GREE ELECTRIC APPLIANCES,INC.OF ZHUHAI

Change for Life

Service Manual

GWH12TB-S3DBA1E

GWH12TB-S3DBA2E

GWH12TB-S3DBA3E

(Refrigerant R410A)

Models:

Service Manual

Table of Contents

Table of Contents

Part

Ⅰ

: Technical Information

.......................................................................1

1. Summary

......................................................................................................................1

2. Specications

..........................................................................................................2

2.1 Specication Sheet ...........................................................................................................2

2.2 Operation Characteristic Curve ........................................................................................4

2.3 Capacity Variation Ratio According to Temperature .........................................................4

2.4 Noise Curve ......................................................................................................................5

2.5 Cooling and Heating Data Sheet in Rated Frequency .....................................................5

3. Outline Dimension Diagram

........................................................................6

3.1 Indoor Unit ........................................................................................................................6

3.2 Outdoor Unit .....................................................................................................................7

4. Refrigerant System Diagram

......................................................................8

5. Electrical Part

...........................................................................................................9

5.1 Wiring Diagram .................................................................................................................9

5.2 PCB Printed Diagram ..................................................................................................... 11

6. Function and Control

......................................................................................13

6.1 Remote Controller Introduction .....................................................................................13

6.2 Operation of Smart Control (Smart Phone, Tablet PC) For Gree ...................................19

6.3 Operation of Smart Control (Smart Phone, Tablet PC) .................................................32

6.4 Brief Description of Modes and Functions ......................................................................45

Part

Ⅱ

: Installation and Maintenance

.................................................53

7. Notes for Installation and Maintenance

..........................................53

8. Installation

................................................................................................................56

8.1 Installation Dimension Diagram ......................................................................................56

8.2 Installation Parts-checking ............................................................................................58

8.3 Selection of Installation Location ....................................................................................58

8.4 Electric Connection Requirement ...................................................................................58

8.5 Installation of Indoor Unit ................................................................................................58

8.6 Installation of Outdoor Unit .............................................................................................61

8.7 Vacuum Pumping and Leak Detection ...........................................................................62

8.8 Check after Installation and Test Operation ...................................................................62

Service Manual

Table of Contents

9. Maintenance

............................................................................................................63

9.1 Troubleshooting for Normal Malfunction .........................................................................63

9.2 Error Code List ...............................................................................................................67

9.3 Troubleshooting for Main Malfunction ............................................................................72

10. Exploded View and Parts List

..............................................................85

10.1 Indoor Unit ....................................................................................................................85

10.2 Outdoor Unit .................................................................................................................88

11. Removal Procedure

.......................................................................................90

11.1 Removal Procedure of Indoor Unit ...............................................................................90

11.2 Removal Procedure of Outdoor Unit ............................................................................97

Appendix:

......................................................................................................................102

Appendix 1: Reference Sheet of Celsius and Fahrenheit ..................................................102

Appendix 2: Conguration of Connection Pipe ...................................................................102

Appendix 3: Pipe Expanding Method .................................................................................103

Appendix 4: List of Resistance for Temperature Sensor ....................................................104

1

Service Manual

Technical Information

Part

Ⅰ

: Technical Information

1. Summary

Indoor Unit:

Remote Controller:

YAC1FB

GWH12TB-S3DBA3E/I

GWH12TB-S3DBA1E/I

GWH12TB-S3DBA2E/I

Outdoor Unit:

GWH12TB-S3DBA3E/O

MODE FAN

TURBO

SLEEPI FEEL

TIMER ON

TIMER OFF

CLOCK

QUIET

X-FAN TEMP LIGHT

2

Service Manual

Technical Information

Parameter Unit Value

Model

1.GWH12TB-S3DBA1E

2.GWH12TB-S3DBA2E

3.GWH12TB-S3DBA3E

Product Code

1.CB148009102 2.CB411003901

3.CB412002902 CB412002903

Power

Supply

Rated Voltage V~ 220-240

Rated Frequency Hz 50/60

Phases 1

Power Supply Mode Outdoor

Cooling Capacity(Min~Max) W 3500(1150~4000)

Heating Capacity(Min~Max) W 3650(2000-5300)

Cooling Power Input(Min~Max) W 890(215~1300)

Heating Power Input(Min~Max) W 900(390~1900)

Cooling Current Input A 4.00

Heating Current Input A 4.00

Rated Input W 1900

Rated Current A 8.50

Air Flow Volume (SH/H/MH/M/ML/L/SL) m3/h 740/670/610/530/460/410/380

Dehumidifying Volume L/h 1.40

AEER 3.93

ACOP 4.06

SEER 7.80

SCOP

Average:4.6

Warmer:5.6

Colder:3.2

Application Area m

2

16-24

Indoor Unit

Indoor Unit Model

1.GWH12TB-S3DBA1E/I

2.GWH12TB-S3DBA2E/I

3.GWH12TB-S3DBA3E/I

Indoor Unit Product Code

1.CB148N09102 2.CB411N03900

3.CB412N02902 CB412N02903

Indoor Unit Fan Type Cross-ow

Indoor Unit Fan Diameter Length(DXL) mm Φ98X662

Cooling Speed (SH/H/MH/M/ML/L/SL) r/min 1350/1070/1000/900/800/700/500

Heating Speed (SH/H/MH/M/ML/L/SL) r/min 1350/1150/1080/1030/980/900/850

Indoor Unit Fan Motor Power Output W 15

Indoor Unit Fan Motor RLA A 0.07

Indoor Unit Fan Motor Capacitor μF /

Evaporator Form Aluminum Fin-copper Tube

Evaporator Pipe Diameter mm Φ7

Evaporator Row-n Gap mm 2-1.5

Evaporator Coil Length (LXDXW) mm 662X25.4X305

Swing Motor Model MP24HA/MP24HB/MP24HC

Swing Motor Power Output W 2.4/2.4/2.4

Fuse Current A 3.15

Sound Pressure Level (SH/H/MH/M/

ML/L/SL)

dB (A) 45/36/34/32/28/24/22

Sound Power Level (SH/H/MH/M/ML/

L/SL)

dB (A) 59/50/48/46/42/38/35

Dimension (WXHXD) mm 866X292X209

Dimension of Carton Box (LXWXH) mm 942X374X282

Dimension of Package (LXWXH) mm 945X377X297

Net Weight kg 11

Gross Weight kg 13

2. Specications

2.1 Specication Sheet

3

Service Manual

Technical Information

Outdoor Unit

Outdoor Unit Model GWH12TB-S3DBA3E/O

Outdoor Unit Product Code CB412W02901

Compressor Manufacturer ZHUHAI LANDA COMPRESSOR CO., LTD

Compressor Model QXAT-B096zE070

Compressor Oil 68EP

Compressor Type Rotary

Compressor Locked Rotor Amp (L.R.A) A 40.00

Compressor Rated Load Amp (RLA) A 5.40

Compressor Power Input W 1130

Compressor Overload Protector 1NT11L-6233

Throttling Method Electron expansion valve

Set Temperature Range °C 16~30

Cooling Operation Ambient

Temperature Range

°C -15~54

Heating Operation Ambient

Temperature Range

°C -30~24

Condenser Form Aluminum Fin-copper Tube

Condenser Pipe Diameter mm Φ7

Condenser Rows-n Gap mm 2.5-1.4

Condenser Coil Length (LXDXW) mm 773X57X550

Outdoor Unit Fan Motor Speed rpm 850/700/600

Outdoor Unit Fan Motor Power Output W 30

Outdoor Unit Fan Motor RLA A 0.15

Outdoor Unit Fan Motor Capacitor μF /

Outdoor Unit Air Flow Volume m3/h 2000

Outdoor Unit Fan Type Axial-ow

Outdoor Unit Fan Diameter mm Φ438

Defrosting Method Automatic Defrosting

Climate Type T1

Isolation I

Moisture Protection IP24

Permissible Excessive Operating

Pressure for the Discharge Side

MPa 4.3

Permissible Excessive Operating

Pressure for the Suction Side

MPa 2.5

Sound Pressure Level (H/M/L) dB (A) 55/-/-

Sound Power Level (H/M/L) dB (A) 62/-/-

Dimension (WXHXD) mm 899X596X378

Dimension of Carton Box (LXWXH) mm 945X417X630

Dimension of Package (LXWXH) mm 948X420X645

Net Weight kg 43.5

Gross Weight kg 46.5

Refrigerant R410A

Refrigerant Charge kg 1.3

Connection

Pipe

Connection Pipe Length m 5

Connection Pipe Gas Additional

Charge

g/m 20

Outer Diameter of Liquid Pipe mm Φ6

Outer Diameter of Gas Pipe mm Φ12

Max Distance Height m 10

Max Distance Length m 20

Note: The connection pipe applies metric diameter.

The above data is subject to change without notice; please refer to the nameplate of the unit.

