GreenEcoTherm GP XX SC Series, GP 20 sc, GP 32 sc, GP 25 sc, GP 18 sc Installation, Operation And Maintenance Manual

MANUAL

FOR INSTALLATION, OPERATION AND MAINTENANCE OF

AN AUTOMATED PELLET BURNER FROM SERIES

“GP xx sc”

http://www.greenecotherm.eu

Pellet burner GP xx sc 1

Manufacturer

ZMM Haskovo PLC

Address

Phone number

Fax

e-mail

home page

67 Saedinenie blvd., 6300 Haskovo, Bulgaria

+359 800 15 145

+359 38 603 070

greenecotherm@erato.bg

www.greenecotherm.eu

The manufacture company thanks you for your choice.

The manufacture company submits this manual to help the team that will install, adjust and

service the pellet burner, as well as to the customer that will operate it.

The manufacturing company requires that the technicians, performing the above mentioned

procedures, had successfully passed the product’s technical training.

Manual for installation, operation and maintenance of an automated pellet burner from series

“GP xx sc”

(Edition: 13.11.2013 г. 14:48)

Pellet burner GP xx sc 2

CONTENT

page.

1. USERS SAFETY INFORMATION. ................................................................................................. 4

2. DESCRIPTION AND ADVANTAGES OF THE AUTOMATED PELLET BURNER “GP xx sc”. ..... 5

3. TECHNICAL DATA OF THE AUTOMATED PELLET BURNER FROM SERIES “GP xx sc”. ....... 7

4. CONSTRUCTION DESCRIPTION OF THE AUTOMATED PELLET BURNER “GP xx sc”. ....... 10

4.1. GENERAL CONDITIONS. ................................................................................................... 10

5. MOUNTING AND INSTALLATION OF THE PELLET BURNER. ................................................. 11

5.1. MAIN REQUIREMENTS FOR INSTALLATION OF A PELLET BURNER ”GP xx sc”. ........ 11

5.2. INSTALLATION OF THE PELLET BURNER. ...................................................................... 11

5.3. OVERALL DIMENSIONS OF THE BURNER’S MAIN MODULE. ....................................... 11

5.4. POSITIONING AND MOUNTING OF THE BURNER’S MODULES. ................................... 12

5.5. INFORMATION ABOUT INSTALLATION AVAILABILITIES OF AN AUTOMATED PELLET

BURNER “GP xx sc” AND ITS CO-OPERATION WITH HOT WATER BOILERS. .......................... 13

6. INITIATION TO OPERATION OF THE AUTOMATED PELLET BURNER “GP xx sc”. ............... 14

6.1. MAIN REQUIREMENTS ABOUT THE USED FUEL TYPES. ............................................. 14

6.2. INITIATION TO OPERATION OF A PELLET BURNER FROM SERIES “GP xx sc”. ......... 14

6.2.1. INTERFACE PANEL OF AN AUTOMATED PELLET BURNER “GP xx sc”. ................... 15

6.2.2. CONNECTING AND POWER SUPPLYING OF THE BURNER. ..................................... 15

6.2.3. SWITCHING ON THE PELLET BURNER FROM SERIES “GP xx sc”. ........................... 16

6.2.4. ALGORITHM OF OPERATION OF A PELLET BURNER “GP xx sc” .............................. 16

6.2.5. OPERATIONAL PARAMETERS FOR ADJUSTMENT OF A BURNER “GP xx sc” ......... 18

6.2.6. DESCRIPTION OF THE PRIMARY MENU, THE METHODS OF STARTING AND

OPERATIONAL PARAMETERS ADJUSTMENT OF A PELLET BURNER “GP xx sc” .................... 19

6.2.7. BURNER ADJUSTMENTS ACCORDING TO THE CONSUMED HEATING OUTPUT ... 22

6.2.8. NOMINAL OPERATION MODE OF THE BURNER. ........................................................ 22

6.2.9. OPERATION MODES OF A PELLET BURNER FROM SERIES “GP xx sc”................... 22

6.2.10. USER MENUS IN THE CONTROL MODULE OF A PELLET BURNER “GP xx sc”. ....... 24

6.2.11. MENU “EFFECT LEVEL”. ................................................................................................. 24

6.3. ADJUSTMENT OF THE BURNER’S HEATING OUTPUT. ................................................. 26

6.3.1. DECREASING THE BURNER’S HEATING OUTPUT. ............................................... 26

6.3.2. INCREASING THE BURNER’S HEATING OUTPUT. ................................................ 26

6.4. STOPPING THE OPERATION OF A PELLET BURNER FROM SERIES “GP xx sc”. ....... 26

6.4.1 STOPPING THE OPERATION OF A PELLET BURNER FROM SERIES “GP xx sc”

THROUGH THE SWITCH “START”. ................................................................................................ 26

6.4.2. STOPPING THE OPERATION OF A PELLET BURNER FROM SERIES “GP xx sc”

THROUGH A MENU FROM ITS COTROLLER KEYBOARD. ......................................................... 26

6.5. SWITCHING OFF A PELLET BURNER FROM SERIES “GP xx sc” THROUGH EXTERNAL

MODULE, MANAGING ITS OPERATION. ....................................................................................... 28

