Page 1

Technical Instructions

Document No. 152-013P25

April 28, 2003

Powers™ Controls

No. 6 Pneumatic Damper Actuator

Basic Actuator Typical Actuator with Clevis and Pin Actuator with Extended Shaft and

Description

Features

The No. 6 Pneumatic Damper Actuator is a heavy-duty, rolling diaphragm, spring return

actuator designed to drive large dampers, centrifugal fan inlet vanes, and other

applications requiring a large effective diaphragm area and long stroke.

• Replaceable ozone-resistant silicone rubber rolling diaphragm

• Safe for use in automotive industry applications

• Pivot mounting for extended shaft or frame mounting

OEM Literature

Frame Mounting Accessories

Product Numbers

Application

• Positioning relay (optional)

• Adjustable forward travel stops (optional)

• Three spring ranges

See Table 1

The No. 6 Pneumatic Damper Actuator is recommended for control of outdoor, return air,

exhaust, face and bypass, and fan discharge dampers. It is recommended for

heavy-duty applications using multi-section dampers where either unison or sequence

operation is required.

Certain actuators in Table 1 are UL Recognized Components under UL’s

Damper Actuator category (EMKU2). This category covers pneumatic

damper actuators used on fire dampers and fire/smoke leakage rated

dampers. Complies with UL's 400°F heated air requirements.

Siemens Building Technologies, Inc.

