Page 1

Technical Product Guide

+Multi Zone Inverter

Heat Pump Systems

World Class Comfort

Page 2

Table of Contents

+Multi Product Overview............................ 2

+Multi Outdoor Units ............................... 6

+Multi Neo Wall Mount Units ....................... 35

+Multi Ceiling Cassettes ...........................43

+Multi Slim Concealed Ducts .......................54

+Multi Universal Floor/Ceiling ......................69

+Multi Mini-Floor Consoles ......................... 78

+Multi Wired Tether Controller......................86

Refer to individual listings within each of the above sections, for specific page references for:

Product Nomenclature, Features and Benefits, Product Performance Data, Dimensional Specifications,

Clearance Specifications, Electrical Wiring, Condensate Removal, Indoor Unit Combinations.

Page 3

PRODUCT OVERVIEW

SUPERIOR DESIGNS PROVIDE EASY SOLUTIONS TO COMPLEX PROBLEMS

GREE Ductless Multi Zone systems provide quiet comfort and energy ecient heating and cooling in up to

five dierent rooms – without ductwork. For most residential and light commercial applications, this is the ideal

solution to balance comfort, eciency and ease of installation. This Inverter-driven system oers Seasonal

Energy Eciency Ratings (SEER) up to 16. With individual room control and variable speed compressor

operation, comfort is boosted throughout your home or oce, while utility bills are held in check.

Gree’s exclusive G-10 Inverter technology powers the twin rotary compressor inside the Multi Zone

outdoor compressor section. The G-10 Inverter constantly adjusts the compressor speed to maintain

a comfortable room temperature. This saves energy, reduces outdoor noise and maintains a steady

room temperature by eliminating the harsh starts and stops of conventional systems.

When laying out a new project, you’ll appreciate the flexibility of Gree’s Multi Zone Systems. A single outdoor unit

can simultaneously power up to five indoor units while eliminating expensive ductwork. Without those ducts, your

installation is simpler, faster and more cost-eective. And the flexibility doesn’t stop there, as you can also mix

and match your choice of Wall Mount, Ceiling Cassette, Concealed Duct, Universal Floor/Ceiling and Mini Floor

Console indoor units to create a unique heating and cooling system to perfectly fit any project.

No pipe sweating

No sweating is needed for the pipe connection

between the indoor and outdoor units. All

piping connections are flared to simplify and

ease the piping installation.

Simple Wiring

No special or hard-to-find communication

wire is needed between the indoor and

outdoor units. The system uses common

14-4 AWG stranded copper THHN 600V

wire. The system’s communication is ready

as soon as the electrical wiring between the

indoor and outdoor units is complete.

High Lift Design

Gree’s High Lift design allows for extended

piping length, up to 262 feet total, as well as

50 feet of vertical lift from the condensing

units. This allows for greater flexibility in the

layout of the system.

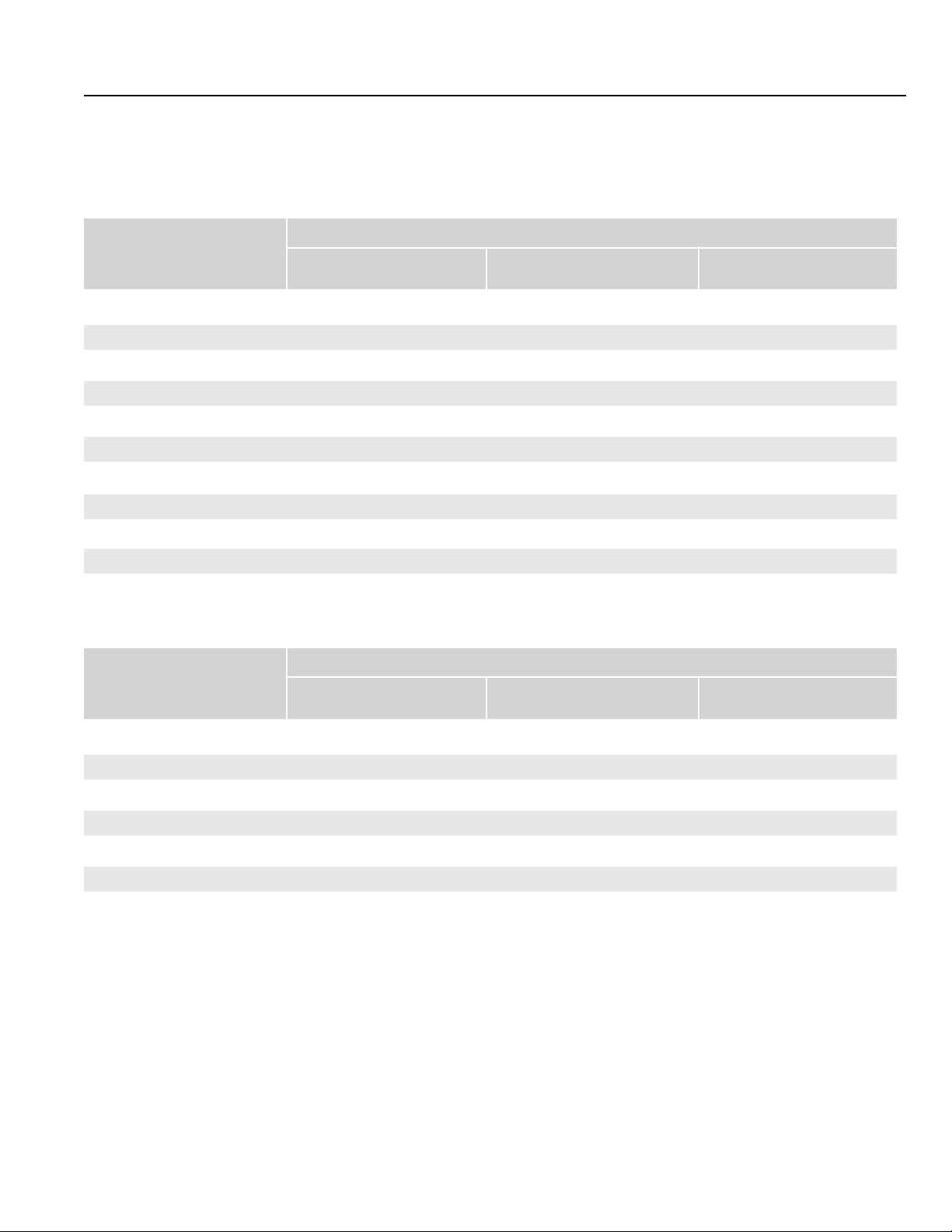

Outdoor Unit

Power

Supply

1st Branching

Section

Indoor Unit

Transmission System

From Outdoor Unit to

the Indoor Unit:

82ft

82ft

Between Indoor Units:

Height Dierence

50ft

and Outdoor Unit:

50ft

Between Indoor Unit

Height Dierence

Allows up to 262 feet of pipe length

Energy Saving

Multi Zone systems allow each room to be individually controlled. Only those rooms requiring air

conditioning (or heating) are cooled (or heated), and all of it is accomplished without ductwork.

In addition, Gree’s G-10 inverter technology reduces energy waste, maximizes eciency and

achieves up to 16 SEER.

2

Page 4

PRODUCT OVERVIEW

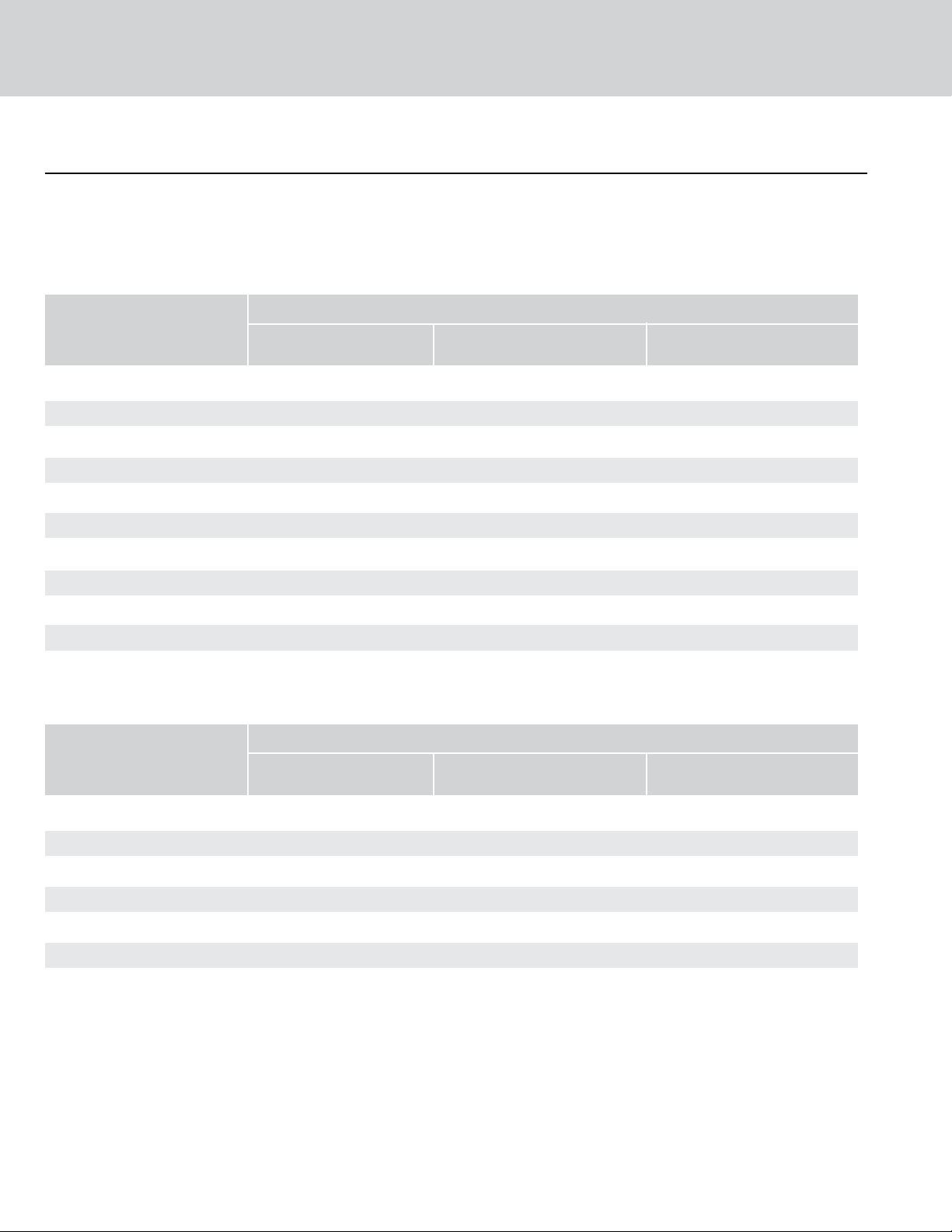

Self-Diagnostics System

Each indoor and outdoor unit continuously runs

a series of multi-point diagnostic tests on the

system, to automatically scan for unacceptable

operating conditions or malfunctions. If such

conditions occur, the system takes corrective

action or stops. The fault code will be shown

on the indoor, outdoor and wired controller displays.

Problems and system status are displayed with

comprehensive diagnostic codes to simplify system

troubleshooting and shorten repair times.

Flexible Design

Gree’s Multi Zone systems have many advantages

for both the property owner and the installer.

Up to five indoor units, powered by a single

outdoor unit, results in flexible zoning solutions

for almost any application. Various styles of

indoor units may be mixed and matched in any

combination to create a unique, multiple zone

heating and cooling system. Choose from Wall

Mount, Ceiling Cassette, Slim Duct, Universal

Floor/Ceiling and Mini Floor Console indoor units.

All are lightweight and compact enough to be

installed on the wall or in any ceiling space.

Diagnostic

Code

E1

E2

E3

E4

E5

E6

E7

E9

F4

Malfunction

Compressor High Pressure Protection

Indoor Coil Anti-Freeze Protection

Low Pressure Protection

High Discharge Temperature Protection

Compressor High Temperature Protection

Indoor/Outdoor Communication Failure

Heating & Cooling Modes Conflict

Condensate Water Too High

Outdoor Coil Sensor Failure

One outdoor unit

can power up to

5 indoor units.

Intelligent Control

Gree’s Multi Zone components use state-of-the

art intelligent controls to generate the ultimate

in room comfort. G-10 Inverter technology

delivers the exact level of required capacity (from

10% to 100%) to maintain room temperature and

humidity in the comfort range. The optimized PID

controls maintain the room temperature within

less than ±1.0°F of the room setpoint temperature.

The result is a virtually constant room temperature

without the typical fluctuations that occur with a

conventional fixed speed ON/OFF system.

Ductless Saves Money

Realize energy savings by eliminating heat loss

from inecient and leaky ductwork. The average

ducted air distribution system could reduce

overall system eciency by up to 30 percent.

Eliminating ductwork allows you to downsize

equipment while upsizing performance.

Cooling

Gree Inverter Control System

Conventional Fixed Speed System

Room temp.

3

Page 5

MULTI OUTDOOR UNITS

Models:

MULTI18HP230V1AO

MULTI24HP230V1AO

MULTI30HP230V1AO

MULTI36HP230V1AO

MULTI42HP230V1AO

Page 6

+Multi Outdoor Units

Table of Contents

Features and Benefits ..............................6-7

Product Nomenclature/AHRI Certification .............. 8

Product Performance Data .........................9-13

Dimensional Specifications........................14-16

Clearance Specifications.............................17

Electrical Wiring.................................18-19

Condensate Removal................................19

Indoor Unit Combinations........................ 20-28

Extended Performance Ratings ................... 29-33

Page 7

+Multi Outdoor Units

Each +Multi heat pump is powered by Gree’s energy ecient G-10 Inverter and a variable speed compressor. These units can

heat and cool up to five zones without distribution boxes, and all oer the G-10 advantages of energy savings, noise reduction

and room temperature consistency. Each outdoor coil also features a corrosion-resistant Gold Fin coating to withstand corrosive

environments and to further promote energy eciency.

