Gree HLR35SM/NaA-M, HLR45SM/NaA-M Service Manual

Modular Mini Chiller Service Manual

(T1/R410A/50Hz)

GREE ELECTRIC APPLIANCES INC. OF ZHUHAI

GREE COMMERCIAL AIR CONDITIONERS MODULAR MINI CHILLER

2

CONTENTS

PRODUCT INTRODUCTION.......................................................................................................................4

1 MODELS LIST .........................................................................................................................................4

1.1 Integral Type ....................................................................................................................................4

2 NOMENCLATURE ..................................................................................................................................4

2.1 Integral Type ....................................................................................................................................4

3 FUNCTION...............................................................................................................................................4

4 PRODUCT DATA.....................................................................................................................................5

4.1 Product Data at Rated Condition..................................................................................................5

4.2 Operation Range.............................................................................................................................6

4.3 Electrical Data .................................................................................................................................6

5 PIPING DIAGRAM..................................................................................................................................6

UNITS CONTROL .........................................................................................................................................8

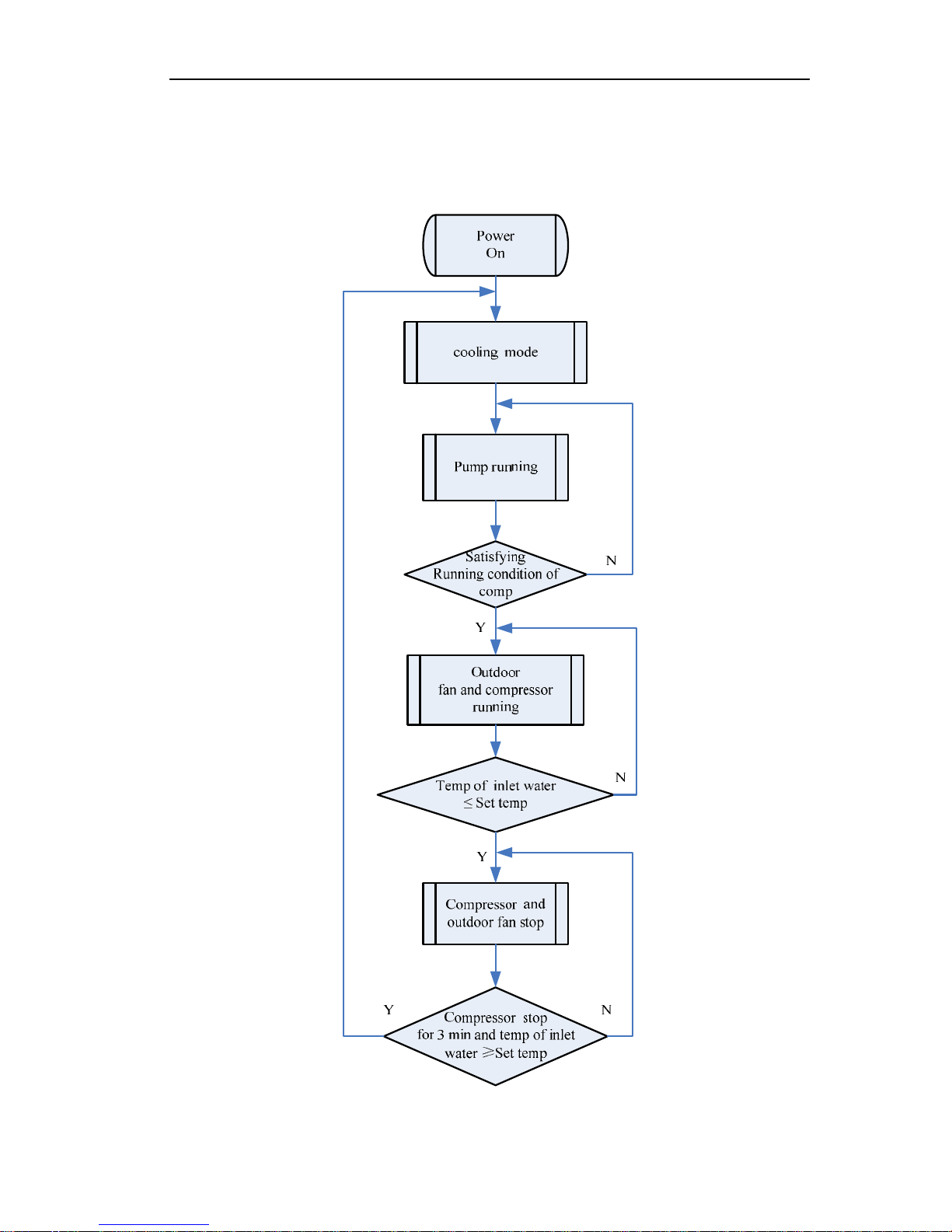

1 OPERATION FLOWCHART....................................................................................................................8

1.1 Cooling Operation...........................................................................................................................8

