green ecotherm GP 45 IV User Manual

Pellet burner GP 45 IV 1

MANUAL

FOR INSTALLATION AND OPERATION OF AUTOMATED

MODULATING WOOD PELLET BURNER FROM SERIES

“GP 45 IV”

http:// www.greenecotherm.eu

Pellet burner GP 45 IV 2

The manufacturing company thanks you for the contribution of your choice.

The manufacturing company provides this manual in help to the team that will install, adjust

and service this wood pellet burner, as well as to the customer that will operate it.

The manufacturing company requires that the technicians performing the above presented

procedures has passed training course for the activities performed with the product.

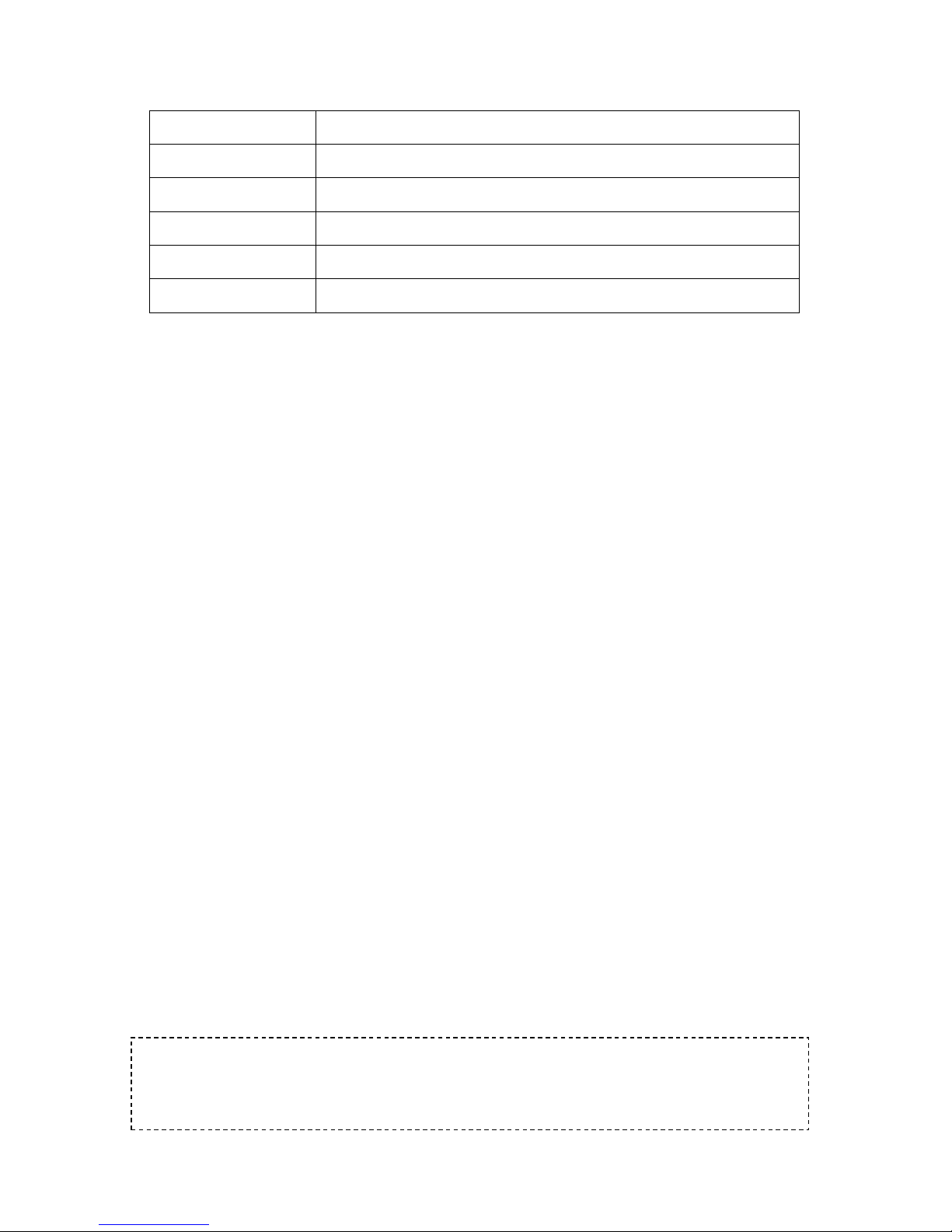

Manufacturer

ZMM Haskovo PLC.

Address

67 Saedinenie, 6300 Haskovo, Bulgaria

Telephone

+359 800 15 145

Fax

+359 38 603070

e-mail

greenecotherm@erato.bg

home page

www.greenecotherm.eu

User manual for installation and operation of automated wood pellet burner from series “GP 45 IV”

(Edition: 1.2.2013 г. 13:52)

Pellet burner GP 45 IV 3

CONTENT

page.

1. USER INFORMATION RELATED TO THE SAFETY.................................................... 5

2. DESCRIPTION AND ADVANTAGES OF AUTOMATED WOOD PELLET BURNER

FROM SERIES “GP 45 IV”................................................................................................ 6

3 TECHNICAL DATA OF AUTOMATED WOOD PELLET BURNER FROM SERIES “GP

45 IV ”................................................................................................................................ 8

4 CONSTRUCTION DESCRIPTION OF AUTOMATED WOOD PELLET BURNER FROM

SERIES “GP 45 IV”..........................................................................................................11

4.1. GENERAL CONDITIONS.....................................................................................11

4.2. CONSTRUCTIONAL MEASURES FOR INCREASING THE OPERATION

SAFETY OF THE BURNER FROM SERIES “GP 45 IV”.................................................15

5. MOUNTING AND INSTALLATION. .............................................................................17

5.1. MAIN REQUIREMENTS FOR INSTALLATION OF AUTOMATED WOOD PELLET

BURNER FROM SERIES “GP 45 IV”..............................................................................17

5.2. BURNER INSTALLATION ……………………………………………………………… 17

5.3. OVERALL AND CONNECTION DIMENSIONS OF THE BURNER’S MAIN

MODULE..........................................................................................................................18

5.4. POSITIONING AND MOUNTING OF THE BURNER’S MODULES......................20

5.5. INFORMATION ABOUT INSTALLATION POSSIBILITIES OF PELLET BURNER

FROM SERIES “GP” AND JOINT OPERATION WITH HOT WATER BOILERS............22

6. INITIALIZATION OF AUTOMATED WOOD PELLET BURNER FROM SERIES “GP 45

IV” IN OPERATION. .........................................................................................................23

