Page 1

Installation and Operation Manual

Household (Townhouse) Central Air Conditioning Unit

GREE ELECTRIC APPLIANCES, INC. OF ZHUHAI

Please read this manual carefully before using this product and keep it properly for future reference.

Page 2

User Notice

Dear Users:

Thank you for choosing our Household (Townhouse) Central Air Conditioning Unit. Please

read this manual carefully before installation, and conduct installation and usage by following the

process instructed in this manual, so that you can comprehensively know and correctly use this

unit.

Specially remind you the meaning of following label:

Warning! Means incorrect operation may cause injuries and deaths or badly hurt.

Notice! Means incorrect operation may cause injuries or property loss.

Warning!

When using this unit in winter, if outer ambient temp. is lower than 0℃, the temperature at

where indoor unit is installed should be approach to outdoor ambient temperature; or if there is no

people in the room for long-time, indoor temperature will approach to outer ambient temperature:

1) Add antifreeze in water system. Refer the actual outdoor ambient temperature for add

proportion.

2) To cooling only unit, when it is not used in winter, drain out water in the unit and pipe to

present pipe heat exchanger, pipeline and water pump from breaking; if it is not sure whether water

in pipeline is drained clearly, do add antifreeze into the system pipeline. And all of these must be

done by professional personnel.

3) Don’t cut off power when unit is off, otherwise auto antifreeze operation protection will be

ineffective.

Warning!

1) Please have the unit installed by authorized service center. For improper installation may

cause water leakage, electric shock and re etc.

2) Don’t use or store ammable and explosive products near the unit.

3) Please cut off power supply immediately when malfunction (such as burning odor is

smelled) occurs.

4) Don’t insert nger or things into exhaust vent or air-in grille.

5) Don’t turn on or cut off the unit by turn on or cut off the power supply.

6) Don’t ret the unit. Please contact with dealer or professional installation personnel when it

is going to repair or move the unit.

7) The appliance shall not be used for children without supervisor.

8) This product must not be disposed together with the domestic waste.This

product has to be disposed at an authorized place for recycling of electrical and

electronic appliances.

9) For appliances not accessible to the general public and which are

intended to permanently connected to xed wiring and which may have leakage

currents exceeding 10 the installation instructions shall specify the rating of the

residual current device (RCD) to installed.

Page 3

10) This appliance is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge, unless they have

been given supervision or instruction concerning use of the appliance by a person responsible for

their safety. Children should be supervised that they do not play with the appliance.

Note!

1) Before installation, please check if the supply power is the same with that listed on

nameplate, and check the safety of power. Done by professionals.

2) Before using, please check and conrm if wires and water pipes are connected correctly

to present occurrence of water leakage, electric shock or re etc.Make sure it must be done by

professional of central air conditioning installation.

3) There must be earth wire at power supply to prevent electric shock. Don’t connect earth to

gas pipe, water pipe, lightning rod or connection wire of telephone.

4) Don’t operate the unit with wet hand, and don’t allow children to operate the unit.

5) The On/off in Owner’s Manual is for the operation to “on and off” button of control panel

for users; cut off power means to stop supplying power to the unit. Don’t directly expose the unit

under the corrosive ambient with water or dampness.

6) Don’t directly expose the unit under the corrosive ambient with water or dampness.

7) Do conduct electric leakage detect after installation by professional of central air

conditioning installation.

8) Operation conditions: Ambient outdoor temperature for heat pump operation must be from

-20℃ to 24℃; At the same time, Ambient outdoor temperature range for cooling operation must

be from 16℃ to 43

℃;

Furthermore, water temperature must be under 50

℃ .

In order to avoid

freezing the Tube-in-tube heater exchanger, water temperature must be beyond 5℃.

9) To be in compliance EN 61000-3-11,the product shall be connected only to a supply of

the system impedance:|Zsys|=0.391 ohms or less.Before connect the product to public power

network, please consult your local power supply authority to ensure the power network meet above

requirement.

10) Electric supply tolerances: (380-415V)±10%, (50±1)Hz.

11) Humidity range:30%-95%.

12) Installation altitude: max 1000m.

13) Transport/storage temperature range: -25

~

55℃. And for short period not exceeding 24h,

the temperature is up to 70

℃ .

14) Main switch provided by end user: main switch handle should be black or gray, it can be

locked in “OFF” position with padlock.

15) The main disconnection device should be installed at a height of 0.6~1.7m. Over current

protection is required(EN 60947-3,EN60947-2) .

16) An all-pole disconnection switch having a contact separation of at least 3mm in all poles

should be connected in xed wiring .

Please contact with local dealer, authorized service center or office, our company if

malfunction occurs.

Page 4

Contents

1. System Instruction ...................................................................................... 1

2. Product Specications ................................................................................. 1

3. Unit Introduction ....................................................................................... 2

3.1 Outline Sketch of Unit ............................................................................. 2

3.2 Outer Wiring Diagram of Unit ................................................................ 3

4. Operation Instructions of Controller ........................................................... 4

4.1 Display function on display board .......................................................... 4

4.2 LCD displaying panel ............................................................................. 4

4.3 Button function on display board ........................................................... 5

4.4 Buzzer ..................................................................................................... 5

4.5 Basic operation ....................................................................................... 6

4.6 Error Code List ....................................................................................... 8

5. Daily Operation and Maintenance .............................................................. 9

6. Common Malfunction and Solution ............................................................ 9

7. Terminal Facilities and Selection Guideline ............................................. 11

8. System Installation .................................................................................... 11

8.1 Unit Installation .................................................................................... 11

8.2 Installation of terminal facilities ........................................................... 12

8.3 Water Pipe Connection ......................................................................... 13

8.4 Anti-frozen Notice ................................................................................ 15

9. System Adjustment (it shall be done by professional) .............................. 16

9.1 discharge water to water system ........................................................... 16

9.2 Check Before Trial Run ........................................................................ 16

9.3 Trial Run .............................................................................................. 16

10. Usage Instruction for Accessories ........................................................... 17

10.1 Auto water ll valve ............................................................................ 17

10.2 Safety valve ......................................................................................... 17

10.3 Auto exhaust valve .............................................................................. 18

Page 5

Household (Townhouse) Central Air Conditioning Unit

1

1. System Instruction

Combination Household (Townhouse) Central Air Conditioning Unit is a kind of small central air

conditioning unit usually installed in high-grade flats, combination buildings, high-grade townhouse, and

unitary office, restaurants, department stores, entertaining places and other places that have special air

conditioning requirements.

