GreenAire RAH-SAU series Installation And Operation Manual

INSTALLATION AND OPERATION

FOR:

RAH–SAU Series

VS.7.14

1

1. Equipment provided

: Locate all equipment provided with your order. The following

make sure to look at your packing slips and purchase orders

to determine exactly what is included in your system.

Generator Control Panel

Reverse Osmosis system

Governing humidity

Installation and Maintenance Manual

Location of the humidifier

Installer. The following rules should be followed:

Place the Control Panel in a place where the outlet fog will

surfaces. Make sure to verify the air patterns in the room to preclude any adverse

flows that would cause the fog to impinge upon any walls, the control cabinet or

If the unit is feeding a test chamber or room then

cabinet as close as possible to the dispersion point of the fog and no greater than

10’ ft. if possible. The longer the run of discharge tubing the more your losses of

fog will be. (Consult with the Factory if thi

Location and Piping:

ocate

the dispersion point

Make sure the Control Panel

tubing to the inlet and outlet stubs on the Control Panel make

sure they are water tight.

Sealant can be used on the

adhesive because these tubes will need to be loosened during maintenance.

When piping try to avoid creating

piping. If you cannot avoid doing so then

(if applicable)

is the preference of the End User or

not impinge on any

try and keep the control

’ ft of equivalent piping

is installed LEVEL! VERY IMPORTANT!

water “traps” or low points in the

drain from such

equipment may be provided –

a.

b.

c.

d.

2. Humidifier location:

A.

other surfaces.

B.

including 4 gal. storage tank

sensor

s is a problem

INSTALLATION:

I) Control Panel

A. As stated above l

distance from

B.

C. When attaching

D.

CAUTION:

trap locations. (see Fig. 1 )

the Control Panel within 10

.

stubs if desired for complete seal.

be sure to plumb a mini-

But not

2

E.

Pipe the drain line

Again be sure not to trap water. If necessary employ a condensate pump/drain to

elevate the drain water and evacuate it during drain cycles.

