connector

-S models: two 3 ft, 18 gauge appliance cables

with 1/2” conduit connectors

3 ft [1m], 10 ft [3m] or 16 ft [5m] 18 GA

appliance or plenum cables, with or without 1/2”

conduit connector

-S models: two 3 ft [1m], 10 ft [3m] or

16 ft [5m] appliance cables, with or without 1/2"

conduit connectors

95°)

motor

< 75 seconds

spring

20 seconds @ -4°F to 122°F [-20°C to 50°C];

< 60 seconds @ -22°F [-30°C]

(0° is full spring return position)

CAN/CSA E60730-1:02, CE acc. to

2004/108/EC & 2006/95/EC

≤62dB(A) spring return

one set at +10°, one adjustable 10° to 90°

Torque min. 180 in-lb, for control of air dampers

Application

For On/Off, fail-safe control of dampers in HVAC systems. Actuator sizing should be

done in accordance with the damper manufacturer’s specifications. Control is On/Off

from an auxiliary contact, or a manual switch.

The actuator is mounted directly to a damper shaft up to 1.05” in diameter by means

of its universal clamp. A crank arm and several mounting brackets are available for

applications where the actuator cannot be direct coupled to the damper shaft.

Operation

The AFB and AFX series actuators provide true spring return operation for reliable failsafe application and positive close off on air tight dampers. The spring return system

provides constant torque to the damper with, and without, power applied to the

actuator.

The AFB and AFX series provides 95° of rotation and is provided with a graduated

position indicator showing 0° to 95°.

The actuator may be stalled anywhere in its normal rotation without the need of

mechanical end switches.

The AFB24-S and AFX24-S versions are provided with two built-in auxiliary switches.

These SPDT switches are provided for safety interfacing or signaling, for example, for

fan start-up. The switching function at the fail-safe position is fixed at +10°, the other

switch function is adjustable between +10° to +90°. The AFB24, AFB24-S, AFX24 and

AFX24-S actuator is shipped at +5° (5° from full fail-safe) to provide automatic

compression against damper gaskets for tight shut-off.

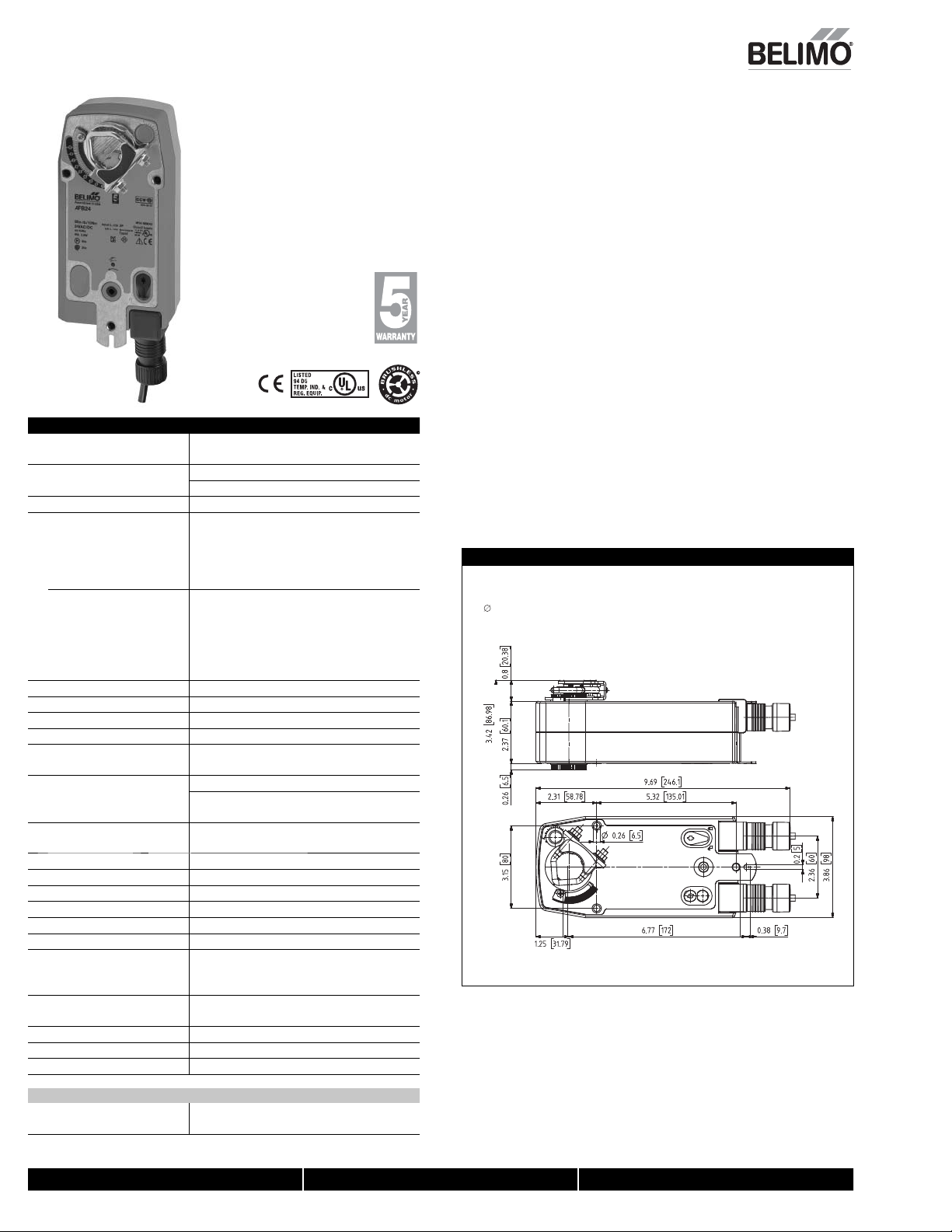

Dimensions (Inches [mm])

K7-2 (supplied)

1/2" Centered

(Default)

3/4" Centered

(Field Selectable)

1.05" Centered

(Field Selectable)

WAFBNFBDim

06/10 - Subject to change. © Belimo Aircontrols (USA), Inc.

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

2

Page 2

9

A

FBUP, AFBUP-S, AFXUP, AFXUP-

S

Torq

n

F

d

f

T

.

