Page 1

Part #471738

®

Temperature Interlock

Installation, Operation and Maintenance Manual

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the

product described. Protect yourself and others by observing all safety information. Failure to comply with instructions

could result in personal injury and/or property damage! Retain instructions for future reference.

General Description

Description

The temperature interlock is designed to automatically

start kitchen hood exhaust fans and keep them

running while heat is being generated from the

cooking appliances. Hood systems should always be

manually started before equipment is turned on. If the

fans are forgotten to be turned on, the interlock will

turn the fans on once heat is detected. The interlock

consists of an adjustable thermostat, junction box,

Evergreen Quik-Seal threaded fitting, and is contained

Product Specification

Temperature Interlock

International Mechanical Code (IMC) 2006 section

507.2.1.1 Compliant Electrical Package

Provide Greenheck temperature interlock electrical

package as shown on plans and in accordance with

the following specification:

The temperature interlock(s) consists of an adjustable

thermostat, junction box, fire proof/leak proof

threaded fitting (Evergreen Quik-Seal® and/or

Evergreen Compression Seal), and shall be a selfcontained unit or as part of another pre-engineered

electrical control package.

The temperature interlock package shall close a

relay powering the fans when the set temperature is

reached at the thermostat. The interlock shall hold the

circuit closed upon fan switch being turned off until

the temperature at the sensor decreases below the

set point at which point the timed relay will begin a

countdown. Once the countdown has expired and as

long as the temperature has remained below the set

point, the fans shall shut down.

The temperature interlock package shall be

constructed by Greenheck in accordance with

International Mechanical Code. The manufacturer

shall provide, upon request, the necessary data that

confirms compliance with the code listed above.

Due to continuous research, Greenheck reserves the

right to change specifications without notice.

in a stand alone box or can be added to a preengineered fan control center.

Purpose

To meet IMC 2006 section 507.2.1.1, interlock

between exhaust fans and cooking equipment. This

system will utilize a temperature sensor in the exhaust

duct collar or in capture area of hood to detect heat

generated from cooking operations and automatically

activate the exhaust fans if not already turned on.

Field wiring may be required depending on location of

components.

Product Application

The temperature interlock is designed to be used

with Type I and Type II Hoods. It is not to be used in

conjunction with exhaust fire dampers. Greenheck

recommends using one interlock per hood system

(activates all fans linked to system simultaneously).

Performance Goals

Automatically energize the exhaust fans when cooking

equipment generates heat. Basic controls will be

provided with a thermostat and will consist of an 8x8

electrical box with controls and a labeled terminal

strip to hook-up incoming power and fan starters.

An adjustable delay is used to keep the exhaust fans

running when the thermostat initially closes to prevent

the fan from cycling on and off at startup and shut

down. Fans will shut down automatically 20 minutes

after the thermostat opens its contact. The time delay

can be adjusted from 1-100 minutes based on jobsite

requirements.

Temperature Interlock

1

®

Page 2

Table of Contents

Product Specification . . . . . . . . . . . . . . . . . . . . . . . . 1

General Description . . . . . . . . . . . . . . . . . . . . . . . . . 1

Receiving and Handling . . . . . . . . . . . . . . . . . . . . . . 2

Installation

Hood Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Duct Collar Mounting . . . . . . . . . . . . . . . . . . . . . . 3

Electrical Connections

Thermostat Connections . . . . . . . . . . . . . . . . . . . 4

Breaker Panel to Control Box or

Fan Control Center . . . . . . . . . . . . . . . . . . . . . . 4

Circuit Connections . . . . . . . . . . . . . . . . . . . . . . . 4

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Control Circuit Diagrams . . . . . . . . . . . . . . . . . . . 5-6

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Frequently Asked Questions . . . . . . . . . . . . . . . . . . 8

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Codes and Standards Compliance . . . . . . . . . . . . . 8

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Receiving and Handling

Upon receiving the equipment, check for both obvious

and hidden damage. If damage is found, record all

necessary information on the bill of lading and file

a claim with the final carrier. Check to be sure that

all parts of the shipment, including accessories, are

accounted for.

