Green&Cool CO2Y 50MT, CO2Y 30MT, CO2Y 100MT, CO2Y 75LT, CO2Y 67MT Operation Instructions Manual

...

CCU-CO2Y

Outdoor Type Refrigeration Unit

(Non-fluorocarbon Refrigeration Unit

with CO2 Refrigerant)

– Installation

– Commissioning

– Operating

– Maintenance

Operation

Instructions

Thank you very much for purchasing Green & Cool

products.

Please read this instruction booklet and correctly comply

with the explanations.

In particular, please read “General start up instructions”

(page 4) and "Cautions for safety" (page 5) for ensuring

safe operations.

Please retain this instruction booklet in a safe place.

Registration of your product 3

General start up instructions 4

Cautions for safety 5-7

Components 8

Scope of application 9

Dimensions 10

Handling of the unit 11

Selection of installation location 12-13

Refrigerant piping work 14-15

Refrigerant circuit diagram 16

Electrical connections 17

Control connections 18

Description of the display 19-31

Maintenance 32-34

Warranty 35-36

Table of content

2

G&C CCU CO2Y instruction 2016-11-14

3

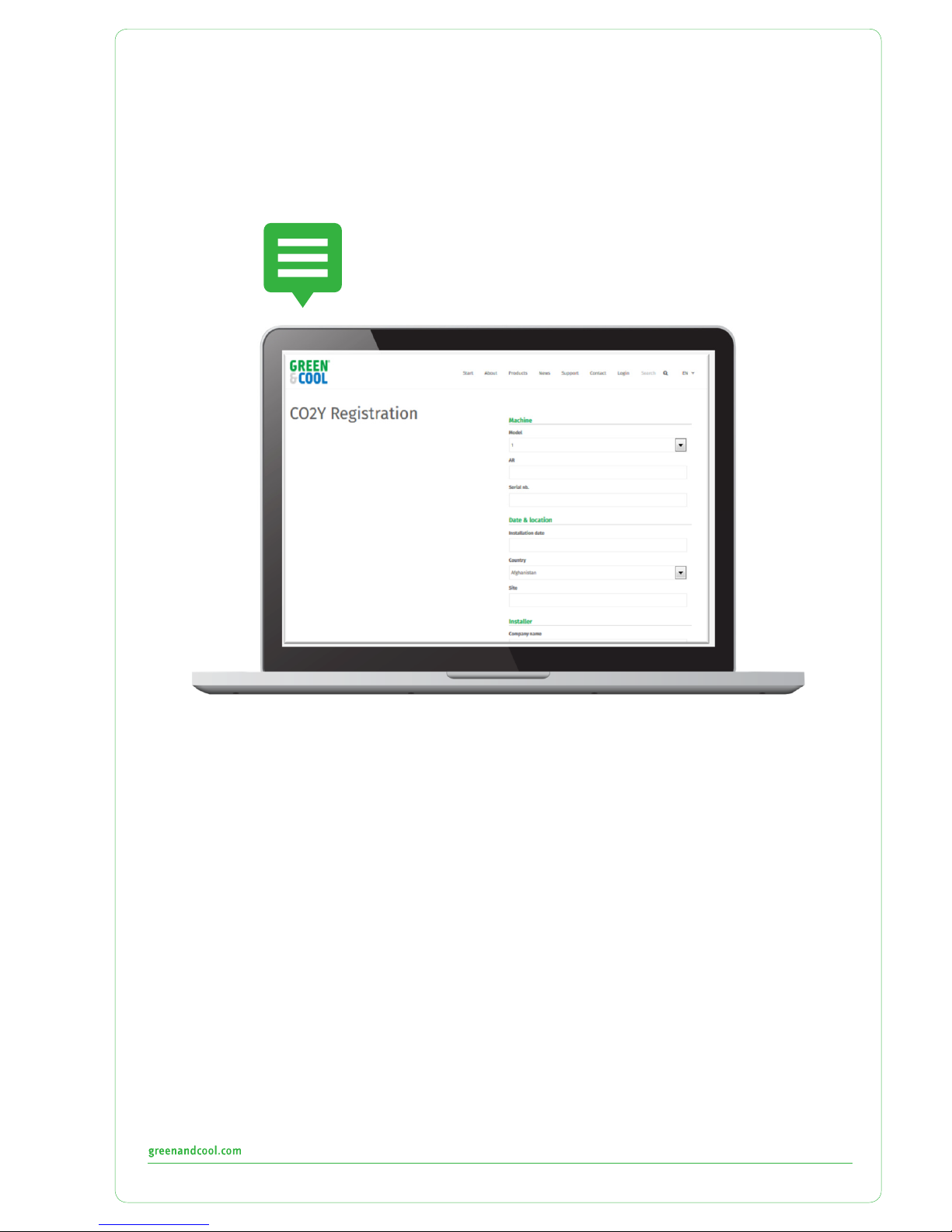

Registration of your CO2Y

Text som beskriver

förfarandet saknas

G&C CCU CO2Y instruction 2016-11-14

4

Evacuation

To avoid inclusion of air or moisture in the refrigerant circuit,

be sure to execute vacuum drying of the entire circuit before

charging refrigerant by using a vacuum pump. Execute

evacuation after securely carrying out airtight/pressure testing.

> When performing vacuum drying, make sure that valve EC1

and EC3 are fully open, please refer to pages 26-27.

Refrigerant Charging

– Calculate the refrigerant charge prior to charging, the system design allows to

a maximum of 3,8L of refrigerant.

– Execute refrigerant charging immediately after evacuation.

– Charge refrigerant R744 (CO2 refrigerant).

– Do not mix with other refrigerant.

– Always use refrigerant grade CO2, moisture content must be below 10 ppm.

Method of Charging

– Close the vacuum valve of the manifold gauge set exclusively for CO2

refrigerant, and separate the vacuum pump.

– To prevent dry ice formation, systems should first be charged with R744

(CO2) vapor to a pressure above the triple point of 4,16 bar.

– Open the joint valve attached to the service piping and Liquid line service

port, and charge liquid state refrigerant.

– Note: Do absolutely not charge liquid refrigerant from the low

pressure side (low pressure service port).

– Avoid overcharging, maximum charging is 3,8 kg

– When the liquid refrigerant no longer goes into the refrigeration unit, close the

