Green Air Products CO2 Generator User Manual

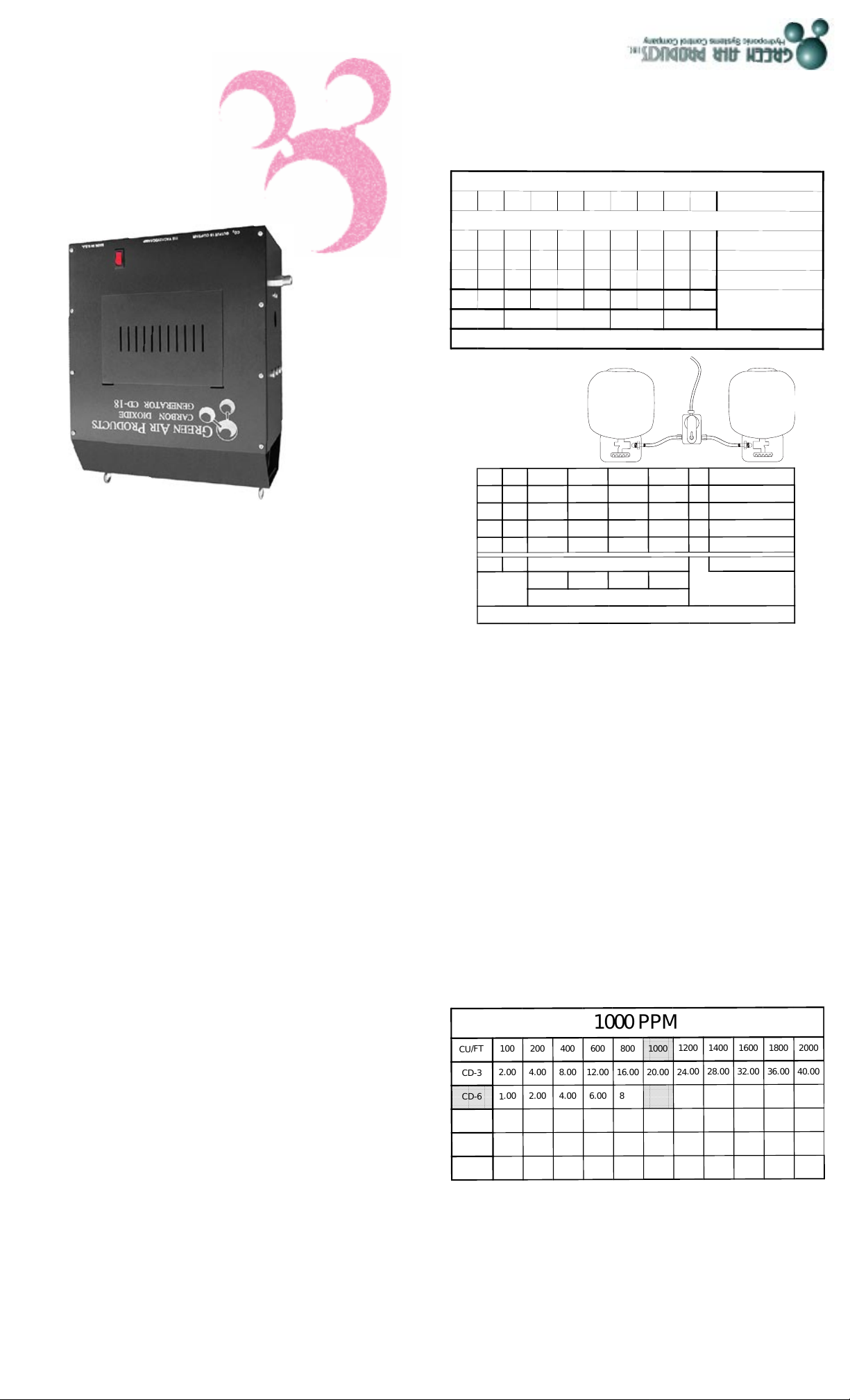

CO2 GENERATOR FUEL CONSUMTION CHART

PROPANE CONSUMPTION

CU.FT. / HR.