O

n

T

s

p

.

T

p

T

.

T

T

-

u

j

A

c

.

P

pply

0%

n

r

W

g

3

W

T

)

C

C

Elec

on

AFBUP...

3

connector

w

s

3

r

condu

s

O

n

C

O

T

m

D

n

g

r

/CC

g

n

)

R

otor

sec

s

]

Positi

vi

°

(

)

de

5

(

³⁄₁₆

d

y

g

Ambi

C]

e

C]

g

A

08/EC & 2006/95/EC

el

s

d

9001

S

d

On/Off, Spring Return, 24 to 240 VAC

Technical Data AFBUP, AFBUP-S, AFXUP, AFXUP-S

ower su

Power consumptio

ransformer sizing 7 VA @ 24 VAC (class 2 power source

trical connecti

AFXUP...

verload protectio

ontrol

orque 180 in-lb [20 Nm] minimu

irection of rotatio

Mechanical angle of rotatio

unning time

on indication

Manual overri

umidit

ent temperature -22°F to 122°F [-30°C to 50°

torage temperatur

ousing Nema 2, IP54, Enclosure Type2

ousing material Zinc coated metal and plastic casin

gency listings † cULus acc. to UL60730-1A/-2-14,

lev

ervicing maintenance free

uality standar

eight 4.6 lbs (2.1 kg), 4.9 lbs (2.25 kg) with switches

Rated Impulse Voltage 4kV, Type of action 1.AA (1.AA.B for -S version), Control Pollution Degree 3.

AFBUP-S, AFXUP-

Auxiliary switches 2 x SPDT 3A (0.5A) @ 250 VAC, UL Approve

24...240 VAC -20% / +10%, 50/60 Hz

24...125 VDC ±1

unning

7

holdin

.5

8.5 VA @ 120 VA

18 VA @ 240 VA

ft, 18 GA appliance cable, 1/2" conduit

-S models: Two 3 ft, 18 gauge appliance cables

ith 1/2” conduit connector

ft [1m], 10 ft [3m] or 16 ft [5m] 18 GA

appliance cable, with or without 1/2” conduit

connecto

-S models: Two 3ft [1m], 10 ft [3m] or

16 ft [5m] appliance cables with or without 1/2"

it connector

Electronic throughout 0 to 95° rotation

n/Off

sprin

eversible with CW

95° (adjustable with mechanical end stop, 35° to

95°

m

< 75

pring

20 sec @ -4°F to 122°F [-20°C to 50°C];

< 60 sec @ -22°F [-30°C

sual indicator, 0° to 95

0° is full spring return position

mm hex crank

max. 95% RH non-condensin

-40°F to 176°F [-40°C to 80°

AN/CSA E60730-1:02, CE acc. to

2004/1

<50dB(A) motor @ 75 second

≤62dB(A) spring return

ISO

one set at +10°, one adjustable 10° to 90°

W mountin

Allen), supplie

ue min. 180 in-lb, for control of air dampers

Applicatio

or On/Off, fail-safe control of dampers in HVAC systems. Actuator sizing should be

one in accordance with the damper manufacturer’s specifications. Control is On/Off

rom an auxiliary contact, or a manual switch.

he actuator is mounted directly to a damper shaft up to 1.05” in diameter by means

of its universal clamp. A crank arm and several mounting brackets are available for

applications where the actuator cannot be direct coupled to the damper shaft

peratio

he AFB and AFX series actuators provide true spring return operation for reliable fail-

afe application and positive close off on air tight dampers. The spring return system

rovides constant torque to the damper with, and without, power applied to the

actuator

he AFB and AFX series provides 95° of rotation and is provided with a graduated

osition indicator showing 0° to 95°.

he actuator may be stalled anywhere in its normal rotation without the need of

mechanical end switches

he AFBUP-S and AFXUP-S versions are provided with two built-in auxiliary switches.

hese SPDT switches provide safety interfacing or signaling, for example, for fan start

p. The switching function at the fail-safe position is fixed at +10°, the other switch

