Gree LSQWRF65MG/NaC-M, LSQWRF160MG/NaC-M, LSQWRF130MG/NaC-M, LSQWF130MG/NaC-M, LSQWF160MG/NaC-M Product And Sales Manual

...

T E C H N I C A L SALES GUIDE

Capacity Range:60~1216KW

T1/R410A/50Hz/60Hz

C SERIES

Contents

1.MODELS LIST

2.NOMENCLATURE

3.FEATURES

4.PRODUCT DATA

5.PERFORMANCE CORRECTION

6.ANTIFREEZE

7.INSTALLATION

8.ELECTRICAL DATA

9.FIELD WIRING DIAGRAM

10.MICROPROCESSOR CONTROLLER

11.WIRED CONTROLLER

12.ACCESSORIES

13.APPLICATION DATA

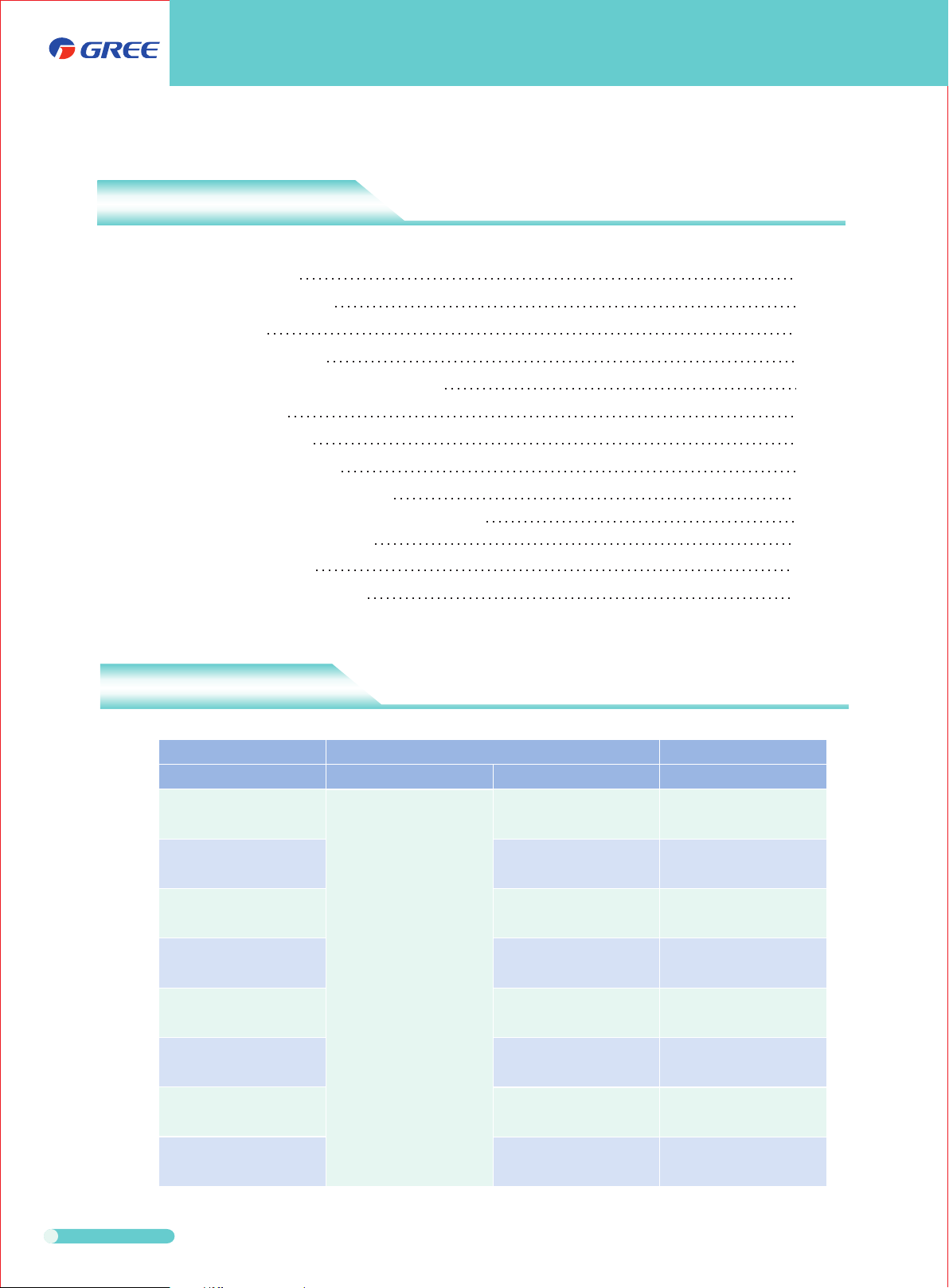

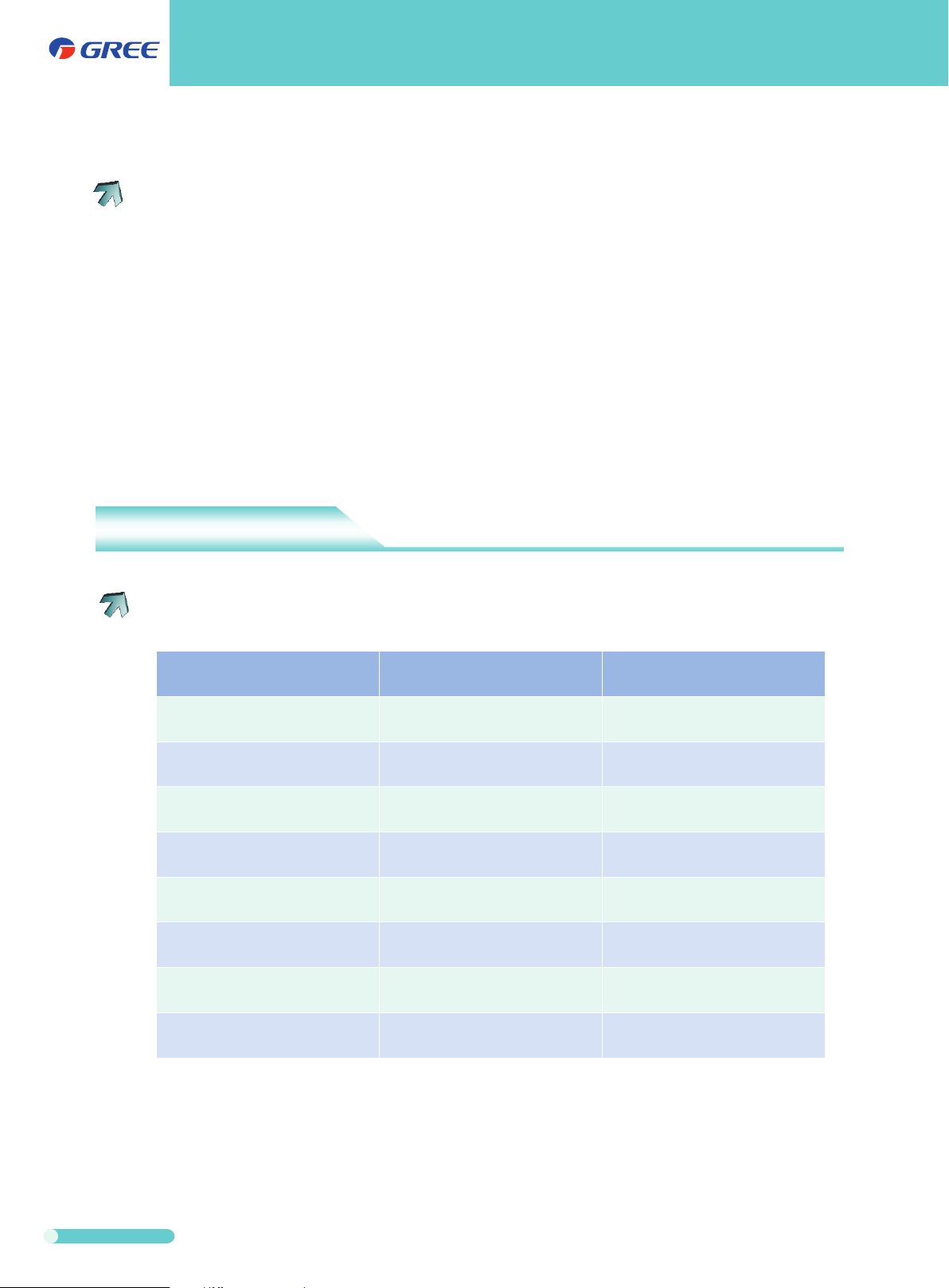

MODELS LIST

1

2

3

3

6

9

10

11

14

15

16

18

20

21

Nominal Capacity

TR

17

22

34

43

17

22

34

43

Refrigerant

R410A

Model

Model Name

LSQWRF65MG/NaC-M

LSQWF65MG/NaC-M

LSQWRF80MG/NaC-M

LSQWF80MG/NaC-M

LSQWRF130MG/NaC-M

LSQWF130MG/NaC-M

LSQWRF160MG/NaC-M

LSQWF160MG/NaC-M

LSQWRF65MG/NaC-F

LSQWF65MG/NaC-F

LSQWRF80MG/NaC-F

LSQWF80MG/NaC-F

LSQWRF130MG/NaC-F

LSQWF130MG/NaC-F

LSQWRF160MG/NaC-F

LSQWF160MG/NaC-F

Power Supply

Ph, V, Hz

3,380,50

3,380,50

3,380,50

3,380,50

3,220,60

