Page 1

Document 452413

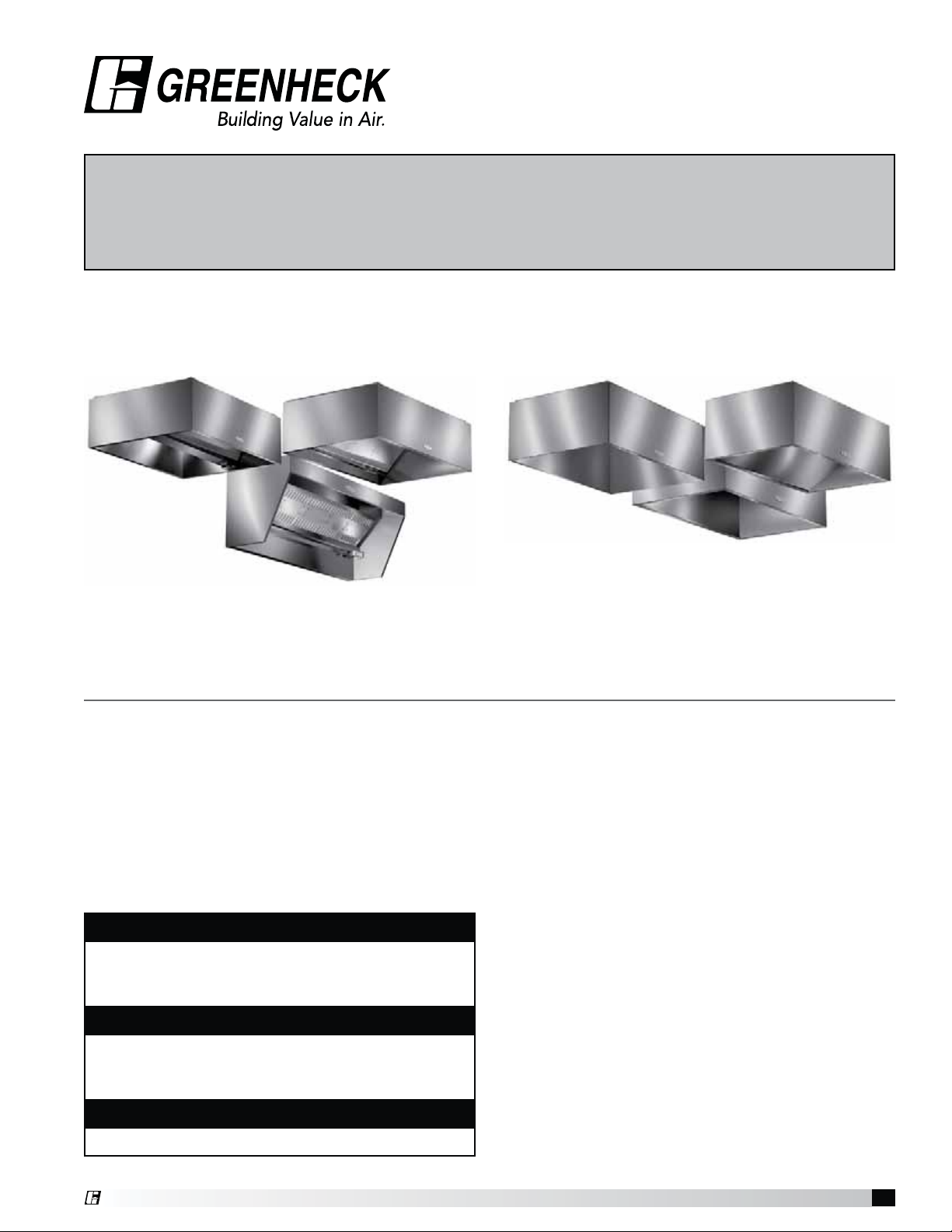

Kitchen Hoods

®

Type I and Type II

Installation, Operation and Maintenance Manual

Please read and save these instructions for future reference. Read carefully before attempting to assemble,

install, operate or maintain the product described. Protect yourself and others by observing all safety

information. Failure to comply with instructions could result in personal injury and/or property damage!

Type IIType I

General Safety Information

Only qualified personnel should install this system.

Personnel should have a clear understanding of these

instructions and should be aware of general safety

precautions. Improper installation can result in electric

shock, possible injury due to coming in contact with

moving parts, as well as other potential hazards. Other

considerations may be required if high winds or seismic

activity are present. If more information is needed,

contact a licensed professional engineer before moving

forward.

DANGER

Always disconnect power before working on or near a

fan. Lock and tag the disconnect switch or breaker to

prevent accidental power up.

CAUTION

When servicing the fan, motor may be hot enough

to cause pain or injury. Allow motor to cool before

servicing.

CAUTION

Precaution should be taken in explosive atmospheres.

1. Follow all local electrical and safety codes, as well as

the National Electrical Code (NEC), the National Fire

Protection Agency (NFPA), where applicable. Follow

the Canadian Electrical Code (CEC) and ULC-S650 in

Canada.

2. The rotation of the fan wheel is critical. It must be free

to rotate without striking or rubbing any stationary

objects.

3. Fan motor must be securely and adequately

grounded.

4. Do not spin fan wheel faster than maximum

cataloged fan rpm. Adjustments to fan speed

significantly affects motor load. If the fan RPM is

changed, the motor current should be checked to

make sure it is not exceeding the motor nameplate

amps.

5. Do not allow the power cable to kink or come in

contact with oil, grease, hot surfaces or chemicals.

Replace cord immediately if damaged.

6. Verify that the power source is compatible with the

equipment.

7. Never open access doors to a duct while the fan is

running.

®

Kitchen Hoods • Type I and Type II

1

Page 2

Receiving

Upon receiving the product, check to make sure all

items are accounted for by referencing the packing

list and ensuring all items were received. Inspect

each crate for shipping damage before accepting

delivery. Notify the carrier if any damage is noticed.

The carrier will make notification on the delivery receipt

acknowledging any damage to the product. All damage

should be noted on all the copies of the bill of lading

which is countersigned by the delivering carrier. A

Carrier Inspection Report should be filled out by the

carrier upon arrival and filed with the Traffic Department.

If damaged upon arrival, file claim with carrier. Any

physical damage to the unit after acceptance is not the

responsibility of Greenheck Fan Corporation.

Unpacking

Verify that all required parts and the correct quantity

of each item have been received. If any items are

missing, report shortages to your local representative

to arrange for obtaining missing parts. Sometimes it

is not possible that all items for the unit be shipped

together due to availability of transportation and truck

space. Confirmation of shipment(s) must be limited

to only items on the bill of lading. Filters are shipped

on a separate skid in their original packaging. Do not

remove factory packaging or install filters until just prior

to commissioning. Remove all other shipping/packing

materials including fan tie down straps.

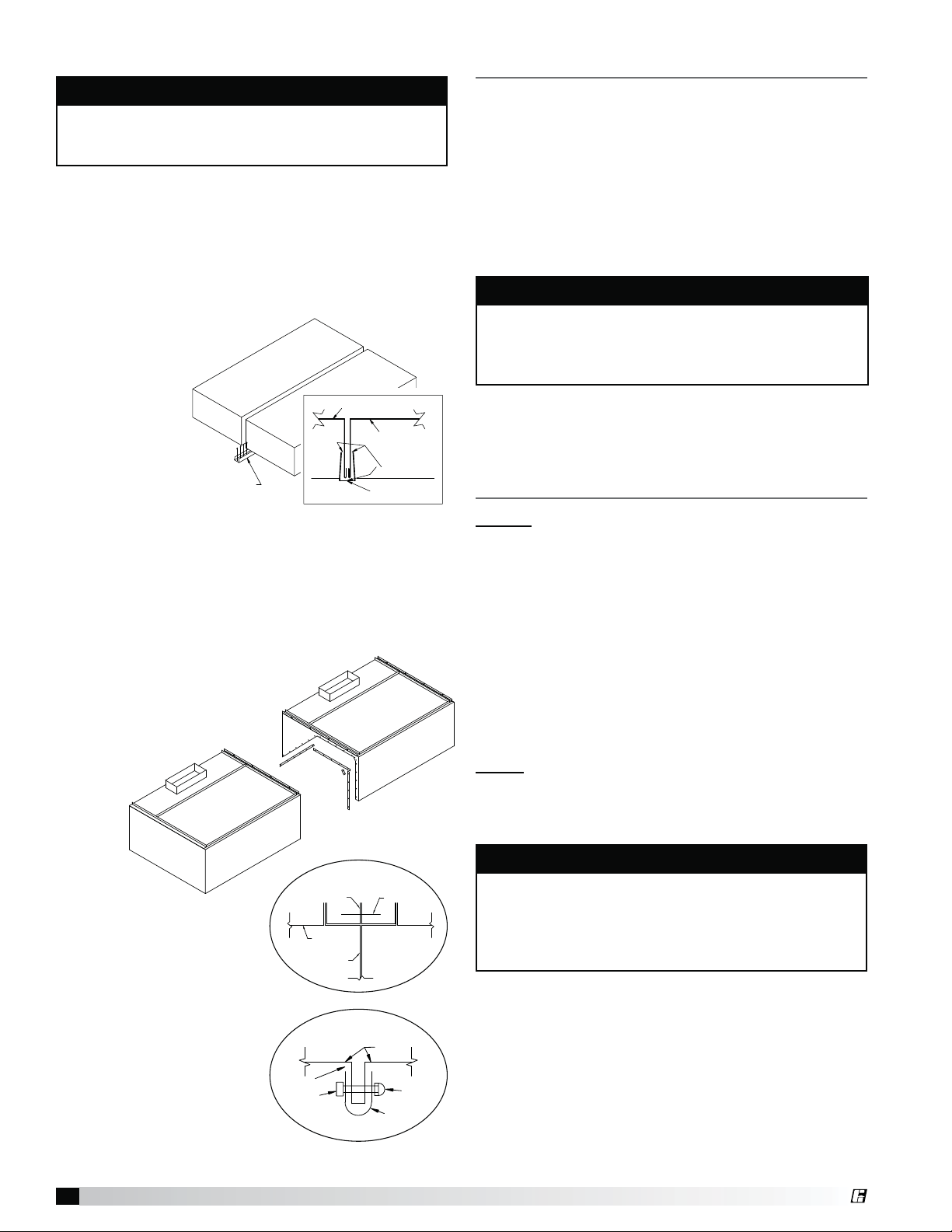

Handling

Units are to be rigged and moved by the lifting brackets

provided or by the skid when a forklift is used. Location

of brackets varies by model and size. Handle in such

a manner as to keep from scratching or chipping the

coating. Damaged finish may reduce ability of unit to

resist corrosion.

Storage

Units are protected against damage during shipment. If

the unit cannot be installed and operated immediately,

precautions need to be taken to prevent deterioration of

the unit during storage. The user assumes responsibility

of the unit and accessories while in storage. The

manufacturer will not be responsible for damage during

storage. These suggestions are provided solely as a

convenience to the user.

INDOOR - The ideal environment for the storage of

units and accessories is indoors, above grade, in a

low humidity atmosphere which is sealed to prevent

the entry of blowing dust, rain, or snow. Temperatures

should be evenly maintained between 30°F (-1°C)

and 110°F (43°C). Wide temperature swings may

cause condensation and “sweating” of metal parts.

All accessories must be stored indoors in a clean, dry

atmosphere.

Remove any accumulations of dirt, water, ice, or snow

and wipe dry before moving to indoor storage. To avoid

“sweating” of metal parts, allow cold parts to reach

room temperature. To dry parts and packages, use a

portable electric heater to get rid of any moisture

buildup. Leave coverings loose to permit air circulation

and to allow for periodic inspection.

OUTDOOR - Units designed for outdoor applications

may be stored outdoors, if absolutely necessary. Roads

or aisles for portable cranes and hauling equipment are

needed.

The unit should be placed on a level surface to prevent

water from leaking into it. The unit should be elevated

on an adequate number of wooden blocks so that it is

above water and snow levels and has enough blocking

to prevent it from settling into soft ground. Locate parts

far enough apart to permit air circulation, sunlight,

and space for periodic inspection. To minimize water

accumulation, place all unit parts on blocking supports

so that rain water will run off.

Do not cover parts with plastic film or tarps as these

cause condensation of moisture from the air passing

through heating and cooling cycles.

Inspection and Maintenance during Storage

While in storage, inspect fans once per month. Keep a

record of inspection and maintenance performed.

If moisture or dirt accumulations are found on parts,

the source should be located and eliminated. At each

inspection, rotate the fan wheel by hand ten to fifteen

revolutions to distribute lubricant on motor. Every three

months, the fan motor should be energized. If paint

deterioration begins, consideration should be given to

touch-up or repainting. Fans with special coatings may

require special techniques for touch-up or repair.

Machined parts coated with rust preventive should be

restored to good condition promptly if signs of rust

occur. Immediately remove the original rust preventive

coating with petroleum solvent and clean with lintfree cloths. Polish any remaining rust from surface

with crocus cloth or fine emery paper and oil. Do not

destroy the continuity of the surfaces. Wipe thoroughly

clean with Tectyl® 506 (Ashland Inc.) or the equivalent.

