INSTALLATION AND OPERATION

FOR:

R

Initial items …………

Humidifier basics……

Installing humidifier

Sequence of

Typical System Diagrams

STS System Diagrams….

Wiring diagram

Trouble Shooting

Mainte

Controller info

Wet Switch ………………

Parts List …………………

More Components ……..

AH – 1000 & 1500 Series

Table of Contents

..… 1

… 2

…… 3

Operation .. 6

7

9

s …………. 12

……….. 15

nance …………… 17

………….. 18

VS.10.13

21

22

23

1

1. Equipment provided

: Locate all equipment provided with your order. The following

make sure to look at your packing slips and purchase orders

to determine exactly what is included in your system.

trol Panel

Control Panel only (for STS units only)

Dispersion Tube Assembly

STS (Split Tank System) Box

Reverse Osmosis system

Governing humidity sensor

Installation and Maintenance Manual

Location of the humidifier

the location shown by the Design Engineer in the Project drawings. The following

guidelines should be adhered to:

The DTA should be placed in

) feet up stream and downstream with no obstructions, branch take offs or

If a vertical section of duct is chosen make sure to slightly angle the DTA

that all condensate will pitch back to the header tube.

rule applies for obstructions as stated previously.

The Generator should be located in close proximity to the DTA. Locations

ld not be located further than 1

For the STS systems the STS Box should be located as near as possible to

the receiving air duct and DTA. The Control Panel for STS systems may be

located as far away as 40 ft. (please consult with your local Rep or Factory if

er distances are desired)

The controlling humidity sensor, if it is a duct mounted sensor, should be

located in the return air duct as long as it is a dedicated return to the same

that the humidifier

then the controlling sensor should be located

a wall mounted humidity sensor.

Service access is very important. Make sure that the Generator unit is

located with adequate clearance around the unit to service it.

is recommended for

The DTA should also be located with good accessibility.

straight section of duct work with at

g distance from the

servicing. If the humidifier has a common retur

in the space being humidified

equipment may be provided –

a. Generator Con

b.

c.

d.

e.

f.

g.

2. Humidifier location:

a.

(2

bends.

b.

upwards so

c.

shou

DTA.

d.

- including hose cuff(s)

(DTA)

including 4 gal. storage tank

, Air flow switch, Hi-limit Switch

and all its components

a

0 ft of equivalent pipin

is critical. Verify

least two

The same

long

e.

zone

is

via

f.

18”

all four sides of the unit.

g.

n

A minimum of

2

h.

The RO Water system will see the most maintenance as filters need to be

replaced annually. Mount the system on a wall where clear access is

If a High Limit Stat is included, it

Flow Switch should be mounted on the supply side (positive pressure)

side of the duct system

I) Generator and DTA Location and Piping:

the Generator and DTA within 1

using the STS system the same rule applies.

installed LEVEL! VERY IMPORTANT!

When installing the DTA make sure it is level or pitching back slightly toward

the supply pipe. Fasten all holes on the DTA flange to the bottom of th

Make sure there are no obstructions

downstream of the DTA for at least 3

Sealant can be used on the flange if desired for complete seal.

Once you have located the Generator in a clear

hose cuffs and begin installing pipe between the Generator and the DTA.

Follow the project plans for piping size but verify that they adhere to the

following guidelines:

3000 Series should utilize 4”ID or greater supply pip

2000 Series should

1000 Series should utilize

When piping try to avoid creating

the piping. If you cannot avoid doing so then

from such trap locations.

3/8”id pipe/tubing and there should be at least a 3” long nipple of ½” size off

down to create enough “head” to drain the line.

e the drain line to an appropriate drain location. Again be sure not to trap

water. If necessary employ a condensate pump/drain to elevate the drain water

and evacuate it during drain cycles.

Determine whether the system you are installing is a

system (please note that the

designates what type of application, supply side or return side, your system

is. If any questions call the Factory Representative).

If the system is a supply si

feed from a take off up stream of the DTA location (consult your Submittal

drawings for more specific information).

10

’ ft of equivalent piping distance from

Make sure the STS tank is

either up stream or

and accessible location use the

*

water “traps” or low points in

sure to plumb a mini

Drain line size must be a minimum of

supply or return air

of ‘S or R’

de installation then you must pipe in a supply air

accessible.

i.

of the DTA.

j. The Air

INSTALLATION:

should be located at least

.

’ ft. downstream

A. Locate

each other.

B. When

C.

D.

E.

F.

-

-

-

CAUTION:

the trap pointed

Pip

0

, bends, or branches

’ft in either direction.

utilize 4”ID or greater supply piping

3”ID or greater supply piping

be

(see Fig. 1 )

e duct.

ing.

.

-drain

G.

humidifier schedule column

H.