3,220,60

3,220,60

3,220,60

2

GREE Central Air Conditioners

Air-Cooled Scroll Chiller Technical Sales Guide

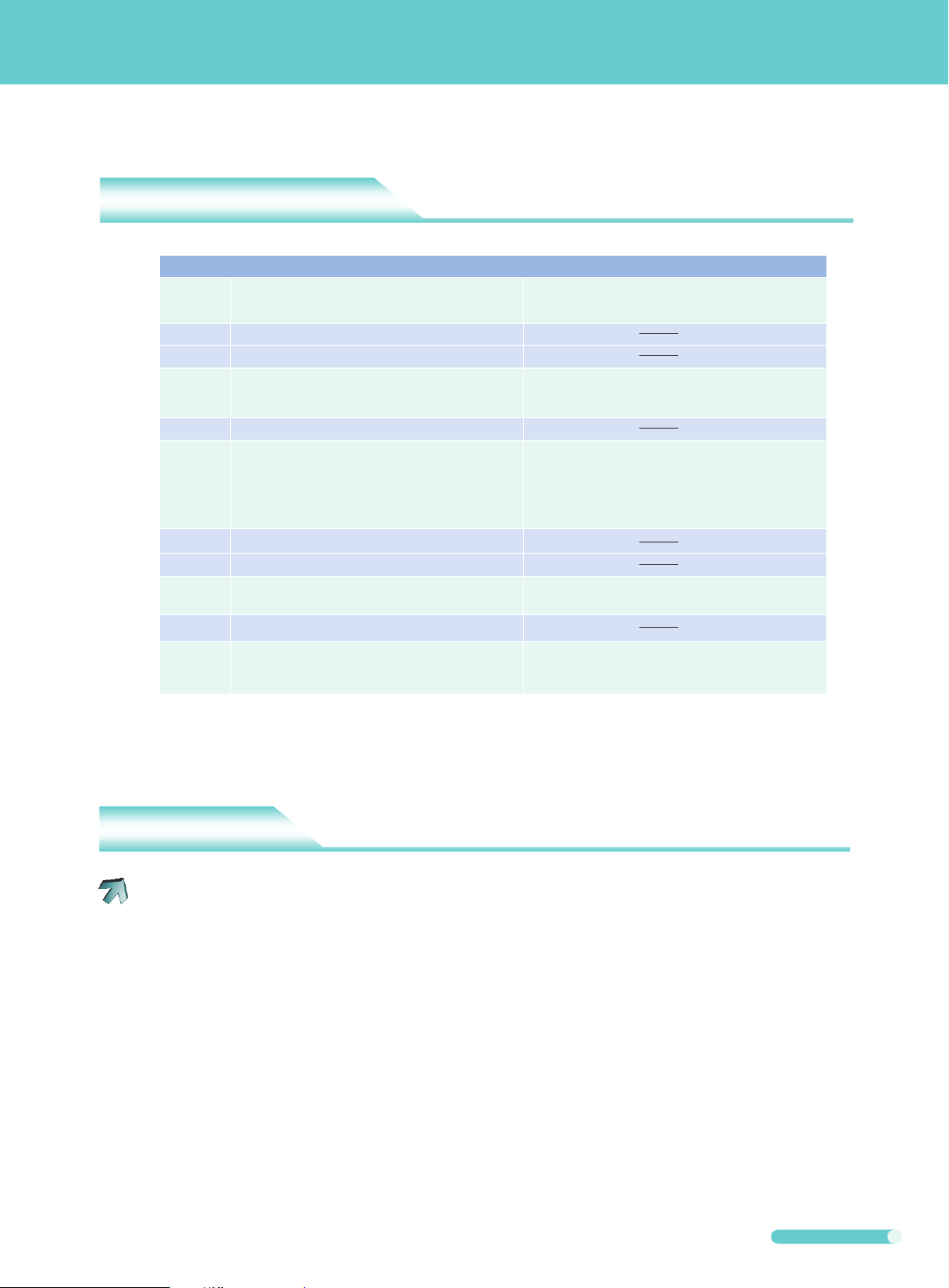

NOMENCLATURE

2

Model

LS

QW

LS QW R F 80 M G/Na C-H

LS QW R F 80 M G/Na C -F

Model

Description

Water Chiller

Scroll Compressor

Options

FEATURES

3

R

F

80

M

G

Na

C

F

Heat Pump

Air Cooled

Nominal Cooling Capacity

Module

Product number

Refrigerant

Series number

Voltage

Default- Cooling only

R-Heat pump

65=60kW= 17 TR

80=76kW= 22 TR

130=120kW=34 TR

160=152kW=43 TR

Na–R410A

F 208~230V 3N~ 60Hz

M 380~415V 3N~ 50Hz

3.1 Brief Introduction

The units with multi refrigerant circuits from to 152 kW have outstanding benefits that

make this product effective for a variety of applications. The units are shipped from

the factory completely ready for installation and use. Each unit is pressure-tested,

evacuated, and fully charged with R410A, and has an initial oil charge. After

assembly, a complete operation test is performed with water flowing through the