6.1. MAIN REQUIREMENTS ABOUT THE USED FUEL.............................................23

6.2. INITIALIZATION OF AUTOMATED WOOD PELLET BURNER FROM SERIES

“GP 45 IV” IN OPERATION.............................................................................................23

6.2.1. INTERFACE CONTROL PANEL OF AUTOMATED WOOD PELLET

BURNER FROM SERIES “GP IV”....................................................................................24

6.2.2. CONNECTING AND POWERING THE BURNER.........................................24

6.2.3. SWITCHING ON THE BURNER FROM SERIES “GP”................................25

6.2.4. BURNER FROM SERIES “GP” OPERATION METHOD..............................26

6.2.5. PARAMETERS FOR OPERATION ADJUSTMENT OF A BURNER FROM

SERIES “GP”. ..................................................................................................................27

6.2.6. DESCRIPTION OF THE MENU, START AND ADJUSTMENT OF THE

BURNER’S OPERATION PARAMETERS........................................................................28

6.2.7. ADJUSTMENT OF THE BURNER OUTPUT ACCORDING TO THE HEAT

CONSUMPTION. ..............................................................................................................31

6.2.8. NOMINAL OPERATION MODE OF THE BURNER......................................31

6.2.9. OPERATION MODE OF THE AUTOMATED WOOD PELLET BURNER

FROM SERIES “GP IV”....................................................................................................31

6.2.10. USER MENUES FROM THE BURNER’S CONTROLLER............................33

6.2.11. USER MENUES FROM THE BURNER’S CONTROLLER............................33

6.2.12. MENU „EFFECT LEVEL”.............................................................................33

6.3. REGULATING THE BURNER’S HEATING OUTPUT. .........................................35

6.3.1. DECREASING THE BURNER’S HEATING OUTPUT. .................................35

6.3.2. INCREASING THE BURNER’S HEATING OUTPUT....................................35

6.4. STOPPING THE BURNER OPERATION.............................................................35

6.4.1 STOPPING THE BURNER OPERATION BY THE SWTICH “START”................35

6.4.2. STOPPING THE BURNER OPERATION BY THE CONTROL MODULE MENU.35

6.5. SWITCHING OFF THE PELLET BURNER FROM SERIES “GP IV” BY

EXTERNAL MODULE, CONTROLLING ITS OPERATION. ............................................37

6.5.1. BURNER EMERGENCY SHUT DOWN........................................................37

6.6. MENU FOR VIZUALIZATION OF ALARMS/ERRORS LIST, OCCURRED

DURING OPERATION OF PELLET BURNER FROM SERIES „GP IV”. ........................38

Pellet burner GP 45 IV 4

6.7. RESTARTING THE PELLET BURNER OPERATION..........................................38

6.8. DESCRIPTION OF THE THERMO-STICKERS FUNCTION FOR MONITORING

THE SYSTEM CONDITION..............................................................................................39

6.9. REMOVING AND INSTALLING THE FIRE-GRATE DURING CLEANING AND

MAINTENANCE OF THE BURNER FROM SERIES “GP”..............................................40

6.10. INTRODUCING THE USER WITH THE MAINTENANCE AND ADJUSTMENT

PROCEDURES OF PELLET BURNER FROM SERIES “GP”.........................................42

6.11. SAFETY AND UNPREDICTED RISKS.................................................................43

6.12. COMPLETING THE BURNER’S WARRANTY CARD..........................................43

6.13. ACTIVITIES AFTER EXPIRY OF THE BURNER LIFE CYCLE PERIOD. ............44

7. FAILURES AND TROUBLESHOOTING..............................................................45

8. WIRING DIAGRAM OF AUTOMATED WOOD PELLET BURNER FROM SERIES “GP

IV”.....................................................................................................................................51

WARRANTY CONDITIONS

Pellet burner GP 45 IV 5

1. USER INFORMATION RELATED TO THE SAFETY.

The installation and operation manual of the automated modulating wood pellets burner from

series „GP 45 IV” is designated for end users and authorized servicing specialists.

The user must know that:

All activities related to the wood pellet burner installation must be performed only by

authorized installers, which have acquired legal rights for such activities from the local

authorities;

All activities related to the electrical installation must be performed only by

electricians;

The initialization in operation, including visual check of the heating installation,

adjustment and burner start up, must be performed by certified technician, authorized

by the manufacturing company representatives;

Please observe the following rules during installation, initial start up, adjustment and

operation initialization of automated modulating wood pellet burner from series “GP 45 IV”:

All legal provisions related to the safety techniques;

Environment protection provisions;

Installation, initial start up and adjustment provisions;

The harmonized EU provisions, applicable in the relevant country;

Please strictly observe the presented safety instructions, in order to avoid risks and harms to

people, properties, as well as to environment polluting.

Please pay attention to the following symbols from the current manual book:

Danger

This symbol warns the users about possible human health risks.

Warning

This symbol warns the users about possible risks and harms to

properties and environment.

Information

This symbol provides additional information to the users.

Notation “GP IV” is used in the present manual book, which includes the wood

pellet burner model “GP 45 IV” with heating output of 45kW. The wood pellet

burners from series “GP IV” are modification of the already known pellet

burners from series “GP”.

For your safety it is important to become well familiar and read carefully

the present instruction, before performing any activities over the

installation and operation of this appliance. Non-observance of the

instructions below might lead to damages and fatal consequences, for

which the manufacturing company will not take responsibility.

Pellet burner GP 45 IV 6

2. DESCRIPTION AND ADVANTAGES OF AUTOMATED WOOD PELLET BURNER

FROM SERIES “GP 45 IV”.

The automated modulating “GP 45 IV” series burner used for utilization of wood pellets is

designated for mounting to hot water boilers and other appliances. The burner utilizes wood

pellets and other types of biomass, described below, as the produced heating energy is

utilized by the hot water boiler’s body heat exchanging surfaces, in which the burner is

mounted.

The pellet burner from series “GP 4 IV” complete kit consists of:

Main module with removable fire-grate – 1 unit;

Fuel transport auger – 1 unit;

Flexible pipe – 1 pc, with tightening brackets – 2 pcs;

A pair of working gloves – 1 set;

Operation manual book – 1 pc;

Main module package – 1 pc;

Transport auger package – 1 pc;

User manual book for installation and operation of wood pellet burner from series

“GP 45 IV” – 1 pc.

The pellet burner from series “GP IV” can utilize the following types of fuel:

Wood pellets with diameter Ø 6-8 mm, category ENplus-A1 according to standard EN

14961-2:2010 or category: A, AB, B according to the methodic developed and used

by the burner manufacturing company;

Dry nuts (from cherries, from morello);

Mixture of pellets and dry nuts (for example 50% - 50% ratio);

Other biomass with pellet shape, but after test approval in the burner’s manufacturing

company laboratory.

