Greencare DB1J 13, DB1S 13, DB1S 16, DB1S 15, DB1S 17 User Manual

...

Models covered DB1J 13

DB1S 13, 15, 16, 17, 18.

DB1L 15, 16, 17, 18, 19, 20, 22.

DB1XL 20, 22, 24

Introduction

Preparing the wheelchair for use

Opening the wheelchair

Closing the wheelchair

Setting up Footrests

Setting up Brakes

Setting up Armrests

Setting up Wheels

Using the wheelchair safely

General advice and routine user maintenance

Getting in and out

Getting in occupant standing forwards

Getting out occupant standing forwards

Occupant side transfer

Outdoor Visibility

Using the wheelchair safely with heavy occupants

Handling heavy occupants

Build specifications for heavy occupants

Getting around safely and environmental features

Planning a trip

Dealing safely with kerbs

Safe slope

Use of castors

Use of accessories

Use of anti tippers

Use of cushions

Fire Precautions

Use of hand rims and tyres

Use of seatbelts (also posture belts)

Transporting the wheelchair in a vehicle

Transportation with occupant in a vehicle.

Use of four point tie downs and occupant restraints

User Safety Routine Checklist

Technical Data Dimensions

Warranty

GREENCARE DB1 – USER INFORMATION

This information is intended for wheelchair users,

occupants or carers. It is also a useful reference

for service professionals who are prescribing or

handing over a wheelchair to a user. Guides are

issued with serial numbers when supplied with a

chair, and also for information with an accessory.

The Greencare DB1 Wheelchair is intended to

provide mobility for people who are unable to

walk. This guide is for all users. The information

provided is intended to help users understand the

wheelchair, and get the best performance out of it

in safety. Different users may have specific

requirements relating to them individually and

their environment, both indoors and outdoors.

Greencare wheelchairs are built specifically to

meet the needs of individuals who have been

assessed by clinical professionals. Wheelchair

service staff responsible for handing over a

wheelchair to a user should explain its operation

and compatibility with other equipment as

necessary. Occupant transfers in and out of the

wheelchair, and accessibility within the intended

environment should be triale d, and the

wheelchair adjusted accordingly.

Greencare component system modularity allows

a chair to be fine tuned at handover, or

subsequently after a trial period by a trained

wheelchair technician. Greencare staff are

available to assist with assessments and

handovers. Users should take time to read and

understand the wheelchair information before

use. User s sh ould understand how the

wheelchair is intended to function for them and

their responsibilities for its safe use and

maintenance. A wheelchair used and maintained

correctly should last 5 years or more.

A service checklist is included in this guide for

user reference. Recommended frequency of

service checks by a wheelchair technician

depends upon an assessment of usage and

environmental factors. For heavy frequent use a

check every 6 months is recommended. For

occasional use, a check every 36 months is

adequate. Where appropriate the recommended

service interval will be advised. If in doubt users

should contact their local wheelchair service.

Our website www.greencaremobility.co.uk has

downloadable copies of User, Assessment and

Technical Service guides.