Page 2

Technical Instructions Powers™ Controls No. 6 Pneumatic Damper Actuator

Document Number 152-013P25

April 28, 2003

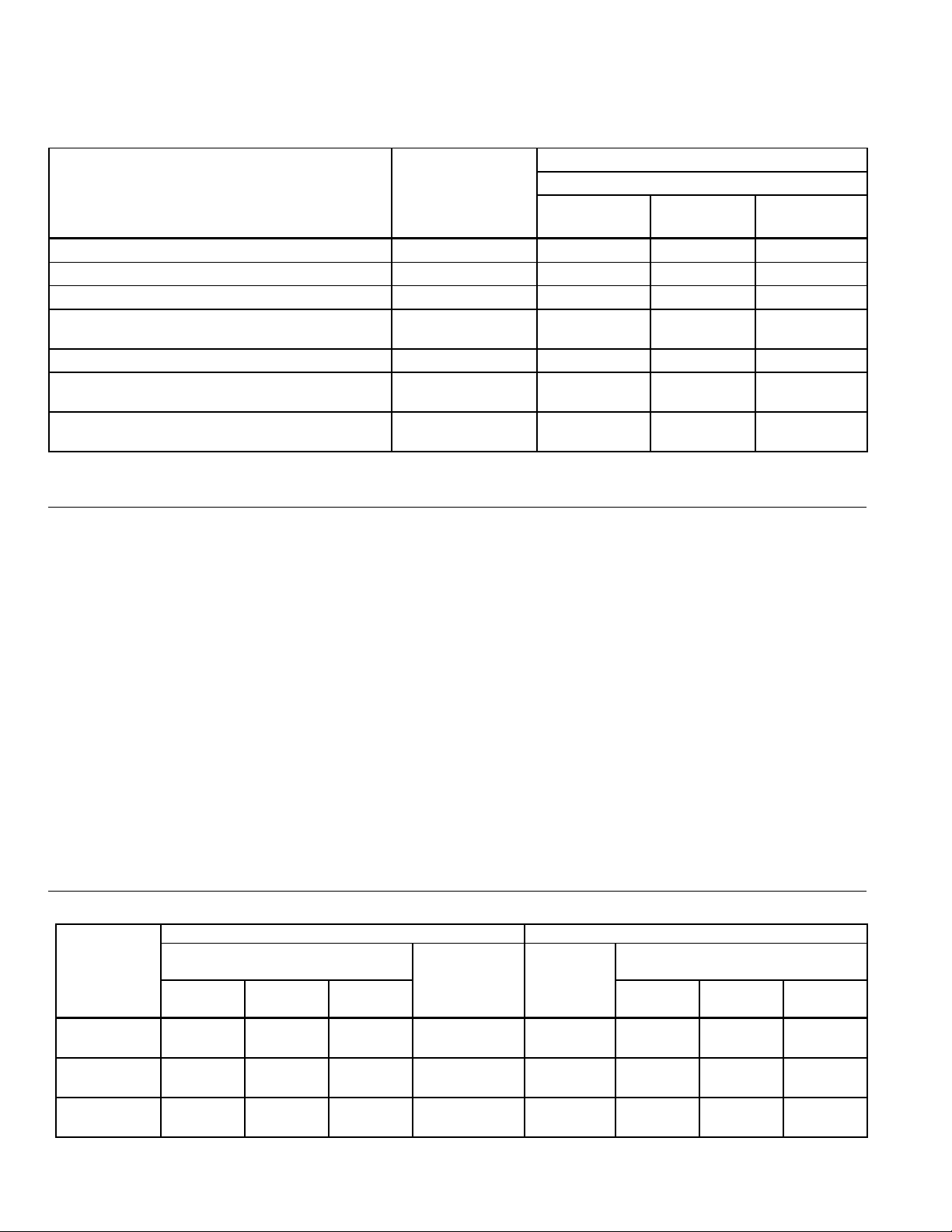

Table 1. Product Numbers for No. 6 Pneumatic Damper Actuators.

Description

Basic Actuator only Pivot 331-2793 331-2794

Basic Actuator only (Marine Finish) Pivot 331-2884

Actuator, with forward travel stops (Figure 1) Pivot – 331-2796 331-2988

Pivot Mount Actuator with clevis, clevis pin, and hitch

pin clip

Same as above with positioner (Figure 6) Pivot – – 332-2856

Actuator and manufacturing assembly for extended

shaft and frame mounting

Same as above with positioner (Figure 6) Universal kit with

Mounting Style

3-8 psi

(21-55 kPa)

Pivot 331-2857 331-2858

Universal kit 331-3012 331-3013

– – 332-3011

positioner

Part Number

Nominal Spring Range

3-13 psi

(21-90 kPa)

8-13 psi

(55-90 kPa)

331-3060*

331-2856*

331-3011*

* UL Recognized Component.

NOTE: Kits must be ordered separately from damper manufacturer.

Specifications

Effective Diaphragm Area 17.9 inch2 (115 cm2)

Stroke 4 inch (102 mm)

Housing Aluminum

Shaft Stainless steel

Diaphragm Ozone-resistant silicone rubber

(contains no migrating silicone lubricant)

Maximum Air Pressure 30 psig (210 kPa)

Nominal Spring Ranges 3 to 8 psi (21 to 55 kPa)

3 to 13 psi (21 to 90 kPa)

8 to 13 psi (55 to 90 kPa)

Ambient Temperature Range

Operating -20°F to 200°F (-29°C to 93°C)

Storage

Air Connection 1/8-inch NPT

Type of Mounting Pivot

Thrust and Torque Rating See Table 2

Dimensions See Figure 3 through Figure 6

Agency Approvals Complies with UL555 and UL555S

400°F heated air requirem ents

Table 2. Thrust Torque Ratings.

Nominal

Spring

Range

15psi

(103 kPa)

3-8 psi

(21-55 kPa)

3-13 psi

(21-90 kPa)

8-13 psi

(55-90 kPa)

* With maximum hysteresis of 2.5 psi (17.2 kPa) @ 90° rotation.

Page 2 Siemens Building Technologies, Inc.