FEATURES AND BENEFITS

High Eciency G-10 Inverter

The G-10 Inverter uses a broad range of variable frequencies to drive the compressor, marking the

highest level of inverter control technology available today. Unlike conventional technology that

generally regulates room temperature by running at maximum capacity and then shutting o

completely, G-10 Inverter technology eliminates these harsh starts/stops. This cutting edge functionality

results in quicker arrival at desired temperatures and superior maintenance of consistent comfort

levels. Higher eciency and significant energy savings? Yes, it yields those too.

Heat Pump Advantage

Multi Zone heat pumps, powered by the G-10 Inverter, provide the same heating capacity as electric

heat, while using as little as 1/3 the electricity.

Intelligent Defrost

The Intelligent Defrost function increases room comfort and saves energy by eliminating unnecessary

defrost cycles. In heating mode, the control system monitors the outdoor coil for frost buildup,

and the system switches to defrost mode only when frost buildup is actually detected. This avoids

unnecessary and wasteful defrosts.

Time Guard

Among the system’s many safeties is a Time Guard function to prevent rapid cycling of the compressor.

A protective three-minute time delay restricts compressor restarts after shuto.

Gold Fin Condenser

The system’s corrosion-resistant Gold Fin condenser coating (1500hr salt spray rating) is made with

a gold-colored anti-corrosion epoxy. This technology maintains excellent heat transfer properties

while extending coil life against damage from salt air and salt water in seacoast installations.

6

Page 8

FEATURES AND BENEFITS

Low Voltage Start Up

Having stable electrical power is not always an option. The Gree Multi Zone units will operate from

170v to 265v which is suitable for unstable power supply areas.

Self-Diagnosis

With an on-board computer using real-time diagnostics, the Gree Multi Zone system helps to

prolong its own life. The automatic diagnosis feature continuously scans for unacceptable operating

conditions or malfunctions. If such conditions occur, the system takes corrective action or stops.

Fault codes are shown on the unit display to facilitate easy troubleshooting and repair.

Agency Listings

All systems are listed with AHRI (Air conditioning, Heating, and Refrigeration Institute) and are

ETL Certified per standards.

7/5 Year Limited Warranty

Enjoy one of the most comprehensive warranties in the industry. Seven (7) years

on compressor and Five (5) years on all parts.

7

Page 9

+Multi Outdoor Units

NOMENCLATURE

Series Designation

MULTI - Multi Zone

Cooling Capacity

18 - 18,000 BtuH

24 - 24,000 BtuH

30 - 30,000 BtuH

36 - 36,000 BtuH

42 - 42,000 BtuH

Model Type

AC - Cooling Only

HP - Heat Pump

HC - Heat/Cool

MULTI 42 1 A O

HP 230V

Product Type

S - System

O - Outdoor Units

H - Indoor High Wall

D - Indoor Duct

C - Indoor Cassette

F - Indoor Floor/Ceiling

Revision Level

Style/Color Designation

Electrical Rating

230V - 208/230V 60Hz 1PH

115V - 115V 60Hz 1PH

AHRI CERTIFICATION

MODEL NUMBER BRAND AHRI CERTIFICATION

MULTI18HP230V1AO GREE 7084754

MULTI24HP230V1AO GREE 7084908

MULTI30HP230V1AO GREE 7084759

MULTI36HP230V1AO GREE 7084898

MULTI42HP230V1AO GREE 7084899

MULTI48HP230V1AO GREE 7117354

MULTI56HP230V1AO GREE 7117355

8

Page 10

PERFORMANCE SPECIFICATIONS

Cooling

COOLING CAPACITY

MODEL NUMBER SEER EER

MULTI18HP230V1A 16 10.2 18,000 (7,000-21,000) 23 °F 118 °F

MULTI24HP230V1A 16 8.2 26,000 (7,500-33,000) 23 °F 118 °F

MULTI30HP230V1A 16 7.3 29,000 (7,500-34,000) 23 °F 118 °F

MULTI36HP230V1A 16 8.0 34,000 (8,530-34,120) 23 °F 118 °F

MULTI42HP230V1A 16 9.3

RATED

(BtuH) MIN

,000

40

RANGE

(BtuH)

(8,530-46,403) 23 °F 118 °F

OUTDOOR TEMP

OPERATING RANGE

MAX

Heating

HEATING CAPACITY

MODEL NUMBER HSPF

MULTI18HP230V1A 8.2 19,000 (8,530-22,600) 5 °F 80 °F

MULTI24HP230V1A 8.2 29,000 (7,500-35,000) 5 °F 80 °F

RATED

(BtuH) MIN

RANGE

(BtuH)

OUTDOOR TEMP

OPERATING RANGE

MAX

MULTI30HP230V1A 8.2

MULTI36HP230V1A 8.2 35,800 (10,663-40,944) 5 °F 80 °F

MULTI42HP230V1A 8.2 44,500 (10,663-47,768) 5 °F 80 °F

Notes:

1.

Ratings are based on: Cooling Standard: 80°F (26.7°C) db, 67°F (19.4°C) wb air entering indoor unit and 95°F (35°C) db air entering

outdoor unit. Heating Standard: 70°F (21.1°C) db air entering indoor unit and 47°F (8.3°C) db, 43°F (6.1°C) wb air entering outdoor unit.

2. Ratings are based on 25 ft. (7.62 m) of interconnecting refrigerant lines.

3. All system ratings are based on fan coil units operating at high fan speed. Consult Physical Data tables for air flows at selected fan speeds.

Legend:

EER - Energy Eciency Ratio

HSPF - Heating Seasonal Performance Ratio

SEER - Seasonal Energy Eciency Ratio

30

,400

(7,500-36,000) 5 °F 80 °F

NUMBER OF PORTS

MODEL NUMBER BRAND

MULTI18HP230V1AO EXV 2

MULTI24HP230V1AO EXV 3

MULTI30HP230V1AO EXV 4

MULTI36HP230V1AO EXV 4

FOR INDOOR UNITS

MULTI42HP230V1AO EXV 5

9

Page 11

+Multi Outdoor Units

AIR FLOW DATA

Outdoor Unit

MODEL NUMBER

MULTI18HP230V1A 1,530

MULTI24HP230V1A 1,530

MULTI30HP230V1A 1,530

MULTI36HP230V1A 2,177

MULTI42HP230V1A 3,237

SOUND DATA

Outdoor Unit

MODEL NUMBER SOUND POWER SOUND PRESSURE

MULTI18HP230V1A 66 dBA 56 dBA

MULTI24HP230V1A 66 dBA 56 dBA

MULTI30HP230V1A 66 dBA 56 dBA

MULTI36HP230V1A 69 dBA 59 dBA

AIR FLOW (CFM)

MULTI42HP230V1A 68 dBA 58 dBA

Note:

1. Sound pressure ratings are estimated sound pressure measurements, 3 feet from unit.

2. Sound power ratings are per AHRI 270 and AHRI 350.

PRODUCT WEIGHT

MODEL NUMBER

MULTI18HP230V1A 95 lbs. 106 lbs.

MULTI24HP230V1A 135 lbs. 146 lbs.

MULTI30HP230V1A 153 lbs. 165 lbs.

MULTI36HP230V1A 161 lbs. 172 lbs

MULTI42HP230V1A 225 lbs. 247 lbs.

PRODUCT WEIGHT

NET OPERATING GROSS SHIPPING

10

Page 12

REFRIGERATION SPECIFICATIONS & DATA

Refrigerant Charge

MODEL NUMBER

MULTI18HP230V1A R-410A 48 oz. 33 ft. 0.2 oz./ft.

MULTI24HP230V1A R-410A 78 oz. 98 ft. 0.2 oz./ft.

MULTI30HP230V1A R-410A 78 oz. 131 ft. 0.2 oz./ft.

MULTI36HP230V1A R-410A 102 oz. 131 ft. 0.2 oz./ft.

MULTI42HP230V1A R-410A 169 oz. 164 ft. 0.2 oz./ft.

TYPE

REFRIGERANT

FACTORY

SYSTEM

CHARGE

MAX TOTAL PIPE

LENGTH W/O ADDING

REFRIGERANT

ADDITIONAL

CHARGE

LEVEL

PIPING LENGTH REQUIREMENTS

L = L1

L2

+ + +

L

S

L

=L1 + L2 + ......L

TOTAL

n

...Ln

Refrigerant Piping Lengths

IN PIPE LENGTH

M

MODEL NUMBER

PER INDOOR

UNIT (Ln)

MULTI18HP230V1A 10 ft. 33 ft. 66 ft.

MULTI24HP230V1A 10 ft. 66 ft. 230 ft.

MULTI30HP230V1A 10 ft. 66 ft. 230 ft.

MULTI36HP230V1A 10 ft. 82 ft. 230 ft.

MULTI42HP230V1A 10 ft. 82 ft. 262 ft.

MAX PIPE

LENGTH PER

INDOOR UNIT (L

)

n

MAX TOTAL PIPE

LENGTH PER

INDOOR UNIT (L

TOTAL

)

11

Page 13

+Multi Outdoor Units

PIPING HEIGHT REQUIREMENTS

H2

H1

L1

L2

L3

Refrigerant Piping Height

MAX ELEVATION

MODEL NUMBER

MULTI18HP230V1A 33 ft. 16 ft.

MULTI24HP230V1A 66 ft. 25 ft.

MULTI30HP230V1A 66 ft. 25 ft.

MULTI36HP230V1A 82 ft. 25 ft.

MULTI42HP230V1A 82 ft. 25 ft.

BETWEEN OUTDOOR &

INDOOR UNITS (H1)

MAX ELEVATION

BETWEEN

INDOOR UNITS (H1)

...Ln

12

Page 14

ELECTRICAL DATA

Outdoor Unit

RATED POWER

MODEL NUMBER

SUPPLY

(volt-phase-hz)

MULTI18HP230V1A 208/230v-1ph-60hz 187-253 1.7 1.6

MULTI24HP230V1A 208/230v-1ph-60hz 187-253 3.1 2.8

MULTI30HP230V1A 208/230v-1ph-60hz 187-253 3.5 2.9

MULTI36HP230V1A 208/230v-1ph-60hz 187-253 4.3 3.6

MULTI42HP230V1A 208/230v-1ph-60hz 187-253 4.4 4.6

VOLTAGE

RANGE

(volts)

RATED INPUT POWER

(KW)

COOLING HEATING

Outdoor Unit

MODEL NUMBER

MULTI18HP230V1A 7.6 7.5 13 20

MULTI24HP230V1A 13.5 12.4 20 30

MULTI30HP230V1A 15.3 12.6 26 45

COOLING HEATING

RATED INPUT CURRENT (amps)

MIN CIRCUIT

AMP (MCA)

MAX FUSE

SIZE (amps)

MULTI36HP230V1A 19.2 15.8 28 45

MULTI42HP230V1A 19.5 20.5 29 50

Outdoor Unit

MODEL NUMBER

MULTI18HP230V1A 9.6 27 0.5 1/12 60

MULTI24HP230V1A 14.7 45 0.6 1/12 60

MULTI30HP230V1A 19.6 45 0.6 1/12 60

MULTI36HP230V1A 21.0 45 0.7 1/8 120

MULTI42HP230V1A 21.5 67 1.1 1/6 140

Legend: RLA – Rated Load Amps HP – Horse Power

RLA (amps) LRA (amps)

RLA (amps) HP INPUT POWER

COMPRESSOR

OUTDOOR FAN

(watts)

13

Page 15

+Multi Outdoor Units

DIMENSIONAL SPECIFICATIONS

Model No: MULTI18HP230V1A 18,000 BtuH

Suction/Gas Line Port Size

Port A 3/8-in OD Flared

Port B 3/8-in OD Flared

Liquid Line Port Size

Port A 1/4-in OD Flared

Port B 1/4-in OD Flared

Model No: MULTI24HP230V1A 24,000 BtuH

Suction/Gas Line Port Size

Port A 3/8-in OD Flared

Port B 3/8-in OD Flared

Port C 3/8-in OD Flared

Liquid Line Port Size

Port A 1/4-in OD Flared

Port B 1/4-in OD Flared

Port C 1/4-in OD Flared

14

Page 16

DIMENSIONAL SPECIFICATIONS

Model No: MULTI30HP230V1A 30,000 BtuH

Suction/Gas Line Port Size

Port A 3/8-in OD Flared

Port B 3/8-in OD Flared

Port C 3/8-in OD Flared

Port D 3/8-in OD Flared

Liquid Line Port Size

Port A 1/4-in OD Flared

Port B 1/4-in OD Flared

Port C 1/4-in OD Flared

Port D 1/4-in OD Flared

Model No: MULTI36HP230V1A 36,000 BtuH

Suction/Gas Line Port Size

Port A 3/8-in OD Flared

Port B 3/8-in OD Flared

Port C 1/2-in OD Flared

Port D 5/8-in OD Flared

Liquid Line Port Size

Port A 1/4-in OD Flared

Port B 1/4-in OD Flared

Port C 1/4-in OD Flared

Port D

3/8-in OD Flared

15

Page 17

+Multi Outdoor Units

DIMENSIONAL SPECIFICATIONS

Model No: MULTI42HP230V1A 42,000 BtuH

Suction/Gas Line Port Size

Port A 3/8-in OD Flared

Port B 3/8-in OD Flared

Port C 1/2-in OD Flared

Port D 1/2-in OD Flared

Port E 5/8-in OD Flared

Liquid Line Port Size

Port A 1/4-in OD Flared

Port B 1/4-in OD Flared

Port C 1/4-in OD Flared

Port D 1/4-in OD Flared

Port E

3/8-in OD Flared

16

Page 18

MINIMUM OUTDOOR CLEARANCE SPECIFICATIONS

The unit installation must meet or exceed the following minimum clearances for proper operation.

