Gree HW18024PNa-D, HW18036PNa-D, HW18042PNa-D, HW18048PNa-D Owner's Manual

Change for life

Thank you for choosing Commercial Air Conditioners, please read this

owner’s manual carefully before operation and retain it for future reference.

For R410A Series

Unitary Ducted Split AC

Commercial Air Conditioners

Owner's Manual

Contents

Safety Considerations ...................................................................................1

1. Installation of the Wired Controller ............................................................2

2. Wiring Terminals of the Wired Controller ...................................................2

3. Main Page .................................................................................................3

4. Function Setting.........................................................................................3

4.1 “ON/OFF” .............................................................................................3

4.2 “Mode” ...................................................................................................4

4.3 “Fan” ...................................................................................................... 4

4.4 “▼/▲” (Temperature Adjustment) ..........................................................4

4.5 “SET” (Parameters/Functions View and Setting) ...................................5

4.6 “Enter/Hold” ...........................................................................................9

4.7 Lock Function ......................................................................................10

4.8 Error Display ........................................................................................ 10

5 Installation Instructions ............................................................................. 11

5.1 Physical Dimension ............................................................................ 11

5.2 Installation Recommendations ...........................................................12

5.3 Installation ..........................................................................................13

Unitary Ducted Split AC

1

Safety Considerations

Improper installation, adjustment, alteration, service, maintenance, or use can cause explosion,

fire, electrical shock, or other conditions which may cause death, personal injury, or property

damage. Consult a qualied installer, service agency, or your distributor or branch for information or

assistance. The qualied installer or agency must use factory--authorized kits or accessories when

modifying this product. Refer to the individual instructions packaged with the kits or accessories

when installing. Follow all safety codes. Wear safety glasses, protective clothing, and work

gloves. Use quenching cloth for brazing operations. Have re extinguisher available. Read these

instructions thoroughly and follow all warnings or cautions included in literature and attached to

the unit. Consult local building codes and National Electrical Code (NEC) for special requirements.

Recognize safety information. This is the safety--alert symbol .When you see this symbol on the

unit and in instructions or manuals, be alert to the potential for personal injury. Understand these

signal words; DANGER, WARNING, and CAUTION. These words are used with the safety--alert

symbol. DANGER identies the most serious hazards which will result in severe personal injury

or death. WARNING signies hazards which could result in personal injury or death. CAUTION is

used to identify unsafe practices which may result in minor personal injury or product and property

damage. NOTE is used to highlight suggestions which will result in enhanced installation, reliability,

or operation.

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury or death.

Before installing, modifying, or servicing system,main electrical disconnect switch must be in

the OFF position. There may be more than 1 disconnect switch. Lock out and tag switch with a

suitable warning label.

This product must not be disposed together with the domestic waste.

This product has to be disposed at an authorized place for recycling of

electrical and electronic appliances.

