GreenGuard Residential Building Wraps User Manual

GREENGUARD® MOISTURE MANAGEMENT

Residential and

Light Commercial

Installation Guide

For GreenGuard® Building Wraps

DEFLECTION/DRAINAGE/DRYING

1-800-241-4402

www.TrustGreenGuard.com

BUILDING WRAP AND FLASHING INSTALLATION

BUILDING WRAP INSTALLATION

1. General

GreenGuard® Building Wraps are polyolen building wraps intended to perform

as water-resistive barriers when installed in accordance with the information

provided in this Guide. They are intended to reduce the risk of air and bulk water

inltration when installed under exterior coverings such as brick, stucco, clay

tile, etc., and various siding materials like wood, vinyl, ber cement, etc. Some

building wraps are recognized as air barrier materials having a higher level of

performance and require additional installation steps as indicated in this Guide.

GreenGuard® Building Wraps meet the compliance requirements of all applicable

building codes and industry standards. Go to www.TrustGreenGuard.com for the

most current compliance information.

2. Description

This Guide provides information for installation of GreenGuard® Building Wraps

in residential and light commercial applications in which a water-resistive barrier

and/or air barrier material may be required.

The information provided represents guidelines and is not intended to address

all potential combinations of building materials. GreenGuard® Building Wraps

are polyolen products that are designed specically for the applications in this

Guide.

3. Usage and Limitations

GreenGuard® Building Wraps are intended to perform as water-resistive barriers

(WRB’s) in residential and light commercial construction applications when

installed in accordance with the guidelines provided in this Guide and the

following guidelines:

•GreenGuard®BuildingWrapsareexcellentwater-resistivebarriersthat

help deect water and wind-driven rain, yet are designed to breathe

to assist trapped moisture vapor to escape, helping walls dry faster.

GreenGuard® Building Wraps are made of synthetic materials that

are generally recognized as not providing a food source for insects,

fungus, mold, or mildew. GreenGuard® Building Wraps should always

be properly installed and stored.

•GreenGuard®BuildingWrapsshallbeinstalledwiththeprintedsidefacingthe

outdoor environment. Refer to the specic product literature for outdoor

exposure limitations.

4. General Installation Guidelines

4.A. Building Wrap Installed Over Sheathing (Applies to All

GreenGuard® Building Wraps)

Note: Alternative installation details may be used if approved in

writing by Pactiv Building Products prior to installation.