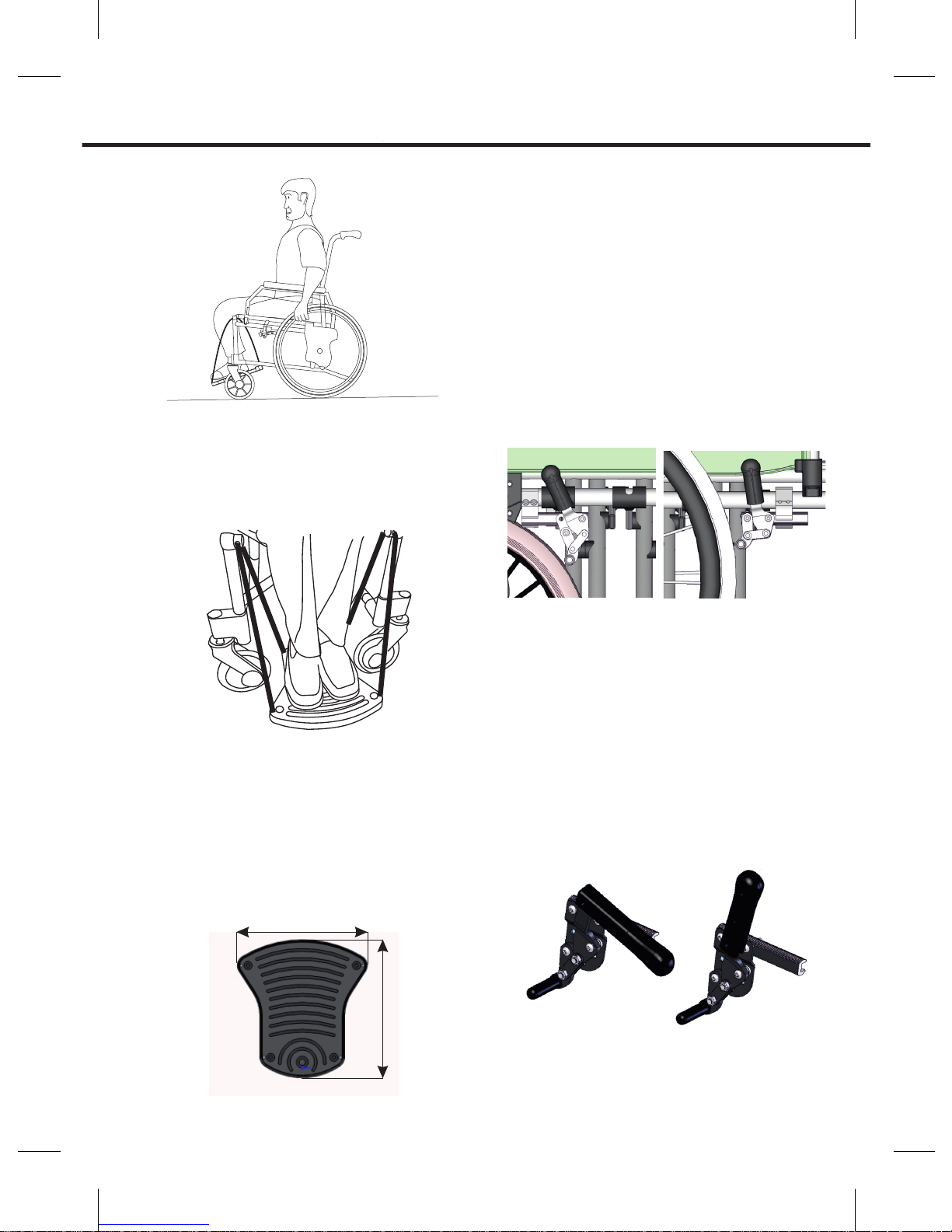

Mobility

Thank you for choosing a Greencare DB1

Wheelchair.

An advanced stylish modular wheelchair, with

build options for occupant and attendant

control. When received, it will have been built

to order with fittings to meet an assessment of

your need.

Please take the time to read all the information

provided, and take care that all information is

kept safe for future reference

The wheelchair description code and batch

date are on a label on the rear cross brace.

This can be read from the back of the chair.

Each wheelchair has its own specific

identification code serial number .

The serial number is a unique identification

reference and is important in the provision of

spares, and for advice regarding your specific

wheelchair

Serial number of this chair is as indicated.

Other important information can be found on

labels secured to the wheelchair, or provided

with accessory items, such as a cushion, are

additional guidance..

Labels should not be removed. Users are

responsible for ensuring that this product is

maintained and used safely and correctly.

Users requiring more specific advice about the

DB1 wheelchair, or who need more information

about other products from Greencare, can

c o n t a c t t h e G r e e n c a r e w e b s i t e

www. greencaremobility.co.uk

For technical service or repair users should

co ntact their App roved Distributor or

Wheelchair Service Centre.

Please dispose of packaging responsibly.

