Gree LIVS12HP115V1B Installation Manual

HIGH-WALL DUCTLESS

AIR CONDITIONING & HEATING SYSTEM

INSTALLATION MANUAL

Models:

LIVS09HP115V1B

LIVS12HP115V1B

LIVS09HP230V1B

LIVS12HP230V1B

LIVS18HP230V1B

LIVS24HP230V1B

LIVS30HP230V1B

LIVS36HP230V1B

Thank you for choosing a Livo Heat Pump

for your customer.

Please read this installation manual carefully before installing and starting up the

Livo System. Take a moment to fill out the product and installation form on the

back cover. Retain both the manual and installation record for future reference.

Table of Contents

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2- 3

Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Suggested Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation Schematic

Installation Site Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 -9

Indoor Unit Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-11

Outdoor Unit Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-14

Piping Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 -18

Power and Wiring Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 -21

Testing and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22- 24

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 -26

Diagnostic Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27-29

Care and Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

SAFETY PRECAUTIONS

Please read the following before operation.

Recognize safety information. This is the safety-alert symbol. When you see this

symbol on the unit and in instructions or manuals, be alert to the potential for personal

injury. Understand these signal words: DANGER, WARNING, and CAUTION. These

words are used with the safety-alert symbol.

DANGER identifies the most serious hazards which will result in severe personal injury or death.

WARNING signifies hazards which could result in personal injury or death.

CAUTION is used to identify unsafe practices which may result in minor personal

injury or product and property damage.

NOTE is used to highlight suggestions which will result in enhanced installation,

reliability, or operation.

N

O

T

E

:

Y

o

u

r

a

c

t

u

a

l

a

i

r

c

o

n

d

i

t

i

o

n

i

n

g

&

h

e

a

t

i

n

g

s

y

s

t

e

m

a

n

d

r

e

l

a

t

e

d

d

e

v

i

c

e

s

m

a

y

d

i

f

f

f

r

o

m

t

h

e

i

m

a

g

e

s

s

h

o

w

n

i

n

t

h

i

s

m

a

n

u

a

l

.

e

r

W

A

R

N

I

N

G

This appliance is not intended for use by children without responsible adult supervision.

Proper care should be taken to ensure safety.

W

A

R

N

I

N

G

Heat pumps, air conditioners & heating equipment should be installed, started up, and

serviced only by qualified installers and service technicians. Air conditioning, heat pumps

and refrigeration systems are hazardous due to high voltage electrical components,

high refrigerant pressures, and moving parts.

2

SAFETY PRECAUTIONS

CAUTION

• The unit should be installed and serviced only by trained, qualified installers and service

technicians. Untrained personnel can perform basic maintenance functions such as

cleaning coils. All other operations should be performed by trained service personnel.

• Owner should be cautioned that children should not play with the appliance.

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury or death.

• Before installing, servicing or modifying the system, the main electrical disconnect

switch must be in the OFF position. There may be more than one disconnect switch.

Lock out and tag all switches with a warning label.

General Safety Precautions

• A dedicated power supply circuit should be used in accordance with local electrical

safety regulations and National Electrical Codes (NEC).

• Ensure that the entire system is properly grounded.

• Use a properly sized circuit breaker to protect equipment against short circuit and

overload conditions.

• The system must be positioned at least 5 feet from combustible surfaces.

• Observe all local codes and regulations.

Installation Site Instructions

A proper installation site is vital for correct and reliable operation of the system.

Avoid the following installation locations :

• High heat sources, vapors, flammable gas or volatile liquids.

• High-frequency electro-magnetic waves, generated by radio equipment, welders

or medical equipment.