For hard to reach internal surfaces or for occasional

use, consider using Tectyl® 511M Rust Preventive or

WD-40

Removing from Storage

As units are removed from storage to be installed

in their final location, they should be protected and

maintained in a similar fashion until the equipment goes

into operation. Prior to installing the unit and system

components, inspect the unit assembly to make sure it

is in working order.

• Check all fasteners, set screws on the fan, wheel,

• Rotate the fan wheel(s), where applicable, by hand

® or the equivalent.

bearings, drive, motor base, and accessories for

tightness.

and assure no parts are rubbing.

Kitchen Hoods • Type I and Type II

2

®

Page 3

Table of Contents

Receiving, Unpacking, Handling and Storage . . . . .2

Inspection and Maintenance during Storage . . . . . .2

Removing from Storage . . . . . . . . . . . . . . . . .2

Hood Weight . . . . . . . . . . . . . . . . . . . . . . .3

Installation

Wall or Single Island Style Hoods . . . . . . . . . . . .4

Hood Installation Overview . . . . . . . . . . . . . . .4

Hanging the Hood . . . . . . . . . . . . . . . . . . . .4

Filler Panel Installation . . . . . . . . . . . . . . . . . .5

Installing Back Supply Plenum . . . . . . . . . . . . .5

Installing the Supply Duct Collar . . . . . . . . . . .5

Hanging the Back Supply Plenum. . . . . . . . . . .5

Hood Hanging Height . . . . . . . . . . . . . . . . . .5

Double Island Style Hoods . . . . . . . . . . . . . . . .6

Installing U-Channel Strips . . . . . . . . . . . . . . .6

Continuous Capture Plenum Hoods. . . . . . . . . . .6

Electrical Connections . . . . . . . . . . . . . . . . . .6

Ductwork . . . . . . . . . . . . . . . . . . . . . . . . .6

Installing External Supply Plenums . . . . . . . . . . .7

Supply Plenum Clip . . . . . . . . . . . . . . . . . . .7

Uni-strut . . . . . . . . . . . . . . . . . . . . . . . . .7

Hanger Brackets and Threaded Rod . . . . . . . . . .7

Installing the Supply Duct Collar to the Plenum . . . .7

External Supply Plenum

Weights and Dimensions . . . . . . . . . . . . . . . .8

Clearance Reduction Methods . . . . . . . . . . . . .8

Installing Enclosure Panels . . . . . . . . . . . . . . .9

Installing End Skirts . . . . . . . . . . . . . . . . . . .9

Installing Backsplash Panels. . . . . . . . . . . . . . 10

Installing Duct Collars

Exhaust Duct Collars . . . . . . . . . . . . . . . . . 11

Supply Duct Collars . . . . . . . . . . . . . . . . . . 11

Exhaust Air Balancing Baffles . . . . . . . . . . . 11-12

Balancing the Kitchen Exhaust System . . . . . . . . 12

Testing Hood Air Volume - Procedures

with Baffle Filters (GH Series) . . . . . . . . . . . 12-15

with High Velocity Cartridge Filters (GK Series). . 16-17

with High Efficiency Filters (GX Series) . . . . . . 18-20

Wiring

Fire Suppression Wiring Diagrams. . . . . . . . . 21-22

Overall Wiring Plan View . . . . . . . . . . . . . . . . 23

Wiring for Hood Switch Panels . . . . . . . . . . . . 24

Circuit Diagrams . . . . . . . . . . . . . . . . . . . . 25

Maintenance . . . . . . . . . . . . . . . . . . . . . . 26

Hood Baffle and Air Diffusers . . . . . . . . . . . . . 26

Grease Grabber™ Filters . . . . . . . . . . . . . 26-27

Filter Cleaning and Maintenance . . . . . . . . . . 27

Filter Washing Frequency Guide . . . . . . . . . . 28

Troubleshooting. . . . . . . . . . . . . . . . . . . 29-30

Replacement Parts . . . . . . . . . . . . . . . . . . . 31

Maintenance Log . . . . . . . . . . . . . . . . . . . . 32

Our Commitment . . . . . . . . . . . . . . . . . . . . 32

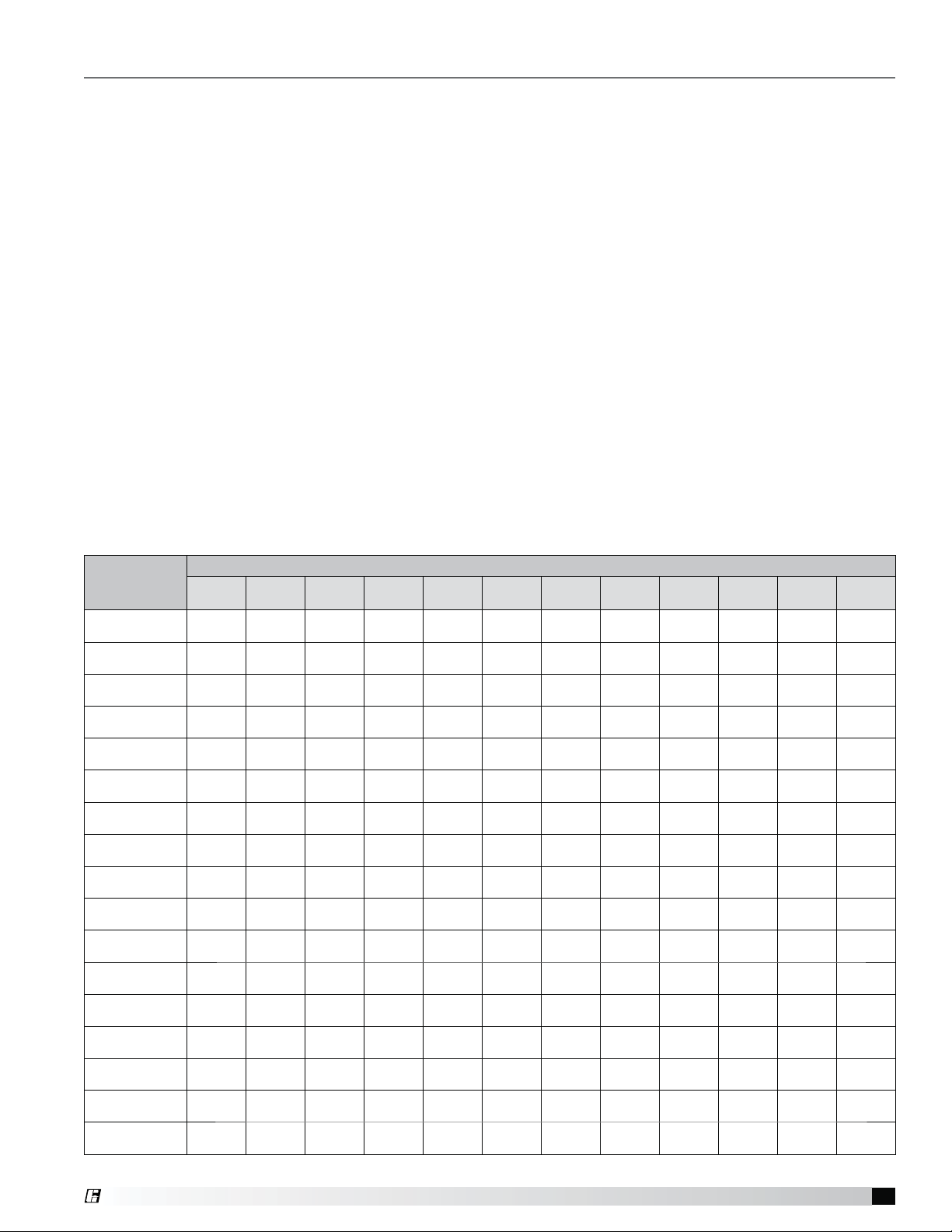

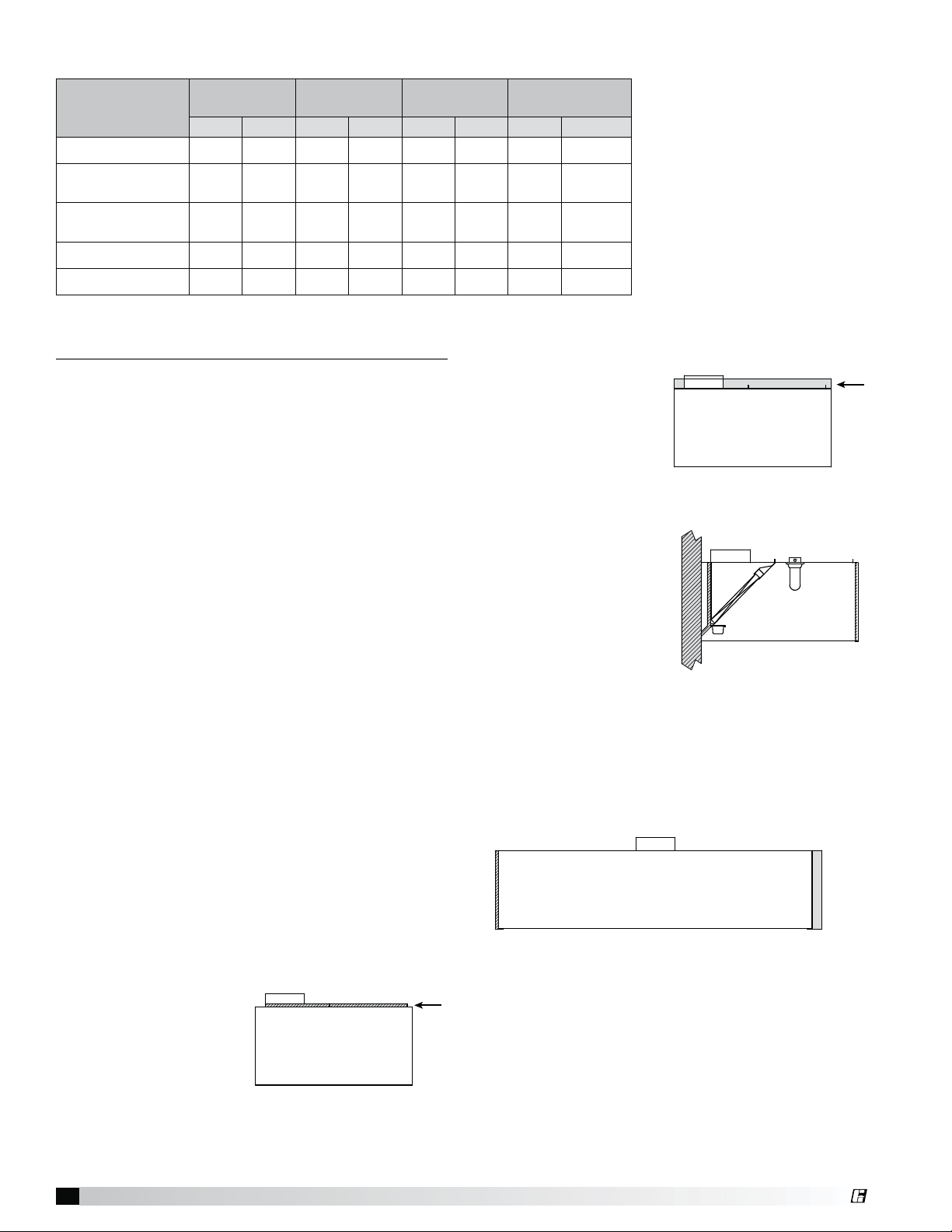

Hood Depth (Multiply by Length) for Hood Weight*

Hood Model

GH, GK, GXEW

GH, GX, GXDW

GH, GK, GXFW

GH, GK, GXCW

GH, GK, GXSW

GGEW

GGDW

GGFW

GGCW

GGSW

GH, GK, GXEV

GH, GK, GXFV

GH, GK, GXCV

GH, GK, GXSV

GO/GD1

GD2

GD3

2 ft

.6096 m

20 lbs/ft

29.76 kg/m

2.5 ft

.762 m

24 lbs/ft

35.72 kg/m

3 ft

.914 m

30 lbs/ft

44.64 kg/m

36 lbs/ft

53.57 kg/m

39 lbs/ft

58.04 kg/m

45 lbs/ft

66.97 kg/m

28 lbs/ft

41.67 kg/m

43 lbs/ft

63.99 kg/m

58 lbs/ft

86.31 kg/m

3.5 ft

1.067 m

32 lbs/ft

47.62 kg/m

38 lbs/ft

56.55 kg/m

40 lbs/ft

59.53 kg/m

48 lbs/ft

71.43 kg/m

44 lbs/ft

65.48 kg/m

41 lbs/ft

61.01 kg/m

47 lbs/ft

69.94 kg/m

49 lbs/ft

72.92 kg/m

57 lbs/ft

84.83 kg/m

53 lbs/ft

78.87 kg/m

32 lbs/ft

47.62 kg/m

48 lbs/ft

71.43 kg/m

64 lbs/ft

95.24 kg/m

4 ft

1.219 m

35 lbs/ft

52.09 kg/m

41 lbs/ft

61.01 kg/m

44 lbs/ft

65.48 kg/m

51 lbs/ft

75.90 kg/m

48 lbs/ft

71.43 kg/m

44 lbs/ft

65.48 kg/m

50 lbs/ft

74.41 kg/m

53 lbs/ft

78.87 kg/m

60 lb/ft

89.29 kg/m

57 lbs/ft

84.83 kg/m

52 lbs/ft

77.38 kg/m

61 lbs/ft

90.78 kg/m

36 lbs/ft

53.57 kg/m

53 lbs/ft

78.87 kg/m

70 lbs/ft