3

CAUTION: For supply air locations there must be at least .075” static

pressure availabl

static pressure then a return air location may be required.

If you have a return side installation no supply air feed is needed.

When installing the STS Box be sure to leave adequate service

must have ‘pull’ room for the tank to be removed if necessary. The cover for

the STS Box is a ‘Zero’ clearance cover. However standard space

requirements are at least 1.5x the width of the STS Box of space is needed in

II

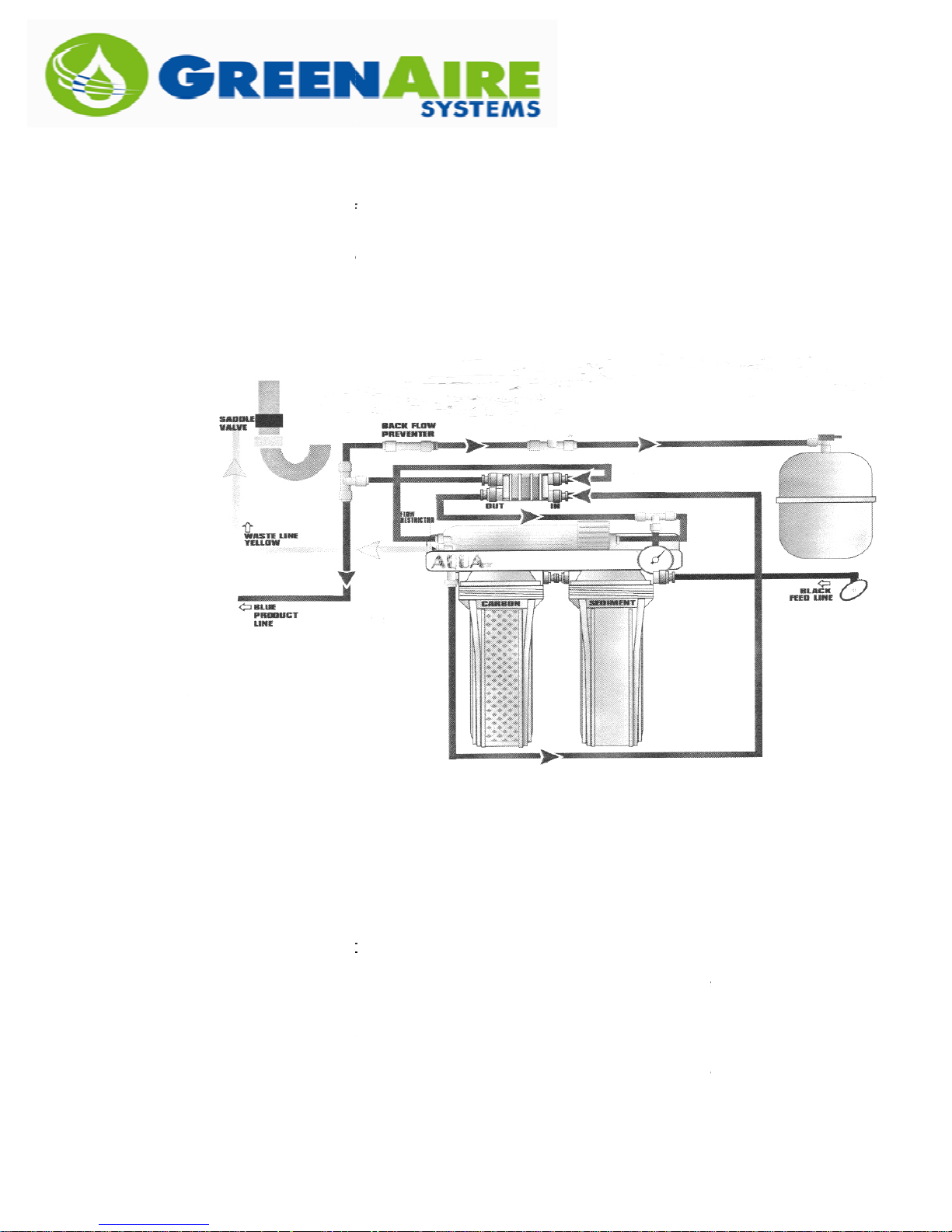

) RO System Location and Piping:

everse

mountable with simply two screws and can be hung as self supporting. Follow

outlined below

respective connections. All connections are simple quick connects. It is

recommended that a shut off valve be placed in line after tapping the domestic

water line for the RO System supply.

Locate and connect the

quipment. This will be the right side as you face the system. The

supply side will consist of Black ¼” tubing.

Locate the Yellow drain line, and place in an appropriate area for

drainage.

HUMIDIFICATION SEASON IS MONTHS AWAY.

CONDENSATE PUMP

Locate the b

humidifiers

system metal

storage tank.

proximity to the RO System.