4

Service Manual

Technical Information

Cooling

0

2

4

6

8

10

1502030405

05

060 70 80 90 15020304060708

090

Compressor speed (rps)

Current (A)

Heating

0

2

4

6

8

10

Compressor speed (rps)

Current (A)

Condition

Indoor:DB27°C WB19°C

Outdoor:DB35°C WB24°C

Indoor air flow: Super High

Pipe length: 5m

Condition

Indoor:DB20°C

Outdoor:DB7°C

Indoor air flow:Super High

Pipe length: 5m

12K

12K

2.2 Operation Characteristic Curve

2.3 Capacity Variation Ratio According to Temperature

Cooling Heating

-30-1532 35 38 42 48

60

70

80

90

100

110

120

50

40

40

50

120

110

100

90

80

70

60

10

70-8-20

Outdoor Temp.(°C) Outdoor Temp.(°C)

• Conditions

Indoor: DB27°C/WB19°C

Outdoor: DB35°C/WB24°C

Indoor air flow: High

Pipe length: 5m

• Conditions

Indoor: DB20°C/WB15°C

Outdoor: DB7°C/WB6°C

Indoor air flow: High

Pipe length: 5m

Capacity ratio(%)

Capacity ratio(%)

5

Service Manual

Technical Information

2.5 Cooling and Heating Data Sheet in Rated Frequency

Cooling:

Rated cooling

condition(°C) (DB/WB)

Model

Pressure of gas pipe

connecting indoor and

outdoor unit

Inlet and outlet pipe

temperature of heat

exchanger

Fan speed of

indoor unit

Fan speed of

outdoor unit

Compressor

revolution

(rps)

Indoor Outdoor P (MPa) T1 (°C) T2 (°C)

27/19 35/- 12K 0.9 ~ 1.2 12 to 14 39 to 43 TURBO High 54

Instruction:

T1: Inlet and outlet pipe temperature of evaporator

T2: Inlet and outlet pipe temperature of condenser

P: Pressure at the side of big valve

Connection pipe length: 5 m.

Heating:

Rated heating

condition(°C) (DB/WB)

Model

Pressure of gas pipe

connecting indoor and

outdoor unit

Inlet and outlet pipe

temperature of heat

exchanger

Fan speed of

indoor unit

Fan speed of

outdoor unit

Compressor

revolution

(rps)

Indoor Outdoor P (MPa) T1 (°C) T2 (°C)

20/15 7/6 12K 2.1 ~ 2.6 34 to 37 3 to 5 TURBO High 56

2.4 Noise Curve

20

25

30

35

40

45

Super

High

Indoor fan motor rotating speed (rps)

Indoor Unit Outdoor Unit

Noise/dB(A)

12K

30

35

40

45

50

55

Compressor speed (rps)

Noise/dB(A)

High Middle

High

Middle Middle

Low

Low Quiet

0820 30 40 50 60 70 80

90

12K

6

Service Manual

Technical Information

3. Outline Dimension Diagram

3.1 Indoor Unit

Unit:mm

Model W H D Q R S W1 W2

12K 866 292 209 162 541 163 160 80

WD

H

QRS

Φ55Φ55

35

W2W1

7

Service Manual

Technical Information

3.2 Outdoor Unit

Unit:mm

596

354

899

303 838

378

550

8

Service Manual

Technical Information

4. Refrigerant System Diagram

Connection pipe specication:

Liquid : 1/4" (6 mm)

Gas :1/2" (12mm)

INDOOR UNIT OUTDOOR UNIT

HEAT

EXCHANGE

(EVAPORATOR)

HEAT

EXCHANGE

(CONDENSER)

COMPRESSOR

GAS SIDE

3-WAY VALVE

LIQUID SIDE

2-WAY VALVE

COOLING

HEATING

Accumlator

Discharge

Suction

4-Way valve

Electron

Strainer

Strainer

expansion

valve

Strainer

Capillary

D

Strainer

Intercooler

9

Service Manual

Technical Information

5. Electrical Part

5.1 Wiring Diagram

● Indoor Unit

●Instruction

Symbol Symbol Color Symbol Symbol Color Symbol Name

WH White GN Green CAP Jumper cap

YE Yellow BN Brown COMP Compressor

RD Red BU Blue Grounding wire

YEGN Yellow/Green BK Black / /

VT Violet OG Orange / /

Note: Jumper cap is used to determine fan speed and the swing angle of horizontal lover for this model.

3OHDVHGRQWWRXFKDQ\

HOHFWURQLFFRPSRQHQWRU

WHUPLQDOZKHQWKHPDFKLQH

LVUXQQLQJVWRSSLQJRU

KDVEHHQSRZHUHGRIIIRU

OHVVWKDQPLQXWHVWR

SUHYHQWHOHFWULFVKRFN

:$51,1*

(/(&75267$7,&

'('867,1*

;

<(*1

+($/7+/

+($/7+1

%8

5'

*(1(5$725

3/$60$

$1'

%2$5'

7(03

7(03

',63

$3

',63

',63/$<

5(&(,9(5

)$102725

'&02725

78%(

5220

6(1625

6(1625

78%(

57

57

5220

$3

6$

6:,7&+

&211(&725

12

;

&

;

%.

:+

&/($1

0

0

83'2:1

02725

67(33,1*

02725

67(33,1*

02725

83'2:1

/()75,*+7

6:,1*8'

6:,1*8'

67(33,1*

35,17('&,5&8,7%2$5'

-803

&$3

6:,1*/5

0

<(*1

<(*1

%8

%.

%1

287'22581,7

%/2&.

&11(&7,1*

&$%/(

7(50,1$/

1

;7

(9$325$725

3(

%8

%.

%1

1

&20287

$&/

3(

&2/'

&20,11(5

;

$3

:,5('

&21752//(5

0

:,),

:,),02'8/(

237,21$/

;

GWH12TB-S3DBA3E/I(CB412N02902)

6361268408

10

Service Manual

Technical Information

● Outdoor Unit

These wiring diagrams are subject to change without notice; please refer to the one supplied with the unit.

GWH12TB-S3DBA3E/O

GWH12TB-S3DBA1E/I GWH12TB-S3DBA2E/I GWH12TB-S3DBA3E/I(CB412N02903)

/1

(;3$16,21

9$/9(

(/(&7521,&

5($&725

9$/9(

:$<

6:,7&+

35(6685(

3527(&72529(5/2$'

9$/9(

:$<

2)$1VA

AC-L2

<9

6$7

/

/

/;

/

2*

:+

/;

&203:&2039

+33

29&&203

///

)$1

&203

3(

&1

(.9

&208

$&/

:$<

$&/

1

5'

8%(<

<(*1

5'

&2038

3(

V

W

U

(

2)$1

57

57 57

0

&203

<9

N2

N3

BU

%1

%.

%8

/

<(*1

/

3(

0$*1(7,&

5,1*

1

%/2&.

7(50,1$/

;7

/

N

<(*1

,1'22581,7

32:(5

3(

%8

%.

%1

<(*1

%8

%1%.

<(*1

RIHOHFWULFVKRFN

3OHDVHGRQWWRXFKDQ\

WHUPLQDOZKHQWKHPDFKLQHLV

UXQQLQJVWRSSLQJRUKDVEHHQ

SRZHUHGRIIIRUOHVVWKDQ

PLQXWHVWRSUHYHQWWKHULVN

/

0RWRU

DSSOLHVWRWKH

LURQVKHOOPRWRU

JURXQGRQO\

78%(

7(03

6(1625

5220

7(03

6(1625

(;+$867

7(03

6(1625

+($7/

+($71

%27720

%$1'

+($71

&2035(6625

%$1'+($7(5

02725

:+ :+

K

K K

+($7(5

97 97

5'

BU BU

&1

E

<(*1

&1

$30DLQ%RDUG

:$51,1*

3

127(

63610000231

600007000019

3OHDVHGRQWWRXFKDQ\

HOHFWURQLFFRPSRQHQWRU

WHUPLQDOZKHQWKHPDFKLQH

LVUXQQLQJVWRSSLQJRU

KDVEHHQSRZHUHGRIIIRU

OHVVWKDQPLQXWHVWR

SUHYHQWHOHFWULFVKRFN

/

/

/

:$51,1*

(/(&75267$7,&

'('867,1*

;

<(*1

+($/7+/

+($/7+1

%8

5'

*(1(5$725

3/$60$

$1'

%2$5'

7(03

7(03

',63

$3

',63

',63/$<

5(&(,9(5

)$102725

'&02725

78%(

5220

6(1625

78%(

57

57

5220

$3

6$

6:,7&+

&211(&725

12

;

&

;

%.

:+

&/($1

0

0

83'2:1

02725

67(33,1*

02725

67(33,1*

02725

83'2:1

/()75,*+7

6:,1*8'

6:,1*8'

67(33,1*

35,17('&,5&8,7%2$5'

-803

&$3

6:,1*/5

0

<(*1

<(*1

%8

%.

%1

287'22581,7

%/2&.

&11(&7,1*

&$%/(

7(50,1$/

1

;7

(9$325$725

3(

%8

%.