Storage

If a temperature interlock must be stored prior

to installation it must be protected from dirt and

moisture. Indoor storage is recommended. For

outdoor storage, cover the hood with a tarp to keep it

clean, dry, and protected from UV (ultraviolet) radiation

damage.

Improper storage which results in damage to the unit

will void the warranty.

Temperature Interlock

2

®

Page 3

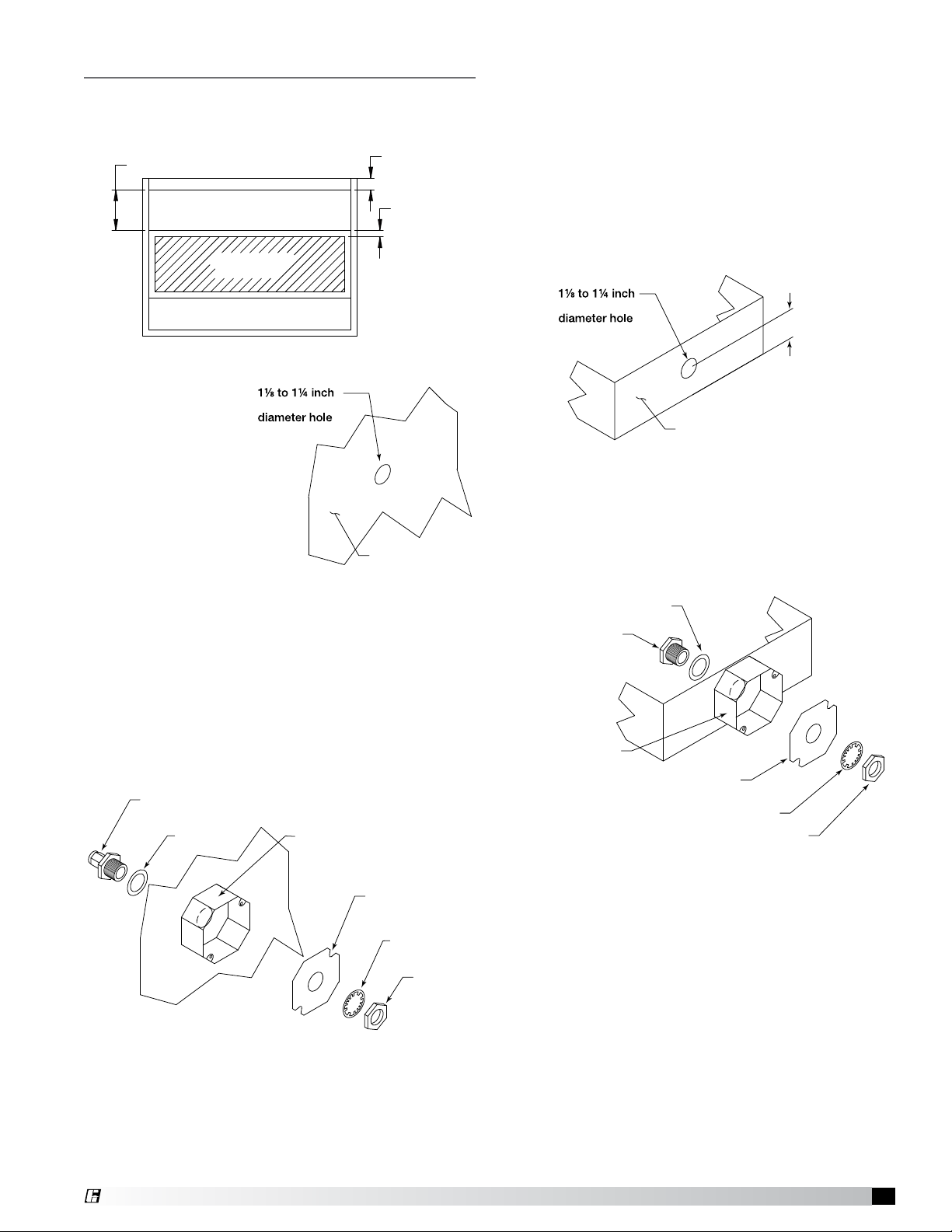

Installation – Hood Mounting

Gasket

Compression Seal

PN 452614

Nut

Lock Washer

Octagon Extension

PN 830125

Junction Box Plate

PN 732396

19.525 inches

3 inch air space

2 inch typical

Exhaust Area

Supply Area

(optional)

Sensor Install

(cut out area)

Gasket

Compression Seal

PN 452614

Nut

Lock Washer

Octagon Extension

PN 830125

Junction Box Plate

PN 732396

Gasket

1/2 inch Quik-Seal

PN 451168

Recommended thermostat mounting location is in

the flat interior of the hood and at least 8 inches

(20.32cm) from light fixture.

Duct Collar Mounting

1. Locate the exhaust duct on top of the hood. A

11⁄8to 1¼-inch (28.58 to 31.75 mm) diameter hole

must be cut into the duct 2inches (50.8 mm)

above the hood top. Center the hole along the

side of the duct. Make sure that the thermostat

will not interfere with any fire system nozzles, or

other items installed in the exhaust duct. If an

exhaust fire damper is present the hood exhaust

collar, it must be removed prior to thermostat

installation.

Hood Plan View

1. Locate the flat

area(s) at the

(28.58 to 31.75 mm)

top interior of

the hood in front

of the filters,

towards the front

of the hood. A

11⁄8 to 1¼ inch

(28.58 to 31.75

mm) diameter

Hood Surface

hole must be cut

into the top of the capture tank. Make sure the

thermostat will not interfere with the fire system

nozzles and is not within 8 inches (20.32cm) of

the light fixtures.

2. Insert the Evergreen Compression Seal fitting into