Make sure to open the valve at the top of the storage tank.

Once installed, allow the system to run for approximately 15

minutes to flush completely. Make sure there are no leaks, parts

can come loose in shipping. Hand tightening may be necessary.

The RO System will run until all the humidifier supply lines and

torage tank are filled and charged to the pressure of the building.

This may take several hours to happen.

PLEASE N

WATER SUPPLY TO THE RO SYSTEM.

if this is a problem)

Pipe supply piping from

or STS Box

Open the inline water

filling of water to the

filling the clear water filter housings on the RO System.

e at the supply feed location. If there is not enough

Water system. These systems are wall

for connecting the colored tubes to their

supply side of the

! EVEN IF THE

e product water line that will provide

(provided and taped to the RO

to hook up the product water (blue line) to the

Locate the 2.5 gallon storage/bladder tank in close

ON

(Consult with the Factory

the RO System to the fitting on the side of the

valve off of the building domestic water supply to begin

System. You should notice water immediately

I.

J.

front to service it.

room. You

A. Now install the R

the instructions

1)

e

2)

3)

4)

5)

Osmosis (RO)

domestic water

NOTE: DRAIN MUST BE OPERABLE

– IT MUST BE ON LINE!

lu

. Utilize a “t” connector

frame)

IF PIPED TO A

RO water to the

6)

s

7)

B.

Panel/Generator

C.

the

OTE: 35 PSI MINIMUM REQUIRED

labeled “water in”.

RO

INCOMING

Control

4

D. Check for leaks.

As stated above The RO System will run until al

supply lines and storage tank are filled and charged to the pressure of the

building. This may take several hours to happen. Again, make sure that the

if the drain line is fed to a condensate pump the pump MUST

The RO System has an automatic shut off valve (ASO) that

is completely mechanical and will only open and pass water to drain when the

pressures are not equalized between the domestic water supply and the

humidifier supply lines. If there are any q

Factory Representative.

If the system was provided with a controlling humidity sensor then install it

and wire it from the Generator panel at the appropriately labeled locations on

Refer to the Wiring Diagram

unit for proper landing locations and line sizes.

recommended but not required.

Do the same as the above with both the High Limit humidistat and the Air

ovided. Terminal locations are again labeled in the Wiring

Diagram provided with your Unit.

S signal is being provided then connect it to the proper terminal

locations in the Generator as labeled in the

In this case a separate 24VAC signal is required to turn on the

uestions or issues please contact your

provided with your

ded control wire is

locate AFS before any

Wiring Diagram provided with the

drain is working –

BE OPERABLE!

l the humidifier

III) Accessories:

A.

the terminals.

B.

Flow switch if pr

CAUTION:

dampers.

C. If a BA

Unit.

humidifier.

(see Fig.2 )

Shiel

zone

5

IV)

Sequence of Operation:

A. Building Automation Control (BA

000 to generate output.

humidifier will first look to the air flow switch (AFS) safety and

the high limit switch (HL) safety before coming on.

efore leaving the RAH in an On

control logic will energize the normally closed water fill solenoid

valve. At the same time the normally opened drain solenoid valve will be closed. The

with water and when the low water safety

system will begin to generate fog

for humidification.

e continuous run time when humidifier is undersized or the space really needs

more humidifiers but the customer elected not to furnish and install them. If your model

has a timer delay relay go to that section in this Manual for more info.

In this configuration the Digital Controller governs the

humidifier. The electronic humidity sensor is wired back to the Control Panel per the

wiring diagram and the Controller will operate the system to maintain the set point.

act relay for activating the AHU Fan when there is a call for

Connecting this relay is at the discretion of the Installer and/or Owner.

Care must be taken to insure that zone dampers are opened as well when this relay is

the Controller determines the humidifier needs to come on to maintain

the humidity level the system will first look to the air flow switch (AFS) safety and the

high limit switch (HL) safety before coming on. Be sure these are installed and

rly before leaving the RAH in an On

control logic will energize the normally closed water fill

solenoid valve. At the same time the normally opened drain solenoid valve will be

l fill with water and when the low water safety float swit

satisfied the system will begin to generate fog (early generations of the RAH had two

low water safeties in series)for humidification. A timer relay may be installed for

essive continuous run time when humidifier is undersized or the space

really needs more humidifiers but the customer elected not to furnish and install them.

If your model has a timer delay relay go to that section in this Manual for more info.