6.5.1. EMERGENCY SHUT DOWN OF A PELLET BURNER FROM SERIES “GP xx sc”. . 28

6.6. MENU DISPLAYING A LIST WITH THE LAST FAILURES, OCCURRED DURING

OPERATION OF A PELLET BURNER FROM SERIES “GP xx sc”. ................................................ 29

6.7. RESTART OF THE PELLET BURNER OPERATION. ........................................................ 29

6.8. DESCRIPTION OF THE TEMPERATURE STICKERS FUNCTION FOR MONITORING OF

THE SYSTEM’S CONDITION. .......................................................................................................... 29

6.9. CLEANING AND MAINTENANCE OF A PELLET BURNER FROM SERIES “GP xx sc”. .. 31

6.10. USER INTRODUCTION WITH THE MAINTENANCE AND ADJUSTMENTS

PROCEDURES OF A PELLET BURNER FROM SERIES “GP xx sc” ............................................. 32

6.11. SAFETY AND UNPREDICTED RISKS. .......................................................................... 32

6.12. COMPLETION OF THE BURNER’S WARRANTY CARD. ............................................. 33

6.13. ACTIONS AFTER EXPIRY OF THE LIFE CYCLE OF A PELLET BURNER FROM

SERIES “GP xx sc”. .......................................................................................................................... 33

7. FAILURES AND TROUBLESHOOTING. ................................................................................. 34

8. WIRING DIAGRAM OF AN AUTOMATED PELLET BURNER FROM SERIES “GP xx sc”. ....... 38

Pellet burner GP xx sc 3

1.

USERS SAFETY INFORMATION.

The manual for installation, operation and maintenance of the automated pellet burner from

series “GP xx sc” is designated for end users and authorized servicing specialists.

The users must know that:

All activities regarding installation of the pellet burner should be performed only by an

authorized installers, which have acquired legal rights by the legal authorities;

All activities regarding the electrical installation must be performed only by electrical-

technicians;

The primary technical initialization to operation, including visual check of the entire

heating installation, adjustments and start of the pellet burner must be performed by a

person that is authorized by the manufacturer.

Please observe the following conditions during installation, start, adjustment and initialization

to operation of the automated pellet burner from series “GP xx sc”:

All legal provisions regarding safety;

All legal provisions regarding environment protection;

Provisions regarding installation, start and adjustment;

All harmonized provisions of the European Union, applicable for your country;

Please strictly observe the presented safety instructions, in order to avoid any risks or harms

to people, properties and environmental polluting.

Please pay attention to the following symbols in the present manual book:

Danger

This symbol warns the users about possible health risks.

Warning

This symbol warns the users about possible risks and harms to properties and

environment.

Information

This symbol presents texts with additional information for the users.

The current manual book uses notation “GP xx sc”, which includes the pellet

burner models "GP 20_18 sc” with heating output of 18kW, “GP 25 sc” with

heating output 25kW and pellet burner “GP 32 sc” with installed heating output

of 32kW.

For your personal safety and before taking any actions regarding the

appliance installation and operation, it is highly recommended to read

carefully this manual book. Non-compliance to the instructions presented

below might lead to fatal consequences, for which the manufacture company

will not be responsible.

Pellet burner GP xx sc 4

2. DESCRIPTION AND ADVANTAGES OF THE AUTOMATED PELLET BURNER

FROM SERIES “GP xx sc”.

The automated modulating pellet burner from series “GP xx sc” utilizing wood pellets is

designated for mounting to hot water boilers and other appliances. The burner utilizes wood

pellets and other types of biomass, which are described below, as the generated heat energy

is adopted by the boiler body’s heat exchanging surfaces, to which it is mounted or by other

heat energy consuming appliances.

The pellet burner from series “GP xx sc” delivery kit consists of:

Main module – 1pc;

Fuel transport auger – 1pc;

Flexible pipe – 1pc, with locking brackets – 2 pcs;

A pair of working gloves – 1pc;

Manual for operation – 1pc;

Main module package – 1pc;

Fuel transport auger package – 1pc;

Manual for installation, operation and maintenance of a pellet burner from series

“GP xx sc” – 1pc.

The automated pellet burner from series “GP xx sc” can utilize the following fuel types:

Wood pellets with diameter Ø 6-8mm, from categories ENplus-A1, ENplus-A2 and

ENplus-B according to standard EN 14961-2:2010, or categories A, AB, B, BC, C,

CD, E, EF according to the manufacture company’s classification;

Dried nuts (from cherries, from morello);

Mixture of pellets and nuts (for example in 50% - 50% ratio);

Other biomass with pellet shape, but after approval test in the burner manufacture

company’s laboratory.

