Gree Versati II Series, Versati II Service Manual

AIR TO WATER HEAT PUMP SERVICE MANUAL

Versati

T1/R410A/50Hz

(GC201308- )

II

CONTENTS

PRODUCT ������������������������������������������������������������������������������������������������������ 2

1 MODELS LIST ������������������������������������������������������������������������������������������������������������ 2

1�1 Main Unit ���������������������������������������������������������������������������������������������������������������������������������������� 2

1�2 Water Tank ������������������������������������������������������������������������������������������������������������������������������������� 2

2 NOMENCLATURE ������������������������������������������������������������������������������������������������������� 2

2�1 Main Unit ���������������������������������������������������������������������������������������������������������������������������������������� 2

2�2 Water Tank ������������������������������������������������������������������������������������������������������������������������������������� 3

3 FUNCTION ����������������������������������������������������������������������������������������������������������������� 3

3�1 Cooling ������������������������������������������������������������������������������������������������������������������������������������������ 3

3�2 Heating ������������������������������������������������������������������������������������������������������������������������������������������ 3

3�3 Water Heating ��������������������������������������������������������������������������������������������������������������������������������3

3�4 Cooling +Water Heating ����������������������������������������������������������������������������������������������������������������3

3�5 Heating+ Water Heating ����������������������������������������������������������������������������������������������������������������3

3�6 Emergency Mode ��������������������������������������������������������������������������������������������������������������������������3

3�7 Quick Water Heating ���������������������������������������������������������������������������������������������������������������������4

3�8 Holiday Mode ��������������������������������������������������������������������������������������������������������������������������������� 4

3�9 Forced Operation Mode ��������������������������������������������������������������������������������������������������������������� 4

3�10 Silent Mode ���������������������������������������������������������������������������������������������������������������������������������� 4

3�11 Disinfection Mode �����������������������������������������������������������������������������������������������������������������������4

3�12 Weather-dependent Heating Mode ��������������������������������������������������������������������������������������������4

4 PRODUCT DATA ��������������������������������������������������������������������������������������������������������� 5

4�1 Product Data at Rated Condition ������������������������������������������������������������������������������������������������ 5

4�2 Operation Range ���������������������������������������������������������������������������������������������������������������������������7

4�3 Electrical Data ������������������������������������������������������������������������������������������������������������������������������8

5 PIPING DIAGRAM ������������������������������������������������������������������������������������������������������� 9

UNITS CONTROL ������������������������������������������������������������������������������������������11

1 OPERATION FLOWCHART �������������������������������������������������������������������������������������� 11

2 MAIN LOGIC ������������������������������������������������������������������������������������������������������������� 12

2�1 Defrosting Mode �������������������������������������������������������������������������������������������������������������������������� 12

2�2 Water-side Auto Anti-freezing in Winter �����������������������������������������������������������������������������������12

2�3 Control of Heating Tape on Chassis ������������������������������������������������������������������������������������������12

2�4 Control of Fan ������������������������������������������������������������������������������������������������������������������������������ 12

2�5 Control of Compressor ��������������������������������������������������������������������������������������������������������������� 12

2�6 Control of Electric Expansion Valve ����������������������������������������������������������������������������������������12

3 WIRED CONTROLLER ��������������������������������������������������������������������������������������������� 13

3�1 Dimension ������������������������������������������������������������������������������������������������������������������������������������ 13

3�2 Function ��������������������������������������������������������������������������������������������������������������������������������������� 13

3�3 Operation Instruction ������������������������������������������������������������������������������������������������������������������ 15

3�4 Precautions ���������������������������������������������������������������������������������������������������������������������������������� 33

4 CONTROL WIRING DESIGN ������������������������������������������������������������������������������������ 33

INSTALLATION ��������������������������������������������������������������������������������������������� 35

1 INSTALLATION OF UNITS ���������������������������������������������������������������������������������������35

1�1 Installation Positions ������������������������������������������������������������������������������������������������������������������ 35

1�2 Matters Need Attention ���������������������������������������������������������������������������������������������������������������35

1�3 Dimension Data and Installation Guide ������������������������������������������������������������������������������������36

1�4 Installation Clearance Data ��������������������������������������������������������������������������������������������������������42

1�5 The method of calculating the charging pressure of expansion vessel needed to be

adjusted is as follows� ���������������������������������������������������������������������������������������������������������������������� 43

1�6 Connection of Pipeline ��������������������������������������������������������������������������������������������������������������45

2 ELECTRIC WIRING WORK �������������������������������������������������������������������������������������� 47

2�1 Wiring Principle ��������������������������������������������������������������������������������������������������������������������������� 47

2�2 PCB Outline ���������������������������������������������������������������������������������������������������������������������������������48

2�3 Electric Wiring Design ���������������������������������������������������������������������������������������������������������������50

UNITS MAINTENANCE ������������������������������������������������������������������������������� 60

1 ERROR CODE LIST ������������������������������������������������������������������������������������������������� 60

2 FLOW CHART OF TROUBLESHOOTING �������������������������������������������������������������� 64

3 DIAGNOSIS OF DRIVING ����������������������������������������������������������������������������������������� 68

3�1 Diagnosis Flowchart of Driving of Single-phase Unit and Three-phase Unit ������������������������68

4 DISASSEMBLY AND ASSEMBLY PROCEDURE OF MAIN PARTS ���������������������� 72

5 EXPLODED VIEWS AND PART LIST ���������������������������������������������������������������������� 82

5�1 Outdoor Exploded View and Part List ��������������������������������������������������������������������������������������� 82

5�2 Indoor Exploded View and Part List ������������������������������������������������������������������������������������������ 84

5�3 Water Tank Exploded View and Part List ���������������������������������������������������������������������������������� 86

1

Air to Water Heat Pump

Service Manual- Versati II Series

PRODUCT

PRODUCT

2

Air to Water Heat Pump

Service Manual- Versati II Series

PRODUCT

PRODUCT

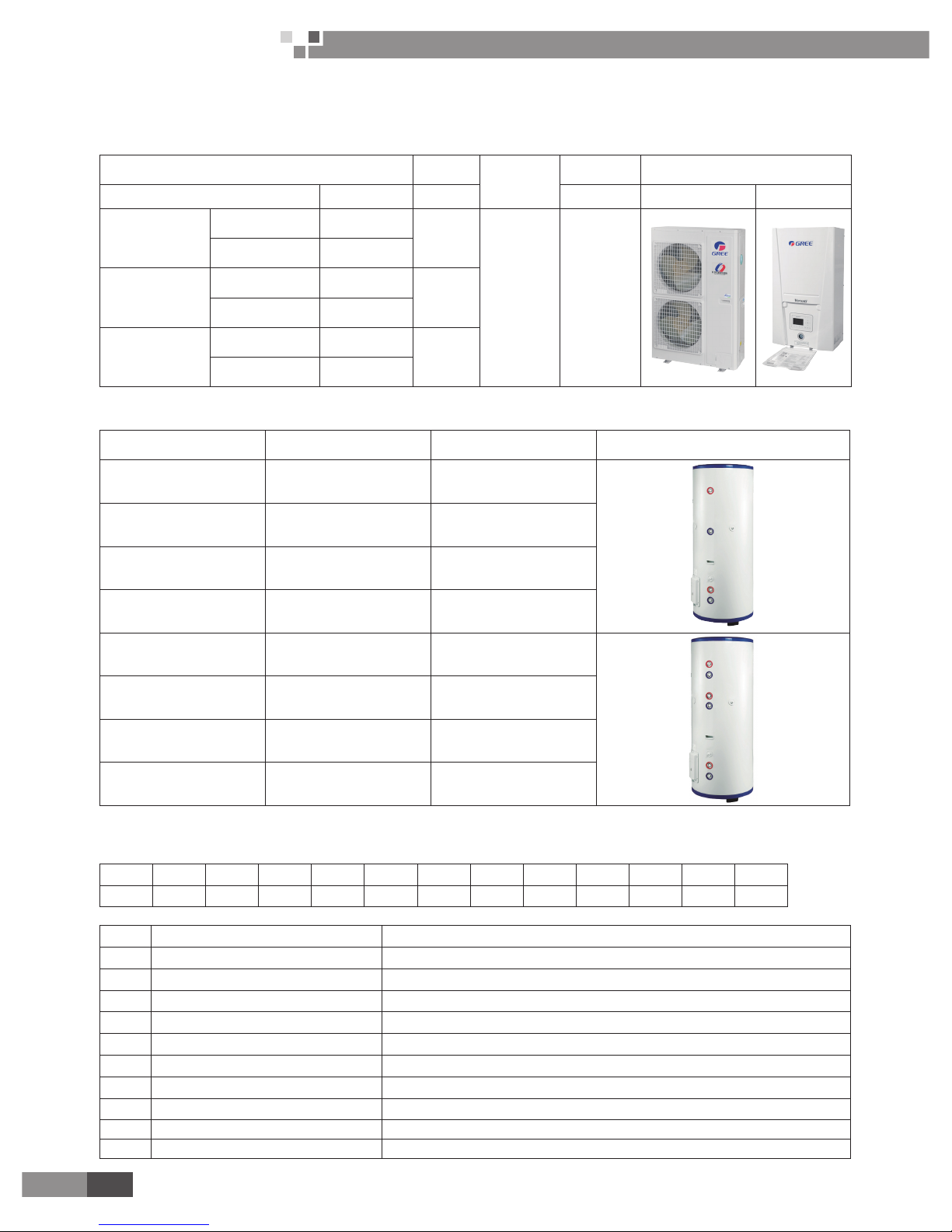

1 MODELS LIST

1�1 Main Unit

Model

Nominal

Capacity

Refrigerant

Power

Supply

Appearance

Model Name Product Code kW V,Ph,Hz Outdoor Unit Indoor Unit

GRS-CQ12Pd/

NaB-K

GRS-CQ12Pd/

NaB-K(I)

ER010N1130

12.5

R410A 230,1,50

GRS-CQ12Pd/

NaB-K(O)

ER010W1130

GRS-CQ14Pd/

NaB-K

GRS-CQ14Pd/

NaB-K(I)

ER010N1140

13.5

GRS-CQ14Pd/

NaB-K(O)

ER010W1140

GRS-CQ16Pd/

NaB-K

GRS-CQ16Pd/

NaB-K(I)

ER010N1150

15.5

GRS-CQ16Pd/

NaB-K(O)

ER010W1150

Note:1Ton =12000Btu/h = 3.517kW

1�2 Water Tank

Model Product Code Nominal Cubage(L) Appearance

SXVD200LCJ/A-K ER20000160 200

SXVD200LCJ/A-M ER20000240 200

SXVD300LCJ/A-K ER20000180 300

SXVD300LCJ/A-M ER20000250 300

SXVD200LCJ2/A-K ER20000170 200

SXVD200LCJ2/A-M ER20000260 200

SXVD300LCJ2/A-K ER20000190 300

SXVD300LCJ2/A-M ER20000270 300

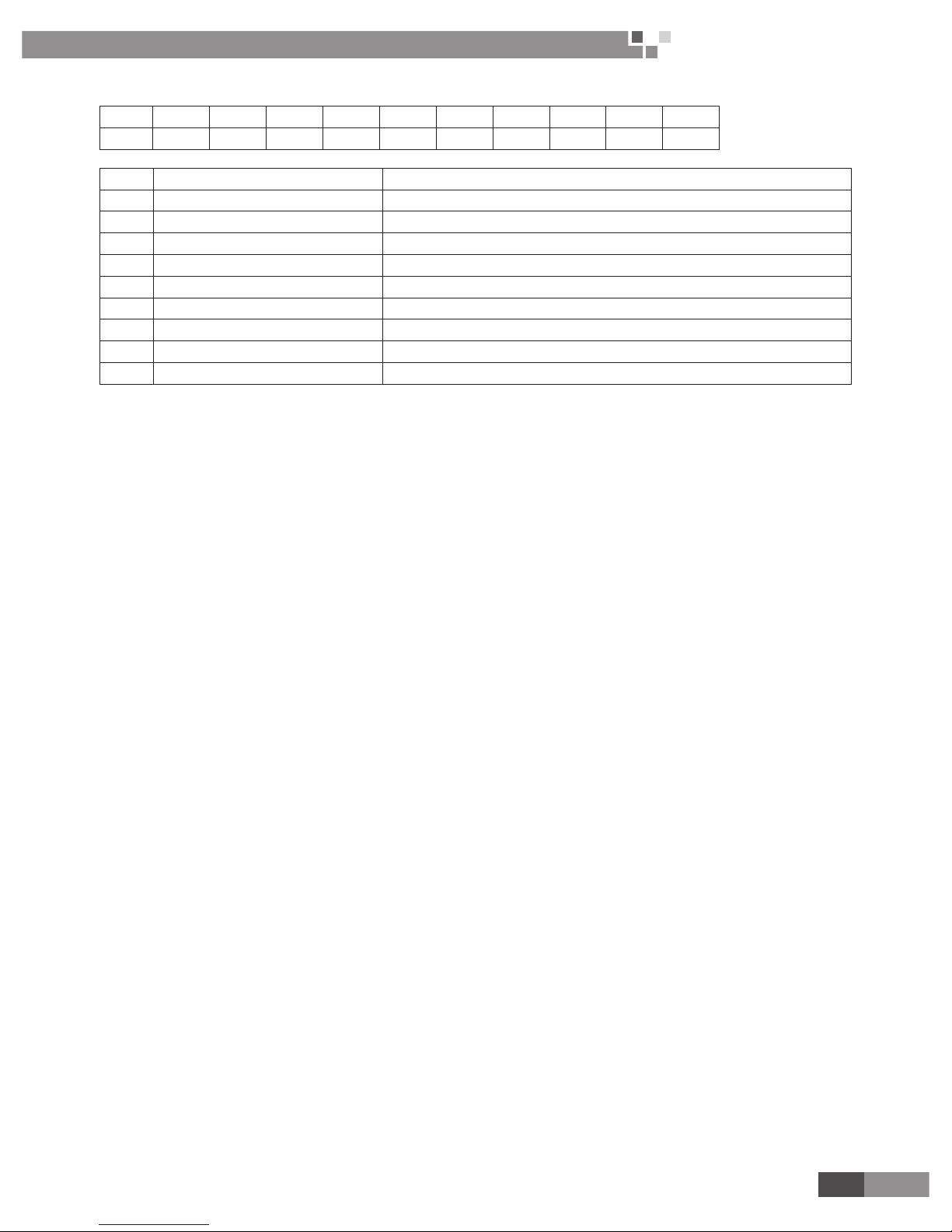

2 NOMENCLATURE

2�1 Main Unit

G RS - C Q 16 Pd / Na B - K (I)

1 2 3 4 5 6 7 8 9 10

NO. Description Options

1 GREE Air to water heat pump -

2 Heat Pump Water Heater -

3 Heating Mode Circulating

4 Multi Heat pump -

5 Nominal Heating capacity 16=16 kW

6 DC Inverter -

7 Refrigerant Type Na-R410A

8 Design Serial Number A,B,C…...

9 Power Supply K=220-240V,~,50Hz; M=380-415V,3N~,50Hz; H=380V,3N~,60Hz

10 Indoor Unit I-Indoor unit, O-outdoor unit

3

Air to Water Heat Pump

Service Manual- Versati II Series

PRODUCT

2�2 Water Tank

SX V D 200 L C J2 / A - K

1 2 3 4 5 6 7 8 9

NO. Description Options

1 Tank Used in Heat Pump /

2 Heat Pump Water Tank for GMV Units /

3 Electric Heater /

4 Volume of Tank /

5 Stand /

6 Pressure-Resistant /

7 Static Heating with Dual Coiled Pipe J=Static Heating with single Coiled Pipe ; J2=Static Heating with Dual Coiled Pipe

8 Design Sequence Number

9 Power Supply K=220-240V,~,50Hz; M=380-415V,3N~,50Hz; H=380V,3N~,60Hz

3 FUNCTION

3�1 Cooling

In cooling mode: the refrigerant is condensed in the outdoor unit and evaporated in the indoor unit. Via the

heat exchange with water in the indoor unit, the temperature of water decreases and it releases heat while the

refrigerant absorbs heat and evaporates. With the help of wired controller, the outow temperature can meet

the user’s requirement. Through the control of valve, the low-temperature water in the system is connected with

indoor fan coil and underground pipe, and exchanges heat with the indoor air so that the indoor temperature

decreases to the required range.