104.17 kg/m

4.5 ft

1.372 m

38 lbs/ft

56.55 kg/m

44 lbs/ft

65.48 kg/m

48 lbs/ft

71.43 kg/m

54 lbs/ft

80.36 kg/m

52 lbs/ft

77.38 kg/m

47 lbs/ft

69.94 kg/m

53 lbs/ft

78.87 kg/m

57 lbs/ft

84.83 kg/m

63 lbs/ft

93.75 kg/m

61 lbs/ft

90.78 kg/m

54 lbs/ft

80.36 kg/m

66 lbs/ft

98.22 kg/m

66 lbs/ft

98.22 kg/m

40 lbs/ft

59.52 kg/m

58 lbs/ft

86.31 kg/m

76 lbs/ft

113.10 kg/m

5 ft

1.524 m

40 lbs/ft

59.53 kg/m

46 lbs/ft

68.46 kg/m

52 lbs/ft

77.38 kg/m

57 lbs/ft

84.83 kg/m

56 lbs/ft

83.34 kg/m

49 lbs/ft

72.92 kg/m

55 lbs/ft

81.85 kg/m

61 lbs/ft

90.78 kg/m

66 lbs/ft

98.22 kg/m

65 lbs/ft

96.73 kg/m

56 lbs/ft

83.34 kg/m

68 lbs/ft

101.20 kg/m

69 lbs/ft

102.68 kg/m

44 lbs/ft

65.48 kg/m

63 lbs/ft

93.75 kg/m

82 lbs/ft

122.03 kg/m

5.5 ft

1.676 m

58 lbs/ft

86.31 kg/m

72 lbs/ft

107.15 kg/m

72 lbs/ft

107.15 kg/m

48 lbs/ft

71.43 kg/m

68 lbs/ft

101.20 kg/m

88 lbs/ft

130.96 kg/m

*Hood weight calculations are based on standard selection. Hood height, accessories and material gauge affect overall hood weight.

6 ft

1.829 m

61 lbs/ft

90.78 kg/m

75 lbs/ft

111.61 kg/m

81 lbs/ft

120.54 kg/m

76 lbs/ft

113.10 kg/m

52 lbs/ft

77.38 kg/m

73 lbs/ft

108.64 kg/m

94 lbs/ft

139.89 kg/m

6.5 ft

1.981 m

63 lbs/ft

93.75 kg/m

79 lbs/ft

117.56 kg/m

84 lbs/ft

125.01 kg/m

79 lbs/ft

117.56 kg/m

7 ft

2.134 m

87 lbs/ft

129.47 kg/m

7.5 ft

2.286 m

90 lbs/ft

133.93 kg/m

®

Kitchen Hoods • Type I and Type II

3

Page 4

Installation

Wall or Single Island Style Hoods

NOTE

If you have a back supply plenum (BSP), this must be

installed before the hood. Please see page 5.

The installation of the canopy hoods shall be in

accordance with NFPA 96 (latest edition) Standard for

Ventilation Control and Fire Protection of Commercial

Cooking Operations and ULC-S650 in Canada.

Greenheck does not recommend walking or standing

on the hood top as damage can result and may

void the warranty. If you must walk on the hood top,

protect the hood with additional support and planks

for flooring.

For wall/single island style hoods, prior to installation,

check with local authorities having jurisdiction on

clearances to combustible surfaces, etc.

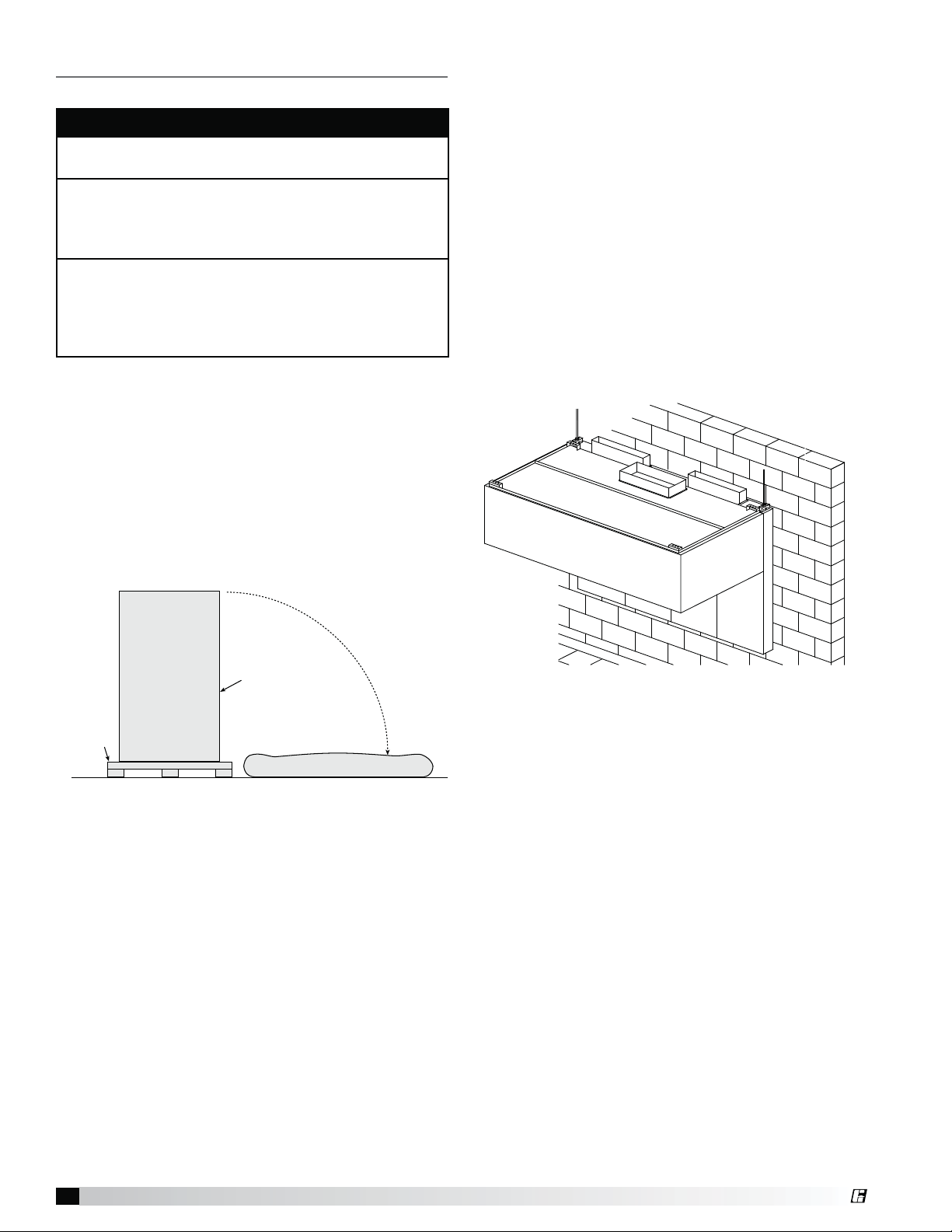

With the hood still inside its packing crate, position the

unit beneath its installation location. Carefully remove

the packing crate. Place some protective material on

the floor next to the crate to avoid damaging the hood

as it is tipped on its side. Tip the hood carefully onto the

protective material. If you have filler panels, install them

now; refer to page 5, Filler Panel Installation. If you have

integral filler panels, no additional installation is needed.

Hanging the Hood

Before hanging the hood according to the hood

installation instructions, please check the following if

applicable:

1. Make sure the back supply plenum is properly

secured, as described on page 5.

2. If the ductwork for the back supply will not interfere

with the hood installation, it should be connected

now.

3. Any filler panels should be attached to the hood

before the hood installation. See page 5 for

instructions.

4. Lift the hood, and position it so the filler panels are

resting lightly on the top outside edges of the back

supply. The back supply is used to position the

hood only, it is not intended to hold any hood

weight.

Bottom of Hood

Pallet

Protective Material

Hood Installation Overview

If a back supply plenum is provided, install it first. Before

raising the hood, insert 1/2 in. (12.7 mm) diameter

threaded rod (by others) into hanger brackets on hood

top. Check the engineering drawings or UL label located

on the inside of the hood for proper hood height above

finished floor. Install filler panels if needed. Raise and

hang the hood from adequate roof or ceiling supports

All hanger brackets must be used and the hood must

be properly supported while lifting to prevent damage

or distortion to the hood. The hood must be hung level

to operate properly. After the hood is secured, make the

exhaust duct connections. The fire system distributor

must be contacted at this time. After the fire system has

been installed, mount the enclosures, then the supply

plenums. If a horizontal supply plenum is provided, it

should be installed before the enclosures. Finally, make

the electrical connections from the switches to the fans

and complete the fire system circuits as required by the

job specification.

5. Connect the remaining ductwork for the back supply

and the hood. It is recommended that caulk be

applied at the mating seams and surfaces of the

back supply, the hood, and the wall.

6. If the hood is equipped with clearance reduction

methods, refer to page 8 for special considerations

with hanging the hood.

