Gree UMAT18HP230V1AO, UMAT30HP230V1AO, UMAT24HP230V1AO, UMAT30HP230V1AD, UMAT36HP230V1AO Installation Manual

...

Models:

Indoor Unit Outdoor Unit

UMAT18HP230V1AD UMAT18HP230V1AO

UMAT24HP230V1AD UMAT24HP230V1AO

UMAT30HP230V1AD UMAT30HP230V1AO

UMAT36HP230V1AD UMAT36HP230V1AO

UMAT42HP230V1AD UMAT42HP230V1AO

UMAT48HP230V1AD UMAT48HP230V1AO

SLIM CONCEALED DUCT

AIR CONDITIONING & HEATING SYSTEM

INSTALLATION MANUAL

Thank you for choosing a

Slim Concealed Duct

unit for your customer.

Please read this installation manual carefully before installing and starting up the

U-Match System. Take a moment to fill out the product and installation form on the

back cover. Retain both the manual and installation record for future reference.

Table of Contents

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Suggested Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

System Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Standard Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installation Site Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8- 9

Indoor Unit Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 -12

Outdoor Unit Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-14

Piping Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 -19

Ductwork Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20- 22

Power and Wiring Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23-25

Controller Installation and setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-27

Testing and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 -30

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31-32

Diagnostic Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33-36

Care and Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

SAFETY PRECAUTIONS

Please read the following before installation.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

This mark indicates procedures which, if improperly performed,

might lead to the death or serious injury of the user.

This mark indicates procedures which, if improperly performed, might

possibly result in personal harm to the user, or damage to property.

Notice is used to address practices not related to personal injury.

General Safety Precautions

1. Instructions for installation and use of this product are provided by the manufacturer.

For proper operation, the system must be installed in accordance with this

installation manual.

2. Installation must be performed in accordance with local laws, regulations and

National Electrical Codes (NEC).

3. If refrigerant leaks while work is being carried out, ventilate the area. Do not allow

refrigerant to come in contact with a flame as it produces toxic gas.

4. Disconnect all electrical power to the indoor and outdoor units until the system is

ready for start-up and checkout.

5. When installing or repairing the system, use only R410A refrigerant. Do not

mix refrigerant with other gases. If air or other gas enter the refrigeration system,

the pressure inside the system may rise to an abnormally high value and cause

damage or injury.

This appliance is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been given

supervision or instruction concerning use of the appliance by a person responsible for their safety.