3

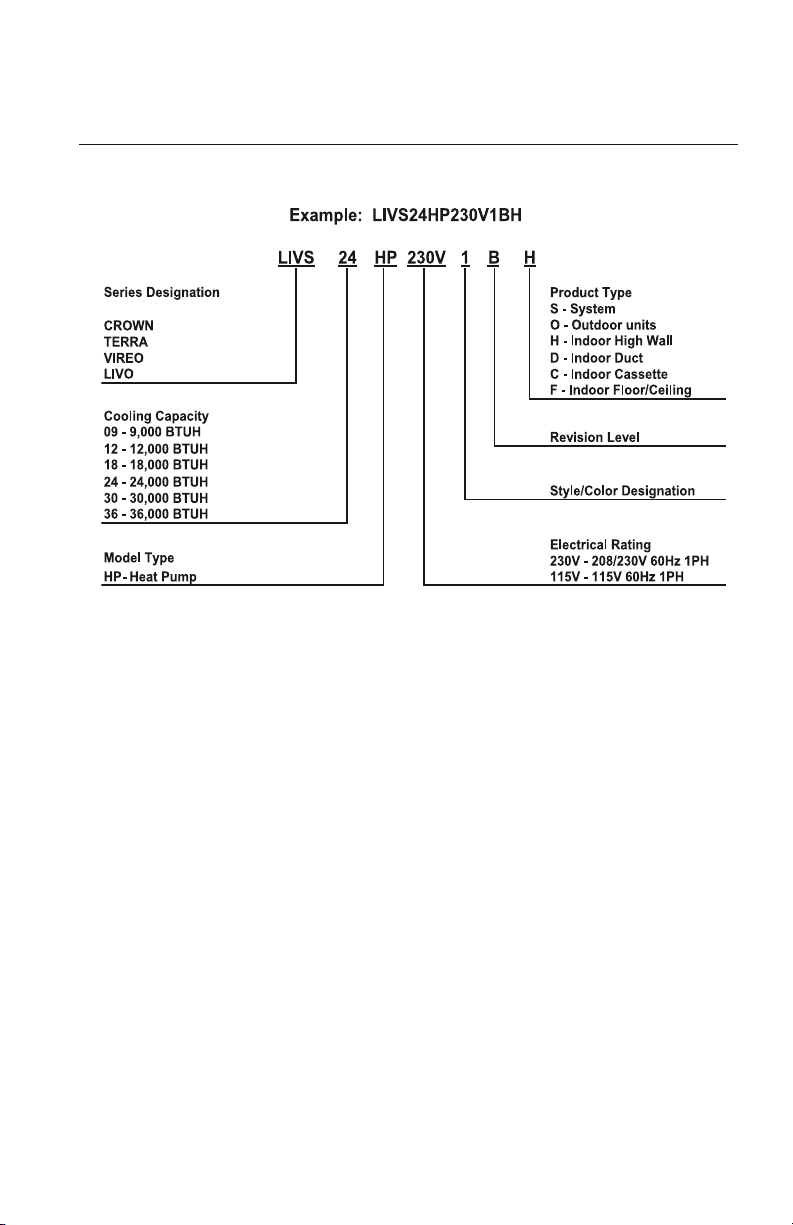

NOMENCLATURE

4

SYSTEM REQUIREMENTS

PIPE SIZE in (mm)

Unit Size

(BtuH)

9,000 115v - 1ph 60hz 1/4 (6)

12,000 115v - 1ph 60hz 1/4 (6)

9,000 208/230v - 1ph 60hz 1/4 (6)

12,000 208/230v - 1ph 60hz 1/4 (6)

18,000 208/230v - 1ph 60hz 1/4 (6)

24,000 208/230v - 1ph 60hz 1/4 (6)

30,000 208/230v - 1ph 60hz 1/4 (6)

36,000 208/230v - 1ph 60hz 1/4 (6)

REFRIGERANT LINE LENGTHS ft (m)

Unit Size

(BtuH) Length Length

9,000 115v - 1ph 60hz 10 (3)

12,000 115v - 1ph 60hz 10 (3) 66 (20)

9,000 208/230v - 1ph 60hz 10 (3) 49 (15)

12,000 208/230v - 1ph 60hz 10 (3)

18,000 208/230v - 1ph 60hz 10 (3) 82 (25)

24,000 208/230v - 1ph 60hz 10 (3) 82 (25)