the hole from the inside of the hood, making sure

the gasket is placed on the fitting before inserting

it into the hole. Install the lock washer and 11⁄2inch

(38mm) nut on the threaded portion of the

compression seal fitting and tighten securely.

Compression Seal

PN 452614

Gasket

Octagon Extension

PN 830125

(28.58 to 31.75 mm)

Hood Exhaust Collar

(front side)

2. Insert the Evergreen Quik-Seal fitting into the

hole from the inside of the duct, making sure the

gasket is placed on the fitting before inserting it

into the hole. Install the lock washer and 1

(38.1mm) nut on the threaded portion of the

Evergreen Quik-Seal fitting and tighten securely.

Gasket

1/2 inch Quik-Seal

Octagon Extension

PN 451168

PN 830125

Junction Box Plate

PN 732396

Lock Washer

Exploded View (Components)

2 inches

(50.8 mm)

Nut

1

⁄2inch

3. Place the junction box provided over the fitting on

4. Thread the thermostat into the compression seal

Junction Box Plate

PN 732396

Lock Washer

Nut

Exploded View (Components)

top of the hood, keeping the fitting centered in the

box.

fitting and tighten to 35 ft-lbs. (4.84 m-kgs).

®

3. Place the junction box provided over the fitting

and tack weld the junction box to the exhaust duct

keeping the fitting centered in the box. (Welding

optional).

4. Thread thermostat into Evergreen Quik-Seal fitting

and tighten to 35 ft-lbs (4.84 m-kgs).

Temperature Interlock

3

Page 4

Electrical Connections

Thermostat Connections

1. Run two 14 awg, 90° minimum conductors, black,

in conduit from each thermostat to the appropriate

electrical circuit connections. (See Step 3 for

connection options).

2. In junction box, connect leads on thermostat to

the 14 awg conductors using appropriate size

wire nuts.

• Wires are interchangeable with one another.

• Wire thermostats in parallel if there are multiple

exhaust ducts.