1

&20287

$&/

3(

&2/'

&20,11(5

;

$3

:,5('

&21752//(5

0

:,),

:,),02'8/(

237,21$/

;

%1

11

Service Manual

Technical Information

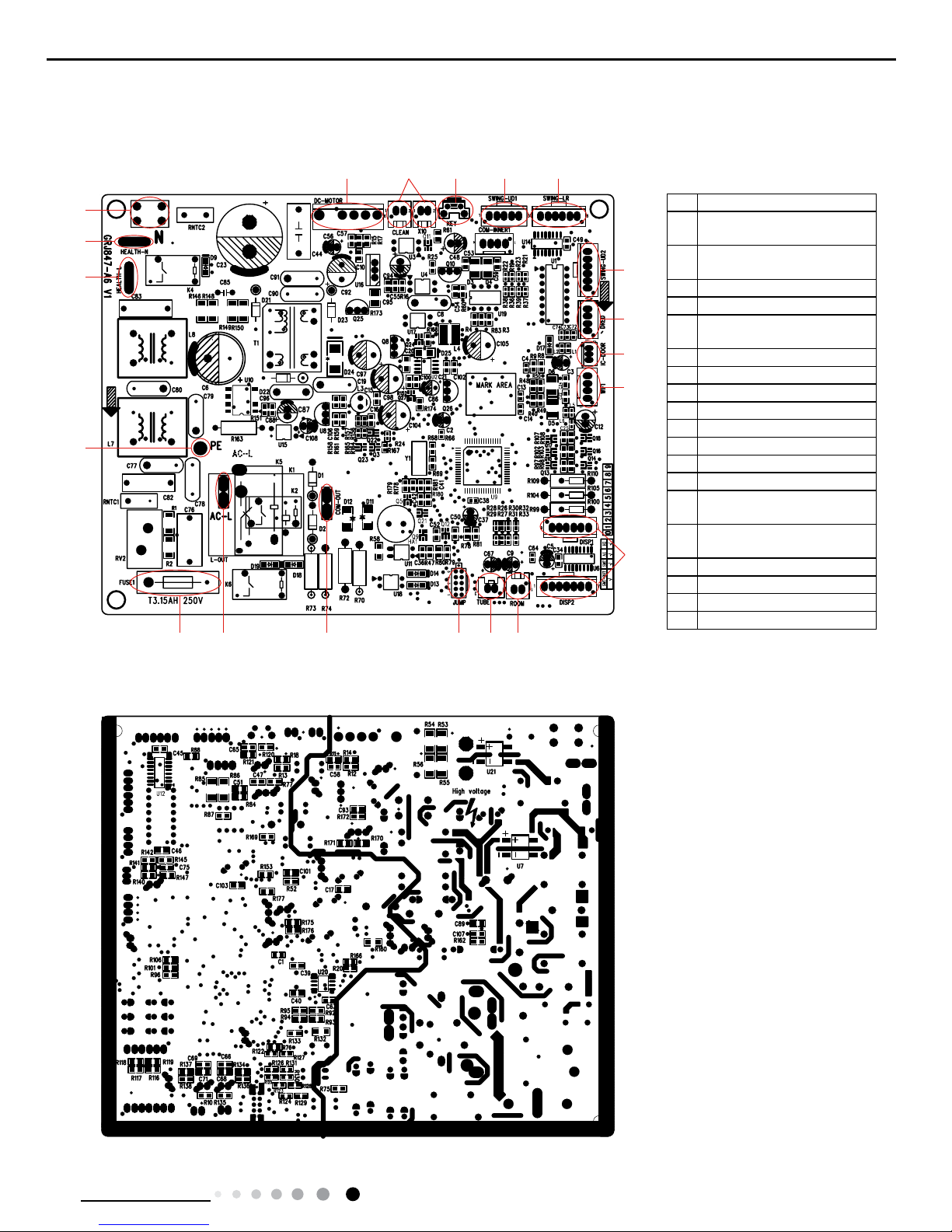

5.2 PCB Printed Diagram

Indoor unit

● Top view

● Bottom view

1

2

3

4

5 6 7 8 9

10

11

12

13

14

151617181920

1 Grounding wire

2

Interface of health function

live wire

3

Interface of health function

neutral wire

4 Neutral wire

5 Interface of DC motor

6

Interface of electrostatuc

dedusting

7 Auto button

8 Up&down swing interface 1

9 eft&right swing interface

10 Up&down swing interface 2

11 Interface of DRED

12 Interface of IC-DOOR

13 Interface of WiFi

14 Display interface

15

Interface of ambient

temperature sensor

16

Interface of tube temperature

sensor

17 Jumper cap

18 Communication interface

19 Live wire interface

20 Fuse

12

Service Manual

Technical Information

Outdoor unit

● Top view

● Bottom view

2

1

3

4

5

6

8

7

9

10

11

12

13

14 15

13

Service Manual

Technical Information

Introduction for icons on display screen

Introduction for buttons on remote controller

Note:

● This is a general use remote controller, it could be used for the air conditioners with multifunction; For some function, which the

model doesn't have, if press the corresponding button on the remote controller that the unit will keep the original running status.

● After putting through the power, the air conditioner will give out a sound. Operation indictor " " is ON (red indicator). After that,

you can operate the air conditioner by using remote controller.

●

Under on status, pressing the button on the remote controller, the signal icon " "

on the display of remote controller will blink once

and the air conditioner will give out a “de” sound, which means the signal has been sent to the air conditioner.

WIFI

6

3

7

9

11

13

15

12

14

16

10

8

5

4

2

1

1 ON/OFF button

2 MODE button

3 FAN button

4 TURBO button

6 button

7 button

9 I FEEL button

14 LIGHT button

15 button

16 TEMP button

11 CLOCK button

12

QUIET button(This function is unavailable for this

model)

13 X-FAN button(Note: X-FAN is the same with BLOW.)

10 TIMER ON / TIMER OFF button

8 SLEEP button

5

▲/ button

▲

WIFI

Send signal

Turbo mode

8℃ heating function

Set temperature

Set time

X-FAN function

TIMER ON /TIMER OFF

Child lock

Up & down swing

Left & right swing

Set fan speed

Light

Temp. display type

:Set temp.

:Outdoor ambient temp.

:Indoor ambient temp.

Sleep mode

Clock

Heat mode

Fan mode

Dry mode

Cool mode

Auto mode

Operation mode

I feel

Healthy mode

Scavenging functions

Quiet

WIFI(This is a general remote controller.Some models have this function while some

do not. Please refer to the actual models.)

6. Function and Control

6.1 Remote Controller Introduction

14

Service Manual

Technical Information

1. ON/OFF button

2. MODE button

3. FAN button

Press this button can turn on or turn off the air conditioner. After turning on the air conditioner, operation indicator " "on indoor unit’s

display is ON (green indicator. The colour is different for different models), and indoor unit will give out a sound.

● When selecting auto mode, air conditioner will operate automatically according to ex-factory setting. Set temperature can’t be adjusted and

will not be displayed as well. Press "FAN" button can adjust fan speed. Press " " / " " button can adjust fan blowing angle.

● After selecting cool mode, air conditioner will operate under cool mode. Cool indicator " "on indoor unit is ON. Press "▲" or " ▲ "

button to adjust set temperature. Press "FAN" button to adjust fan speed. Press " " / " " button to adjust fan blowing angle.

● When selecting dry mode, the air conditioner operates at low speed under dry mode. Dry indicator " " on indoor unit is ON. Under dry

mode, fan speed can’t be adjusted. Press " " / " " button to adjust fan blowing angle.

● When selecting fan mode, the air conditioner will only blow fan, no cooling and no heating. All indicators are OFF. Press "FAN" button to

adjust fan speed. Press " " / " " button to adjust fan blowing angle.

● When selecting heating mode, the air conditioner operates under heat mode. Heat indicator " " on indoor unit is ON. Press "▲" or " ▲

" button to adjust set temperature. Press "FAN" button to adjust fan speed. Press " " / " " button to adjust fan blowing angle. (Cooling

only unit won’t receive heating mode signal. If setting heat mode with remote controller, press ON/OFF button can’t start up the unit.

Note:

● For preventing cold air, after starting up heating mode, indoor unit will delay 1~5 minutes to blow air (actual delay time is depend on indoor

ambient temperature).

● Set temperature range from remote controller: 16~30℃(61-86°F); Fan speed: auto, low speed, medium speed, high speed.

4. TURBO button

Under COOL or HEAT mode, press this button to turn to quick COOL or quick HEAT mode. " " icon is displayed on remote controller.

Press this button again to exit turbo function and " " icon will disappear. If start this function, the unit will run at super-high fan speed to

cool or heat quickly so that the ambient temp. approachs the preset temp. as soon as possible.

5. ▲/▲ button

6. button

● Press " ▲ " or " ▲ " button once increase or decrease set temperature 1℃(°F). Holding " ▲ " or " ▲ " button, 2s later, set temperature

on remote controller will change quickly. On releasing button after setting is finished, temperature indicator on indoor unit will change

accordingly. (Temperature can’t be adjusted under auto mode)

● When setting TIMER ON, TIMER OFF or CLOCK, press " ▲ " or " ▲ " button to adjust time. (Refer to CLOCK, TIMER ON, TIMER OFF

buttons) When setting TIMER ON, TIMER OFF or CLOCK, press " ▲ " or " ▲ " button to adjust time. (Refer to CLOCK, TIMER ON, TIMER

OFF buttons)

Press this button can select left & right swing angle. Fan blow angle can be selected

circularly as below:

Note:

● Press this button continuously more than 2s, the main unit will swing back and forth from left to right, and then loosen the button, the unit

will stop swinging and present position of guide louver will be kept immediately.