The pellet burner from series “GP 45 IV” is fitted with:

Microprocessor controller for management of the burner’s modules operation;

Display with keyboard, showing the burner operation mode and for adjustment of the

burner operation parameters;

Firing air fan (fresh air) with Holl sensor that regulates the fan rotation frequency;

Electrical heating element, for fuel ignition (primary firing);

Transport auger, for automated fuel feeding from a hopper to the burner;

Combustion chamber, for establishment of optimized burning process;

Removable fire-grate, providing easy cleaning of the combustion chamber;

Photo-sensor for dynamic monitoring of the burning process;

Reversible thermo-sticker for indication of the system operation mode and the

necessity of cleaning, of either the appliance or the chimney to which it is mounted;

Irreversible thermo-sticker for indication of registered overheating of the burner, a

precondition for warranty claim disapproval.

The burner is equipped with:

Automatic fuel firing system;

Automatic system for fuel feeding to the combustion chamber;

Safety system, which block the burner fuel inlet, in case the pellets feeding pipe has

been overheated due to emergency situations;

Photo-sensor for dynamic monitoring of the burning process;

System for modulation of the firing air flow rate during the fuel ignition process;

System for modulation of the burner operation mode, which provides optimal

operation modes and low fuel consumption;

Availability for periodical performance of final combustion with blowing, used for

cleaning followed by new automatic restart.

Pellet burner GP 45 IV 7

Advantages of the burner:

The burner is designated to utilize biomass, which makes it ecologically clean and

does not contribute to environment polluting;

Serves for changing hot water boilers fuel component, which previously have used

fossil fuels – oil, gas, coal;

Easy for mounting to boilers that are manually refueled with solid fuels – coal,

firewood, without necessity of significant reconstruction of the boiler installation;

The price of the produced heat energy from biomass utilization, as local energy

source, is less influenced than the global fuel prices, which makes the cost of the

acquired energy more competitive compared to the convectional heating sources;

The burner is automated and provides operation comfort near to that provided by

burners utilizing fossil fuels (for example liquid or gaseous fuel), which provides

availability for usage in systems equipped with programmable room thermostat;

The burner is equipped with automatic fuel ignition system;

Automatic operation of the burner, availability for smooth operation adjustment,

compatibility with room thermostat (weekly programmer), which guarantees maximum

heat comfort and fuel economy;

Modulation of the operating process, providing optimal operation parameters and

constant high efficiency;

Simplified installation and adjustment of the burner, which accelerates the installation

works;

Availability for utilization of biomass with pellet shape (wood pellets), dry cherry nuts

and others, according to the requirements presented in the fuel characteristics table;

High efficiency;

Low levels of harmful emissions;

Automatic fuel feeding from a hopper, which is built according to the local conditions

(the hopper is not part of the burner delivery kit);

Simplified maintenance and servicing;

Minimum operation costs.

Pellet burner GP 45 IV 8

3 TECHNICAL DATA OF AUTOMATED WOOD PELLET BURNER FROM SERIES

“GP 45 IV ”

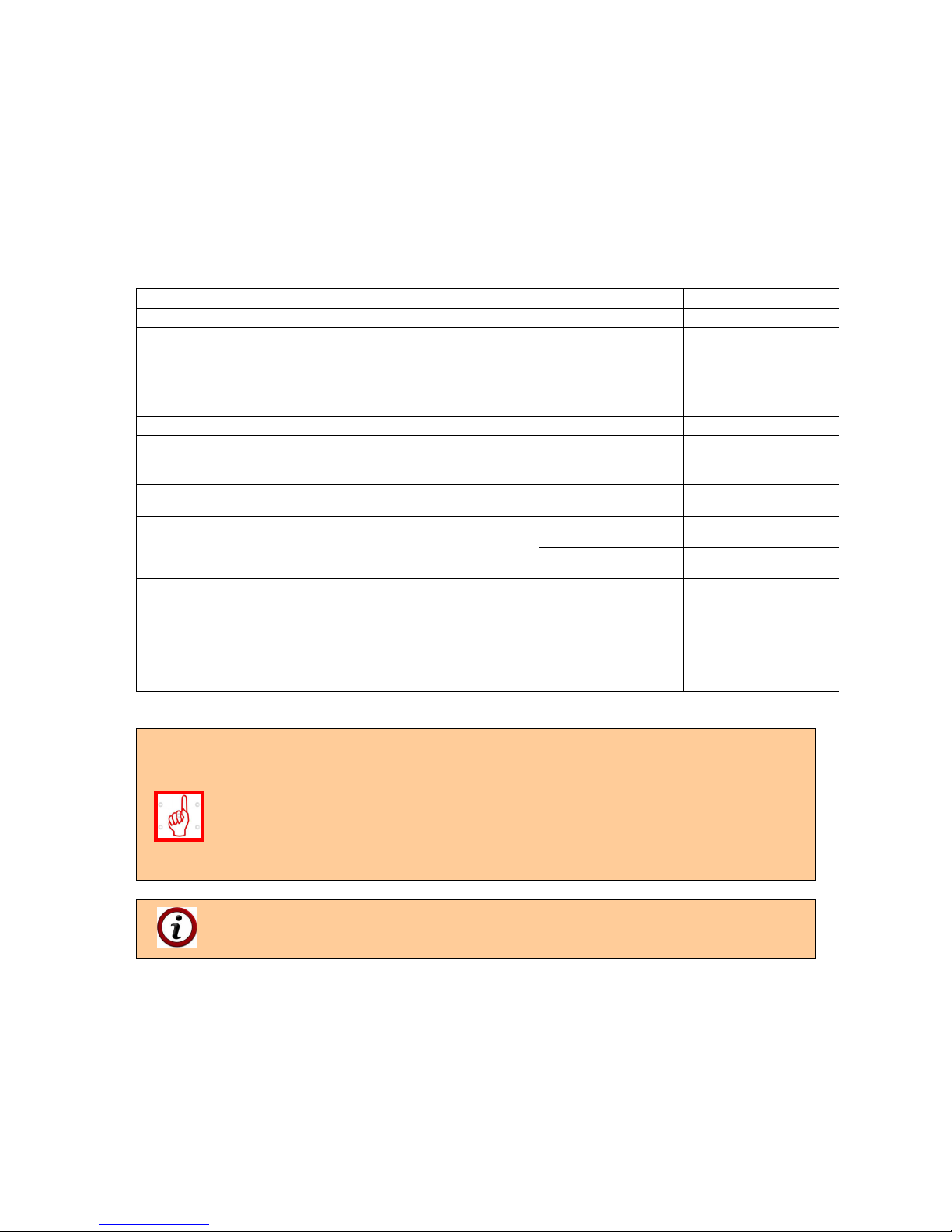

Heating-technical parameters of automated pellet burner from series “GP 45 IV” operating

with wood pellets are presented in Table 3.1.