function is ad

FXUP-S actuator is shipped at +5° (5° from full fail-safe) to provide automatic

ompression against damper gaskets for tight shut-off

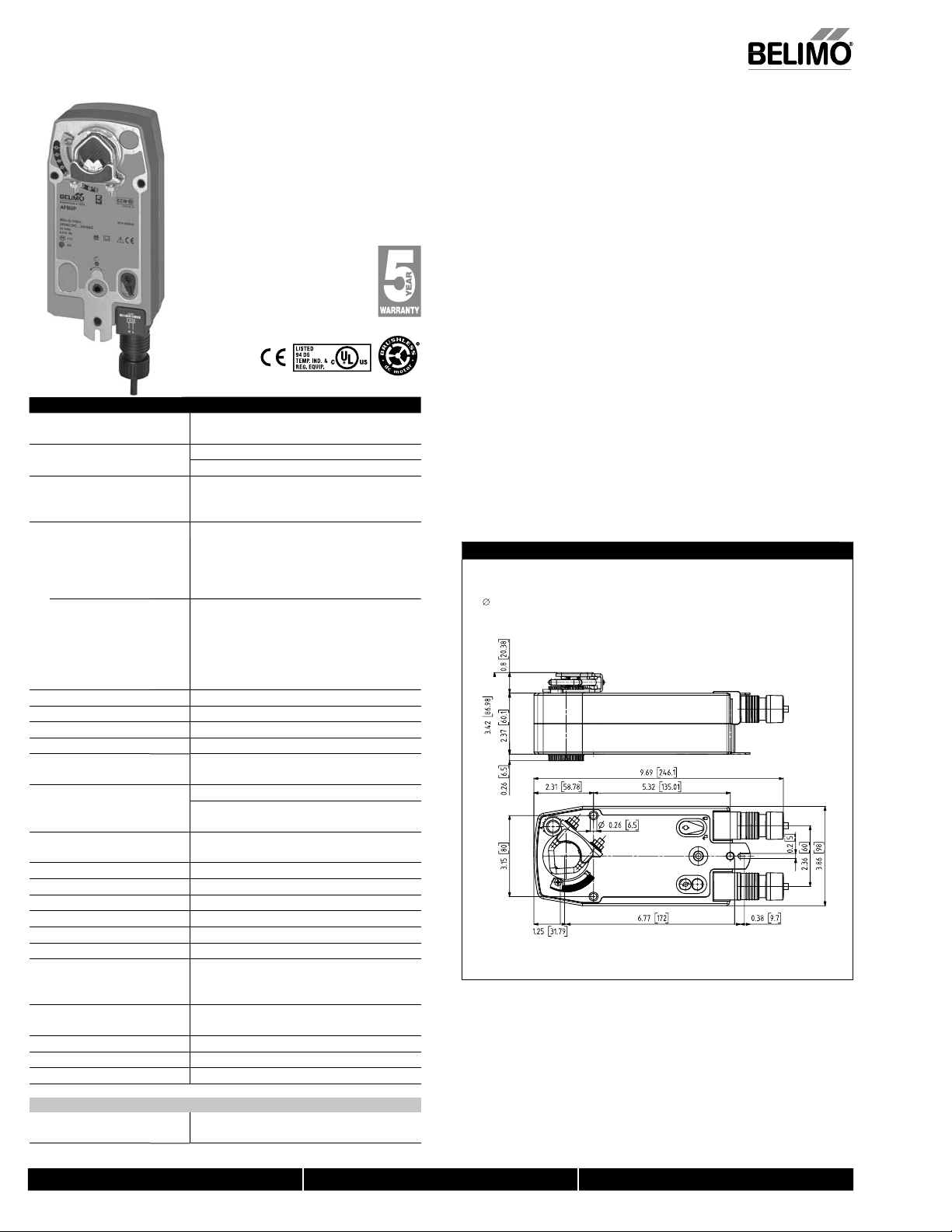

Dimensions (Inches [mm])

ustable between +10° to +90°. The AFBUP, AFBUP-S, AFXUP and

K7-2 (supplied)

1/2" Centered

(Default)

3/4" Centered

(Field Selectable)

1.05" Centered

(Field Selectable)

WAFBNFBDim

M40024 - 05/10 - Subject to change. © Belimo Aircontrols (USA), Inc.

1

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

Page 3

0

AFBUP, AFBUP-S, AFXUP, AFXUP-S

AV

s

S

06

ch

00

t

t

8

III or IV or Johnson

s

l)

)

60

g

300

g

.

!

.

.

-

Live Electrical Components!

.

(

)

P

(

)

S

A

S

j

g

(

)

On/Off, Spring Return, 24 to 240 VAC

Accessories

8-25

-

7-2 Universal clamp for up to 1.05” dia jackshaft

-

F-CC U

l-

-1

-101

G-11

-AFB

-AFB118

S-100

-150

-2

-

ote: When using AFBUP, AFBUP-S, AFXUP, AFXUP-S actuators, only use accessories listed on

this page.

or actuator wiring information and diagrams, refer to Belimo Wiring Guide.

haft extension

Damper position indicator

rank arm

onduit fitting

mm and 10 mm wren

Universal mounting bracke

niversal mounting bracke

Mounting bracket for Barber ColmanMA 3../4.., Honeywell

Series 100 replacement or new crank

arm type installation

rank arm adaptor kit

rank arm adaptor kit

eather shield (meta

eather shield (polycarbonate

Explosion-proof housin

NEMA 4X housin

Typical Specification

On/Off spring return damper actuators shall be direct coupled type which require

o crank arm and linkage and be capable of direct mounting to a jackshaft up to a

1.05” diameter. The actuators must be designed so that they may be used for either

clockwise or counterclockwise fail-safe operation. Actuators shall be protected

from overload at all angles of rotation. If required, two SPDT auxiliary switch shall

e provided having the capability of one being adjustable. Actuators with auxiliary

switches must be constructed to meet the requirements for Double Insulation so

an electrical ground is not required to meet agency listings. Actuators shall be

cULus approved and have a 5 year warranty, and be manufactured under ISO 9001

nternational Quality Control Standards. Actuators shall be as manufactured by

elimo.