S Control a

Once the 24VAC signal is sent

Be sure these are installed and

Assuming the two

)

(early generations of the RAH had two low water

A timer relay may be installed for prevention of

Line state. Assuming the two

signal is sent to the RAH-1

the system for output the

operating properly b

above safeties are good

system will fill

safeties in series)

excessiv

B. Local Control:

There is a dry cont

humidification.

energized. Once

S) Control: With BA

-Line state.

float switche(s

24VAC

to

are satisfied the

operating prope

above safeties are good,

closed. The system wil

prevention of exc

-

ch(s) are

6

WATER PURIFICATION

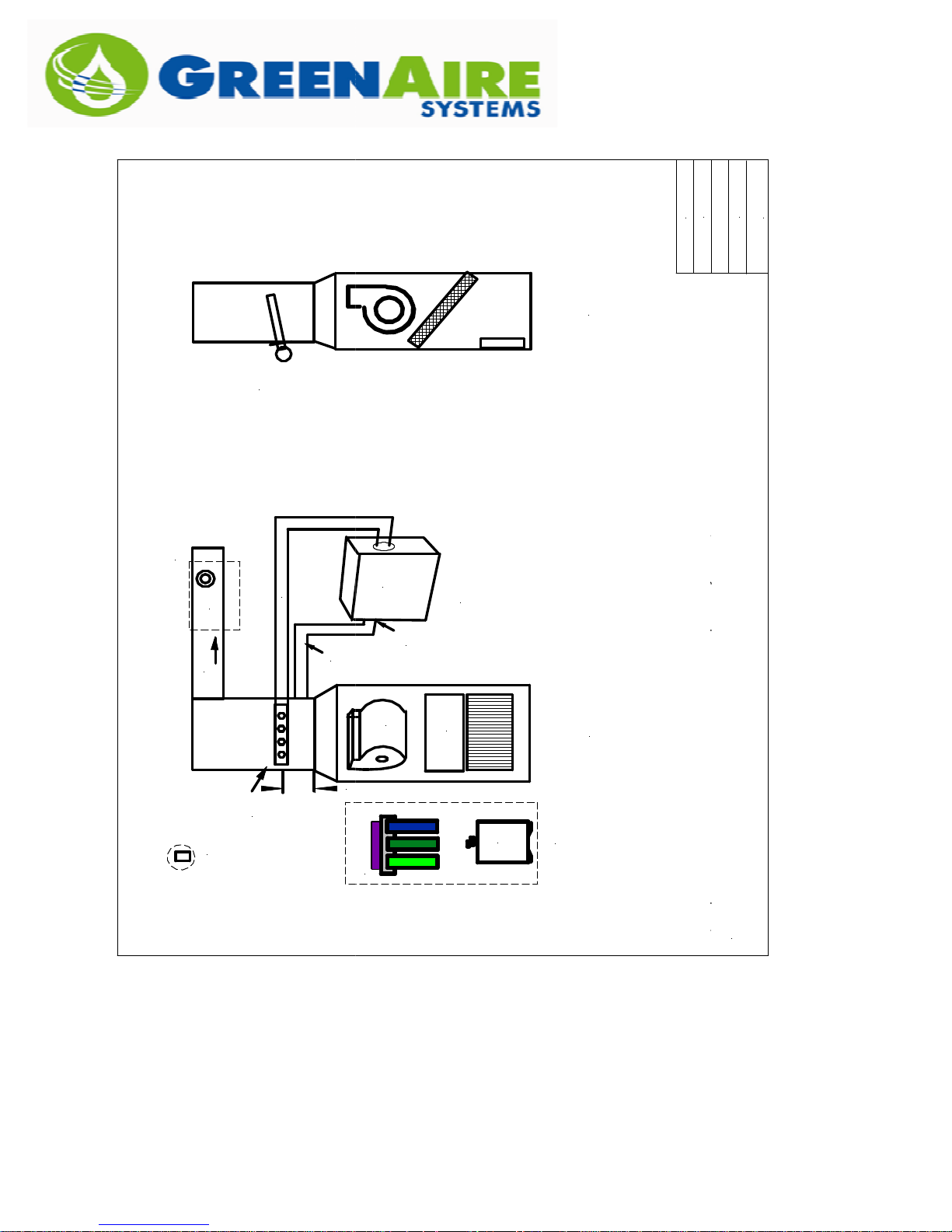

SUPPLY SIDE TYPICAL INSTALLATION

1)Componentsoutlinedindashed linesinadditiontoPanelandDTAprovidedbyReensAir,

TYPICAL UNIT

WATER PURIFICATION

SCALE: 1"=24"

BY: DJR -12/11/08

ISSUE:01 REV: 00

SIDEVIEW

ofcondensate

InstallDTAatslight

anglefordrainback

PANEL

WIREBACK

TOCONTROL

SWITCH

AIRFLOW

SUPPLYAIR

3"ODCOPPER

4"OD

METAL

SHEET

9"

Tube

Assembly

Dispersion

el/Generator

iredbackto

tronicWall

Elec

sensorw

ControlPan

R

0

O

0

T

0

A

1

R

H

E

A

N

R

E

G

completelyopen

InstallGeneratorat

TO

REDUCE

3"ATPANEL

FAN

angleso doorcanswing

HX

FILTER

INTAKE

R

ROMCLOSETDOO

t

FRONTVIEWF

TANK

STATION

STORAGE

isfornotifiationonly.

necessarillyhere. This

Note:water stationlocationis no

NOTES:

all otherpiping,wiring,mounting andinstallationbyothers.

