Gree GWH12TB-D3DNA1A, GWH09TB-D3DNA1A, GWH18TC-D3DNA1A, GWH24TD- D3DNA1A Installation, Service & Troubleshooting

DUCTLESS HEAT PUMP

Installation, Service & Troubleshooting

Models:

GWH09TB-D3DNA1A

GWH12TB-D3DNA1A

GWH18TC-D3DNA1A

GWH24TD- D3DNA1A

Table of Contents

Safety Precautions & Warnings.........................................................................................................................

Model Number Identi cation............................................................................................................................

Physical & Electrical Data.................................................................................................................................

Product Introduction (System Overview)......................................................................................................

Product Introduction (Refrigeration Cycles).................................................................................................

Indoor & Outdoor Components.......................................................................................................................

Operational Data................................................................................................................................................

Basic Functions 9,000/12,000 btuh Systems....................................................................................................

Basic Functions 18,000/24,000 btuh Systems..................................................................................................

Remote Control Operation................................................................................................................................

Refrigerant Lines, Connection, Evacuating and Charging............................................................................

3

4

5 - 6

7

8 - 9

10 - 11

12 - 16

17 - 26

27 - 37

38 - 39

40 - 42

Installation...........................................................................................................................................................

Filter Maintenance and Emergency Operation..............................................................................................

Electrical Schematics..........................................................................................................................................

Troubleshooting Outdoor Components..........................................................................................................

Fault & Status Displays.......................................................................................................................................

Error Code Diagnostics......................................................................................................................................

Disassembly of Indoor Unit 9,000/12,000 btuh Models................................................................................

Disassembly of Indoor Unit18,000 btuh Model..............................................................................................

Disassembly of Indoor Unit24,000 btuh Model..............................................................................................

Disassembly of Outdoor Unit 9,000/12,000 btuh Models..............................................................................

Disassembly of Outdoor Unit 18,000 btuh Models........................................................................................

43 - 47

48

49 - 56

57 - 62

63 - 70

71 - 89

90 - 97

98 - 105

106 - 112

113 - 115

116 - 118

Disassembly of Outdoor Unit 24,000 btuh Models........................................................................................

Appendix 1 - 3 Temperature Sensor Resistance Tables..................................................................................

2

119 - 122

123 - 128

Safety Precautions & Warnings

!

Installing, starting up, and servicing air conditioner can be

hazardous due to system pressure, electrical components,

and equipment location, etc. Only trained, quali• ed

installers and service personnel are allowed to install, startup, and service this equipment. Untrained personnel can

perform basic maintenance functions such as cleaning

coils. All other operations should be performed by trained

service personnel. When handling the equipment, observe

precautions in the manual and on tags, stickers, and labels

attached to the equipment. Follow all safety codes. Wear

safety glasses and work gloves. Keep quenching cloth and

• re extinguisher nearby when brazing. Read the instructions

thoroughly and follow all warnings or cautions in literature

and attached to the unit. Consult local building codes and

current editions of national as well as local electrical codes.

Recognize the following safety information:

Warning: Incorrect handling could result in

!

personal injury or death.

Caution: Incorrect handling may result in minor

!

injury, or damage to product or property.

Warning

!

• Never install the unit in a place where a combustible

gas might leak, or it may lead to • re or explosion.

• Make a proper provision against noise when the unit is

installed at a telecommunication center or hospital.

• Provide a GFIC circuit when the local or national

electric code requires it.

• Never wash the unit with water.

• Handle unit transportation with care. Use two people

when the weight exceeds the capacity for one person.

• Never touch the heat exchanger • ns with bare hands,

sharp edges could cause personal injury.

• Never touch the compressor or refrigerant tubing

without proper hand protection.

• Do not operate th unit without the air • lters in place.

• Should any emergency occur, stop the unit and

disconnect the electrical supply.

• Properly insulate tubing running inside the room to

prevent water damage from condensation.

!

All installation or repair work shall be performed by your

dealer or a specialized subcontractor as there is the risk of

• re, electric shock, explosion or injury

Caution

Warning

!

Warning

All electrical work must be performed by a quali ed,

licensed electrician according to local and national

codes as well mas the instructions provided in the

manual.

• Before installing, modifying, or servicing the

system, the main electrical disconnect must be o .

ere may be more than one disconnect switch.

Lock out and tag switch with a suitable warning

label.

• Never supply power to the unit unless all wiring and tubing are completed, reconnected and

checked.

• is system adopts highly dangerous electrical

voltage. Incorrect connections or inadequate

grounding can cause personal injury or death.

Refer to your local and national codes for proper

grounding.

• Have the unit properly grounded with all connections tight. Loose connections can cause overheating and a possible re hazard.

!

Warning

Pressurized Refrigerant

Personal injury could result in failure to follow this warning.

System contain oil and refrigerant under high pressure,

proper refrigerant handling techniques should be

completed by a quali• ed technician.

!

Warning

Live Electrical Components

Personal injury, property damage, or death could result in

failure to follow this warning.

Follow all electrical precautions when servicing this

system, it may be necessary to service or troubleshoot with

live electrical circuits. All work should be completed by a

quali• ed technician.

3

Safety Considerations & Warnings

G W H 24 TB - D 3 D N A 1 A/I

Gree

Wall Mount

C = Cooling Only

H = Heat Pump

Nominal Capacity

09 = 9,000 BTUH

12 = 12,000 BTUH

18 = 18,000 BTUH

24 = 24,000 BTUH

30 = 30,000 BTUH

36 = 36,000 BTUH

42 = 42,000 BTUH

48 = 48,000 BTUH

Product Series

TERRA - TB/TC/YD

EVO+ - AB/AC

NEO - MA/MA/MA/MA/LB

RIO - KF/KG

A = 110v

D = 208/230v

R410a

DC Inverter

T1

Panel No.

Revision No.

I = Indoor Unit

O = Outdoor Unit

Model Number Identi cation

4

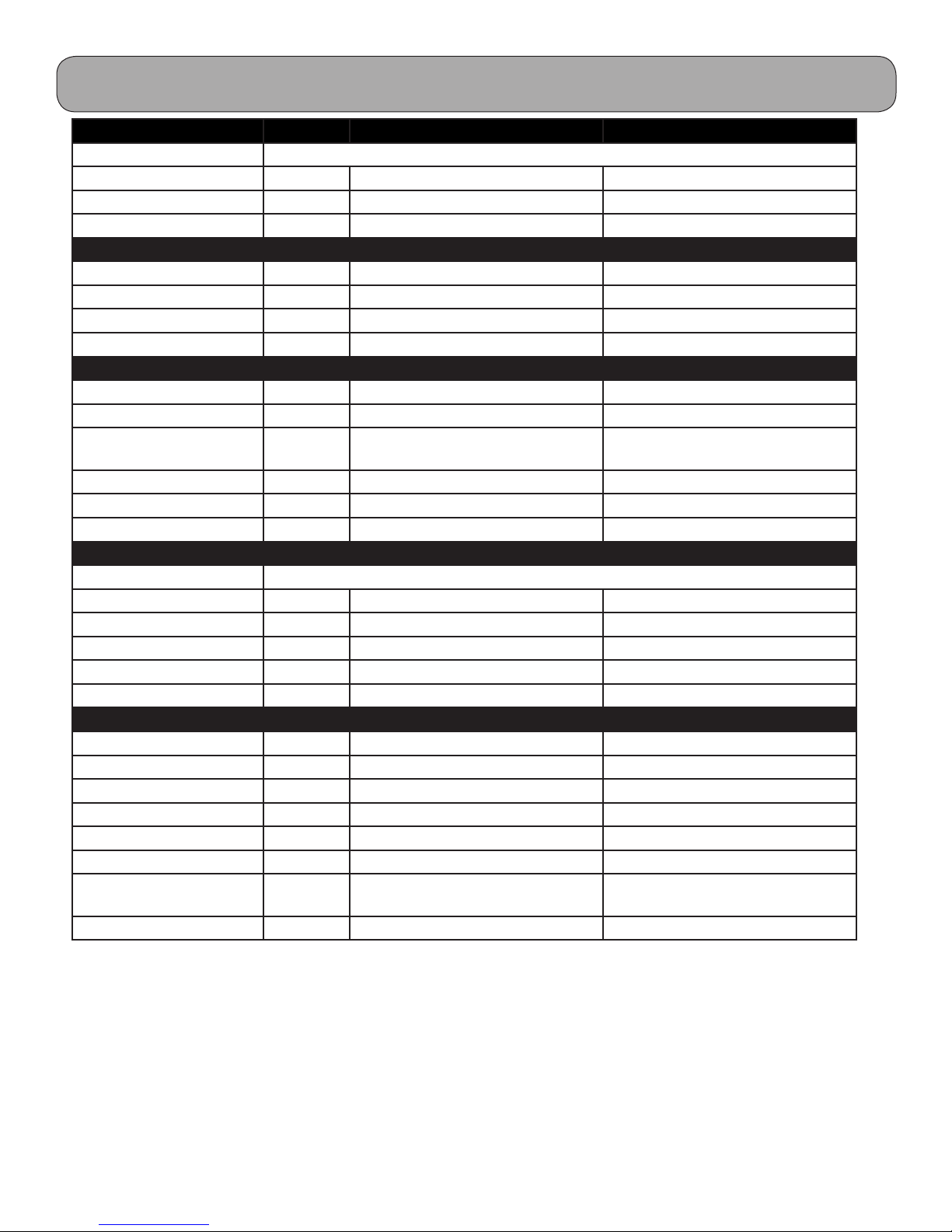

Physical & Electrical Data, cont.