A

BD

C

Air Outlet

Outdoor Unit Minimum Distance

A 20 in

B 24 in

C 78 in

D 12 in

E 20 in

Air Inlet

E

17

Page 19

+Multi Outdoor Units

ELECTRICAL WIRING

The main power is supplied to the outdoor unit. System must be on a single dedicated circuit. Use appropriate

wire size and circuit breaker (or fuse) size for proper system overcurrent protection. Follow all local building

codes and NEC (National Electrical Code) regulations.

Interconnecting Cable Wiring Diagram

The indoor units are powered by the outdoor unit. The interconnecting cable between the outdoor and indoor

units must be a 14/4 AWG stranded copper conductors THHN 600V unshielded wire. The interconnecting cable

should not be buried underground and must be recognized by UL or ETL and CSA certified.

Note: Use shield cable if installation is in close proximity of RF and EMI transmitting devices.

18

Page 20

ELECTRICAL WIRING

Local codes may require a disconnect switch within sight of the indoor unit. For these installations, use

a DFS Disconnect Switch Accessory Kit (Part No: DFS-SWITCH-A) to break wires going to the N(1), 2, 3,

terminals on the indoor unit, as shown in the wiring diagram below:

Interconnecting Cable with Disconnect Switch Wiring Diagram

CONDENSATE REMOVAL

Install condensate drain to bottom of outdoor unit to safely and eectively route condensate water to a

safe location. Use a flexible condensate drain hose to fit over the factory 5/8-inch (16mm) drainage port.

The high wall indoor units have an internal condensate trap. Adding an external trap is not required.

All condensate drains must meet local codes and regulations. If adequate gravity drainage cannot be

provided, a field-installed condensate pump must be used. Refer to manufacturer’s installation instructions,

specifications and operating details supplied with condensate pump.

19

Page 21

+Multi Outdoor Units

INDOOR UNIT COMBINATIONS

SELECTION CRITERIA

When selecting a variable speed system, match the system capacity to the calculated load of the building.

Since a variable speed system can accommodate a wide range of loads, it is important to understand the

percentage of time that the system will be required to run at both maximum and minimum load points.

Generally there will be more load diversification in residential applications (shifting from low load to high

load). Commercial applications tend to be more steady during normal daytime hours, and go to low load

levels after hours. The tables below are guidelines for selecting the proper size.

Model No: MULTI18HP230V1A 18,000 BtuH

Cooling Capacity (BtuH)

INDOOR UNITS

COMBINATIONS

9K 9,000 5,118~11,940 9,000

12K 12,000 6,824~15,000 12,000

9K+9K 18,000 7,000~21,000 9,000 9,000

9K+12K 21,000 7,100~22,000 9,000 12,000

12K+12K 24,000 7,200~22,000 12,000 12,000

RATED SYSTEM

CAPACITY

(BtuH)

CAPACITY RATING

(MIN – MAX)

(BtuH)

INDOOR

UNIT A

(BtuH)

INDOOR

UNIT B

(BtuH)

Heating Capacity (BtuH)

INDOOR UNITS

COMBINATIONS

9K 9,500 5,460~15,360 9,500

12K 13,000 6,150~16,400 13,000

9K+9K 19,000 8,530~22,600 9,500 9,500

9K+12K 22,500 8,530~22,600 9,500 13,000

RATED SYSTEM

CAPACITY

(BtuH)

CAPACITY RATING

(MIN – MAX)

(BtuH)

INDOOR

UNIT A

(BtuH)

INDOOR

UNIT B

(BtuH)

12K+12K 26,000 8,530~22,600 13,000 13,000

Note: It is critical to size the outdoor unit for the entire building load and each indoor unit for its individual zone load.

Capacity data is based on the following conditions:

Cooling Nominal Test Conditions Heating Normal Test Conditions

Indoor: 80°F DB/67°F WB Indoor: 70°F DB/60°F WB

Outdoor: 95°F DB/75°F WB Outdoor: 47°F DB/43°F W

20

Page 22

INDOOR UNIT COMBINATIONS

Model No: MULTI24HP230V1A 24,000 BtuH

Cooling Capacity (BtuH)

INDOOR UNITS

COMBINATIONS

9K+9K 18,000 6,824~26,600 9,000 9,000

9K+12K 21,000 7,165~27,300 9,000 12,000

12K+12K 24,000 7,200~30,000 12,000 12,000

9K+18K 25,000 7,300~32,000 8,400 16,600

12K+18K 25,000 7,400~32,500 10,000 15,000

18K+18K 25,500 7,500~32,500 12,750 12,750

9K+9K+9K 26,000 7,500~34,000 8,667 8,667 8,667

9K+9K+12K 26,000 7,500~34,000 8,000 8,000 10,000

9K+12K+12K 26,000 7,500~34,000 6,000 10,000 10,000

9K+9K+18K 26,000 7,500~34,000 7,000 7,000 12,000

12K+12K+12K 26,000 7,500~34,000 8,667 8,667 8,667

RATED SYSTEM

CAPACITY

(BtuH)

CAPACITY RATING

(MIN – MAX)

(BtuH)

INDOOR

UNIT A

(BtuH)

INDOOR

UNIT B

(BtuH)

INDOOR

UNIT C

(BtuH)

Heating Capacity (BtuH)

INDOOR UNITS

COMBINATIONS

RATED SYSTEM

CAPACITY

(BtuH)

CAPACITY RATING

(MIN – MAX)

(BtuH)

INDOOR

UNIT A

(BtuH)

INDOOR

UNIT B

(BtuH)

INDOOR

UNIT C

(BtuH)

9K+9K 19,000 71,00~33,000 9,500 9,500

9K+12K 22,500 7,100~33,500 9,500 13,000

12K+12K 26,000 7,200~34,000 13,000 13,000

9K+18K 27,000 7,300~34,000 9,000 18,000

12K+18K 28,000 7,400~34,000 11,200 16,800

18K+18K 28,500 7,400~34,400 14,250 14,250

9K+9K+9K 29,000 7,500~35,000 9,667 9,667 9,667

9K+9K+12K 29,000 7,600~35,000 9,000 9,000 11,000

9K+12K+12K 29,000 7,600~35,000 6,000 11,500 11,500

9K+9K+18K 29,000 7,600~35,000 6,000 6,000 17,000

12K+12K+12K 29,000 7,600~35,000 9,667 9,667 9,667

Note: It is critical to size the outdoor unit for the entire building load and each indoor unit for its individual zone load.

Capacity data is based on the following conditions:

Cooling Nominal Test Conditions Heating Normal Test Conditions

Indoor: 80°F DB/67°F WB Indoor: 70°F DB/60°F WB

Outdoor: 95°F DB/75°F WB Outdoor: 47°F DB/43°F W

21

Page 23

+Multi Outdoor Units

INDOOR UNIT COMBINATIONS

Model No: MULTI30HP230V1A 30,000 BtuH

Cooling Capacity (BtuH)

RATED

INDOOR UNITS

COMBINATIONS

9K+9K 18,000 6,824~26,600 9,000 9,000

9K+12K 21,000 7,165~27,300 9,000 12,000

12K+12K 24,000 7,200~30,000 12,000 12,000

9K+18K 25,000 7,300~32,000 8,400 16,600

12K+18K 25,500 7,400~32,500 10,000 15,000

18K+18K 26,000 7,500~32,500 12,750 12,750

9K+9K+9K 26,000 7,500~34,000 8,667 8,667 8,667

9K+9K+12K 26,000 7,500~34,000 8,000 8,000 10,000

9K+12K+12K 26,000 7,500~34,000 6,000 10,000 10,000

9K+9K+18K 26,000 7,500~34,000 7,000 7,000 12,000

12K+12K+12K 26,000 7,500~34,000 8,667 8,667 8,667

9K+12K+18K 27,000 7,500~34,000 6,800 7,200 13,000

12K+12K+18K 28,000 7,500~34,000 6,500 6,500 15,000

9K+9K+9K+9K 29,000 7,500~34,000 7,250 7,250 7,250 7,250

9K+9K+9K+12K 29,000 7,500~34,000 7,000 7,000 7,000 8,000

9K+9K+12K+12K 29,000 7,500~34,000 6,800 6,800 7,700 7,700

SYSTEM

CAPACITY

(BtuH)

CAPACITY

RATING

(MIN – MAX)

(BtuH)

INDOOR

UNIT A

(BtuH)

INDOOR

UNIT B

(BtuH)

INDOOR

UNIT C

(BtuH)

INDOOR

UNIT D

(BtuH)

Heating Capacity (BtuH)

RATED

INDOOR UNITS

COMBINATIONS

9K+9K 19,000 7,100~33,000 9,500 9,500

9K+12K 22,500 7,100~33,500 9,500 13,000

12K+12K 26,000 7,200~34,000 13,000 13,000

9K+18K 27,000 7,300~34,000 9,000 18,000

12K+18K 28,000 7,400~34,000 11,200 16,800

18K+18K 28,500 7,400~34,400 14,250 14,250

9K+9K+9K 29,000 7,500~35,000 9,667 9,667 9,667

9K+9K+12K 29,000 7,600~35,000 9,000 9,000 11,000

9K+12K+12K 29,000 7,600~35,000 6,000 11,500 11,500

9K+9K+18K 29,000 7,600~35,000 6,000 6,000 17,000

12K+12K+12K 29,000 7,600~35,000 9,667 9,667 9,667

SYSTEM

CAPACITY

(BtuH)

CAPACITY

RATING

(MIN – MAX)

(BtuH)

INDOOR

UNIT A

(BtuH)

22

INDOOR

UNIT B

(BtuH)

INDOOR

UNIT C

(BtuH)

INDOOR

UNIT D

(BtuH)

Page 24

INDOOR UNIT COMBINATIONS

Model No: MULTI30HP230V1A 30,000 BtuH (cont.)

Heating Capacity (BtuH)

RATED

INDOOR UNITS

COMBINATIONS

9K+12K+18K 29,000 7,600~35,000 6,802 9,309 12,888

12K+12K+18K 29,000 7,600~35,000 8,567 8,567 11,862

9K+9K+9K+9K 30,500 7,600~36,000 7,625 7,625 7,625 7,625

9K+9K+9K+12K 30,500 7,600~36,000 7,100 7,100 7,100 9,200

9K+9K+12K+12K 31,000 7,600~36,000 6,500 6,500 9,000 9,000

Note: It is critical to size the outdoor unit for the entire building load and each indoor unit for its individual zone load.

Capacity data is based on the following conditions:

Cooling Nominal Test Conditions Heating Normal Test Conditions

Indoor: 80°F DB/67°F WB Indoor: 70°F DB/60°F WB

Outdoor: 95°F DB/75°F WB Outdoor: 47°F DB/43°F W

SYSTEM

CAPACITY

(BtuH)

CAPACITY

RATING

(MIN – MAX)

(BtuH)

INDOOR

UNIT A

(BtuH)

INDOOR

UNIT B

(BtuH)

INDOOR

UNIT C

(BtuH)

INDOOR

UNIT D

(BtuH)

Model No: MULTI36HP230V1A 36,000 BtuH

Cooling Capacity (BtuH)

INDOOR UNITS

COMBINATIONS

RATED

SYSTEM

CAPACITY

(BtuH)

CAPACITY

RATING

(MIN – MAX)

(BtuH)

INDOOR

UNIT A

(BtuH)

INDOOR

UNIT B

(BtuH)

INDOOR

UNIT C

(BtuH)

INDOOR

UNIT D

(BtuH)

9K+9K 17,060 10,236~26,614 8,530 8,530

9K+12K 20,472 10,236~27,297 8,530 12,283

9K+18K 24,226 10,236~31,391 7,506 16,719

9K+24K (2) 27,297 10,236~31,391 6,824 20,472

12K+12K 20,472 10,236~31,391 10,236 10,236

12K+18K 27,297 10,236~32,415 10,577 13,648

12K+24K (2) 27,297 10,236~32,415 10,236 17,060

18K+18K 27,297 10,236~32,415 13,648 13,648

18K+24K (2) 27,297 10,236~32,415 12,283 15,354

24K +24K (2) 27,297 10,236~32,415 13,648 13,648

9K+9K+9K 24,567 10,236~30,709 8,189 8,189 8,189

9K+9K+12K 24,567 10,236~30,709 6,994 7,336 10,236

9K+9K+18K 29,685 10,236~32,756 7,165 7,165 15,354

9K+9K+24K (2) 29,685 10,236~32,756 6,312 6,312 17,060

9K+12K+12K 29,685 10,236~32,756 7,506 11,089 11,089

9K+12K+18K 29,685 10,236~32,756 6,141 10,065 13,477

9K+12K+24K (2) 29,685 10,236~32,756 5,459 8,018 16,207

9K+18K+18K 29,685 10,236~32,756 5,971 11,771 11,771

9K+18K+24K (2) 29,685 10,236~32,756 5,459 9,042 15,184

23

Page 25

+Multi Outdoor Units

INDOOR UNIT COMBINATIONS

Model No: MULTI36HP230V1A 36,000 BtuH (cont.)

