Gree GRS-CQ12Pd/NaEK, GRS-CQ14Pd/NaEK, GRS-CQ14Pd/NaEM, GRS-CQ16Pd/NaEM, SXVD200LCJ/A-K Service Manual

...

Air-to-water Heat Pump Split Versati

Commercial AC R&D Department

Ⅰ

March , 2016

Contents

Product ........................................................................................................................................ 1

1. Product Data ........................................................................................................................... 1

1.1 Lineup ............................................................................................................................ 1

1.1.1 Main Unit .............................................................................................................. 1

1.1.2 Water Tank ........................................................................................................... 2

1.2 Nomenclature ................................................................................................................. 2

1.2.1 Main Unit .............................................................................................................. 2

1.2.2 Water Tank ........................................................................................................... 2

1.3 Product Features ............................................................................................................ 3

1.3.1 General ................................................................................................................ 3

1.3.2 Features ............................................................................................................... 3

1.4 Operating Principle ......................................................................................................... 4

1.4.1 Schematic Diagram .............................................................................................. 4

1.5 Technical Data ............................................................................................................... 5

1.5.1 Parameter List ...................................................................................................... 5

1.5.2 Nominal Working Conditions ................................................................................ 9

1.5.3 Operation Range .................................................................................................. 9

1.5.4 Electric Data ................................................................................................ ......... 9

1.5.5 Capacity Correction ............................................................................................ 10

2 Outline Dimensions ................................................................................................................ 11

2.1 Outline dimensions of outdoor unit ............................................................................... 11

2.2 Outline dimensions of indoor unit ................................................................................. 13

3 Explosive Views and Part Lists ............................................................................................... 14

4 Supply Scope ......................................................................................................................... 24

Design and Selection ................................................................................................................ 26

1 Installation Example ............................................................................................................... 26

2 Model Selection ...................................................................................................................... 28

2.1 Speculations of Power Supply ...................................................................................... 28

2.2 Operation Conditions .................................................................................................... 28

2.3 Flowchart of Model Selection........................................................................................ 29

2.4 Design Principle ........................................................................................................... 29

3 Selection of the Underfloor Coils ............................................................................................ 29

3.1 Calculation of Unit Load for Floor Heating .................................................................... 29

3.2 Selection of Tube Spacing of the Underfloor Coils ........................................................ 30

3.3 Selection of Loop Quantity of Coils for Each Room ...................................................... 30

3.3.1 Type of Underfloor Coils ..................................................................................... 30

3.3.2 Selection of Loop Quantity for Each Room ......................................................... 31

4 Quantity and Location of the Water Traps and Collectors ....................................................... 31

4.1 Design Requirements on Loop Quantity for Circulation Water ...................................... 31

4.2 Requirements on Installation of the Water Trap (Collector) .......................................... 33

5 Section of FCU ....................................................................................................................... 33

5.1 FCU Type Selection ..................................................................................................... 33

5.2 Matching of Capacity ................................................................ .................................... 33

6 Selection of the Water Tank ................................................................................................... 34

6.1 Specifications of the Water Tank .................................................................................. 34

6.2 Volume Selection of the Water Tank ............................................................................ 34

6.2.1 Selection Based on Water Consumption Per Capita ........................................... 34

6.2.2 Selection Based on Sanitary Utensils ................................................................. 35

6. 2.3 Selection of the Water Tank .............................................................................. 35

7 Examples for Model Selection ................................................................................................ 35

7.1 General Introduction to the Example Project ................................................................ 35

7.2 Heat Load Calculation ................................................................ .................................. 35

7.2.1 Load Calculation of a Single Floor ...................................................................... 35

7.2.2 Arrangement Design of the Underfloor System for A Single Floor ...................... 36

7.2.3 Arrangement Design of the Underfloor System for the Bath Room ..................... 36

7.2.4 Arrangement Design of the Underfloor System for the Master and Bath Rooms. 36

7.2.5 Check ................................................................................................................. 36

7.3 Model Selection ............................................................................................................ 37

Unit Control ............................................................................................................................... 38

1 Integral Control Concept ......................................................................................................... 38

1.1 Control Principle Diagram ............................................................................................. 38

1.2 Control Flowchart ......................................................................................................... 41

2 Main Control Logics ................................................................................................................ 41

2.1 Cooling ......................................................................................................................... 41

2.1.1 Control to the Compressor ................................................................................. 41

2.1.2 Freeze Protection ............................................................................................... 42

2.2 Heating ......................................................................................................................... 42

2.2.1 Control to the Compressor ................................................................................. 42

2.2.2 Over-temperature Protection .............................................................................. 42

2.2.3 Control to the Auxiliary Electric Heater ............................................................... 42

2.3 Water Heating .............................................................................................................. 42

2.3.1 Water Heating by the Main Unit .......................................................................... 42

2.3.2 Water Heating by the Solar System .................................................................... 43

2.4 Shutdown ..................................................................................................................... 43

2.5 Control to the Compressor ........................................................................................... 43

2.6 Control to the Fan ......................................................................................................... 43

2.7 Control to the 4-way Valve ........................................................................................... 44

2.8 Control to the Water Pump ........................................................................................... 44

2.9 Control the Electrostatic Expansion Valve .................................................................... 44

2.10 Protection Control ....................................................................................................... 44

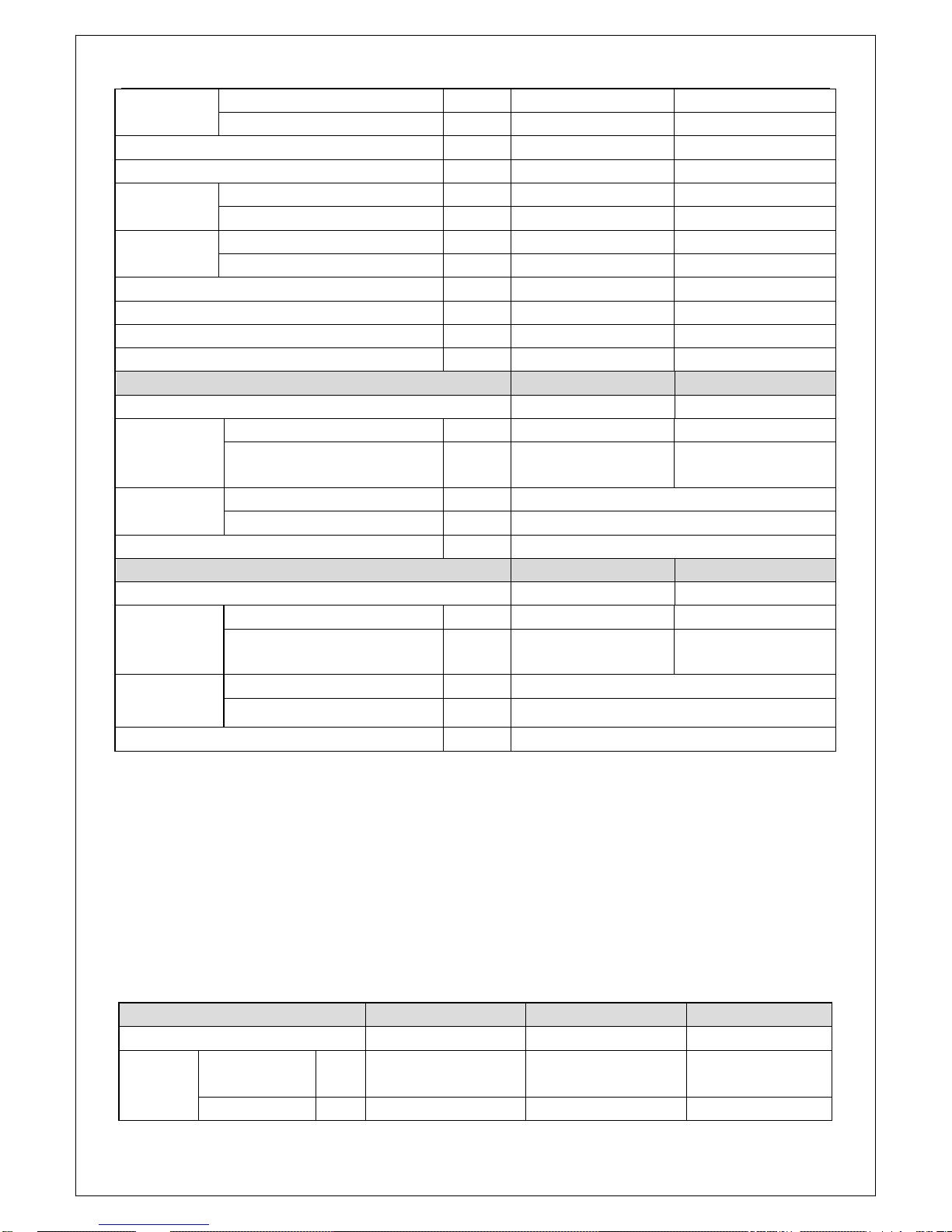

3 Controller ............................................................................................................................... 45

3.1 External View ............................................................................................................... 45

3.1.1 Keys & Indicating LEDs ...................................................................................... 45

3.1.2 Standby Page and Homepage ............................................................................ 46

3.2 Operation Instructions .................................................................................................. 47

3. 2.1 On/Off ............................................................................................................... 47

3.2.2 Function Setting ................................................................................................. 48

3.2.3 Parameter Setting (Parameter Set) .................................................................... 68

3. 2.4 View .................................................................................................................. 71

3. 2.5 General Setting ................................................................................................. 76

3. 2.6 Key Lock ........................................................................................................... 77

Unit Installation .......................................................................................................................... 79

1. Installation Guides ................................................................................................................. 79

1.1 Installation Positions of the outdoor unit ....................................................................... 80

1.2 Installation Positions of the indoor unit ......................................................................... 80

1.3 Matters Need Attention ................................................................................................. 80

2 Filed Supplied Pipes and Valves ............................................................................................ 80

3 Service Tools ......................................................................................................................... 82

4 Instalaltion Instructions ........................................................................................................... 83

4.1 Installation Examples ................................................................................................... 83

4.2 Pre-Installation ............................................................................................................. 84

4.3 Selection of Installation Location .................................................................................. 84

4.4 Outline Dimension of Outdoor Unit ............................................................................... 85

4.5 Installation Clearance Data .......................................................................................... 87

4.6 Outline Dimension of Indoor Unit .................................................................................. 87

4.7 Installation Clearance Data .......................................................................................... 88

4.8 Installation of Water Tank ............................................................................................. 88

4.9 Electric Wiring .............................................................................................................. 91

4.10 Wiring of the Terminal Board ...................................................................................... 94

4.11 Wiring of the 2-Way Valve .......................................................................................... 96

4.12 Wiring of the3-Way Valve ........................................................................................... 97

4.13 Wiring of Other Auxiliary Heat Sources ...................................................................... 98

4.14 Wiring of the Gate-Controller ...................................................................................... 98

4.15 Wiring of the Remote Air Temperature Sensor ........................................................... 99

4.16 Wiring of the Thermostat .......................................................................................... 100

4.17 Wiring of the Control ................................................................................................. 102

5 Commissioning and Trial Run............................................................................................... 104

5.1 Check before startup .................................................................................................. 104

5.2 Test run ...................................................................................................................... 105

Test Operation & Troubleshooting & Maintenance .................................................................. 107

1 Trial Run .............................................................................................................................. 107

1.1 Check for Wiring ......................................................................................................... 107

1.2 Check for the Water System ....................................................................................... 107

1.3 Check for the Communication System ........................................................................ 107

1.4 Trial Run .................................................................................................................... 108

2 Error Code List ................................ ..................................................................................... 108

3 Flow Chart Of Troubleshooting ............................................................................................. 110

3.1 Comp High-pressure Protection E1 .......................................................................... 110

3.2 Comp Low- pressure Protection E3 ......................................................................... 111

3.3 Comp Discharge Temp Protection E4 ........................................................................ 112

3.4 Overload Protection of Compressor or Driver Error .................................................... 113

3.5 DC Fan Error EF ........................................................................................................ 114

3.6 Temperature Sensor Error .......................................................................................... 114

3.7 Communication Malfunction E6 .................................................................................. 115

3.8 Capacity Switch Error (Code:"C5") ............................................................................. 116

4 Diagnosis of Driving ............................................................................................................. 116

4.1 Diagnosis Flowchart of Driving of Single-phase Unit and Three-phase Unit ............... 116

5 Daily Maintenance and Repair.............................................................................................. 121

5.1 Daily Maintenance ...................................................................................................... 121

5.2 Troubleshooting.......................................................................................................... 122

5.3 Repair ........................................................................................................................ 122