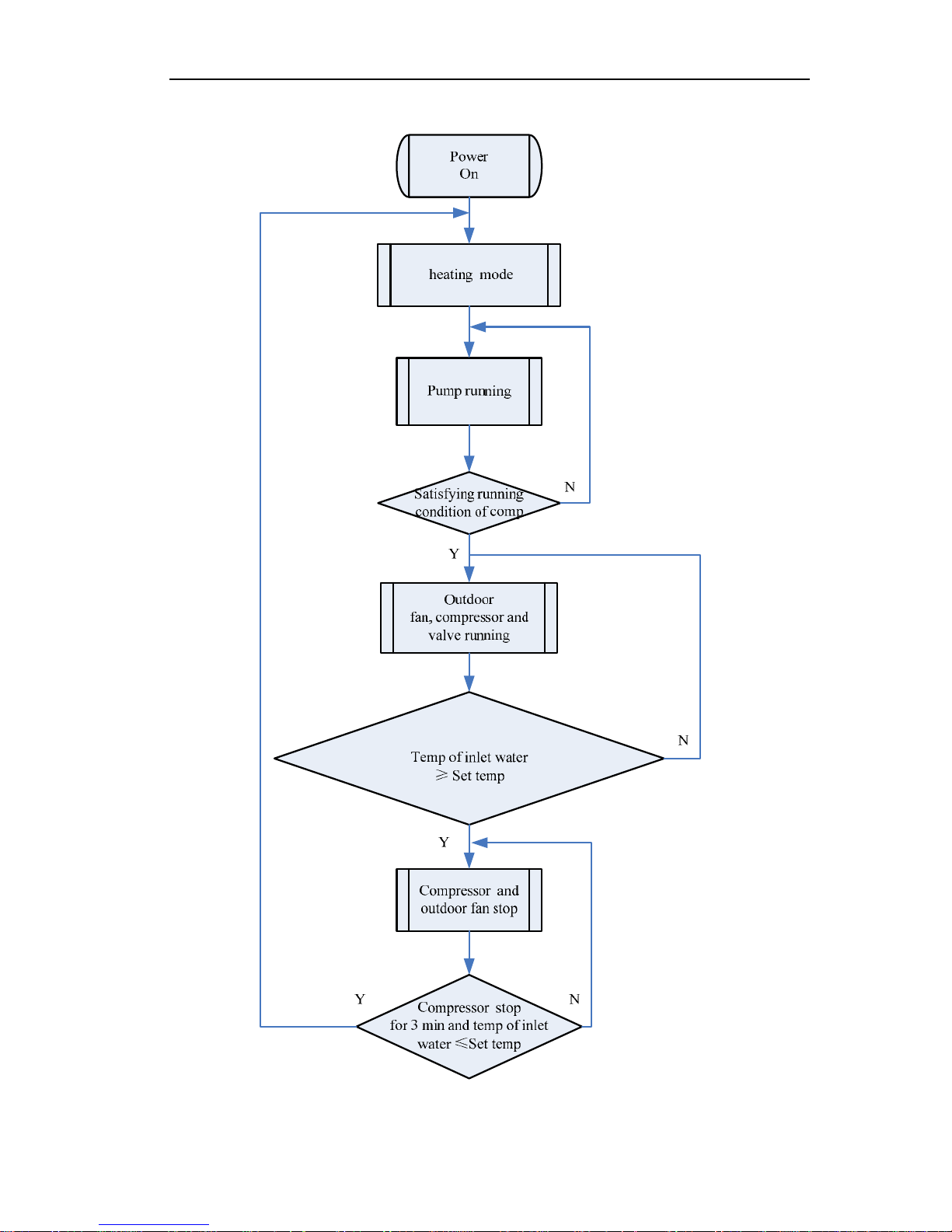

1.2 Heating Operation...........................................................................................................................9

2 MAIN LOGIC .........................................................................................................................................10

2.1 Cooling Mode ................................................................................................................................10

2.2 Heating Mode ................................................................................................................................10

2.3 Anti-freezing Running ...................................................................................................................11

2.4 Control of Compressor.................................................................................................................11

2.5 Control of Four-way Valve ...........................................................................................................11

2.6 Control of Water Pump.................................................................................................................11