3. Choose the final connection based on:

• Terminals T1 & T2 in fan control center (KFCC).

• Terminals 5 & 6 in control box on top of hood/

utility cabinet.

CAUTION

Do not connect thermostat in series with fan power.

On/off cycling of the fans will result during startup and shutdown periods. Use the thermostat for

control wiring only.

Calibration

Thermostat is preset by factory to 95°F and has a

slow make and break contact. It will make contact on

a temperature rise and break contact on temperature

fall. The temperature set point may have to be

adjusted slightly depending of both ambient and

cooking conditions. The adjustment knob is located

on the back of the thermostat. Use a small blade

screwdriver to make the adjustments.

1. Turn counterclockwise to increase the temperature

set point, turn clockwise to decrease the

temperature set point.

2. Quarter revolution in either direction corresponds

to a 22.5°F adjustment. Be sure to make small

adjustments, about 1/16 of a turn (≈6°F) or less at

one time.

3. Do not exceed more than one-half revolution in

either direction.

4. Check system operation before making additional

adjustments.

Breaker Panel to Control Box or Fan Control

Center

1. Connect a Single Pole Single Throw (SPST) switch

to one of the following based on application:

• Terminals 3 & 4 in the control box.

• Terminals S1 & S1H in the fan control center.

Circuit Connections

1. Standard Interlock Control

• 120V, 10 or 15 amp circuit to terminals 1 & 2

• Control voltage for fan starter activation

• 120V, 24V or other control circuit

(drawing on page 8)

• Control circuit power to terminal 7

• Terminal 8 to fan starter coils

• 120V only control circuit

(drawing on page 9)

• Terminals 7 & 8 to fan starter coils

2. Fan Control Center Integration (KFCC)

• Power to H1 & N1 in fan control center

• No additional control circuits are required fan

starters are factory wired

Temperature Interlock

4

®

Page 5

BK

YW

YW

WT

OR OR

RD

RD

CONTROL INPUT: 120VAC, 10AMPS FROM BREAKER

CONTROL VOLTAGE FROM BREAKER

OPTIONAL EXHAUST ON IN FIRE

FAN STARTERS

L1

N

G

Painted Only

NEMA 3R

L1

N

G

2

TS1

TS2

5

6

1

7 3 4 8

S1

C

1

6

2

NO

NO NC

ST

ST

ST

COM

EXHAUST

FS

FIRE SYSTEM

MICROSWITCH

383271 (OFF DELAY 1-100 MINUTES)

THERMOSTAT(S)

EXHAUST

SUPPLY

GREENHECK

Control Circuit Diagram (Standard Control)

TS1

TS2

COM

THERMOSTAT(S)

FAN STARTERS

ST

EXHAUST

ST

EXHAUST

ST

SUPPLY

L1

YW

1

BK

RD

7 3 4 8

OPTIONAL EXHAUST ON IN FIRE

CONTROL INPUT: 120VAC, 10AMPS FROM BREAKER

5

YW

6

1

C

OR OR

S1

6

383271 (OFF DELAY 1-100 MINUTES)

2

NO

FS

FIRE SYSTEM

MICROSWITCH

NO NC

RD

WT

8.0

G

N

GREENHECK

2

Painted Only

NEMA 3R

8.0

4.0

L1

CONTROL VOLTAGE FROM BREAKER

Thermostat factory set at 95ºF (35ºC)

Do not turn adjustment screw more than

1/2 revolution in either direction.

1/8 turn equals 12ºF (6.7ºC)

Counterclockwise = increase temperature setting

Clockwise = decrease temperature setting

G

N

ADJUSMENT

SCREW

THERMOSTAT

CONNECTIONS

Circuit

Control

Fan Switch

Connection

Thermostat

Connection

Fan Starter

Control Circuit

FIELD

Torque to 18 in-lbs.