Model GWH09TB-D3DNA1A GWH12TB-D3DNA1A

System Type Heat Pump

Power Supply 208-230V / 60Hz 208-230V / 60Hz

Rated Current Cooling Amps 5.7 6.0

Rated Current Heating Amps 7.0 7.5

System Performance

Cooling Cap (Min/Max) Btu/h 9,000 (3,500-9,600) 12,000 (3,100-13,000)

Heating Cap (Min/Max) Btu/h 9,800 (2,200-11,000) 13,000 (2,400-14,000)

SEER/EER 27 / 14.5 25 / 12.8

HSPF/COP 9.0 / 3.8 9.0 / 3.5

Indoor Unit

Air! ow

T/H/MH/M/ML/L/mute CFM 418/300/282/247/218/182/118 453/312/288/259/221/182/118

Sound Pressure Level

T/H/MH/M/ML/L/mute

Unit Size (WxHxD) Inches 34.1 x 11.5 x 8.2 34.1 x 11.5 x 8.2

Package Size (WxHxD) Inches 37.2 x 14.9 x 11.7 37.2 x 14.9 x 11.7

Net/Gross Weight Lbs 24 / 31 24 / 31

Outdoor Unit

Compressor Type DC Inverter-Driven

Sound Pressure Level dBa 49 49

Unit Size (WxHxD) Inches 35.4 x 23.5 x 14.9 35.4 x 23.5 x 14.9

Package Size (WxHxD) Inches 37.3 x 25.4 x 16.5 37.3 x 25.4 x 16.5

Net/Gross Weight Lbs 86 / 90 87 / 92

Refrigerant/Charge Oz. R410A / 45.9 R410A / 45.9

Installation

Line Set Size (Liq-Suc) Inches 1/4” - 1/2” 1/4” - 1/2”

Pre-Charge Feet 25 25

Max Line Run Feet 50 66

Max Elevation Feet 33 33

MCA Amps 10 10

MOCP Amps 15 15

Wire Size to Outdoor

Unit, # of wires

Wire Size / # Wires AWG 14 / 4 14 / 4

dBa 42/38/36/34/30/26/23 44/38/36/34/30/26/24

AWG 14 14

Note: The manufacturer reserves the right to modify the design and/or change the speci" cations without notice. Please

refer to speci" c installation manual for current information.

5

Physical & Electrical Data, cont.

Model GWH18TC-D3DNA1A GWH24TD-D3DNA1A

System Type Heat Pump

Power Supply 208-230V / 60Hz 208-230V / 60Hz

Rated Current Cooling Amps 7.4 8.5

Rated Current Heating Amps 7.8 10.3

System Performance

Cooling Cap (Min/Max) Btu/h 18,000 (4,600-22,180) 24,000 (6,826-29,352)

Heating Cap (Min/Max)

SEER/EER 21 / 12.0 21 / 12.0

HSPF/COP 9.8 / 3.5 9.2 / 3.3

Indoor Unit

Air! ow

T/H/MH/M/ML/L/mute

Sound Pressure Level

T/H/MH/M/ML/L/mute

Unit Size (WxHxD) Inches 40.1 x 12.6 x 9.1 46.4 x 12.8 x 10.4

Package Size (WxHxD) Inches 43.2 x 15.6 x 13.4 49.2 x 16.2 x 14.0

Net/Gross Weight Lbs 31 / 42 40 / 53

Outdoor Unit

Compressor Type DC Inverter-Driven

Sound Pressure Level

Unit Size (WxHxD) Inches 37.6 x 27.6 x 15.6 38.6 x 31.1 x 16.8

Package Size (WxHxD) Inches 40.5 x 29.5 x 18.0 42.6 x 33.7 x 19.2

Net/Gross Weight Lbs 110 / 121 153 / 164

Refrigerant/Charge Oz. R410A / 56.4 R410A / 77.6

Installation

Line Set Size (Liq-Suc) Inches 1/4” - 5/8” 1/4” - 5/8”

Pre-Charge Feet 25 25

Max Line Run Feet 82 98

Max Elevation Feet 33 33

MCA Amps 15

MOCP Amps 25

Wire Size to Outdoor Unit, #

of wires

Wire Size / # Wires AWG 14 / 4 14 / 4

Btu/h 19,000 (3,400-24,900) 25,000 (7,509-37,543)

CFM 588/512/465/418/371/330/282 706/647/589/530/471/412/353

dBa 51/48/45/43/39/36/33 52/49/47/45/43/41/38

dBa 56 56

20

30

AWG 10 10

Note: The manufacturer reserves the right to modify the design and/or change the speci• cations without notice. Please

refer to speci• c installation manual for current information.

6

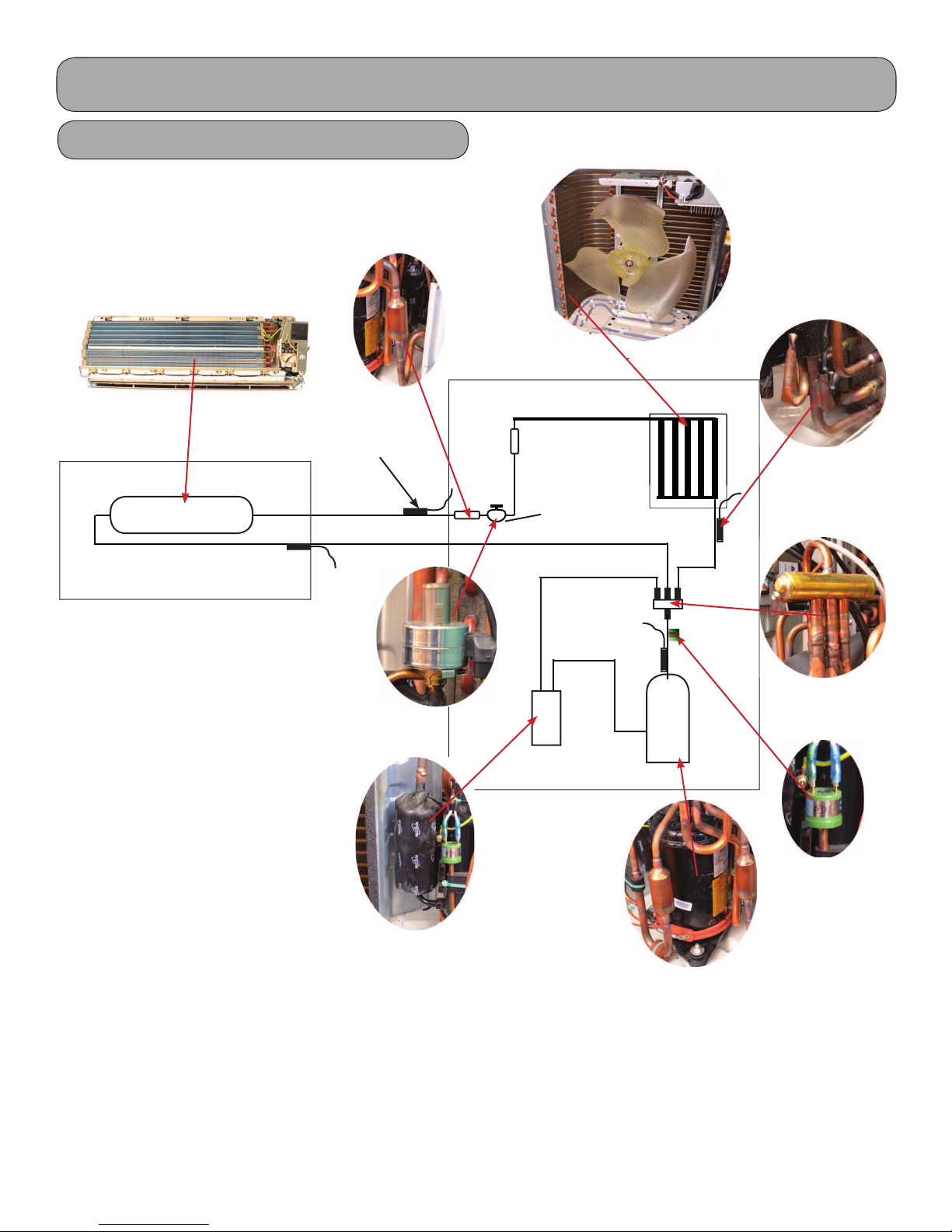

Product Introduction

System Overview

e Terra Ductless split heat pumps are a single zone

unit available in size from 9000 btuh to 24, 000 btuh

providing heating and cooling. All comfort settings

are controlled by a remote control. e Terra unit has

many features to enhance comfort and e ciency. e

operation of these features will be explained later in

this service manual.

Superior inverter technology is used to control capacity while maintaining maximum e ciency. e Terra

systems are equipped with G10 inverter technology

providing precise control over the compressor frequency based on operating pressures and temperatures.

Should an abnormal condition occur, the so ware will

adjust the compressor frequency or shut down the

system indicating the appropriate fault.

Indoor Display

e indoor unit contains a digital display, which will

indicate the current fault. e evaporator, swing motors, fan motors and circuit board are also components

of the indoor unit. e indoor units have a bypass

switch to bypass the remote control if lost or batteries

fail. is will be explained later in this service manual.

e systems require R410A and are pre-charged for 25’

of lineset. Please refer to your installation manual for

additional charge for linesets longer than 25’.

e systems use a PVE oil and should require no additional oil. All Terra units utilize an Oil Return Mode

which will return oil to the compressor should the

need arise.