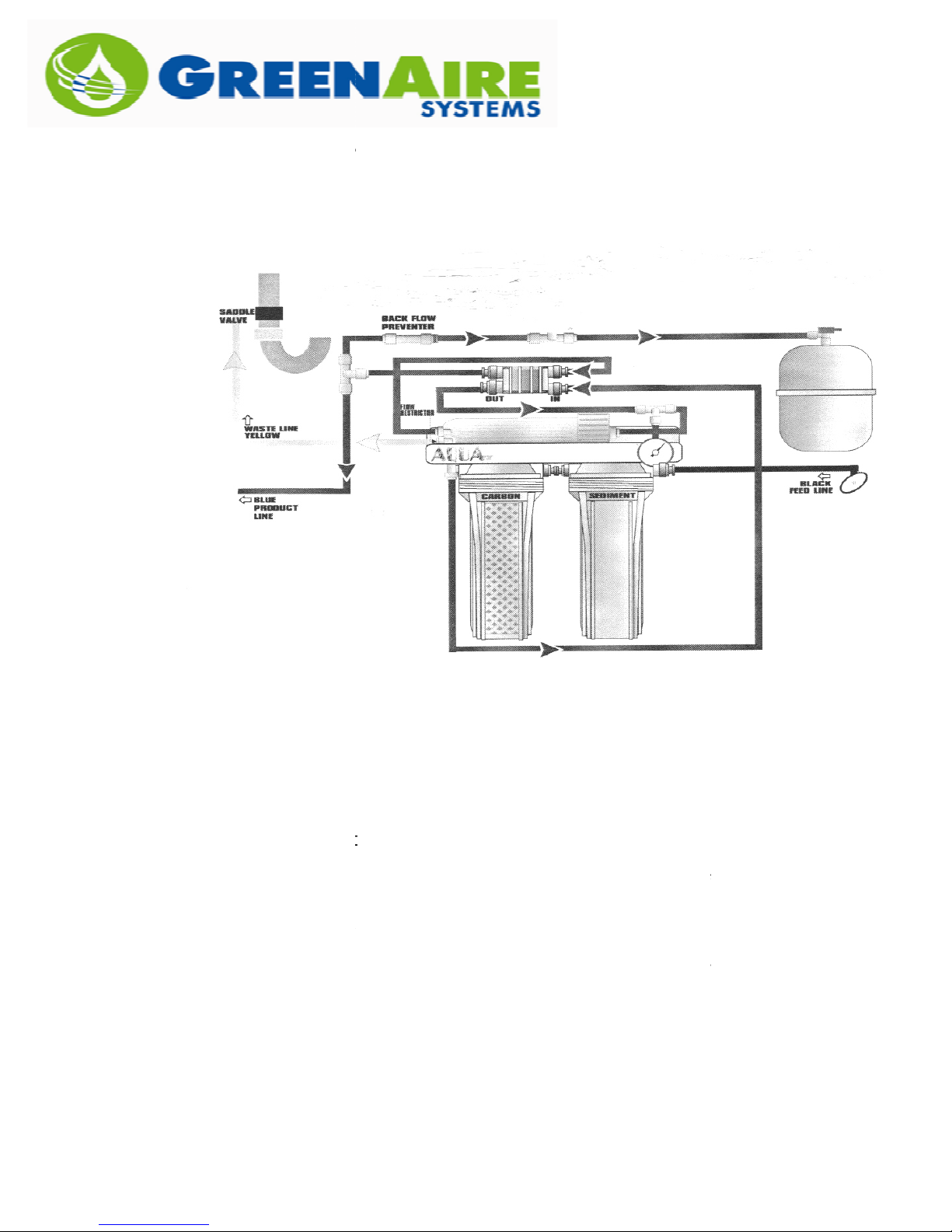

II) RO System Location and Piping:

everse

mountable with simply two screws and can be hung as self supporting. Follow

outlined below

respective connections. All connections are simple quick connec

recommended that a shut off valve be placed in line after tapping the domestic

water line for the RO System supply.

Locate and connect the

quipment. This will be the right side as you face the system. The

ply side will consist of Black ¼” tubing.

Locate the Yellow drain line, and place in an appropriate area for

drainage.

HUMIDIFICATION SEASON IS MONTHS AWAY.

CONDENSATE PUMP

Locate the b

humidifiers

system metal frame)

storage tank.

proximity to the RO System.

Make sure to open the valve at the top of the storage tank.

Once installed, allow the system to run for approximately 15

minutes to flush completely. Make sure there are no leaks, parts

can come loose in shippin

The RO System will run until all the humidifier supply lines and

storage tank are filled and charged to the pressure of the building.

This may take several hours to happen.

PLEASE N

WATER SUPPLY TO THE RO SYSTEM.

if this is a problem)

Pipe supply piping from

or STS Box

Open the inline water valve off of the build

filling of water to the

filling the clear water filter housings on the RO System.

As stated above The RO System will run until all the humidifier

lines and storage tank are filled and charged to the pressure of the

building. This may take several hours to happen. Again, make sure that the

if the drain line is fed to a condensate pump the pump MUST

The RO System h

to an appropriate drain location.

Water system. These systems are wall

for connecting the colored tubes to their

supply side of the

NOTE: DRAIN MUST BE OPERABLE! EVEN IF THE

e product water line that will provide

(provided and taped to the RO

to hook up the product water (blue line) to the

Locate the 2.5 gallon storage/bladder

g. Hand tightening may be necessary.

OTE: 35 PSI MINIMUM REQUIRED ON INCO

(Consult with the Factory

the RO System to the fitting on the side of the

ing domestic water supply to begin

System. You should notice water immediately

as an automatic shut off valve (ASO) that

from the Control Panel

A. Now install the R

the instructions

1)

e

sup

2)

3)

4)

5)

Osmosis (RO)

domestic water

– IT MUST BE ON LINE!

lu

. Utilize a “t” connector

ts. It is

IF PIPED TO A

RO water to the

tank in close

6)

7)

B.