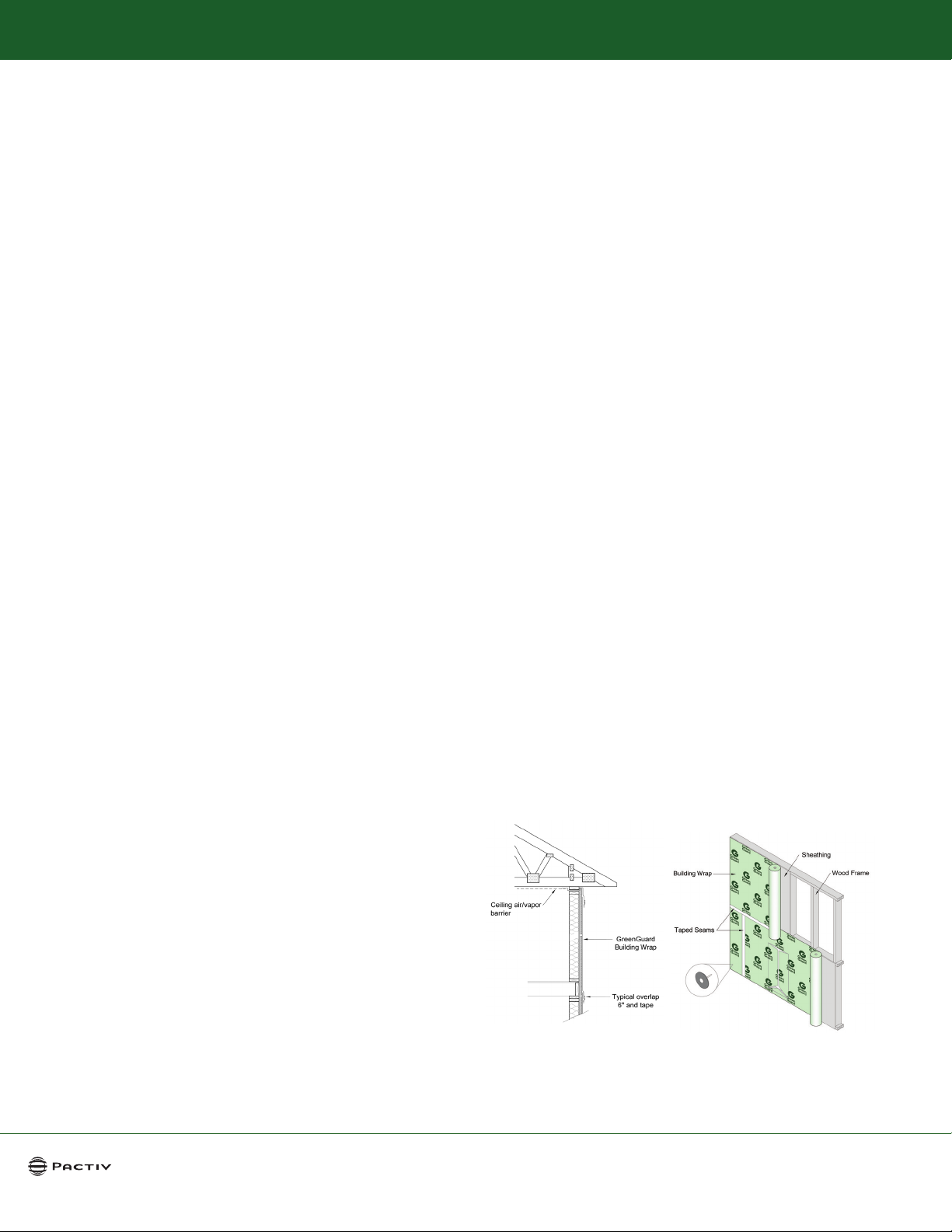

1. Install building wrap over structural sheathing board, over insulation

board (see Figures 1 and 2), or directly to framing members.

2. Begin by aligning the bottom edge of the roll with the base of the

wall, approximately 2 feet around a corner, fastening securely to a structural

sheathing, through insulation boards to studs or directly to the studs.

3. Unroll the building wrap with the printed side facing out, wrapping the entire

building, including door and window rough openings. Acceptable fasteners

include: common galvanized roong nails, plastic cap nails, 1-inch crown

staples and 3/8-inch non-corrosive staples. The following applicable fastener

spacing shall be used:

· In applications in which the building wrap is intended to perform as a water resistive barrier only, the fastener spacing shall be 36 inches to 48 inches along

every other stud location.

· In applications in which the building wrap is intended to perform as the primary

air barrier material in the wall assembly, only minimum 1 inch long fasteners

with plastic or metal caps can be uded and the spacing shall be 16 to 18

inches along every other stud location.

· In applications in which the siding or cladding installation will immediately

follow installation of the building wrap, then the building wrap can be installed

using fewer fasteners in order to provide adequate attachment necessary to hold

the building wrap in place. However, environmental conditions must be taken

into consideration so that the building wrap is not damaged by wind or becomes

detached, allowing moisture penetration. The installer assumes responsibility

when fewer fasteners are used.

At the bottom of a wall in which through-wall ashing will be installed, the bottom

12 inches of building wrap may remain unfastened in order to integrate the

through-wall ashing, but must be sealed prior to installation of the siding or

cladding if the building wrap is the primary air barrier material in the wall

assembly.

•GreenGuard®BuildingWrapsarenotintendedtobeusedasroong

paper.

•GreenGuard®BuildingWrapsarenotintendedtobeusedasa

vapor retarder.

