Gree GWH18PD-K3NNA1A, GWH24PD-K3NNA1A Service Manual

GREE ELECTRIC APPLIANCES,INC.OF ZHUHAI

Service Manual

Change for Life

Models:GWH18PD-K3NNA1A(CA414000100)

GWH18PD-K3NNA1A(CA414000101)

GWH18PD-K3NNA1A(CA414000102)

GWH24PD-K3NNA1A(CA414000201)

GWH24PD-K3NNA1A(CA414000202)

(Refrigerant R410A)

Table of Contents

Table of Contents

Summary and Features

.........................................................................................1

1. Safety Precautions

..............................................................................................2

2. Specications

..........................................................................................................3

2.1 Unit Specications ............................................................................................................3

2.2 Capacity Variation Ratio According to Temperature .........................................................7

2.3 Operation Data .................................................................................................................7

3. Construction Views

............................................................................................8

3.1 Indoor Unit ........................................................................................................................8

3.2 Outdoor Unit .....................................................................................................................8

4. Refrigerant System Diagram

....................................................................10

5. Schematic Diagram

..........................................................................................11

5.1 Electrical Data ................................................................................................................11

5.2 Electrical Wiring ..............................................................................................................11

5.3 Printed Circuit Board ......................................................................................................15

6. Function and Control

......................................................................................16

6.1 Remote Controller Description ......................................................................................16

6.3 Description of Each Control Operation ...........................................................................20

7. Installation Manual

............................................................................................24

7.1 Notices for Installation ....................................................................................................24

7.2 Installation Drawing ........................................................................................................26

7.3 Install Indoor Unit ...........................................................................................................27

7.4 Installation of Outdoor Unit .............................................................................................28

7.5 Check after Installation and Test Operation ...................................................................29

7.6 Installation and Maintenance of Healthy Filter ...............................................................30

Table of Contents

8. Exploded Views and Parts List

..............................................................31

8.1 Indoor Unit ......................................................................................................................31

8.2 Outdoor Unit ...................................................................................................................34

9. Troubleshooting

..................................................................................................38

9.1 Precautions before Performing Inspection or Repair .....................................................38

9.2 Conrmation ...................................................................................................................38

9.3 Judgement by Flashing LED of Indoor/Outdoor Unit ......................................................38

9.4 How to Check Simply the Main Part ...............................................................................40

10. Removal Procedure

.......................................................................................47

10.1 Removal Procedure of Indoor Unit ...............................................................................47

10.2 Removal Procedure of Outdoor Unit ..........................................................................55

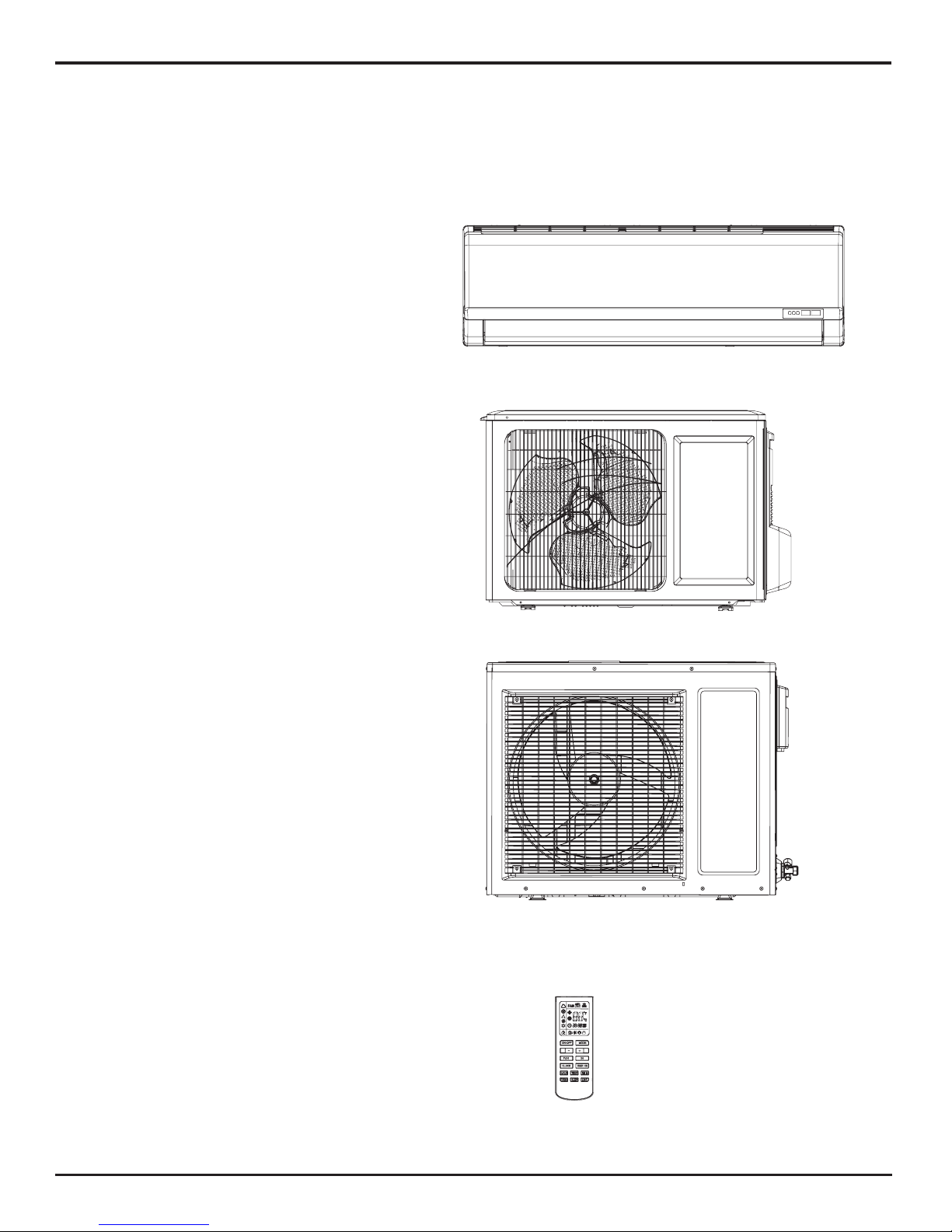

Summary and Features

1

Summary and Features

Indoor Unit

Outdoor Unit

Remote Controller

YAM1F

GWH18PD-K3NNA1A/I(CA414N00100)

GWH18PD-K3NNA1A/I(CA414N00101)

GWH24PD-K3NNA1A/I(CA414N00201)

GWH24PD-K3NNA1A/I(CA414N00200)

GWH18PD-K3NNA1A/O

GWH24ND-K3NNB1A/O

2

Safety Precautions

1. Safety Precautions

Installing, starting up, and servicing air conditioner can be

hazardous due to system pressure, electrical components,

and equipment location, etc.

Only trained, qualified installers and service personnel are

allowed to install, start-up, and service this equipment.

Untrained personnel can perform basic maintenance functions such as cleaning coils. All other operations should

be performed by trained service personnel.

When handling the equipment, observe precautions in the

manual and on tags, stickers, and labels attached to the

equipment. Follow all safety codes. Wear safety glasses

andwork gloves. Keep quenching cloth and fire extinguisher

nearby when brazing.

Read the instructions thoroughly and follow all warnings or

cautions in literature and attached to the unit. Consult local

building codes and current editions of national as well as

local electrical codes.

Recognize the following safety information:

Incorrect handling could result in

personal injury or death.

Incorrect handling may result in

minor injury,or damage to product

or property.

Warning

Caution

Caution

Warning

All electric work must be performed by a licensed technician

according to local regulations and the instructions given in

this manual.

Before installing, modifying, or servicing system, main

electrical disconnect switch must be in the OFF position.

There may be more than 1 disconnect switch. Lock out

and tag switch with a suitable warning label.

Never supply power to the unit unless all wiring and tubing are completed, reconnected and checked.

This system adopts highly dangerous electrical voltage.

Incorrect connection or inadequate grounding can cause

personal injury or death. Stick to the wiring diagram and

all the instructions when wiring.

Have the unit adequately grounded in accordance with

local electrical codes.

All installation or repair work shall be performed by your dealer or a specialized subcontractor as there is the risk of fire,

electric shock, explosion or injury.

Have all wiring connected tightly. Loose connection may

lead to overheating and a possible fire hazard.

Make sure the outdoor unit is installed on a stable, level

surface with no accumulation of snow, leaves, or trash

beside.

Make sure the ceiling/wall is strong enough to bear the

weight of the unit.

Make sure the noise of the outdoor unit does not disturb

neighbors.

Follow all the installation instructions to minimize the risk

of damage from earthquakes, typhoons or strong winds.

Avoid contact between refrigerant and fire as it generates

poisonous gas.

Apply specified refrigerant only. Never have it mixed with

any other refrigerant. Never have air remain in the

refrigerant line as it may lead to rupture and other hazards.

Make sure no refrigerant gas is leaking out when installation is completed.

Should there be refrigerant leakage, the density of refrigerant in the air shall in no way exceed its limited value,

or it may lead to explosion.

Keep your fingers and clothing away from any moving

parts.

Clear the site after installation. Make sure no foreign objects are left in the unit.

Always ensure effective grounding for the unit.

Never install the unit in a place where a combustible gas

might leak, or it may lead to fire or explosion.

Properly insulate any tubing running inside the room to

prevent the water from damaging the wall.

Make a proper provision against noise when the unit is

installed at a telecommunication center or hospital.

Provide an electric leak breaker when it is installed in a

watery place.

Never wash the unit with water.

Should any emergency occur, stop the unit and disconnect the power immediately.

Handle unit transportation with care. The unit should not

be carried by only one person if it is more than 20kg.

Never touch the heat exchanger fins with bare hands.

Never touch the compressor or refrigerant piping without

wearing glove.

Do not have the unit operate without air filter.