Panel/Generator

labeled “water in”.

C.

the

RO

D. Check for leaks.

supply

drain is working –

BE OPERABLE!

MING

Control

3

is completely mechanical and will only open and pass water to drain when the

pressures are not equalized between the domestic water supply and the

humidifier supply lines. If there are any questions or issues plea

Factory Representative.

If the system was provided with a controlling humidity sensor then install it

and wire it from the Generator panel at the appropriately labeled locations on

the terminals. Refer to the Wiring

landing locations and line sizes.

Do the same as the above with both the High Limit humidistat and the Air

Flow switch if provided. Terminal locations are

Diagram provided with your Unit.

S signal is being provided then connect it to the proper terminal

locations in the Generator as labeled in the Wiring Diagram provided with the

In this case a separate 24VAC signal is required to turn on the

provided with your unit for proper

ded control wire is recommended but

again labeled in the Wiring

locate AFS before any

se contact your

III) Accessories:

A.

not required.

B.

dampers.

C. If a BA

Unit.

humidifier.

Diagram

Shiel

CAUTION:

zone

4

IV)

Start Up Procedure:

Verify Piping connections

double check the inlet and outlet water connections to the system

either at the generator panel or at the S

open up any shut off valves up stream to the water inlet and make sure

that, with the water charged, there are no leaks while the System is off.

now check the fogging inlet and outlet connections from the UPC t

(these are typically 3” or 2” connections). Make sure that the hose

couplings are tightened.

evaluate the installing contractor’s piping from the fogging outlet

connection to the DTA and make sure it isn’t excessively long (in

excess of 10’) and

where condensate can accumulate without a drain. (please note

typical steam piping practices should be utilized when piping a fogging

supply line; i.e. don’t create traps and do use the manufacturers

mmended pipe size)

if a vertical header DTA was used make sure the drain connection at

the bottom of the header has been connected to a drain.

Turning the System On:

go to the control panel and make sure the panel on/off switch is off.

open up the

if CB is showing green then the CB is in the ‘off’ position. If it is

showing ‘red’ it is in the ‘on’ position and power will pass through the

now remove the fuse on the 48VAC transformer a

place it nearby.

verify that the 120V line to the panel is connected and live.

verify that the Air Flow switch is installed and wired appropriately to the

proper terminals in the control panel (see wiring diagram that came

with the pan

verify that the Hi

the proper terminals in the control panel (see wiring diagram that came

with the panel and/or was submitted for that job)

verify that the controll

been installed and has been wired back to the proper terminals in the

control panel (see wiring diagram that came with the panel and/or was

submitted for that job)

verify that the AC System to which the humidifi

and running. Make sure it is running at the expected speed and

volume as scheduled in the Submittals and on the Humidifier

Schedule. If the volume (CFM) is more than 20% different than what

was planned for during the design and s

TS box. Connections should

that no ‘traps’ have been created in the piping

control panel and make sure the circuit breaker (CB) is off

nd hold on to it or

Limit switch is installed and has been wired back to

ing humidity sensor (if supplied by GAS) has

er is connected to is on

izing of the humidifier please

A.

1.

2.

3.

4.

5.

B.

:

–

be tight.

ank

–

reco

1.

2.

–

3.

4.

5.

6.

7.

8.

CB.

el and/or was submitted for that job)

-

5

call the Factory. Also make sure that the Cooling Cycle/Coil is off and

not operating when the humidifier is on. Remember

will be running in the winter time/heating season so in most cases the

cooling coil

are year around cooling loads

taken to turn off the cooling coil or control it differently than normal

when integrating a humidifier into the System.

