Page 1

A111-3EN • 1/2009

VALV-POWR – VPVL double-opposed piston actuators

combine the benefits of high cycle life, a rugged construction, and an extremely compact and symmetrical

design with a unique range of features and options.

They are specifically designed for fast efficient operation of ball, butterfly, and other rotary type valves.

FEATURES

Single-Source Responsibility

■■

Valves,actuators, and accessories are designed to operate as a unit with the highest degree of compatibility.

■■

Valves, actuators, and accessories can be supplied

completely assembled to provide unit responsibility

from a single source.

Versatility

■■

Modular designs with same body and end caps for

double-acting and spring-return reduce inventory.

Springs can be added in the field to convert doubleacting to spring-return or for changes in supply pressure.

■■

Failure direction can be easily reversed from springto-open or spring-to-close orientation simply by

inverting the pistons.

■■

Actuator to valve attachments comply with ISO

5211/1 and EN 12116.

■■

Solenoid valve and accessory attachments comply

with NAMUR VDI/VDE 3845.

■■

A wide range of optional accessories and control

devices that include limit switches, solenoid valves,

and mechanical safety lockouts are available to satisfy

virtually all automated valve requirements.

■■

Several models of 180 degree VPVL’s are optionally

available.

High Cycle Life

■■

Bearings on all sliding and rotating moving parts to

ensure long life.

■■

Dual piston rack-and-pinion mechanism for simple

construction, high cycle life, and constant torque.

■■

Hard-anodized PTFE-coated extruded aluminum

body with honed internal surface for strength and

lower coefficient of friction.

■■

Mechanically multi-guided aluminum pistons for

precise movement, low friction, and high cycle life.

VALV-POWR® SERIES VPVL

MODEL C DOUBLE-ACTING

AND SPRING-RETURN RACKAND-PINION COMPACT

PNEUMATIC ACTUATORS

■■

Machined teeth on piston racks and pinions for

excellent rack and pinion engagement and maximum

efficiency.

Corrosion Resistant

■■

Hard-anodized PTFE-coated body, polyester-coated

end caps, and epoxy-coated springs, along with

internal and external stainless steel fasteners,

provide corrosion resistance in a variety of difficult

applications and environments.

Reliability

■■

Safety-contained multi-spring design with preloaded

and heavy-duty coated springs for simpler range

versatility,greater safety, and corrosion resistance.

■■

External adjustable stops in both directions assure

flexibility and accuracy when setting the valve in

the open and closed positions.

■■

As an added safety feature,the external adjustment

screws are slotted.The slot will indicate the presence

of internal pressure. Pressure will begin to vent

before the adjustment screws are completely

backed out of the actuator.

SPECIFICATIONS

Maximum Supply Range: 116 psi (8 bar)

Temperature Range:

Standard -4˚F to +175˚F (-20˚C to +80˚C)

Optional -40˚F to +300˚F (-40˚C to +150˚C)