3

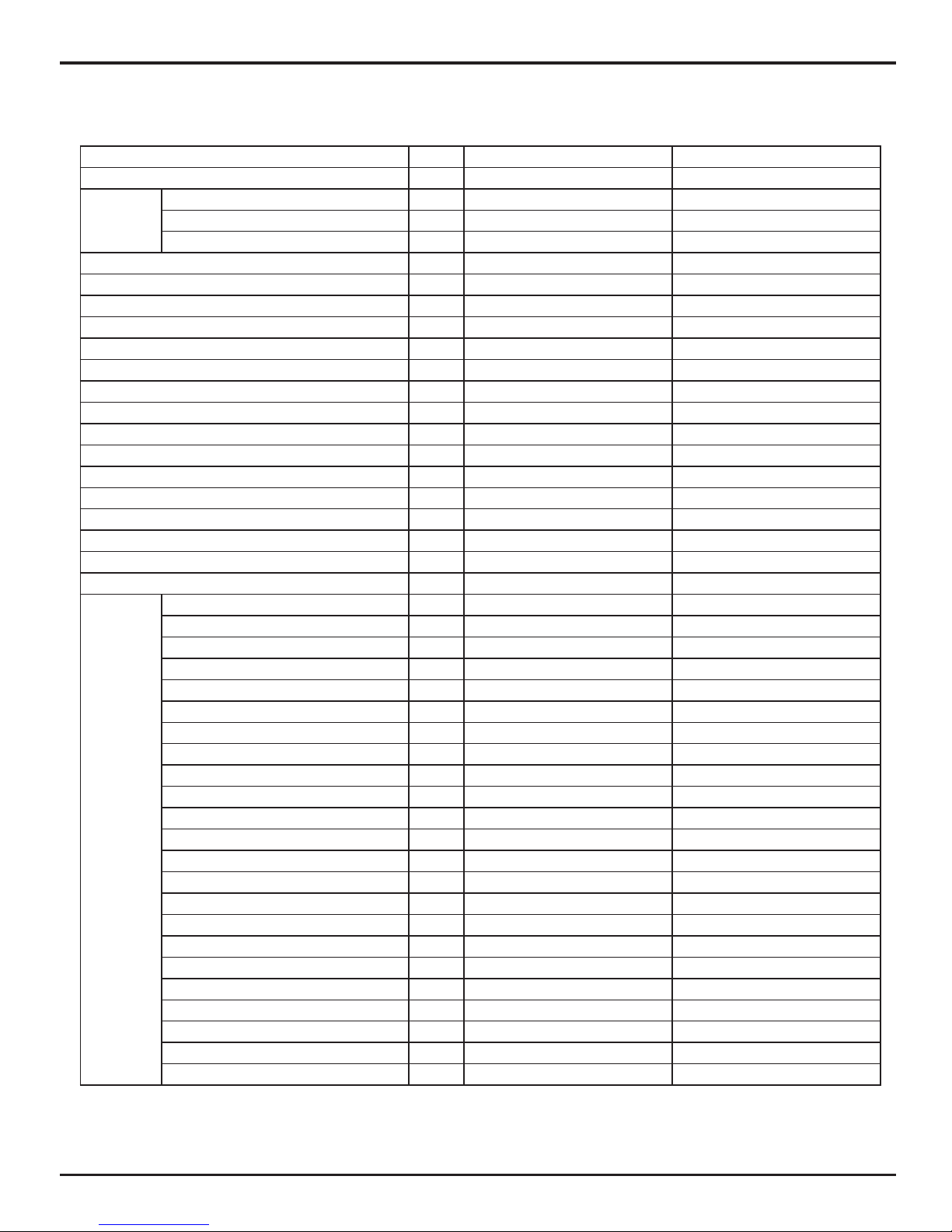

Specications

2. Specications

2.1 Unit Specications

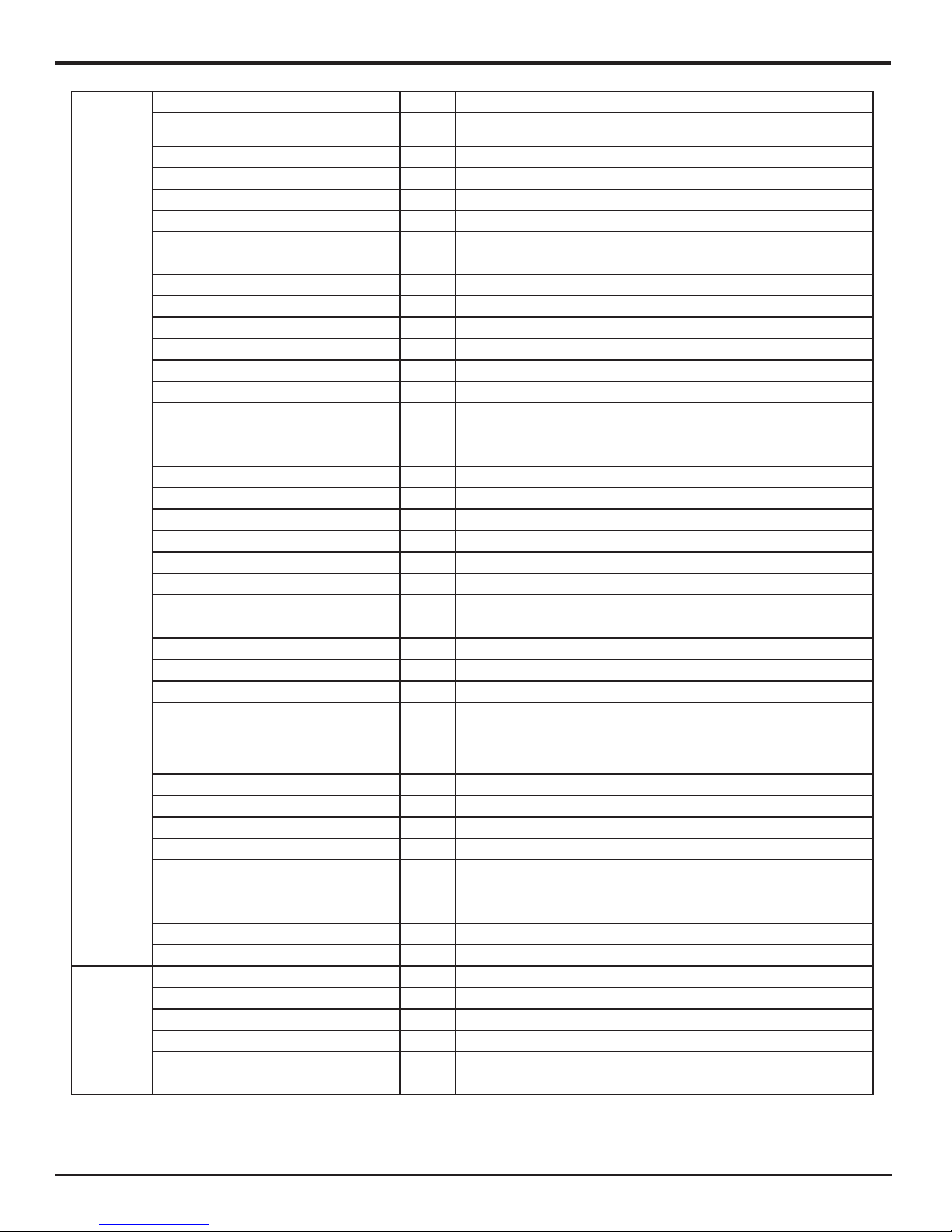

Model GWH18PD-K3NNA1A GWH18PD-K3NNA1A

Product Code CA414000100 /CA414000101 CA414000102

Power

Supply

Rated Voltage V

~

220-240 220-240

Rated Frequency Hz 50 50

Phases 1 1

Power Supply Mode Indoor Indoor

Cooling Capacity W 4700 4700

Heating Capacity W 4900 4900

Cooling Power Input W 1460 1460

Heating Power Input W 1430 1430

Cooling Power Current A 6.50 6.50

Heating Power Current A 6.35 6.35

Rated Input W 1980 1980

Rated Current A 10 9.8

Air Flow Volume(SH/H/M/L/SL) m

3

/h 850/780/650/500/- 850/780/650/500/-

Dehumidifying Volume L/h 1.8 1.8

EER W/W 3.22 3.22

COP W/W 3.43 3.43

SEER W/W / /

HSPF W/W / /

Application Area m

2

23-34 23-34

Indoor Unit

Model of indoor unit GWH18PD-K3NNA1A/I GWH18PD-K3NNA1A/I

Fan Type Cross-ow Cross-ow

Diameter Length(DXL) mm Φ98X710 Φ98X710

Fan Motor Cooling Speed(SH/H/M/L/SL) r/min 1350/1200/1000/800/- 1350/1200/1000/800/-

Fan Motor Heating Speed(SH/H/M/L/SL) r/min 1420/1250/1100/950/- 1420/1250/1100/950/-

Output of Fan Motor W 20 20

Fan Motor RLA A 0.31 0.31

Fan Motor Capacitor μF 1.5 1.5

Input of Heater W / /

Evaporator Form Aluminum Fin-copper Tube Aluminum Fin-copper Tube

Pipe Diameter mm Φ7 Φ7

Row-n Gap mm 2-1.4 2-1.4

Coil Length (LXDXW) mm

715X25.4X304.8 715X25.4X304.8

Swing Motor Model MP28VB MP28VB

Output of Swing Motor W 2 2

Fuse A 3.15 3.15

Sound Pressure Level (SH/H/M/L/SL) dB (A) 45/42/37/33/- 45/42/38/34/-

Sound Power Level (SH/H/M/L/SL) dB (A) 55/52/47/43/- 55/52/48/44/-

Dimension (WXHXD) mm 945X298X200 945X298X200

Dimension of Carton Box (LXWXH) mm 1010X380X285 1010X380X285

Dimension of Package(LXWXH) mm 1013X383X300 1013X383X300

Net Weight kg 13 13

Gross Weight kg 17 17

4

Specications

The above data is subject to change without notice. Please refer to the nameplate of the unit.

Outdoor

Unit

Model of Outdoor Unit GWH18PD-K3NNA1A/O GWH18PD-K3NNA1A/O

Compressor Manufacturer/Trademark

Shanghai Hitachi Electrical

Appliances Co.,Ltd

ZHUHAI LANDA

COMPRESSOR CO.,LTD.