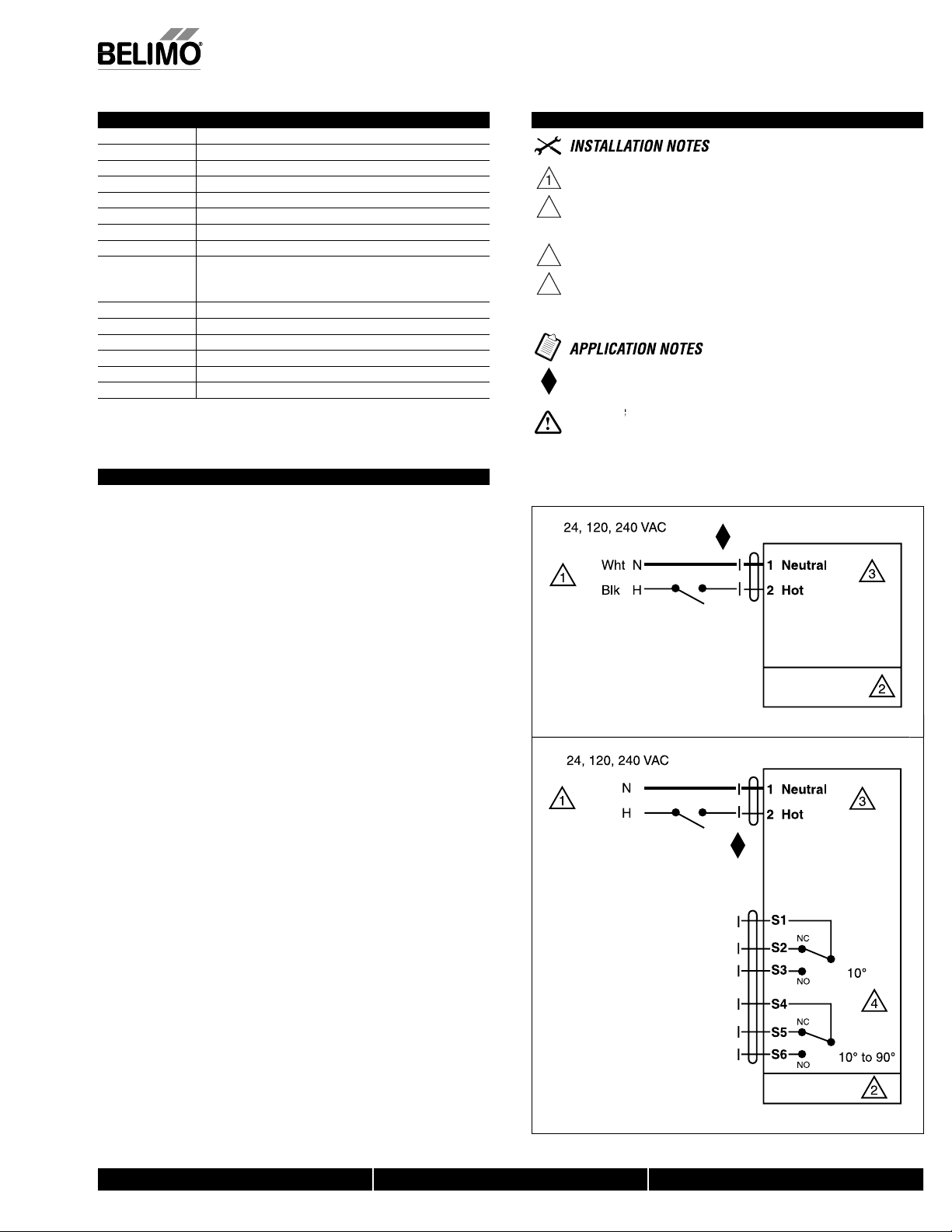

Wiring Diagrams

Provide overload protection and disconnect as required

AUTION Equipment Damage

Actuators may be connected in parallel.

Power consumption and input impedance must be observed.

No ground connection is required

For end position indication, interlock control, fan startup, etc.,

AFBUP-S and AFXUP-S incorporates two built-in auxiliary switches: 2 x

SPDT, 3A (0.5A) @250 VAC, UL Approved, one switch is fi xed at +10°, one

s adjustable 10° to 90°

Meets cULus requirements without the need of an electrical ground con

nection.

During installation, testing, servicing and troubleshooting of this product, it may be

necessary to work with live electrical components. Have a qualifi ed licensed electrician or other

individual who has been properly trained in handling live electrical components perform these

tasks. Failure to follow all electrical safety precautions when exposed to live electrical components could result in death or serious injury

UP

X

066_AFB

AFBUP, AFBUP-S

AFXUP, AFBUP-S

, Inc.

USA

On/Off wiring for AFBUP, AFXU

Wht

UPX

067_AFB

Blk

e. © Belimo Aircontrols

ect to chan

M40024 - 05/10 - Sub

AFBUP-S

AFXUP-S

uxiliary Switches for AFBUP-S, AFXUP-

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

2

Page 4

AFB24-MFT, AFB24-MFT-S, AFX24-MFT, AFX24-MFT-

S

b

)

)

n

A

n

)

.

N

n

f

.

g

.

A

AFBNFBDim

ly

z

%

r

lding

W

g

)

n

r

AFX...

3

ft [1m]

tors

n

)

e

)

l

x

e

)

f

g

l

*

)

]

)

A

n

)

*

%

%

n

°

)

Allen)

d

g

Ambi

e

)

e

C)

2

g

l

t

dB(A)

A

/CS

1

g

ee

h

g

S

A

s

d

.

Proportional, Spring Return, 24 V, Multi-Function Technology

Torque min. 180 in-l

Control 2 to 10 VDC (DEFAULT

Feedback 2 to 10 VDC (DEFAULT

Applicatio

or proportional modulation of dampers and control valves in HVAC systems. The

FB24-MFT, AFX24-MFT provides mechanical spring return operation for reliable failafe application.

Technical Data AFB24-MFT, AFB24-MFT-S,

AFX24-MFT, AFX24-MFT-S

ower supp

owe

onsumption

ransformer sizin

ectrical connectio

FB..

verload protectio

Operating range Y* 2 to 10 VDC, 4 to 20 mA (default

nput impedanc

eedback output U* 2 to 10 VDC, 0.5 mA ma

orqu

Direction o

rotation*

echanica

angle of rotation

unning time

ngle of Rotation

adaptatio

Override control

osition indicatio

anual override

umidity

ent temperatur

torage temperatur

ousing NEMA 2, IP54, Enclosure Type

ousing material zinc coated metal and plastic casin

oise leve

gency listings

Quality standard ISO 900

Servicin

eight 4.6 lbs. (1.9 kg), 4.9 lbs. (2 kg) with switc

* Variable when configured with MFT options

Rated Impulse Voltage 800V, Type of action 1.AA (1.AA.B for -S version), Control Pollution Degree 3.

Programmed for 70 sec motor run time. At 150 sec motor run time, transformer sizin

24 VAC, +/- 20%, 50/60 H

24 VDC, +20% / -10

running

.5 W

o

0 VA (Class 2 power source

ft, 18 GA appliance cable, 1/2" conduit connecto

-S models: two 3 ft, 18 gauge appliance cables with

2” conduit connectors

ft [1m], 10 ft [3m] or 16 ft [5m] 18 GA appliance or

lenum cables, with or without 1/2” conduit connector

-S models: two

, 10 ft [3m] or

6 ft [5m] appliance cables with or without 1/2" conduit

connec

lectronic throughout 0 to 95° rotation

variable (VDC, PWM, floating point, on/off)

00 k for 2 to 10 VDC (0.1 mA

00

for 4 to 20 mA

for PWM, floating point and on/off contro

nimum 180 in-lb (20 Nm

pringeversible with cw/ccw mountin

otoreversible with built-in switch

95° (adjustable with mechanical end stop, 35° to 95°

pring<20 sec @ -4°F to 122°F [-20° C to 50° C];

<60 sec @ -22°F [-30° C

motor*50 seconds (default), variable (70 to 220 seconds

off (default

n position = 0%

id. position = 50

ax. position = 100

visual indicator, 0° to 95

0° is spring return position

mm hex crank (₁₆

, supplie

ax. 95% RH, non-condensin

22 to 122° F (-30 to 50° C

40 to 176° F (-40 to 80°

40dB(A) motor @ 150 seconds, run time dependen

≤62

spring return

cULus acc. to UL60730-1A/-2-14, CAN

:02, CE acc. to 2004/108/EC & 2006/95/EC

intenance fr

A E60730-

efault/Configuratio

Default parameters for 2 to 10 VDC applications of the AFB24-MFT, AFX24-MFT

ctuator are assigned during manufacturing. If required, custom versions of the

ctuator can be ordered. The parameters noted in the Technical Data table are

riable.

