Gree GWH28AAE-K3NNA1A, GWH28AAE-K3NNA2A, GWH28AAE-K3NNA1A/I, GWH28AAE-K3NNA2A/I, GWH28AAE-K3NNA1A/O Service Manual

GREE ELECTRIC APPLIANCES,INC.OF ZHUHAI

Change for Life

Service Manual

Models: GWH28AAE-K3NNA1A

GWH28AAE-K3NNA2A

(Refrigerant:R410A)

Table of Contents

Service Manual

Part

1. Summary

2. Specications

2.1 Specication Sheet ...........................................................................................................2

2.2 Capacity Curve in Different Outdoor Temperature ...........................................................4

2.3 Cooling and Heating Data Sheet in Rated Frequency .....................................................4

: Technical Information

Ⅰ

......................................................................................................................1

..........................................................................................................2

3. Outline Dimension Diagram

3.1 Indoor Unit ........................................................................................................................5

3.2 Outdoor Unit .....................................................................................................................5

4. Refrigerant System Diagram

5. Electrical Part

5.1 Wiring Diagram .................................................................................................................7

5.2 PCB Printed Diagram .......................................................................................................9

6. Function and Control

...........................................................................................................7

...................................................................................... 11

.......................................................................1

........................................................................5

......................................................................6

6.1 Remote Controller Introduction .....................................................................................11

6.2 Brief Description of Modes and Functions ......................................................................14

Part

: Installation and Maintenance

Ⅱ

7. Notes for Installation and Maintenance

8. Installation

8.1 Installation Dimension Diagram ......................................................................................22

8.2 Installation Parts-checking ............................................................................................24

8.3 Selection of Installation Location ....................................................................................24

8.4 Electric Connection Requirement ..................................................................................24

8.5 Installation of Indoor Unit ................................................................................................24

8.6 Installation of Outdoor Unit .............................................................................................27

8.7 Vacuum Pumping and Leak Detection ...........................................................................28

8.8 Check after Installation and Test Operation ...................................................................28

9. Maintenance

................................................................................................................22

............................................................................................................29

.................................................19

..........................................19

9.1 Error Code ......................................................................................................................29

9.2 Procedure of Troubleshooting ........................................................................................32

9.3 Maintenance Method for Normal Malfunction .................................................................43

Table of contents

Service Manual

10. Exploded View and Parts List

10.1 Indoor Unit ....................................................................................................................45

10.2 Outdoor Unit .................................................................................................................47

11. Removal Procedure

11.1 Removal Procedure of Indoor Unit ...............................................................................49

11.2 Removal Procedure of Outdoor Unit ............................................................................54

Appendix:

Appendix 1: Reference Sheet of Celsius and Fahrenheit ....................................................59

Appendix 2: Conguration of Connection Pipe .....................................................................59

Appendix 3: Pipe Expanding Method ...................................................................................60

Appendix 4: List of Resistance for Temperature Sensor ......................................................61

........................................................................................................................59

.......................................................................................49

..............................................................45

Service Manual

Part

Ⅰ

: Technical Information

1. Summary

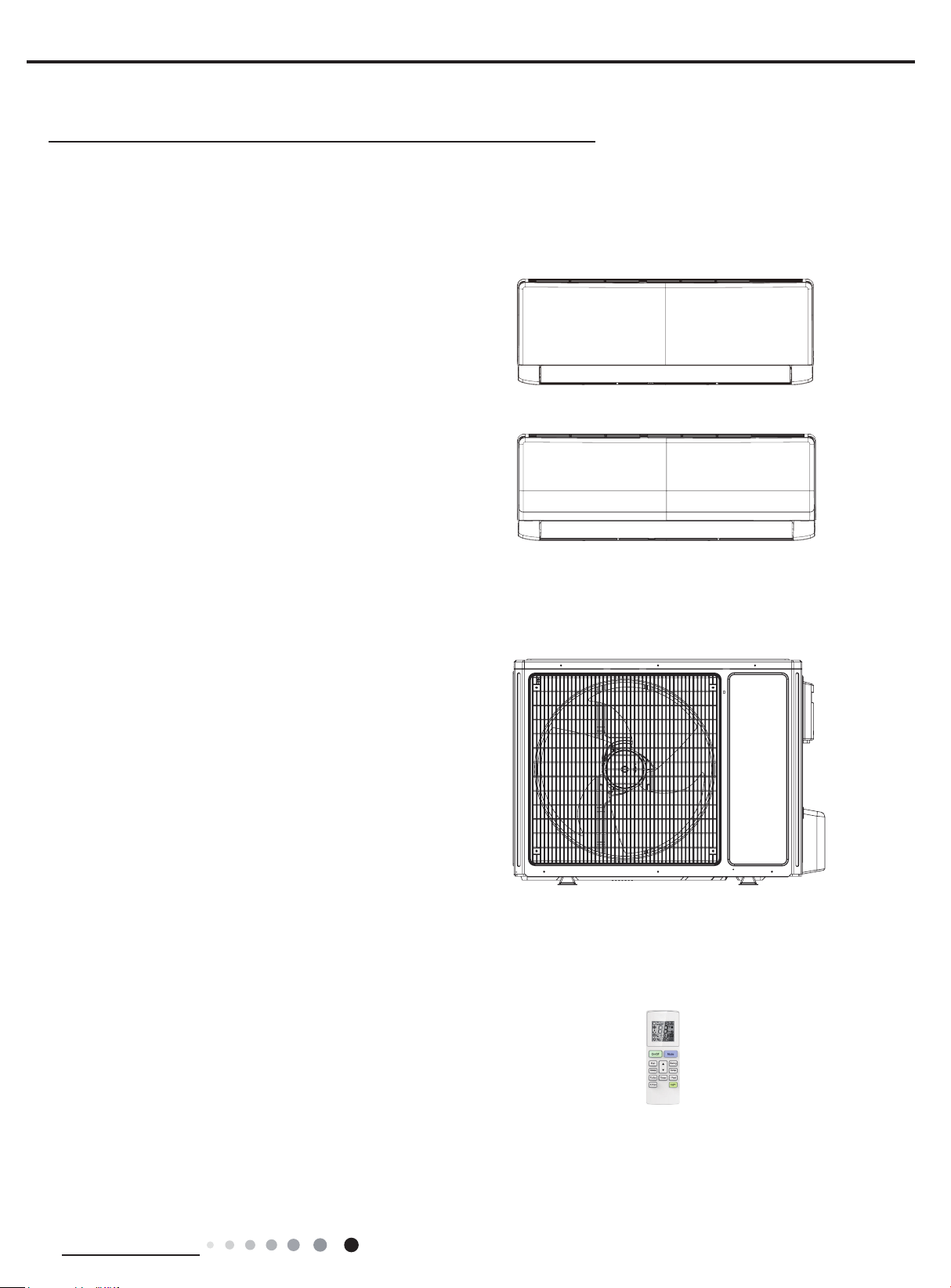

Indoor Unit:

GWH28AAE-K3NNA1A/I

GWH28AAE-K3NNA2A/I

Outdoor Unit:

GWH28AAE-K3NNA1A/O

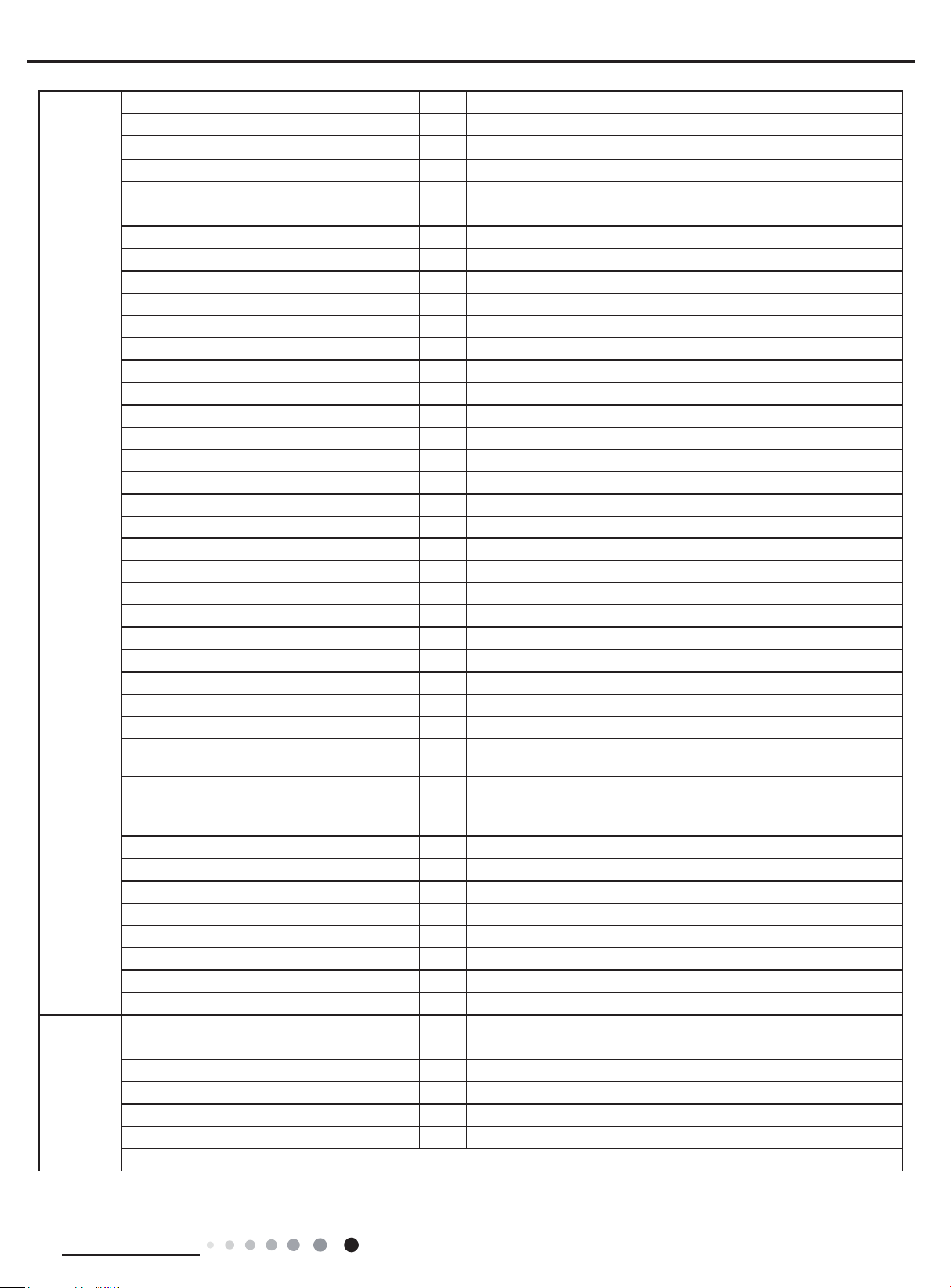

Remote Controller:

YAW1F1

Technical Information

1

2. Specications

2.1 Specication Sheet

Service Manual

Model

Product Code

Power

Supply

Power Supply Mode Outdoor

Cooling Capacity W 8000

Heating Capacity W 8500

Cooling Power Input W 2846

Heating Power Input W 2647

Cooling Current Input A 12.3

Heating Current Input A 12

Rated Input W 3650

Rated Current A 20

Air Flow Volume(SH/H/M/L/SL) m3/h 1200/1100/1000/850/-

Dehumidifying Volume L/h 3.0

EER W/W 2.81

COP W/W 3.21

SEER W/W /

HSPF W/W /

Application Area m

Indoor Unit

Rated Voltage V~ 220-240

Rated Frequency Hz 50

Phases 1

2

Fan Type

Product Code of Indoor Unit

Fan Type Cross-ow

Diameter Length(DXL) mm Ф108X830

Fan Motor Cooling Speed(SH/H/M/L/SL) r/min 1330/1200/1000/900/-

Fan Motor Heating Speed(SH/H/M/L/SL) r/min 1330/1200/1000/900/-

Output of Fan Motor W 35

Fan Motor RLA A 0.35

Fan Motor Capacitor μF 3

Evaporator Form Aluminum Fin-copper Tube

Pipe Diameter mm Ф7

Row-n Gap mm 2.5-1.5

Coil Length (LXDXW) mm 845X25.4X342.9

Swing Motor Model MP35CP

Output of Swing Motor W 2.5

Fuse A 3.15

Sound Pressure Level (SH/H/M/L/SL) dB (A) 51/48/42/39/-

Sound Power Level (SH/H/M/L/SL) dB (A) 61/58/52/49/-

Dimension (WXHXD) mm 1080X325X245

Dimension of Carton Box (LXWXH) mm 1125X397X320

Dimension of Package (LXWXH) mm 1145X400X330

Net Weight kg 16.5

Gross Weight kg 19.5

GWH28AAE-K3NNA1A

GWH28AAE-K3NNA2A

CA476002101

CA477001301

46-70

GWH28AAE-K3NNA1A/I

GWH28AAE-K3NNA2A/I

CA476N02101

CA477N01301

2

Technical Information

Service Manual

Outdoor Unit

Connection

Pipe

Model of Outdoor Unit GWH28AAE-K3NNA1A/O

Outdoor Unit Product Code CA476W02101

Compressor Manufacturer/Trademark ZHUHAI LANDA COMPRESSOR CO., LTD

Compressor Model QXAS-F305N450

Compressor Oil ATMOS-RB68EP or equivalent

Compressor Type Rotary

L.R.A. A 60

Compressor RLA A 11.6

Compressor Power Input W 2525

Overload Protector /

Throttling Method Capillary

Operation Temp

Ambient Temp (Cooling)

Ambient Temp (Heating)

o

C 16~30

o

C 18~43

o

C -7~24

Condenser Form Aluminum Fin-copper Tube

Pipe Diameter mm Ф7

Rows-n Gap mm 2.5-1.4

Coil Length (LXDXW) mm 820X38.1X660

Fan Motor Speed rpm 850

Output of Fan Motor W 35

Fan Motor RLA A 0.8

Fan Motor Capacitor μF 4.5

Air Flow Volume of Outdoor Unit m3/h 1800

Fan Type Axial-ow

Fan Diameter mm Ф520

Defrosting Method Automatic Defrosting

Climate Type T1

Isolation I

Moisture Protection IPX4

Permissible Excessive Operating Pressure for

the Discharge Side

Permissible Excessive Operating Pressure for

the Suction Side

MPa 4.3

MPa 2.5

Sound Pressure Level (H/M/L) dB (A) 59/-/-

Sound Power Level (H/M/L) dB (A) 69/-/-

Dimension (WXHXD) mm 965X700X396

Dimension of Carton Box (LXWXH) mm 1026X455X735

Dimension of Package (LXWXH) mm 1029X458X750

Net Weight kg 61

Gross Weight kg 65.5

Refrigerant R410A

Refrigerant Charge kg 1.9

Length m 5

Gas Additional Charge g/m 15

Outer Diameter Liquid Pipe mm Ф6

Outer Diameter Gas Pipe mm Ф16

Max Distance Height m 10

Max Distance Length m 30

Note: The connection pipe applies metric diameter.

The above data is subject to change without notice; please refer to the nameplate of the unit.

Technical Information

3

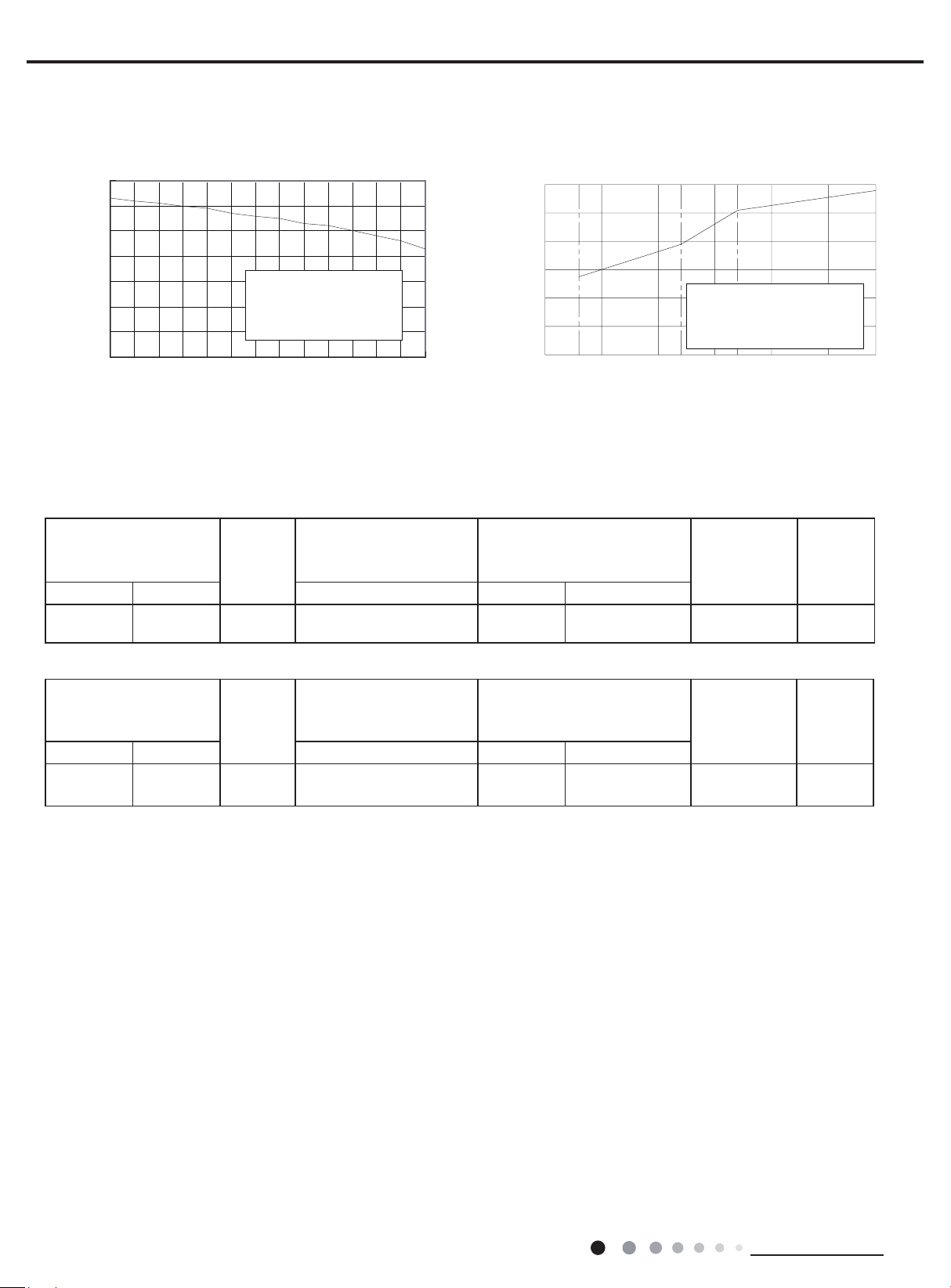

2.2 Capacity Curve in Different Outdoor Temperature

) % ( a p a c i t y r a t i o C

24

01

Cooling Heating

Service Manual

110

100

90

80

70

60

50

40

Condition

Indoor:DB27

Indoor air flow: Super High

Pipe length:5m

°C

WB19

°C

30 31 32 33 34 35 36 37 38 39 40 41 42 43

Outdoor temp.( ) Outdoor temp.( )

°C

120

100

80

60

40

20

0

-1 5

2.3 Cooling and Heating Data Sheet in Rated Frequency

Cooling:

Rated cooling condition(°C)

(DB/WB)

Indoor Outdoor P (MPa) T1 (°C) T2 (°C)

27/19 35/24 28K 0.9~1.1

Model

Pressure of gas pipe

connecting indoor and

outdoor unit

Inlet and outlet pipe temperature

of heat exchanger

in:6~8

out:10~12

in:75~85

out:37~43

Condition Heating

Indoor:DB20

Indoor air flow: Super High

Pipe length:5m

°C

0

157-7 -5 02

°C

Fan speed of

indoor unit

Super High High

Fan speed

of outdoor

unit

Heating:

Rated heating condition(°C)

(DB/WB)

Indoor Outdoor P (MPa) T1 (°C) T2 (°C)

20/- 7/6 28K 2.8~3.0

Instruction:

T1: Inlet and outlet pipe temperature of evaporator

T2: Inlet and outlet pipe temperature of condenser

P: Pressure at the side of big valve

Connection pipe length: 5 m.