30,000 208/230v - 1ph 60hz 10 (3) 98 (30)

36,000 208/230v - 1ph 60hz 10 (3) 98 (30)

Voltage

REFRIGERANT CHARGE

Unit Size

(BtuH) Type Charge oz (kg) Charge oz/ft (g/m)

9,000 115v - 1ph 60hz R410A

12,000 115v - 1ph 60hz R410A

9,000 208/230v - 1ph 60hz R410A

12,000 208/230v - 1ph 60hz R410A

18,000 208/230v - 1ph 60hz R410A

24,000 208/230v - 1ph 60hz R410A

30,000 208/230v - 1ph 60hz R410A

36,000 208/230v - 1ph 60hz R410A

Voltage

ELECTRICAL REQUIREMENTS

Unit Size

(BtuH) Amps (MCA) Protection (MOP) Wire Size (AWG)*

9,000 115v - 1ph 60hz

12,000 115v - 1ph 60hz

9,000 208/230v - 1ph 60hz

12,000 208/230v - 1ph 60hz

18,000 208/230v - 1ph 60hz

24,000 208/230v - 1ph 60hz

30,000 208/230v - 1ph 60hz

36,000 208/230v - 1ph 60hz

*Main power wire from electrical panel to outdoor unit.

Notes: 1) System must be on a single dedicated circuit.

2) Main power is supplied to the outdoor unit.

3) Use table above to size over current protection.

4) Follow all local building codes and NEC (National Electrical Code) regulations.

Interconnecting Cable: Recommended cable - 14/4 AWG stranded bare copper conductors THHN 600V unshielded wire

Note: Use shield cable if installation is in close proximity of RF and EMI transmitting devices.

Condensate Drain Size: 5/8-in OD 7/16-in ID

Voltage

Voltage

Min Line Max Line Max

Refrigerant Factory System Additional

Min Circuit Max Overcurrent Main Power

17

20

9

9

16

16

20

24

Liquid Line Suction/Gas Line

Pre-Charge

Line Length

25 (7.5)

25 (7.5)

25 (7.5)

25 (7.5)

25 (7.5)

25 (7.5)

25 (7.5)

25 (7.5)

24.7 (0.7)

31.8 (0.9)

24.7 (0.7)

30.0 (0.9)

49.4 (1.4)

65.3 (1.9)

84.7 (2.4)

91.7 (2.6)

49 (15)

66 (20)

25

30

15

15

25

25

30

40

3/8 (9.5)

3/8 (9.5)

3/8 (9.5)

3/8 (9.5)

1/2 (12)

5/8 (16)

5/8 (16)

5/8 (16)

Elevation

33 (10)

33 (10)

33 (10)

33 (10)

33 (10)

33 (10)

33 (10)

33 (10)

0.2 (20)

0.2 (20)

0.2 (20)

0.2 (20)

0.2 (20)

0.54 (50)

0.54 (50)

0.54 (50)

12/3

10/3

14/3

14/3

12/3

12/3

10/3

8/3

5

SUGGESTED TOOLS

• Standard Wrench

• Adjustable/Crescent Wrench

• Torque Wrench

• Hex Keys or Allen Wrenches

• Drill & Drill Bits

• Hole Saw

• Pipe Cutter

• Screw drivers (Phillips & Flat blade)