Circuit Board with

G10 Technology

Compressor

7

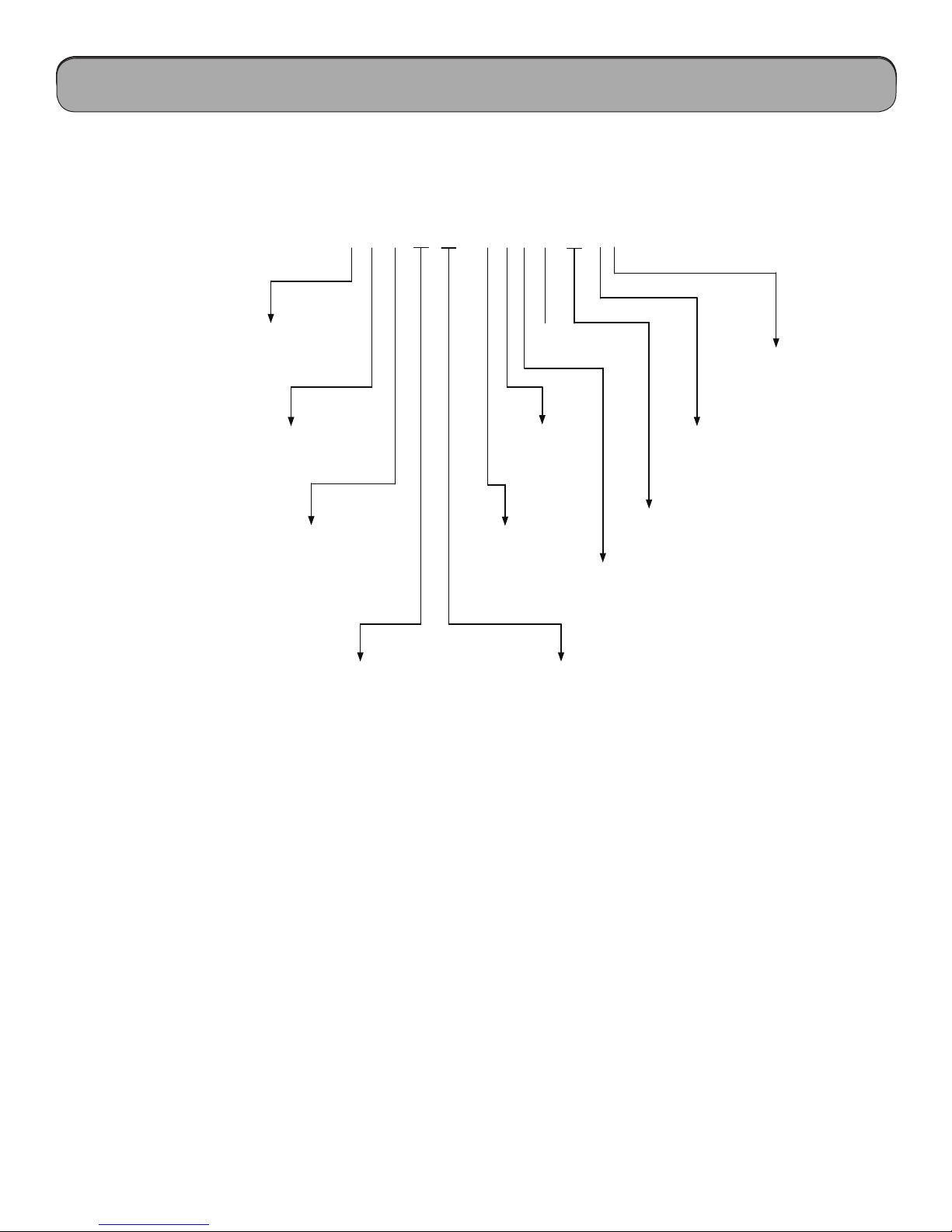

Product Introduction

Refrigeration Components

Indoor Unit

Heat Exchanger

Strainer

Temperature

Sensor

Outdoor Unit

Heat

Exchanger

Temperature

Sensor

Accumulator

Note;

Component locations may vary depending on models.

Compressor

Inverter

Compressor

4-way

High

Pressure

Switch

8

Indoor Unit

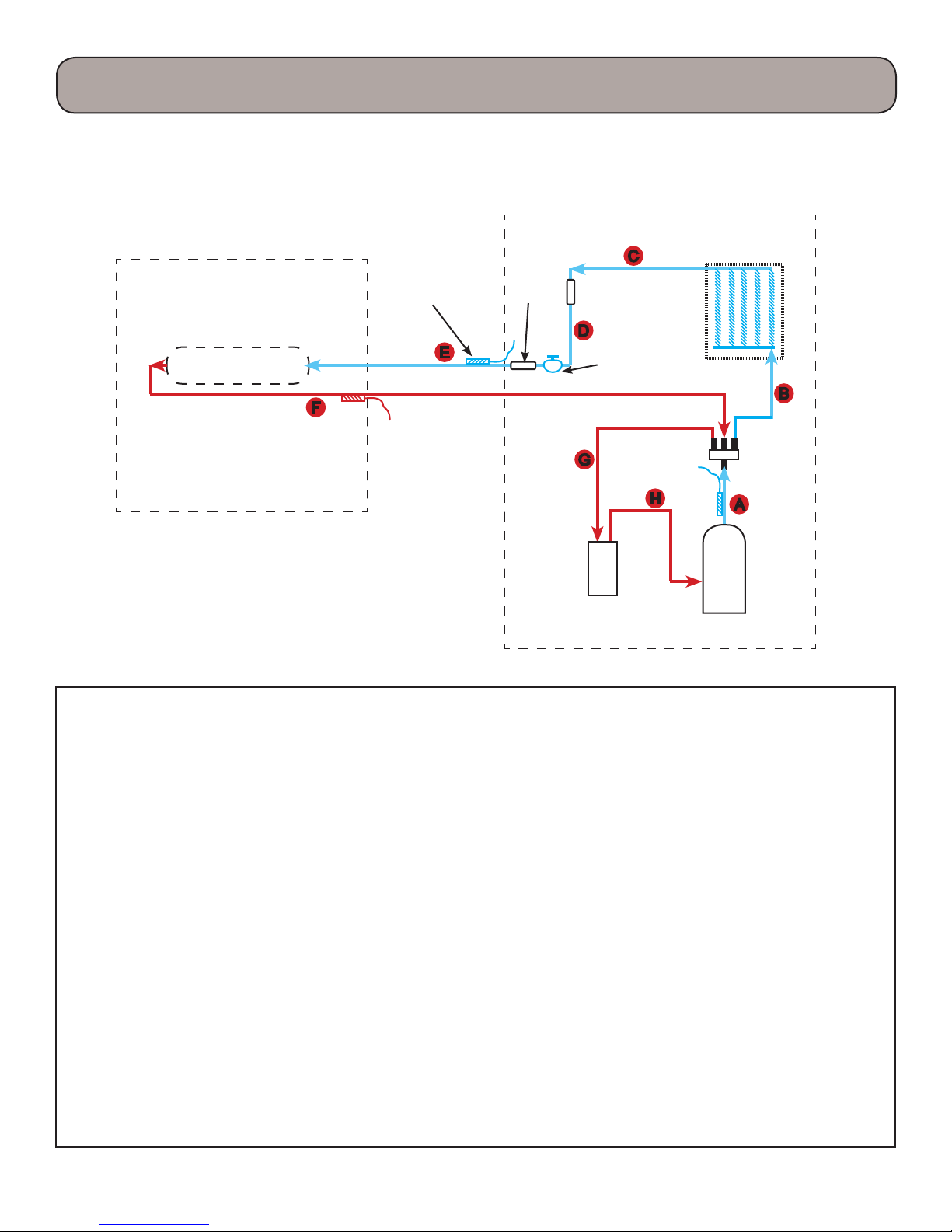

Product Introduction

Cooling Mode

Outdoor Unit

Heat Exchanger

Temperature

Sensor

Filter

Electronic

expansion

Accumulator not

on all sizes

Heat

Exchanger

valve

4-way

valve

Compressor

Inverter

A. Hot gas is discharged from the compressor. e temperature of the gas in monitored by the Discharge Tem-

perature sensor and sent to the outdoor control panel.

B. e hot gas is directed through the 4-way valve, then enters the outdoor coil. e hot gas will be slightly sub-

cooled, however there are no pressure ports to take measurements.

C. e subcooled liquid will enter the lter to remove contaminates.

D. e subcooled liquid will enter the Electronic Expansion Valve (EEV) and will be regulated to about a 10 de-

gree F superheat level. e EEV will adjust its ow based upon the temperature sensor readings. e adjust-

ment process and compressor speed are controlled by the outdoor circuit board.

E. e refrigerant leaving the EEV will be in a low pressure/temperature saturated state. is cold saturated re-

frigerant will move through the coil absorbing heat. is liquid will ash to a vapor and will be superheated

to about 10 degrees F. Since this tubing is cold, it must be insulated.

F. e superheated vapor in returned to the outdoor unit’s 4-way valve.

G. e refrigerant will ow to the accumulator (not all models will have an accumulator) where liquid and

vapor are separated.

H. e refrigerant will ow to the compressor and complete another refrigeration cycle.

e control board will monitor the temperature and pressures and adjust the frequency of the compressor and

ow rate of the EEV as needed. ere are no pressure charts to evaluate temperature or pressures.