The pellet burner from series “GP xx sc” is equipped with:

Microprocessor controller managing the burner’s modules;

Display panel with keyboard, used to manage the burner’s modules;

Fan for fresh firing air supply equipped with Holl sensor, which controls the rotation

frequency;

Electrical heating element used for ignition of the fuel;

Auger for automatic fuel transportation from a hopper to the burner;

Combustion chamber, in which an optimal burning process is realized;

Photic sensor for dynamic control of the burning process;

Reversible temperature sticker for indication of the system’s operation mode and of

the necessity for cleaning of the appliance/chimney, to which it is fixed;

Irreversible temperature sticker for indication of registered overheating of the burner,

used also as precondition to deny a warranty claim.

The pellet burner is equipped with:

System for automatic fuel ignition;

System for automatic feeding of the fuel to the burner’s combustion chamber;

System for automatic cleaning of the combustion chamber

Security system, which blocks the burner in case the fuel feeding inlet pipe has been

overheated, as a result from emergency situations;

Photic sensor for dynamic control of the burning process;

System for modulation of the firing air flow rate during the process of initial fuel

ignition;

System for modulation of its operation mode, providing optimal operation modes and

low fuel consumption;

Availability to perform final combustion followed by blowing, through a defined period

of time, for cleaning purposes and for new automatic restart.

Pellet burner GP xx sc 5

Advantages of the pellet burner:

The burner is designated for biomass utilization, which makes it ecologically clean

and does not contribute to environment polluting and to planet’s global warming;

It is used to replace the fuel type in boilers for utilization of wood and coal;

Modern and multifunctional microprocessor control module, made in Sweden,

providing precise operation of the burner’s process components, through parameters

adjustment;

Automatic testing of the system’s functions;

Five levels for modulation of the heating output through quick access, as they can be

easily changed by the users;

Automatic modulation – adjustment of the needed fresh air quantity, according to the

heating output chosen by the user;

Automatic self-adjustment of the system, according to the transport auger’s feeding

rate / productivity, to specific climate conditions and to the fuel’s caloricity;

Indication of the heat carrier (or water) temperature in the boiler;

Availability to save the current adjustments and to restore the factory settings;

Passwords for limiting the access to certain levels, to parameters for the users and

for the servicing staff;

Availability for operation with temperature sensor, boiler and room thermostats;

Special measures to increase the reliability and the safety of the product;

Independence from the quality of the burned wood pellets with diameter Ø 6-8mm;

Availability to choose from 4 types of adjustments, depending on the quality of the

burned pellets, at stable efficiency;

Innovative and unique automatic cleaning of the combustion chamber, through

mechanical scraping of the combustion chamber’s fire-grate;

Availability to control a circulations pump;

Availability to control a flue extraction fan;

Easier servicing through the control module’s function – “History errors”;

The burner is equipped with system for automatic fuel ignition;

Simplified installation and adjustment of the burner, which accelerates the installer’s

work;

High efficiency;

Low harmful emission;

Automatic fuel feeding from a hopper, which can be build according to the local

conditions (it is not included in the burner’s standard delivery kit);

Simplified maintenance;

Minimum operation costs.

Pellet burner GP xx sc 6

+1100

3. TECHNICAL DATA OF THE AUTOMATED PELLET BURNER FROM SERIES “GP

XX SC”.