2)Controllingwall mountedsensor,airflowswitch, providedbyReensAir.

3)Donot trapsupplypipingtoDTA- mustdrainbacktoPanel.

7

15AmpCir.

RETURN AIR SIDE INSTALLATION

2)Controllingsensor, air flowswitchprovidedbyReensAir.

15AmpCir.

NTS

2)Controllingsensor, air flowswitchprovidedbyReensAir.

1000SERIES

FIGURE 1: TYPICAL LAYOUT

COLD

WATER

BY: D.J.REENS

TODRAIN

STATION

WATER PURIFICATION

FIGURE 1: TYPICALLAYOUT

CONTROL PANEL

1/4" LINETOADDITIONAL

PANEL

120V

OUTLET

3"PVC

DUCT MTD. SENSOR (4 WIRE)

AIRFLOW SWITCH

SUPPLYAIR

20"x20"x12"

REENSAIR

CONTROL

3"L-1/2" pipe

nippleminimum.

DRAINALLLOWPOINTS

10"

TANK

STORAGE

DUCT

RETURN

ELECTRONIC

AIRFILTER

NOTES:

1)Components outlinedin dashed circles providedbyReensAir,

allother piping, wiring, mountingandinstallationbyothers.

3)Allattic spacehumidifierlocationsmustbeheatedandfreezeprotected.

4)Alllowpointsofdistributiontubingmustbedrained.

5)Pleasereviewall ProjectdocumentationandIO&Ms formoreinformation.

8

STORAGE

STORAGE

0

06/14/13

Rev.

Date

GREENAIRESYSTEMS,LLC

270D ROWEAVE.

MILFORD, CT06460

(203)683-1644

Room

Res.

Greer

Project

HL

AFS

FOGON

38

40

J K

H

I

SETPT.

RETURN

CONTROLLER

ON/OFF

14"H x 12"Wx 7"D

RAH-1030/1050-STS

Product

VisitGreenAireat www.greenairesystems.com

AIR

SUPPLY

cable

RHC

CC

lowvoltage

multi-conductor

HorizontalAC Unit

FILTER

andhorizontal tubes

DTA-Vertical header

'P'Trap

G

Duct extension

16"LSheet Metal

F

C

RETURN SIDEAPPLICATION

TANK

3 GAL.

:

1050-STSUNIT

20"Lx12"Wx10"H

3/8"OD

waterdrain

E

Humidity Sensor, duct orroommounted.

Air FlowSwitch

SupplyHi-Limit Switch

Humidifiers

3/8" Main to

D

3/8" Main

1/4"OD

C

ROFeed

ADDITIONAL ITEMS

HL

STATION

AFS

ROWATER

B

A

9

1/4" OD

AFS

1/4" OD

SUPPLY SIDEAPPLICATION

* PleaseNote: One(1)ROWater Stationcanserve

SUPPLY SIDEAPPLICATION

* PleaseNote: One(1)ROWater Stationcanserve

HL

38

AIR

SUPPLY

40

HOUR

004550

SETPT.

RETURN

CONTROLLER

METER

HI J K

FOGON

ON/OFF

header and

DTA- vertical

horizontaltubes

'P'Trap

16"Hx 12"Wx7"D

RAH-1090-STS

F

G

cable

1/4"OD

ROFeed

1050-STSUNIT

20"Lx12"Wx10"H

waterdrain

lowvoltage

multi-conductor

E

D

3/8" Main

C

RHC

CC

:

HorizontalACUnit

FILTER

AirFlowSwitch

SupplyHi-Limit Switch

HumiditySensor, ductor roommounted.

ADDITIONALITEMS

HL

AFS

C

TANK

3 GAL.

STORAGE

Humidifiers

3/8" Mainto

STATION

ROWATER

B

ROStation is not uncommon.

multiplehumidifiers. Uptofive(5)humidifiers per

A

10

DUCT

DUCT

DTA

POSSIBLE LOCATIONS

STS UNIT

AIR

FEED

SUPPLY

SUPPLYDUCT

DTA

STSUNIT

AIR

FEED

SUPPLY

PLANVIEW

ACUNIT

STS UNIT

DTA

EXT.

STS UNIT

STS UNIT

STS UNIT

11

STS WIRING with CONTROLLER

- DENOTES ITEMLOCATION OUTSIDEOFCONTROL PANEL/GENERATOR.