liquid line service port and start the refrigeration unit in cooling operation to

adjust refrigerant quantity by charging gas in to the suction line service port.

– After completing refrigerant quantity adjustment, close the refrigerant cylinder

valve and check that the low pressure and high pressure service ports have

been closed.

General startup instructions

G&C CCU CO2Y instruction 2016-11-14

5

As professional, the installer must:

- Define the operating conditions of the refrigeration

equipment under his own responsibility regarding the

design. This device needs to be incorporated in machines

conforming to the Machines Directive. Its commissioning

is only authorized if it has been incorporated in machines

which fully satisfy the legal regulations.

- Complete and adapt these recommendations, if

necessary, by adding other safeties and /or controls

according to the refrigeration equipment’s operating

conditions.

- Have performed all the installing, commissioning and

maintenance operations by qualified professionals and

conforming with standards EN 378, EN 14276, EN

13136, EN 13313, EN 60204 and EN 60335, the EU

directives, the safety rules generally recognized, sound

engineering practice, the local regulations; as well as

those which may be set up, taking into account the

evolution of the technology and the regulations.

- If the installation, the commissioning, the operating, the

maintenance are not realised according to this operating

instructions, the responsibility of Profroid cannot be

involved.

- Completely inform the customer on the control,

maintenance and follow-up of the refrigeration

equipment.

Cautions for safety

G&C CCU CO2Y instruction 2016-11-14

6

The devices are delivered under pressurized nitrogen or dry air (make

sure at reception that material is under pressure by using a pressure

gauge). Respect the standard for transport and handling of pressure

devices.

Install device in a space with sufficient ventilation regarding standards

and regulations because device is under pressure of nitrogen; except

dry cooler, brine air cooler.

Very important: before performing any servicing operation on

refrigeration equipment, the electric power supply must be turned off.

The contractor or the company in charge of the installation shall be

responsible for carrying out the required instructions.

Green & Cool disclaims any responsibility for change(s) or repair(s) on its

devices made without its prior agreement.

The devices are exclusively intended for professionals, for refrigeration

purposes and for their limits of use.