3�2 Heating

In heating mode: the refrigerant evaporates in the outdoor unit and is condensed in the indoor unit. Via

the heat exchange with water in the indoor unit, the water absorbs heat and its temperature increases while

the refrigerant releases heat and is condensed. With the help of wired controller, the outflow temperature

can meet the user’s requirement. Through the control of valve, the high-temperature water in the system is

connected with indoor fan coil and underground pipe, and exchanges heat with the indoor air so that the indoor

temperature increases to the required range;

3�3 Water Heating

In water heating mode: the refrigerant evaporates in the outdoor unit and is condensed in the indoor unit.

Via the heat exchange with water in the indoor unit, the water absorbs heat and its temperature increases

while the refrigerant releases heat and is condensed. With the help of wired controller, the outow temperature

can meet the user’s requirement. Through the control of valve, the high-temperature water in the system is

connected with the coil pipe of bearing water tank, and exchanges heat with the water in the water tank so that

the temperature of water tank increases to the required range.

3�4 Cooling +Water Heating

When cooling mode exists together with the water heating mode, the user can set the priority of these two

modes based on the needs. The default priority is heat pump. That is under the default setting, if cooling mode

exists together with the water heating mode, the heat pump gives priority to cooling. In that case, water heating

can only realized with e-heater of the water tank. Inversely, the heat pump gives priority to water heating and

switches to cooling after nishing water heating.

3�5 Heating+ Water Heating

When heating mode exists together with the water heating mode, the user can set the priority of these two

modes based on the needs. The default priority is heat pump. That is under the default setting, if heating mode

exists together with the water heating mode, the heat pump gives priority to heating. In that case, water heating

can only realized with e-heater of the water tank. Inversely, the heat pump gives priority to water heating and

switches to heating after nishing water heating.

3�6 Emergency Mode

Emergency mode: this mode is only available for heating and water heating. When the outdoor unit stops

due to malfunction, it will enter the corresponding emergency mode; as to heating mode, after entering the

emergency mode, heating can only be realized through e-heater of the indoor unit. When the setting outow

temperature or indoor temperature is reached, the e-heater of indoor unit will stop running; as to water heating

mode, the e-heater of indoor unit stops while the e-heater of water tank runs. When the setting temperature or

4

Air to Water Heat Pump

Service Manual- Versati II Series

PRODUCT

water tank is reached, the e-heater will stop running.

3�7 Quick Water Heating

In quick water heating mode, the unit runs according to the water heating control of heat pump and the

e-heater of water tank runs at the same time.

3�8 Holiday Mode

This mode is only available for heating mode. This mode is set to keep indoor temperature or outflow

temperature in a certain range, so as to prevent water system of the unit from freezing or protect certain indoor

articles from freezing damage. (This mode requires installing indoor temperature sensor). When the outdoor

unit stops due to malfunction, the two e-heaters of the unit will run.

3�9 Forced Operation Mode

This mode is only used for refrigerant recovery and debugging of the unit.

3�10 Silent Mode

Silent mode is available in cooling, heating and water heating mode. In silent mode, the outdoor unit will

reduce the running noise via automatic control.

3�11 Disinfection Mode

In this mode, the water heating system can be disinfected. When starting up the disinfection function and

setting corresponding time to meet the requirement of disinfection mode, the function will start. After the setting

temperature is reached, this mode will terminate.

3�12 Weather-dependent Heating Mode

This mode is only available for space heating. In weather-dependent heating mode, the indoor temperature

is detected and controlled automatically.

3�13 Floor Commissioning

This function is intended to preheat the oor periodically for the initial use.

3�14 Air Removal of the Water System

This function is intended to replenish water and remove air in the water system to make the equipment run

at the stabilized water pressure.

5

Air to Water Heat Pump

Service Manual- Versati II Series

PRODUCT

4 PRODUCT DATA

4�1 Product Data at Rated Condition

Due to continues improvement on the products, the specifications listed above are subject to change

without notice, and the ones on the products nameplate should be referred to as nal.

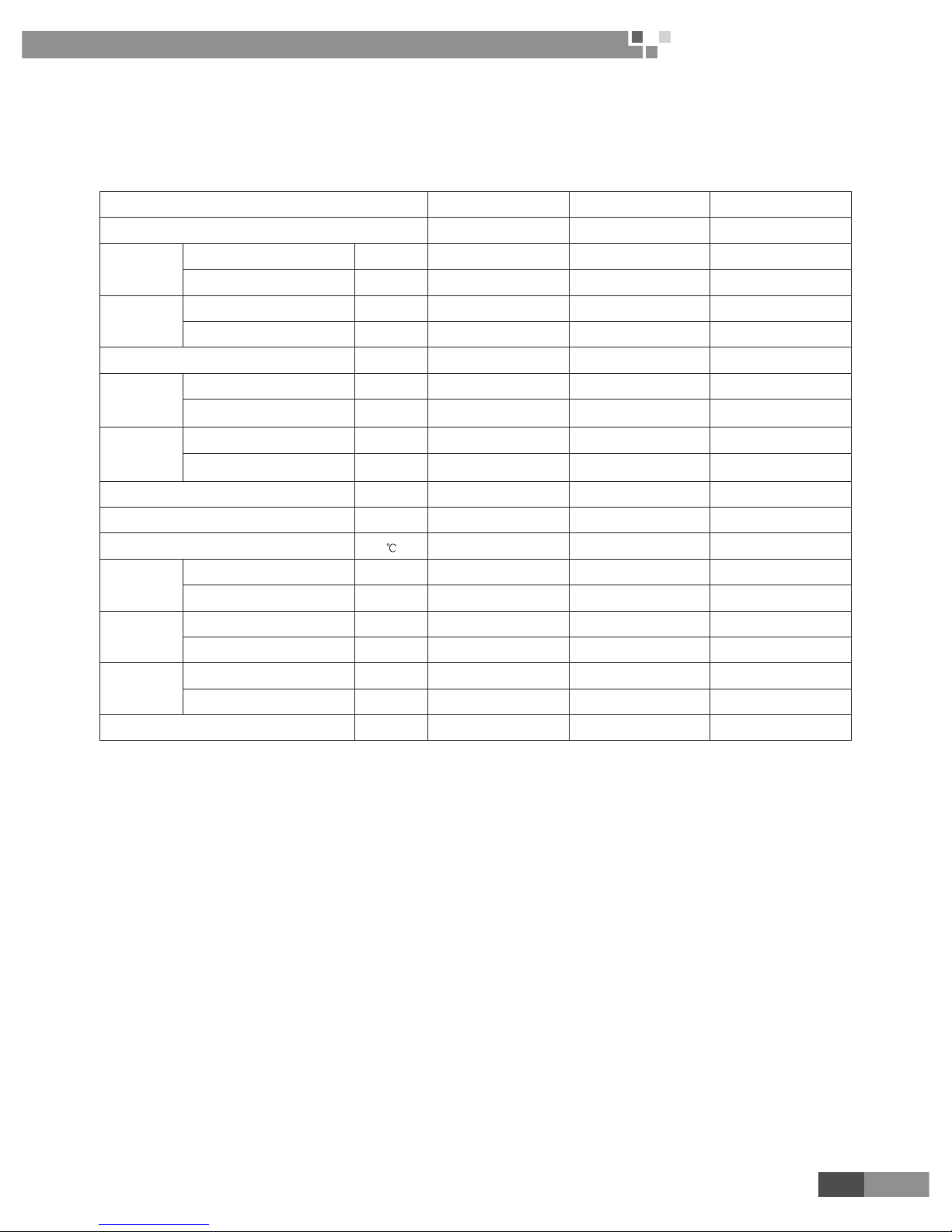

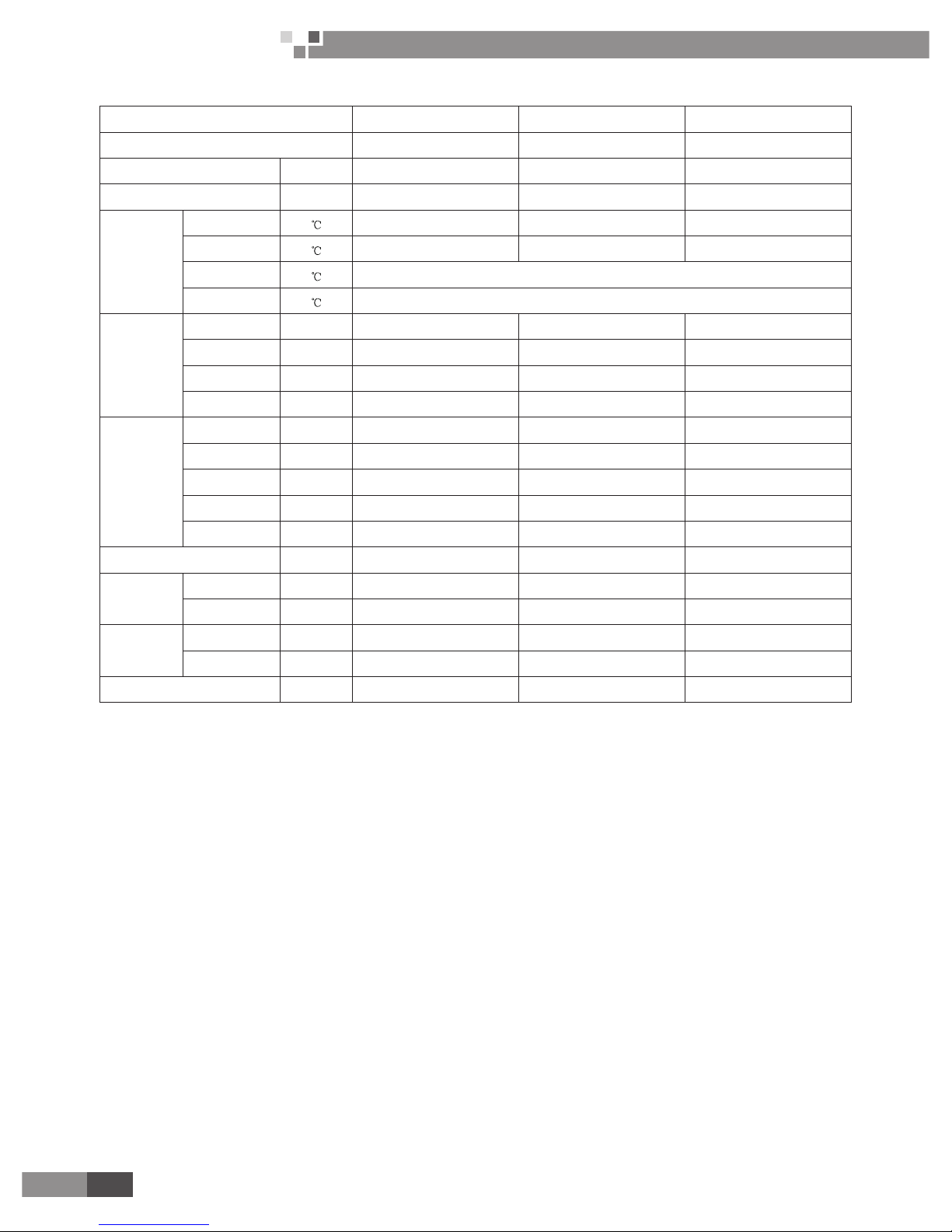

4.1.1 Outdoor Unit

Model

GRS-CQ12Pd/NaB-K(O) GRS-CQ14Pd/NaB-K(O) GRS-CQ16Pd/NaB-K(O)

Product Code ER010W1130 ER010W1140 ER010W1150

Capacity*

1

Cooling(oor cooling) kW 12.5 13.5 14.5

Heating(oor heating) kW 12.5 13.5 15.5

Power

Input*

1

Cooling(oor cooling) kW 3.57 4.09 4.53

Heating(oor heating) kW 2.81 3.07 3.78

EER/COP*

1

W/W 3.5/4.45 3.3/4.4 3.2/4.1

Capacity*

2

Cooling(for Fan coil) kW 9.5 10 10.5

Heating(Fan coil or

Radiator)

kW 11 12 14

Power

Input*

2

Cooling(for Fan coil) kW 3.39 3.57 3.96

Heating(Fan coil or

Radiator)

kW 3.14 3.48 4

EER/COP*

2

W/W 2.8/3.5 2.8/3.45 2.65/3.5

Refrigerant charge volume kg 3.2 3.2 3.2

Sanitary water Temperature 40~80 40~80 40~80

Sound

Pressure

Level

cooling dB(A) 55 55 57

heating dB(A) 57 57 58

Connecting

pipe

Gas inch(mm)

φ

5/8(15.9)

φ

5/8(15.9)

φ

5/8(15.9)

Liquid inch(mm)

φ

3/8(9.52)

φ

3/8(9.52)

φ

3/8(9.52)

Dimensions

(W×D×H)

Outline mm 900×412×1345 900×412×1345 900×412×1345

Packaged mm 998×458×1515 998×458×1515 998×458×1515

Net weight/Gross weight kg 106/118 106/118 106/118

Notes:

1

Capacities and power inputs are based on the following conditions:

a. Cooling conditions

Indoor Water Temperature 23°C/18°C;

Outdoor Air Temperature 35°CDB/24°CWB

b. Heating conditions

Indoor Water Temperature 30°C/35°C;

Outdoor Air Temperature 7°CDB/6°CWB

c. Standard piping length 7.5m

2

Capacities and power inputs are based on the following conditions:

a. Cooling conditions

Indoor Water Temperature 12°C/7°C;

Outdoor Air Temperature 35°CDB/24°CWB

b. Heating conditions

Indoor Water Temperature 40°C/45°C;

Outdoor Air Temperature 7°CDB/6°CWB

c. Standard piping length 7.5m

6

Air to Water Heat Pump

Service Manual- Versati II Series

PRODUCT

4.1.2 Indoor Unit

Model GRS-CQ12Pd/NaB-K(I) GRS-CQ14Pd/NaB-KI) GRS-CQ16Pd/NaB-K(I)

Product Code ER010N1130 ER010N1140 ER010N1150

Power Supply V/Ph/Hz 1/220-240/50 1/220-240/50 1/220-240/50

Norminal input W 6200 6200 6200

Leaving

water

temperature

Cooling*

1

7~25 7~25 7~25

Cooling*

2

18~25 18~25 18~25

Heating*

1

25~55(High temperature cycle )

Heating*

2

25~45(Low temperature cycle )

Pump

Type - Water-cooled Water-cooled Water-cooled

Nr. of speed - 3 3 3

Power input W 200 200 200

Water flow limit LPM 7.5 7.5 7.5

Electric

Heater

Operation - Automatic Automatic Automatic

Steps - 2 2 2

Capacity kW 3 3 3

Combination kW 3+3 3+3 3+3

Power input Ph/V/Hz 1/230/50 1/230/50 1/230/50

Sound pressure level dB(A) 31 31 31

Connecting

pipe

Gas inch(mm)

φ

5/8(15.9)

φ

5/8(15.9)

φ

5/8(15.9)

Liquid inch(mm)

φ

3/8(9.52)

φ

3/8(9.52)

φ

3/8(9.52)

Dimensions

(W×D×H)