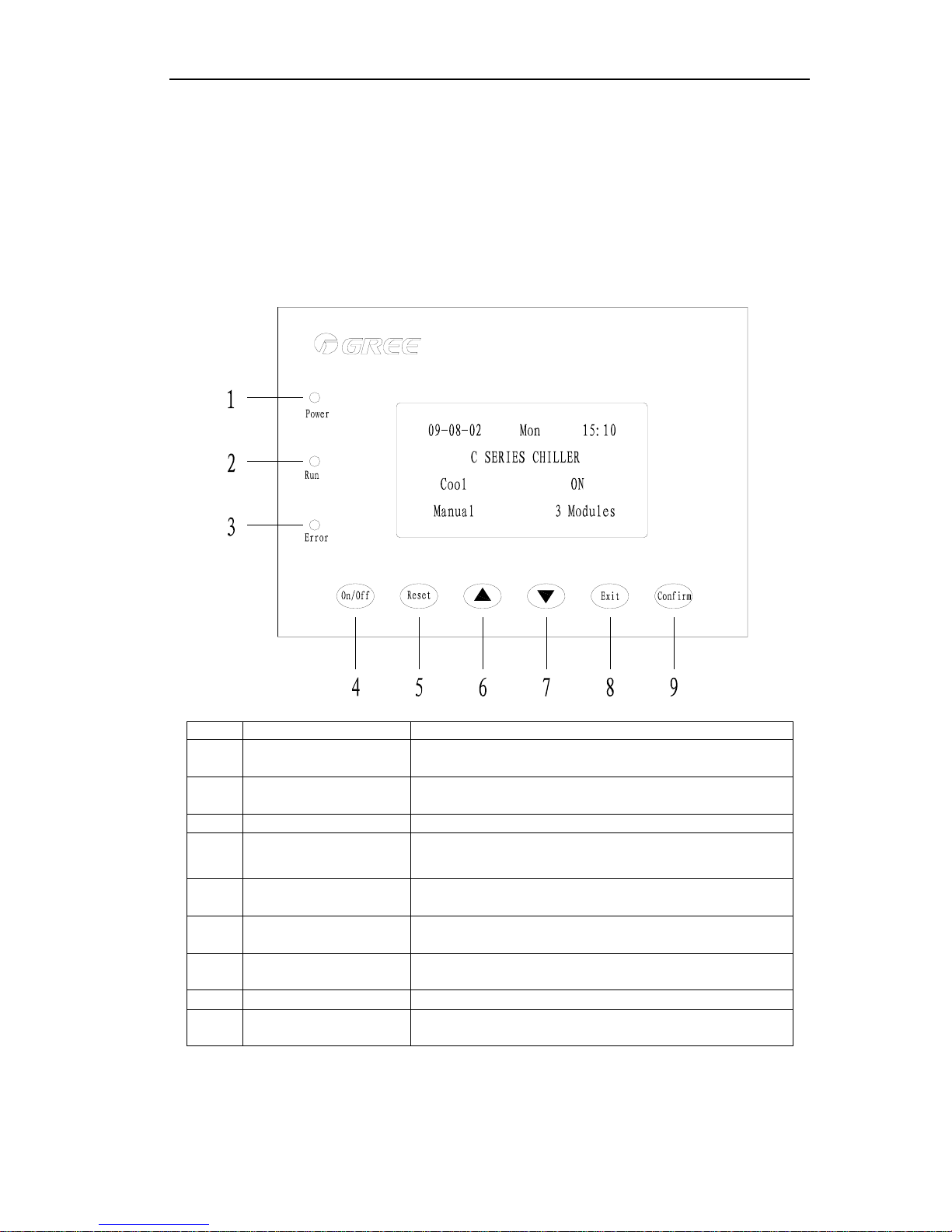

3 WIRED REMOTE CONTROLLER........................................................................................................ 12

3.1 Function..........................................................................................................................................12

3.2 Operation View..............................................................................................................................12