Working principle of Combination Household (Townhouse) Central Air Conditioning Unit: Firstly, the

unit produces cooled (or heated) water, after being press by water pump, this cooled (heated) water will be

transferred to every indoor fan coil by water pipe (or other terminal facilities), then through fan coil to conduct

heat exchange with indoor air circle and make indoor air temperature lower (or higher), thus, indoor air

conditioning can achieved. Meanwhile, fresh air unit can be installed in the system, lead certain quantity of

fresh air in and blow it into rooms after ltering or lowering (or heating up) temperature, then the indoor air

can still remain fresh and comfortable.

Combination Household (Townhouse) Central Air Conditioning System consists three parts: ①Household

(Townhouse) Central Air Conditioning Unit: There are 2 types of cooling only and heat pump. Outdoor units

are placed at outdoor balcony, roof or special at roof; and indoor units can be placed in washing room or

other indoor places. Outdoor and indoor units can also be piled together and places outdoors.

②

Terminal

facilities: It is usually fan coil, it is recommended to adopt horizontal type invisible fan coil under common

circumstance, for it can be easily combined with indoor decoration, and will always produce satisfying effect;

③

Water system: For connecting host and terminal fan coil and work for transferring cool and heat. It is

commonly made with galvanized pipe or seamless copper pipe, it can also adopt new type pipes such as PVC

pipes, PPR pipes, or aluminum-plastic pipe etc..

2. Product Specications

1) Humanized design, both split installation and whole installation are available.

2) Ultra-thin indoor unit design, height is only 288mm, convenient for hanging.

3) Adopting junction box heat exchanger, unit performance, antifreeze ability and reliability can be

enhanced greatly.

4) System realized trinity

A set of heat pump system can both cool and heat, it saves gas system, and also collocate with household

replace, water boiler or city heating net. Thus, cooling, heating, and water heating become trinity.

5) Large range of cool water and heat water supply

When cooling, supply range for cool water is 7

℃~15℃

; when heating, supply range for heat water is

35

℃~50℃

.

6) High reliability

Heat transfer media of this unit is water and with no distance limitation, only considering enough water

pump lift can realize long-distance heating and cooling.

7 ) Control function in subrooms

It is available to conduct on or off control to host in rooms, that is, when order of turning on from only

a single room, host on; when all rooms send unit off order, host off; general control spot can be set at living

room to conduct prior control to unit.

8) Easy operation

Adopting advanced total computer control system, main control system can conduct complete control to

the unit. Since it is very easy and quick to reset the operation, it can satisfy users’ requirements. With multi-

point control function, it is available to control on/off of host from several rooms, i.e. when order of unit on

from only a single room, host on; when all rooms send unit off order, host off; general control spot can be set

Page 6

Household (Townhouse) Central Air Conditioning Unit

2

at living room to conduct prior control to unit.

9) Easy dialogue interface:

Host displays in English, and every operation data can be nd. When malfunction occur, unit will displays

error informational automatically, thus, repair and maintenance is very easy.

3. Unit Introduction

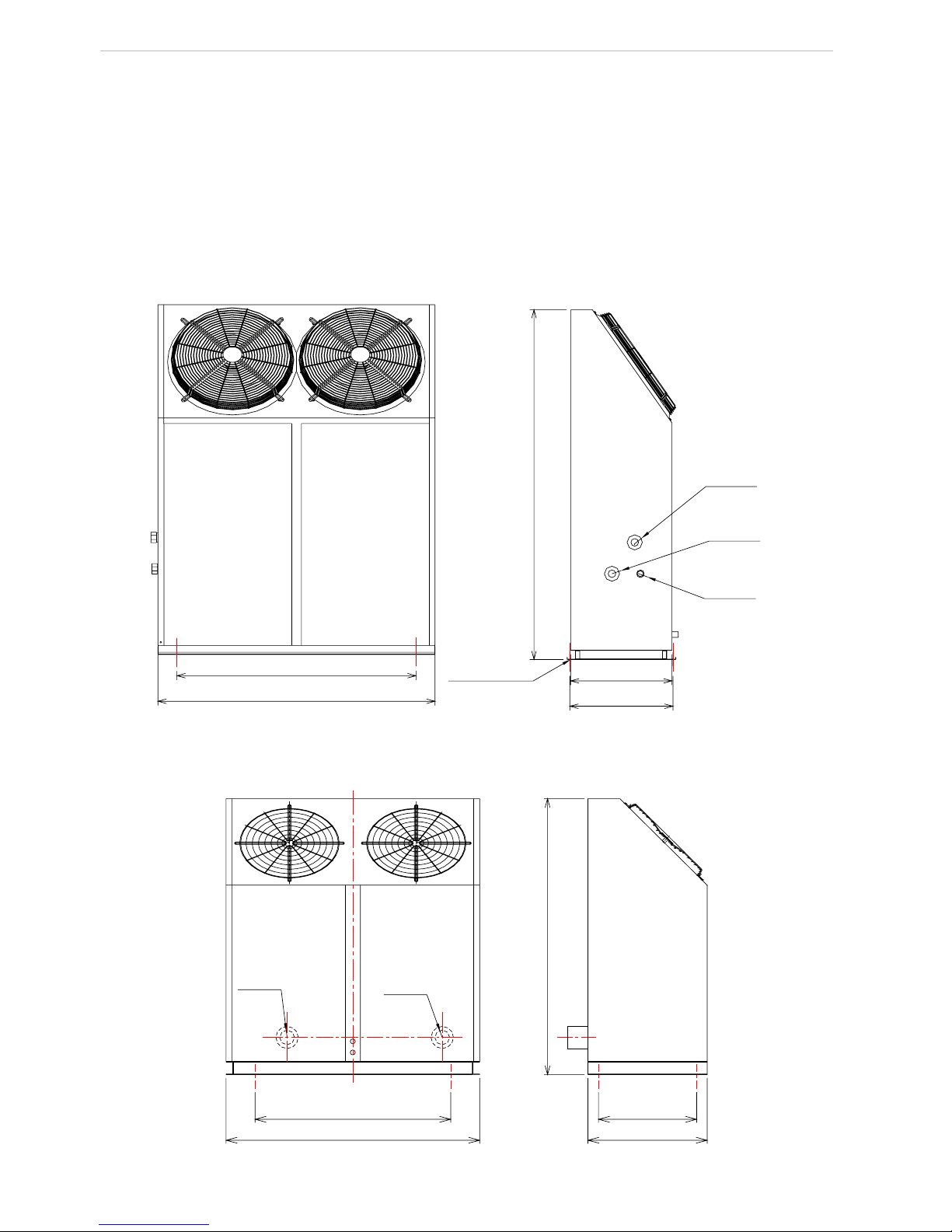

3.1 Outline Sketch of Unit

Outline Dimension of Outdoor Unit Outline dimension diagram of HLR22SNa-M 、HLR25SNa-M