9

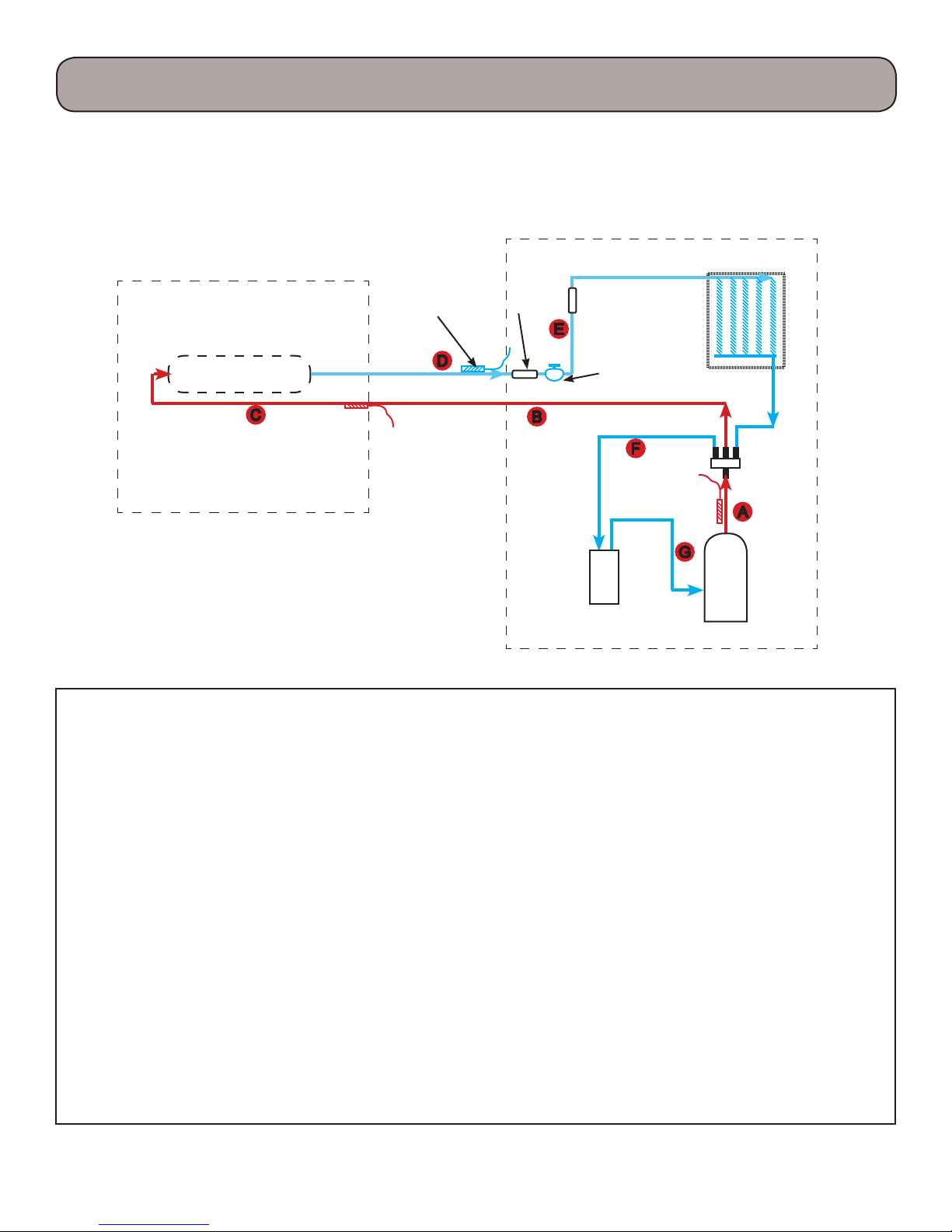

Indoor Unit

Product Introduction

Heating Mode

Outdoor Unit

Heat Exchanger

Temperature

Sensor

Filter

Electronic

expansion

Accumulator not

on all sizes

Heat

Exchanger

valve

4-way

valve

Compressor

Inverter

A. Hot gas is discharged from the compressor. e temperature of the gas in monitored by the Discharge Tem-

perature sensor and sent to the outdoor control panel.

B. e hot gas is directed through the 4-way valve to the indoor coil making the line a hot gas line.

C. e hot gas will enter the indoor coil and condense to a saturated mix as it travel through the coil and will be

slightly subcooled.

D. e refrigerant returns to the outdoor unit through the lter, then trough the EEV reducing the refrigerant

to a low pressure liquid and will maintain 10 degrees F of superheat.

E. e cold refrigerant will travel through the outdoor coil (evaporator) and will pickup heat from the outdoor

air. is will cause the cold saturated refrigerant to ash to a saturated mixture which will be superheated to

10 degrees F.

F. e superheated vapor will travel through the 4-way valve to the accumulator which will prevent liquid

oodback.

G. e superheated gas will enter the compressor for another refrigeration cycle.

e control board will monitor the temperature and pressures and adjust the frequency of the compressor and

ow rate of the EEV as needed. ere are no pressure charts to evaluate temperature or pressures.