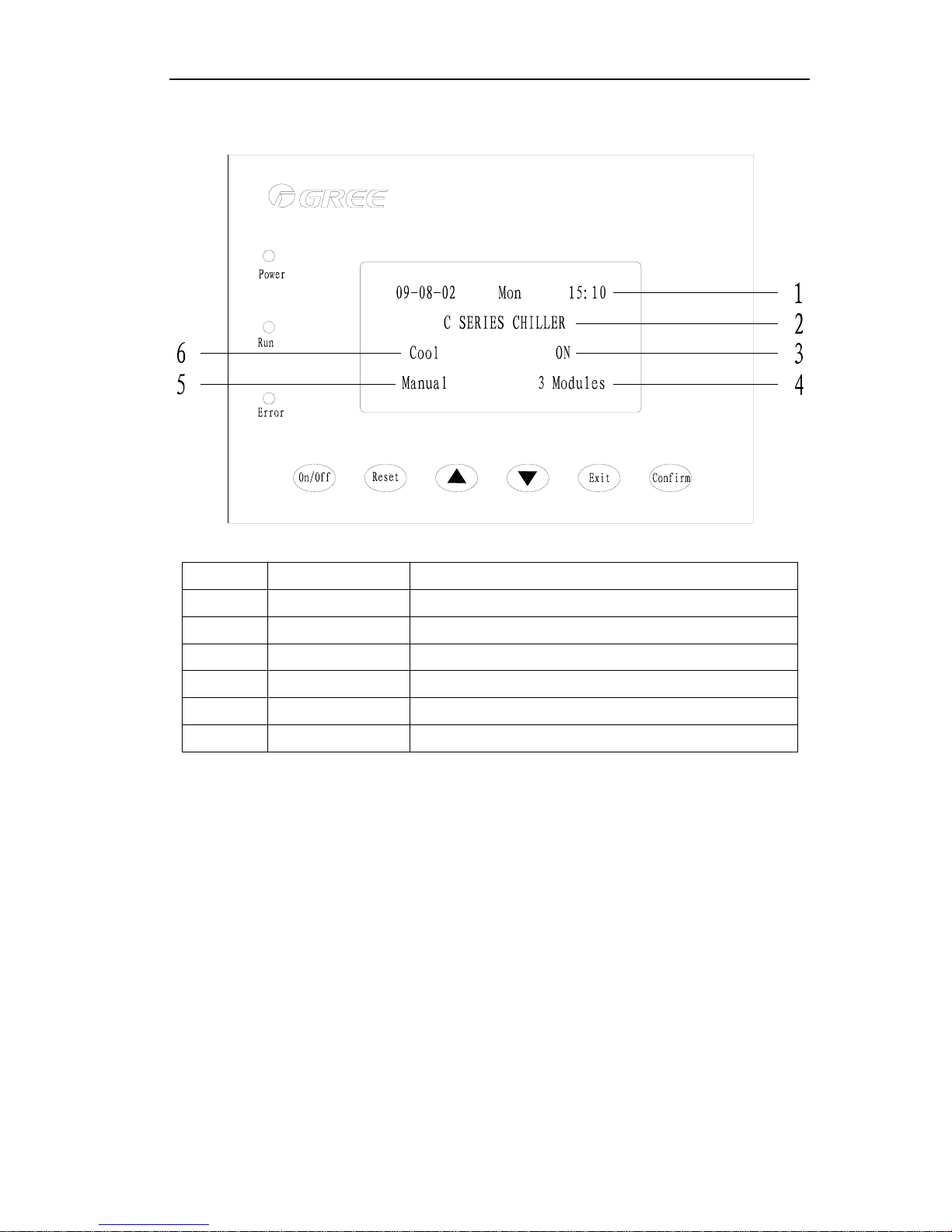

3.3 Display View ..................................................................................................................................13

3.4 Wired Controller Operation Instructions ....................................................................................13

3.5 Controller Menu Structure............................................................................................................26

4. SKETCH MAP OF DIP SWITCH ..........................................................................................................27

UNITS INSTALLATION ..............................................................................................................................29

1 UNITS INSTALL....................................................................................................................................29

1.1 Installation Positions.....................................................................................................................29

1.2 Matters need Attention.................................................................................................................29

1.3 Dimension Data.............................................................................................................................29

1.4 Installation Clearance Data .........................................................................................................30

2 WATER PIPING WORK.........................................................................................................................31

2.1 Installation Procedure...................................................................................................................31

2.2 Matters of Attention.......................................................................................................................31

2.3 Antifreeze .......................................................................................................................................31

3 ELECTRIC WIRING WORK..................................................................................................................31

3.1 Wiring Principle .............................................................................................................................31

3.2 Electrical Wires are Connected with Consumers.....................................................................32

3.3 Specification of Power Cord & Air Switch..................................................................................32

3.4 Wiring Diagram..............................................................................................................................33

UNITS MAINTENANCE..............................................................................................................................35

1 TROUBLE TABLE .................................................................................................................................35

2 FLOW CHART OF TROUBLESHOOTING...........................................................................................37

3 DISASSEMBLY AND ASSEMBLY PROCEDURE OF MAIN PARTS.................................................41

3.1 Integral Type ..................................................................................................................................41

4 EXPLODED VIEW AND PARTS LIST..................................................................................................43

4.1 Exploded View and Parts List- Integral Type............................................................................43

MODULAR MINI CHILLER PRODUCT

3

PRODUCT

MODULAR MINI CHILLER PRODUCT

4

PRODUCT INTRODUCTION

1 MODELS LIST

1.1 Integral Type

Model

Nominal

Capacity

Power

Supply

Refrigerant Model Name kW (V,Ph,Hz)