Unitary Ducted Split AC

2

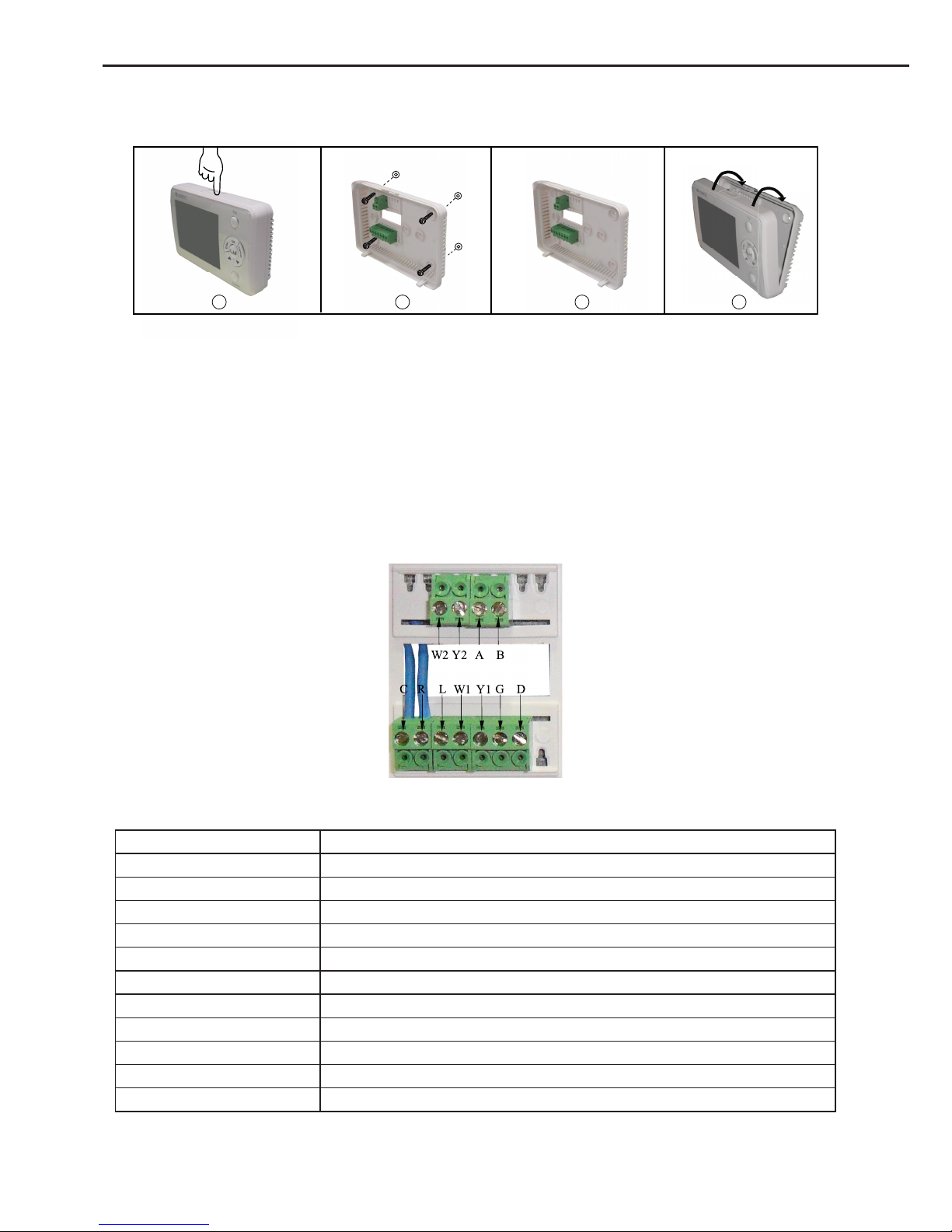

1. Installation of the Wired Controller

1 2 3 4

Fig.1 Installation Diagram

Step 1: Press the button at the top of the wired controller to remove the front panel and the

bottom plate.

Step 2: Reinstall the bottom plate in accordance with the locating holes either shown in the

gure above or decided by the user.

Step 3: Conduct the wiring and see section 2 for more details.

Step 4: Reinstall the front panel.

2. Wiring Terminals of the Wired Controller

Fig 2 Wiring Terminals Diagram

Table 1

Terminal Code Description

C 24 Volt (Neutral)

R 24 Volt Emergency (Hot)

O Four-Way Valve

G Indoor Unit

Y1 Compressor 1

Y2 Compressor 2(Reserved)

