GreenGuard Synthetic Roofing Underlayment User Manual

GreenGuard® Synthetic Roong Underlayment Installation Guide

General Information

Installation of GreenGuard® Synthetic Roong Underlayment shall be in accordance with applicable building codes and this

Installation Guide. The Installation Guide shall be available at the jobsite during installation.

GreenGuard® Synthetic Roong Underlayment is intended for use on new construction, sloped residential roofs (2:12

pitch or greater) or for retrot applications, where the existing roof covering has been removed and the underlayment

can be installed directly over the existing roof deck. The GreenGuard® Synthetic Roong Underlayment can be used as

underlayment installed under asphalt roof shingles, concrete or clay roof tiles, metal roof panels or wood roof shakes.

Damaged roof sheathing shall be replaced prior to installation of the GreenGuard® Synthetic Roong Underlayment.

Safety Precautions

• Review this Installation Guide prior to beginning installation. Refer to the Material Safety Data Sheet for additional

information. Go to www.green-guard.com for the most current product information.

• CAUTION: Roof underlayments may be slippery when wet or covered with mud, dust, frost, ice, snow, etc. OSHA and other

applicable requlations for roof work shall be followed. Always use an approved fall protection system when working on roofs.

• CAUTION: Like most building materials, roof underlayments are combustible and may ignite if exposed to re of sufcient

heat and intensity. Protect roof underlayments from exposure to open ame or other ignition sources during shipping,

storage and installation.

• Installation shall comply with OSHA and other applicable regulations for roof work.

• Always use an approved fall protection system when working on roofs.

• Use roof jacks with planks, toe boards or storage platforms secured to the substrate to prevent slippage of stored materials.

• Stay away from power lines and avoid body and equipment contact.

• On steep pitch surfaces, roof jacks with planks should be used for standing.

• Follow all ladder safety standards and regulations.

• Never leave scraps, wrappers or other debris on the roof surface.

• Dispose of waste materials in accordance with applicable local regulations.