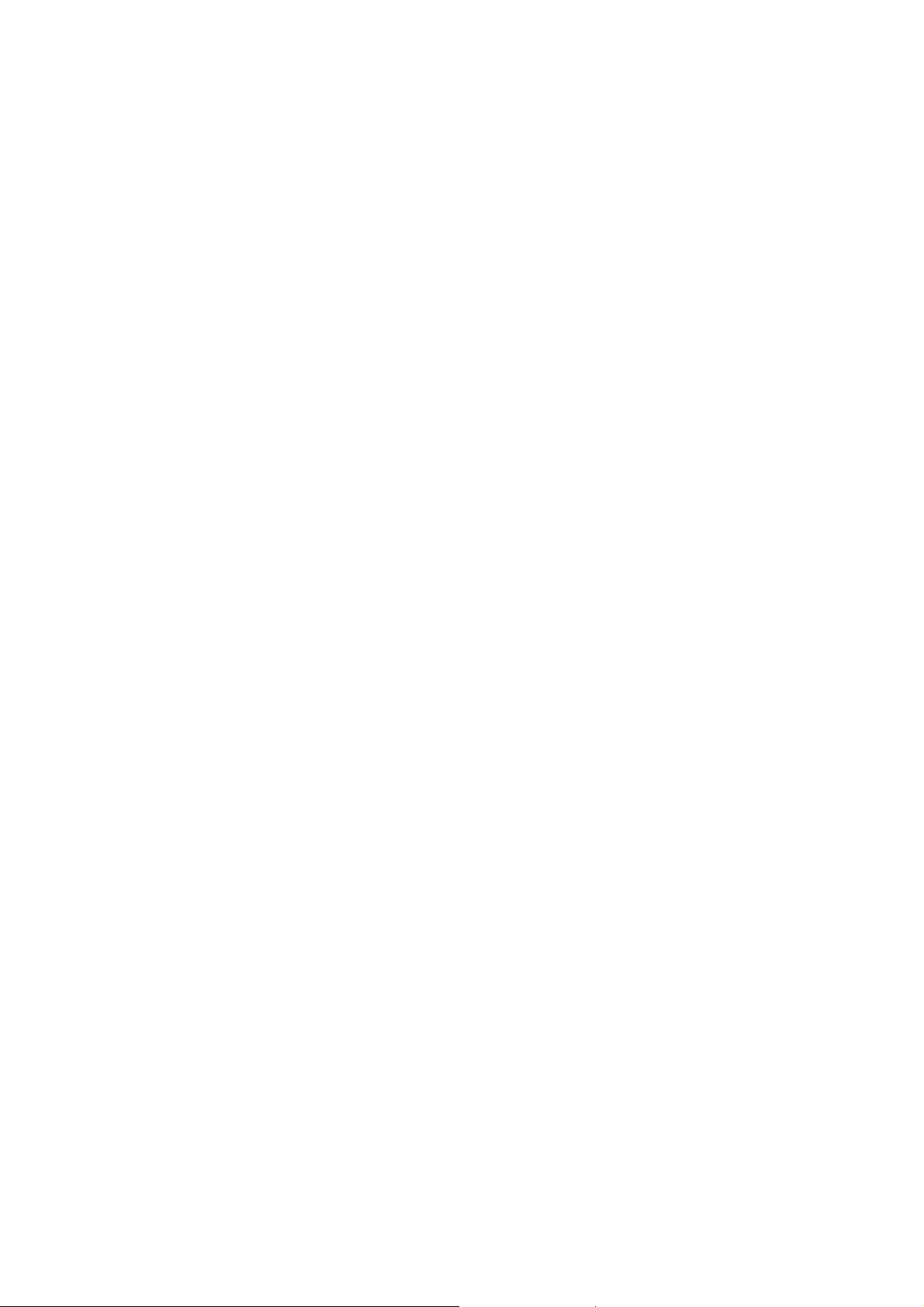

The technical data of the automated pellet burner from series “GP xx sc”, operating with

wood pellets, is presented in Table 3.1.