W1 Auxiliary Electric Heater 1

W2 Auxiliary Electric Heater 2

L Temperature Sensor Error Output

A 485 Communication Port

B 485 Communication Port

Unitary Ducted Split AC

3

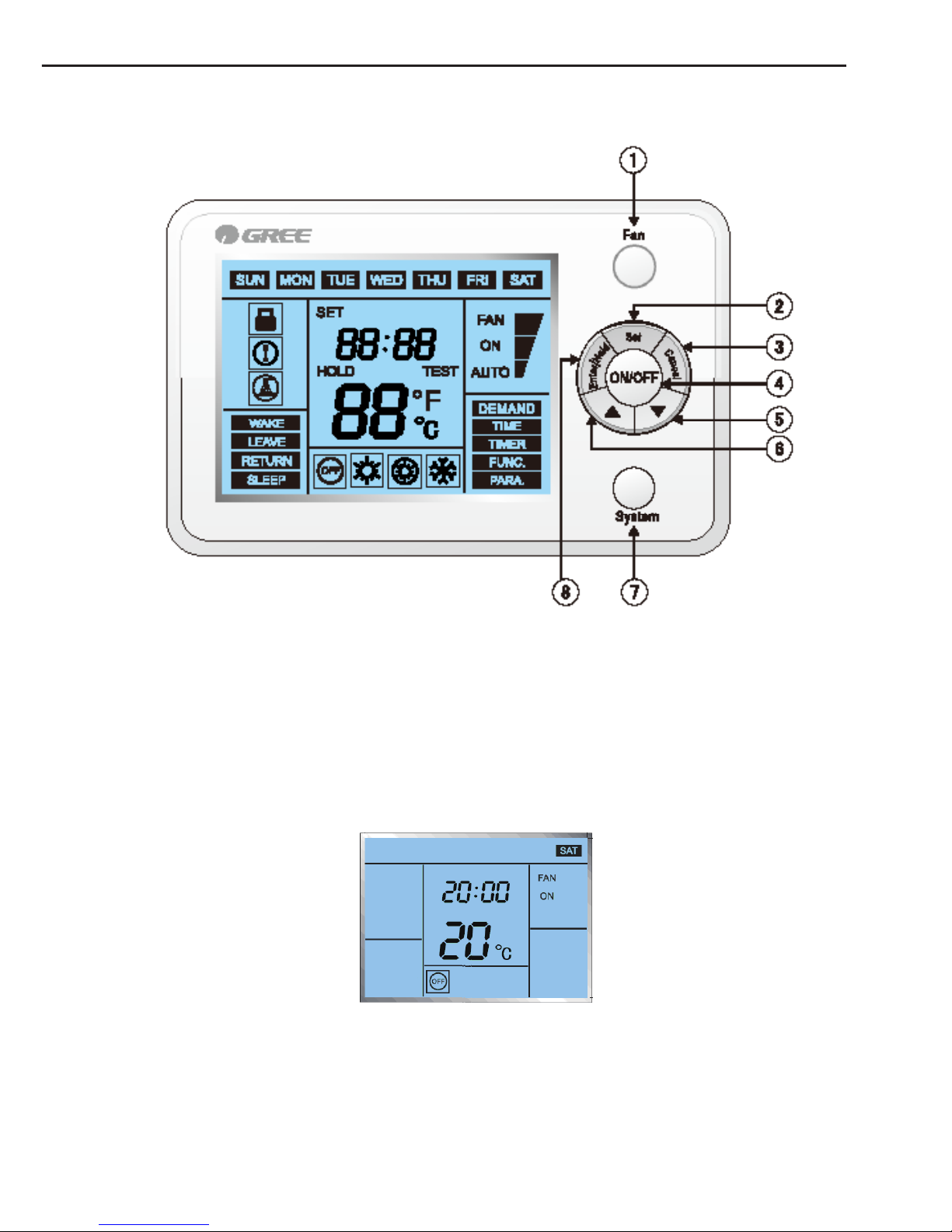

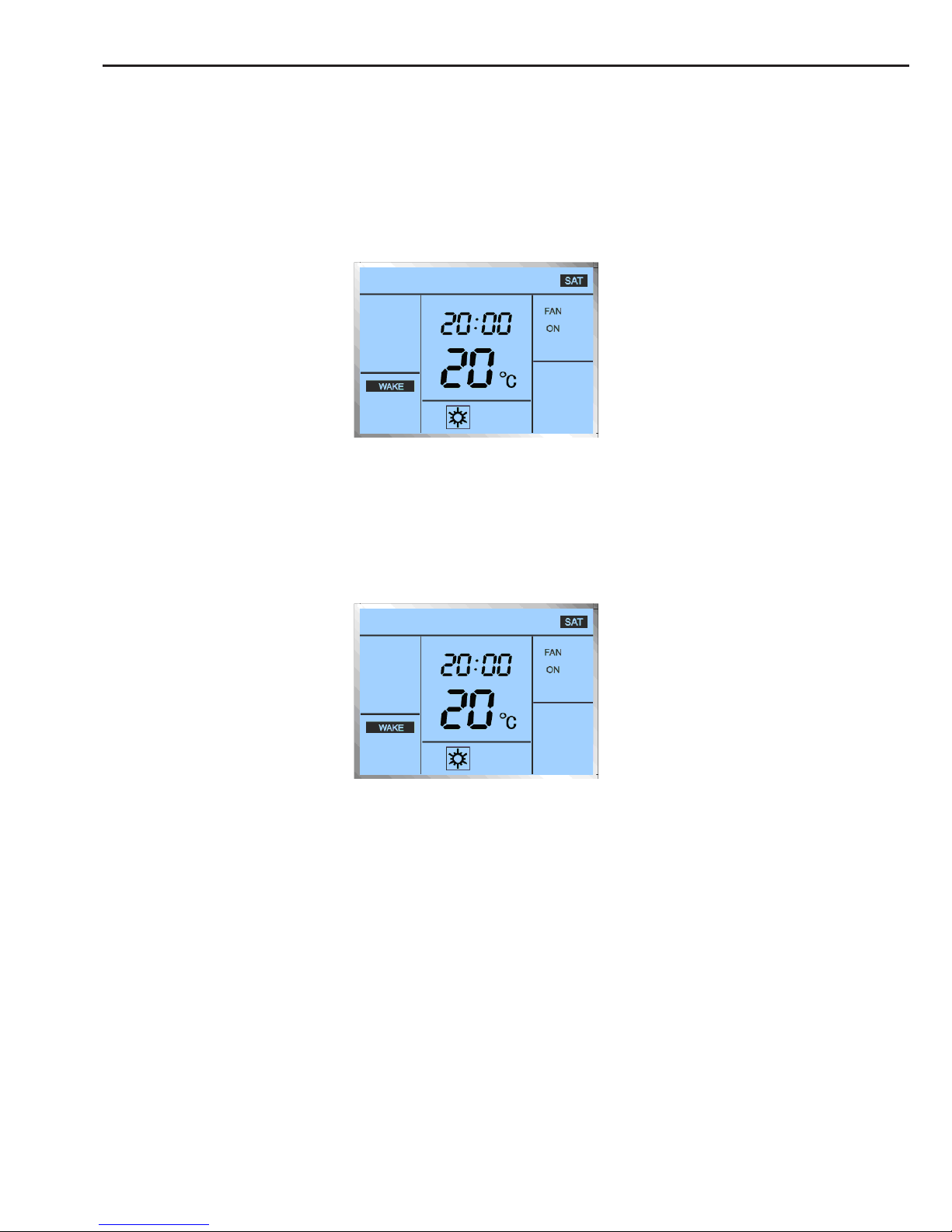

3. Main Page

Fig.3 Main Page

①

“Fan” ③ “Cancel” ⑤ “▼” ⑦ “Mode”

②

“Set” ④ “ON/OFF” ⑥ “▲” ⑧ “Enter/Hold”

4. Function Setting

4.1 “ON/OFF”

The controller can be turned on/off by pressing this button, with the corresponding ON/OFF

symbol displayed.

Fig.4

Unitary Ducted Split AC

4

4.2 “Mode”

One among various mode options can be selected by pressing the “Mode” button

● As for the cooling only unit, the switchover order of mode options is: E-HEATER→COOL.

● As for the cooling and heating unit, the switchover order of mode options is: HEAT→

E-HEATER →COOL

Note: the unit type is identied by the main board of the unit.

Fig. 5

4.3 “Fan”

It is available to select the desirable fan option by pressing the “Fan” button

● Under the “FAN ON” option, the fan will always keep running.

● Under the “FAN AUTO” option, the fan will be automatically shut down or started up in

accordance with the actual Mode and temperature.

Fig. 6

4.4 “▼/▲” (Temperature Adjustment)

Under the main page, the temperature for the current Mode can be adjusted by pressing the

“▼/▲” button.

● During temperature adjustment, the temperature value will blink, with the symbol “SET”

displayed.

● After the adjustment, it will automatically back to the main page and display the current

environment temperature.