Introduction

1

PREPARING THE WHEELCHAIR FOR USE

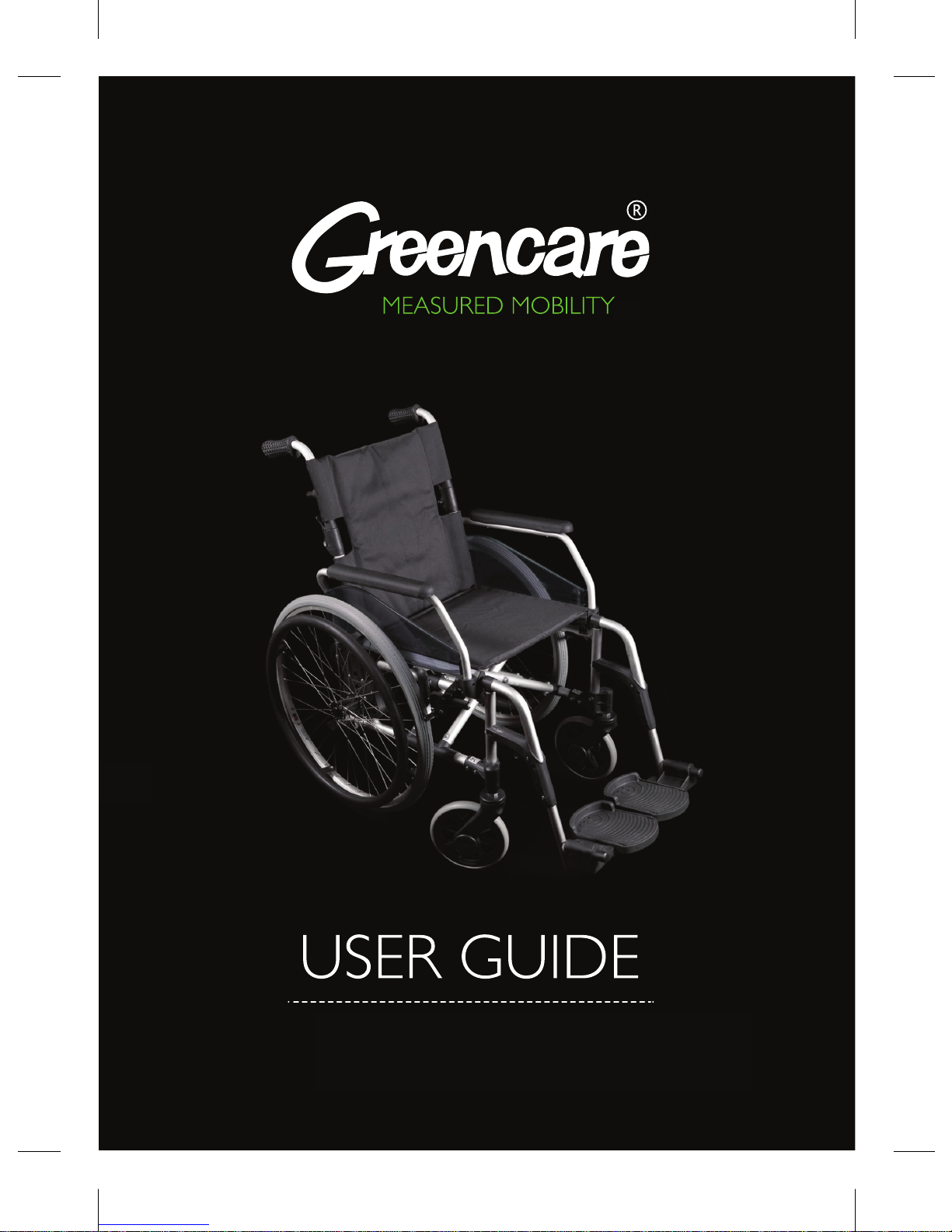

Opening the wheelchair

Grip the armrests and push them apart as far

as possible. This may be easier by tilting the

wheelchair sideways slightly, so that the

wheels on one side are clear of the ground.

Put hands on the seat canvas with fingers

pointing into the middle of seat. Push down

and out, with the flat of the hand on the two

sides of the seat, until the chair is completely

open.

The Greencare frame is positively located in

the open position. Press down on the seat

rails and you will feel the frame going into

the final open position. This positive open

lock makes the frame rigid, the seat position

comfortable, and also enables more

effective maneuverability and control.

The Greencare DB1 backrest is available

optionally as a non folding, or folding frame

tube. If a none folding version has been fitted,

the lifting weight of the frame is slightly less,

but the chair will not fold down to the most

compact size. Subsequent changes in

method of use may mean a change of

backrest specification to the other option.

Modularity of build will allow this.

When fitted with a folding backrest, the upper

push handle section will be folded down at the

back of the wheelchair frame. To raise the

backrest, lift the push handles. Backrest

latches on each side will click into position

when the push handle is fully up, provided that

the back brace tension is released. When the

backrest catches locate, push down on the

back brace to tension chair back.

DB1 has the option of an integral lightweight

easy folding cushion support backrest or

tension adjustable cushion support backrest

upholstery. The type provided will be based

upon the assessment of your need.

For occupant comfort and support the backrest

has an additional folding comfort brace. This

unit operates on the over centre lock principle.

It will need to be pressed down in the centre, to

lock out, before the occupant sits in the

wheelchair. Carers should take care when

closing this brace, keeping fingers away from

the closing surfaces, because it locates quickly

to lock out.

The tension adjustable backrest has a support

back cushion supplied separately. when the

chair is packed in its carton. This cushion

should be attached to the inner tension strap

support frame by Velcro.

The tension back support requires to be set up

to conform to the required shape. This should

be set up for you at handover, when the chair

frame has been opened.

Finally push the lower back flap upwards and

under the seat so that the Velcro engages to

close and secure the seat fabric assembly

If a separate seat cushion is provided, as part

of the final specification it should now be

placed in position on the seat (see page 16)

2

Closing the wheelchair

For transit and storage, foot plates should be

swivelled upright, or detached. The footplate

has an inbuilt friction grip which retains the

upright position when folded.

Release the Velcro flap securing the back

support to the underside of the seat. For some

users this operation may require more effort

than expected because velcro is such a strong

connection. Where ease of operation is a

priority, the velcro flap may be left to hang down

without attaching.

The back support upholstery options as shown

on the previous page, affect wheelchair folding.

The thin lightweight integrated back cushion

support, can be conveniently folded.

The thicker more supportive back cushion is

attached by Velcro to inner tension adjustable

support frame straps. This thicker cushion

increases the folded width, and if the storing

space available is limited, it is recommended

that this thicker cushion is removed for folding to

the minimum size.

The comfort locking brace assembly keeps the

backrest tubes in line when the tension straps

are set. This reduces backrest deflection, under

tension pressure and occupant load. This brace

has a central folding feature, which should be

lifted to release when folding.

Backrests may be built with specially re enforced

components for very heavy occupants or those

who create excessive pressure.

On folding backrest models, press down the

latch lever at the back of the hinge. This releases

the backrest locking pin.

To fold the frame, grasp the middle of the seat

canvas at the front and back, and give a sharp

pull upwards. The frame will release from its

location, and the two sides will start to come

together.

PREPARING THE WHEELCHAIR FOR USE

Press the armrests inwards until the chair is

fully closed.

A Velcro secured closing strap is provided at

the top of the pushing handle to keep the

wheelchair in the folded closed position.

This is particularly useful when the tension

adjustable assembly with the thicker back

cushion is left in place when the wheelchair is

folded. This strap should be wrapped around

the opposing push handles to keep the chair

frame from accidentally re opening.