5.3.1 Key Components .............................................................................................. 122

5.3.2 Charging and Discharging of Refrigerant .......................................................... 124

Product

1

Product

1. Product Data

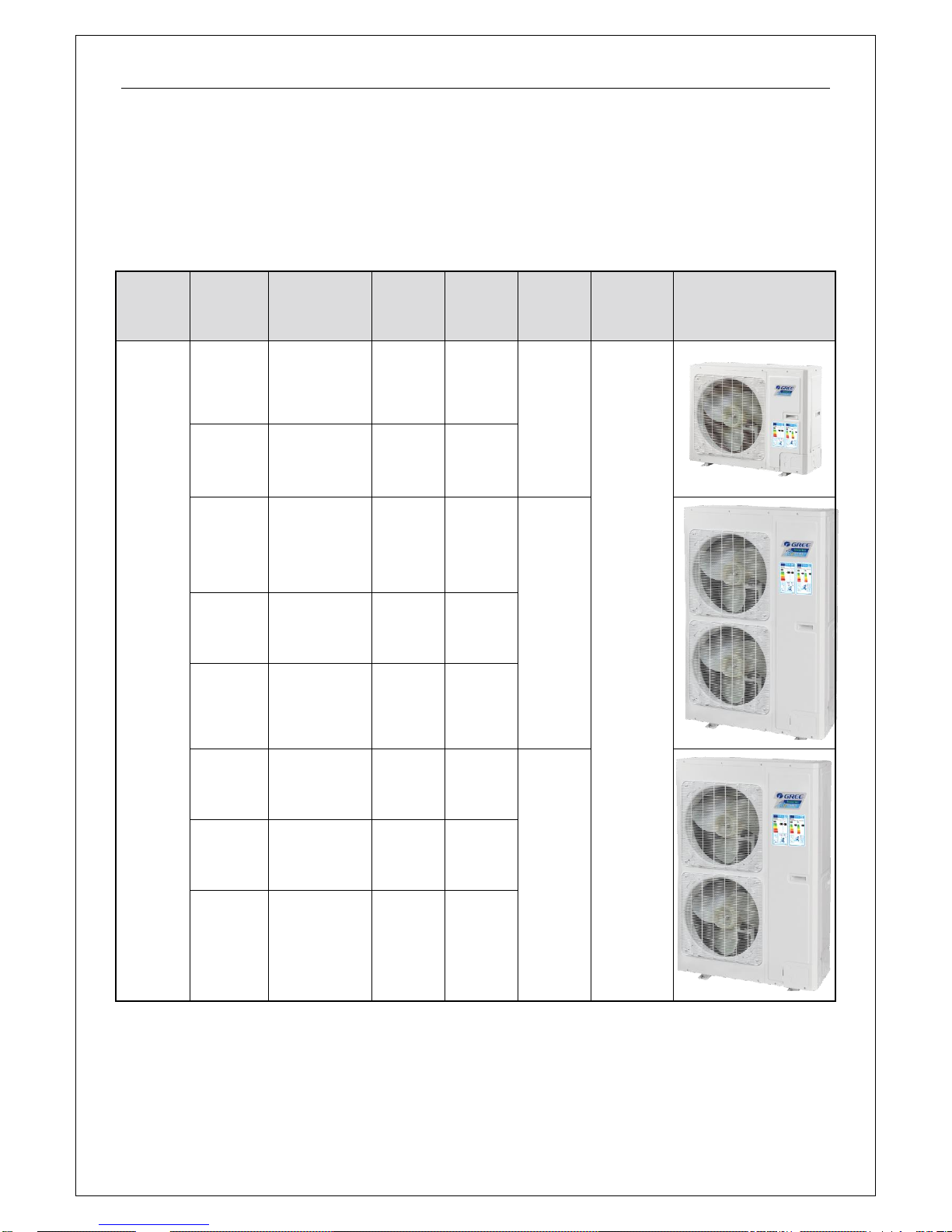

1.1 Lineup

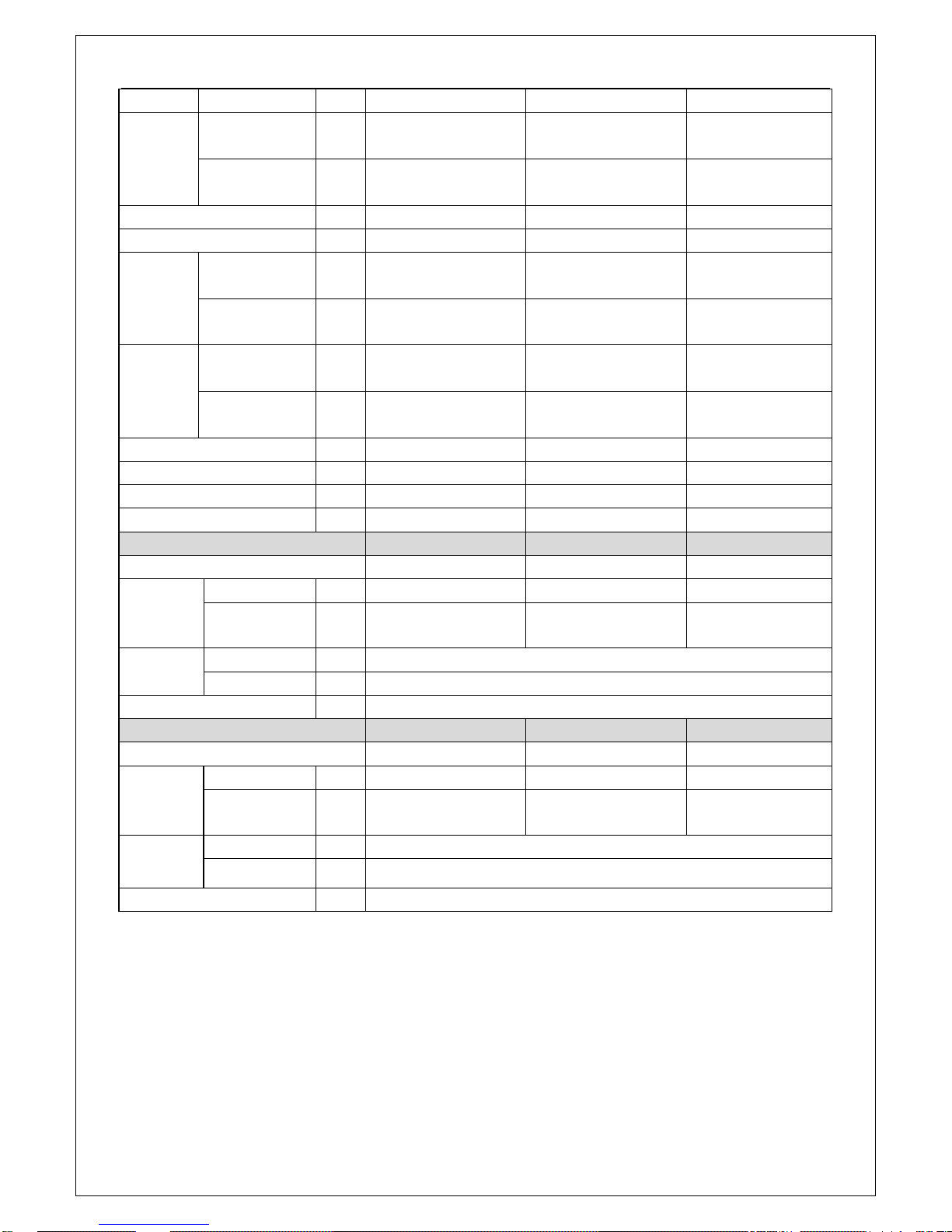

1.1.1 Main Unit

Series

Model

Product Code

Cooling

Capacity

(kW)

Heating

Capacity

(kW)

Power

Supply

Refrigerant

Appearance

VERSATI

Ⅱ

GRS-CQ8

.0Pd/NaE-

K

ER01001300

7.8

8

220-240V

,~,50Hz

R410A

GRS-CQ1

0Pd/NaE-

K

ER01001290

8.2

10

GRS-CQ1

2Pd/NaE-

K

ER01001280

12.5

12

220-240V

,~,50Hz

GRS-CQ1

4Pd/NaE-

K

ER01001270

13.5

14

GRS-CQ1

6Pd/NaE-

K

ER01001260

14.5

15.5

GRS-CQ1

2Pd/NaE-

M

ER01001250

13.5

12

380-415V,3

N~,50Hz

GRS-CQ1

4Pd/NaE-

M

ER01001240

14.5

14

GRS-CQ1

6Pd/NaE-

M

ER01001230

15

15.5

Product

2

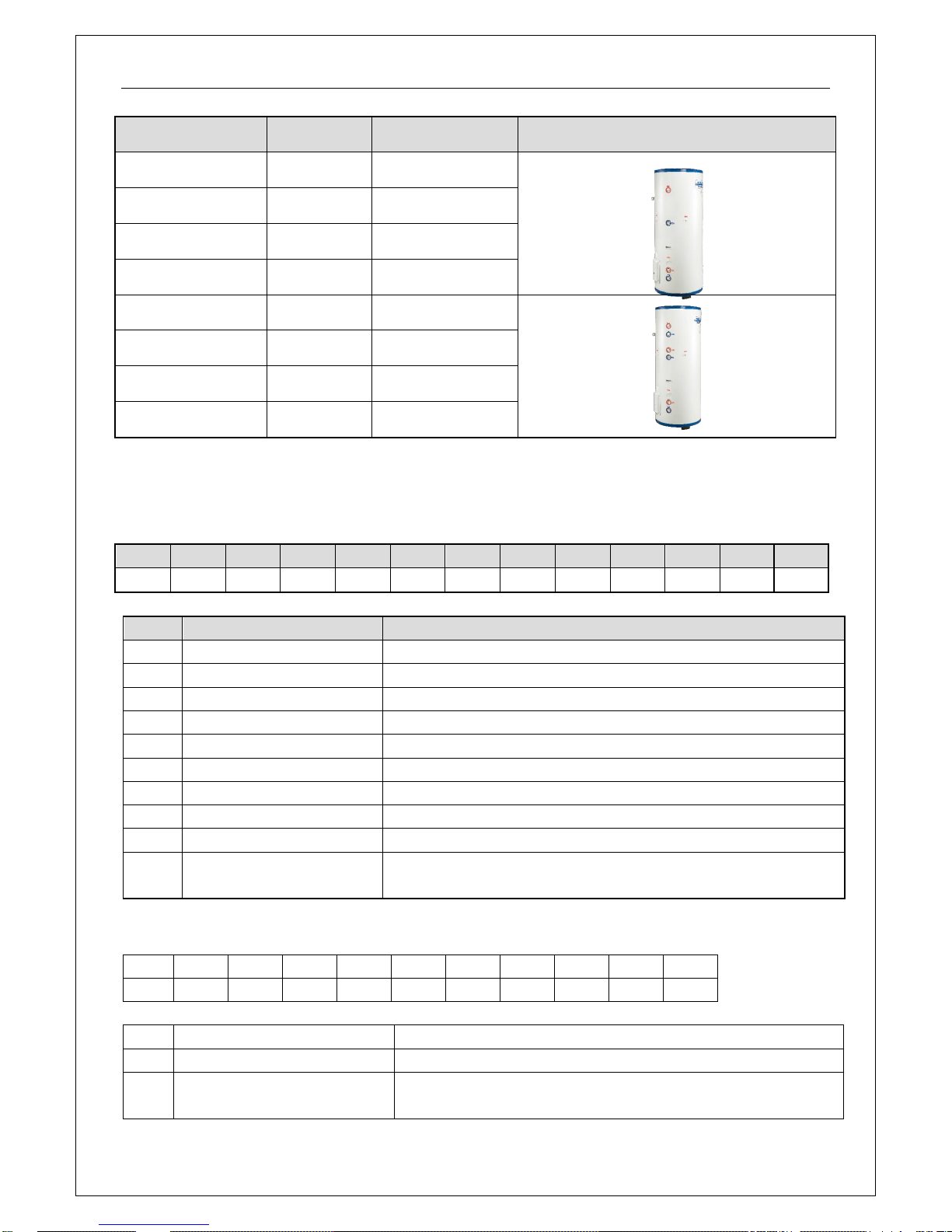

1.1.2 Water Tank

Model

Product Code

Nominal Cubage(L)

Appearance

SXVD200LCJ/A-K

ER20000160

200

SXVD200LCJ/A-M

ER20000240

200

SXVD300LCJ/A-K

ER20000180

300

SXVD300LCJ/A-M

ER20000250

300

SXVD200LCJ2/A-K

ER20000170

200

SXVD200LCJ2/A-M

ER20000260

200

SXVD300LCJ2/A-K

ER20000190

300

SXVD300LCJ2/A-M

ER20000270

300

1.2 Nomenclature

1.2.1 Main Unit

G

RS - C Q 16

Pd / Na E - M (O) 1 2 3 4 5 6 7 8 9

10 NO.

Description

Options

1

GREE

G-GREE Air to water heat pump

2

Heat Pump Water Heater

RS 3 Heating Mode

S= Static; C=Circulating

4

Function

Q=Multi-function; Omit=Single-function

5

Nominal Heating Capacity

6.0=6.0kW; 8.0=8.0kW;10=10kW; 12=12kW; 14=14kW; 16=16kW

6

Compressor Style

Pd=DC Inverter; Omit=On/Off

7

Refrigerant

Na=R410A

8

Design Serial Number

B,C,D...... 9 Power Supply

K=220-240V,~,50Hz; M=380-415V,3N~,50Hz;H=380V,3N~,60Hz

10

Indoor and Outdoor Unit

Code

I=Indoor unit; O=Outdoor unit

1.2.2 Water Tank

SX V D

200 L C

J2 / A - K 1 2 3 4 5 6 7 8

9 NO.

Description

Options

1

Symbol of Heat Pump Water Tank

SX

2

Tank Type

Default-Common heat pump water tank;

V-Heat pump water tank for multi VRF system

Product

3

3

Function Code

Default-No electric heating function;

D-Electric heating function available

4

Nominal Water Tank Volume

200=200L,300=300L

5

Structure Type

B-Wall mounted type; L-Floor standing type

6

Bearing

Default-Non-bearing water tank;

C-Bearing water tank

7

Type of Heat Exchange Tube

Default-No heat exchanger;

J-Inner coil static heating(J-Single coil; J2-Double coils);

JW-Outer coil static heating

8

Serial Number

A,B,C……

9

Power Supply

K=220-240V,~,50Hz; M=380-415V,3N~,50Hz; H=380V,3N~,60Hz

1.3 Product Features

1.3.1 General

GREE air to water heat pump is a completely flexible, energy efficient home heating system that

extracts the heat from the outside air, raises this heat to a higher temperature and then distribute

swarmth around the home using under-floor heating, radiators or fan convector heat emitters.

1.3.2 Features

Wide Operation Range

Heating: -22~35°C; Cooling: 10~48°C; Water Heating: -22~45°C.

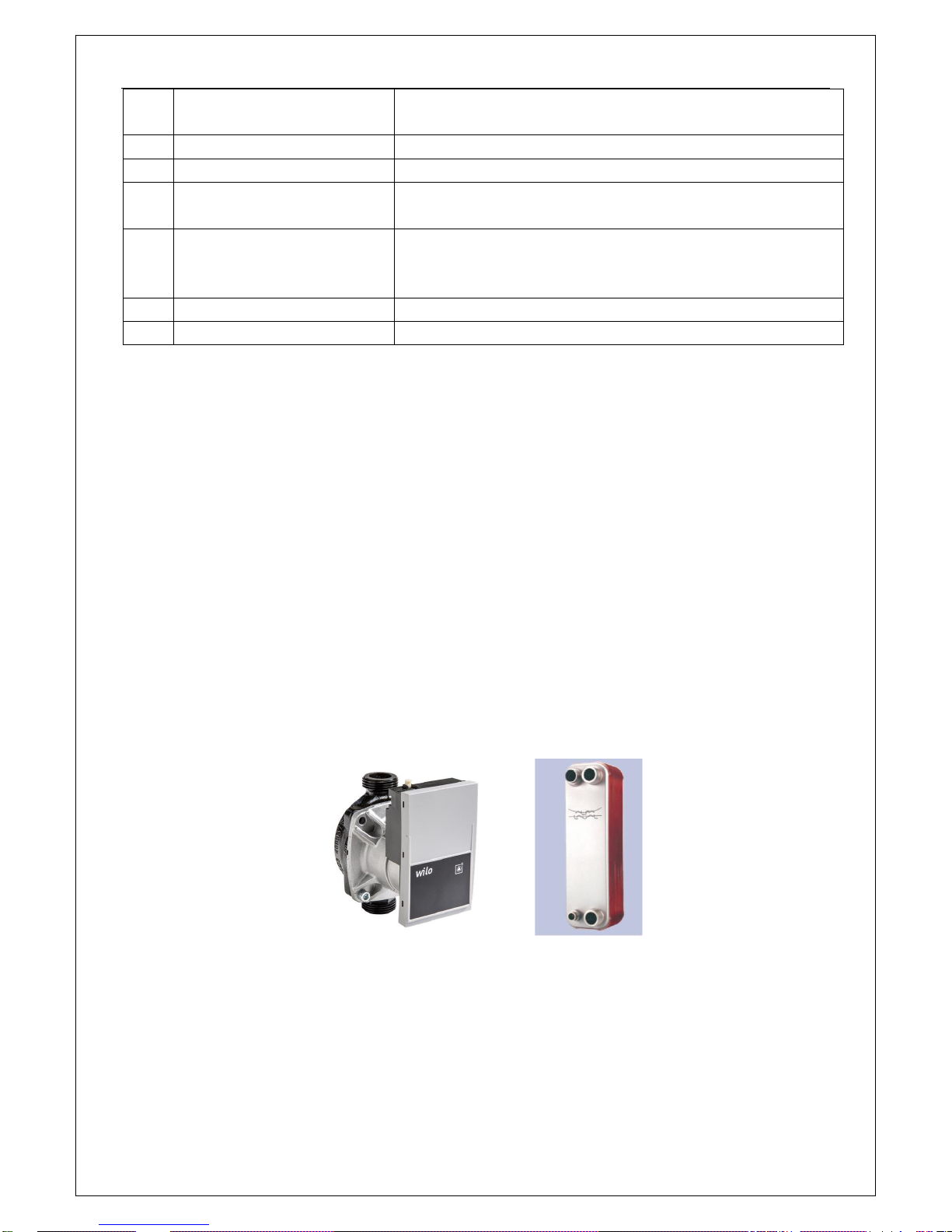

High-efficiency Component(Inverter pump, Inverter fan, Plate heat exchanger)

1. The A-class high-efficiency inverter water pump which complies with the European Erp directive,

can control the running frequency based on the actual load. Therefore, it can enhance the operation

effcieicy and control the water temperature more accurately.

2. The DC inverter fan can control the air volume accuratately and make the system run more stably

and save more energy.

3. The high-efficiency plate heat exchanger will improve the unit’s performance largely at a low price.

All-in-one Design

1. The unit can integrate with terminal units, like the radiator, floor heating device, FCU, water

heating device, solar kit, gas furnace and swimming pool etc. Versatile functions can meet various kinds

of demands from different users and enhance applicability of this product.

2. The all-in-one structure design can save more installation cost, reduce risks of refrigerant leak,

and improve safety and reliability of the system.

Brand-new Controller

1. White appearance, exquisite design, and the wall-mounted design will facilitate installation.

Product

4

2. The dot-matrix display can show in both English and Chinese to show information in a more direct

and convenient way.

3. The six-lattice display pattern will accommodate more information.

4. The 12V JACK interface can supply power to the control separately and lengthen the

communication distance.