PROPANE TANK SIZE

G

E

N

ER

A

T

O

R

O

U

TPU

T

1

5

10

25

MODEL

HOURS OF OPERATING TIME

M

A

X

BT

U

/H

R

C

U

.FT

.

C

O

2/H

R

CD-3

1

36

180

360

900

2183

3

CD-6

2

18

90

180

450

4366

6

CD-12

4

12

60

120

300

8732

12

CD-18

6

6

30

60

150

1310

18

CD-36

12

3

15

30

75

2620

36

Generator

1000 PPM

CU/FT

100

200

400

600

800

1000

1200

1400

1600

1800

2000

CD-3

2.00

4.00

8.00

12.00

16.00

20.00

24.00

28.00

32.00

36.00

40.00

CD-6

1.00

2.00

4.00

6.00

8.00

10.00

12.00

14.00

16.00

18.00

20.00

CD-12

.50

1.00

2.00

3.00

4.00

5.00

6.00

7.00

8.00

9.00

10.00

CD-18

.33

0.66

1.33

2.00

2.66

3.30

4.00

4.66

5.33

6.00

6.60

CD-36

.17

0.33

0.66

1.00

1.33

1.66

2.00

2.33

2.66

3.00

3.30

P

ro

p

a

n

e

G

as

Tan

k

P

rop

an

e

G

as

Ta

n

k

Change Over Valve

H

o

se to

C

arb

o

n

D

io

xide

G

e

n

era

to

r

Specifications

CO2 Output

CD-3

CD-6

CD-12

CD-18

CD-36

LP

NG

LP

NG

LP

NG

LP

NG

LP

NG

Cu Ft CO2 / Hr

3.2

3.4

6.2

6.4

12.4

12.8

18.6

19.2

37.2

38.4

Pounds CO2 / Hr

.376

.388

.753

.776

1.51

1.56

2.27

2.33

4.54

4.66

Max BTU / Hr

2183 2172

4366

4343

8733

8686

13098

13029

26196

26058

Fuel Consumption

Cu FT / Hr

1.03

2.01

2.05

4.02

4.1

8.04

6.15

10.06

12.3

20.12

Transfo r mer 110/12VDC 1Amp Max

Carbon Dioxide

ACCESSORY

OPTIONAL

VALVE

CHANGEOVER

PROP ANE

AUTOMATIC

info@greenair.com www.greenair.com

1-800-669-2113 Fax 1-503-663-1147

P.O. Box 1318 Gresham Or. 97030 USA

dealer or Green Air Products service department.

alterations of original construction will void warranty obligations. For further warranty information contact your

service is only performed at the factory or authorized service center. Any usage contrary to proper application or

for 2 years and electrical parts for 90 days. At our option we will repair or replace defective equipment. Warranty

Products warrants the original purchaser of this equipment against defects in mechanical parts and workmanship

Green Air Products guarantees that this equipment will perform as implied for the purpose it is intended. Green Air

TWO YEAR LIMITED WARRANTY

operation in compliance with local, state and federal laws

For professional use by qualified personnel in a facility suited for proper

Generator

2

Introduction

Carbon Dioxide Enrichment will dramatically increase the growth of green

plants. Green plants use carbon dioxide (CO2 ) and water in the presence of

light to synthesize organic compounds. The plant then converts these organic

compounds into elements that it can use (food). This process is called

photosynthesis. If any of these ingredients (CO2, water or light) are at levels

below what the plant can use for maximum efficiency, it will only be able to

perform at that level and no greater. Adding carbon dioxide to a growing

environment that is not receiving proper nutrients or is low on light will not

produce the desired results. Similarly, plants that are receiving plenty of

sunshine and nutrients will only perform as well as the level of CO2 will allow.

