Page 1

Condensing Unit Service Manual

T1/R410A/60Hz

(GC201408-І)

Page 2

PRODUCT ..................................................................................................... 2

1 MODELS LIST .......................................................................................................... 2

1.1 Indoor Unit .................................................................................................................................... 2

2 NOMENCLATURE ..................................................................................................... 2

2.1 Indoor unit .....................................................................................................................................2

3 FUNCTION ................................................................................................................ 3

4 PRODUCT DATA ....................................................................................................... 4

4.1 Product Data at Rated Condition ..................................................................................................4

4.2 Operation Range ........................................................................................................................... 4

4.3 Electrical Data .............................................................................................................................. 5

CONTROL ...................................................................................................... 7

1 OPERATION FLOWCHART ...................................................................................... 7

1.1 Cooling/Dry Operation ................................................................................................................... 7

2 MAIN LOGIC .............................................................................................................. 8

2.1 Cooling Mode (for Cooling Only and Heat Pump) ......................................................................... 8

2.2 Dry Mode ....................................................................................................................................... 9

2.3 Fan Mode ...................................................................................................................................... 9

3 CONTROLLER ....................................................................................................... 10

3.1 wireless remote controller ..........................................................................................................10

3.2 Wired Controller (Chosen Accessory Part) ................................................................................14

INSTALLATION ............................................................................................ 19

1 INDOOR UNIT INSTALLATION ............................................................................... 19

1.1 Installation of Ceiling Type ..........................................................................................................19

3 REFRIGERATION PIPING WORK .......................................................................... 22

3.1 Refrigeration Piping Work Procedures ........................................................................................ 22

3.2 Caution in Connecting Pipes ....................................................................................................... 26

3.3 Specication of Connection Pipe ................................................................................................26

4 ELECTRIC WIRING WORK ..................................................................................... 26

4.1 Wiring Principle ...........................................................................................................................26

4.2 WIRING DIADRAM ....................................................................................................................28

4.3 Electric Wiring Design ................................................................................................................. 29

MAINTENANCE ........................................................................................... 31

1TROUBLE TABLE(Only for oor ceiling) ................................................................... 31

2 FLOW CHART OF TROUBLESHOOTING ............................................................. 31

2.1 Air ow volume from air outlet of unit is abnormal ......................................................................31

2.2 The unit can not start up for cooling ........................................................................................... 32

2.3 Poor cooling effect .......................................................................................................................33

2.4 Noise or abnormal vibration of unit .............................................................................................34

4 DISASSEMBLY AND ASSEMBLY PROCEDURE OF MAIN PARTS ....................... 35

5 EXPLODED VIEWS AND PART LIST ..................................................................... 38

CONTENTS

Page 3

1

Condensing Unit

Service Manual

PRODUCT

PRODUCT

Page 4

2

Condensing Unit

Service Manual

PRODUCT

PRODUCT

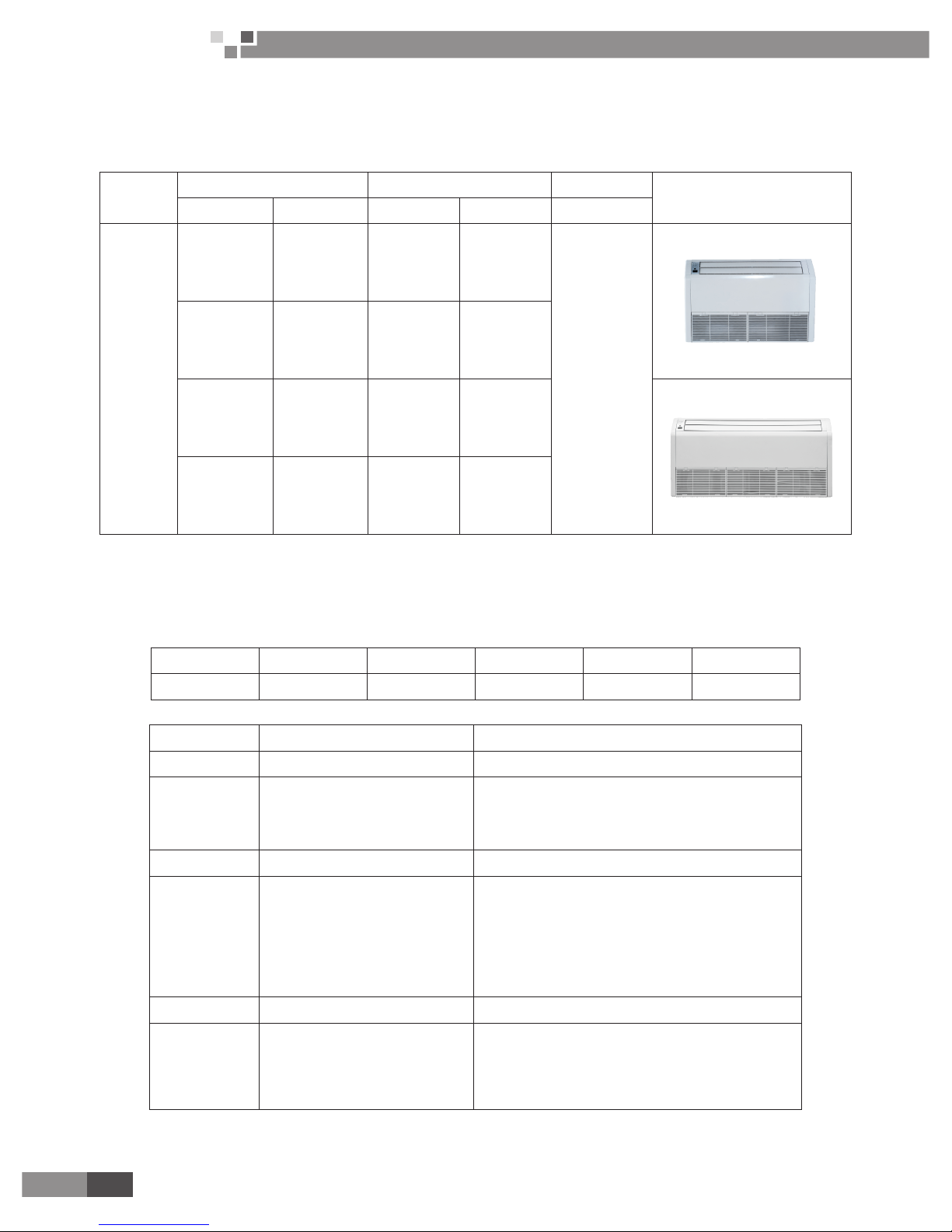

1 MODELS LIST

1.1 Indoor Unit

Refrigerant

Model Nominal Capacity Power Supply

Appearance

Model Name Product Code Cooling(Ton) Heating(Ton) V, Ph, Hz

R410a

HNTF24/A-D EM116N0760 2 2

220V-230v

1PH 60HZ

HNTF36/A-D EM116N0780 3 3

HNTF48/A-D EM116N0800 4 4

HNTF60/A-D EM116N0820 5 5

Note:1 Ton =12000Btu/h = 3.517kW

2 NOMENCLATURE

2.1 Indoor unit

HN T F 36/ A D

1 2 3 4 5 6

NO Description Options

1 Unit Series Type HN: Split Series

2

Unit Type

U=Match Outdoor Unit

F=Duct Type

K=Cassette Type

T= Ceiling Type

3 / /

4

Nominal Cooling Capacity

018=18000Btu/h

024=24000 Btu/h

030=30000 Btu/h

036=36000 Btu/h

042=42000 Btu/h

048=48000 Btu/h

060=60000 Btu/h

5 Product Serial Number A, B, C...

6 Power Supply

D:1Ph,208/230V,60Hz

K:1Ph,220/240V,60Hz

M:3Ph,380/415V,50Hz

F:3Ph,208/230V,60Hz

Page 5

3

Condensing Unit

Service Manual

PRODUCT

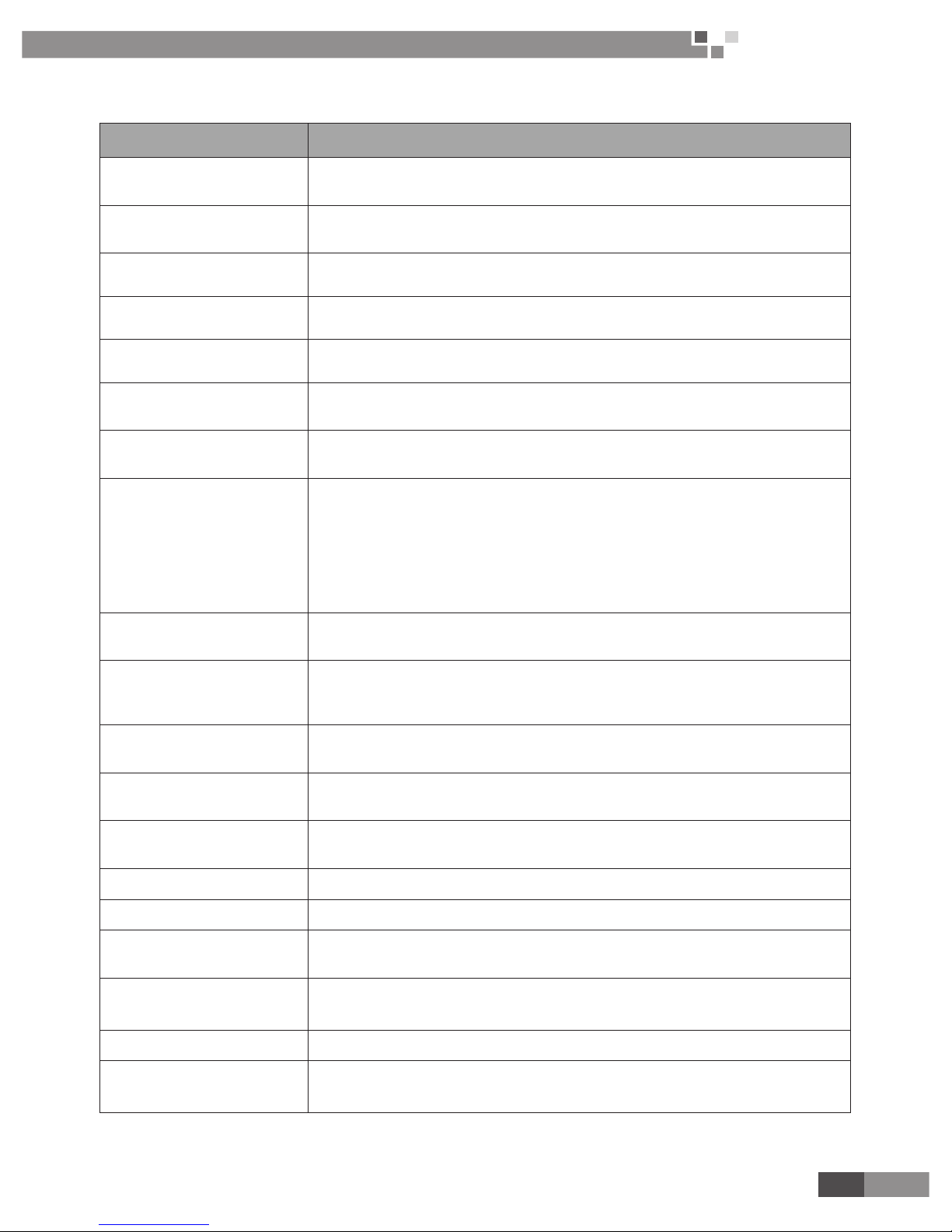

3 FUNCTION

Function

Description

Memory function

when unit restart after power off, it will run on former status,

the mode and parameter are kept the same

Remote control function

wireless controller and remote controller can be opted, and the

maximum control distance of remote controller is 10m.