On/Off

7

2

500VA

FLOATSWITCH

10

10

1

3

L1

120V/1PH

Circuit

Breaker

7.5Amp

+

CONTROLLER

CRC

120VAC

48VAC

3

N

2

RH

SENSOR

-

Power On

R

12

12A

12C

13

11

11

3

9

CRC

WETSWITCH

AFSSWITCH

HILIMIT

TIMER

RELAY

HHLS FLS

10Amp

Fuse

16

5

120VAC

24VAC

9

CR3

12B

CR3

SAFETY

17

10

1813

50VA

LLS

7

STS

BOX

6

CR4

WET

SWITCH

LowWater

17B

A

CR1

WS

R

TIMER

RELAY

CR5

Drain

SV-1

NO

CR4

15

21

FogOn

G

CR3

CR2

2

CR2

FCR

CR2

REMOTE START/STOPRELAY

CR-1

24 25

NOTES:

Fill

19

SV-2

NC

WiringDiagram

w/Controller

STS1090,70,50,30

Issue:01Rev:00

Date: 09/18/13

Scale:1"-3"

12

STS WIRING for REMOTE CONTROL

- DENOTESITEMLOCATIONOUTSIDE OFCONTROL PANEL/GENERATOR.

On/Off

120VAC

10

FLOAT SWITCH

18

10

1

11

11

12

L1

3

3

9

120V/1PH

Circuit

Breaker

7.5Amp

CR1

WETSWITCH

10Amp

Fuse

120VAC

48VAC

3

24VAC

9

REMOTESTART/STOP

24 25

500VA

7

5

2

40VA

CR3

12B

CR1

CR4

HI

LIMIT

Power On

7

6

LowWater

17B

R

STS

BOX

WET

SWITCH

A

WS

N

2

2

CR5

R

NOTES:

12A

12C

AFSSWITCH

HILIMIT

TIMER

RELAY

13

17

CR3

SAFETY

13

HHLS FLS

16

FCR

CR2

LLS

CR2

Drain

SV-1

NO

CR4

15

21

19

TIMER

RELAY

FogOn

G

Hour Meter

1111

CR2

Fill

SV-2

NC

CR3

10

Remote Control

Wiring

STS1090,70,50,30

Issue: 02Rev:01

Date: 10/11/13

Scale:1"-3"

13

STANDARD RAH WIRING WITH CONTROLLER

- DENOTESITEM LOCATION OUTSIDEOFCONTROLPANEL/GENERATOR.

On/Off

2

500 VA

50VA

FLOAT SWITCH

2

10

10

1

3

L1

120V/1PH

Circuit

Breaker

7.5Amp

+

CONTROLLER

CRC

120VAC

48VAC

3

N

RH

SENSOR

-

Power On

R

12

12A

12C

13

11

11

3

9

CRC

WET SWITCH

AFSSWITCH

HILIMIT

TIMER

RELAY

10Amp

Fuse

120VAC

24VAC

9

HHLS FLS

16

5

CR3

12B

CR3

SAFETY

7

7

UPC

TANK

6

CR4

10

WET

SWITCH

LowWater

17B

A

CR1

WS

R

TIMER

RELAY

Drain

SV-1

NO

FogOn

G

CR4

17

15

LLS

1813

21

Hour Meter

1111

CR3

CR2

2

CR2

FCR

CR2

FAN ONRELAY

CR-1

24 25

NOTES:

Fill

19

SV-2

NC

WiringDiagram

w/Controller

1090,70,50,30

Issue:01Rev:00

Date:10/5/13

Scale:1"-3"

14

TROUBLE SHOOTING SECTION

1.

No Power or Lites When Unit is turned on

breaker in the wiring circuitry. Make sure the breaker is turned on and there are fuses

located at each of the transformers in the Control Panel.

Power is on but no fog is produced:

Verify that the water valves are open.

Verify that the digital controller

lite value (target humidity set point) than the red, process value lite (actual

humidity level being read by the sensor). If the red value is above your target

required humidity levels have been satisfied and there is no need for

the humidifier to operate. To verify that the system is properly working

temporarily raise the set point to a higher value and make sure that the

comes on.

he air flow switch has closed after properly sensing that air is

moving in the duct.

Check the Wet Switch and verify that the green LED on the switch is lit. If it is

red that means that moisture was sensed by the switch and there is a leak

be fixed.

Water is not filling into the Tank:

Verify that the RO System is on line, i.e. the water valve is open and the

water filter housings have filled up and the unit is draining water as it makes

Make sure the shut off valve on

then pressurize the system.