5. The remote monitoring interface can monitor the unit through the Mobus interface and be

integrated into the BMS system.

Smart Control, Powerful Function

1. The running mode can be switched freely. Furthermore, based on different demands, the holiday

mode, environment-dependent mode, quite timer, temperature timer and floor commissioning can

activated.

2. Multiple protections can make this product much safer. The added electric heater will prevent the

plate heat exchanger from being frostbitten owing to too low water temperature and resultantly extend

the service life of the product and enhance its safety and reliability.

3. The newly developed smart defrosting control program, “do defrost when necessary; do not

defrost when unnecessary; defrost more when it frosts heavily; defrost less when it frosts lightly”, can

bring more comfortability, avoid inadequacy of heat supply and ensure sustainable heat supply for the

users.

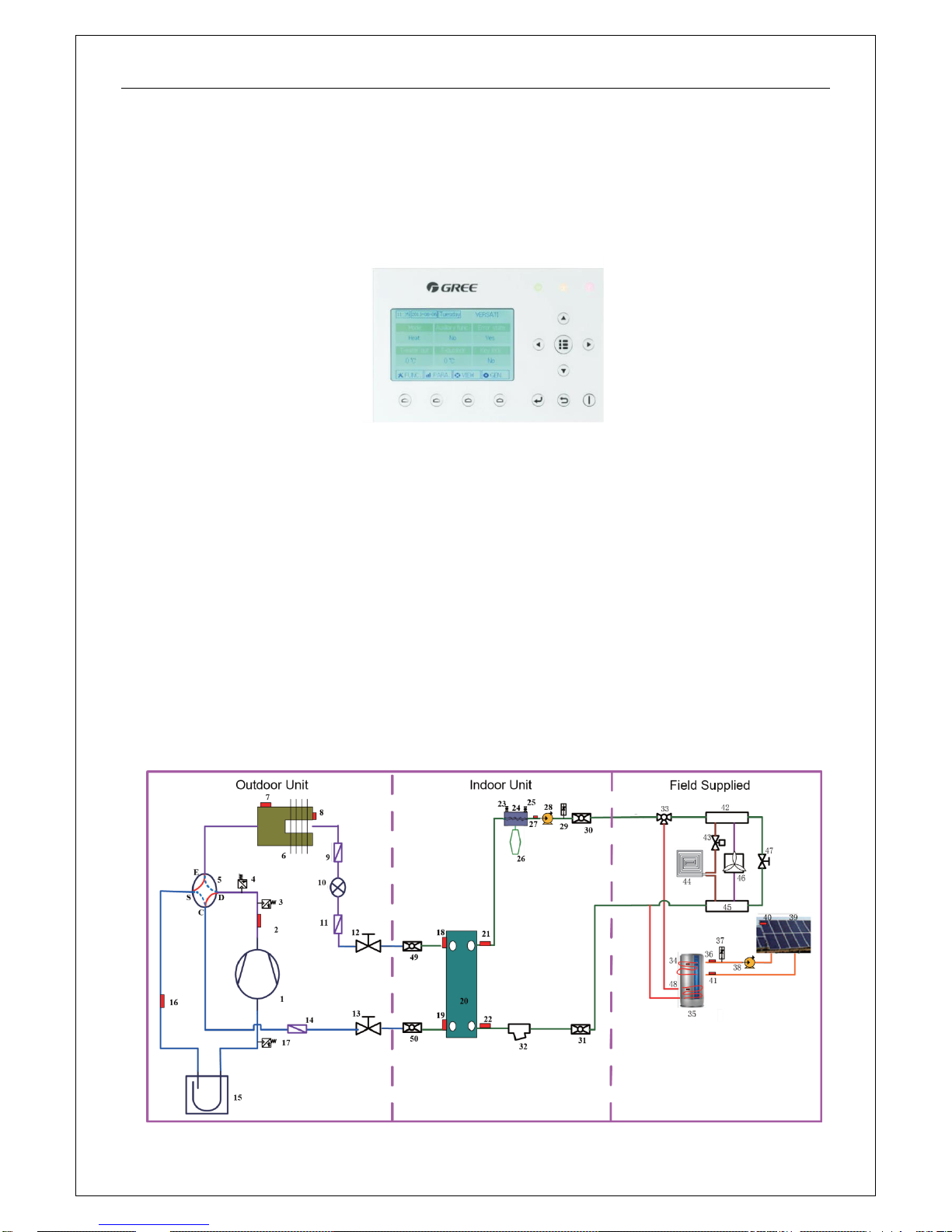

1.4 Operating Principle

1.4.1 Schematic Diagram

Product

5

No.

Name

No.

Name

No.

Name

1

Compressor

18

Liquid Temperature

Sensor of the PHE

35

Water Tank

2

Discharge Temperature

Sensor

19

Gas Temperature Sensor

of the PHE

36

Leaving Water Temperature

Sensor of the Solar System

3

High Pressure Switch

20

Plate-type Exchanger

37

Flow Switch for the Solar

System

4

Pressure Sensor

21

Leaving Water

Temperature

of the PHE

38

Water Pump for the Solar

System

5

4-way Valve

22

Entering Water

Temperature

of the PHE

39

Solar Panel

6

Finned Exchanger

23

Automatic Exhaust Valve

40

Solar Panel Temperature Sensor

7

Environment Temperature

Sensor

24

Electric Heater

41

Entering Water Temperature

for the Solar System

8

Defrosting Temperature

Sensor

25

Safety Valve

42

Water Knockout Vessel

9

Filter

26

Expansion Tank

43

Electric 2-way Valve 1

10

Electrostatic Expansion

Valve

27

Leaving Water

Temperature

of the Electric Heate

44

Floor Radiator

11

Filter

28

Water Pump

45

Water Collector

12

Liquid Valve

29

Flow Switch

46

FCU

13

Gas Valve

30

Leaving Water Pipe

Connector

47

Pressure Differential Bypass

Valve

14

Filter

31

Entering Water Pipe

Connector

48

Water Tank Temperature

Sensor 2

15

Vapor-liquid Separator

32

Water Filter

49

Liquid Valve Connector

16

Suction Temperature Sensor

33

Electric 3-way Valve 2

50

Gas Valve Connector

17

Pressure Sensor

34

Water Tank Temperature

Sensor 1

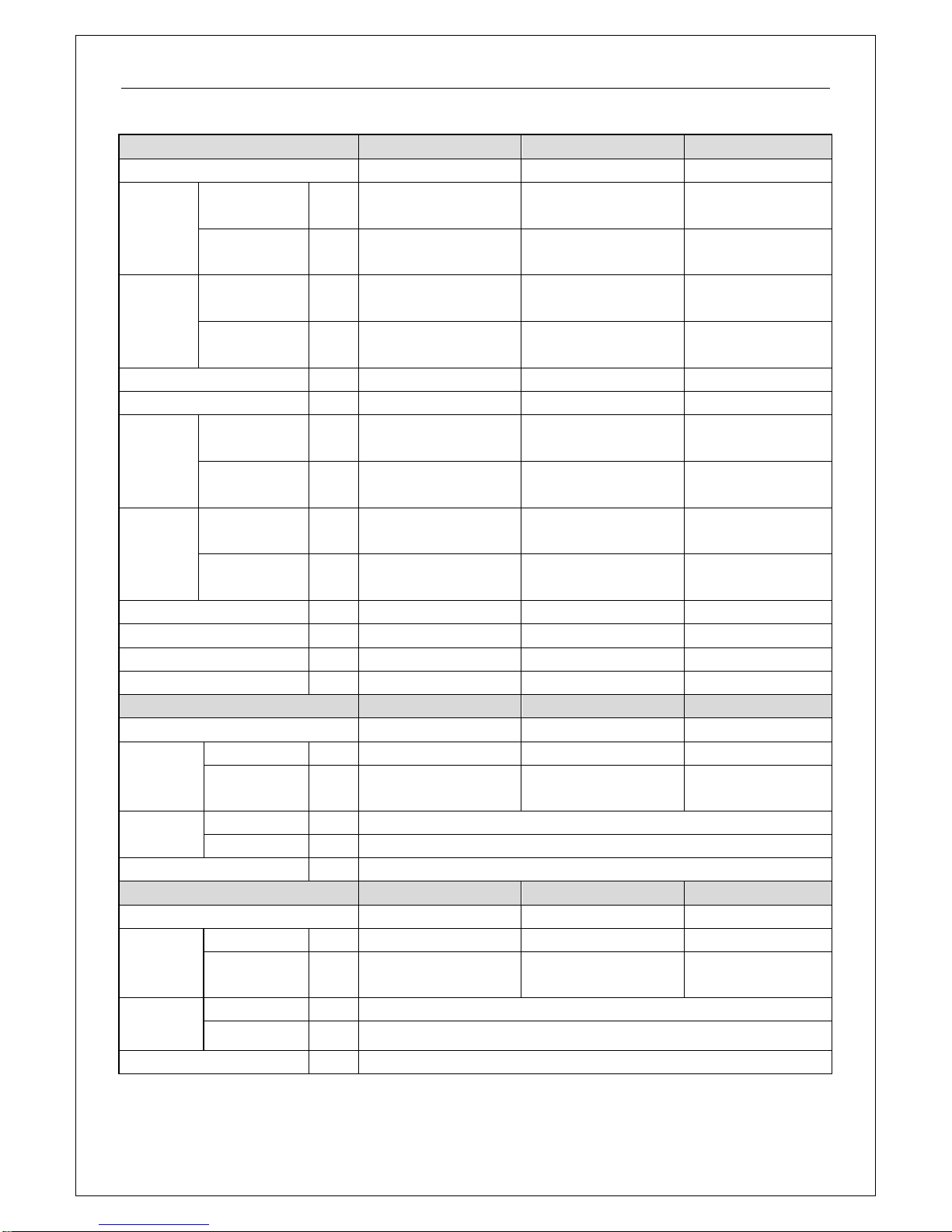

1.5 Technical Data

1.5.1 Parameter List

Model

GRS-CQ8.0Pd/NaE-K

GRS-CQ10Pd/NaE-K

Product Code

ER01001300

ER01001290

Capacity*1

Cooling(floor cooling)

kW

7.8

8.2

Heating(floor heating)

kW 8 10

Product

6

Power Input*1

Cooling(floor cooling)

kW

1.95

2.1

Heating(floor heating)

kW

1.778

2.273

EER*1(floor cooling)

W/W

3.9

4.0

COP*1(floor heating)

W/W

4.4

4.5

Capacity*2

Cooling(for Fan coil)

kW

6.3

7.2

Heating(Fan coil or Radiator)

kW

7.6

9.5

Power Input*2

Cooling(for Fan coil)

kW

2.33

2.77

Heating(Fan coil or Radiator)

kW

2.24

2.88

EER*2(for Fan coil)

W/W

2.6

2.7

COP*2(Fan coil or Radiator)

W/W

3.3

3.4

Refrigerant charge volume

kg

2.3

2.3

Sanitary water Temperature

℃

40~80

40~80

Outdoor Unit Model

GRS-CQ8.0Pd/NaE-K(O)

GRS-CQ10Pd/NaE-K(O)

Outdoor Unit Product Code

ER010W1300

ER010W1290

Sound

Pressure

Level

cooling

dB(A)

54

54

heating

dB(A)

56

56

Dimensions

(W×D×H)

Outline

mm

980×427×788

Packaged

mm

1097×862×477

Net weight/Gross weight

kg

80/85

Indoor Unit Model

GRS-CQ8.0Pd/NaE-K(I)

GRS-CQ10Pd/NaE-K(I)

Indoor Unit Product Code

ER010N1300

ER010N1290

Sound

Pressure

Level

cooling

dB(A)

31

31

heating

dB(A)

31

31

Dimensions

(W×D×H)

Outline

mm

981×324×500

Packaged

mm

1043×395×608

Net weight/Gross weight

kg

56/65

Notes

“*1” indicates the capacity and power input are tested based on the conditions below:

① Cooling

Indoor Water Temperature: 23°C/18°C; Outdoor Temperature: 35°CDB/24°CWB

② Heating

Indoor Water Temperature: 30°C/35°C; Outdoor Temperature: 7°CDB/6°CWB

“*2” indicates the capacity and power input are tested based on the conditions below:

① Cooling

Indoor Water Temperature: 12°C/7°C; Outdoor Temperature: 35°CDB/24°CWB

② Heating

Indoor Water Temperature: 40°C/45°C; Outdoor Temperature: 7°CDB/6°CWB

Model

GRS-CQ12Pd/NaE-K

GRS-CQ14Pd/NaE-K

GRS-CQ16Pd/NaE-K

Product Code

ER01001280

ER01001270

ER01001260

Capacity*1

Cooling(floor

cooling)

kW

12.5

13.5

14.5

Heating(floor

kW

12

14

15.5

Product

7

heating)

Power

Input*1

Cooling(floor

cooling)

kW

3

3.4

3.8

Heating(floor

heating)

kW

2.8

3.3

3.75

EER*1(floor cooling)

W/W

4.2 4 3.8

COP*1(floor heating)

W/W

4.3

4.2

4.1

Capacity*2

Cooling(for Fan

coil)

kW

8.5

9

9.5

Heating(Fan coil

or Radiator)

kW

11.5

12.5

14.5

Power

Input*2

Cooling(for Fan

coil)

kW

2.7

3

3.3

Heating(Fan coil

or Radiator)

kW

3.4

3.8

4.5

EER*2(for Fan coil)

W/W

3.1 3 2.9

COP*2(Fan coil or Radiator)

W/W

3.35

3.3

3.2

Refrigerant charge volume

Kg

3.6

3.6

3.6

Sanitary water Temperature

℃

40~80

40~80

40~80

Outdoor Unit Model

GRS-CQ12Pd/NaE-K(O)

GRS-CQ14Pd/NaE-K(O)

GRS-CQ16Pd/NaE-K(O)

Outdoor Unit Product Code

ER010W1280

ER010W1270

ER010W1260

Sound

Pressure

Level

cooling

dB(A)

56

56

56

heating

dB(A)

58

58

58

Dimensions

(W×D×H)

Outline

mm

900×412×1345

Packaged

mm

998×458×1515

Net weight/Gross weight

kg

107/117

Indoor Unit Model

GRS-CQ12Pd/NaE-K(I)

GRS-CQ14Pd/NaE- K(I)

GRS-CQ16Pd/NaE- K(I)

Indoor Unit Product Code

ER010N1280

ER010N1270

ER010N1260

Sound

Pressure

Level

cooling

dB(A)

31

31

31

heating

dB(A)

31

31

31

Dimensions

(W×D×H)

Outline

mm

981×324×500

Packaged

mm

1043×395×608

Net weight/Gross weight

kg

57/66

Notes

“*1” indicates the capacity and power input are tested based on the conditions below:

① Cooling

Indoor Water Temperature: 23°C/18°C; Outdoor Temperature: 35°CDB/24°CWB

② Heating

Indoor Water Temperature: 30°C/35°C; Outdoor Temperature: 7°CDB/6°CWB

“*2” indicates the capacity and power input are tested based on the conditions below:

① Cooling

Indoor Water Temperature: 12°C/7°C; Outdoor Temperature: 35°CDB/24°CWB

Product

8

② Heating

Indoor Water Temperature: 40°C/45°C; Outdoor Temperature: 7°CDB/6°CWB

Model

GRS-CQ12Pd/NaE-M

GRS-CQ14Pd/NaE-M

GRS-CQ16Pd/NaE-M

Product Code

ER01001250

ER01001240

ER01001230

Capacity*1

Cooling(floor

cooling)

kW

13.5

14.5

15

Heating(floor

heating)

kW

12

14

15.5

Power

Input*1

Cooling(floor

cooling)

kW

3.55

3.95

4.2

Heating(floor

heating)

kW

2.8

3.35

3.85

EER*1(floor cooling)

W/W

3.8

3.7

3.6

COP*1(floor heating)

W/W

4.3

4.2

4.05

Capacity*2

Cooling(for Fan

coil)

kW

10

10.5

11

Heating(Fan

coil or Radiator)

kW

12

13.5

14

Power

Input*2

Cooling(for Fan

coil)

kW

3.35

3.6

3.8

Heating(Fan

coil or Radiator)

kW

3.55

4.05

4.25

EER*2(for Fan coil)