hese parameters can be changed by three means:

Pre-set configurations from Belimo

Custom configurations from Belimo

Configurations set by the customer using the MFT PC tool (version 3.4 or higher

oftware application

Handheld ZTH-GE

peratio

he AFB24-MFT, AFX24-MFT actuator provides 95° of rotation and is provided with a

raduated position indicator showing 0° to 95°. The actuator will synchronize the 0°

mechanical stop or the physical damper or valve mechanical stop and use this point

or its zero position during normal control operations. A unique manual override allows

the setting of any actuator position within its 95° of rotation with no power applied.

his mechanism can be released physically by the use of a crank supplied with the

ctuator. When power is applied the manual override is released and the actuator

rives toward the fail-safe position

he actuator uses a brushless DC motor which is controlled by an Application Specific

ntegrated Circuit (ASIC) and a microprocessor. The microprocessor provides the

ntelligence to the ASIC to provide a constant rotation rate and to know the actuator’s

exact position. The ASIC monitors and controls the brushless DC motor’s rotation and

rovides a Digital Rotation Sensing (DRS) function to prevent damage to the actuator

n a stall condition. The position feedback signal is generated without the need for

mechanical feedback potentiometers usin

nywhere in its normal rotation without the need of mechanical end switches

he AFB24-MFT, AFX24-MFT is mounted directly to control shafts up to 1.05" diameter

y means of its universal clamp and anti-rotation bracket. A crank arm and several

mounting brackets are available for damper applications where the actuator cannot be

irect coupled to the damper shaft. The spring return system provides minimum

pecified torque to the application during a power interruption. The AFB24-MFT,

FX24-MFT actuator is shipped at +5° (5° from full fail-safe) to provide automatic

compression against damper gaskets for tight shut-off.

NOTE: Please see documentation on Multi-Function Technology.

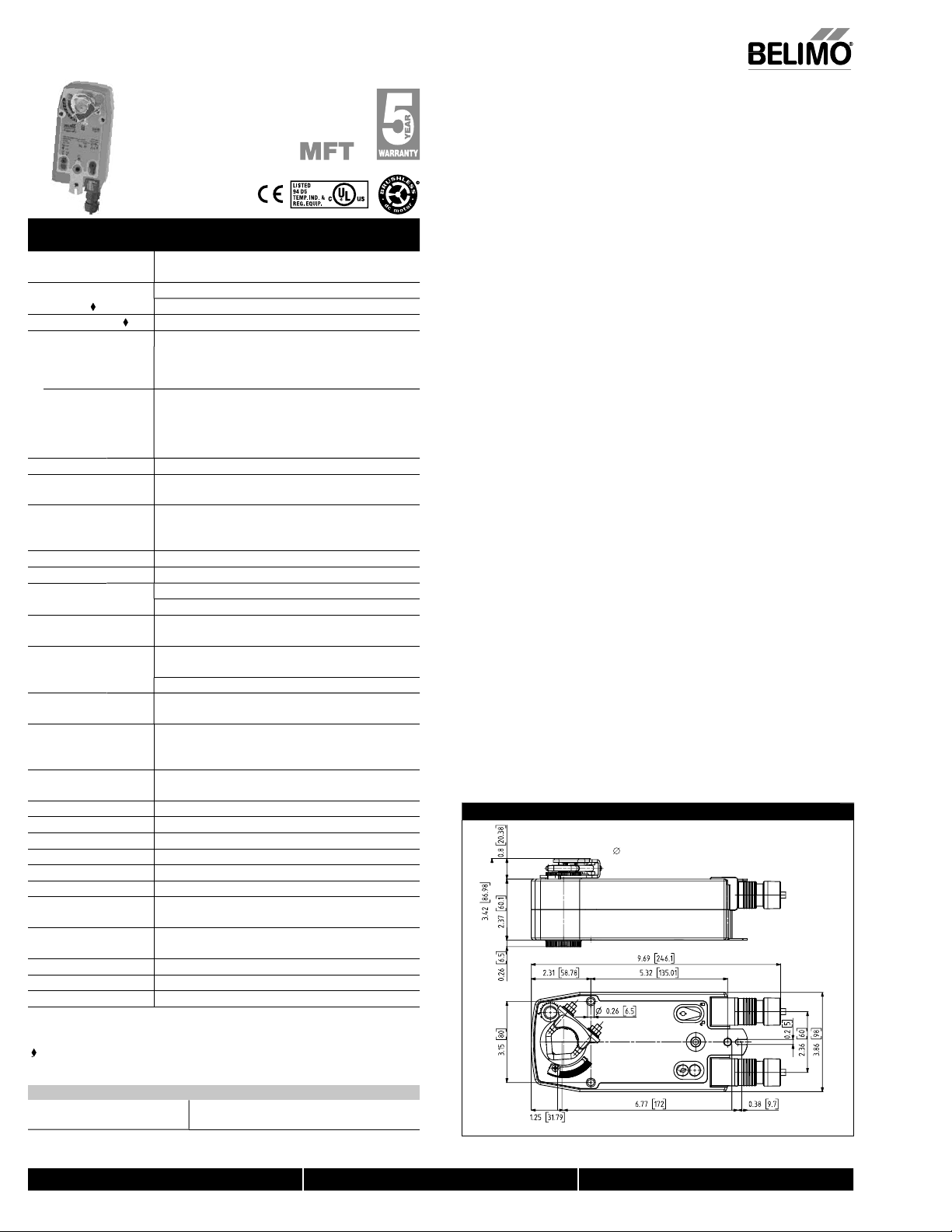

Dimensions (Inches [mm])

DRS. The actuator may be stalled

K7-2 (supplied)

1/2" Centered

(Default)

3/4" Centered

(Field Selectable)

1.05" Centered

(Field Selectable)

M40024 - 05/10 - Subject to change. © Belimo Aircontrols (USA), Inc

AFB24-MFT-S, AFX24-MFT-

uxiliary switche

2 x SPDT 3A (0.5A) @ 250 VAC, UL approve

one set at +10°, one adjustable 10° to 90°

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

Page 5

AFB24-MFT, AFB24-MFT-S, AFX24-MFT, AFX24-MFT-

S

y

S

VDC/

A

8

l

AV

n

US

g

6

h

00

1

2

t

n

III

n

S

s

B

)

50

)

g

300

g

d.