cooler to assure that the refrigeration circuit operates correctly.

The units can be installed on the rooftop, ground outside and so on instead of being

equipped within a special machine room. It can be widely applied in new built or

reconstructed industry and civil-building project, such as hotel, apartment, restaurant,

office building, shopping mall, theater, gymnasium, hospital and so on, as well as

supplies required cooling water for factories in technical process of producing, so it's

especially suitable for some special locations around where there are high-level

requirements for noise and environments and cooling tower are difficult to install.

60

GREE Central Air Conditioners

3

3.2 Standard Specifications

High Efficiency Full Load Operation

Utilizing new scroll compressor technology, the chillers meet or exceed the

performance requirements of ASHRAE 90.1. All system components are selected for

optimum performance, including the condenser coil areas and evaporator sizes.

Excellent Part Load Performance

By using multi compressors on each chiller, unloading characteristics and part load

performance are outstanding. Integrated part load value (IPLV) is a part load

performance indicator as outlined in ARI Standard 550/590-1998. The IPLV rating

compares the performance of different chillers under identical conditions. When the

IPLV is listed in EER (Energy Efficiency Ratio), a higher EER will indicate that the chiller's

overall performance is better.

Compact Design with Small Footprint

The chillers have a reputation for a compact design and small footprint. A small

footprint can save installation costs by minimizing the size of the concrete mounting

pad or reduces the amount of structural steel if the unit is mounted on the rooftop.

Quiet Operation

The chillers are designed with quiet scroll compressors. Fans are selected for good

performance and lower sound levels. The attention to detail with sound is critical in the

design. Small issues such as refrigerant piping, supports for piping, securing

components to the structure are all important to making a quiet product. We proudly

publish our sound performance.