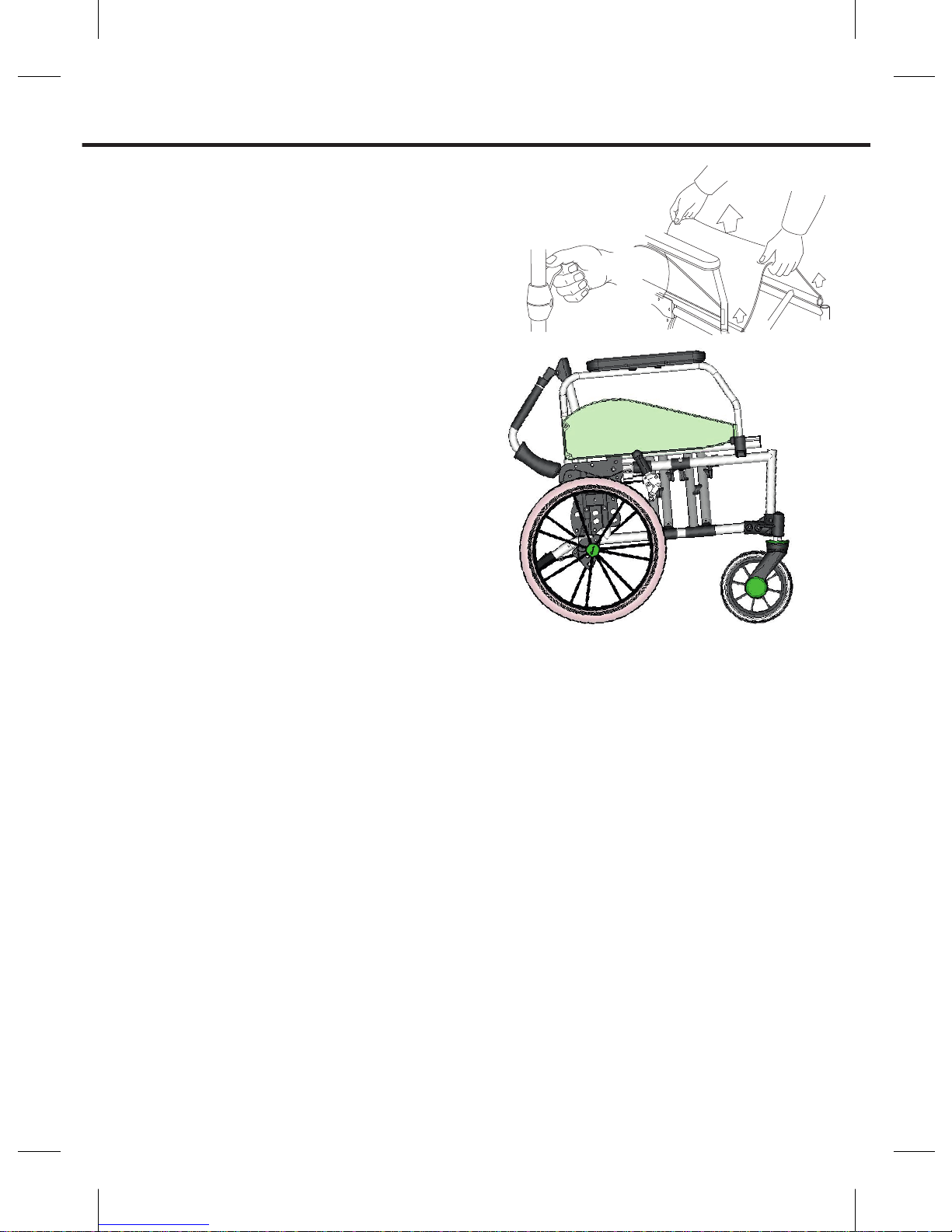

On occupant-propelled wheelchairs, the QD

(quickly detachable) wheels can be removed

to further reduce the individual component

size, or reduce the weight for lifting.

Make sure that the folded wheelchair and

detached components are stored securely

and available for next use.