Timing function it can timing ON/ OFF separately, meanwhile, it also can timing on circularly

Self-diagnosis with alarm function once unit has malfunction, the malfunction code will be indicated

Sleep function

it can self control for saving energy in energy saving mode.

Automatic function

the fan of indoor unit can adjust fan speed automatically based on

actual demand when cooling or heating under automatic mode

Cool air proof function

the fan starts only when the temperature of indoor unit heat exchanger

is higher than indoor temperature under heating mode

Weekly Timer

Centralized Control and Week Timer Functions: The centralized controller and

the weekly timer are integrated in the same wire controller. The system has both

the centralized control and the week timing functions. Up to 16 sets of units can

be controlled simultaneously by the centralized controller (weekly timer). The

weekly timer has the function of invalidating the lower unit. The weekly timing

function is able to realized four timing ON/OFF periods for any unit every day, so

as to achieve fully automatic operation. No timing control can be set for holidays.

High/low pressure protection

when suction pressure is too low or discharge pressure is too high,

compressor will stop and unit display malfunction code

Overload protection

compressor has its own overheat protection, once the temperature

of compressor is higher than allowable level, compressor will stop

and only when temperature recovery, compressor restart

Over current protection

once the current of compressor is higher that normal level,

compressor will stop and unit display malfunction code

Discharge high

temperature protection

once the discharge temperature of compressor is higher than allowable

value, compressor will stop and unit display malfunction code

Reverse (open) phase protection

once the phase sequence of power supply is incongruent

or the phase is absent, unit can’t work

Anti-high temperature protection once the heat exchanger temperature of indoor unit is too high, compressor stop.

Timing ON/OFF display display and timing turn ON/OFF time (only with wired controller have this function)

Fan speed display

display the speed (high, medium, low) of fan(only

with wired controller have this function)

Function model display

cooling mode, dehumidifying mode, heating mode, fan mode

(only with wired controller have this function)

Testing display

display testing mode(only with wired controller have this function)

Temperature display

display room temperature and set temperature (with wired

controller or remoter board have this function)

Page 6

4

Condensing Unit

Service Manual

PRODUCT

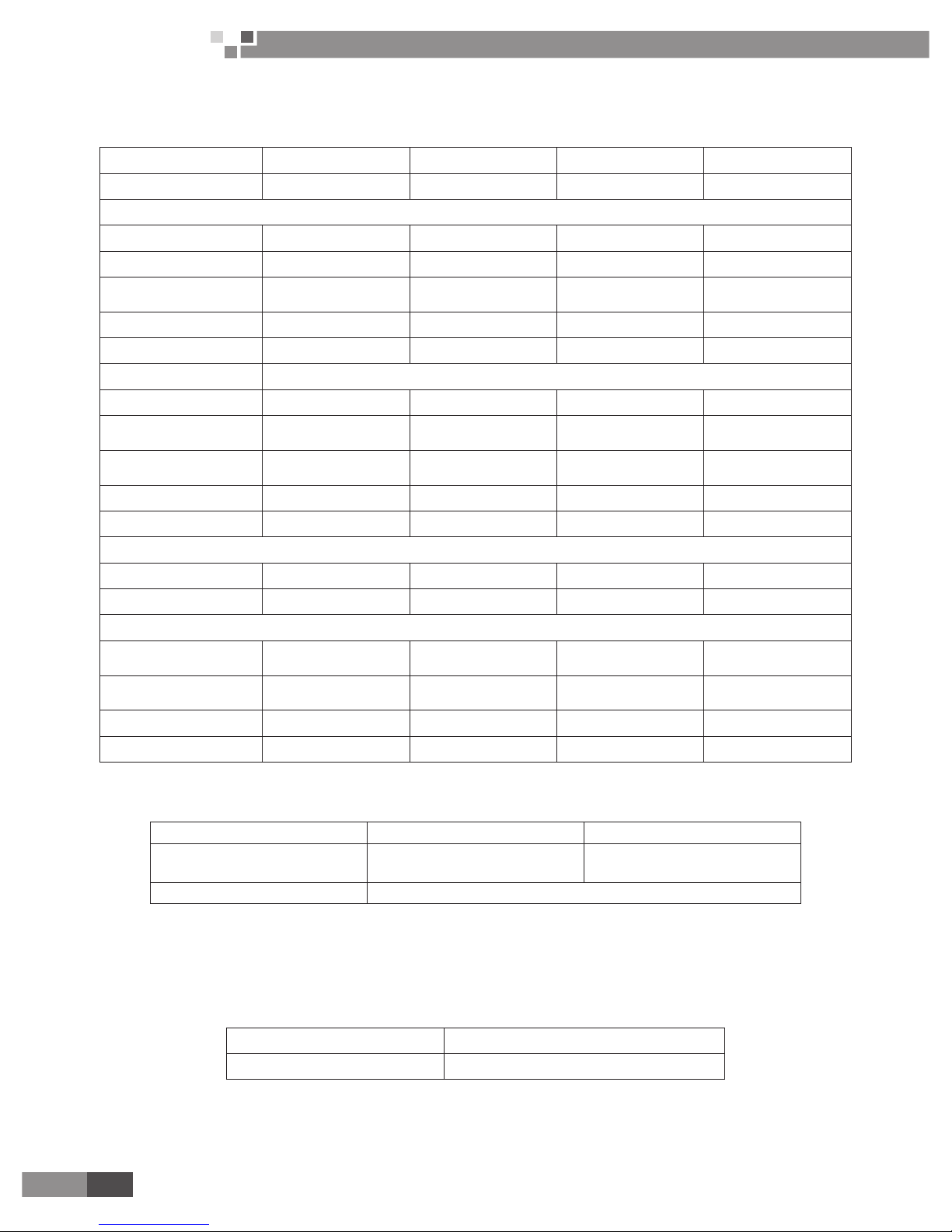

4 PRODUCT DATA

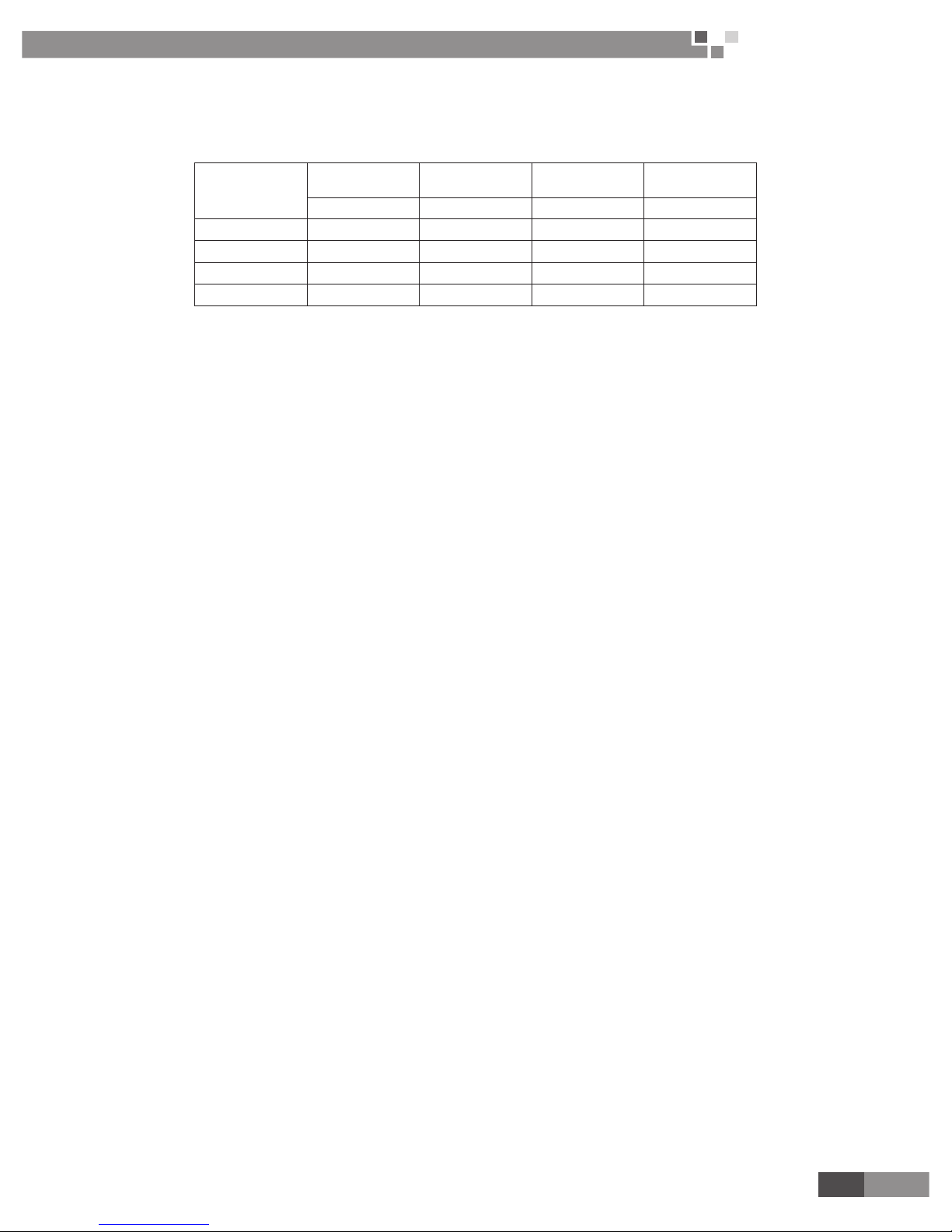

4.1 Product Data at Rated Condition

HNTF24/A-D HNTF36/A-D HNTF48/A-D HNTF60/A-D

Product Code EM116N0760 EM116N0780 EM116N0800 EM116N0820

Blower

Diameter(inch) 5 5 6 6

Width(inch) 4 4 7 7

Coil Drain Connection

FPT(inch)

7/8 7/8 7/8 7/8

Liquid(inch) 3/8 3/8 3/8 1/2

Suction(inch) 5/8 3/4 7/8 7/8

Electrical Data

Voltage(V) 220-230 220-230 220-230 220-230

Min Circuit

Ampacity (A)

13 13 13 13

Max .Overcurrent

Device(A)

15 15 15 15

Min volts (V) 198 198 198 198

Max volts (V) 254 254 254 254

Fan motor

FLA 0.65 0.65 1.6 1.6

Power output (HP) 1/15 1/15 1/5 1/5

Dimension

Outline Dimension

(W/H/D)(mm)

1220*225*700 1220*225*700 1420*245*700 1420*245*700

Package Dimension

(W/H/D)(mm)

1343*315*823 1343*315*823 1548*345*828 1548*345*828

Net Weight(kg) 41 41 50.5 50.5

Gross Weight(kg) 50 50 58.5 58.5

Note:

a. Nominal capacities are based on the follow conditions.