• Manifold and Gauges

• Level

• R410A Flaring Tool

• Clamp on Amp Meter

• Vacuum Pump

• Safety Glasses

• Work Gloves

• Refrigerant Scale

• Micron Gauge

6

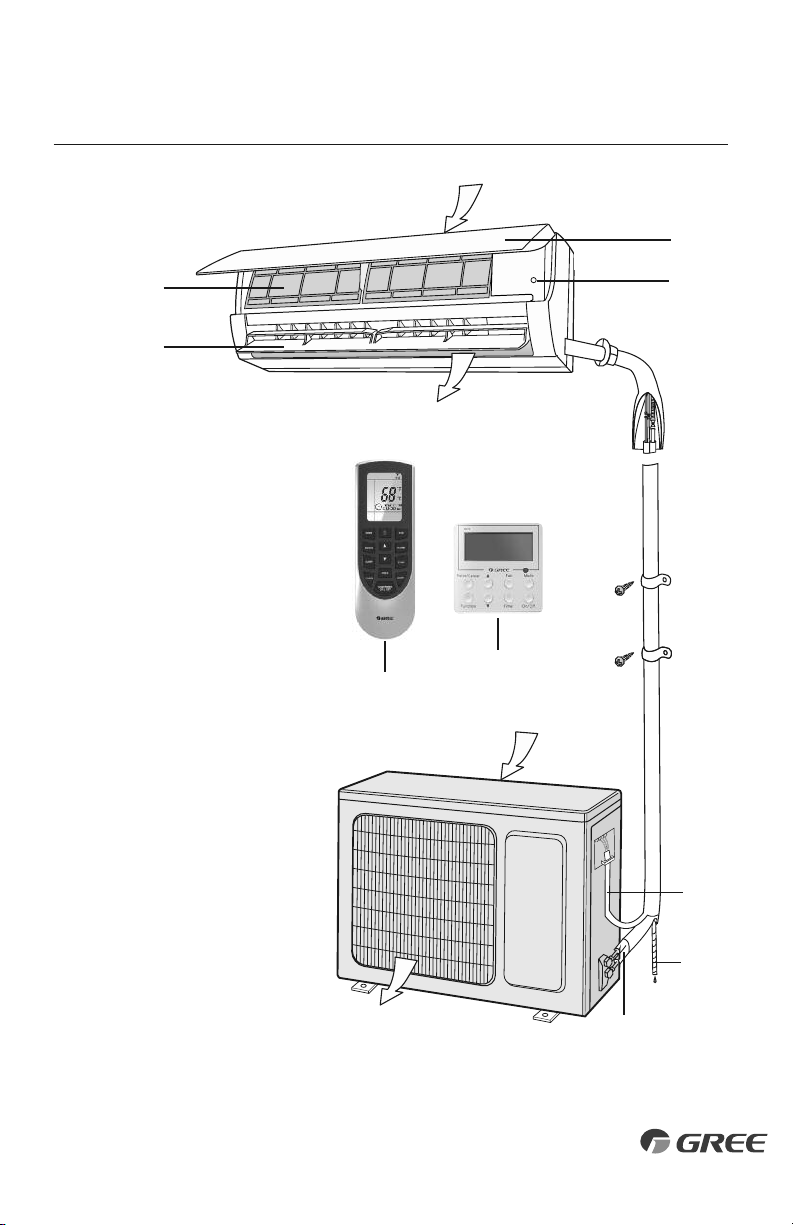

INSTALLATION SCHEMATIC

Indoor unit

3

4

Installation Components*

1. Front Panel

2. Aux. Button

3. Air Filter

4. Horizontal Louver

5. Remote Controller

6. Wired Programmable Controller

(sold separately)

7. Inter-Connecting Wire

(sold separately)

