Greenheck 479677 Installation Manual

Document 479677

Model MiniCore

®

Energy Core Ventilator

Installation, Operation and Maintenance Manual

Please read and save these instructions for future reference. Read carefully before attempting to assemble, install,

operate or maintain the product described. Protect yourself and others by observing all safety information. Failure

to comply with these instructions will result in voiding of the product warranty and may result in personal injury

and/or property damage.

Energy Recovery Technical Support

Call 1-800-240-0870

General Safety Information

Only qualified personnel should install this system.

Personnel should have a clear understanding of these

instructions and should be aware of general safety

precautions. Improper installation can result in electric

shock, possible injury due to coming in contact with

moving parts, as well as other potential hazards.

Other considerations may be required if high winds

or seismic activity are present. If more information is

needed, contact a licensed professional engineer before

movingforward.

DANGER

Always disconnect power before working on or near

this equipment. Lock and tag the disconnect switch or

breaker to prevent accidental power up.

CAUTION

When servicing the unit, the internal components may

be hot enough to cause pain or injury. Allow time for

cooling before servicing.

CAUTION

Precaution should be taken in explosive atmospheres.

1. Follow all local electrical and safety codes, as well as

the National Electrical Code (NEC), the National Fire

Protection Agency (NFPA), where applicable. Follow

the Canadian Electrical Code (CEC) in Canada.

2. All moving parts must be free to rotate without

striking or rubbing any stationary objects.

3. Unit must be securely and adequately grounded.

4. Do not spin fan wheel faster than maximum cataloged

fan RPM. Adjustments to fan speed significantly

affects motor load. If the fan RPM is changed, the

motor current should be checked to make sure it is

not exceeding the motor nameplate amps.

5. Do not allow the power cable to kink or come in

contact with oil, grease, hot surfaces or chemicals.

Replace cord immediately if damaged.

6. Verify that the power source is compatible with

theequipment.

7. Never open access doors to the unit while it

isrunning.