Kitchen Hoods • Type I and Type II

4

®

Page 5

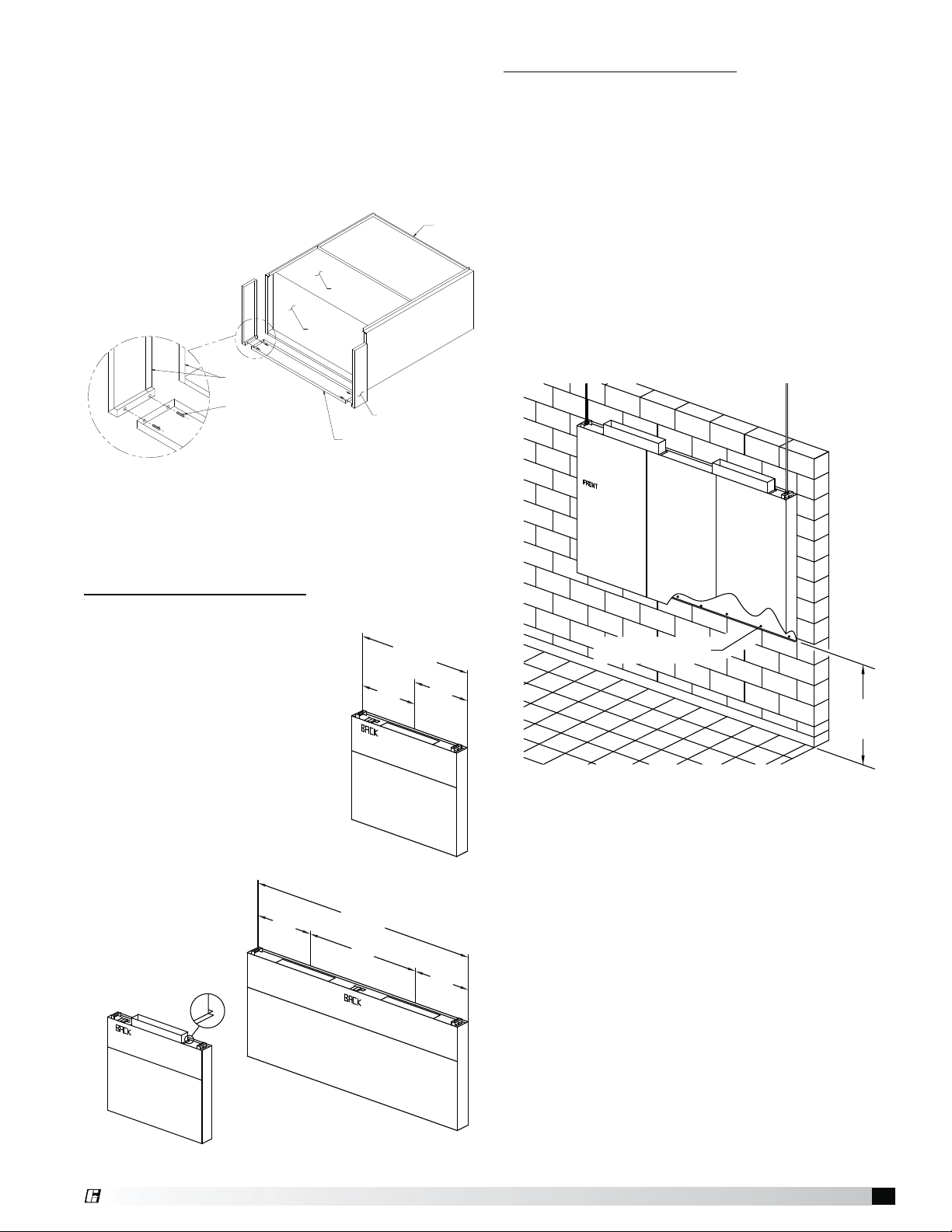

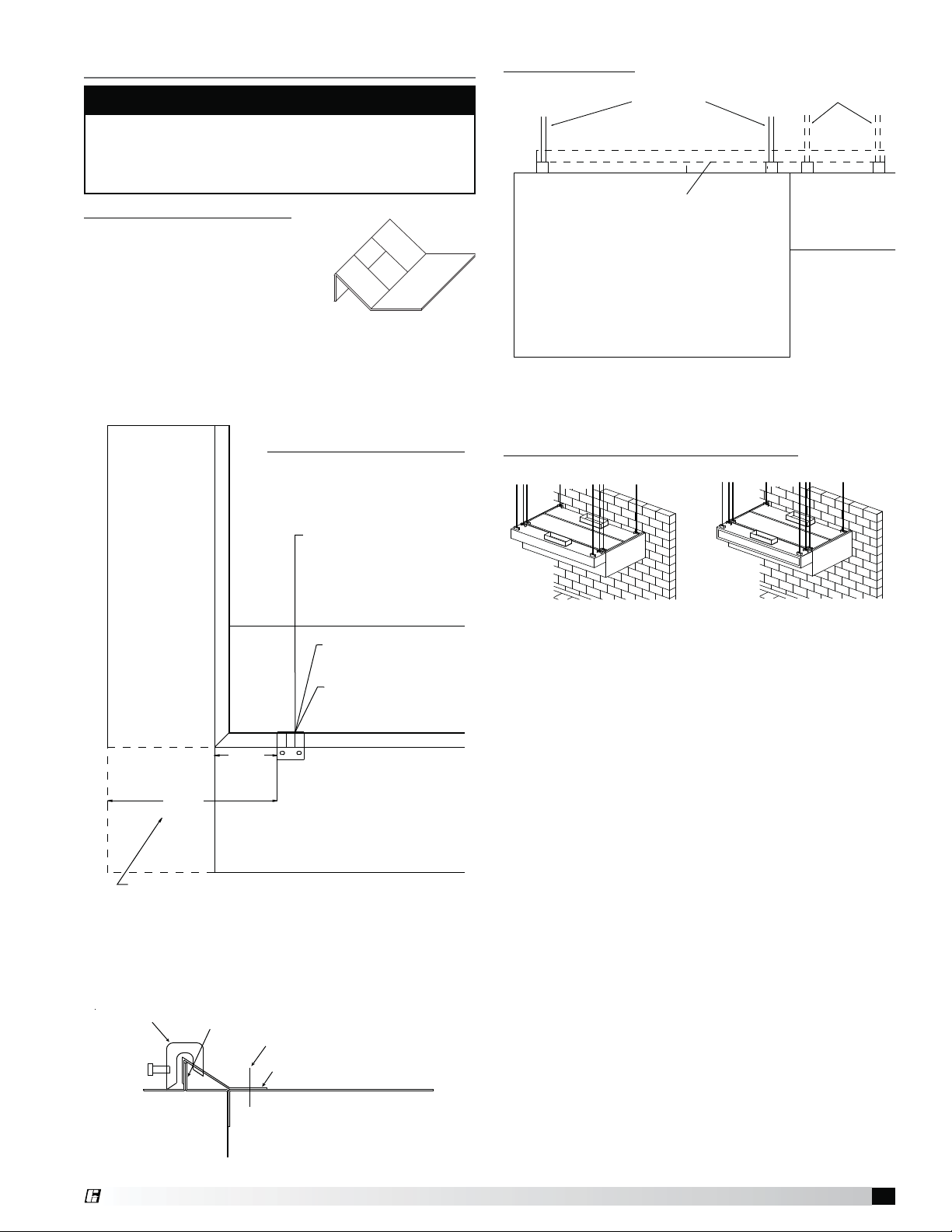

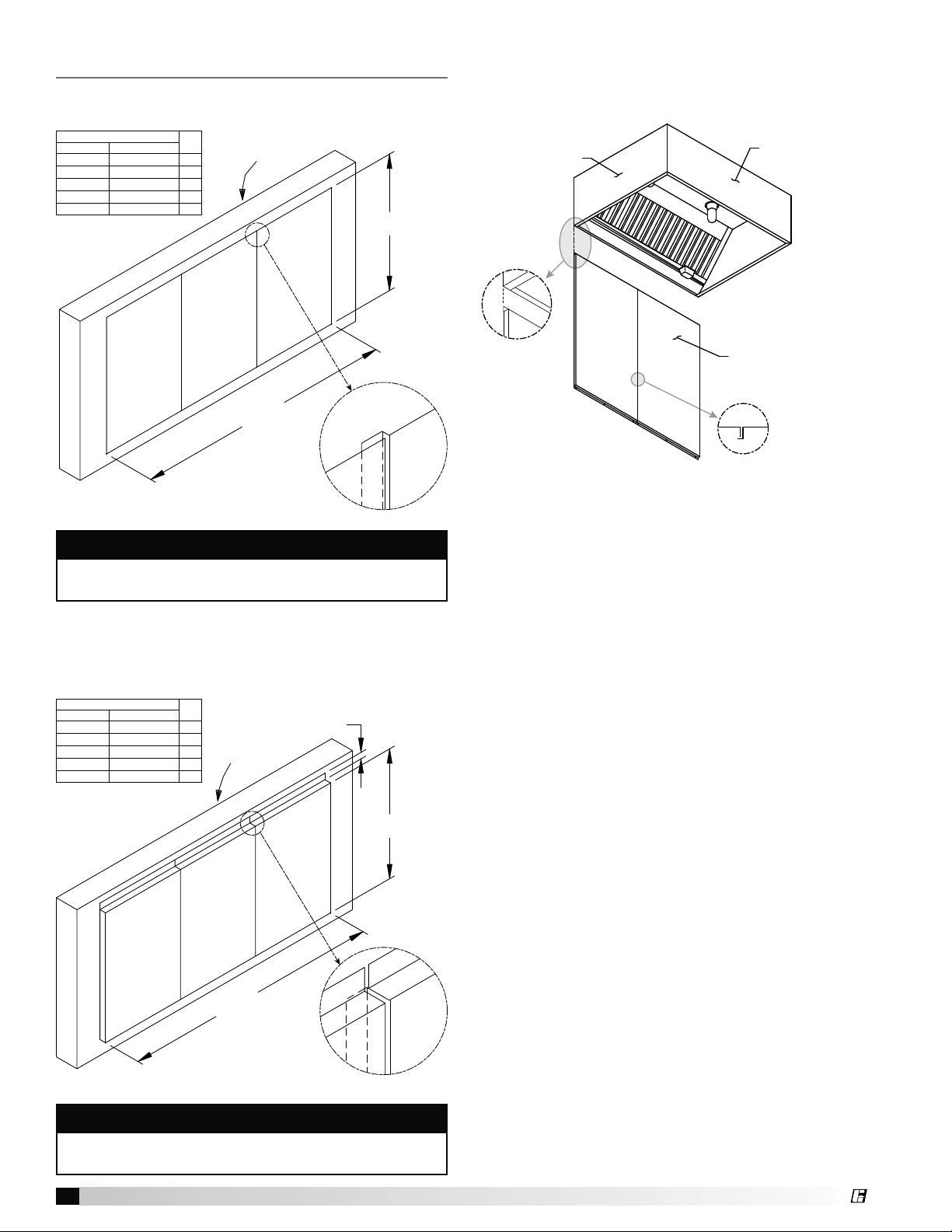

Filler Panel Installation

1. Uncrate the hood and lay it on the floor with

protective material between the hood and the floor.

2. Bolt the filler panels together with 5/16 in. bolts

provided in the hardware package.

3. Position the filler panels to the hood back, and tackweld them into place.

HOOD

HOOD

HOOD

TACK-WELDED TO

HOOD BACK

5/16 IN. X 3/4 IN. BOLTS

WITH WASHERS & NUTS

4. To allow for ease of cleaning, caulk the external

seams with NSF Approved silicone caulk (GE

SCS1009, or its equivalent). The caulk is not

provided.

RIGHT FILLER PANEL

BOTTOM FILLER PANEL

Hanging the Back Supply Plenum

5. Hang the back supply plenum from the ceiling.

• The back supply plenum needs to be mounted

31.25in. (79.375 cm) above the finished floor. This

is measured from the lowest rear edge of the back

supply plenum to the finished floor.

• Hang using threaded rod placed through the hanger

brackets.

6. Fasten the back supply to the wall, going through the

lower back supply wall.

• These fasteners are to help maintain the location of

the back supply, and are not intended to hold the

weight of the back supply unit.

• The fasteners should not interfere with the

removable air diffusers

Installing the Back Supply Plenum

Installing the Supply Duct Collar

1. Find the center of the back supply plenum.

2. If the back supply plenum is

to have one opening, cut the

opening such that it is centered

at L /2 from the plenum end.

(Fig.1)

3. If the back supply plenum is to

have two openings, cut openings

such that they are centered

at L /4 from each end of the

plenum. (Fig. 2)

4. Place the duct collar(s) over the

opening(s), fastening with screws

or tack-welds

every 4 to 6 in.

(10.16 to 15.24

cm). (Fig. 3)

Fig. 3

L/4

L (MODULE LENGTH)

L (MODULE LENGTH)

L/2

L/2

Fig. 1

L/2

Fig. 2

L/4

FASTENERS HOLDING THE

BACKSUPPLY TO THE WALL

31.25 INCH

CRITICAL

DIMENSION

Hood Hanging Height

The hood hanging height is critical. Hanging the hood at

the incorrect height may significantly reduce the ability

of the hood to function properly and may be in violation

of codes. The hood hanging height, typically 78in.

(198.12 cm) above the finished floor, is given on the

UL label located on the end panel on the inside of the

hood. The hood must be hung level to operate properly.

The grease trough is pitched to drain into the grease

container.

®

Kitchen Hoods • Type I and Type II

5

Page 6

Double Island Style Hoods

DOUBLE ISLAND CLIP

BOLT OR WELD

HOOD TOP

HOOD END

SUPPORT ANGLES

CAULK

BOLT

U-CLIP

HOOD

ACORN

NUT

2. RAISE

AND SU

3. FASTE

4. FASTE

5. CAULK

& CAP

1. REMO

HOOD FRONT

HOOD FRONT

REMOVE

SUPPORT

ANGLES ON

THE OPEN

END PANEL

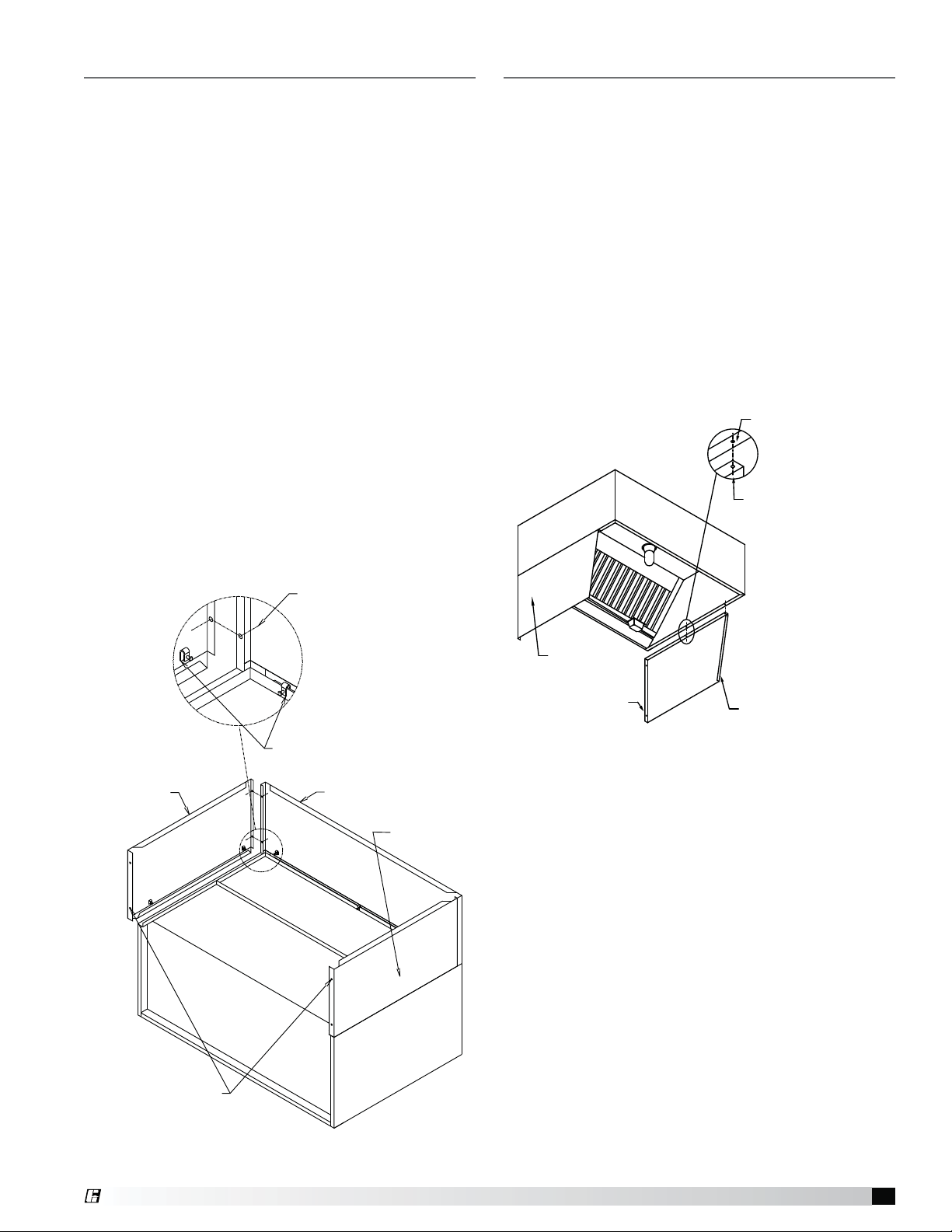

A double island hood is created by installing two

wall style hoods back to back. Use the installation

procedure described on page 4 for single island hoods;

install and level both hoods. After leveling, secure the

hoods together by tack-welding and/or bolting the rear

mounting brackets together.

