Green Air Products CDMC-7 User Manual

and

setpoint

LED is off, the

regardless of the photoperiod.

controller will operate continuously

activated

When the

enrichment during darkness periods.

enrichment. This mode will defeat

This is the normal setting for CO2

will operate only when light is present.

the

LED is lit the controller

activated

photo sensor “on” and “off” modes. If

The SENSOR button toggles between

Feature Identification

levels are constant and maintained at all times with complete accuracy.

automatically compensate for the next dosage. This will assure that the proper

cycle the controller senses that excess CO2 has been administered it will

regardless of the particular characteristics of the enclosure. If on the initial

parameters necessary to keep any size area enriched within a set tolerance

Logic programming which will automatically maintain the proper dosing

The CDDS-2 Carbon Dioxide Digital Sequencer features Overshoot Protection

CO2 level.

mode automatically after five seconds and continuously display the current

Press SET again to enter your hysteresis. The system will return to operation

setpoint value. Press the UP or DOWN buttons to achieve any desired value.

To make setpoint adjustments press SET and the LED will flash the current

1050 is reached and then it will shut off.

equipment outlet will come "On" and enrichment will continue until a level of

In the example if the CO2 level falls below the setpoint (1000 ppm) the CO2

Example : Set point = 1000 ppm Hysteresis = 50

example below a 50 ppm hysteresis setting will turn CO2 "Off" at 1050 ppm.

This value determines at what point the CO2 equipment will turn "Off". In the

value. The hysteresis is the value between "On" and "Off" functions.

hysteresis

The SET button allows you to choose an enrichment level

removed from the area.

used primarily for mushroom cultivation or HVAC control where CO2 is to be

Venting

mode is for purposes of removing excessive levels of CO2. This is

is the normal mode for CO2 enrichment operations.

Enrichment

functions.

The MODE button switches between CO2 enrichment or CO2 venting

please refer to www.greenair.com/cdmc.htm

device other than the CDDS-2 controller, or for complete instructions manual

advanced settings and features of this product, or using this sensor with a

protection device. Approved for indoor use only. For information about

power outlet. All valuable electrical equipment should be plugged into a surge

Mount the Sequence Controller in a convenient, dry location near a 120V

vibrations or water. Breathing near the sensor will cause high CO2 readings.

equipment. Avoid locations where sensor may be vulnerable to impacts,

plant zone atmosphere. Do not locate near heaters, drafts or CO2 producing

Install the monitor indoors in a location representing an even air mix from

Features

outlet during darkness periods.

values. The built in photo sensor automatically defeats the CO2 equipment

signals and functions the CO2 equipment outlet according to predetermined

Sequencer logic translating circuits. The sequencer then interprets these

display screen, while transmitting linear millivolt signals to the Digital Event

each second and displays current CO2 values in parts per million (ppm) on its

event programmer and photo sensor. The monitor samples atmosphere once

CDM-7001 monitor with LCD display and a CDDS-2 digital sequencer with

This carbon dioxide monitor controller model CDMC-7 package includes the

Description

performance.

the most advanced detection providing precise, accurate and dependable

producing equipment according to user programmable set points. It employs

system is designed to detect atmospheric CO2 levels and function CO2

Infrared Carbon Dioxide Monitor and Digital Event Sequencer system. This

This booklet will discuss the features and functions of the Green Air Products

Introduction

Specifications for CO2 Monitor

Method - Dual Beam Absorption Infrared

Sample Method - Diffusion or flow through (50 - 100 ml/min)

Warranty - 18 months parts and labor

Performance of C02 Channel

Measurement Range - 0-4,000 ppm output (0-10,000 ppm display)

Sensitivity - ± 1 ppm

Accuracy - ±50 ppm or ±5% of reading

Repeatability - ±20 ppm

Temperature Dependence - ±0.1% of reading per °C or ±2 ppm per °C, @ 25°C

Pressure Dependence - 0.13% of reading per mm Hg

Annual Drift - ± 20 ppm typical

Response Time - <60 seconds for 90% of step change

Warm-Up Time - <60 seconds at 22 °C

Operating Conditions - 32 to 122°F (0 to 50°C) 0-95% RH, non-condensing

Storage Temperatures - (-40 to 140°F or -40 to 60°C)

Calibration Interval - 12 months, full factory calibration available

Temperature Channel

Voltage output - (32 to 104°F or 0 to 40°C)

Display - (32 to 122°F or 0 to 50°C)

Display Resolution - (0.1°F or 0.1°C)

Display Options - °F, °C, or Off. Set with panel button.