Cooling Capacity (BtuH)

RATED

INDOOR UNITS

COMBINATIONS

12K+12K+12K 29,685 10,236~32,756 9,895 9,895 9,895

12K+12K+18K 29,685 10,236~32,756 8,530 8,530 12,624

12K+12K+24K (2) 29,685 10,236~32,756 7,506 7,506 14,672

12K+18K+18K 29,685 10,236~32,756 9,212 12,283 12,283

18K+18K+18K 29,685 10,236~32,756 9,895 9,895 9,895

9K+9K+9K+9K 33,438 10,236~34,121 8,359 8,359 8,359 8,359

9K+9K+9K+12K 33,438 10,236~34,121 7,506 7,506 7,506 10,918

9K+9K+9K+18K 33,438 10,236~34,121 6,824 6,824 6,824 12,283

9K+9K+9K+24K (2) 33,438 10,236~34,121 6,141 6,141 6,141 15,013

9K+9K+12K+12K 33,438 10,236~34,121 6,824 6,824 9,895 9,895

9K+9K+12K+18K 33,438 10,236~34,121 6,312 6,312 8,871 12,283

9K+9K+18K+18K 33,438 10,236~34,121 5,459 5,459 11,260 11,260

9K+12K+12K+12K 33,438 10,236~34,121 7,847 8,530 8,530 8,530

9K+12K+12K+18K 33,438 10,236~34,121 6,141 7,506 7,506 12,283

12K+12K+12K+12K 33,438 10,236~34,121 8,359 8,359 8,359 8,359

SYSTEM

CAPACITY

(BtuH)

CAPACITY

RATING

(MIN – MAX)

(BtuH)

INDOOR

UNIT A

(BtuH)

INDOOR

UNIT B

(BtuH)

INDOOR

UNIT C

(BtuH)

INDOOR

UNIT D

(BtuH)

Heating Capacity (BtuH)

RATED

INDOOR UNITS

COMBINATIONS

9K+9K 22,178 15,354~29,003 11,089 11,089

9K+12K 26,614 15,354~32,756 11,089 15,968

9K+18K 31,494 15,354~33,780 9,758 21,735

9K+24K (2) 32,756 15,354~33,780 8,189 24,567

12K+12K 26,614 15,354~33,780 13,307 13,307

12K+18K 32,756 15,354~33,780 12,693 16,378

12K+24K (2) 32,756 15,354~33,780 12,283 20,472

18K+18K 32,756 15,354~33,780 16,378 16,378

18K+24K (2) 32,756 15,354~33,780 14,740 18,425

24K +24K (2) 32,756 15,354~33,780 16,378 16,378

9K+9K+9K 27,024 15,354~33,780 9,008 9,008 9,008

SYSTEM

CAPACITY

(BtuH)

CAPACITY

RATING

(MIN – MAX)

(BtuH)

INDOOR

UNIT A

(BtuH)

24

INDOOR

UNIT B

(BtuH)

INDOOR

UNIT C

(BtuH)

INDOOR

UNIT D

(BtuH)

Page 26

INDOOR UNIT COMBINATIONS

Model No: MULTI36HP230V1A 36,000 BtuH (cont.)

Heating Capacity (BtuH)

RATED

INDOOR UNITS

COMBINATIONS

9K+9K+12K 27,024 15,354~33,780 7,694 8,069 11,260

9K+9K+18K 35,622 15,354~37,533 8,598 8,598 18,425

9K+9K+24K (2) 35,622 15,354~37,533 7,574 7,574 20,472

9K+12K+12K 35,622 15,354~37,533 9,008 13,307 13,307

9K+12K+18K 35,622 15,354~37,533 7,370 12,078 16,173

9K+12K+24K (2) 35,622 15,354~37,533 6,551 9,622 19,449

9K+18K+18K 35,622 15,354~37,533 7,165 14,126 14,126

9K+18K+24K (2) 35,622 15,354~37,533 6,551 10,850 18,220

12K+12K+12K 35,622 15,354~37,533 11,874 11,874 11,874

12K+12K+18K 35,622 15,354~37,533 10,236 10,236 15,149

12K+12K+24K (2) 35,622 15,354~37,533 9,008 9,008 17,606

12K+18K+18K 35,622 15,354~37,533 11,055 14,740 14,740

18K+18K+18K 35,622 15,354~37,533 11,874 11,874 11,874

9K+9K+9K+9K 40,126 15,354~40,945 10,031 10,031 10,031 10,031

9K+9K+9K+12K 40,126 15,354~40,945 9,008 9,008 9,008 13,102

9K+9K+9K+18K 40,126 15,354~40,945 8,189 8,189 8,189 14,740

9K+9K+9K+24K (2) 40,126 15,354~40,945 7,370 7,370 7,370 18,016

9K+9K+12K+12K 40,126 15,354~40,945 8,189 8,189 11,874 11,874

9K+9K+12K+18K 40,126 15,354~40,945 7,574 7,574 10,645 14,740

9K+9K+18K+18K 40,126 15,354~40,945 6,551 6,551 13,512 13,512

9K+12K+12K+12K 40,126 15,354~40,945 9,417 10,236 10,236 10,236

9K+12K+12K+18K 40,126 15,354~40,945 7,370 9,008 9,008 14,740

12K+12K+12K+12K 40,126 15,354~40,945 10,031 10,031 10,031 10,031

SYSTEM

CAPACITY

(BtuH)

CAPACITY

RATING

(MIN – MAX)

(BtuH)

INDOOR

UNIT A

(BtuH)

INDOOR

UNIT B

(BtuH)

INDOOR

UNIT C

(BtuH)

INDOOR

UNIT D

(BtuH)

Notes: 1) It is critical to size the outdoor unit for the entire building load and each indoor unit for its individual zone load.

2) 24K size is reserved for Ceiling Cassettes, Concealed Ducts, and Floor/Ceilings units only. Not Wall Mount units.

Capacity data is based on the following conditions:

Cooling Nominal Test Conditions: Heating Normal Test Conditions

Indoor: 80°F DB/67°F WB Indoor: 70°F DB/60°F WB

Outdoor: 95°F DB/75°F WB Outdoor: 47°F DB/43°F W

25

Page 27

+Multi Outdoor Units

INDOOR UNIT COMBINATIONS

Model No: MULTI42HP230V1A 42,000 BtuH

Cooling Capacity (BtuH)

RATED

INDOOR UNITS

COMBINATIONS

9K+9K 20,472 11,942~30,709 8,530 8,530

9K+12K 20,472 11,942~30,709 8,530 11,942

9K+18K 24,226 11,942~30,709 7,506 16,719

9K+24K (2) 27,297 11,942~30,709 6,824 20,472

12K+12K 20,472 11,942~27,297 10,236 10,236

12K+18K 27,297 11,942~30,709 10,577 16,719

12K+24K (2) 32,415 11,942~37,533 10,236 22,178

18K+18K 32,415 11,942~37,533 16,207 16,207

18K+24K (2) 32,415 11,942~37,533 13,989 18,766

24K +24K (2) 32,415 11,942~37,533 16,207 16,207

9K+9K+9K 24,567 11,942~30,709 8,189 8,189 8,189

9K+9K+12K 24,567 11,942~30,709 6,994 7,336 10,236

9K+9K+18K 32,415 11,942~37,533 8,018 8,018 16,378

9K+9K+24K (2) 35,486 11,942~41,628 8,189 8,189 19,107

9K+12K+12K 29,685 11,942~32,756 8,530 10,577 10,577

9K+12K+18K 35,486 11,942~41,628 8,530 10,918 16,037

9K+12K+24K (2) 39,580 11,942~46,405 7,847 9,553 22,178

9K+18K+18K 39,580 11,942~46,405 7,165 15,013 15,013

9K+18K+24K (2) 39,580 11,942~46,405 6,824 13,648 19,107

9K+24K+24K (2) 39,580 11,942~46,405 5,800 16,890 16,890

12K+12K+12K 35,486 11,942~41,628 11,771 11,771 11,942

12K+12K+18K 35,486 11,942~41,628 10,918 10,918 13,648

12K+12K+24K (2) 39,580 11,942~46,405 10,065 10,065 19,449

12K+18K+18K 39,580 11,942~46,405 9,553 15,013 15,013

12K+18K+24K (2) 39,580 11,942~46,405 9,042 14,160 16,378

12K+24K+24K (2) 39,580 11,942~46,405 8,530 15,525 15,525

18K+18K+18K 39,580 11,942~46,405 13,136 13,136 13,307

18K+18K+24K (2) 39,580 11,942~46,405 12,283 12,283 15,013

9K+9K+9K+9K 35,486 11,942~41,628 8,871 8,871 8,871 8,871

9K+9K+9K+12K 35,486 11,942~41,628 8,189 8,189 8,189 10,918

9K+9K+9K+18K 39,580 11,942~46,405 7,847 7,847 7,847 16,037

9K+9K+9K+24K (2) 39,580 11,942~46,405 6,824 6,824 6,824 19,107

9K+9K+12K+12K 35,486 11,942~41,628 7,165 7,165 10,577 10,577

9K+9K+12K+18K 39,580 11,942~46,405 6,824 6,824 10,577 15,354

9K+9K+12K+24K (2) 39,580 11,942~46,405 6,312 6,312 9,553 17,572

9K+9K+18K+18K 39,580 11,942~46,405 6,483 6,483 13,307 13,307

9K+9K+18K+24K (2) 39,580 11,942~46,405 6,141 6,141 10,407 16,890

9K+12K+12K+12K 39,580 11,942~46,405 7,847 10,577 10,577 10,577

9K+12K+12K+18K 39,580 11,942~46,405 7,165 8,700 8,700 15,013

9K+12K+12K+24K (2) 39,580 11,942~46,405 6,483 7,933 7,933 17,231

9K+12K+18K+18K 39,580 11,942~46,405 6,483 8,189 12,454 12,454

SYSTEM

CAPACITY

(BtuH)

CAPACITY

RATING

(MIN – MAX)

(BtuH)

INDOOR

UNIT A

(BtuH)

INDOOR

UNIT B

(BtuH)

INDOOR

UNIT C

(BtuH)

INDOOR

UNIT D

(BtuH)

INDOOR

UNIT E

(BtuH)

26

Page 28

INDOOR UNIT COMBINATIONS

Model No: MULTI42HP230V1A 42,000 BtuH (cont.)

Cooling Capacity (BtuH)

RATED

INDOOR UNITS

COMBINATIONS

9K+18K+18K+18K 39,580 11,942~46,405 5,800 11,260 11,260 11,260

12K+12K+12K+12K 39,580 11,942~46,405 9,895 9,895 9,895 9,895

12K+12K+12K+18K 39,580 11,942~46,405 8,359 8,359 8,359 14,501

12K+12K+12K+24K (2) 39,580 11,942~46,405 7,506 7,506 7,506 17,060

12K+12K+18K+18K 39,580 11,942~46,405 7,847 7,847 11,942 11,942

9K+9K+9K+9K+9K 39,580 11,942~46,405 7,916 7,916 7,916 7,916 7,916

9K+9K+9K+9K+12K 39,580 11,942~46,405 7,421 7,421 7,421 7,421 9,895

9K+9K+9K+9K+18K 39,580 11,942~46,405 6,824 6,824 6,824 6,824 12,283

9K+9K+9K+9K+24K (2)

9K+9K+9K+12K+12K 39,580 11,942~46,405 7,165 7,165 7,165 9,042 9,042

9K+9K+9K+12K+18K 39,580 11,942~46,405 6,483 6,483 6,483 8,274 11,857

9K+9K+9K+18K+18K 39,580 11,942~46,405 6,483 6,483 6,483 10,065 10,065

9K+9K+12K+12K+12K 39,580 11,942~46,405 6,483 6,483 8,871 8,871 8,871

9K+9K+12K+12K+18K 39,580 11,942~46,405 5,971 5,971 8,018 8,018 11,601

9K+12K+12K+12K+12K 39,580 11,942~46,405 6,483 8,274 8,274 8,274 8,274

9K+12K+12K+12K+18K 39,580 11,942~46,405 6,141 7,592 7,592 7,592 10,662

12K+12K+12K+12K+12K 39,580 11,942~46,405 7,916 7,916 7,916 7,916 7,916

SYSTEM

CAPACITY

(BtuH)

39,580 11,942~46,405 6,483 6,483 6,483 6,483 13,648

CAPACITY

RATING

(MIN – MAX)

(BtuH)

INDOOR

UNIT A

(BtuH)

INDOOR

UNIT B

(BtuH)

INDOOR

UNIT C

(BtuH)

INDOOR

UNIT D

(BtuH)

INDOOR

UNIT E

(BtuH)

Heating Capacity (BtuH)

RATED

INDOOR UNITS

COMBINATIONS

9K+9K 25,591 15,354~33,780 10,662 14,928

9K+12K 25,591 15,354~33,780 10,662 14,928

9K+18K 30,282 15,354~33,780 9,383 20,899

9K+24K (2) 34,121 15,354~33,533 8,530 25,591

12K+12K 25,591 15,354~30,026 12,795 12,795

12K+18K 34,121 15,354~37,533 13,222 20,899

12K+24K (2) 40,519 15,354~42,651 12,795 27,723

18K+18K 40,519 15,354~42,651 20,261 20,261

18K+24K (2) 40,519 15,354~42,651 17,487 23,458

24K+24K (2) 40,519 15,354~42,651 20,261 20,261

9K+9K+9K 30,709 15,354~40,945 10,236 10,236 10,236

9K+9K+12K 30,709 15,354~40,945 8,745 9,171 12,795

9K+9K+18K 40,519 15,354~42,651 10,024 10,024 20,472

9K+9K+24K (2) 44,357 15,354~45,040 10,236 10,236 23,884

9K+12K+12K 37,107 15,354~40,945 10,662 13,222 13,222

9K+12K+18K 44,357 15,354~45,040 10,662 13,648 20,046

9K+12K+24K (2) 45,040 15,354~47,769 8,929 10,871 25,239

9K+18K+18K 45,040 15,354~47,769 8,155 17,084 17,084

9K+18K+24K (2) 45,040 15,354~47,769 7,766 15,532 21,742

9K+24K+24K (2) 45,040 15,354~47,769 6,599 19,220 19,220

12K+12K+12K 44,357 15,354~45,040 14,716 14,716 14,928

SYSTEM

CAPACITY

(BtuH)

CAPACITY

RATING

(MIN – MAX)

(BtuH)

INDOOR

UNIT A

(BtuH)

INDOOR

UNIT B

(BtuH)

INDOOR

UNIT C

(BtuH)

INDOOR

UNIT D

(BtuH)

INDOOR

UNIT E

(BtuH)

27

Page 29

+Multi Outdoor Units

INDOOR UNIT COMBINATIONS

Model No: MULTI42HP230V1A 42,000 BtuH (cont.)