The ambient level of CO2 in the earth's atmosphere is generally between 300

and 400 ppm. Most plants receive far more water and energy in the form of

sunshine than they can use. Increasing the CO2 in the growing area will let

the plant use the excess water and energy that is stored in the leaves. The

result is a substantial increase in the growth rate of any plant that uses

chlorophyll in the process of photosynthesis. Enrichment should commence

at sunrise or when photoperiod begins and refrain during darkness hours.

The average CO2 level that is recommended is 1000 to 2000 parts per million

(PPM). The object is to maintain a constant level in the atmosphere. You can

run a small unit continuously during photoperiods or you can use a larger unit

and time it to function periodically . Where exhaust requirements are frequent,

the latter method is preferable. After the exhaust function the generator can

be cycled to replenish CO2 quickly to maintain rapid plant photosynthesis.

Use the operation time charts to determine the size of generator and the

number of minutes of operation required for the level of CO2 desired. Frequency

of recharge depends on the rate of consumption. For the greatest fuel economy

and accuracy of recharge it is recommended that the Green Air Products

CO2 Monitor Controller (CDMC) be used with all generator and emitter

systems.

CO

Operation Manual

Installation and

Rules For Safe Operation

** IMPORTANT **

• Read and understand the information in this manual before operating the

equipment. Observe all CAUTIONS.

• Unit should be operated in a safe, clean and ventilated area free of flammable

materials.

• Housing becomes hot under normal operating conditions. T o avoid possible

burns, never touch equipment during operation.

• To service or repair this unit always disconnect power source and shut off

fuel supply.

• Do not operate if gas fumes are noticed. It is recommended the fuel tank be

located outdoors or in a well ventilated area free of sparks or open flame.

• For service or repair always send the unit back to the factory or an authorized

service center.

Never overfill propane tank. Allow room for expansion of contents due to

contrast in temperatures. It is recommended that tank be located outside the

enclosure for safest operation. A properly burning flame should burn clean

and blue and produce no toxic emissions. Remember a flame requires oxygen

to burn so adequate fresh air intake and circulation is important. Always check

for leaks after refitting.

Size and Timing Chart

you can operate the Co2 generator.

you have. The number that corresponds with the two selections will be the number of hours that

first you will look in the left column to pick a model, then follow it across to the propane tank size

This chart is used to decide how long a tank of propane will last. This chart is fairly self explanatory

Principals of Operation

Carbon dioxide generators operate by burning carbonaceous fuels such as

propane or natural gas. The burners used in Green Air Products CO2

generators are specially designed to maximize the production of CO2 and

minimize heat as a by-product. Green Air Products generators provide CO2

far more economically than any other means of enrichment. A constant

burning pilot is used to ignite the gas when the generator is turned on. A

thermocouple is used to monitor the pilot flame. If the pilot flame is lost, a

safety valve will close so that unburned fuel will not be released into the

enclosure. CO2 generator operations may be automatically functioned

according to actual ambient values when installed in conjunction with a CDMC

controller. This control device continually samples the level of carbon dioxide

in the growing area and functions the generator whenever CO2 levels do

not meet your predetermined values. Generators are easily installed,

dependable and efficient. Transformer included. Operates on 110VAC.

This chart will give you the minutes of operation required for the areas and

models shown. Top row of the chart represents cubic feet of area in the

enclosure (LxWxH) The left column is the model size. Model numbers

represent maximum CO2 output per hour in cubic feet (CD-3 = 3 cuft/hr CO2)

Example: A CD-6 will take 10 minutes to produce a CO2 level of 1000 ppm

in a 1000 cu. ft. enclosure. The area should be charged as quickly as possible

for maximum advantage. Charging the atmosphere quickly insures that the

rapid photosynthesis process will not be interrupted and the plants growth

rate reduced. Five to ten minutes is a good charge time. Try not to exceed

twenty minutes. Your microclimate will need to be recharged every 1 to 4

hours depending on how much CO2 is lost due to plant usage or drafts (leaks).