Appearance

HLR35SM/NaA-M 35

R410A

HLR45SM/NaA-M 45

380∼415V,

3Ph, 50Hz

Note:1Ton =12000Btu/h = 3.517kW

2 NOMENCLATURE

2.1 Integral Type

HL R 35 S

M

Na - M

1 2 3 4

5

6 7

NO. Description Options

1 Mini chiller 2 Product type R=Heat pump

3 Nominal Cooling Capacity

35=35kW

45=45kW

4 Refrigeration Circuits

Default=One circuit

S=Twin circuit

5 Module 6 Refrigerant Na=R410A, Default=R22

7 Voltage

M=380∼415V 3Ph 50Hz

3 FUNCTION

Indoor Unit Type Function Description

Integral Type

Heating/Cooling

Interface kit for up to 16 indoor

units

Memory restart

Two circuits optimized design

Low noise design

Safety and reliability thanks to

advance compressor balance

control

MODULAR MINI CHILLER PRODUCT

5

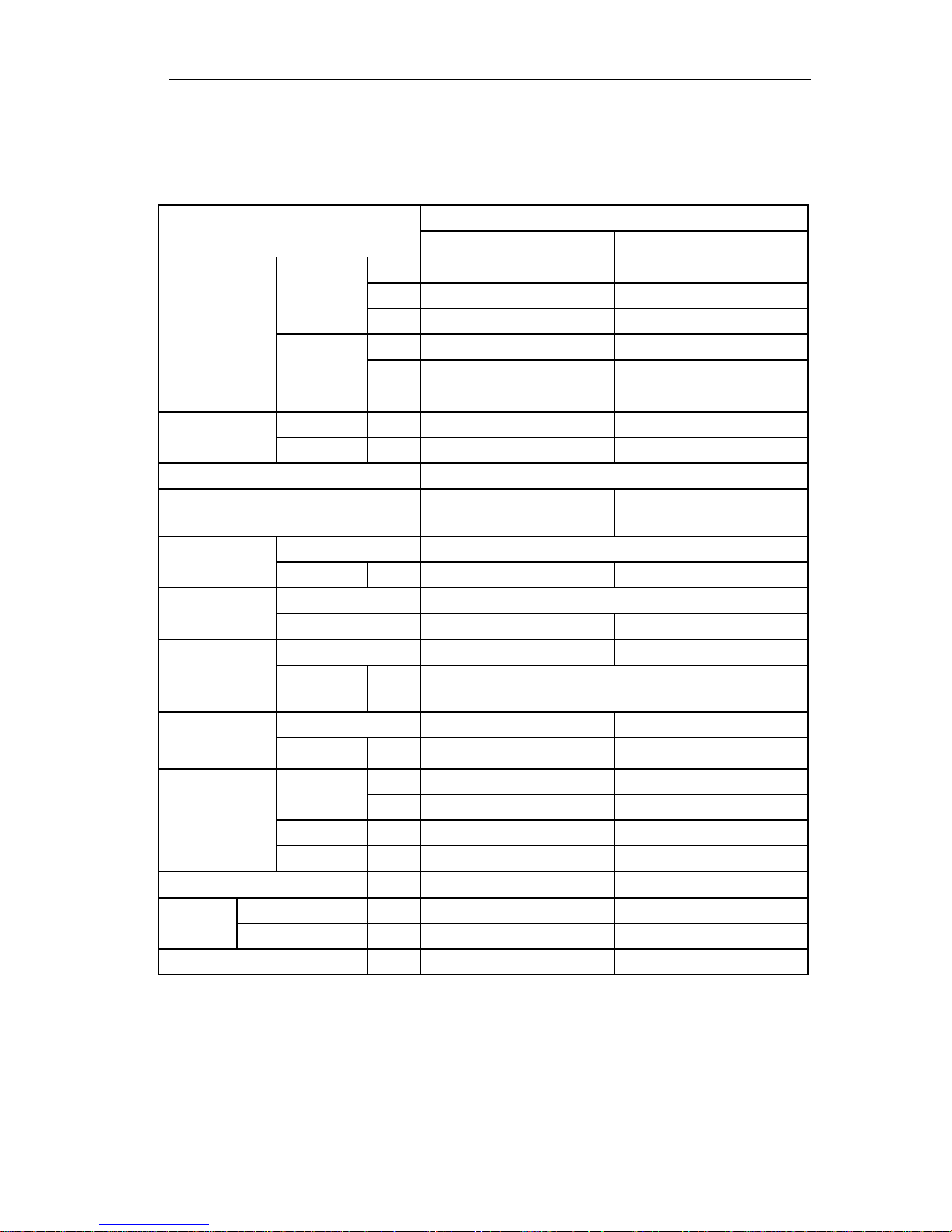

4 PRODUCT DATA

4.1 Product Data at Rated Condition

4.1.1 Integral Type

HLR SM/NaA-M

Models

35 45

kW 31 42

Btu/h 105772 143303

Cooling

RT 8.8 11.9

kW 36 49

Btu/h 122832 167187

Capacity

Heating

RT 10.3 13.9

Cooling kW 11.9 18.3

Power input

Heating kW 12.5 17.5

Power Supply 380~415V,3Ph,50Hz

Safeties Auto air evacuation valve

Safety valve;

Auto water replenishing valve;

Auto air evacuation valve

Type R410A

Refrigerant

Charge kg 6.5X2 7.3X2

Type scroll

Compressor

NO. 2 2

Heat Exchanger Shell and tube Shell heat exchanger

Evaporator

Water In/Out

Pipe

Diameter

inch 1-1/2”