Outline mm 900x500x324 900x500x324 900x500x324

Packaged mm 1040×605×380 1040×605×380 1040×605×380

Net weight/Gross weight kg 57/66 57/66 57/66

7

Air to Water Heat Pump

Service Manual- Versati II Series

PRODUCT

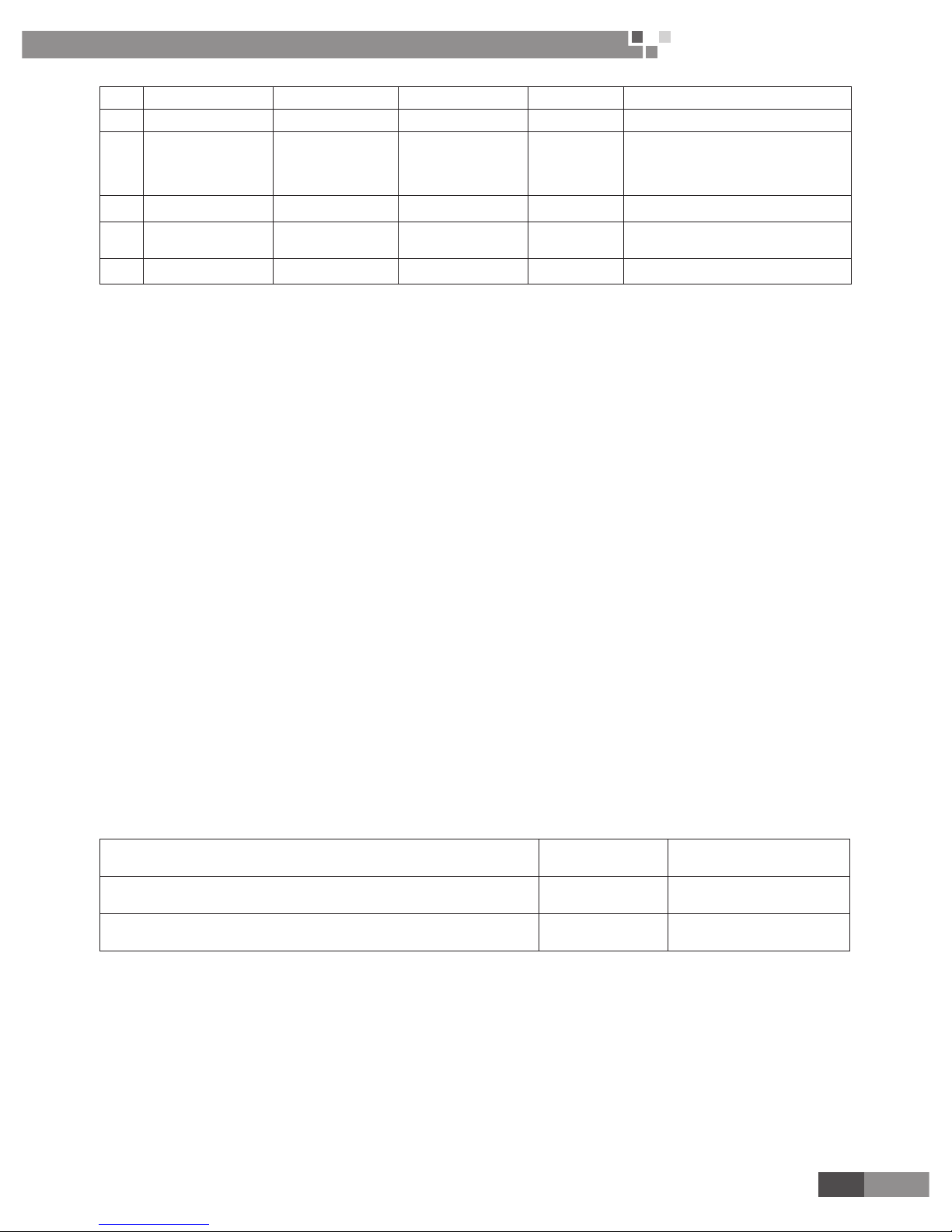

4.1.3 Water Tank (optional)

Models SXVD200LCJ/A-K SXVD200LCJ2/A-K SXVD300LCJ/A-K SXVD300LCJ2/A-K

Product Code ER20000160

ER20000170

ER20000180

ER20000190

Models SXVD200LCJ/A-M SXVD200LCJ2/A-M SXVD300LCJ/A-M SXVD300LCJ2/A-M

Product Code ER20000240 ER20000260 ER20000250 ER20000270

Models SXVD200LCJ/A-H

SXVD200LCJ2/A-H

SXVD300LCJ/A-H

SXVD300LCJ2/A-H

Product Code ER20000280 ER20000290 ER20000300 ER20000310

Water Tank Volume L 200 300

Electric Heater Power W 3000

Cool Water

Inlet Pipe

Outer

diameter

mm DN15

inch 1/2

Screw thread spec 1/2″Female BSP

Hot Water

Outlet Pipe

Outer

diameter

mm DN15

inch 1/2

Screw thread spec 1/2″Female BSP

Circulation Water

Inlet/Outlet Pipe

Outer

diameter

mm / DN20 / DN20

inch / 3/4 / 3/4

Screw thread spec / 3/4″Female BSP / 3/4″Female BSP

Water Inlet/

Outlet(Heat

Pump) Pipe

Outer

diameter

mm DN20

inch 3/4

Screw thread spec 3/4″Female BSP

Outline Dimension(ΦD×H) mm Φ540×1595 Φ620×1620

Net Weight kg 68 71 82 87

Note :

Tank is optional part, and the specific model of tank shall be selected according to local weather and

professional suggestions.

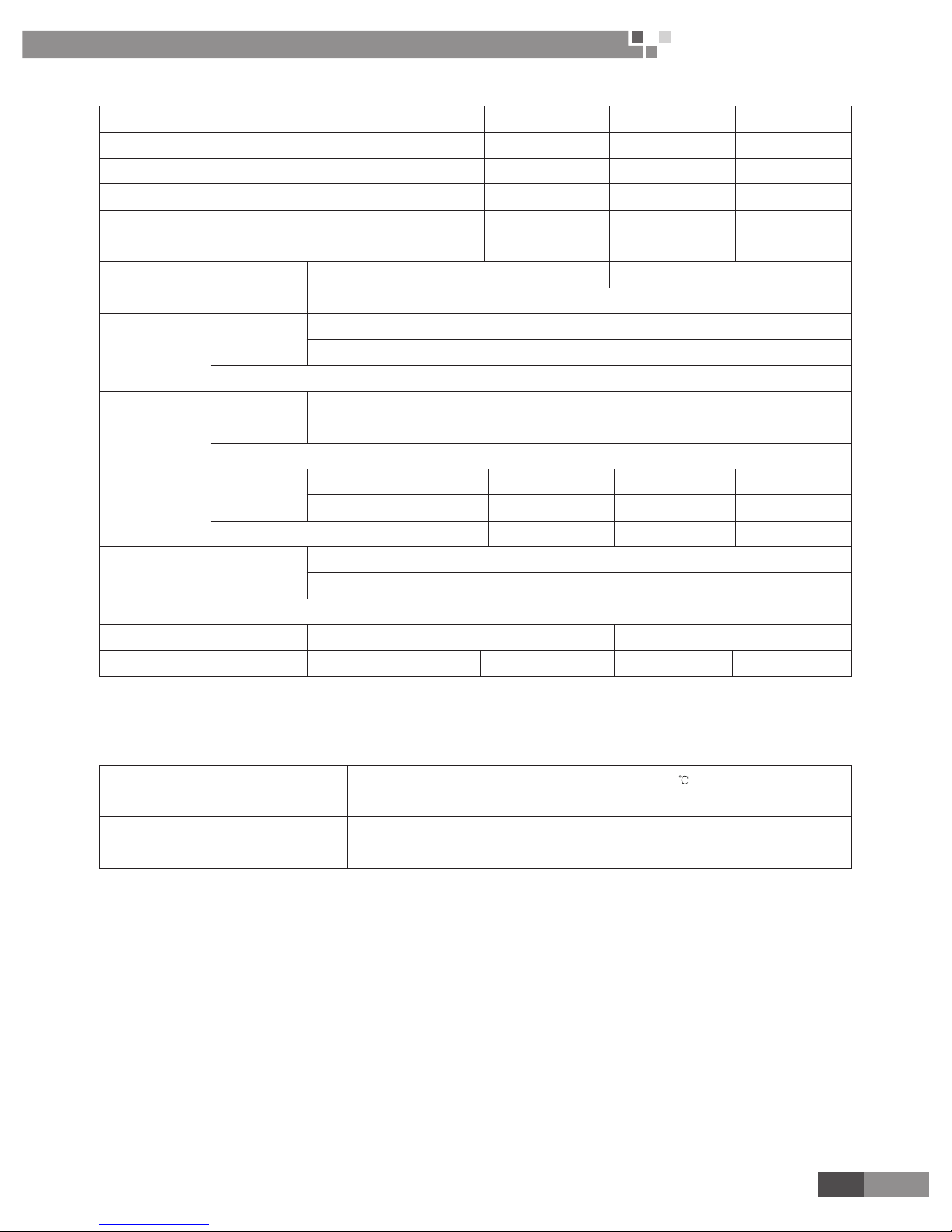

4�2 Operation Range

Mode Range of Outdoor Temperature( )

Heating -20~35

Cooling 10~48

Water heating -20~45

8

Air to Water Heat Pump

Service Manual- Versati II Series

PRODUCT

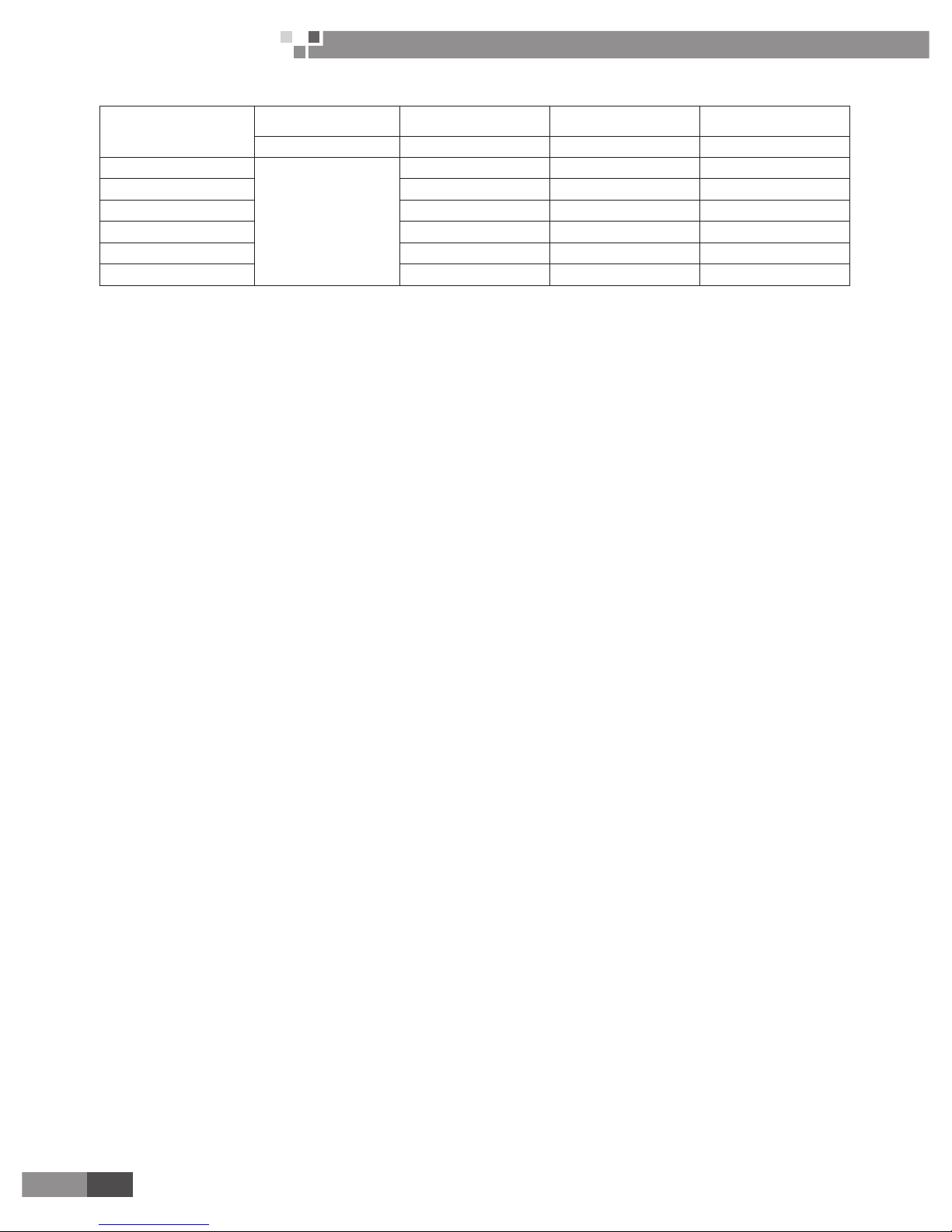

4�3 Electrical Data

Model

Power Supply Leakage Switch

Minimum Sectional

Area of Earth Wire

Minimum Sectional Area

of Power Supply Wire

V,Ph,Hz (A) (mm2) (mm2)

GRS-CQ12Pd/NaB-K(I)

220-240V,~,50Hz

50 10 3×10

GRS-CQ14Pd/NaB-K(I) 50 10 3×10

GRS-CQ16Pd/NaB-K(I) 50 10 3×10

GRS-CQ12Pd/NaB-K(O) 32 4 3×4

GRS-CQ14Pd/NaB-K(O) 32 4 3×4

GRS-CQ16Pd/NaB-K(O) 32 4 3×4

Note:

①

Leakage Switch is necessary for additional installation. If circuit breakers with leakage protection are in

use, action response time must be less than 0.1 second, leakage circuit must be 30mA.

②

The above selected power cable diameters are determined based on assumption of distance from the

distribution cabinet to the unit less than 75m. If cables are laid out in a distance of 75m to 150m, diameter of

power cable must be increased to a further grade.

③

The power supply must be of rated voltage of the unit and special electrical line for air-conditioning.

④

All electrical installation shall be carried out by professional technicians in accordance with the local

laws and regulations.

⑤

Ensure safe grounding and the grounding wire shall be connected with the special grounding equipment

of the building and must be installed by professional technicians.

⑥

The specications of the breaker and power cable listed in the table above are determined based on the

maximum power (maximum amps) of the unit.

⑦

The specications of the power cable listed in the table above are applied to the conduit-guarded multi-

wire copper cable (like, YJV XLPE insulated power cable) used at 40℃ and resistible to 90℃(see IEC 60364-5-

52). If the working condition changes, they should be modied according to the related national standard.

⑧

The specications of the breaker listed in the table above are applied to the breaker with the working

temperature at 40℃. If the working condition changes, they should be modied according to the related national

standard.