Large greenhouses logically require longer charge times and multiple units

may be necessary. The CD-36 takes 1.66 minutes per 1000 cu.ft. area to

charge to 1000 ppm. Therefore a 20,000 cu. ft. area would be 20 X 1.66 which

is 33.2 minutes. For this application that may be an acceptable charge time.

WALL MOUNT

Bracket wall mount screw holes must be 10 inches center to center. Mount

Generator Installation

brackets to wall and housing will slip over screw heads and fit snug into

slotted holes in housing back. This allows for easy removal of housing from

wall brackets. Make certain bracket screws are secure in wall and use good

judgement when choosing mounting location.

SUSPENDED

Use chain, eyebolts and ceiling hooks found in hardware pack. Hang unit

from sturdy location at least 18 inches from ceiling. The unit must operate in

level upright position. “CAUTION” Should unit fall during operation fire may

result.

FREE STANDING

Remove the four screws holding the bottom plate to the housing. Locate the

holes on the bracket to match and replace the screws.

Propane Hook-up

Igniting Pilot Burner

1. Plug the transformer into a grounded 110 volt timer or other power source.

2. Depress the RED button located on the inside of the generator for 90 seconds

to clear the air from the hose.

3. Once gas is present at the pilot let up button and wait 60 seconds for

excess gas to clear from the housing. Now depress the RED button again

and light the pilot burner. Maintain holding the button down for an additional

30 seconds to allow the thermocouple to heat to operating temperature.

4. Push the front on-off switch to the “ON position. Fuel will pass through the

solenoid valve and the main burner will be ignited by the pilot flame. As your

timer cycles on and off so will the main burner flame.

5. For the CD-18 and CD-36 , the brass needle valve may be used to very the

flame size. This will increase or decrease the time that the unit needs to

charge the area with CO2. The specs are based on the valve being fully open.

Burner

Propane

Gas Tank

Regulator Assembly

Generator

hose

1. For propane applications use a propane tank that has been filled to only

80% of it’s capacity . This is very important for all propane burning mechanisms.

Failure to observe this common rule will make your generator hard to ignite

and will not stay lit (refer to troubleshooting).

2. Carefully thread the regulator flange nut in the tank valve counterclockwise

with your fingers until you feel the flange seat. Tighten firmly with adjustable

end wrench. DO NOT USE PLIERS! Fasten hose between regulator and

generator gas inlet in same fashion.

3. Turn the propane tank valve to wide open “ON” position.

4. Check for gas leaks. A solution of 25% hand dish soap and 75% water in

a spray bottle will work well for detecting gas leaks. Apply solution to all

previously connected fittings. Bubbles will occur around loose connections.

Always use two wrenches when tightening multiple fittings.

Natural Gas Hook-up

Gas Supply

Line

Shut Off

Valve

Nipple

Regulator AssemblyReducer

1. Turn gas supply off before you begin work. Now connect a gas shut off

valve (not included) onto your incoming gas supply line. If needed reduce to

1/2 male nipple to accept enclosed regulator. Note gas flow direction indicator

arrow. Use gas compatible pipe compound on all pipe thread fittings and

tighten securely.

2. Connect regulator to shut off valve nipple with compound and tighten.

3. Check for gas leaks. A solution of 25% hand dish soap and 75% water in a

spray bottle will work well detecting gas leaks. Apply solution to all previously

connected fittings. Bubbles will occur around loose connections. Always use

two wrenches when tightening gas fittings.

Generator

hose

Thermocouple

Junker Valve

Gas feed hose from

regulator

Pilot Light

To solenoid valve

"On" "Off" switch

Solenoid Valve

Trouble Shooting Tips (see www.greenair.com for further information)

PILOT LIGHT FAILS TO IGNITE:

Make sure propane tank has fuel and valve is fully open. For natural gas

generators make sure gas supply is "On" and shut off valve is open. Make

sure propane tank has not been overfilled. If so, take tank outdoors and open

valve to release gas for a few seconds and reconnect. Remember red button

must be depressed to light pilot.