Indoor Outdoor

Cooling

DB:27oC(80.6oF)

WB:19oC(66.2oF)

DB:35oC(95oF)

WB:24oC(75.2oF)

Piping Length 7.6m

b. The air volume is measured at the relevant standard external static pressure.

c. Noise is tested in the Semianechoic Room, so it should be slightly higher in the actual operationdue

to environmental change.

4.2 Operation Range

Mode Range of Outdoor TemperatureoC (oF)

Cooling 67-115

Page 7

5

Condensing Unit

Service Manual

PRODUCT

4.3 Electrical Data

Indoor unit

Power Supply Fan Motor FLA

Fuse/Breaker

Capacity

Min. Power

Supply Cord

V/Ph/Hz A A mm

2

HNTF24/A-D 220-230,1,60 0.65 15 1.3

HNTF36/A-D 220-230,1,60 0.65 15 1.3

HNTF48/A-D 220-230,1,60 1.6 15 1.3

HNTF60/A-D 220-230,1,60 1.6 15 1.3

Notes:

RLA:Rated load amperes

LRA:Locked rotor amperes

FLA:Full load current

a. Install the disconnect device with a contact gap of at least 3mm in all poles nearby the units (Both

indoor unit and outdoor unit).The appliance must be positioned so that the plug is accessible.

b. The specications of the breaker and power cable listed in the table above are determined based on

the maximum power (maximum amps) of the unit.

c. The specications of the power cable listed in the table above are applied to the conduit-guarded

multi-wire copper cable (like, YJV copper cable, consisting of PE insulated wires and a PVC cable jacket) used

at 40°С and resistible to 90°С(see IEC 60364-5-52). If the working condition changes, they should be modied

according to the related national standard.

d. The specications of the breaker listed in the table above are applied to the breaker with the working

temperature at 40°С. If the working condition changes, they should be modied according to the related national

standard.

Page 8

6

Condensing Unit

Service Manual

CONTROL

CONTROL

Page 9

7

Condensing Unit

Service Manual

CONTROL

CONTROL

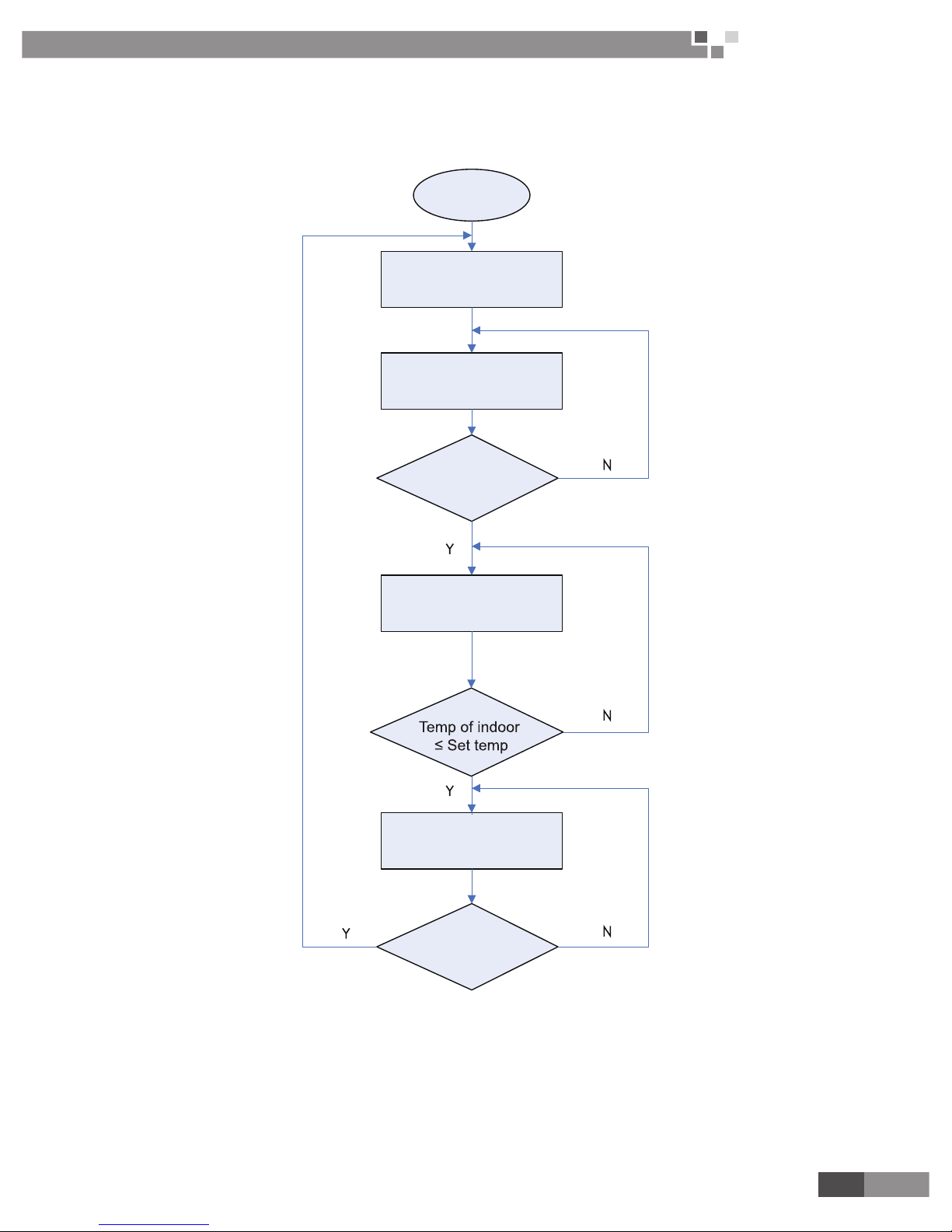

1 OPERATION FLOWCHART

1.1 Cooling/Dry Operation

Power on

Uint start and running

at cool or dry mode

Indoor fan run

Satisfying start

Comp.conditon

Comp.and

outdoor fan run

Comp.and outdoor

fan stop

Comp.stop

for 3 min

Page 10

8

Condensing Unit

Service Manual

CONTROL

2 MAIN LOGIC

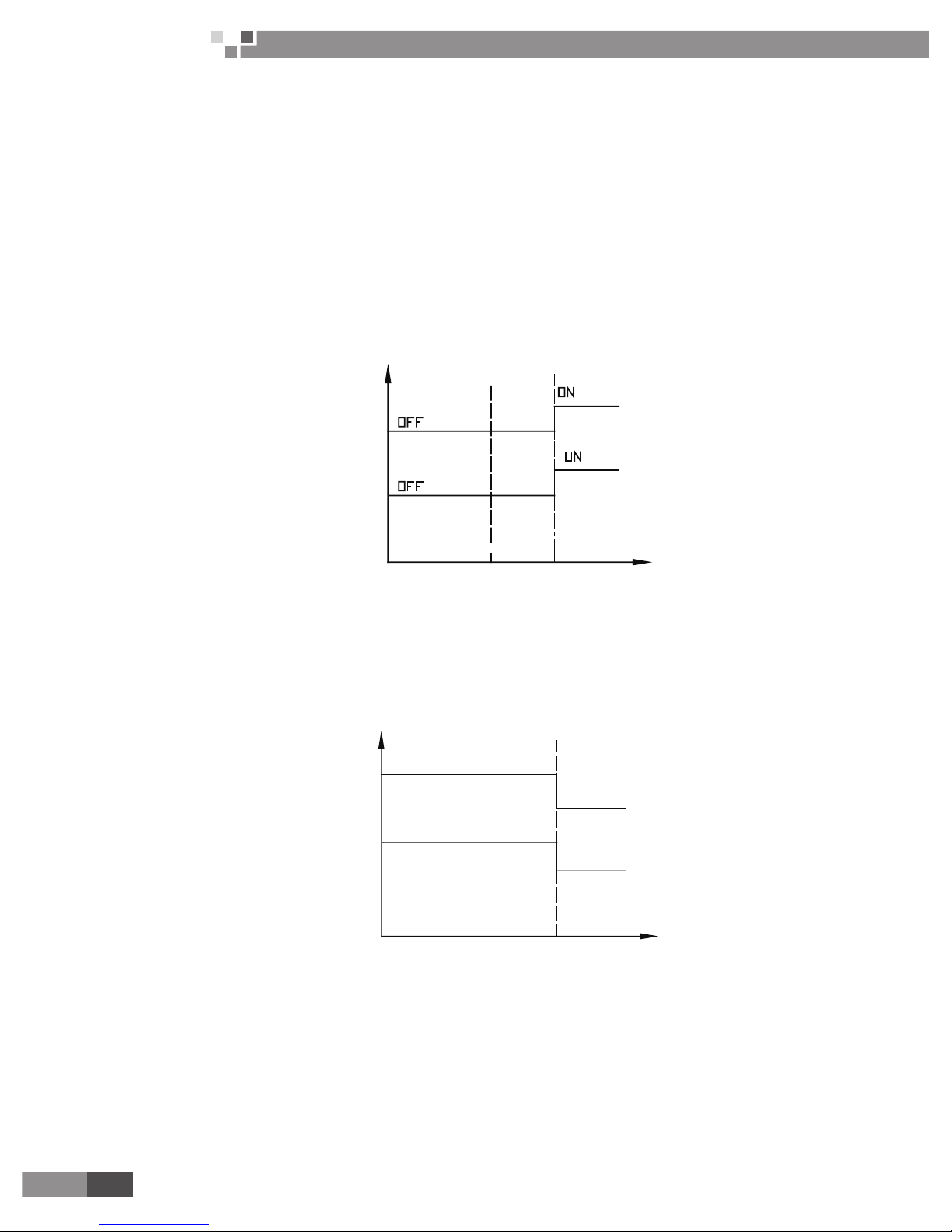

2.1 Cooling Mode (for Cooling Only and Heat Pump)

The temperature of condensing unit is set at the wired controller equipped by users

When the control-board of the outdoor unit detects the ON signal from wired controller, it will enter cooling

ON sub mode, and compressor, outdoor fan will start running synchronously.

When control-board detects the Stop signal from wired controller, it enters cooling Stop sub mode and the

compressor and outdoor fan stop synchronously.

When control-board detects the OFF signal from wired controller, it enters the cooling OFF sub mode and

compressor and outdoor fan stop synchronously.