Model

Pressure of gas pipe

connecting indoor and

outdoor unit

Inlet and outlet pipe temperature

in:75~85

out:37~43

of heat exchanger

in:1~3

out:2-5

Fan speed of

indoor unit

Super High High

Fan speed

of outdoor

unit

4

Technical Information

Service Manual

340

897

1080

245

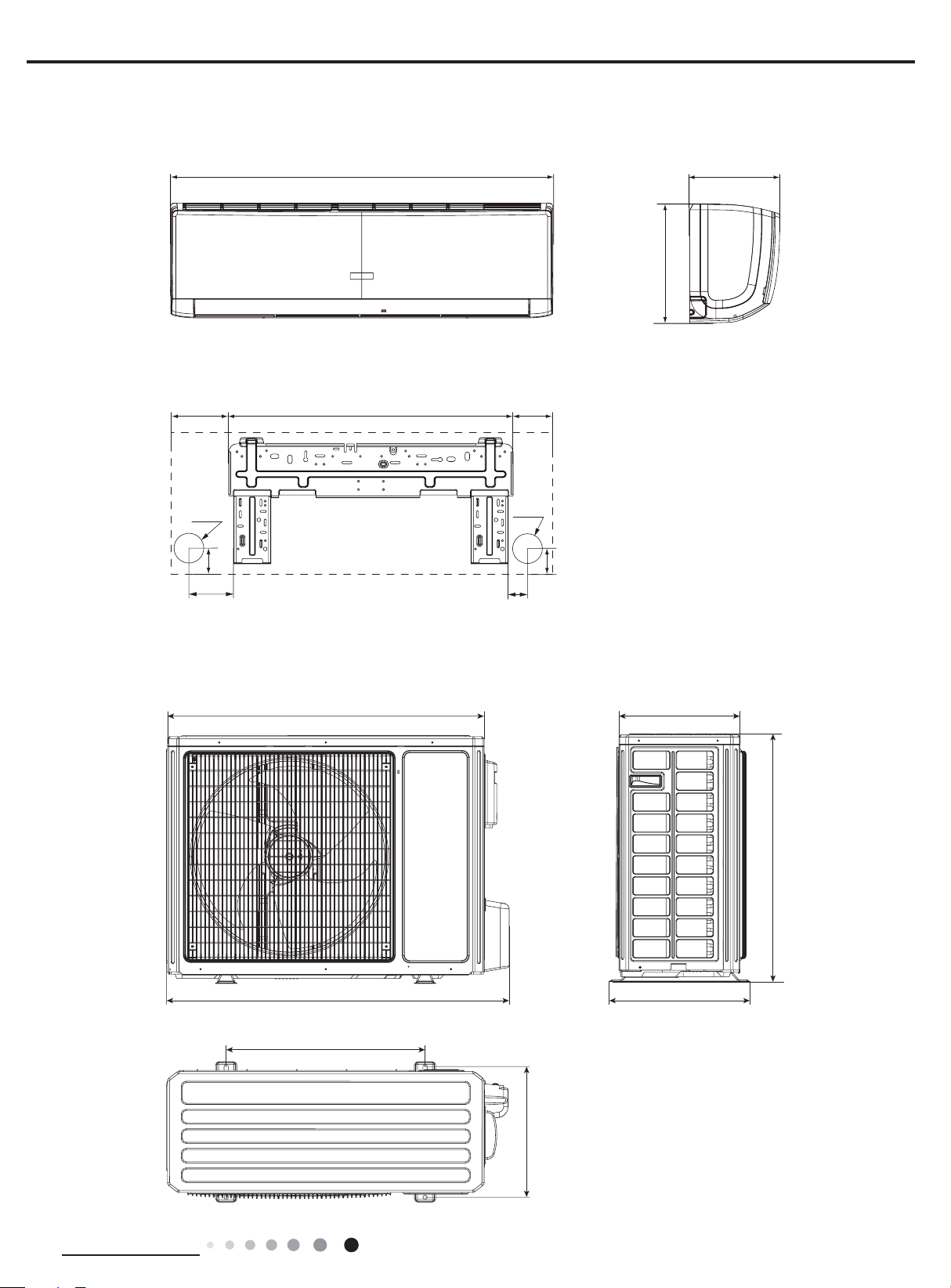

3. Outline Dimension Diagram

3.1 Indoor Unit

207 685 188

324

Φ70

43

154

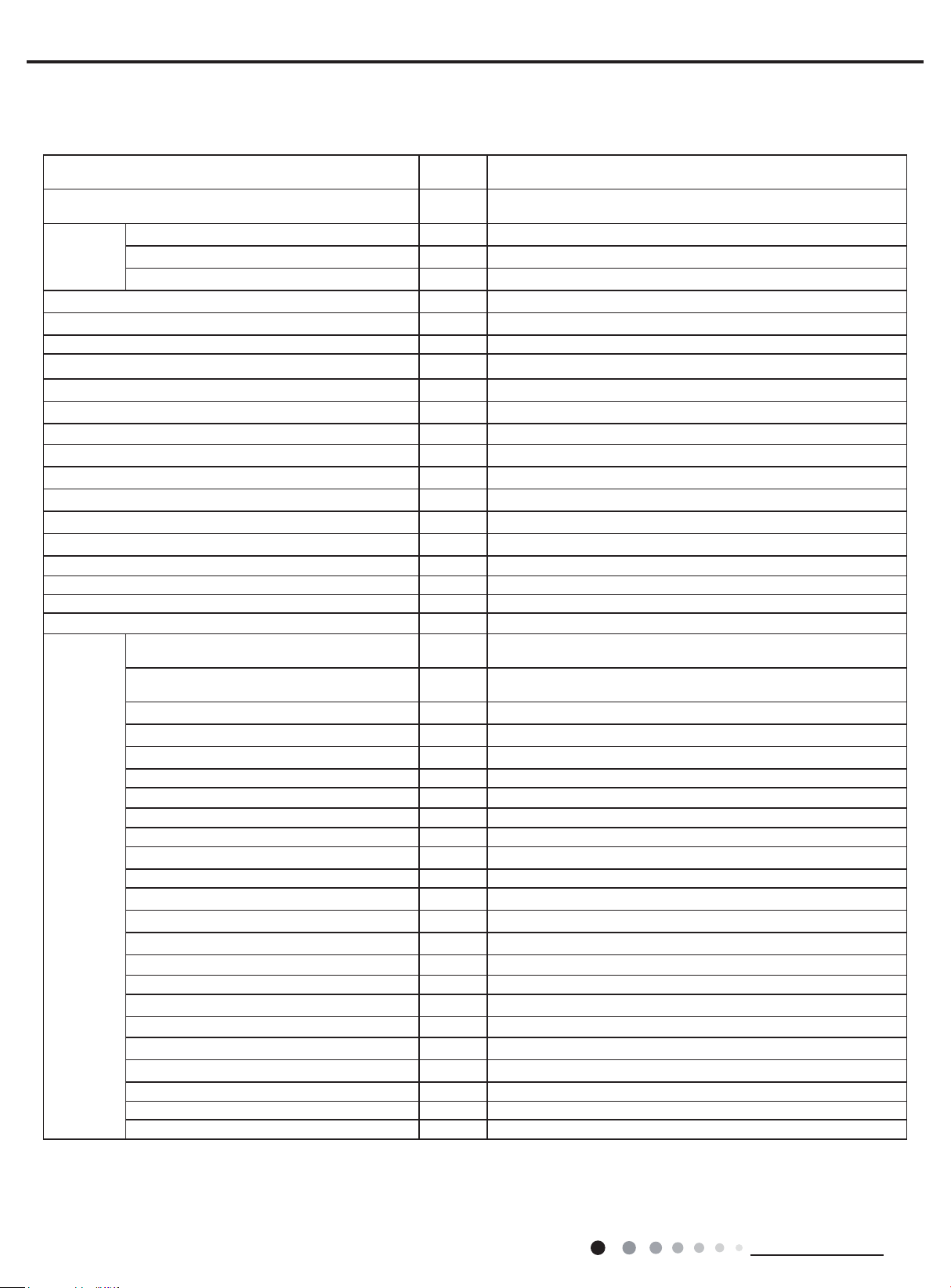

3.2 Outdoor Unit

79

Φ70

43

Unit:mm

700

Technical Information

965

560

396

364

Unit:mm

5

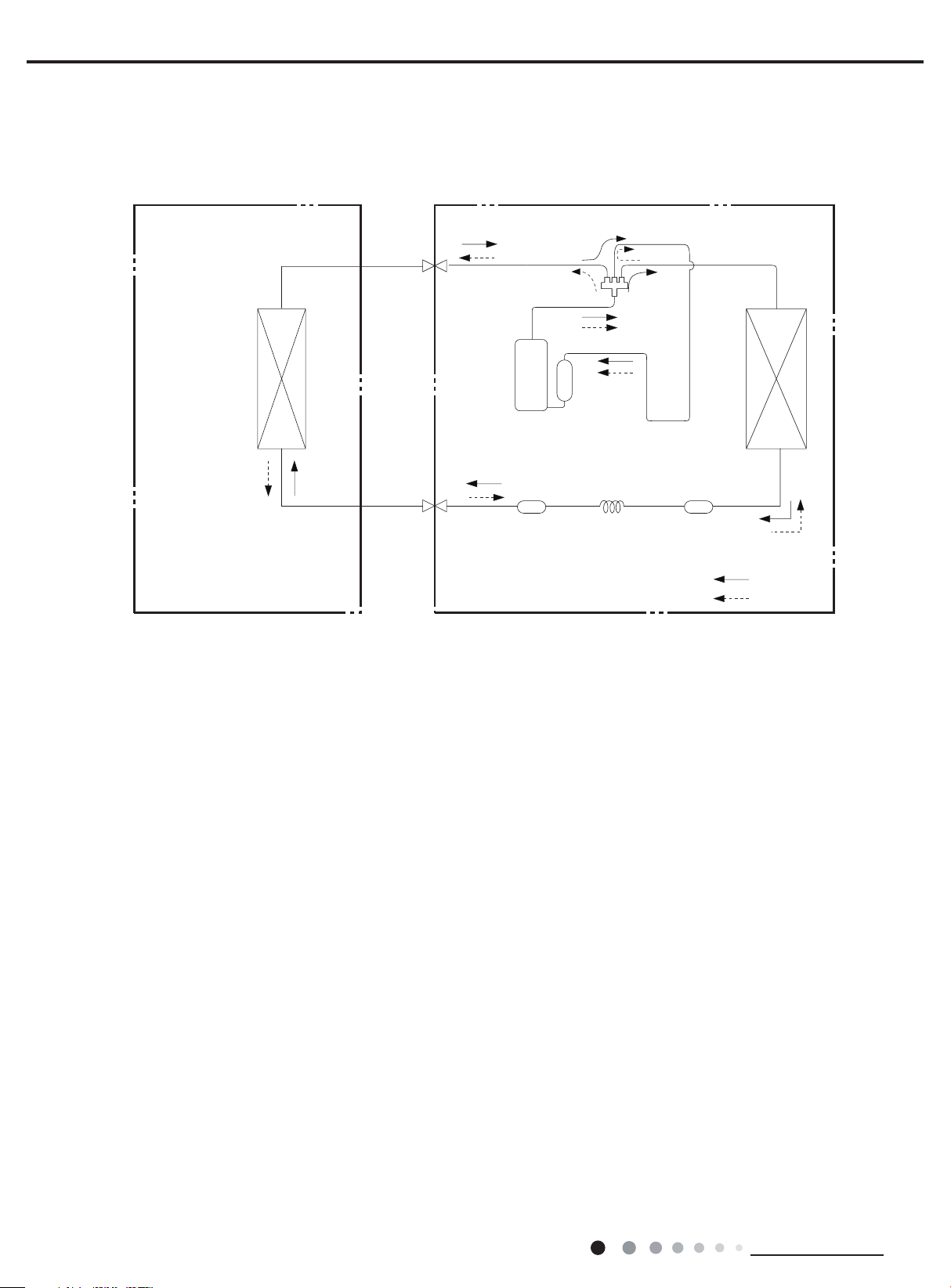

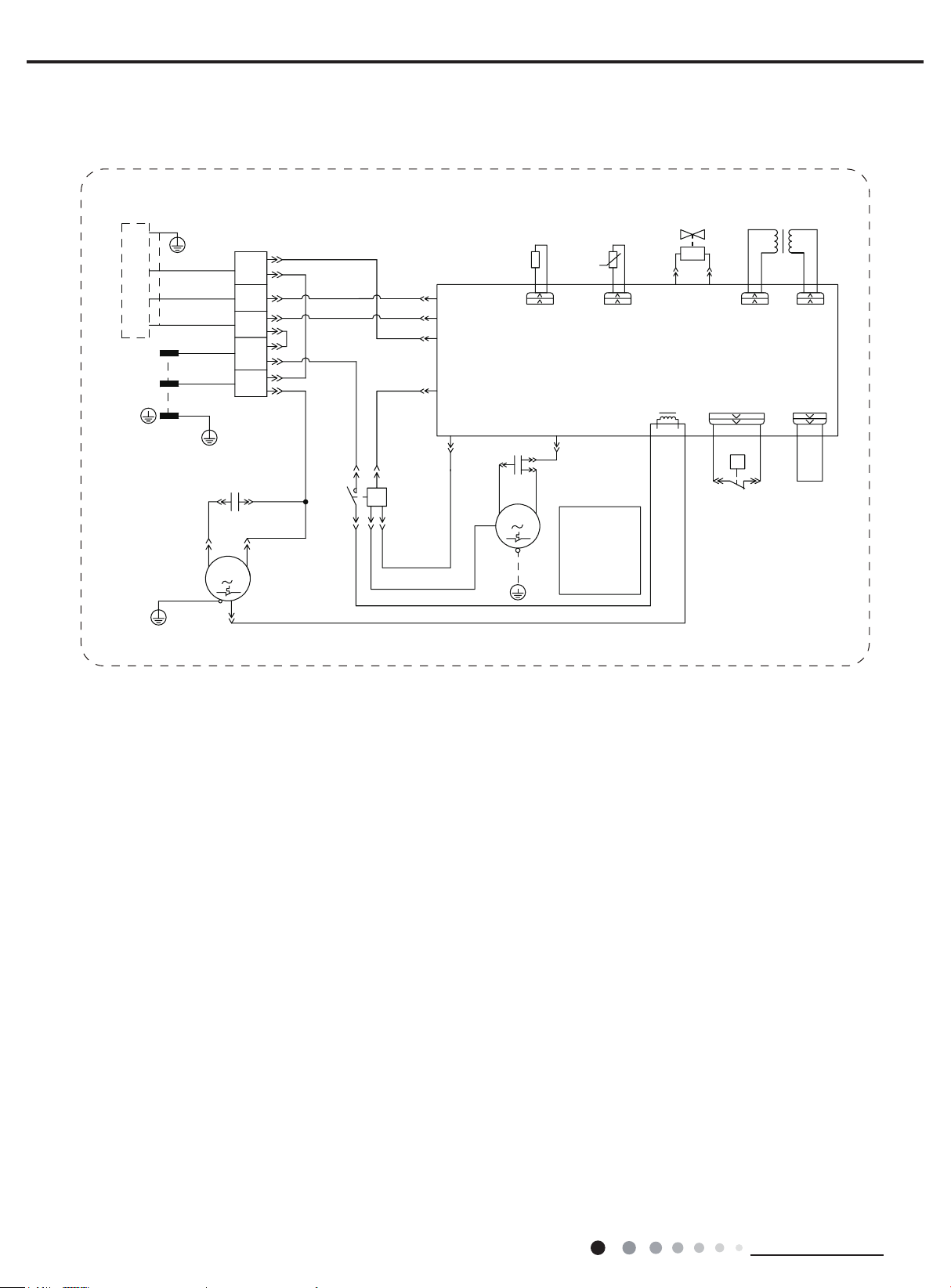

4. Refrigerant System Diagram

Indoor unit

Outdoor unit

Indoor unit

Outdoor unit

Accumlator

COOLING

Discharge

Suction

Heat

exchanger

(evaporator)