W/W 3 2.95

2.9

COP*2(Fan coil or Radiator)

W/W

3.4

3.35

3.3

Refrigerant charge volume

Kg

3.6

3.6

3.6

Sanitary water Temperature

℃

40~80

40~80

40~80

Outdoor Unit Model

GRS-CQ12Pd/NaE-M(O)

GRS-CQ14Pd/NaE-M(O)

GRS-CQ16Pd/NaE-M(O)

Outdoor Unit Product Code

ER01001250

ER01001240

ER01001230

Sound

Pressure

Level

cooling

dB(A)

55

55

55

heating

dB(A)

57

57

57

Dimensions

(W×D×H)

Outline

mm

900×1345×412

Packaged

mm

998×1515×458

Net weight/Gross weight

kg

114/124

Indoor Unit Model

GRS-CQ12Pd/NaE-M(I)

GRS-CQ14Pd/NaE- M(I)

GRS-CQ16Pd/NaE- M(I)

Indoor Unit Product Code

ER01001250

ER01001240

ER01001230

Sound

Pressure

Level

cooling

dB(A)

31

31

31

heating

dB(A)

31

31

31

Dimensions

(W×D×H)

Outline

mm

981×324×500

Packaged

mm

1043×395×608

Net weight/Gross weight

kg

58/67

Notes

“*1” indicates the capacity and power input are tested based on the conditions below:

Product

9

① Cooling

Indoor Water Temperature: 23°C/18°C; Outdoor Temperature: 35°CDB/24°CWB

② Heating

Indoor Water Temperature: 30°C/35°C; Outdoor Temperature: 7°CDB/6°CWB

“*2” indicates the capacity and power input are tested based on the conditions below:

① Cooling

Indoor Water Temperature: 12°C/7°C; Outdoor Temperature: 35°CDB/24°CWB

② Heating

Indoor Water Temperature: 40°C/45°C; Outdoor Temperature: 7°CDB/6°CWB

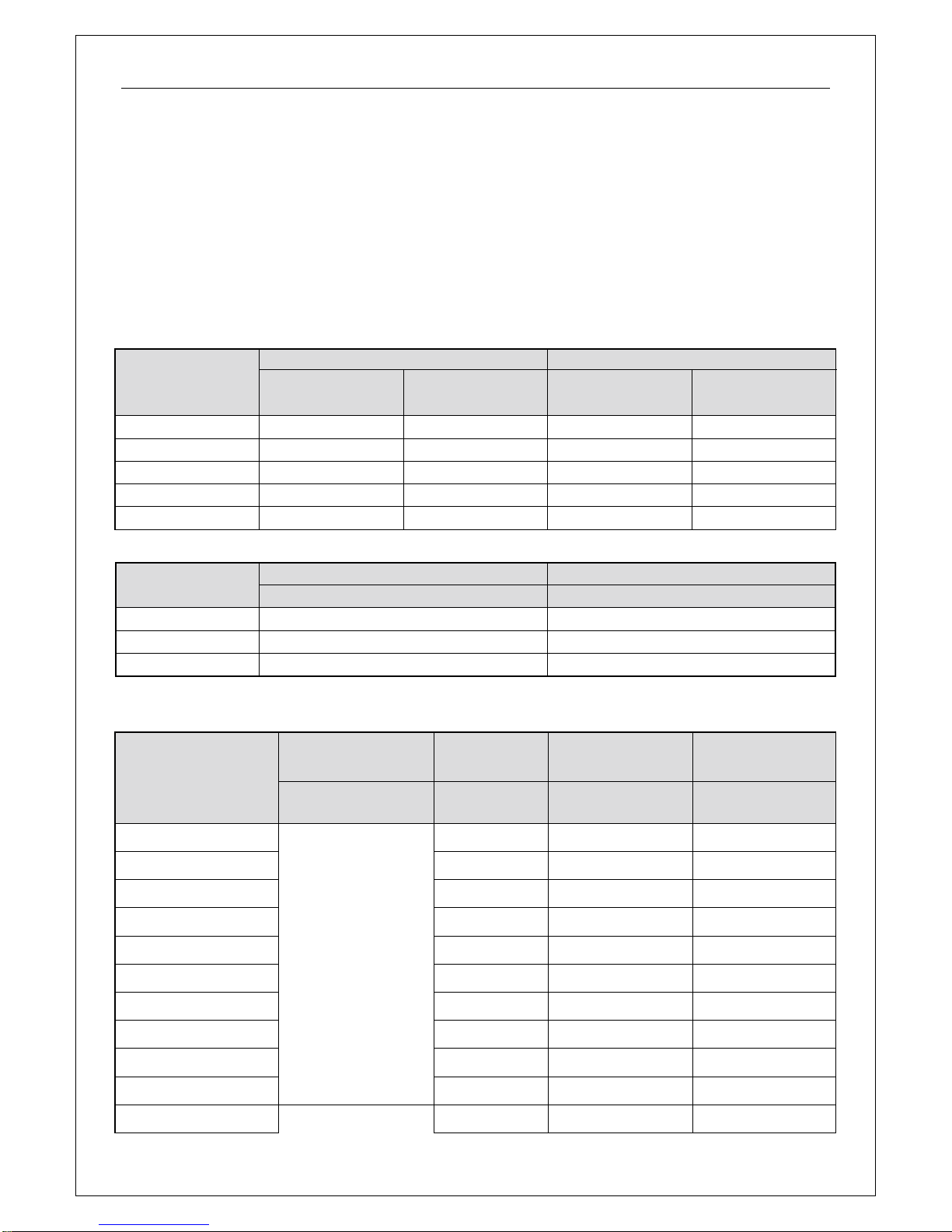

1.5.2 Nominal Working Conditions

Item

Water Side

Air side

Entering Water Temp

(°C)

Leaving Water

Temperature (°C)

Dry Bulb

Temperature (°C)

Wet Bulb

Temperature (°C)

Floor Heating

30

35 7 6

FCU Heating

40

45 7 6

Floor Cooling

23

18

35

—

FCU Cooling

12 7 35

—

Water Heating

10

50 7 6

1.5.3 Operation Range

Item

Water Side

Air side

Leaving Water Temperature (°C)

Environment Dry Bulb Temperature (°C)

Cooling

7~25

10~48

Heating

25~55

-22~35

Water Heating

40~80 (Water Tank Temperature)

-22~45

Note: when operating conditions are out of the range listed above, please contact GREE.

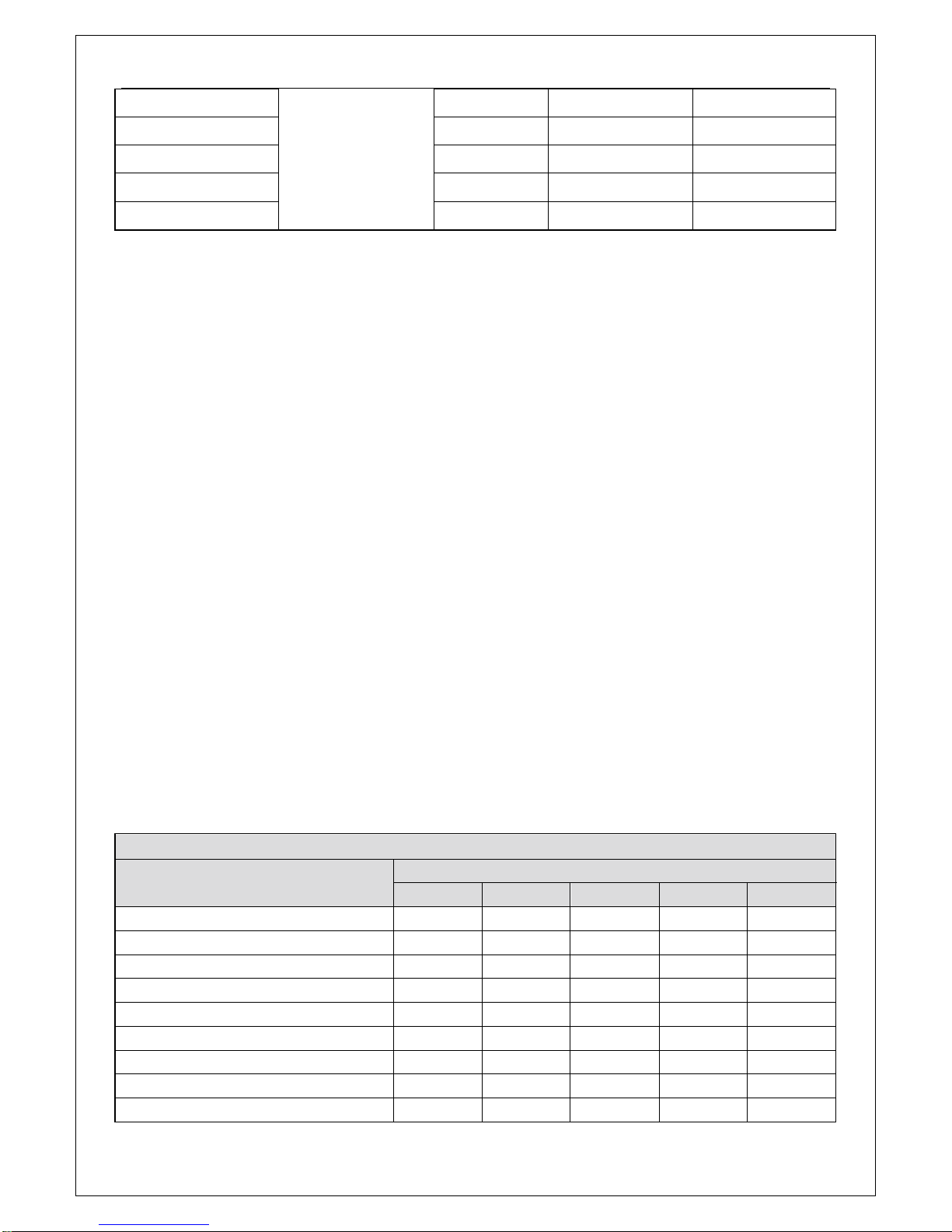

1.5.4 Electric Data

Model

Power Supply

Leakage Switch

Minimum Sectional

Area of Earth Wire

Minimum Sectional

Area of Power

V,Ph,Hz

(A)

(mm2)

(mm2)

GRS-CQ8.0Pd/NaE-K(O

220-240V,~,50Hz

25

3.3

2×3.3

GRS-CQ10Pd/NaE-K(O)

25

3.3

2×3.3

GRS-CQ8.0Pd/NaE-K(I)

50

13.3

2×13.3

GRS-CQ10Pd/NaE-K(I)

50

13.3

2×13.3

GRS-CQ12Pd/NaE-K(O)

35

8.4

2×8.4

GRS-CQ14Pd/NaE-K(O)

35

8.4

2×8.4

GRS-CQ16Pd/NaE-K(O)

35

8.4

2×8.4

GRS-CQ12Pd/NaE-K(I)

50

13.3

2×13.3

GRS-CQ14Pd/NaE-K(I)

50

13.3

2×13.3

GRS-CQ16Pd/NaE-K(I)

50

13.3

2×13.3

GRS-CQ12Pd/NaE-M(O)

380-415V,3N~,50Hz

25

3.3

4×3.3

Product

10

GRS-CQ14Pd/NaE-M(O)

25

3.3

4×3.3

GRS-CQ16Pd/NaE-M(O)

25

3.3

4×3.3

GRS-CQ12Pd/NaE-M(I)

20

3.3

4×3.3

GRS-CQ14Pd/NaE-M(I)

20

3.3

4×3.3

GRS-CQ16Pd/NaE-M(I)

20

3.3

4×3.3

Notes

① L

eakage Switch is necessary for additional installation. If circuit breakers with leakage

protection are in use, action response time must be less than 0.1 second, leakage circuit must

be 30mA.

②

The above selected power cable diameters are determined based on assumption of distance

from the distribution cabinet to the unit less than 75m. If cables are laid out in a distance of 75m

to 150m, diameter of power cable must be increased to a further grade.

③

The power supply must be of rated voltage of the unit and special electrical line for

air-conditioning.

④

All electrical installation shall be carried out by professional technicians in accordance with the

local laws and regulations.

⑤

Ensure safe grounding and the grounding wire shall be connected with the special grounding

equipment of the building and must be installed by professional technicians.

⑥

The specifications of the breaker and power cable listed in the table above are determined

based on the maximum power (maximum amps) of the unit.

⑦

The specifications of the power cable listed in the table above are applied to the

conduit-guarded multi-wire copper cable (like, YJV XLPE insulated power cable) used at 40°C

and resistible to 90°C(see IEC 60364-5-52). If the working condition changes, they should be

modified according to the related national standard.

⑧

The specifications of the breaker listed in the table above are applied to the breaker with the

working temperature at 40°C. If the working condition changes, they should be modified

according to the related national standard.

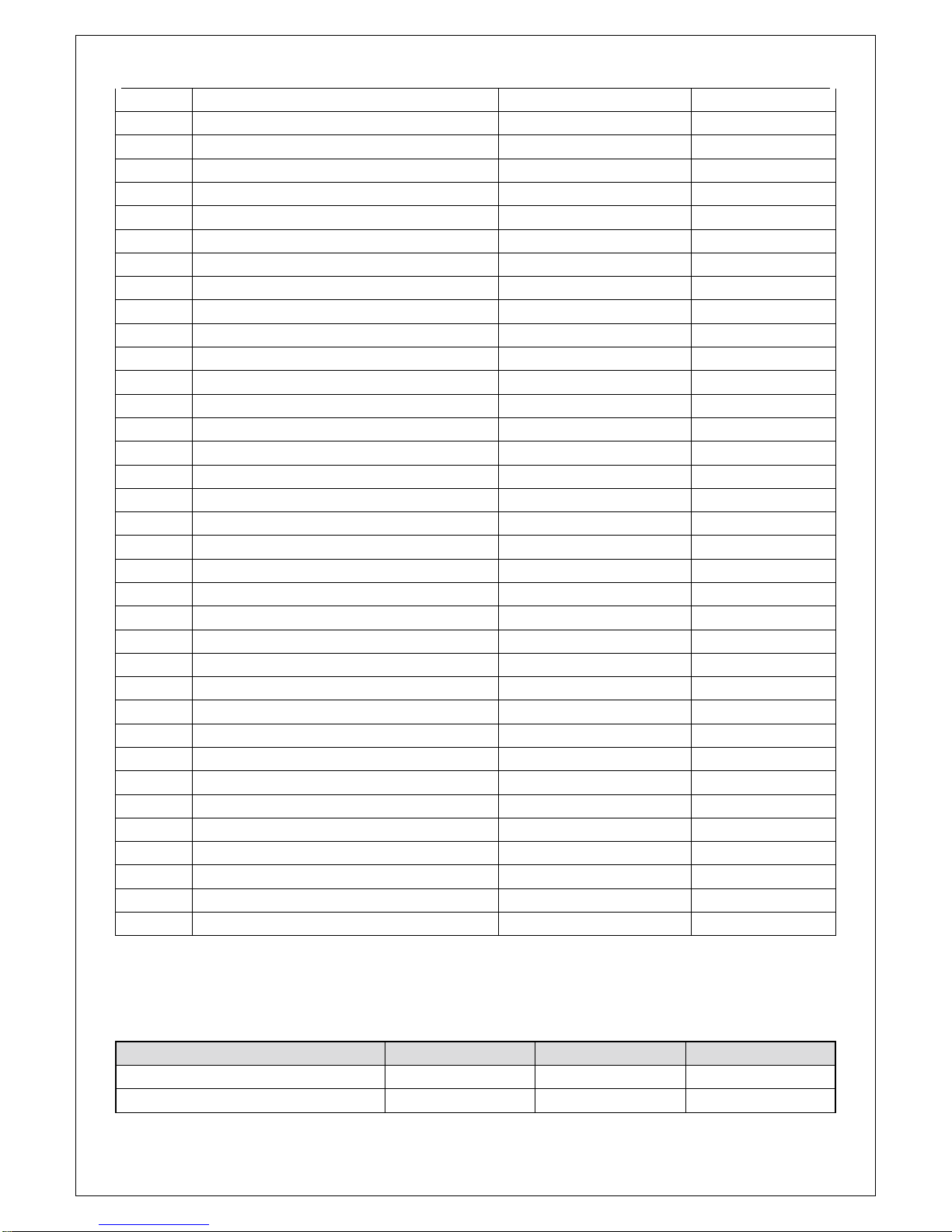

1.5.5 Capacity Correction

Cooling Capacity Correction

GRS-CQ8.0Pd/NaE-K,GRS-CQ10Pd/NaE-K,GRS-CQ12Pd/NaE-K,GRS-CQ14Pd/NaE-K,

GRS-CQ16Pd/NaE-K,GRS-CQ12Pd/NaE-M,GRS-CQ14Pd/NaE-M,GRS-CQ16Pd/NaE-M.