Compressor Model ASL180SV-C7LU QXA-C18B030

Compressor Oil HAF68D1 RB68EP

Compressor Type Rotary Rotary

L.R.A. A 32 32

Compressor RLA A 6.8 7

Compressor Power Input W 1500 1520

Overload Protector UP3-83G Internal

Throttling Method Capillary Capillary

Operation Temp ºC 16~30 16~30

Ambient Temp (Cooling) ºC 18~43 18~43

Ambient Temp (Heating) ºC -7~24 -7~24

Condenser Form Aluminum Fin-copper Tube Aluminum Fin-copper Tube

Pipe Diameter mm Φ7 Φ7

Rows-n Gap mm 2-1.6 2-1.6

Coil Length (LXDXW) mm 735X25.4X495 735X25.4X495

Fan Motor Speed rpm 770 850

Output of Fan Motor W 35 35

Fan Motor RLA A 0.3 0.37

Fan Motor Capacitor μF 2.5 2.5

Air Flow Volume of Outdoor Unit m

3

/h 1800 1800

Fan Type Axial-ow Axial-ow

Fan Diameter mm Φ394.5 Φ394.5

Defrosting Method Automatic Defrosting Automatic Defrosting

Climate Type T1 T1

Isolation I I

Moisture Protection IP24 IP24

Permissible Excessive Operating

Pressure for the Discharge Side

MPa 4.3 4.3

Permissible Excessive Operating

Pressure for the Suction Side

MPa 2.5 2.5

Sound Pressure Level (H/M/L) dB (A) 55/-/- 55/-/-

Sound Power Level (H/M/L) dB (A) 65/-/- 65/-/-

Dimension (WXHXD) mm 848X540X320 848X540X320

Dimension of Carton Box (LXWXH) mm 878X360X580 878X360X580

Dimension of Package(LXWXH) mm

881X363X595 881X363X595

Net Weight kg 40 40

Gross Weight kg 44 44

Refrigerant R410A R410A

Refrigerant Charge kg 1.15 1.15

Connection

Pipe

Length m 4 5

Gas Additional Charge g/m 20 30

Outer Diameter Liquid Pipe mm Φ6 Φ6

Outer Diameter Gas Pipe mm Φ12 Φ12

Max Distance Height m 10 10

Max Distance Length m 25 25

5

Specications

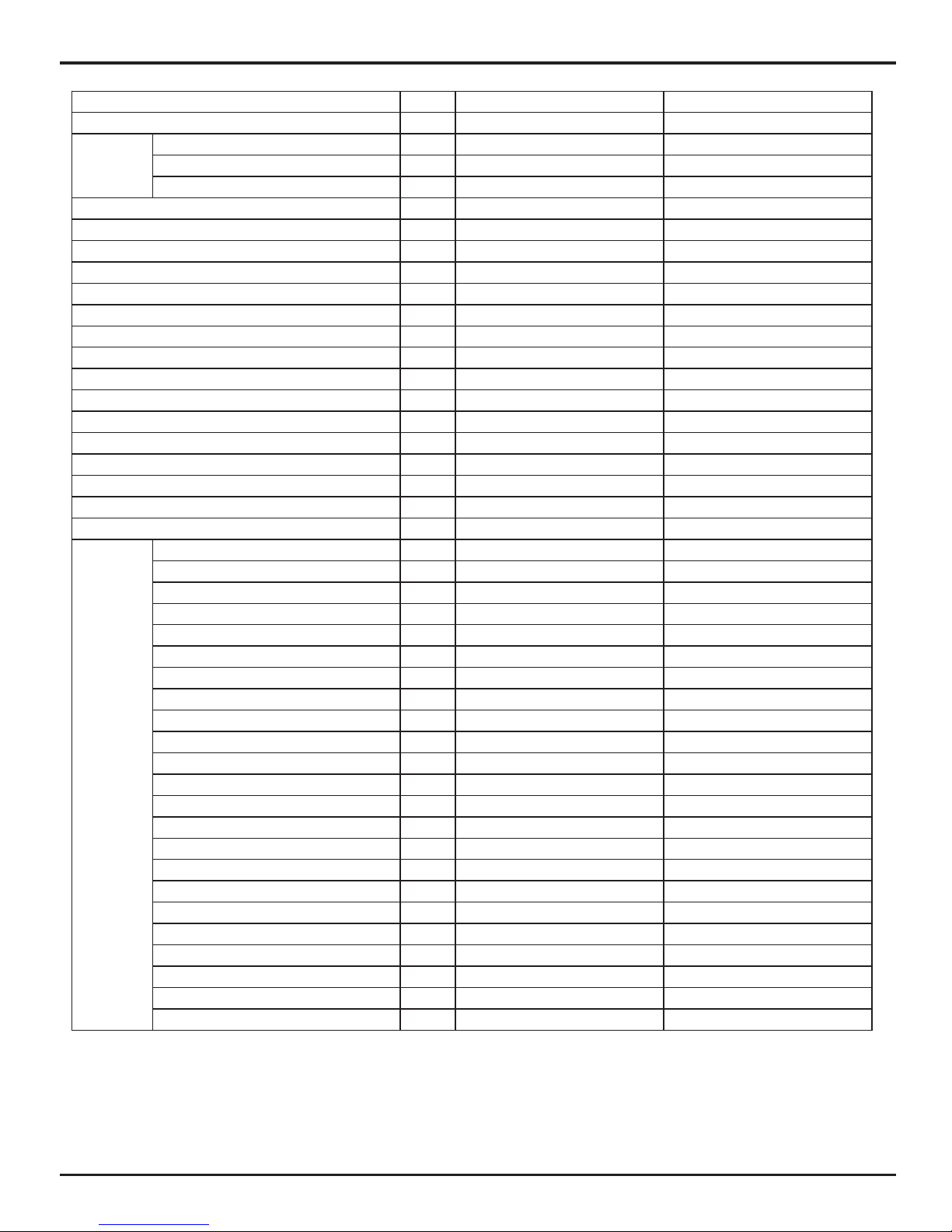

Model GWH24PD-K3NNA1A GWH24PD-K3NNA1A

Product Code CA414000201 CA414000202

Power

Supply

Rated Voltage V

~

220-240 220-240

Rated Frequency Hz 50 50

Phases 1 1

Power Supply Mode Indoor Indoor

Cooling Capacity W 6155 6155

Heating Capacity W 6500 6500

Cooling Power Input W 1900 1900

Heating Power Input W 1900 1900

Cooling Power Current A 8.5 8.5

Heating Power Current A 8.8 8.8

Rated Input W 2700 2700

Rated Current A 15.7 15.7

Air Flow Volume(SH/H/M/L/SL) m

3

/h 850/780/650/500/- 850/780/650/500/-

Dehumidifying Volume L/h 1.8 1.8

EER W/W 3.24 3.24

COP W/W 3.42 3.42

SEER W/W / /

HSPF W/W / /

Application Area m

2

23-34 23-34

Indoor Unit

Model of indoor unit GWH24PD-K3NNA1A/I GWH24PD-K3NNA1A/I

Fan Type Cross-ow Cross-ow

Diameter Length(DXL) mm Φ98X710 Φ98X710

Fan Motor Cooling Speed(SH/H/M/L/SL) r/min 1350/1200/1000/800/- 1350/1200/1000/800/-

Fan Motor Heating Speed(SH/H/M/L/SL) r/min 1420/1250/1100/950/- 1420/1250/1100/950/-

Output of Fan Motor W 20 20

Fan Motor RLA A 0.31 0.31

Fan Motor Capacitor μF 1.5 1.5

Input of Heater W / /

Evaporator Form Aluminum Fin-copper Tube Aluminum Fin-copper Tube

Pipe Diameter mm Φ7 Φ7

Row-n Gap mm 2-1.4 2-1.4

Coil Length (LXDXW) mm

715X25.4X304.8 715X25.4X304.8

Swing Motor Model MP28VB MP28VB

Output of Swing Motor W 2 2

Fuse A 3.15 3.15

Sound Pressure Level (SH/H/M/L/SL) dB (A) 45/42/37/33/- 45/42/37/33/-

Sound Power Level (SH/H/M/L/SL) dB (A) 55/52/47/43/- 55/52/47/43/-

Dimension (WXHXD) mm 945X298X200 945X298X200

Dimension of Carton Box (LXWXH) mm 1010X380X285 1010X380X285

Dimension of Package(LXWXH) mm 1013X383X300 1013X383X300

Net Weight kg 13 13

Gross Weight kg 17 17

6

Specications

The above data is subject to change without notice. Please refer to the nameplate of the unit.

Outdoor

Unit

Model of Outdoor Unit GWH24ND-K3NNB1A/O

Compressor Manufacturer/Trademark Shanghai Hitachi Electrical Appliances Co.,Ltd/Highly

Compressor Model ASH232SV-C8LU

Compressor Oil HAF68D1 or equivalent

Compressor Type Rotary

L.R.A. A 40

Compressor RLA A 8.8

Compressor Power Input W 1900

Overload Protector Internal

Throttling Method Capillary

Operation Temp ºC 18~30

Ambient Temp (Cooling) ºC 18~43

Ambient Temp (Heating) ºC -7~24

Condenser Form Aluminum Fin-copper Tube

Pipe Diameter mm Φ7

Rows-n Gap mm 2-1.4

Coil Length (LXDXW) mm 865X38.1X660

Fan Motor Speed rpm 780

Output of Fan Motor W 68

Fan Motor RLA A 0.75

Fan Motor Capacitor μF 3

Air Flow Volume of Outdoor Unit m

3

/h 2800

Fan Type Axial-ow

Fan Diameter mm Φ460

Defrosting Method Automatic Defrosting

Climate Type T1

Isolation I

Moisture Protection IP24

Permissible Excessive Operating

Pressure for the Discharge Side

MPa 4.3

Permissible Excessive Operating

Pressure for the Suction Side

MPa 2.5

Sound Pressure Level (H/M/L) dB (A) 56/-/-

Sound Power Level (H/M/L) dB (A) 66/-/-

Dimension (WXHXD) mm 913X378X680

Dimension of Carton Box (LXWXH) mm 997X431X740

Dimension of Package(LXWXH) mm 1000X434X755

Net Weight kg 46

Gross Weight kg 50

Refrigerant R410A

Refrigerant Charge kg 1.45

Connection

Pipe

Length m 4

Gas Additional Charge g/m 20

Outer Diameter Liquid Pipe mm Φ6

Outer Diameter Gas Pipe mm Φ12

Max Distance Height m 10

Max Distance Length m 25

7

Specications

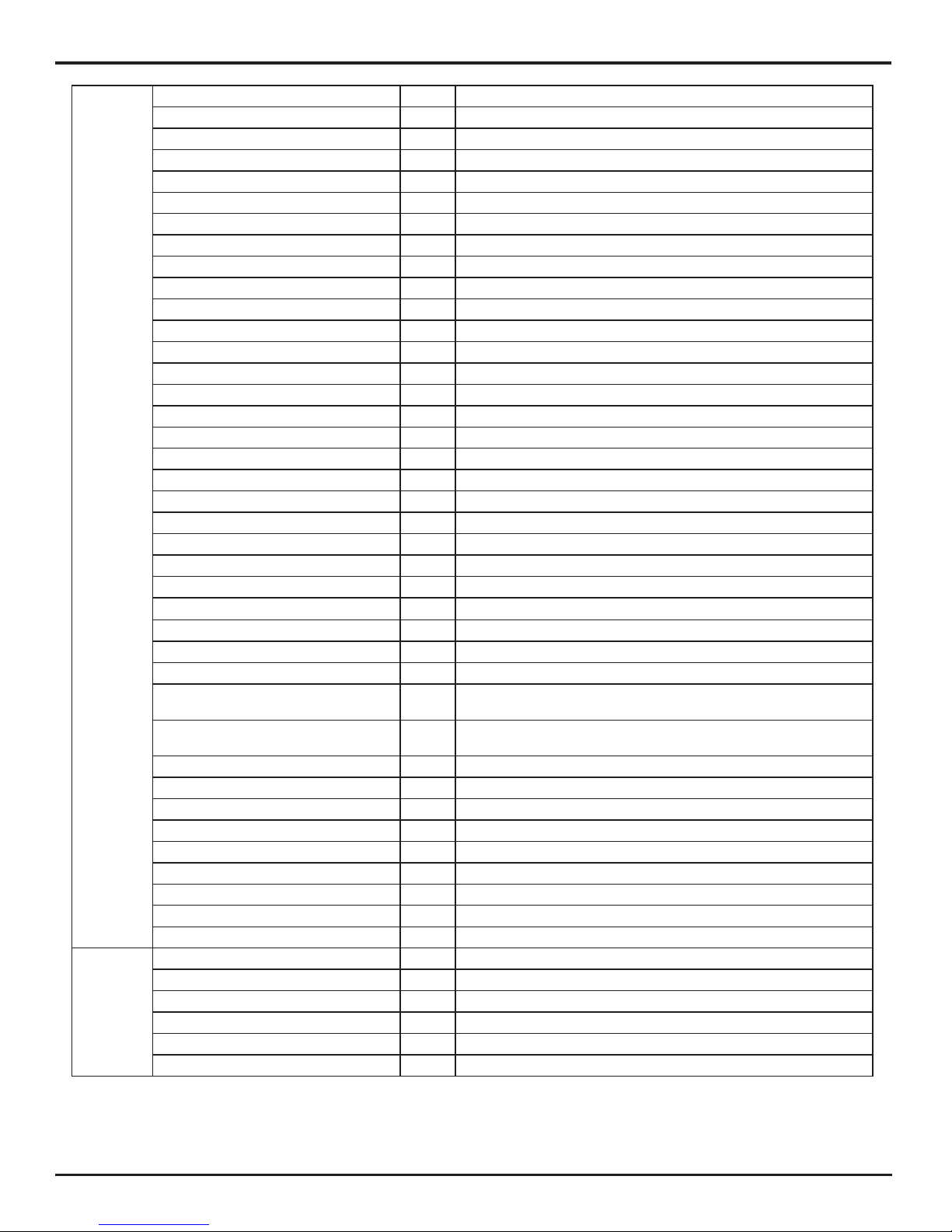

2.2 Capacity Variation Ratio According to Temperature

Cooling Heating

0

20

40

60

80

100

120

5 10

Outdoor t emp.( )

157-7-10 -5 0 2

Outdoor t emp.( )

4845434139373533312927252321

110

100

90

80

70

60

50

24

Condition Cooling

Indoor:DB27

WB19

Indoor air flow: Super High

Pipe length:4m or 5m

Condition Heating

Indoor:DB20

Indoor air flow: Super High

Pipe length:4m or 5m

Capacity ratio( )

%

Capacity ratio( )

%

2.3 Operation Data

Cooling

Temperature condition

(°C)

Model

name

Standard

pressure

Heat exchanger pipe temp.