120/1 - 10 A

NEUTRAL

S1

H

MUA EX EX

N

T2T1

1

2

3

4

5

6

7

8

®

Temperature Interlock

Part #471503

5

Page 6

closed w/power at H1/N1 & fire system armed

Control Circuit Diagram (Fan Control Center)

L1

CONTROL INPUT: 120VAC, 15AMPS FROM BREAKER

H1

TYP. 1 SENSOR PER

TS1

EXHAUST COLLAR

TS2

WIRED IN PARALLEL

FACTORY MOUNTED SWITCH

LT1

S1N

R

ST1

A1ORA2

OL1

96

RD

T1

S1H

6

T2

R8

1

2

(Off Delay 1-100 minutes)

NOC

S1

S1

FACTORY WIRING TO SWITCH

OR

N

G

N1

WH

WH

95

INPUT POWER

3 WIRE

208/3 PHASE

FROM BREAKER

INPUT POWER

3 WIRE

208/3 PHASE

FROM BREAKER

12.0

LIGHTS

FANS

18.0

6.0

L1

L2

L3

L1

L2

L3

CONTROL PANEL

Installation Location:

Ship Loose

"LIGHTS" SWITCH

"FAN" SWITCH

OL1 ST1

T1

T1

L1

L2

L3

L1

L2

L3

T2

T2

T3

T3

OL2 ST2

T1

T1

T2

T2

T3

T3

Exh

FAN 1

Supply

FAN 2

Panel Mark:

Hood Mark(s):

F1-E EF-1 1.5 208 3 5.7 14 ga 15 amp

F2-S SF-1 1 208 3 4.6 14 ga 15 amp

Qty. Fan Switches (0-3)

1

Qty. Light Switches (0-3)

1

Qty. Temp. Switches (0-1)

0

One Switch for L & F

Temperature Interlock

X

Mounted Sensors - Factory

0

Mounted Sensors - Field

1

Heat Switch

Cool Switch

G

AD Switch

Remote Switches

Audible Alarm

Gas Reset

Power for Gas Solenoid

Power for Shunt Trip

G

Spare Fire Switch Contact

(dry contacts for building alarm)

Spare Relay Contacts

(can be used for shunt trip, alarms, etc.)

A

B

open w/power at H1/N1 & fire system armed

A

closed on fire or no power

B

open on fire or no power

RD

OR

R1

R1

YW

1

3

4

1

ST2

A1YWA2

OL2

96

WH

95

Fan MarkMotor HP

RD/RD

C2

BR/BK

NC2

BK/YW

NO2

RD

C3

BR

NO3

BK

NC3

Mark 1

Volt

Tempering SW

Gas Off w/Fans

NC

C

NO

4

R2

1

3

WirePH FLA Breaker

Exhaust in Fire

X

MUA Interface

Lights Out in Fire

Fire Relay (#1)

X

Extra Fire Relay (#2)

Extra Fire Relay (#3)

DPDT Relay w/SF

DPDT Relay w/EF

Off Delay Relay

SF Failure Light

EF Failure Light

Fan Failure Light (Appl.)

Damper

Aux. Supply Contact

Tie in WWCP

Ansul / Amerex

RD/RD

BR/BK

FS2

BK/YW

(activated by FS1)

RD

C4

BR

NO4

A

B

NC4

5

BK

6

R2

8

RD

C1

THERMOSTAT

RD(RD)

ADJUSTMENT

SCREW

FS1

BR(BK)

NC

C

BK(YW)

NO

NC1

NO1

BR

R1

2

7

THERMOSTAT CALIBRATION

FACTORY SETTING AT 95°F (35°C)

DO NOT TURN ADJUSTMENT SCREW MORE THAN

1/2 REVOLUTION IN EITHER DIRECTION

1/8 TURN = 12°F (6.7°C)

INCREASE TEMPERATURE = COUNTERCLOCKWISE

DECREASE TEMPERATURE = CLOCKWISE

Switches Mounting - On Control Package

L1

BK

H2

WH

R2

7

2

LIGHT INPUT: 120VAC,

15AMPS FROM BREAKER

S-1

B2

LT

1400W max.