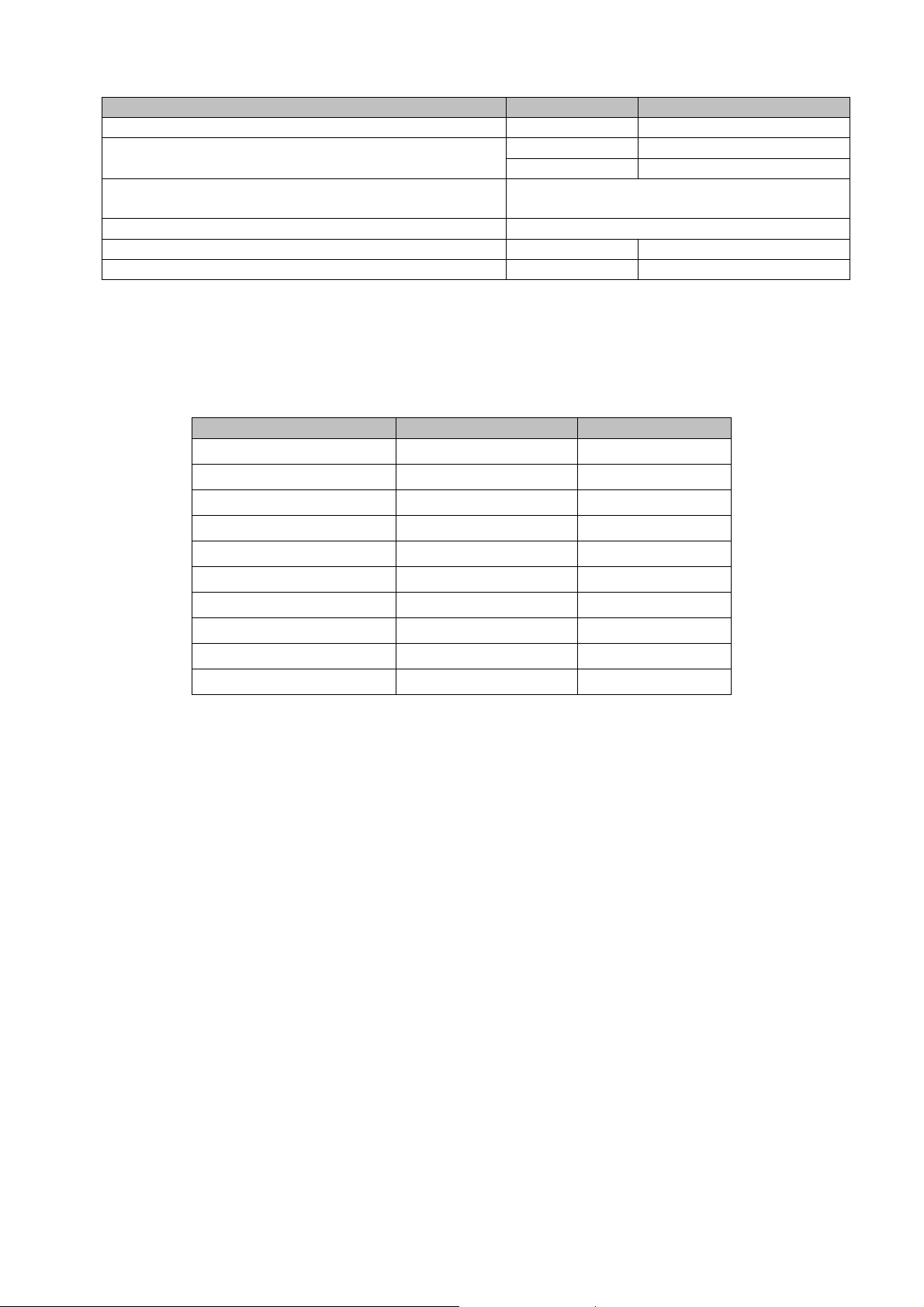

Table 3.1. Technical parameters of the automated pellet burner from series “GP xx sc”,

operating with wood pellets.

PARAMETER DIMENSION VALUE

Burner model - GP 20_18 sc GP 25 sc

GP 32 sc

Nominal heating output kW 18 25 32

Heating output adjustment range kW 7-18 7-25 10-32

Used fuel - Wood pellets

Wood pellets category according to

- ENplus-A1, ENplus-A2 и Enplus-B

standard EN 14961-2:2010

Used pellets categories (according to

- A, AB, B, BC, C, CD, E, EF

the manufacture company’s

classification)

Wood pellets consumption at nominal

kg/h 4.2 5.3 6.8

heating output

The quantity depends on the pellets ash

Wastes after complete fuel burning Ash

content and on the burner’s operation

mode

The automated pellet burner from series “GP xx sc” is designated for utilization of

wood pellets complying with the classification of standard EN14961-2:2010,

categories ENplus-A1, ENplus-A2 and Enplus-B, and also with the developed

classification by the manufacture company.

The dimensions and technical parameters of the automated pellet burner from series “GP xx

sc” are presented in Table 3.2.

Table 3.2. Dimensions and technical parameters of an automated pellet burner from series

“GP xx sc”.

PARAMETER DIMENSION VALUE

Model - GP 20_18 sc GP 25 sc GP 32 sc

Weight

Main module kg 19.6 19.6

Fuel feeding

kg 8.5 8.5 8.5

19.6

auger

Overall

dimensions

(WхLхH)

Main module mm 250х705х 488

Fuel feeding

auger

mm 184x1520x107

Power supply voltage - L1, N, PE, 50Hz; 230V;

Electrical

consumption

In nominal mode

In ignition mode A 4.5 4.5 4.5

Electrical power W

A 0.2 0.2 0.2

<100

(with ignition)

Electrical protection - IP20

Table 3.3 Recommended fuel parameters.

Pellet burner GP xx sc 7

≥

<

≥

<

≥

<

≥

<

≥

<

PARAMETER DIMENSION VALUE

Pellets diameter mm 6 - 8

Recommended fuel caloricity (low temperature of

combustion)