Heat

exchanger

(condenser)

Valve

Valve

Liquid pipe

side

Gas pipe

side

Compressor

Strainer

Capillary

Cooling and heating model

Gas pipe

side

Valve

Service Manual

4-Way valve

Heat

exchanger

(evaporator)

Connection pipe specication:

Liquid pipe:1/4" (6mm)

Gas pipe:5/8" (16mm)

Liquid pipe

side

Valve

Discharge

Suction

Compressor

Strainer StrainerCapillary

Accumlator

Heat

exchanger

(condenser)

COOLING

HEATING

6

Technical Information

Service Manual

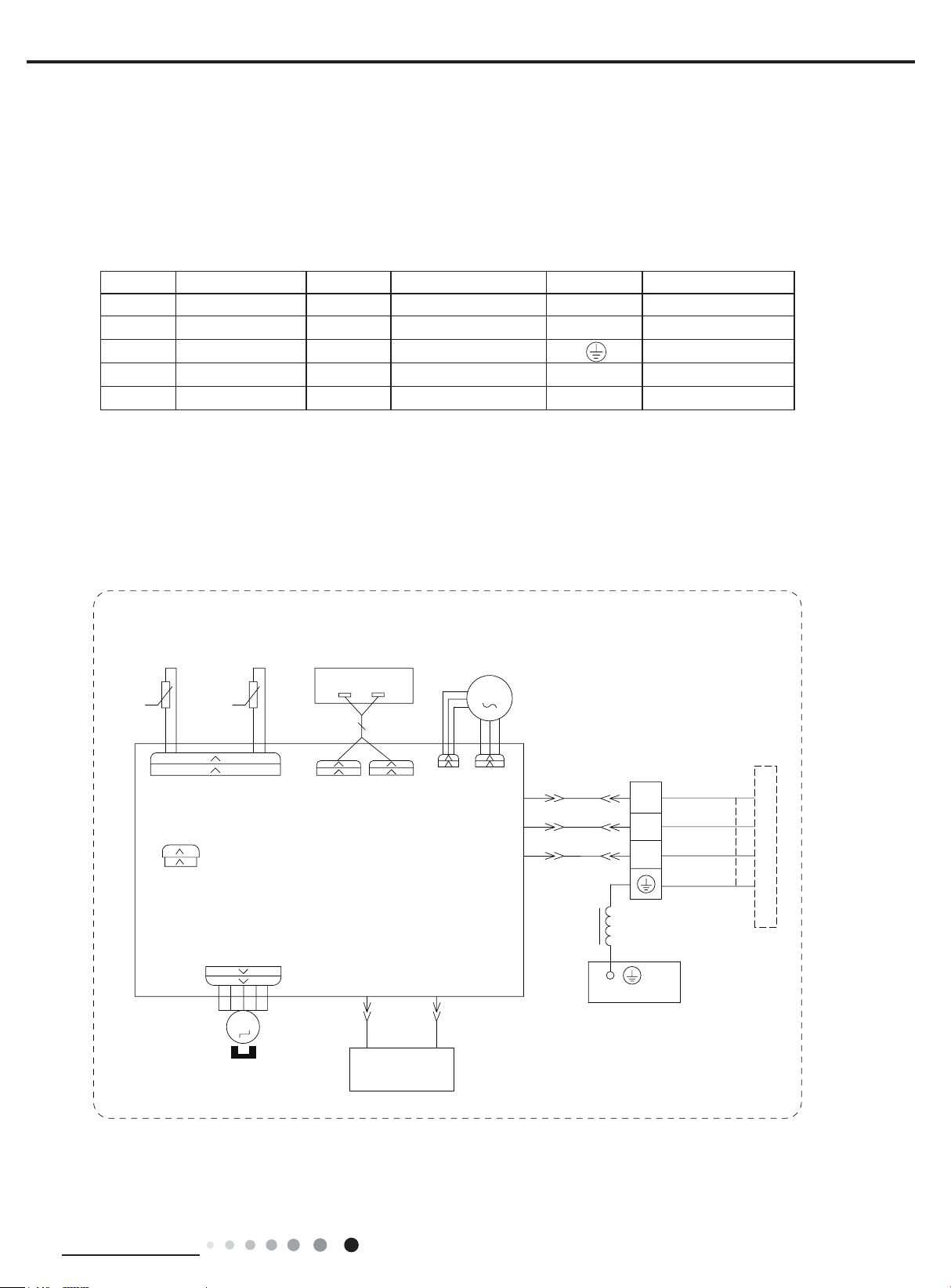

5. Electrical Part

5.1 Wiring Diagram

● Instruction

Symbol Symbol Color Symbol Symbol Color Symbol Name

WH White GN Green CAP Jumper cap

YE Yellow BN Brown COMP Compressor

RD Red BU Blue Grounding wire

YEGN Yellow/Green BK Black / /

VT Violet OG Orange / /

Note: Jumper cap is used to determine fan speed and the swing angle of horizontal lover for this model.

● Indoor Unit

78%(

6(1625

57

7(03

76(1625

&$3

-803

5220

6(1625

7(03

5(&(,9(5$1'

',63/$<%2$5'

$3

57

',63

$3

35,17('&,5&8,7%2$5'

6:,1*

6:,1*8'

+($/7+/

',63/$<

',63

)$102725

3*)

&20287

/$&/

+($/7+1

0

3*

1

%8

%.

%1

0$*1(7,&

5,1*

/

7(50,1$/

%/2&.

1

;7

<(*1

3(

(9$325$725

%8

%.

%1

<(*1

&211(&7,1*

&$%/(

287'22581,7

Technical Information

0

83'2:1

67(33,1*

02725

'58%

&2/'3/$60$

*(1(5$725

6363247703

7

● Outdoor Unit

Service Manual

<(*1

3(

%8

%.

,1'22581,7

/

1

32:(5

%1

%1

%8

<(*1

<(

6 50

<(*1

3(

%.

3(

;7

1

7(50,1$/

%/2&.

3(

&$3

&

&203

&

/

1

&203

%8

%1

%8

7

%8

-

/ $

%8

%.

%8

%.

%1

%1

.0

5'

$

&20,11(5

$&/

1

&203

1

$&&217$&725

%8

%.

%8

6+,(/',1*

5(6,6725

5

2875220

28778%(

7(03

57

28778%(

6(1625

:$<9$/9(

<9

97

9 1

$335,17('&,5&8,7%2$5'

/

2)$1+

5'

)$1

02725

&$3

&

0

3(

<(*1

%1

%1

127(0RWRU

JURXQGRQO\

DSSOLHVWR

WKHLURQ

VKHOOPRWRU

3(

<( :+

+,*+35(6685(

6:,7&+

75$16)250(5

97

+33

600007000636

7&

+3

3

ėĖ

7528775,1

/33

%.

These wiring diagrams are subject to change without notice; please refer to the one supplied with the unit.

