Page 1

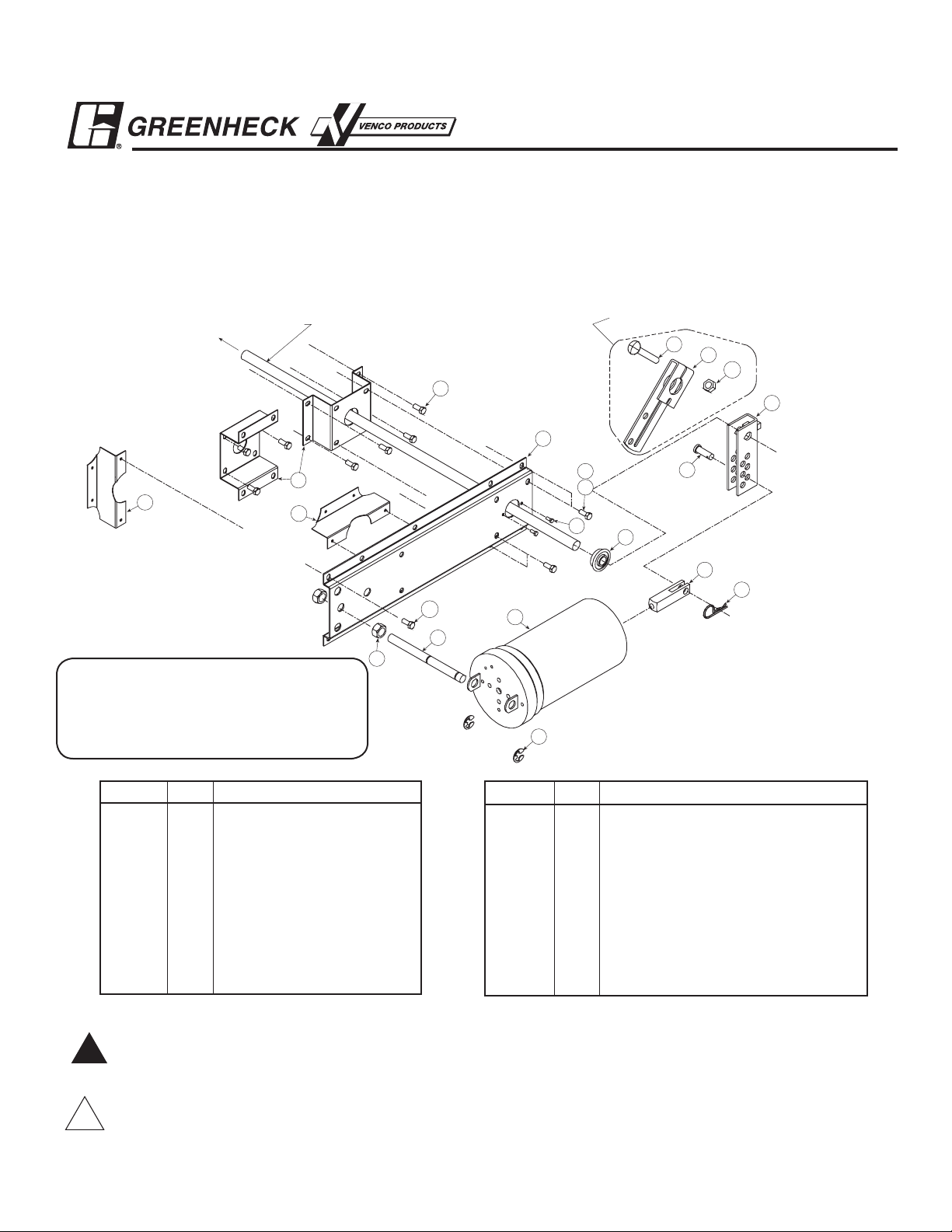

15

12

11

17

13

4

9

1

3

17

2

7

16

14

16

5

19

6

18

8

Damper Shaft

10

Parts for 1 in. Jackshaft

Part number 454202

! !

Siemens #4 Actuator

UL Listed Pneumatic Actuators with Spring Return

Models 331-2976 & 331-2968

INSTALLATION INSTRUCTIONS

These instructions apply to the external field installation of Siemens actuators on Greenheck model VCD Control Dampers when

they are duct mounted or sleeved.