9. Take

the wet switch safety and place it temporarily off the floor of the

Panel or STS Box. There should be enough of a tether on the wire

harness to allow you to hang it outside the panel/STS box or to hang it

at a higher position temporarily. Some models no

thick small section of plexiglass as a permanent resting plate for the

wet switch. If this is present then none of the above is required and

the Wet Switch can remain in it’s normal position.

now turn the CB into the ‘on’ position.

rn on the panel door on/off switch. It is a lighted switch so it

should light up when in the ‘on’ position.

with the panel turned on, if there is a controller provided with the

system it should become active and show figures on it’s display. The

should correspond to both the actual humidity level and the

target set point humidity level. Make sure their respective readings

make sense and seem accurate for the time of year you are

conducting this start up.

oller go to the section in this Manual titled Controller.

Assuming you have relevant readings on the controller raise the Set

Point humidity level to above what the actual humidity level is reading.

This is especially important when starting up the Syst

warmer or summer time conditions. For example

reading 58%Rh in the target space and your humidity winter

time/heating season target is 35%Rh then the Controller will not

energize the System to produce fog because the actua

humidity is 23 points above target. In this scenario you must adjust the

set point to an artificially high set point in order for the controller to

energize system.

Once the controller is in a ‘call for humidification’ mode and the target

humidity set point is higher than the actual humidity level then the

system should begin preparing to humidify.

Verify that water has begun to flow into the UPC tank. You should

have heard the solenoid valves energize. You can also check by

opening up t

model type.

Verify that the Wet Switch is showing a ‘green’ lite.

Verify that there are no leaks in the tubing within the Panel or STS box

as the water fills. (tubing may have gotten loosened

installation

would not be on. For some applications and facilities there

if this is the case then care must be

w come with a ¼”

For more details and specifics on the

em during

if the controller is

he top latches of the UPC tank if it is a side inlet and outlet

during shipping or

all Systems are live tested before they ship from the

10.

11. now tu

12.

figures

–

the humidifier

–

13.

14.

15.

16.

17.

Contr

–

l space relative

–

Factory)

6

18.

Depending on what kind of water pressure is available in the Facility,

the System should take about 3

proper level for fog

the green panel lite labeled ‘Fog On’ will lite up.

When the green ‘Fog On’ lite come on

On/Off Switch on the panel door and at the CB. Now re

der on the 48VAC transformer. Go ahead and turn on the

CB and On/Off switch on the Panel Door.

You should now hear, when standing very close to the UPC Tank, the

System operating. It should sound like water bubbling within the tank.

If this is the case

operating properly.

check the Panel or STS Box for any leaks

Now go to an air diffuser on the AC System being humidified and take

a humidity reading. It should read several point

space RH is.

Now several additional tests need to be done prior to completion of the

(a) Have the AC System turned off and verify that the Humidifier turns

off as well as air flow stops.

(b) With the AC System back on, if pos

and lower its setting to as low as it can go. The switch should open

and cause the humidifier to shut down. Verify that this is the case.

Then raise it back up to 75%Rh setting. The System should come

the System is turned off the water from the UPC tank should

slowly drain out of the tank. Verify that this is indeed happening with

the System off.

(d) If an artificially higher target humidity set point was used for the

controller then lower the target

setting and verify that the humidifier de

(e) When the system is off and draining and has been doing so for

several minutes, verify that there no continuity between terminal 15

and 10. (for

connections on Relay 3). If there is

measuring the continuity again. When the tank has largely emptied

then 15 and 10 should have no continuity. If there is still contin

the Factory and do NOT turn the system on again.

Allow the System to run for a while. Anywhere from 30 minutes to 1.5

hours when starting it up. Or if it is during the heating season and

there is currently a need for humidification then leave t

Finally, make sure the Wet Switch is back in it’s location and showing a

‘green’ lite.

7 minutes to fill the tank to the

generation. When it does reach the proper level

turn off the System at both the

then you are generating fog and the system is

there should be none.

s above what the

sible, locate the HiLimit switch

humidity set point back to it’s normal

energizes appropriately.

earlier models you can measure this right at the coil

wait awhile longer before

–

19.

into it’s hol

20.

21. Re-

22.

23.

Start Up.

back on.

(c) When

–

-insert the fuse

–

–

24.

25.

-

uity call

he system on.

7

Loading...

Loading...