Unitary Ducted Split AC

5

Fig. 7

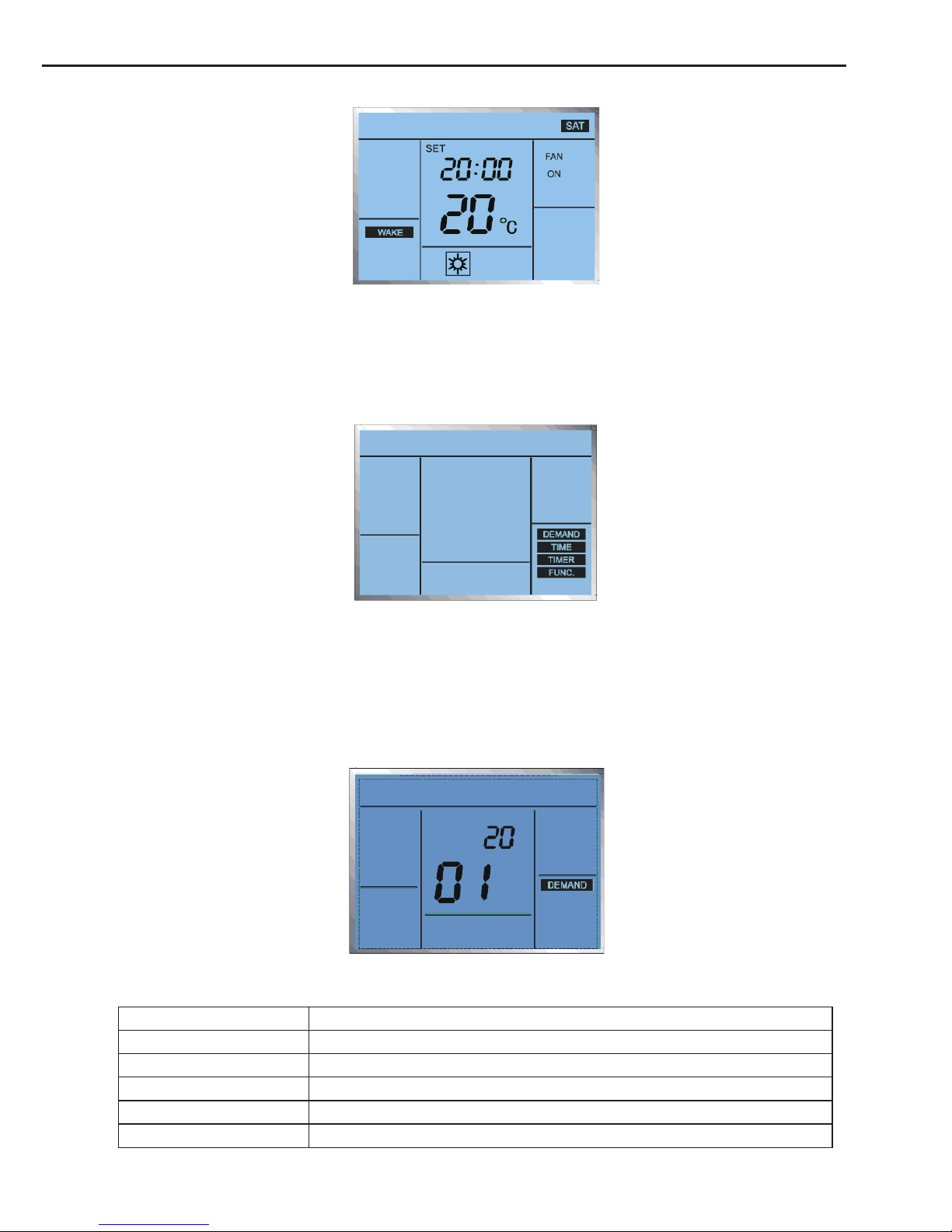

4.5 “SET” (Parameters/Functions View and Setting)

It is available to go the parameters/functions view and setting page by pressing the “Set”

button, and then desired option can be selected by pressing the “▼/▲” button, nally go to the

corresponding view and setting page by pressing the “Enter/Hold” button.

Fig.8 Parameters/Functions View and Setting

4.5.1 “DEMAND”

After accessing to the “DEMAND” page, it is available to select the desired parameter by

pressing the “▼/▲” button.

The upper value indicates the desired parameter, while the lower value indicates the parameter

No.

Fig.9

Table 2

Parameter No. Parameter Description

01 Compressor Runtime

02 Opening Angle of the Electronic Expansion Valve

03 Outdoor Environment Temperature

04 Tube Inlet Temperature of the Outdoor Unit

05 Tube Midway Temperature of the Outdoor Unit

Unitary Ducted Split AC

6

06 Tube Outlet Temperature of the Outdoor Unit

07 Discharge Air Temperature of the Outdoor Unit

08 Preset Frequency

09 Running Frequency

10 IPM Radiator or IPM Temperature

● This page can quit by pressing the “Enter/Hold” button,

● The accumulated “Compressor Runtime” can be cleared by pressing the “Mode” button for

ve seconds.

Note: when the accumulated “Compressor Runtime” exceeds 1500 hours, a symbol on the main

page will be displayed to remind the user clearing the runtime.