Performance correction

Leaving Chilled Water ℃(℉)

Ambient Temperature ℃(℉)

25(77)

30(86)

35(95)

40(104)

45(113)

5(41.0)

0.995

0.955

0.905

0.855

0.805

6(42.8)

1.045

1.005

0.955

0.905

0.855

7(44.6)

1.090

1.050

1.000

0.950

0.900

8(46.4)

1.145

1.102

1.052

1.000

0.950

9(48.2)

1.190

1.150

1.100

1.050

1.002

10(50.0)

1.245

1.200

1.150

1.100

1.050

11(51.8)

1.290

1.250

1.202

1.152

1.102

12(53.6)

1.340

1.300

1.252

1.200

1.152

13(55.4)

1.390

1.350

1.302

1.252

1.202

Product

11

14(57.2)

1.442

1.402

1.350

1.302

1.252

15(59.0)

1.490

1.450

1.400

1.350

1.302

18(64.4)

1.539

1.502

1.451

1.402

1.350

Computer of actual cooling capacity: actual cooling capacity = nominal cooling capacity x cooling

capacity correction coefficient.

Heating Capacity Correction

GRS-CQ8.0Pd/NaE-K,GRS-CQ10Pd/NaE-K,GRS-CQ12Pd/NaE-K,GRS-CQ14Pd/NaE-K,

GRS-CQ16Pd/NaE-K,GRS-CQ12Pd/NaE-M,GRS-CQ14Pd/NaE-M,GRS-CQ16Pd/NaE-M.

Performance Correction

Outflow

Heated

Water ℃(℉)

Ambient Temperature ℃(℉)

-15(5)

-10(14)

-5(23)

0(32)

5(41.0)

10(50)

15(59.0)

20(68.0)

25(77.4)

30(86)

0.81

0.91

1.00

1.10

1.18

1.26

1.35

1.41

1.45

35(95)

0.74

0.84

0.93

1.03

1.11

1.19

1.28

1.36

1.41

40(104)

0.67

0.77

0.87

0.96

1.04

1.12

1.20

1.25

1.31

45(113)

0.60

0.70

0.80

0.89

0.97

1.05

1.13

1.19

1.25

50(122)

0.53

0.63

0.73

0.82

0.90

0.98

1.06

1.11

1.18

55(131)

0.46

0.56

0.66

0.74

0.83

0.90

0.98

1.05

1.10

Computer of actual heating capacity: actual heating capacity = nominal heating capacity x heating

capacity correction coefficient.

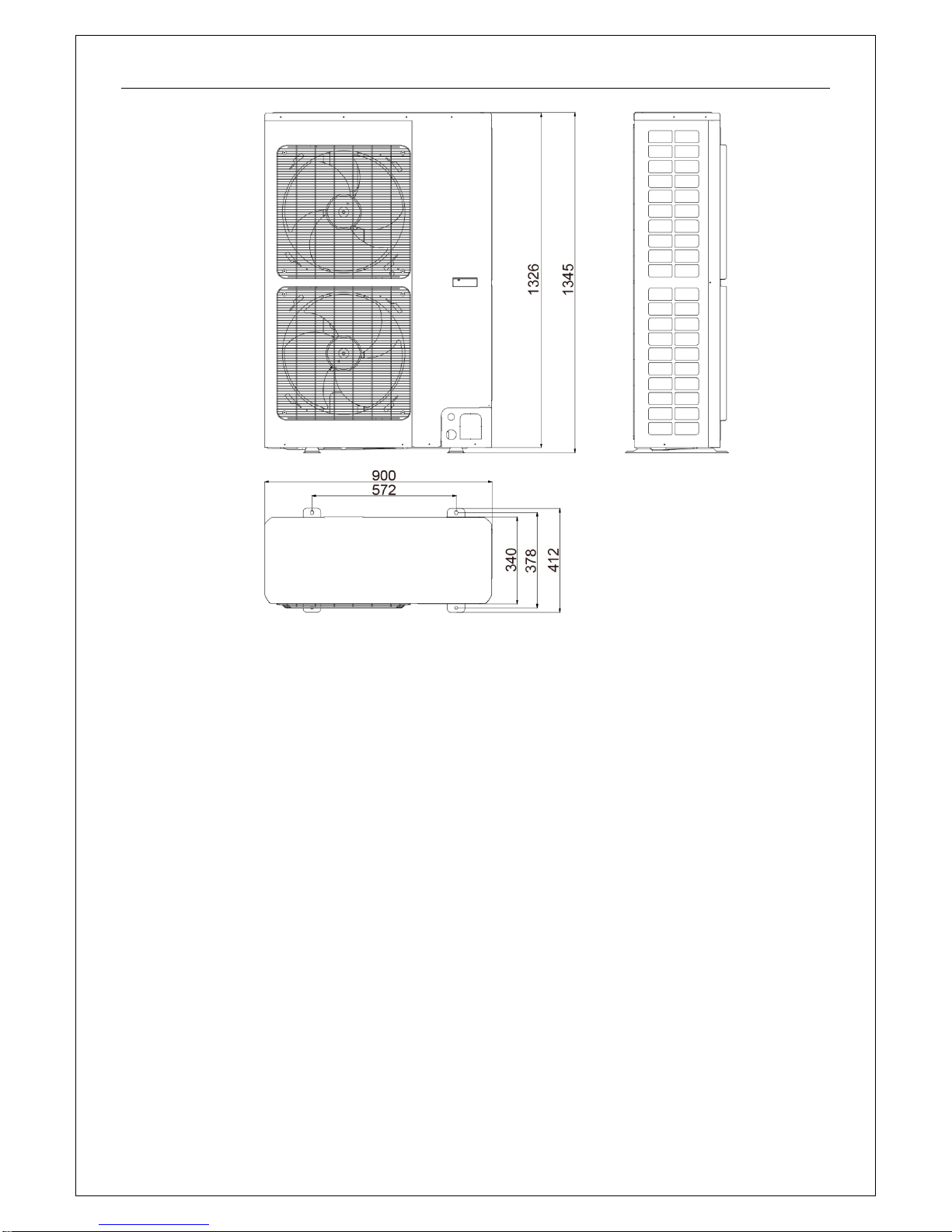

2 Outline Dimensions

2.1 Outline dimensions of outdoor unit

GRS-CQ8.0Pd/NaE-K(O), GRS-CQ10Pd/NaE-K(O)

Product

12

GRS-CQ12Pd/NaE-K(O), GRS-CQ14Pd/NaE-K(O) , GRS-CQ16Pd/NaE-K(O)

GRS-CQ12Pd/NaE-M(O), GRS-CQ14Pd/NaE-M(O) , GRS-CQ16Pd/NaE-M(O)

Product

13

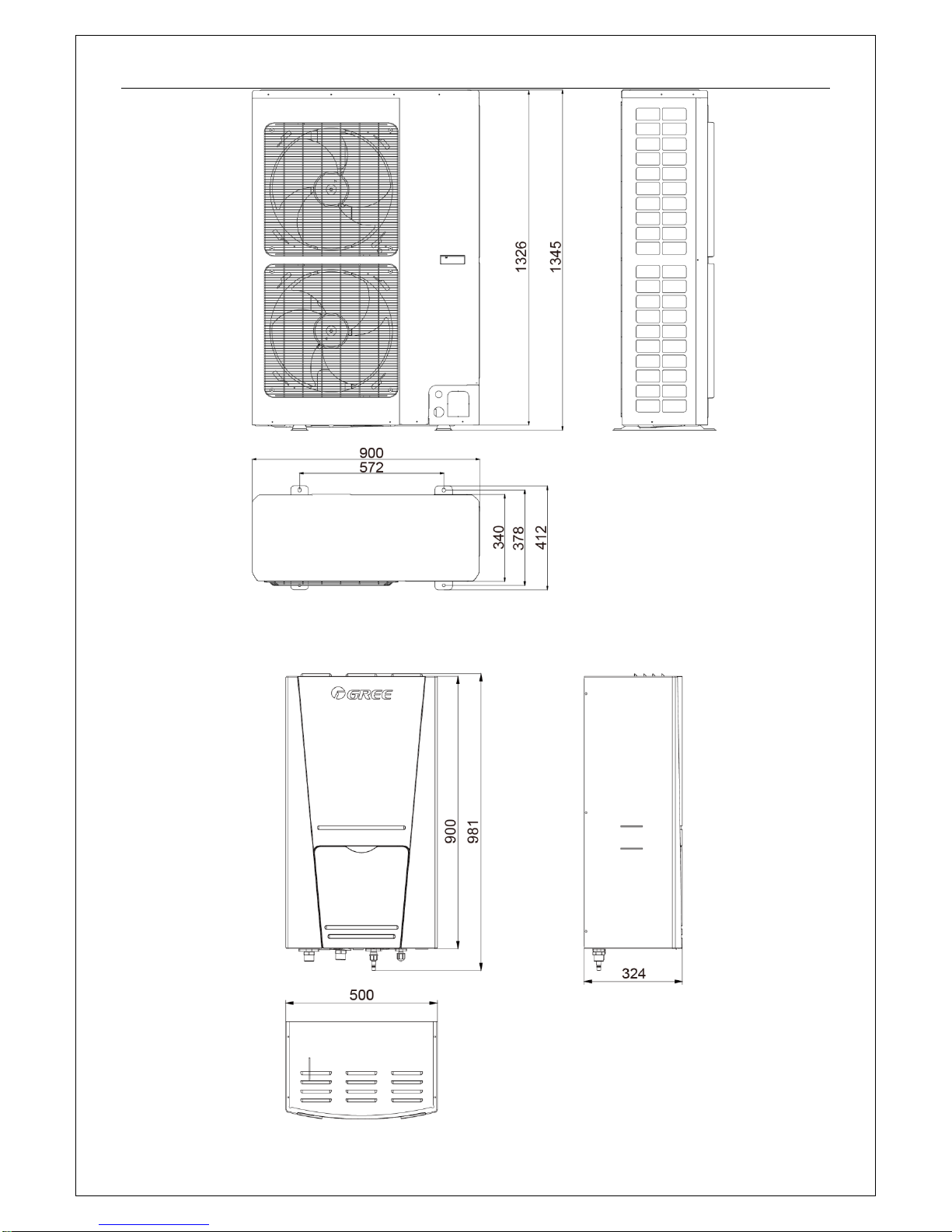

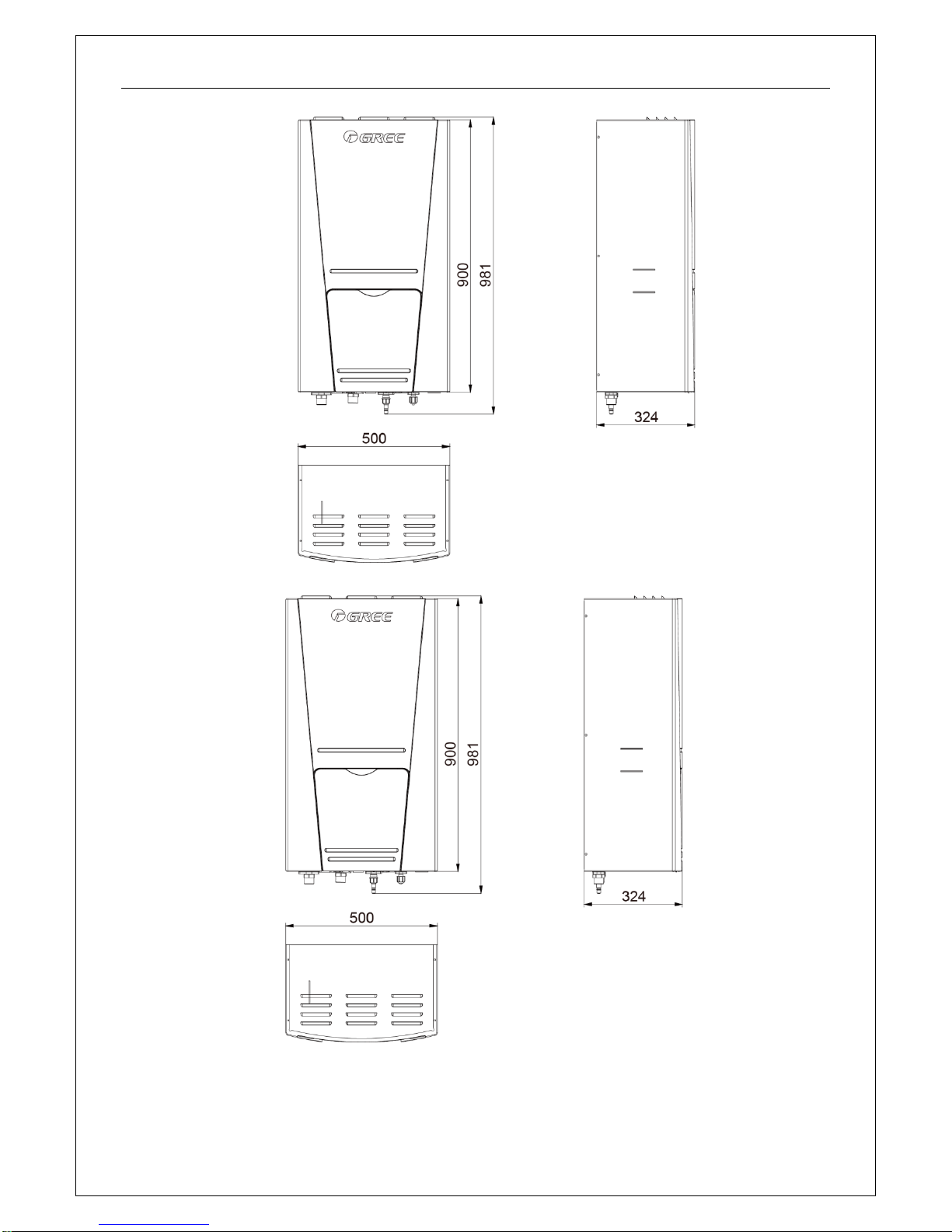

2.2 Outline dimensions of indoor unit

GRS-CQ8.0Pd/NaE-K(I), GRS-CQ10Pd/NaE-K(I)

Product

14

GRS-CQ12Pd/NaE-K(I), GRS-CQ14Pd/NaE-K(I) , GRS-CQ16Pd/NaE-K(I)

GRS-CQ12Pd/NaE-M(I), GRS-CQ14Pd/NaE-M(I) , GRS-CQ16Pd/NaE-M(I)