10

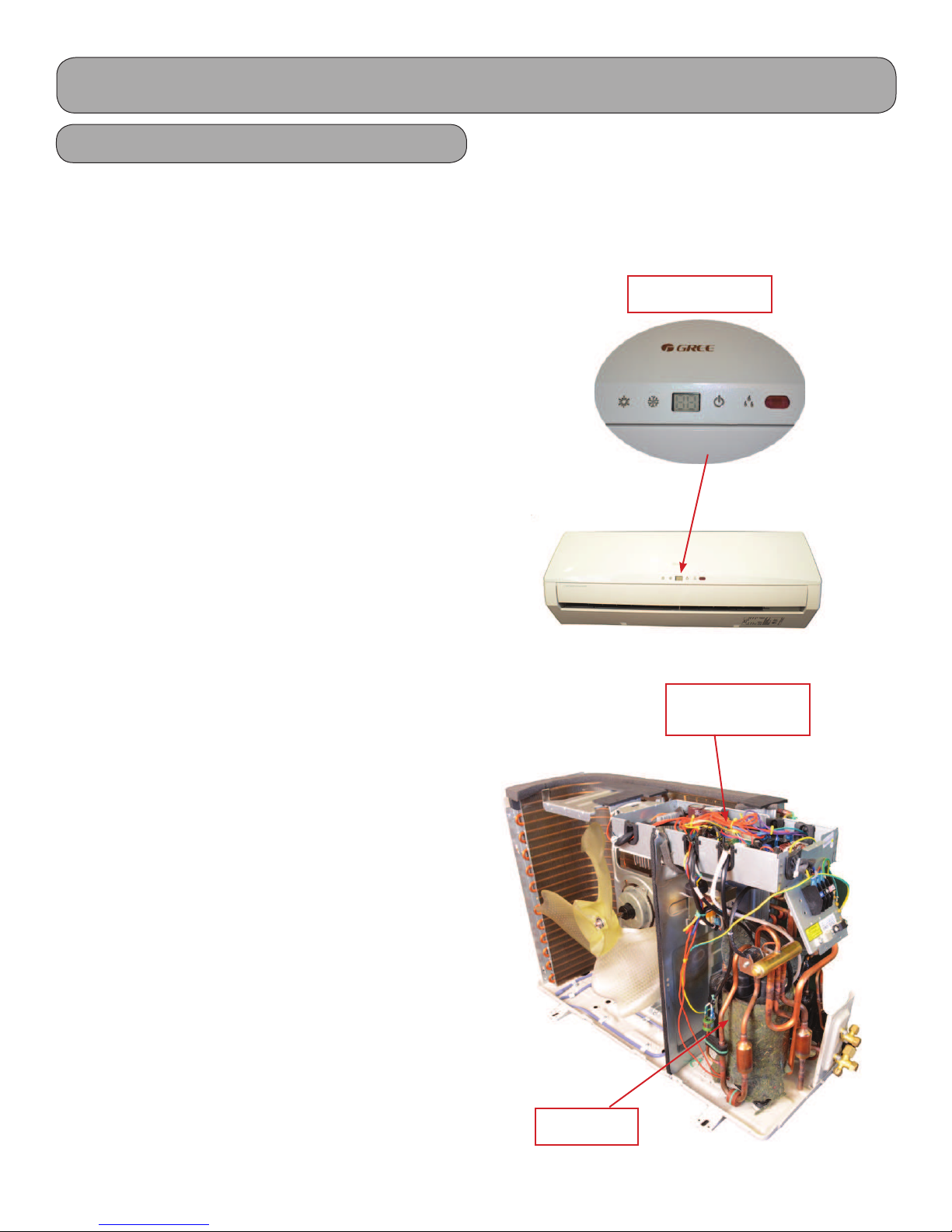

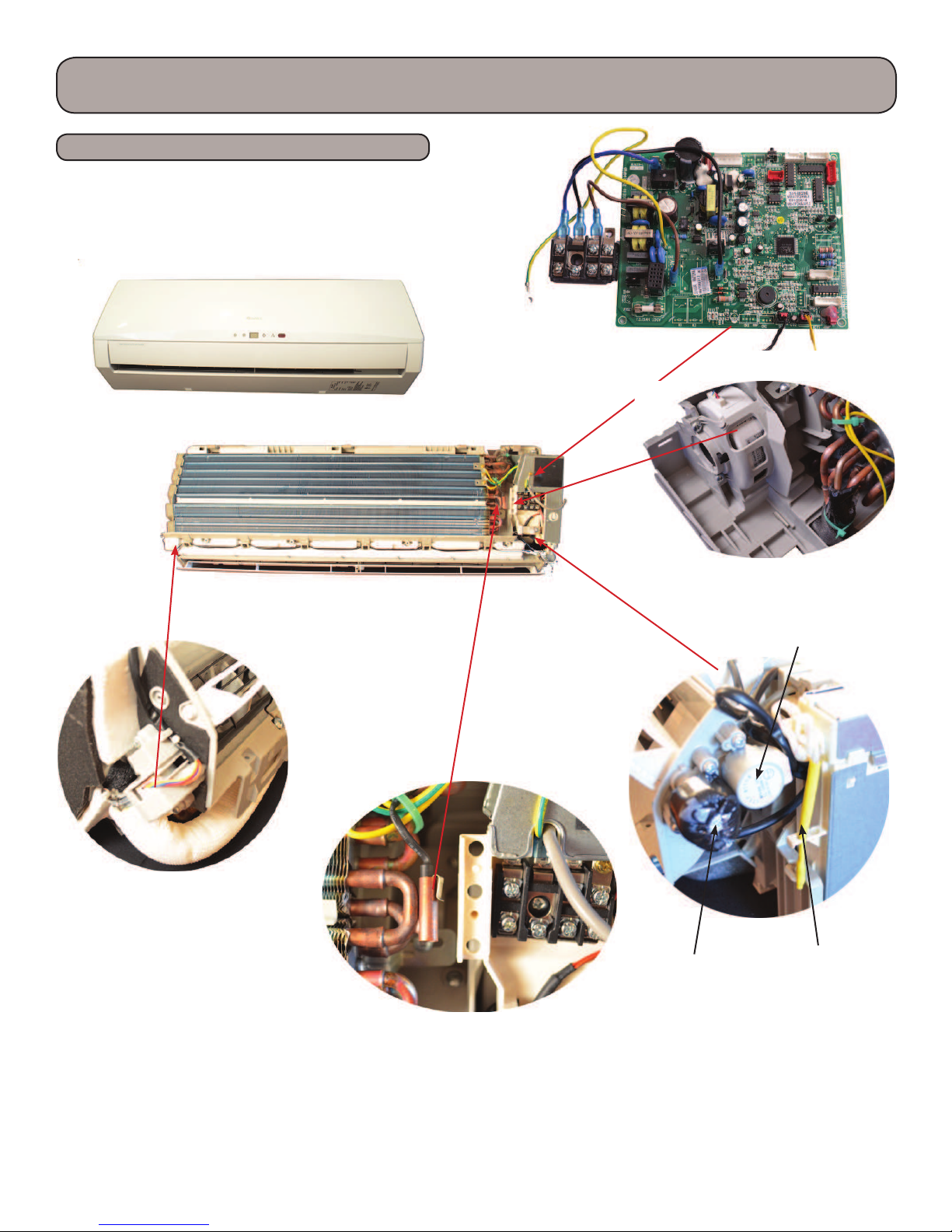

Product Introduction

Indoor Unit Components

Terra 9,000 btuh Indoor Unit

Other Terra models may very slightly.

Indoor Circuit

Board

Horizontal Swing Motor

Indoor Tube ermistor

Fan Motor

Vertical Swing

Motor

Step Motor

Ambient

Temperature

Sensor

11

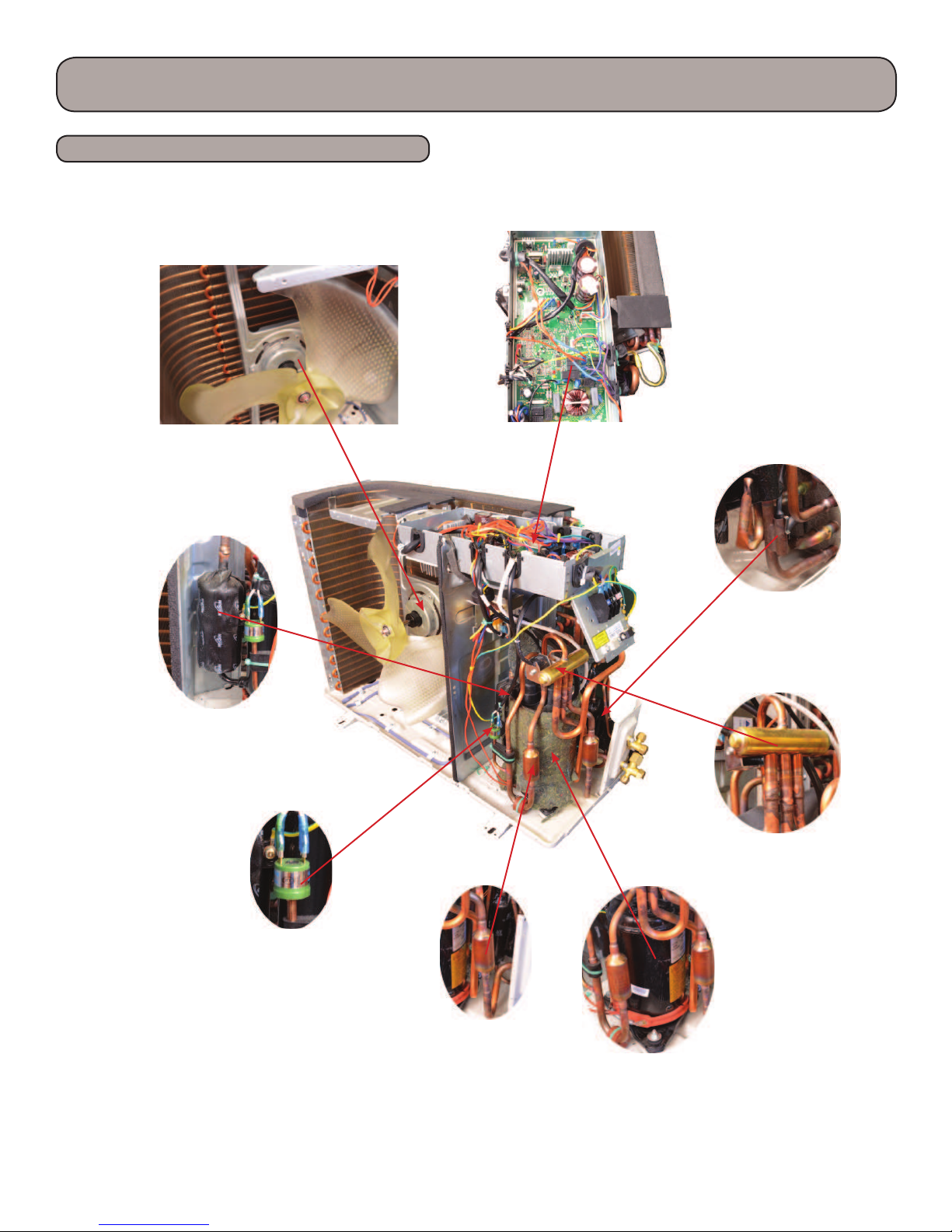

Product Introduction

Outdoor Unit Components

Terra 9,000 btuh Outdoor Unit

Other Terra models may very slightly.

Outdoor Fan

Accumulator

Circuit Board

Temperature

Sensor

4-way

High

Pressure

Switch

Note;

Component locations may vary depending on models.