These Siemens pneumatic actuators have an effective diaphragm area of 11 square inches and a 4 in. stroke. They all extend to

their holding position when air pressure is applied and spring return to their fail position when the air supply is interrupted. All

models have a maximum air pressure of 25 psi.

Tools Required:

Wrenches:

(1) 3/8 in., (2) 1/2 in., (1) 7/16 in.,

3

and (1)

Part No. Qty. Description

1 1 Actuator Siemens #4

2 2 1/2 in.-20 Hex Nut

3 1 Post

4 1 Clevis

5 1 Crankarm

6 1 Crankarm 1 in.

7 2 1/2 in. E-ring

8 1 3/8 in. Clevis Pin

9 1 Cotter Pin

10 4 1/4 in.- 20 x 1/2 in. Bolt

WARNING

Equipment Damage or Electrical Power Hazard. Line voltage can cause death or serious injury and short equipment

circuitry. Disconnect power supply before installation.

CAUTION

Device Malfunction Hazard. Improper set screw tightening causes device malfunction. Tighten set screws with

proper torque to prevent damper shaft slippage.

/4 in.

1

/2 in.

Part No. Qty. Description

13 1 Ball Bearing

14 1 Stand Off Bracket

15 4 #14 x 3/4 in. Tek Screw

17 4 #10 x

18 1

19

11 4

12 1 Mounting Bracket

16

1

/4 in.-20 Spinlock Nut

1 Auxiliary Bracket

1

/2 in. Tek Screw

3

/8 in.-16 x 21/2 in. Carriage Bolt

3

1

/8 in.-16 Spinlock Nut

Page 2

Instructions:

