Green eco Therm Pelletherm v2 User Manual

USER MANUAL

of hot water pellet boiler

of series “Pelletherm v2”

http:// www.greenecotherm.eu

p. 2/52

Thank You for buying hot water pellet boiler of series „Pelletherm

v2”. This manual will help You to use and maintain the unit properly.

The boiler’s producer company requires the installer technicians, which will

perform the installation, maintenance and service procedures of the boilers of

series “Pelletherm v2” to be trained and certified by the producer.

NOTE: in the following document is used the designation “Pelletherm v2”,

which includes all the models of the hot water pellet boilers: “Pelletherm 30v2”

and “Pelletherm 45 v2”.

ATTENTION!

IN INTEREST OF YOUR PERSONAL SECURITY IT IS

OBLIGATORY TO READ THOROUGHLY AND CAREFULLY THIS

INSTRUCTION MANUAL BEFORE PROCEEDING WITH ANY

ACTIONS WITH THE BOILER – MOUNTING, CONNECTING, ETC.

IN CASE THAT REQUIREMENTS, DEPICTED IN THIS MANUAL ARE

NOT SATISFIED, FAILURES OF THE UNIT COULD BE EXPECTED,

OR EVEN FATAL CONSEQUENCES, FOR WHICH THE PRODUCER

COMPANY DOES NOT TAKE RESPONSIBILITY.

Producer ZMM Haskovo Plc.

Address Bulgaria, Haskovo 6300, “Saedinenie” 67 blvd.

Phone +359 800 15 145

Fax +359 38 603070

e-mail greenecotherm@erato.bg

home page www.greenecotherm.eu

Hot water pellet boiler of series “Pelletherm v2” user manual ; (document version: 31.10.2011 15:51)

p. 3/52

CONTENTS

page

1. Hot water pellet boiler of series “Pelletherm v2” – description,

properties and advantages.................................................................................. 5

The unit could utilize following types of fuel: ............................................... 5

The unit is equipped with:............................................................................... 6

The unit is supplied with :............................................................................... 6

2. Hot water boiler of series “Pelletherm v2” technical data.................... 8

Table 2.1 Thermal and technical data for hot water pellet boiler of series

“Pelletherm v2”, utilizing wood pellets............................................................. 9

Table 2.2 Dimensions and technical data for hot water pellet boiler of series

“Pelletherm v2”................................................................................................ 10

Table 2.3 Recommended solid fuel properties – wood pellets. ...................... 11

Table 2.4 Pellets classification, considering their physical properties (based

on fuel proximate analysis) – according to fuel evaluation methods, developed

and applied in boiler’s producer company; ..................................................... 11

Table 2.5 ENplus - European standard for wood pellets; ............................... 12

3. Description of hot water pellet boiler of series “Pelletherm v2”........ 13

4. Installation process. ................................................................................17

4.1. Hot water pellet boiler connection methodology ............................... 20

4.1.1. Connecting to the chimney ....................................................... 20

4.1.2. Connecting to the heating system ............................................ 20

5. Hot water boiler installation and starting procedures. ....................... 23

5.1. Basic fuel requirements....................................................................... 23

5.2. Starting hot water pellet boiler of series “Pelletherm v2” procedure.

............................................................................................................... 24

5.2.1. Interface control board of hot water pellet boiler of series

“Pelletherm v2” .................................................................................................25

5.2.2. Hot water boiler power supply. ...............................................26

5.2.3. Hot water boiler very first start............................................... 26

5.2.4. Main parameters for boiler operation. ................................... 27

5.2.5.

Adjustment process of the boiler according to the thermal

load of the building/consumer.......................................................................... 31

p. 4/52

5.2.6. Changing the working parameters of the process control

module. ..................................................................................................... 34

5.2.7. Nominal operation mode of the boiler..................................... 37

5.3. Adjustment of the thermal capacity of the boiler............................. 38

5.3.1. Decreasing the thermal capacity of the boiler:....................... 38

5.3.2. Increasing the thermal capacity of the boiler: ....................... 39

5.4. Stopping the operation of hot water pellet boiler............................. 39

5.5. Turning OFF the boiler....................................................................... 40

Emergency boiler stop. ......................................................................... 40

5.6. Showing and teaching the end user about the maintenance and

adjustment procedures. ................................................................................. 41

5.7. Safety and unexpected risks ...............................................................41

5.8. Operation faults and their repairing ................................................. 43

5.9. Hot water boiler warranty form completion. ..................................... 46

5.10. Actions, after the unit is not in exploitation anymore...................... 46

6. Electrical scheme of automatic pellet boiler of series “Pelletherm v2”.

................................................................................................................... 47

QUALITY CERTIFICATE .............................................................................49

WARRANTY FORM........................................................................................ 50

WARRANTY CONDITIONS .......................................................................... 51

WARRANTY SERVICE PROCEDURES LIST ........................................... 52

p. 5/52

1. Hot water pellet boiler of series “Pelletherm v2” – description,

properties and advantages.

“Pelletherm v2” is steel-plate hot water pellet boiler, which uses solid

biomass fuel in shape of pellets. The boiler is designed to be connected to local

hot-water heating systems, as well as heating up domestic hot water. The boiler

uses wood pellets, as well as other type/shape of biomass, the resulting heat

energy from thermo-chemical conversion (i.e. combustion process) is

transmitted to the circulation water in its water jacket and the heat energy is

transported to the heating system/consumer.