Indoor fan

mode

Outdoor fan

mode

Indoor Outdoor P (MPa) T1 (°C) T2 (°C)

27/19 35/24

18K 0.8~0.9 in:8~11 out:11~12 in:75~85 out:37~43

Super High High

24K 0.8~1.0 in:8~11 out:11~14 in:75~85 out:36~43

NOTES :

(1) T1: Inlet and outlet pipe temperature of evaporator

T2: Inlet and outlet pipe temperature of condenser

P: Pressure of air pipe connecting indoor and outdoor units(on the side of gas pipe)

(2) Measure surface temperature of heat exchanger pipe around center of heat exchanger path U bent.(The rmistor the mometer)

(3) Connecting piping condition : 4m or 5m

Heating

Temperature condition

(°C)

Model

name

Standard

pressure

Heat exchanger pipe temp.

Indoor fan

mode

Outdoor fan

mode

Indoor Outdoor P (MPa) T1 (°C) T2 (°C)

20/- 7/6

18K 2.7~2.9 in:75~85 out:37~43 in:1~3 out:3~4

Super High High

24K 2.6~3.0 in:75~85 out:36~43 in:1~3 out:3~4

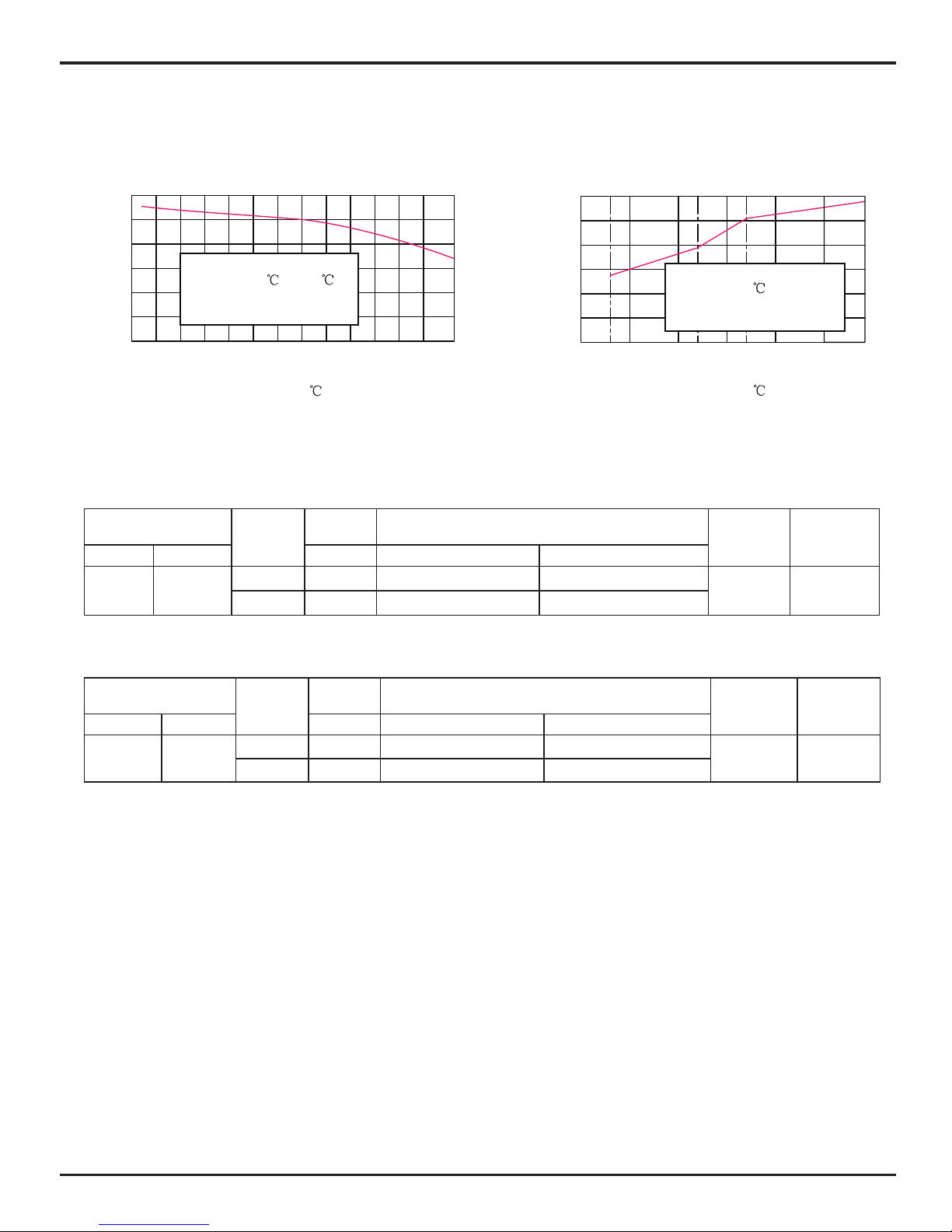

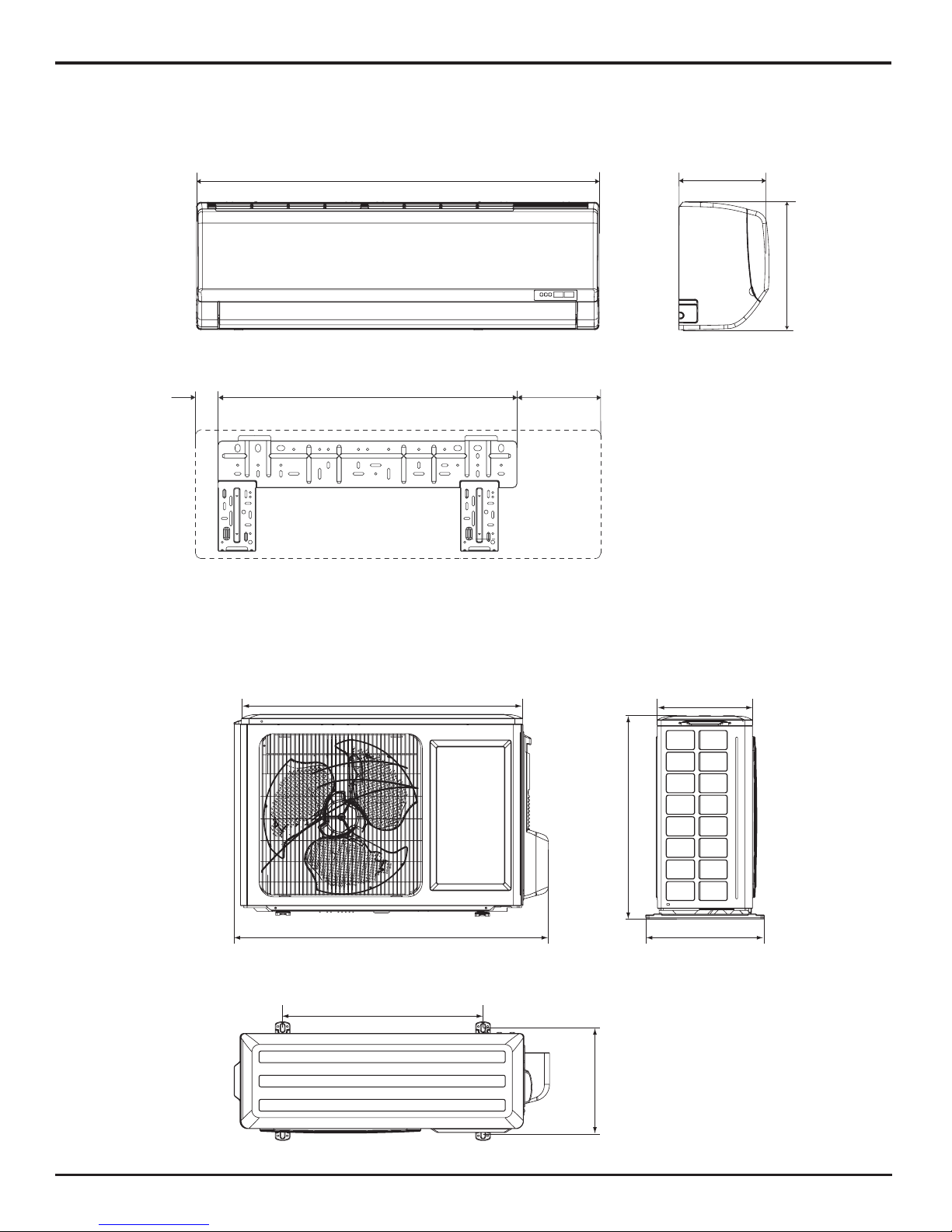

Construction Views

8

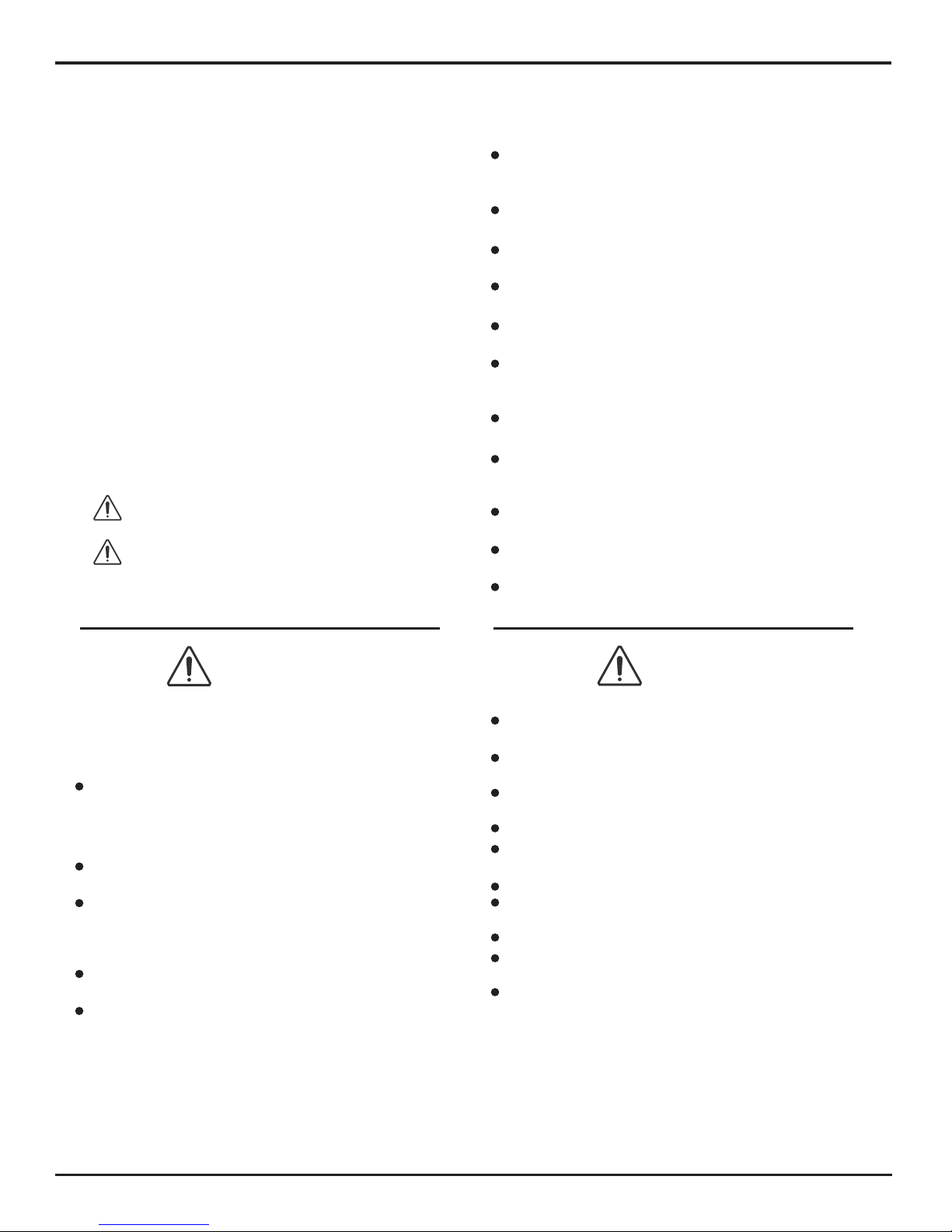

3. Construction Views

3.1 Indoor Unit

3.2 Outdoor Unit

848

257

540

286

320

762

540

694

945

200

298

194

57

Unit: mm

Unit: mm

18K

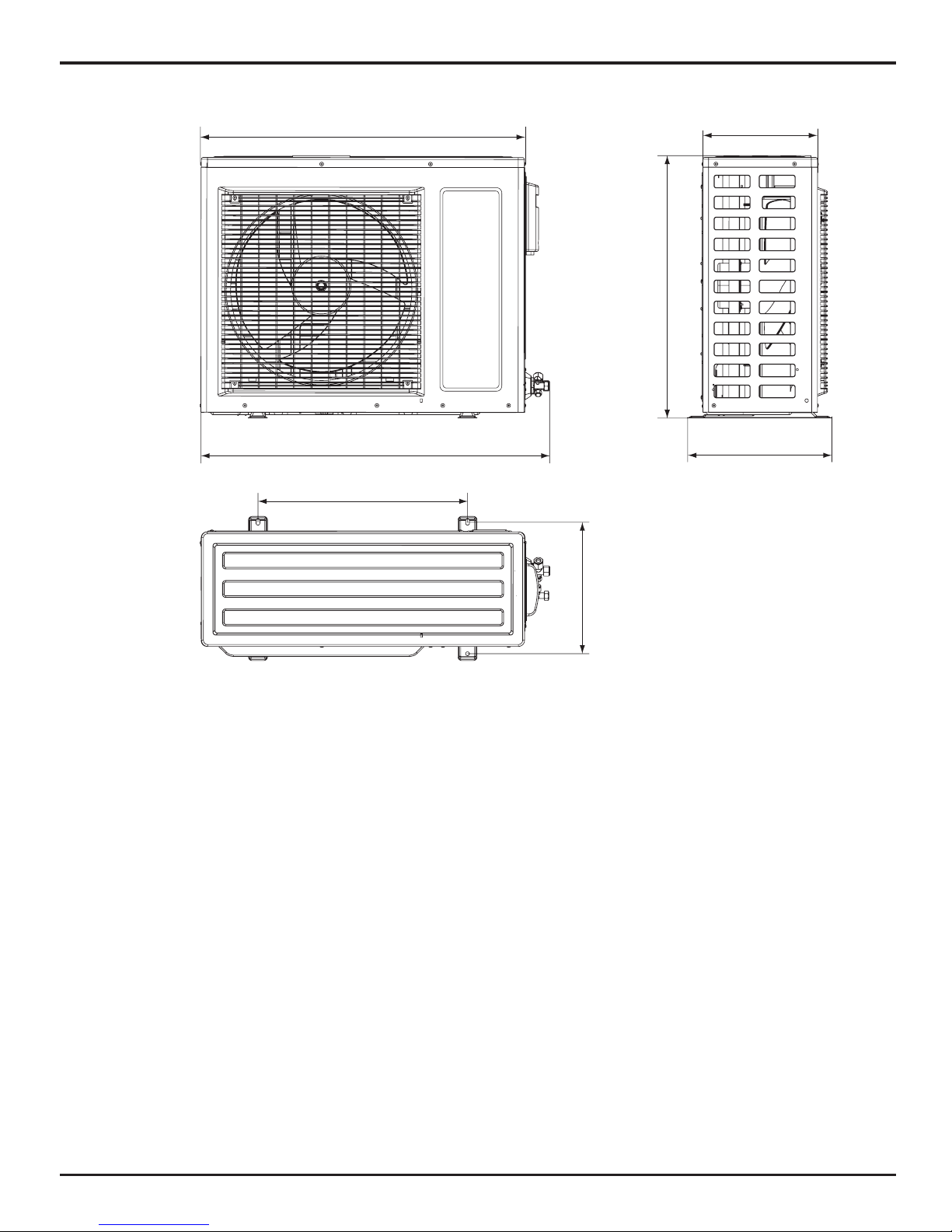

9

Construction Views

24K

847

300

913

680

378

549

348

Unit: mm

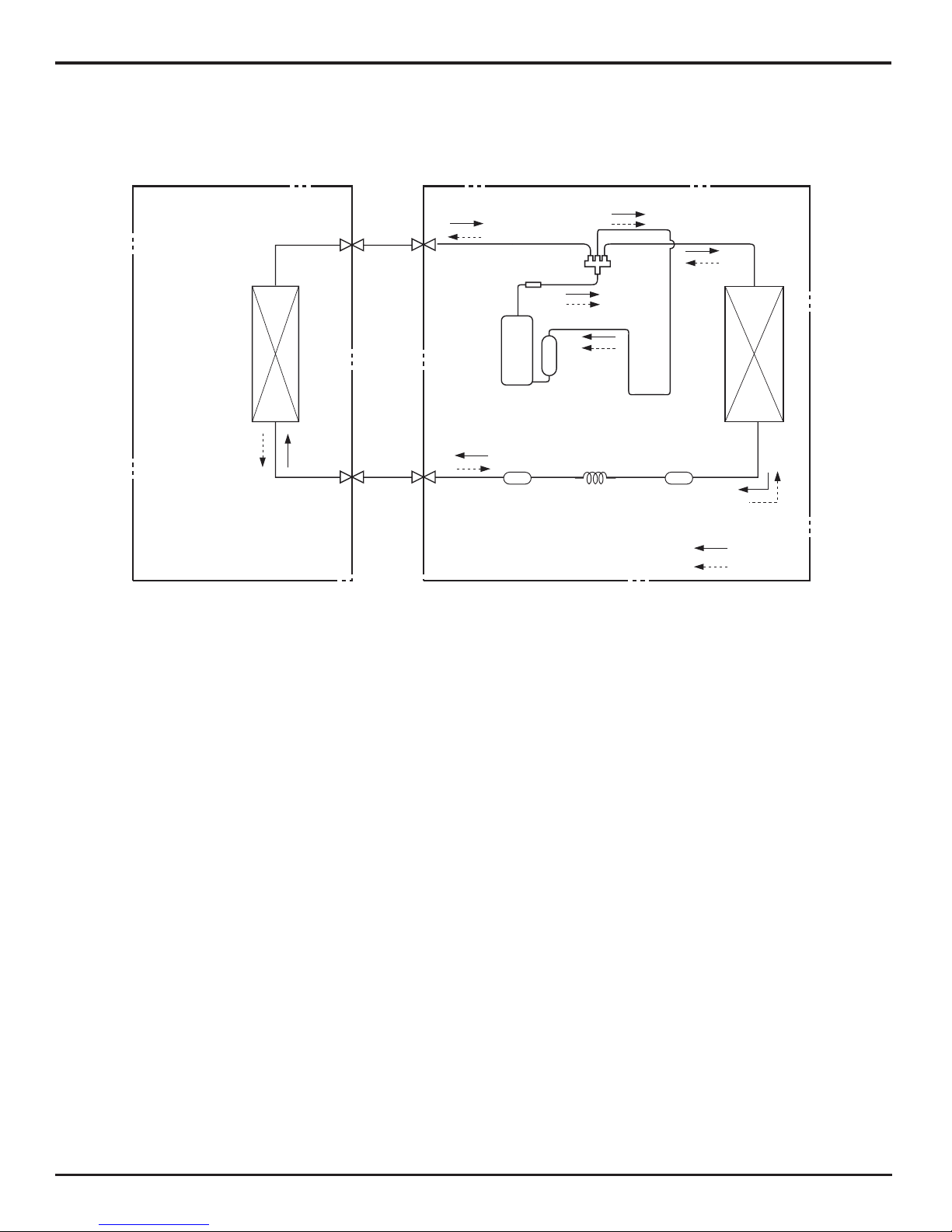

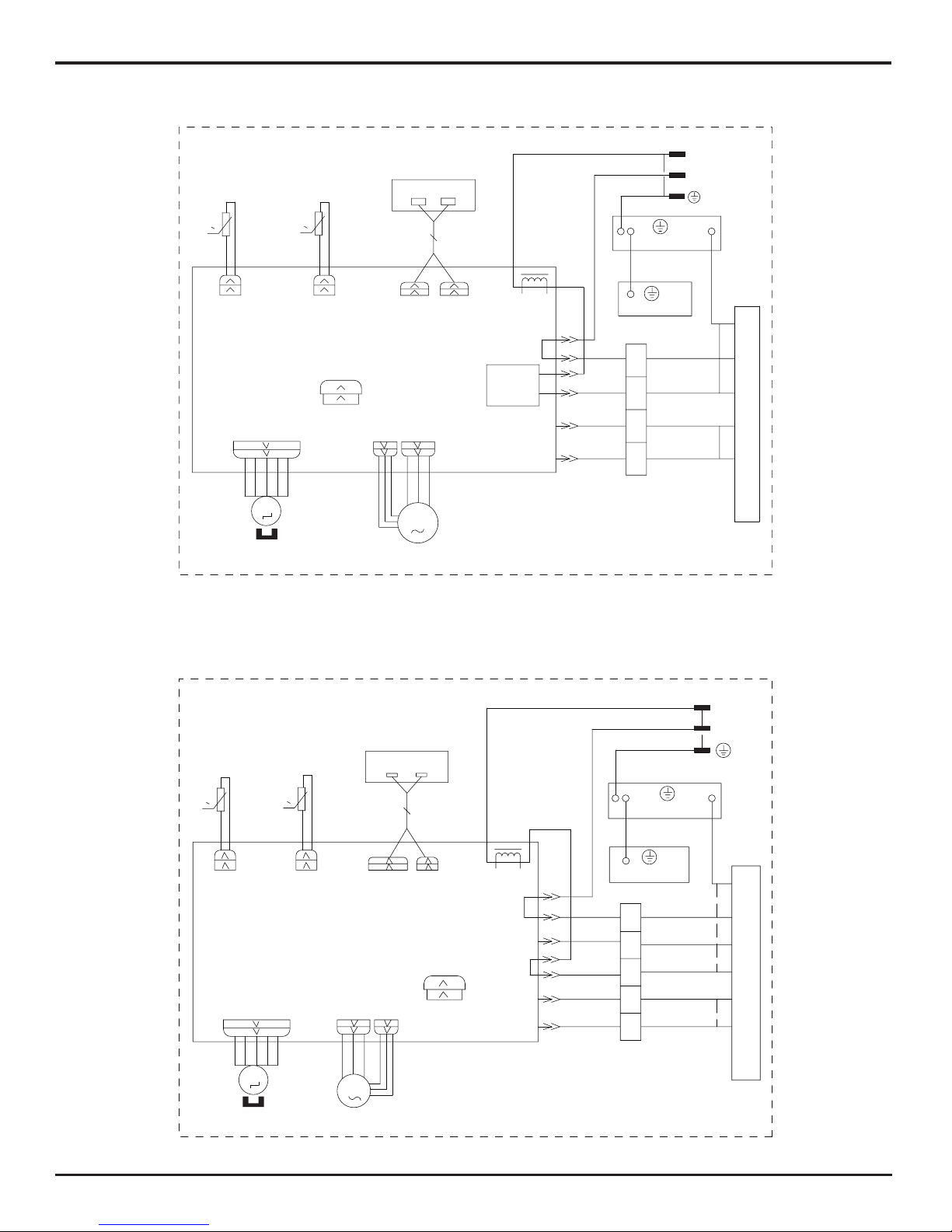

Refrigerant System Diagram

10

4. Refrigerant System Diagram

Refrigerant pipe diameter

Liquid : 1/4" (6 mm)