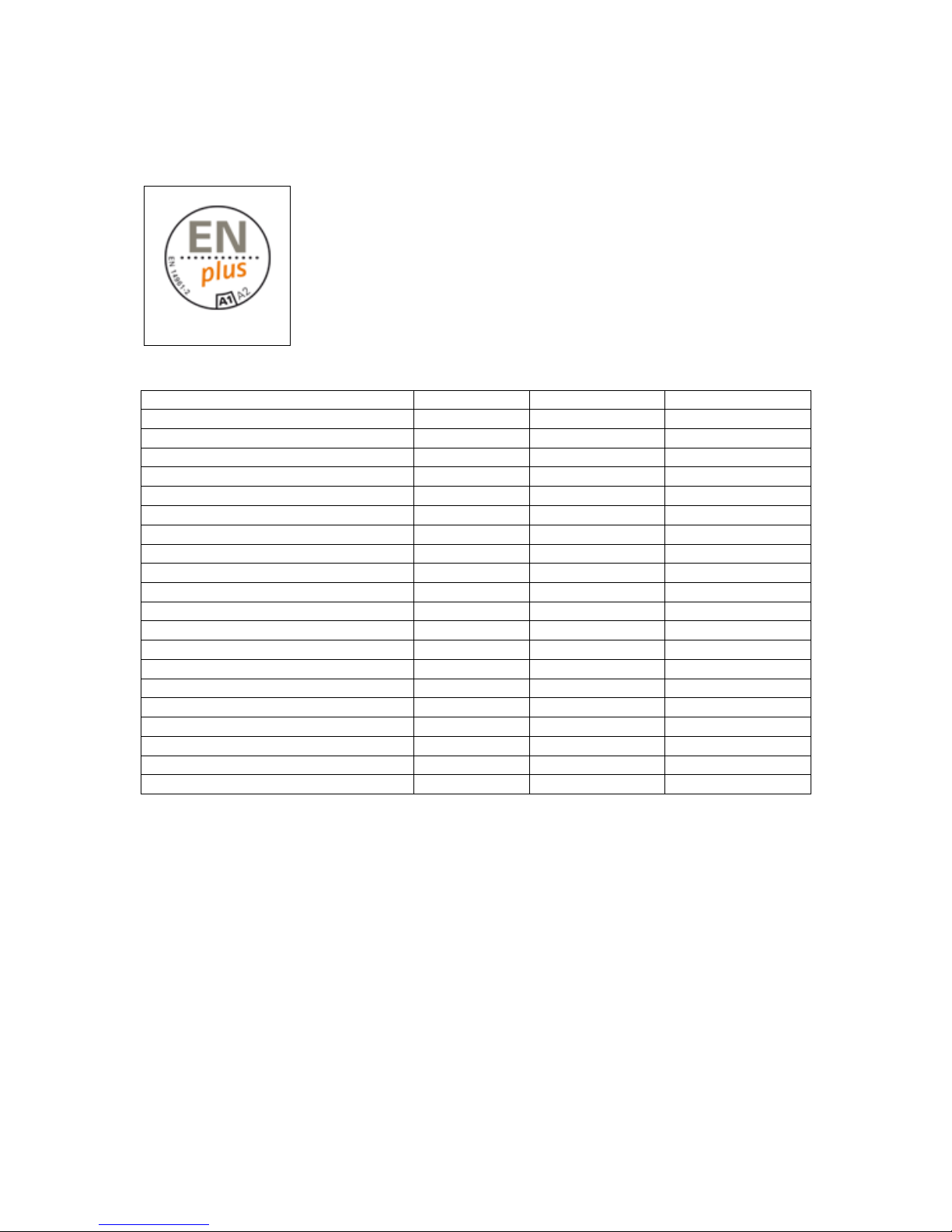

Table 3.1. Heating-technical parameters of automated pellet burner from series “GP 45 IV”

operating with wood pellets.

Parameter Dimension Value

Burner model - GP 45 IV

Nominal heating output kW 45

Heating output adjustment range kW 14-45

Used fuel - Wood pellets, dry

cherry nuts

Wood pellets category, according to EN 14961-2 - ENplus-A1

Used pellets categories (according to the burner

manufacturing company classification)

- A, AB, B

Wood pellets consumption at nominal heating output kg/h 9.6

kg/h 75-90 Needed air quantity for efficient burning process

m3/h 70-84

Average wood pellet consumption in the heating

installation

kg/h 5.0-7.0

Wastes from fuel combustion Ash

The quantity

depends on the fuel

ash content and the

operation mode

The automated pellet burner from series “GP” is designated for utilization of wood

pellets that comply with the presented classifications, according to standard EN

14961-2, category ENplus-А1 and to the pellets categorization developed by the

burner manufacturing company. As an exception it is allowed to utilize noncomplying to the specification wood pellets, only for a short period of time (in a

few hours), mostly with higher ash content, which will require more frequent

cleaning of the ash gathered on the burner’s fire-grate and over the appliance

heat exchanging surfaces, to which the burner is mounted.

The presented values for average wood pellets consumption in the heating

installation refer to buildings and premises with good heat isolation and sealed

window frames.

Pellet burner GP 45 IV 9

The dimensions and technical parameters of automated wood pellet burner from series “GP

45 IV” are presented in Table 3.2.

Table 3.2. Dimensions and technical parameters of automated wood pellet burner from

series “GP 45 IV”.

Parameter Dimension Value

Burner model - GP 45 IV

Main module kg 23.3

Weight

Fuel feeding auger kg 12.0

Main module mm 250х645х555 Overall dimensions

(WxLxH)

Fuel feeding auger mm 184x1870x107

Power supply - L1, N, PE, 50Hz; 230V;

Nominal mode A 0.2 Electricity

consumption

Ignition mode A 4.5

Electric power W

<100 + 800 (with

ignition)

Electric protection - IP20

Recommended fuel parameters are presented in Table 3.3.

Table 3.3 Recommended fuel parameters.

Parameter Dimension Value

Granules(pellets) diameter mm 6 - 8

MJ/kg >17.2 Recommended fuel caloricity (lower burning point)