!

C.

)

.

.

.

.

.

500

dling li

Accessories

8-25

IND-AFB Damper position indicator

K7-2 Universal clamp for up to 1.05” dia jackshafts

TF-CC

ool-0

ZG-1

ZG-10

ZG-10

ZG-118 Mounting bracket for Barber Colma

ZG-AF

ZG-AFB118

ZS-100 Weather shield (metal

ZS-1

ZS-260 Explosion-proof housin

ZS-

NOTE: When using AFB24-MFT, AFB24-MFT-S, AFX24-MFT and AFX24-MFT-S actuators, only use

accessories listed on this page.

For actuator wiring information and diagrams, refer to Belimo Wiring Guide.

Typical Specification

Spring return control damper actuators shall be direct coupled type which require no

rank arm and linkage and be capable of direct mounting to a jackshaft up to a 1.05”

diameter. The actuator must provide proportional damper control in response to a 2 to

10 VDC or, with the addition of a 500

electronic controller or positioner. The actuators must be designed so that they may be

sed for either clockwise or counterclockwise fail-safe operation. Actuators shall use

a brushless DC motor controlled by a microprocessor and be protected from overload

at all angles of rotation. Run time shall be constant, and independent of torque. A 2 to

10 VDC feedback signal shall be provided for position feedback. Actuators shall be

ULus Approved and have a 5 year warranty, and be manufactured under ISO 9001

International Quality Control Standards. Actuators shall be as manufactured by Belimo.

haft extensio

rank arm

onduit fittin

8mm and 10 mm wrenc

Universal mounting bracket

Universal mounting bracket

Multiple actuator mounting bracke

od

or IV or Johnso

arm type installation

rank arm adaptor kit

rank arm adaptor kit

Weather shield (polycarbonate

NEMA 4X housin

eries 100 replacement or new crank

resistor, a 4 to 20 mA control input from an

®

MA 3../4.., Honeywell

Proportional, Spring Return, 24 V, Multi-Function Technolog

AFB24-MFT-S

AFX24-MFT-S

Auxiliary Switches for AFB24-MFT-S, AFX24-MFT-

4-20 m

W600_AFB_AFXW399_08

399_08

Wiring Diagrams

M40024 - 05/10 - Subject to change. © Belimo Aircontrols (USA), Inc.

rovide overload protection and disconnect as require

AUTION

2

Actuators may be connected in parallel if not mechanically mounted to the same

shaft. Power consumption and input impedance must be observed.

Actuators may also be powered by 24 VD

osition feedback cannot be used with Triac sink controller.

The actuator internal common reference is not compatible.

ontrol signal may be pulsed from either the Hot (source

or the Common (sink) 24 VAC line

ontact closures A & B also can be triacs

A & B should both be closed for triac source and open for triac sink

r triac sink the common connection from the actuator

must be connected to the hot connection of the controller

eets UL requirements without the need of an electrical ground

nnection

The ZG-R01

quipment Damage

resistor may be used.

ARNINGLive Electrical Components!

uring installation, testing, servicing and troubleshooting of this product, it may be

necessary to work with live electrical components. Have a qualifi ed licensed electrician

r other individual who has been properly trained in han

perform these tasks. Failure to follow all electrical safety precautions when exposed to

ve electrical components could result in death or serious injury.

ve electrical components

W399_08

W399_0

loating Point contro

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

22

Page 6

roduct Cross Referenc

e

on

.

urrent to New Generati

Torque

AF120 US, AF120-S US

AF230 US, AF230-S US AFBUP, AFBUP-S, AFXUP, AFXUP-S

133 in-lb [15 Nm] minimum 180 in-lb. [20 Nm] minimum

Running Time

Noise Level

Motor Technology

OPERATION

Overload Protection

Operating Temperature

Operating Humidity

Control Signal

CONTROL

Dimensions (L x W x H)

Motor

Spring

< 75 seconds <75 seconds

< 60 seconds

Max. 45 dB (A)

20 seconds @ -4°F to 122°F [-20°C to 50°C];

<60 seconds @ -22°F [-30°C]

<50dB(A) motor @ 75 seconds;

62dB(A) Spring Return

DC Motor DC Motor

Electronic throughout 0° to 95° rotation Electronic throughout 0° to 95° rotation

-22°F to 122°F [-30°C to 50°C] -22°F to 122°F [-30°C to 50°C]

5 to 95% RH non-condensing 5 to 95% RH, non-condensing

On/Off On/Off

0.65" [16.5]

[57]

2.24"

3.25" [82.7]

0.19" [5]

0.39" [10]

0.35" [9]

2.64"

[67]

10.47" [266]

5.85" [148.5]

0.26" [6.5]

1.93"

[49]

3.86" [98]

3.15" [80]

With Conduit Fitting

Shaft Dimensions

Direction of Rotation

Manual Override

MOUNTING & COMMISSIONING

1.97"

[50]

10.47" [266] x 3.86" [98] x 3.25" [82.7] 9.69" [246] x 3.86" [98] x 3.42" [87]

Up to 1.05” Up to 1.05”

Reversible with CW/CCW mounting Reversible with CW/CCW mounting

3 mm hex crank supplied

5 mm hex crank

(3/16" Allen), supplied

Position Indication

to 95° (0° is Spring

Return position)

95°, adjustable 30

Visual indicator, 0°

Angle of Rotation

to 95° w/ ZDB-AF2

US accessory

Visual indicator, 0° to

95° (0° is Spring

Return position)

M40024 - 05/10 - Subject to change. © Belimo Aircontrols (USA), Inc

95° (adjustable with

mechanical end stop,

35° to 95°)