8. Drain Hose (sold separately)

9. Refrigerant Lines (sold separately)

* Not all items in this schematic are

included with equipment purchase

Air inlet

1

2

Air outlet

6

5

Air inlet

Outdoor unit

Air outlet

7

8

9

7

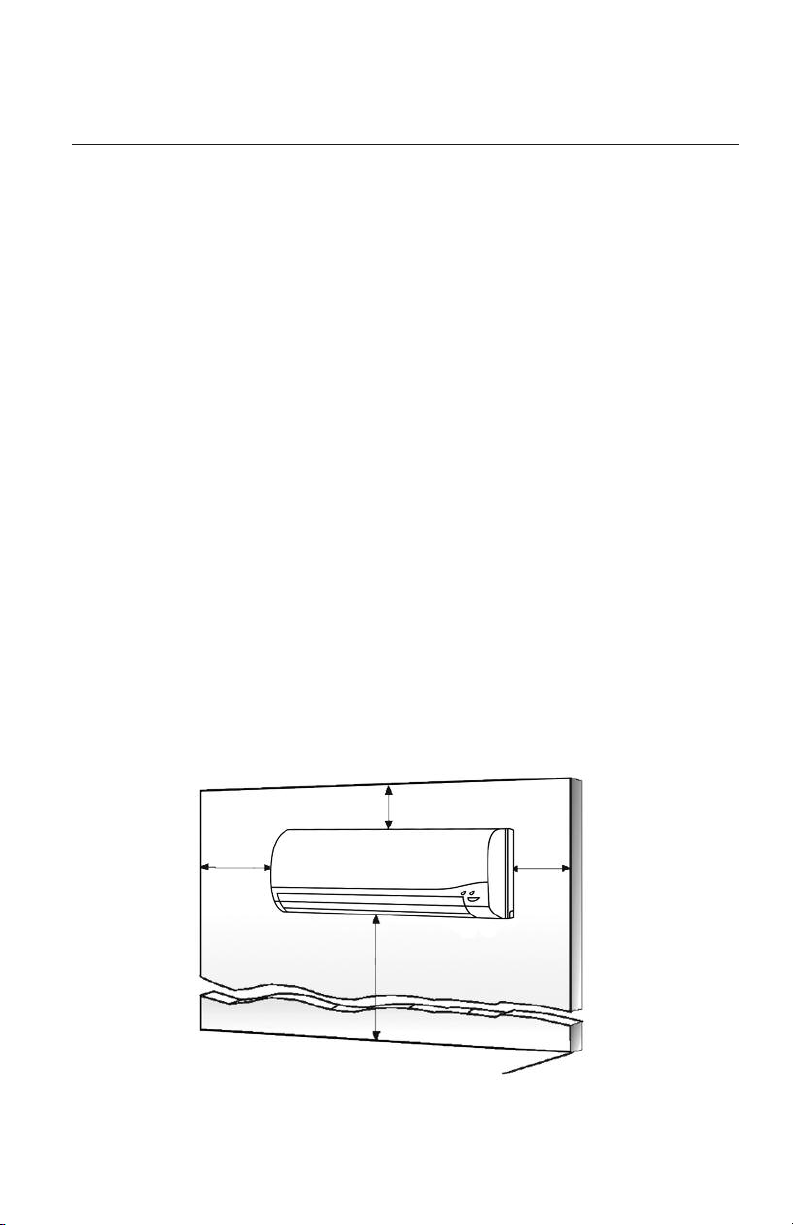

INSTALLATION SITE INSTRUCTIONS

Indoor Unit

Select a site that allows for the following:

1. Ensure the installation complies with the installation minimum dimensions (defined below)

and meets the minimum and maximum connecting piping length and maximum change in

elevation as defined in the System Requirements section.

2.

Air inlet and outlet will be clear of obstructions, ensuring proper airflow throughout the room.

3. Condensate can be easily and safely drained.

4. All connections can be easily made to outdoor unit.

5. Indoor unit is out of reach of children.

6.

A mounting wall strong enough to withstand four times the full weight and vibration of the unit.

7. Filter can be easily accessed for cleaning.

8. Leave enough free space to allow access for routine maintenance.

9. Install at least 10 ft. (3 m) away from the antenna of TV set or radio. Operation of the air

conditioner may interfere with radio or TV reception in areas where reception is weak.

An amplifier may be required for the affected device.

10. Do not install in a laundry room or by a swimming pool due to the corrosive environment.

Minimum Indoor clearances

6 in

(1500mm)

Ceiling

6 in (1500mm)

6 in

(1500mm)

6 ft (1.8m)