LT

W2

WH

N

N2

TORQUE:

TERMINAL STRIPS = 18 IN/LB.

GROUNDING BAR = 20 IN/LB.

LABEL DESCRIPTION

Exhaust Fan

EF

Supply Fan

SF

Starter

ST

OverLoad

OL

Contactor

C

Ground

G

Switch

S

Light

LT

Fire Switch

FS

Relay

R

Air Flow Switch

AF

Gas Solenoid

SV

STB

Shunt Trip Breaker

Damper

D

PushButton

PB

Evap Cooler

EC

NOTES:

Drawing shown de-energized at L1 (term. #H1),

w/ Fire System armed (non-fire mode).

(normal operation, R1 & R2 are energized) If wall

mounted prewire, or field installed fire system,

the fire system microswitches must be field wired.

UL LISTED

Wiring Diagram #

UNDER SUBJECT 891

FIELD WIRING:

USE MINIMUM

60° Copper Wire

FACTORY WIRING

FIELD WIRING

ALL WIRING 90°C 14 GA.

UNLESS SPECIFIED

WIRE COLOR

BK - black

BL - blue

BR - brown

OR - orange

PR - purple

RD - red

YW - yellow

WT - white

FILE #E200616

T110-2-311

Temperature Interlock

6

®

Page 7

Testing

Troubleshooting

1. Turn fan switch on, then off to ensure proper fan

operation before cooking equipment is started.

Once this is verified, testing can proceed.

2. For testing only, locate the time delay relay. Turn

the time adjustment knob counterclockwise to the

first mark in order to expedite the testing process.

Make a note as to where the timer was originally

set.

3. Heat up cooking equipment with fans off. Once

the duct temperature reaches the set point of the

thermostat the fans will start, preferably within

5minutes. If the fans take more than 5 minutes

to start, decrease the temperature set point by

turning the adjustment screw 1/16 turn clockwise.

Do not apply direct flame to the thermostat

4. If an adjustment was made in Step 3, repeat now.

5. After verification of fan start-up, shut down

cooking equipment. The fan switch should still be

in the off position. Once cooking equipment has

cooled, the thermostat will open triggering the

timer to begin. Once time has expired, the fans will

shut down. Thermostat operation can be verified

by checking voltage (120V) between T2 and

neutral on either the control box or KFCC. 120V

will be present when the thermostat senses heat.

6. Once proper operation has been verified, set

the dial on the timer relay to its original setting

(approximately 20 minute delay).

NOTE

During testing, if fans do not start automatically in

the first 10 minutes of cooking equipment activation,

manually start fans to avoid accidental fire system

dump due to heat build-up.

Fans do not turn on automatically upon cooking

equipment activation.

• Check wiring to control panel or relay box,

thermostats must be wired in parallel

• Temperature set point to high, decrease set point

• No power to fans, check breakers/starters/relays

Fans do not shut off.

• Switch must be in the off position

• Cooking equipment hot, wait for it to cool

• Temperature set point too low, increase set point

• Ensure wires connected to appropriate control

circuit

• Time delay too great, turn down timer

Fans cycle off to on when turned off.

• Cooking equipment not cooled enough, retry in

5minutes

Fans do not turn on quick enough.

• Decrease temperature set point

Maintenance

Daily

Clean thermostat with cloth and degreaser. Keep

clean for best performance. (Can clean weekly

depending upon grease accumulation).

Weekly

Dependant on grease production and grease filter

type, clean thermostat.

Seasonal

May have to change temperature setting on back of

thermostat if ambient kitchen temperatures fluctuate

between summer and winter seasons.

Operation

1. Turn fans on and off using the fan switch. It is

normal for the fans to remain running after the

switch is turned off. The exhaust duct thermostat

will open after heat is no longer present under

the hood which will activate the timer to begin

its countdown. Once time has expired, fans will

shut down. The timer is adjustable from 1-100

minutes. The recommended time delay setting is

approximately 20 minutes.