1. Preparation

A. The roof deck shall be dry, free from dust, dirt, loose debris and obstructions.

B. At the time of installation, the ambient air temperature shall be above 40° F.

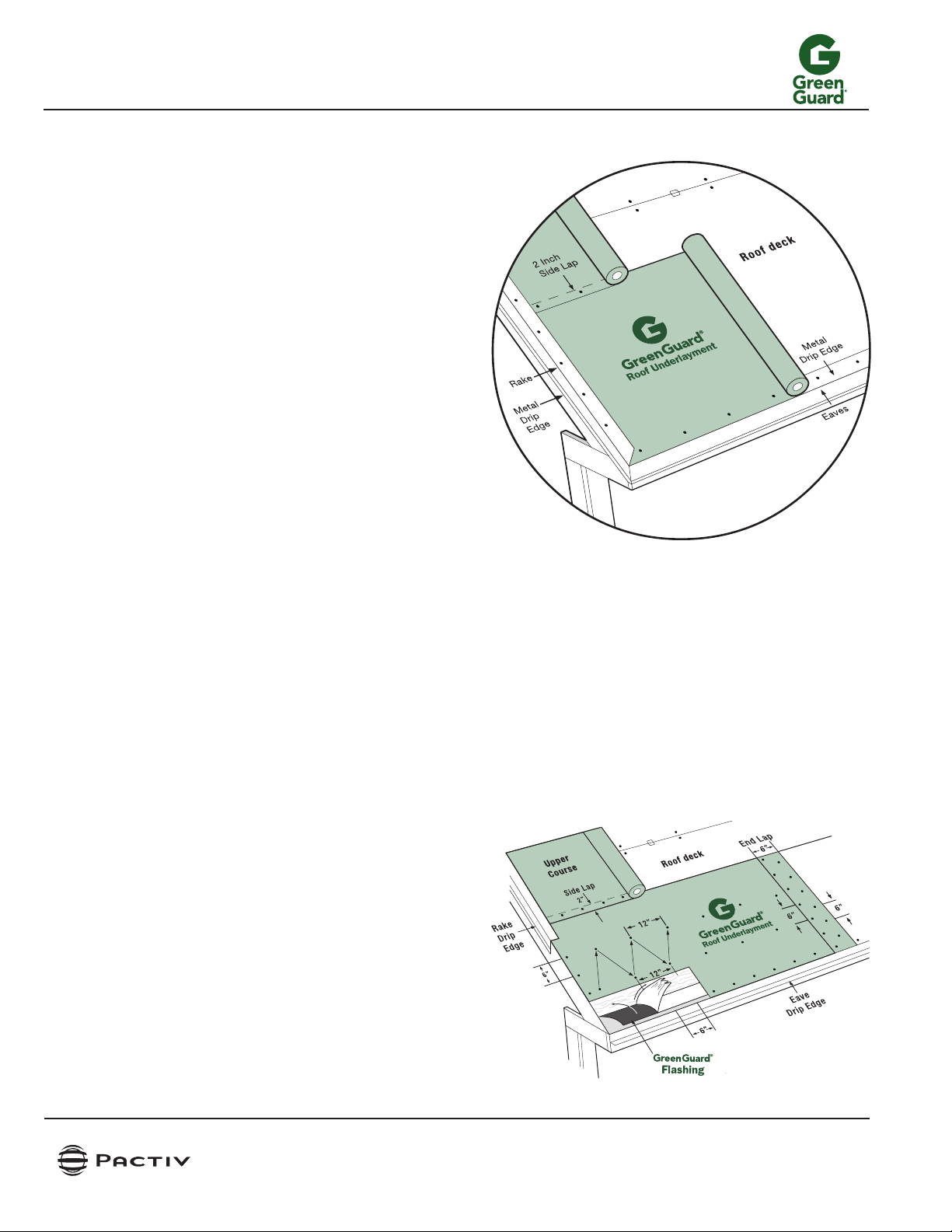

2. Installation – Roong Underlayment

A. Begin by unrolling several feet of the underlayment parallel with the eaves along the lower edge of the roof, with the

print side up.

B. The rst course shall overlap the drip edge eave ashing and shall go under the drip edge at the rake.

C. If the underlayment becomes misaligned, the roll shall be cut and restarted, overlapping the ends a minimum of 6 inches.

1-800-241-4402 www.green-guard.com

GreenGuard® Synthetic Roong Underlayment Installation Guide

2. Installation – Roong Underlayment (cont.)

D. Around the perimeter of the underlayment, place

roong nails or roong nails with a 1 inch plastic cap

approximately 6 inches apart and about 1 inch from

the edge. If the roof covering is to immediately follow

installation of the underlayment, then No. 16 gauge

staples with a minimum 7/16 inch crown may be used.

The fasteners must be long enough to penetrate through

the thickness of the roof deck. If battens are to be

installed over the underlayment, then the underlayment

need only be preliminarily attached pending attachment

of the battens or counterbattens.

E. In the main area of the underlayment, two rows of nails

are used, with the rst row placed 12 inches up from the

bottom edge and the second row placed 12 inches down

from the upper edge (the spacing between the two rows is

24 inches). The rows of nails shall be offset so that the nail

in one row is opposite the open area on the second row.

F. Install additional courses of underlayment by overlapping

all horizontal joints a minimum of 4 inches and vertical

joints a minimum of 6 inches. All vertical joints shall

be located at least 6 – 8 inches from vertical joints in

adjacent courses so that joints are staggered.

Figure 1: Installation of Roong Underlayment

3. Installation - High Wind Zone/Coastal Areas

A. In high wind zone or coastal areas, the underlayment

shall be installed in accordance with the applicable local

building code. In these areas, decrease the nail spacing

to 4 inches apart on both head and end laps and 12

inches apart in the eld areas.

B. In areas with wind speeds in excess of 90 miles per hour,

or wind speeds in excess of 110 miles per hour, the roof

underlayment shall be installed in accordance with Section

1507.2.8.1 of the IBC and Section R905.3.3.3 of the IRC.

4. Installation – Hurricane Zones

A. Considered High-Velocity Hurricane Zones (HVHZ) - the

underlayment shall be installed in accordance with

Section 1518.2 of the Florida Building Code.

5. Installation – Ice Barriers

A. For roofs required to have an ice barrier in accordance

with local building codes, use a self-adhering membrane

complying with ASTM D 1970 or ICC-ES Acceptance

Criteria AC148. The ice barrier shall be installed prior

installation of the roof underlayment so that the roof

underlayment overlaps the ice barrier. See Figure 2.

Figure 2: Installation of Ice Barrier Membranes

1-800-241-4402 www.green-guard.com

Loading...

Loading...