The identification of device and his range of use are written on the name

plate. The name plate is stuck on device. Name plates are located: on the

coil for heat exchangers, on the frame for racks, on the housing for

condensing units, on the receiver for liquid receiver sets and for liquid subassembly. The name plate is joined to this operating instructions (.pdf). The

complete installation must be designed and used not to exceed the range of

use. Device is designed for a maximum ambient temperature of 43°C (as

standard configuration).

The user or operator shall ensure the control and maintenance of the

equipment with qualified professional complying with the instructions below,

possibly completed by the installer. For these operations, the standards and

directives mentioned above remain useful.

This is also available during the stop of the refrigeration installation.

The average life cycle for the design of our devices is of a minimum of 10

years, provided if you follow our operating instructions.

Green & Cool cannot be held responsible in case of violation to the

recommendations of them.

Pipings of Green & Cool D equipment are made with different types :

in copper, standard NF EN 12735

in steel, standard NF EN 10216-2 (type P265GH ; n° 1.0425)

in stainless steel, standard NF EN 10217-7 (type 304L – X2CrNi18-9 ; n°

1.4307)

These pipings must be inspected regularly following standards, sound

engineering practice and local regulations in the country of use.

Some heat transfer fluids can be harmful or corrosive, and their uses must

be realised in relation with their risks, if there is a leak on pipings.

Cautions for safety

G&C CCU CO2Y instruction 2016-11-14

7

– Do not use other than the designated refrigerant (for charging, adding or

recharging)

– Refrigerant gas leak may cause suffocation.

– Piping, equipment components and tools should be appropriate for use

with R744 (CO2 refrigerant).

– Use of unsuitable components or those designed for HFC refrigerant may

cause serious incidents such as equipment failure and rupture of the

refrigerant cycle.

– Securely place the cover on the electrical box and enclosure panel.

Incomplete attachment may lead to penetration of water and living

creatures, meaning potential current leak and fire/electrical shock.

– Do not change the set values of the safety device.

– Using the refrigeration unit with changed values may cause failure of the

safety stop function and lead to a burst or fire.

– When abnormal operation is detected, or before starting disassembly or

repair, turn off the main power switch.

– Specified components must be used for repair.

– Use of non-specified components may cause failure of the safety stop

function and lead to burst or fire.

– Incorrect moving may cause falling or dropping of the refrigeration unit,

and cause injury.

– Request a specialty operator for disposing the refrigeration unit.

– Make sure that access and emergency exit ways are not obstructed to

comply with the local regulations.