Unit: mm

Diameter

12mm

water outlet

water

inlet

water-filled

valve

Basement

fixing hole

G1/2 "

544

530

1260

1460

1850

G1 "

G1 "

Outline dimension diagram of HLR35SNa-M 、HLR45SNa-M

Unit: mm

Water Inlet

Water Outlet

1290

1750

1760

710

800

G1-1/2

"

G1-1/2

"

Page 7

Household (Townhouse) Central Air Conditioning Unit

3

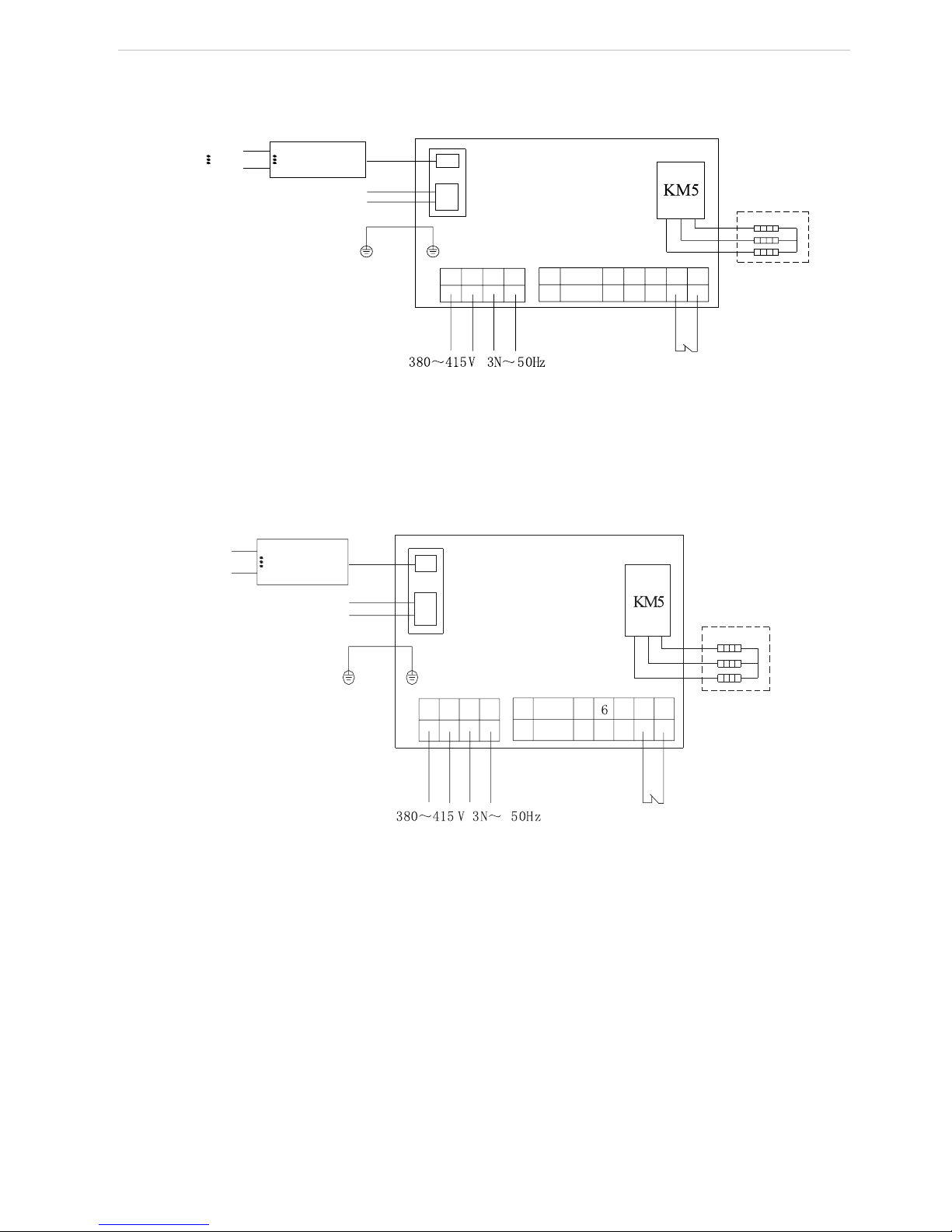

3.2 Outer Wiring Diagram of Unit

Wiring Diagram of HLR22SNa-M 、HLR25SNa-M

:

X16

X17

PC

CONT ROLL ER

E

E

L1

XT1

11

XT2. 1、 XT2. 2

AUXI LIARY

ELECTRICAL

HEATER

HEAT

X1

X1

XN

term inal

switchboard

term inal unit1

termi nalu nitN

2

4

6

L2 L3 N

5

6

1

2

if the chiller is connected with fancoil units, please remove the wire between" 6 " on XT2 patching board

and X16 on PC , then connect X16 to X1 on fancoil unit patching board.

Wiring Diagram of HLR35SNa-M 、HLR45SNa-M

:

X16

X17

PC

CONTROLLER

E

E

L1 L2 L3 N

XT1

11 5

XT2.1、XT2.2

HEAT

2

4

6

10 11

X1

XN

X1

terminal

switchboard

unit1

unit N

AUXI LIARY

ELECTRIC AL

HEATER

if the chiller is connected with fancoil units, please remove the wire between" 6 " on XT2 patching board

and X16 on PC , then connect X16 to X1 on fancoil unit patching board.