8

Technical Information

Service Manual

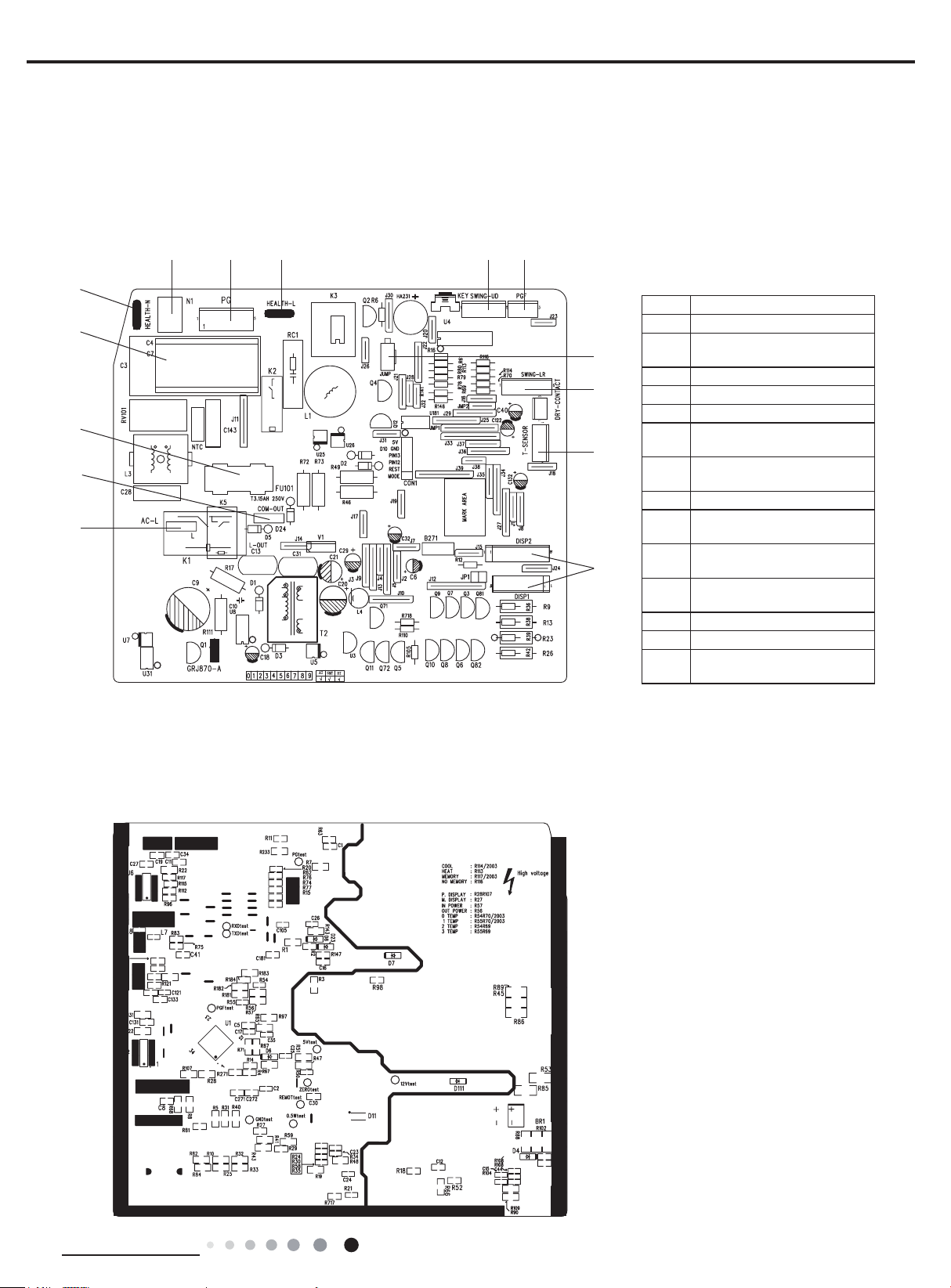

5.2 PCB Printed Diagram

Indoor Unit

● Top view

7 8

6

5

4

3

2

9 10

11

12

13

14

1

No. Name

Interface of display

1

Live wire interface of power

2

supply

3 Communication wire

4 Fuse

5 Indoor fan driven capacitor

Neutral wire interface of cold

6

plasma

Neutral wire interface of

7

power supply

8 Interface of indoor fan

Live wire interface of cold

9

plasma

Interface of up & down swing

10

motor

Interface of indoor fan

11

feedback

12 Jumper cap

13 Interface of left & right motor

Temperature sensor

14

interface

● Bottom view

Technical Information

9

12 34

10

11

12

13

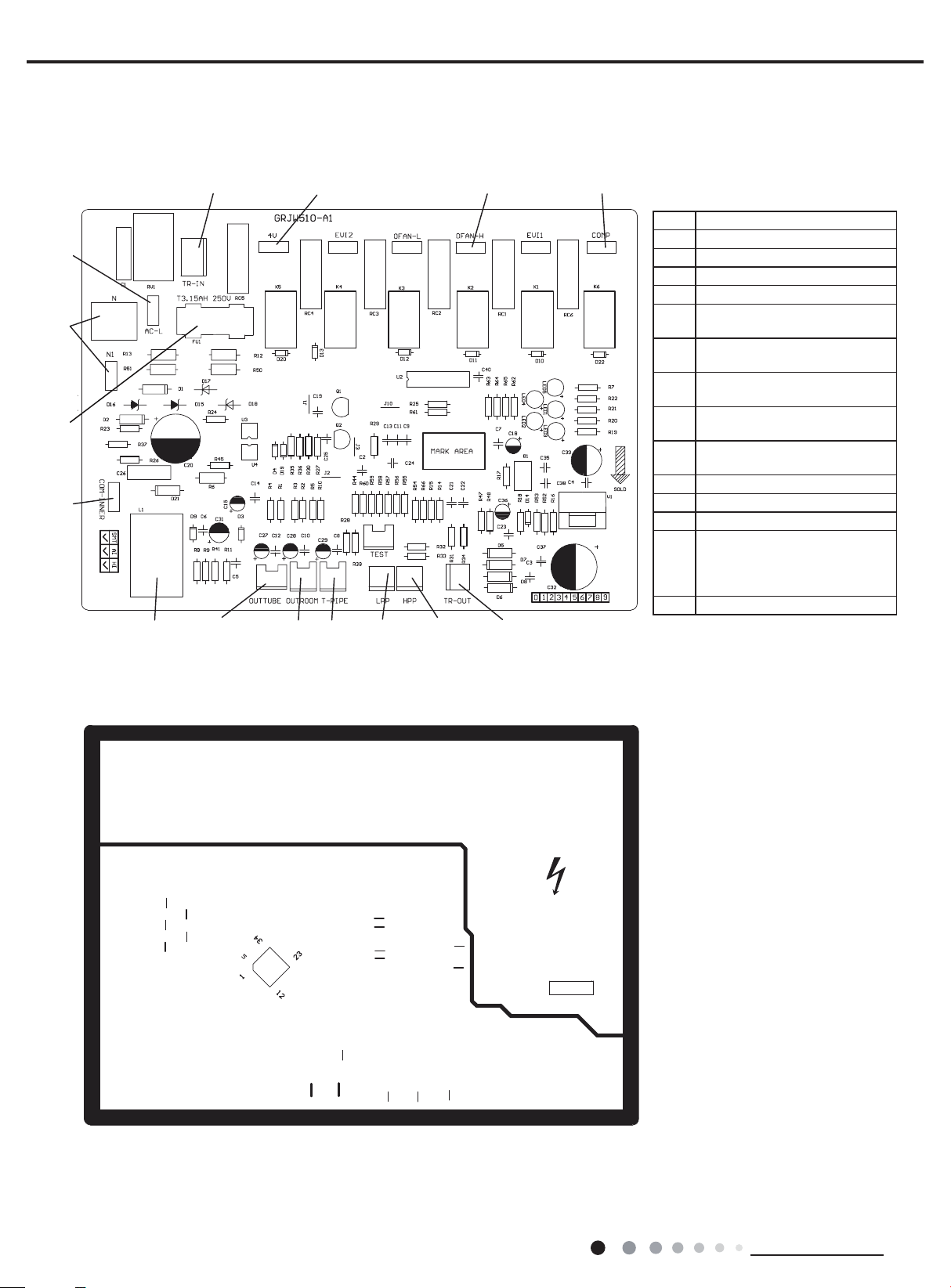

Outdoor Unit

● Top view

81415 9

7

6

5

Service Manual

1 Input of transformer

2 Terminal for 4-way valve

3 Terminal for outdoor fan

4 Terminal for compressor

5 Output of transformer

Terminal for high pressure

6

protection

Terminal for low pressure

7

protection

Terminal for outdoor ambient

8

temp sensor

Terminal for outdoor pipe temp

9

sensor

Terminal for communication

10

wire

11 Protective tube

12 Terminal for neutral wire

13 Terminal for live wire

Wiring terminal of outdoor

discharge temperature sensor

14

(Only for the models with this

function)

15 Current mutual-inductor

● Bottom view

10

Technical Information

Service Manual

Temp. display type

Sleep mode

do not. Please refer to the actual models.

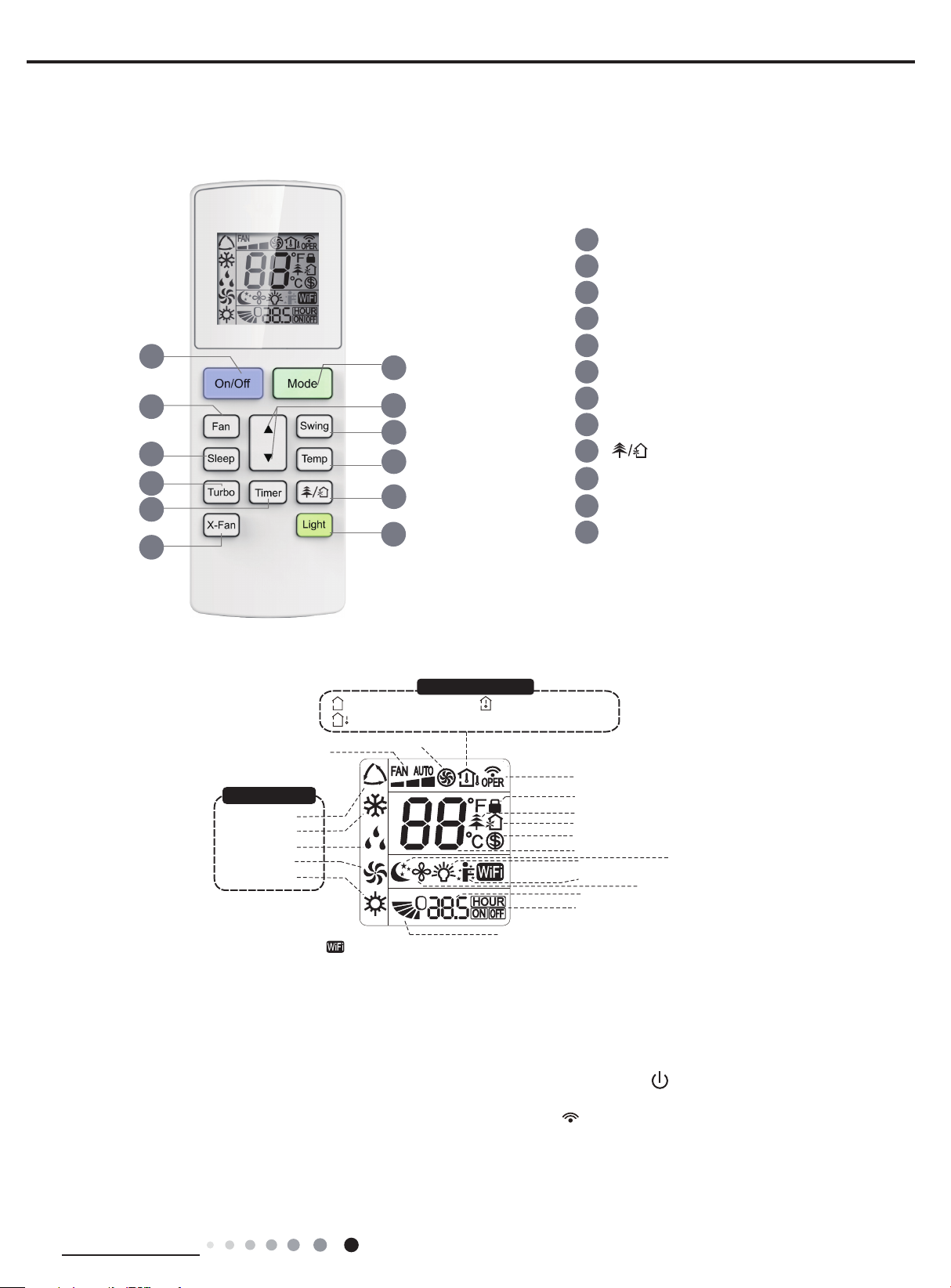

6. Function and Control

6.1 Remote Controller Introduction

1

3

6

8

10

11

2

4

5

7

9

12

1

On/Off button

2 Mode button

3 Fan button

4

5

6 Sleep button

7 Temp button

8 Turbo button

9

10 Timer button

11 X-Fan button

12 Light button

▲

▲/ button

Swing button

button

Introduction for icons on display screen

Set fan speed

Operation mode

Auto mode

Cool mode

Dry mode

Fan mode

Heat mode

NOTICE:

:Set temp.

:Outdoor ambient temp.

Turbo mode

“ ” This is a general remote controller. Some models have this function while some

:Indoor ambient temp.

Send signal

Child lock

health function

ventilation operation

8ć heating function

Set temperature

Light function

I feel function

Set time

TIMER ON /TIMER OFF

Up & down swing

X-fan mode

Introduction for buttons on remote controller

Note:

● This is a general use remote controller, it could be used for the air conditioners with multifunction; For some function, which the

model doesn't have, if press the corresponding button on the remote controller that the unit will keep the original running status.

● After putting through the power, the air conditioner will give out a sound. Operation indictor " " is ON (red indicator). After that,

you can operate the air conditioner by using remote controller.

●

Under on status, pressing the button on the remote controller, the signal icon " "

and the air conditioner will give out a “de” sound, which means the signal has been sent to the air conditioner.

Under off status, set temperature and clock icon will be displayed on the display of remote controller (If timer on, timer off and light

functions are set, the corresponding icons will be displayed on the display of remote controller at the same ime); Under on status, the

display will show the corresponding set function icons.

on the display of remote controller will blink once

Technical Information

11

Service Manual

A

*

1. On/Off button

Press this button to turn on the unit. Press this button again to turn off the unit.

2. Mode button

Each time you press this button,a mode is selected in a sequence that goes from AUTO, COOL, DRY, FAN, and HEAT *, as the following:

UTOCOOL DRY FAN

HEAT

Note: Only for models with heating function.

3. Fan button

This button is used for setting Fan Speed in the sequence that goes from AUTO, , , to , then back to Auto.

4. ▲/▲ button

● Press ▲ / button to increase/decreaseset temperature. In AUTO mode, set temperature is not adjustable.

● When setting Timer On or Timer Off, press "▲" or " " button to adjust the time.

▲

▲

5. Swing button

Press this button to set up & down swing angle.

6. Sleep button

Under Cool, Heat or Dry mode, press this button to turn on Sleep function.

Press this button again to cancel Sleep function. Under Fan and Auto modes, this function is unavailable.

7. Temp button

Press this button, you can see indoor set temperature, indoor ambient temperatureon indoor unit’s display. The setting on remote controller

is selected circularly as below:

no display

Note:

Outdoor temperature display is not available for some models. At that time, indoor unit receives " " signal, while it displays indoor set

temperature.

8. Turbo button

Press this button to activate / deactivate the Turbo function.

9. button

Press this button to achieve the on and off of healthy and scavenging functions in operation status. Press this button for the rst time to start

scavenging function; LCD displays " ". Press the button for the second time to start healthy and scavenging functions simultaneously;

LCD displays " " and " " . Press this button for the third time to quit healthy and scavenging functions simultaneously. Press the button

for the fourth t ime to start healthy function; LCD display " " .

Press this button again to repeat the operation above.

● This function is only available for some models.

10. Timer button

● Under ON status, press this button to set timer OFF; Under OFF status, press this button to set timer ON.

● Press this button once and the characters of HOUR ON (OFF) will ash to be displayed. Meanwhile, press "▲" button or " " button to

adjust timer setting (time will change quickly if holding "▲" or " " button). Time setting range is 0.5~24hours.

▲

Press this button again to conrm timer setting and the characters of HOUR ON (OFF)will stop ashing.

If the characters are ashing but you haven’t press timer button,timer setting status will be quit after 5s.If timer is conrmer, press this button

again to cancel timer.

11. X-Fan button

Press this button in COOL or DRY mode to turn on X-fan function.

When this function is started up, indoor fan will still operate at low fan speed for a while after turning off the unit by remote controller.

12. Light button

Press this button to turn on the display's light and press this button again to turn off the display's light.

12

Technical Information

▲

Service Manual

Function introduction for combination buttons

1. Combination of "MODE" and " ▲ " buttons:

About switch between Fahrenheit and centigrade

and

℃

At unit OFF, press "MODE" and " ▲ " buttons simultaneously to switch between

2. Combination of "TEMP" and "TIMER" buttons:

About Energy-saving Function

Press "TEMP" and "TIMER" simultaneously in COOL mode to start energy-saving function.

Nixie tube on the remote controller displays "SE". Repeat the operation to quit the function.