kWh/kg >4.7

Wood pellets category according to standard EN

14961-2

ENplus-A1

Wood pellets category A, AB, B

Ash content % See table 3.4

Water content % Max. 8 – 10%

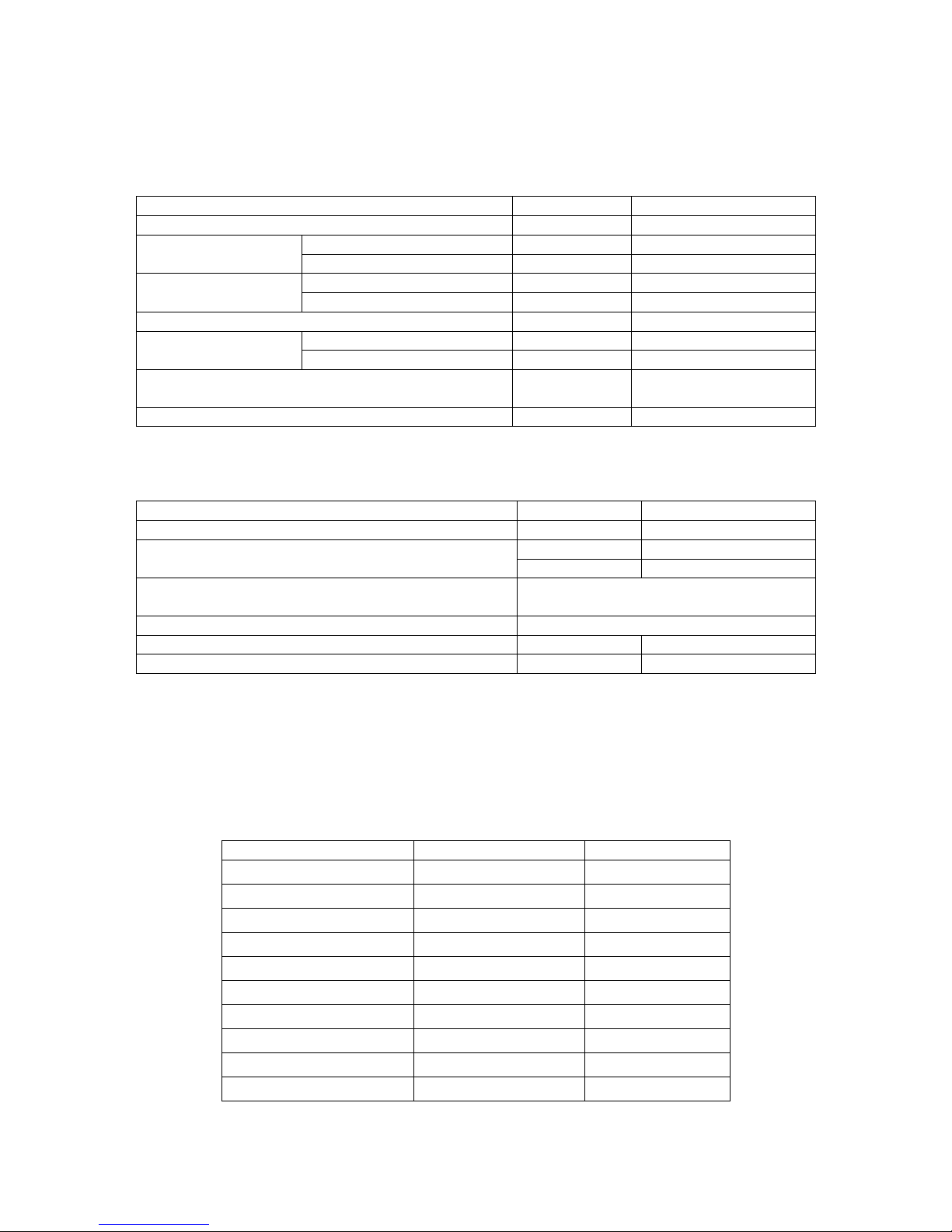

The wood pellets classification depending on their physical parameters and in accordance to

the methodic developed and implemented by the burner manufacturing company is

presented in Table 3.4.

Table 3.4. Wood pellets classification depending on their physical parameters and in

accordance to the methodic developed and implemented by the burner manufacturing

company.

Pellets category Ad DU

A

%6.0≤

d

A

%0.97

≥

DU

AB

%6.0≤

d

A

%0.97

<

DU

B

%0.16.0 ≤<dA

%0.97

≥

DU

BC

%0.16.0 ≤<dA

%0.97

<

DU

C

%0.2%0.1 ≤<dA

%0.97

≥

DU

CD

%0.2%0.1 ≤<dA

%0.97

<

DU

D

%0.3%0.2 ≤<dA

%0.97

≥

DU

DE

%0.3%0.2 ≤<dA

%0.97

<

DU

E

%0.3>

d

A

%0.97

≥

DU

EF

%0.3>

d

A

%0.97

<

DU

Pellet burner GP 45 IV 10

Where,

A

d

– ash content of dry mass , [%];

DU – mechanical durability, [%];

With the acceptance of the new European Union wood pellets

standard (EN 14961-2) in 2010, new certificates, ENplus for pellets

used in boilers for domestic purposes and EN-B for industrial pellets

used in industrial boilers, are introduced. The standard ENplus defines

two quality categories: A1 and A2. In category A1 are implemented the

most strict limits for ash content in the pellets. In category A2 the ash

content is up to 1,5%. For industrial pellets the EN-B certificate is

applied, which is with significantly decreased quality requirements.

Table 3.5 European standard for wood pellets EN 14961-2.

Parameters Dimension ENplus-A1 ENplus-A2

Diameter mm 6 (± 1) 6 (± 1)

Length mm 3,15 ≤ L ≤ 40 1) 3,15 ≤ L ≤ 40 1)

Bulk Density kg/m³ ≥ 600 ≥ 600

Caloricity MJ/kg ≥ 16.5 ≥ 16.5

Water content % ≤ 10 ≤ 10

Dust % ≤ 13) ≤ 1

3)

Mechanical durability % ≥ 97.5

4)

≥ 97.5

4)

Ash content % 2) ≤ 0,7 ≤ 1.5

Ash melting point °C ≥ 1200 ≥ 1100

Chlorine content %

2)

≤ 0.02 ≤ 0.03

Sulfur content %

2)

≤ 0.05 ≤ 0.05

Nitrogen content %

2)

≤ 0.3 ≤ 0.5

Copper content mg/kg

2)

≤ 10 ≤ 10

Chromium content mg/kg

2)

≤ 10 ≤ 10

Arsenic content mg/kg

2)

≤ 1 ≤ 1

Cadmium content mg/kg

2)

≤ 0.5 ≤ 0.5

Mercury content mg/kg

2)

≤ 0.1 ≤ 0.1

Lead content mg/kg

2)

≤ 10 ≤ 10

Nickel content mg/kg

2)

≤ 10 ≤ 10

Zink content mg/kg

2)

≤ 100 ≤ 100

1) no more than 1% from the pellets can be longer than 40 mm, maximum length of 45 mm;

2) the data are determined with dry mass;

3) particles <3.15 mm, fine particles, before deliver of the goods;

4) for measurements, performed with Lignotester maximum allowed value ≥ 97.7 mass %;

Pellet burner GP 45 IV 11

4 CONSTRUCTION DESCRIPTION OF AUTOMATED WOOD PELLET BURNER FROM

SERIES “GP 45 IV”

4.1. GENERAL CONDITIONS

The pellet burner from series “GP 45 IV” consists of the following components/modules:

The main part of the system is a main module that consists of:

Combustion chamber, which forms the conditions for optimal burning process

and is made of high quality stainless steel;

Combustion chamber fire-grate, which is easy removable and provides

availability for cleaning of the ash deposits;

Air distribution tract, which provides uniform supply of firing air and also air for

cooling of the burner’s parts;

Electrical heating element, which serves for primary ignition of the fuel,

positioned in the combustion chamber under the tilted part of the fire-grate;

Firing air supply fan, equipped with sensor for reading the rotation frequency

and availability for regulation;

Photo-sensor for monitoring of the burning process, mounted on the burner’s

side for its easy cleaning;

Emergency temperature sensor for protection from the so called “back fire” in

the main module’s fuel inlet pipe;

Control module for monitoring and managing the burner operation;

Display module with keyboard, used for visualization of the burner operation

mode and for performing all necessary adjustments;

Connector for the fuel transport auger, used for the auger power supply;

Reversible thermo-sticker, used for monitoring of the temperature in specific

zone of the burner and for evaluating the necessity for cleaning of the

appliance to which it is mounted, or for evaluating the necessity of inspection

of the chimney draught;

Irreversible thermo-sticker, for indication of registered overheating of the

burner, precondition for warranty claim denial.