3

PREPARING THE WHEELCHAIR FOR USE

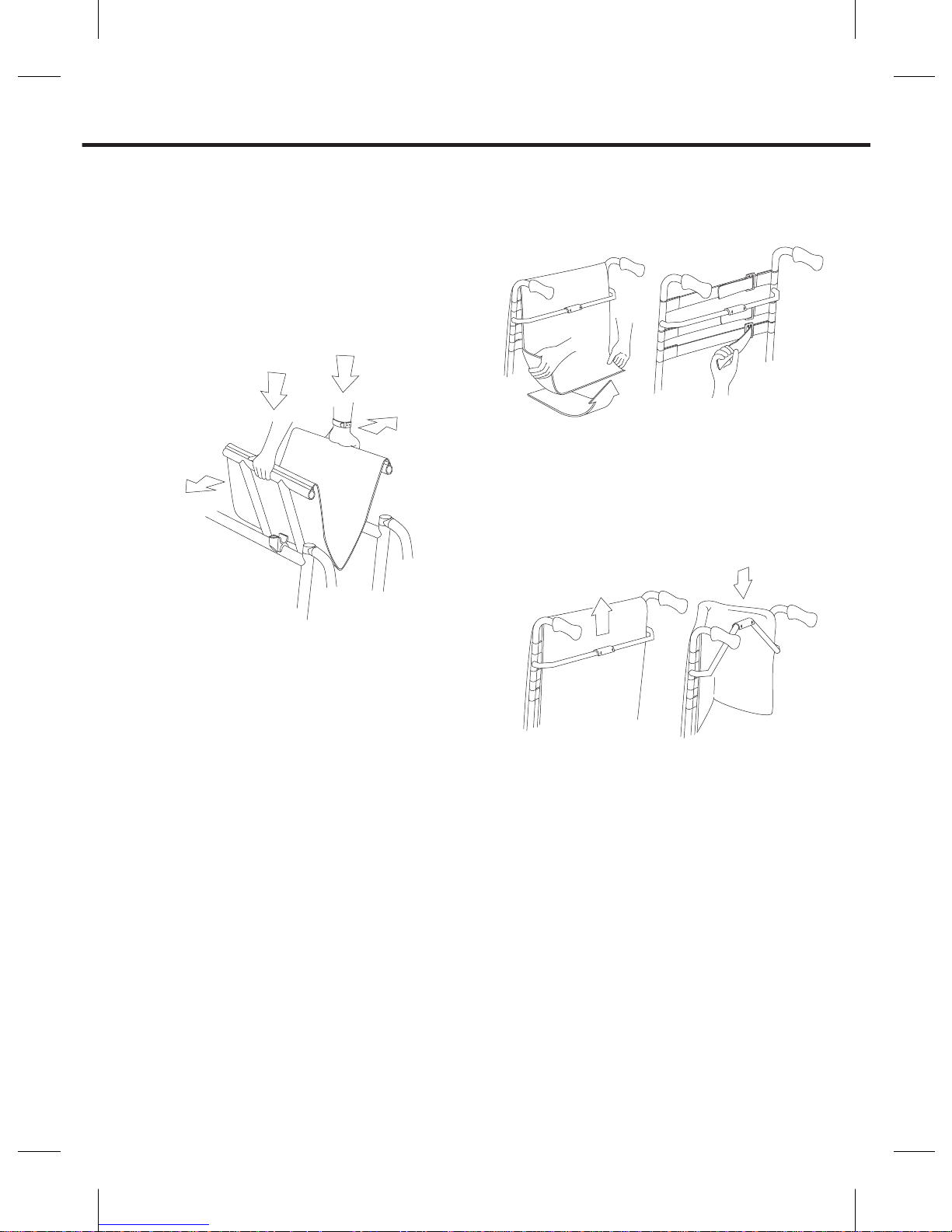

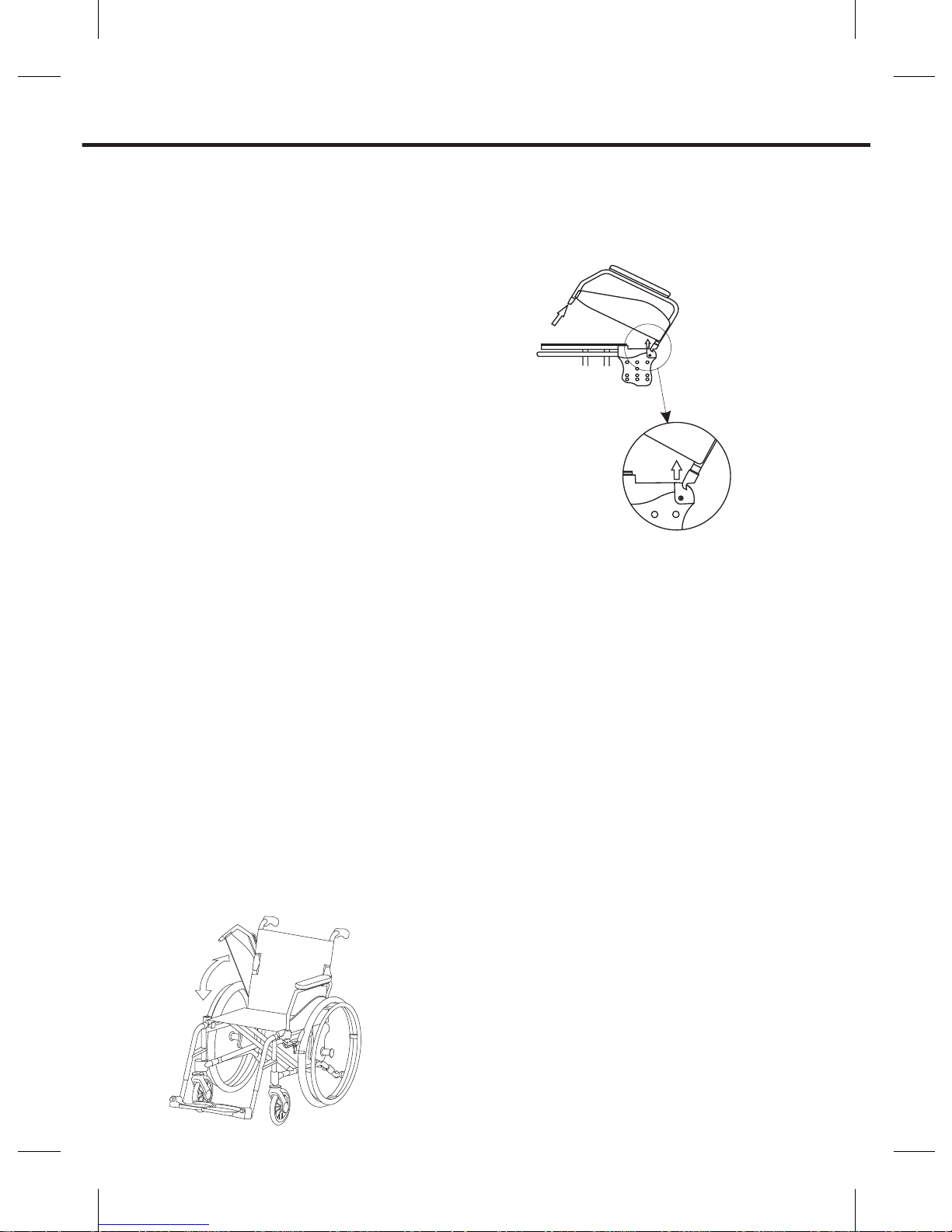

Setting up Backrests

Backrests are built according to occupant

measurements and assessed requirements.

They may include specially reinforced

components for heavy occupants or those

who create excessive pressure.