12

Strainer

Compressor

Product Introduction

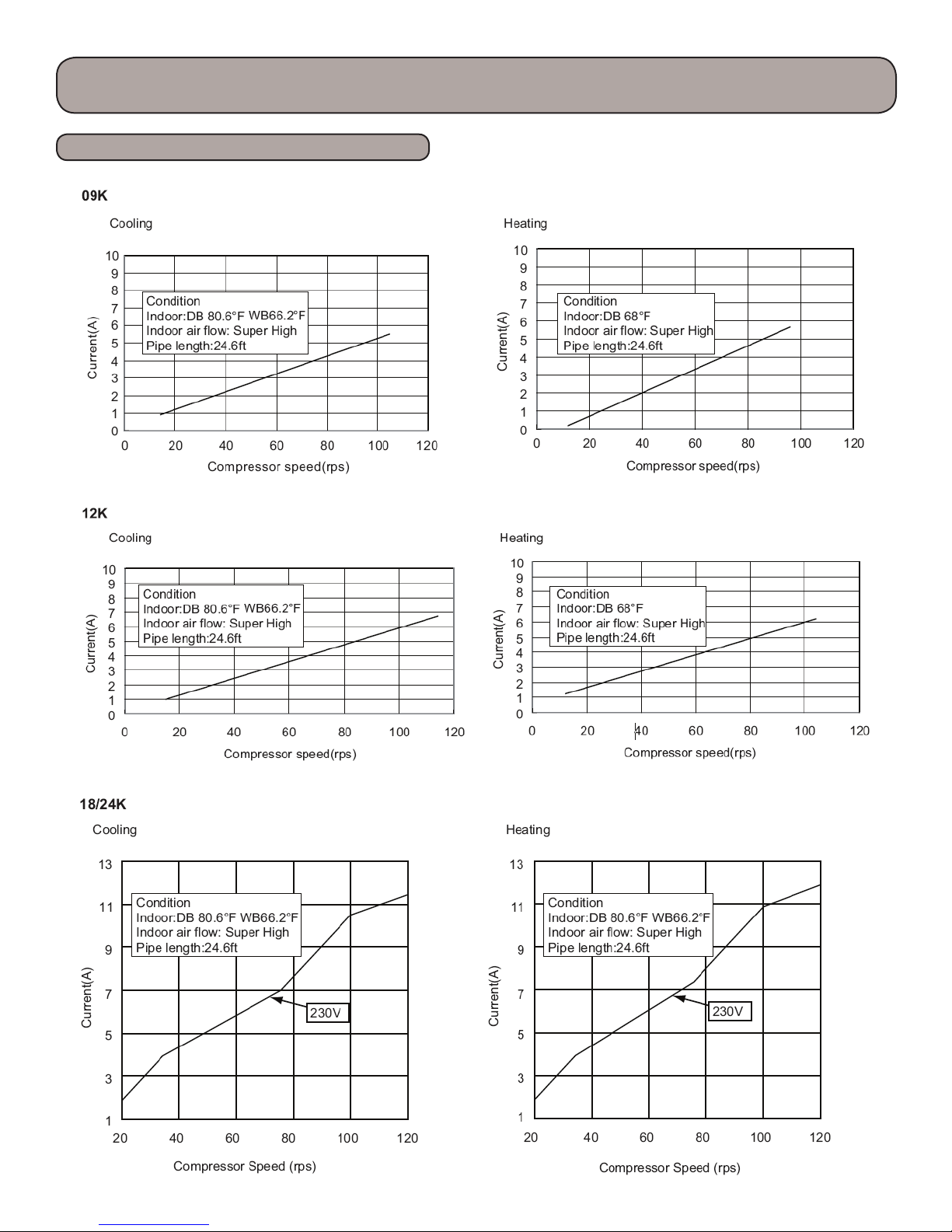

Operation Characteristic Curve

13

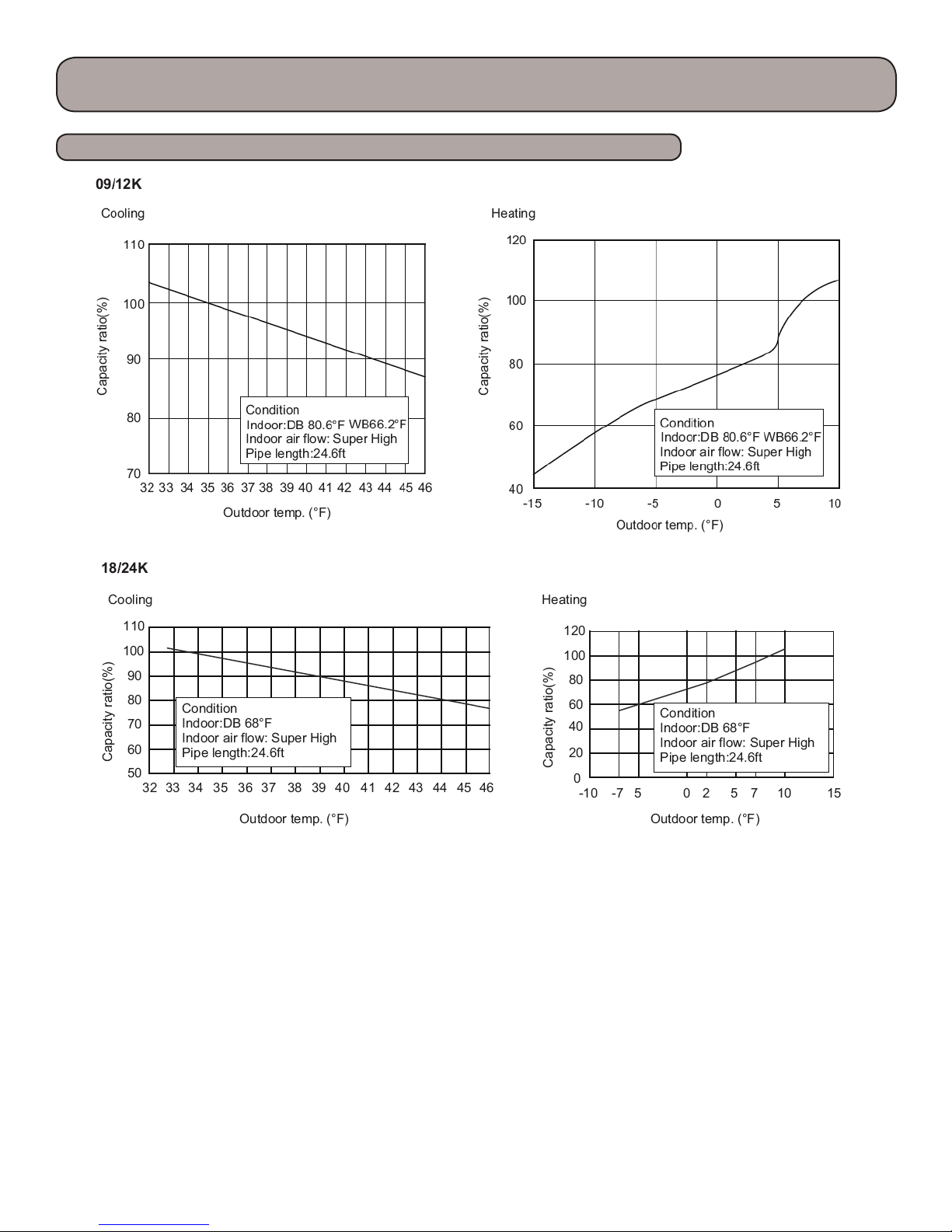

Product Introduction

Capacity Variation Ratio According to Temperature

14

Cooling

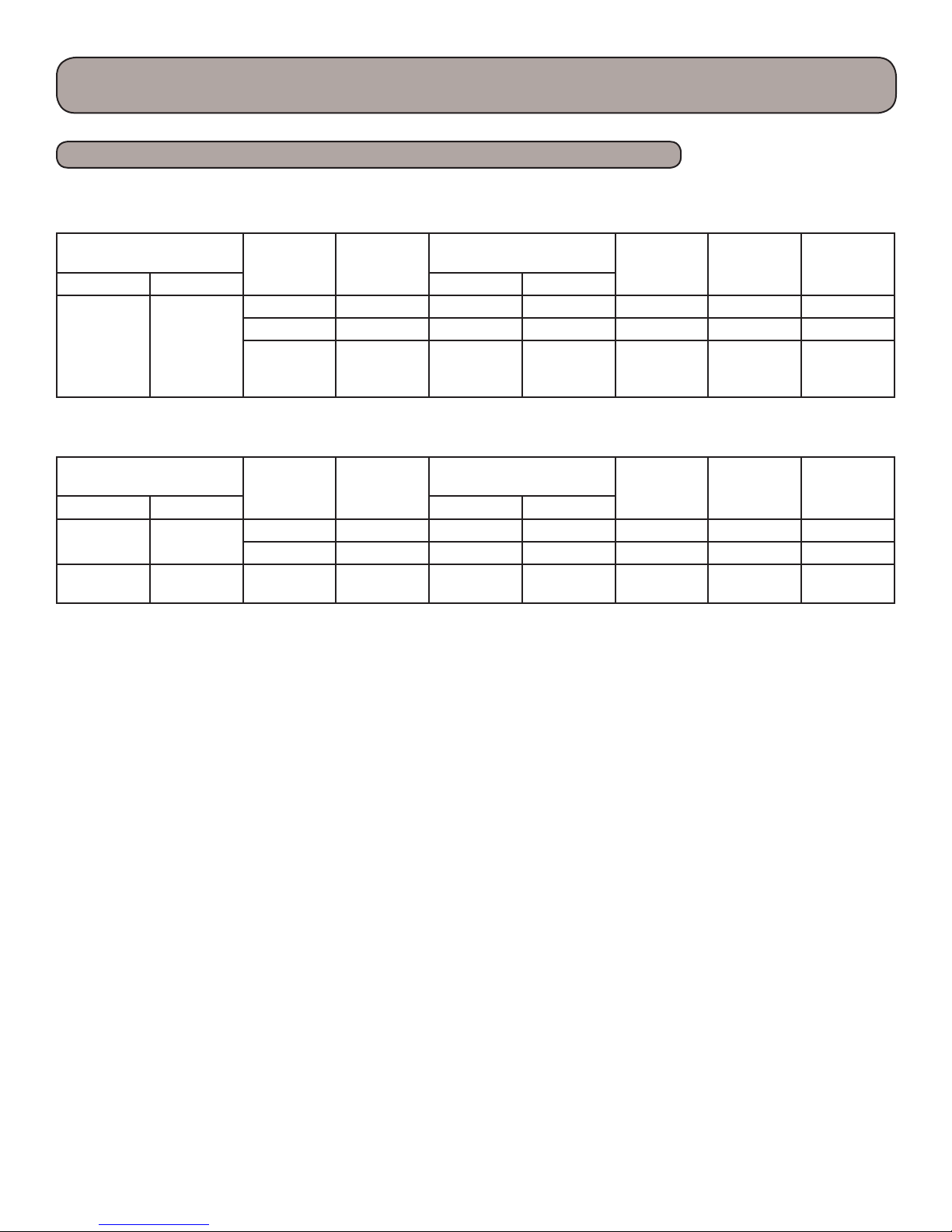

Product Introduction

Operation Data

Temperature Condition (OF)

Indoor Outdoor T1 (

80.6/66.6 95/75.2

Model

9K 135 57.2 98.6 Turbo High 46

12K 152 59 98.6 Turbo High 70

18/24K 131-160

Pressure

(PSI)

Heat Exchanger

Pipe Temperature

O

F) T2 (OF)

46.4-51.8 to

51.6-57.2

Indoor Fan

Mode

167-181.4 to

98.6-118.4 Turbo High 75

Outdoor Fan

Mode

Heating

Temperature Condition (OF)

Indoor Outdoor T1 (

70/60 47/43

68/59 44.6/42.8 18/24K 319-348

Model

9K 401 113 41 Turbo High 56

12K 308 107.6 41 Turbo High 73

Pressure

(PSI)

Notes:

(1) Measure surface temperature of heat exchanger pipe around center of heat exchanger path U-Bend.