Heating Capacity (BtuH)

RATED

INDOOR UNITS

COMBINATIONS

12K+12K+18K 44,357 15,354~45,040 13,648 13,648 17,060

12K+12K+24K (2) 45,040 15,354~47,769 11,454 11,454 22,131

12K+18K+18K 45,040 15,354~47,769 10,871 17,084 17,084

12K+18K+24K (2) 45,040 15,354~47,769 10,291 16,112 18,637

12K+24K+24K (2) 45,040 15,354~47,769 9,707 17,668 17,668

18K+18K+18K 45,040 15,354~47,769 14,948 14,948 15,143

18K+18K+24K (2) 45,040 15,354~47,769 13,979 13,979 17,084

9K+9K+9K+9K 44,357 15,354~47,769 11,089 11,089 11,089 11,089

9K+9K+9K+12K 44,357 15,354~47,769 10,236 10,236 10,236 13,648

9K+9K+9K+18K 45,040 15,354~47,769 8,929 8,929 8,929 18,248

9K+9K+9K+24K (2) 45,040 15,354~47,769 7,766 7,766 7,766 21,742

9K+9K+12K+12K 44,357 15,354~47,769 8,956 8,956 13,222 13,222

9K+9K+12K+18K 45,040 15,354~47,769 7,766 7,766 12,038 17,473

9K+9K+12K+24K (2) 45,040 15,354~47,769 7,182 7,182 10,871 19,995

9K+9K+18K+18K 45,040 15,354~47,769 7,377 7,377 15,143 15,143

9K+9K+18K+24K (2) 45,040 15,354~47,769 6,988 6,988 11,843 19,220

9K+12K+12K+12K 45,040 15,354~47,769 8,929 12,038 12,038 12,038

9K+12K+12K+18K 45,040 15,354~47,769 8,155 9,902 9,902 17,084

9K+12K+12K+24K (2) 45,040 15,354~47,769 7,377 9,028 9,028 19,609

9K+12K+18K+18K 45,040 15,354~47,769 7,377 9,318 14,170 14,170

9K+18K+18K+18K 45,040 15,354~47,769 6,599 12,812 12,812 12,812

12K+12K+12K+12K 45,040 15,354~47,769 11,260 11,260 11,260 11,260

12K+12K+12K+18K 45,040 15,354~47,769 9,513 9,513 9,513 16,501

12K+12K+12K+24K (2) 45,040 15,354~47,769 8,540 8,540 8,540 19,415

12K+12K+18K+18K 45,040 15,354~47,769 8,929 8,929 13,590 13,590

9K+9K+9K+9K+9K 45,040 15,354~47,769 9,008 9,008 9,008 9,008 9,008

9K+9K+9K+9K+12K 45,040 15,354~47,769 8,445 8,445 8,445 8,445 11,260

9K+9K+9K+9K+18K 45,040 15,354~47,769 7,766 7,766 7,766 7,766 13,979

9K+9K+9K+9K+24K (2) 45,040 15,354~47,769 7,377 7,377 7,377 7,377 15,532

9K+9K+9K+12K+12K 45,040 15,354~47,769 8,155 8,155 8,155 10,291 10,291

9K+9K+9K+12K+18K 45,040 15,354~47,769 7,377 7,377 7,377 9,414 13,491

9K+9K+9K+18K+18K 45,040 15,354~47,769 7,377 7,377 7,377 11,454 11,454

9K+9K+12K+12K+12K 45,040 15,354~47,769 7,377 7,377 10,096 10,096 10,096

9K+9K+12K+12K+18K 45,040 15,354~47,769 6,793 6,793 9,124 9,124 13,201

9K+12K+12K+12K+12K 45,040 15,354~47,769 7,377 9,414 9,414 9,414 9,414

9K+12K+12K+12K+18K 45,040 15,354~47,769 6,988 8,639 8,639 8,639 12,133

12K+12K+12K+12K+12K 45,040 15,354~47,769 9,008 9,008 9,008 9,008 9,008

SYSTEM

CAPACITY

(BtuH)

CAPACITY

RATING

(MIN – MAX)

(BtuH)

INDOOR

UNIT A

(BtuH)

INDOOR

UNIT B

(BtuH)

INDOOR

UNIT C

(BtuH)

INDOOR

UNIT D

(BtuH)

INDOOR

UNIT E

(BtuH)

Notes: 1) It is critical to size the outdoor unit for the entire building load and each indoor unit for its individual zone load.

2) 24K size is reserved for Ceiling Cassettes, Concealed Ducts, and Floor/Ceilings units only. Not Wall Mount units.

Capacity data is based on the following conditions:

Cooling Nominal Test Conditions: Heating Normal Test Conditions

Indoor: 80°F DB/67°F WB Indoor: 70°F DB/60°F WB

Outdoor: 95°F DB/75°F WB Outdoor: 47°F DB/43°F W

28

Page 30

EXTENDED PERFORMANCE RATINGS

Model No: MULT18HP230V1A 18,000 BtuH

Cooling Performance

INDOOR ENTERING AIR TEMPERATURES (DB) 50% RH

OUTDOOR AMBIENT

OUTDOOR AMBIENT

TEMPERATURE (DB)

TEMPERATURE (DB)

25°F 22,145 16,443 23,936 17,330 25,587 18,422

35°F 21,641 16,423 23,047 16,825 24,167 17,473

45°F 20,572 15,799 22,000 16,324 23,571 17,089

55°F 19,805 15,329 2 1,1 19 15,839 22,640 16,528

65°F 19,130 14,864 21,049 15,977 22,320 16,316

75°F 18,378 14,371 19,800 15,226 21,296 15,716

85°F 17,640 14,006 18,900 14,591 20,520 15,329

95°F 16,740 13,375 18,000 14,382 19,692 14,789

TC SHC

TC SHC

INDOOR ENTERING AIR TEMPERATURES (DB) 50% RH

62°F

62°F

TC SHC

TC SHC

67 F

67°F

72 F

72°F

TC SHC

TC SHC

105°F 15,840 12,862 17,060 13,614 18,540 14,239

115°F 14,939 12,309 15,839 12,829 16,919 13,248

Heating Performance

OUTDOOR AMBIENT

TEMPERATURE (DB)

(80% RH)

5°F 15,608 15,608 14,731 14,731 14,370 14,370

15°F 16,684 16,684 15,221 15,221 15,130 15,130

25°F 17,702 17,702 16,802 16,802 15,846 15,846

35°F 18,691 18,691 17,300 17,300 16,574 16,574

45°F 19,667 19,667 19,000 19,000 17,849 17,849

55°F 19,693 19,693 19,124 19,124 18,287 18,287

65°F 19,600 19,600 19,314 19,314 18,719 18,719

TC- Total Capacity (BtuH) SHC- Sensible Capacity (BtuH)

Capacity data is based on the following conditions:

Cooling Nominal Test Conditions Heating Normal Test Conditions

Indoor: 80°F DB/67°F WB Indoor: 70°F DB/60°F WB

Outdoor: 95°F DB/75°F WB Outdoor: 47°F DB/43°F W

TC SHC

INDOOR ENTERING AIR TEMPERATURES (DB)

65°F

70°F

TC SHC

75°F

TC SHC

29

Page 31

+Multi Outdoor Units

EXTENDED PERFORMANCE RATINGS

Model No: MULT24HP230V1A 24,000 BtuH

Cooling Performance

OUTDOOR AMBIENT

TEMPERATURE (DB)

25°F 31,988 23,751 34,575 25,032 36,959 26,610

35°F 31,260 23,723 33,291 24,302 34,907 25,238

45°F 29,716 22,821 31,777 23,579 34,047 24,684

55°F 28,608 22,142 30,506 22,879 32,703 23,873

65°F 27,633 21,471 30,405 23,077 32,240 23,567

75°F 26,546 20,759 28,600 21,994 30,760 22,701

85°F 25,480 20,231 27,300 21,075 29,640 22,141

95°F 24,180 19,320 26,000 20,774 28,444 21,361

105°F 22,880 18,579 24,643 19,665 26,780 20,567

115°F 21,578 17,780 22,878 18,531 24,438 19,135

TC SHC

INDOOR ENTERING AIR TEMPERATURES (DB) 50% RH

62°F

TC SHC

67°F

72°F

TC SHC

Heating Performance

OUTDOOR AMBIENT

TEMPERATURE (DB)

(80% RH)

65°F

TC SHC

INDOOR ENTERING AIR TEMPERATURES (DB)

70°F

TC SHC

TC SHC

75°F

5°F 23,823 23,823 22,484 22,484 21,933 21,933

15°F 25,465 25,465 23,232 23,232 23,092 23,092

25°F 27,019 27,019 25,645 25,645 24,186 24,186

35°F 28,528 28,528 26,405 26,405 25,297 25,297

45°F 30,018 30,018 29,000 29,000 27,243 27,243

55°F 30,058 30,058 29,189 29,189 27,912 27,912

65°F 29,916 29,916 29,479 29,479 28,571 28,571

TC- Total Capacity (BtuH) SHC- Sensible Capacity (BtuH)

Capacity data is based on the following conditions:

Cooling Nominal Test Conditions Heating Normal Test Conditions

Indoor: 80°F DB/67°F WB Indoor: 70°F DB/60°F WB

Outdoor: 95°F DB/75°F WB Outdoor: 47°F DB/43°F W

30

Page 32

EXTENDED PERFORMANCE RATINGS

Model No: MULTI30HP230V1A 30,000 BtuH

Cooling Performance

OUTDOOR AMBIENT

INDOOR ENTERING AIR TEMPERATURES (DB) 50% RH

TEMPERATURE (DB)

25°F 35,679 26,492 38,564 27,920 41,224 29,681

35°F 34,867 26,460 37,132 27,106 38,935 28,150

45°F 33,144 25,454 35,444 26,300 37,976 27,532

55°F 31,909 24,697 34,026 25,519 36,476 26,628

65°F 30,821 23,948 33,913 25,740 35,960 26,287

75°F 29,609 23,154 31,900 24,531 34,310 25,320

85°F 28,420 22,565 30,450 23,507 33,060 24,696

95°F 26,970 21,549 29,000 23,171 31,726 23,826

105°F 25,520 20,722 27,486 21,934 29,870 22,940

115°F 24,068 19,832 25,518 20,669 27,258 21,343

TC SHC

62°F

TC SHC

67°F

72°F

TC SHC

Heating Performance

OUTDOOR AMBIENT

TEMPERATURE (DB)

(80% RH)

TC SHC

INDOOR ENTERING AIR TEMPERATURES (DB)

65°F

70°F

TC SHC

75°F

TC SHC

5°F 24,974 24,974 23,570 23,570 22,992 22,992

15°F 26,694 26,694 24,354 24,354 24,207 24,207

25°F 28,324 28,324 26,883 26,883 25,353 25,353

35°F 29,905 29,905 27,679 27,679 26,518 26,518

45°F 31,467 31,467 30,400 30,400 28,558 28,558

55°F 31,509 31,509 30,598 30,598 29,260 29,260

65°F 31,360 31,360 30,902 30,902 29,950 29,950

TC- Total Capacity (BtuH) SHC- Sensible Capacity (BtuH)

Capacity data is based on the following conditions:

Cooling Nominal Test Conditions Heating Normal Test Conditions

Indoor: 80°F DB/67°F WB Indoor: 70°F DB/60°F WB

Outdoor: 95°F DB/75°F WB Outdoor: 47°F DB/43°F W

31

Page 33

+Multi Outdoor Units

EXTENDED PERFORMANCE RATINGS

Model No: MULTI36HP230V1A 36,000 BtuH

Cooling Performance

OUTDOOR AMBIENT

TEMPERATURE (DB)

25°F 41,830 31,059 45,213 32,734 48,331 34,798

35°F 40,878 31,022 43,534 31,780 45,648 33,004

45°F 38,859 29,843 41,555 30,834 44,523 32,279

55°F 37,410 28,955 39,892 29,919 42,765 31,219

65°F 36,135 28,077 39,760 30,178 42,160 30,819

75°F 34,714 27,146 37,400 28,761 40,225 29,686

85°F 33,320 26,456 35,700 27,560 38,760 28,954

95°F 31,620 25,264 34,000 27,166 37,196 27,934

105°F 29,920 24,295 32,225 25,716 35,020 26,895

115°F 28,220 23,253 29,920 24,235 31,960 25,025

TC SHC

INDOOR ENTERING AIR TEMPERATURES (DB) 50% RH

62°F

TC SHC

67°F

72°F

TC SHC

Heating Performance

OUTDOOR AMBIENT

TEMPERATURE (DB)

(80% RH)

TC SHC

INDOOR ENTERING AIR TEMPERATURES (DB)

65°F

TC SHC

70°F

75°F

TC SHC

5°F 26,628 26,628 25,131 25,131 24,515 24,515

15°F 28,463 28,463 25,967 25,967 25,811 25,811

25°F 30,200 30,200 28,664 28,664 27,033 27,033

35°F 31,886 31,886 29,513 29,513 28,275 28,275

45°F 33,552 33,552 32,414 32,414 30,450 30,450

55°F 33,597 33,597 32,414 32,414 31,198 31,198

65°F 33,438 33,438 32,949 32,949 31,934 31,934

TC- Total Capacity (BtuH) SHC- Sensible Capacity (BtuH)