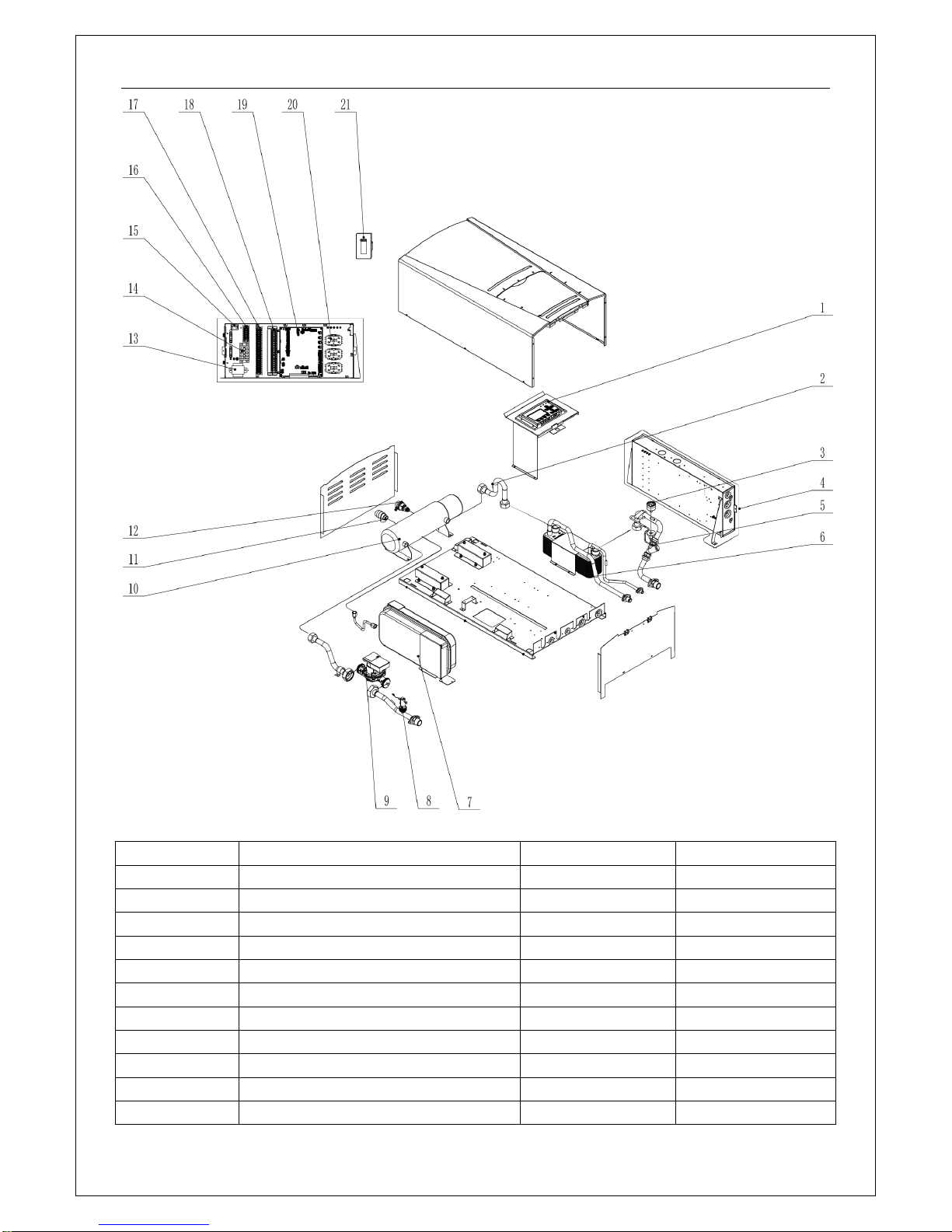

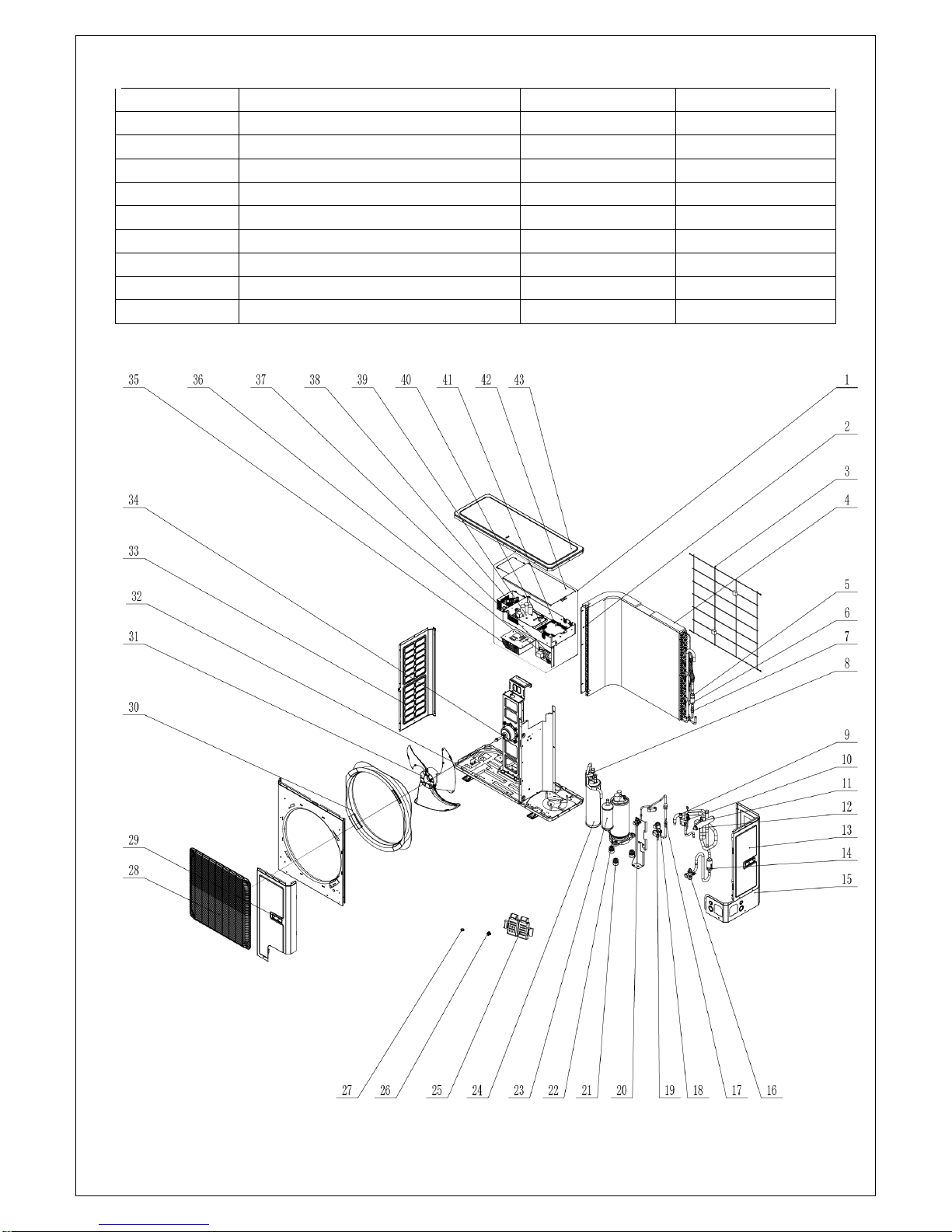

3 Explosive Views and Part Lists

(1) GRS-CQ8.0Pd/NaE-K(I), GRS-CQ10Pd/NaE-K(I)

Product

15

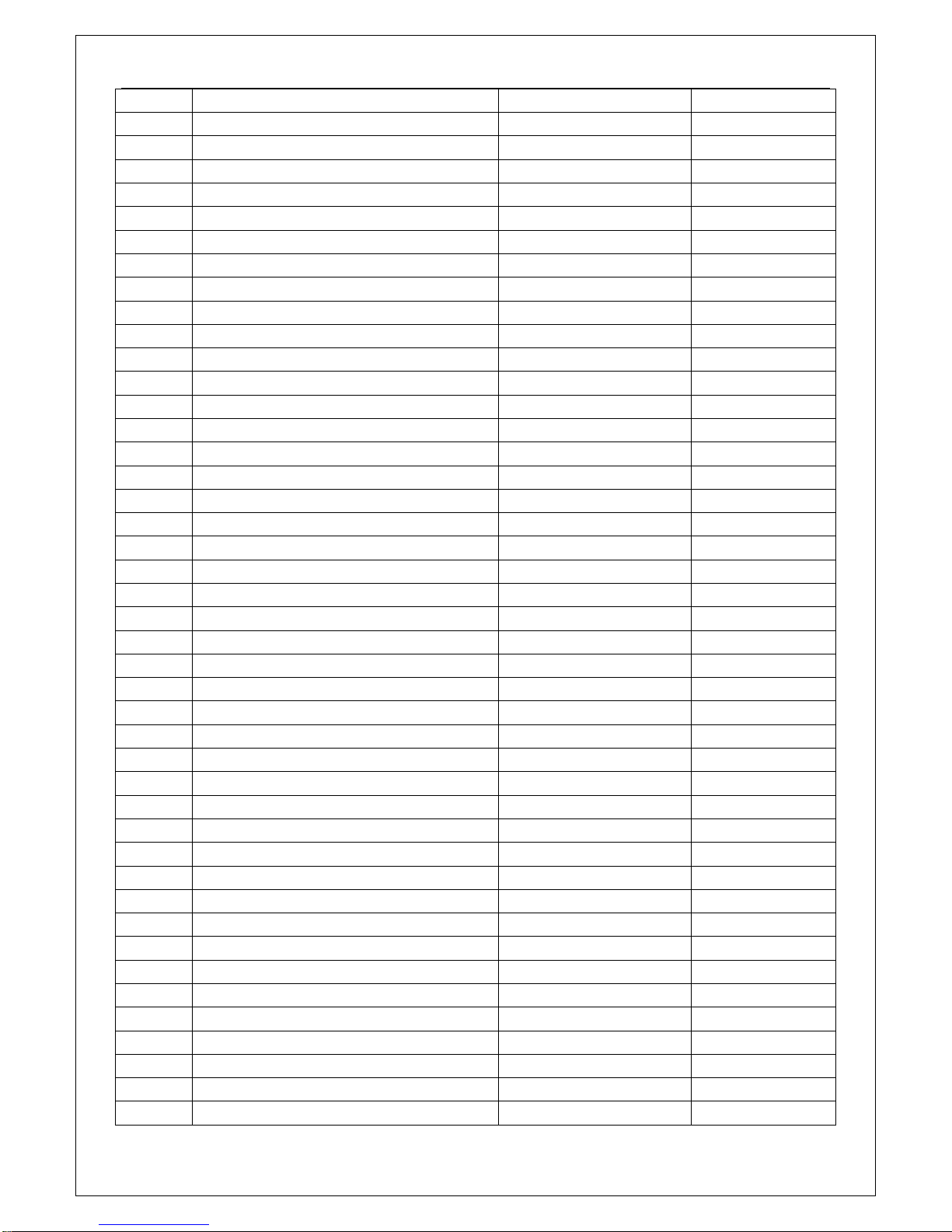

Parts List of GRS-CQ8.0Pd/NaE-K(I) for ER010N1300, GRS-CQ10Pd/NaE-K(I)for ER010N1290.

No.

Name of part

Part Code

Quantity 1 Display Board

30292000047

1 2 Temp Sensor Sleeving

05212423

5 3 Water Pressure Gauge

49028009

1 4 Electric Box Assy

100002000198

1

5

Strainer

07412808

1 6 Plate-type Heat Exchanger

00902812

1 7 Expansion Drum

07422800004

1

8

Steam current Switch sub- Assy

45028062

1 9 Water Pump

812007000002

1

10

Electric Heater

32112800005

1

11

Relief Valve

07382814

1

Product

16

12

Auto Air Outlet Valve

07108208

1

13

Transformer

4311027001

1

14

Terminal Board

42011051

1

15

Thermostat

4504800201

1

16

Terminal Board

42011255

1

17

Terminal Board

42010249

1

18

Terminal Board

42011254

1

19

Main Board

30223000120

1

20

Bipolar AC Contactor

44010221

3

21

Receiver Board

30261014

1

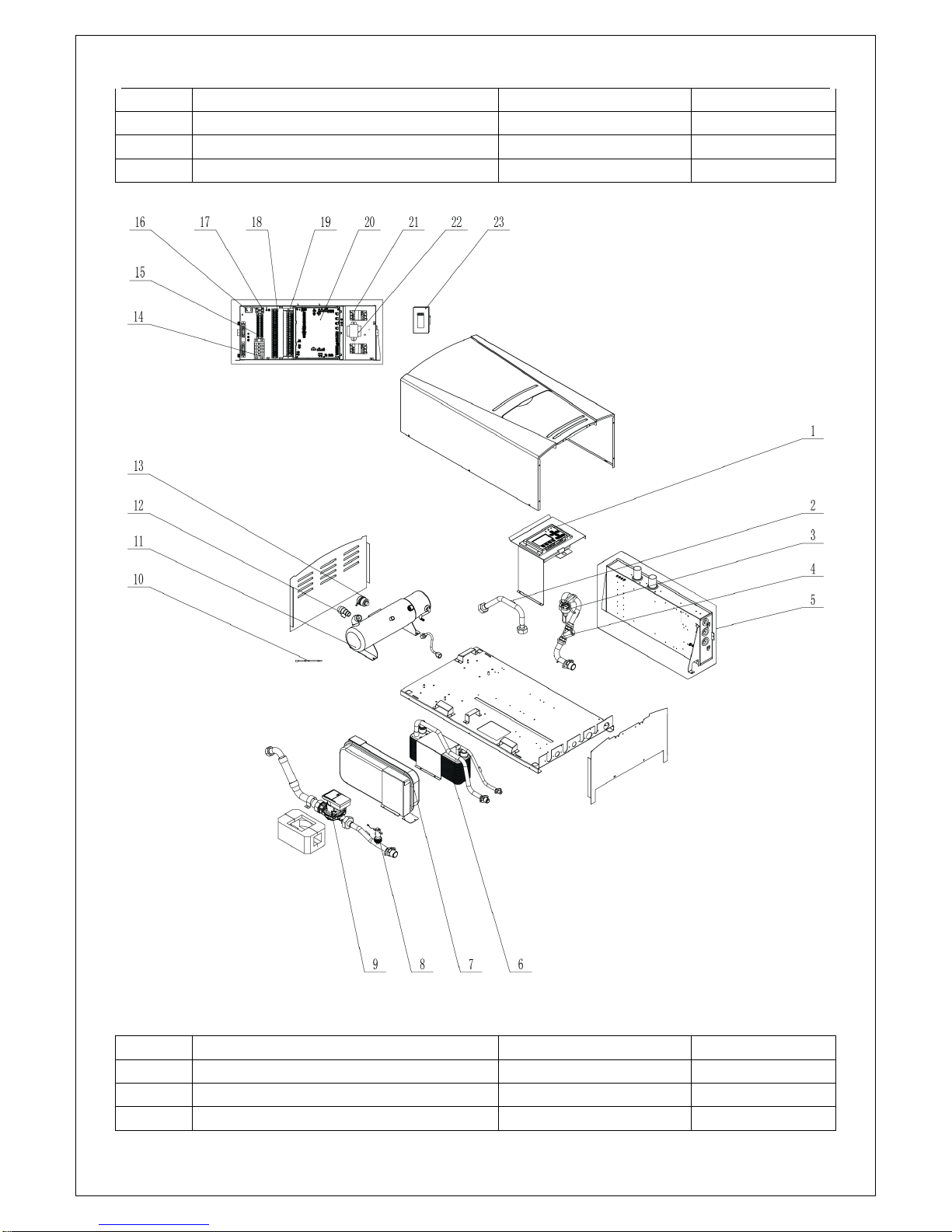

(2) GRS-CQ8.0Pd/NaE-K(O), GRS-CQ10Pd/NaE-K(O)

Parts List of GRS-CQ8.0Pd/NaE-K(I) for ER010N1300, GRS-CQ10Pd/NaE-K(I)for ER010N1290.

Product

17

No.