Accuracy - ±2°F or ±1°C

Response Time - 20-30 minutes (case must equilibrate with environment)

Calibration Interval - 12 months, full factory calibration available

Output - Analog

C02 - 0 to 4 VDC, 1mV/ppm (4,000 ppm max)

Temperature - 0 to 4 VDC linear, 32-104°F (0-40°C)

Output Impedance - 100 Ohms

Wiring Connection - Via RJ45 to (accessory cable 2070 or 2071)

Output - Digital

Wiring Connection - Via RJ45 to DB9 serial port cable

Display - LCD with independent CO2/ temperature readings

Power Supply

Battery Type - four AA batteries, not included

Battery Operation - 48 hours (alkaline)

External - 6 VDC from external AC/DC adapter included

Power Requirements - 400 mA Peak, 20 mA average from 6V

Certification - FCC Class 15 Part B

Accessories

2070 Datalogging cable for analog output

2071 Datalogging cable Recordaire

2075 Calibration kit

1058 Recordaire data logger, 4-channel

105BGSW VG Graphing software

All specifications and instructions subject to

change without notice. Protected by United

States Patents - 5,060,508 and 5,163,332.

P.O. Box 1318 Gresham Or. 97030 USA

1-800-669-2113 Fax 1-503-663-1147

info@greenair.com www.greenair.com

Installation and

Operation Manual

CDMC-7

Carbon Dioxide

Monitor Controller

Features

1. Lightweight - Made of ABS plastic.

2. Display - C02 and Temperature and adjustments to

mode settings.

3. Soft Touch - Attractive, gives comfort and durability.

4. Up/Down Button - Used to increase or decrease values

while in the edit mode.

5. Mode Button - Toggles between menu options.

6. Power - Turns the power on and off.

7. Enter - Enter button will select desired menu option for

editing (e.g. Altitude settings). After changes have been

made, the Enter key will also confirm settings and return

to the main menu.

8. Calibration Port - Gas connection for calibration.

9. Calibration Activation Switch - Located in the battery

compartment, used to activate the calibration process for

C02 or Temperature.

10. Voltage Output - The sensor is equipped with an output

for data logging. (see accessories).

11. Built-in Kickstand - Supports in upright position.

12. Power Connection - For 6V power adapter.

13. Batteries - 4 AA Batteries for portable operation.

14. Battery Cover

Model 7001

Portable Infrared

Carbon Dioxide Monitor

Display

Modes of operation visible on the display and accessible through the on-board buttons.

Warm-Up Mode - One minute warm-up indicated by the word WARM-UP in the upper left corner.

Normal Operating Mode - After warm-up the sensor will stabilize and display current conditions.

Elevation Settings Mode - This feature allows the user to correct the monitor for elevation changes.

Calibration Settings Mode - Set the C02 concentration or temperature when calibrating.

Calibration in Prog Mode - Displays when calibration is in progress.

Low Battery - Displays when the power source is low.

Start - Up

Battery Operation - For portable use, the monitor operates on 4 AA batteries.

Normal (Non-Alkaline) up to 50 hrs - Alkaline up to 70 hrs - Rechargeable up to 60 hrs.

Battery Installation - Remove the battery cover (located on the back) by pressing the pressure clip

(located on the bottom near the kickstand) and pull upward.

Follow the battery diagram imprinted on the plastic on the back cover for proper installation.

Low Battery - Depending on the battery a warning signal will flash (indicated by the blinking Low

Battery LCD) when there is less than 30 minutes of battery life. At this point the batteries should be

replaced or the AC adapter should be used as a substitute.

If operation continues, the unit will become inoperable and only the Low Battery will be blink on the

LCD display.

AC Power - The sensor is shipped with a 6V DC 5OOmA AC/DC adapter.

To use the AC adapter, connect the plug into the back of the unit and plug the transformer into any

standard wall outlet.