125 (556) 179 (796) 304 (1352)

36 (160) 89 (396) 214 (952) 54 (240) 50 (5.6) 50 (5.6) 75 (8.5) 75 (8.5)

36 (160) 89 (396) 214 (952) 144 (640) 50 (5.6) 50 (5.6) 125 (14) 202 (23)

Maximum Thrust lbs. (N) Torque Rating* lb-in (Nm)

Full Stroke Forward 2-Position Operation

Spring

Return

18 psi

(124 kPa)

25 psi

(172 kPa)

(No Stroke)

0 psi (0 kPa)

54 (240) 50 (5.6) 75 (8.5) 75 (8.5) 75 (8.5)

Gradual

Operation

15 psi

(103 kPa)

or Positioner

18 psi

(124 kPa)

25 psi

(172 kPa)

Page 3

Powers™ Controls No. 6 Pneumatic Damper Actuator Technical Instructions

Document Number 152-013P25

April 28, 2003

NOTE: The No. 6 Pneumatic Damper Actuator does not require any periodic cycling. However, it is strongly

suggested that all systems are functionally checked periodically, and per local codes and ordinances.

Accessories

Damper shaft extension kits:

1/2-inch (13 mm) diameter (See TB-128) 331-631

1/2-inch (13 mm) diameter, 9-inch (229 mm) long,

hollow rod 333-184

1/2-inch (13 mm) diameter, 9-inch (229 mm) long 333-042

1-inch (25 mm) diameter, 11-5/8-inch (295 mm) long 333-194

Actuator shaft extensions:

10-1/8 inch (257 mm) long 331-434A

Adapter kit for 1/2 inch NPT pipe 333-030

Damper shaft extension kit adapter - 3/8 inch (9.5 mm) 331-632

Cranks—damper shaft:

3/8-inch (9.5 mm) - 1/2 inch (13 mm) diameter,

selectable radius 331-941

5/8-inch (16 mm) diameter 333-182

3/4-inch (19 mm) diameter 333-183

1-inch (25 mm) diameter 333-181

Cast iron crank with setscrews 333-078

Linkage kit (4-inch, 102 mm, link and crank) 331-958

Remote mounting kit (extended shaft) 331-618

Universal mounting plate

3/4-inch damper shaft 331-623

1-inch damper shaft (use with 333-194) 331-623A

Right angle mounting plate 333-208

Bearing 331-862

Positioning relay 147-2000

Positioning relay mounting kit 147-276

Mounting lug 331-569

Screws (three required for frame mounting lug) 034-123K

Offset mounting bracket 333-176

Travel stop rods 333-197

Service Kits

Siemens Building Technologies, Inc. Page 3

Diaphragms (Package of five) 333-572

Page 4

Technical Instructions Powers™ Controls No. 6 Pneumatic Damper Actuator

=

Document Number 152-013P25

April 28, 2003

Actuator Sizing

The quantity of actuators required depends on several torque factors. To determine

the quantity of actuators required for the installation:

• Obtain damper torque ratings (ft-lb/ft

2

) from the damper manufacturer.

• Determine the area of the damper.

• Calculate the total torque required to move the damper:

Total Torque = Torque Rating x Damper Area

• Calculate the total quantity of actuators required:

Number of Total Damper Torque Required

Safety Factor

Actuators

1

Safety Factor: When calculating the number of actuators required, a safety factor

SF1 x Actuator Torque (Table 2)

should be included for unaccountable variables such as slight misalignments, aging of

the damper, etc. A suggested safety factor is 0.80 (or 80% of the rated torque).

See AB-300 Damper Actuator Sizing and Selection Application Bulletin in the HVAC

Systems/Controls Reference Data (125-1853) for additional sizing information. See

TB-181 Powers™ Controls Maximum Thrust Ratings of Pneumatic Damper Actuators

Technical Bulletin (155-219P25) for additional torque requirements.

Operation

The air tubing from a controlling instrument is connected to the actuator’s upper housing.

With no control pressure to the actuator, the compression spring forces the spring seat

Standard Actuator

(Figure 1)

and actuator shaft toward the upper housing but is limited by the E”–ring. As the control

pressure increases, the spring compression is overcome and the actuator shaft

gradually moves outward. Conversely, as control pressure decreases, the spring returns

the shaft to the position at which the air pressure on the diaphragm balances the spring

tension. For each value of control pressure there is a corresponding position of the shaft

Table 3. Construction Components.