Verify that you have at least 30

do not then a small booster pump may be required to supply adequate

temperature of the incoming water supply. If it is real cold, near or

below 40F, then the RO s

filters and make sure they are not clogged and filled with dirt

and debris. It is not uncommon with ne

water initially as the domestic water supplies come on line. This dirt and

suspended solids can sometimes prematurely clog the filters. If this is the

case call the factory for replacement filters.

that the Unit is Humidifying:

Keep track of the Panel mounted controller readings to see if the humidity is

Open up the Control Panel and observe the tank and if you see a cloudy, wet

tank along with the gurgling noise of water then the uni

and an overall circuit

has a higher green

Verify that the HiLimit switch circuit is closed.

top of the water tank is open. This will fill and

35PSI of water pressure to work with. If you

not make sufficient water.

w construction sites to have very dirty

t is definitely making

2.

3.

a.

b.

then the

humidifier

c. Verify that t

d.

that must

a.

: There are fuses

, if the Humidifier has one,

b.

c.

d. Check the

e. Check the pre-

4. Verifying

a.

b.

RO Water.

-

pressure.

ystem may

rising.

15

If the tank is clear and you can see to the bottom of it then it is not

c.

For verifying the amount of moisture being produced measure the air

conditions before the DTA and then downstream of it. You should measure

oth a decrease in dry bulb temperature and an increase in relative humidity.

Plot these on a Psychometric chart or call the Factory for further interpolation.

Low Humidity conditions continue to persist

Moisture migrates very quickly. Make su

humidified zone are closed or not opened long. Make sure no new or un

seen sources of outside air have been introduced to the space being

humidified as this will increase the load on the humidifier.

blower fan is turning on when there is a call for humidification

and not just when there is a call for heat. There is a dry contact relay in the

panel for exactly this purpose. Contact the Installer to verify that he utilized

this relay and that the cont

has been set up to run the fan only when there is a call for humidification.

Also make sure that the necessary zone dampers are also opening to allow

moisture to be delivered to the appropriate spaces.

ake sure the air filters to the furnace/blower/heat pump are not completely

clogged and restricting air flow.

Verify that the amperage draw for the 120VAC and 48VAC side of the circuits

at or near the rated amount for that system. If it is below the labeled

ratings then some of the UPC

fill solenoid valve is going on and off too frequently as well as the

Check water supply

Open the tank a

Verify that the RO System has had ample time to charge the system (this can

eral hours depending on the quantity and dis

supply piping to the humidifiers.

Ensure that there is enough

that feeds the RO System. A minimum of 35 PSI is required.

re all windows and doors to the

rol sequence on the blower system or heat pump

circuits are not functioning. Call the Factory if

situation happens when there is not enough water

will be very slow.

tance of pipe in the RO

pressure in the domestic water supply

fog.

working.

b

5.

a.

fore

b. Verify that the

c. M

d.

are

this is the case.

6. Unit is Cycling – the

‘Fog On’ lite.

a.

to fill the tank.

b.

take sev

:

-

– this

nd observe the rate of fill – it

c.

‘house’

16

PREVENTATIVE MAINTENANCE:

I. Humidifier Control Panel:

at the end or beginning of the season

the inside of the tank with a clean and non

down each of the discs as well. To take the tank lid off disconnect the supply

(and inlet supply if the unit is a supply side unit) then loosen

all the wing nuts and disconnect the fan wires at either the terminal or at the

Total time estimated:

1. verify the output is adequate by observ

making sure all the UPC discs that should be running are indeed doing so.

You may do this by observing the operation with a flash light and peering

through the plastic lid or taking the lid off (see above instructions) and

the unit on briefly (for 3

NOT EVER JUMP OUT THE LOW WATER FLOAT SWITCHES.

2. remember that the 1000 series

To determine whether how many are on line for

how many pairs of #6 and #7 wires are attached to the terminal switch. You

may have one or two spare banks (each bank has a capacity of

approximately 3 lbs/hr of gross fog production) depending on the required

unit. If you observe any non

add one of the spare banks by attaching their #6 & #7 lines to the terminals.

3. replace the float switch tank. Call the Factory for a replacement.

Replace the filters and the membrane on the RO Plant.

Total time estimated:

take the tank lid off and wipe down

abrasive rag. Make sure to wipe

ing the unit under operation and

5 seconds) WATER MUST BE IN THE TANK

output levels possible.

your particular unit

performing UPCs then you may

A) Every 2 – 3 years:

1.

pipe coupling

fan.

B) Every 5 years:

30 Minutes

–

-

turning

– DO

can have multiple

simply see

load for your

II. RO System:

A) Annually:

1.

-

15 minutes

17

DIGITAL CONTROLLER

18

19

Controller

Configuration

I) Initial Programming:

their controllers pre

is somehow lost, here is the access and settings:

A. To Access the “Initial Setting Mode” press

button for 3 seconds.