Capacity data is based on the following conditions:

Cooling Nominal Test Conditions Heating Normal Test Conditions

Indoor: 80°F DB/67°F WB Indoor: 70°F DB/60°F WB

Outdoor: 95°F DB/75°F WB Outdoor: 47°F DB/43°F W

32

Page 34

EXTENDED PERFORMANCE RATINGS

Model No: MULTI42HP230V1A 42,000 BtuH

Cooling Performance

OUTDOOR AMBIENT

INDOOR ENTERING AIR TEMPERATURES (DB) 50% RH

TEMPERATURE (DB)

25°F 49,212 36,540 53,192 38,511 56,860 40,939

35°F 48,092 36,497 51,216 37,388 53,704 38,828

45°F 45,716 35,110 48,888 36,275 52,380 37,976

55°F 44,012 34,065 46,932 35,199 50,312 36,728

65°F 42,512 33,032 46,776 35,503 49,600 36,258

75°F 40,840 31,937 44,000 33,836 47,324 34,925

85°F 39,200 31,125 42,000 32,424 45,600 34,063

95°F 37,200 29,723 40,000 31,960 43,760 32,864

105°F 35,200 28,582 37,912 30,254 41,200 31,642

115°F 33,200 27,357 35,200 28,512 37,600 29,441

TC SHC

62°F

TC SHC

67°F

72°F

TC SHC

Heating Performance

OUTDOOR AMBIENT

TEMPERATURE (DB)

(80% RH)

TC SHC

INDOOR ENTERING AIR TEMPERATURES (DB)

65°F

70°F

TC SHC

75°F

TC SHC

5°F 34,729 34,729 32,776 32,776 31,973 31,973

15°F 37,122 37,122 33,867 33,867 33,664 33,664

25°F 39,388 39,388 37,384 37,384 35,257 35,257

35°F 41,586 41,586 38,491 38,491 36,876 36,876

45°F 43,759 43,759 42,275 42,275 39,713 39,713

55°F 43,818 43,818 42,275 42,275 40,690 40,690

65°F 43,611 43,611 42,973 42,973 41,649 41,649

TC- Total Capacity (BtuH) SHC- Sensible Capacity (BtuH)

Capacity data is based on the following conditions:

Cooling Nominal Test Conditions Heating Normal Test Conditions

Indoor: 80°F DB/67°F WB Indoor: 70°F DB/60°F WB

Outdoor: 95°F DB/75°F WB Outdoor: 47°F DB/43°F W

33

Page 35

MULTI WALL MOUNT UNITS

Models:

NEO09HP230V1AH

NEO12HP230V1AH

NEO18HP230V1AH

Page 36

+Multi Wall Mount Units

Table of Contents

Features and Benefits .........................36-37

Product Nomenclature ...........................38

Clearance Specifications..........................38

Product Performance Data .................... 39-40

Dimensional Specifications........................41

Page 37

+Multi Wall Mount Units

When it comes to fighting the heat, you need the NEO +Multi Wall Mount at your side. Don’t be

fooled by its compact design. Our +Multi Wall Mount is energy ecient, yet powerful for year round

comfort. Gree’s whisper quiet fan technology silences distracting noise. Its attractive compact design

mounts in a small wall space near the ceiling, and fits seamlessly into any decor. The fully featured

+Multi Wall Mount can be operated by an infrared remote controller or tether controller, allowing you

to easily manage a variety of useful features to further enhance room comfort.

FEATURES AND BENEFITS

Whisper Quiet

Gree systems are both energy ecient and quiet. Wall mounted units operate with sound levels

starting as low as 32 dB(A).

Subtle Appearance

Designed for a comfortable fit in virtually any living space. This slim compact cabinet sits

inconspicuously on the wall, and blends into most interior designs.

Multi-Speed Fan

The indoor fan can run at up to four dierent speeds (Low, Medium, High or Turbo) for either

COOLING or HEATING mode for maximum comfort and quiet operation.

Time Guard

Among the system’s many safeties is a Time Guard function to prevent rapid cycling of the compressor.

A protective five-minute time delay restricts compressor restarts after shuto.

Power Failure Mode

Power interruptions are no problem. User selections and system parameters are stored in non-volatile

memory. These parameters are retained during a power failure. When power is returned, the system

will automatically return to the last operating mode.

Controller

The unit comes with a factory supplied wired Tether Controller or Wireless Remote Controller.

Note: the controllers are mutually exclusive. They cannot be used at the same time.

IR Wireless Remote Controller

The Gree multi-functional infrared hand held wireless controller is sleek, ergonomically

designed, easy to use and has a large backlit LCD display.

Tether Controller (Optional)

The Gree tether controller mounts to the wall up to 25 feet from the unit. It provides complete

control over operation mode, desired temperature, fan speed, airflow direction and more.

Mode Button

The units can be set to five dierent operating modes: HEAT, COOL, DRY, FAN ONLY and AUTO.

Note: AUTO MODE has fixed setpoints of 68° F heating and 78° F cooling, which are not changeable.

The system will automatically select heating or cooling to maintain room temperature within this band.

36

Page 38

FEATURES AND BENEFITS

Intelligent Pre-Heating

The Multi Zone system guards against the annoying COLD BLOW in heating mode, and constantly

monitors the discharge air temperature. It will delay the indoor fan until the indoor coil has warmed

up to prevent blowing uncomfortable cool air into the room.

Timer Mode

The unit can be programmed to turn ON or OFF after a specific amount time. The time period is

adjustable between one half and 24 hours.

I Feel Mode

The unit will sense room temperature at the remote controller instead of at the indoor unit. It then adjusts

airflow and temperature accordingly for the ultimate in personal comfort control and energy savings.

Swing Louver

The unit has adjustable swing louvers which can be controlled from the wired tether or wireless

controllers. Vertical swing louver allows five dierent vertical (up & down) air discharge directions

including Continuous Sweep. Maximize comfort by adjusting the direction of airflow in the room by

moving the louvers up or down.

Privacy Lock Mode

Both wired tether and wireless controllers have a Privacy Lock to avert unauthorized access and stop

tampering with system settings.

Sleep Mode

The unit will automatically adjust room temperature during sleep time. This slight change in

temperature will not aect your comfort level due to the natural eects that sleeping has on the

body, but it will save on energy consumption and will lower electric bills.

Fahrenheit °F / Celsius °C

The wired tether and wireless controllers can be set to display in either °F or °C.

Polymeric Air Filters

Two-piece removable polymeric air filters easily slide in and out from the front of the indoor unit and

are interchangeable. The front panel does not need to be removed to access or change the filters.

The filters are washable and permanent.

Self-Diagnosis

With an on-board computer using real-time diagnostics, the Gree Multi Zone system helps to

prolong its own life. The automatic diagnosis feature continuously scans for unacceptable operating

conditions or malfunctions. If such conditions occur, the system takes corrective action or stops.

Fault codes are shown on the unit display to facilitate easy troubleshooting and repair.

Agency Listings

All systems are listed with AHRI (Air conditioning, Heating, and Refrigeration Institute) and are

ETL Certified per UL Standards.

7/5 Year Limited Warranty

Enjoy one of the most comprehensive warranties in the industry. Seven (7) years on compressor

and Five (5) years on all parts.

37

Page 39

+Multi Wall Mount Units

NOMENCLATURE

NEO 12 1 A H

Series Designation

NEO - Neo Indoor High Wall

MULTI - Multiple Port Outdoor Unit

DUCT - Slim Duct Indoor Unit

CAS - Ceiling Cassette

FLR - Floor/Ceiling Unit

CONS - Mini Console

Cooling Capacity

9- 9,000 BtuH

12 - 12,000 BtuH

18 - 18,000 BtuH

Model Type

AC - Cooling Only

HP - Heat Pump

HC - Heat/Cool

HP 230V

Product Type

S - System

O - Outdoor Units

H - Indoor High Wall

D - Indoor Duct

C - Indoor Cassette

F - Indoor Floor/Ceiling

Revision Level

Style/Color Designation

Electrical Rating

230V - 208/230V 60Hz 1PH

115V - 115V 60Hz 1PH

MINIMUM INDOOR CLEARANCE SPECIFICATIONS

The unit installation must meet or exceed the following minimum clearances for proper operation.

Ceiling

6 in (0.15m)

6 in

(0.15m)

6 ft (1.8m)

Floor

6 in

(0.15m)

38

Page 40

PERFORMANCE SPECIFICATIONS & DATA

Indoor High Wall Units

MODEL NUMBER

NEO09HP230V1AH 9,000 9,800 2.5

NEO12HP230V1AH 12,000 13,000 3.0

NEO18HP230V1AH 18,000 19,800 3.8

COOLING CAPACITY

(BtuH)

HEATING CAPACITY

(BtuH)

DEHUMIDIFICATION

(Pts./hr.)

Indoor High Wall Units

MODEL NUMBER

NEO09HP230V1AH Polymeric Mesh 4-way Crossflow

NEO12HP230V1AH Polymeric Mesh 4-way Crossflow

NEO18HP230V1AH Polymeric Mesh 4-way Crossflow

AIR FILTER TYPE

AIR FLOW

FAN TYPE

Indoor High Wall Units

COOLING (CFM)

MODEL NUMBER

NEO09HP230V1AH 218 253 277 306

LOW FAN

MEDIUM FAN

HIGH FAN

TURBO FAN

NEO12HP230V1AH 217 253 277 335

NEO18HP230V1AH 324 383 459 500

Indoor High Wall Units

HEATING (CFM)

MODEL NUMBER

NEO09HP230V1AH 218 253 277 306

NEO12HP230V1AH 217 253 277 335

NEO18HP230V1AH 324 383 459 500

LOW FAN

MEDIUM FAN

HIGH FAN

TURBO FAN

AIR THROW DATA

Indoor High Wall Units

APPROXIMATE AIR THROW

MODEL NUMBER

LOW

MEDIUM

HIGH

TURBO

NEO09HP230V1AH 18 ft. 21 ft. 24 ft. 28 ft.

NEO12HP230V1AH 18 ft. 21 ft. 24 ft. 30 ft.

NEO18HP230V1AH 22 ft. 27 ft. 33 ft. 39 ft.

39

Page 41

+Multi Wall Mount Units

SOUND DATA

Indoor High Wall Units

LOW FAN

MODEL NUMBER

NEO09HP230V1AH 42 dBA 32 dBA 45 dBA 35 dBA 48 dBA 38 dBA 52 dBA 42 dBA

NEO12HP230V1AH 43 dBA 33 dBA 46 dBA 36 dBA 49 dBA 39 dBA 54 dBA 44 dBA

NEO18HP230V1AH 45 dBA 35 dBA 50 dBA 40 dBA 54 dBA 44 dBA 59 dBA 49 dBA

Note: 1. Sound pressure ratings are estimated sound pressure measurements, 3 feet from unit.

2. Sound power ratings are per AHRI 270 and AHRI 350

SOUND

POWER

SOUND

PRESSURE

MEDIUM FAN

SOUND

POWER

SOUND

PRESSURE

HIGH FAN

SOUND

POWER

SOUND

PRESSURE

TURBO FAN

SOUND

POWER

SOUND

PRESSURE

ELECTRICAL DATA

Indoor High Wall Units

MODEL NUMBER

NEO09HP230V1AH 208/230v-1ph-60hz 187-253 0.2 20.0

NEO12HP230V1AH 208/230v-1ph-60hz 187-253 0.2 20.0

RATED POWER SUPPLY

(volt-phase-hz)

VOLTAGE RANGE

(volts)

RLA (amps)

INDOOR FAN

POWER (watts)

NEO18HP230V1AH 208/230v-1ph-60hz 187-253 0.3 20.0

Legend: RLA – Rated Load Amps

PRODUCT WEIGHT

Indoor High Wall Units

PRODUCT WEIGHT

MODEL NUMBER

NEO09HP230V1AH 22 lbs. 29 lbs.

NEO12HP230V1AH 22 lbs. 29 lbs.

NEO18HP230V1AH 24 lbs. 31 lbs.

NET OPERATING GROSS SHIPPING

40

Page 42

DIMENSIONAL SPECIFICATIONS

Model No: NEO09HP230V1AH 9,000 BtuH

Model No: NEO12HP230V1AH 12,000 BtuH

7.1 (180)

10.8

(275)

Suction/Gas Line Port Size

Port 1 3/8-in OD Flared

Liquid Line Port Size

Port 1 1/4-in OD Flared

Model No: NEO18HP230V1AH 18,000 BtuH

Drain Connector

Drain Line 0.625-in OD

7.9 (200)

11.7

(298)

Suction/Gas Line Port Size

Port 1 1/2-in OD Flared

Liquid Line Port Size

Port 1 1/4-in OD Flared

41

Drain Connector

Drain Line 0.625-in OD

Page 43

MULTI CEILING CASSETTES

Models:

CAS12HP230V1AC

CAS18HP230V1AC

CAS24HP230V1AC

Page 44

+Multi Ceiling Cassettes

Table of Contents

Features and Benefits ........................ 44-46

Product Nomenclature .......................... 46

Product Performance Data .....................47-48

Dimensional Specifications.................... 49-50

Clearance Specifications..........................51

Installation of Mounting Hangers...................52

Condensate Drain Designs ........................53

Page 45

+Multi Ceiling Cassettes

Gree’s +Multi Ceiling Cassette will inconspicuously provide quiet performance through innovative design. The +Multi Ceiling Cassette

is extremely suitable for any room, and can be easy installed in suspended ceilings with only a discreet decorative discharge grille

visible. Gree’s fan technology quietly and evenly distributes conditioned air throughout the room, and an internal condensate lift pump

reliably disposes condensate water to a safe location. The +Multi Ceiling Cassette is ideal for light commercial applications which

require comfort control in large, open spaces. Each +Multi Ceiling Cassette can be operated by an infrared remote control or wired

tether controller, allowing maximum flexibility for any application.