®

Energy Core Ventilator

1

Table of Contents

Unit Overview

General Safety Information . . . . . . . . . . . . . . 1

Unit Overview . . . . . . . . . . . . . . . . . . . . . 2

Receiving, Handling, Storage . . . . . . . . . . . . . 3

Dimensional Data and Weights . . . . . . . . . . . . 4

Service Clearances and Access Panel Locations . . . 4

Intake and Discharge Locations . . . . . . . . . . . . 5

Installation . . . . . . . . . . . . . . . . . . . . . . . 6

Electrical Connections . . . . . . . . . . . . . . . . .8

Wiring Schematics . . . . . . . . . . . . . . . . . . .9

System Start-Up . . . . . . . . . . . . . . . . . . . 10

Routine Maintenance . . . . . . . . . . . . . . . . 12

Standard Components. . . . . . . . . . . . . . . . 13

Troubleshooting . . . . . . . . . . . . . . . . . . . 14

Maintenance Log. . . . . . . . . . . . . . . . . . . 15

Our Commitment. . . . . . . . . . . . . . .Backcover

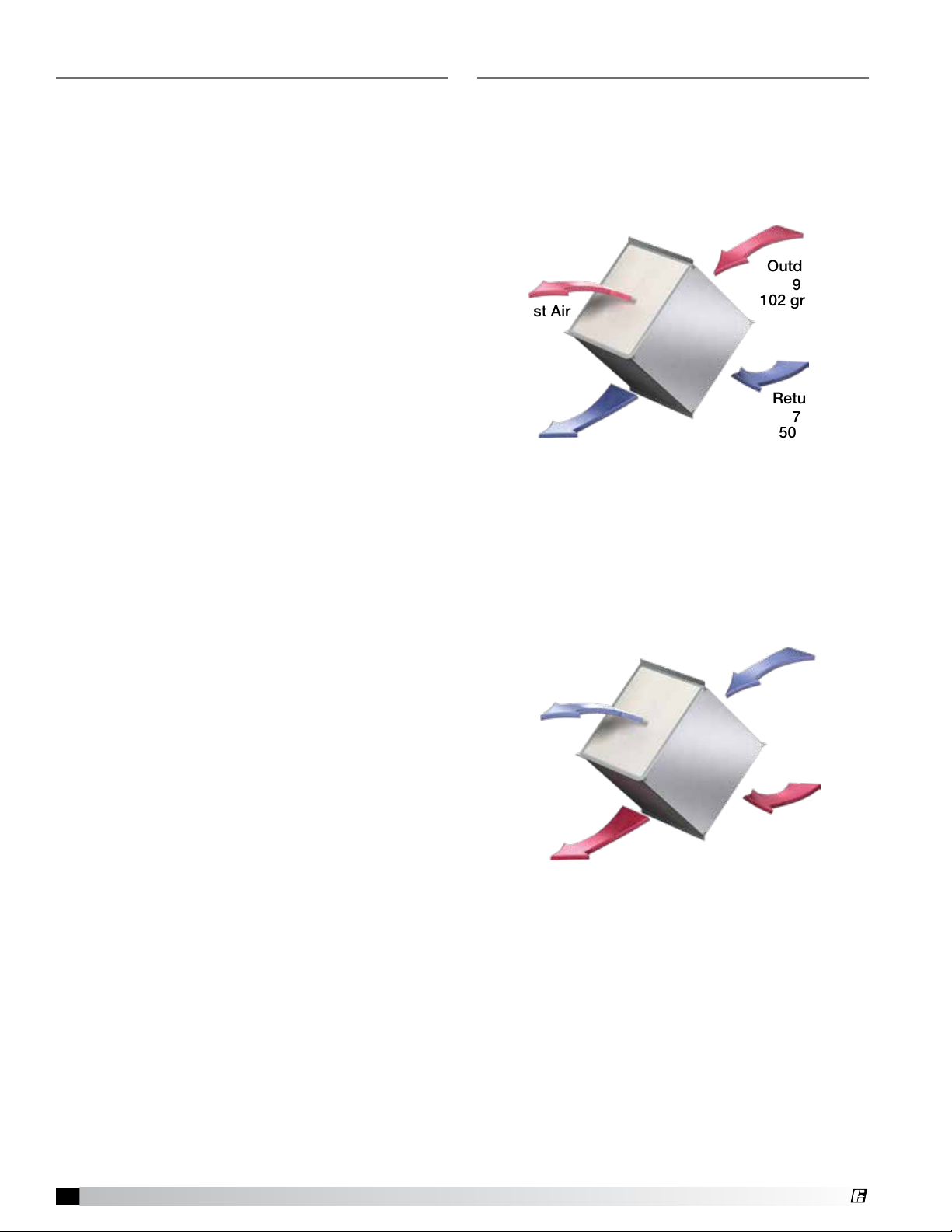

Summer Operation

Outdoor air is preconditioned (temperature and moisture

levels are decreased) by the transfer of energy from the

cooler, drier return air through the energy recovery core.

The preconditioned air is typically mixed with return air

going back to the air handler for final conditioning.

Outdoor Air

95°F

Exhaust Air

102 grains/lb.

Return Air

75°F

50% RH

Supply Air

82°F

87 grains/lb.

Winter Operation

Outdoor air is preconditioned (temperature and moisture

levels are increased) by the transfer of energy from

the warmer, more humid return air through the energy

recovery core. The preconditioned air is typically

mixed with return air going back to the air handler for

finalconditioning.

Exhaust Air

Supply Air

40°F

20 grains/lb.

Outdoor Air

-13°F

1 grains/lb.

Return Air

72 °F

50% RH

Energy Core Ventilator

2

®

Receiving

This product may have been subject to road salt

during transit. If so, immediately wash off all visible

white reside from all exterior surfaces. Upon receiving

the product, check to ensure all items are accounted

for by referencing the delivery receipt or packing list.

Inspect each crate or carton for shipping damage before

accepting delivery. Alert the carrier if any damage is

detected, do not refuse shipment. The customer shall

make notation of damage (or shortage of items) on the

delivery receipt and all copies of the bill of lading should

be countersigned by the delivering carrier. If damaged,

immediately contact your manufacturer’s representative.

Any physical damage to the unit after acceptance is not

the responsibility of the manufacturer.

Handling

Units are to be rigged and moved by the lifting brackets

provided or by the skid when a forklift is used. Location

of brackets varies by model and size. Handle in such

a manner as to keep from scratching or chipping the

coating. Damaged finish may reduce ability of unit to

resist corrosion.

Unpacking

Verify that all required parts and the correct quantity of

each item have been received. Inspect interior of unit

cabinet for any shipped loose items. If any items are

missing, report shortages to your local representative to

arrange for obtaining missing parts. Sometimes it is not

possible that all items for the unit be shipped together

due to availability of transportation and truck space.

Confirmation of shipment(s) must be limited to only

items on the bill of lading.

Storage

Units are protected against damage during shipment. If

the unit cannot be installed and operated immediately,

precautions need to be taken to prevent deterioration of

the unit during storage. The user assumes responsibility

of the unit and accessories while in storage. The

manufacturer will not be responsible for damage during

storage. These suggestions are provided solely as a

convenience to the user.

The ideal environment for the storage of units and

accessories is indoors, above grade, in a low humidity

atmosphere which is sealed to prevent the entry of

blowing dust, rain, or snow. Units designed for outdoor

applications may be stored outdoors. All accessories

must be stored indoors in a clean, dry atmosphere.

Indoor

Maintain temperatures evenly to prevent condensation.