Installing U-Channel Strip

1. After the hood

2. Position and

3. Caulk edges to seal out grease and allow for ease

Continuous Capture Plenum Hoods

Remove the support angles provided

for support during shipping on

the open end panels. Use the

installation procedure

described on page 4

for single island

hoods;

install

and level

both

hoods.

After

leveling, secure

the hoods together by tackwelding and/or bolting the

angles that are located at

the top of the hoods along

its width (Fig. 4).

Next, fasten the hoods

together at its inside plenum

profile using u-clips and

bolts (Fig. 5). Caulk this joint

with NSF Approved silicone

caulk (GE SCS1009 or its

equivalent). The caulk is not

provided.

After the hood is installed, remove all protective plastic.

6

NOTE

Before hanging the hoods, please verify the hood

marks to make sure the correct hood is hung on the

correct side.

is hung in

position and

leveled, apply

caulk to the

inside edge

of the double

island clip.

install the clip

by tapping

into position along clip (friction fit).

of cleaning. Caulk with NSF Approved silicone caulk

(GE SCS1009 or its equivalent). The caulk is not

provided.

Kitchen Hoods • Type I and Type II

ITEM-1B

ITEM-1A

HOOD-1A

HOOD FRONT

Fig. 4

Fig. 5

HOOD-1B

SILICONE CAULK

(GE SCS1009)

DOUBLE ISLAND CLIP

Electrical Connections

Access for wiring the hood control panel (when

applicable) is provided by a junction box located on top

of the hood when the control panel is mounted in the

hood, or by the switch junction box when the control

panel is mounted in the fire protection cabinet. The

box is labeled “Control Voltage Wiring to Roof Top Fan

Package”. Use minimum 14 AWG copper wire. After

all the wiring is completed, install the light bulbs (light

bulbs not provided; standard light bulbs up to 100 watt

may be used).

CAUTION

For multiple hood systems that have more than 14

lights total (incandescent or fluorescent), the hood

lights must be wired to multiple circuits. Each circuit

must have less than 14 lights total.

Standard Greenheck light switches shipped on hoods

are rated for 15 amps and shall not have more than

14lights connected to them. Higher amperage switches

are available upon special request.

Ductwork

Exhaust

As specified in NFPA 96, Ch. 7.5 (latest edition), exhaust

duct systems must be constructed in the following

manner:

Materials: Ducts shall be constructed of and supported

by carbon steel not less than 1.37 mm (0.054 in.) (No.

16 MSG) in thickness, or stainless steel not less than

1.09 mm (0.043 in.) (No. 18 MSG) in thickness.

Installation: All seams, joints, penetrations, and duct to

hood collar connections shall have a liquid-tight external

weld. If you have an automatic fire damper, please refer

to that manual for installation instructions now.

Supply

Supply ductwork (where applicable) should be

connected to the hood in a manner approved by the

local code authorities.

NOTE

For hoods with fire dampers in the exhaust and

supply duct collars, an access panel for cleaning and

inspection shall be provided in the duct. This panel

shall be as close to the hood as possible but should

not exceed 18 in. (45.72 cm).

For proper installation of duct collars when they are

shipped unattached, see page 11.

®

Page 7

Installing External Supply Plenums

NOTE

The supply plenum is provided with plenum clips that

assist in hanging the plenum. Do not hang plenums

using only the clips. Threaded rod or uni-strut must

also be used.

Using the Supply Plenum Clip

1. Fasten the hanging clip to the

supply plenum. Two clips are

needed for plenums less than

96 in. (243.84 cm) long and

three for plenums greater than

96 in. (243.84 cm). The third

clip is located in the center

of the plenum length. If there is a cabinet, the clip

should be 23.5 in. (59.69 cm) from the outside edge

of the cabinet.

Supply Plenum Clip

TOP VIEW

HOOD

Using the Uni-strut

THREADED ROD

THREADED ROD

THE UNI-STRUT (U-CHANNEL) THAT HOLDS THE

HOOD UP CANTILEVERS OVER THE END OF

THE HOOD AND IS MOUNTED TO THE ASP

HANGER BRACKETS

SUPPLIED BY OTHERS

END VIEW

HOOD

The uni-strut (supplied by others) supporting the hood,

may be cantilevered over the end of the hood and used

to mount to the hanger brackets on the supply plenums.

Using Hanger Brackets and Threaded Rod

FOR PLENUMS <= 96 INCHES (243.8 CM)

2 CLIPS ARE NEEDED

FOR PLENUMS > 96 INCHES (243.8 CM)

3 CLIPS ARE NEEDED

THE THIRD CLIP IS LOCATED

IN THE CENTER OF THE

PLENUM LENGTH

ATTACH HANGING CLIP TO

HOOD STANDING SEAM WITH

THE SUPPLIED "C" CLAMPS

(OPTIONAL: DRILL AND BOLT A

OPTIONAL UTILITY CABINET

23.5 IN.

(59.69 CM)

11.5 IN.

(29.2 CM)

1/4-20 SS BOLT THROUGH

THE CLIP AND HOOD STANDING

SEAM)

TOP VIEW

SUPPLY PLENUM

HANGING CLIP COULD BE 23.5 INCHES (59.69 CM) FROM END IF THERE IS

A UTILITY CABINET ON THE END OF THE HOOD

2. Using the c-clamps provided, clamp the supply

plenum hanging clip to the hood standing seam.

Option: Drill and bolt a 1/4-20 SS bolt through the

clip and hood standing seam.

"C" CLAMP

HOOD FRONT

HOOD STANDING SEAM

HANGING CLIP FASTENED TO PLENUM SHELL

HANGING CLIP

SUPPLY PLENUM SHELL

Air Curtain Supply Plenum

ASP

HSP or VSP

Variable Supply Plenum

1. Insert 1/2 in. (12.7 mm) diameter threaded rod (by

others) into hanger brackets on the supply plenum

top. Raise and hang the external supply plenum from

adequate roof or ceiling supports.

2. The external supply plenum should be resting lightly

against the hood. The hood is used to position the

plenum only, it is not intended to support the plenum.

All hanger brackets must be used and the plenum

must be properly supported while lifting to prevent

damage or distortion. The supply plenum must be

hung level to operate properly.

3. It is recommended that caulk be applied at the

mating seams and surfaces of the plenum, the hood,

and the wall. If the supply plenum is next to a wall,

you will also need to caulk around the surface next to

the wall. Caulk the joints with NSF Approved silicone

caulk (GE SCS1009, or its equivalent). The caulk is

not provided.

Installing the Supply Duct Collar to the Plenum

Place the duct collar(s) over the opening, fastening

with tack-welds at 1 to 2 in. (2.54 to 5.08 cm) intervals,

or sheet metal screws at 3 to 6 in. (7.62 to 15.24 cm)

intervals.

®

Kitchen Hoods • Type I and Type II

7

Page 8

Weights and Dimensions

External Supply

Plenum Type

Back Supply 35.0 52.09 6 152.4 Variable Variable 3 to 16 .91 to 4.88

Air Curtain Supply

• 14 inch

Air Curtain Supply

• 24 inch

Variable Supply 16.0 23.81 12 304.8 18 457.20 3 to 16 .91 to 4.88

Horizontal Supply 14.0 20.83 12 304.8 18 457.20 3 to 16 .91 to 4.88

Weight Width Height

(lbs/ft) (kg/m) (in) (mm) (in) (mm) (ft) (m)

9.5 14.14 14 355.6 10 254 3 to 16 .91 to 4.88

12.5 18.60 24 609.6 10 254 3 to 16 .91 to 4.88

Length

per section

Clearance Reduction Methods

Clearance reduction methods have been evaluated and

tested and are listed by UL (Underwriters Laboratory).

The method of test was derived from the UL 710 test

standard.

The hood may be installed with zero clearance to

combustible materials if constructed in the following

manner.

1. One inch (2.54 cm) thick layer of insulation of Owens

Corning® Type 475, Johns Manville Type 475, IIG®

MinWool-1200® Flexible Batt, or Knauf Insulation

Type EI 475.

2. Insulation must be held securely in place. Pins that

are welded or secured with an adhesive may be

used.

3. A backsplash panel must be attached to the wall

(insulated or uninsulated).

To comply with the UL listing, the cooking appliances

must be as follows:

• Maximum surface temperature is 700°F (371°C)

• Appliances are located at least 3 in. (7.62 cm) from

the rear wall

• Appliances are at least 40 in. (101.6 cm) below the

bottom front edge of the hood

The hood may be installed with 3 in. (7.62 cm) clearance

to limited combustible materials per NFPA 96 if

constructed in one of the following methods:

• 3 in. (7.62 cm) rear uninsulated stand-off

• 3 in. (7.62 cm) top enclosure panel system

• 3 in. (7.62 cm) end uninsulated stand-off

Top Clearance Reduction Options

One inch (2.54 cm) layer

of insulation installed

on top of the hood

(optional) meets zero

inch requirements for

clearance to combustible

surfaces as outlined under

the clearance reductions methods.

Three inches (7.62cm)

insulated airspace

installed on top of hood

(optional) meets NFPA 96

requirements for clearance

to limited combustible

surfaces.

Back and Front Clearance Reduction Options

One inch (2.54 cm) layer

of insulation in 3 in. (7.62

cm) back stand-off meets

zero inch requirements for

clearance to combustible

surfaces as outlined under

the clearance reduction

methods.

Three inches (7.62 cm) uninsulated back stand-off

meets NFPA 96 requirements for clearance to limited

combustible surfaces.

One inch (2.54 cm) layer of insulation factory-installed

on the front of the hood (optional) meets zero inch

requirements for clearance to combustible surfaces.

End Clearance Reduction Options

One inch (2.54 cm) layer of insulation factory-installed

on the end of the hood (optional) meets zero inch

requirements for clearance to combustible surfaces

under the clearance reduction methods.

Three inches (7.62 cm) uninsulated airspace installed on

end of hood (optional). Meets NFPA 96 requirements for

clearance to limited combustible surfaces.

Kitchen Hoods • Type I and Type II

8

®

Page 9

Installing Enclosure Panels

Installing End Skirts

Before installing the enclosure panels, make sure the

hood is hung in position with all the ductwork attached

and electrical connections completed.

1. Position the end enclosure panels on the hood, and

clamp into place with clamps provided or tack-weld

the panels into place.

2. Fasten the end enclosure panels to the wall, method

depends on wall construction. (Fasteners provided

by others).

If the hood is a double island, bolt the end enclosure

panels together. (Fasteners provided by others).

3. Position the front enclosure panel(s) on the hood,

and bolt to the end enclosure panels with the 5/16 in.

bolts provided in the hardware package.

4. Tack-weld or clamp the front enclosure panel(s)

to the hood. If clamps are used, they must be

positioned 4in. (10.16 cm) from the ends and in the

center of the front enclosure panel.

5. To allow for ease of cleaning, caulk the external

seams with NSF Approved silicone caulk

(GE SCS1009, or its equivalent). The caulk is not

provided.

6. Installation instructions may not be applicable for

concrete ceilings.

1. After the hood is hung in position, line up the top of

the end skirt with the end panels of the hood.

2. Drill a hole in the hood end panel to line up with

the hole in the end skirt. Attach the end skirt with a

1/4in. bolt and cap nut to the inside of the hood, or

tack-weld the end skirt to the hood.

3. Position the end skirt against the wall and attach. The

method depends on the wall construction. (Fasteners

provided by others).

4. Caulk the internal joint formed by the end skirt and

the hood end panel with NSF Approved silicone caulk

(GE SCS1009 or its equivalent). The caulk is not

provided.

5. To allow for ease in cleaning, also caulk all the

external seams.

HOLE DRILLED

BY INSTALLER

1/4 INCH BOLT AND CAP NUT

SUPPLIED BY MANUFACTURER

END ENSLOSURE

PANEL

HOOD TOP

HOOD BACK

BOLT PANELS TOGETHER

WITH 5/16 INCH BOLTS

SUPPLIED BY MANUFACTURER

CLAMP PANELS TO HOOD

STANDING SEAM WITH HARDWARE

SUPPLIED BY MANUFACTURER

FRONT ENCLOSURE PANEL

END ENSLOSURE

PANEL

FULL END SKIRT

ATTACH TO WALL

FASTENERS BY OTHERS

HEMMED EDGE

ATTACH TO WALL

FASTENERS BY OTHERS

®

Kitchen Hoods • Type I and Type II

9

Page 10

Installing Backsplash Panels

WALL

WALL

Flat Backsplash Panel

Material: Stainless

LENGTH

Inches Millimeters

<=47 <=1193.8 1

>47 <=93 >1193.8 <=2362.2 2

>93 <=138.8 >2362.2 <=3525.5 3

>138.8 <=185 >3525.5 <=4699 4

>185<=231.3 >4699 <=5875.0 5

QTY

HEIGHT

HOOD END PANEL

HOOD FRONT PANEL

LENGTH

NOTE

Panels up to 47 in. (1193.8 mm) wide ship in one

piece; over 47 in. (1193.8 mm) in multiple pieces.