Name of part

Part Code

Quantity 1 Electric Box Assy

100002000095

1 2 Supporting Strip(Condenser)

01894100053

1

3

Rear Grill

01574100010

1 4 Condenser Assy

01122800082

1

5

Silencer

07245012

1 6 Temp Sensor Sleeving

05212423

2

7

Strainer

0721212101

1 8 Pressure Protect Switch

46020007

1 9 Pressure Protect Switch

46020006

1

10

Sensor (High Pressure)

322101032

1

11

Magnet Coil

4300040032

1

12

4-Way Valve

43040000002

1

13

Rear Side Plate

01314100045P

1

14

Strainer

07210032

1

15

Right Side Plate Sub-Assy

01314100109

1

16

Cut off Valve

07334100016

1

17

Strainer

0721200102

1

18

Electric Expand Valve Fitting

4300034402

1

19

Electronic Expansion Valve

07135176

1

20

Cut off Valve

07330000002

1

21

Compressor Gasket

76713066

3

22

Electrical Heater(Compressor)

7651873209

1

23

Compressor and Fittings

00205200003

1

24

Gas-liquid Separator

07422809

1

25

Sensor Support

26905202

1

26

Drainage Connecter

06123401

1

27

Drainage hole Cap

06813401

3

28

Front Grill

01572800003

1

29

Handle

26235253

2

30

Diversion Circle

10474100003

1

31

Axial Flow Fan

10335014

1

32

Electrical Heater

765100047

1

33

Left Side Plate

01314100043P

1

34

Brushless DC Motor

15702800004

1

35

Radiator

430034000006

1

36

Filter Board

30226000065

1

37

Terminal Board

42011242

1

38

Inductance

43120011

1

39

Main Board

30221000003

1

40

Filter Board

300020000004

1

41

Main Board

30227000038

1

42

Insulated Board (Cover of Electric Box)

20113003

1

43

Coping

01264100027P

1

Product

18

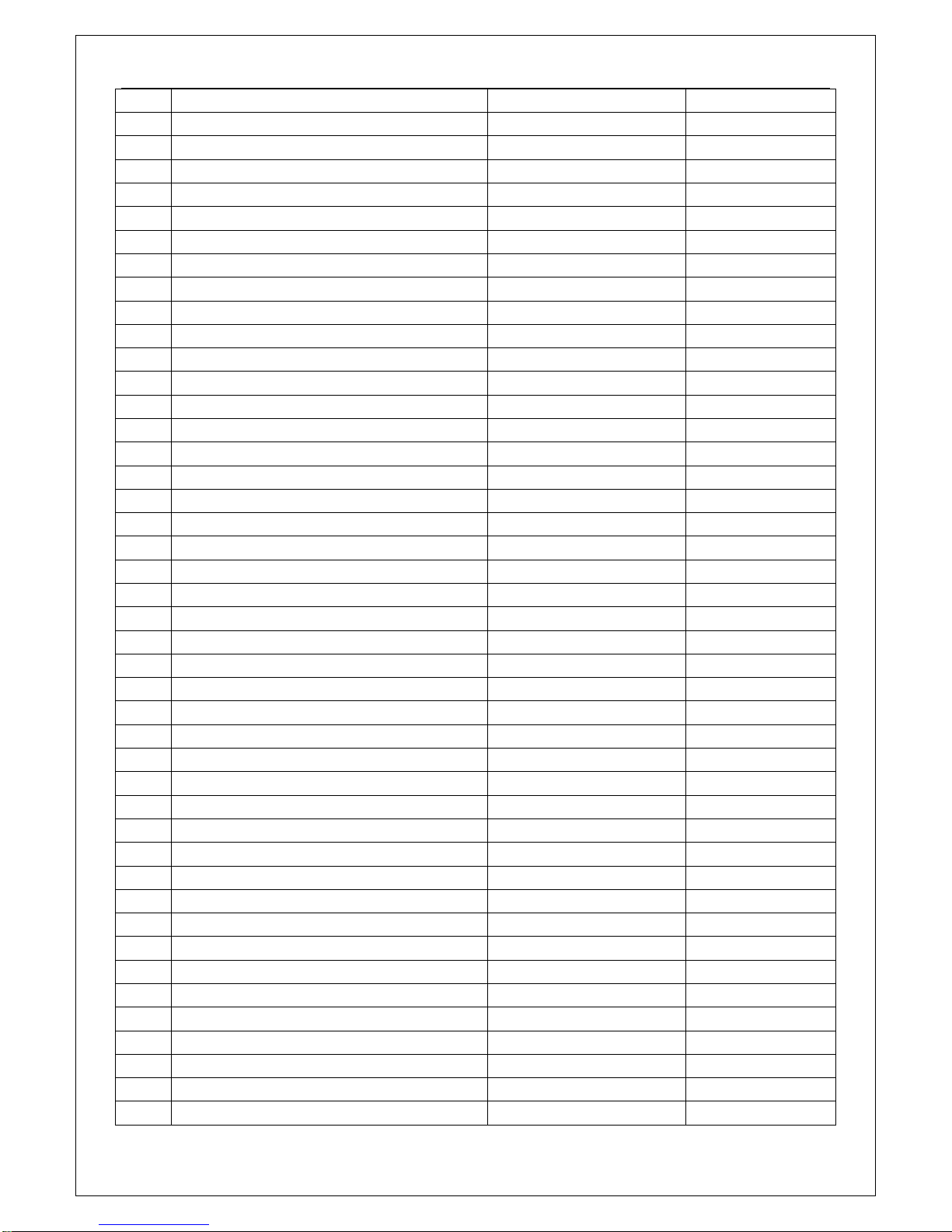

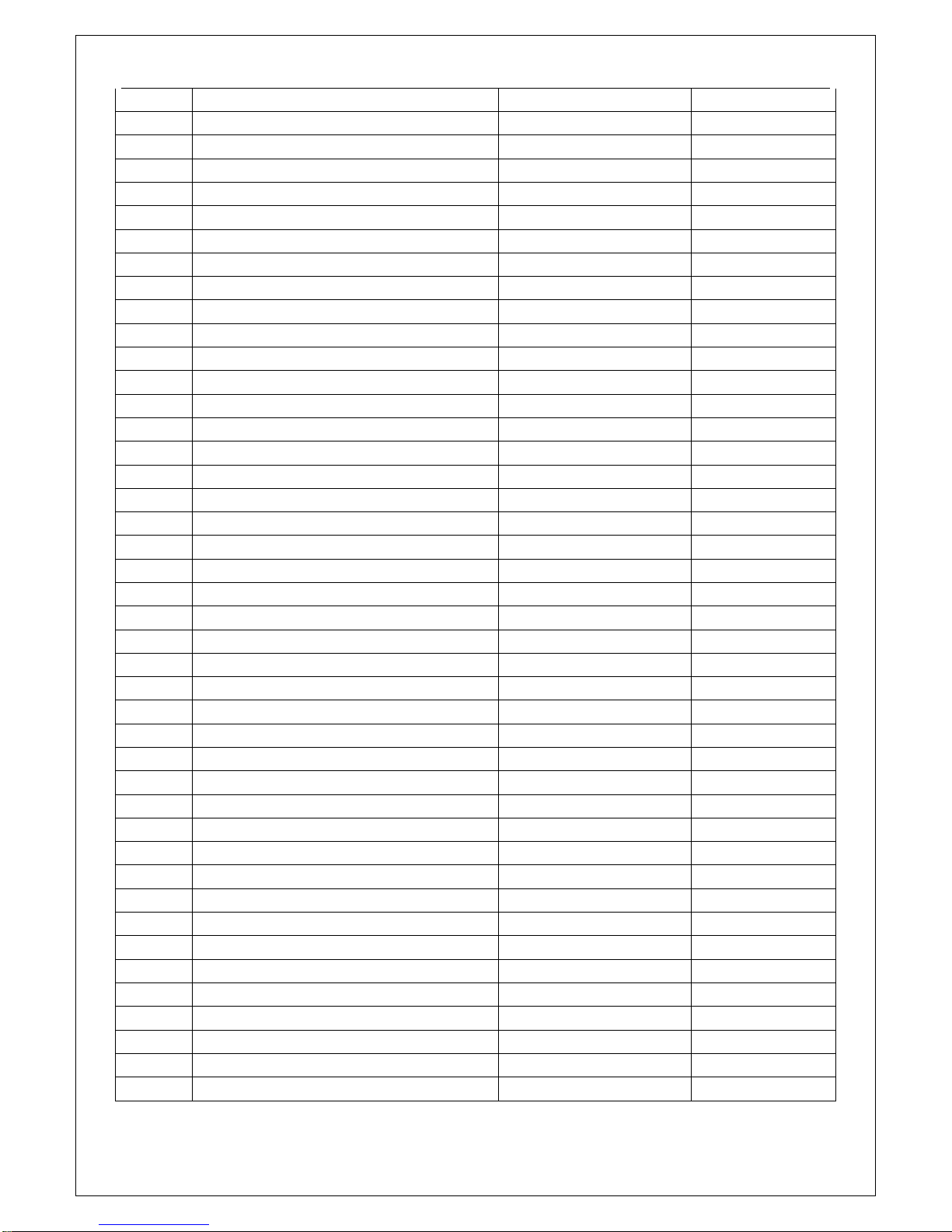

(3) GRS-CQ12Pd/NaE-K(I), GRS-CQ14Pd/NaE-K(I) , GRS-CQ16Pd/NaE-K(I).

Parts List of GRS-CQ12Pd/NaE-K(I) for ER010N1280, GRS-CQ14Pd/NaE-K(I) for ER010N1270,

GRS-CQ16Pd/NaE-K(I) for ER010N1260.

No.

Name of part

Part Code

Quantity

1

Display Board

30292000047

1 2 Temp Sensor Sleeving

05212423

5 3 Water Pressure Gauge

49028009

1

4

Strainer

07412808

1 5 Electric Box Assy

100002000198

1

6

Plate-type Heat Exchanger

00902800030

1 7 Expansion Drum

07422800004

1

Product

19

8

Steam current Switch sub- Assy

45028062

1

9

Water Pump

812007000002

1

10

Electric heater

32102802

1

11

Auto Air Outlet Valve

07108208

1

12

Relief Valve

07382814

1

13

Temperature Sensor

3900028316G

1

14

Transformer

4311027001

1

15

Terminal Board

42011051

1

16

Terminal Board

42010249

1

17

Thermostat

4504800201

1

18

Terminal Board

42011255

1

19

Terminal Board

42011254

1

20

Main Board

30223000120

1

21

Bipolar AC Contactor

44010221

3

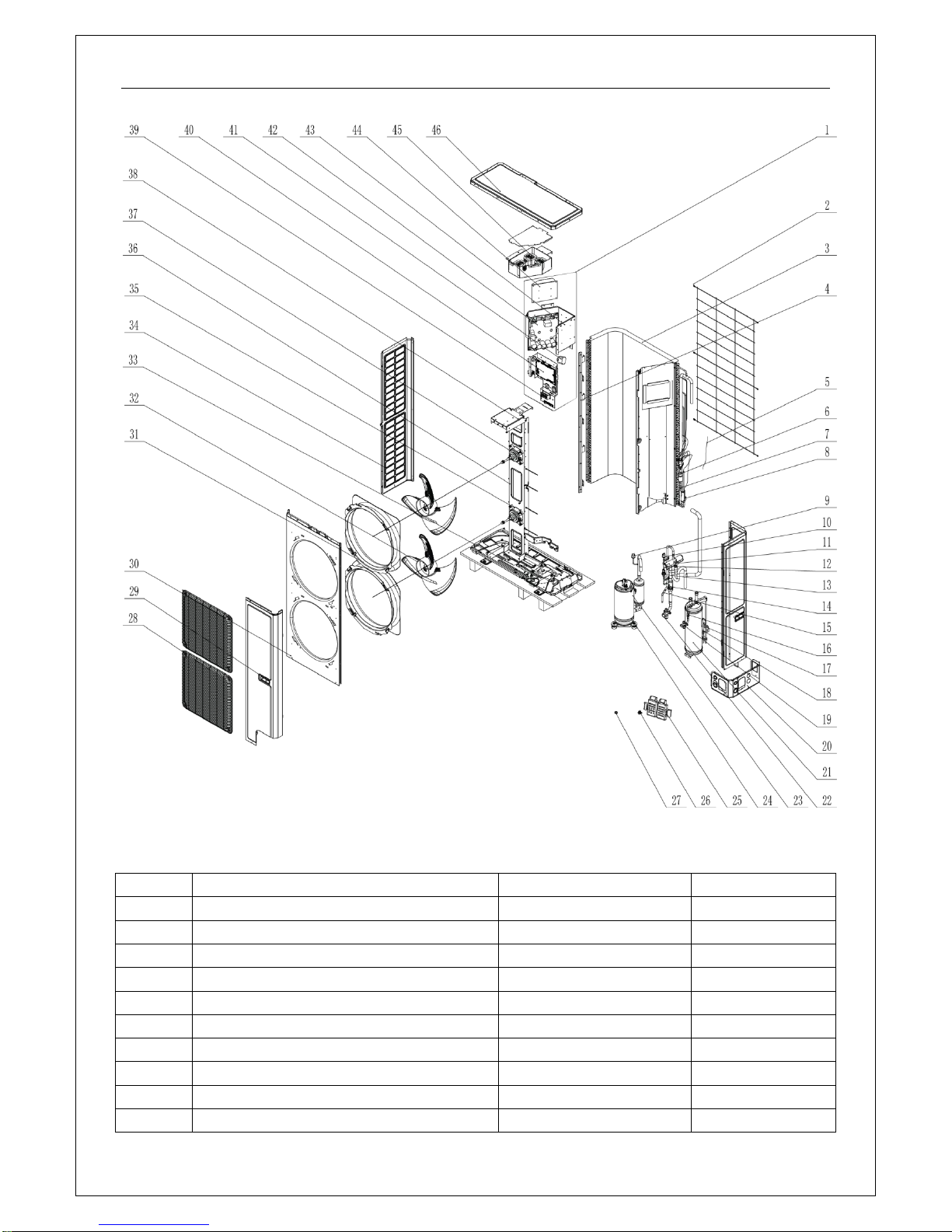

(4) GRS-CQ12Pd/NaE-K(O),GRS-CQ14Pd/NaE-K(O) ,GRS-CQ16Pd/NaE-K(O).

Parts List of GRS-CQ12Pd/NaE-K(O) for ER010W1280, GRS-CQ14Pd/NaE-K(O) for

ER010W1270, GRS-CQ16Pd/NaE-K(O) for ER010W1260.

No.