2. In the event that the cooking equipment is started

without turning the fans on manually, the fans

will turn on automatically and remain running

with the presence of heat under the hood. The

exhaust duct thermostat will open after heat is no

longer present under the hood which will activate

the timer to begin its countdown. Once time has

expired, fans will shut down.

®

Whom to call

Contact your local Greenheck representative.

What to have ready for the call

Sales order, serial number and description of product.

Sales Order Number _______________________

Serial Number _____________________________

Temperature Interlock

7

Page 8

Frequently Asked Questions

Replacement Parts

What temperature is the thermostat set from the

factory?

95º Fahrenheit.

Will the temperature interlock automatically start/

stop the fans?

When connected properly to fan starters the

temperature interlock will automatically control the

fans without input from the user. However intended,

use as a back-up to manual control.

May I connect the power going to my fan directly

through the control box?

No, the control box should only use control voltage

only (24-120V), and a separate 120V power source

is required to run the temperature interlock controls.

Greenheck recommends the use of starters sized for

each fan.

What is the purpose of the timer in the control box?

The timer is used to delay the shut down of the fans

to prevent fan on/off cycling while the temperature

in the exhaust duct can reach steady state. Without

the delay, cycling could occur both on startup

or shutdown of cooking equipment. The delay is

typically set at 20 minutes.

Can I use one control box for multiple hood systems?

This can be done, however, it is not recommended.

Any one of the thermostats would turn on all hoods

running on that control box. It is better to have one

hood/fan per control box, plus a significant energy

savings can be obtained if one or more of the hoods

is not in operation.

Can I still turn my fan on and off?

Yes, the temperature interlock is designed to be

operated with a typical on/off switch. The fan may

not turn off directly after turning the fan switch off, it

will sense when the cooking operations have cooled

and then turn off.

Quantity

1 383923

1 451168

1 830125

1 380926

1 381460

3 382859

2 382858

1 383271

1 452614

Part

Number

Description

Thermostat, Vulcan 1C2B9

5/8-inch Type C

Evergreen Quik-Seal, 1/2-inch

#171 (1-1/8 inch hole size)

Ext, Octagon (drilled)

SC55151-1/2 (380928)

Cover, Octagon Box

SC#54-C-1RACO 722

Encl, 8X8X4 NEMA3R

ELMATE RC-884-SC3R

Terminal Block, 3 pole,

DIN-RAIL MT, BUS NDN3-WH

Jumper, DIN-RAIL Terminal

Block #JNDN3

Timer SSAC #KRDB424 SPST

1-100 min.

Evergreen Compression Seal,

5/8-inch, #302

Codes and Standards Compliance

UL 710

•

• National Fire Protection Association (NFPA 96)

• International Mechanical Code (IMC) 2006

Section 507.2.1.1

Warranty

Greenheck warrants this equipment to be free from defects in material and workmanship for a period of one year from

the shipment date. Any units or parts which prove defective during the warranty period will be replaced at our option

when returned to our factory, transportation prepaid. Motors are warranted by the motor manufacturer for a period of

one year. Should motors furnished by Greenheck prove defective during this period, they should be returned to the

nearest authorized motor service station. Greenheck will not be responsible for any removal or installation costs.

As a result of our commitment to continuous improvement, Greenheck reserves the right to change specifications

without notice.

AMCA Publication 410-96, Safety Practices for Users and Installers of Industrial and Commercial Fans, provides additional

safety information. This publication can be obtained from AMCA International, Inc. at: www.amca.org.

®

Phone: (715) 359-6171 • Fax: (715) 355-2399 • E-mail: gfcinfo@greenheck.com • Web site: www.greenheck.com

471738 • Temperature Interlock, Rev. 1, April 2010 Copyright 2010 © Greenheck Fan Corporation

8

Loading...

Loading...