PILOT LIGHT WON’T STAY LIT:

Hold the red button down to clear all pockets of air from inside the hose. Make

sure the propane tank has not been overfilled. If so, take tank outdoors and

open valve to release gas for a few seconds and reconnect. Remember, red

button must be depressed for 30 seconds or until the thermocouple heats to

operating temperature and holds pilot open.

BURNER FAILS TO IGNITE:

Check that the tank valve is fully open. Be sure all air has bled from the hose

and gas is present. Make sure the transformer is plugged into a working power

source. Make sure power indicator switch is in “ON” position. Check that

needle valve is open.

BURNER WON’T STAY LIT:

Check that needle valve is open enough to support a strong minimum flame.

Check timer and power source operation.

FLAME BURNS IRREGULAR:

Dirt or residue could constrict burner orifice. Low fuel pressure due to depleted

or contaminated fuel supply. Lack of oxygen content in room due to inadequate

fresh air intake. Excessive air movement or gust from fan or ventilation.

Generator not setting level.

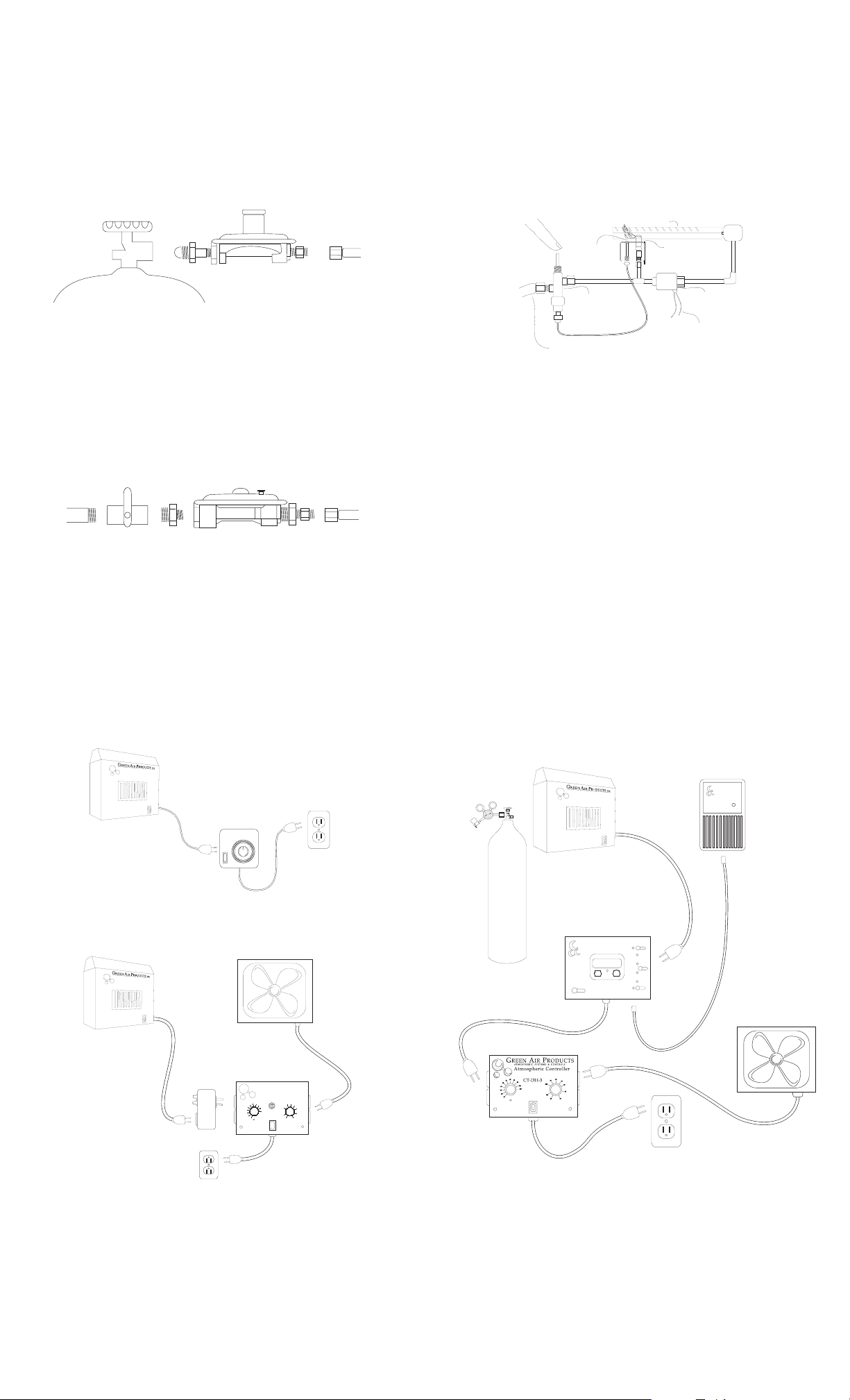

Control Diagram

24 Hr.

Clock Timer

12

11

1

10

2

9

3

8

4

7

5

6

6

5

7

4

8

3

9

2

10

1

11

12

This example shows the simplest method of CO2 generator control. Set the

Green Air ProductsTimestat, Cyclestat or PDT-1 timer for short intervals

during light hours only.

G

REEN

A

IR

P

RODUCTS

PROFESSIONAL GREENHOUSE EQUIPMENT

AtmosphericControlle

CT-DH-3P

70

80

70

80

60

90

50

40

30

20

10

60

OFF

100

50

110

4

0

ON

20

30

Exhaust Syncronized Operation

This diagram demonstrates an exhaust synchronized system where the CO2

equipment is disabled during exhaust functions and immediately replenished

when exhaust is completed. The CT-DH-3P temperature and humidity