NOTE: Use the supplied adapter. Using the wrong adapter may cause damage to the unit. If power

is lost during operation, battery operation will not function as a back up.

CO2 Monitor Operation

Power-Up

Press the Power button. A two second delay will occur before the display becomes visible. A 10

second delay before current C02 readings are displayed. "Warm-up" will display for one minute.

Elevation Correction - Factory elevation is set at "zero" (sea level). For altitudes greater than 500

feet, adjustment will assure sensor accuracy. For elevation correction follow the steps below.

1. While in Normal Mode press the “Mode” button once. The LCD will begin blinking. Press Enter.

2. Press mode to toggle the elevation reading between feet (ft) and meters (m).

3. Use the Up/Down button to adjust the altitude. The altitude can be adjusted in increments of 500

(feet) or 100 (meters). Once the correct altitude is set, press Enter to lock the setting.

Display in Fahrenheit or Celsius - To change the temperature to read in Celsius or Fahrenheit, or

to turn the temperature display off, use the Up or the Down button.

Stand-alone Monitoring - Once the batteries have been installed the sensor will begin to accurately

display current room conditions.

Monitoring using an External Data Logger -Voltage outputs for both C02 and temperature are

available via an RJ-45 jack on the rear of the unit.

CO2 Calibration

I. The calibration procedure will last approximately 5 minutes. First remove the battery cover to

provide access to the C02 calibration activation switch. Connect the supplied AC adapter to the

back of the sensor. If you do not have the AC adapter, new batteries should be used.

2. Power up the sensor and wait for the Warm-up to end.

3. Next, verify the Elevation correction has been set. Refer to Elevation Correction for procedure.

4. Press the Mode button twice. The Calibration mode will begin blinking. Press Enter.

5. Use the Up/Down Rocker button to adjust the lower reading on the display to the current ambient

conditions. Pressing the button once will change the readings in increments of 10 ppm.

6. Next, on the backside of the unit locate the push button switch (under the battery cover, in the

small round hole to the right of the connector jack), use a small pointed object to depress and hold

the switch for 5 seconds. The Calibration light will begin to blink. Press Enter.

7. Calibration In Progress will blink. The unit will program itself based on the C02 value that was

input in Step 6. The calibration process will take about 5 minutes. When Calibration is complete, the

display will return to the steady Calibration mode. Press Enter to return to normal operation mode.

T emperature Calibration

Use this procedure to adjust the temperature output when, for example, you wish to have the

temperature output match a reference sensor. The accuracy of a field adjustment is dependent upon

the stability of the environment is which the procedure is performed, and upon the accuracy of the

reference sensor.

1. Before performing the temperature adjustment, connect the supplied AC adapter to the bark of

the sensor. If you do not have the AC adapter, new batteries should be used.

2. Power up the sensor and, using the kickstand, place it on a flat surface in a stable environment

relatively free of drafts or temperature changes. Wait 30 minutes for the unit to fully equilibrate with

the environment. Do not hold the unit in your hand during this period.

3. Press the Mode button three times. The word “TEMPERATURE” at the bottom of the display will

begin blinking.

4. Press Enter. Both the word “TEMPERATURE” and the numeric temperature display will begin

blinking in unison.

5. Use the Up/Down Rocker button to adjust the temperature reading to match the reference.

6. Press Enter. The temperature offset is immediately adjusted, the blinking stops, and the unit is

now in normal operating mode.