WARNING

CAUTION

NOTICE

2

WARNING

3

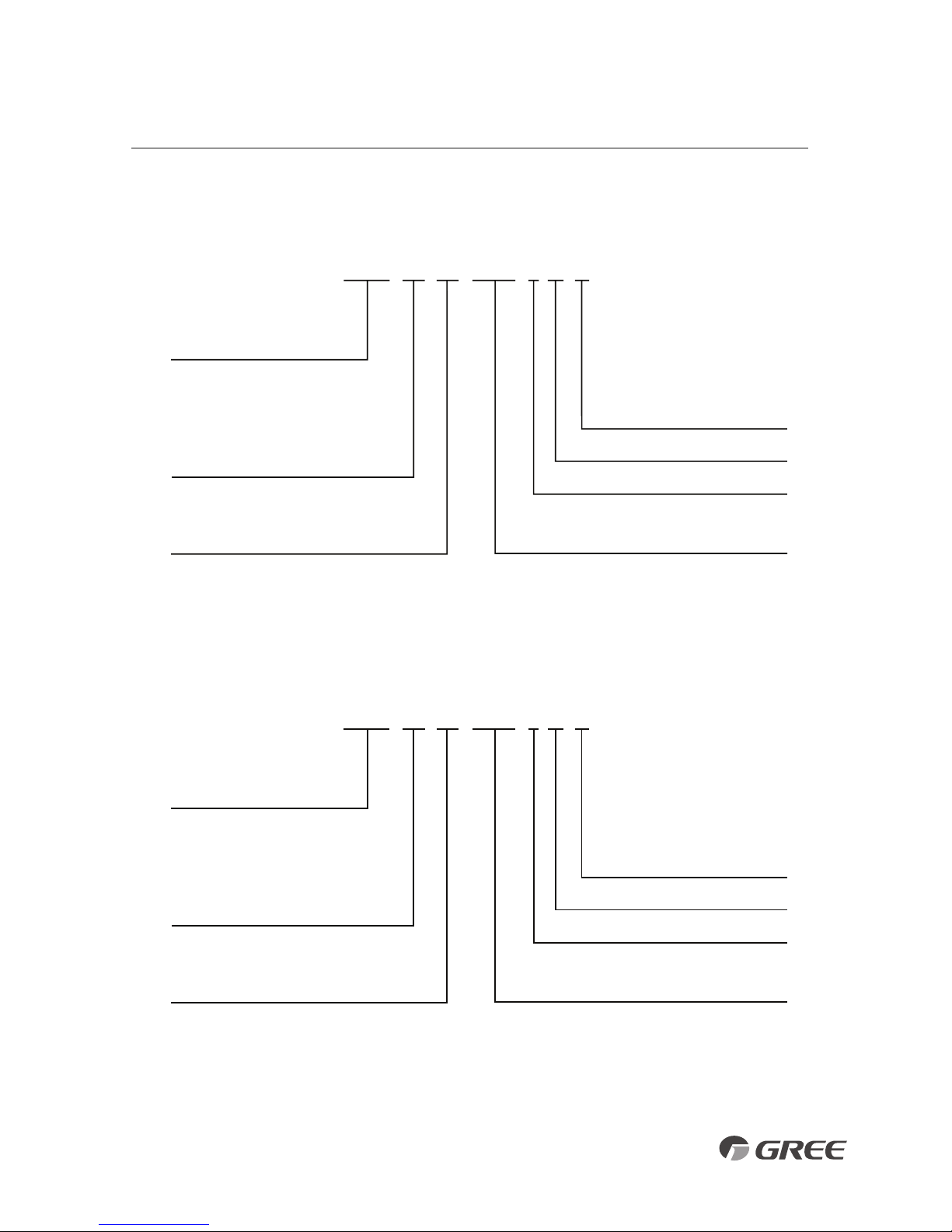

Indoor unit

Outdoor unit

NOMENCLATURE

UMAT 18 1 A D

Series Designation

UMAT – U-Match Series

Product Type

S - System

O - Outdoor Units

H - Indoor High Wall

D - Indoor Duct

C - Indoor Cassette

F - Indoor Floor/Ceiling

Revision Level

Style/Color Designation

Electrical Rating

230V - 208/230V 60Hz 1PH

115V - 115V 60Hz 1PH

HP

230V

Cooling Capacity

18 - 18,000 BtuH

24 - 24,000 BtuH

30 - 30,000 BtuH

36 - 36,000 BtuH

42 - 42,000 BtuH

48 - 48,000 BtuH

Model Type

AC - Cooling Only

HP - Heat Pump

HC - Heat/Cool

Example: UMAT18HP230V1AD

UMAT 18 1 A O

Series Designation

UMAT – U-Match Series

Product Type

S - System

O - Outdoor Units

H - Indoor High Wall

D - Indoor Duct

C - Indoor Cassette

F - Indoor Floor/Ceiling

Revision Level

Style/Color Designation

Electrical Rating

230V - 208/230V 60Hz 1PH

115V - 115V 60Hz 1PH

HP

230V

Cooling Capacity

18 - 18,000 BtuH

24 - 24,000 BtuH

30 - 30,000 BtuH

36 - 36,000 BtuH

42 - 42,000 BtuH

48 - 48,000 BtuH

Model Type

AC - Cooling Only

HP - Heat Pump

HC - Heat/Cool

Example: UMAT18HP230V1AO

SYSTEM REQUIREMENTS

REFRIGERANT CHARGE

INDOOR UNIT ELECTRICAL REQUIREMENTS

PIPE SIZE in (mm)

Notes: Insulate both refrigerant lines, separately.