Page 8

Household (Townhouse) Central Air Conditioning Unit

4

Selection of power supply wiring and air switch:

Model Power supply type air switch (A) power supply cord

HLR45SNa-M 3Ph 63 H07RN-F 5G10.0mm

2

HLR35SNa-M 3Ph 50 H07RN-F 5G6.0mm

2

HLR25SNa-M 3Ph 32

H07RN-F 5G4.0mm

2

HLR22SNa-M 3Ph 25

Note

:

① .

The power supply wire must be copper core wire, and the working temperature can not be higher

than limited value.

② .

If the length of power supply wire is longer than 15meters, do please increase the section area to

avoid any accident due to over-load.

③ .

If the supply cord is damaged, it must be replaced by the manufacturer or its service agent or a similar

qualied person in order to avoid a hazard.

④ .

The appliance shall be installed according to national regulations.

⑤ .

When installing the connection wiring for manual controller, the wire must be put inside a separate

protective sheath to avoid direct sunshine.

4. Operation Instructions of Controller

4.1 Display function on display board

17

16

15

13

12

11

2

1

4

6

7

8

9

10

5

3

14

OFF

ON

EXIT

MODE

CHECK

PARAMETER SET PASSWORD

DEFROST ABC TEST

4.2 LCD displaying panel

1) HEAT: It displays when unit is heating, otherwise it would not display.

2) ERROR CODE: It shows the error code displayed on Main Display Area. It displays when there is

Page 9

Household (Townhouse) Central Air Conditioning Unit

5

error at system or communication.

3) COOL: It displays when cooling is running, otherwise it would not display.

4) TEMP: It shows temperature value displays at main display area.

5) Auxiliary display area: It contains 2 numbers and a comma, for showing temperature and number of

parameter at main display area. It only displays when under Check mode and Parameter checking mode.

6) Main display area: It contains a minus, 2 numbers and 1 temperature unit, for displaying value of

temperature and parameter (temperature or time value) and error code. When temperature value is displayed,

it shows value in algorism and temperature unit; when time is displayed, it shows algorism value but no

temperature unit (default unit is min); when it is code, it displays specic error (refer to Malfunction Error

List) but no temperature unit. Individual temperature or parameter may exceed 99, then adopt AX for 100

~

109, bX for 110~119, CX for 120~129, dX for 130~139, EX for 140~149, FX for 150~159, and X

stands for a number between 0~9. Under normal state, it shows temperature for back water.

7) Parameter list: It means the value shown at present main display area is parameter. It shows onlyunder

Parameter Check mode.

8) DEFROST: It displays when defrosting, otherwise it doesn’t displays.

9) ABC: It displays when system or compressor orders, for showing which system is defrosting.

10) TEST: For testing, it displays under compel operation. 11~17. Buttons: Functions and contents are

shown in instructions for buttons function below.

When unit is off, it displays only temperature of out water. When unit is on, under normal state, if there is

no error, it displays temperature of out water, if there is error, it displays error code; when there is no operation

after 60s of pressing the button, it quit back to normal state display automatically.

Auto antifreeze operation display (only for heat pump unit)

When auto antifreeze function is started and relevant conditions are satised, unit begins auto antifreeze

operation. At this time, LCD main displaying area displays code d2 (if there is error it displays error code).

4.3 Button function on display board

1) MODE: It can switch between cooling and heating, this button is available only on cooling and heating

unit.

2) Turn On: To turn on the unit; when under compel operation, press once to quid compel operation.

3) Turn Off: To turn off the unit; press it once to quit compel operation when the unit is under compel

operation.

4) ▲ : To increase present set value or change set/check object.

5) ▼: To decrease present set value or change set/check object.

6) Check: Press it once under normal state to enter check mode, under check mode, press this button

when “17” is displayed can change the value of “17”. Under parameter set mode, press this once can switch

the adjusting objection between parameter and value, press this button for long (about 5s) to save and quit this

parameter setting.

7) EXIT: Under Set and Check mode, press it once to quit this mode. Under parameter set mode, this set

value would not be saved. Press this button for long (about 5s) to set sound, and make sound switches between

always on and always off.

8) EXIT +▲: 20s after electrify, press this two buttons simultaneity for about 3s (EXIT rst, and then

▲, the interval between pressing the two buttons should not be longer than 4s), to enter parameter check

mode.

Page 10

Household (Townhouse) Central Air Conditioning Unit

6

4.4 Buzzer

When unit is always off, buzzer will not sound under any circumstance. When unit is always on, buzzer

sounds once when electried reset and quick test. It also sounds when button is pressed and when there is key

error under unit on state. When unit is operating in anti-high temperature or antifreeze, buzzer doesn’t sounds.

4.5 Basic operation

1) Turn On: Press On once when unit is off then unit be in waiting state, and LCD displays temperature

of water back and operation mode (cooling or heating). When it detected there is terminal on, unit operates

automatically and operation mode blinks; if it detected there is no terminal on, unit turns off after delaying for

certain time, then system back to waiting state.

2) Turn Off: Press OFF once when unit is on to stop the unit from working and make it in off state. At

that time, LCD only displays temperature for back water.

3) Mode Switch: It is only available to heat pump unit, cooling only unit only contains cooling mode.

To heat pump unit, press Mode once, then system mode switches to cool from the previous heating, or to heat

from present cooling. When there is error, this button doesn’t work.

4) Check system temperature point and state: Press Check once to enter check mode. Under check

mode, Auxiliary display area shows checking object, main display area shows the value of the object. Press

▲ and ▼ to change the check object, press EXIT to quit from check mode. The content that can be check are

as follow:

0:Temperature for back water

1:Temperature for out water

2:Outdoor ambient temperature

3:Antifreeze temperature 1

4:Antifreeze temperature 2

5:Defrost temperature 1 (This temperature has no meaning to cooling only unit)

6:Defrost temperature 2 (This temperature has no meaning to cooling only unit)

7:Exhaust temperature 1

8:Exhaust temperature 2

9:Unidentied

10:Unidentied

11:Real time error code

12:Defrost and terminal =0XH is no defrosting; =FXH is defrosting;

=

X0H means no terminal is on; =XFH means there is terminal on.