Cautions for safety

G&C CCU CO2Y instruction 2016-11-14

8

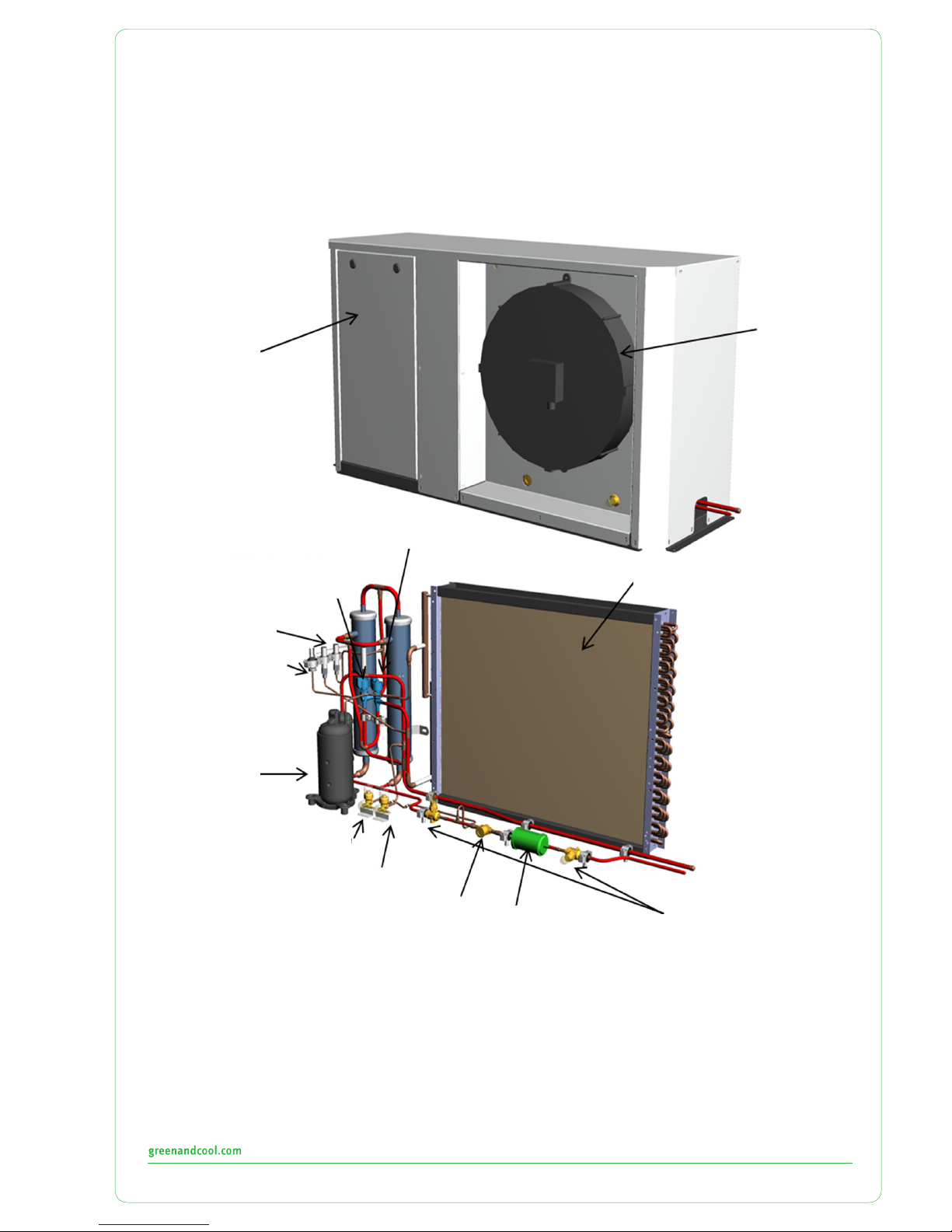

Components

Electrical

compartme

nt

EC1 high

pressure

control valve

EC3 intermediate

pressure control

valve

LP/HP

pressure

transducers

HP safety

switch

Compressor

Suction line service

valve

Liquid line service

valve

Sight

glass

Filter

Drier

Liquid line shut off

valve

Gas

cooler

Fan motor

G&C CCU CO2Y instruction 2016-11-14

9

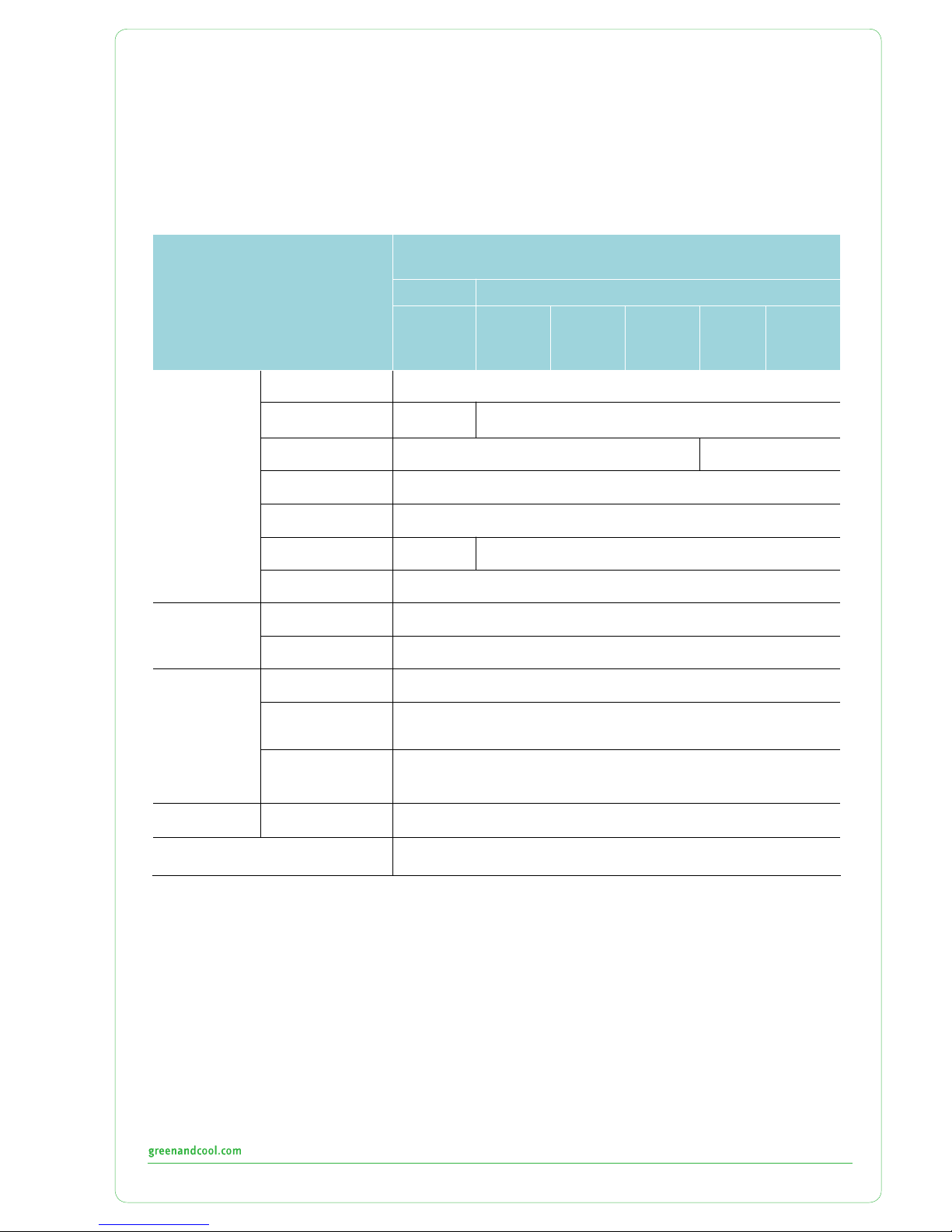

Scope of application

Product

CO2Y Series

GMCC Toshiba

CO2Y

50MT

CO2Y

30MT

CO2Y

67MT

CO2Y

100MT

CO2Y

75LT

CO2Y

167LT

Refrigerant

system

Refrigerant R744

Oil type

PAG

PZ100S

PAG oil VG100

Evaporating

temperature

-20°C to +5°C -32°C to -20°C

Suction

superheating

20K or below

Discharge gas

temperature

+120°C or below

Inverter operation

40–100

RPS

25–90 RPS

Nominal Revolution 70 RPS

Ambient

Temperature -15°C–42°C (the ambient temperature can be -30°C if EC fan is installed)

Relative Humidity 10%–90%

Optional:

Water system

(applicable for

liquid-cooled

condenser)

Inlet liquid

temperature

-8°C to 38°C (nominal +7°C / +12°C

Liquid mass flow Variable according to capacity.