(2) Length of connecting tubing = 24.6 .

(3) P = Pressure PSI

T1 = Inlet and Outlet Temperature for Evaporator

T2 = Inlet and Outlet Temperature for Condenser

Heat Exchanger

Pipe Temperature

O

F) T2 (OF)

167-181.4

98.6-113

33.8-37.4 to

35.6-42.8

Indoor Fan

Mode

Turbo High 75

Outdoor Fan

Mode

Compressor

Speed

(rps)

Compressor

Speed

(rps)

15

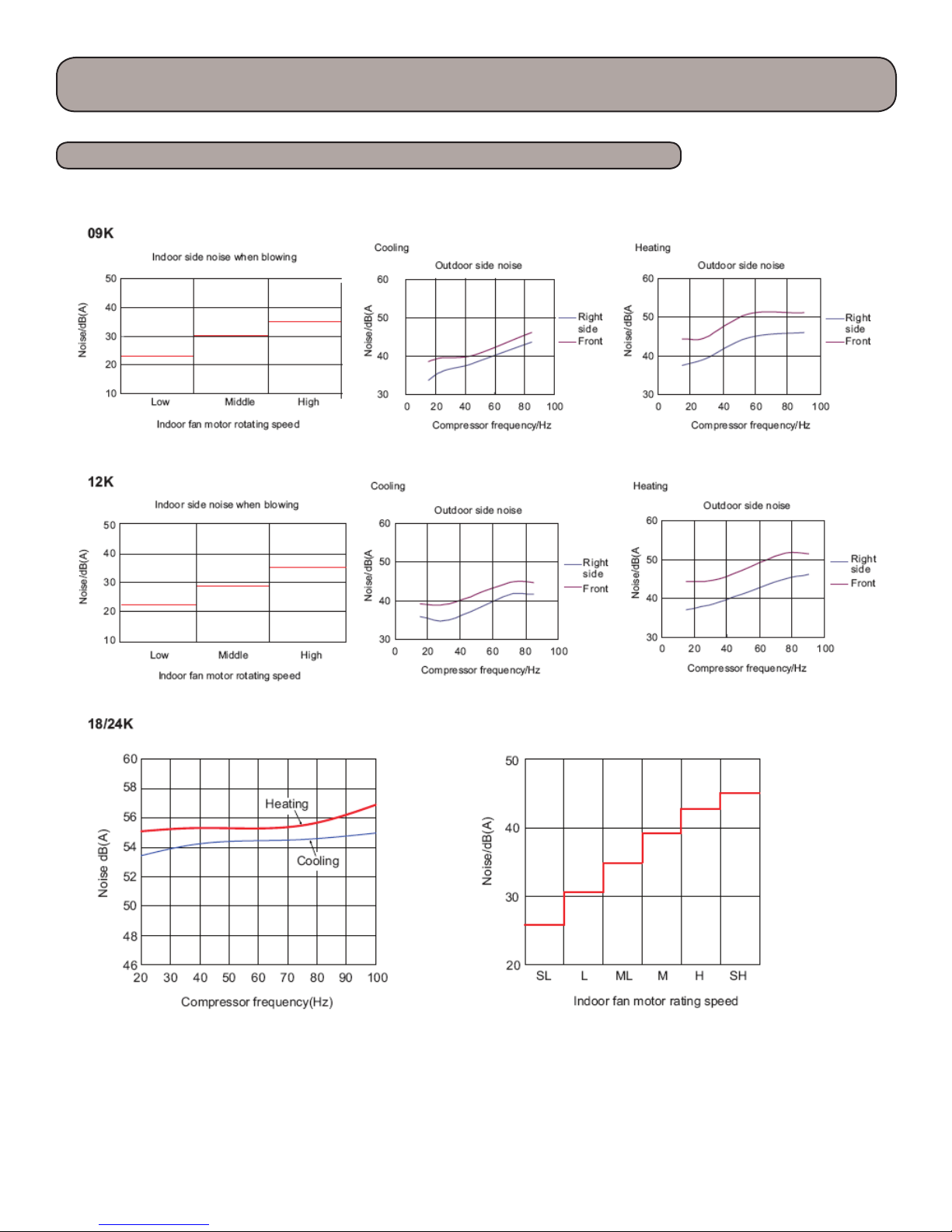

Product Introduction

Noise Criteria Curve Tables

16

Product Introduction

System Operation 9,000/12,000 btuh Models

Basic Functions

e compressor should stay o for at least 3 minutes before starting the unit. e compressor circuit has a 3 minute delay if

the compressor is de-energized during a run cycle. If the compressor starts from a de-energized cycle, there will be no time

delay. e compressor has a minimum runtime of 6 minutes regardless of room temperature.

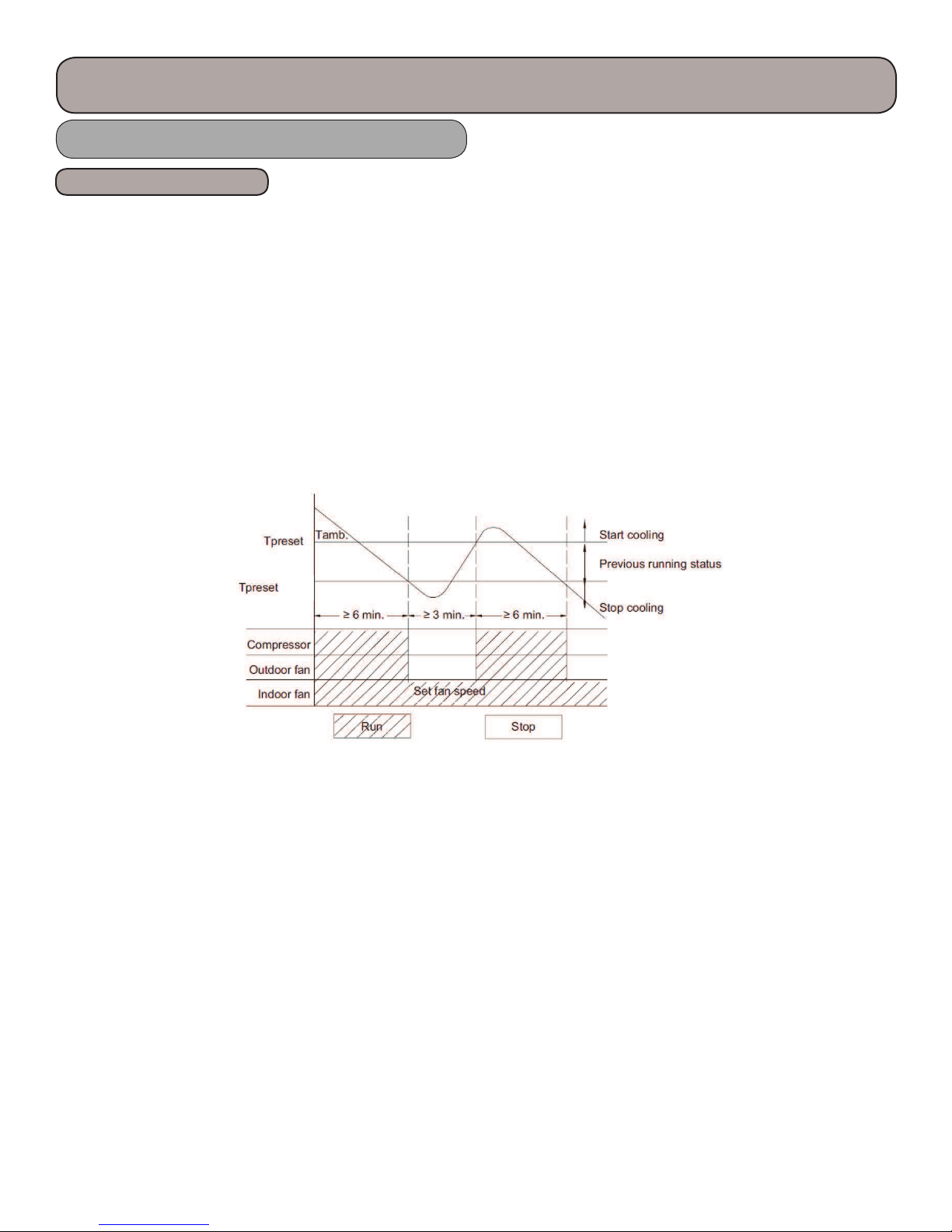

1) Cooling Mode

Cooling Process

When the indoor ambient rises 2 F above the preset temperature, the unit will start the cooling cycle. e outdoor fan

and compressor will start. e indoor fan will run continuously at the selected speed. e outdoor unit will monitor the

appropriate temperatures and pressure and adjust the compressor speed and the EEV as required. If the indoor ambient is

> 2 F then the preset temperature, the compressor will increase the frequency; < 2 F the compressor will begin reducing

the frequency. e G10 technology will control compressor speed based on indoor load and compressor amperage. When

the indoor temperature is satis ed, the compressor will stop, then 30 seconds later the outdoor fan will stop.

Evaporator Freeze Protection

e so ware will monitor the indoor evaporator coil form freezing.

e following will occur 6 minutes a er the compressor has been operating in the cooling or dry mode:

If the evaporator temperature drops below 36 F, the compressor will operate at a reduced frequency. If the evaporator

is below 30 F for 3 minutes, the compressor will stop, 30 seconds later the outdoor fan will stop. In cooling mode, the

indoor fan and swing motor will remain on. If the evaporator temperature is >= 50 F and the compressor is o for at least

3 minutes, the compressor will resume its normal operation state.