Superior Controls

GREE has provided the latest technology in controlling the chillers. The new controller

provides a“user friendly”environment for the operator. The control logic is designed

to provide maximum efficiency, to help provide continuing operation in unusual

operating conditions through proactive controls, and to provide a history of conditions

to aid in problem resolutions. Perhaps the greatest benefit is the Protocol for

integrating with your building automation system (BAS).

Compressors

These rugged hermetic compressors are constructed with an integral cast iron frame,

cast iron scrolls, three Teflon impregnated bearings, and three oil filtration devices for

each compressor. One to thity-two compressors can run, depending on the load of

the system, resulting in excellent Part-load efficiency. Each refrigerant circuit has

specially designed oil and gas equalization lines to control oil migration.

The design also offers radial and axial compliance, a large internal volume for liquid

handling, a removable suction screen, and a rotary dirt trap and oil screen. In

addition, the compressor is self-compensating for wear, handles moderate liquid

slugging, and inherently yields high efficiency.

4

GREE Central Air Conditioners

Air-Cooled Scroll Chiller Technical Sales Guide

This well protected compressor includes a solid-state motor protection module, 4

individual motor winding sensors, a patented internal discharge temperature probe,

and a patented shutdown feature that prevents reverse rotation. An internal

discharge check valve helps prevent shutdown noise and comes standard with high

and low pressure taps with Schrader valves, a sight glass, an oil level adjustment valve,

and an off cycle crankcase heater.

Evaporator

The evaporator is direct expansion, shell-and-tube type with water flowing in the

baffled shell side and refrigerant flowing through the tubes. Two independent

refrigerant circuits within the evaporator serve the module's dual refrigerant circuits.

The evaporator has a carbon steel shell and seamless high efficiency copper tubes

roller expanded into a carbon steel tube sheet. Refrigerant heads are carbon steel

with multi-pass baffles to provide oil return . For water removal, 10mm vent and drain

plugs are provided on the top and bottom of the shell. An ambient air thermostat

controls the heater cable. The fitted and glued in place insulation has a K factor of

0.28. The refrigerant side maximum working pressure is 4400 kPa. The water side

working pressure is 1048 kPa. Each evaporator is designed, constructed, inspected,

and stamped according to the requirements of the ASME Boiler and Pressure Vessel

Code.

Condenser

Cond enser coils have internally enhanced seamless copper tubes arranged i n a

stag gered row pattern. The coils are mechanically expanded into flat aluminum

fins with full fin collars. A variety of optional coil ma terial and coatings are

avai lable for corrosive atmospheres.

Fans -The condenser fans are co mposed of corrosion resistant aluminum hub

and glass-fiber-reinfo rced polypropylene composite blades molded into a low

nois e airfoil section. They are designed for maximum efficiency and are

stat ically and dynamically balanced for vibration-free oper ation. They are

dire ctly driven by independent motors, and positioned fo r vertical ai r discharge.

The fan guards are constructed of heavy-gauge, rust-resistant, c oated steel. Al l

blad es are statically and dynamically balan ced for vibration-free ope ration.

Motors-The fan motors are totally enclosed air-wver, squirrel-cage type. They feature

ball bearings that are double-sealed and permanently lubricated.

3.3 Standard Accessories

Unit on-off switch: ON-OFF switch is provided for manually switching the unit control

circuit.

Indicator lights: LED lights indicate power on to unit, running state and fault indications

due to safety devices.

Filter: Refrigeranting circuits are kept free of sludge, acid and oil contamination with it.

Under voltage and phase protection: Protects against low incoming voltage as well as

single phase, phase reversal.

Liquid line solenoid valve: IT coses when the compressor is off to prevent any liquid

refrigerant from accumulating in the evaporator.

GREE Central Air Conditioners

5

3.4 Standard Control & Safety Devices

The chiller's Unit Control Module is an innovative, modular microprocessor control

design. It coordinates the actions of the chiller in an efficient manner and provides

stand-alone operation of the unit. A Human Interface Panel is a standard component

of the Chiller. Access to all unit controls is via the Human Interface Panel.

Safety valve: Protects the unit against high discharge pressure.

Compressor In-built protection device: Motor winding temperature, discharge gas

temperature and phase reversal for direction of rotation.