The hot water pellet boiler of series “Pelletherm v2” includes:

• hot water boiler – 1 sp.;

• ash tray – 1 sp.;

• foot-screws for installation and leveling – 8 sp.;

• pair of working gloves – 1sp.;

• working apron – 1 sp.;

• instruction manual – 1 sp.;

• annex of the instruction manual – 1 sp;

The unit could utilize following types of fuel:

• Wood pellets, having diameter 6 up to 14 mm, categorized in the range

of: A, AB, B, BC, C, CD, E, EF (according to the methodology,

developed for pellets properties estimation in boiler’s producer

company);

• Pre-dried nuts (cherries for example);

• Fuel mixture – pellets and nuts (for example mixture ratio could be

50% - 50%);

• Pellets, produced of any other solid biomass (for example olive husk

residue);

• Other solid biomass based pellets, but confirmation for these fuels

utilization need testing and approval by boiler’s producer company

laboratory;

p. 6/52

The unit is equipped with:

• Steel plates welded heat exchanger for heating-up the circuit water;

• Flue gas fan;

• Fresh air supplying fan;

• Burner’s ash removal mechanism – removes the ash residuum out of

the burner’s grate;

• Daily fuel hopper with capacity of about 100 kg;

• Programmable operating module, which controls the functions of the

unit and is adjustable to the specific need of a heating system as well as

the properties of the fuel;

• Ash residue container with capacity of approximately 5 kg;

• Manually driven semi-automatic ash cleaning system (this system

cleans the ash, deposited on the internal surface of the pipes of boiler’s

convective section);

The unit is supplied with :

• Automatic fuel ignition system;

• Automatic burner’s ash removal system;

• Semi-automatic ash (deposited on the surfaces of the heat exchanger

pipes) cleaning system;

• Automatic fuel feeding auger system;

Unit’s advantages :

• The hot water boiler is designed to utilize solid biomass fuel, making it

environmentally friendly, CO

2

neutral and does not contribute to the

global warming process – result of fossil fuel utilization;

• The specific price of the heat energy, delivered by solid biomass

utilization is less dependent on the world fuel market trends and

practically the heat energy price is competitive to the conventional energy

sources;

p. 7/52

• The boiler is automatic and the thermal comfort achieved is close to that,

originating from exploitation of fully automatic boilers, (for example

liquid or gas fuel, as well as electric boiler), which makes is applicable in

heating systems, equipped with programmable room thermostat;

• The unit is equipped with automatic fuel ignition system and another one

for burner’s grate ash cleaning;

• The design of the heat exchanger is optimized and realizes three way flue

gas duct, thus allowing intensive heat exchange rate and high efficiency

of the boiler (above 90%) and reduced fly ash emissions to the chimney;

• Automatic unit operation. Hot water boiler could be connected to

programmable room thermostat (weekly programmable), which

guarantees maximal thermal comfort and economical fuel consumption;

• The unit utilizes solid biomass fuel, in shape of pellets (wood pellets),

dried nuts (cherry nuts for example), which have ash contents higher that

the limits, defined in following norms : ENplus (EN 14961-2:2010),

ONORM M7135, DIN 51731 и DINPlus;

• High efficiency;

• Low pollutant contents in the flue gases;

• The unit is applicable for domestic hot water heating purposes;

• Automatic fuel feeding system, transported from the built-in “daily”

hopper to the burner;

• The control operating module can operate the function of additional

external fuel feeding system, which deliver fuel to the built-in fuel hopper

from external one;

• Simplified maintenance and service procedures;

• Minimized running costs;

p. 8/52

2. Hot water boiler of series “Pelletherm v2” technical data.

• Thermal and technical data for hot water pellet boiler of series

“Pelletherm v2”, utilizing wood pellets are given in Table

2.1;

• Dimensions and technical data for hot water pellet boiler of

series “Pelletherm v2” are given in Table 2.2;

• Recommended solid fuel properties – wood pellets, are given

in Table 2.3;

• Pellets classification, considering their physical properties

(based on fuel proximate analysis) are shown in Table 2.4;

• ENplus – the European standard for wood pellets is shown in

Table 2.5;