9

Air to Water Heat Pump

Service Manual- Versati II Series

PRODUCT

5 PIPING DIAGRAM

R3T gas line temperature sensor

17

15

16

INDOOR UINTOUTDOOR UINT

M

M

M

M

1

2

3

4

5

6

7

8

10

11

20

19

5

18

12

1 compressor

2 four-way valve

3 finned coil exchanger

4 fan motor

5 filter

6 electronic expansion valve

7 plate heat exchanger

11 flow switch

10 electric heater

9 air-vent valve

8 pump

18 water tank

12 3-way valve

17 other thermal system

16 radiator

15 under-floor heating

R6T water tank temperature sensor 1

R4T returning water temperature sensor

R1T plate outlet temperature sensor

t

R1T

R3T

t

R5T

t

R4T

t

t

R6T

t

R2T

9

19 expansion tank

20 safety valve

R2T Liquid line temperature sensor

R5T leaving water temperature sensor

t

R7T

R7T water tank temperature sensor 2

13

14

13 2-way valve

14 by-pass valve

10

Air to Water Heat Pump

Service Manual- Versati II Series

CONTROL

CONTROL

11

Air to Water Heat Pump

Service Manual- Versati II Series

CONTROL

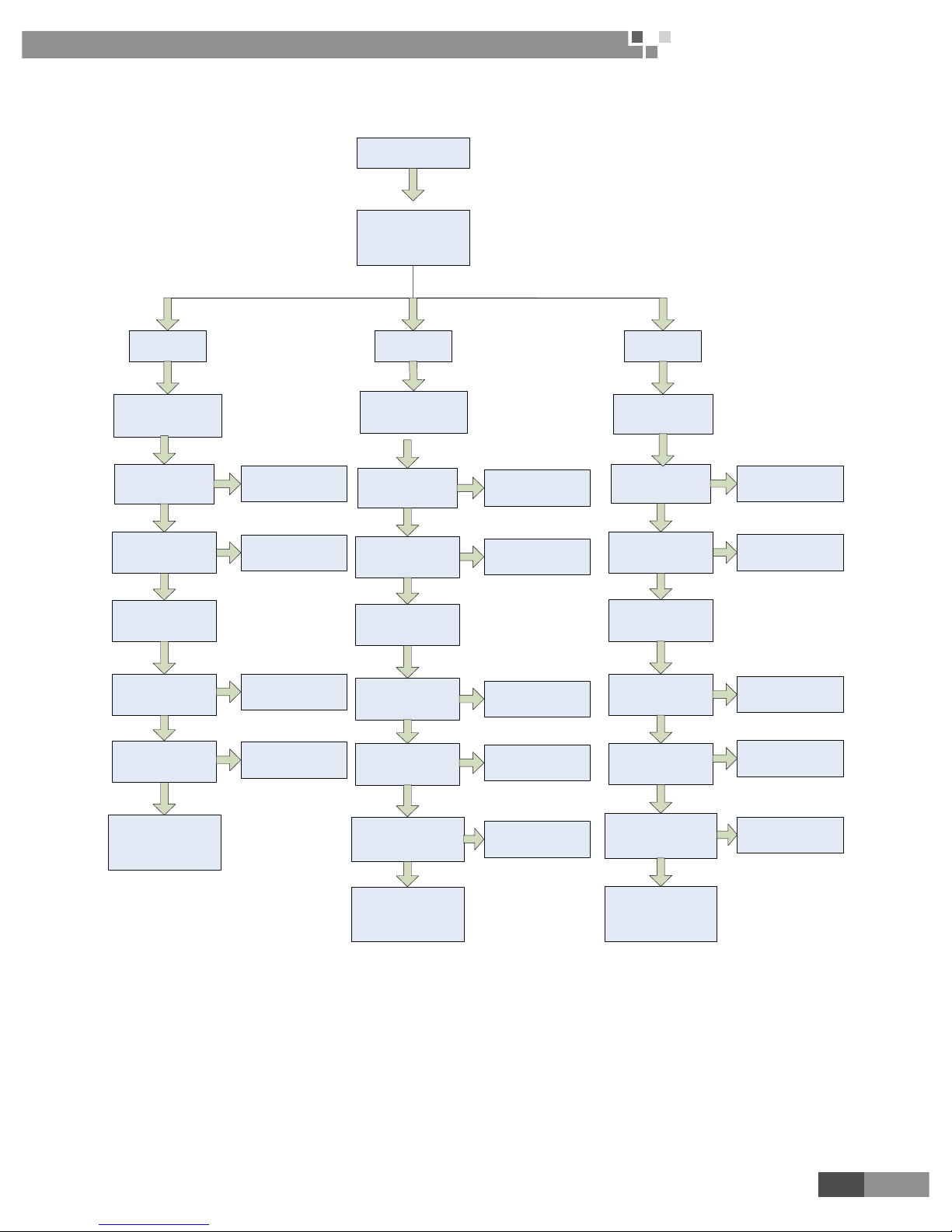

UNITS CONTROL

1 OPERATION FLOWCHART

Power Switch ON

Operation Mode

Judgment

Cooling Heating

YES

Cooling

Operation

Heating

Operation

Water

Heating

Water Pump

Control

Electric Expansion

Valve Control

Error Indication

Outdoor fan Motor

Control

Compressor

Control

Error Indication

Water Flow

Switch Control

YES

NO

Error Indication

NO

Error Indication

NO

YES

YES

YES

Water Pump

Control

Electric Expansion

Valve Control

Error Indication

Outdoor fan Motor

Control

Compressor

Control

Error Indication

Water Flow

Switch Control

YES

NO

NO

Error Indication

YES

YES

YES

Error Indication

4-Wa y Valve

Control

Error Indication

3-Way Valve and

2-Way Valve

Control

Water Heating

Operation

Water Pump

Control

Electric Expansion

Valve Control

Error Indication

Outdoor fan Motor

Control

Compressor

Control

Error Indication

Water Flow

Switch Control

YES

NO

NO

Error Indication

YES

YES

YES

Error Indication

4-Way Valve

Control

Error Indication

NO

YES

YES

YES

NO

NO

3-Wa y Valve and

2-Wa y Valve

Control

3-Way Valve and

2-Way Valve

Control

YES

NO

YES

NO

12

Air to Water Heat Pump

Service Manual- Versati II Series

CONTROL

2 MAIN LOGIC

2�1 Defrosting Mode

2.1.1 The condition of start defrosting mode:

Under heating mode or water heating mode, if the accumulative running time of compressor is over the

set interval time of defrosting(default 50min),and the defrosting temperature(outdoor unit heat exchanger

temperature) is lower than the set starting temperature(default -4 ),the unit will start running defrosting, and the

4-way valve will shut off and the outdoor fan will stop.

2.1.2 The condition of quit defrosting mode:

Under defrosting mode, if the continual defrosting time is over the set continual time of defrosting(default

10min) ,or the defrosting temperature is over the set stopping temperature(default 15 ) ,the unit will restart

running heating mode, and the 4-way valve will turn on and the outdoor fan will run.

2�2 Water-side Auto Anti-freezing in Winter

In low temperature, When the compressor stops (including normal or abnormal stop of the unit), if auxiliary

electric heater water-out temperature is lower than 5 , 30s later the water pump will automatically operate and

120s later the compressor operates.

When outlet water temperature is less than 20 ,the unit will operate while it will stop when the outlet water

temperature is more than 20 .

However, if there is malfunction of the unit, anti-freezing operation will be started by indoor electric heater

(two sets).

2�3 Control of Heating Tape on Chassis

When heating operation starts in low temperature, in order to prevent the condensation water generated

by defrosting from freezing in chassis, which will incur malfunction of drainage, the heating tape is installed

in chassis. If the ambient temperature is lower than 0 , when the compressor operates, electric heating will

operate; if the ambient temperature is higher than 2 or compressor stops, the electric heating will stop.

2�4 Control of Fan

In cooling, the outdoor fan will adjust fan speed according to pressure detected by high pressure sensor.

In heating or water heating, the fan will adjust fan speed according to ambient temp.

2�5 Control of Compressor

Output capacity of compressor is adjusted according to the comparison of current outlet water temperature

and setting outlet water temperature or the comparison of indoor ambient temperature and setting indoor

temperature;

The output capacity will not be adjusted within 6 min after the compressor operates; once compressor

stops, it can’t be started within at least 3 min.

2�6 Control of Electric Expansion Valve

In heating or water heating operation, electric expansion valve is adjusted according to superheat degree of

outdoor heat exchanger.

In cooling operation, electric expansion valve is adjusted according to superheat degree of plate-type heat

exchanger.

Electric expansion valve will not be adjusted within 3 min after the unit operates.

13

Air to Water Heat Pump

Service Manual- Versati II Series

CONTROL

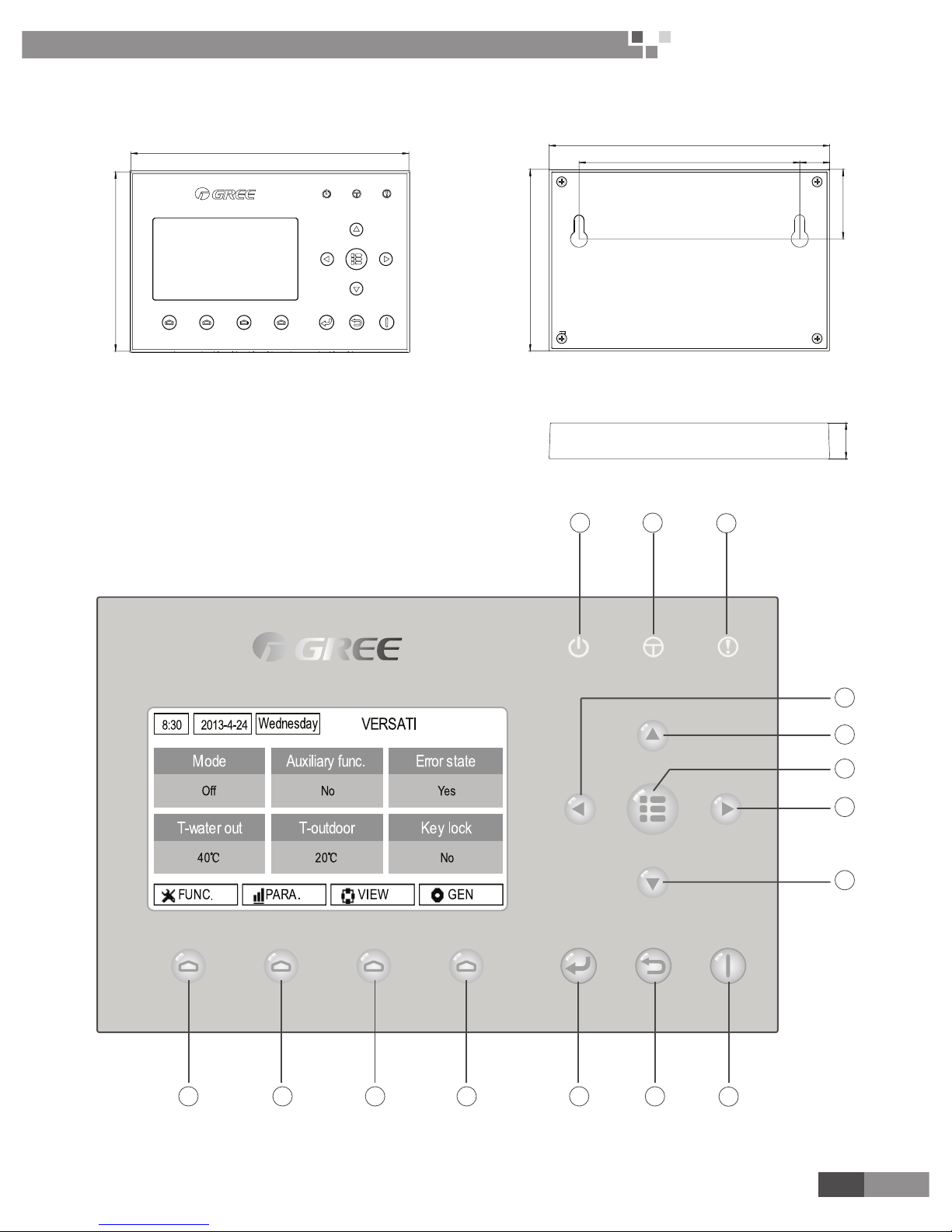

3 WIRED CONTROLLER

3�1 Dimension

163

164.4

129.4 17.5

105

106.4

40.7

21

3�2 Function

3.2.1 External View

1 2

3

101112131415

9

4

5

6

7

8

(This effect drawing is just for reference)

14

Air to Water Heat Pump

Service Manual- Versati II Series

CONTROL

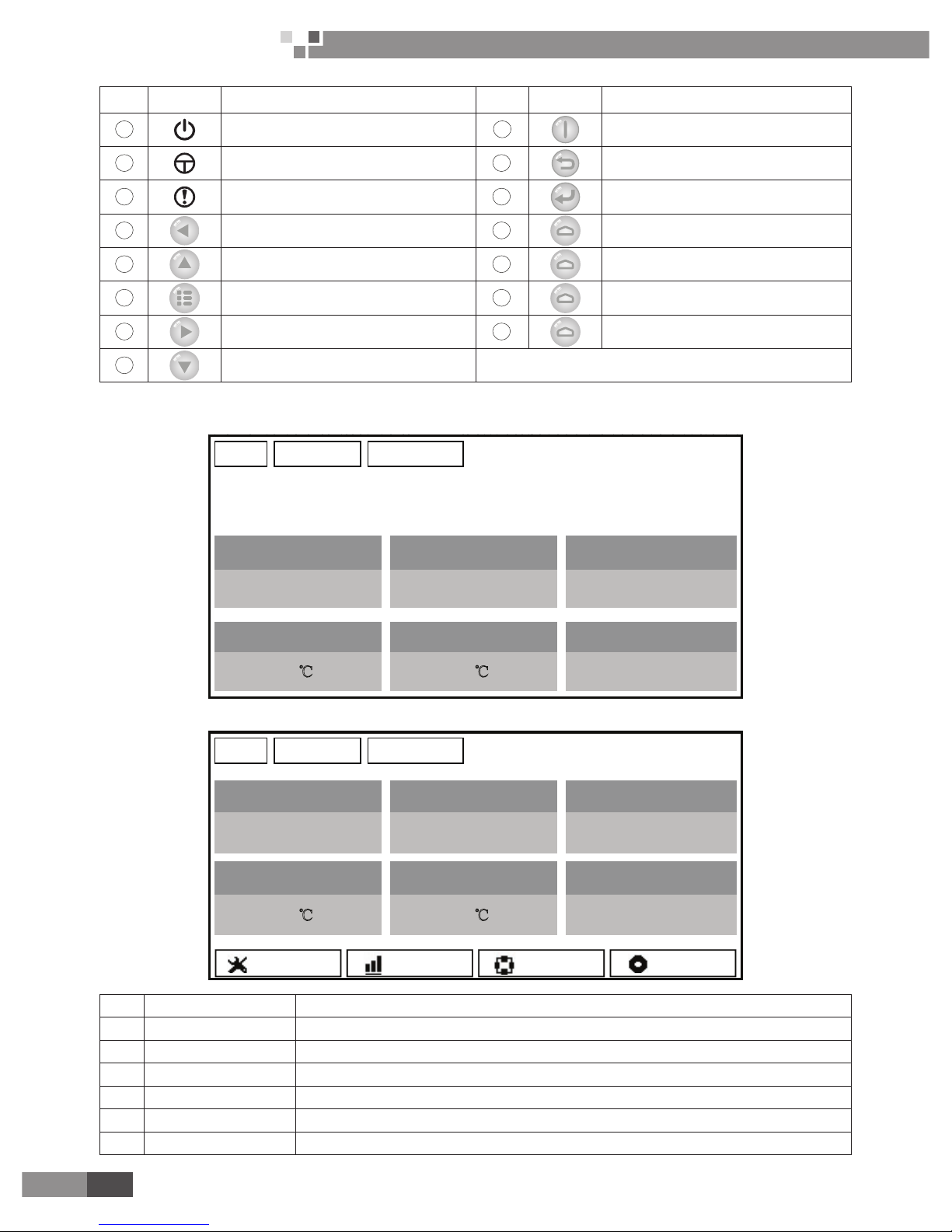

No� Symbol Description No� Symbol Description

1

Running indicating LED

9

ON/OFFF

2

Power indicating LED

10

Cancel/Return key

3

Error indicating LED

11

OK key

4

Left key

12

Function key no. 4

5

Up key

13

Function key no. 3

6

Menu key

14

Function key no. 2

7

Right key

15

Function key no. 1

8

Down key

3.2.2 Standby Page and Homepage

Standby Page

T-outdoor Key lock

8:30

2013-4-24

Wednesday

VERSATI

Mode Auxiliary func.

Error state

40℃ 20℃ No

Off No Yes

T-water out

Home Page

Yes

T-water out T-outdoor Key lock

40℃ 20℃ No

Mode Auxiliary func.

Off No

Error state

8:30 2013-4-24

Wednesday

VERSATI

FUNC. PARA. VIEW GEN.

No� Item Functional Description

1 Mode It is intended to access to the actual running mode.

2 Auxiliary Func. It indicates the auxiliary function note 1.

3 Error state It indicates if there is any error.

4 T-water out It indicates the actual leaving water temperature.

5 T-outdoor It indicates the actual outdoor environment temperature.

6 Key lock It indicates if the key lock is activated or deactivated.

15

Air to Water Heat Pump

Service Manual- Versati II Series

CONTROL

Note:

it includes the “Sanitize mode”, “Quiet” mode, “Auto” mode, “Floor debug” mode, “Emergen�mode”,

“Holiday mode”, “Forced Cooling” mode, “Forced Heating” mode, and “Debug” mode.

3.2.3 Keys

No� Item Functional Description

1 ON/OFF key It is intended to turn on or off the unit.

2 OK key It is intended to save the setting or go to the submenu.

3 Cancel/Return key It is intended to go to the higher level menu.

4 Menu key It is intended to call out the main menu or back to the homepage.

5 Left/Right key It is intended to move the cursor Left/Right.

6 Up/Down key It is intended to modify the setting state or value of the selected parameter.

7 Function keys (4) It is intended to perform different functions at difference pages.

3.2.4 Indicating LEDs

No� Item Functional Description

1 On/Off indicating LED (green) It will light on/off when the unit is turned on/off.

2 Power indicating LED (yellow) It will light on/off when the unit is powered on/off.

3 Fault indicating LED (red) It will light on when some fault occurs.

3�3 Operation Instruction

3�3�1 On/Off

At the homepage, by pressing the ON/OFF key, the unit will be turned on/off.

When the unit is ON, the green indicating LED located at the upper right of the control will light on. When

the unit is OFF, the green indicating LED will light off.

[Notes]

①

The unit is defaulted to be OFF when energized for the rst time.

②

The ON/OFF key operation works only at the home page and the standby page.

③

When the “Holiday mode” or the “Emergen�mode” is activated, the ON/OFF key operation will become

ineffective.

④

When the “Forced Heating” or “Forced Cooling” is activated, it will be deactivated by pressing the “ON/

OFF” key, and then press the ON/OFF key again to start the unit.

⑤

ON/OFF operation will be memorized by setting “Memory” to be “On” at the “GEN.” setting page. That

is, in case of power failure the unit will resume running upon power recovery. Once “Memory” is set to be “Off”,

in case of power failure the unit will keep “Off” upon power recovery.