3. Combination of "TEMP" and "TIMER" buttons:

About 8℃ Heating Function

Press "TEMP" and "TIMER" simultaneously in HEAT mode to start 8℃ Heating Function Nixie tube on the remote controller displays " "

and a selected temperature of "8℃".

(46℉ if Fahrenheit is adopted). Repeat the operation to quit the function.

4. WIFI Function

Press "MODE" and "TURBO" button simultaneously to turn on or turn off WIFI function. When WIFI function is turned on, the "

be displayed on remote controller; Long press "MODE" and "TURBO" buttons simultaneously for 10s, remote controller will send WIFI reset

code and then the WIFI function will be turned on. WIFI function is defaulted ON after energization of the remote controller.

● This function is only available for some models.

℉

.

WiFi

" icon will

Replacement of batteries in remote controller

1. Press the back side of remote controller marked with " ", as shown in the g, and then push out

arrow direction.

2. Replace two 7# (AAA 1.5V) dry batteries, and make sure the position of "+" polar and "-" polar are correct.

3. Reinstall the cover of battery box.

signal sender battery

reinstall

remove

Cover of battery box

the cover of battery box along the

Technical Information

13

Service Manual

Heating

indicato

Temp.

Coolin

indicato

Power

indicato

r

indicator

6.2 Brief Description of Modes and Functions

1. Summary

(1) Buzzer

When the controller is energized or receives signal from button (emergency operation switch on air conditioner) or remote controller, the

buzzer will give out a beep.

(2) Display

After energization, all icons will be displayed once. Operation icon is in red under standby status. After turning on the unit by remote

◆

controller, operation icon is bright and corresponding set operation mode icon will be displayed (Mode icon include: cooling, heating,

drying).

r

g

r

r

(3) Temperature parameter

Indoor set temperature (Tpreset)

◆

Indoor ambient temperature (Tamb.)

◆

Inner tube temperature of indoor evaporator (Ttube)

◆

2. Introduction of Basic Mode Function

Once the compressor is energized, there should be a minimum interval of 3 mins between two start-ups.

◆

If the unit is with memory function and is off before power failure, the compressor can be restarted without an interval of 3 mins; if the

◆

unit is on before power failure, the compressor will be restarted with an interval of 3 mins.

◆

Once compressor is started, it won’t stop within 6 mins according to the change of room temp.

(1) Auto mode

Operation condition and process for auto mode

①

Under auto mode, the system will automatically select operation mode (cooling, heating, and fan) according to indoor ambient

temperature. There swill be 30s delayed for protection between mode switchover.

When Tamb≥26 , unit will be in cooling mode℃ Ex-factory set temperature is 20

◆

Cooling and heating unit: When Tamb≤(19℃+Tcompensation), unit will be in heating mode Tpreset=20℃.

◆

Cooling only unit: When Tamb≤22℃(or 72℉), unit will be in fan mode Tpreset=25℃.

◆

For cooling and heating unit under condition that (19℃+Tcompensation)<Tamb<26℃ (For cooling only unit under condition that

◆

22℃<Tamb<26℃), when unit is initially turned on in auto mode, it will operate according to auto fan mode. When unit is changed to

auto mode from other modes, it will maintain its previous working status (If auto mode is turned on from

drying mode, unit will operate according to auto fan mode).

② Display: Operation icon, actual operation mode icon, set temperature (that’s the display content of dual-8 nixie tube)

③ Protection function is same as that under each mode.

indicator

drying

Receive

window

℃

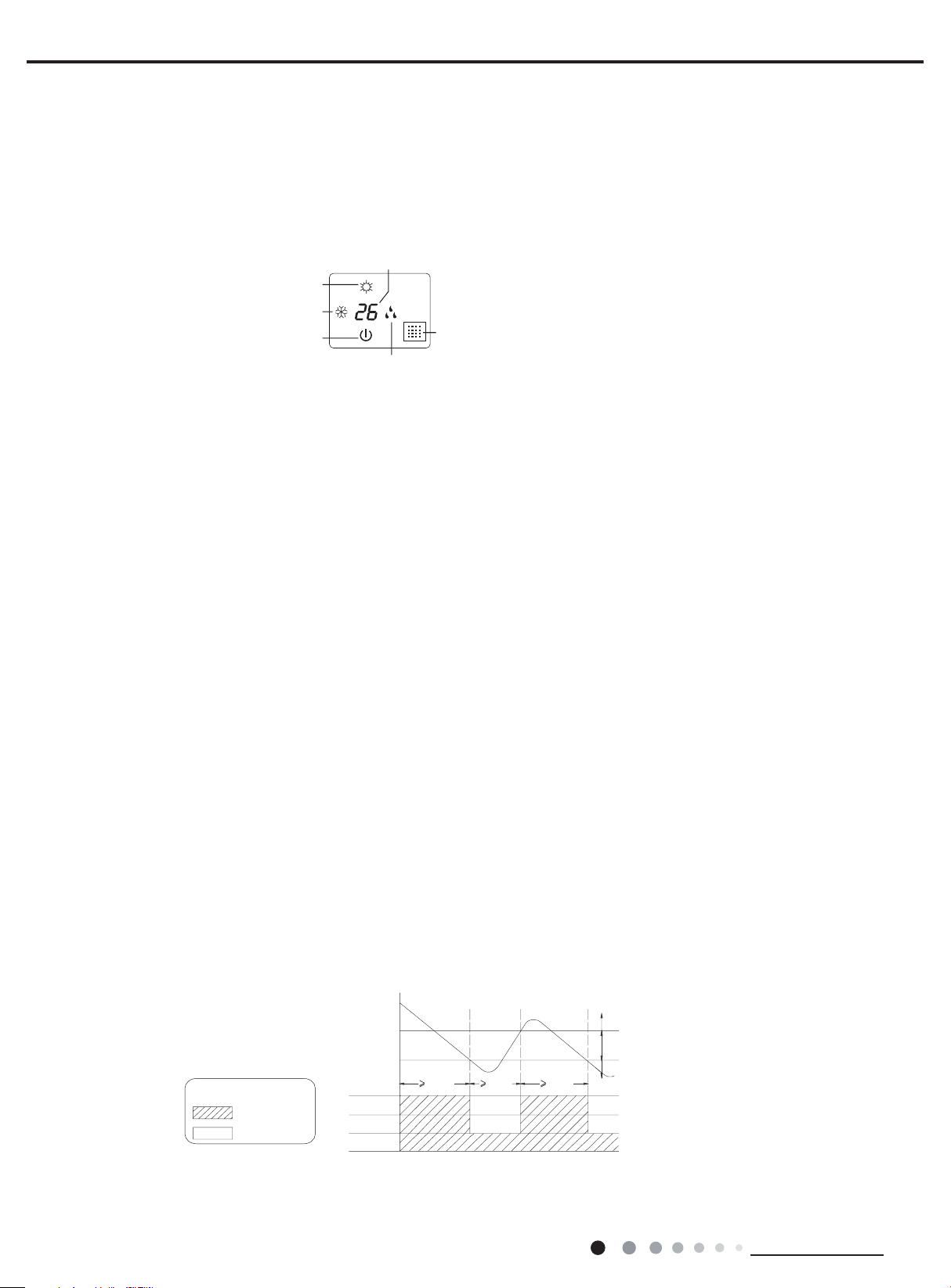

(2) Cooling mode

Operation condition and process for cooling mode

①

When Tamb. ≥Tset+1℃, the system operates under cooling mode. In this case, the compressor, the ODU fan motor and the IDU fan

◆

motor operates at set speed.

When Tamb. ≤Tset-1℃, the compressor and the ODU fan motor stop, while the IDU fan motor operates at set speed.

◆

When Tset-1℃<Tamb. <Tset+1℃, the system will maintain its previous operation status.

◆

In cooling mode, the 4-way valve is de-energized (4-way valve is not available for cooling only unit). Temperature setting range is

16~30℃.

Start cooling

Original operating status

Stop cooling

Technical Information

14

Tpreset +1 ˚C

Tpreset –1 ˚C

Graphic instruction:

(Same as below)

Indicates operation

Indicates stop

Display: Operation icon, cooling icon, set temperature.

②

Outdoor fan motor

Indoor fan motor

Tamb.

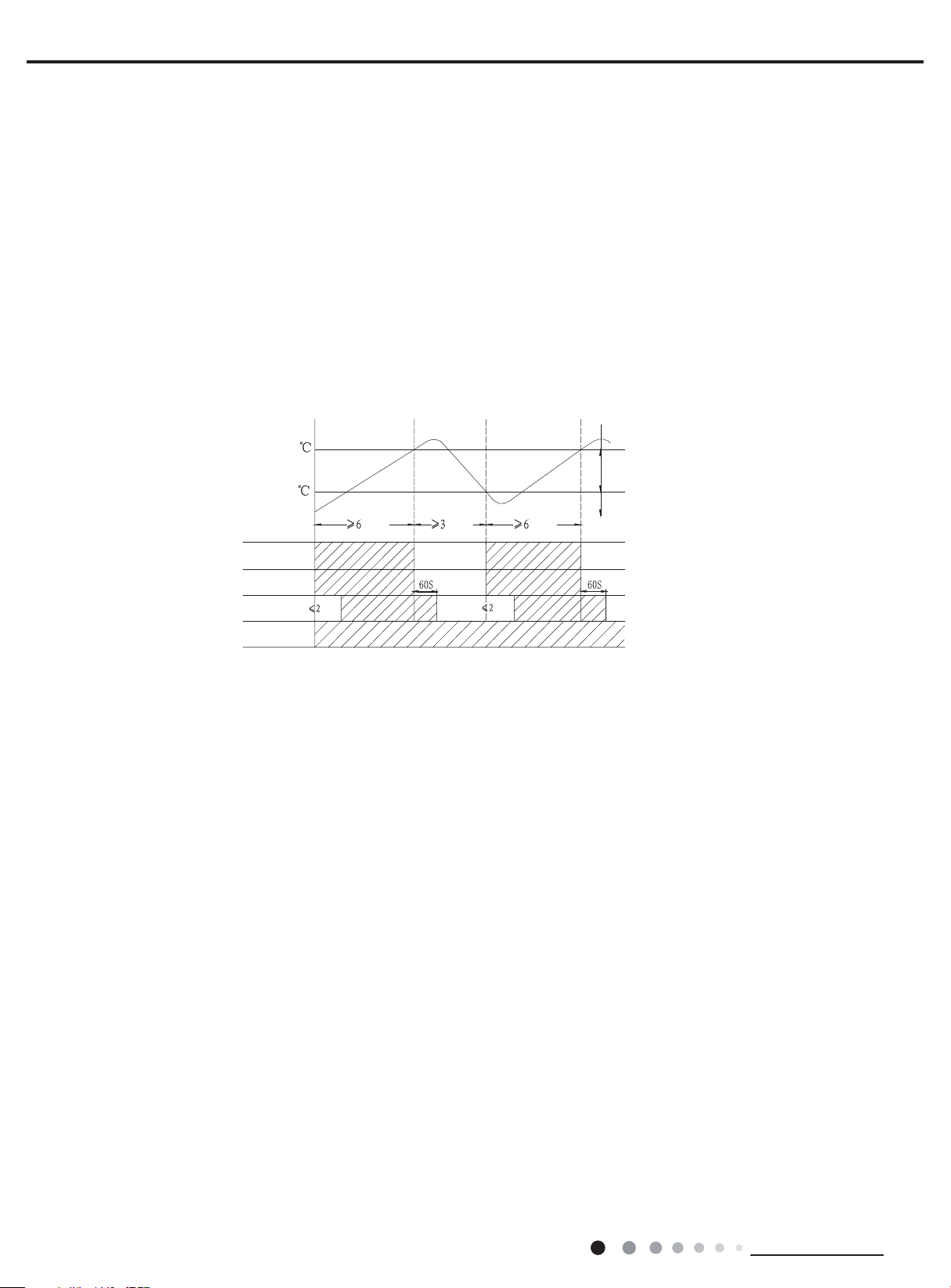

6 min. 3 min. 6 min.

Compressor

Set fan speed

Service Manual

T

amb.

Outdoor fan motor

Outdoor fan moto

Protection function

③

Freeze protection

◆

During operation, when controller detected that Ttube≤0℃ for a consecutive period of time, the system enters into freeze protection. In

that case, the compressor and the ODU fan stop operation, while the IDU operates at set fan speed. If freeze protection is released and

the compressor has been out of operation for 3 mins, the unit will resume its previous operation status.