Rotation Adjustment: -4˚ to +4˚; 86˚ to 94˚

Supply Media: Air, mineral-based hydraulic fluid

STANDARDS

Actuator to valve mounting: EN12116 ISO 5211/1

Actuator to solenoid mounting: Namur,VDI/VDE3845**

Actuator to accessory mounting: Namur, VDI/VDE3845*

* Except VPVL011 ** Except VPVL011,650,700, 800

Page 2

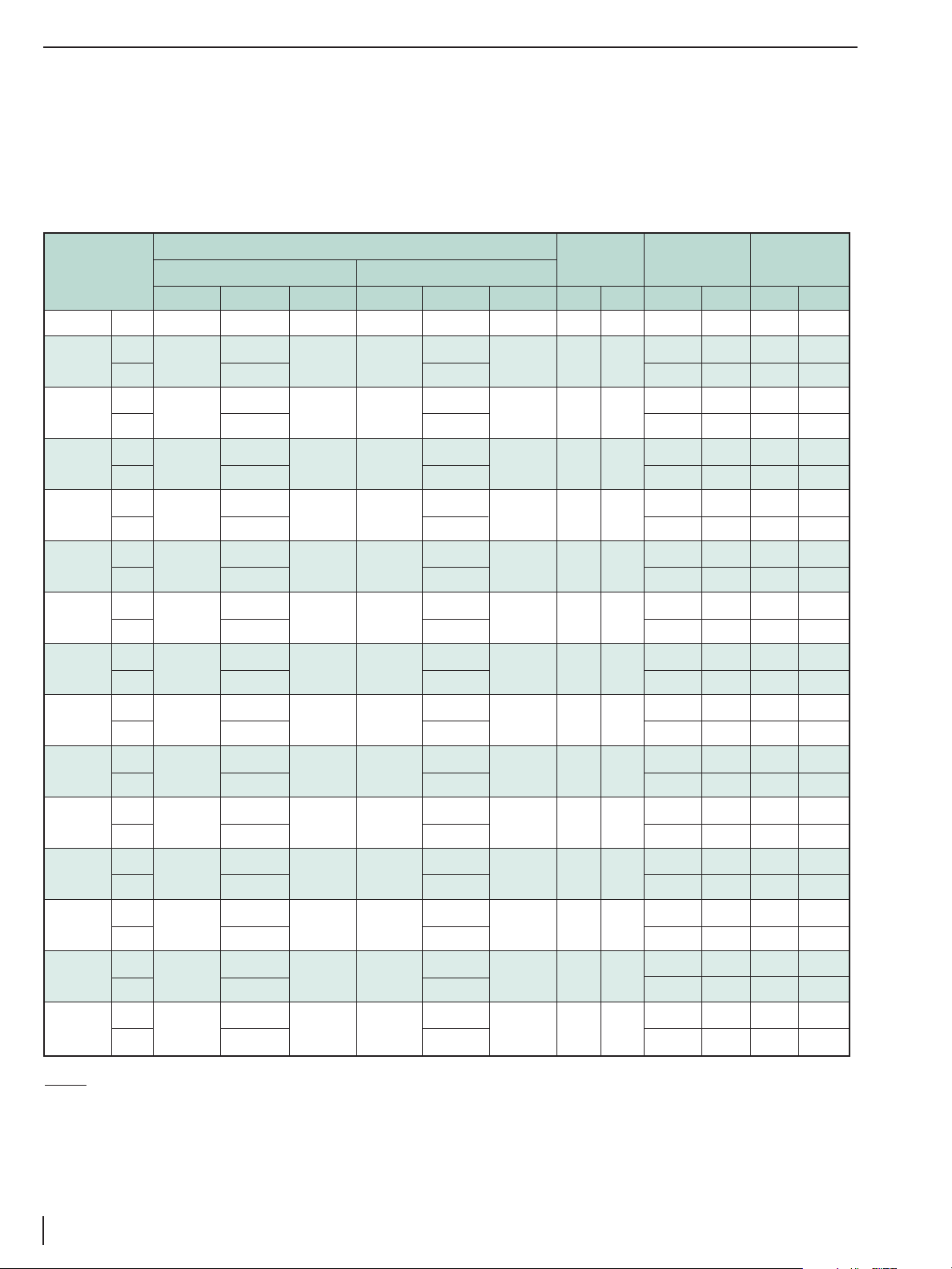

TECHNICAL BULLETIN 1/09

2

METSO A111-3EN

Air Volume

Moving Time

Actuator Model in.

3

ml

Bore Diam.

Seconds

1

Wei ght

Opening Closing Swept Opening Closing Swept in. mm Opening Closing lb. kg

VPVL011 DA 3.1 4 1.2 50.8 65.6 20.3 1.5 38 0.2 0.2 1.0 0.5

VPVL051

DA

5.5

9.2

3.4 90.1

150.8

55.5 1.97 50

0.2 0.3 2.1 1.0

SR – – 0.3 0.3 2.3 1.1

VPVL100

DA

9.8

15.9

6.0 160.6

260.6

97.8 2.48 63

0.3 0.3 3.3 1.5

SR – – 0.3 0.4 3.8 1.7

VPVL200

DA

18.9

29.9

11.8 309.7

490

194.1 2.95 75

0.3 0.4 5.9 2.7

SR – – 0.4 0.5 7.0 3.2

VPVL250

DA

31.1

47.6

18.6 509.6

780

305.4 3.46 88

0.4 0.5 8.4 3.8

SR – – 0.5 0.6 9.7 4.4

VPVL300

DA

43.3

67.7

27.1 709.6

1109

443.7 3.94 100

0.5 0.6 11.9 5.4

SR – – 0.7 0.9 14.3 6.5

VPVL350

DA

72.6

109.8

43.8 1190

1799

717.2 4.53 115

0.7 0.8 18.6 8.4

SR – – 0.9 1.1 21.7 9.8

VPVL400

DA

94

143

56 1540

2443

924 4.92 125

0.9 1.1 22.5 10.2

SR – – 1.2 1.4 27.8 12.6

VPVL450

DA

147

231

89 2409

3765

1451 5.71 145

1.2 1.4 32.0 14.5

SR – – 1.5 1.8 39.9 18.1

VPVL500

DA

192

300

116 3146

4916

1893 6.30 160

1.5 1.7 43.7 19.8

SR – – 1.8 2.1 52.9 24.0

VPVL550

DA

260

420

156 4261

6883

2556 7.09 180

2.0 2.2 55.1 25.0

SR – – 2.4 2.8 69.7 31.6

VPVL600

DA

362

577

217 5932

9455

3549 7.87 200

2.7 3.2 78.3 35.5

SR – – 3.5 4.0 99.4 45.1

VPVL650

DA

610

928

364 10000

15200

5963 9.45 240

3.5 4.0 115 53

SR – – 4.1 4.6 139 64

VPVL700

DA

885

1305

528 14503

21385

8655 10.43 265

4.0 4.5 183 83

SR – – 4.5 5.0 225 102

VPVL800

DA

1526

2441

917 25000

40000

15032 12.99 330

6.0 7.0 295 134

SR – – 7.5 8.5 373 169

To select an actuator for a particular valve and service,first

determine the maximum operating torque that will be

required from the applicable valve bulletin.Then refer to the

appropriate torque output table and select an actuator

that will, at the available supply pressure,provide a torque

output no less than the required operating torque for the

valve. For spring-return units, both the spring torque and

the air torque must be sufficient.In the event confirmation

is desired for the selection of an actuator under specific

service conditions,include full details on trim, seat materials,

and media characteristics.