Electrically driven outer transport auger, which transports the fuel from a hopper to

the burner, depending on the burner operation mode. The auger consists of motorgear with electric motor, equipped with integrated overheating protection, pipe for

transferring the fuel to the drop hole (where it drops down by gravity) and to the

flexible pipe;

Flexible pipe, made of special transparent thermo-resistant material (in case of fire it

does not separate harmful or toxic substances), which connects the auger and the

main module.

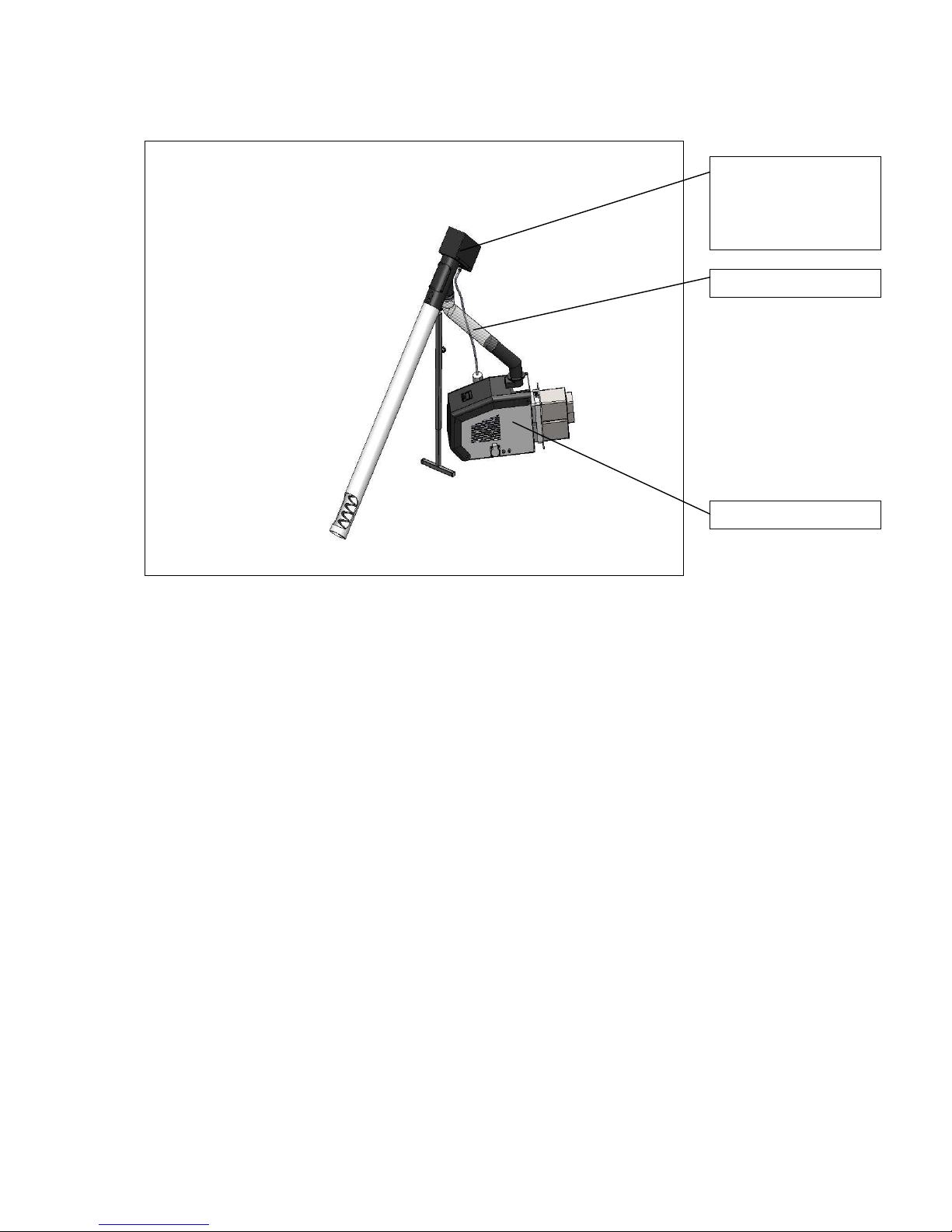

The main burner modules and their positioning are presented in Figure 4.1.

Pellet burner GP 45 IV 12

Figure 4.1. Main modules positioning of burner from series “GP 45 IV”(side view).