13:Outdoor unit operation state: 0x01= Turn off unit when cooling, 0x02= Turn off unit when heating

0x11= Turn on unit when cooling, 0x12= Turn on unit when heating

0xd2= Auto antifreeze is running, 0xF1= Compel cooling, 0xF2=

Compel heating

14:Outdoor unit operation state

15:Indoor unit operation state :

0x01= Turn off unit when cooling, 0x02= Turn off unit when heating

0x11= Turn on unit when cooling, 0x12= Turn on unit when heating

0xd2= Auto antifreeze is running, 0xF1= Compel cooling, 0xF2= Compel heating

16:Indoor unit operation state

Page 11

Household (Townhouse) Central Air Conditioning Unit

7

17:=00 is stopping auxiliary heating, stopping antifreeze; =01 is turning on auxiliary heating, stopping

antifreeze;=02 is stopping auxiliary heating, turning on antifreeze; =03 is turning only auxiliary heating,

turning on antifreeze (it has no meaning to cooling only unit).

18:Communication state.

19:Error in history.

5

) Turn On/Off Auxiliary Heater: It is only available for heat pump unit. Press Check once to enter

Check mode. Press ▲ and ▼ to change check object, press Check again till the present check object becomes

“17”, value “17” switches between 01/03 (auxiliary heater on) and 00/02 (auxiliary heater off). That is 00 Off

—>01 On —>00 Off, or 02 Off —>03 On —>02 Off.

6

) Check Parameter: After electrify for 20s, press EXIT then ▲ to enter parameter checking mode.

Under this mode, Auxiliary display area shows the checking object, Main display area displays the value

for the checking object. Press ▲ and ▼ to change the checking object. Press EXIT to quit from the check

mode. Content that can be checked are shown below: Name for Parameter

:

NO. Name for Parameter

0 If auxiliary heater is on

1 Set temperature for cooling water out

2 Set temperature for heating water out

3 Begin temp. for defrost

4 End temp. for defrost

5 Set interval between defrost

6 Duration for defrost

7 Antifreeze temp.

8 End temp. for antifreeze

9 Anti overheated temp.

10 Temp. to quit from anti overheated

11 Deviation to set temp.

12 Outdoor ambient temp. for defrost

13 Exhaust pipe high-temp. protect temp.

14 Interval between terminals off and host stops

Page 12

Household (Townhouse) Central Air Conditioning Unit

8

4.6 Error Code List

Error code Meaning for Error Method of Clearing Error

E1 Compressor 1 high-pressure protection Press OFF to clear

E2 System-antifreeze protection Resumes automatically

E3 Compressor 1 low-pressure protection Press OFF to clear

E4 Compressor 1 exhaust temp. protection Press OFF to clear

E5 Compressor 1 overload protection Press OFF to clear

E6 Water pump overload protection Press OFF to clear

E7 Water-ow on/off error Press OFF to clear

E8 Fan 1 overload protection Press OFF to clear

E9 System 1 anti high-temp. Resumes automatically

b1 Compressor 2 high-pressure protection Press OFF to clear

b2 System 2 antifreeze protection Resumes automatically

b3 Compressor 2 low-pressure protection Press OFF to clear

b4 Compressor 2 exhaust temp. protection Press OFF to clear

b5 Compressor 2 overload protection Press OFF to clear

b8 Fan 2 overload protection Press OFF to clear

b9 System 2 anti-high temp. Resumes automatically

F1 Antifreeze temp. sensor 1 error Resumes automatically

F2 Antifreeze temp. sensor 2 error Resumes automatically

F3 Defrost temp. sensor 1 error Resumes automatically

F4 Defrost temp. sensor 2 error Resumes automatically

F5 Exhaust temp. sensor 1 error Resumes automatically

F6 Exhaust temp. sensor 2 error Resumes automatically

F7 Outdoor ambient temp. sensor error Resumes automatically

F8 Water-in temp. sensor Resumes automatically

F9 Water-out temp. sensor Resumes automatically

EC Communication malfunction Resumes automatically

1) Auto reset: It means after error is cleared and compressor stop protection time is satised, unit resumes

running automatically.

2) Manual reset: It means manually press OFF to clear error code rst, and then press ON to make the unit

operates after malfunction is cleared.

3) When low-pressure protection is detected for 3 times in consecutive 30min, reset mode changes

to manual mode from auto mode. When overload at compressor and fan motor is detected for 3 times in

consecutive 30min, reset mode changes to manual mode from auto mode. Note:The installation of the

controller must be done by professionals.

Note:The installation of the controller must be done by professionals.

Page 13

Household (Townhouse) Central Air Conditioning Unit

9

5. Daily Operation and Maintenance

When adjustment and test had completed, daily operation such as turn on/off unit, switch cooling

and heating, and set parameter etc. are to be done through the manual control that installed indoor.

1) All safety protection settings in the unit are set well before outgoing, please don’t modify them to avoid

damaging the unit.

2) The on/off control to fan coil in every room should be operated individually by temp. controller and the

3-speed switch installed in every room. When there is no connect control between host and fan coil, after the

last fan coil is turned off, host should stop.

3) Don’t cut off power immediately after unit had stopped. If the unit stopped and disconnected to power

supply for more than 2 days, please switch on the power supply for more than 6h before restart the unit.

Otherwise, the unit may not be able to operate normally.

4) Don’t put things on the unit or its accessories, keep all around dry, clean and well ventilation. Clean

it on time by professional personnel when there is much dust on n of condenser to prevent the dust from

affecting the performance.

5) Don’t block the air outlet and air intake vents of indoor fan coil, lter at air intake vent should be

disassembled and cleaned regularly. (it shall be done by professional)

6) Do add antifreeze into water system of heat pump unit, the additional proportion is shown in this

manual on page 26. Please let the professional to add the antifreeze. Please cut off the power supply before

adding the antifreeze. For cooling only unit, when it is not used in winter, do drain out all water in the unit and

pipeline to prevent the tube-in-tube heat exchanger, pipes and pump from breaking; when it is not sure water

in pipeline had drained completely, do add antifreeze into system pipeline. Don’t cut off power supply when

turn off the unit, otherwise auto antifreeze operation protection will be useless.

7) To heat pump unit, if not for use for a long time, water in the pipeline will be the same temperature

as ambient water. In that case, cool air may blow out in winter when unit begins to operate in heating mode.

