Greenheck 331-4551 Service Manual

Powers™ Controls

No. 3 Pneumatic Damper Actuator

Technical Instructions

Document No. 152-040P25

Rev. 4, May, 2001

OEM Literature

Basic Actuator

Typical Actuator with Fixed Bracket Mounting

Description

Features

The No. 3 Pneumatic Damper Actuator is a compact, modular, totally enclosed,

rolling diaphragm-type actuator designed for modulating or two position actuation.

• All metal body modular construction

• Fixed or pivot mounting models

• Positioning relay available as an option

• Variety of mounting/linkage kits to fit any application

Basic Actuator with Pivot Mounting

Typical Actuator with Extended Shaft

Mounting

Product Numbers

Application

• Threaded shaft for easy mounting of accessory items

See Table 1

Typical applications are for control of fire/smoke leakage rated (*) dampers or air

valves. Other applications include unit ventilators, unit conditioners, air handlers, and

other HVAC applications.

* Must be certified by recognized agency.

Certain actuators in Table 1 are UL Recognized Components under UL’s

Damper Actuator category (EMKU2). This category covers pneumatic

damper actuators intended to be employed on fire dampers and

fire/smoke leakage rated dampers.

Siemens Building Technologies, Inc.

Technical Instructions Powers™ Controls No. 3 Pneumatic Damper Actuator

Document Number 152-040P25

Rev. 4, May, 2001

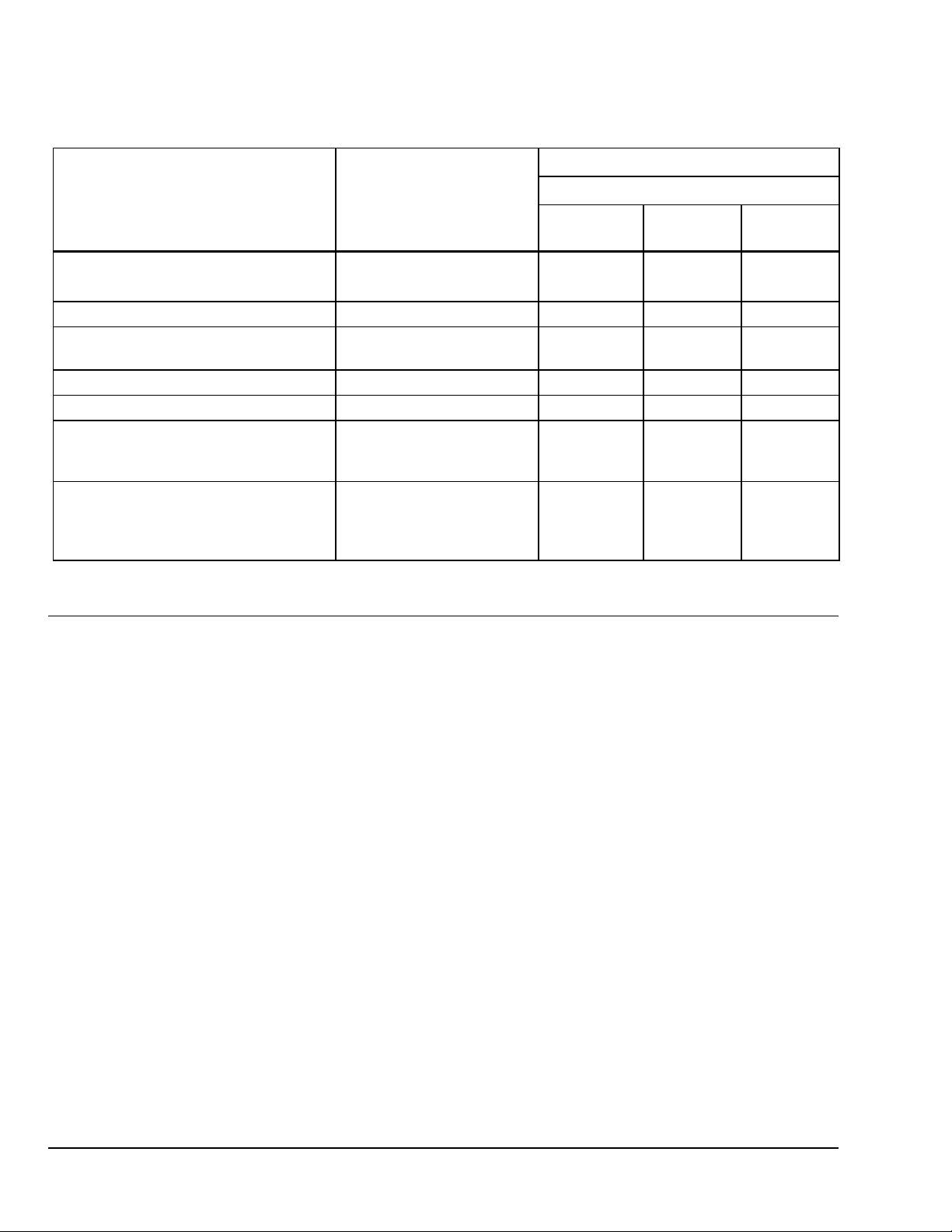

Table 1. Product Numbers for No. 3 Pneumatic Damper Actuators.

Description

Mounting Style

3-7 psi

(21-48 kPa)

Basic Actuator only — 331-4326*

331-4327*

Part Number

Nominal Spring Range

5-10 psi

(35-69 kPa)

331-4526*

331-4527*

8-13 psi

(55-90 kPa)

331-4826*

331-4827*

Actuator with pivot bracket Pivot 331-4322 331-4522 331-4822

Actuator with front mounted fixed

Fixed bracket 331-4323 331-4523 331-4823

bracket

Actuator with clevis Basic 331-4324* 331-4 524 * 331-4824*

Actuator with clevis and positioner relay Basic ‡ ‡ 332-4824

Actuator with pivot bracket, pivot post,

clevis, and miscellaneous hardware

Pivot 331-4351 331-4551* 331-4851*

331-4829*

331-4841*

Actuator with pivot bracket, pivot post,

Extended shaft mounting — — 331-4821*

clevis, crank assembly, extended shaft

mounting plate, damper drive blade,

and mounting hardware

* UL Recognized Component.

‡

Available upon request.

Specifications

Effective diaphragm area 8 inches2 (51.6 cm2)

Stroke 2-3/4 inches (70 mm)

Housing (totally enclosed) Aluminum

Stem Plated steel

Diaphragm Ozone resistant rubber

Spring Steel

Cup Zytel

Maximum air pressure 25 psig (172 kPa)

Nominal spring ranges See Table 1

Operating temperature -20 to 160°F (-29 to 71°C)

Air Connection Straight barb fitting for

1/4 inch O.D. plastic tubing

installed in 1/8 inch

NPT opening

Type of Mounting Fixed or pivot

Thrust and Torque Rating See Table 2

Shipping Weight:

Basic Ac tuat or 1.3 lbs. (0.58 kg)

Actuator with Extended Shaft Mounting 3.1 lbs. (1.4 kg)

Actuator with Fixed Bracket 2.5 lbs. (1.1 kg)

Actuator with Fixed Bracket and Clevis 2.7 lbs. (1.2 kg)

Actuator with Extended Shaft Mounting

and Positioning Relay 4.8 lbs. (2.2 kg)

Dimensions See Figures 4 through 8

Agency Approvals Complies with UL555 and UL555S

Page 2

Siemens Building Technologies, Inc.

Loading...

Loading...