Backrests may be foldable, with a hinged

push-handle which automatically locks into

place when the back is lifted to the occupant

supporting position. A folding back will allow

storage in a car boot or small space.

When a chair is specified as needing specific

storage requirements, this should be

checked at the handover to ensure

equipment compatibility. Rigid backrests are

suitable when the wheelchair is not stored in

a small space.

If the wheelchair is to be used in transport,

accessibility to this should be checked at

assessment and handover to ensure

equipment compatibility. Backrests can be

supplied to meet occupant requirements with

a range of different support angles. When an

adjustable reclining backrest is fitted, it

allows the carer to set the backrest to a

required occupant support position.

On reclining back chairs the backrest angle is

cable controlled by operating levers on the

push handles. The support height of reclining

backrests will normally have an extension to

the level of the occupants head, according to

assessed need.

Backrest extensions are integrated into the

backrest build and located on special upper

frame tubes. They are supplied with

adjustable tension straps and separate

cushioning of similar construction to the main

back support upholstery.

When the occupant is reclined, weight distribution

reduces the rearward stability of the wheelchair.

As a build standard, rear wheels will be set in the

most stable position, usually with anti-tip

stabili sers. With the backrest rec lined,

manoeuvrability is more difficult for the carer.

A situation in which frequent removal of the head

support extension is required is in vehicle

transportation. In this application an extended

head support may be inconvenient for other

aspects of normal use, because it restricts

visibility and communication for general use. In

such cases the backrest extension will be

removable, with a separate option of individual

push handles, which can be located at the

required pushing height by adjustable fixings. The

separate backrest components should be safely

stored when not in use.

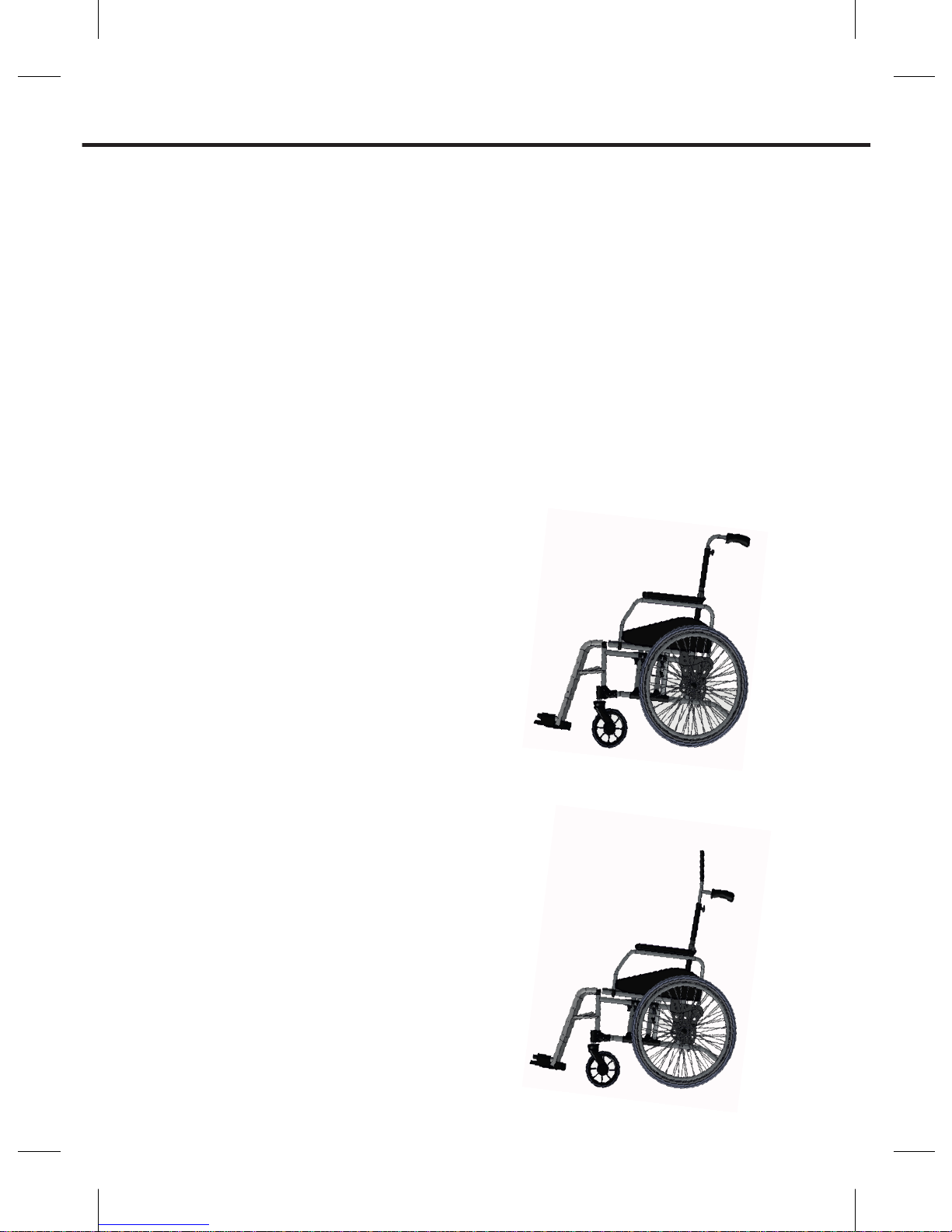

These illustrations show chairs with and without a

backrest extension.