If there is no connected control system between host and fan coil, it is better to turn on host 5~10min before

turning on the unit for heating, then turn on indoor fan coil to heating mode directly after water in pipeline

become warmer; if there is connected control between host and fan coil, turn on a fan coil rst and turn on

host for 5~10min, then turn on the fan coil in room that needs heating after water in pipeline become warmer.

These can prevent cool wind from blowing out in the rst few minutes when fan coil is just turned on.

6. Common Malfunction and Solution

When there is problem occur during operation, please contact with our nearest local dealer or ofce.

The following phenomena are not malfunctions:

1) When cooling (heating in winter), load is small (i.e. little fan coils operate), temperature of system

water is lowered (raising) rapidly, antifreeze (anti high-temp) protection will work and will stop when water

temperature back to set point.

2) When heating, since the surface temperature of heat exchanger is lower than outer ambient temperature,

and when surface temperature of heat exchanger lower than 0℃, there will be frost on the surface and affect

heat exchanging effect, thus the control system would conduct defrost regularly to melt the frost on the surface

of heat exchanger.

3) If unit is used at area where temperature at winter will below 0℃, when system is in waiting state

(don’t cut off power), and when ambient temp. and system water temp. are about 0℃, in order to prevent

water system from freezing and damaging equipments, control system will conduct auto antifreeze operation,

start water pump and compressor until water temperature reach safe point.

Page 14

Household (Townhouse) Central Air Conditioning Unit

10

When dealing with problems, professional personnel can remove malfunctions according to following list:

Common error Reason Solution (done by professionals)

1. Compressor doesn’t work.

A、Error on power

B、 Wire loose

C、Error on relay or insurance

D、Temp. is set too high

E、 Error on compressor

●Check and re-tighten

●Check error reason and repair

●Reset ●Change compressor

2. Fan noise is large

A、Fan xing bolts are loose

B、Fan louver touched outer case

or net cover

C、Operation of fan is not steady

●Retighten fan xing bolt

●Check reason and adjust

●Change fan

3. Compressor noise is large

A、 Liquid hit produced when

liquid refrigerant ows in compressor

B、 Components inside compressor

are damaged.

●Check is expand value is

ineffective, temp. sensor is

loose, and repair

●Changer compressor

4. Water pump doesn’t

operate or operate abnormally

A、Error on power or wiring

B、Error on relay

C、There is gas in water pipe

●Check reason and repair

●Exchanger relay

●Exhaust all gas

5. Cooling effect is bad.

A、 Freon in cooling system leaks

B、Heat preservation of water

pipe is bad.

C、Water ow quantity is not enough

D、Heavy dust on condenser

E、 Cooling system

●Check and repair and recharge Freon.

●Strengthen heat preservation

●Clean water lter

●Clean condenser

●Check or change dry lter

6.Compressor frequently on

and off.

A、Fr eon leak ag e on sy st em and

refrigerant shortage

B、Dry lter is blocked

C、Error on heat expand

valve.

D、Water system circulation is bad.

●Exhaust some refrigerant

●Water system is blocked or there

is a ir. Chec k water pum p, valve,

pipeline, clean water lter or exhaust

air.

●Adjust load or increase energy store

facility.

7. Refrigerate system and

refrigerant

A、 Freon leakage on system and

refrigerant

shortage.

B、Dry lter is blocked

C、Error on heat expand

valve.

D、Water system circulation is bad.

●Ch eck and re pair a nd re cha rge

refrigerant.

●Change dry lter

●Check if expanse valve is

blocked, temp. sensor is leaking, then

repair or change.

●Check water system and solve.

8.Compressor operates but

unit doesn’t cool.

A、All refrigerant is leaked

B、Freeze evaporator is freeze.

C、Compressor error

●Check, repair and charge

refrigerant

●Check reason and remove

Freezing

●Change compressor

Page 15

Household (Townhouse) Central Air Conditioning Unit

11

7. Terminal Facilities and Selection Guideline

Household (Townhouse) Central Air Conditioning Terminal Facilities are mainly for the heat exchanger

facilities installed indoor, Usually it is fan coil with several models. Such as horizontal invisible fan coil,

horizontal visible fan coil, vertical visible fan coil, suspending fan coil and so on. User can select different

type of fan coil according to house structure and indoor decoration style. Normally, we recommend selecting

horizontal invisible fan coil, because it is in smaller dimension and can be concealed well, it is easy for indoor

decoration. At the same time, its noise is lower, and it is relatively cheaper. Suggestions are as following:

Models FP-34 FP-51 FP-68 FP-85 FP-102 FP-136

Room area m

2

8~12 10~18 15~25 20~30 25~35 30~45

Control to the fan coil at every room is conducted by the temperature control on wall and the 3-speed

switch. Temperature control is for setting room temperature, 3-speed switch, with high, medium, and low

speeds, for adjusting airow and cooling capacity of the fan coil.

8. System Installation

Do have the unit installed by the authorized company or professional central air conditioning installation

project company, don’t try to install it by yourself.

8.1 Unit Installation

8.1.1 Select of installation location

1) This Household (Townhouse) unit can be installed on roof, ceiling, special at or other place that is

easy for installation and be able to stand its weight.

2) Select a place with well ventilation and smooth exhausting, and the place will not produce short-circuit

circulation, and where exhausted air from the unit will not bother neighbors.

3) When placing the unit at roof, pay attention to wind direction to prevent direct up wind; when placing

it on ground, avoid placing it at where there is strong wind.

4) There should be no heat source, exhaust vent of other facilities, strong steam and ammable gas around

the unit.

5) When installing several units, ensure there is enough suction space to prevent short-circuit circulation.

6) Place where there is no large snow in winter.

7) There should be no obstruction near air intake vent or air outlet vent.

8) Place where with drainage pipe around the unit to drain cooling or heating water.

9) Place that near power for easy wiring.

10) Place that near supply water source for convenient pipe construction.

11) There should be open space around the unit.

Page 16

Household (Townhouse) Central Air Conditioning Unit

12

8.1.2 Installation space requirement for outdoor unit

Whole installation:

Connect water fitting

from this side

Set electric power

cabinet at this side

Air

outiet

>1200mm

>1000mm

>1000mm

>1000mm

>2000mm

8.1.3 Move and disassembly

1) It is better to use forklift or crane when moving the unit.