Insulated Backsplash Panel

Material: Stainless

Insulation: 1 in. (25.4 mm)

LENGTH

Inches Millimeters

<=45 <=1143 1

>45 <=90 >1143 <=2286 2

>90 <=135 >2286 <=3429 3

>135 <=180 >3429 <=4572 4

>180 <=225 >4572 <=5715 5

QTY

1 IN. (25.4 MM)

HEIGHT

SLIDE FLANGE

BEHIND BACK

OF THE HOOD

BACKSPLASH PANEL

SECTION VIEW

OF BACKSPLASH

PANEL OVERLAP

1. After the hood is hung in position, slide the flat flange

of the backsplash panel behind the back of the hood.

Note: If the backsplash panel length is greater than

45 in. (1143 mm), it will be shipped in multiple pieces.

2. After the backsplash panel has been positioned, drill

holes in the panel and fasten to the wall. (Fasteners

provided by others).

Note: The holes should be spaced to adequately

secure the panel to the wall.

3. Caulk the joints between the hood and the

backsplash panel with NSF Approved silicone caulk

(GE SCS1009, or its equivalent). The caulk is not

provided.

4. Caulk the joint between the backsplash panels when

multiple panels are required, with NSF Approved

silicone caulk (GE SCS1009, or its equivalent). The

caulk is not provided.

LENGTH

NOTE

Panels up to 45 in. (1143 mm) wide ship in one piece;

over 45 in. (1143 mm) in multiple pieces.

Kitchen Hoods • Type I and Type II

10

®

Page 11

Installing Duct Collars

Exhaust Collars

1. The exhaust duct connection needs to be located

within 48 in. (121.92 cm) from the center of the hood

length to the center of the duct connection and within

shaded area as shown.

Top View of the Hood

8 in.

Back View of the Hood

8 in. 8 in.

1 in.

12 in.

2. The exhaust duct connection is to be a continuous

liquid-tight weld. Weld with a non-ferrous filler wire,

such as silicon bronze or stainless steel filler wire.

Protect all stainless steel areas from weld splatter.

Supply Collars

1. The supply duct connection needs to be located

within the shaded Supply Plenum area as in the

drawing above.

2. The supply duct connection is tack-welded at 1 to

2inch (2.54 to 5.08 cm) intervals or sheet metal

screws at 3 to 6 in. (7.62 to 15.24 cm) spacing to

the hood.

Supply Duct

Connection

Hanger Bracket

Exhaust Plenum

Supply Plenum

Hood Length

Hood Top

Duct cut out area

Front of hood

Exhaust Plenum

Duct cut out area

Supply duct connection to be tack

welded with 1 to 2 inch tack or

sheet metal screws at 3 to 6 inch

spacing to hood.

14 in.

16 in.

8 in.

3 in.

Hood

Width

3 in.

Exhaust Air Balancing Baffles (EABB)

This is a guide to assist in determining if multiple

hoods on one fan can be balanced to have equal static

pressure. For multiple hoods on one fan to achieve their

designed exhaust flow, all of the hoods must have equal

static pressure at their designed exhaust flow.

The laws of physics force the static pressure for each

branch of a duct system on one fan to always be equal.

This will happen by the flow rate increasing in low static

branches and decreasing in high static branches until

the static pressure is equal in all branches.

Checking for Balance

Every hood with exhaust air balancing baffles (EABB)

has a range for its static pressure. The low static

pressure number (when EABB is open) in this range is

given by the standard calculation for hood static and is

printed on the CAPS submittal page for that hood. The

high static pressure number (when EABB is closed) in

this range can be found by calculating the maximum

potential increase of static and adding that value to the

low static pressure number.

High static pressure number = low static pressure

number + maximum increase

The maximum potential increase in static is given in the

graph, or can be calculated from the following formula:

Maximum Increase = 0.00000036 x (Duct velocity)

Maximum Increase in Static Pressure for Exhaust Air Balancing Baffle

4.5

4

3.5

3

2.5

2

1.5

1

Increase in Collar Staitc Pressure

0.5

0

500 1000 1500 2000 2500 3000 3500

(Fully Closed)

Duct Velocity FPM

2

3. For hoods that are insulated, the edges of the

insulation must be taped after the hole is cut. (The

insulation tape

is provided by

Internal Supply

Chamber

Supply Fire Damper

others).

4. On combination

hoods, make

certain the

fire damper

is located

over the

internal supply

chamber.

Exhaust Capture

®

Hood

Insulated

Supply

Plenum

Kitchen Hoods • Type I and Type II

11

Page 12

Step 1: Find the hood with the lowest static pressure

as shown on the CAPS submittal pages.

Step 2: Calculate the high static pressure number for

this hood as instructed above.

Step 3: Compare this high static pressure number to

the low static pressure number of the remaining hoods.

If the remaining hood’s low static pressure number is

lower than the high static pressure number calculated,

then the system can be balanced; if the low static

pressure number is higher than the calculated high

static pressure number, then the system cannot be

balanced. Refer to the examples.

Example 1:

Hood 1: Ps = 0.58 in. wg

Duct Velocity = 1900 ft/min.

Hood 2: Ps = 0.44 in. wg

Duct Velocity = 1800 ft/min.

Hood 2 has the lower Ps, at 1800 ft/min. the maximum

increase in Ps is 1.17. The range for Hood 2 is 0.44 to

1.61. Hood 1 is less than 1.61 so these hoods can be

balanced.

Example 2:

Hood 3: Ps = 2.00 in. wg

Duct Velocity = 2000 ft/min.

Hood 4: Ps = 0.44 in. wg

Duct Velocity = 1500 ft/min.

Hood 4 has the lower Ps, at 1500 ft/min. the maximum

increase in Ps is .81. The range for Hood 4 is 0.44 to

1.25. Hood 3 is higher than 1.25, so these hoods cannot

be balanced.

NOTE

For many systems, exhaust air balancing baffles may

not be needed on the hood that has the highest static

pressure. The exception to this is if the individual

ductwork has uneven static pressures.

NOTE

When sizing the fan, use the static pressure from the

highest hood and sum the CFM from all the hoods.

Balancing the Kitchen Exhaust

System

B. To determine proper kitchen air balance:

1. Refer to engineering drawings to determine total

exhaust from the kitchen area. (exhaust hoods,

dishwasher hoods, etc.)

2. Determine total CFM of make-up air supplied to

kitchen area. (make-up air hoods, heating and air

conditioning units, etc.)

3. Subtract #1 from #2 above. The result should be a

negative number. If the result is a positive number,

a positive pressure is present in the kitchen area.

Kitchen odors could be forced into the dining

area. Also, a positively balanced kitchen area can

adversely affect the performance of the exhaust

hood.

CAUTION

According to NFPA 96, Ch. 8-3 Replacement Air:

Replacement air quantity shall be adequate to prevent

negative pressures in the commercial cooking area(s)

from exceeding 4.98 kPa (0.02 in. wg).

NOTE

The airflow rates were established under controlled

laboratory conditions.

NOTE

Greater exhaust and/or lesser supply air may be

required for complete vapor and smoke control in

specific installations.

Testing Hood Air Volume - Rotating Vane

Method

Baffle Filter Style Hoods

A. Exhaust:

With all the filters in place, determine the total hood

exhaust volume with a rotating vane anemometer as

follows:

1. All cooking equipment should be on.

2. Measure the velocities. Velocity measurements

should be taken at five locations per filter. These

must be over a filter slot as in Fig. 6.

Fig. 6

A. To determine the proper dining room air balance:

1. Refer to engineering drawings to determine total

exhaust CFM from dining areas. (exhaust fans,

heating and air conditioning units, rest rooms, etc.)

2. Determine the total CFM of make-up air supplied

to dining area.

3. Subtract #1 from #2 above. If the result is a

negative number, a negative pressure is present in

the dining area. In this case, kitchen exhaust odors

could be drawn from the kitchen to the dining

area. Therefore, exhaust or supply air should be

adjusted to provide a slight positive pressure in

the dining area.

Kitchen Hoods • Type I and Type II

12

X

X

X

L

Nominal Filter Size

X

X

H/4

H

H/2

H/4

®

Page 13

Measure and record the velocity of each location.

A digital 2.75 in. (69.85 mm) rotating vane anemometer

or equivalent is suggested. The center of the

anemometer should be held 2 in. (50.8 mm) from the

face of the filters. It is helpful to make a bracket to keep

the anemometer at the 2 in. (50.8 mm) distance and

parallel to the filter. Both squareness and distance are

very important for accuracy.

Rotating Vane

Anemometer

Airflow

2 in.

(50.8 mm)

Calculate the average velocity for the filter.

3. Determine the filter’s conversion factor from the

table.

4. Calculate the filter’s volume in CFM (m

3

/hr) by

multiplying the average velocity by the conversion

factor.

5. Calculate the hood’s volume by repeating the

process for the remaining filters and summing the

individual filter volumes.

Nominal Filter Size (H x L) Imperial

Inches Millimeters

Conversion

Factor

16 x 16 400 x 400 1.63 .157

16 x 20 500 x 400 2.13 .198

20 x 16 400 x 500 1.90 .177

20 x 20 500 x 500 2.48 .230

Metric

Conversion

Factor

Example: Exhaust only hood with three 20 x 16 filters

Measured velocities in ft/min. for one 20 x 16 filter

Average Velocity =

(Imperial)

(Metric)

=

=

For a nominal filter size of 20 x 16, the conversion factor is 1.90 Imperial (.177 Metric)

Volume for one filter = Conversion Factor x Average Velocity

(Imperial)

(Metric)

= 1.90 x 249.8 ft/min. = 474.6 cfm

= .177 x 4568 m/hr = 809 m3/hr

Total hood volume = (Filter 1 Volume) + (Filter 2 Volume) + (Filter 3 Volume)

(Imperial)

(Metric)

= 474.6 + 455.4 + 470.1 = 1400.1 cfm

= 809 + 880 + 799 = 2488 m3/hr

Sum of Velocity Readings

Number of Readings

255 + 250 + 256 + 248 + 240

5

4663 + 4572 + 4681 + 4535 + 4389

5

=

249.8 ft/min.

= 4568 m/hr

255

(4663.44 m/h)

248

(4535.42 m/h)

256

(4681.73 m/h)

250

(4572 m/h)

240

(4389.12 m/h)

®

Kitchen Hoods • Type I and Type II

13

Page 14

B. Supply (if applicable):

Perforated Face Supply

1. Hood set up.

If the make-up air unit has a temperature control, it

should be used to keep the supply air at the desired

room discharge air temperature.

2. Measure velocities.

Divide the perforated face panel into a grid of equal

areas, each approximately 4 in. (101.6 mm) square.

Measure the velocity at the center of each grid

area. A digital 2.75 in. (69.85 mm) rotating vane

anemometer or equivalent is suggested. The center

of the anemometer should be held tight to the face

of the panel and parallel to the filter. Both squareness

and distance are important for accuracy. Calculate

the average velocity of the panel.

3. Measure the length and height of the perforated face

panel.

4. Calculate the perforated face panel volume using the

following formula:

CFM = avg. velocity x length (in.) x height (in.) x 0.005

m/hr = avg. velocity x length (m) x height (m) x 0.72

5. Calculate the system’s volume by repeating the

process for the remaining panels and adding the

individual panel volumes together.

Filter Readings (ft/min.)

260 250 255 260 250 255 265

270 275 270 280 265 265 270

290 285 280 280 275 290 295

285 275 280 260 270 265 260

Filter Readings (m/hr)

4755 4572 4663 4755 4572 4663 4846

4938 5029 4938 5121 4846 4846 4938

5304 5212 5121 5121 5029 5304 5395

5212 5029 5121 4755 4938 4846 4755

Example: Face supply hood with three 28 inch (.711 m) perforated panels

Measured velocities in ft/min. for one perforated panel

Average Velocity =

(Imperial)

(Metric)

=

=

Measure length and height. 28 inches (.711 m) long perforated panel by 16 inches (.406 m) high

Volume for one panel = Conversion Factor x Average Velocity x Length x Height

(Imperial)

(Metric)

= 0.005 x 270.7 ft/min. x 28 x 16 = 606.4 cfm

= 0.72 x 4951 m/hr x .711 x .406 = 1029 m3/hr

Total system volume = (Panel 1 Volume) + (Panel 2 Volume) + (Panel 3 Volume)

(Imperial)

(Metric)

= 606.4 + 614.3 + 593.8 = 1814.5 cfm

= 1029 + 1044 + 1009 = 3082 m3/hr

Sum of Velocity Readings

Number of Readings

260 + 250 + ... + 265 + 260

28

4755 + 4572 + ... + 4846 + 4755

28

= 270.7 ft/min.