Freeze protection period

Compressor

3 min

r

Indoor fan motor

Overcurrent protection ( this protection function is not available for those models whose cooling capacity ≤12000Btu/h)

◆

Set fan speed

During operation process, if controller detected that system current exceeds the limit value for 3s consecutively (overcurrent), only the

fan operates. About 3 mins later, if overcurrent is released, the system will resume original operation.

If overcurrent protection occurs for 6 times consecutively, and resume operation time won’t exceed 6min every time, overcurrent protection information will be displayed. After turning off the unit, display won’t be displayed.

If turn on the unit again, the system will be restated up again. Overcurrent protection information will be eliminated.

Please refer to maintenance part for display information and disposal method for details.

Locked protection to IDU fan motor

◆

During operation of IDU fan motor, if controller detected that the rotation speed of IDU fan motor less than 300/min or stop rotation, the

motor operates abnormally. In order to prevent damage to motor, controller will protect automatically, the system stops operation and

blocked information of IDU fan motor will be displayed. After turning off the unit, display won’t be displayed.

If turn on the unit again, the system will be restated up again. Blocked information of IDU fan motor will be eliminated. (For some models,

they can only be restated up after re-energized)

Please refer to maintenance part for display information and disposal method for details.

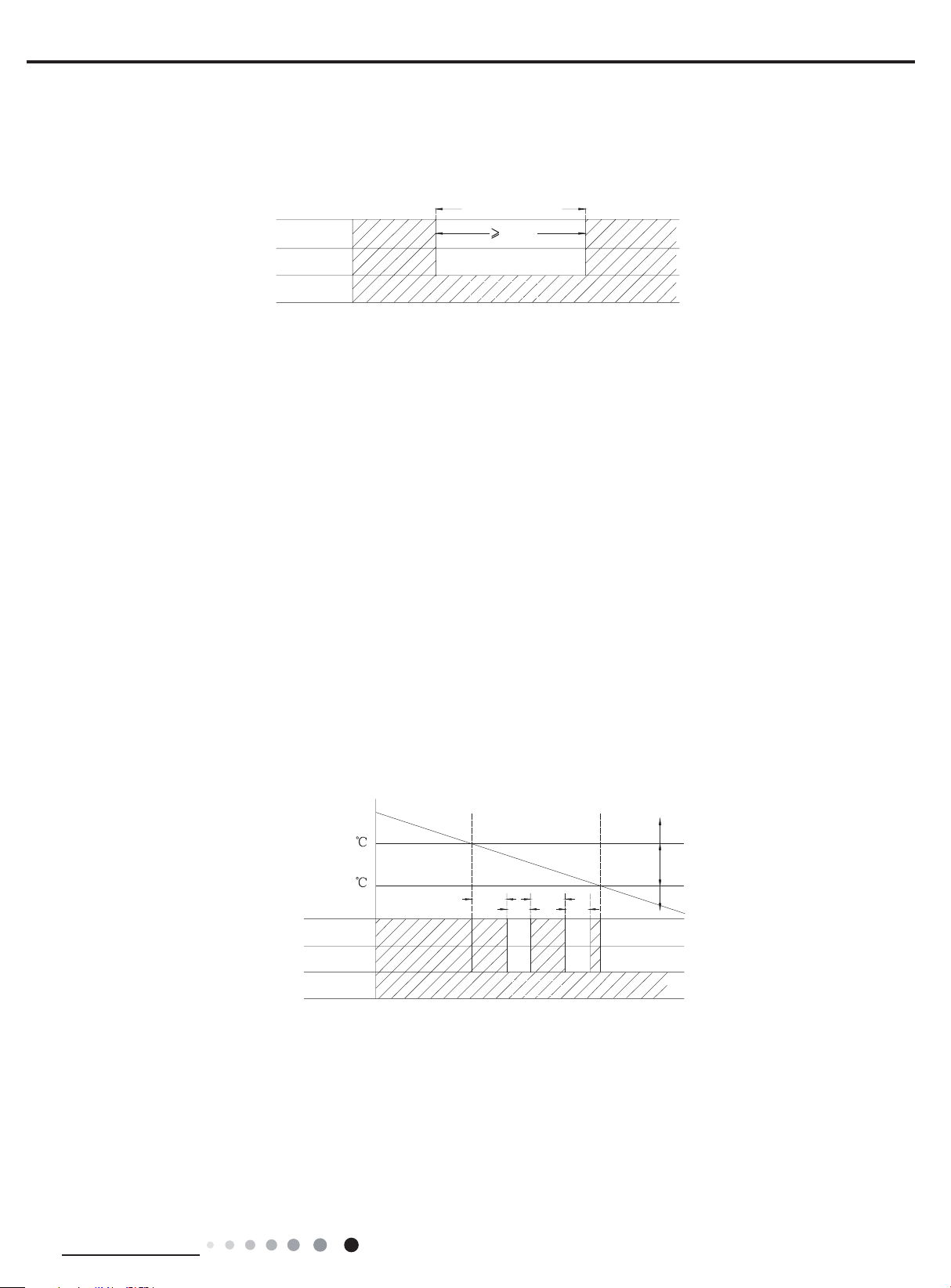

(3) Drying mode

Operation condition and process for drying mode

①

When Tamb. >Tset+2℃, the system starts drying and cooling. In this case, the compressor and the ODU fan motor operate, and the

◆

IDU fan motor operates at low speed.

When Tset-2℃≤Tamb. ≤Tset+2℃, the system will start drying. In this case, the IDU fan motor operates at low speed; the compressor

◆

and the ODU fan motor operate for 6 minutes and stop for 4 minutes in cycle.

When Tamb.<Tset-2℃, the compressor and the ODU fan motor stop, while the IDU fan motor runs at low speed.

◆

In drying mode, the 4-way valve is de-energized (4-way valve is not available for cooling only unit); Temperature setting range is

16~30℃. Fan speed can’t be adjusted.

Display: Operation icon, drying icon, set temperature.

②

Protection function

③

Freeze protection

◆

During dying and cooling operation, when the controller detected that Ttube≤0℃ for a period of time consecutively, the system will enter

into freeze protection. In that case, the compressor and the ODU fan motor stops operation, while the IDU fan motor operates at low

speed. When freeze protection is release and the compressor has stopped for 3min, the system will resume original operation.

During drying operation, when the controller detected that Ttube≤0℃ for a period of time consecutively, the system enters into freeze

protection. In that case, the compressor, the ODU fan motor stops operation, while the IDU fan motor operates at low speed. When

freeze protection is release and the compressor has stopped for 4min, the system will resume original operation.

Other protection is same as that under cooling mode.

◆

(4) Fan mode

Technical Information

T

preset

+2

T

preset-

2

Compressor

Indoor fan motor

6 min

6min.

4min.

Low speed

4min.

Cooling

Drying

Stop

15

Service Manual

Reversing

Operation condition and process for fan mode

①

In fan mode, the IDU fan motor operates at set speed, while the compressor and the ODU fan motor stop. 4-way valve is de-energized

(4-way valve is not available for cooling only unit). Temperature setting range is 16~30℃.

Display: Operation icon, set temperature.

②

Protection function

③

In fan mode, there are overcurrent protection and blocked protection of IDU fan motor. Please refer to corresponding protection function

under cooling mode for details.

(5) Heating mode(no heating mode is not available for cooling only unit)

Operation conditioner and process for heating mode

①

When Tamb-Tcompensation≤Tpreset-1℃, unit will operate in heating mode. 4-way valve will be energized while compressor and

◆

outdoor fan starts operation at the same time. Indoor fan will start some time later so that air condition won’t blow out cold air.

When Tamb-Tcompensation≥Tpreset+1℃, compressor and outdoor fan will stop operation while 4-way valve is still power on. Indoor

◆

fan will continue operation for a while at set fan speed to blow out the residual heat so that temperature within the air conditioner won’t

be too high.

When Tpreset-1

◆

Tamb-Tcompensation<Tpreset+1℃, system will maintain its previous working status.

℃<

In heating mode, 4-way valve is energized. Temperature setting range is 16~30℃.

T

preset

+4

T

preset

+2

amb

.

T

Compressor

Outdoor unit

Intdoor unit

Display: Operation icon, heating icon, set temperature.

②

Defrosting condition and process

③

min.

valve

min.

min.

.nim.nim

Set fan speedSet fan speed

Stop heating

Original operating status

Start heating

For ensusing heating effect, air conditioner will defrost automatically according to defrosting status on outdoor unit. During defrosting,

heating icon will be on and off.

Protection function

④

Overheating prevention protection

◆

During operation, when controller detects that Ttube≥55℃,the ODU fan motor stops operation; When Ttube is resumed normally, the

ODU fan motor resumes operation.

Noise silencing protection

◆

When turning off the unit or during mode switchover, the 4-way valve is closed. In order to decrease noise, the 4-way valve will delay

2mins to be closed.

Overcurrent protection ( this protection function is not available for those models whose cooling capacity ≤12000Btu/h)

◆

During operation process, if controller detected that system current exceeds the limit value for 3s consecutively(overcurrent), the

system stops operation. About 3mins later, if overcurrent is released, the system will resume original operation. If overcurrent protection

occurs for 6 times consecutively, and resume operation time won’t exceed 6min every time, overcurrent protection information will be

displayed. After turning off the unit, display won’t be displayed.

If turn on the unit again, the system will be restated up again. Overcurrent protection information will be eliminated.

Please refer to maintenance part for display information and disposal method for details.

Locked protection to IDU fan motor

◆

During operation of IDU fan motor, if controller detected that the rotation speed of IDU fan motor less than 300/min or stop rotation, the

motor operates abnormally. In order to prevent damage to motor, controller will protect automatically, the system stops operation and

blocked information of IDU fan motor will be displayed. After turning off the unit, display won’t be displayed.

If turn on the unit again, the system will be restated up again. Blocked information of IDU fan motor will be eliminated. (For some models, they can only be restated up after re-energized)

Please refer to maintenance part for display information and disposal method for details.

16

3. Other Control Function Introduction

(1)Timer function

Technical Information

Service Manual

Clock timer: The precision of clock timer is 1minute. 24hours circulated timer can be set.

Timer ON: If timer ON is set during operation of the unit, the unit will continue to operate. If timer ON is set at unit OFF, upon ON

◆

time reaches, the unit will start to run according to previous setting status.

Timer OFF: If timer OFF is set at unit OFF, the system will keep standby status. If timer OFF is set at unit ON, upon OFF time

◆

reaches, the unit will stop operation.

Timer change:

◆

Although timer has been set, the unit still can be turned on/off by pressing ON/OFF button on the remote controller. You can also reset

the timer.

If timer ON and timer OFF are set at the same time during operation of the unit, the unit will keep running at current status till OFF

time reaches. Upon ON time reached, the system will be turned on automatically. The unit will operate circularly like that every

24hours.

If timer ON and timer OFF are set at unit OFF status, the system keep OFF status till ON time reaches. Upon OFF time reaches, the

system will be turned OFF automatically. The unit will operate circularly like that every 24hours.

(2) Emergency operation switch

After pressing this button, the system will operate according under auto mode and the IDU fan motor operates at auto speed. Swing

motor operates when the IDU fan motor operates. Press this button again to turn off the unit.

Emergency

operation switch

OFF status

Press

ON status(Auto mode)

Press

(3) Sleep function

In this mode, the system will select proper sleep curve to operate according to different set temperature.

If start up sleep function under cooling or drying mode, the system will increase set temperature automatically within a certain

①

range to operate.

If start up sleep function under heating mode, the system will decrease set temperature automatically within a certain range to

②

operate.

(4) Turbo function

Turbo function can be set under cooling and heating modes. During operation of turbo function, the system operates at the maximum

fan speed.

(5) Dry function

Dry function can be set under cooling and drying modes. During operation of drying function, the fan will stop operation after operating

for a period of time when turning off the unit.

(6) Auto fan speed control

Auto fan speed control can be set under cooling, heating and fan mode. During operation of auto fan speed control, the IDU fan motor

will adjust the fan speed (high, medium or low speed) according to ambient temperature.