Heat Exchanger Aluminum fin-copper tube Fin sleeve Heat exchanger

Condenser

Fan Motor

Power Input

kW 0.6 0.8

L/s \ 2.2

Water Flow

GPM \ 29

Delivery Lift m \ 27

Pump

Power Input kW \ 1.5

Expansion Vessel Volume L \ 8

Outline(WxDxH) mm 1750×800×1760 1750×800×1760

Dimension

Packaged(WxDxH) mm 1910×960×1970 1910×960×1970

Net/Gross Weights

kg

600/610 755/765

NOTE:

1、Cooling capacity is based on the following conditions:leaving chilled water temp.7 ,outdoor air temp.35℃℃

2、Heating capacity is based on the following conditions:leaving warmed water temp.45 , outdoor air ℃

temp.7℃

3、Water flow range for operation must be from 70% to 120% of the rated water flow。

4、The maximum allowable pressure for water pipe is 0.9MPa

MODULAR MINI CHILLER PRODUCT

6

4.2 Operation Range

Mode

Range of Outdoor Temperature℃ (℉)

Cooling 16~48

Heating -15~28

4.3 Electrical Data

4.3.1 Integral Type

Compressor Fan Motor Total

Model

Rated Power

Supply

NO.

LRA

each

(A)

MRC

each

(A)

NO.

MRC

(A)

MRC

(A)

NRC

(A)

HLR35SM/NaA-M

380~415V 3Ph

50Hz

2 101 17.3 2 1 36.6 26.3

Notes:

LRA: Locked rotor amps (A)

MRC: Maximum running current (A)

NRC: Nominal running current (A)