Wood pellets category according to standard EN

14961-2:2010

Wood pellets category A, AB, B, BC, C, CD, E, EF

Ash content % See tables 3.4 and 3.5

Water content % Max. 8 – 10%

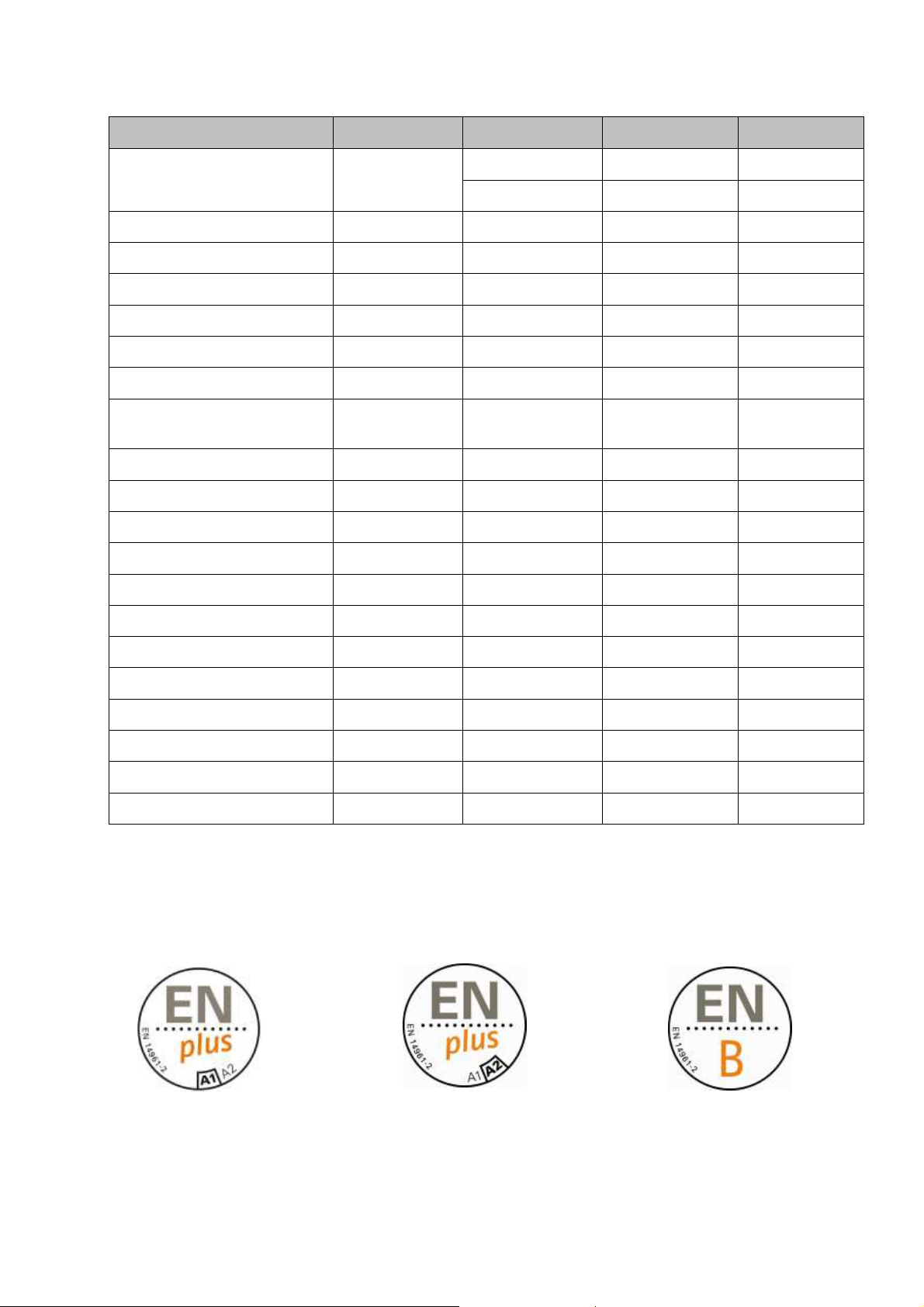

Wood pellets classification, developed and applied by the manufacture company, depending

on their physical properties is presented in table 3.4.

Table 3.4. Wood pellets classification, developed and applied by the manufacture company,

depending on their physical properties.

PELLETS CATEGORY AD DU

A

AB

B

BC

C

CD

D

DE

E

EF

In which:

Ad – ash content as dry mass, %;

DU – mechanical durability, %.

With the adoption of the new EU standard for wood pellets (EN 14961-2) in 2010, a new

certificate ENplus for wood pellets used in domestic hot water boilers has been introduced,

as well as EN-B for industrial pellets used in industrial hot water boilers (Table 3.5). The

ENplus standard defines two quality categories: A1 and A2. The strictest limits for content of

ash in the pellets are introduced in class A1. The ash content in class A2 is up to 1.5%. The

certificate EN-B is applied for industrial pellets with reduced quality requirements.

d

A

d

A

d

A

d

A

MJ/kg >17.2

kWh/kg >4.7

ENplus-A1, ENplus-A2 and Enplus-B

%6.0≤

%6.0≤

%0.16.0 ≤<dA

%0.16.0 ≤<dA

%0.2%0.1 ≤<dA

%0.2%0.1 ≤<dA

%0.3%0.2 ≤<dA

%0.3%0.2 ≤<dA

%0.3>

%0.3>

DU

DU

DU

DU

DU

DU

DU

DU

DU

DU

%0.97

%0.97

%0.97

%0.97

%0.97

%0.97

%0.97

%0.97

%0.97

%0.97

Pellet burner GP xx sc 8

1)

Table 3.5 Wood pellets standard EN 14961-2:2010

PARAMETER DIMENSION ENplus-A1 ENplus-A2 EN-B

6 (± 1) 6 (± 1) 6 (± 1)

Diameter mm

8 (± 1) 8 (± 1) 8 (± 1)

Length mm 3,15 ≤ L ≤ 40 1) 3,15 ≤ L ≤ 40 1) 3,15 ≤ L ≤ 40

Bulk density kg / m2 ≥ 600 ≥ 600 ≥ 600

Caloricity MJ / kg ≥ 16,5-19 ≥ 16,3-19 ≥ 16,0-19

Water content Ма .-% ≤ 10 ≤ 10 ≤ 10

Dust Ма .-% ≤ 1 3) ≤ 1 3) ≤ 1 3)

Mechanical durability Ма .-% ≥ 97,5 4) ≥ 97,5 4) ≥ 96,5 4)

Ash Ма .-% 2) ≤ 0,7 ≤ 1,5 ≤ 3,5

Ash melting point °C ≥ 1200 ≥ 1100 -

Chlorine content Ма .-% 2) ≤ 0,02 ≤ 0,02 ≤ 0,03

Sulfur content Ма .-% 2) ≤ 0,03 ≤ 0,03 ≤ 0,04

Nitrogen content Ма .-% 2) ≤ 0,3 ≤ 0,3 ≤ 1,0

Cuprum content mg / kg 2) ≤ 10 ≤ 10 ≤ 10

Chromium content mg / kg 2) ≤ 10 ≤ 10 ≤ 10

Arsenic content mg / kg 2) ≤ 1,0 ≤ 1,0 ≤ 1,0

Cadmium content mg / kg 2) ≤ 0,5 ≤ 0,5 ≤ 0,5

Mercury content mg / kg 2) ≤ 0,1 ≤ 0,1 ≤ 0,1

Plumbum content mg / kg 2) ≤ 10 ≤ 10 ≤ 10

Nickel content mg / kg 2) ≤ 10 ≤ 10 ≤ 10

Zink content mg / kg 2) ≤ 100 ≤ 100 ≤ 100

1) No more than 1% of the pellets can be longer than 40mm, as the maximum length is