• WARNING: GreenGuard® Building Wraps will ignite if exposed to re of

sufcient heat and intensity. Protect building wraps from exposure

to open ame or other ignition sources during shipping, storage,

and installation.

•BuildiingcodesrequiretheuseoftwolayersofGradeDbuildingpaperover

wood sheathing when a cementitious covering (conventional stucco) is used. As

an alternative, one layer of Grade D building paper can be used in conjunction

with one layer of foam plastic insulation. Check with a local building code

ofcial to verify requirements.

1-800-241-4402 www.TrustGreenGuard.com

FIGURE 1: EXTERIOR WALL

CROSS-SECTION

1

FIGURE 2: EXTERIOR WALL WITH GREEN-

GUARD BUILDING WRAP

GUIDE FOR RESIDENTIAL APPLICATIONS

4. At window rough openings, cut the building wrap using a modied “I”

pattern, folding excess material to the inside of the opening and fasten to

studs (see Figure 3). Alternative details for installing building wrap at rough

openings are shown in sections 5A and 5B of this Guide. Use of GreenGuard

Flashing Products is optional unless the building wrap is intended to perform

as the primary air barrier material in the wall assembly. In this case,

GreenGuard® Butyl Flashings or other butyl self-adhering ashing approved by

Pactiv Building Products must be used.

5. When the end of a roll is reached, rmly attach the loose end of the building

wrap to a stud or structural sheathing. Seams must be overlapped a minimum

of 6 inches for vertical seams and 2 inches for horizontal seams. The upper

courses of building wrap must overlap the lower courses in shingle fashion.

Sealing of building wrap seams using GreenGuard® Seam Tape (Standard or

Custom) or other sealing method approved by Pactiv Building Products is

optional unless the building wrap is intended to perform as the primary air

barrier. In this case, the seams must be sealed using 3 inch wide

GreenGuard® Seam Tape (Custom) or other tape approved by Pactiv.

GreenGuard® Building Wraps that are recognized as air barrier materials may be

installed as the primary air barrier material in a wall assembly by sealing around all

windows, doors and wall penetrations. Other air barrier applications may include

knee wall backing, exterior walls of chimney structures, exterior walls of tub/shower

enclosures, etc.

®

FIGURE 3: EXAMPLE OF MODIFIED “I” CUT AT A WINDOW OPENING

6. Many common adhesives and sealants are compatible with GreenGuard®

Building Wrap and GreenGuard® Flashing products. For more information

regarding adhesives, sealants+ and primers for use with GreenGuard® Building

Wrap and GreenGuard® Flashing products, go to www.TrustGreenGuard.com and

look for the applicable Technical Bulletin under “Product Literature.”