(this sets the input type, which is 0

(this sets the high of the process, RH)

(this sets the low of the process, RH)

(this sets the control type your using)

(control mode, use

(this feature not used)

(this feature not used)

(this feature not used)

(this feature not used)

(this feature not used)

(baud rate if data transfer was used)

(this feature not

Parity

Stop bit setting

humidifiers have

programmed in the Factory but if it

Here are the settings as shown

page 13:

:

All ReenAir

-

on

inPT = u10

tP-H = 100

tP-L = 0

Ctrl = on/off

S-HC= heat

ALA1= 0

SALA= off

CoSH= off

C-SL= ASCII

C-no = 1

bPS = 9600

LEN = 7

Prty = even

Stop = 1

-10v)

heat)

used)

20

21

2.4 MHz Nebulizer Board

Model#579R3 304SS with welds, stand brackets, top flange w/ PEMS and bottom hole

Polypropylene Float Switch

Way NC Stainless Stl Sol.Valve

Way NO Stainless Stl. Sol.Valve

Wall Metal Enclosure (20x20x12)

Terminal connector blocks

Terminal Connector End Blocks

120VAC to 48VAC Transformer. Rated

120VAC to 24VAC Transformer. Rated for 250VA. Open.

2 channels

-

Control Panel for the RAH 2000 & 3000

Relay 24VAC, 15 Amp, Dpdt, 8 terminal

8 terminal

Lexan Clear Poly Sheet .22"thk, 24"x24" sheet

PLC Controller for Humidity

Duct HMD50U

Wall HMW50U

Humidity Switch / simple controller

Duct 10

Nema 1 Control Panel 12x12z6

Gen Purpose Relay 24VAC 10Amp

8 SS Pan Head Phillips Machine Screw 8

8 SS Machine Screw Hex Nut. 8

EPDM Rubber cushioning and sealing washer #8 screw size, .150 ID, 5/16 OD, .062 thick, ...

8 Pan Head Phillips Machine Screw 8

12" x 24" x 1/4"

EPDM O Ring size: 4.5" OD

24VAC

red 120V

6 Amp 120V

Idec Double Pole Relay

Idec Double Pole Socket

-

Idec Single Pole Socket

PARTS LIST

32 Trhread, 1/2" Length, Pack of 100

Sales

Part No.

6001

6002

6003 Gasket for UPC Tank 6004

6005 26006 26007

6008

6009

6010 Jumpers - 2 Pole

6011

6012

6013 Hobo Data Logger

6014 Hobo Data Logger 6015 50 GPD RO System

6016 Redington Hour Meter

6017

6019 1.65 MHz PC Board

6020

6021 Relay Socket 6024

6025

6026 Humidity Sensor 6027 Humidity Sensor 6028

6029 Humidity Sensor 6030

6031

6032 Screw 186033 Nut 186034 Washer 6035 Screw 186036 Nat.Rubber Sheet 6037

6038 15 Amp Littlefuse

6039 Idec Pilot Lite - Red 6040 Switch - 2 pos., lited 6041 Circuit Breaker 6043 Idec Pilot Lite - Green 6045

6046

6047 Idec Single Pole Relay

6048

UPC Tank w/PE...

Item Description

Model#:579R3

for 500VA. Open.

24V

-35VDC input required. 0 - 10 VDC output.

-

-32, 5/16 width 100 per pack

-32, 3/4" long, 100 per pack

24VAC

- 24V

24VAC

Price

31.00

144.00

10.00

28.52

35.60

66.36

332.00

0.94

1.40

0.64

89.00

64.80

250.00

240.00

258.00

54.52

1,350.00

27.28

16.26

11.24

69.44

160.00

250.00

270.00

80.00

148.00

170.00

32.00

0.00

0.00

0.00

0.00

0.00

25.00

19.75

25.00

52.00

36.00

25.00

13.40

8.46

12.60

7.00

22

6050 EMI/RFI Fan Guard

Plastic Fan Guard for 4.69" Fan

Bulkhead Conn. 1/4T x 1/8MPT Brass Part#: B

clear w/ paper back in square ft units

10 Amp fuse, 12/32" dia. time delay, 250 VAC,

Amp Fuse, 13/32" dia., 250VAC time delay type

Little Giant Condensate pump. 120HP, 1/50 HP, 1.1 amps, 40 GPH at 8' head

Miniature Pressure Switch. Sensitive to .5" H2O <. Quick connect electrical connections. SPST...

All above prices are subject to change. Please call Factory or Factory

Representative for current pricing.

6051

6052

6053 .5" Acryllic Sheet 6055

6056 5

6057

6058

6124 Timer On/Off Relay

PLEASE NOTE:

1)

-400-11-2

10.00

2.00

9.00

22.00

7.00

7.00

75.00

55.00

146.00

23

Loading...

Loading...