This button is used for setting Fan Speed in the sequence that goes from AUTO , , , , to then back to Auto.

Press this button to select your required operation mode.

AUTO COOL FA N

DRY HEAT

no display

(stops at current position)

Auto

Medium spee

d

Low-Medium speedLow speed

High speedMedium-High speed

15

Service Manual

Technical Information

● Under swing left and right mode, when the status is switched from off to , if press this button again 2s later, status will switch to off

status directly; if press this button again within 2s, the change of swing status will also depend on the circulation sequence stated above.

7. button

8. SLEEP button

9. I FEEL button

10. TIMER ON / TIMER OFF button

Press this button can select up & down swing angle. Fan blow angle can be selected

circularly as below:

Press this button, can select Sleep 1 ( ), Sleep 2 ( ), Sleep 3 ( ) and cancel the Sleep, circulate between these, after electried,

Sleep Cancel is defaulted.

● Sleep 1 is Sleep mode 1, in Cool modes; sleep status after run for one hour, the main unit setting temperature will increase 1°C, two hours,

setting temperature increa sed 2°C, then the unit will run at this setting temperature; In Heat mode: sleep status after run for one hour, the

setting temperature will decrease 1°C, two hours, setting temperature will decrease 2°C, then the unit will run at this setting temperature.

● Sleep 2 is sleep mode 2, that is air conditioner will run according to the presetting agroup of sleep temperature curve.

● Sleep 3-the sleep curve setting under Sleep mode by DIY;

(1)Under Sleep 3 mode, press “Turbo” button for a long time, remote controller entersinto user individuation sleep setting status, at this time,

the time of remote controllerwill display “1hour”, the setting temperature “88” will display the corresponding temp-erature of last setting sleep

curve and blink (The rst entering will display according tothe initial curve setting value of original factory);

(2)Adjust “+” and “-” button, could change the corresponding setting temperature, afteradjusted, press “Turbo” button for conrmation;

(3)At this time, 1hour will be automatically increased at the timer postion on the remotecontrol, (that are "2hours" or "3hours" or "8hours"),

the place of setting temperature "88"will display the corresponding temperature of last setting sleep curve and blink;(4) Repeat the above

step (2)~(3) operation, until 8 hours temperature setting nished,sleep,curve setting nished, at this time, the remote controller will resume

the original timer display; temperature display will resume to original setting temperature.

● Sleep3- the sleep curve setting under Sleep mode by DIY could be inquired:The user could accord to sleep curve setting method to inquire

the presetting sleep curve, enter into user individuation sleep setting status, but do not change the tempera-ture, press “Turbo” button directly

for conrmation. Note: In the above presetting or enquiry procedure, if continuously within 10s, there is no button pressed, the sleep curve

setting within 10s, there is no button pressed, the sleep curve setting status will be automatically quit and resume to display the original

displaying. In the presetting orenquiry procedure, press "ON/OFF" button, "Mode" button, "Timer" button or "Sleep" button, the sleep curve

setting or enquiry status will quit similarly.

Press this button to start I FEEL function and " " will be displayed on the remote controller. After this function is set, the remote controller

will send the detected ambient temperature to the controller and the unit will automatically adjust the indoor temperature according to the

detected temperature. Press this button again to close I FEEL function and " " will disappear.

● Please put the remote controller near user when this function is set. Do not put the remote controller near the object of high temperature

or low temperature in order to avoid detecting inaccurate ambient temperature.

● TIMER ON button

"TIMER ON" button can set the time for timer on. After pressing this button, " " icon disappears and the word "ON" on remote controller

blinks. Press " ▲ " or " ▲ "button to adjust TIMER ON setting. After each pressing " ▲ " or " ▲ " button, TIMER ON setting will increase

or decrease 1min. Hold " ▲ " or " ▲ " button, 2s later, the time will change quickly until reaching your required time. Press "TIMER ON" to

conrm it. The word "ON" will stop blinking. " " icon resumes displaying. Cancel TIMER ON: Under the condition that TIMER ON is started

up, press "TIMER ON" button to cancel it.

● TIMER OFF button

● When selecting " ", air conditioner is blowing fan automatically. Horizontal louver will automatically swing up & down at maximum angle.

● When selecting " 、 、 、 、 ", air conditioner is blowing fan at xed position. Horizontal louver will stop at the xed position.

● When selecting " 、 、 " , air conditioner is blowing fan at xed angle. Horizontal louver will send air at the xed angle.

● Hold " "button above 2s to set your required swing angle. When reaching your required angle, release the button.

Note:

● " 、 、 " may not be available. When air conditioner receives this signal, the air conditioner will blow fan automatically.

● Press this button continuously more than 2s, the main unit will swing back and forth from up to down, and then loosen the button, the unit

will stop swinging and present position of guide louver will be kept immediately.

● Under swing up and down mode, when the status is switched from off to , if press this button again 2s later, status will switch to off

status directly; if press this button again within 2s,the change of swing status will also depend on the circulation sequence stated above.

no display

(horizontal louvers stops

at current position)

16

Service Manual

Technical Information

11. CLOCK button

Press this button to set clock time. " " icon on remote controller will blink. Press " ▲ " or " ▲ " button within 5s to set clock time. Each

pressing of " ▲ " or " ▲ " button, clock time will increase or decrease 1 minute. If hold " ▲ " or " ▲ " button, 2s later, time will change quickly.

Release this button when reaching your required time. Press "CLOCK" button to conrm the time. " " icon stops blinking.

Note:

● Clock time adopts 24-hour mode.

● The interval between two operation can’t exceeds 5s. Otherwise, remote controller will quit setting status. Operation for TIMER ON/TIMER

OFF is the same.

"TIMER OFF" button can set the time for timer off. After pressing this button," "icon disappears and the word "OFF" on remote controller

blinks. Press " ▲ " or " ▲ " button to adjust TIMER OFF setting. After each pressing " ▲ " or " ▲ " button, TIMER OFF setting will increase

or decrease 1min. Hold " ▲ " or " ▲ " button, 2s later, the time will change quickly until reaching your required time. Press "TIMER OFF"

word "OFF" will stop blinking. " " icon resumes displaying. Cancel TIMER OFF. Under the condition that TIMER OFF is started up, press

"TIMER OFF" button to cancel it.

Note:

● Under on and off status, you can set TIMER OFF or TIMER ON simultaneously.

● Before setting TIMER ON or TIMER OFF, please adjust the clock time.

● After starting up TIMER ON or TIMER OFF, set the constant circulating valid. After that, air conditioner will be turned on or turned off

according to setting time. ON/OFF button has no effect on setting. If you don’t need this function, please use remote controller to cancel it.

12. QUIET button

Press this button, the Quiet status is under the Auto Quiet mode (display " " and "AUTO" signal ) and Quiet mode (display " " singal)

and Quiet OFF (there is no signal of " " displayed), after powered on, the Quiet OFF is defaulted.

Note:

●

The Quiet function can be set up in all modes; Under the Quiet mode,the fan speed is not available.

● When quiet function is selected:

Under cooling mode: indoor fan operates at notch 4 speed. 10 minutes later or when indoor ambient temperature≤28°C, indoor fan will

operate at notch 2 speed or quiet mode according to the comparison between indoor ambinet temperature and set temperature.

Under heating mode: indoor fan operates at notch 3 speed or quiet mode according to the comparison between indoor ambient temperature

and set temperature.

Under dry, fan mode: indoor fan operates at quiet mode.

Under auto mode: the indoor fan operates at the auto quiet mode according to actual cooling, heating or fan mode.

● The Quiet function is only available for some models.

13. X-FAN button

Pressing this button in COOL or DRY mode, the icon " " is displayed and the indoor fan will continue operation for 2 minutes in order to

dry the indoor unit even though you have turned off the unit. After energization, X-FAN OFF is defaulted.X-FAN is not available in AUTO,

FAN or HEAT mode.

This function indicates that moisture on evaporator of indoor unit will be blowed after the unit is stopped to avoid mould.

● Having set X-FAN function on: After turning off the unit by pressing ON/OFF button indoor fan will continue running for about 2 min. at low

speed. In this period, press X-FAN button to stop indoor fan directly.

● Having set X-FAN function off: After turning off the unit by pressing ON/OFF button, the complete unit will be off directly.

14. LIGHT button

15. button

Press this button to turn off display light on indoor unit. " " icon on remote controller disappears. Press this button again to turn on

display light. " " icon is displayed.

Press this button to achieve the on and off of healthy and scavenging functions in operation status. Press this button for the rst time to start

scavenging function; LCD displays " ". Press the button for the second time to start healthy and scavenging functions simultaneously;

LCD displays " " and " " . Press this button for the third time to quit healthy and scavenging functions simultaneously. Press the button

for the fourth t ime to start healthy function; LCD display " " . Press this button again to repeat the operation above.

● This function is applicable to partial of models.