Gas : 1/2" (12mm)

TINU ROODTUOTINU ROODNI

HEAT

EXCHANGE

(EVAPORATOR)

HEAT

EXCHANGE

(CONDENSER)

COMPRESSOR

GAS SIDE

3-WAY VALVE

LIQUID SIDE

2-WAY VALVE

COOLING

HEATING

Accumlator

Discharge

Suction

Muffler

4-Way valve

Capillary reniartSreniartS

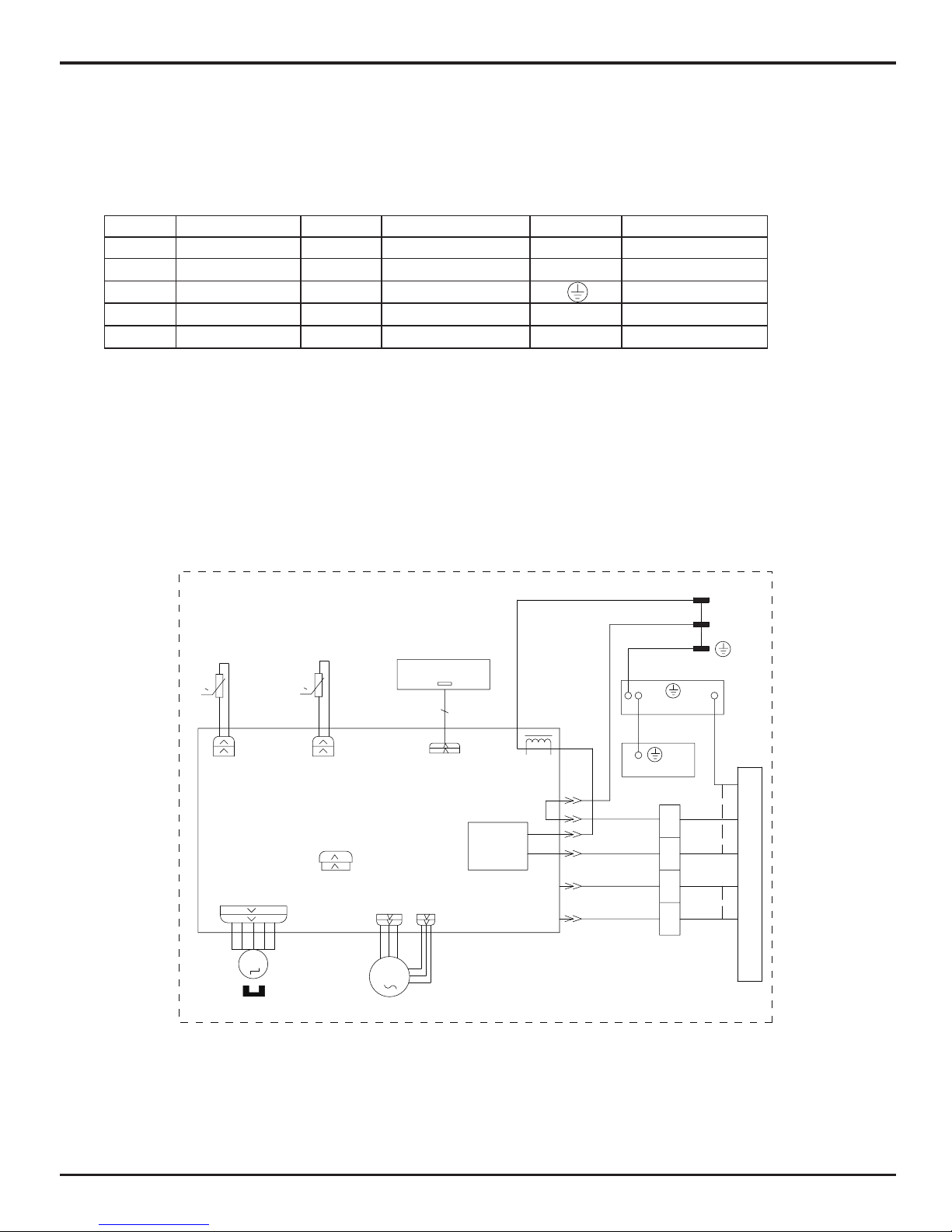

11

Schematic Diagram

5. Schematic Diagram

5.1 Electrical Data

Meaning of marks

5.2 Electrical Wiring

Symbol Color symbol Symbol Color symbol Symbol Parts name

WH WHITE GN GREEN SAT OVERLOAD

YE

YELLOW

BN

BROWN COMP COMPRESSOR

RD

RED

BU

BLUE PROTECTIVE EARTH

YEGN

YELLOW GREEN

BK

BLACK

/ /

VT VIOLET

OG ORANGE

/ /

● Indoor Unit

GWH18PD-K3NNA1A/I(CA414N00100)

COMP

L(AC-L)

DISP1

AP1

DISPLAY BOARD

RECEIVER AND

AP1 PRINTED CIRCUIT BOARD

JUMP

CAP

M1

PG

PGF

FAN MOTOR

BU

BK

VT

OG

YEGN

YEGN

EVAPORATOR

PE

PE

EARTH-PLATE

N1

BU

BK

XT

4V

OFAN

VT

OG

K1

5

4

2

N(1)

M2

OUTDOOR UNIT

ROOM

RT2

RT1

TUBE

SENSOR

SENSOR

ROOM TEMP.

TUBE TEMP.

L101

BLOCK

TERMINAL

YEGN(GN)

BU(WH)

BN(BK)

POWER

STEPPING MOTOR

SWING-UD

(SWING)

0

0

L

N

12

Schematic Diagram

GWH18PD-K3NNA1A/I(CA414N00101)

GWH24PD-K3NNA1A/I(CA414N00201)

L(4)

COMP(3)

BU

BK

VT

OG

POWER

EVAPORATOR

PE

PE

EARTH-PLATE

BU

BK

XT

VT

OG

5

4

2

N(1)

OUTDOOR UNIT

CAP

JUMP

AP1 PRINTED CIRCUIT BOARD

RT2

RT1

AP2

BU(WH)

BN(BK)

YEGN(GN)

CABLE

CONNECTING

TEMP.ROOM

SENSOR

YEGNYEGN

BLOCK

TERMINAL

TEMP.TUBE

SENSOR

M1

PGF

PG

FAN MOTOR

DISPLAY BOARD

RECEIVER AND

DISP1

DISP2

TUBE

ROOM

L101

M2

(SWING)

SWING-UD

STEPPING MOTOR

N1

4V

OFAN

K1

DISPLAY

0

0

N

L

DISPLAY

VT

BN

COMP

OG

BN

BK

BU

3

OG

VT

YEGN

YEGN

EVAPORATOR

PE

PE

EARTH-PLATE

OFAN

4V

5

4

XT

2

N(1)

OUTDOOR UNIT

CAP

JUMP

AP1 PRINTED CIRCUIT BOARD

ROOM

RT2

RT1

TUBE

SENSOR

SENSOR

ROOM

TUBE

BN(BK)

BU(WH)

L

BK

BU

N

YEGN(GN)

N1

L101

RECEIVER AND

DISPLAY BOARD

DISP2

AP2

DISP1

CABLE

TERMINAL

BLOCK

CONNECTING

POWER

TEMP.

TEMP.

M2

SWING-UD

STEPPING MOTOR

(SWING)

M1

FAN MOTOR

PG

PGF

L(AC-L)

0

0

13

Schematic Diagram

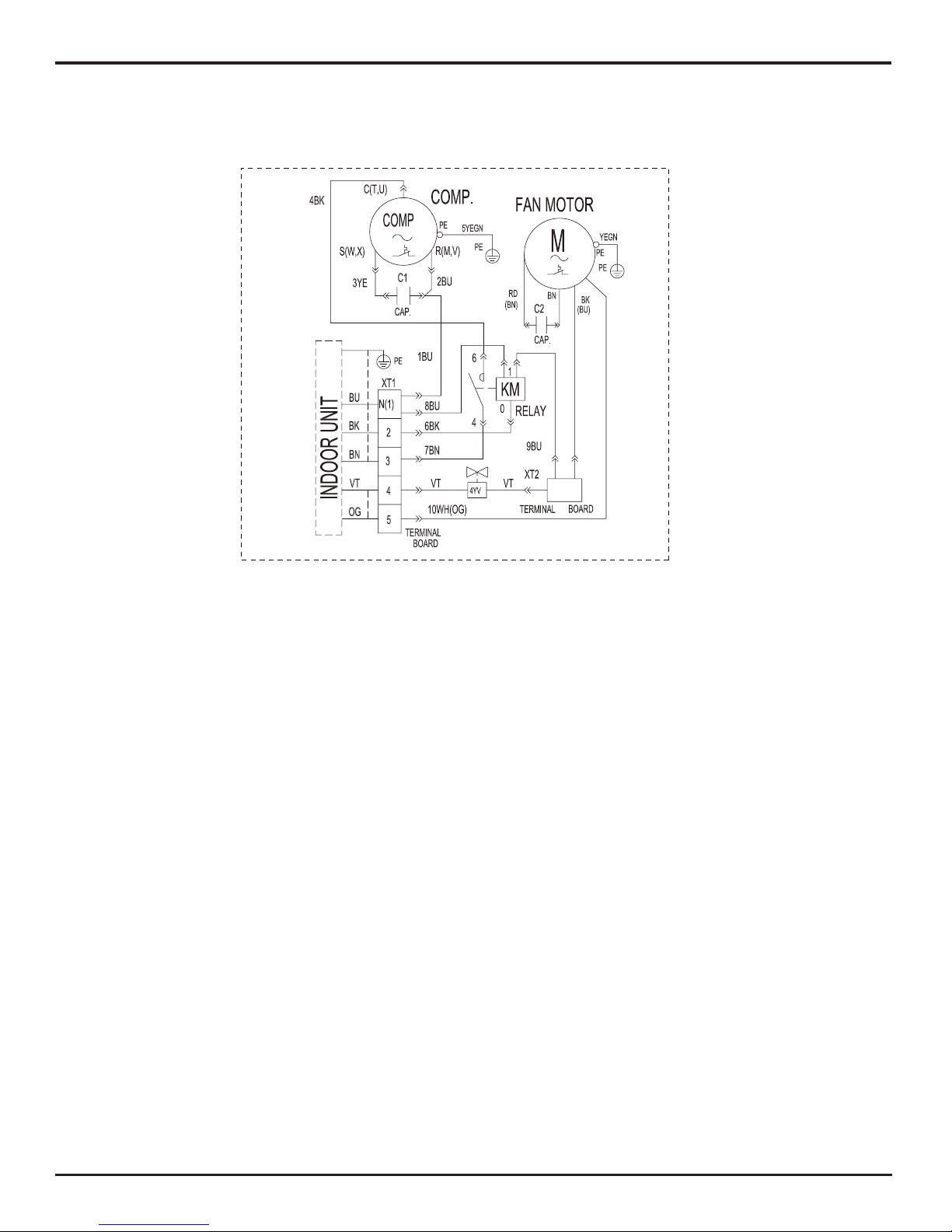

● Outdoor Unit

GWH24PD-K3NNA1A/I(CA414N00200)

GWH18PD-K3NNA1A/O

0

0

DISP1

AP1

DISPLAY BOARD

L101

N1

YEGN(GN)

BU

BK

BU(WH)

BN(BK)

POWER

TUBE TEMP.