Item Part No. Description Qty. Material

1 047-061J Retaining E-ring 1 Steel

2 333-217 1 × 1-1/4 in. Hex Nut 1 Brass

3 — Spring Retainer 1 —

4 — Stem Guide Assembly 1 —

5 — Lower Housing 1 Aluminum

Diaphragm 1

5/16 in.-18 × 1

Large Hex Cap Screw

Piston Plate and Stem

Assembly

6 Steel

1

Silicone

rubber

Aluminum/

Stainless

Steel

Figure 1. Standard Actuator.

6

333-572

(pkg. of 5)

7 599-00413

8 — Upper Housing 1 Aluminum

9 — Helical Compression Spring 1

331-091 3 to 13 psi (21 to 90 kPa) —

331-208 3 to 8 psi (21 to 55 kPa) —

331-094 8 to 13 psi (55 to 90 kPa) —

10 —

11 — Retaining C-ring 1 Steel

12 333-197 Stop Kit (Optional) — Steel

Page 4 Siemens Building Technologies, Inc.

Page 5

Powers™ Controls No. 6 Pneumatic Damper Actuator Technical Instructions

Document Number 152-013P25

April 28, 2003

Operation,

Continued

Figure 2. Extended Shaft/Frame Mounting Actuator Assembly.

Table 4. Extended Shaft/Frame Mounting Assemblies.

Item Part No. Description Qty. Material

1 041-162J Nut 1 Steel

2 146-020K Lock washer 1 Steel

3 047-061K E-ring 2 Steel

4 331-565 Pivot post 1 Steel

5 041-142 Nut 1 Steel

6 333-207 Clevis 1 Zinc plated steel

7 331-293 Clevis pin 1 Zinc plated steel

8 331-807 Hitch pin 1 Zinc plated steel

9 331-941 Crank assembly 1 Zinc plated steel

10 331-623 Actuator mounting plate 1 Steel

— 034-283 Mounting screws 4 Steel

F 333-034 Rocker — Zinc plated steel

F 034-123K Mounting screws 3 Steel

F 041-230J Nut 2 Steel

F 030-510J Screws 2 Steel

“F” Parts for Frame Mounting.

Siemens Building Technologies, Inc. Page 5

Page 6

Technical Instructions Powers™ Controls No. 6 Pneumatic Damper Actuator

Document Number 152-013P25

April 28, 2003

Dimensions

Figure 3. Dimensions Shown in Inches (Millimeters).

Offset Mounting

Bracket

This bracket is designed to offset

the Universal Mounting Plate

331-623 or 331-623A from

ductwork.

NOTE: Depending on the

application, two

brackets may be

required to support the

actuator and universal

mounting plate.

Figure 4. Offset Mounting Bracket 331-176.

Dimension in Inches (Millimeters).

Figure 5. Actuator Mounting Plate.

Dimensions in Inches (Millimeters).

Page 6 Siemens Building Technologies, Inc.

Page 7

Powers™ Controls No. 6 Pneumatic Damper Actuator Technical Instructions

Document Number 152-013P25

April 28, 2003

Dimensions,

Continued

Figure 6. No. 6 Pneumatic Damper Actuator with the RL 147 Positioning Relay Mounted.

Dimensions in Inches (Millimeters).

Information in this publication is based on current specifications. The company reserves the right to make c hanges i n specifications and models as

design improvements are introduced. Powers is a trademark of Siemens Building Technologies, Inc. Other product or company names mentioned

herein may be the trademarks of their respective owners. © 2003 Siemens Building Technologi es, I nc.

Siemens Building Technologies, Inc.

1000 Deerfield Parkway

Buffalo Grove, IL 60089-4513

U.S.A.

Your feedback is important to us. If you have

comments about this document, please send

them to technical.editor@siemens.com

Document No. 152-013P25

Printed in the U.S.A.

Page 7

Loading...

Loading...