FEATURES AND BENEFITS

Whisper Quiet

Gree systems are both energy ecient and quiet. Wall mounted units operate with sound levels

starting as low as 35 dB(A).

Subtle Appearance

This flexible ceiling mount unit conveniently disappears above the surface of any room’s hard or

drop ceiling.

Convenient Size (12K and 18K only)

The Gree ceiling cassettes can be easily mounted in a hard ceiling (with an access panel for servicing

or in 2’x2’ drop ceiling. They provide great air distribution, quiet operating and a less obtrusive style.

Multi-Speed Fan

The indoor fan can run at up to three dierent speeds (Low, Medium, or High) for either COOLING

or HEATING mode for maximum comfort and quiet operation.

4-Way Discharge Air

The Gree ceiling cassette is designed to bring return air in through the center and quietly discharge

the air out along each of the four exterior sides.

Decorative Discharge Air Grille (sold separately)

The cassette Decorative Grille is made of strong resilient polymer. It’s designed to fit attractively in any interior

décor. The Decorative Grille is sold separately and is required to complete installation of the systems.

Built-In Condensate Lift Pump

The unit features a built-in drain pump that lifts condensation up to 11 inches above the drain pan to a

gravity condensate drain system. In most cases, the internal condensate lift mechanism will avoid the

need for an external condensate pump.

Condensate Sentry

The unit’s fail-safe mechanism recognizes when there is a high level in the condensate pan and shuts

o the system to prevent overflow problems.

44

Page 46

FEATURES AND BENEFITS

Intelligent Pre-Heating

The Multi Zone system guards against the annoying COLD BLOW in heating mode. The system constantly

monitors the discharge air temperature. It will delay the indoor fan until the indoor coil has warmed

up to prevent blowing uncomfortable cool air into the room.

Controller

The unit comes with a factory supplied wired Tether Controller or Wireless Remote Controller.

Note: the controllers are mutually exclusive. They cannot be used at the same time.

IR Wireless Remote Controller

The Gree multi-functional infrared hand held wireless controller is sleek, ergonomically

designed, easy to use and has a large backlit LCD display.

Tether Controller (Optional)

The Gree wired tether controller mounts to the wall up to 25 feet from the unit. It provides

complete control over operation mode, desired temperature, fan speed, airflow direction

and more.

Mode Button

The units can be set to five dierent operating modes: HEAT, COOL, DRY, FAN ONLY and AUTO.

Note: AUTO MODE has fixed setpoints of 68° F heating and 78° F cooling, which are not changeable.

The system will automatically select heating or cooling to maintain room temperature within this band.

Timer Mode

The unit can be programmed to turn ON or OFF after a specific amount time. The time period is

adjustable between one half and 24 hours.

I Feel Mode

The unit will sense room temperature at the remote controller instead of at the indoor unit. It then adjusts

airflow and temperature accordingly for the ultimate in personal comfort control and energy savings.

Swing Louver

The unit has adjustable swing louvers which can be controlled from the wired tether or wireless

controllers. Vertical swing louver allows five dierent air discharge directions including Continuous

Sweep. Maximize comfort by adjusting the direction of airflow in the room by moving the louvers

up or down.

Privacy Lock Mode

Both wired tether and wireless controllers have a Privacy Lock to avert unauthorized access and stop

tampering with system settings.

Sleep Mode

The unit will automatically adjust room temperature during sleep time. This slight change in

temperature will not aect your comfort level due to the natural eects that sleeping has on the

body, but it will save on energy consumption and will lower electric bills.

Fahrenheit °F / Celsius °C

The wired tether and wireless controllers can be set to display in either °F or °C.

45

Page 47

+Multi Ceiling Cassettes

FEATURES AND BENEFITS

Power Failure Mode

Power interruptions are no problem. User selections and system parameters are stored in non-volatile

memory. These parameters are retained during a power failure. When power is returned, the system

will automatically return to the last operating mode.

Polymeric Air Filter

One piece removable polymeric air filter easily slides in and out from the ceiling cassette. The filter

is washable and permanent.

Self-Diagnosis

With an on-board computer using real-time diagnostics, the Gree Multi Zone system helps to prolong

its own life. The automatic diagnosis feature continuously scans for unacceptable operating conditions

or malfunctions. If such conditions occur, the system takes corrective action or stops. Fault codes are

shown on the unit display to facilitate easy troubleshooting and repair.

Fresh Air Intake (24K model only)

The 24K size ceiling cassette has a ventilation air knockout that allows a 4 inch flex duct connection and a

field supplied duct booster fan. The maximum fresh air allowed is 10% of unit high speed fan airflow rating.

Agency Listings

All systems are listed with AHRI (Air conditioning, Heating, and Refrigeration Institute) and are

ETL certified per UL Standards.

7/5 Year Limited Warranty

Enjoy one of the most comprehensive warranties in the industry. Seven (7) years on compressor

and Five (5) years on all parts.

NOMENCLATURE

Series Designation

CAS - Ceiling Cassette

MULTI - Multiple Port Outdoor Unit

DUCT - Slim Duct Indoor Unit

NEO - Neo Indoor High Wall

FLR - Floor/Ceiling Unit

CONS - Mini Console

Cooling Capacity

12 - 12,000 BtuH

18 - 18,000 BtuH

24 - 24,000 BtuH

Model Type

AC - Cooling Only

HP - Heat Pump

HC - Heat/Cool

CAS 12 1 A C

HP 230V

Product Type

S - System

O - Outdoor Units

H - Indoor High Wall

D - Indoor Duct

C - Indoor Cassette

F - Indoor Floor/Ceiling

Revision Level

Style/Color Designation

Electrical Rating

230V - 208/230V 60Hz 1PH

115V - 115V 60Hz 1PH

46

Page 48

PERFORMANCE SPECIFICATIONS AND DATA

Ceiling Cassette

MODEL NUMBER

CAS12HP230V1AC 11,946 13,652 3.0

CAS18HP230V1AC 15,359 17,065 3.8

CAS24HP230V1AC 22,867 27,304 4.4

COOLING CAPACITY

(BtuH)

HEATING CAPACITY

(BtuH)

DEHUMIDIFICATION

(Pts./hr.)

Ceiling Cassette

MODEL NUMBER

CAS12HP230V1AC Polymeric Mesh 4-way Axial

CAS18HP230V1AC Polymeric Mesh 4-way Axial

CAS24HP230V1AC Polymeric Mesh 4-way Axial

AIR FILTER TYPE

AIR FLOW

FAN TYPE

Ceiling Cassette

MODEL NUMBER

LOW FAN MEDIUM FAN HIGH FAN

COOLING (CFM)

CAS12HP230V1AC 251 292 353

CAS18HP230V1AC 251 292 353

CAS24HP230V1AC 465 509 694

Ceiling Cassette

MODEL NUMBER

CAS12HP230V1AC 251 292 353

CAS18HP230V1AC 251 292 353

CAS24HP230V1AC 465 509 694

LOW FAN MEDIUM FAN HIGH FAN

HEATING (CFM)

47

Page 49

+Multi Ceiling Cassettes

SOUND DATA

Ceiling Cassette

LOW FAN

MODEL NUMBER

CAS12HP230V1AC 52 dBA 42 dBA 54 dBA 44 dBA 56 dBA 46 dBA

CAS18HP230V1AC 52 dBA 42 dBA 54 dBA 44 dBA 56 dBA 46 dBA

CAS24HP230V1AC 55 dBA 35 dBA 47 dBA 37 dBA 49 dBA 39 dBA

Note: 1. Sound pressure ratings are estimated sound pressure measurements, 3 feet from unit.

2. Sound power ratings are per AHRI 270 and AHRI 350

SOUND

POWER

SOUND

PRESSURE

MEDIUM FAN

SOUND

POWER

PRESSURE

SOUND

HIGH FAN

SOUND

POWER

SOUND

PRESSURE

ELECTRICAL DATA

Ceiling Cassette

MODEL NUMBER

CAS12HP230V1AC 208/230v-1ph-60hz 187-253 0.2 11.0

CAS18HP230V1AC 208/230v-1ph-60hz 187-253 0.2 11.0

CAS24HP230V1AC 208/230v-1ph-60hz 187-253 0.4 50.0

RATED POWER SUPPLY

(volt-phase-hz)

VOLTAGE RANGE

(volts)

RLA (amps) POWER (watts)

INDOOR FAN

Legend: RLA – Rated Load Amps

PRODUCT WEIGHT

Ceiling Cassette

MODEL NUMBER

CAS12HP230V1AC 40 lbs. 51 lbs.

CAS18HP230V1AC 40 lbs. 51 lbs.

CAS24HP230V1AC 62 lbs. 77 lbs.

NET OPERATING

Decorative Grill

MODEL NUMBER

CAS12HP230V1AC 6 lbs. 8 lbs.

CAS18HP230V1AC 6 lbs. 8 lbs.

NET OPERATING

PRODUCT WEIGHT

GROSS SHIPPING

PRODUCT WEIGHT

GROSS SHIPPING

CAS24HP230V1AC 6.5 lbs. 10 lbs.