16. TEMP button

By pressing this button, you can see indoor set temperature, indoor ambient temperature or outdoor ambient temperature on indoor unit’s

display. The setting on remote controlleris selected circularly as below:

no display

17

Service Manual

Technical Information

1. Energy-saving function

● When selecting " " or no display with remote controller, temperature indicator on indoor unit displays set temperature.

● When selecting " " with remote controller, temperature indicator on indoor unit displays indoor ambient temperature.

● When selecting " " with remote controller, temperature indicator on indoor unit displays outdoor ambient temperature.

Note:

●

Outdoor temperature display is not available for some models. At that time, indoor

unit receives " "signal, while it displays indoor set

temperature.

● It’s defaulted to display set temperature when turning on the unit.There is no display in the remote controller.

● Only for the models whose indoor unit has dual-8 display.

● When selecting displaying of indoor or outdoor ambient temperature, indoor temperature indicator displays corresponding temperature and

automatically turn to display set temperature after three or ve seconds.

Under cooling mode, press "TEMP" and " CLOCK" buttons simultaneously to start up or turn off energy-saving function. When energy-saving

function is started up, "SE" will be shown on remote controller, and air conditioner will adjust the set temperature automatically according to

ex-factory setting to reach to the best energy-saving effect. Press "TEMP" and "CLOCK"buttons simultaneously again to exit energy-saving

function.

Note:

● Under energy-saving function, fan speed is defaulted at auto speed and it can’t be adjusted.

●

Under energy-saving function, set temperature can’t be adjusted. Press "TURBO"

button and the remote controller won’t send signal.

● Sleep function and energy-saving function can’t operate at the same time. If energy-saving function has been set under cooling mode,

press sleep button will cancel energy-saving function. If sleep function has been set under cooling mode, start up the energy-saving function

will cancel sleep function.

Function introduction for combination buttons

Operation guide

2. 8℃ heating function

3. Child lock function

4. Temperature display switchover function

Under heating mode, press "TEMP" and "CLOCK" buttons simultaneously to start

up or turn off 8℃ heating function. When this function is

started up, " " and "8℃" will be shown on remote controller, and the air conditioner keep the heating status

at 8℃. Press "TEMP" and

"CLOCK" buttons simultaneously again to exit 8℃heating function.

Note:

● Under 8℃ heating function, fan speed is defaulted at auto speed and it can’t be adjusted.

● Under 8℃ heating function, set temperature can’t be adjusted. Press "TURBO" button and the remote controller won’t send signal.

● Sleep function and 8℃ heating function can’t operate at the same time. If 8℃heating function has been set under cooling mode, press

sleep button will cancel 8℃ heating function. If sleep function has been set under cooling mode, start up the 8℃ heating function will cancel

sleep function.

● Under ℉ temperature display, the remote controller will display 46℉ heating.

Press " ▲ " and " ▲ " simultaneously to turn on or turn off child lock function. When child lock function is on, " " icon is displayed on

remote controller. If you operate the remote controller, the " " icon will blink three times without sending signal to the unit.

Under OFF status, press " ▲ " and "MODE" buttons simultaneously to switch temperature display between ℃ and ℉.

1. After putting through the power, press "ON/OFF" button on remote controller to turn on the air conditioner.

2. Press "MODE" button to select your required mode: AUTO, COOL, DRY, FAN, HEAT.

3. Press " ▲ " or " ▲ " button to set your required temperature. (Temperature can’t be adjusted under auto mode).

4. Press "FAN" button to set your required fan speed: auto, low, medium and high speed.

5. Press "SWING" button to select fan blowing angle.

5. WIFI fuction

Press "MODE" and "TURBO" button simultaneously to turn on or turn off WIFI function. When WIFI function is turned on, the " WiFi" icon will

be displayed on remote controller; Long press "MODE" and "TURBO" buttons simultaneously for 10s, remote controller will send WIFI reset

code and then the WIFI function will be turned on. WiFi function is defaulted ON after energization of the remote controller.

● This function is only available for some models.

18

Service Manual

Technical Information

Replacement of batteries in remote controller

1. Press the back side of remote controller marked with " ", as shown in the g, and then push out

the cover of battery box along the

arrow direction.

2. Replace two 7# (AAA 1.5V) dry batteries, and make sure the position of "+" polar and "-" polar are correct.

3. Reinstall the cover of battery box.

Note:

● During operation, point the remote control signal sender at the receiving window on indoor unit.

● The distance between signal sender and receiving window should be no more than 8m, and there should be no obstacles between

them.

● Signal may be interfered easily in the room where there is uorescent lamp or wireless telephone; remote controller should be close to

indoor unit during operation.

● Replace new batteries of the same model when replacement is required.

● When you don’t use remote controller for a long time, please take out the batteries.

● If the display on remote controller is fuzzy or there’s no display, please replace batteries.

signal sender battery

Cover of battery box

remove

reinstall

19

Service Manual

Technical Information

6.2 Operation of Smart Control (Smart Phone, Tablet PC) For Gree

NOTE:One AC can be controlled by 4 smart phones in maximum at the same time.

(2).Short-distance and long-distance control setting for air conditioner connecting with router

Step 1: Under short-distance control, return to the homepage "Home Control". Tap at the top right corner of the homepage "Device".

Operation Instructions

Download and install APP

Scan the following QR code with your smart phone and download Wi Smart.

Conguration

Step 2: Open APP and the screen will show the air conditioner that you just connected. Tap the name of this air conditioner on

your phone to enter and realize short-distance control, as shown below. Please refer to "Functions introduction" for specic control

methods.

Install the APP according to its guidance. When successfully installed, your smart phone homepage will show this icon

User of IOS system can search for the Gree Smart in Apple store to download the Apple version APP.

NOTE: Select either the original conguration or AP conguration according to the APP functions.

1.Original conguration

Before operation, please nish the following conguration in order to realize Wi control and the connection between air conditioner and

intelligent device.

(1).Short-distance control setting for air conditioner using Wi hotspot

Step 1: Air conditioner Wi is set in AP mode in factory. You can search the air conditioner Wi hotspot through your smart phone. The

name of Wi hotspot is the last 8 numbers of the air conditioner mac address. Password is 12345678.

20

Service Manual

Technical Information

2.AP conguration

4 steps of conguration

Step 1: Enter homepage "Device", and then tap at the top right corner.

Select "Add device" and enter the page "Add device". Tap "Manual Conguration".

Step 2: Tap "Next" in the First Step.

Step 3: Select the wireless network of air conditioner. APP will show the password 12345678 (default password of the network of air

conditioner). Then tap "Next"; select the name of home Wi router, then enter the correct password and select a server.

Select "Add device" and enter the page of "Add device". Tap "Manual conguration" and enter the page "Manual conguration".

Step 2: Select the correct network name and enter the password. Select the server (The server setting here must keep the same as the

server setting in "Settings" mentioned below. Otherwise, remote control will fail.), then tap the button "Add device" for conguration. At

this time, "Conguring" is displayed on the APP. The buzzer in the indoor unit will give out a sound when conguration succeeds.

21

Service Manual

Technical Information

Step 4: If conguration is successful, a window will pop up and read "Conguration succeeded". Then conguration is completed.

NOTE: After conguration is completed, the air conditioner hot spot connected to your phone will disAPPear. You should reconnect your

phone to the home Wi router to realize long-distance control.

The above conguration only needs one phone. Other types of phones shall install this APP, connect with the air conditioner hot spot or

wireless router of Wi air conditioner. When connection is done, open the APP to use short-distance operation to control the air conditioner

and then you can use the long-distance control.

Functions introduction

1.User registration

Purpose: To realize long-distance control

Operation instruction: For the rst time login, you have to register a new username. If you already have a username, skip the registration

step and enter email address and password on the "Login Page" to log in. If password is forgotton, you can reset the password.

Operation steps:

(1) Select the sever address

(2) Account login: Slide the page "Device", and enter the page "Menu" on the left. Tap "Login" to enter the page "Register username". New

user must rst register a username. Tap "Register”.

(3) Enter your email address. Wait until you receive the verication code. Enter the code and then tap "OK" to log in.

22

Service Manual

Technical Information

(4) If password is forgotten, you can reset the password with your email address.

Tap "Forgot password" and enter the page "Forgot password". Tap "Get verication code" to get an email verication code. Enter a new

password and tap "OK" to log in.

2.Personal settings

Purpose: Set name (device name, preset name, etc.) and images (device image) in order to identify a user easily.

(1) Set device name

After quick conguration, a list of controllable smart devices will be generated. Default name for air conditioner is the last 8 numbers of the

air condtioner mac address.

Step 1: Tap and hold "a0b417ac" to enter the page "Edit device". Tap "Image" to select the source of image. Select from "Default images"

or "Take photo" or "Choose from photos" and save an image.

Step 2: Tap "Name" to change device name. Save it and the new device name will be shown. Enable button ''Lock device'' to lock the

device so that other smart phones can’t search the device. Tap "Temp unit" to change the temperature unit.

Step 3: Tap "Firmware update" to upgrade the rmware of the device. Tap"1.8" and then the device will be updated automatically.

23

Service Manual

Technical Information

(2) Set preset name

Step 1: Tap at the top right corner of the homepage "Device". Select "Add preset" and enter the page "Preset edit".