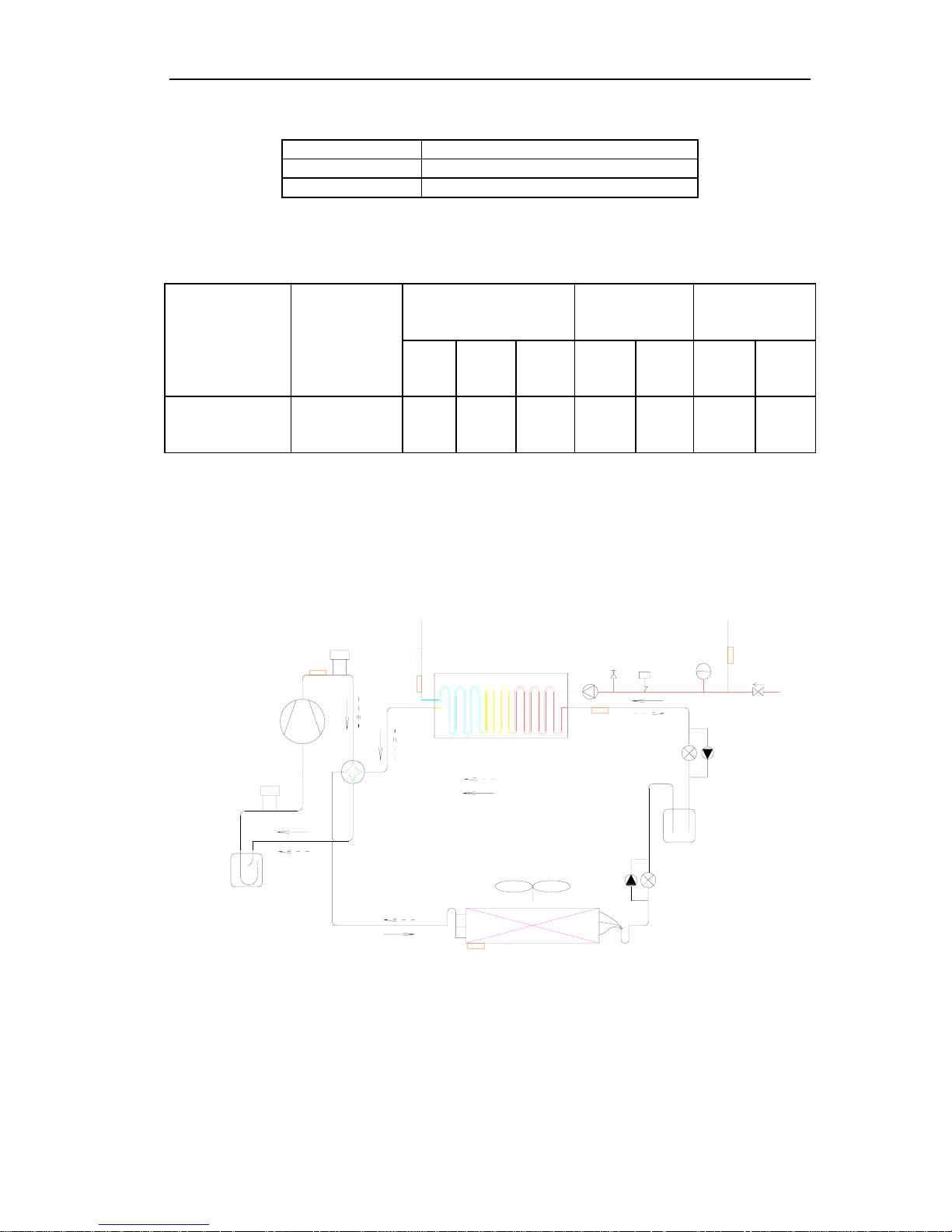

5 PIPING DIAGRAM

Heating circuit

Cooling circuit

Pump

Relief

valve

Flow

switch

Expansion

drum

High pressure

tank

Aluminum fin-copper tube

coil

Four-way valve

Shell and tube heat

exchanger

Inlet

Outlet

High-pressure

switch

Compressor

Low-pressure

switch

Liquid-gas separator

F

GREE COMMERCIAL AIR CONDITIONERS MODULAR MINI CHILLER

7

CONTROL

MODULAR MINI CHILLER CONTROL

8

UNITS CONTROL

1 OPERATION FLOWCHART

1.1 Cooling Operation

MODULAR MINI CHILLER CONTROL

9

1.2 Heating Operation

MODULAR MINI CHILLER CONTROL

10

2 MAIN LOGIC

2.1 Cooling Mode

2.1.1 Control of Compressor

(1)Start-stop Control--- “first start, first stop; first stop, first start”

During running of the unit, the compressor is numbered instantly. It is controlled according

to the principle of “first start, first stop; first stop, first start”.

(2)Water Temperature Drop (Rise) Rate Control

The water temperature interval is the main control, while the temperature drop (rise) rate is

the auxiliary control. This can adapt to the load variation of the terminal, keeping water

temperature stable and avoiding fierce variation. In this control mode, the system is based on

the temperature and temperature drop rate: when the water temperature is too high and if the

temperature drop is rapid, it means the output load is bigger than the terminal load. In that

case, it is not necessary to startup the other compressor. The temperature interval and

temperature drop is decided by experience, other theories and test so that the water

temperature can be kept stable and frequent stop can be avoided.

2.1.2 Anti-freezing Protection

For each module, when the anti-freezing temperature is lower than the required value for

protection, the anti-freezing protection will start then the compressor of this module will stop.

When the anti-freezing temperature is higher than the required value for resume, this system

will eliminate the anti-freezing protection.

When the anti-freezing temperature is between the above two temperature, it will not affect

the anti-freezing protection.

If the unit is low temperature unit, the anti-freezing protection is invalid.

2.1.3 Stop of the Unit

Stop the unit manually or via timer: the compressor stops and then the fan stops. After

certain control time, the water pump will stop.

Stop the unit upon reaching a temperature spots: the compressor stops and then the fan

stops (on condition that both compressor stops). The water pump will not stop.

Disorderly closedown: the compressor stops and then the fan stops (except the

malfunction of the fan). After the corresponding compressor stops for a period. The water

pump will not stop.

2.2 Heating Mode

2.2.1 Control of Compressor

The control principle is the same with that of cooling mode.

2.2.2 Superheat Protection

For each module, when the superheat temperature is higher than the required value for

protection, the superheat protection will start then the compressor of this module will stop.

When the superheat temperature is lower than the required value for resume, this system will

eliminate the superheat protection.

When the superheat temperature is between the above two temperature, it will not affect

the superheat protection.

2.2.3 Control of Auxiliary E-heater

MODULAR MINI CHILLER CONTROL

11

If the control function of auxiliary e-heater is switched on in the display board, it can be

controlled automatically according to the inflow water temperature. It is necessary to set an

interval to restart the e-heater.

When the temperature detected by inflow water temperature sensor is ≤T1, the second

group of auxiliary e-heaters will work.

When the inflow water temperature is ≥T2, the second group of auxiliary e-heaters will

stop.

When the inflow water temperature is between the above two temperature, the second

group of auxiliary e-heaters remain the original state.

When the temperature detected by inflow water temperature sensor is ≤T1+tr0, the first

group of auxiliary e-heaters will work.

When the inflow water temperature is ≥T2+tr1, the first group of auxiliary e-heaters will

stop.

When the inflow water temperature is between the above two temperature, the first group

of auxiliary e-heaters remain the original state.

After startup of the unit, the auxiliary e-heater will work after all the compressor runs for a

certain period and all the above condition is reached.

2.2.4 Stop of the Unit (subject to the stop of the compressor)

Stop the unit manually or via timer: the compressor, the auxiliary e-heater and the fan

stops in sequence. After certain setting time, the four-way valve will be de-energized and the

water pump will stop.

Stop the unit upon reaching the temperature spots: the compressor stops and then the fan

stops. The four-way valve will remain the original state and the water pump will not stop.

Disorderly closedown: the compressor stops and then the fan stops (unless the fan is

wrong). After the corresponding compressor stops for a period. The water pump will not stop

while the four-way valve will remain the original state.