Cooling only

Cooling ON Sub Mode Flowchart:

Cooling ON signal is

sent out from wired

controller

Electrity

Compressor

Outdoor fan

Object

Time

Cooling Stop Sub Mode Flowchart:

Object

Compressor

Outdoor fan

OFF

OFF

ON

ON

Time

Stop signal is sent out

from wired controlle

r

Page 11

9

Condensing Unit

Service Manual

CONTROL

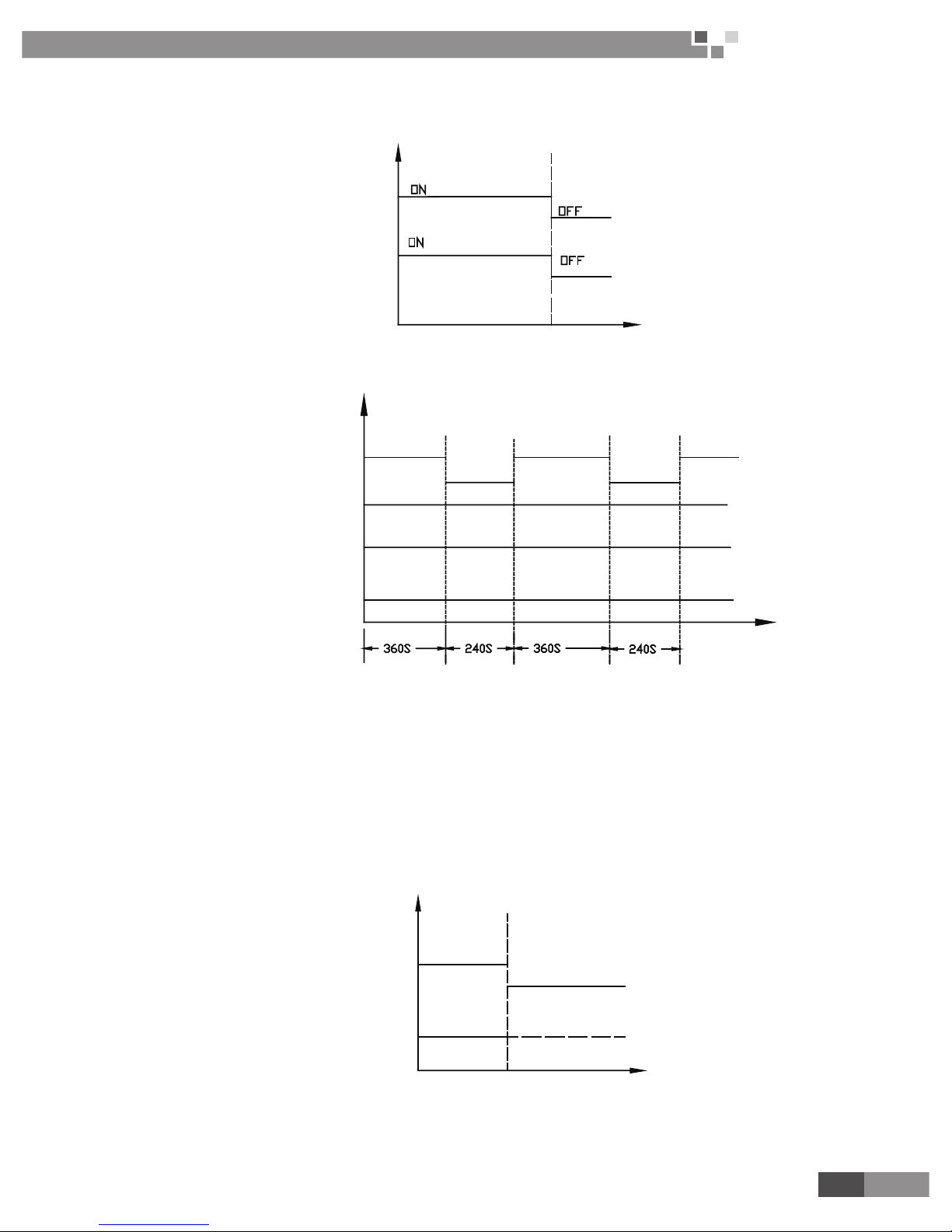

Cooling OFF Sub Mode Flowchart:

OFF signal is sent

out from wired

controller

Compressor

Outdoor fan

Object

Time

2.2 Dry Mode

Dry mode operation is as follows:

4-way valve Wire (O)

4-way valve Wire (B)

Compressor Control Wire

Indoor fan

Control Object

Time

ON(24V)

ON(24V)

OFF(OV)

(Low speed)

OFF(OV)

OFF(OV)

ON(24V)

ON(24V)O N(24V)

OFF(OV)

When Tambient≥Tset+2°C, the unit will start in cooling mode; In this case, the compressor starts and

indoor fan runs at set speed. After 20s, 4 way valve for cooling start running.

When Tambient≤Tset-2°C, the unit will stop during cooling operation; In this case, the compressor stops

and indoor fan runs at set speed. The 4-way valve for cooling remains original state.

When Tset-2°C<Tambient<Tset+2°C, the unit will operate in the state that the compressor starts 6min and

then stops 4min in cycle. In this case, indoor fan runs at low speed and the 4-way valve for cooling is always

running.

2.3 Fan Mode

(Vset)

ON

ON

OFF

Control objects

Other loads

Indoor fan

Time

Indoor fan will run at high speed for 5s and then at set speed. In this case, other loads stop.

3 CONTROLLER

Page 12

10

Condensing Unit

Service Manual

CONTROL

3.1 wireless remote controller

3.1.1 User notice

CAUTION !

①.

Be sure that there are no obstructions between receiver and wireless remote controller.

②.

Don't drop or throw the wireless remote controller.

③.

Don't let any liquid in the wireless remote controller and put the wireless remote controller directly under

the sunlight or any place where is very hot.

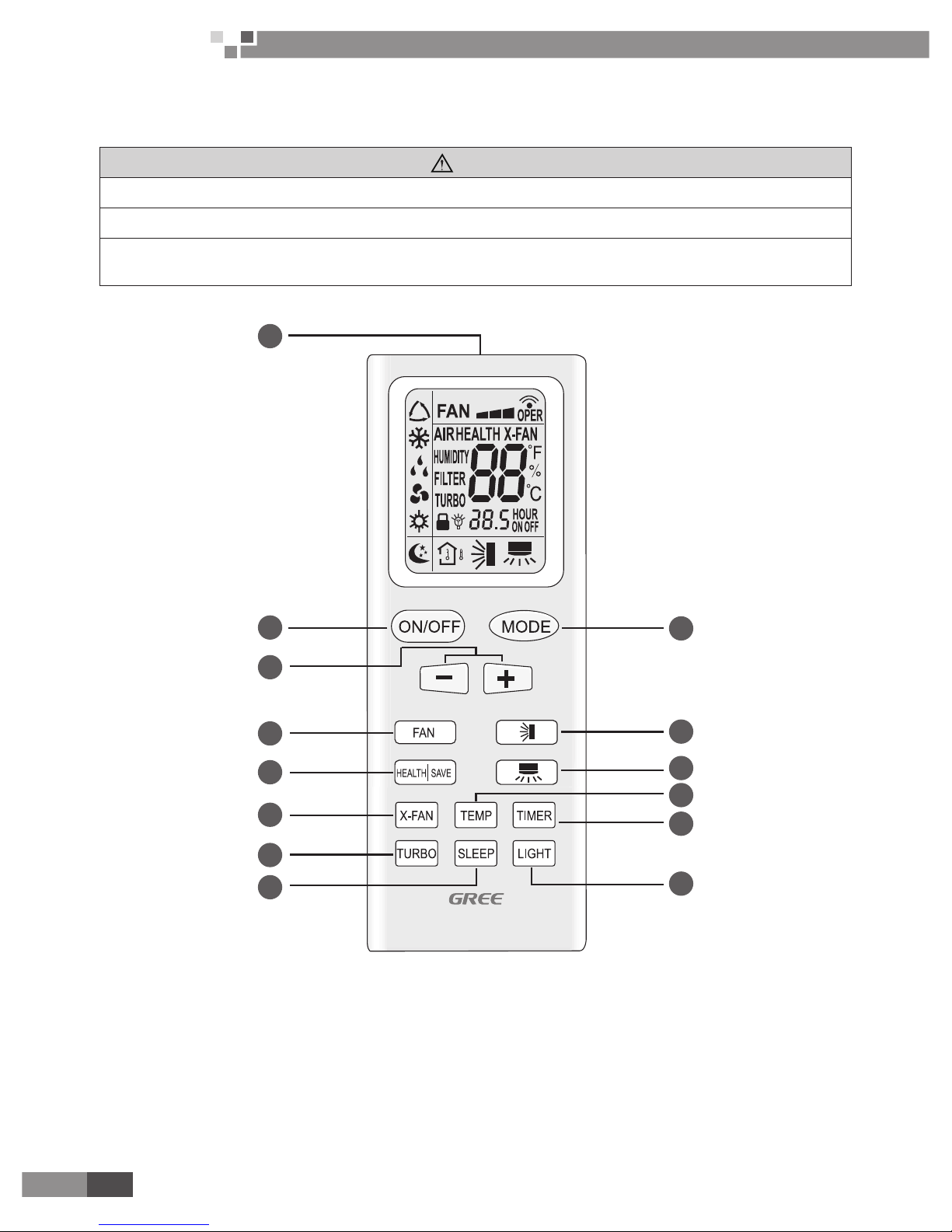

3.1.2 Control panel of the wireless remote controller

1

4

2

5

7

9

3

8

6

10

14

13

12

11

Page 13

11

Condensing Unit

Service Manual

CONTROL

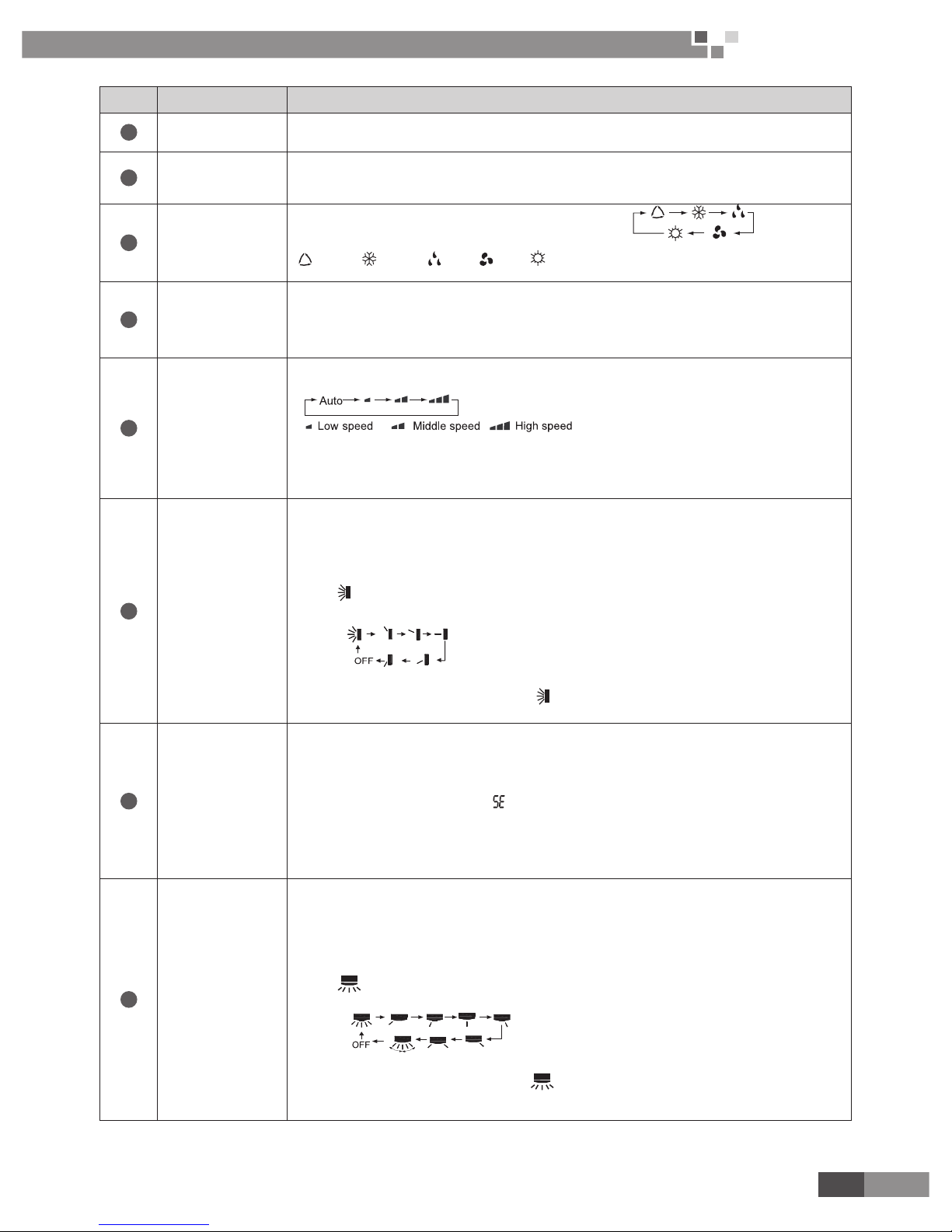

No.