Step 2: Choose the time. Tap "Name". As shown in the picture, its name is "baby room". For timer type, select "On". Then select the

repeating days. Save the setting of preset name.

(3) Set device image

Please refer to step 1 in 2(1)

3.Control functions

(1) Common control functions: General control on the operation of smart devices (On/Off, temperature, fan speed, mode, etc.) and the

setting of advanced functions (air exchange, dry, health, light, sleep, energy saving upper limit).

Step 1: General control

Enter the homepage "Home control" rst. Take "babyroom"as an example.

Tap "babyroom" and enter the page of air conditioner control. Tap to turn on the control switch.

24

Service Manual

Technical Information

Tap or to increase or decrease temperature. Tap to change working mode. Tap to enter the page of fan speed

adjustment.

Tap and go around the circle to adjust fan speed.

Step 2: Advanced settings

Tap to enter advanced settings. You may select "Air", "Dry", "Health", "Light", "Sleep" or "Energy saving".

(2) Advanced control functions: Set scene; Preset; Link; Infrared control (only APPlicable to smart phones with infrared emitter)

Set scene: Preset the operation of several smart devices by one tap.

On the page "Home control", tap the image of "Home control" to enter the page "Edit scene".

25

Service Manual

Technical Information

Tap "Add scene" and edit the scene name, for example, "Back home". Add execution devices.

Tap to add commands. On the page "Select execution device", select the air conditioner named "babyroom". Then select "ON" or

"OFF".

Continue to select the next execution device as instructed above. Tap to set the interval.

Tap "Save". Tap the scene picture displayed on homepage "Device" to send the command. Then the scene "Back home" will be in execution.

You may view the execution condition of the scene.

26

Service Manual

Technical Information

(3) Preset includes single-device preset and multi-device preset

Single-device preset: This can preset a certain device to be On/Off at a specic time.

On the homepage "Device", take air conditioner "babyroom" as an example. Tap at the bottom of the page "babyroom". Then you will

enter the page "Preset edit".

Slide up and down to set the time. If you need to synchronize the time, tap " synchronize". If such "Hint" interface doesn't show up, please

skip this operation step.

Tap "Name" to customize the preset name.

Preset device can’t be selected and it will default to "babyroom". Select "On" for the timer type. Select repeating days to complete the

preset.

Multi-device preset: This can preset multiple devices to execute a command at a specic time.

Please refer to the instructions as how to set preset time, name, timer type and repeating days for a single device.

Tap "Preset device" to select one or more devices. Then return to the page "Device".

27

Service Manual

Technical Information

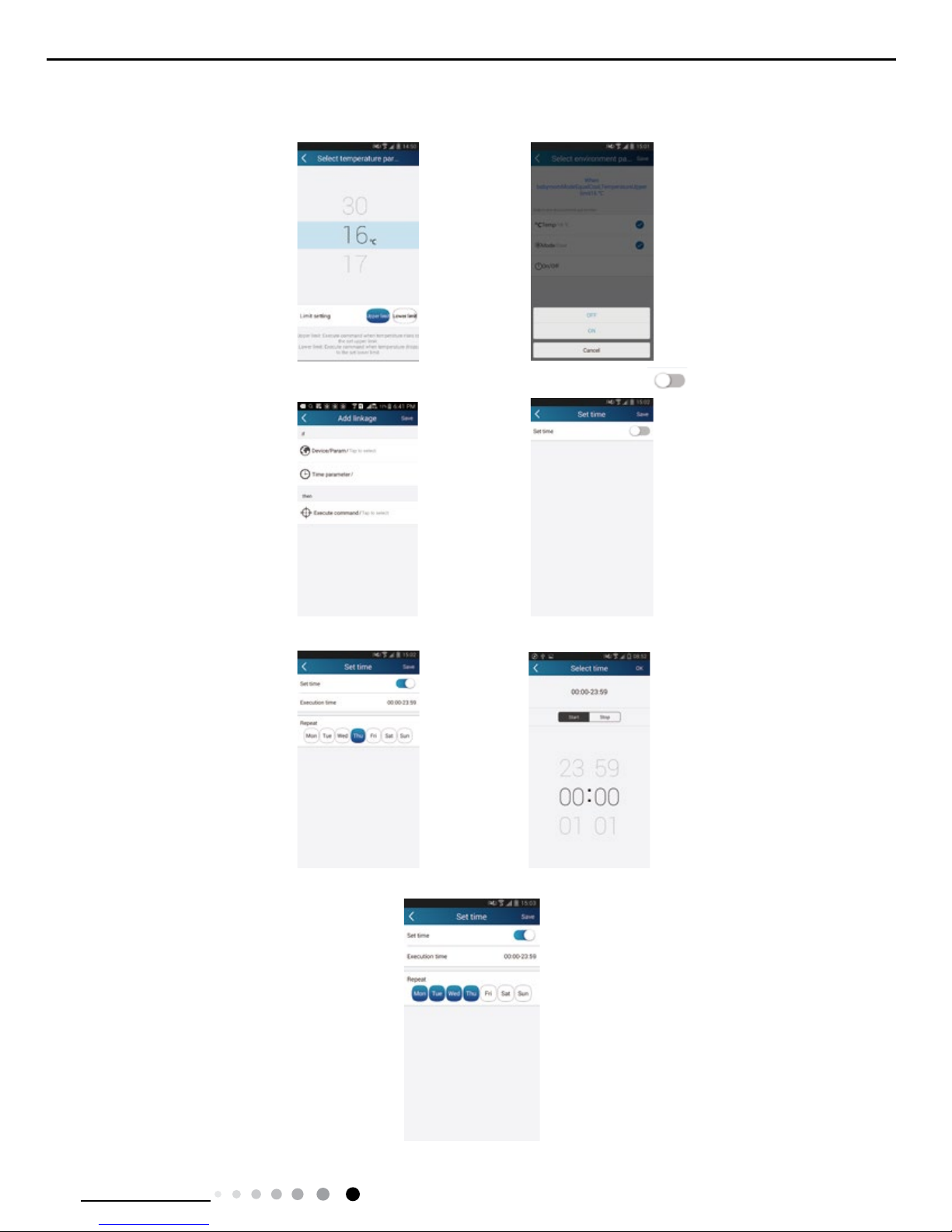

(4) Link(This function is APPlicable to some models)

Select a master device. When the environment satisfies the parameters as set in the master device, slave devices will execute

commands to realize devices linkage.

Step 1: Set the parameters of master device (Select master device, select environment parameters, select master device status).

Tap at the top right corner of the homepage "Device". Select "Link" and enter the page "Add linkage". Tap "Device/Param" to

enter the page "Select device". Take "baby room" as an example. Tap "babyroom".

Enter the page "Select environment parameters".

Tap "Temperature" to enter the page "Select temperature parameter". Slide up or down to adjust temperature. Tap "Upper limit" or

"Lower limit".

Tap "Mode" and "On/Off" to select the status of master device. Then tap "Save".

Step 2: Set time parameter for linkage. Tap "Time parameter" to enter the page "Set time". Slide rightwards to turn on the

setting time.

Tap "Execution time"; then tap "Start" and "Stop" to set start time and stop time respectively. Tap "OK" at the top right corner to save the

setting.

28

Service Manual

Technical Information

Tap the days below "Repeat" to select the repeating days. Then tap "Save".

Step 3: Select "Execute command"

Tap "Execute command" and enter the page "Select device".

Tap the name of device that you want to control. Tap "ON" or "OFF" and then tap "Save" to complete the linkage.

Tap "Save" and then repeat the above steps to set linkage of several scenes.

29

Service Manual

Technical Information

(5) Infrared control (only APPlicable to smart phones with infrared emitter).

Function: Smart phone can be used as a remote controller.

Tap at the top right corner of the homepage "Device". Select "Infrared" and enter the page "Remote controller". Tap and

slide up to enter the page of advanced functions.

Tap to turn on the device. Tap to select mode. Tap to adjust fan speed and swing angle. Tap "Health", "Energy

saving", "Sleep" etc. to set advanced functions.

Tap "Sleep" to enter the page "Sleep". You can select "Traditional sleep", "Expert sleep" or "DIY sleep". Tap "DIY sleep" and then tap

the left and right arrows to set sleep time. Tap up and down arrows to adjust temperature at a specic sleep time.

4.Menu functions

Menu functions (Share, Set, History, Feedback)

(1) Share: To share quick conguration information and unit’s information, including local export and local import.

For local import, you just need to tap "Local import" and wait for the data download.

Local export

Step 1: Export local data to another smart phone.

Enter "Menu" on the left side and tap "Share" to enter the page "Share". Then tap "Local export".

30

Service Manual

Technical Information

Step 2: Another smart phone to be imported.

Tap the model name and wait for the download.

(2) Backup: To keep backup of the quick conguration information and unit’s information, including backup to cloud and backup list on

the cloud.

Backup to cloud

Enter the "Menu" on the left and tap "Backup".

Tap "Backup to cloud" and then tap "Yes". Then wait for the data download.

Select "Backup list on the cloud". Then backup records will APPear. Tap "Record" to download data and recover data to local unit.