⑥

At the home page, the ON/OFF key is intended to turn on/off the unit if applicable. The Function keys

no.1 to no.4 are corresponding to “FUNC�”, “PAPA”, “VIEW” and “GEN�” setting pages respectively.

⑦

At the standby page, the Menu key is used to back to the homepage, the ON/OFF key is used to turn

on/off the unit if applicable, and all other key operations are ineffective.

⑧

The control will return automatically to the homepage where there is no any key operation in 10

consecutive minutes.

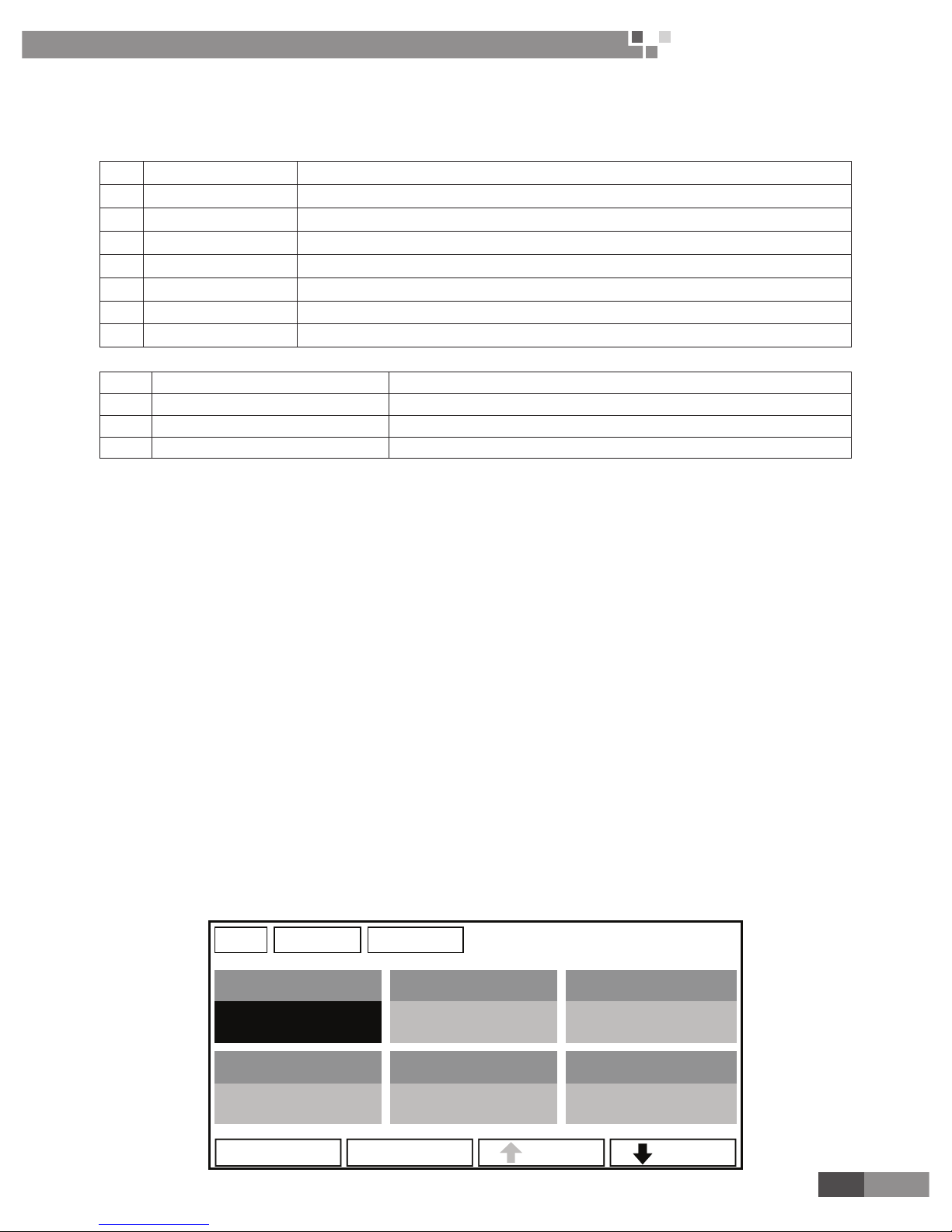

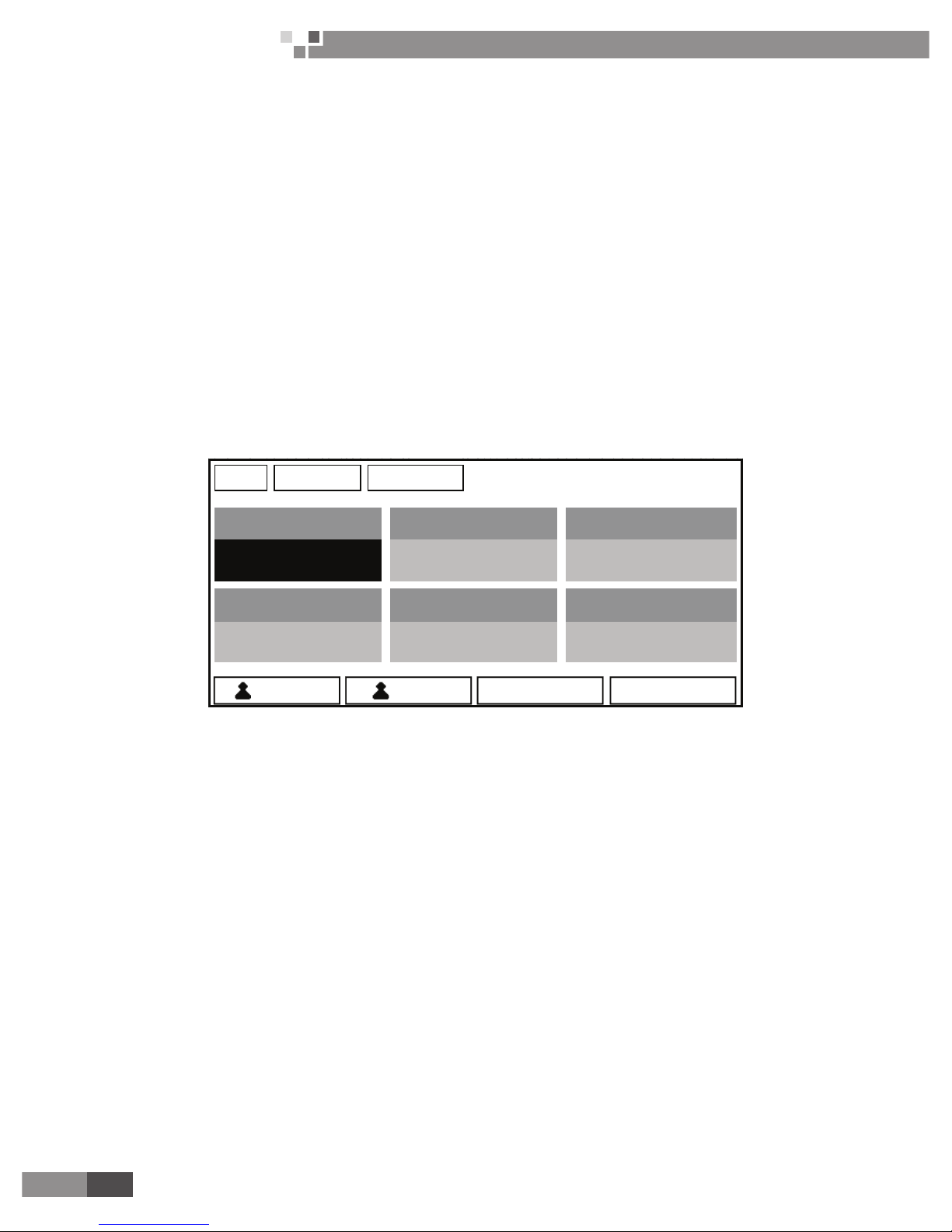

3�3�2 Function Setting

1) At the homepage, by pressing the Function key no. 1, the control will access to the FUNCTION page 1,

as shown in the gure below.

Last Next

Off

T-water ctrl. Cool+hot water Heat+hot water

Low temp. Cool Heat

Mode Ctrl. state

Heat T-room

Fast hot water

8:30 2013-4-24

Wednesday

FUNCTION

Last Ne xt

FUNCTION page 1

16

Air to Water Heat Pump

Service Manual- Versati II Series

CONTROL

2) At the FUNCTION page, by the Right/Left key, the desired function option can be selected, and by the

Up/Down key, the setting of the current function option can be modied. The function key no. 3 or no. 4 can

be used for switch pages. After the setting is nished, by pressing the Menu key, the control will back to the

homepage, or by pressing the Return key the control will back to the higher level menu.

[Notes]

Move the cursor to the desired option and “Enter” will be displayed at the lower left side of the LCD,

reminding you that you are allowed to access to the submenu by pressing the OK key.

At the FUNCTION page, when the setting of some function option is changed and needs to be memorized,

then in case of power failure it will be saved automatically and resume upon power recovery.

Function Settings

No� Full Name Displayed Name Range Default Remarks

1

Running mode

setting

Mode

Cool/Heat/

Hot water/

Cool+Hot water/

Heat+Hot water

Heat

When the water tank is unavailable,

then only “Cool” and “Heat” are

included in the range.

2 Control state Ctrl. state T-water out /T-room T-water out

“T-Room” is available only when

“Remote Sensor” is set to “With”.

3 Fast hot water Fast hot water On/Off Off

When the water tank is unavailable,

this function will be reserved, and the

LCD will display ‘Reserved’.

4

Water out

temperature control

T-water ctrl.

High temp.

/Low temp.

Low temp. /

5 Cool+hot water Cool+hot water Cool/Hot water Cool

6 Heat+hot water Heat+hot water Heat/Hot water Heat

When the water tank is unavailable,

this function will be reserved, and the

LCD will display ‘Reserved’.

7 Quiet mode Quiet mode On/Off Off /

8 Quiet timer Quiet timer On/Off Off /

9 Auto mode Auto mode On/Off Off /

10 Holidayrelease Holidayrelease On/Off Off /

11 Sanitize Sanitize On/Off Off

When the water tank is unavailable,

this function will be reserved, and the

LCD will display ‘Reserved’.

12 Weekly timer Weekly timer On/Off Off /

13 Clock timer Clock timer On/Off Off /

14 Temperature timer Temp. timer On/Off Off /

15 Floor debug Floor debug On/Off Off /

16 Emergency mode Emergen. mode On/Off Off /

17 Holiday mode Holiday mode On/Off Off /

18 Thermostat Thermostat With/Without Without /

19 IDU heater IDU heater 1/2/Off 1 /

20 Other heater Other heater With/Without Without /

21 Chassis heater Chassis heater On/Off On /

22 Water tank Water tank With/Without Without /

23 Tank sensor Tank sensor 1/2 2

When the water tank is unavailable,

this function will be reserved,and the

LCD will display ‘Reserved’ .

17

Air to Water Heat Pump

Service Manual- Versati II Series

CONTROL

24 Solar heater Solar heater With/Without Without /

25 FCU FCU With/Without Without /

26 Remote sensor Remote sensor With/Without Without

When it is set to “Without”, the “Control

state” will be automatically changed to

“T-water out”.

27 Air removal Air removal On/Off Off /

28 Address Address

[0~12]

[127~253]

0 /

29 Doorguard Doorguard On/Off Off /

3�3�2�1 Mode

At the equipment OFF state, access to the FUNCTION page and then move through the Left/Right key the

cursor to the “Mode” whose characters will be reversed, then press the Up/Down key to modify its setting.

[Notes]

①

The “Heat” mode is defaulted when the unit is energized for the rst time.

②

The running mode is allowed to be changed only when the unit is not in operation. If it is done with the

unit being on, a window will pop up, warning “please turn off the system rst”.

③

When the water tank is disabled, only the ‘Heat” or the “Cool” mode is allowed.

④

When the water tank is enabled, “Cool”, “Heat”, “Hot water”, “Cool+hot waterr”, “Heat+hot water” is

allowed.

⑤

For the heat pump, the “Cool” mode is allowed; for the heating only unit, “Cool+ Hot water” and “Cool”

are unallowable.

⑥

This setting can be memorized upon power failure.

3�3�2�2 Control State (Ctrl� state)

Go to the FUNCTION page and locate Ctrl� state, then, congure it through the Up/Down key.

[Notes]

①

If “Remote sensor” is set to “With”, “T-out water” and “T-room” are available. While if “Remote

Sensor” is set to “Without”, only “T-out water” is selectable.

②

This setting will be memorized upon power failure.

3�3�2�3 Fast Hot Water

Go to the FUNCTION page and locate “Fast hot water”, then, congure it through the Up/Down key, “On”

or “Off”.

[Notes]

①

It works only when “Water tank” is set to “With”.

②

This setting will be memorized upon power failure.

3�3�2�4 T-water Ctrl (Water Temperature Control for Heating)

Go to the FUNCTION page and locate “T-water ctrl�”, then, congure it through the Up/Down key, “High

temp�” or “Low temp�”.

[Notes]

①

When this setting is changed, the following parameters will return to the default values.

Water out temperature for heating WOT-Heat

45℃/113℉[High]

35℃/95℉[Low]

Upper limit water-out temperature at the auto mode for heating Upper WT-Heat

48℃/118℉[High]

35℃/95℉[Low]

Lower limit water-out temperature at the auto mode for heating Lower WT-Heat

40℃/104℉[High]

29℃/84℉[Low]

②

This setting will be memorized upon power failure.

3�3�2�5 Cool + Hot water

Go to the FUNCTION page and locate “Cool+hot water”, then, congure it through the Up/Down key, “Cool”

or “Hot water”.

[Notes]

①

“Hot water” will take precedence only when “Water tank” is available, other it will tell “Reserved”.

②

This setting will be memorized upon power failure.

3�3�2�6 Heat + Hot water

Go to the FUNCTION page and locate Heat+hot water, then, congure it through the Up/Down key, “Heat”

or “Hot water”.

18

Air to Water Heat Pump

Service Manual- Versati II Series

CONTROL

[Notes]

①

“Hot water” will take precedence only when “Water tank” is available, other it will tell “Reserved”.

②

This setting will be memorized upon power failure.

3�3�2�7 Quiet Mode

Go to the FUNCTION page and locate “Quiet mode”, then, congure it through the Up/Down key, “On” or

“Off”.

[Notes]

①

It can be set to “On” or “Off” no matter if the unit is in operation or not.

②

Once it is activated, it should be deactivated manually or by Quiet Timer.

③

It will not memorized and defaulted to be off upon power failure.

④

It will be deactivated when the unit is turned off.

3�3�2�8 Quiet Timer

1) Go to the FUNCTION page and locate Quiet timer, then, access to the QUIET TIMER setting page.

2) At the QUIET TIMER setting page, select “Start time” or “End time” through the Left/Right keys and then

congure the desired time through the Up/Down keys.

3) When the mode setting is nished, then by pressing “Save”, a pop-up window will pop up to remind if

you are determined to save this setting. If so, press the “OK” key. If not, press the “Cancel” key to not save this

setting.

4) When the setting is saved, the control then will back to the FUNCTION page and the cursor will be where

the “Quiet timer” option is, then by the Up/Down key, it can be set to be “On” or “Off”.

Start time End time

08:30 17:30

8:30 2013-4-24

Wednesday

QUIET TIMER

Minute Save

[Notes]

①

Once it is activated, it should be deactivated manually.

②

It will not be memorized and be defaulted to be off upon power failure.

③

The saved “Start time” and “End time” will be memorized upon power failure.

④

It is congurable no matter if the unit is in operation or not.

3�3�2�9 Auto Mode

Go to the FUNCTION page and locate Auto mode, then, congure it through the Up/Down key, “On” or “Off”.

[Notes]

①

Once it is activated, it should be deactivated manually.

②

It will be defaulted to be off upon power failure.

③

At the “Parameter View” page, it is able to check the set point at the Auto mode.

④

When it is activated, it is allowed to set the room temperature but the set point does not take effective.

However, when it is deactivated, the unit will run according to this set point.

⑤

It can be set to “On” or “Off” no matter if the unit is in operation or not, but be activated only when the

unit is in operation.

⑥

This mode works only for the air conditioning function.

3�3�2�10 Holiday Release

Go to the FUNCTION page and locate “Holiday release”, then, congure it through the Up/Down key, “On”

or “Off”.

[Notes]

①

When it is activated, at the WEEKLY TIMER page, it is able to set some week day to “Holiday

release”. In this case, the “Weekly timer” in this day is ineffective unless it is set to “Effective” manually.