p. 9/52

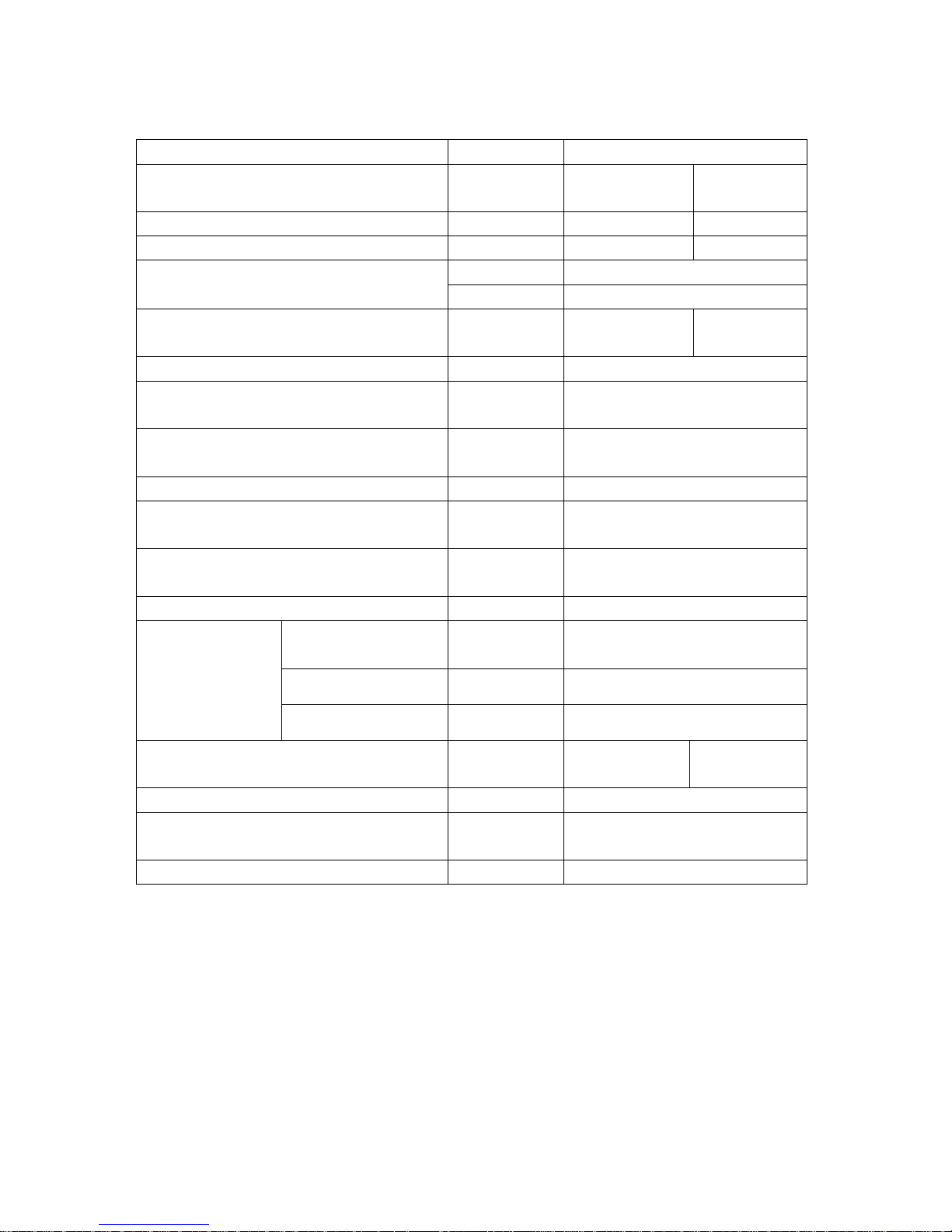

Parameter Dimension Value

Model of the hot water boiler

Pelletherm

30v2

Pelletherm

45v2

Nominal thermal capacity kW 30 45

Thermal capacity operation range kW 9 – 30 13 - 45

Utilized solid fuel

• Wood pellets;

• Pre-dried cherry nuts;

• Other dried nuts;;

Utilized wood pellets, complying

ENplus

ENplus-A1, ENplus-A2,

ENplus-B

Utilized pellets, complying with boiler’s

producer classification methodology

A, AB, B, BC, C, CD, D, DE

Wood pellets fuel consumption rate at

nominal thermal capacity

kg/h 6.9 10.4

kg/h 50 - 60 75 - 90

Fresh air flow rate, required for

effective combustion process and boiler

operation

m

3

/h 42 - 50 63 - 75

Mass flow rate of the exhaust gases g/s 18.6 27.9

Averaged wood pellets consumption

rate

(the unit is operating in a popular heating system)

kg/h 4.5 6.75

Thermal efficiency at nominal capacity ℅ 93.4 93.2

Air excess ratio λ 1.4 – 1.6

Flue gases temperature at nominal

thermal capacity

ºC 110 – 120 140 - 150

Solid fuel residue ash

The quantity depends on

the ash contents in the raw

fuel, as well as operating

conditions

Table 2.1 Thermal and technical data for hot water pellet boiler of

series “Pelletherm v2”, utilizing wood pellets.

p. 10/52

Parameter Dimension Value

Model of the hot water boiler

Pelletherm

30v2

Pelletherm

45v2

Weight kg 460 575

Water jacket capacity dm³ 95 120

dm³ 152 Fuel hopper capacity

kg 100 kg wood pellets

Overall dimension of the unit

(WxDxH)

mm

1515 x 850 x

1375

1618 x 850

x 1380

Class (according to EN 303-5) - 3

Operating overpressure of the

circulating water

MPa 0.25

Heating system expansion vessel

type

-

Opened or closed (up to

0.25MPa)

Factory tested overpressure MPa 0.4

Recommended circulating water

temperature

ºC 80

Minimal recommended return

water temperature

ºC 60

Draught hPa 0.1 - 0.2

Supply/return

flow

G 1½”

Drainage

G

½”

Connections

Flue gases duct

mm 150

Hydraulic losses of the circulating

water at nominal thermal capacity

hPa 2.95 5.94

Power supply - L1, N, PE, 50Hz; 230V

Electrical capacity

VA

120 + 250 (at ignition

process)

Electric protection - IP20

Table 2.2 Dimensions and technical data for hot water pellet boiler of

series “

Pelletherm v2”.