Pressure loss in the

liquid side for the

BPHX

30 kPa or below

Vibration Velocity 20 mm/s and below

On/off cycle period 5 min or longer for on/off cycles

G&C CCU CO2Y instruction 2016-11-14

10

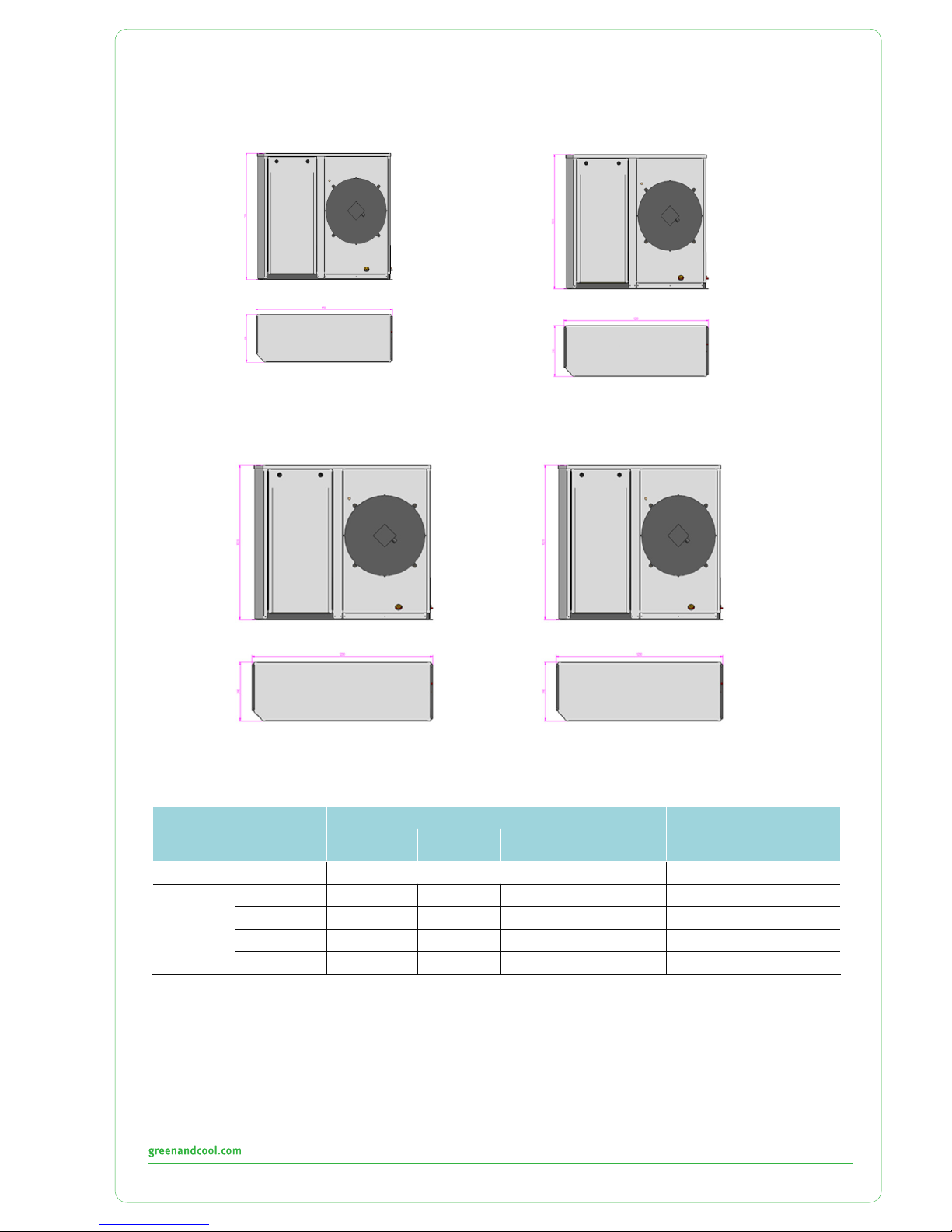

Dimensions

CO2Y MT series air cooled CO2Y LT series air cooled

CO2Y 30MT

CO2Y

50MT

CO2Y

67MT

CO2Y

100MT

CO2Y 75LT

CO2Y

167LT

Fig 1 Fig 2 Fig 3 Fig 4

Dimension

s

Length (mm) 1190 1190 1190* 1190* 1190 1190*

Width (mm)

390 390 390 390 790 790

Height (mm)

1028 1028 1028 1500* 1028 1500*

Weight (kg)

125* 130 160* 185* 185* 210*

Fig 1 Fig 2

Fig 3

Fig 4

*prel.