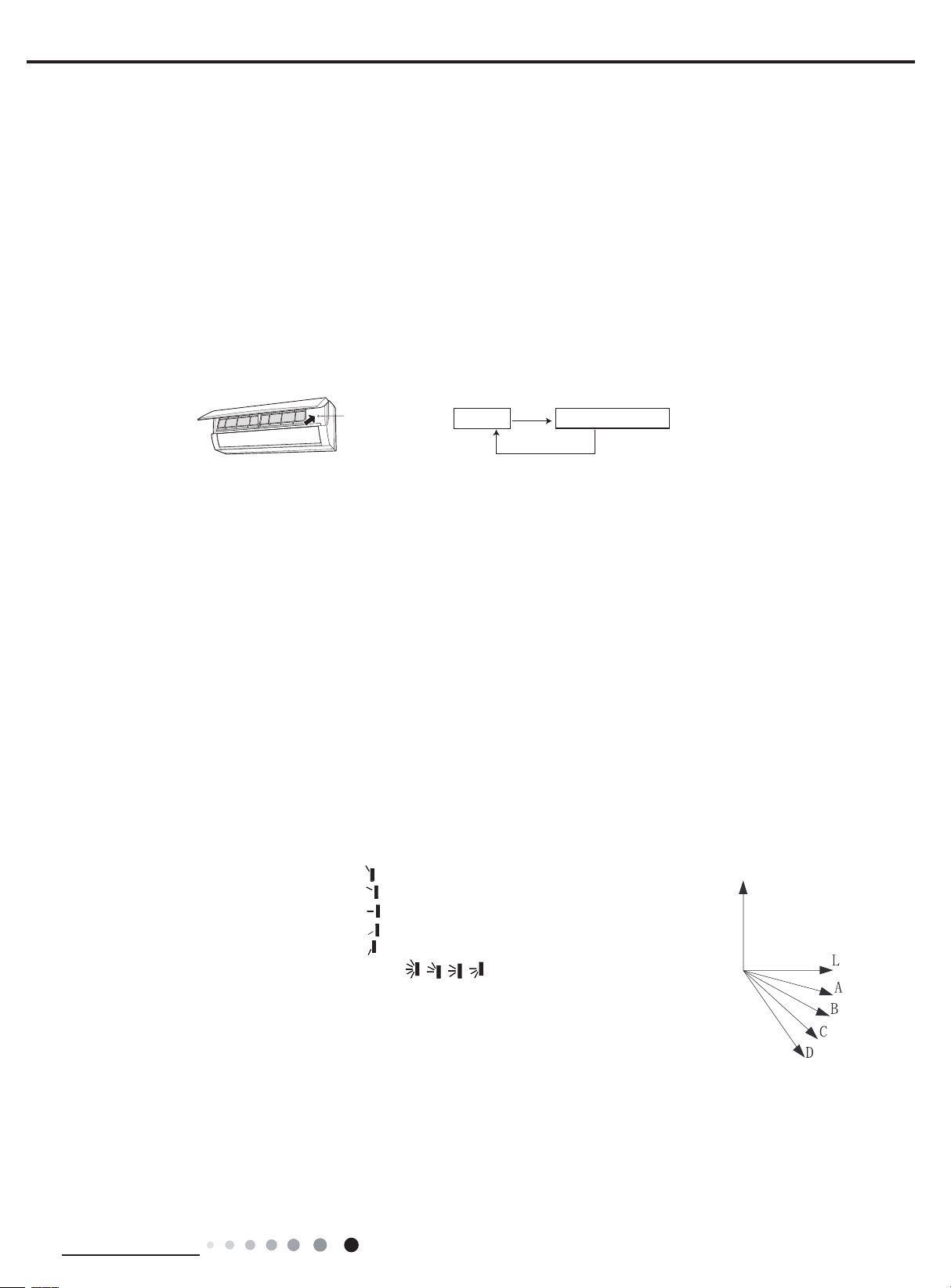

(7) Up&down swing control

After energization, up & down swing motor will rstly have the horizontal louver rotate anticlockwise to position O to close air outlet.

①

If swing function has not been set after start-up of the unit, horizontal louver will turn clockwise to position D in heating mode, or turn

clockwise to level position L in other modes.

If swing function is set when turning on the unit, the horizontal louver will swing between L and D.

②

Horizontal louver has 7 swing statuses:

Stay at position L: control by remote controller:

◆

Stay at position A: control by remote controller:

◆

Stay at position B: control by remote controller:

◆

Stay at position C: control by remote controller:

◆

Stay at position D: control by remote controller:

◆

Swing between L and D: control by remote controller: , , ,

◆

Stop at any postion between L and D (angles between L and D are equiangular) and no display

◆

O(0°)

on remote controller.

When turning off the unit, horizontal louver will close at position O.

③

Swing action is valid only when set swing command and the IDU fan motor is operating.

④

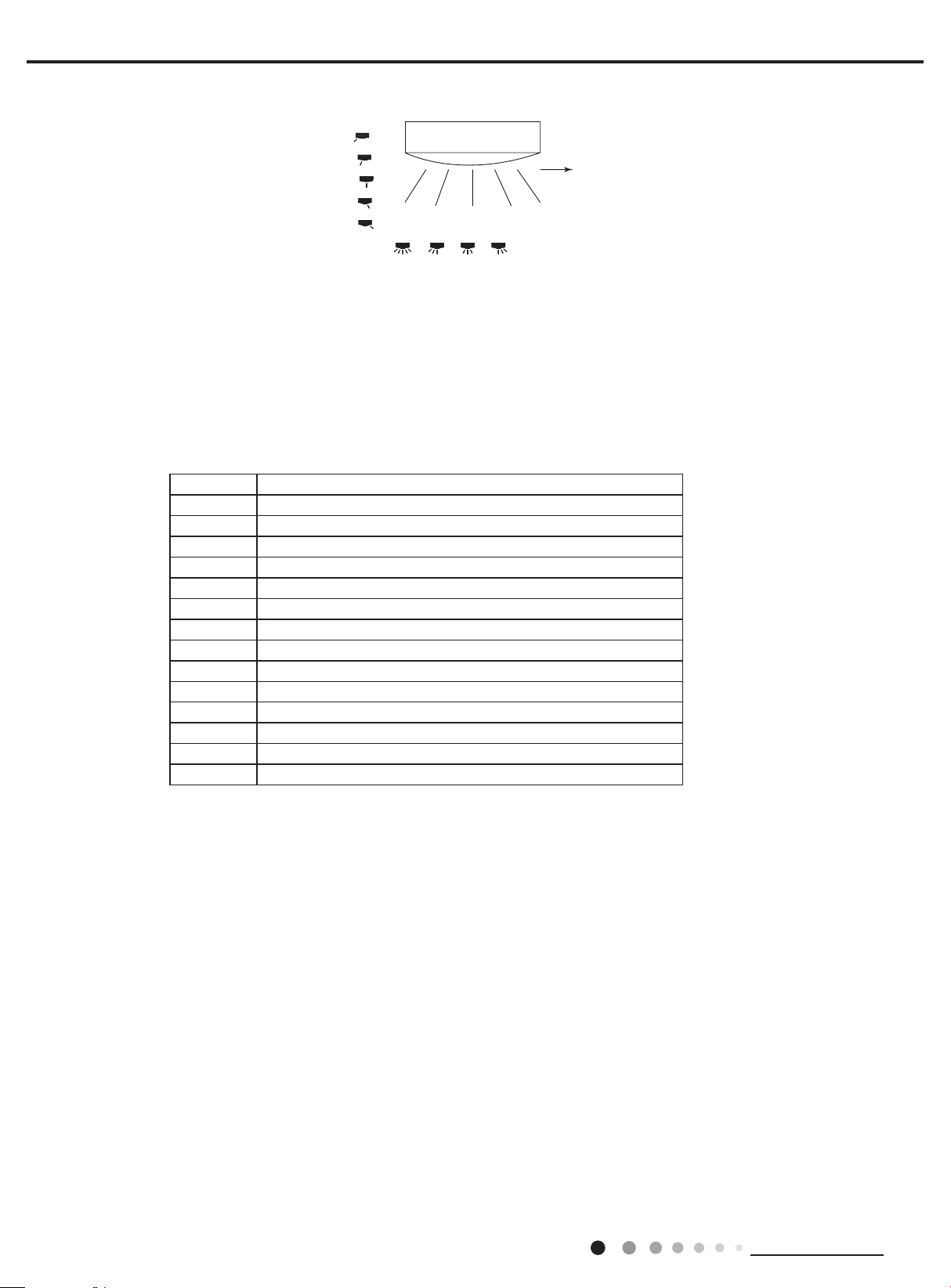

(8) Left&Right swing control(This function is only available for some model)

After energization, swing motor will rstly have the vertical louver rotate anticlockwise to position O to close air outlet. If swing

①

function has not been set after start-up of the unit, vertical louver will turn clockwise to position D in heating mode, or turn clockwise to

position L in other modes.

If swing function is set when turning on the unit, the vertical louver will swing between L and D.

②

Technical Information

17

Service Manual

ǃǃǃǃ

L

A

B

Vertical louver has 7 swing statuses:

Stay at position L: control by remote controller:

◆

Stay at position A: control by remote controller:

◆

Stay at position B: control by remote controller:

◆

Stay at position C: control by remote controller:

◆

Stay at position D: control by remote controller:

◆

Swing between L and D: control by remote controller:

◆

Stop at any position between L and D (angles between L and D are equiangular), control by remote controller: OFF

◆

When turning off the unit, vertical louver will close at position O.

③

Swing action is valid only when swing command has been set and the IDU fan motor is operating.

④

, , ,

C

Set this position as starting point 0(0

D

O

)

(9) Dual-8 nixie tube display

When the air conditioner is turned on for the rst time, dual-8 nixie tube defaulted to display current set temperature.

◆

When controller receives signal of display set temperature, dual-8 nixie tube displays set temperature. When received remote control

◆

signal is switched to indoor ambient temperature display status signal from other display status, dual-8 nixie tube will display indoor

ambient temperature for 3-5s, and then turn back to display set temperature. If remote control to set other status, the display keeps the

same.

When air conditioner has a malfunction,dual-8 nixie tube will show relevant error code.

◆

F1 Indoor ambient temperature sensor is open/short-circuited

F2 Indoor evaporator temperature sensor is open/short-circuited

H6 Blocked protection of IDU fan motor

C5 Malfunction protection of jumper cap

U8 Zero-crossing inspection circuit malfunction of the IDU fan motor

F3 Outdoor ambient temperature sensor is open/short-circuited

F4 Outdoor condenser temperature sensor is open/short-circuited

F5 Outdoor discharge temperature sensor is open/ short-circuited

E1 High pressure protection

E3 Low pressure protection of compressor

E4 High discharge temperature protection of compressor

E5 Overcurrent protection

E6 Communication malfunction

H3 Overload protection compressor

E8 Overload malfunction

When air conditioner is in auto defrosting, heating icon will be on and off.

◆

If turn off light button, all display will be turned off.

◆

(10) Memory function

Power failure when turning on the unit

①

Memory content: ON status, mode, up&down swing, light, set temperature, set fan speed, general timer, Fahrenheit/ Celsius

◆

General timer can be memorized. Time of timer is calculated again from energization.

◆

Clock timer can’t be memorized.

◆

Power failure when turning off the unit

②

Memory content: OFF status, mode, up&down swing, light, set temperature, set fan speed, general timer, Fahrenheit/ Celsius

◆

General timer can be memorized. Time of timer is calculated again from energization.

◆

Clock timer can’t be memorized.

◆

4. Special Function

(1) Health function (for the model with health function)

During operation of the IDU fan motor, press health button on the remote controller to start health function (If there is not health button on

the remote controller, the unit defaults health function ON).

(2) I Feel function (for all models, but it needs the remote controller which can set this function)

When I FEEL command is received, the controller will operate according to the ambient temperature sent by the remote controller (For

defrosting and cold air prevention, the unit operates according to the ambient temperature sensed by the air conditioner). The remote

controller will regularly send ambient temperature data to the controller. When the data has not been received for a long time, the unit

will operate according to the temperature sensed by the air conditioner. If I FEEL function is not set, the ambient temperature will be that

sensed by the air conditioner.

18

Technical Information

Loading...

Loading...