p. 11/52

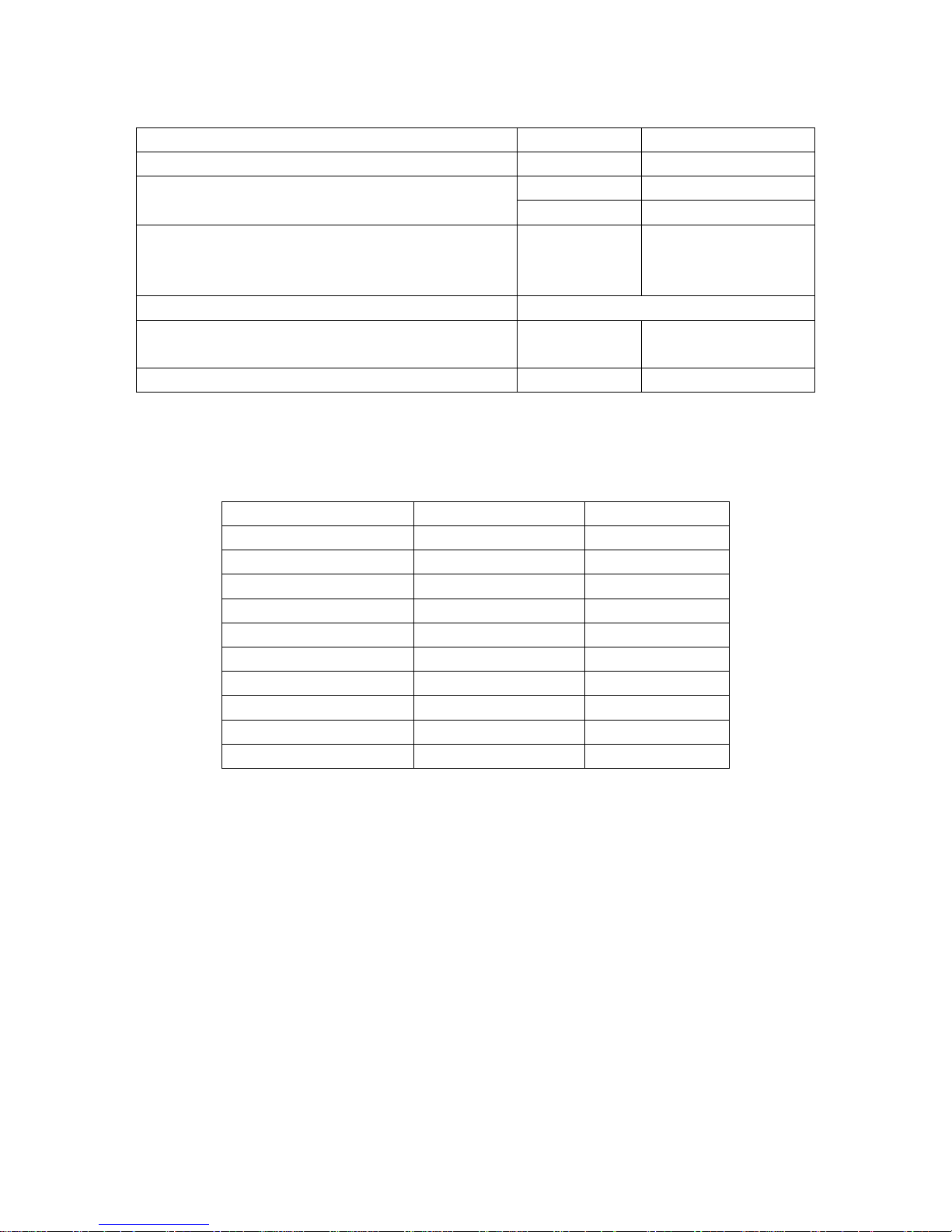

Parameter Dimension Value

Pellet’s characteristic size mm 6 – 14

MJ/kg >17.2 Recommended fuel net calorific value (low

heating value)

kWh/kg >4.7

Wood pellet class

---

ENplus-A1,

ENplus-A2,

ENplus-B

Wood pellets category

A, AB, B, BC, C, CD, E, EF

Ash content % See Table 2.4. and

Table 2.5

Moisture content % Max. 8 – 10%

Table 2.3 Recommended solid fuel properties – wood pellets.

Pellet’s category Ad DU

A %6.0≤

d

A %0.97≥DU

AB %6.0≤

d

A %0.97

<

DU

B %0.16.0 ≤<

d

A

%0.97≥DU

BC %0.16.0 ≤<

d

A %0.97

<

DU

C %0.2%0.1 ≤<

d

A %0.97≥DU

CD %0.2%0.1 ≤<

d

A

%0.97

<

DU

D %0.3%0.2 ≤<

d

A %0.97≥DU

DE %0.3%0.2 ≤<

d

A %0.97

<

DU

E %0.3>

d

A

%0.97≥DU

EF %0.3>

d

A %0.97

<

DU

Table 2.4 Pellets classification, considering their physical properties

(based on fuel proximate analysis) – according to fuel evaluation

methods, developed and applied in boiler’s producer company;

where:

A

d

– ash contents, dry basis, [%];

DU – mechanical durability, [%];

p. 12/52

The European wood pellets standard EN 14961-2:2010

defines wood pellets certificate ENplus for pellets, utilized in

boilers and appliances for domestic heating systems. The

certificate EN-B is applied for pellets, utilized in industrial

boilers. In principal the ENplus standard defines two quality

classes: А1 и А2. The class А1 is highly restricted,

considering the ash content. The class А2 the limit of the ash content of the

wood pellets is higher – up to 1.5%. For industrial boilers the certificate EN-B is

applicable, which defines fewer restrictions on the pellets quality.

Parameter Dimension ENplus-A1 ENplus-A2

Diameter mm 6 (± 1) 6 (± 1)

Length mm 3,15 ≤ L ≤ 40 1) 3,15 ≤ L ≤ 40 1)

Bulk density kg/m³ ≥ 600 ≥ 600

Low calorific value MJ/kg ≥ 16.5 ≥ 16.5

Moisture content % ≤ 10 ≤ 10

Dust % ≤ 1

3)

≤ 1

3)

Mechanical durability % ≥ 97.5

4)

≥ 97.5

4)

Ash content % 2) ≤ 0,7 ≤ 1.5

Ash melting point temperature °C ≥ 1200 ≥ 1100

Cl %

2)

≤ 0.02 ≤ 0.03

S %

2)

≤ 0.05 ≤ 0.05

N %

2)

≤ 0.3 ≤ 0.5

Cu mg/kg

2)

≤ 10 ≤ 10

Cr mg/kg

2)

≤ 10 ≤ 10

As mg/kg

2)

≤ 1 ≤ 1

Cd mg/kg

2)

≤ 0.5 ≤ 0.5

Hg mg/kg

2)

≤ 0.1 ≤ 0.1

Pb mg/kg

2)

≤ 10 ≤ 10

Ni mg/kg

2)

≤ 10 ≤ 10

Zn mg/kg

2)

≤ 100 ≤ 100

1) not more that 1% of the wood pellets should be with length of 40 mm, the maximal pellet

length is 45 mm ;

2) determined on dry mass;

3) the particles are <3.15 mm, fine particles, before fuel delivery;

4) in case the test measurements are performed with Lignotester, than the limit value is ≥

97.7% m.w.;

Table 2.5 ENplus - European standard for wood pellets;

p. 13/52

3. Description of hot water pellet boiler of series

“Pelletherm v2”.