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

Page 7

6

Product Cross Referenc

e

n

urrent to New Generatio

Power Supply

Power

Consumption

Transformer Sizing /

VA Rating

Auxiliary Switches

ELECTRICAL WIRING

Electrical Connection

Running

Holding

AF120 US, AF120-S US

AF230 US, AF230-S US

AF120: 120 VAC ± 10% 50/60 Hz

AF230: 230 VAC ± 15% 50/60 Hz

AF120: 8 W

AF230: 8.5 W

AF120, AF230: 3 W 3.5 W

AF120, AF230: 11 VA

(-S Models): 2 x

SPDT 7A (2.5A) @

250 VAC,

UL Approved, one set

at +5°, one adjustable

5° to 85°

3 ft, 18 GA appliance

cable 1/2” conduit

connector,

(-S Models): Two 3 ft,

18 GA, appliance

cables, ½" conduit

connectors

AFBUP, AFBUP-S, AFXUP, AFXUP-S

24…240 VAC -20 %/+10%, 50/60 Hz;

24…125 VDC +/- 10 %

7 W

7 VA @ 24 VAC

8.5 VA @120 VAC

18 VA @ 240 VAC

(-S Models): Two SPDT

3A (0.5A inductive) @

250V UL Approved, one

set at +10°, one

adjustable 10° to 90°

3 ft, 18 GA, appliance

cable, ½" conduit

connector, (-S Models):

Two 3 ft, 18 GA,

appliance cables, ½"

conduit connectors;

Optional 10 or 16 ft

cables with X types

M40024 - 05/10 - Subject to change. © Belimo Aircontrols (USA), Inc.

Housing Rating

Housing Material

Agency Listings

Storage Temperature

CONSTRUCTION

Weight

NEMA 2, IP54 NEMA 2, IP54, Enclosure Type2

Zinc coated steel Zinc coated metal and plastic casing

cULus acc. to UL 873 and CAN/CSA C22.2 No.

24-93

-40°F to 176°F [-40°C to 80°C] -40°F to 176°F [-40°C to 80°C]

7.3 lbs (3.3 kg)

cULus acc. to UL60730-1A/-2-14, CAN/CSA

E60730-1:02, CE acc. to 2004/108/EC &

2006/95/EC

4.6 lbs (2.1 kg), (-S Models): 4.9 lbs (2.25 kg)

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

2

Page 8

roduct Cross Referenc

e

on

.

urrent to New Generati

Torque

Running Time

Noise Level

Motor Technology

OPERATION

Overload Protection

Operating Temperature

Operating Humidity

Motor

Spring

AF24-MFT US, AF24-MFT-S US

AFB24-MFT, AFB24-MFT-S,

AFX24-MFT, AFX24-MFT-S

133 in-lb. [15 Nm] minimum 180 in-lb. [20 Nm] minimum

150 seconds (default),

variable (75 to 300 seconds)

<20 sec spring return fail safe position

<45 dB (A)

<20 seconds @ -4°F to 122°F [-20°C to 50°C];

40dB(A) motor @ 150 seconds, run time dependant;

150 seconds (default),

variable (70 to 220 seconds)

<60 seconds @ -22°F [-30°C]

62dB(A) spring return

Brushless DC motor Brushless DC motor

Electronic throughout 0 to 95° rotation Electronic throughout 0 to 95° rotation

-22 to 122° F (-30 to 50° C) -22 to 122°F (-30 to 50°C)

5 to 95% RH, non-condensing Max. 95% RH, non-condensing

Operating Range 'Y'

Input Impedance

CONTROL

Feedback Output 'U'

Dimensions (L x W x H)

With Conduit Fitting

Shaft Dimensions

2 to 10 VDC, 4 to 20 mA w/500 ȍ resistor;

Programmable Variable

100 kȍ for 2 to 10 VDC (0.1 mA); 500 ȍ

for 4 to 20 mA; 1500 ȍ for PWM,

Floating Point and On/Off

2 to 10 VDC, 0.5 mA max, variable when

configured with MFT options

0.65" [16.5]

[57]

2.24"

3.25" [82.7]

0.19" [5]

0.39" [10]

0.35" [9]

3.86" [98]

3.15" [80]

1.97"

[50]

2.64"

[67]

10.47" [266]

5.85" [148.5]

0.26" [6.5]

1.93"

[49]

2 to 10 VDC, 4 to 20 mA w/500 ȍ resistor;

Variable (VDC, PWM, Floating Point, On/Off)

100 kȍ for 2 to 10 VDC (0.1 mA); 500 ȍ for 4 to 20 mA;

1500 ȍ for PWM, Floating Point, On/Off

2 to 10 VDC, 0.5mA max,

variable when configured with MFT options

10.47" [266] x 3.86" [98] x 3.25" [82.7] 9.69" [246] x 3.86" [98] x 3.42" [87]

Up to 1.05" Up to 1.05"

Direction of

Rotation

Motor

Reversible with

built-in switch

MOUNTING & COMMISSIONING

Spring

Manual Override

Reversible with CW/CCW mounting Reversible with CW/CCW mounting

3 mm hex crank (supplied)

Reversible with built-in

switch

5 mm hex crank

(3/16" Allen),

supplied

M40024 - 05/10 - Subject to change. © Belimo Aircontrols (USA), Inc

Position Indication

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

Visual indicator, 0°

to 95° (0° is Spring

Return position)

Visual indicator, 0°

to 95° (0° is Spring

Return position)

Page 9

8

Product Cross Referenc

e

n

urrent to New Generatio

Angle of Rotation

MOUNTING &

COMMISSIONING

Power Supply

Power

Consumption

Transformer Sizing

Auxiliary Switches

ELECTRICAL WIRING

Electrical Connection

Running

Holding

AF24-MFT US, AF24-MFT-S US

95°, adjustable 30 to

95° w/ ZDB-AF2 US

accessory

24 VAC, ± 20%, 50/60 Hz; 24 VDC, ±10% 24 VAC, ± 20%, 50/60 Hz; 24 VDC, +20/-10%

6 W 7.5 W

2.5 W 3 W

10 VA (Class 2 power source) 10 VA (Class 2 power source)*

(-S Models): 2 x

SPDT 7A (2.5A) @

250 VAC,

UL Approved, one set

at +5°, one adjustable

25° to 85°

3 ft, 18 GA appliance

cable 1/2” conduit

connector,

(-S Models): Two 3 ft,

18 GA, appliance

cables, ½" conduit

connectors

Two 3 ft, 18 GA, appliance

connectors; Optional 10 or

models only) with X types

AFB24-MFT, AFB24-MFT-S,

AFX24-MFT, AFX24-MFT-S

95° (adjustable with

mechanical end stop,

35° to 95°)