45mm;

2) Defined from dry mass;

3) Particles <3.15mm, fine dust particles, before delivery of the goods;

4) For measurements through “Lignotester” maximum allowed value is ≥ 97.7 mass %.

Logo of ENplus-A1 Logo of ENplus-A2 Logo of EN-В

Pellet burner GP xx sc 9

4. CONSTRUCTION DESCRIPTION OF THE AUTOMATED PELLET BURNER FROM

SERIES “GP XX SC”.

4.1. GENERAL CONDITIONS.

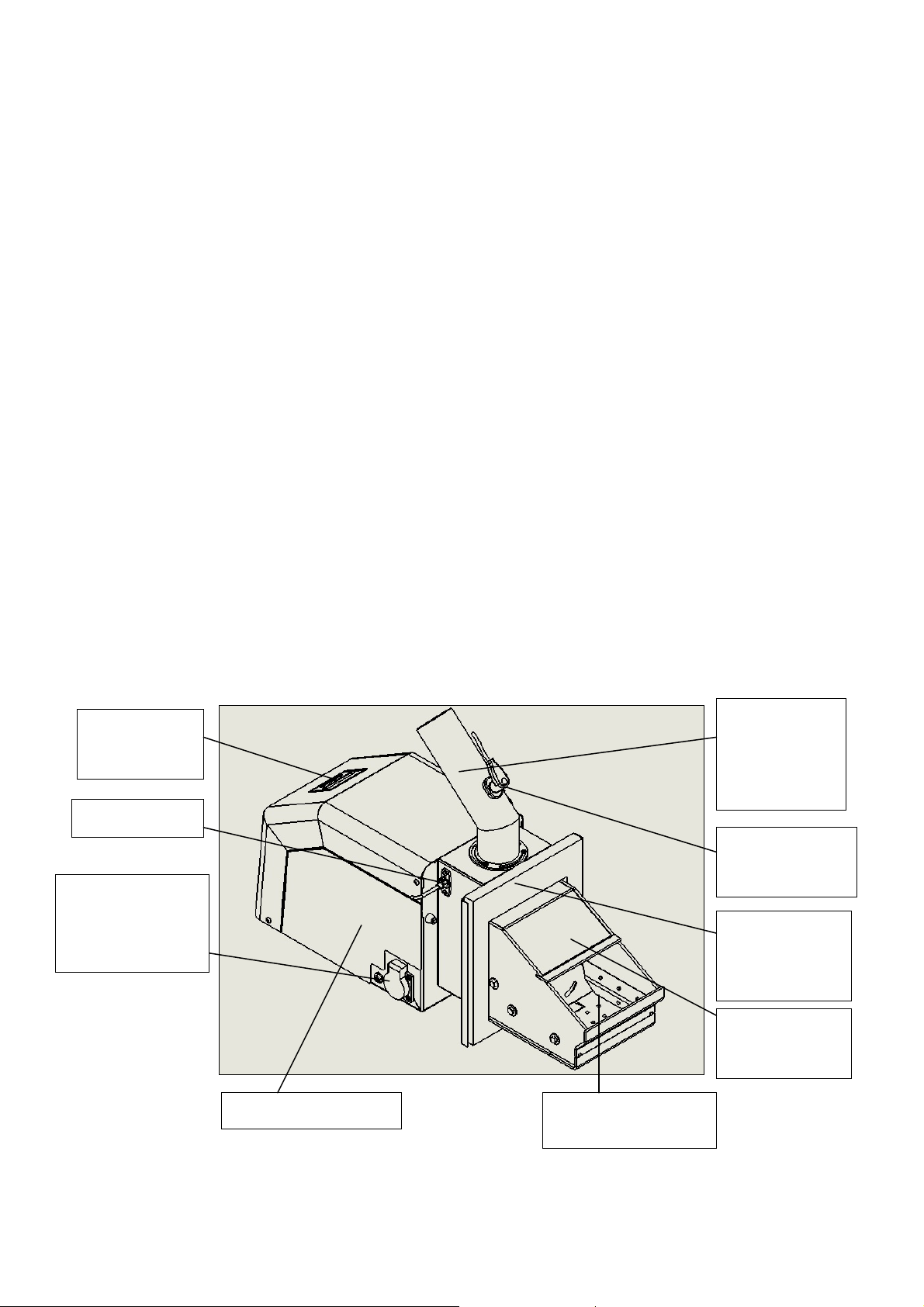

The main part from the construction of a pellet burner from series “GP xx sc” is the main

module, which consists of:

Combustion chamber, which forms conditions for optimal burning process and is

made of high quality stainless steel;

Combustion chamber’s fire-grate;

System for automatic cleaning of the combustion chamber;

Air distribution tract, which provides equal firing air feeding and also cooling of the

burner’s components;

Heating element, which ignites the fuel, positioned under the tilted part of the

combustion chamber’s fire-grate;

Firing air feeding fan, equipped with sensor for controlling of the rotation frequency

and also for adjustments;

Photic sensor, which monitors the burning process, mounted on the burner’s side and

with availability for easy cleaning;

Emergency temperature sensor for protection from the so called “back fire” in the

main module’s pellets feeding pipe;

Control module, which monitors and manages the burner’s operation;

Display panel with keyboard, which visualizes the burner’s operation mode and is

used to perform the necessary adjustments;

Connector for the fuel transport auger, used to supply the auger with electrical power;

Flexible pipe, made of special transparent high temperature resistant material (in

case of fire it does not separate toxic substances), used to connect the auger and the

main module of the burner.

Figure 4.1. View of the main module of a pellet burner from series “GP xx sc”.

Interface panel

(display +

keyboard)

Pellets feeding

inlet pipe to

combustion

chamber

Photic sensor

Socket for power

supply and control

of the transport

auger

Main module housing Combustion

chamber’s fire-grate

Pellet burner GP xx sc 10

Emergency

sensor for “back

fire” protection

Flange for

mounting of the

main module to

an appliance

Combustion

chamber

5. MOUNTING AND INSTALLATION OF THE PELLET BURNER.

5.1. MAIN REQUIREMENTS FOR INSTALLATION OF A PELLET BURNER FROM

SERIES ”GP XX SC”.

The following requirements must be observed during installation of a pellet burner from

series “GP xx sc”:

The burner must be positioned in a way providing enough free space for its cleaning

and maintenance;

The burner must be mounted to appliance (hot water boiler, or other heat energy

consumer) in a way providing availability for easy maintenance and cleaning of the

appliance;

It is not allowed to mount the burner to appliance, which has been installed in living

premises, including corridors;

The installation and mounting of the burner to appliance must be performed only by a

qualified technician;

The installation and maintenance of the automated pellet burner must be performed

by specialized companies which have acquired legal rights for such activities;

The automated pellet burner from series “GP xx sc” must be connected to the

electrical supply installation only by an authorized electrical technician;

Before initiation of the burner to operation, the heat energy consuming appliance’s

operational condition must be checked;

The burner attendance must be performed only by adult persons, which are well

familiar with the appliance’s manual for operation.

The mounting of the burner to a boiler (consumer-appliance) can be performed

through bolts (or studs) and nuts. The tightening of the burner has to be

performed by a tool (for example wrench). It is not allowed to fix it through

handles or others. The fixing and dismounting operations of the burner must be

performed by a qualified person equipped with proper tools.

5.2. INSTALLATION OF THE PELLET BURNER.

The installation of the pellet burner from series “GP xx sc” to appliance requires preliminary

prepared technical project, complying with the acting provisions and regulations:

In case the consuming appliance is a hot water boiler, then the requirements

presented in standard BNS EN 303-5/2000 – “Hot water boilers for central heating

part 5 – Hot water solid fuel boilers with nominal heating output up to 300 kW –

terminology, tests and notifications”, must be observed;

In case the heat energy consuming appliance is not a hot water boiler, then the

requirements presented in the relevant standards for such type of appliances must be

observed;

Fire safety provisions;

About the electrical supply network – BNS EN 60335-1/1997 – “Securing of electrical

domestic appliances”.

When installing a pellet burner to a hot water boiler, please observe the relevant

chimney draught requirements, presented in the boiler’s technical data sheet.

5.3. OVERALL DIMENSIONS OF THE BURNER’S MAIN MODULE.

Figure 5.1 and 5.2 present the overall dimensions of the burner’s main module, which have

to be taken in mind during the mounting and installation of the appliance.

Pellet burner GP xx sc 11

Figure 5.1. Main module’s overall dimensions of a pellet burner from series “GP xx sc”.

Figure 5.2. Overall dimensions of the burner’s main module.

5.4. POSITIONING AND MOUNTING OF THE BURNER’S MODULES.

The main module of a pellet burner from series “GP xx sc” has to be mounted horizontally to

the appliance, which will consume the heat energy generated by the fuel burning. Depending

on the appliance type a technical evaluation has to be performed in advance, regarding the

burner’s main module position, in order to achieve reliable operation, easy cleaning,

maintenance and servicing.

The burner’s main module has to be mounted to the heat energy consuming appliance by

using the attached sealing. The fuel transport auger has to be positioned near to the burner,

in order to ensure the connection between it and the main module through the flexible tube,

through which the fuel transits. It is also recommended that the tilting angle between the

transport auger and the horizontal plane is fixed to 45o, which will provide optimal operation

of the auger’s electric motor and of the burning process.

Pellet burner GP xx sc 12

Loading...

Loading...