Communication Cable: Recommended cable - 18/2 AWG stranded bare copper conductors THHN 600V unshielded wire

Note: Use shield cable if installation is in close proximity of RF and EMI transmitting devices.

Unit Size

(BtuH)

18,000 1/4 (6) 1/2 (12) 10 (3) 25(7.5) 66 (20) 49 (15)

24,000 3/8 (10) 5/8 (15) 10 (3) 25(7.5) 98 (30) 49 (15)

30,000 3/8 (10) 5/8 (15) 10 (3) 25(7.5) 98 (30) 49 (15)

36,000 3/8 (10) 5/8 (15) 10 (3) 25(7.5) 98 (30) 49 (15)

42,000 3/8 (10) 5/8 (15) 10 (3) 25(7.5) 164 (50) 98 (30)

48,000 3/8 (10) 5/8 (15) 10 (3) 25(7.5) 164 (50) 98 (30)

Min Line

Max. Pre-Charge

Max Line

Max Elevation

Length

Line Length

Length

(ID over OD)

Liquid Suction/Gas

Line Line

Unit Size Refrigerant Factory System Additional

(BtuH) Type Charge oz (kg)* Charge oz/ft (g/m)

18,000 R410A 49.4 (1.4) 0.3 (30)

24,000 R410A 78.4 (2.2) 0.6 (60)

30,000 R410A 84.6 (2.4) 0.6 (60)

36,000 R410A 123.2 (3.6) 0.6 (60)

42,000 R410A 131.2 (3.8) 0.6 (60)

48,000 R410A 141.8 (4.1) 0.6 (60)

Unit Size

Voltage

Min Circuit Max Overcurrent Main Power

(BtuH) Amps (MCA) Protection (MOCP) Wire Size (AWG)

18,000 208/230v - 1ph 60hz 1.0 15 14

24,000 208/230v - 1ph 60hz 2.0 15 14

30,000 208/230v - 1ph 60hz 2.0 15 14

36,000 208/230v - 1ph 60hz 3.0 15 14

42,000 208/230v - 1ph 60hz 3.0 15 14

48,000 208/230v - 1ph 60hz 5.0 15 14

OUTDOOR UNIT ELECTRICAL REQUIREMENTS

Unit Size

Voltage

Min Circuit Max Overcurrent Main Power

(BtuH) Amps (MCA) Protection (MOCP) Wire Size (AWG)

18,000 208/230v - 1ph 60hz 17.0 25 10

24,000 208/230v - 1ph 60hz 24.0 40 10

30,000 208/230v - 1ph 60hz 24.0 40 10

36,000 208/230v - 1ph 60hz 29.0 45 8

42,000 208/230v - 1ph 60hz 31.0 50 8

48,000 208/230v - 1ph 60hz 45.0 70 6

*Precharge amount for up to 25-ft of refrigerant pipe.

REFRIGERANT LINE LENGTHS ft (m)