ACTUATOR SELECTION

NOTES:

(1) The above times are based on the following conditions: A) Room temperature ,B) Solenoid valve orifice diameter of 4 mm (5/32 in.) and a flow rate

capacity of 400 L/min (14.1 cfm), C) Minimum inner piping diameter of 8 mm (5/16 in.),D) 5.5 bar (80 psi) air supply pressure, E) Without valve loading.

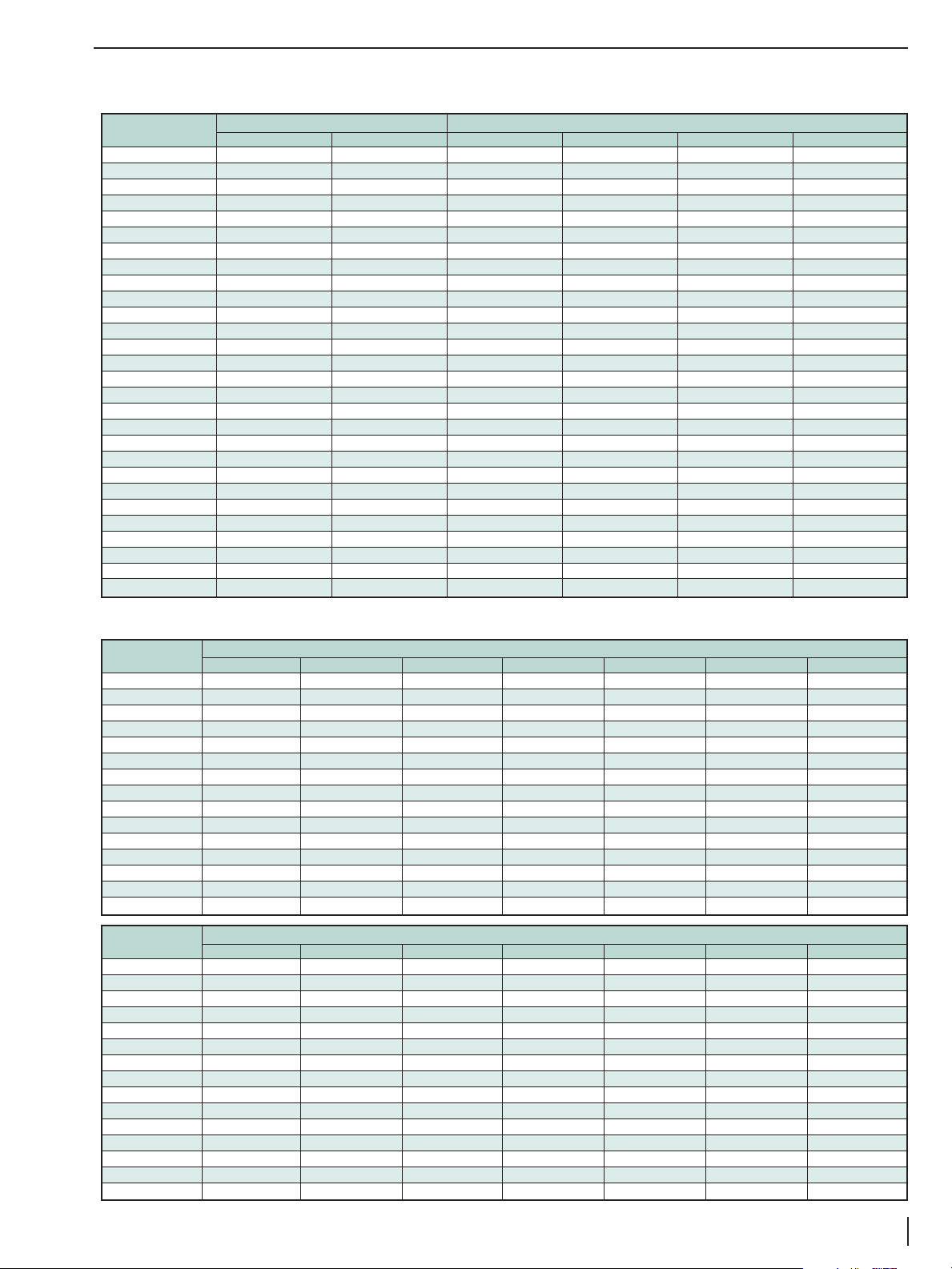

Page 3

TECHNICAL BULLETIN 5/08

3

VALV-POWR SERIES VPVL MODEL C DOUBLE-ACTING AND SPRING-RETURN RACK- AND-PINION COMPACT PNEUMATIC ACTUATORS

A111-3EN

ACTUATOR SELECTION (CONTINUED)