4

PREPARING THE WHEELCHAIR FOR USE

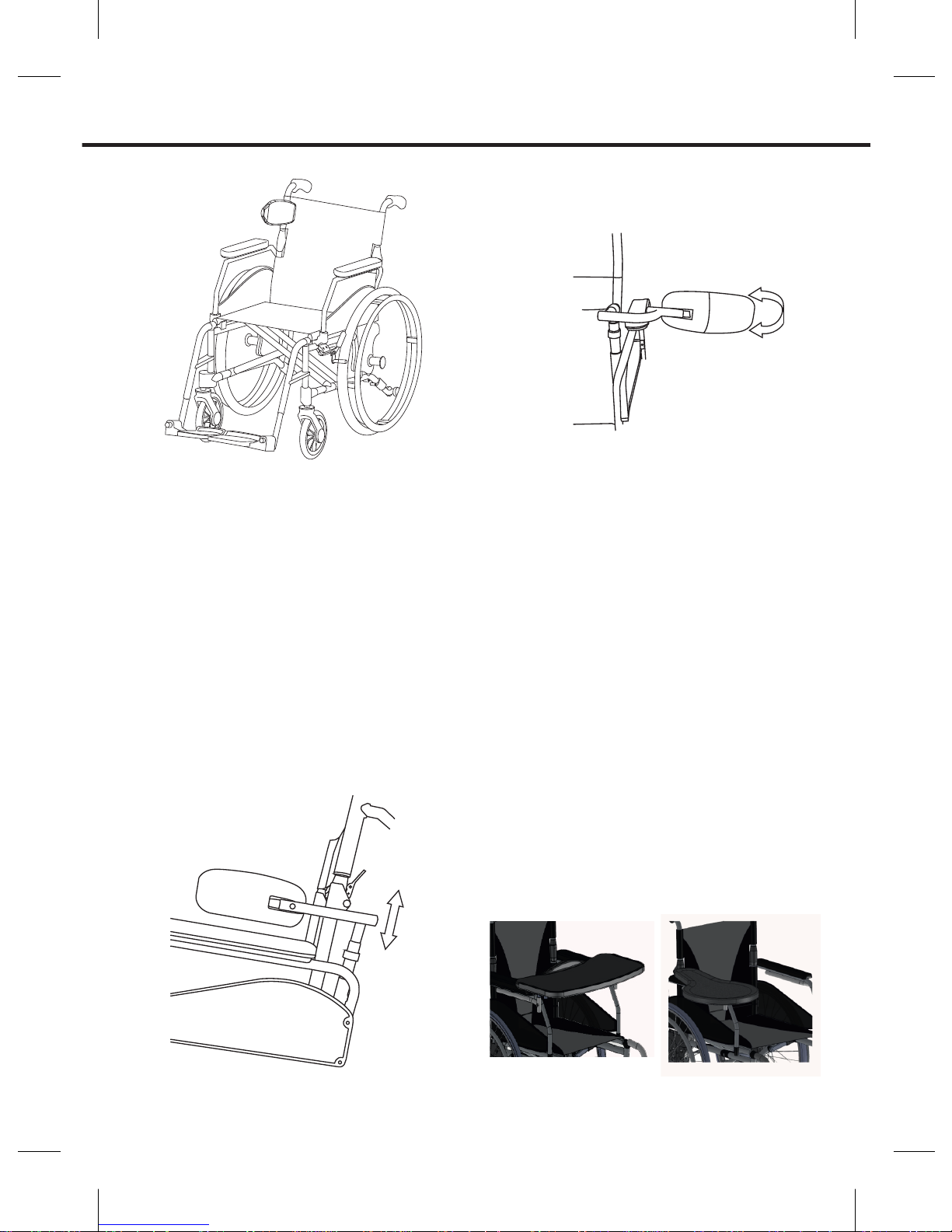

Setting up the Footrests

The chair that you have been supplied with

will have a footrest specification configured

to meet your assessed needs. Environment

of use and functional operation determine

the final specification required.

In addition to the configurable foot support

plates, shown opposite, Greencare DB1 has

a choice of detachable footrest brackets, and

footrest support options including an angle

adjustable type a rigid foot bar and a dynamic

foot support for use in tight spaces

The lift and swing type bracket features a

double locking action for increased security.

The frame location stud for this is also

smaller when footrests are removed for

transfer. The swing type bracket swivels into

position and releases with a single touch,

these are easier for the occupant.

To attach the footrest brackets, locate the

upper pivot spigot in the top of the front frame

tube, press down or swivel to locatet in the

forward facing position. To release depress

the trigger on the underside of the mounting

support feature. Footrest brackets should be

swivelled away or removed for occupant

transfer. It is possible to pivot the footrest

bracket inwards or outwards depending on

the user requirement. Footrest brackets

should normally be removed for storage.

For complete footrest bracket removal,

continue to lift so that the upper pivot clears

the front tube location. When removed, place

the footrests carefully in a safe position ready

for the next use.

Lateral position, height and the angle of footrest

support plates on the Greencare DB1 wheelchair

are adjustable. This is set by means of three fixing

screws on the underside of each unit. Each DB1

footrest has a choice of three alignment positions.

This will normally be set to meet user need, with

the central gap between footrests minimized,

when the wheelchair is handed over. It is possible

to adjust footrest height and position, if .

A jacking screw at the end of the footrest bracket

stem adjusts the sideways angle of the footplate.

When unloaded this will be slightly upward facing.