②

This setting will be memorized upon power failure.

19

Air to Water Heat Pump

Service Manual- Versati II Series

CONTROL

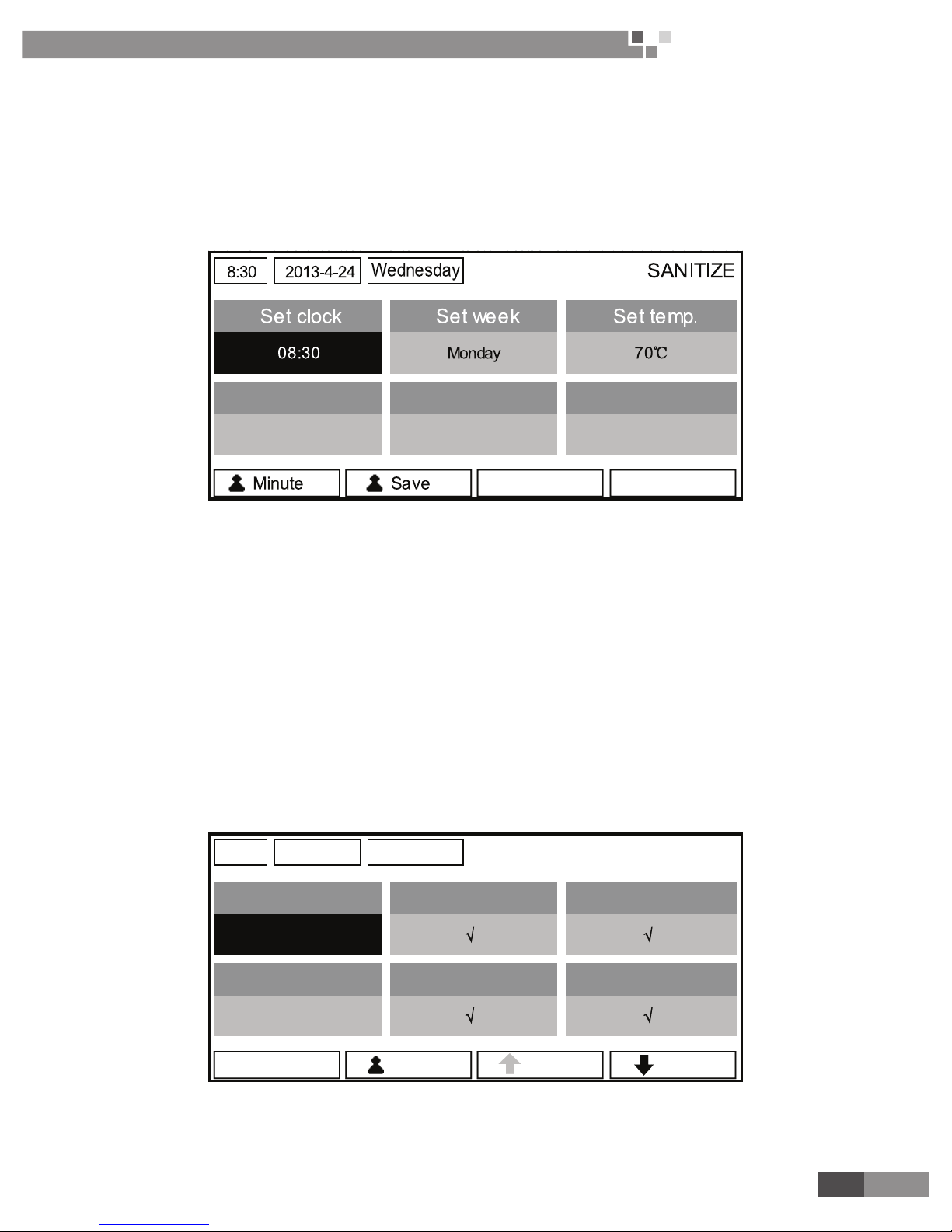

3�3�2�11 Sanitize

1) At the FUNCTION page, locate “Sanitize”, and then access to the SANITIZE setting page by pressing

the OK key.

2) At the SANITIZE setting page, select “Set clock”, “Set week” or “Set temp” through the Left/Right key

and then modify the corresponding setting through the Up/Down key.

3) When the mode setting is nished, then by pressing “Save”, a pop-up window will pop up to remind if you

are determined to save this setting. If so, press the OK key. If not, press the Cancel key to not save this setting.

4) When the setting is saved, the control then will back to the FUNCTION page and the cursor will be where

the “Sanitize timer” is, then by the Up/Down key, it can be set to “On” or “Off”.

[Notes]

①

It can be activated only when the “Water tank” is set to “With”.

②

It can be set to “On” or “Off” no matter if the unit is in operation or not

③

When “Sanitize” is set to “On”, if you intend to set the “Emergen� mode”, “Holiday mode”, “Floor

Debug”, then a window will pop up, warning “Please disable the Sanitize Mode!”.

④

It can be set to “On” or “Off” no matter if the unit is in operation or not, and “Hot water” mode always

takes precedence.

⑤

When Sanitize is activated, “Sanitize” will show on the home page of the control until this operation is

nished. If this operation fails, “Sanitize fails” will show. In this case, by pressing any key, “Sanitize failure” will

be cleared or it will be always there.

⑥

When Sanitize is activated, it will quit upon “Communication error with the indoor unit” or “Water

tank heater error”.

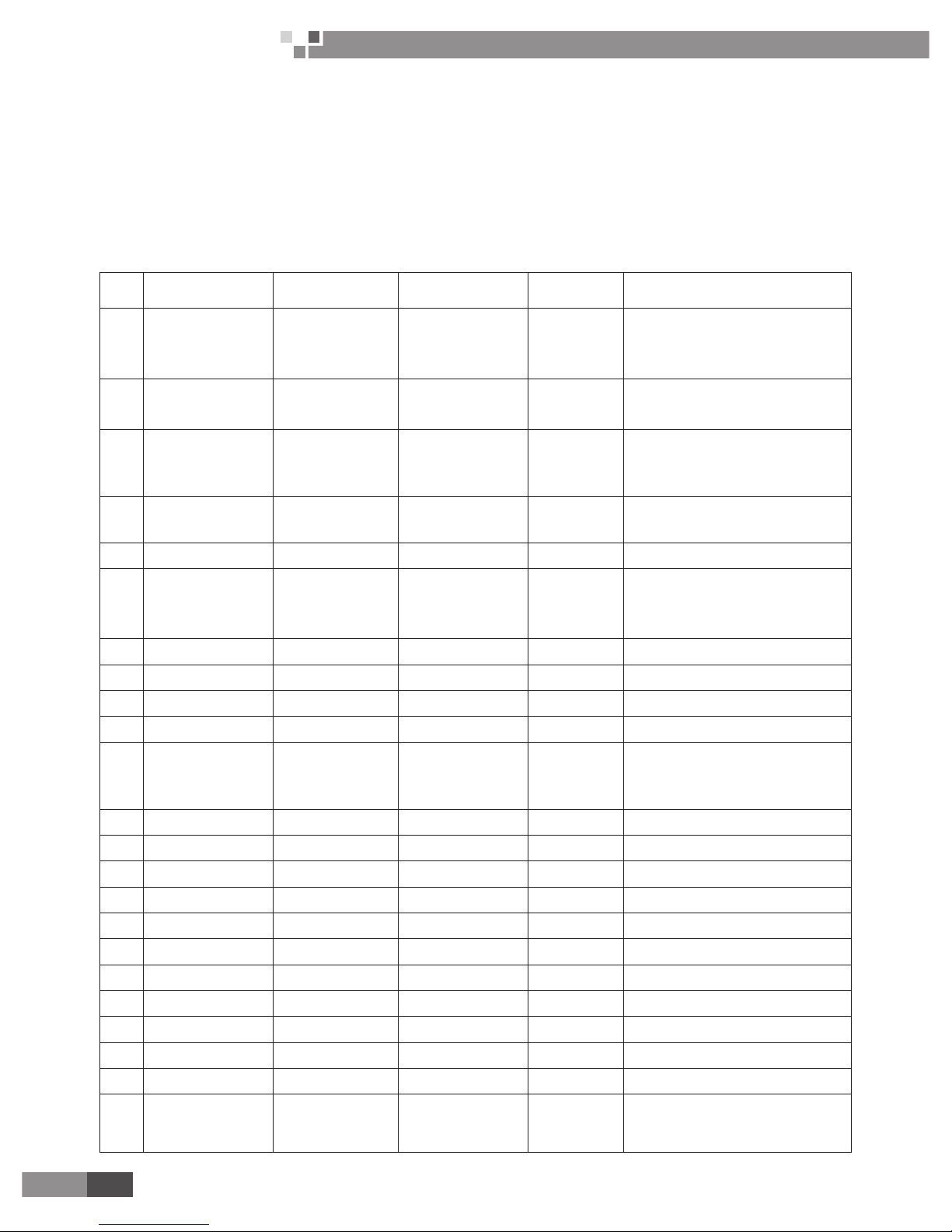

3�3�2�12 Weekly Timer

1) At the homepage, by pressing the Function key access to the FUNCTION page, and then locate where

“Weekly timer” is by switching pages, after that, press OK key to go to the WEEKLY TIMER setting page.

2) At the WEEKLY TIMER setting page, by the Right/Left key it is able to select the desired week day and

then by the Up/Down key to set this day, “√”, “×” or “Holiday”, as shown in the gure below. When this setting is

nished, press OK key to go to this day’s setting page.

Thursday Friday Saturday

Holiday

Monday Tuesday

X

Wednesday

8:30 2013-4-24

Wednesday

WEEKLY TIMER

Save Last Next

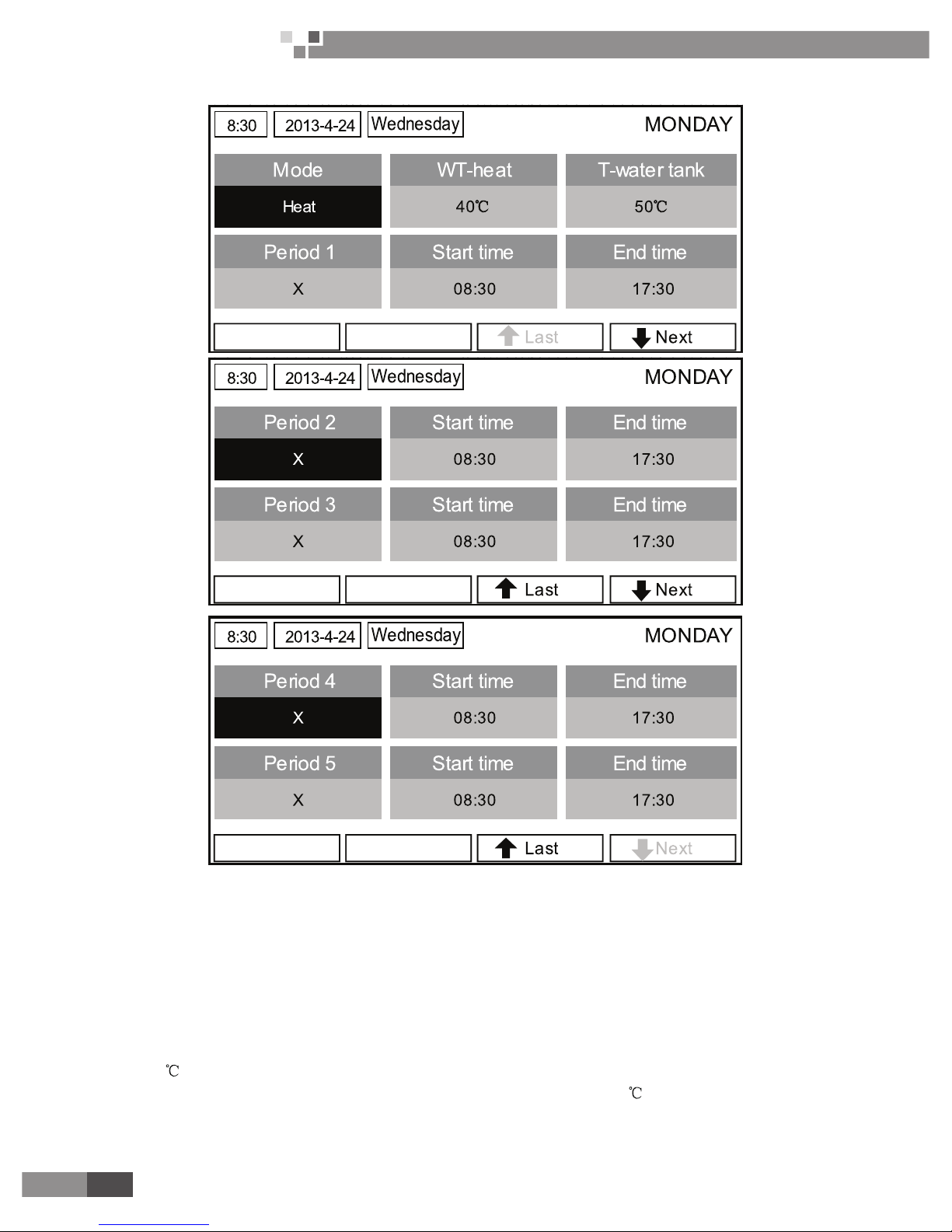

3) At the week day’s setting page, it is allowed to set the running mode (Mode), temperature set point (WTHEAT), and water tank temperature (T-Water Tank). The running mode includes “Heat”, “Cool”, “Hot water”,

“Heat+ hot water”, “Cool+ hot water” (the last three ones are available only when “Water tank” is set to “With”.

There are totally ve periods for each day, and each period can be set to “√”or “×”. Besides, it is able to set the

20

Air to Water Heat Pump

Service Manual- Versati II Series

CONTROL

“Start time” and “End time” for each period, as shown in the gure below.

4) When above settings are nished, pressing the Return key and then pressing “Save”, a pop-up window

will pop up to remind if you are determined to save these settings. If so, press the OK key. If not, press the

Return key to not save these settings.

5) In this case, nally by pressing the Up key, “Weekly timer” will be activated.

[Notes]

①

Totally ve periods are allowed to be set for each time. For each period, “Start time” must be earlier

than “End time”. Similarly, the preceding period must be earlier than its following period.

②

When “Weekly timer” has been set successfully, by changing “FCU”, “Water tank”, “Ctrl state”, or

“T-water ctrl”, then the temperature set point for “Weekly timer” will be automatically changed to the set point

of last setting. For instance, if “Heat” is set for Monday of “Weekly timer”, “FCU” is set to “With” and the “T-water

out” is 20 , by resetting “FCU” to “Without”, then “T-water out” will be the value of last setting. In this case, if

FCU is disabled for last setting, then “T-water out” will be the default value (18 ).

③

At the “WEEKLY TIMER” setting page there are totally three setting types for each day

“√”: it indicates once the Week Timer is activated, the timer on this day is effective and will not be affected

by the “Holiday” mode.

21

Air to Water Heat Pump

Service Manual- Versati II Series

CONTROL

“×”: it indicates even if the Week Timer is activated, the timer on this day is ineffective.

“Holiday”: it indicates when the Week Timer is activated but “Holiday” is not activated, then the timer on

this day is effective; when “Holiday” is also activated, the timer on this day is ineffective.

④

When “Weekly timer” has already been set and the concerned modes include “Hot water”, if resetting

“Water tank” from “With” to “Without”, then “Hot water” mode will be automatically changed to “Heat”,

“Cool+hot water”/ “Heat+hot water” changed to “Cool”/ “Heat”.

⑤

Temperature Setpoint

The control is able to decide the temperature type and temperature range based on the current “Clock

Timer”, “FCU”, “T-water Ctrl�”, and “Ctrl� state” settings. See the followings for more details.

If the set mode is “Hot water”, the temperature set point shows nothing, indicating there is no need to set

“T-water out” and “T-room” but only “T- tank”. If the set mode “Cool” or “Heat”, then water tank temperature

box will show nothing, indicating there is no need to set “T-tank”.