4

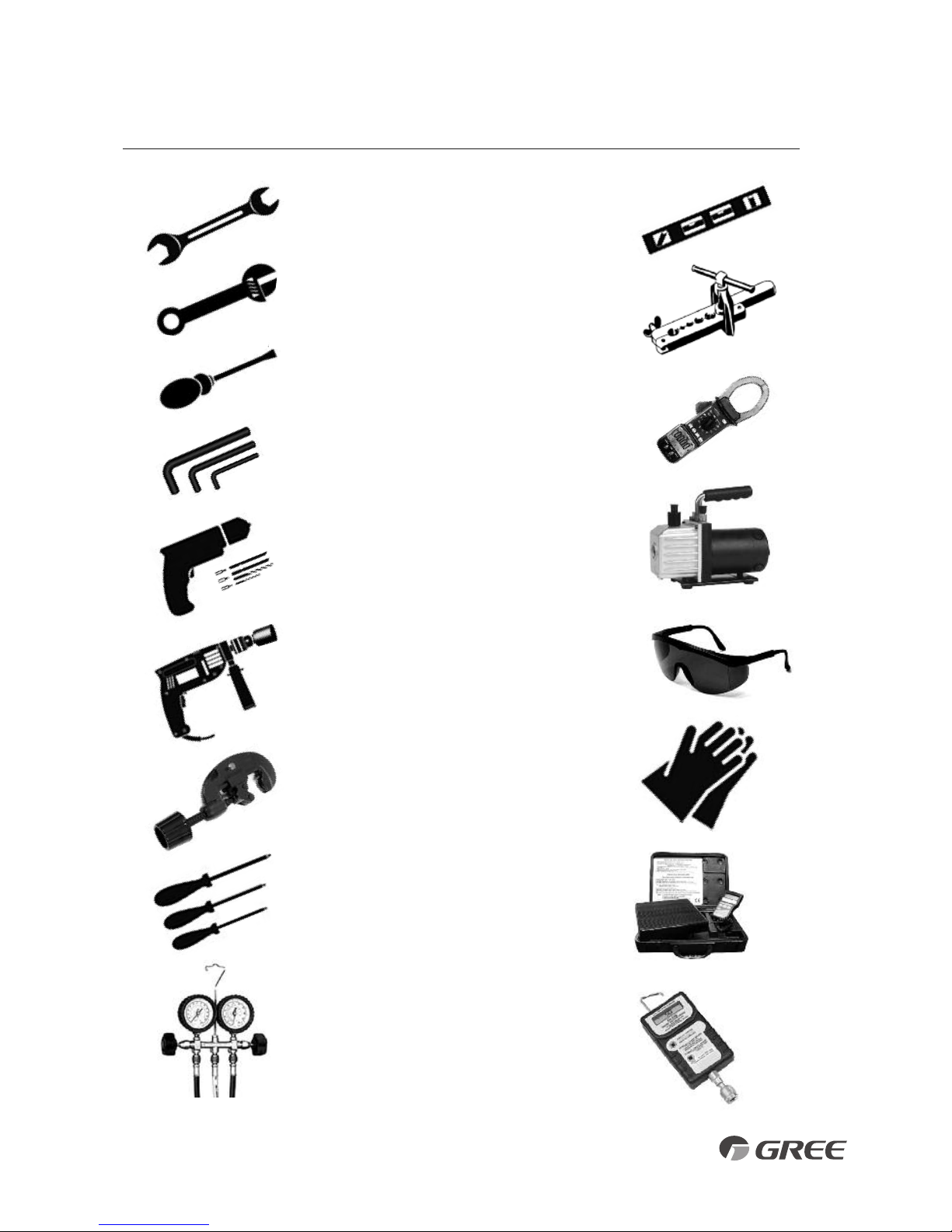

• Standard Wrench

• Adjustable/Crescent Wrench

• Torque Wrench

• Hex Keys or Allen Wrenches

• Drill & Drill Bits

• Hole Saw

• Pipe Cutter

• Screw drivers (Phillips & Flat blade)

• Manifold and Gauges

• Level

• R410A Flaring Tool

• Clamp on Amp Meter

• Vacuum Pump

• Safety Glasses

• Work Gloves

• Refrigerant Scale

• Micron Gauge

SUGGESTED TOOLS

5

SYSTEM PARTS

Indoor Unit

Part Name

1. Indoor Power Supply

2. Electric Box

3. Communication Cable

4. XK-60 Wired Tether Controller

5. Communication Cable

6. Front Panel

7. Service Cover

8. Liquid Pipe

9. Gas Pipe

10. Drain Hose

11. Outdoor Power Supply

Outdoor Unit

3

1

Air outlet

Air outlet

Air inlet

2

10

9

87

11

6

The refrigerant pipe, drain pipe, electrical wiring, and duct for this unit should be installed

by a qualified HVAC professional only.