Name Function Description

1

Signal transmitter

● Signal transmitter

2

ON/OFF button

● Press this button, the unit will be started or stopped, which can clear the timer or sleeping

function of last time.

3

MODE button

● Press this button, the running mode will change as below:

AUTO ; COOL; DRY; FAN; HEAT (only for cooling and heating unit)

4

+/- button

● When press + button , the setting temp. will be increased by 1 oC ,When press - button,the

setting temp. will be decreased by 1 oC. The temp. will be changed quickly by pressing the

button continuously and setting temp. range is 16-30 oC

5

FAN button

● Press this button once, fan speed will change as below:

Note: Under the DRY mode, the fan will be kept running at the low speed and the fan

speed isn't adjustable.

6

Swing up and

down button

● Simpleness swing mode is defaulted for wireless remote controller, in this mode, press

this button, could turn on or turn off the Up and down swing function.

● When unit is turned off, synchronously press "+" and Up and down swing buttons, it could

be switched between the simpleness swing mode and stationary swing mode, at this

time, blinks 2 seconds.

● In Stationary swing mode, press this button,the angle for Up and down swing as show in

below:

● When up and down swing louver is working,when turn off the unit, the siwng louver will

immediately stop at current position. shows up and down swing louver swings back

and forth as show in the above gure.

7

HEALTH |

SAVE button

● HEALTH function: press the left part of this button,can set up Health function on or off.

After unit is turned on ,Health function ON is defaulted.

● Save energy function: Under Cool mode ,press the right part of this button, the wireless

remote controller will display “ ”, the whole unit will enter into “Electricity Save mode”,

repress this button, the whole unit will quit this mode, other mode button is not available.

Under the Energy Save mode, the temperature and the Fan speed on the wireless

remote controller are not adjustable.

8

Left and right

swing button

● Simpleness swing mode is defaulted for wireless remote controller,in this mode,press this

button, could turn on or turn off the Left and right swing function.

● When unit is turned off, synchronously press "+" and Left and right swing buttons, it could

be switched between the simpleness swing mode and stationary swing mode, at this

time, blinks 2 seconds.

● In Stationary swing mode, press this button,the angle for Left and right swing as show in

below:

● When left and right swing louver is working, when turn off the unit, the siwing louver will

immediately stop at current position. shows left and right swing louver swings back

and forth as show in the above gure.

Page 14

12

Condensing Unit

Service Manual

CONTROL

9

X-FAN button

● Pressing X -FAN button in COOL or DRY mode, the icon "X-FAN" is displayed and the

indoor fan will continue operation for 10 minutes in order to dry the indoor unit even

though you have turned off the unit. After energization, X-FAN OFF is defaulted. X-FAN is

not available in AUTO,FAN and HEAT mode.

10

TEMP button

● After powered on, displaying presetting temperature is defaulted,(According to customer

requirements to display,if there are no requirements,the presetting temperature displaying

is defaulted, there is no signal display on the wireless remote controller). Press this

button, (display ), display the presetting temperature; (display ), display indoor

ambient temperature, will not change current display status. If current display status

is indoor ambient temp. when received other wireless remote controller sginal, then will

display presetting temp., 5s later return to ambient temp. display.

● Other models haven't this function. But pressing this button, the main unit will click and

keep the original status.

11

TIMER button

● On the status of the unit on, press this button to set timer off. On the status of the unit off,

press this button to set timer on. Press this button once, words Hour on(off) will appear

and icker. In which case, press +/- button to adjust time (press +/- button continuously

to change timing value quickly ), the setting time range is from 0.5 to 24 hr. ; press this

button once again to fix the time,then the wireless remote controller will send out the

signal immediately and hour on/off will stop ickering.If the time of that no press timer

button under ickering status is above 5s,the timer setting will quit. If the timer has been

set,press this button once again to quit it.

12

TURBO button

● Set turbo on or off(the characters of turbo will appear or disappear ) by pressing this

button under cooling or heating mode.Once energized, the unit will be defaulted to be

turbo off. This function can not be set under auto, dehumidify or fan mode, and characters

of turbo won't appear.

13

SLEEP button

● Press this button, enter into SLEEP state,when repressed, it will quit. The sleep function

will be canceled with the stop of the unit. There is no SLEEP function under AUTO and

FAN mode. is the icon for sleep function.

● At COOL, X-FAN mode: the SLEEP mode runs after 1hour, the setting temp. will be

increased by 1 oC, 2 hour later, the setting temp. will be increased by 2 oC and then will

run at this setting temperature.

● At HEAT mode: the SLEEP mode runs after 1 hour, the setting temp. will be decreased

by 1 oC, 2 hours later the setting temp. will be decreased by 2 oC, then it will run at setting

temperature.

14

LIGHT button

● Press this button to select LIGHT on or off in the displayer. When the LIGHT on is set,the

icon will be displayed and the indicator light in the displayer will be on. When the

LIGHT off is set, the icon will be not displayed and the indicator light in the displayer

will be off.

3.1.3 Introduction for special function

About X-FAN function

This function indicates that moisture on evaporator of indoor unit will be blowed after the unit is stopped to

avoid mould.

(1). Having set X-FAN function on: After turning off the unit by pressing ON/OFF button indoor fan will

continue running for about 10 min. at low speed. In this period, press X-FAN button to stop indoor fan

directly.

(2). Having set X-FAN function off: After turning off the unit by pressing ON/OFF button, the complete unit will

Page 15

13

Condensing Unit

Service Manual

CONTROL

be off directly.

About AUTO RUN

When AUTO RUN mode is selected, the setting temperature will not be displayed on the LCD, the unit will

be in accordance with the room temp. automatically to select the suitable running method and to make ambient

comfortable.

About turbo function

If start this function, the unit will run at super-high fan speed to cool or heat quickly so that the ambient

temp. approachs the preset temp. as soon as possible.

About lock

Press +and - buttons simultaneously to lock or unlock the keyboard. If the wireless remote controller is

locked, the icon will be displayed on it, in which case, press any button, the mark will icker for three times. If

the keyboard is unlocked, the mark will disappear.

About switch between Fahrenheit and Centigrade

Under status of unit off, press MODE and - buttons simultaneously to switch oC and oF.

About new function of defrosting

It indicates: after starting this function by wireless remote controller and the unit has been under defrost

status, If turn off the unit by wireless remote controller, the unit will not stop defrosting until it is finished; if

change setting mode by wireless remote controller, the function ,which is set last time, won't be carried out until

defrosting nished.

Operation of this function on or off: If wireless remote controller is under off status, press mode button and

X-FAN button simultaneously in order to enter or cancel this new function. If the unit is under defrost mode, dual

eight position on wireless remote controller will display H1.If switch to heat mode, the position will display H1,

which ickers for 5s, in which case, press +/- button, H1 will disappear and setting temp. be displayed.

After wireless remote controller is powered on , the new defrost function will be defaulted to be closed.

3.1.4 Replacement of batteries

1

Slightly press the place with along the arrowhead direction and push the back cover of the wireless

remote controller.

2

Take out the used batteries.

3

Insert two new AAA 1.5V dry cell batteries and pay attention to their polarity.

4

Put back the cover of the wireless remote controller.

2

3

4

1

Note:

When changing the batteries, do not use the old or different batteries, otherwise, it can cause the

malfunction of the wireless remote controller.

If the wireless remote controller will not be used for a long time, please take them out, and don't let the

leakage liquid damage the wireless remote controller.

It should be placed where is 1m away from the TV set or stereo sound sets.

The operation should be in its receiving range.

If the wireless remote controller cannot operate normally, please take the batteries out, and then reinsert it

30s later; if it is also abnormal ,please replace the batteries

If the main unit needs to be remote controlled, please aim wireless remote controller at the receiver of

main unit in order to improve the receiving sensitivity of the main unit.

Page 16

14

Condensing Unit

Service Manual

CONTROL

When the wireless remote controller sends out signal, a mark will icker for about 1s. The bell will ring if

the main unit receives effective signal.

3.2 Wired Controller (Chosen Accessory Part)

3.2.1 Display View

Fig.3.2.1 Outline of wired controller

3.2.2 Operation View

Fig.3.2.2 Instruction to Function of Buttons

No. Description Function of Button

1 Enter/cancel Function selection and canceling;

2 ▲

①

Running temperature setting of indoor unit, range :16~30°C.

②

Timer setting, range:0.5-24hr

③

Switchover between quiet/auto quiet

6 ▼

3 Fan Setting of high/middle/low/auto fan speed

4 Mode Setting of cooling/heating/fan/dry mode of indoor unit

5 Function Switch over among these functions of air/sleep/turbo/save/e-heater/blow /quiet

Page 17

15

Condensing Unit

Service Manual

CONTROL

7 Timer Timer setting

8 On/off Turn on/off indoor unit

4 Mode

and

2 ▲

Memory function

Press Mode and ▲for 5s under off state of the unit to enter/cancel key memory

function (If memory is set, indoor unit will resume original setting state after

power failure and then power recovery. If not, indoor unit is defaulted to be off

after power recovery. Memory function is defaulted to be set before outgoing.)

2 ▲

and

6 ▼

Lock

Upon startup of the unit without malfunction or under off state of the unit, press

▲ ▼ key at the same time for 5s in to lock state. In this case, any other buttons

won’t respond the press. Repress ▲ ▼ key for 5s to quit lock state.

5 Function

And 7Timer

Setting Ambient

Temperature Sensor

and three Grades of

Speed for Indoor Fan

Under off state of the unit, press Function and Timer buttons continuously for 5s

to go to the debugging menu. Press Mode button to adjust the setting items and

▲ or ▼ button to set the actual value.