The heat exchanger of the boiler complies with the acting requirements

for such kind of units, defined in operating norm : EN 303-5/2000 – „Heating

boilers for solid fuels, hand and automatically fired, nominal heat output up to

300 kW. Terminology, requirements, testing and marking”.

The unit consists of:

• Main part of the unit is heat exchanger. In the combustion chamber of

this exchanger is mounted specialized grate burner, designed for

horizontal fuel feeding;

• The heat exchanger is welded construction of carbon steel plates and

steel pipes. The lower part of the exchanger is designed as combustion

chamber. The burner is mounted in this chamber and conditions efficient

combustion process;

• Stainless steel burner, mounted in the combustion chamber of the heat

exchanger;

• Ash container, positioned in the lower part of the combustion chamber,

below the burner;

• Fuel hopper is mounted aside of the boiler’s heat exchanger. Beneath the

hopper is mounted a fuel-auger separator (which also acts as fuel

proportioner), followed by horizontal transport auger. The fuel

proportioner prevent the so called “back fire” process, i.e. ignition of the

fuel in the hopper by the hot flue gases in the auger duct in case of

abnormal situations;

• Fresh air fan is mounted on the air duct of the burner. The fan is

equipped with position adjustable flap in order to set the air flow rate.

Additionally the air duct is equipped with flaps for individual adjustment

of the primary and secondary air flow rate. These flaps are factory set and

in principal need no adjustment;

• Inflow and outflow connections (to/from the heating system) of the

supply and return circulating water are internal threads, positioned in the

rear side of the heat exchanger;

• Draining connection is internal thread, diameter G½” and is positioned

on the lower part of rear side of the heat exchanger. An appropriate

drainage valve should be connected;

p. 14/52

• Flue gases exit duct is positioned in the upper rear side of the heat

exchanger (after the flue gases fan, concerning the flue gases track),

utilized for forced flue gases extraction;

• Boiler’s heat exchanger is covered with decorative covers, isolated with

mineral wool plates, ensuring low heat losses to the ambient environment;

• Outer decorative covers are carbon steel plates color painted details;

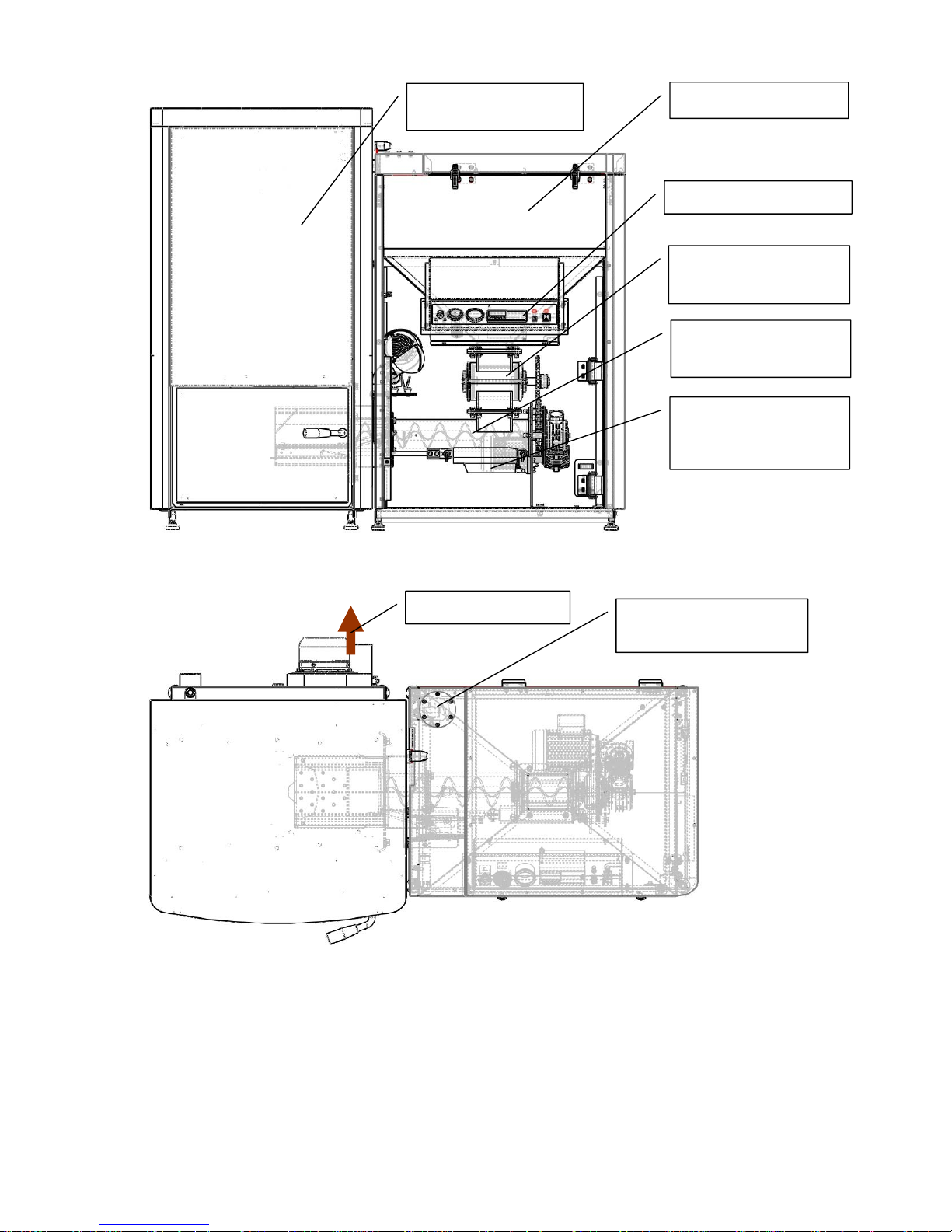

Figure 3.1 External view of hot water pellet boiler of series “Pelletherm v2”;