2) When suspending, please adopt canvas gallus, round the gallus at base of the unit and bundle it tightly,

meanwhile, ensure that the gallus would not tough heat exchanger.

3) When moving the unit, the slant angle should be smaller than 30°.

8.1.4 Installation mode

1) Fix the unit on separated concrete base with expand bolts directly.

2) It is also available to adopt angle iron or steel supporter that make off channel steel, add shake-

absorbing gaskets, and then place the unit on oor or roof. Ensure to keep the unit horizontally.

8.2 Installation of terminal facilities

Installation of indoor terminal fan coil should obey the installation regulation for air conditioning

facilities.

1) Suspend the fan coil according to the elevation shown on air conditioning project construction chart,

and please be aware to keep it horizontally.

2) Connect water in/out and water in/out joint of fan coil by soft joint; connect condensate water out pipe

on water tray and condensate water drainage hose by plastic host.

3) Electric wiring of fan coil, 3-speed switch and temperature control are as following:

Page 17

Household (Townhouse) Central Air Conditioning Unit

13

Electric wiring diagram for no connection control between fan coil and host

M

M

M

M

M

M

Fan coil

Fan coil

Fan coil

Electric

valve

Electric

valve

Electric

valve

N

L

E

Temperature

control

Temperature

control

Temperature

control

Electric wiring diagram for connected control between fan coil and host Special notice:

M

M

X2

X3

X4

M

M

M

M

Fan coil

Fan coil Fan coil

Electric

valve

Electric

valve

Electric

valve

N

L

E

Temperature

control

Temperature

control

Temperature

control

1) When connected the control wire between fan coil and host, connect the live wire of fan coil controller

to the port X2~X7 on terminal switch board inside electric case through the switch of temperature control;

Meanwhile, disconnect the original connecting wire between main controller and end-switch . Then connect

the port X1 at switch board to end-switch at main board of indoor unit.

2) When connect control is not conducted between fan coil and host, please connect the end-switch at

main board with live wire (short connected when outgoing).it shall be done by professional.

3) Method of shutting off the power is cutting off the air switch. Contact distance between the electrodes

of the air switch must be beyond 3mm.

4) Installation should conform to the local electric standard.

5) The appliance shall be installed in accordance with national wiring regulations.

6) Before obtaining access to terminals, all supply circuits must be disconnected.

7) If the supply cord is damaged, it must be replaced by the manufacturer or its service agent or a similarly

qualied person in order to avoid a hazard. 8、An all-pole disconnection switch having a contact separation of

at least 3mm in all poles should be connected in xed wiring. 9、The appliance shall not be used by children

without supervisor.

8.3 Water Pipe Connection

When connecting water pipe, please screw off the plug at water in pipe and water out pipe, connect

the water-in hose and water-out hose separately with the water-in pipe and water-out pipe of the unit.

Please note the following points when constructing:

1) Water connect pipes must be new, do not use old pipes instead of new ones.

Page 18

Household (Townhouse) Central Air Conditioning Unit

14

2) Construction must be correctly designed and conducted according to the water and heat pipeline design

criteria and standard.

3) Select corresponding pipe diameter according to the given dimension of pipes.

4) here is expand can set in the unit, water ow switch, auto water lling valve, safety valve, and water

system adopts our Household (Townhouse) Unit standard installation sketch (as shown in the next page).

5) The proportion of electric 2-way valve and electric 3-way valve in water system should refer to

technical criteria (the recommended value is 2:1). And electric 3-way valve must be assembled at the furthest

end of water system.

6) Try to decrease the pressure difference between indoor fan coil or main host with water in or out port

of the unit.

7) Do install water lter at water-in pipe of the unit to prevent block at heat exchanger inside the unit.

8) After piping water system, according to relevant criteria for HVAC, conduct leakage test with hydraulic

pressure of 0.6MPa. and maintain the pressure for 24h. Ensure that there is no leakage in the whole pipeline

system, then wrap heat preservation layer.

9) After completed piping of water system, do drain out contamination inside water system. Ensure that

inside of water pipe is clean without contaminations such as rust dregs, so that there will be no blockage in

pipeline and sleeve heat exchanger in the unit and water pump, which will damage the unit.

10) Exhaust air inside water system with auto exhaust valve. Auto exhaust valve must be installed at the

highest point at water return pipe.

11) Drainage valve should be installed at the lowest point of water pipe.

12) hermometer and hydraulic pressure meter must be set at water-in and water-out pipe of unit for

convenient check when unit is operating.

13) Water pipe must conduct heat preservation and moisture proof, to prevent loss of cooling or heating

capacity and forming condensation water.

14) Inlet water pipe pressure must be lower than 0.62MPa. ,otherwise safety valve will open automatically

release pressure. At the same time ,its minimal pressure must be beyond 0.15MPa..

15) Cleaning and maintenance must be done by professionals.

Warning: Water filter with at least 60 meshes must be installed on water-in

pipeline system of the unit to avoid b locking the sleeve

heat exchanger

in the

unit and causing damage. Do clean it regularly. It must be down by professionals

Page 19

Household (Townhouse) Central Air Conditioning Unit

15

1

3

5

4

6

7

8

2

13

16

15

14

12

11

10

9

Connected with

Illustration

1.Air conditioning host

9.Check valve

10.Flowmeter

11.Drainage valve

12.Electric 2-way valve

13.Electric 3-way valve

14.Ball valve

16.Base

15.Auto exhaust valve

2.Fan coil

3.Rubber soft joint

4.Thermometer

5.Pressure meter

6.Cut-off valve

7.By-pass valve

8.Y-shape filter

tap water

Standard Installation Sketch for this Household (Townhouse) Unit

8.4 Anti-frozen Notice

1) To heat pump unit, when it is used at where temperature in winter would below 0℃, do conduct heat

preservation with insulation material, and add antifreeze according actual situation.

2) On control system there is auto antifreeze operation set for assisting system. Its principle is: When unit

is at standby state (don’t cut off power), and ambient temperature and system water temperature is at about 0

degree, control system will start water pump and compressor till water temperature reaches safety point.