4 Mode

and 6▼

Select Centigrade or

Fahrenheit

Under off state of the unit, press Mode and ▼ at the same time for 5s, the

displayer panel will switch between Centigrade and Fahrenheit.

5 Function

and 6▼

Enquiry of Historical

Errors

Continuously press Function and ▼ buttons for 5s to go to the enquiry state.

In this state, press Enter/Cancel button to quit, or it will automatically quit after

there is not any operation of button in 30min

3.2.3 Display View

Fig.3.2.3 LCD display

Table 3.2.3

No. Description Instruction to Displaying Contents

1 Swing Swing function

2 Air

*

Air exchange function

3 Sleep Sleeping states

4 Running mode Each kind of running mode of indoor unit (auto mode)

5 Cooling Cooling mode

Page 18

16

Condensing Unit

Service Manual

CONTROL

6 Dry Dry mode

7 Fan Fan mode

8 Heating Heating mode

9 Defrost Defrosting state

10

Gate-control

card

*

Gate control

11 Lock Lock state

12 Shield

Shielding state (buttons, temperature, on/off, mode or save is shielded by long-distance

monitoring

13 Turbo Turbo function state

14 Memory

Memory state (Indoor unit resumes original setting state after power failure and then

power recovery)

15 Twinkle Flicking when unit is on without operation of buttons

16 Save Energy-saving state

17 Temperature Ambient/setting temperature value

18 E-Heater

*

Mark that E-heater is allowed to turned on

19 Blow Blow mark

20 Timer Timer-displayed location

21 Quiet Quiet state(two types: quiet and auto quiet)

Notes: The functions with * are reserved for other models and are not applicable for the models listed in this manual.

3.2.4

Dimension

Fig.3.2.4

Page 19

17

Condensing Unit

Service Manual

CONTROL

3.2.5 Installation

Fig.3.2.5 Sketch for Installation of Wired Controller

No. 1 2 3 4 5

Description

Socket’s base

box installed in

the wall

Soleplate of

controller

Screw M4×25

Front panel of

controller

Screw ST 2.9×6

(1). Cut off power supply of heavy-current wire embedded in mounting hole in the wall before installation. It is

prohibited to perform the whole procedure with electricity.

(2). Pull out 4-core twisted pair line in mounting hole and then make it through the rectangle hole at the back

of controller’s soleplate.

(3). Joint the controller’s soleplate on wall face and then x it in mounting hole with screws M4×25.

(4). Insert the 4-core twisted pair line through rectangle hole into controller’s slot and buckle the front panel

and soleplate of controller together.

(5). At last, x the controller’s front panel and soleplate with screws ST 2.9×6.

Caution:

During connection of wirings, pay special attention to the following items to avoid interference of

electromagnetism to unit and even failure of it.

①.

To ensure normal communication of the unit, signal line and wiring (communication) of wired controller

should be separate from power cord and indoor/outdoor connection lines. The distance between them

should be kept 20cm in min.

②.

If the unit is installed at the place where there is interference of electromagnetism, signal line and wiring

(communication) of wired controller must be shielded by twisted pair lines.

Page 20

18

Condensing Unit

Service Manual

INSTALLATION

Page 21

19

Condensing Unit

Service Manual

INSTALLATION

1 INDOOR UNIT INSTALLATION

1.1 Installation of Ceiling Type

1.1.1 Before Installation

When the unit arrives, please check if any damage due to transport is existent. If any hurt is found on the

surface or inside, please declare to the transport company or the manufacturer in writing.

When the unit arrives, please check if any damage due to transport is existent. If any hurt is found on the

surface or inside, please declare to the transport company or the manufacturer in writing.

Correct handling route and method shall be decided to prevent damage to the unit. For protecting the unit

and ensuring its safety, carrying the unit with its package is recommended. If such carrying method is

difcult under particular conditions, the canton shall not be removed to avoid looseness or falling during

handling.

Confirm the foundation is secure. When the unit is installed on the metal part of a building, electrical

insulation must be in compliance with relevant standards.

Conrm the installation position is away from storage zone of inammable and explosive substances, or

otherwise leakage of inammable and explosive substances may lead to explosion or a re.

1.1.2 Installation Site

Such a place where cool air can be distributed throughout the room.

Such a place where condensation water is easily drained out.

Such a place that can handle the weight of indoor unit.

Such a place which has easy access for maintenance.

Such a place where is permitting easy connection with the outdoor unit.

Such a place where is 1m or more away from other electric appliances such as television, audio device,

etc.

Avoid a location where there is heat source, high humidity or inammable gas.

Do not use the unit in the immediate surroundings of a laundry, a bath, a shower or a swimming pool.

Be sure that the installation conforms to the installation dimension diagram.

The space around the unit is adequate for ventilation

1.1.3 Caution for Installation

Adjust the distance from the unit to the ceiling slab beforehand (Refer to Figure 1-2-1).

Fix the hanger bracket to the suspension bolt (Refer to Figure 1-2-2).

Make sure that extended suspension bolt from the ceiling stays inside the arrowed position. Readjust the

hanger bracket when it is outside the arrowed position. (Refer to Figure 1-2-3)

Suspension bolt stays inside the cap of indoor unit .Never remove the cap. Lift the unit and slide forward

unit the dent. (Refer to Figure 1-2-4)

Screw tightly both hanger bracket setting bolts (M8) (Refer to Figure 1-2-2)

Screw tightly both hanger bracket xing bolts (M6) to prevent the movement of the indoor unit. (Refer to

Figure 1-2-2)

Adjust the height by turning the nut with a spanner. Insert the spanner from the hanger bracket opening.

(Refer to Figure 1-2-5)

40mm or less

Suspension bolt

Ceiling

Hanger bracket

Hanger bracket

setting bolt(M8)

Hanger bracket

foxing bolt(M6)

Hanger bracket Figure 1-2-1 Figure 1-2-2

Page 22

20

Condensing Unit

Service Manual

Figure 1-2-3 Hanger bracket Figure 1-2-4

In case of hanging:

It is possible to install using inward facing hanger bracket by not removing the brackets from the indoor unit.

(Refer to Figure 1-2-6) Be sure to use only the specied accessories and parts for installation work.

Figure 1-2-5 Figure 1-2-6

1.1.4 Dimension Data

Figure 1-2-7

Page 23

21

Condensing Unit

Service Manual

Table 6

Unit: mm

Model A B C D H

HNTF24/A-D

1220 225 1158 280 700

HNTF36/A-D

HNTF48/A-D

1420 245 1354 280 700

HNTF60/A-D

1.1.5 Installation Clearance Data

100cm or m ore

30cm or m ore

60cm or m ore

60cm or m ore

150cm or m ore

Figure 1-2-8

1.1.6 Drain Piping Work

(1). Installation of Drainage Pipeline

A Drainage outlet is located at both the left and right sides of the indoor unit. After selecting one Drainage

outlet, the other outlet shall be blocked by rubber plug. Bundle the blocked outlet with string to avoid

leakage, and also use thermal insulation materials to wrap the blocked outlet.

When shipped out from factory, both the Drainage outlets are blocked by rubber plugs.

When connecting the drainage pipe with the unit, do not apply excessive force to the pipeline at the side of

the unit. The xing position of the pipeline shall be near the unit.

Purchase general-purpose hard PVC pipe locally to be used as the drainage pipeline. When carrying

out connection, place the end of the PVC pipeline into the drainage hole. Use exible drainage tube and

tighten it with thread loop. Never use adhesive to connect the drainage hole and the exible drainage tube.

(As shown in Figure 1-2-9)

When the laid drainage pipe is used for multiple units, the common pipe shall be about 100mm lower than

the drainage outlet of each set of unit. A pipe with thicker wall shall be used for such purpose.

Sponge (gray)

Drain hose

Clamp

Clamp(attachment)

Sponge(attachment)

Below 4mm

Figure 1-2-9

Page 24

22

Condensing Unit

Service Manual

(2). Testing of Drainage System

After the electrical installation is completed, carry out the testing of the drainage system.

During the test, check if the water correctly flows through the pipelines. Carefully observe the joints to

ensure that there is no leakage. If the unit is to be installed in a new house, carry out testing before

decorating the ceiling.

(3). Matters of Attention

The drain pipe outlet direction can be chosen from either the right rear or right.

The diameter of the drain pipe should be equal to or greater than the diameter of the connecting pipe.

(Vinyl tube; pipe size: 20mm; outer dimension: 26mm)

Keep the drain pipe short and incline downwards at a gradient of at least 1/100 to prevent air pockets.

(Refer to Figure 1-2-10) .

When drain hose is connected

Incline the drain hose

Not to be lifted

Not foldings

Not to be soaking in water

Figure 1-2-10

No folding of drain hose inside the indoor unit. (Refer to Figure 1-2-11)

Conrm that smooth drainage is achieved after the piping work. Pour 600 cc of water into the drain pan

from the air outlet for conrming drainage. (Refer to Figure 1-2-12).

Wartering can Air outlet

Figure 1-2-11 Figure 1-2-12

3 REFRIGERATION PIPING WORK

3.1 Refrigeration Piping Work Procedures

(1). Connecting pipelines

Connection pipes must be in accordance with the following requirements: the basic principle --- keeping

dry, clean and no leakage inside.

Page 25

23

Condensing Unit

Service Manual

Dry Clean Air tight

Make syre there is no

moisture inside the pipes

Make sure there is no

dirt inside the pipe

Make sure the refrigerant

does not leak out

Moisture

(V0965)

Dirt

(V1148)

Leak

(V1149)

Figure 3-1-1

Align copper pipe are with the center of screwed connector and tighten fully the nut of the are by hand.

Tighten the are nut with a torque spanner until the torque spanner makes a click, as shown in Figure 3-1-

1. Moment needed for tightening a nut is shown in Tab. 3-1-1.

Fitting Pipe for Indoor Unit Flaring Nuts Fitting pipe

Torque Spanner

Spanner

Figure 3-1-2

Form 3-1-1 the tightening torque needed for tightening nut

Pipe diameter Tightening torque

1/4" 15-30 (N·m)

3/8" 35-40 (N·m)

5/8" 60-65 (N·m)

1/2" 45-50 (N·m)

3/4" 1-75 (N·m)

7/8" 85-90 (N·m)

Curvature of piping shall not be too small, or otherwise piping may be broken. So installation personnel

should use a pipe bender to bend pipes.

Upward or longitudinal welding joint method is usually applied to the welding of pipelines. The welding

method that mouth of pipe is downward (face-down welding) should be avoided as far as possible,

because such method is prone to welding defects and even would cause leakage, as shown in Figure 3-1-

3.

Page 26

24

Condensing Unit

Service Manual

Bume

r

Solder

Downward facing

Side facing

Recommended methed

Upward facing

Figure 3-1-3

Uninsulated connecting pipes and connectors should be packed with sponge and tied with plastic adhesive

tapes.

(2). Vacuum-pumping and leak detection

Dismantle the bonnet of refrigerant valve and air valve.

Align with the center of piping and adequately tighten nuts of connecting pipes by hand

Tighten the nuts with a spanner.

Remove the one way valve cap of air valve.

Unscrew the spool of refrigerant valve for 1/4 turn with a socket head wrench, and at the same time push

up the spool of air valve with a screwdriver to let air give off.