2.3 Anti-freezing Running

Under the stop state of any mode (except manual defrosting mode), the automatic

anti-freezing function can be switched on via the display board. The defaulted setting of this

function is OFF.

For all the modules that reach automatic anti-freezing running condition, the compressor

will run according to the setting condition and the regulation of “run for 6min and stop for 4

min”.

2.4 Control of Compressor

All compressors run according to the principle of “first start, first stop; first stop, first start”.

For other information, refer to the control section of 1.3.1 and1.3.2.

2.5 Control of Four-way Valve

In cooling mode, the four-way valve is off. In heating mode, the four-way valve will run after

the corresponding compressor runs. In defrosting mode, the four-way valve will be off. When

eliminating the defrosting function, the four-way valve runs. When stop the unit, the four-way

valve will stop after the corresponding compressor stops.

2.6 Control of Water Pump

When any of the modules needs to be started up, all the water pumps will run. When one

module stops upon reaching certain temperature spots, all the water pumps remain running.

When one module is stopped manually or via timer or due to malfunction, the water pump of

this module remains running. Only when all the modules are stopped manually or via timer, the

water pump will stop 5 min after all the compressor stops.

MODULAR MINI CHILLER CONTROL

12

3 WIRED REMOTE CONTROLLER

3.1 Function

The display of modular air-cooled scroll chiller shows the running parameter in real time. It can

be connected with the remote control system.

3.2 Operation View

NO. Name Function description

1 Power LED (red)

When the display board is energized, this LED lights;

otherwise, it is dark.

2 Running LED (green)

When the display board is turned on, this LED lights; otherwise,

it is dark.

3 Error LED (red) When there is malfunction, this LED lights; otherwise it is dark.

4 ON/OFF button

Control the start or stop of the unit. Under stop state, press the

button (for 3s) to start up the unit. Under running state, press

the button (for 3s) to stop the unit.

5 RESTORE button

Press this button to remove error and lock of exhaust

temperature sensor.

6 UP button

Press this button to move the cursor upward or leftward. When

modify the data, press this button to increase the value.

7 DOWN button

Press this button to move the cursor downward or rightward.

When modify the data, press this button to decrease the value.

8 EXIT button Press this button to return to last page.

9 CONFIRM button

Press this button to enter the next page. When modify the data,

press this button to confirm the value and transfer the cursor.

MODULAR MINI CHILLER CONTROL

13

3.3 Display View

NO. Name Function description

1 Time display Display the current time.

2 Unit name Unit name

3 Running state Display the current running state of the unit.

4 Number of modules The number of connected unit

5 ON/OFF mode ON/OFF mode of the system

6 Running mode Display the current running mode

3.4 Wired Controller Operation Instructions

3.4.1 Turning on/off of the Unit

The unit under non-commissioning state can be turned on/off via the manual mode or the

timing mode. The manual mode is given priority to the timing mode.

●Manual mode:

1)、Manual start: in the unit stop state, press the on/off button for 3 seconds and start the

unit, and at that time the operation indicator is on. When the compressor begins to run

after a delay, the manual starting process is finished.

2)、Manual stop: in the unit operation state, press the on/off button for 3 seconds and

stop the unit, and at that time the operation indicator is off. When the unit stops, the

compressor immediately ceases and the cooling tower fan, the cooling pump and the

chilled water pump are shut off. The manual stop process is finished.

When ambient temperature is lower than -16℃, pressing the start/stop button, the

MODULAR MINI CHILLER CONTROL

14

following prompt window comes up on the manual operator.

Press the Confirm

button for acknowledgement.

If ambient temperature sensors of all linked units are at fault, pressing the on/off button,

the following prompt window comes up on the manual operator.

Press the Confirm

button for acknowledgement.

In the manual defrosting mode, pressing the on/off button, the following prompt

window comes up on the manual operator.

Press the Confirm

button for acknowledgement.

By pressing the up selection

button or the down selection button, you can convert

between YES

and NO. Press the Exit to quit selection and go back to home page. When

the unit is in the cooling & heat recovery mode stop state, if you select YES

and press the

Confirm

, you can go back to the home page and the unit is in the heating & heat recovery

operation state; and if you select NO

and press the Confirm, you can go back to the

home page and the unit is in the cooling & heat recovery operation state.

●Timing mode:

After the unit is energized or reset, press the Manual Mode to turn on/off the unit.

Conversion between the manual mode and the timing mode is detailed in 3.4.2.2 Main

Menu

3.4.2 Menu Operation Instructions

3.4.2.1 Home page

When the controller is powered on, the microcomputer will make a 3-second

automatic detection and the LCD on the wired controller will display the following content.

Don’t ON/OFF under

manual defrost!

OK

No ON/OFF

Under low ambient

Temp.

OK

No ON/OFF under

all ambient temp.

sensor fail!

OK

Loading...

Loading...