The unit is designed and assembled in two main modules – the heat exchanger

(the left one) and the fuel hopper module (the right one). These modules are

easily detachable and could be assembled onsite if necessary;

The producer reserves the right to make changes of the design of the hot water

boiler of series “Pelletherm v2” without obligations to inform the clients for

that process.

p. 15/52

Figure 3.2 Partly sectioned view of hot water pellet boiler of series “Pelletherm

v2” – front view;

Figure 3.3 External view of hot water pellet boiler of series “Pelletherm v2” –

top view;

Fuel hopper

Control board

Fuel proportioner

Fuel transport auger

Heat exchanger of

Burner’s ash cleaning

system

Flue gases exit duct

External fuel delivery

orifice

p. 16/52

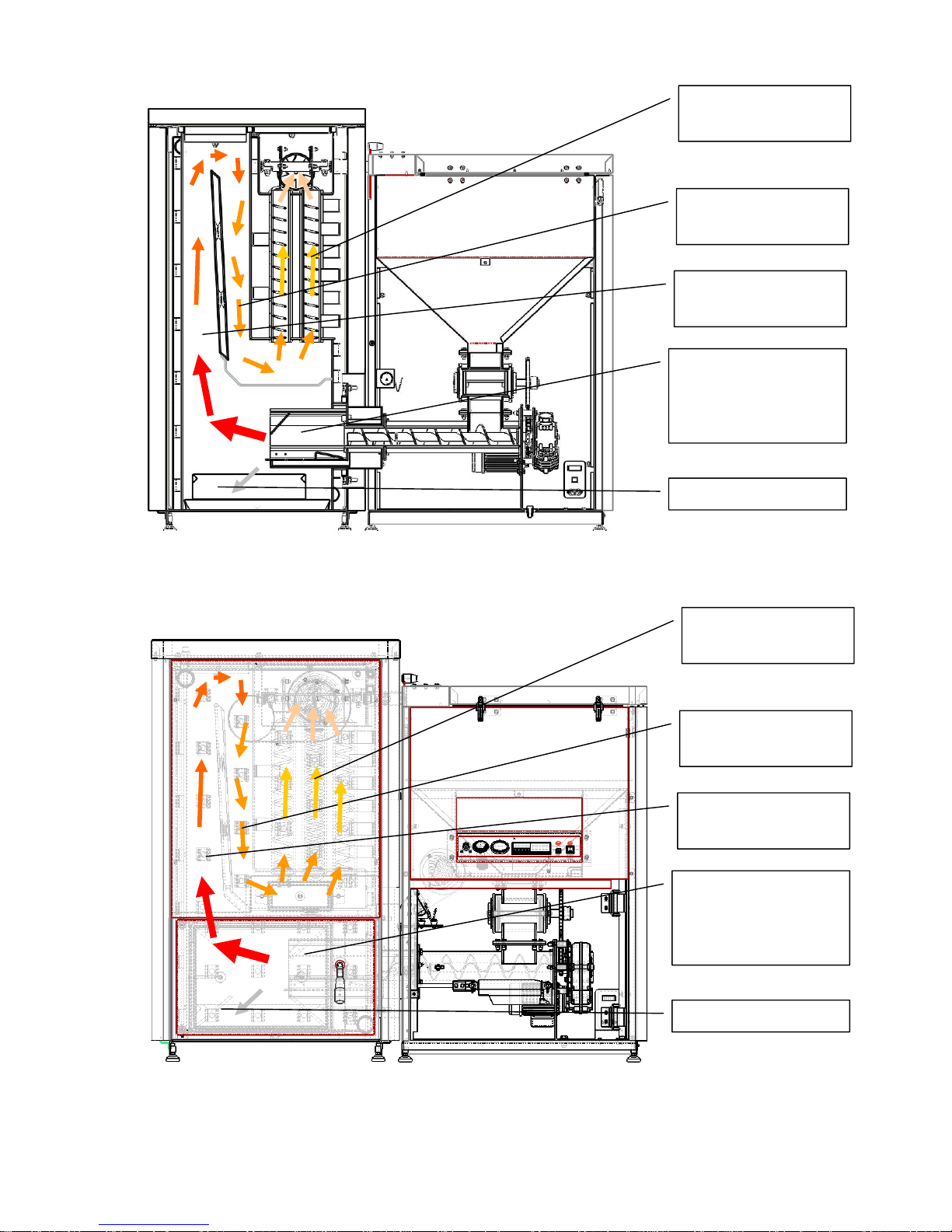

Figure 3.4 Cross section view of hot water pellet boiler of series “Pelletherm 30

v2”. The flue gasses duct and streamlines are visualized as well;

Figure 3.5 Cross section view of hot water pellet boiler of series “Pelletherm

45v2”. The flue gasses duct and streamlines are visualized as well;

Specialized pellet

burner, equipped with

ash cleaning

mechanism

Tertiary pass of flue

gasses

Secondary pass of

flue gasses

Primary pass of flue

gasses

Ash container

Specialized pellet

burner, equipped with

ash cleaning

mechanism

Tertiary pass of flue

gasses

Secondary pass of

flue gasses

Primary pass of flue

gasses

Ash container

p. 17/52

4. Installation process.

Norms and recommendations.