31

Service Manual

Technical Information

(3) Settings

User can set vibration, message alerts, server, updates, etc. The server setting here must be the same as the server setting in

"Conguration" mentioned before.

Otherwise, remote control will be invalid.

(4) Feedback

User can feedback suggestions to back-stage management for maintenance and development.

Tap "Feedback". Enter your suggestions and then submit it.

32

Service Manual

Technical Information

6.3 Operation of Smart Control (Smart Phone, Tablet PC)

Operation Instructions

Download and install APP

Scan the following QR code with your smart phone and download Wi Smart.

Conguration

1.Original conguration

Before operation, please nish the following conguration in order to realize Wi control and the connection between air conditioner and

intelligent device.

(1).Short-distance control setting for air conditioner using wi hotspot

Step 1: Air conditioner wi is set in APP mode in factory.

You can search the air conditioner wifi hotspot through your smart phone.The name of wifi hotspot is the last 8 numbers of the air

conditioner mac address. Password is 12345678.

Step 2: Open APP and the screen will show the air conditioner that you just connected. Tap the name of this air conditioner on your

phone to enter and realize short-distance control, as shown below. Please refer to "Functions introduction" for specic control methods.

Install the APP according to its guidance. When successfully installed, your smart phone homepage will show this icon

NOTE: Select either the original conguration or AP conguration according to the APP functions.

User of IOS system can search for the Wi Smart in Apple store to download the Apple version APP. Android user can

search "WiFi Smart" on Google Play to download it.

gree-a

gr-cn

gr-cn

gr-dh

33

Service Manual

Technical Information

2.Conguration method for Android phones

4 steps of conguration

Step 1: Enter homepage "Device", and then tap at the top right corner.

Select "Add device" and enter the page "Add device".

Tap "Manual conguration" and enter the page "Manual conguration".

Step 2: Tap "Next" in the First Step.

Step 3: Select the wireless network of air conditioner. APP will show the password 12345678 (default password of the network of air

conditioner). Then tap "Next"; select the name of home WiFi router, then enter the correct password and select a server.

Step 4: If conguration is successful, a window will pop up and read “WIFI module starts to connect the congured wireless router”.Then

conguration is completed.

34

Service Manual

Technical Information

NOTE: After conguration is completed, the air conditioner hot spot connected to your phone will disappear. You should reconnect your

phone to the home WiFi router to realize long-distance control.The above conguration only needs onephone. Other types of phones

shall install this APP, connect with the air conditioner hot spot or wireless router of WiFi air conditioner. When connection is done, open

the APP to use short-distance operation to control the air conditioner and then you can use the long-distance control.

3.Conguration method for Apple phones

Step 1: Turn on Wi-Fi “Settings” on the phone.

Step 2: In general, the hot spot signal of air conditioner is the last 8 bits of MAC address. Eg: Select “a0b41737” and enter

the defaulted password “12345678” to connect it.

Notice:

Finally, press “Conguration”, and APP will send the lled information to Wi Smart. At this time, the buzzer will give out a sound, which

indicates it has started to connect the wireless router.

Step 3: Turn on APP, press “+” button, press “Add device” to enter into the page of “Add device” and then select “Manual conguration”.

Enter wireless router’s SSID and PSW on the page of “Manual conguration”. The display on the server will be the same as the selection

when registering the account ( server selection in “Setting”).

Eg: WiFi name: Tenda_XXX;

WiFi password:123456789

Server: Europe

Check whether the filled information is correct. If the information is wrong, configuration will fail. Press “Configuration” to start

conguration.

35

Service Manual

Technical Information

If the name of router or the password is wrong, Wifi Smart can’t connect to the wireless router. 2 mins later, please conduct the

conguration operation again. Reset Wi-Fi adaptor by pointing you remote at the indoor unit and holding the mode and Turbo buttons on

your remote control for 10 seconds and until you hear the beep.

Wrong server selection will cause long-distance control invalid. Therefore, please make sure thatthe server selection when

registering the account is the same as this one.

If the password is blank, no password is defaulted for the wireless router, which is the OPEN mode.

Conguration should be conducted at one time. As for other phones, they can automatically search for the device after connecting to the

wireless router (such as Tenda_XXX) and turning on the APP.

Functions introduction

1.User registration

Purpose: To realize long-distance control.

Operation instruction: For the rst time login, you have to register a new username. If you already have a username, skip the registration

step and enter email address and password on the "Login Page" to log in. If password is forgotton, you can reset the password.

Operation steps:

(1) Select the sever address.

(2) Account login: Slide the page "Device", and enter the menu page on the left.Tap "Login" to enter the page "Register

username". New user must rst register a username. Tap "Register”.

(3) If password is forgotten, you can reset the password with your email address.

Tap "Forgot password" and enter the page "Forgot password". Enter your registered email account the rst. Tap "Get verication code" to

get an email verication code. Enter a new password and tap "OK" to log in.

36

Service Manual

Technical Information

2.Personal settings

Purpose: Set name (device name, preset name, etc.) and images (device image) in order to identify a user easily.

(1) Set device name

After quick conguration, a list of controllable smart devices will be generated. Default name for air conditioner is the last 8 numbers of

the air condtioner mac address.

Step 1: Tap and hold the Wi model name, such as “a0b417ac”, to enter the page "Edit device". Tap "Image" to select the source of

image. Select from "Default images " or " Take photo" or "Choose from photos" and save an image.

Step 2: Tap "Name" to change device name. Save it and the new device name will be shown. Enable button ''Lock device''to lock the

device so that other smart phones can’t search the device. Tap "Temperature unit" to change the temperature unit.

Notice: If this device is not locked, other phones within the local area network can be found through wi smart APP and operate the

device.

Step 3: Tap "Firmware update" to upgrade the rmware of the device. Tap"1.7" and then the device will be updated automatically.

37

Service Manual

Technical Information

(2) Set preset name

Step 1: Tap at the top right corner of the homepage "Device". Select "Add preset" and enter the page "Preset edit".

Step 2: Choose the time. Tap "Name". As shown in the picture, its name is "baby room". For timer type, select "On". Then select the

repeating days. Save the setting of preset name.

(3) Set device image

Please refer to step 1 in 2(1)

3.Control functions

(1) Common control functions: General control on the operation of smart devices (On/Off, temperature, fan speed, mode, etc.) and the

setting of advanced functions (air exchange, dry, health, light, sleep, energy saving upper limit).

Step 1: General control

Enter the homepage "Device" rst. Take "babyroom" as an example.

38

Service Manual

Technical Information

Tap "babyroom" and enter the page of air conditioner control. Tap to turn on the control switch.

Tap or to increase or decrease temperature. Tap to change working mode. Tap to enter the page of fan speed

adjustment.

Tap and go around the circle to adjust fan speed.

Step 2: Advanced settings

Tap to enter advanced settings. You may select "Air", "Dry", "Health", "Light", "Sleep" or "Energy saving".

(2) Advanced control functions; Set scene; Preset; Link: Infrared control(only applicable to smart phones with infrared emitter)

Set scene: Preset the operation of several smart devices by one tap. On the page "Device", tap the image of "Device" to enter the page

"Edit scene".

Tap "Add scene" and edit the scene name, for example, "Back home". Add execution devices.

Tap to add commands. On the page "Select execution device", select the air conditioner named "babyroom". Then select "ON" or

"OFF".

39

Service Manual

Technical Information

Continue to select the next execution device as instructed above. Tap to set the interval.

Tap "Save". Tap the scene picture displayed on homepage "Device" to send the command. Then the scene "Back home"

will be in execution. You may view the execution condition of the scene.

(3) Preset includes single-device preset and multi-device preset

Single-device preset: This can preset a certain device to be On/Off at a specic time.

On the homepage "Device", take air conditioner "babyroom" as an example. Tap at the bottom of the page "babyroom".

Then you will enter the page "Preset edit".

Slide up and down to set the time. If you need to synchronize the time, tap " synchronize". If such "Hint" interface doesn't

show up, please skip this operation step.

40

Service Manual

Technical Information

Tap "Name" to customize the preset name.

Preset device can’t be selected and it will default to "babyroom". Select "On" for the timer type. Select repeating days to complete the

preset.

Multi-device preset: This can preset multiple devices to execute a command at a specic time.

Please refer to the instructions as how to set preset time, name, timer type and repeating days for a single device.

Tap "Preset device" to select one or more devices. Then return to the page "Device".

(4) Link(This function is applicable to some models)

Select a master device. When the environment satisfies the parameters as set in the master device, slave devices will execute

commands to realize devices linkage.

Step 1: Set the parameters of master device (Select master device, select environment parameters, select master device status).

Tap at the top right corner of the homepage "Device". Select "Link" and enter the page "Add linkage". Tap "Device/Param" to enter

the page "Select device". Take "baby room" as an example. Tap "babyroom".

Enter the page "Select environment parameters".

41

Service Manual

Technical Information

Tap "Temperature" to enter the page "Select temperature parameter". Slide up or down to adjust temperature. Tap "Upper limit" or "Lower

limit".

Tap "Mode" and "On/Off" to select the status of master device. Then tap "Save".

Step 2: Set time parameter for linkage. Tap "Time parameter" to enter the page "Set time". Slide rightwards to turn on the setting

time.