Floor

8

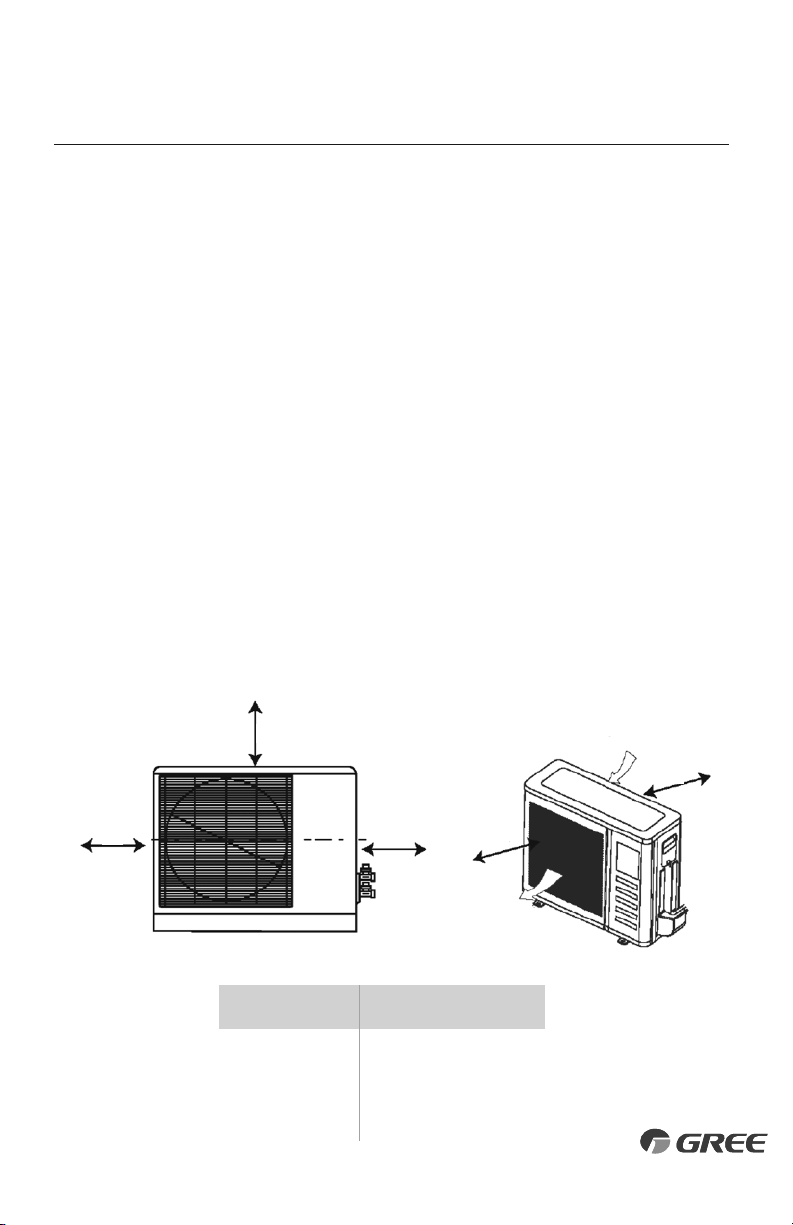

INSTALLATION SITE INSTRUCTIONS

Outdoor Unit

Select a site that allows for the following:

1.

Outdoor location meets all minimum installation clearances defined below.

2.

Sound from outdoor unit will not annoy neighbors.

3.

All connections can be easily made to indoor unit.

4.

Air inlet and outlet will be clear of obstructions to ensure proper airflow.

5.

Wall or roof is strong enough to withstand the full weight and vibration of the outdoor

unit (for wall or roof installation only).

6.

Outdoor unit is out of reach of children and does not obstruct walkways.

7.

Outdoor unit is not exposed to direct sunlight, excessive dust or strong wind.

8. Condensate water can drain freely during heating

9.

Maintenance and repairs can be easily performed on the outdoor unit.

10.

Ensure the installation complies with the minimum and maximum connecting piping

length and maximum change in elevation as defined in the System Requirements section.

Minimum Outdoor Clearances

A

B

Outdoor Unit

A 20 (500)

B 12 (305)

C 20 (500)

D

E

C D

Air outlet

Minimum Distances

in (mm)

24 (609

)

4 (101)

Air inlet

E

9

Loading...

Loading...