Crankcase heaters: Protects the unit against refrigerant migration, oil dilution and

potential compressor failure.

High pressure switch: Provides protection in case of excessive discharge press-ure.

Low pressure switch: Provides protection in case of unsafe low suction pressure.

PRODUCT DATA

4

4.1 Ratings

Model Name

LSQWRF65MG/NaC-M

LSQWF65MG/NaC-M

LSQWRF80MG/NaC-M

LSQWF80MG/NaC-M

LSQWRF130MG/NaC-M

LSQWF130MG/NaC-M

LSQWRF160MG/NaC-M

LSQWF160MG/NaC-M

LSQWRF65MG/NaC-F

LSQWF65MG/NaC-F

LSQWRF80MG/NaC-F

LSQWF80MG/NaC-F

LSQWRF130MG/NaC-F

LSQWF130MG/NaC-F

LSQWRF160MG/NaC-F

LSQWF160MG/NaC-F

KW/TR

60 / 17

76 / 22

120 /34

152 / 43

60 / 17

76 / 22

120 /34

152 / 43

EER

9.4

9.4

9.4

9.4

9.4

9.4

9.4

9.4

EER=Energy Efficiency Ratio at full load-the cooling capacity in Btu's per hour(Btu/h)

divided by the power input in watts, expressed in Btu/h per watts((Btu/h)/watt).