Ctrl� state Set Mode Object Range Default Accuracy

T-water

out

Cool

Water out temperature

for cooling(WT-cool)

7-25

℃

(With FCU)

18-25

℃

(Without FCU)

7℃ (With FCU)

18℃ (Without FCU)

1

℃

Heat

Water out temperature

for heating(WT-heat)

High temp. 25-55

℃

45

℃

1

℃

Low temp. 25-45

℃

35

℃

1

℃

T-room

Cool

Room temperature

for cooling(RT-cool)

18-30

℃

20

℃

1

℃

Heat

Room temperature

for heating(RT-heat)

18-30

℃

26

℃

1

℃

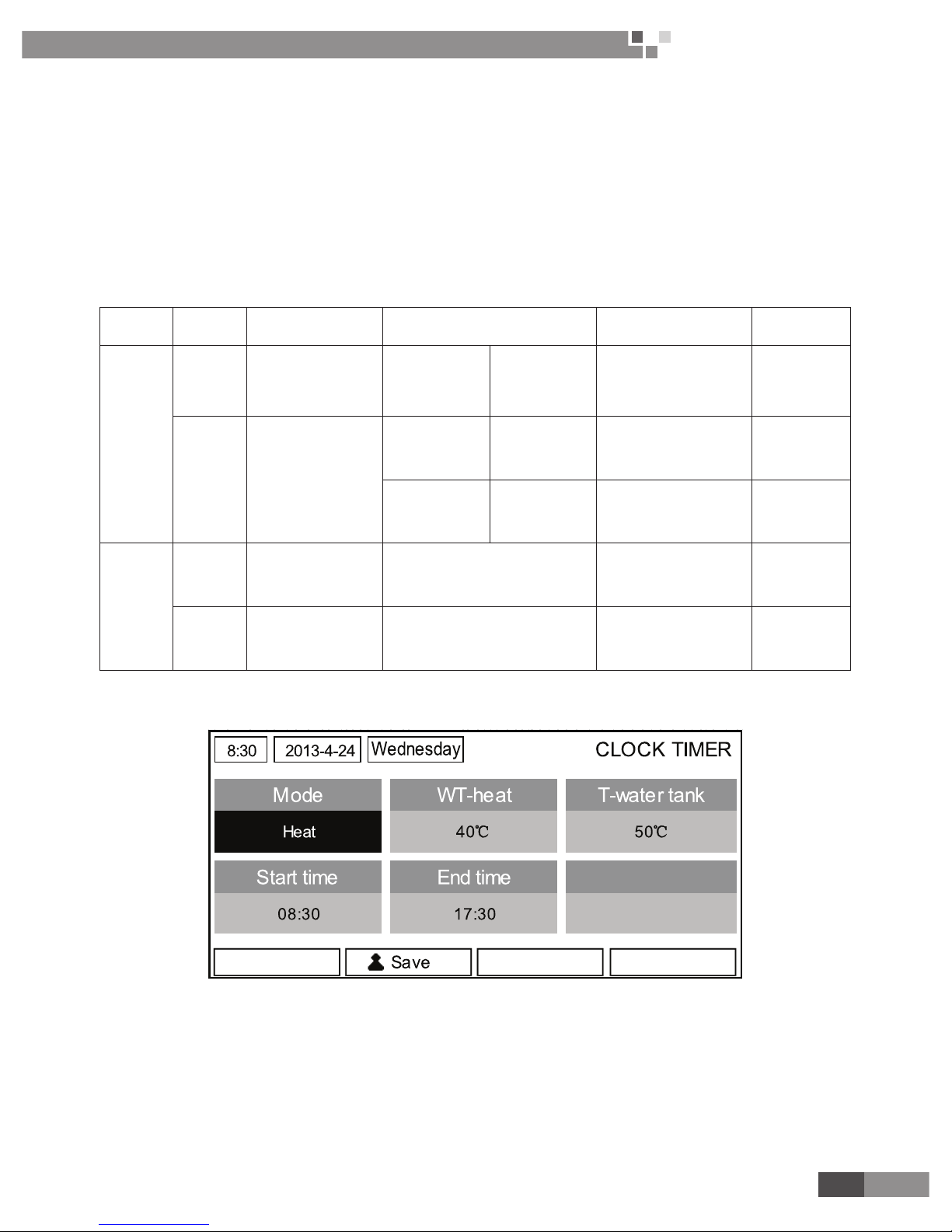

3�3�2�13 Clock Timer

1) At the homepage, by pressing the Function no.1 key access to the FUNCTION page, and then locate

where “Clock timer” is, after that, press OK key to go to the COLCK TIMER setting page.

2) At the CLOCK TIMER setting page, by the Left/Right key select the desired parameter and then by the

Up/Down key congure it.

3) When this setting is concerned about time value, by pressing the Function key no. 1 alternately set the

hour or minute values, and by pressing the Up/Down key increase or decrease the corresponding value which

will be continuously changed by pressing and holding the key.

(Unless otherwise specied, all timer settings follow the similar way.)

4) When the setting is finished, save it by pressing the Function key no. 2, or this setting without being

saved is ineffective.

5) When the setting has been saved, activate the “Clock Timer” at the FUNCTION page.

22

Air to Water Heat Pump

Service Manual- Versati II Series

CONTROL

[Notes]

①

When “Weekly timer” and “Clock timer” settings are performed at the same time, the latter takes

precedence.

②

When the water tank is available, the allowed running modes include “Heat”, “Cool”, “Heat+ hot water”,

“Cool+hot water”, and “Hot water”.

③

When the water tank is unavailable, the allowed running modes only include “Heat” and “Cool”.

④

When “Clock timer” has already been set and the concerned modes include “Hot water”, if resetting

“Water tank” from “With” to “Without”, then “Hot water” mode will be automatically changed to “Heat”,

“Cool+hot water”/ “Heat+hot water” changed to “Cool”/ “Heat”.

Full Name Displayed Name Range Default

Set Mode Mode

Cool/

Heat/

Hot water/

Cool+hot water/

Heat+hot water

Heat

Water out temperature for cooling /

Room temperature for cooling /

Water out temperature for heating /

Room temperature for heating

WT-heat/

RT-heat/

WT-cool/

RT-cool

Refer to the temperature

setting range of

“Weekly Timer”.

35

℃

Tank temperature T-water tank 40~80℃/104~176

℉

50℃/122

℉

Start time Start time 00:00-23:59 08:30

End time End time 00:00-23:59 17:30

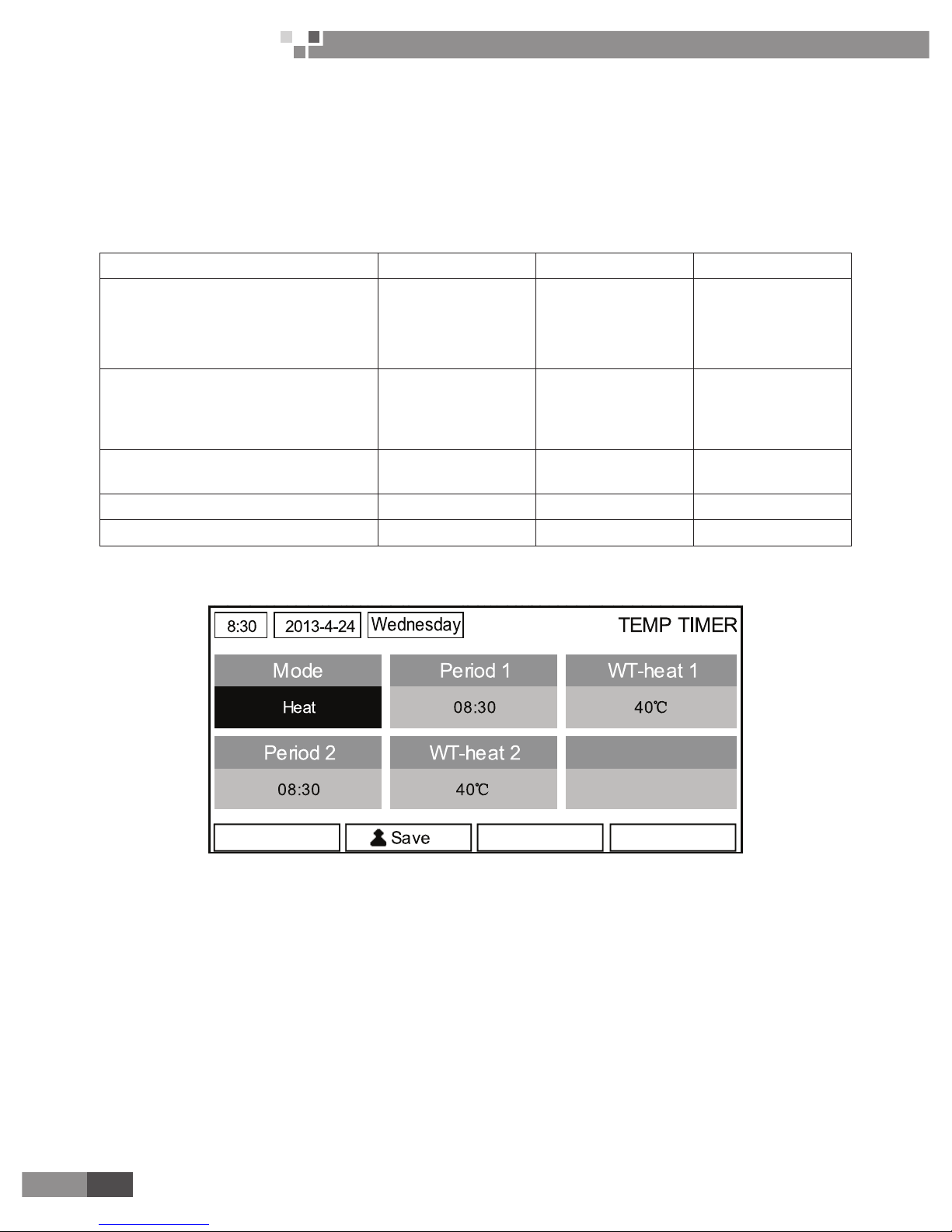

3�3�2�14 Temp� Timer

1) At the homepage, by pressing the Function key access to the FUNCTION page, and then locate where

“Temp timer” is, after that, press OK key to go to the TEMP TIMER setting page.

2) At the TEMP TIMER setting page, by the Left/Right key select the desired parameter and then by the Up/

Down key congure it. The congurable parameters include “Mode”, “Period 1”, “WT-HEAT 1”, “Period 2” and

“WT-HEAT 2”.

4) When the setting is finished, save it by pressing the Function key no. 2, or this setting without being

saved is ineffective.

5) When the setting has been saved, activate the “Temp� timer” at the FUNCTION page.

[Notes]

①

When “Weekly timer”, “Clock timer”, and “Temp� timer” settings are performed at the same time, the

last one takes precedence.

②

This function works only when the unit is in operation.

③

The allowed running modes include “Heat” and “Cool”

④

When the start time of “Period 2” is equal to that of “Period 1”, then the set point of “Period 2” takes

precedence.

⑤

TEMP� TIMER is judged by the timer value.

⑥

During the setting, the temperature set point which is set manually always takes precedence.

23

Air to Water Heat Pump

Service Manual- Versati II Series

CONTROL

Full Name Displayed Name Range Default

Set Mode Mode Cool/Heat Heat

Period 1 running time Period 1 00:00-23:59 08:30

Water out temperature for cooling /

Room temperature for cooling /

Water out temperature for heating /

Room temperature for heating

WT-heat 1/

RT-heat 1/

WT-cool 1/

RT-cool 1

Refer to the temperature

setting range of

“Weekly Timer”.

35℃/95

℉

Period 1 running time Period 2 00:00-23:59 17:30

Water out temperature for cooling /

Room temperature for cooling /

Water out temperature for heating /

Room temperature for heating

WT-heat 2/

RT-heat 2/

WT-cool 2/

RT-cool 2

Refer to the temperature

setting range of

“Weekly Timer”.

35℃/95

℉

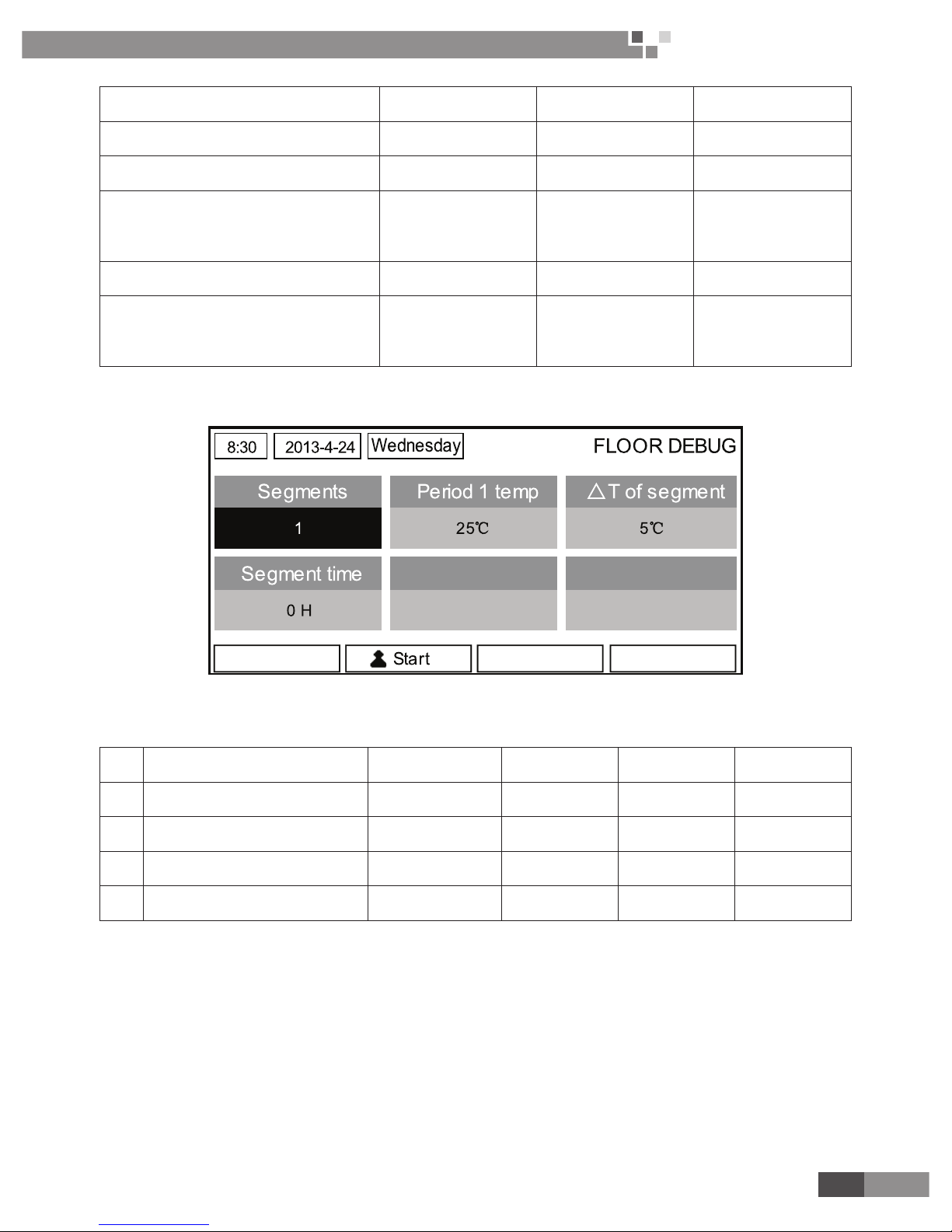

3�3�2�15 Floor Debug

1) At the homepage, by pressing the Function key access to the FUNCTION page, and then locate where

“Floor debug” is, after that, press OK key to go to the FLOOR DEBUG setting page.

2) At the FLOOR DEBUG setting page, by the Left/Right key select the desired parameter and then by

the Up/Down key configure it. The configurable parameters include “Segments”, “Period 1 temp”, “ΔT of

segment”, and “Segment time”, as listed in the following table..

No� Full Name Displayed Name Range Default Accuracy

1 Segments for oor debug Segments 1~10 1 1

2 First temperature for oor debug Period 1 temp

25~35℃/

77~95

℉

25℃/77

℉

1℃/1

℉

3

Segment temperature

difference for oor debug

ΔT of segment 0~72H 0 12H

4 Segments duration for oor debug Segment time

2~10℃/

36~50

℉

5℃/41

℉

1℃/1

℉

3) After the above setting is nished, by pressing the function key no. 2 activate this function and a dialog

box will pop up, reminding “Start the Floor Debug Mode now?”. If so, press the “OK” key. Once “Floor debug”

has been activated, by pressing the function key no. 2, a dialog box also will pop up, reminding “Stop the Floor

Debug Mode now?” If so, press the OK key; if not, press “Cancel” to go on.