48

Page 50

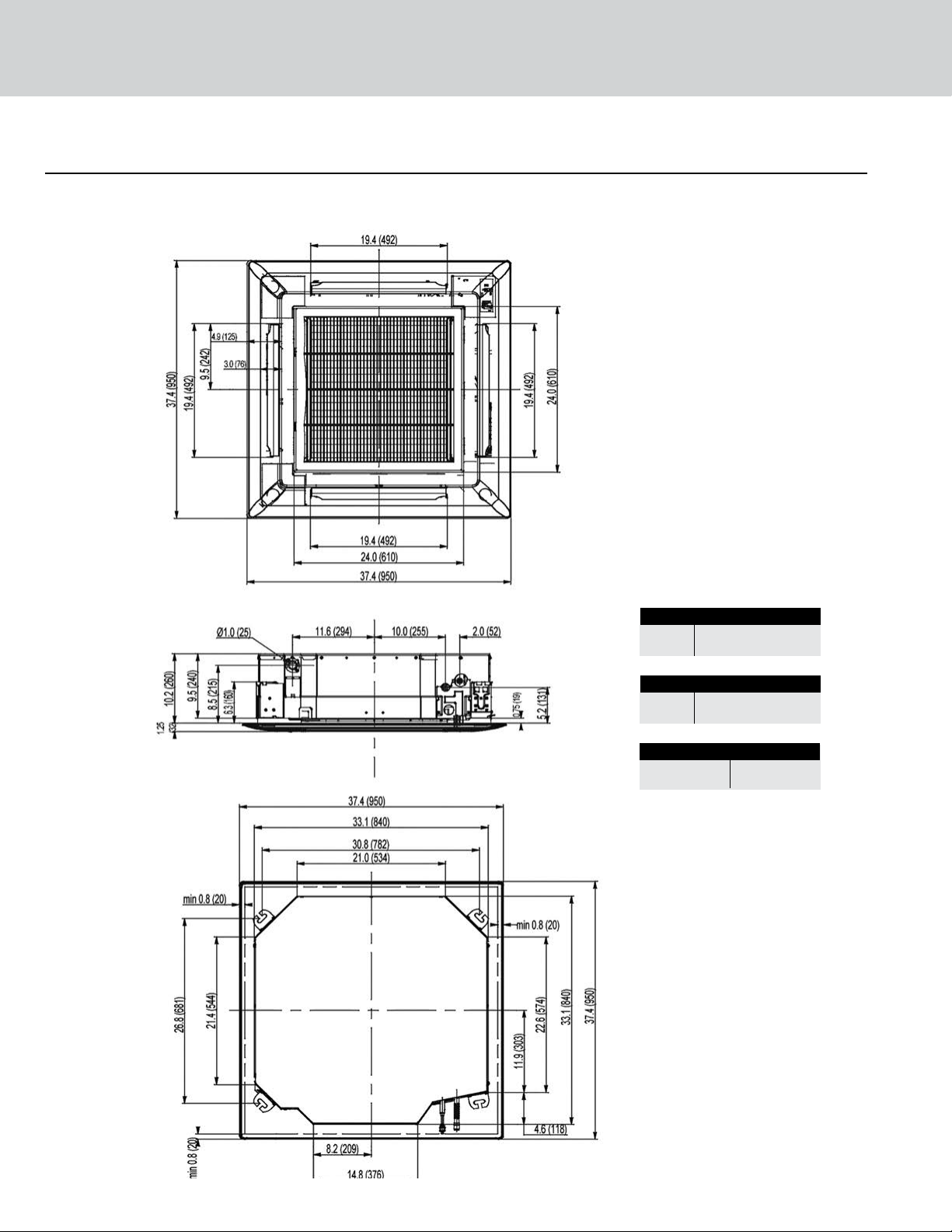

DIMENSIONAL SPECIFICATIONS

Model No: CAS12HP230V1AC 12,000 BtuH

Model No: CAS18HP230V1AC 18,000 BtuH

49

Suction/Gas Line Port Size

12,000 BtuH 3/8-in OD Flared

18,000 BtuH 1/2-in OD Flared

Liquid Line Port Size

12,000 BtuH 1/4-in OD Flared

18,000 BtuH 1/4-in OD Flared

Drain Line Connection

12,000 BtuH 1.2-in OD Flared

18,000 BtuH 1.2-in OD Flared

Page 51

+Multi Ceiling Cassettes

DIMENSIONAL SPECIFICATIONS

Model No: CAS24HP230V1AC 24,000 BtuH

Suction/Gas Line Port Size

Port 1 5/8-in OD Flared

Liquid Line Port Size

Port 1 3/8-in OD Flared

Drain Connector

Drain Line 1.2-in OD

50

Page 52

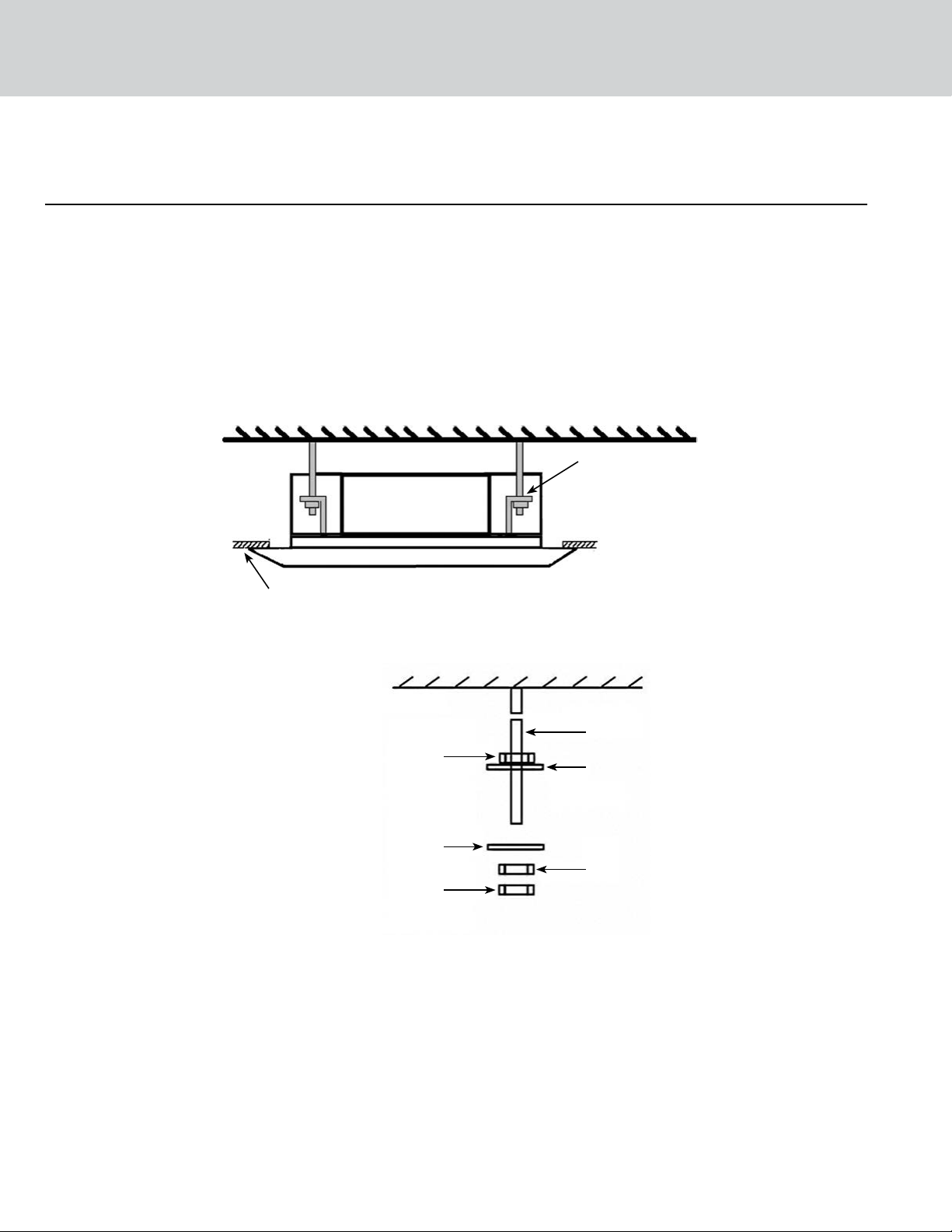

MINIMUM INDOOR CLEARANCE SPECIFICATIONS

The unit installation must meet or exceed the following minimum clearances for proper operation.

Ceiling

Installation stands for main body of the unit.

6.25-in

Above 0.75-in

Drainage hose

Refrigerant pipes

Air outlet vent

Pipe insulation

Air inlet grille

51

Page 53

+Multi Ceiling Cassettes

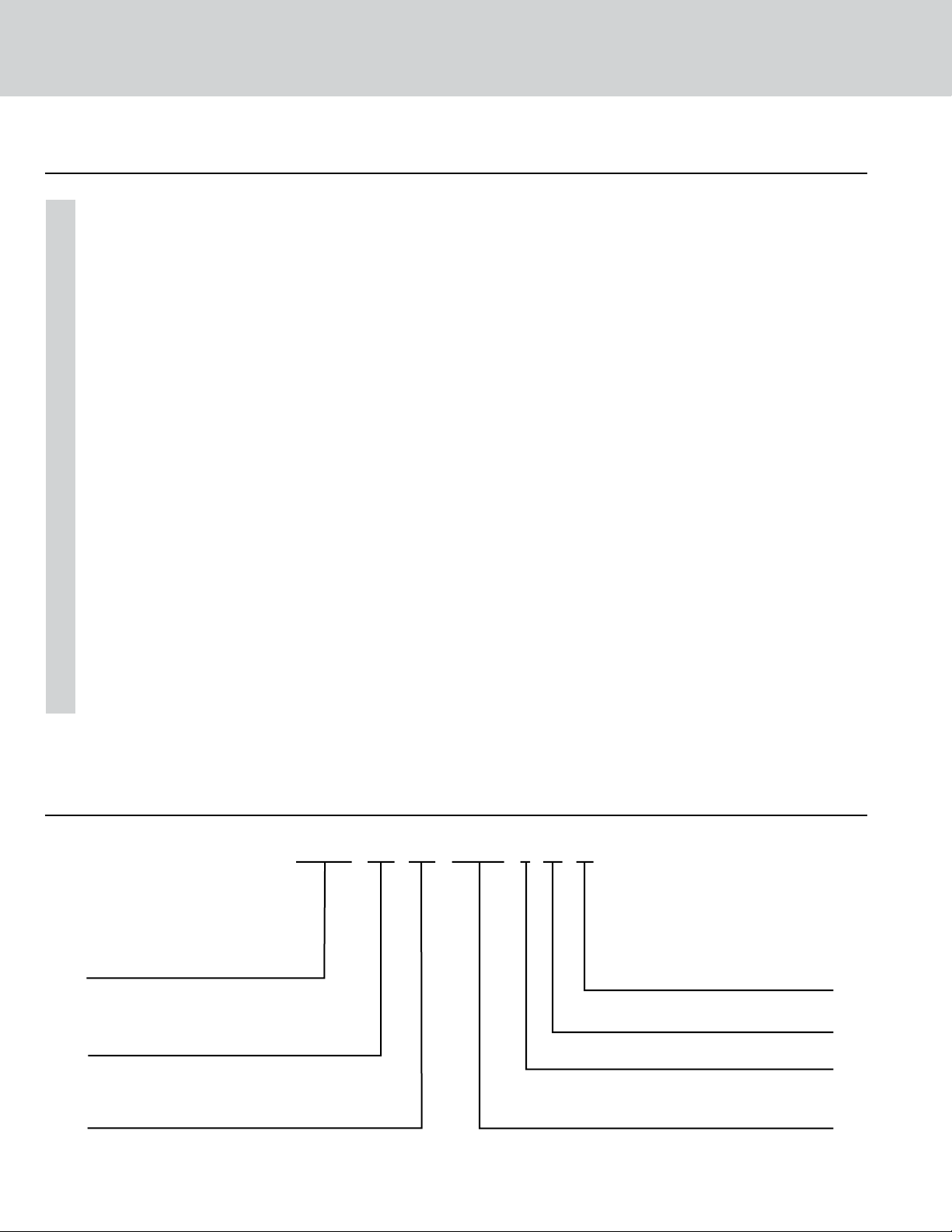

INSTALLATION OF MOUNTING HANGERS

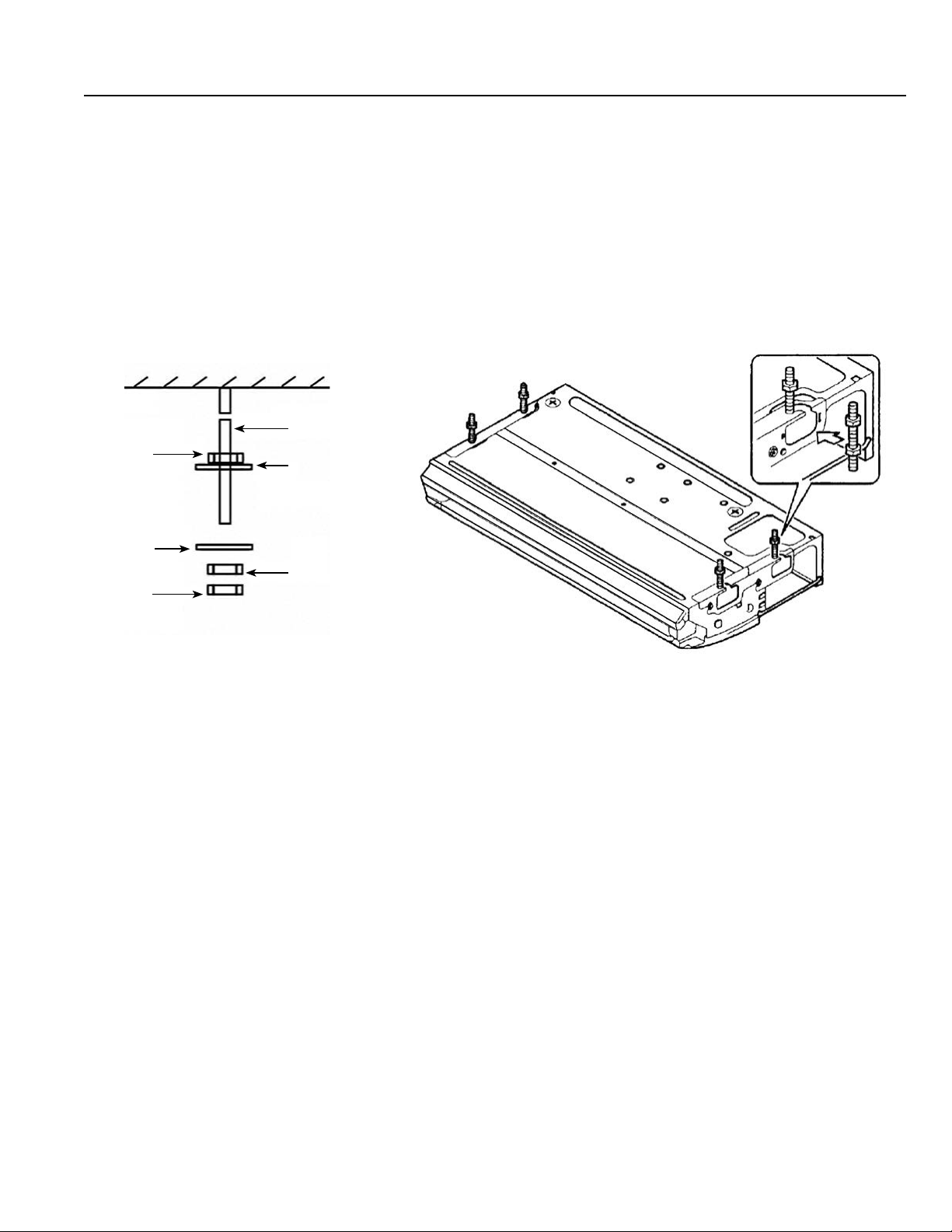

Depending on the type of ceiling, threaded hanger bolts (field supplied) are recommended for securing

Ceiling Cassette to the ceiling or support studs.

Proper mounting hardware is critical which includes upper nuts, lower flat washers (with insulation), top

flat washers (without insulation), top nuts and locking nuts (double) on the threaded hanger bolts as show

in diagram below.

Mounting

Bracket

Ceiling

FPO

Nut

Washer

Nut

Threaded

Hanger Bolt

Washer

Nut

52

Page 54

CONDENSATE DRAIN DESIGNS

It’s recommended to build the condensate drain system with hard polyvinyl chloride (PVC) pipe and matching

connectors. Use pipe with either the same diameter or larger than the unit drainage port.

Gravity Drainage Systems with P-trap & Vent

Pitch the condensate drain pipes at a gradual 2.5%

pitch (Example: 1/4-in. drop over a 10-in. length)

without obstructions. Use pipe hanger/brackets to

support the condensate drain pipe from drooping.

Insulate all pipes to prevent sweating and water

damage.

Multiple Units with Common Drain

The following is the recommended condensate

drainage system for multiple units that share a

common drain line. Connecting multiple units to one

trap allows air to be pulled through one or more of

the units, bypassing the trap. An alternate method

is having individual drains and traps for each unit.

Ceiling

Hangers

Wall

Hanger

Wall

Ceiling

Wall

Vertical Lift Drainage System

If a gradual pitch from the drainage port is not

obtainable, the Ceiling Cassette contains an internal

condensate pump with limited head or lift. The

condensate drain pipe may have a vertical height of

11-in. (280 mm) maximum above the unit drainage

port within the first 12-in. (300 mm) as long as the

remaining condensate drain pipe gradually descends

from that point and aligns with drainage port.

Use an auxiliary condensate pump with float valve

for vertical height greater than 11-in. (280 mm) above

the unit drainage port. A float valve is recommended

to shut o the system if the auxiliary pump fails.

53

Ceiling

11-in

max

12-in

max

Hangers

Wall

Page 55

MULTI SLIM

CONCEALED DUCTS

Models:

DUCT09HP230V1AD

DUCT12HP230V1AD

DUCT18HP230V1AD

DUCT24HP230V1AD

Page 56