= 4951 m/hr

Kitchen Hoods • Type I and Type II

14

®

Page 15

Testing Hood Air Volume - Shortridge Method

Baffle Filter Style Hoods

A. Exhaust:

With all the filters in place, determine the total hood

exhaust volume with a Shortridge meter as follows:

1. All cooking equipment should be on. If the hood has

internal short circuit make-up air, it should be turned off.

2. Measure velocities

• Set up the Shortridge meter.

• For 20 in. (500 mm) wide filters, position the

grid as shown in Fig. 7 and 8. Average the two

measurements.

• For 16 in. (400 mm) wide filters position the grid as

shown in Fig. 9.

• Take velocity readings for each filter.

3. Calculate each filter’s volumetric flow rate as follows:

Calculate each filter’s average velocity by summing

the velocity readings and dividing by the number of

readings for each filter.

Multiply the average velocity by the conversion factor

to obtain the volumetric flow rate for each filter.

4. Calculate the hood’s total volumetric flow rate by

summing the volumetric flow rate of each individual

filter in the hood as calculated in Step 3.

NOTE

For best accuracy multiply the velocity of each filter

by its conversion factor and sum the flow rates.

Averaging the velocity measured for all filters may

cause error.

Place standoff spacers against

face of outlet or inlet grill,

filter, coil, etc.

Maintain 1½ inch

(38.1 mm) margin

Swivel bracket

Tubing connectors

Extension rods

Captive knob screws

Nominal Filter Size (H x L)

Inches Millimeters

Pushbutton handle and plug

Handle bracket

Edge of outlet/inlet

active face area

Tubing harness

Pressure input ports

External read jack

Imperial

Conversion

Factor

Maintain 1½ inch

(38.1 mm) margin

Conversion

16 x 16 400 x 400 1.66 .154

16 x 20 400 x 500 2.10 .195

20 x 16 500 x 400 1.96 .182

20 x 20 500 x 500 2.40 .223

Neckstrap

Metric

Factor

Example: Measured velocities for a 20 x 20 filter = 185 and 189 ft/min.

Average Velocity =

(Imperial)

(Metric)

Flow rate for one filter =

(Imperial)

(Metric)

Total hood flow rate = (Filter 1 Flow Rate) + … + (Filter x Flow Rate)

(Imperial)

(Metric)

Sum of Velocity Readings

Number of Readings

185 + 189

=

3383 + 3456

=

2

2

Conversion

Factor

= 187.0 ft/min.

= 3420 m/hr

Average

x

Velocity

= 2.40 x 187.0 ft/min. = 448.8 cfm

= .223 x 3420 m/hr = 763 m3/hr

= 448.8 + 457.8 + 437.5 + 444.8 = 1788.9 cfm

= 763 + 778 + 743 + 756 = 3040 m3/hr

Fig. 7

Fig. 8

Fig. 9

14 in.

14 in.

(355.6 mm)

(355.6 mm)

2.75 in.

2.75 in.

(69.85 mm)

(69.85 mm)

17.25 in.

17.25 in.

(2978.15 mm)

(2978.15 mm)

14 in.

14 in.

(355.6 mm)

(355.6 mm)

2.75 in.

2.75 in.

(69.85 mm)

(69.85 mm)

6 in.

6 in.

(152.4 mm)

(152.4 mm)

10 in.

10 in.

(254 mm)

(254 mm)

10 in.

10 in.

(254 mm)

(254 mm)

10 in.

10 in.

(254 mm)

(254 mm)

®

Kitchen Hoods • Type I and Type II

15

Page 16

High Velocity Cartridge Filters - Rotating Vane

A

Method

A. Exhaust

With all the filters in place, determine the total hood

exhaust volume with a rotating vane anemometer as

follows:

1. All cooking equipment should be on. If the hood has

internal short circuit make-up air, it should be turned off.

2. Measure velocities.

Velocity measurements should be taken at three

locations per filter. These must be over the inlet

opening as shown in Fig. 10.

Measure the velocity of each location. A digital

2.75 in. (69.85 mm) rotating vane anemometer

or its equivalent is suggested. The center of the

anemometer should be held 2 in. (50.8 mm) from

the face of the filters as in Fig. 11. It is helpful to

make brackets to keep the anemometer at the 2 in.

(50.8 mm) distance and parallel to the filter. Both

squareness and distance are important for accuracy.

3. Calculate the average slot velocity.

4. Calculate the CFM per linear foot by dividing

the average velocity by a conversion factor

listed in the following table.

5. Calculate each filter’s volumetric flow rate in

CFM by multiplying the average velocity for

each filter by the conversion factor.

Fig. 10

1/4 Width

Fig. 11

Rotation Vane

nemometer

2 in.

(50.8 mm)

1/2 Width

Cartridge Filter Size

16 in. (400 mm) high with 4 in. (100 mm) high inlet

20 in. (500 mm) high with 4 in. (100 mm) high inlet

16 in. (400 mm) high with 7 in. (120 mm) high inlet

20 in. (500 mm) high with 7 in. (120 mm) high inlet

1/4 Width

Imperial

Conversion

Factor

3

ft

1.63 1/

3

ft

2.15 1/

3

ft

1.24 1/

3

ft

1.58 1/

1/2 Height

Inlet

Height

Filter

Height

Metric

Conversion

Factor

5.35 1/m

7.05 1/m

4.07 1/m

5.18 1/m

3

3

3

3

Example:

Measure the slot velocities in ft/min. for a 9 ft. (2.74 m) hood with four 20 x 20 in. (500 x 500 mm) filters with the

standard 4 in. (101.6 mm) opening, three readings per filter.

Average Velocity =

(Imperial)

(Metric)

CFM per linear foot =

(Imperial)

(Metric)

Hood exhaust volume = CFM/linear foot (m3/hr / m) x Hood Length

(Imperial)

(Metric)

Sum of Velocity Readings

Number of Readings

5330

=

12

97474

=

12

= 444.2 ft/min.

= 8123 m/hr

Average Slot Velocity

Conversion Factor

444.2 ft/min.

=

=

2.15

8123 m/hr

7.05

= 206.6 cfm/linear ft.

= 1152 m3/hr

Filter Readings (ft/min.)

470 440 425

482 430 453

455 431 441

399 439 465

Filter Readings (m/hr)

8595 8047 7772

8815 7864 8284

8321 7882 8065

7297 8028 8504

= 206.6 x 9 ft. = 1859.4 cfm

= 1152 x 2.74 m = 3156 m3/hr

Kitchen Hoods • Type I and Type II

16

®

Page 17

High Velocity Cartridge Filters - Shortridge Meter

A. Exhaust

With all the filters in place, determine the total hood

exhaust volume with a Shortridge meter as follows:

1. All cooking equipment should be on. If the hood has

internal short circuit make-up air, it should be turned

off.

2. Measure velocities

• Set up the Shortridge meter. Leave all holes of

VelGrid open. Do NOT tape over holes that are not

over openings. The conversion factor takes this into

account.

• Position the grid over each filter. Refer to Fig. 12

• Take velocity readings for each filter.

3. Calculate each filter’s volumetric flow rate as follows:

Calculate each filter’s average velocity by summing

the velocity readings and dividing by the number of

readings for each filter.

Multiply the average velocity by the conversion factor

to obtain the volumetric flow rate for each filter.

4. Calculate the hood’s total volumetric flow rate by

summing the volumetric flow rate of each individual

filter in the hood as calculated in Step 3.

NOTE

For best accuracy multiply the velocity of each filter

by its conversion factor and sum the flow rates.

Averaging the velocity measured for all filters may

cause error.

Place standoff spacers against

face of outlet or inlet grill,

filter, coil, etc.

Maintain 1½ inch

(38.1 mm) margin

Swivel bracket

Tubing connectors

Extension rods

Nominal Filter Size

(H x L)

Inches Millimeters

16 x 16 400 x 400

16 x 20 400 x 500

20 x 16 500 x 400

20 x 20 500 x 500

Pushbutton handle and plug

Handle bracket

Captive knob screws

Imperial

Conversion

Factor

Edge of outlet/inlet

active face area

External read jack

2

ft

1.22

2

ft

1.67

2

ft

1.21

2

ft

1.50

Maintain 1½ inch

(38.1 mm) margin

Tubing harness

Pressure input ports

Neckstrap

Metric

Conversion

Factor

2

.113 m

2

.155 m

2

.112 m

2

.139 m

Example:

Measured velocities for 20 x 20 filter = 282 ft/min. (5157 m/hr)

Flow rate for one filter =

(Imperial)

(Metric)

Conversion

Factor

= 1.50 x 282 ft/min. = 423.0 cfm

= .139 x 5157 m/hr = 717 m3/hr

Total hood flow rate = (Filter 1 Flow Rate) + … + (Filter X Flow Rate)

(Imperial)

(Metric)

= 423.0 + 421.8 + 420.7 + 418.2 = 1683.7 cfm

= 717 + 717 + 715 + 711 = 2860 m3/hr

x

Average

Velocity

Fig. 12

1/2 width

1/2 height

®

Kitchen Hoods • Type I and Type II

17

Page 18

Grease-X-Tractor™ High Efficiency Filters or

Grease Grabber™ Multi-Filtration System

Rotating Vane Method

A. Exhaust

With all the filters in place, determine the total hood

exhaust volume with a rotating vane anemometer as

follows:

1. All cooking equipment should be off. If the hood has

internal short circuit make-up air, it should be turned

off.

2. Measure velocities

Measurement should be taken at six locations per

filter. They must be over the inlet opening as shown

in Fig. 13.

Measure the velocity of each location. A digital

2.75 in. (69.85 mm) rotating vane anemometer

or its equivalent is suggested. The center of the

anemometer should be held 2 in. (50.8 mm) from

the face of the filters as in Fig. 14. It is helpful to

make brackets to keep the anemometer at the 2 in.

(50.8 mm) distance and parallel to the filter. Both

squareness and distance are important for accuracy.

3. Calculate the average velocity for the filter.

4. Determine the filter’s conversion factor from the

table.

5. Calculate each filter’s volumetric flow rate in CFM by

multiplying the average velocity for each filter by the

conversion factor.

Fig. 13

1/4 Width

Nominal Filter Size (H x L)

Inches Millimeters

16 x 16 400 x 400

16 x 20 400 x 500

20 x 16 500 x 400

20 x 20 500 x 500

1/2 Width

Rotating Vane

Anemometer

Fig. 14

Imperial

Conversion

Factor

1.31

1.65

1.23

1.65

1/4 Width

1/2 Height

2

ft

2

ft

2

ft

2

ft

2 in.

(50.8 mm)

Metric

Conversion

Factor

2

.122 m

2

.153 m

2

.114 m

2

.153 m

Example: (Imperial)

Hood Length: 7 feet 0 inches with four 20 x 20 filters.

Measure the velocities in ft/min. for each 20 x 20 filter

(six readings per filter)

Filter 1

Filter 2

Filter 3

Filter 4

Average slot velocity for Filter 1 =

(repeat for each filter)

For a nominal filter size of 20 x 20, the conversion factor is 1.65

Volume for Filter 1 = Conversion Factor x Average Velocity

Total hood volume

Filter 1

=

Volume

= 346.0 + 377.6 + 386.9 + 378.1 =

225 201 187

210 238 197

228 222 226

237 240 220

230 245 240

250 223 219

225 265 219

245 221 200

= 1.65 ft

=

346.0 cfm (repeat for each filter)

+

Filter 2

Volume

+

Volume

Filter 3

Sum of Velocity Readings

Number of Readings

1258

=

2

+

Volume

6

Filter 4

= 209.7 ft/min.

x 209.7 ft/min.

1488.6 cfm

Example: (Metric)

Hood Length: 2.13 meters, with four 500 x 500 mm filters.

Measure the velocities in m/hr for each 500 x 500 mm filter

(six readings per filter)

Filter 1

Filter 2

Filter 3

Filter 4

Average slot velocity for Filter 1 =

(repeat for each filter)

For a nominal filter size of 500 x 500, the conversion factor is .153

Volume for Filter 1 = Conversion Factor x Average Velocity

Total hood volume

Filter 1

=

Volume

= 587 + 642 + 657 + 642 =

4114.80 3675.88 3419.86

3840.48 4352.54 3602.74

4169.66 4059.94 4133.08

4334.26 4389.21 4023.36

4420.12 4480.56 4389.12

4572.00 4078.22 4005.07

4114.80 4846.52 4005.07

4480.56 4041.65 3657.60

=

2

+

+

= .153 m

=

Filter 2

Volume

586.7 m3/hr (repeat for each filter)

Filter 3

+

Volume

Sum of Velocity Readings

Number of Readings

23006

6

Filter 4

Volume

= 3834 m/hr

x 3834 m/hr

2528 m3/hr

Kitchen Hoods • Type I and Type II

18

®

Page 19

Grease-X-Tractor™ High Efficiency Filters

or Grease Grabber™ Multi-Filtration System

Shortridge Method

A. Exhaust

With all the filters in place, determine the total hood

exhaust volume with a Shortridge meter as follows:

1. All cooking equipment should be on. If the hood has

internal short circuit make-up air, it should be turned off.