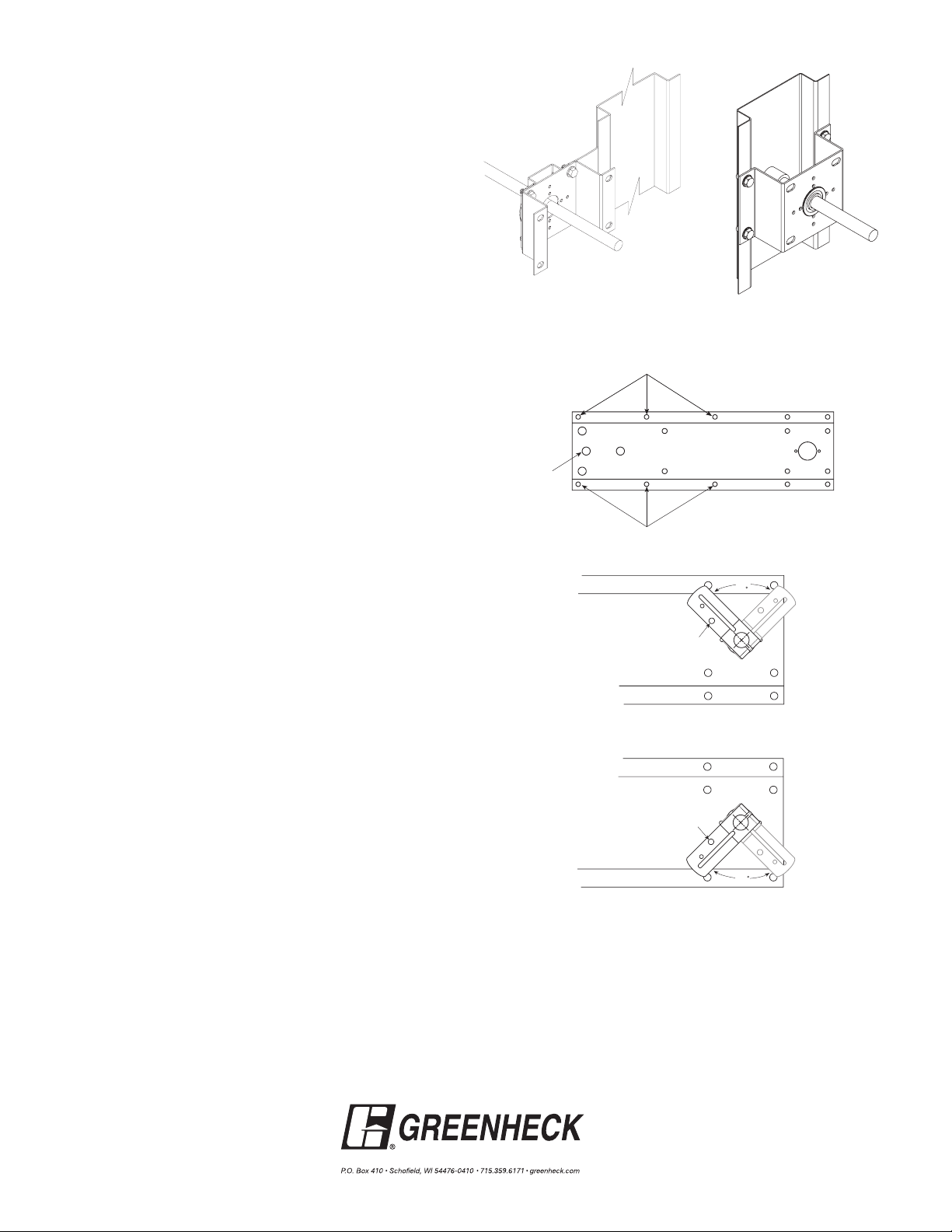

BB

B

A

C

90

Fail Power

C

90

Fail Power

These installation instructions assume the damper is already

mounted in a duct or sleeve with the damper shaft extending

beyond the sleeve or duct 6 inches.

1. Install the stand off bracket.

Dampers with a jackshaft

1a. Mount the stand off bracket onto the jackshaft bracket

1

/4 in.-20 X 1/2 in. thread cutting screws. Orient

)

with (4

the stand off bracket perpendicular to the damper on the

duct or sleeve so that the bracket's shaft hole is centered

on the jackshaft.

Dampers without a jackshaft (shaft extension)

1b. Mount the stand off bracket spanning across the damper

frame flanges. Orient the stand off bracket perpendicular

to the damper on the duct or sleeve so that the bracket's

shaft hole is centered on the jackshaft. Fasten to the

damper frame with (4) #14 Tek screws, supplied with this

kit. Be sure not to run the screws into the damper linkage,

which is between the flanges.

2. Attach the auxiliary bracket, part #17, to the mounting

bracket into two of the 6 holes labeled “B” at right, with (2)

#10 Tek screws supplied.

3. Mount the mounting bracket to the stand off bracket using

1

/4 in.-20 x 1/2 in. bolts and

(4)

(4)

1

/4 in.

- 20 Spinlock

nuts included with this kit. Use the outer four holes of the

mounting bracket for jackshafted models and the inner

four holes for directly driven models. Fasten the auxiliary

bracket to the duct using (2) #10 Tek screws provided.

4. If the damper shaft has a diameter of 1/2 in., mount the

roller bearing to the mounting plate using (2) #10 Tek

screws supplied. If the damper shaft is 1 in. in diameter

discard the roller bearing.

5. Assemble the mounting post, part #3, to the mounting

bracket, part #12, with the (2)

1/2 in.-20 hex nuts supplied.

Use the hole illustrated in “A” above.

Orientation of Stand Off

Bracket for a jackshaft driven

damper

Crankarm Orientation for Counter

Clockwise Fail Rotation

Orientation of Stand Off Bracket

for a directly driven damper

6. Mount the actuator to the post using two E-rings supplied.

7. Note the damper shaft rotation for fail direction and orient

the linkage appropriately. Position the crankarm in one of

the positions shown to the right.

Note: All fail rotations refer to the damper shaft rotation

needed to achieve the desired blade fail postion. Inspect

the damper blades and the damper shaft to determine

the proper damper shaft rotation for the desired blade fail

position.

8. Attach the crankarm to the clevis on the actuator with

the clevis pin and the hitch pin supplied through hole “C”

shown above and to the right. For a

1

/2 in. jackshaft, use

crankarm, part #5, and locate the clevis at the hole 2 3/4

in. from the center of the jackshaft. For a 1 in. jackshaft,

use the crankarm, part #6.

9. Run the supply pressure to the actuator and regulate it to

a maximum of 25 psi.

Crankarm Orientation for

Clockwise Fail Rotation

10. Apply air pressure to the actuator. The damper

blades should fully open or close and return to the fail

position when power is disconnected; if they do not,

adjustments can be made by resetting the crankarm

position on the damper or actuator shaft or by changing

the distance from the actuator face to the center of the

hole in the clevis.

Copyright © 2006 Greenheck Fan Corporation

454202 Siemens #4 Rev. 6 October 2006

Loading...

Loading...