ROOM TEMP.

SENSOR

SENSOR

TUBE

RT1

RT2

ROOM

AP1 PRINTED CIRCUIT BOARD

JUMP

CAP

OUTDOOR UNIT

N(1)

2

XT

4

5

4V

OFAN

EARTH-PLATE

PE

PE

EVAPORATOR

YEGN

YEGN

VT

OG

3

BU

BK

BN

OG

COMP

BN

VT

L

PGF

PG

M1

STEPPING MOTOR

M2

FAN MOTOR

RECEIVER AND

BLOCK

TERMINAL

CONNECTING

CABLE

SWING-UD

(SWING)

N

L

14

Schematic Diagram

These circuit diagrams are subject to change without notice, please refer to the one supplied with the unit.

GWH24ND-K3NNB1A/O

YEGN

15

Schematic Diagram

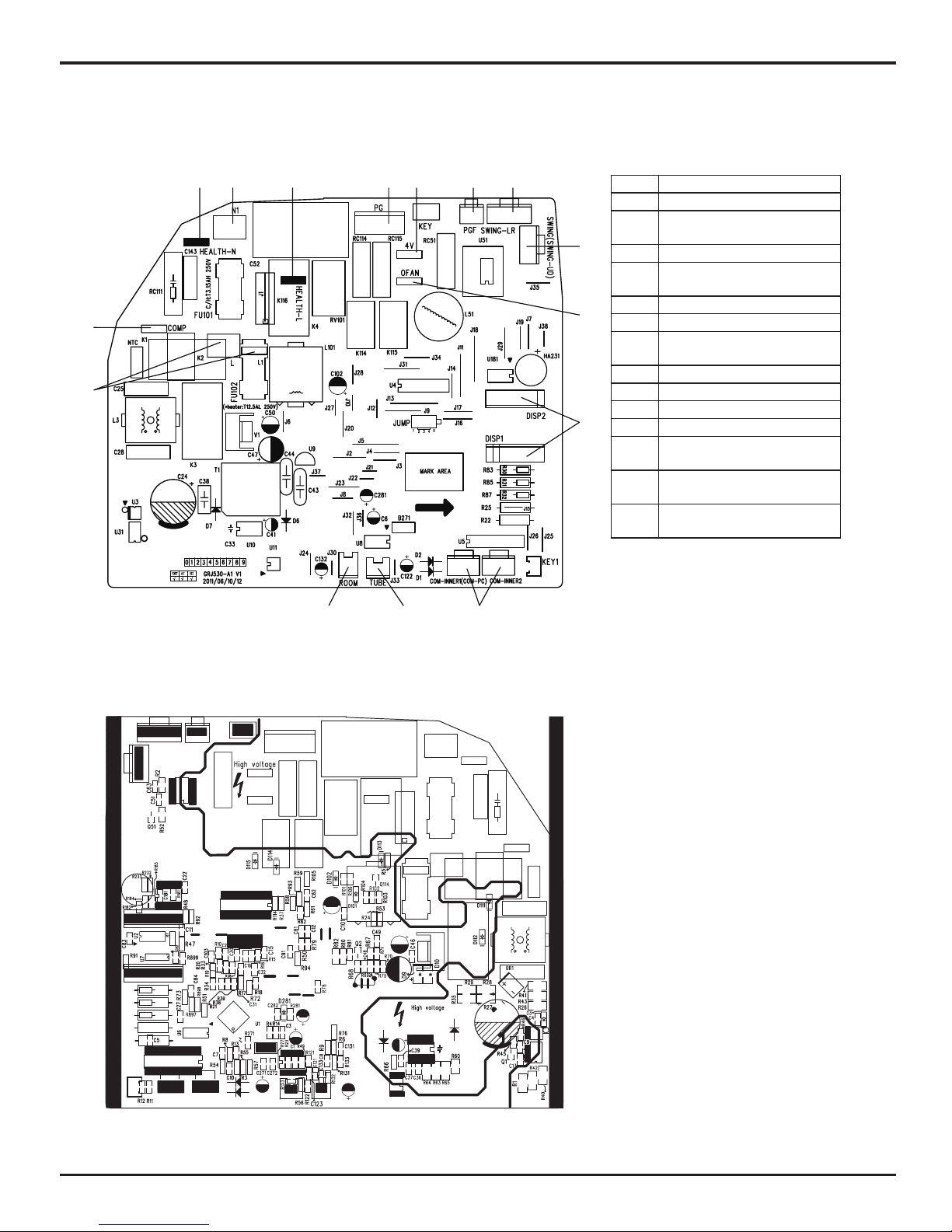

5.3 Printed Circuit Board

●TOP VIEW

●BOTTOM VIEW

1

2

3 4 5 6 7 8 9

10

11

12

131415

1 Interface of live wire

2 Interface of compressor

3

Interface of neutral wire for

health function

4 Interface of neutral wire

5

Interface of live wire for

health function

6 Control terminal of PG motor

7 Interface of 4-way valve

8

Feedback interface of PG

motor

9 Left&right swing

10 Up&down swing

11 Interface of outdoor fan

12 Display interface

13

Interface of remote control

motor

14

Interface of indoor tube

temperature sensor

15

Interface of indoor ambient

temperature sensor

Function and Control

16

6. Function and Control

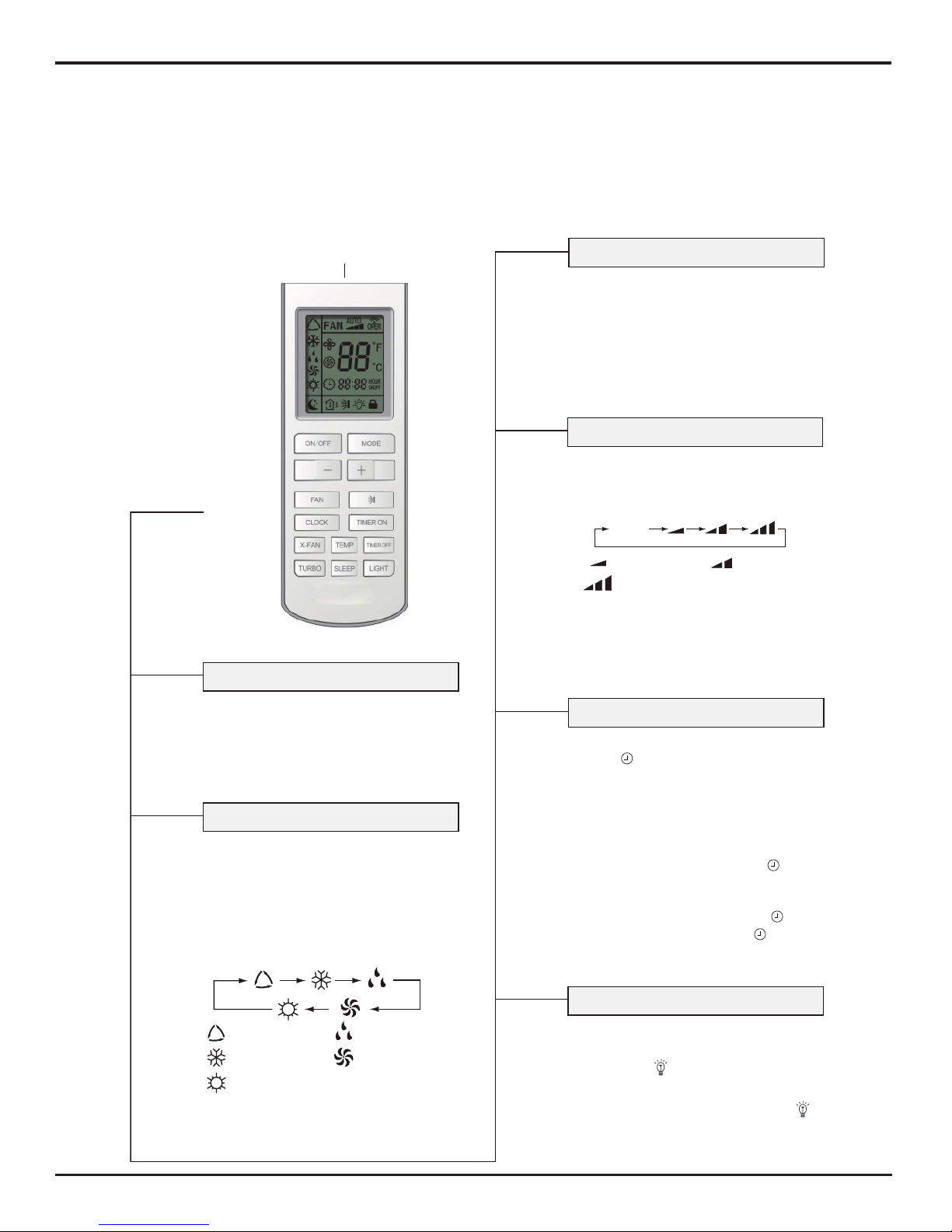

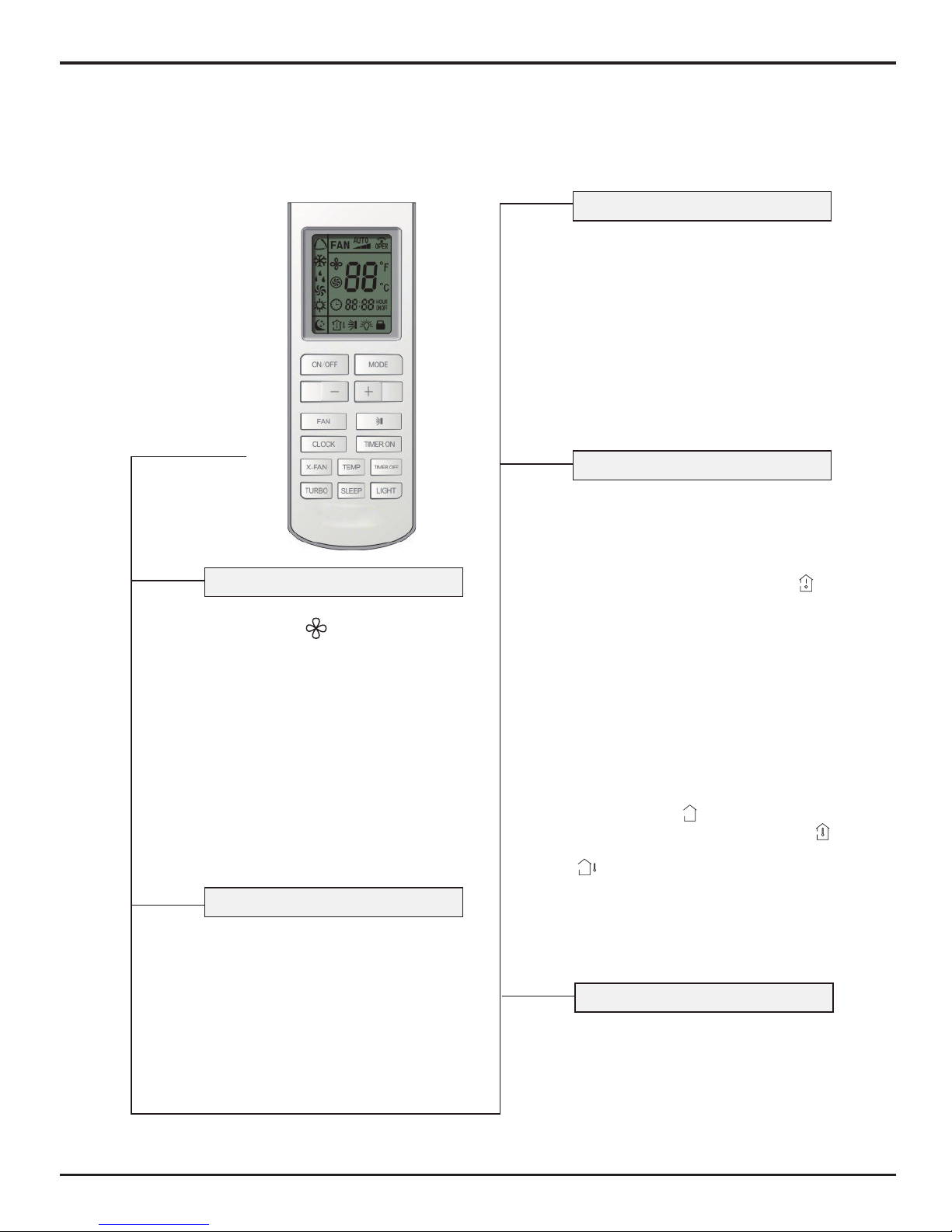

6.1 Remote Controller Description

●

Press thisbutton to select LIGHT on or off

in the displayer. When the LIGHT on is

LIGHT button

LIGHT

set,the icon will be displayed and the

indicator light in the displayer will be on.