2

BUILDING WRAP AND FLASHING INSTALLATION

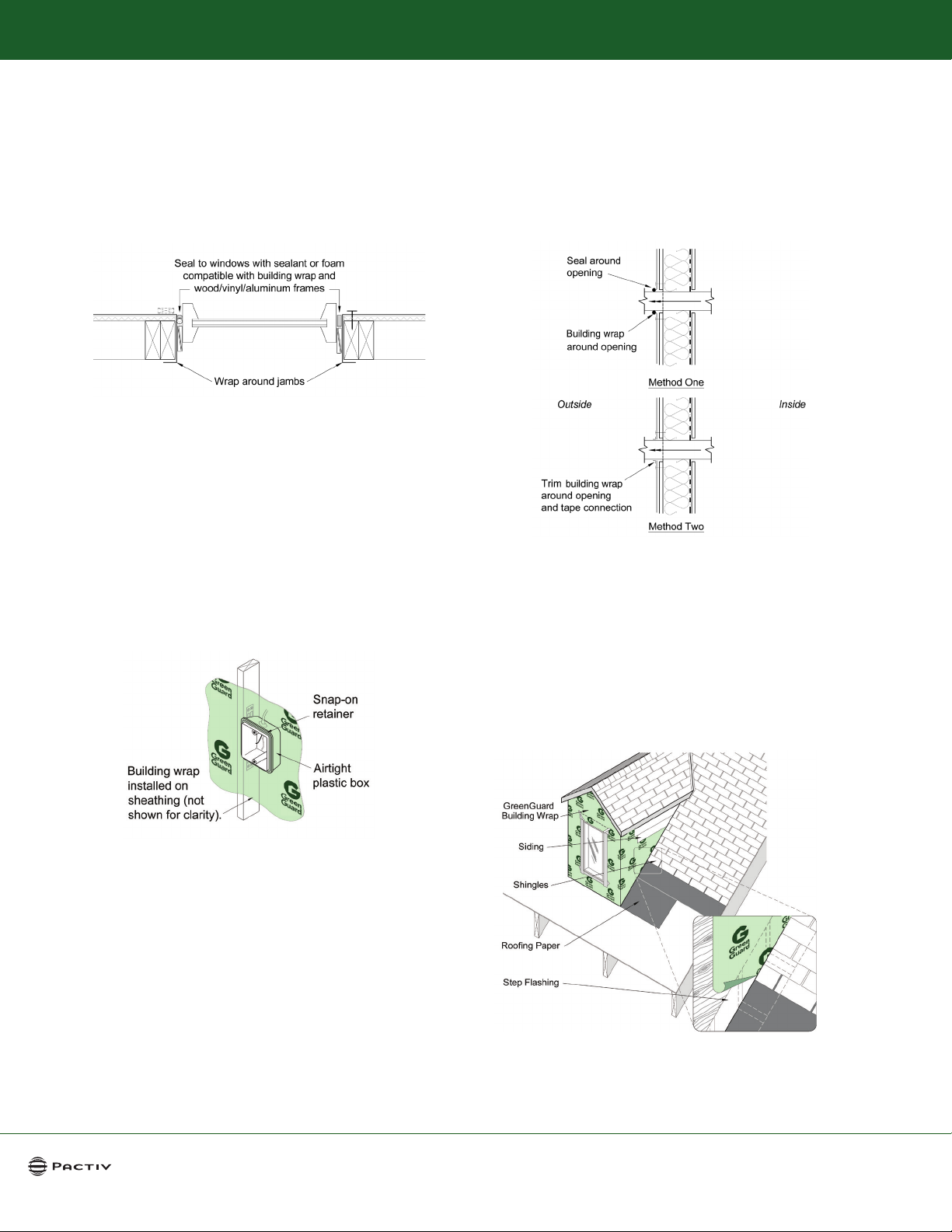

4.B. Installation of Building Wrap at Window Frame Detail

Figure 4 shows an example of a window frame detail where the building wrap

is installed over the sheathing and is wrapped around the window jambs to the

interior of the wall. Windows should be sealed in accordance with the window

manufacturer’s installation instructions.

FIGURE 4: WINDOW FRAME CROSS-SECTION

4.C. Installation of Building Wrap at Exterior Electrical Boxes

All exterior electrical boxes and other penetrations through the building wrap

should be sealed to prevent air and moisture intrusion at the openings. The

building wrap must be taped to the electrical box in order to provide an adequate

seal (see Figure 5).

4.D. Installation of Building Wrap at Wall Penetrations

When penetrations, such as those for pipes and ducts, breach the building wrap,

they must be sealed to the building wrap using a sealant that is compatible with

both the building wrap and the pipe or duct material (see Figure 6).

FIGURE 6: INSTALLATION OF BUILDING WRAP

AT WALL PENETRATIONS

4.E. Installation of Building Wrap (Roof/Roof and Roof/

Wall Intersections)

FIGURE 5: INSTALLATION OF BUILDING WRAP

AT EXTERIOR ELECTRICAL BOXES

GreenGuard® Building Wrap should overlap the step ashing at the

roof to wall intersection (see Figure 7).

FIGURE 7: INSTALLATION OF BUILDING WRAP/WALL INTERSECTION

1-800-241-4402 www.TrustGreenGuard.com

3