6

4

CAUTION

5

STANDARD PARTS

Indoor Unit Accessories

Outdoor Unit Accessories

No. Name Appearance Qty Usage

1 Wired Controller 1 Controls the indoor unit

2 Hanger or 4 Supports the indoor unit

3 Nut with Washer 8 Fastens the hanger brackets

to the cabinet of the unit

4 Nut with Washer 4 Fastens the hanger brackets

to the cabinet of the unit

5 Nut 4 Used with the suspension

bolt for installing the unit

6 Washer 4 Used with the suspension

bolt for installing the unit

7 Pipe Insulation 1 Insulates the gas pipe

8 Pipe Insulation 1 Insulates the liquid pipe

9 Fastener 4

Fastens the insulation blanket

10 Flare Nut 1 Connects the liquid pipe

11 Flare Nut 1 Connects the gas pipe

7

No. Name Appearance Qty Usage

1 Drain Plug 2 or 3 Plugs the unused drain hole

2 Drainage Connecter

or

1

Connects with the hard

PVC drain pipe

INSTALLATION SITE INSTRUCTIONS

Indoor Unit

The unit must be installed in a location which can withstand twice the weight of the unit.

Inadequate building support at the installation location may result in serious property

damage and injuries.

Review the installation location with the customer as follows:

1. Ceiling is strong enough to support twice the weight of the unit.

2. Ductwork can easily be installed using the shortest amount of duct.

3. Location allows easy installation of drain pipe.

4. Electrical power can easily be run as a dedicated circuit.

5. Space is left around the unit as required in Fig. 1.1 for future service and maintenance.

6. Air inlet and outlet of the unit should never be blocked, so airflow can reach every

corner of the room.

8

WARNING

Fig. 1.1

>12 in.

>72 in.

>12 in.

INSTALLATION SITE INSTRUCTIONS

Outdoor Unit

9

Do not install the unit at a location where the distance exceeds the maximum length indicated in

the table. The maximum length of the connection pipe is listed in the System Requirements section.

CAUTION

WARNING

Outdoor Unit

Minimum Distances

in (mm)

A 20 (500)

B 20 (500)

C 24 (610)

D 12 (305)

E 12 (305)

Air inlet

Air outlet

A

B

C D

E

Fig. 1.2

The unit should be installed level on a pad that can support twice the weight of the unit.

If the outdoor unit will be exposed to strong winds, it must be adequately secured.

1. Install the outdoor unit at a location that is capable of withstanding twice the weight of the unit.

2. Install the outdoor unit where it is convenient to connect refrigerant lines to the indoor unit.

3. I nstall the outdoor unit where the condensate water can be drained unobstructed during the

heating mode to a safe location.

4. Do not locate the unit where the noise may be objectionable to neighbors.

5. Provide the space shown in Fig. 1.2, so that the air flow is not blocked and future service and

maintenance can be performed.

For the units: 18K

For the units: 24-42K

INDOOR UNIT INSTALLATION

10

Model ABCD EFGHI J

UMAT24HP230V1AD 43-3/8 20-3/8 32-1/4 45-5/8 50-3/8 22 39-1/2 6-1/4 9-1/4 10-1/2

UMAT30HP230V1AD (1101) (517) (820) (1159) (1279) (558) (1002) (160) (235) (268)

UMAT36HP230V1AD 39-3/4 29-1/2 32-1/4 43-7/8 48-1/4 30-1/2 38-1/2 6-1/4 9-1/8 11-3/8

UMAT42HP230V1AD (1010) (748) (820) (1115) (1226) (775) (979) (160) (231) (290)

INDOOR UNIT DIMENSIONS in (mm)

Model ABCD EFGHI J

UMAT18HP230V1AD

37-1/4 24-3/8 29 35-1/8 40-7/8 28-3/8 29 4-7/8 8 10-1/2

(945) (618) (738) (892) (1037) (721) (738) (125) (203) (266)

INDOOR UNIT DIMENSIONS in (mm)

(Approx)

For the units: 48K

INDOOR UNIT INSTALLATION

11

Model ABCD EFGHI J

UMAT48HP230V1AD

43-3/8 25-3/8 33-1/2 45-1/4 52-3/4 29-1/2 37-1/2 7-1/2 12-1/2 13-3/4

(1101) (646) (852) (1150) (1340) (750) (953) (190) (316) (350)

INDOOR UNIT DIMENSIONS in (mm)

Loading...

Loading...