When the LIGHT off is set, the icon will

be displayed and the indicator light in

the displayer will be off.

●

ON/OFF button

ON/OFF

Remote control

Signal transmitter

AUTO

COOL

DRY

FAN

HEAT

(Only for cooling and heating unit.

As for cooling only unit, it won’t

have any action when it receives

the signal of heating operation.)

Middle fan

●

Press this button, Auto, Cool, Dry, Fan,

Heat mode can be selected circularly.

MODE button

MODE

Auto mode is default while power on.

Under Auto mode, the temperature will not

eht ,edom taeH rednU ;deyalpsid eb

initial value is 28ć

;Under other

modes,

the initial value is 25ć .

●

Press this button, Sleep On and Sleep

Off can be selected. After powered on,Sleep

SLEEP button

SLEEP

Off is defaulted. After the unit is turned

off, the Sleep function is canceled. After

Sleep function set up, the signal of Sleep

will di splay. In this mode, the time of timer

can be adjusted. Under Fan and Auto

modes, this function is not available.

●

Press this button, Auto, Low, Middle, High

sp eed can be c i rc ul arl y se l ecte d. Aft er

FAN button

FAN

powered on,Auto fan speed is default.

Low fan

AUTO

High fan

●

Press this button, the clock can b e set up,

signal blink and display.Within 5

CLOCK button

CLOCK

seconds, the value can be adjusted by

pressing + or - button, if continuously

press this button for 2 seconds above,

in every 0.5 sec onds, the value on ten place

of Minute will be increase d 1. During blin king,

repress the Clock button, signal will be

constantly displayed and it denotes the

sett ing succeeded. After powered on, 12:0 0

is defaulted to display and signal will

be displayed. If there is signal be

value is Clock value, otherwise is Timer value.

displayed t hat denotes the current time

(

o

F)

82

(

o

F)

77

Press this button, the unit will be turned on,

press it once more, the unit will be turned

off. When turning on or turning off the unit,

the Timer, Sleep function will be canceled,

but the presetting time is still remained.

adjustable, low fan speed is imperative,

Note:Under the Dry mode, the fan speed isn't

adjustable, low fan speed is imperative,

but wh en op erating this bu tt on, the wireless

Names and Functions of Wireless Remote Control

Note: Be sure that there are no obstructions between receiver and remote controller ;Don't drop or throw the remote control; Don't let

any liquid in the remote control and put the remote control directly under the sunlight or any place where is very hot.

Function and Control

17

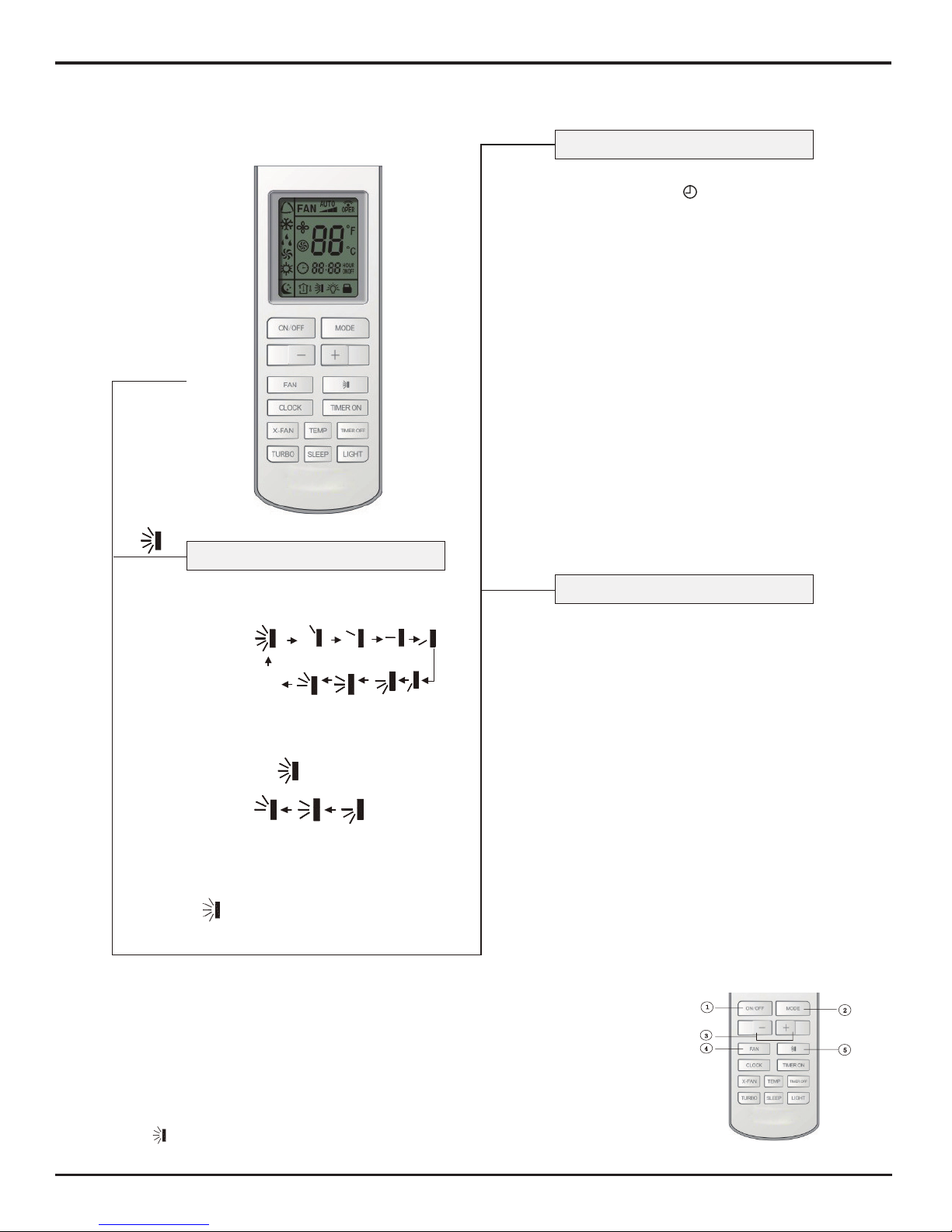

Remote control

●

X-FAN button

X-FAN

●

TURBO button

TURBO

●

+ button

+

● Presetting temperature can be decreased.

Press this button, the temperature can be

- button

-

set up, continuously press this button

and hold for two seconds, the relative

contents can quickly change, until unhold

this button and send the order that theć

(

o

F) signal will be displayed all the time.

The temperature adjustment is unavailable under the Auto mode, but the order

can be sent by if pressing this button.

In Cool or Heat mode, press this button

can turn on or turn off the Turbo function.

After turned on the Turbo function, its

signal will be displayed. When switching

the mode or changing fan speed, this

function will be canceled automatically.

For presetting temperature increasing.

Press this button,can set up the temperature,

when unit is on. Continuously press and

hold this button for more than 2 seconds,

the corresponding contents will be

changed rapidly, until unpress the button

ć˄˅

llaying all along. In Auto mode, the temp-

erature can not be set up, but operate this

button can send the signal. Centigrade

setting range:16-30; Fahrenheit scale

setting range 61-86.

then send the information, is disp-

TEMP button

TEMP

●

Press this button, could select displaying

the indoor setting temperature or indoor

ambient temperature.When the indoor unit

firstly power on it will display the setting

temperature, if the temperature's displaying

," "ot sutats rehto morf degnahc si sutats

displays the ambient temperature, 5s later

or within 5s, it receives other remote control

signal that will return to display the setting

temperature. if the users haven't set up the

temperature displaying status,that will

display the setting temperature.

●

After powered on, the setting temperature

displaying is defaulted, (according to

customers requirements to display, if

there is no requirement that will default

to display the presetting temperature

and there is no icon displayed on wireless

remote control). Press this button,

(When displaying ), will display

presetting temperature; (when displaying )

will display indoor ambient temperature,

current displaying status will not be

changed. If current displays indoor

ambient temperature, if received the other

remote control signal, it will display

presetting temperature, 5s later, will back

to display the ambient temperature.

(This function is applicable to partial ofmodels)

(This function is applicable to partial of models)

PressingX-FAN button in COOL or DRY

mode,the icon

After energization, X-FAN OFF is defaulted.

X-FAN is not available in AUTO,FAN or

HEAT mode.

is displayed and the

indoor fan will continue operation for

10 minutes in order to dry the indoor unit

even though you have turned off the unit.

Notice: This is a general use remote controller, it could be used for the air conditioners with multifunction; For some function, which the

model dosen't have, if press the corresponding button on the remote controller that the unit will keep the original running status.

Function and Control

18

OFF

This is an universal use remote controller. If

remote controller sends the following three

kinds of status that the swing status of main

unit will be:

When the guide louver start to swing up and

down, if turn off the Swing, the air guide louver

will stop at current position.

which indicates the guide louver swings up

and down between that all five positions.

●

Press this button, to set up swing angle,

which circularly changes as below:

SWING UP AND DOWN BUTTON

TIMER ON

TIMER ON BUTTON

Timer On setting: Signal “ON” will blink

and display, signal will conceal, the

numerical section will become the timer

on setting status. During 5 seconds blink,

by pressing + or - button to adjust the

time value of numerical section, every

press of that button, the value will be

increased or decreased 1 minute. Hold

pressing + or -button, 2 seconds later,

it quickly change, the way of change is:

During the initial 2.5 seconds, ten numbers

change in the one place of minute, then

the one place is constant, ten numbers

change in the tens place of minute at 2.5

seconds speed and carry. During 5s blink,

press the Timer button, the timer setting

succeeds. The Timer On has been set up,

repress the timer On button, the Timer

On will be canceled. Before setting the

Timer, please adjust the Clock to the

current actual time.

TIMER OFF BUTTON

Once press this key to enter into

TIMER OFF setup, in which case

the TIMER OFF icon will blink.

The method of setting is the same

as for TIMER ON.

TIMER OFF

●

Remote control

●

Notice: This is a general use remote controller, it could be used for the air conditioners with multifunction; For some function, which the

model dosen't have, if press the corresponding button on the remote controller that the unit will keep the original running status.

Guide for Operation - General Operation

1. After powered on, press ON/OFF button, the unit will start to run. (Note: When it is powered

on, the guide louver of main unit will close automatically.)

2. Press MODE button, select desired running mode.

3. Pressing + or - button, to set the desired temperature. (It is unnecessary to set the temp. at

AUTO mode.)

4. Pressing FAN button, set fan speed, can select AUTO FAN, LOW, MID and HIGH.

5. Pressing button, to select the swing.

Loading...

Loading...