Thickness of glycol liquid—freezing point list:

Thickness % Freezing point

℃

Thickness % Freezing point

℃

Thickness % Freezing point

℃

4.6 -2 19.8 -10 35 -21

8.4 -4 23.6 -13 38.8 -26

12.2 -5 27.4 -15 42.6 -29

16 -7 31.2 -17 46.4 -33

In the list: Thickness of glycol is mass thickness.

Page 20

Household (Townhouse) Central Air Conditioning Unit

16

9. System Adjustment (it shall be done by professional)

9.1 discharge water to water system

Fill water to the water pipe, meanwhile, conduct auto gas exhaust from exhaust valve till the whole pipe

lled with water, and conrm air in pipe had completely be exhausted.

9.2 Check Before Trial Run

Checking must be done by professional personnel.

9.2.1 Check indoor fan coil

1) Check if power cord connection of all indoor fan coils is correct, and rotation direction of fan motor is

correct.

2) Check if the valve on entrance and exit pipes of fan coil is completely open.

3) Exhaust it from exhaust valve when there is gas inside fan coil.

9.2.2 Check unit

1) Check if the outer appearance of unit and pipeline system is damaged during transportation.

2) Check if wiring terminals for electric components inside unit is loose, if phase sequence is correct.

3) Check if vane of fan motor would touch the outer case and grille when rotating.

4) Check if temperature sensor had inserted well.

9.2.3 Check pipeline system

1) Check if valves at pipeline system had open completely.

2) Check if water had lled the whole pipeline system, if air is exhausted completely.

3) Check if heat preservation to pipeline system is well.

9.3 Trial Run

Trial run can only be conducted after passing all above checking, then do it under the guideline of

professional personnel.

1) Switch on the power supply and turn on the unit. To the unit that uses 3-phase power, when power

sequence is reverse, phase sequence protection works, then fan motor, compressor and water pump will not

operate At that time, cut off power rst, exchange the two phases among the 3-phase power, then switch on the

power supply again and turn on the unit.

2) During operation, circle water pump should operates steadily. If it operates unsteadily, and indicator

of pressure meter swings a lot, it means there is air inside water system. At that time, exhaust air completely

through exhaust valve and then turn on the unit. After turning on the unit for 3 minutes, fan and compressor

start automatically.

3) After compressor had started, when abnormal sound is heard, stop the unit immediately and check.

4) When cooling in summer, when temperature of water-out Tout≥15℃, compressor starts; when Tout≤7℃,

compressor stops, and water pump keeps on running.

5) To heat pump unit, when it is operating heating in winter, and if water-out temperature Tout≤45℃,

compressor starts running; when Tout≥50℃, compressor stops, and water pump continues running.

6) Obverse if water temperature for in and out is normal, when the temperature difference between

water in and out ∆T>5℃, it means water ow in the system is small, at this time, check that whether there is

blockage in water lter, air in the pipe had not been exhausted, resistance in pipeline system is too great etc.

when ∆T is between 3~5℃, it can achieve best performance.

7) After trial run, clean the filter on pipeline first, and then the unit can begin normal operation. It is

Page 21

Household (Townhouse) Central Air Conditioning Unit

17

necessary to assembly and cleans the lter after a certain period (say, 3 months) to remain normal operation.

10. Usage Instruction for Accessories

10.1 Auto water ll valve

Application specication The auto water ll valve contains pressure regulation and pressure decreasing

settings, it can automatically maintain pressure in system, remain

system hydraulic pressure to a steady value. When system pressure

is lowered, valve turns on automatically and lls water into system;

when it reaches set pressure, valve closes automatically.

When auto water ll valve is under normal operation, when system

hydraulic pressure is larger than the set pressure, water fill valve

contains inverted function, i.e., even if system pressure increased,

water in the system will not flow back. When system repairing or

draining, screw manual cut-off valve tightly and turn off water source.

Pressure setting

Setting for auto water ll valve is determined by system working

pressure, and it is able to adjust automatically. When adjusting, auto

water ll valve is in working state. Connect pressure meter to joint of G1/4", loosen tightened nut and adjust

the pressure adjusting screw, when adjusted pressure to system working pressure, tighten nut.

Note: if pressure of water source is lower than the set pressure of auto water ll valve for a long time

(abnormal working state), add a one-way valve or cut-off handwheel of manual-closed auto water ll valve at

the exit of auto water ll valve. Dimension of joint of water ll pipe is G1/2";

Note:

This accessory h ad been installed inside the u nit, t esting p ersonnel m ust conduct p ressure

setting w hen w ater fill p ressure is lower than 0.15MPa and must according t o actual situation. It

shall be done by professional

10.2 Safety valve

Safety valve is for preventing system

pressure from raising suddenly, such as water hummer, over lled, open/close

or ineffective of valve and uctuation of system water temperature with the change

of ambient and load, and uctuation of system pressure with the change cubage of

water for temperature. When pressure exceeds the setting for safety valve, the valve

will open automatically to release pressure and prevent system pressure from going

too high and system breaking.

Working pressure of valve should be set about 10% larger than system operation

pressure normally, and it should be installed at place that is easy to product pressureconvergence, such as near

expand water case or water pump.

Note:

This accessory h ad been installed inside the u nit, unprofessional personnel please don’t turn or

assemble it.

82.5

G1/4〞

G1/2〞

Tighten nut

Press Handwheelure

adjusting screw

Handwheel

black ABS

G1/2A

G1/2

Page 22

Household (Townhouse) Central Air Conditioning Unit

18

10.3 Auto exhaust valve

If air in water system is not exhausted, it would cause effects:

1) Temperature at some parts will be uneven.

2) Noise is produced.

3) Oxygen contain in the air would cause metal oxygenation.

4) Too much air would damage water pump.

Auto exhaust valve should be installed at the top of pipeline, the place that

gas is easily gathered, and it should be installed vertically; self-close valve or

cut-off valve should be installed at bottom of exhaust valve, it is convenient for

system water ll or is used when repairing; exhaust valve cannot be installed at place that is easy to be frozen.

G3/8〞

Page 23

Gree Electric Appliances,Inc. of Zhuhai

Jin Ji West Road, Qianshan, Zhuhai, Guangdong 519070 P.R. China

http: //www. gree. com

GREE 66172104

Loading...

Loading...