(-S Models): Two SPDT

3A (0.5A inductive) @

250V UL Approved, one

set at + 10°, one

adjustable 10° to 90°

3 ft, 18 GA, appliance

cable, ½" conduit

connector, (-S Models):

cables, ½" conduit

16 ft cables and plenum

rated cables (non -S

Housing Rating

Housing Material

Agency Listings

Storage Temperature

CONSTRUCTION

Weight

*10 VA @ 70 second run time

8.5 VA @ 150 second run time

8 VA @ 220 second run time

M40024 - 05/10 - Subject to change. © Belimo Aircontrols (USA), Inc.

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

NEMA 2, IP54 NEMA 2, IP54, Enclosure Type2

Zinc coated metal Zinc coated metal and plastic casing

cULus acc. to UL 873 and

CAN/CSA C22.2 No. 24-93

-40 to 176° F (-40 to 80° C) -40 to 176°F (-40 to 80°C)

6.0 lbs. (2.7 kg)

cULus acc. to UL60730-1A/-2-14, CAN/CSA

E60730-1:02, CE acc. to 2004/108/EC &

2006/95/EC

4.6 lbs. (2.1 kg), (-S Models): 4.9 lbs.(2.25 kg)

2

Page 10

roduct Cross Referenc

e

on

.

urrent to New Generati

Torque

Running

Time

Noise Level

Motor Technology

OPERATION

Overload Protection

Operating Temperature

Operating Humidity

Operating Range 'WRB'

Motor

Spring

AF24-MFT95 US AFB24-MFT95, AFX24-MFT95

133 in-lb. [15 Nm] minimum 180 in-lb. [20 Nm] minimum

150 seconds (default), variable (75 to 300

seconds)

<20 sec spring return fail safe position

<45 dB (A)

Brushless DC motor Brushless DC motor

electronic throughout 0 to 95° rotation Electronic throughout 0 to 95° rotation

-22 to 122° F (-30 to 50° C) -22 to 122°F (-30 to 50°C)

5 to 95% RH, non-condensing Max. 95% RH, non-condensing

0 to 135 Honeywell electronic series 90,

or a 0 to 135 input

150 seconds (default), variable (70 to 220

seconds)

<20 sec @ -4°F to 122°F [-20°C to 50°C]; <60

sec @ -22°F [-30°C]

40dB(A) motor @ 150 seconds, run time

dependant; 62dB(A) spring return

0 to 135 Honeywell electronic series 90,

or a 0 to 135 input

Feedback Output 'U'

CONTROL

Dimensions

(L x W x H) [mm]

With Conduit Fitting

Shaft Dimensions

Direction of

Rotation

MOUNTING & COMMISSIONING

Motor

Spring

2 to 10 VDC, 0.5mA max, Variable when

configured with MFT options

0.65" [16.5]

[57]

2.24"

3.25" [82.7]

0.19" [5]

0.39" [10]

0.35" [9]

3.86" [98]

3.15" [80]

1.97"

[50]

2.64"

[67]

10.47" [266]

5.85" [148.5]

0.26" [6.5]

1.93"

[49]

2 to 10 VDC, 0.5mA max, Variable when

configured with MFT options

10.47" [266] x 3.86" [98] x 3.25" [82.7] 9.69" [246] x 3. 86" [98] x 3.42" [87]

up to 1.05" up to 1.05"

Reversible with built-in

switch

Reversible with built-in

switch

Reversible with CW/CCW mounting Reversible with CW/CCW mounting

Manual Override

Position Indication

Visual indicator, 0°

3 mm hex crank (supplied)

to 95°

(3/16" Allen),

supplied

M40024 - 05/10 - Subject to change. © Belimo Aircontrols (USA), Inc

Visual indicator, 0°

to 95° (0° is Spring

Return position)

5 mm hex crank

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

Page 11

G

Product Cross Referenc

e

n

urrent to New Generatio

AF24-MFT95 US AFB24-MFT95, AFX24-MF T95

Angle of Rotation

MOUNTING &

COMMISSIONIN

Power Supply

Power

Consumption

Transformer Sizing

Auxiliary Switches

ELECTRICAL WIRING

Electrical Connection

Housing Rating

Housing Material

Running

Holding

95°, adjustable 30 to

95° w/ ZDB-AF2 US

accessory

24 VAC, ± 20%, 50/60 Hz; 24 VDC, ±10%

6 W

2 W

95° (adjustable with

mechanical end stop,

35° to 95°)

24 VAC, ± 20%, 50/60 Hz;

24 VDC, +20/-10%

7.5 W

3 W

10 VA (Class 2 power source) 10 VA (Class 2 power source)*

N/A N/A

3 ft, 18 GA, plenum

cable, ½" conduit

3 ft, 18 GA appliance

cable, 1/2” conduit

connector

connector; AFX

Model: 3 ft, 18 GA,

plenum rated cable

with or without 1/2"

conduit connector

NEMA 2, IP54 NEMA 2, IP54, Enclosure Type2

Zinc coated metal Zinc coated metal and plastic casing

Agency Listings

CONSTRUCTION

Storage Temperature

Weight

* 10 VA @ 70 second run time

8.5 VA @ 150 second run time

8 VA @ 220 second run time

M40024 - 05/10 - Subject to change. © Belimo Aircontrols (USA), Inc.

cULus acc. to UL 873 and

CAN/CSA C22.2 No. 24-93

-40 to 176° F (-40 to 80° C) -40 to 176°F (-40 to 80°C)

6.0 lbs. (2.7 kg) 4.6 lbs. (2.1 kg)

cULus acc. to UL60730-1A/-2-14,

CAN/CSA E60730-1:02, CE acc. to

2004/108/EC & 2006/95/EC

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

Loading...

Loading...