G&C CCU CO2Y instruction 2016-11-14

11

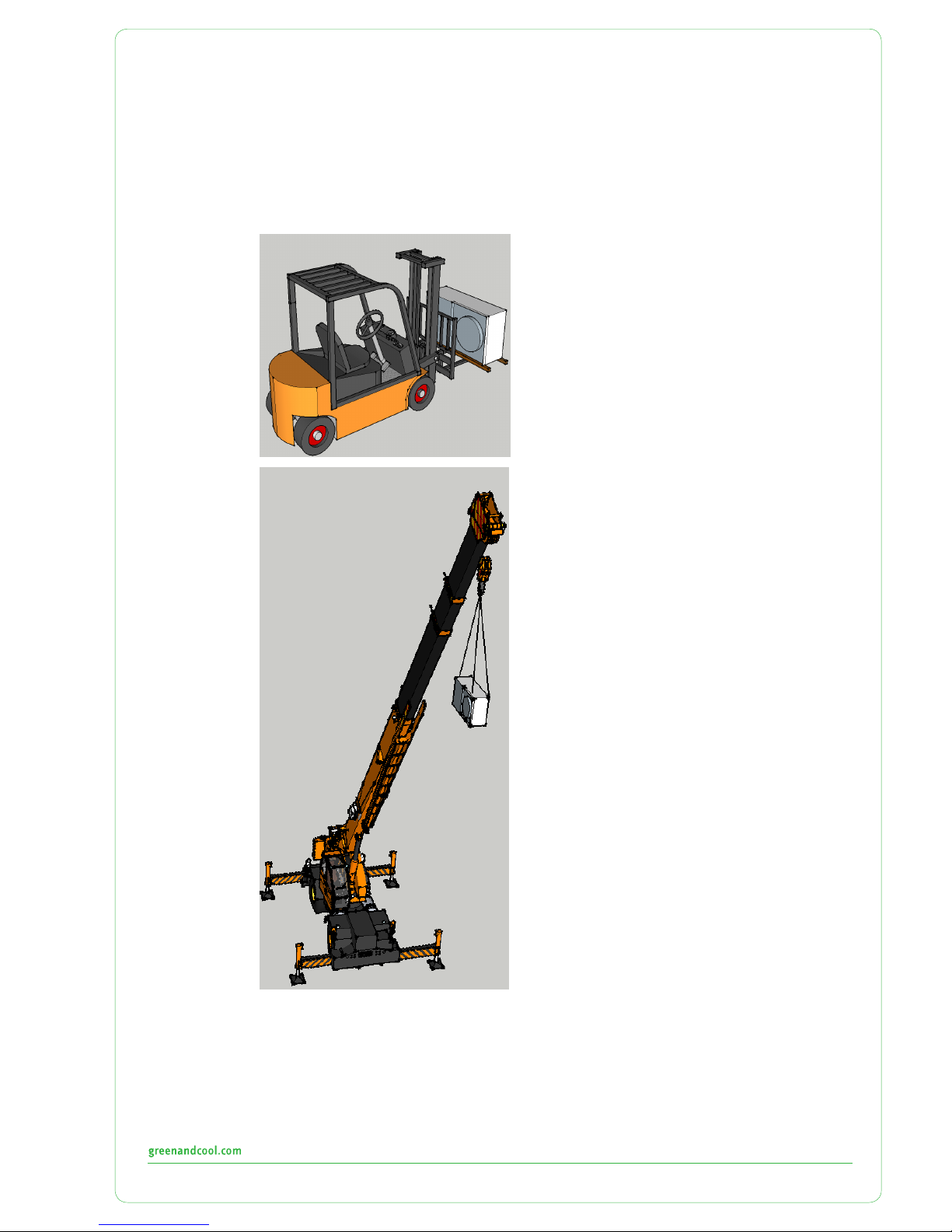

Handling of the unit

- Make sure that the equipment or

its accessories have not been

damaged during shipping and no

parts are missing.

- Carry the refrigeration unit gently

by keeping the vertical position

as much as possible.

- Absolutely avoid a lay-down

position of the refrigeration unit.

The loading and unloading

operations must be performed

with adequate handling

equipment (forklift, crane, etc.)

using possible lifting points

provided for this purpose.

- The qualified professional should

be certified and will wear

individual safety equipment

(protective gloves, glasses,

safety shoes, etc.) ; operators will

never circulate under the load

during lifting operations.

-

FORKLIFT

- When carrying the refrigeration

unit by a forklift, use a packaging

wood base or pallet for

maintaining the refrigeration unit

in the vertical position.

CRANE

– When carrying the refrigeration

unit by a crane, use a packaging

wood base or pallet for

maintaining the refrigeration unit

in the vertical position.

– Make sure that the unit is safely

secured to the lifting straps.

– During handling, the operator will

ensure a good balance to prevent

the equipment from swinging.

Carry-in Operation

Loading...

Loading...