Tap "Execution time"; then tap "Start" and "Stop" to set start time and stop time respectively. Tap "OK" at the top right corner to save the

setting.

Tap the days below "Repeat" to select the repeating days. Then tap "Save".

Step 3: Select "Execute command" Tap "Execute command" and enter the page "Select device".

42

Service Manual

Technical Information

Tap the name of device that you want to control. Tap "ON" or "OFF" and then tap "Save" to complete the linkage.

Tap "Save" and then repeat the above steps to set linkage of several scenes.

4.Menu functions

Menu functions (Share, Set, History, Feedback)

(1) Share: To share quick conguration information and unit’s information, including local export and local import.

For local import, you just need to tap "Local import" and wait for the data download.

Local export

Step 1: Export local data to another smart phone.

Enter menu page on the left side and tap "Share" to enter the page "Share". Then tap "Local export".

43

Service Manual

Technical Information

Step 2: Another smart phone to be imported.

Tap the model name and wait for the download.

Notice:

This function requires that the two phones are of the same operating system. They are either Android phones or Apple phones,and are

connecting to the same wireless router.

(2) Backup: To keep backup of the quick conguration information and unit’s information, including backup to cloud and backup list on

the cloud.

Backup to cloud

Enter the menu page on the left and tap "Backup".

Tap "Backup to cloud" and then tap "Yes". Then wait for the data download.

Select "Backup list on the cloud". Then backup records will appear. Tap "Record" to download data and recover data to local unit.

44

Service Manual

Technical Information

(3) Settings

User can set vibration, message alerts, server, updates, etc. The server setting here must be the same as the server setting in

"Conguration" mentioned before.

Otherwise, remote control will be invalid.

(4) Help

Please refer to “Help” of APP for the instruction of the latest functions.

45

Service Manual

Technical Information

6.4 Brief Description of Modes and Functions

1.Temperature Parameters

Indoor preset temperature (Tpreset)

Indoor ambient temperature (Tamb.)

2.Basic functions (The temperature in this manual is expressed by Centigrade. If Fahrenheit is used, the switchover between them

Tf=TcX1.8+32.)

Once the compressor is energized, there should be a minimum interval of 3 minutes between two start-ups. But if the unit is de-energized

and then energized, the compressor can restart within 3 minutes.

(1)Cooling mode

①

Cooling conditions and process

When Tamb. ≥Tpreset, the unit starts cooling operation. In this case, the compressor and the outdoor fan operate and the indoor fan

operates at set speed.

When Tamb. ≤Tpreset-2°C, the compressor will stop, the outdoor fan will delay 30 seconds to stop, and the indoor fan will run at the set

speed.

When Tpreset-2°C<Tamb.<Tpreset, the unit will maintain its previous running status.

In cooling mode, temperature setting range is 16~30°C; the indoor unit displays operation icon, cooling icon and set temperature.

②

When outdoor unit has malfunction or stops for protection, indoor unit will keep previous operation status and display malfunction

code.

(2)Dry Mode

When Tamb.>Tpreset, the unit operates in cooling mode. Meanwhile, compressor and outdoor fan operate, and indoor fan operates at

set fan speed (low fan speed, quiet fan speed or auto quiet fan speed).

When Tpreset-2°C<Tamb. ≤Tpreset, the unit keeps previous operation status.

When Tamb.≤Tpreset-2°C, the compressor will stop, the outdoor fan will stop with a time lag of 30s and indoor fan operate at set fan

speed (low fan speed, quiet fan speed or auto quiet fan speed).

Under this mode, the temperature setting range is 16~30°C. Display displays operation icon, drying icon and set temperature.

(3)Heating mode (not available for cooling only type)

①

Heating conditions and process

When Tamb. ≤Tpreset+2°C, the unit starts heating operation. In this case, compressor and outdoor fan operate simultaneously; the

indoor fan operates at cold-air prevention mode.

When Tamb.≥Tpreset+5°C,the compressor will stop, the outdoor fan will stop with a time lag of 30s; the indoor fan blows residual heat.

When Tpreset+2°C<Tamb.<Tpreset +5°C, the unit will maintain its previous running status.

Under this mode, temperature setting range is 16~30°C; the indoor unit displays operation icon, heating icon and set temperature.

Tpreset

Tpreset –2 ˚C

Compressor

Outdoor fan

Indoor fan

Run

Tamb.

Stop

Stop cooling

Start cooling

Original operating status

≥ 6 min.

30S 30S

≥ 3 min. ≥ 6 min.

Set fan speed

Tpreset

Tpreset –2 ˚C

Compressor

Outdoor fan

Indoor fan

Run

Tamb.

Stop

Stop drying

Start drying

Original operating status

≥ 6 min.

30S 30S

≥ 3 min. ≥ 6 min.

Set fan speed

Tpreset

Tpreset –2 ˚C

Compressor

Outdoor fan

Indoor fan

Run

Tamb.

Stop

Stop cooling

Start cooling

Original operating status

≥ 6 min.

30S 30S

≥ 3 min. ≥ 6 min.

Set fan speed

●

Indoor Unit

46

Service Manual

Technical Information

②

Defrosting and Oil Return

When receiving the signal of defrosting and oil return, the horizontal louver(big one) will rotate to the position where the angle is minimum

and the other horizontal louver(small one) will close. In 10 seconds later, indoor fan will stop operation. During defrosting, oil return and

5 minutes after quit, all indoor pipe temperature sensors will not be detected. When receiving oil return signal or defrosting signal sent by

outdoor unit, Heating indicator on indoor unit is off for 0.5s and then blinks for 10s.

③

Blow residual heat

In heating mode, when temperature reaches the set temperature, the compressor and outdoor fan will stop.

The horizontal louver (big one) will rotate to the default position for cooling and the other one (small one) will close. Indoor unit will

operate at set speed for 60s and then stop operation.

When the unit is in heating mode or auto heating mode, and also the compressor and indoor fan are operating, if turning off the

unit,compressor and outdoor fan will stop. Horizontal louver (big one) will rotate to the position where gentle wind is blown out (default

position for cooling) and the other horizontal louver (small one) will close. Indoor unit will operate at low speed for 10 seconds and then

the unit will be turned off.

(4)Fan Mode

In this mode, indoor fan operates at set speed while compressor and outdoor fan stop operation. The set temperature range is 16~30°C.

Operation icon and set temperature are displayed.

(5)Auto Mode

In this mode, operation mode (Cool, Heat, Fan) will be automatically selected according to change of ambient temperature. Operation

icon, actual operation icon and set temperature will be displayed. There is 30s delay for protection when changing mode. The protection

function is as the same as that under each mode.

①

When Tamb.≥26°C the unit will operate at cooling mode, the default set temperature is 25°C.

②

When Tamb. ≤21°C the unit will operate at heating mode, the default set temperature is 20°C if the cooling only unit operates at fan

mode, the default set temperature is 25°C;

③

When 22°C≤Tamb.≤25°C and the unit is turned on for the rst time, if it changes to auto mode from other mode, the previous operation

mode will be maintained; If it changes to auto mode from dry mode, the unit will operate at fan mode.

④

When the unit operates at auto mode, the frequency of compressor is as the same as that under cooling mode, while it is as the same

as that under heating mode.

Protection function

A. Under cooling mode, the protection function is as the same as that under cooling mode.

B. Under heating mode, the protection function is as the same as that under heating mode.

(6) “8°C” Heating

Under heating mode, press buttons “Temp” and “Clock” simultaneously, the 8°C heating function will be activated and “cold air prevention”

will be shielded.

①

8°C heating can’t co-exist with sleep function. If 8°C heating function is set, it can be cancelled by pressing sleep button, In that case,

the set temperature will be that before entering 8 heating; If sleep function is set, press buttons “Temp” and “Clock” simultaneously to

activate 8°C function and cancel sleep function at the same time.

②

Set temperature is 8°C and it is displayed on the indoor display panel.

Heating mode Tpreset

=20

(if cooling-only

unit, it is Fan mode,

T

preset=25

Keep current

operation mode

Cooling mode,

Tpreset=25

Tpreset

Tpreset +2 ˚C

Tpreset +5 ˚C

Tamb.

Compressor

Outdoor unit

Indoor unit

4-way valve

6 min.3 min.

2 min.

2 min.

Blow residual

heat

6 min.

Start heating

Previous running status

Start heating

Blow residual heat

Stop

Run

21℃ 26℃

T

preset

+5

T

preset

+2

Stop heating

Original operating status

Start heating

Run

Indoor fan

valve

Outdoor fan

Compressor

Stop

3min.6min. 6min.

T

amb

.

preset

Reversing

wind

60s

preset

wind

60s

30s

30s

<2 min.

<2 min.

47

Service Manual

Technical Information

③

In this mode, TURBO can’t be set and fan speed can’t be adjusted.

④

In this mode, when compressor operates, fan speed will be adjusted as follows; when compressor stops operation, indoor unit will

operate at blowing residual heat.

When Tindoor amb. ≤9°C, indoor fan operates at high fan speed;

When 9°C<Tindoor amb.<11°C, indoor fan operates at medium fan speed;