Basic requirements for installation of hot water pellet boiler of series

“Pelletherm v2”:

• The room, dedicated to mount the boiler, should be supplied with fresh air

supply duct, necessary for optimal combustion process as well as room

ventilation;

• Installation of the unit in inhabitable premises, including dwelling

corridors, is not allowed;

• The hot water boiler should be connected to the heating system by

authorized personal only;

• Installation and service procedures of solid fuel hot water boilers should

be performed by authorized qualified and certified personal ONLY;

• The hot water pellet boiler of series “Pelletherm v2” should be connected

to heating system, supplied with OPENED or CLOSED expansion

vessel. In case the heating system is equipped with closed expansion

vessel, then the system should be equipped with over-pressure safety

valve, which opens at pressure exceeding the operating one of the hot

water boiler (0.25 MPa) and this overpressure safety valve should be

certified according to PED 97/23;

• Both the entire heating system and the boiler should be totally filled with

circulating fluid (water) and air-free before operating the boiler;

• Maintenance procedures of the boiler should be performed by trained

adult persons, which have read the user manual of the unit;

Installation procedure of the boiler requires engineering project for the

heating system, prepared according to the acting local norms and

recommendations as follows:

• To the heating system - EN 303-5/2000 - „Heating boilers. Part 5 :

Heating boilers for solid fuels, hand and automatically fired, nominal

heat output of up to 300 kW. Terminology, requirements, testing and

marking”;

• To the chimney;

• Fire prevention requirements;

• To the power circuit - EN 60335-1/1997- “Household and similar

electrical appliances – safety, Part 1 – General requirements”;

p. 18/52

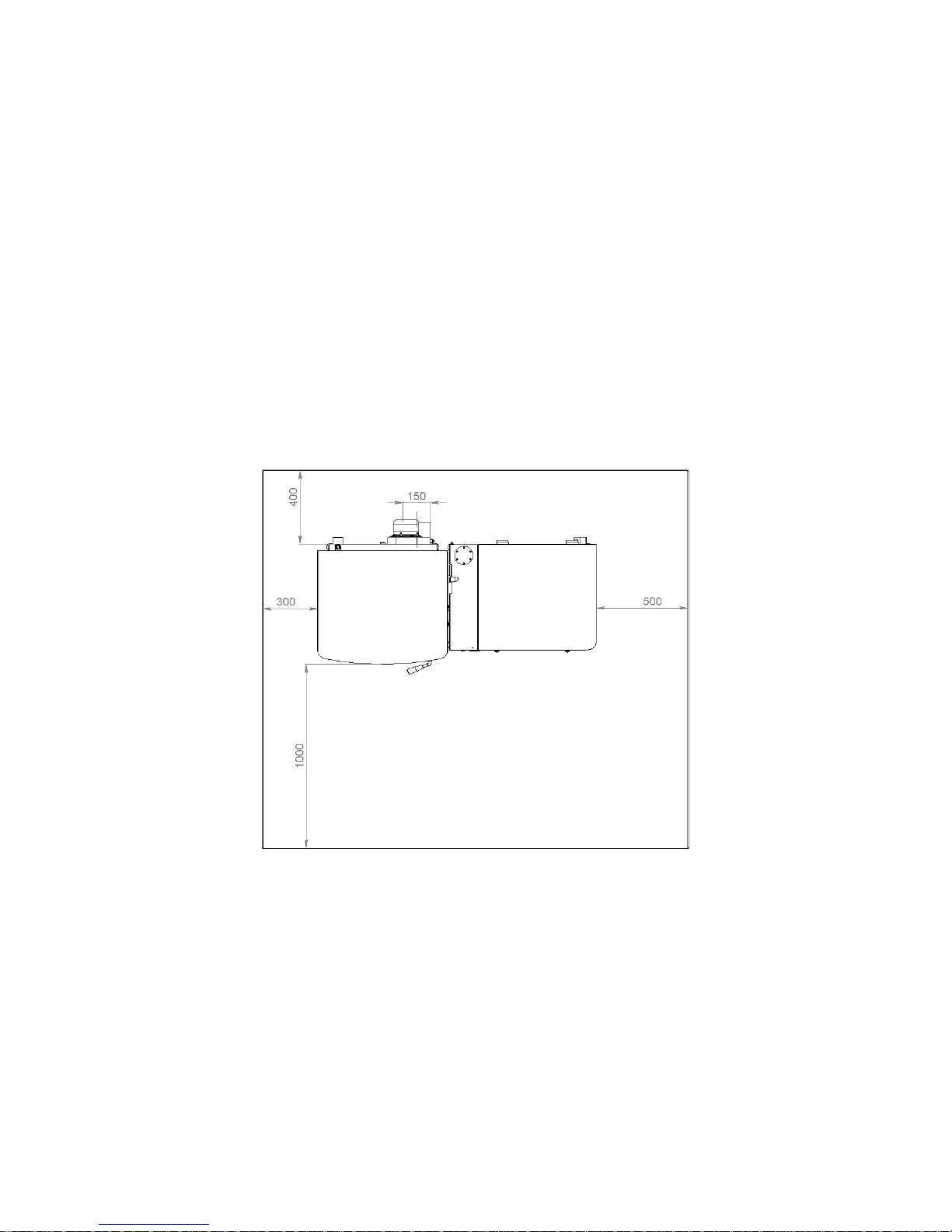

• Appliance positioning in order to achieve comfortable maintenance.

o Minimal distance of 1000mm in front of the unit and any wall should

be provided;

o Minimal distance of 400mm from the rear wall of the unit and any wall

should be provided;

o Minimal distance of 500mm from the right hand side of the unit and

any wall should be provided, in order to guarantee easy access to the

fuel transporting auger;

o Minimal distance of 300mm from the left hand side of the unit and any

wall should be provided, in order to guarantee easy access at servicing

of the flue gas fan of the unit;

o Minimal distance of 500mm above of the unit and any ceiling(wall)

should be provided, in order to guarantee easy access to the fuel’s

hopper, as well as enough room for cleaning purposes of the heat

exchanger body as well as fuel hopper charging;

Figure 4.1 Positioning of hot water pellet boiler of series “ Pelletherm v2” – the

minimal distances between the unit and any walls/obstacles of the boiler’s room

are shown;

• The hot water boiler should be positioned in the boiler’s room according to

the requirements for attaching electrical appliances to the power circuit – the

unit should be positioned in a way, that will provide easy access to the power

supply plug (230V/50Hz);