It is normal for this to deflect under foot pressure,

and it can be adjusted to be horizontal by this

screw

The foot support plate height is adjustable by a

range of fixing screw positions, and a series of

threaded holes in the inner stem. Using this

combination of holes, the footrest can be aligned

and tightened in its location.

Footrest height settings are important. A correctly

set footrest height will help to spread the load of

the occupant weight, easing pressure, and

improving the comfort.

The most comfortable seating position is usually

obtained when the occupant thighs are horizontal

and the hips and knees are at right angles.

Footrest adjustments should be explained and

completed at the handover.

Footbar

As an alternative to separate type foot plates it is

possible to fit a foot bar. This is a telescopic frame

that fits into the footrest brackets and locates as

previously described for the footrest. When fitted,

the front of the chair becomes compact and is

more manoeuvrable.

Dynamic Footboard

This is an option for indoor use in a compact

environment like a kitchen. It is an option that can

be fitted or removed as and when required. The

dynamic footboard is suspended by cables set to

measurements from the assessment. It allows the

occupants to be able to get closer to objects like

sinks, tables and etc.

5

PREPARING THE WHEELCHAIR FOR USE

Setting up Brakes

The Greencare brake unit is a toggle action,

requiring operation of a handle on either side.

Brakes should exert sufficient pressure on tyres

to hold the chair on an 8-degree slope. This test

is not a usage recommendation. (Read section

on outdoor safety.)

Brake shoe action of pressing onto the surface

of a pneumatic tyre, requires the tyre to be fully

inflated to the correct operating pressure of 3

bar. Puncture free tyres have a constant

pressure.

When correctly set, brakes should be easily

operated by occupant or carer, as required. A

build option with an extended brake handle is

available to reduce the operating effort.

This extended handle unit can be set up rigidly

or to allow folding down if handle height

reduction is required for side transfer.

When the extended handle is set for folding

down, care should be taken to ensure that it is

returned to the upright position for operation.

Handle options can be fitted retrospectively if

user needs change.

6

It also helps with moverability in confined

spaces, which with the standard footrest

would not be possible.

The dynamic footboard comes in one size but

is able to fit most foot sizes comfortably. The

height is set to length by the suspension

cables and will be made to suit the user of the

wheelchair. The footrest angle can also be

adjusted by fixing the cable length shorter or

longer, front to rear, and this can be held with a

grub screw.

287mm

308mm

PREPARING THE WHEELCHAIR FOR USE

The range of wheel positions on the

Greencare frame system require brake

settings to suit wheelchair configuration.

Brakes are clamped in position on the frame.

Position of the clamp can be changed using a

hexagonal Allen key. The brake clamps

incorporate safety grips to maintain the set

position during use. Users should frequently

check that the brake is positioned effectively.

Brake adjustment may be carried out by a

competent person/carer if technical service

support is not available.

Lubrication of the brake mechanism, with a

none toxic lubricant will maintain effective

operation over a long period of use. Lubricant

on the operating face of the brake contact

shoe should be avoided.

Cable operated brakes with levers on the

pushing handle are an additional option to

allow attendant to slow down the chair without

having to reach for the brake handle. Holding

back the speed when going downhill is an

increasing benefit as the occupant weight

increases. It is a recommendation on 150Kg

and 175Kg occupant chairs.

Setting up Armrests and Supports

Armrests are latched at the front of the frame,

in socket locations, and pivoted at the rear of

the backrest location. They can be released at

the front and pivoted upwards and back for

transfer in and out of the chair. They are not be

removable from the chair unless specially

adapted for this purpose.

7

can be made detachable , which can help with

the compactness of the wheelchair and also in

side transfer (see page 11)

The armrest is removed by releasing the latch

and pivoting on the rear of the arm rest. When it

reaches a 30 degree angle the armrest will

release vertically and can be removed.

When not in use for transfer, armrests should be

fully located in the front socket at all times. An

armrest that is not fully located is prone to

accidental damage.

The front socket has a quarter turn feature that

releases the armrest. The armrest can be

swivelled back into the front socket, where it will

latch into position automatically.

The armrest should be secured in position at all

times. It is not recommended that the armrests

are grasped by the attendants to lift the chair

and occupant. Heavy lifting operations should

be avoided.

Thoracic supports are also available, these

positioning accessories are most often used to

improve occupant side stability and balance.

They can also ask as tactile reminders, to allow

the occupant maintain optimised posture.

If needed for a special purpose, the armrest

PREPARING THE WHEELCHAIR FOR USE

The adjustable thoracic support pads can

offer a wide range of vertical, lateral, depth,

and angle adjustments, while providing

excellent anterior as well as lateral support.

they are also contoured for a natural fit.

It is usual to fit thoracic supports with a none

folding back. When a folding back is fitted the

height adjustability of the thoracic pad position

is restricted.

The thoracic support should not interfere with

the occupants comfort. The support pad can

be raised and swung away during transfers.

8

The thoracic supports can be used singly or as

a pair depending on the users needs.

Greencare support pads are manufactured in a

wipe clean durable material. They should be

kept clean using a mild detergent

Greencare side panels my be produced in a

semi transparent grade of structural plastic,

which has some flexability or rigid aluminium as

determined by the assessment. They should be

kept clean using a soft damp cloth, and mild

detergent. They should not be rubbed with an

abrasive pad.

The Greencare wheelchair has the possibility

to fit an arm pad safety option, Armalight. This

unit has an integral chargeable lighting system.

Tray Supports

The adjustment of support pads positions may

be done at the time of handover.

Loading...

Loading...