controller activates the exhaust fan and shuts off the CO2 during the exhaust

cycle. It has a built in photo sensor to limit CO2 enrichment to photoperiods

only . Enrichment will only occur when exhaust fan is off and light is present.The

CO2 “On” cycles are timed by the Cyclestat repeat cycle timer which cycles

the CO2 equipment according to your preset periods. An example might be

that the timer is set for 5 minutes every hour. The CO2 generator would be

operated according to that hour schedule. In the event that there is an exhaust

function at any time the CO2 will come on for 5 minutes immediately after the

exhaust cycle is completed. It will repeat again one hour after that point.

Replenishment of CO2 will always follow an exhaust cycle to maintain a

constant and continuous enrichment level.

This system is the ultimate in precise automated CO2 control. The CDM-6000

sensor continuously determines atmospheric CO2 values. The CDDS-2

controller interprets these values and provides flexible set point adjustments

to sequence CO2 equipment functions. The CDDS-1 has a built in photo

sensor to disable CO2 production during darkness. The CDMC-2 system can

be combined with the CT-DH-3 temperature and humidity controller to defeat

CO2 production during exhaust functions. The CO2 generator (or emitter

system) and the monitor are plugged into the CDDS-2 controller. CDDS-2

controller and the fan are plugged into the CT-DH-3 as shown. Plug the

power cord

on the CT-

from the CDDS-2 controller into the left hand equipment outlet

DH-3. The power to the sequencer will be interrupted when ever

the temperature or humidity conditions constitute an exhaust function. CO2

production will resume immediately after exhaust cycle is completed. Co2

levels will be maintained precisely and automatically. Order the CDMC-6 for

this Carbon Dioxide Monitor Controller combination.

Loading...

Loading...