Basic Hook Up Procedure

Green Air products

ppm

420

F

68.5

Green Air products

4 2 0

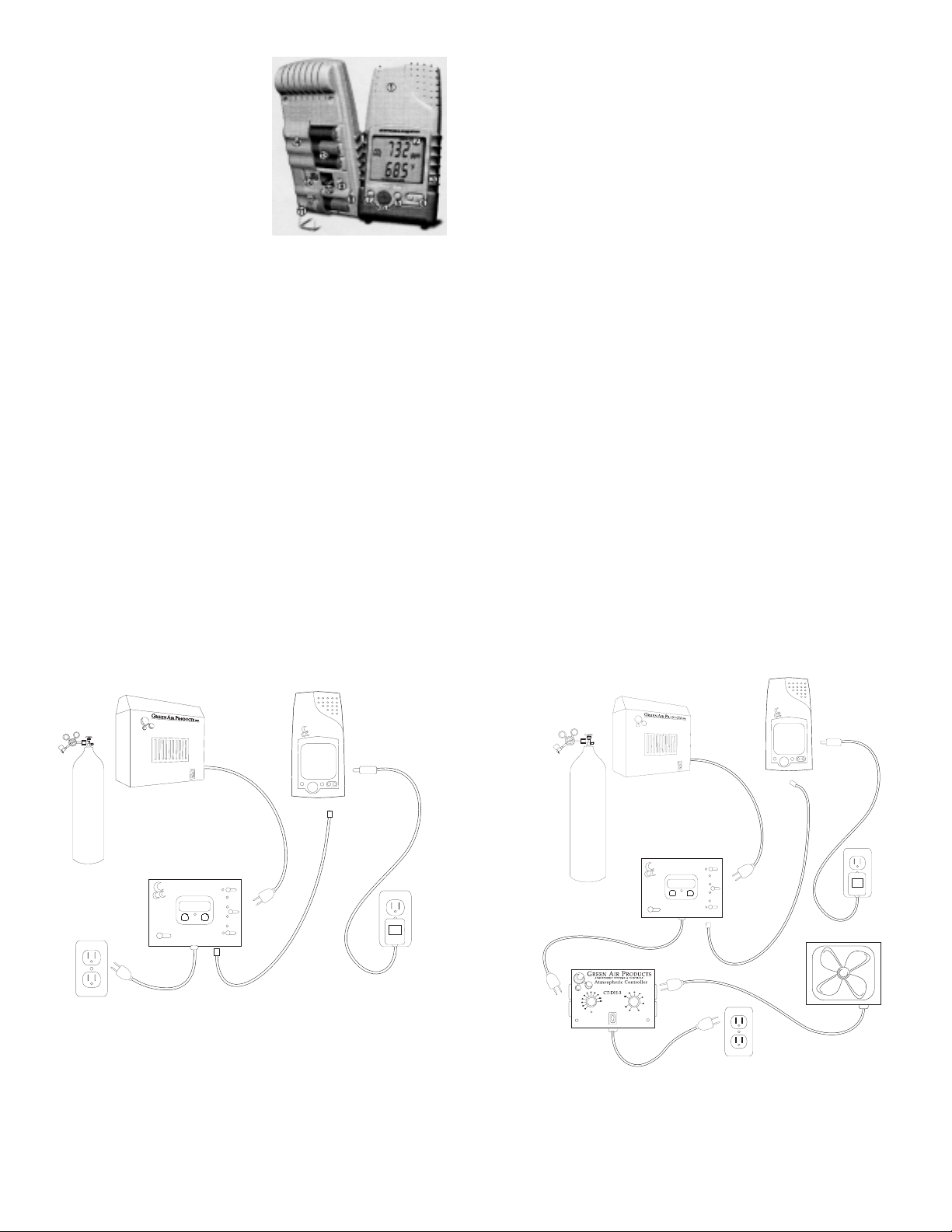

1. Plug the CDDS-2 sequencers power cord into a 120 volt outlet.

2. Plug the CO2 monitors transformer into a 120 volt outlet.

3. Insert the transformer plug into the monitors power input jack.

4. Connect the patch cord between the monitor and the sequencer.

5. Turn the model 7001monitor and the CDDS-2 sequencer "on".

Allow both units a 2 to 3 minute warm up period.

6. Plug CO2 producing equipment into the outlet located on the

underside of the CDDS-2 sequencer. The system is now ready

to operate.

7. Set monitor and controller according to programming instructions.

Exhaust Syncronized Operation

Green Air products

ppm

420

F

68.5

Green Air products

4 2 0

The CDMC-7 system can be combined with the Green Air Products

CT-DH-3 temperature and humidity controller to defeat CO2

production during exhaust functions. Plug power cord from CDDS-2

sequencer into the left hand equipment outlet on the CT-DH-3 and

power to the sequencer will be interrupted when ever temperature

or humidity conditions constitute an exhaust function. CO2 production

will resume immediately after exhaust cycle is completed.

Loading...

Loading...