Air exhaust continues for 15 seconds until coolant gas appears, immediately shut off one way valve and

tighten the valve cap.

Totally open the spool of refrigerant valve and air value (as shown in Figure 3-1-4)

One-Way Valve

Gas Valve

Liquid Valve

Valve Cap

Inner Hexagon

Spanner

Screwdriver

Valve Stem

Figure 3-1-4

Tighten the valve caps and use soapy water or a leak detector to check any leakage on indoor unit,

outdoor unit and connection parts of pipes.

Caution:

If conditions are allowed, a vacuum pump shall be used for drawing off air inside the system at a valve. Method

for creation of vacuum by using a vacuum pump is as follows:

Take out the nut cover of the inlet for refrigerant.

Connect the tube of the vacuum watch with the vacuum pump, having the low-pressure end linking to the

inlet for refrigerant. (As shown in Figure 3-1-5)

Page 27

25

Condensing Unit

Service Manual

Pressure Gage Pressure Gage

“LO” Knob

“HI” Knob

Liquid Valve Vacuum Pump

Connecting Hose

Gas Valve

Figure 3-1-5

Starting the vacuum pump, when the indicator turns to-1 bar, closing the low pressure handle and stopping

vacuumize. Keep for 15 minutes, ensuring the pressure of the vacuum watch remains.

Take out the valve cover of the gas valve together with the liquid valve.

Loosing the cord of liquid valve until the pressure rise to 0 bar.

Dismantle the tube from the cover of the inlet for refrigerant then, tighten the cover.

Loose the valve cord of the gas valve as well as the liquid valve entirely.

Tighten the valve cover of the gas valve and liquid valve so as to check whether leakage occurred.

(3). Installation of Protective Layer of Connecting Pipe

To avoid generation of condensate on the connecting pipe and avoid leakage, the big pipe and the small

pipe of the connecting pipe must be covered by thermal insulation materials, be bundled by adhesive tape,

and be isolated from air.

The joint connecting to the indoor unit must be wrapped by thermal insulation material. There shall be no

gap between the connecting pipe joint and the wall of the indoor unit. Refer to Figure 3-1-6.

Figure 3-1-6 Figure 3-1-7

Use adhesive tape to bundle the connecting pipe and the cables together. To prevent condensate from

overflowing out from the drainage pipe, separate the drainage pipe firm the connecting pipe and the

cables.

Use thermal insulation tape to wrap the pipes from the bottom of the outdoor unit until the upper end of the

pipe where the pipe enters the wall. When wrapping thermal insulation tape, the later circle of tape must

cover half of the front circle of tape (Figure 3-1-7).

Wrapped pipe must be xed to wall using pipe clamps.

Caution:

After the pipes are wrapped by protective materials, never bend the pipes to form very small angle, and

Page 28

26

Condensing Unit

Service Manual

otherwise the pipes may crack or break.

Do not wrap the protective tape too tight, otherwise the efciency of thermal insulation may be decreased.

Ensure that the condensate drainage exible tube is separate from the bundled pipes.

After the protective work is completed and the pipes are wrapped, use seal material to block the hole in the

wall, so as to prevent rain and wind from entering the room.

3.2 Caution in Connecting Pipes

Arrangement of connecting pipes shall be performed according to sit conditions with reference to the

following principles.

Try to shorten the length of connecting pipes, within 5m for the better.

Try to reduce height difference between indoor unit and outdoor unit.

Try to reduce number of joint bends of connecting pipes.

If the length of connecting pipes is more than 20m, adequacy of lubricant of the system must be checked;

and if necessary, add more lubricant properly.

Filling amount of refrigerant in the system is matched to a 7m connecting pipe. If the connecting pipe is

needed to lengthen, appropriate amount of refrigerant should be added. How much refrigerant should be

added for every meter extension refers to the following table. Allowable maximum pipe length is 30m.

If height difference between indoor unit and outdoor unit exceeds 10m in installation of air conditioner, an

oil return bend must be mounted at an interval of 6m.

If heights of indoor unit and outdoor unit are different, pipes should be laid out with reference to Figure 3-2-

1.

3.3 Specication of Connection Pipe

Mode

External Diameter

Maximum Length

of Connection Pipe

Maximum Difference

in Height between

Outdoor and Indoor Unit

Additional Charge

of Refrigerant

Gas Pipe Liquid Pipe (m) (m) (m)

HNTF24/A-D 3/8 5/8 15 15 0.6

HNTF36/A-D 3/8 3/4 30 15 0.6

HNTF48/A-D 3/8 7/8 30 15 0.6

HNTF60/A-D 1/2 7/8 30 15 1.2

4 ELECTRIC WIRING WORK

4.1 Wiring Principle

4.1.1General

Perform wiring of the power supply in conformance with the regulations of the local electric company.

For the control wires connecting indoor units, and between indoor and outdoor units, use of double-core

shield wires is recommended to prevent noise trouble.

Be sure to set the earth leakage breaker and the switches to the power supply section of the indoor unit.

Supply power to each outdoor unit and provide an earth leakage breaker or hand switch for each outdoor

unit.

Store wiring system for control and refrigerant piping system in the same line.

Arrange the cables so that the electric wires do not come to contact with high-temperature part of the

refrigerant pipe; otherwise coating melts and an accident may be caused.

Do not turn on power of the indoor unit until vacuuming of the refrigerant pipe will nish.

Installation should be conducted by National Wiring Regulation.

The rated voltage and exclusive power supply must be adopted for the air conditioners.

The power cable should be reliable and xed, in order to avoid the wiring terminal be suffered from force.

And do not drag the power cable forcibly.

The wire diameter of power cable should be large enough, if power cable and connection wire be

Page 29

27

Condensing Unit

Service Manual

damaged, it should be replaced by the exclusive cable.

All electric installation must be done by professional personnel according to local law, regulation and this

manual.

It should be reliably earthed, and it should be connected to the special earth device, the installation work

should be operated by the professional.

The creepage protect switch and air switch must be installed.

Air switch should have the thermal dropout and magnetic dropout function, in order to avoid the short

circuit and overload.

The on spot connection should refer to the circuit diagram, which is stuck on the unit body.

The unit should be reliably earth, if it is improperly earthed that may cause electric shock or re.

Air conditioner is the “I” class electric appliance, thus please do conduct reliable grounding measure.

The yellow-green two-color wiring of air conditioner is grounding wire and cannot be used for other

purposes. It cannot be cut off and be xed by screw, otherwise it would cause electric shock.

The user must offer the reliable grounding terminal. Please don’t connect the grounding wire to the

following places:

a. Water pipe;

b. Gas pipe;

c. Blowing pipe;

d. Other places that professional personnel consider them unreliable;

4.1.2 Connection of electric wires with the terminal

(1). Caution

Before installing the electrical equipment, please pay attention to the following matters which have been

specially pointed out by our designers:

Check to see if the power supply used conforms to the rated power supply specied on the nameplate.

The capacity of the power supply must be large enough. The section area of tting line in the room shall be

larger than 2.5mm2.

The lines must be installed by professional personnel.

An electricity leakage protection switch and an air switch with gap between electrode heads larger than 3

mm shall be installed in the xed line.

(2). Connection of single wire

Use wire stripper to strip the insulation layer (25mm long) from the end of the single wire.

Remove the screw at the terminal board of the air-conditioning unit.

User pliers to bend the end of the single wire so that a loop matching the screw size is formed.

Put the screw through the loop of the single wire and x the loop at the terminal board.

(3). Connection of multiple twisted wires

Use wire stripper to strip the insulation layer (10mm long) from the end of the multiple twisted wires.

Remove the screw at the terminal board of the air-conditioning unit.

Use crimping pliers to connect a terminal (matching the size of the screw) at the end of the multiple twisted

wires.

Put the screw through the terminal of the multiple twisted wires and x the terminal at the terminal board.

25

10

A. Singel wireB . Multiple twisted wires

Terminal

Insulation layer

Page 30

28

Condensing Unit

Service Manual

Warning:

If the power supply exible line or the signal line of the equipment is damaged, only use special exible line

to replace it.

Before connecting lines, read the voltages of the relevant parts on the nameplate. Then carry out line

connection according to the schematic diagram.

The air-conditioning unit shall have special power supply line which shall be equipped with electricity

leakage switch and air switch, so as to deal with overload conditions.

The air-conditioning unit must have grounding to avoid hazard owing to insulation failure.

All tting lines must use crimp terminals or single wire. If multiple twisted wires are connected to terminal

board, arc may arise.

All line connections must conform to the schematic diagram of lines. Wrong connection may cause

abnormal operation or damage of the air-conditioning unit.

Do not let any cable contact the refrigerant pipe, the compressor and moving parts such as fan.

Do not change the internal line connections inside the air-conditioning unit. The manufacturer shall not be

liable for any loss or abnormal operation arising from wrong line connections.

4.2 WIRING DIADRAM

(1). Model: HNTF24/A-D, HNTF36/A-D, HNTF48/A-D, HNTF60/A-D

Page 31

29

Condensing Unit

Service Manual

4.3 Electric Wiring Design

Model: HW24Na/A-D + HNTF24/A-D, HW36Na/A-D + HNTF36/A-D;

Indoor Unit

POWER

220/230V

1PH

60HZ

POWER

220/230V

1PH

60HZ

Outdoor Unit

Model:HW48Na/A-D+HNTF48/A-D; HW60Na/A-D+ HNTF60/A-D;

POWER

220/230V

1PH

60HZ

POWER

220/230V

1PH

60HZ

Indoor Unit

Outdoor Unit

Page 32

30

Condensing Unit

Service Manual

MAINTENANCE

Page 33

31

Condensing Unit

Service Manual

MAINTENANCE

1TROUBLE TABLE(Only for oor ceiling)