Remove any accumulations of dirt, water, ice, or snow

and wipe dry before moving to indoor storage. To

avoid condensation, allow cold parts to reach room

temperature. Leave coverings loose to permit air

circulation and to allow for periodic inspection.

The unit should be stored at least 3½ in. (89 mm) off

the floor. Clearance should be provided to permit air

circulation and space for inspection.

Outdoor

The unit should be placed on a level surface to prevent

water from leaking into the unit. The unit should be

elevated so that it is above water and snow levels.

Ensure sufficient support to prevent unit from settling

into soft ground. Locate parts far enough apart to

permit air circulation, sunlight, and space for periodic

inspection. To minimize water accumulation, place all

unit parts on blocking supports so that rain water will

run off.

Do not cover parts with plastic film or tarps as these

cause condensation of moisture from the air passing

through heating and cooling cycles.

Inspection and Maintenance

While in storage, inspect units once per month. Keep a

record of inspection and maintenance performed.

If moisture or dirt accumulations are found on parts,

the source should be located and eliminated. At each

inspection, rotate the fan wheel by hand ten to fifteen

revolutions to distribute lubricant on motor. If paint

deterioration begins, consideration should be given to

touch-up or repainting. Units with special coatings may

require special techniques for touch-up or repair.

Machined parts coated with rust preventive should be

restored to good condition promptly if signs of rust

occur. Immediately remove the original rust preventive

coating with petroleum solvent and clean with lint-free

cloths. Polish any remaining rust from surface with

crocus cloth or fine emery paper and oil. Do not destroy

the continuity of the surfaces. Wipe thoroughly clean

with Tectyl® 506 (Ashland Inc.) or the equivalent. For

hard to reach internal surfaces or for occasional use,

consider using Tectyl® 511M Rust Preventive, WD-40®

or the equivalent.

Removing from Storage

As units are removed from storage to be installed

in their final location, they should be protected and

maintained in a similar fashion until the equipment goes

into operation.

Prior to installing the unit and system components,

inspect the unit assembly to make sure it is in

workingorder.

1. Check all fasteners, set screws on the fan, wheel,

bearings, drive, motor base, and accessories

fortightness.

2. Rotate the fan wheel(s) by hand and assure no parts

are rubbing.