Name of part

Part Code

Quantity

Product

20

1

Electric Box Assy

01392800230

1

2

Rear Grill

01574100004

1 3 Condenser Sub-Assy

0115410000802

1 4 Supporting Strip(Condenser)

01894100026

1

5

Capillary tube

81020167

4

6

Silencer

07245012

1

7

Strainer

0721212101

1 8 Temp Sensor Sleeving

05212423

2 9 Pressure Protect Switch

46020006

1

10

Pressure Protect Switch

46020007

1

11

Magnet Coil

4300040032

1

12

4-Way Valve

43040000002

1

13

Sensor (High Pressure)

322101032

1

14

Strainer

07210037

1

15

Temp Sensor Sleeving

05210001

1

16

Strainer

0721200102

1

17

Electric Expand Valve Fitting

4304413221

1

18

Electronic Expansion Valve

43044100172

1

19

Cut off Valve

07330000002

1

20

Gas-liquid Separator

07424100014

1

21

Right Connection Board

01344100003P

1

22

Cut off Valve

07334100016

1

23

Compressor and Fittings

00204100001

1

24

Electrical Heater(Compressor)

7651521216

1

25

Compressor Gasket

76710247

3

26

Sensor Support

26905202

1

27

Drainage Connecter

06123401

1

28

Drainage hole Cap

06813401

3

29

Front Grill

01574100009

2

30

Handle

26235253

2

31

Cabinet

01514100002P

1

32

Diversion Circle

10474100001

2

33

Axial Flow Fan

10338731

2

34

Left Side Plate

01314100013P

1

35

Electrical Heater

765100047

1

36

Brushless DC Motor

15704100013

1

37

Motor Support

01805200243

1

38

Brushless DC Motor

1570410001301

1

39

Motor Support Sub-Assy

01805200244

1

40

Terminal Board

42011242

1

41

Main Board

30227000038

1

42

Filter Board

30226000065

1

43

Main Board

300027000068

1

44

Filter Board

300020000003

1

Product

21

45

Inductance

43120122

1

46

Inductance Assy

01394100050

1

47

Radiator

49018000013

1

48

Coping

01264100008P

1

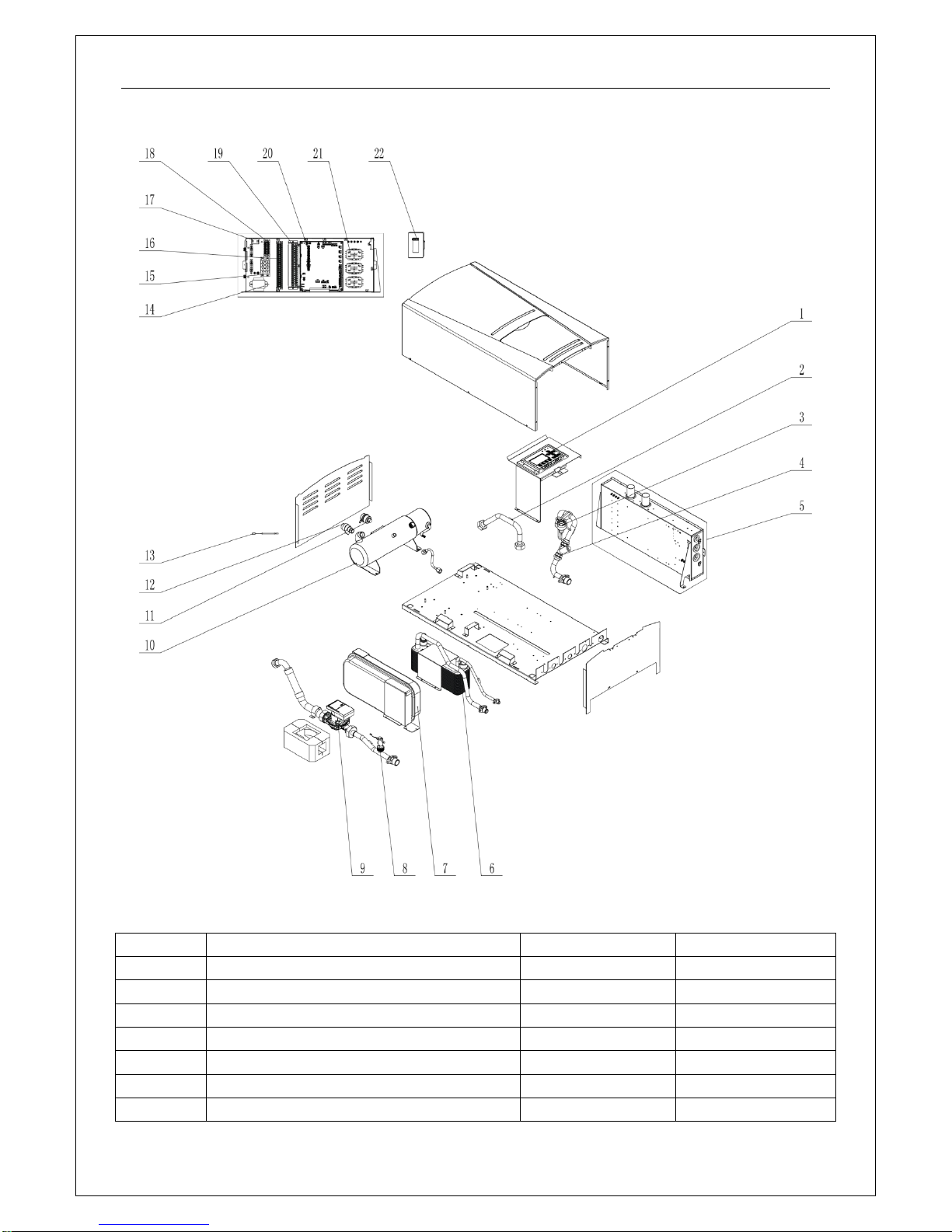

(5) GRS-CQ12Pd/NaE-M(I),GRS-CQ14Pd/NaE-M(I) ,GRS-CQ16Pd/NaE-M(I).

Parts List of GRS-CQ12Pd/NaE-M(I) for ER010N1250, GRS-CQ14Pd/NaE-M(I) for ER010N1240,

GRS-CQ16Pd/NaE-M(I) for ER010N1230.

No.

Name of part

Part Code

Quantity 1 Display Board

30292000047

1

2

Temp Sensor Sleeving

05212423

5 3 Water Pressure Gauge

49028009

1

Product

22

4

Strainer

07412808

1 5 Electric Box Assy

100002000197

1 6 Plate-type Heat Exchanger

00902800030

1 7 Expansion Drum

07422800004

1 8 Steam current Switch sub- Assy

45028062

1

9

Water Pump

812007000002

1

10

Temperature Sensor

3900028316G

1

11

Electric Heater

32000004

1

12

Relief Valve

07382814

1

13

Auto Air Outlet Valve

07108208

1

14

Terminal Board

42011051

1

15

Terminal Board

42011135

1

16

Thermostat

4504800201

1

17

Terminal Board

42011103

1

18

Terminal Board

42010249

1

19

Terminal Board

42011254

1

20

Main Board

30223000120

1

21

AC Contactor

44010232

2

22

Transformer

4311027001

1

23

Receiver Board

30261014

1

1

Display Board

30292000047

1 2 Temp Sensor Sleeving

05212423

5 3 Water Pressure Gauge

49028009

1

4

Strainer

07412808

1 5 Electric Box Assy

100002000197

1 6 Plate-type Heat Exchanger

00902800030

1 7 Expansion Drum

07422800004

1 8 Steam current Switch sub- Assy

45028062

1

9

Water Pump

812007000002

1

10

Temperature Sensor

3900028316G

1

11

Electric Heater

32000004

1

12

Relief Valve

07382814

1

13

Auto Air Outlet Valve

07108208

1

14

Terminal Board

42011051

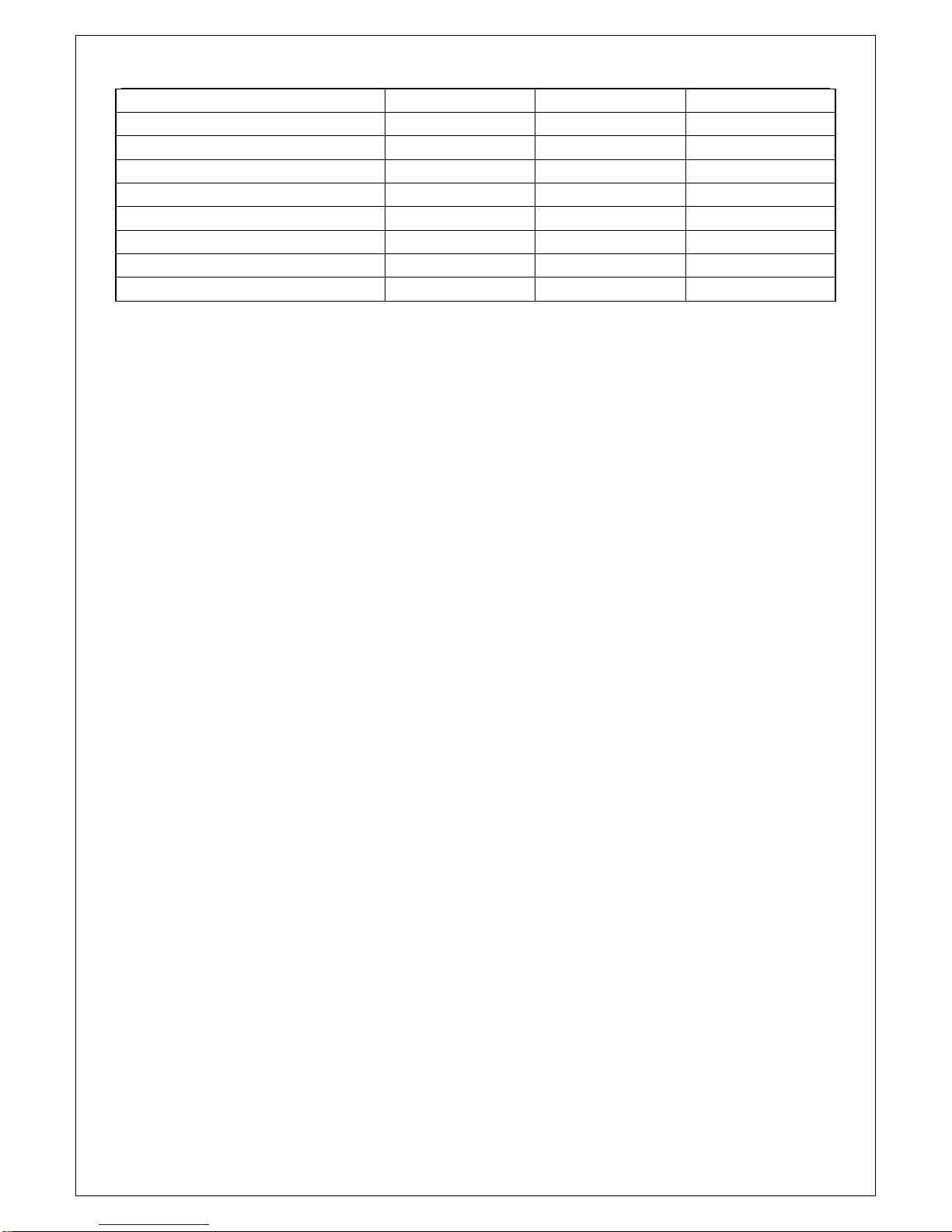

1

15

Terminal Board

42011135

1

16

Thermostat

4504800201

1

17

Terminal Board

42011103

1

18

Terminal Board

42010249

1

19

Terminal Board

42011254

1

20

Main Board

30223000120

1

21

AC Contactor

'44010232

2

22

Transformer

4311027001

1

23

Receiver Board

30261014

1

Product

23

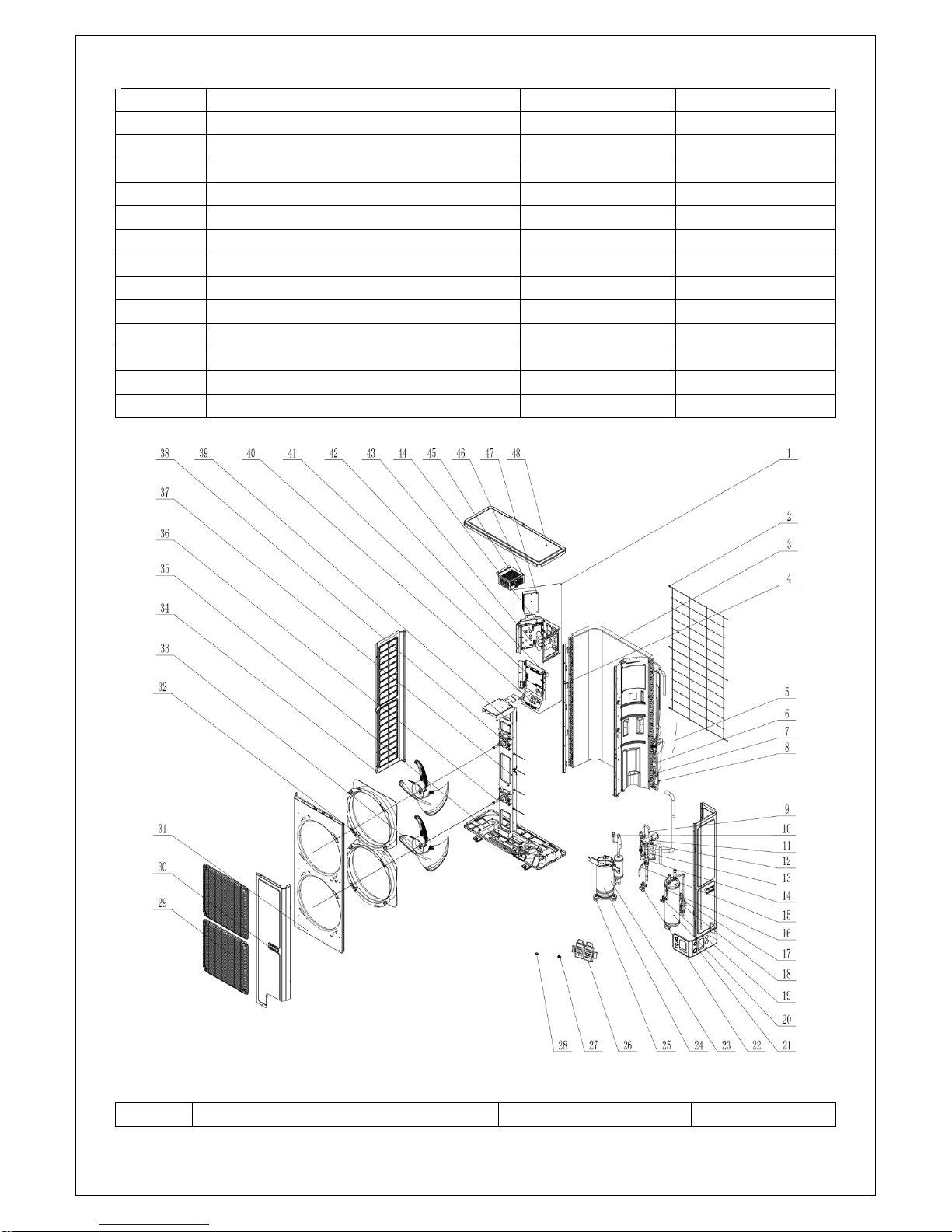

(6) GRS-CQ12Pd/NaE-M(O),GRS-CQ14Pd/NaE-M(O) ,GRS-CQ16Pd/NaE-M(O).

Parts List of GRS-CQ12Pd/NaEM(O) for ER010W1250, GRS-CQ14Pd/NaE-M(O) for

ER010W1240, GRS-CQ16Pd/NaE-M(O) for ER010W1230.

No.

Name of part

Part Code

Quantity 1 Electric Box Assy

100002000085

1

2

Rear Grill

01574100004

1

3

Condenser Assy

000100000009

1

4

Supporting Strip(Condenser)

01894100026

1

5

Capillary tube

81020167

4

6

Silencer

07245012

1

7

Strainer

0721212101

1

8

Temp Sensor Sleeving

05212423

2

9

Pressure Protect Switch

46020007

1

10

Pressure Protect Switch

46020006

1

Product

24

11

Magnet Coil

4300040032

1

12

4-Way Valve

43040000002

1

13

Pressure Sensor(High Pressure)

322101038

1

14

Strainer

07210037

1

15

Temp Sensor Sleeving

05210001

1

16

Strainer

0721200102

1

17

Electric Expand Valve Fitting

4304413221

1

18

Electronic Expansion Valve

43044100172

1

19

Cut off Valve

07330000002

1

20

Right Connection Board

01344100003P

1

21

Gas-liquid Separator

07424100014

1

22

Cut off Valve

07334100016

1

23

Compressor and Fittings

00204100018

1

24

Electrical Heater(Compressor)

7651521216

1

25

Sensor Support

26905202

1

26

Drainage Connecter

06123401

1

27

Drainage hole Cap

06813401

3

28

Front Grill

01574100009

2

29

Handle

26235253

2

30

Cabinet

01514100002P

1

31

Diversion Circle

10474100001

2

32

Axial Flow Fan

10338731

2

33

Electrical Heater

765100047

1

34

Left Side Plate

01314100013P

1

35

Brushless DC Motor

15704100013

1

36

Motor Support

01805200243

1

37

Brushless DC Motor

1570410001301

1

38

Motor Support Sub-Assy

01805200244

1

39

Terminal Board

42011221

1

40

Main Board

30227000038

1

41

Inductance

43128000014

1

42

Main Board

30223000038

1

43

Filter Board

30223000044

1

44

Radiator

49018000087

1

45

Reactor

43130192

3

46

Coping

01264100008P

1

4 Supply Scope

S= Standard O= Optional F= Field Supplied

Name

Standard

Optional

Field Supplied

Owner's Manual for the Main Unit

√ / /

Owner’s Manual for the Control

√ / /

Product

25

2-way Valve

/ / √

3-way Valve

/

/

√

Remote Temperature Sensor

√ / /

Wired Controller

√ / /

Communication Cable

√ / /

Water Tank Temperature Sensor

√ / /

Expansion Bolt

√ / /

Solar System Water Pump

/

√ / Solar System Flow Switch

/

√

/

Loading...

Loading...