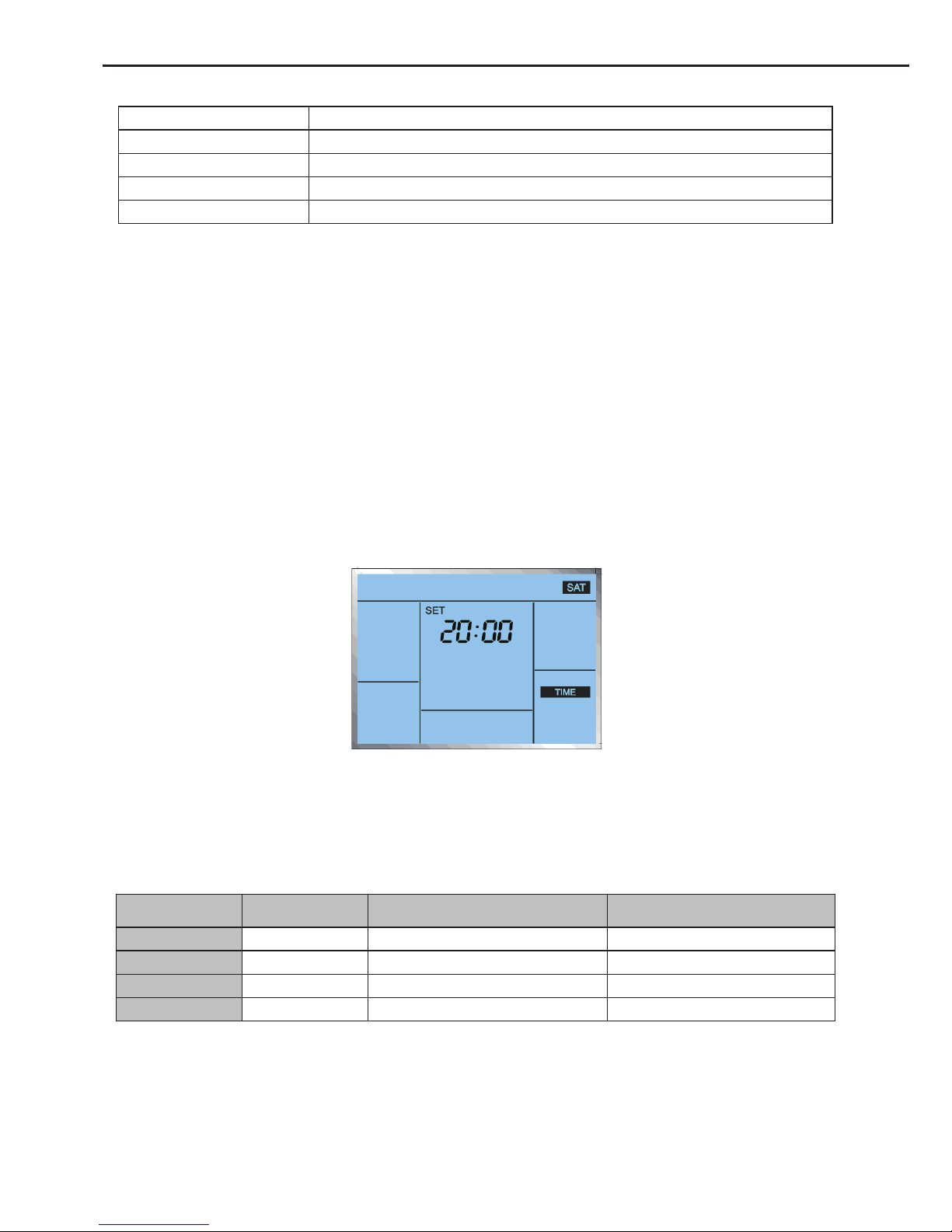

4.5.2 “TIME”

After going into the “TIME” page, it is available to adjust the time.

● Switch to the time value in the order of DAY →HOUR →MINITE,

● Adjust the blinking value by pressing the “▼/▲” button,

● After the MINUTE is set, press the “Enter/Hold” button for conrmation to make this setting

come effective and back to the previous interface.

If the setting is canceled prior to the conrmation, then the related parameter will not be saved

and come into effect.

Fig.10

4.5.3 “TIMER”

It is capable of timing four periods for each day of one week,

For instance:

Table 3

No. Period Cooling Temperature

Heating Temperature

(Auxiliary Heating)

Period 1 06:00 24

℃

21

℃

Period 2 08:00 28

℃

17

℃

Period 3 18:00 24

℃

21

℃

Period 4 22:00 26

℃

17

℃

When the unit is currently under the cooling mode, the temperature will be set to

24℃ automatically at 06:00, 28℃ at 8:00, 24℃ at 18:00 and 26℃ at 22:00.

When the unit is currently under the heating or auxiliary heating mode, the temperature will be

set to 21℃ automatically at 06:00, 17℃ at 8:00, 24℃ at 21:00 and 17℃ at 22:00.

①

After going to this function page, the day (like, “SAT”) will blink and then adjust it through the

Loading...

Loading...