6

GREE Central Air Conditioners

Air-Cooled Scroll Chiller Technical Sales Guide

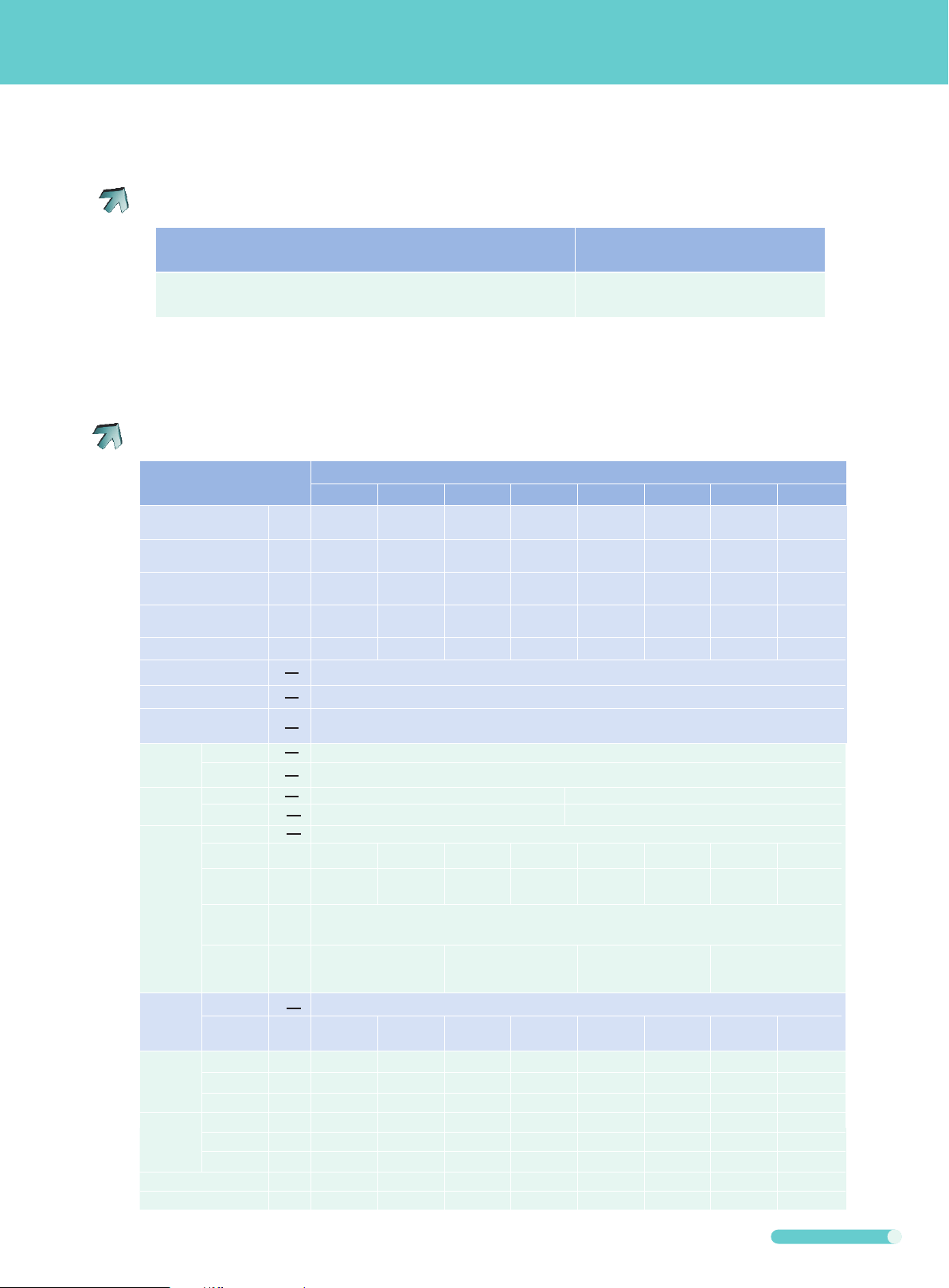

4.2 UNIT APPLICATION DATA

Voltage Variation

Ambient Air on Condenser coil

4.3 SPECIFICATION

Models

Model

Rated cooling

capacity

Input power

for cooling

Rated heating

capacity

Hea ting input

pow er

Noise

Power supply

Operating control

Safety protection

devices

Comp-

ressor

Refrig-

erant

Water

side

heat

excha-

nger

Air side

heat

excha-

nger

Outline

dime-

nsion

Package

dime-

nsion

Gross weight

Starting

mode

Control

Water

Water

resistance

Maximum

bearing

pressure

Diameter

Fan Motor

input power

Depth

Height

Depth

Height

Net weight

Type

Type

Type

flow

loss

of

water

pipes

Type

Width

Width

kW

kW

kW

kW

dB(A)

m³/h

kPa

MPa

mm

kW

mm

mm

mm

mm

mm

mm

kg

kg

342/420(50Hz)

Min./Max.

Min./Max.℃(℉)

LSQWF_MG/NaC-M

65

80

130 160 65 80 130 160

60 76 120 152

21.8 27.6 43.6 55.3

/ / / /

/ / / /

67

68 69 70

198/242(60Hz)

-15/46 ( 41/115)

LSQWRF_MG/NaC-M

60 76 120 152

21.8 27.6 43.6 55.3

65 80 130 160

21.7 26.7 43.3 53.3

67

68 69 70

380~415V 3N~50Hz

Micro compu ter c ontro l, oper ati ng stat us disp lay a nd abno rmal st atu s alarm

High an d low v olt age s witch es, f ree ze pr event ion s wit ch, over-c urr ent p rotectio n swi tch , phase

lacki ng pro tec tor, com pre sso r ove rhe at pro tecti on dev ice and sof twa re delay st art ing

compr ess or pr ote ction

Totally enclosed flexible scroll compressor

Direct starting

R410A

Electronic expansion valve Electronic expansion valve

Efficient shell and tube heat exchanger

R410A

10.3 13.1 20.6 26.1 10.3 13.1 20.6 26.1

30 35 30 35 30 35 30 35

1

DN 50

DN 150 DN 50 DN 150

Efficient finned coil tube exchanger

0.7*3 0.7*3 0.7*6 0.7*6 0.7*3 0.7*3 0.7*6 0.7*6

1100 1100

2200 2200

2265 2265 2265 2265 2265 2265 2265

2214 2214 2214 2214 2214 2214 2214

1180 1180

2280 2280

2345 2345 2345 2345 2345 2345 2345

2214 2214 2214 2214 2214 2214 2214

900 1000

1780 1980 950

910 1010 1800 2000 960 1060 2100

1100 1100

1180 1180

1050

2200

2265

2214

2280

2345

2214

1880

1900

2200

2280

2080

GREE Central Air Conditioners

7

Loading...

Loading...