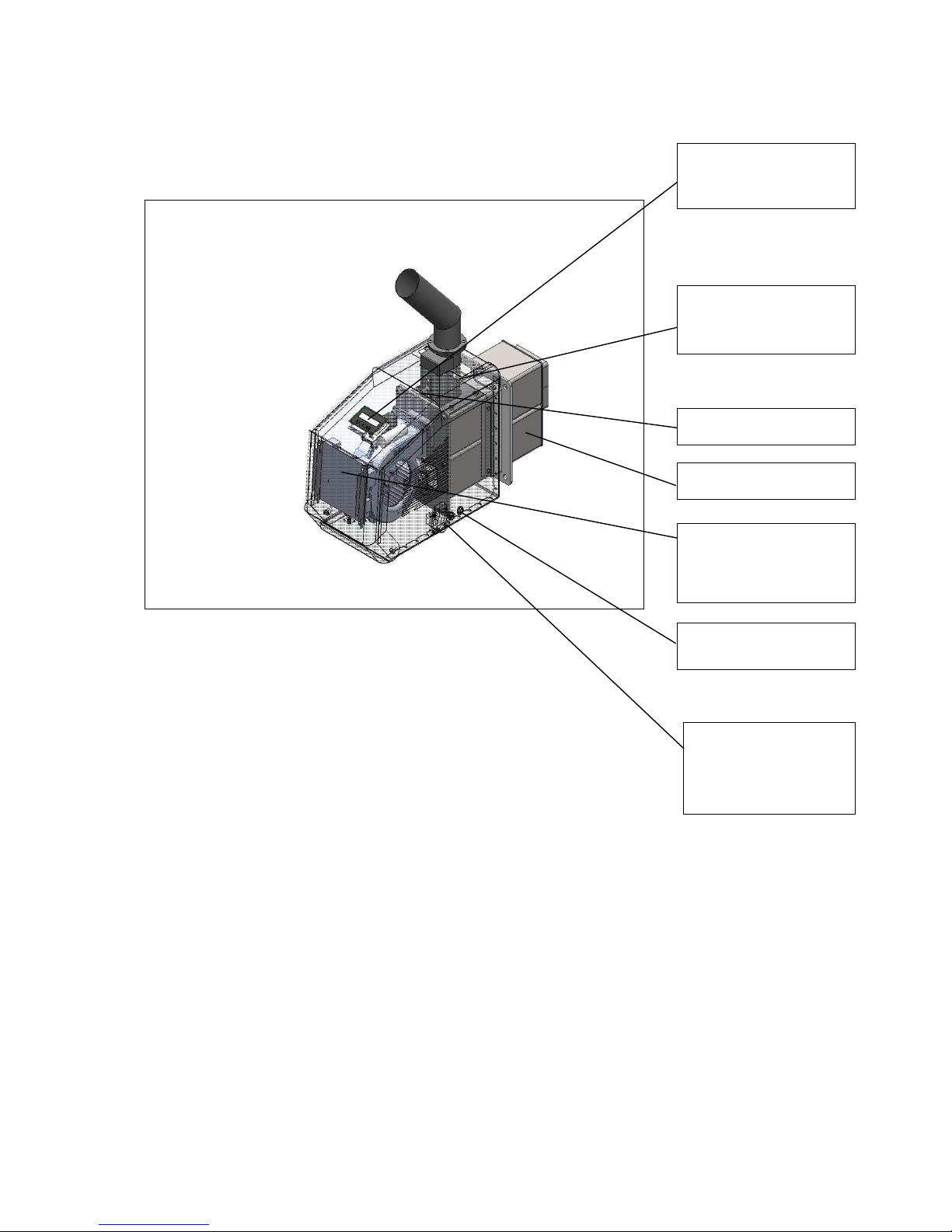

Main module’s components of a burner from series “GP IV” are presented on Figure 4.2 and

Figure 4.3.

Flexible pipe

Main module

Outer fuel transport

auger, from a

hopper to the main

burner module

Pellet burner GP 45 IV 13

Figure 4.2. Main module section view and components of burner from series “GP 45 IV”.

`

Emergency sensor

protecting from “back

fire”

Interface panel

(display + keyboard)

Photo-sensor

Combustion chamber

Burner’s control pcboard

Burner’s power

supply cable

Plug for managing

and power supply of

the fuel transport

auger

Pellet burner GP 45 IV 14

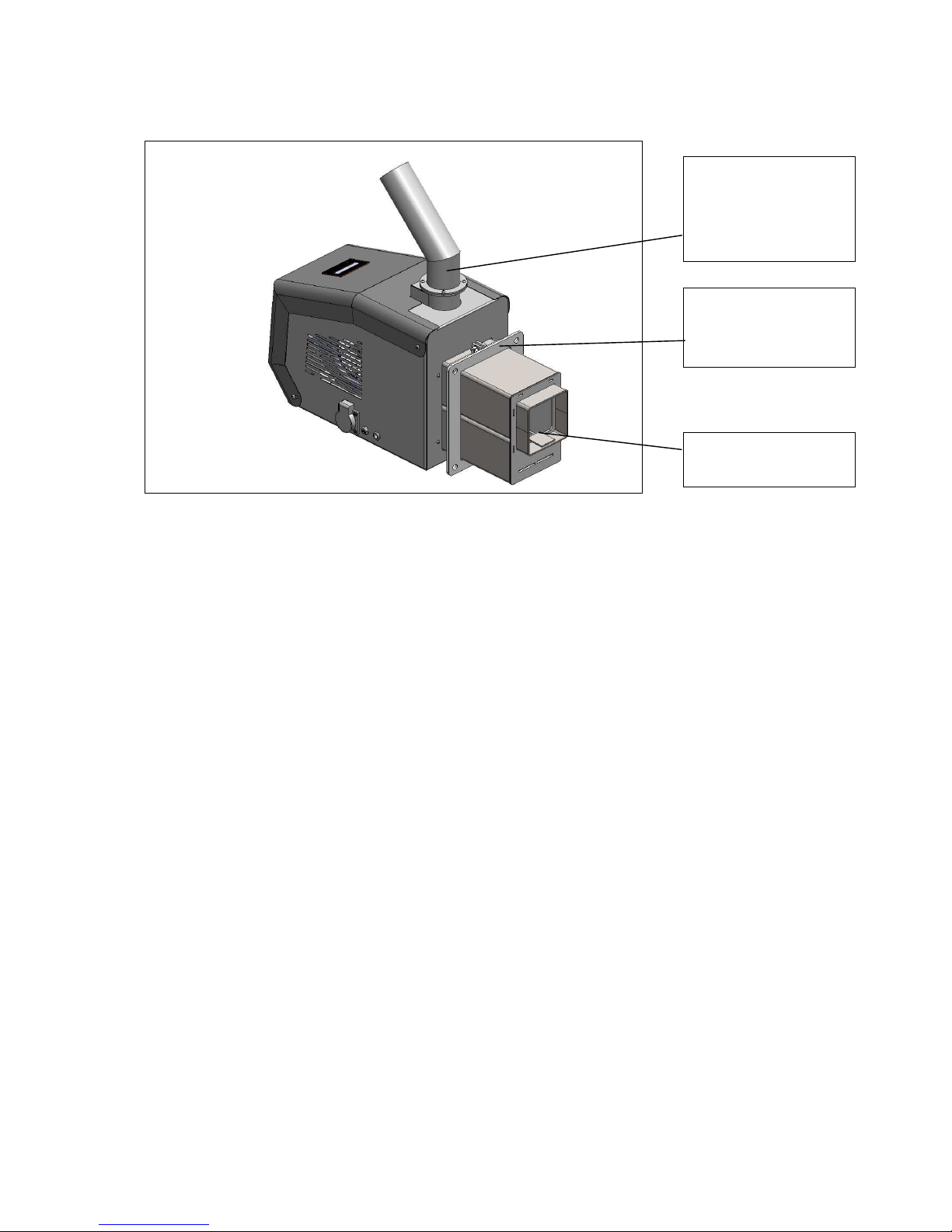

Figure 4.3. Main module view of burner from series “GP 45 IV”.