Fault code Fault Fault code Fault

E2

Indoor Frost-

Proof Protection

F0

Failure of Indoor Room

Sensor at Air Intake

E6 Communications Failure F1 Failure of Evaporator Temp. Sensor

EH

Failure of Auxiliary

Heater

F5

Failure of Indoor Room

Sensor at Wire Controller

2 FLOW CHART OF TROUBLESHOOTING

2.1 Air ow volume from air outlet of unit is abnormal

Yes

Yes

Yes

Yes

No

No Yes

No Yes

Yes

No

Air flow volume from

air outlet of unit is

abnomal

Filter in air return

box isn’t blocked

Re-connect

power cord

Capacitor in centrifugal

fan’s return circuit is

burnt out

Replace capacitor

centrifugal fan

normally runs

centrifugal fan motor

has malfunction

Repair or replace

motor

Power cord of centrifugal

fan is in good contact

and not broken

Power of centrifugal

fan is on

Clean fifiter

Page 34

32

Condensing Unit

Service Manual

2.2 The unit can not start up for cooling

The unit can not start

up for coolin g

Power supply is normal,

fuse is not burned out and

circuit does not break

Power switc h is switche d

on and in good contact

Resume power suppl y,repl ace

fuse or re-connect circuit

Yes

Yes

No

No

Conn ection of power

cord of unit is correct

No

Yes

Electrical elements in

electric box are

undamaged

Repair or replace power switch

to swi tch on pow er supply

Re -conn ect powe r cord

Replace damag ed elements

Yes

No

Page 35

33

Condensing Unit

Service Manual

2.3 Poor cooling effect

Poor cooling effect

Yes

Eliminate affected factors or

re-select installation location of unit

No

No

No

Clear sundries

Clean filter

No

Repair or replace motor

Compressor runs

Yes

Axial flow fan runs

Installa tion location

of unit co nforms to requir ements or th ere

isn’t an y factor around the unit wh ich

affects heat di spersion of unit

Yes

Yes

Yes

No

Repair or replace

compressor

Condenser isn’t

blocked by sundries

Filter in air return

box is not blocked

Repair or replace motorCentrifugal fan runs

Yes

No

Yes

Pipeline system is

normal in respect of low/high

pressure detection

Shortage of refrigerant

or nozzle for adding

freon leaks refrigeran

Piping system,capillary

or strainer is blocked

No

Clean or replace

it after disassembly

Replace

Yes

Yes

Page 36

34

Condensing Unit

Service Manual

2.4 Noise or abnormal vibration of unit

The unit can not start

up for cooling

Yes

Re-install unit or eliminate

affected factors

No

No

No

Adjust tightness of compressor

Tighten loose part

Repair or replace motor

No

Repair or replace compressor

Fan motor runs

Yes

Compressor runs

Installation of unit or pedestal meet requirements

Fixation of compressor’s

holding bolt is all right, and there is no strenuous

vibration of compressor

Fixation of fan bracket

is all righ t, moto r is tight ened, and th ere is no strenuou s

vibration of fan

Yes

Yes

Yes

No

Page 37

35

Condensing Unit

Service Manual

4 DISASSEMBLY AND ASSEMBLY PROCEDURE OF MAIN PARTS

Model:

HNTF24/A-D, HNTF36/A-D, HNTF48/A-D, HNTF60/A-D

Disassembly of panel grating module

Remark: Make sure that the power supply is cut off before disassembling and protect all the parts during disassembly. Do not put lter

screen near the high temperature heat source.

Step Illustration Handling Instruction

Disassembly of sub-assy of

front grill

●Unscrew the 2 clasps of the upper grill and the

2 screws of the clasps.

●Open the grill, disassemble the 2 down clasps

to remove the grill.

Disassembly of right and left nishing plates

Remark: Make sure the power supply is cut off before disassembling and protect all the parts during disassembly. Do not scratch the outer

parts.

Step Illustration Handling Instruction

Disassembly of right and left

nishing plates

●Disassemble the screws as shown in the

graph with screwdriver and then push upward

to remove the right and left nishing plates.(As

is shown in the graph, arrow represents the

position of screws.)

Disassembly of panel parts

Remark: Make sure the power supply is cut off before disassembling and protect all the parts during disassembly. Do not scratch the outer

parts.

Step Illustration Handling Instruction

Disassembly of panel parts

●Unscrew the 3 sides’ screws on the cover to

remove the cover.

Disassembly of sub-assy of electric box

Remark: Make sure that the power supply is cut off before disassembling and protect all the parts during disassembly, especially the

components inside the box in case of water and hit.

Step Illustration Handling Instruction

Disassembly of electric box

cover

●Disassemble 3 screws as shown by the arrow

in the graph on left and remove the electric box

cover.

Disassembly of air deecting plate modules

Remark: Make sure the power supply is cut off before disassembling and protect all the parts during disassembly, especially the joints of

the air deecting plate.

Step Illustration Handling Instruction

Disassembly of sub-assy of

air deecting plate

●Remove the air deflecting plates from the air

deflecting plate support assembly, and then

remove both ends from the air sweeping

motor. joint (As is shown in the graph, arrow

represents the support assembly and circle the

air sweeping motor joint.)

Page 38

36

Condensing Unit

Service Manual

Disassemble of water-containing plate modules

Remark: Make sure the power supply is cut off before disassembling and protect all the parts during disassembly.

Step Illustration

Handling Instruction

Disassemble of water-

containing plate modules

●Remove the water-containing plate modules.

Disassembly of evaporator components

Remark: Make sure that the power supply is cut off and protect the copper tube and aluminum n. If the time for disassembly shall be long,

seal the copper tube .

Step Illustration Handling Instruction

Disassembly of evaporator

components

●Unscrew the 6 screws of evaporator, 3 screws

of water groove press board and the 2 screws

of water board to remove the evaporator.

Disassembly of xing plate sub-assy for air sweeping fans

Remark: Make sure that the power supply is cut off before disassembling and protect all the parts during disassembly.

Step Illustration Handling Instruction

Disassembly of xing plate

sub-assy for air sweeping

fans

●Remove the display board, mounting support

and mounting plate of swing motor in turn.

Disassembly of fan and motor components

Remark: Make sure that the power supply is cut off before disassembling and protect all the parts during disassembly, especially the

fastening screws for fans.

Step Illustration Handling Instruction

1. Disassembly of front and

back scroll cases

●Press the buckle at the joints of front and back

scroll cases with hands and pull upward to

remove the front scroll case. Then remove the

screws on the back scroll case. Lift the buckle

of back scroll case with hands and remove

it.(As is shown in the graph, circle represents 2

screws on left and right.)

2. Disassembly of fans

●Unscrew the 2 screws of coupling, take out

the rotating shaft and louver, then loosen the

tighten screw of louver to remove the louver

3. Disassembly of bearing

xing plates

●Unscrew the 3 screws and 2 nuts of support to

remove the mounting support.

Page 39

37

Condensing Unit

Service Manual

4. Disassembly of motor

●Loosen the 2 screws of the motor attaching

clamp, remove the motor attaching clamp and

motor attaching clamp subassembly to remove

the motor.

Disassembly of right and left xing plates

Remark: Make sure that the power supply is cut off before disassembling and protect all the parts during disassembly.

Step Illustration Handling Instruction

Disassembly of right and left

xing plates

●Disassemble the bolts on right and left fixing

plates with tools. (As is shown by the arrow in

the graph.)

Page 40

38

Condensing Unit

Service Manual

5 EXPLODED VIEWS AND PART LIST

(1). Model: HNTF24/A-D, HNTF36/A-D

Exploded Views

Page 41

39

Condensing Unit

Service Manual

HNTF24/A-D, HNTF36/A-D Spare Parts List

NO Description Product Code Qty

1 Top Cover Board Sub-Assy '01269409 1

2 Water Tray Assy '01289404 1

3 Filter Sub-Assy '07210028 1

4 Connected Board (Evaporator) '01349421 1

5 Evaporator Assy '01022200017 1

6 Temperature Sensor '3900020723 1

7 Room Sensor '39000191 1

8 Remote Controller '305100611 1

9 Right Cover Plate '26909444 1

10 Connection Board '02229406 1

11 Axile Bush '10542704 2

12 Right Side Plate Sub-Assy '01319429 1

13

Plate Board of Water

Releasing Flume

'26909442 1

14 Water Releasing Flume '02284106P 1

15

Guide Louver Supporting

Sub-Assy

'0180941601 1

16 Air Louver '10619404 16

17 Guide Louver '10619403 2

18 Rotating Shaft '26909430 4

19 Front Connection Board '01349414P 1

20 Membrane '63079403 1

21 Fixed Mount '26909426R 1

22 Display Board '30294220 1

23 Rear Side Plate Assy '01319400008 1

24 Rotating Shaft '26909413 1

25 Rotating Shaft '26909412 1

26 Stepping Motor '1521240206 1

27 Left Side Plate Sub-Assy '01319428 1

28 Electric Box Assy '01392200049 1

29 Transformer '4311023701 1

30 Transformer '43110286 1

31 Main Board '30224220 1

32 Electric Box Cover '01429420 1

33 Terminal Board '4201019601 1

34 Terminal Board '42011147 1

35 Terminal Board '42010194 1

36 Left Cover Plate '26909443 1

37 Capacitor '33010025 1

38 Mid-clapboard sub-Assy '01249416 1

39 Support Of Motor Bearing '01792408 2

Page 42

40

Condensing Unit

Service Manual

40 O-Gasket of Bearing '76512404 2

41 Centrifugal Fan '10425200 4

42 Front Volute Casing '26905205 4

43 Rear Connection board '01349422 1

44 Bar Clasp Sub-Assy '70818000001 1

45 Fan Motor '15709409 1

46 Joint Slack '73018731 2

47 Drainage Pipe Sub-Assy '05235434 1

48 Rear Volute Casing '26905206 4

49 Filter Sub-Assy '11729402 1

50 Front Grill Sub-Assy '01579403 2

Note: Above data is subject to change without notice, pls reference the SP in global service website.

Page 43

41

Condensing Unit

Service Manual

(2). Model: HNTF48/A-D, HNTF60/A-D

Exploded Views

HNTF48/A-D, HNTF60/A-D Spare Parts List

NO Description Product Code Qty

1 Top Cover '01269404P 1

2 Water Tray Assy '01289405 1

3 Air Louver '26909418 18

4 Connected Board (Evaporator) '01349413 1

5 Filter Sub-Assy '07210029 1

6 T h r o t t l e V a l v e S u b - a s s y '07332200032 1

7 Evaporator Assy '01022200026 1

8 Room Sensor '39000191 1

9 Tube sensor '3900020720G 1

10 Remote Controller '305100611 1

11 Right Side Plate Sub-Assy '01319408 1

12 Right Cover Plate '26909422 1

Page 44

42

Condensing Unit

Service Manual

13 Connection Board '02229406 1

14 Right Foam Assy '12509425 1

15 Axile Bush '10542704 2

16

Plate Board of Water

Releasing Flume

'26909442 1

17 Water Releasing Flume '26909441 1

18 Rotating Shaft '26909413 1

19 Guide Louver '26909432 2

20 Front Connection Board '01349408P 1

21

Front Connection

Board Foam Assy

'12509424 1

22 Membrane '63079403 1

23 Fixed Mount '26909426R 1

24 Display Board '30294220 1

25 Rear Side Plate Assy '01319400005 1

26 Stepping Motor '1521240206 1

27 Left Foam Assy '12509408 1

28 Electric Box Assy '01392200054 1

29 Transformer '4311023701 1

30 Transformer '43110286 1

31 Main Board '30224220 1

32 Terminal Board '4201019601 1

33 Terminal Board '42011147 1

34 Terminal Board '42010194 1

35 Capacitor CBB61 '33010014 1

36 Electric Box Cover '01429410P 1

37 Left Cover Plate '26909416 1

38 Mid-Clapboard Sub-Assy '01249412 1

39 Bracket 1 01809404 1

40 Support Of Motor Bearing '01792408 1

41 O-Gasket of Bearing '76512404 1

42 Centrifugal Fan '1041410101 3

43 Rear Volute Casing '26909419 3

44 Joint Slack '73018731 1

45 Fan Motor '15709407 1

46 Front Volute Casing '26905208 3

47 Back Connection Board '01349418 1

48 Drainage Pipe Sub-Assy '05235434 1

49 Rotating Shaft '26909430 6

50 Rotating Shaft '26909412 1

51 Front Grill Sub-Assy '01579402 3

Note: Above data is subject to change without notice, pls reference the SP in global service website.

Page 45

JF00302341

Loading...

Loading...