SPRING RETURN

Actuator Spring-Return Torque Output Air Torque Output at Specified Supply Pressure

Model FT•LBS N•m FT•LBS, @ 60 psi N•m @ 4.2 bar FT•LBS @ 80 psi N•m @ 5.5 bar

051 SR4/5 4.5 6.1 3.7 4.9

051 SR6 6 8.1 4.9 6.6

100 SR4/5 7.4 10 6.7 8.5

100 SR6 9.8 13.3 8.9 12

200 SR4/5 14.7 19.9 12 17

200 SR6 19.6 26.5 16 22

250 SR4/5 24.3 33 17 24

250 SR6 32.5 44.5 23 32

300 SR4/5 33.6 45.6 28 40

300 SR6 44.9 60.8 38 51

350 SR4/5 54.4 73.8 44 62

350 SR6 72.6 98.4 58 79

400 SR4/5 69.7 95 59 84

400 SR6 93 126 79 107

450 SR4/5 109 148 94 133

450 SR6 146 198 126 169

500 SR4/5 149 202 126 178

500 SR6 199 269 168 225

550 SR4/5 210 285 153 278

550 SR6 280 379 204 274

600 SR4/5 282 383 231 327

600 SR6 376 510 308 414

650 SR4/5 479 649 399 541

650 SR6 638 865 532 721

700 SR4/5 724 981 520 737

700 SR6 966 1308 693 931

800 SR4/5 1221 1656 1105 1498

800 SR6 1628 2207 1473 1997

DOUBLE ACTING

Actuator Torque Output in FT•LBS - VPVL XXDA Double-Acting Actuator at Specified psi Supply Pressures

Model 40 psi 50 psi 60 psi 70 psi 80 psi 90 psi 100 psi

VPVL 011 DA 2.5 3.1 3.7 4.3 4.9 5.5 6.2

051 6.8 8.5 10.1 11.8 13.5 15.2 16.9

100 12 14.9 17.9 20.9 23.9 26.8 29.8

200 23.7 29.6 35 41 47 53 59

250 37.2 46.6 55 65 74 83 93

300 54 67.6 81 94 108 122 135

350 87.5 109 131 153 175 197 219

400 113 141 169 197 225 254 282

450 177 221 265 310 354 398 442

500 231 289 346 404 462 519 577

550 312 390 467 545 623 701 779

600 433 541 649 757 866 974 1082

650 727 909 1091 1272 1454 1636 1818

700 1055 1319 1583 1847 2111 2375 2638

800 1833 2291 2749 3207 3665 4123 4581

Actuator Torque Output in N•m - VPVL XXDA Double-Acting Actuator at Specified bar Supply Pressures

Model 2.7 bar 3.5 bar 4.2 bar 4.8 bar 5.5 bar 6.2 bar 6.9 bar

VPVL 011 DA 3.2 4.2 5.1 5.8 6.7 7.6 8.5

051 8.9 11.6 14 16 18.3 20.7 23

100 16 20.5 24.6 28.1 32 36 40

200 31 40 48 55 64 72 80

250 48 66 79 90 103 117 130

300 68 93 112 128 146 165 184

350 115 150 181 207 236 266 296

400 143 194 233 266 305 344 383

450 224 304 365 417 478 539 600

500 293 397 477 545 624 703 782

550 395 536 643 735 842 949 1056

600 575 745 893 1021 1170 1319 1468

650 986 1232 1479 1725 1971 2218 2465

700 1338 1815 2179 2490 2853 3216 3579

800 2485 3106 3727 4348 4969 5590 6211

Page 4

TECHNICAL BULLETIN 1/09

4

METSO A111-3EN

OPTIONS

Solenoid Valves

Direct-mounted solenoid valves are available in both 3-way

and 4-way configuration, which mount directly to the

actuator in accordance with NAMUR and VDI/VDE 3845

standards, excluding the VPVL011, 650, 700 and 800. In

general,3-way solenoids are used for spring-return actuators

and 4-way versions for double-acting.

NOTE: Please consult factory for other solenoid valves or additional options

including special voltages,double solenoids, special electrical connections,etc.

Mechanical Safety Lockout

To comply with the intent of OSHA requirements for locking actuators in position prior to performing maintenance,

an actuator can have the mechanical safety lockout option

added to it. Design of the stop cam allows for locking the

actuator in either the full-open or full-closed position.

Actuators equipped with this option have a special lockout

screw and a tamperproof cover attached to the housing of

the actuator with stainless steel wire. The lockout kits are

readily available to permanently lock the actuator in place

to prevent unwanted operation.