ATTENTION: the installation process of the boiler is finalized by performing

so called “hot tests” procedure of the heating installation and the warranty card

is filled with the required information.

p. 19/52

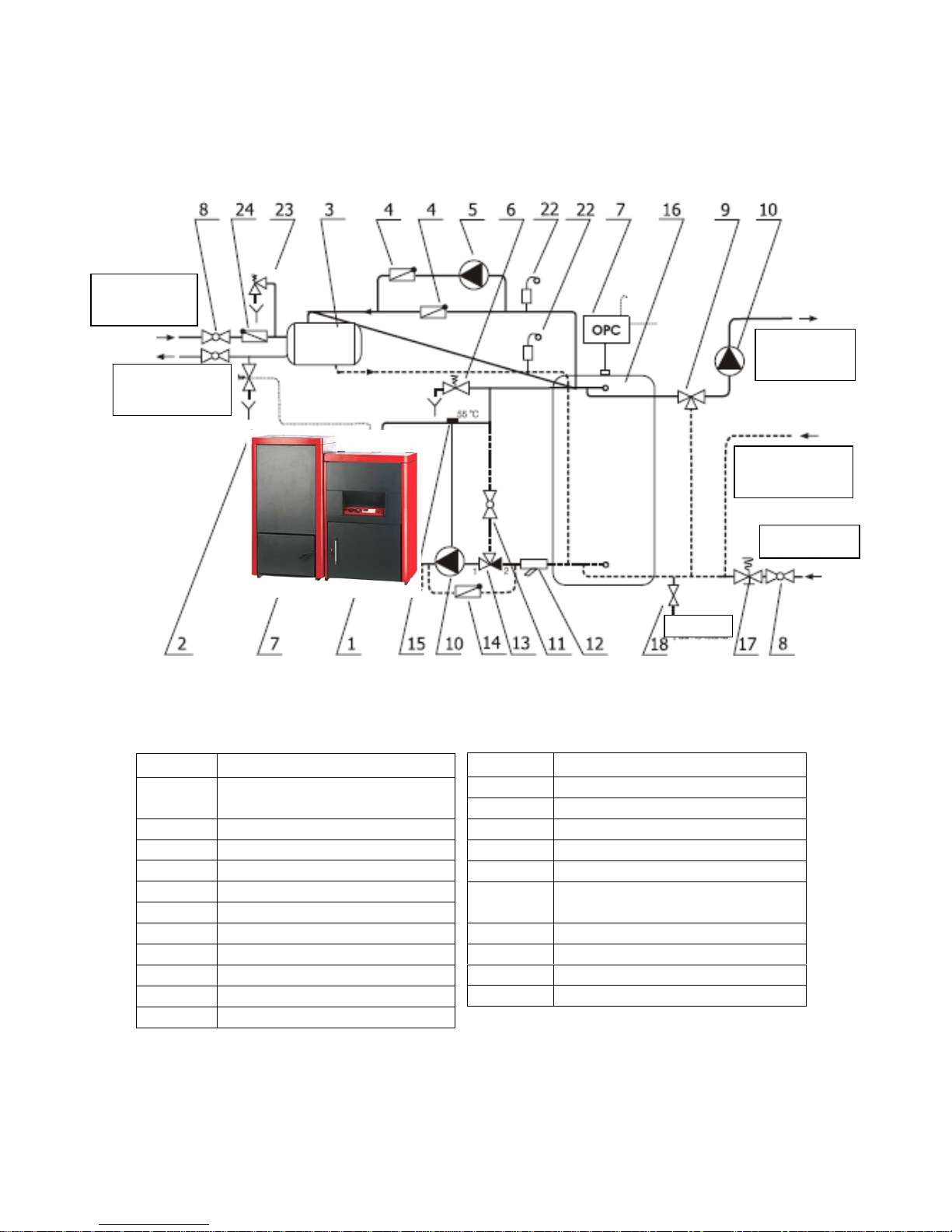

The recommended principal hydraulic scheme for connecting the hot water

pellet boiler of series “Pelletherm v2” to the heating system is snow on the

following figure.

Figure 4.2. Recommender principal hydraulic scheme for connecting the hot

water pellet boiler of series “Pelletherm v2” to the heating system, equipped

with mixing valve and heat accumulator;

Index Designation

1

Hot water boiler of series

“Pelletherm v2”

2

Safety valve

3

Hot water boiler

4

Return valve

5

Circulating pump 1

6

Control valve

7

Expansion vessel

8

Control valve

9

Three way mixing valve

10

Circulating pump 2

11

Control valve

Table 4.1. Designation of the elements, indexed on figure 4.2

Index Designation

12

Water filter

13

Thermovalve TV

14

Return valve

15

Contact thermostat

16

Heat accumulator

17

Automatic circulating water

charger

18

Drainage valve

22

Automatic air separator

23

Safety valve

24

Return valve

From heating

s

y

ste

m

To heating

s

y

ste

m

Tap water

drainage

Cold tap

wate

r

Domestic hot

wate

r

p. 20/52

NOTE : According to EN 303-5 the heat accumulator is obligatory module of a

heating system, equipped with solid fuel hot water boiler. The dimensioning of

the heat accumulator tank is described in the above mentioned standard. The

boiler producer could assist in appropriate designing of that module as well.

4.1. Hot water pellet boiler connection methodology

4.1.1. Connecting to the chimney

After the boiler has been positioned and leveled (utilizing the leveling screws,

installed in the lower corners of the heat exchanger as well as the fuel hopper

module), the unit should be connected to an appropriately sized and designed

chimney.

4.1.2. Connecting to the heating system

After the flue gas duct of the boiler is connected to a chimney, the boiler should

be connected to the heating system – utilize appropriately sized fitting,

according to the preliminary prepared project.

Loading...

Loading...