2. Measure velocities

• Set up the Shortridge meter. Leave all holes of

VelGrid open. Do NOT tape over holes that are not

over openings. The conversion factor takes this

into account.

• For 20 in. (500 mm) high filters, position the grid

as shown in Fig. 15 and 16. Average the two

measurements.

• For 16 in. (400 mm) high filters position the grid as

shown in Fig. 17.

• For 20 in. (500 mm) wide filters, position the grid

over the left and right side of the filter. Average the

two measurements.

• Take velocity readings for each filter.

3. Calculate each filter’s volumetric flow rate as follows:

Calculate each filter’s average velocity by summing

the velocity readings and dividing by the number of

readings for each filter.

Multiply the average velocity by the conversion factor

to obtain the volumetric flow rate for each filter.

4. Calculate the hood’s total volumetric flow rate by

summing the volumetric flow rate of each individual

filter in the hood as calculated in Step 3.

Nominal Filter Size (H x L)

Inches Millimeters

16 x 16 400 x 400

16 x 20 400 x 500

20 x 16 500 x 400

20 x 20 500 x 500

Imperial

Conversion

Factor

2

ft

1.53

2

ft

2.00

2

ft

2.25

2

ft

3.00

Metric

Conversion

Factor

.142 m

.185 m

.209 m

.279 m

NOTE

For best accuracy multiply the velocity of each filter

by its conversion factor and sum the flow rates.

Averaging the velocity measured for all filters may

cause error.

Place standoff spacers against

face of outlet or inlet grill,

filter, coil, etc.

Maintain 1½ inch

(38.1 mm) margin

Swivel bracket

Tubing connectors

Extension rods

Pushbutton handle and plug

Handle bracket

Captive knob screws

Edge of outlet/inlet

active face area

Maintain 1½ inch

(38.1 mm) margin

Tubing harness

Pressure input ports

External read jack

Neckstrap

2

2

2

2

Example:

Measured velocities for 20 x 20 in. (500 x 500 mm) filter.

Average Slot Velocity =

(Imperial)

(Metric)

Flow rate for one filter =

(Imperial)

(Metric)

Total hood flow rate = (Filter 1 Flow Rate) + … + (Filter x Flow Rate)

(Imperial)

(Metric)

Sum of Velocity Readings

Number of Readings

198 + 205

=

3021 + 3749

=

Conversion

2

2

Factor

= 201.5 ft/min.

=

3385 m/hr

Average

x

Velocity

= 3.0 x 201.5 ft/min. = 604.5 cfm

= .279 x 3385 m/hr = 944 m3/hr

= 604.5 + 600.3 + 592.4 + 613.3 = 2410.5 cfm

= 944 + 1020 + 1006 + 1042 = 4012 m3/hr

Fig. 15

Fig. 16

(63.5 mm)

(63.5 mm)

Fig. 17

2.5 in.

2.5 in.

14.25 in. (361.95 mm)14.25 in. (361.95 mm)

2.75 in.

2.75 in.

(69.85 mm)

(69.85 mm)

3.25 in. (82.55 mm)3.25 in. (82.55 mm)

14.75 in. (374.65 mm)14.75 in. (374.65 mm)

14.25 in. (361.95 mm)14.25 in. (361.95 mm)

2.75 in.

2.75 in.

(69.85 mm)

(69.85 mm)

2.75 in.

2.75 in.

(69.85 mm)

(69.85 mm)

2.75 in.

2.75 in.

(69.85 mm)

(69.85 mm)

®

Kitchen Hoods • Type I and Type II

19

Page 20

Testing Hood Air Volume - Rotating Vane

Method

Short Circuit Hoods

A. Supply

All cooking equipment should be off. The hood exhaust

should also be off.

1. Measure Velocities

Velocity measurements should be made with a digital

2.75 in. (69.85 mm) rotating vane anemometer or its

equivalent.

One velocity measurement should be taken for

every 8 in. (203.2 mm) of short circuit opening

length, starting tight against one edge of the

opening, and finishing tight against the other edge.

The anemometer should be placed at the bottom

edge of the opening, flush with the bottom lip.

Both squareness and placement are important for

accuracy.

2. Calculate the average slot velocity.

3. Calculate the volumetric flow rate per linear foot by

dividing the average velocity by a conversion factor

of 5.52 per ft. If metric units are used, divide the

average velocity by a conversion factor of 1.68 per

meter.

4. Calculate the hoods supply volume by multiplying the

CFM per linear foot by the total hood length.

Example: 4 ft. (1.22 m) short circuit hood (36 inch (.914 m) short circuit opening

Number of readings = 36 in. / 8 in. => 6 readings (.914 m / .2 m => 6 readings)

Average Velocity =

(Imperial)

(Metric)

=

1335 + 1529 + 1913 + 1780 + 1888 + 1894

=

CFM per linear foot =

(Imperial)

(Metric)

1014.3 ft/min.

=

=

Hood supply volume = CFM/linear foot (m

(Imperial)

(Metric)

= 183.8 x 4 ft. = 735.2 cfm

= 1026 x 1.22 m = 1252 m3/hr

Sum of Velocity Readings

Number of Readings

786 + 900 + 1126 + 1048 + 1111 + 1115

6

6

Average Slot Velocity

Conversion Factor

5.52

1723 m/hr

1.68

= 183.8 cfm/linear ft.

= 1026 m3/hr

3

/hr / m) x Hood Length

=

=

6086

6

10339

6

= 1014.3 ft/min.

= 1723 m/hr

Kitchen Hoods • Type I and Type II

20

®

Page 21

Amerex Wiring Plan View

PRM

MICROSWITCH

INSTALLER PROVIDED JUNCTION BOXES

BASIC WIRING DIAGRAM

RED (COMMON)

YELLOW (N.O)

POWER SOURCE

POWER SOURCE

BLACK (N.C.)

MANUAL RESET RELAY

ELECTRIC GAS VALVE

MANUAL RESET RELAY

MICROSWITCH

NOTE: DO NOT USE YELLOW WIRE ON MICROSWITCH IN NORMAL

INSTALLATION. THE YELLOW WIRE IS TO BE USED ONLY FOR

EXTINGUISHER ALARM, LIGHTS, CIRCUITS, ETC.

BASIC WIRING DIAGRAM

MANUAL RESET RELAY

RED (COMMON)

120V/60HZ

YELLOW (N.O)

BLACK (N.C.)

MICROSWITCH

NOTES:

1. DENOTES FIELD INSTALLATION

2. DENOTES FACTORY INSTALLATION

3. GAS VALVE: UL LISTED ELECTRICALLY-OPERATED SAFETY VALVE FOR NATURAL OR LP GAS AS NEEDED OF

APPROPRIATE PRESSURE AND TEMPERATURE RATING, 110V/60HZ OR AMEREX GAS VALVES, PN 12870, 12871,

12872, 12873, 12874, 12875 and 12876.

4. K1a and K1b ARE N.0. WHEN K1 IS DE-ENERGIZED.

L1

L2

K1

Ka

K1b

CURRENT DRAW MAX:

8A RESISTIVE

8A INDUCTIVE

120VAC

GAS VALVE

PUSHBUTTON SWITCH

GAS VALVE

SEE NOTE 3

®

Kitchen Hoods • Type I and Type II

21

Page 22

Amerex Wiring Plan View

2 Snap-Action Switches provided by manufacturer

may be wired as shown.

Four typical examples shown

Equipment

NO

120 VAC

N

NC

Electric gas valve - If reset relay is

used, see option A or B at right.

Mechanical gas shut off valve does not

require electrical connection.

Alarms

NO

NC

NO

Input

NC

Waterwash

3

NO

NC

4

5

6

Fans

Power to cooking

equipment

Shunt Trip Breaker

Input

Voltage Free

Contacts for

Building Alarm(s)

Power to

Fan(s)

Terminal strip in

Waterwash Control Panel

Fan

Starter

Option A

Relay Part No. 14702

L1

110V/60HZ

Black

Red

Brown

Snap-Action Switch

Part No. 423878

Relay Part No. 426151

L2

Option B

AB

Relay Coil

Manual Reset Relay

(Part No. 426151)

Electrical Rating

1/3 HP, 10 AMP, 120 VAC

1/2 HP, 10 AMP, 240 VAC

13 AMP, 28 VDC

* K1a and K1b are N.O. when K1 is de-energized

Manual Reset Relay

1

Part No. 14702

2

3

5

6

7

8

Reset

6

9

3

4

7

1

N.O.

K1b

Power

Indicator

N.O.

K1*

K1a

Push Button

Switch

Ansul Snap-Action Switch

(Switch contacts shown with Ansul

Automan in the cocked position)

GND

Screw

5

4

3

2

1

Gas Valve

See Note 3

Black

Red

Brown

Gas Valve

See Note 3

Snap-Action Switch

Part No. 423878

L2 Neutral

L1 Hot

110 VAC/60HZ

NO

120 VAC

N

NC

If prohibited by local codes, do not shut down

exhaust fans with this method of wiring.

Input

Manual Switch

Power to

fan(s)

Fan Starter

Note:

1. Denotes field installation.

2. Denotes factory installation.

3. Gas Valves: “UL Listed electrically-operated safety valve for natural or LP gas

as needed of appropriate pressure and temperature rating, 110V/60HZ”

or Ansul gas valves.

4. Do not use black wire on snap-action switch in normal installation. Black

wire may only be used for extraneous alarm, light circuits, etc.

Kitchen Hoods • Type I and Type II

22

®

Page 23

Overall Wiring Plan View for Kitchen Systems with Make-Up Air Control Centers

FROM MAKE-UP AIR

TO EXHAUST FAN

DISCONNECT SWITCH

WIRED THROUGH

BREATHER TUBE ONLY

SUPPLY POWER

TO MAKE-UP AIR

CONTROL CENTER

SUPPLY POWER TO

JUNCTION BOX

ON HOOD FOR HOOD LIGHTS

POWER

PANEL

FIELD WIRING

STARTER #3

FROM MAKE-UP AIR

STARTER #2

TO EXHAUST FAN

DISCONNECT SWITCH

WIRED THROUGH

BREATHER TUBE ONLY

EXHAUST FAN-1A EXHAUST FAN-1B

CONTROL CENTER

MAKE-UP AIR UNIT

FIVE (5) CONTROL WIRES

FROM SWITCH JUNCTION

BOX ON HOOD TO MAKE-UP

AIR CONTROL CENTER

TWO (2) CONTROL WIRES FROM

ANSUL SNAP ACTION SWITCH TO

MOTOR CONTROLS AREA.

ELECTRICAL CONTRACTOR TO

PROVIDE HANDIBOX ON SIDE

OF AUTOMAN.

HOOD-1BHOOD-1A

JUNCTION BOX ON

TOP OF HOOD FOR

FIELD CONNECTION

OF SUPPLY POWER

ANSUL AUTOMAN IS NOT AN

ELECTRICAL RATED BOX.

NO CONNECTIONS INSIDE.

Overall Wiring Plan View for Kitchen Systems with Kitchen Fan Control Centers

This arrangement requires individual power connections for each supply and exhaust fan from remote circuit breakers

thru the fans starter in the Kitchen Fan Control Center (KFCC). The make-up air fan will be wired directly from a remote

breaker. It requires control wiring to be run to the KFCC.

TYPICAL

MAKE-UP AIR FAN

NOTE: Make-up air

fan will have starters

in make-up air only.

Control wiring must

be run to KFCC.

M1

24 VCD make-up air controls

TYPICAL

HOOD

M2

TYPICAL

EXHAUST

FAN

Optional

Disconnect

Switch

(field installed)

TO REMOTE CIRCUIT BREAKERS

______V ____Ph ____ Amp for make-up air fan

120 V 1 Ph 15 Amp for controls

120 V 1 Ph 15 Amp for hood lights

______V ____Ph ____ Amp for exhaust fan

______V ____Ph ____ Amp for supply fan

To appliance shunt trip breaker

To electrial gas valve

To building alarm

FIELD WIRING

TYPICAL

SUPPLY FAN

M1

Fire System

Kitchen

Fan

Control

Center

Control Box

NC

NC

To mechanial gas valve

These components may be

mounted in a hood-mounted end

cabinet or on a wall near the hood.

Disconnect

Switch in

Control Center

120/1

7

NO

8

9

10

NO

IN KFCC

11

12

TERMINAL STRIP

15 AMP

HOOD LIGHTS

(1400 WATT MAX.)

S1

Light and Fan Switch Locations:

A. KFCC D. UDS

B. Utility Cabinet E. Hood

C. Wall F. WWCP

®

Kitchen Hoods • Type I and Type II

23

Page 24

Wiring for Hood Switch Panels

The diagrams below show a typical hood switch panel

remote mounted. For hood mounted switches refer to

the wiring connection decal on the cover of the junction

box on the hood top.

The diagram shows how to wire the exhaust and supply

fans with a control panel to a fire suppression contact

COMBINED EXHAUST & SUPPLY SWITCHING

JUNCTION BOX

ON TOP OF HOOD

FOR FIELD

CONNECTION OF

120 VOLT

SUPPLY POWER

HOOD

LIGHTS

N

LIGHT

SWITCH

CONTROL

VOLTAGE

(FSC1). When wired properly, the supply fan will be