100% Adjustable Travel Stop

To limit the rotation on the stroke beyond the standard

±4˚ of a VPVL actuator, a stainless steel 100%-adjustable

travel stop option can be added.The stops, located in the

Direct-Mount Solenoid Valves

Part Number 031-0576-01 031-0580-01

Enclosure NEMA IV NEMA VII

Configuration 3 or 4-way

Pipe Size 1/4" Inlet, 1/8" Exhaust

Cv 0.7

Voltage Standard: 120 VAC 60 Hz (110/50)

Optional: 240 VAC 60 Hz, 12 VDC, 24 VDC

Body Material Black Anodized Aluminum

Power Consumption AC: 6.9 watts

DC: 6.3 watts

end caps, allow the valve position to be set anywhere

between full closed and full open. This option limits travel

of only the counter-clockwise stroke for standard doubleacting and spring-closed units. The 100% Adjustable Stop

option is specified in the actuator ordering code.

Special longer bolt used to

lock the actuator in one

position when needed.

Lockout Kits

VPVL051 LD78

VPVL100 LD79

VPVL200 LD80

VPVL250 LD81

VPVL300 LD82

VPVL350 LD83

VPVL400 LD84

VPVL450 LD85

VPVL500 LD86

VPVL550 LD87

VPVL600 LD88

VPVL650 LD89

VPVL700 LD90

VPVL800 LD91

100% Travel Stop Lengths

Actuator

L Min L Max

inch mm inch mm

VPVL051 6.2 158 7.3 186

VPVL100 7.2 184 8.5 216

VPVL200 9.5 242 11.3 286

VPVL250 11.0 280 13.0 330

VPVL300 11.9 303 14.1 359

VPVL350 14.0 356 16.7 424

VPVL400 14.5 368 17.5 444

VPVL450 17.7 449 21.1 537

VPVL500 18.1 461 21.9 555

VPVL550 20.9 531 24.8 631

VPVL600 24.7 628 29.1 739

VPVL650 25.7 653 30.9 785

VPVL700 30.0 762 36.1 918

VPVL800 35.8 910 42.8 1086

Stop Screw

Type A

VPVL051-300

Stop Screw

Type B

VPVL350-800

L Min. Approx.

L Max. Approx.

Page 5

TECHNICAL BULLETIN 5/08

5

VALV-POWR SERIES VPVL MODEL C DOUBLE-ACTING AND SPRING-RETURN RACK- AND-PINION COMPACT PNEUMATIC ACTUATORS

A111-3EN

Declutchable Manual Override

A side-declutchable manual override is available for VPVL

actuators. It consists of a manual gear actuator mounted

between the actuator and the valve.The device is normally

disengaged from the shaft. Upon engagement of the

override clutch, overriding the actuator is done with ease,

aided by the high-reduction ratio of the manual gear unit.

VPVL Actuator Declutchable

Approximate Dimensions - Inches

Model Override

Approx.

(DA or SR) Kit

BCDE FGHJ SWeight

lbs.

VPVL250 and VPVL300 DO-1 5.75 6.89 5.61 2.36 4.53 1.44 8.94 7.87 0.47 22

VPVL350 and VPVL400 DO-2 7.68 9.49 6.06 2.48 5.63 2.09 10.28 7.87 0.59 40

VPVL450 and VPVL500 DO-3 8.74 11.12 7.46 3.31 6.30 2.48 10.63 11.81 0.79 50

VPVL550 and VPVL600 DO-4 9.84 12.84 9.00 4.23 6.77 2.36 13.31 19.69 0.79 84

VPVL650 and VPVL700* DO-5 10.87 14.45 10.16 5.00 7.48 2.68 14.41 35.43 0.98 141

VPVL800 DO-6 13.39 16.69 12.32 6.06 8.07 3.07 15.63 39.37 0.98 201

VPVL Actuator Declutchable

Approximate Dimensions - mm

Model Override

Approx.

(DA or SR) Kit

BCDE FGHJ SWeight

kgs.

VPVL250 and VPVL300 DO-1 146 175 142 60 115 37 227 200 12 10

VPVL350 and VPVL400 DO-2 195 241 154 63 143 53 261 200 15 18

VPVL450 and VPVL500 DO-3 222 282 190 84 160 63 270 300 20 23

VPVL550 and VPVL600 DO-4 250 326 228 107 172 60 338 500 20 38

VPVL650 and VPVL700* DO-5 276 367 258 127 190 68 366 900 25 64

VPVL800 DO-6 340 424 313 154 205 78 397 1000 25 91

* The VPVL700 DA unit may be used if the air pressure required to produce the needed output torque is lower than 95 psi.

* The VPVL700 DA unit may be used if the air pressure required to produce the needed output torque is lower than 6.5 bar.