®

Energy Core Ventilator

3

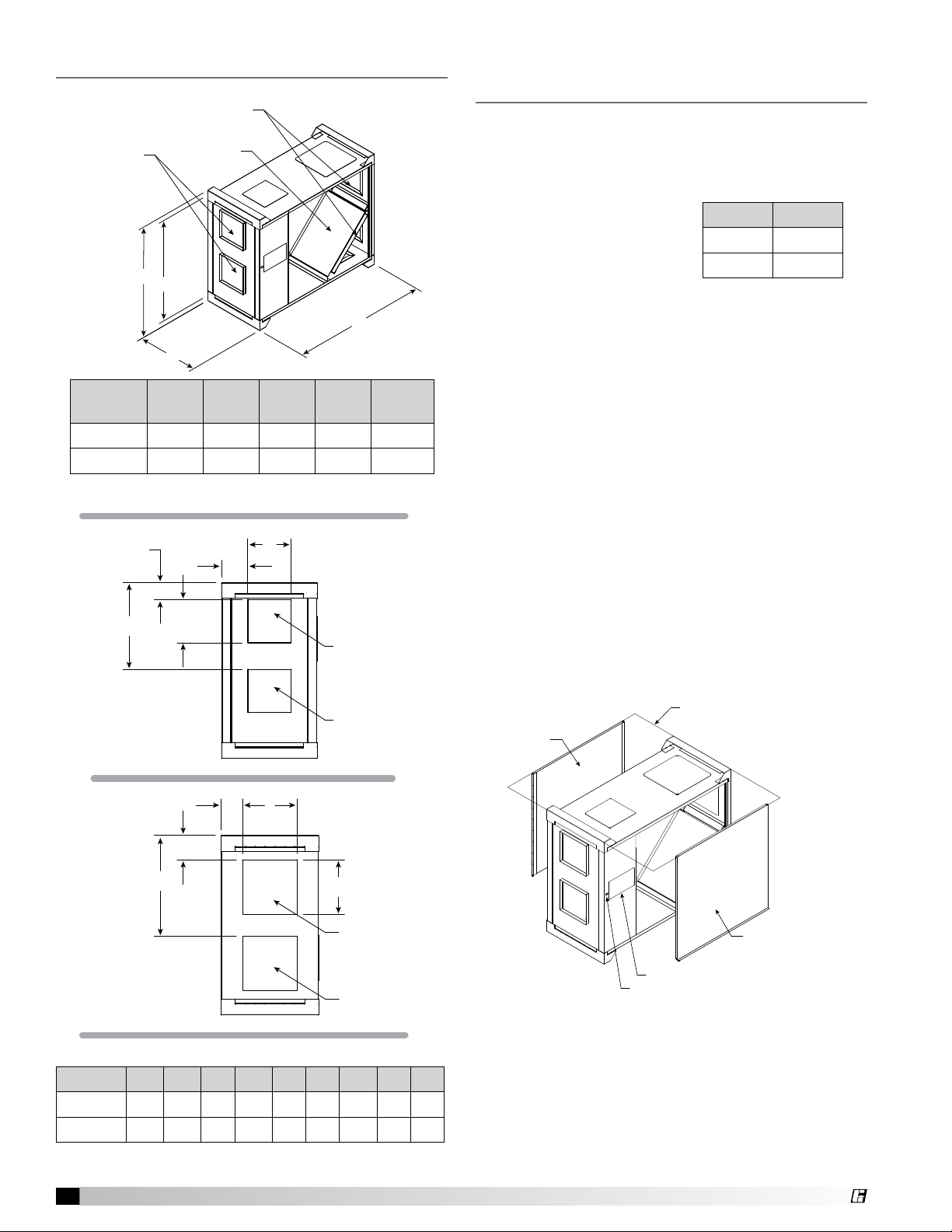

Energy Core and Filter

Dimensional Data and Weights

DISCHARGE

INLET

END

END

A

A1

MiniCore A A1 B C

5

10

All dimensions are in inches.

39.4 34.4 16.3 47.3 215

39.4 34.4 21.5 47.3 245

F

CORE

C

B

E

H

Weight

(lbs.)

Service Clearances and Access

Panel Locations

Recommended Service Clearances

The MiniCore requires minimum clearances to perform

routine maintenance, such as filter replacement, energy

core cleaning and fan inspection. Fan and motor

assemblies, energy recovery

core, and filter sections

are provided with a service

door or panel for proper

component access.

When mounted on its side, the MiniCore only requires

access on one side of the unit. It is recommended that

access is kept on the electrical input side.

Minimum service clearance should be provided on

the side of the unit for routine service and component

removal should it become necessary.

If the MiniCore unit is to be mounted on its side

(Reference the Mounting Options sections of this

IOM), then service clearance should be on the electrical

input side.

Access Panel Locations

• Outdoor and exhaust fans, and motor

• Electrical connection

• Energy core and internal filters

MiniCore Inches

5

10

30

30

Discharge End

Intake End

G

D

Discharge A

Discharge B

Access Panel

LM

J

K

L

Intake B

Intake A

Electrical Input

Service Clearance

Energy Core and Filter

Access Panel

Electrical Access Panel

MiniCore D E F G H J K L M

5

10

All dimensions are in inches.

Energy Core Ventilator

4

9.7 9.7 3.7 19.8 3.3 5.3 22.1 12 2.2

9.7 9.7 3.7 19.4 5.9 5.3 22.1 12 4.8

®

Intake and Discharge Locations

The MiniCore comes standard with end connections.

The option for configurable intake and discharge

connections (shaded in below drawing) are available

and can be interchanged based on application in

thefield.

Outdoor Air

Exhaust Air

Discharge

Outdoor Air

Discharge

Changing the Discharge Location

Step 1 - Disconnect and lockout all power switches.

Step 2 – Remove the sheet metal block off from the

desired discharge location.

Step 3 – Cut the insulation from the desired discharge

location opening.

Step 4 – Remove the backdraft damper from its current

position and reinstall in the desired discharge location.

The hinged door should be on the discharge end of

theunit.

Step 5 – Glue the cut out insulation to the sheet metal

block off. Install where the damper had been located.

Step 6 – Using a 1/2-inch wrench, remove the four

(4) bolts from the discharge end of the unit that holds

theblowers.

Step 7 – Remove the four (4) plastic plugs from the

desired discharge location and reinstall the plastic

plugs in the holes where the bolts were removed from

inStep6.

Step 8 – Position the blowers to line up with the

desired discharge location. The motor needs to be on

the discharge end of the blower and unit. If the motor

is positioned on the return side of the blower/unit, the

motor/blower will interfere with the energy recovery

core. The blower adjacent to the control center needs to

be rotated 90°. The blower not adjacent to the control

center needs to be flipped and rotated such that the

motor is now opposite the control center side of the

unit. It may be necessary to unwire the motors.

Step 9 – Bolt the blowers in their desired locations.

Securely reconnect and fasten all wires.

Intake

Exhaust Air

Intake

Changing the Inlet Location

Step 1 - Remove the metal cover for optional inlet

location by unfastening the four (4) sheet metal screws

holding it in place.

Step 2 - Hand bend flanges out to form a duct collar in

the newly uncovered intake opening.

Step 3 - Cut insulation.

Step 4 - Hand bend flanges in on original intake and

replace metal cover removed in Step 1.

®

Energy Core Ventilator

5

Loading...

Loading...