[Notes]

①

This function can be activated only when the unit is OFF. When it is intended to activate this function

with the unit being ON, a dialog box will pop up, warning “Please turn off the system rst!”.

②

When this function has been activated, it is unable to turn on or off the unit. In this case, when pressing

the ON/OFF key, a dialog will pop up, warning “Please disable the Floor Debug Mode!”.

③

When this function has been set successfully, “Timer week”, “Clock timer” and “Temp timer” will be

deactivated.

④

“When “Floor debug” mode has been activated, “Emergen�mode”, “Sanitize”, “Holiday mode” is not

24

Air to Water Heat Pump

Service Manual- Versati II Series

CONTROL

allowed to be activated, or a dialog box will pop up, warning “Please disable the Floor Debug Mode!”.

⑤

Upon power failure, this function will be OFF and runtime will be cleared.

⑥

At the FlOOR DEBUG setting page, the control will remain at this page and never back to the

homepage unless pressing the Return key or Menu key.

⑦

When this function is activated, it is allowed to check the target temperature and runtime of “Floor

Debug” at the Parameter View page.

⑧

Before activating “Floor debug”, please make sure each period for “Floor debug” is not zero, or a

dialog box will pop up, warning “Wrong Floor Debug time!”. It will resume only by pressing “OK” and then

correcting the time.

3�3�2�16 Emergency Mode (Emergen� Mode)

1) Set “Mode” to “Heat” or “Hot water” at the Parameter Set page

2) Then, switch pages to go the page where “Emergen� mode”, locate it by the Left/Right key, and congure

it to “On” or “Off” by the Up/Down key.

3) When it is set to “On”, “Auxiliary func�” at the homepage will be replaced by “Emergen� Mode”.

4) When it is set to “On” but the running mode is not “Heat” or “Hot water”, a dialog will pop up, warning

“Wrong running mode!”. In this case, by pressing the OK key, the control will go to the Mode setting page, or

by pressing the Cancel key, the control will return to the “Emergen� Mode” page.

[Notes]

①

When the unit is performing “Heat” at the Emergency mode, if there is water ow switch protection, IDU

assistant heater welding protection, or leaving water temperature sensor error, the Emergency mode will quit

and will not be allowed to be activated.

②

When the unit is performing “Hot water” at the Emergency mode, if there is water tank heater welding

protection, or water tank temperature sensor error, the Emergency mode will quit and will not be allowed to be

activated.

③

At the Emergency mode, the ON/OFF key operation will be disabled; the running mode will not be

allowed to be changed; the Quiet and Auto modes cannot be deactivated; “Weekly timer”, “Clock timer” and

“Temp timer” also cannot be activated, or will be deactivated if being activated.

④

At the Emergency mode, commands from the Thermostat is ineffective.

⑤

At the Emergency mode, only one running mode between “Heat” and “Hot water” is allowed.

⑥

This function can be activated only when the unit is OFF, or a dialog box will pop up, warning “Please

turn off the system rst!”

⑦

Under the Emergency mode, “Floor debug”, “Sanitize”, “Holiday mode”, cannot be activated, or a

dialog box will pop up, warning “ Please disable the Emergency Mode!”.

⑧

Upon power failure, the “Emergen� mode” will be defaulted to be “Off”.

3�3�2�17 Holiday Mode

1) Locate where “Holiday mode” at the FUNCTION page

2) Set Holiday to “On” or “Off” by the Up/Down key.

[Notes]

①

At the holiday mode, “Mode” setting of the control and On/Off key operation both are disabled.

②

When it is activated, “Weekly timer”, “Clock timer” or “Temp timer” will be deactivated.

③

At the holiday mode, when “T-Room” is adopted, the temperature set point should be 15 ; when “T-Out

water” is adopted, then the temperature set point should be 30 .

④

It will quit when the thermostat effectively works (“Cool” or “OFF” operation).

⑤

When this setting is saved successfully, it will be memorized upon power failure.

⑥

This function can be activated only at the “Heat” mode and with the unit turned off. When it is done

with the unit turned on, a prompt dialog box will pop up, warning “Please turn off the system rst!”; or when

it is done at other modes except the “Heat” Mode with the unit turned off, also a prompt dialog box will pop up,

warning “Wrong running mode!”.

⑦

When it is activated, the ON/OFF key operation is disabled, or a dialog box will pop up, warning “Please

disable the Holiday Mode !”.

⑧

Under the Holiday mode, “Floor debug”, “Sanitize”, “Emergen� mode” cannot be activated, or a dialog

box will pop up, warning “Please disable the Holiday Mode !”.

3�3�2�18 Thermostat

1) Locate where “Thermostat” is at the FUNCTION page

2) By pressing the Up/Down key, Thermostat can be set to “On” or “Off”. When it is “On”, the control follows

the running mode of the thermostat and is not allowed to set the running mode; when it is “Off”, the control

follows the running mode set by itself.

25

Air to Water Heat Pump

Service Manual- Versati II Series

CONTROL

[Notes]

①

When “Floor debug” or “Emergen� Mode” is activated, then the control will not receive signals from the

thermostat.

②

If “Thermostat” is set to “On”, the control will automatically disable some functions concerning timer, and

run in accordance with the mode set by the thermostat. In this case, the running mode is unchangeable and the

ON/OFF key operation of the control is ineffective.

③

When this setting is saved successfully, it will be memorized upon power failure.

④

The state of the Thermostat can be changed when the unit is turned off.

3�3�2�19 IDU Heater

Go to the FUNCTION page and locate “IDU Heater”, then, congure it through the Up/Down key, “With” or

“Without”.

[Notes]

it will be memorized upon power failure.

3�3�2�20 Other Heater

Go to the FUNCTION page and locate Other heater, then, congure it through the Up/Down key, “With” or

“Without”.

[Notes]

it will be memorized upon power failure.

3�3�2�21 Underpan Heater

Go to the FUNCTION page and locate “Underpan Heater” then, congure it through the Up/Down key, “With”

or “Without”.

[Notes]

it will be memorized upon power failure.

3�3�2�22 Water Tank

Go to the FUNCTION page and locate “Water tank” then, congure it through the Up/Down key, “With” or

“Without”.

[Notes]

①

It will be memorized upon power failure.

②

This setting is allowed only when the unit is turned off.

3�3�2�23 Tank Sensor

Go to the FUNCTION page and locate “Water tank”, then, congure it through the Up/Down key, “1” or “2”.

When the water tank is unavailable, this option will be reserved.

[Notes]

it will be memorized upon power failure.

3�3�2�24 Solar Heater

Go to the FUNCTION page and locate “Solar heater”, then, congure it through the Up/Down key, “With” or

“Without”.

[Notes]

it will be memorized upon power failure.

3�3�2�25 FCU

Go to the FUNCTION page and locate “FCU”, then, configure it through the Up/Down key, “With” or

“Without”.

[Notes]

It will be memorized upon power failure.

3�3�2�26 Remote Sensor

Go to the FUNCTION page and locate “Remote sensor”, then, congure it through the Up/Down key, “With”

or “Without”.

[Notes]

It will be memorized upon power failure.

“T-room ctrl” can be selected only when the Remote Sensor is set to “With”.

3�3�2�27 Air removal

Go to the FUNCTION page and locate “Air removal”, then, congure it through the Up/Down key, “On” or

“Off”.

[Notes]

①

It will not be memorized upon power failure.

②

It can be set only when the unit is turned off.

26

Air to Water Heat Pump

Service Manual- Versati II Series

CONTROL

3�3�2�28 Address

Go to the FUNCTION page and locate “Address”, then, congure it through the Up/Down key to set the

address.

[Notes]

①

It indicates the address of the control and is intended for the group control.

②

It will not be memorized upon power failure.

③

The address range is [0,125] and [127,253]

④

The default address is 0 for the initial use.

3�3�2�29 Doorguard

Go to the FUNCTION page and locate “Doorguard”, then, congure it through the Up/Down key, “On” or

“Off”.

[Notes]

⑤

When it is activated, the control will check the card is inserted or not. If inserted, the control will run

normally; if not, the control will turn off the unit and back to the homepage. In this case, any key operation

is ineffective (except for the combined key operation), or a dialogue box will pop up, warning “Keycard

uninserted!”.

⑥

It will not be memorized upon power failure.

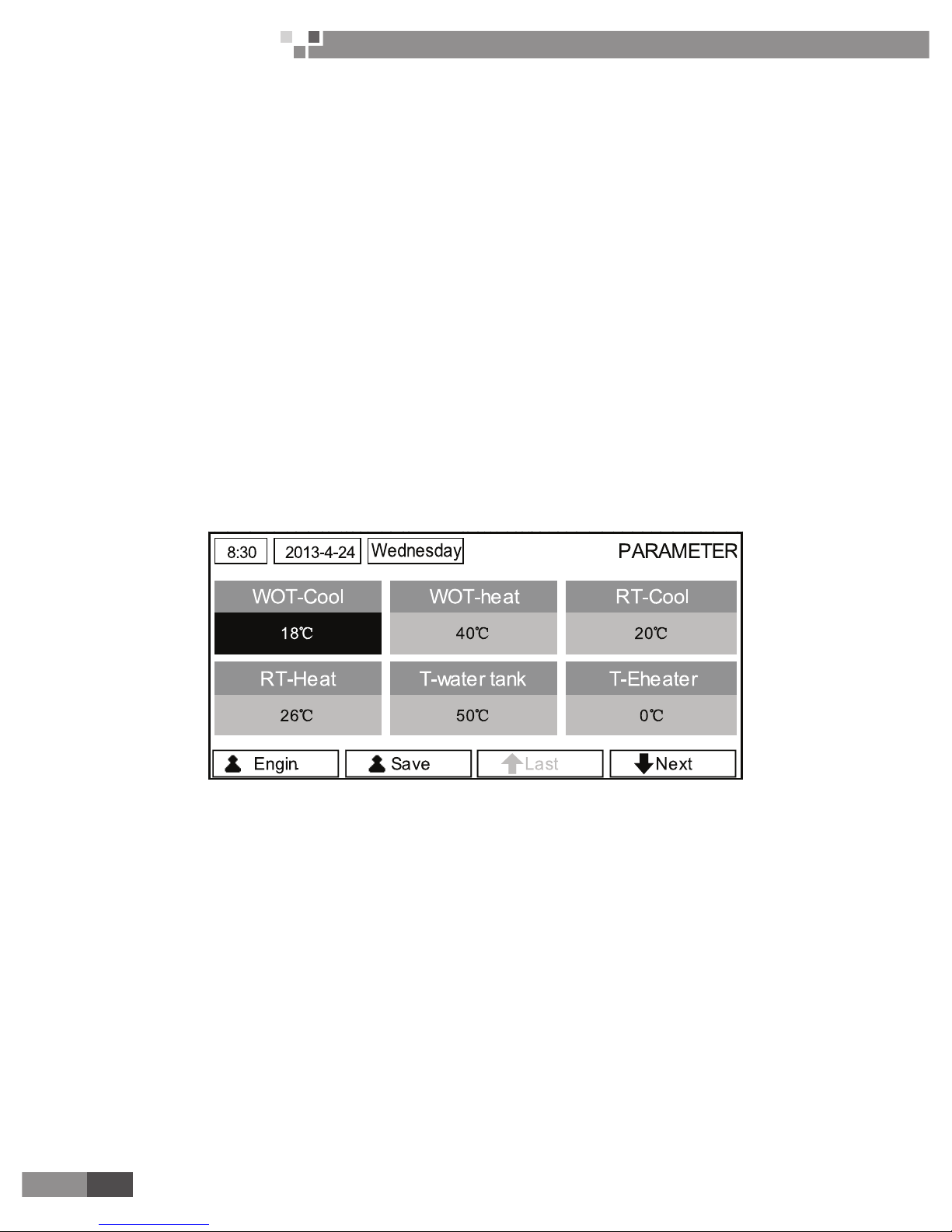

3�3�3 Parameter Setting (Parameter Set)

3�3�3�1 User Parameter Setting

1) At the homepage, it is able to go to the PARAMETER page by pressing the Function key no.2.

2) At the Parameter Set page, by the Left/Right key select the desired option and then by the Up/Down key

increase or decrease the setting value which will be continuously changed when pressing and holding the key.

3) When the setting is nished, press “Save” and a dialog box will pop up, reminding “Save settings?”. If

so, press the OK key; if not press the Cancel key to not save this setting.

User Setting

27

Air to Water Heat Pump

Service Manual- Versati II Series

CONTROL

No� Full Name

Displayed

Name

Range(℃) Range(℉) Default

1

Water out temperature

for cooling

WOT-Cool

7~25

℃

[With FCU]

18~25

℃

[Without FCU]

45~77

℉

[With FCU]

64~77

℉

[Without FCU]

7

℃

/45

℉

[With FCU]

18

℃

/64

℉

[Without FCU]

2

Water out temperature

for heating

WOT-Heat

25~55

℃

[High temp.]

25~45

℃

[Low temp.]

77~131

℉

[High temp.]

77~113

℉

[Low temp.]

45

℃

/113

℉

[High temp.]

35

℃

/95

℉

[Low temp.]

3

Room temperature for

cooling

RT-Cool 18~30

℃

64~86

℉

20

℃

/68

℉

4

Room temperature for

heating

RT-Heat 18~30

℃

64~86

℉

26

℃

/79

℉

5 Tank temperature T-water tank 40~80

℃

104~176

℉

50

℃

/122

℉

6

Eheater-on ambient

temperature

T-Eheater -20~18

℃

-4~64

℉

0

℃

/32

℉

7

Extra-heater-on

ambient temperature

T-Extraheater -20~18

℃

-4~64

℉

0

℃

/32

℉

8

Max heat pump

waterout temperature

(no eheater)

T-HP Max 40~50

℃

104~122

℉

50

℃

/122

℉

9

Lower limit ambient

temperature at the auto

mode for heating

Lower AT-Heat

-20~5

℃

-4~41

℉

-15

℃

/5

℉

10

Upper limit temperature

at the auto mode for

heating

Upper AT-Heat

10~20

℃

50~68

℉

15

℃

/59

℉

11

Upper limit room

temperature at the auto

mode for heating

Upper RT-Heat

22~30

℃

72~86

℉

24

℃

/75

℉

12

Lower limit room

temperature at the auto

mode for heating

Lower RT-Heat

18~21

℃

64~70

℉

20

℃

/68

℉

13

Upper limit water-out

temperature at the auto

mode for heating

Upper WT-Heat

46~55

℃

[High temp.]

30~35

℃

[Low temp.]

115~131

℉

[High temp.]

86~95

℉

[Low temp.]

48

℃

/118

℉

[High temp.]

35

℃

/95

℉

[Low temp.]

14

Lower limit water-out

temperature at the auto

mode for heating

Lower WT-Heat

36~45

℃

[High temp.]

25~29

℃

[Low temp.]

97~113

℉

[High temp.]

77~84

℉

[Low temp.]

40

℃

/104

℉

[High temp.]

29

℃

/84

℉

[Low temp.]

15

Lower limit ambient

temperature at the auto

mode for cooling

Lower AT-Cool

10~25

℃

50~77

℉

25

℃

/77

℉

16

Upper limit temperature

at the auto mode for

cooling

Upper AT-Cool

26~48

℃

79~118

℉

40

℃

/104

℉

17

Upper limit room

temperature at the auto

mode for cooling

Upper RT-Cool

24~30

℃

75~86

℉

27

℃

/81

℉

18

Lower limit room

temperature at the auto

mode for cooling

Lower RT-Cool

18~23

℃

64~73

℉

22

℃

/72

℉

19

Upper limit water-out

temperature at the auto

mode for cooling

Upper WT-Cool

15~25

℃

[With FCU]

22~25

℃

[Without FCU]

59~77

℉

[With FCU]

72~77

℉

[Without FCU]

15

℃

/59

℉

[With FCU]

23

℃

/73

℉

[Without FCU]

20

Lower limit water-out

temperature at the auto

mode for cooling

Lower WT-Cool

7~14

℃

[With FCU]

18~21

℃

[Without FCU]

45~57

℉

[With FCU]

64~70

℉

[Without FCU]

7

℃

/45

℉

[With FCU]

18

℃

/64

℉

[Without FCU]

21

Temperature deviation

for cooling

△

T-Cool 2~10

℃

36~50

℉

5

℃

/41

℉

22

Temperature deviation

for heatling

△

T-Heat 2~10

℃

36~50

℉

10

℃

/50

℉

23

Temperature deviation

for heating water

△

T-hot water 2~8

℃

36~46

℉

5

℃

/41

℉

Loading...

Loading...