Actuator

Mounting

Side

F B

G

J

S

H

E

D

C

DIMENSIONS

Page 6

TECHNICAL BULLETIN 1/09

6

METSO A111-3EN

DIMENSIONS

Model VPVL 051 – 800

C

L

I

H

C

4

Z

B

M

L

M

B

4

BottomView ISO5211

T Connection

Detail X

Detail X

Port 4

Port 2

R

S

D

M5xE

G

F

N

M6x12

N

P

4

12

M6

12

X P Y

A

45˚

45˚

W

CH

Q

Model VPVL011

B1

R

S

D

Port 2

Port 4

Port 2

Port 4

VPVL 011, 650 – 800VPVL 051 – 600

Page 7

TECHNICAL BULLETIN 5/08

7

VALV-POWR SERIES VPVL MODEL C DOUBLE-ACTING AND SPRING-RETURN RACK- AND-PINION COMPACT PNEUMATIC ACTUATORS

A111-3EN

Size

Dimensions- inches / lb.

ISO Weight

A B B1 C D E F G H I L M N O P Q R S W X Y T NPT

Flange

CH Z

DA SR

011 4.50 1.70 0.00 1.70 M5x4 0.28 1.97 0.98 0.79 0.39 0.80 0.80 0.43 - 0.79 1.40 0.94 1.26 M5 0.57 0.32 1/8 F03 0.35 1.57 1.0 -

051 5.53 2.72 1.36 2.32 M5x8 0.16 3.15 1.18 0.98 0.47 1.14 1.63 0.43 1.04 0.79 1.40 1.26 0.94 M5 0.57 0.31 1/8 F03 0.43 1.57 2.1 2.3

100 6.24 3.35 1.67 2.83 M5x8 0.31 3.15 1.18 1.38 0.63 1.42 1.85 0.43 1.18 0.79 1.97 1.26 0.94 M6 0.57 0.31 1/8 F05 0.55 1.57 3.3 3.8

200 8.29 4.02 2.01 3.33 M5x8 0.31 3.15 1.18 1.38 0.63 1.67 2.05 0.67 1.20 0.79 1.97 1.26 0.94 M6 0.57 0.31 1/8 F05 0.55 1.57 5.9 7.0

250 9.74 4.53 2.26 3.84 M5x8 0.31 3.15 1.18 2.17 0.83 1.95 2.24 0.67 1.28 0.79 2.76 1.26 0.94 M8 0.57 0.31 1/8 F07 0.75 1.57 8.4 9.7

300 10.57 5.00 2.50 4.37 M5x8 0.31 3.15 1.18 2.17 0.83 2.20 2.64 0.67 1.48 0.79 2.76 1.26 0.94 M8 0.57 0.31 1/4 F07 0.75 1.57 11.9 14.3

350 12.40 5.71 2.85 5.00 M5x8 0.31 3.15 1.18 2.76 0.94 2.52 3.03 1.06 1.67 1.18 4.02 1.26 0.94 M10 0.96 0.57 1/4 F10 0.87 2.20 18.5 21.7

400 13.58 6.18 3.09 5.35 M5x8 0.31 3.15 1.18 2.76 0.94 2.74 3.23 1.06 1.77 1.18 4.02 1.26 0.94 M10 0.96 0.57 1/4 F10 0.87 2.20 22.5 27.8

450 16.08 6.97 3.88 6.16 M5x8 0.31 3.15 1.18 3.35 1.38 3.15 3.60 1.06 1.85 1.18 4.92 1.26 0.94 M12 0.96 0.57 1/4 F12 1.06 2.56 32 40

500 17.22 7.72 3.86 6.65 M5x8 0.31 3.15 1.18 3.35 1.38 3.46 3.90 1.06 2.05 1.18 4.92 1.26 0.94 M12 0.96 0.57 1/4 F12 1.06 2.56 44 53

550 19.17 8.68 4.39 7.51 M5x8 0.31 5.12 1.18 3.94 1.57 3.90 4.13 1.42 2.28 1.97 5.51 1.26 0.94 M16 1.75 0.79 1/4 F14 1.42 3.15 55 70

600 21.38 9.65 4.80 8.39 M5x8 0.31 5.12 1.18 3.94 1.57 4.33 4.41 1.42 2.44 1.97 5.51 1.26 0.94 M16 1.75 0.79 1/4 F14 1.42 3.15 78 99

650 24.45 11.75 5.93 9.88 M6x10 0.31 5.12 1.18 5.12 1.89 5.16 5.16 1.42 3.09 1.97 6.50 1.57 1.77 M20 1.75 0.79 3/8 F16 1.81 4.53 115 139

700 26.93 12.99 6.50 11.75 M6x10 0.31 5.12 1.18 5.12 1.97 6.44 6.54 1.42 6.50 1.97 6.50 1.57 1.77 M20 1.75 0.79 1/2 F16 1.81 4.53 183 225

800 34.39 16.14 6.50 15.08 M6x10 0.31 5.12 1.18 7.87 2.24 8.03 8.43 1.42 7.28 1.97 10.00 1.57 1.77 M16 1.75 0.79 1/2 F25 2.17 4.53 295 373