EXPLANATION:

The reversible (self-recovering) liquid crystal thermo-sticker serves for indication of

the temperature in the zone where it is attached. This temperature indicates also the

burner operation mode and the flue gas resistance within its route to the appliance’s

chimney, to which the burner is mounted. The initial condition of the thermo-sticker is

such that all of its temperature scale zones are dark colored. When the temperature

increases the surface of the scale zones become lighter, corresponding to the

operating temperature. Increase of the temperature in this zone indicates the

necessity for cleaning of the appliance from the ash deposits and/or the flue gas

extraction line. When it cools down the sticker reverse to its previous condition and

color;

The irreversible (not recovering) liquid crystal thermo-sticker is indicator for (at least

once) overheating of the burner’s pellet inlet pipe. This sticker has single action and

when it reaches critical temperature its color changes irreversibly. At initial condition

its indication element color is white and after its critical temperature has been

reached it becomes dark.

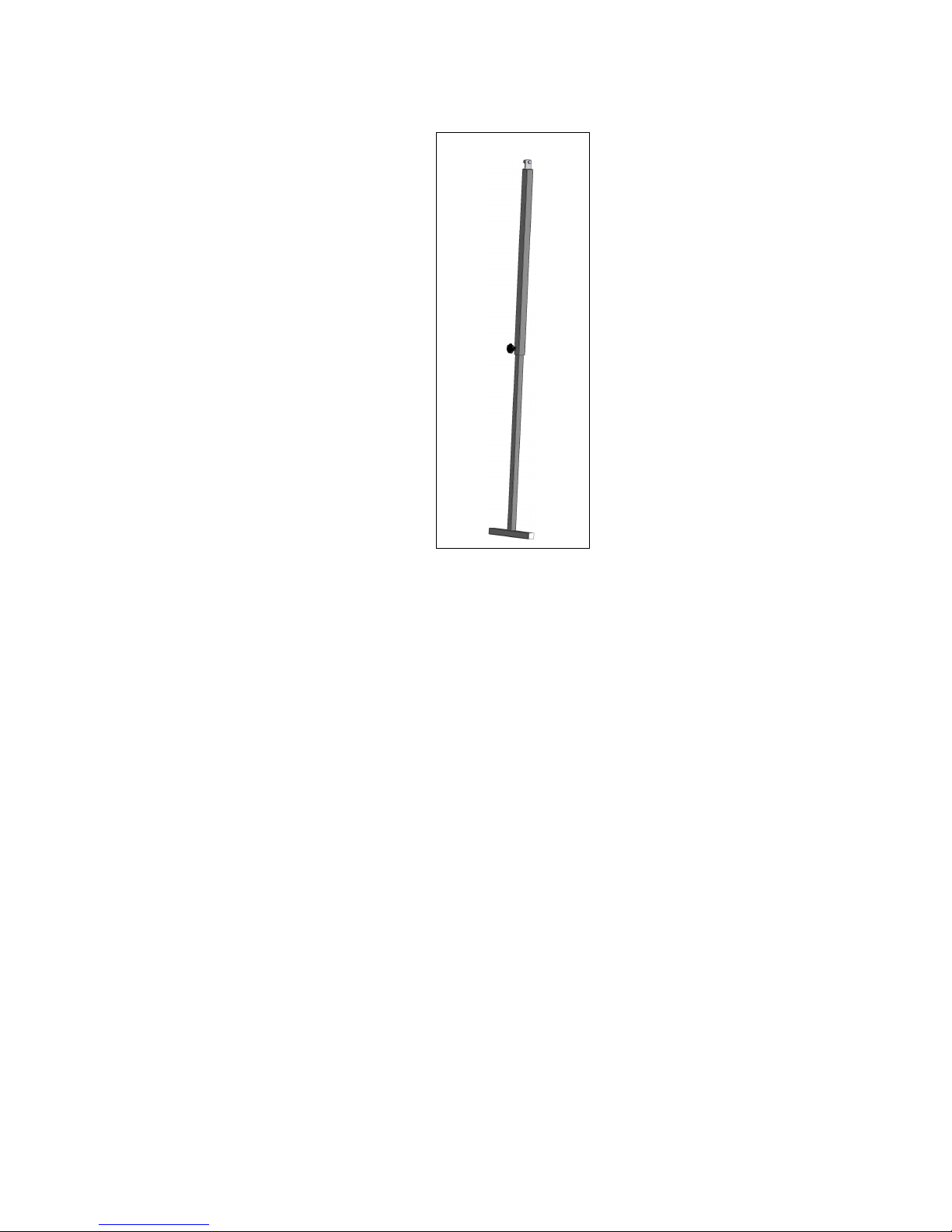

In case that the fuel transport auger of the burner has to be supported, then a telescopic

support can be ordered, as an optional equipment to the burner, which provides availability

for adjustment of the auger tilting angle and its stable positioning (Figure 4.4).

Pellets inlet pipe to

burner’s combustion

chamber

Main module

mounting flange to

appliance (to boiler)

Combustion

chamber fire-grate

Pellet burner GP 45 IV 15

Figure 4.4. Fuel transport auger support bar view, for burner from series “GP 45 IV”.

4.2. CONSTRUCTIONAL MEASURES FOR INCREASING THE OPERATION SAFETY

OF THE BURNER FROM SERIES “GP 45 IV”

The ignition and burning processes are monitored by micro-processor logic module;

The ignition and burning processes are monitored by photo-sensor and if the fuel

does not fire after two attempts for ignition, then the burner transits to “Stop” mode

with relevant indication for transiting to such mode;

If during operation the fuel hopper has been depleted the burner transits to “Stop”

mode with respectively activated indication for transition in such mode;

The flexible pellets transport pipe is transparent and is made of special temperature-

resistant material;

There are stickers (labels) indicating the proper operation and handling of the burner;

The burner is equipped with safety components for protection against fuel firing

(occurrence of the so called “back fire”):

Dropping flap chamber, which cuts the pellets flow from the transport auger to

the main module. The chamber depth is around 250mm. Besides that the

transport auger is connected to the burner through flexible pipe, which is not full

with fuel. There is small doze of fuel in the burner, which burns completely while

the transport auger operation is paused and there is no risk of reverse firing of

the fuel;

Emergency temperature sensor, positioned on the burner’s fuel feeding pipe,

which activates when the surface temperature in this zone exceeds 90 – 95

o

C. If

during operation this sensor registers temperature increase (90 – 95oC), then

the transport auger stops and the system transits to emergency mode,

respectively the burner operation stops as well. This is indicated on the burner’s

display with the sign “STOCKER FAULT”. After removing the normal operation

disturbance reason the burner can be started again by switching off and then on

its power supply (restarting);

Pellet burner GP 45 IV 16

The reversible thermo-sticker from liquid crystals, which indicates the current

temperature value in its attachment zone, serves for easy evaluation of the

system operation mode, where the burner is installed and the necessity for

cleaning of the appliance and/or the chimney tract/line.

Loading...

Loading...