Size

Dimensions- mm / kg

ISO Weight

A B B1 C D E F G H I L M N O P Q R S W X Y T NPT

Flange

CH Z

DA SR

011 114 43 0.0 43 M5x4 7 50 25 20 10 20 20 11 - 20 36 24 32 M5 14.5 8.0 1/8 F03 9 40 0.45 -

051 140 69 34.5 59 M5x8 4 80 30 25 12 29 41 11 26 20 36 32 24 M5 14.5 8.0 1/8 F03 11 40 0.95 1.04

100 158 85 42.5 72 M5x8 8 80 30 35 16 36 47 11 30 20 50 32 24 M6 14.5 8.0 1/8 F05 14 40 1.5 1.7

200 211 102 51.0 85 M5x8 8 80 30 35 16 42 52 17 30 20 50 32 24 M6 14.5 8.0 1/8 F05 14 40 2.7 3.2

250 247 115 57.5 98 M5x8 8 80 30 55 21 50 57 17 33 20 70 32 24 M8 14.5 8.0 1/8 F07 19 40 3.8 4.4

300 268 127 63.5 111 M5x8 8 80 30 55 21 56 67 17 38 20 70 32 24 M8 14.5 8.0 1/4 F07 19 40 5.4 6.5

350 315 145 72.5 127 M5x8 8 80 30 70 24 64 77 27 42 30 102 32 24 M10 24.5 14.5 1/4 F10 22 56 8.4 9.8

400 345 157 78.5 136 M5x8 9 80 30 70 24 70 82 27 45 30 102 32 24 M10 24.5 14.5 1/4 F10 22 56 10 13

450 408 177 98.5 156 M5x8 8 80 30 85 35 80 91 27 47 30 125 32 24 M12 24.5 14.5 1/4 F12 27 65 15 18

500 437 196 98.0 169 M5x8 8 80 30 85 35 88 99 27 52 30 125 32 24 M12 24.5 14.5 1/4 F12 27 65 20 24

550 487 220 111.5 191 M5x8 8 130 30 100 40 99 105 36 58 50 140 32 24 M16 44.5 20.0 1/4 F14 36 80 25 32

600 543 245 122.0 213 M5x8 8 130 30 100 40 110 112 36 62 50 140 32 24 M16 44.5 20.0 1/4 F14 36 80 35 45

650 621 298 150.5 251 M6x10 8 130 30 130 48 131 131 36 78 50 165 40 45 M20 44.5 20.0 3/8 F16 46 115 53 64

700 684 330 165.0 298 M6x10 8 130 30 130 50 164 166 36 165 50 165 40 45 M20 44.5 20.0 1/2 F16 46 115 83 102

800 876 410 165.0 383 M6x10 8 130 30 200 57 204 214 36 185 50 254 40 45 M16 44.5 20.0 1/2 F25 55 115 134 169

Page 8

TECHNICAL BULLETIN 1/09

8

METSO A111-3EN

No. Unit Qty Part Description Material Specifications

Corrosion

Protection

1 1 Octi-Cam (Stop Arrangement) Stainless Steel

1

EN 10088-3/ISO 1083

1

2 2 Stop Cap Screw Stainless Steel ASTM A193

3 2 Washer (Stop Cap Screw) Stainless Steel ISO 3506

4 2 Nut (Stop Cap Screw) Stainless Steel ISO 3506

5* 2 Bearing (Piston Back) Polyphthalamide Amodel ET1001HS

6* 1 Bearing (Pinion Top) Polyetherimide Stanyl TW300

7* 1 Bearing (Pinion Bottom) Polyetherimide Stanyl TW300

8* 2 Thrust Bearing (Pinion) Polyphthalamide Amodel ET1001HS

9* 2 Plug (Transfer Port) Nitrile Rubber NBR 70Shore A

10 1 Thrust Washer (Pinion) Stainless Steel EN 10088-3

11* 2 O-ring (Stop Cap Screw Seal) Nitrile Rubber NBR 70Shore A

12 2 Piston Guide Polyphthalamide GF Amodel AS1145

13 8/12/

2

Cap Screw (End Cap) Stainless Steel ISO 3506

14* 2 O-ring (End Cap) Nitrile Rubber NBR 70Shore A

15* 2 Bearing (Piston Head) Polyphthalamide Amodel ET1001HS

16* 2 O-ring (Piston) Nitrile Rubber NBR 70Shore A

17 min. 4/ max.12 Spring (Cartridge) Alloy Steel DIN 17223 Part2 Epoxy Coated

18 1 Spring Clip (Pinion) Carbon Steel DIN 17222 ENP

19 1 Position Indicator Polypropylene GF Hostalen PPN

20* 1 O-ring (Pinion Bottom) Nitrile Rubber NBR 70Shore A

21* 1 O-ring (Pinion Top) Nitrile Rubber NBR 70Shore A

30 1

3

Right End Cap

3

Aluminum UNI 5075 Polyester-Coated

31 1

3

Left End Cap

3

Aluminum UNI 5075 Polyester-Coated

39 1 Cap Screw (Indicator) Stainless Steel ISO 3506

40 2 Pistons Aluminum UNI 5075 Anodized

41 1 Actuator Identification Label Polyester Aluminum

42 2 End Cap Label Polyester Aluminum

50 1 Body Aluminum ASTM B221

Anodized

PTFE-Coated

60 1 Drive Shaft Carbon Steel Plated ASTM A105 ENP

5*

BILL OF MATERIALS AND PARTS LIST

50

41 10 18

39

19

8*

30

11*

3

2

4

17

7*

60

6*

21*

1

9*124016*

15*

14*

8*

31

42

13

20*

* Suggested Spare Parts

for Maintenance

* Suggested spare parts for maintenance

Notes: (1) AISI 420 for models VPVL-051 through 300; GS400-15 for models VPVL-350 through 800

(2) Qty 8 pieces for models VPVL-051 through 600; Qty 12 pieces for model VPVL-700

(3) For models VPVL500 through VPVL700, right and left end-caps are symmetric

Page 9

TECHNICAL BULLETIN 5/08

9

VALV-POWR SERIES VPVL MODEL C DOUBLE-ACTING AND SPRING-RETURN RACK- AND-PINION COMPACT PNEUMATIC ACTUATORS

A111-3EN

HOW TO ORDER

To specify a complete VALV-POWR VALUE-LINE Actuator, simply make a selection from the code boxes below.

EX

AMPLE: VPVL 400 SR4/5 B AS C, shown below, is a 59 FT•LBS 60-psi (84 N•m @ 4.2 bar) spring-return actuator with

spring-to-close rotation, hard-anodized PTFE-coated body, polyester-coated end caps, standard temperature rating, and

100% adjustable travel stops.

1

Product Group

VPVL VALV-POWR VALUE-LINE Double-Opposed Piston Actuator

4

Exterior Protection*

B

Hard-Anodized PTFE-Coated Body &

Polyester-Coated End Caps

123456

VPVL 400 SR4/5 B AS C

3

Series+

DA VALV-POWR VALUE-LINEDouble-Opposed Piston Actuator

SR4/5 Spring-Return 60-psi (4.1 bar) Spring-to-Close (CW Rotation)

SR6 Spring-Return 80-psi (5.5 bar) Spring-to-Close (CW Rotation)

2

Size

011, 051,

100, 200,

250, 300,

350, 400,

Select from torque table

450, 500,

550, 600,

650, 700,

800

5 Options

– Standard Temperature Rating: -4˚F to +175˚F (-20˚C to +80˚C)

HT High-Temperature Rating: -4˚F to +300˚F (-20˚C to +150˚C)

LT Low-Temperature Rating: -40˚F to +175˚F (-40˚C to +80˚C)

LX Low-Temperature Rating:-60˚F to +175˚F (-51˚C to +80˚C)

FO Spring-to-Open (CCW Rotation)

AS 100% Travel Stop

LD Mechanical Safety Lockout

NOTE: for multiple options, specify them in order as listed in Item 5, for example:VPVL400 SR4/5 B HT AS Model C.

+ Other spring rates on application

* Consult factory for other protection options.

6

Model

C Model C

7

Modifier Code

– Standard

XB ATEX Approval

7

—

Note* “LX” option must be ordered complete from the factory.

Page 10

Subject to change without prior notice.

Metso Automation Inc.

Europe, Levytie 6, P.O. Box 310, 00811 Helsinki, Finland.

Tel. +358 20 483 150. Fax +358 20 483 151

North America, 44 Bowditch Drive, P.O. Box 8044, Shrewsbury, MA 01545, USA.

Tel. +1 508 852 0200. Fax +1 508 852 8172

Europe, 6-8 rue du Maine, 68271 Wittenheim Cedex, France.

Tel. +33 (0)3 89 50 64 00. Fax +33 (0)3 89 50 64 40

South America, Av. Independéncia, 2500- Iporanga, 18087-101, Sorocaba-São Paulo

Brazil. Tel. +55 15 2102 9700. Fax +55 15 2102 9748/49

Asia Pacific, 238A Thomson Road, #25-09 Novena Square Tower A, 307684 Singapore.

Tel. +65 6511 1011. Fax +65 6250 0830

China, 19/F, the Exchange Beijing, No. 118, Jianguo Lu Yi, Chaoyang Dist, 100022 Beijing, China.

Tel. +86-10-6566-6600. Fax +86-10-6566-2575

Middle East, Roundabout 8, Unit AB-07, P.O. Box 17175, Jebel Ali Freezone, Dubai,

United Arab Emirates. Tel. +971 4 883 6974. Fax +971 4 883 6836

www.metso.com/automation

Loading...

Loading...