Overcurrent Protection

e so ware will monitor the compressor current to maintain it in a safety and reliable operating range.

If the total current <= 6 amps, the compressor speed frequency is allowed to increase. If the current >= 7 amps, the

compressor speed frequency will not increase. If the total current >= 8 amps, the unit will operate and decrease the

compressor speed. If the current >= 9 amps, the compressor will stop and the indoor fan will stop a er 30 seconds.

2) Dry Mode

Drying Process

is feature will not take the place of a dehumidi er, it is intended to dry the ler and slightly cool the air. If the indoor

ambient temperature is greater than the preset temperature, the unit will enter the cooling and drying mode, in which

case the compressor will operate and the indoor fan will run at a low speed. When the indoor ambient temperature is at or

below the preset temperature, the unit will operate in it previous running state. When the indoor ambient drops to more

than 2 F below the preset temperature the compressor will stop running, then 30 seconds later the outdoor fan will stop,

the indoor fan will run at low speed.

- 2 F

17

Product Introduction

System Operation 9,000/12,000 btuh Models, cont.

Basic Functions

3)Heating Mode

Heating Process

When the indoor ambient drops 2 F below the preset temperature, the unit will start the heating cycle. e outdoor fan,

compressor and 4-way valve will operate. e indoor fan will operate in the “Cold Air Prevention” mode in which the

indoor fan will have a 2 minute delay a er the call for heating. e indoor evaporator coil temperature must reach 104 F

before the indoor fan will start, this will prevent cold air from discharging from the indoor coil. When the indoor evaporator coil temperature is > 104 F, the indoor fan will operate at low speed for 1 minute. With 1 minute of operation or 2

minutes of no fan operation and the indoor evaporator coil temperature is > 108 F, the indoor fan will operate at its preset

condition.

If the indoor ambient temperature is < 9 F and > 2 F of the preset temperature, the unit will run in its original mode of

operation.

If the compressor is running and the mode is changed from cooling to heating, the 4-way valve will be energized 2-3 minutes later.

If the indoor ambient temperature is >= 9 F than the preset temperature, the compressor will stop and the outdoor fan will

stop a er a 30 second delay. e indoor fan will continue to operate at its preset mode.

e G10 technology will determine compressor frequency based on ambient temperatures.

+9 F

+ 2 F

Stop heating

18

Product Introduction

System Operation 9,000/12,000 btuh Models, cont.

Basic Functions

Defrost Process

1) e unit will enter defrost when the following conditions are met:

A. Outdoor ambient <= 41 F

B. Compressor had accumulated more than 3 hours of operation in heating mode

C. e outdoor coil <= 32 F

Note: e compressor runtime will be cleared when the outdoor ambient is > 41 F or when the compressor has started

up a er changing to cooling or drying mode and defrost has nished. e runtime will not be cleared when the unit has

stopped a er reaching the setpoint temperature, a protection fault or changing to fan mode.

ere are 3 perimeters used in the defrost algorithms, Outdoor ambient(T

a calculated T

T

compensation

D. A er power-up, for the rst defrost T

E. T

F. T

compensation

is calculated by the following:

tube > 36 F then T

outdoor

tube <= 36 F then T

outdoor

compensation = 32

compensation = 32

compensation = 37

F

F

F

ambient), Outdoor tube(T

outdoor

outdoor

tube) and

2) When heating has operated continuously for 45 minutes, or accumulated for 90 minutes, the unit will enter defrost

mode in 3 minutes a er meeting any of the conditions below:

A. Outdoor ambient >= 41 F and outdoor coil <= 28 F

B. 28 F <= T

C. 23 F <= T

D. 14 F <= T

ambient< 41 F, T

outdoor

ambient < 28 F <= T

outdoor

ambient < 23 F , T

outdoor

outdoor

outdoor

outdoor

tube <= 21 F

tube <= 18 F

tube -T

compensation

<= (T

ambient - 37 F)

outdoor

3) During defrost, if run time for the compressor does not reach 3 minutes, the defrost cycle will not start for the next 2

hours. At that time the compressor stops operation and 30 seconds later the outdoor fan will stop. 30 seconds a er this the

4-way reversing valve will de-energized. Following another 30 second delay, the compressor will increase its compressor

speed for defrosting. Defrosting will last for 450 seconds or until the T

tube >= 50 F, at this temperature the compres-

outdoor

sor will decrease it compressor speed for 30 seconds, then will stop. In another 30 seconds the 4-way valve will energize,

the 60 seconds later the compressor and outdoor fan will start. e compressor speed for defrosting will be 85hz.

During Defrost mode, a “H1” will be displayed on the indoor front panel display indicating the user selected mode has

been overridden and the system is performing a outdoor coil defrost operation.

19

Product Introduction

System Operation 9,000/12,000 btuh Models, cont.

Basic Functions

System Protection

Cold Air Prevention (Heating mode with compressor running)

e system guards against discharging cold air in heating mode. It will delay the indoor fan until the evaporator coil has

warmed up to discharge warm, comfortable air into the room.

1) When the T

ambient < 75 F and the T

indoor

to run at low speed a er a 2 minute delay. is will reduce cold air upon heating startup. Within 2 minutes, if

T

tube > 104 F, the indoor fan will run at low speed. A er 1 minute of operation, the fan will run at the preset fan

indoor

mode. Within 1 minute of low speed operation or 2 minutes of no fan operation, with the T

run at the preset mode.

tube <= 104 F with the fan in a stopped state, the indoor fan will begin

indoor

tube > 108 F, the fan will

indoor

2) If the T

at the preset mode. A er 1 minute of low speed operation, if the and the T

ambient >= 75 F and the T

indoor

tube <= 108 F the indoor fan will run at low speed for 1 minute than run

indoor

tube > 108 F the fan will operate at its

indoor

preset mode.

Note:

e T

Overcurrent and Speed Protection (Total Current = I

ambient in 1 & 2 above refers to the unit going into the heating mode coming out of defrost.

indoor

)

total

e so ware will monitor the compressor current draw and adjust the compressor speed in order to maintain the inverter and

compressor in a safety and reliable operating range.

A. If I

B. If I

C. If I

D. If I

<= 6, an increase in frequency will be allowed

total

>= 7, increasing the frequency is not allowed.

total

>= 8, the compressor will decrease its frequency

total

>= 9, the compressor will stop and the indoor fan will stop a er 30 seconds.

total

4)Fan Mode

Under this mode, the fan will run at the preset speed and the outdoor fan, compressor and 4-way valve will stop.

5)Auto Mode

Auto Mode Process

Setting the auto mode will run the unit in heat or cool automatically depending on T

1)Operating Parameters

A. If the T

B. If the T

C. When the T

ambient >= 79 F the unit will operate in cooling mode. e set temperature is 77 F.

indoor

ambient <= 72 F the unit will operate in heat mode. e set temperature is 68 F.

indoor

ambient <= 73 F and >= 77 F, the unit will operate in the previous state. If it is energized

indoor

for the rst time, it will run in Fan mode

D. In auto mode, the cooling frequency will be the same as the cooling only mode and the heating frequency will

be the same as the heating only mode.

2) Protection

A. In cooling operation, protection is the same as the cooling only mode

B. In heating operation, protection is the same as the heating only mode

C. When the indoor ambient temperature changes, the operation mode will be automatically selected. Once started

the compressor will have a 6 minute runtime.

20

indoor

ambient

Product Introduction

System Operation 9,000/12,000 btuh Models, cont.

Basic Functions

6)Common Protection Functions and Fault Displays

Coil High Temperature Protection

= measured temperature of outdoor coil in cooling mode, measured temperature of indoor coil in heating mode.

T

tube

1) Outdoor Coil High Temperature Protection - In cooling mode the so ware will monitor the outdoor coil for an abnor-

mal high temperature condition.

A. If T

B. If T

C. If T

D. If T

2) Indoor Coil Temperature Protection - In heating mode the so ware will monitor the indoor coil for an abnormal high

temperature condition.

A. If T

B. If T

C. If T

D. If T

<= 126 F, the unit will return to its original operation state

tube

>= 131 F, frequency rise is not allowed

tube

>= 136 F, the compressor will run at reduced frequency

tube

>= 144 F, the compressor will stop and the indoor fan will operate at preset speed

tube

<= 122 F, the unit will return to its original operation state

tube

>= 127 F, frequency rise is not allowed

tube

>= 133 F, the compressor will run at reduced frequency

tube

>= 140 F, the compressor will stop and the indoor fan will blow residual heat and then stop

tube

3) Compressor Discharge Temperature Protection

e so ware will monitor the compressor discharge for an abnormal high temperature condition.

A. If T

B. If T

C. If T

D. If T

>= 208 F, frequency rise is not allowed

tube

>= 217 F, the compressor will run at reduced frequency

tube

>= 230 F, the compressor will stop

tube

<= 194 F and the compressor has been off for at least 3 minutes, the compressor will resume operation

tube

Communication Fault

If the unit fails to receive correct signals for a 3 minutes, communication fault will occur and the whole system will stop

and a “E6” will be displayed on the front panel of the indoor unit.

Module Protection

Under module protection mode, the compressor will stop. When the compressor remains o for 3 minutes, the compressor will resume operation. If the module protection occurs six time in succession, the compressor will remain o . is is a

thermal protection for the indoor module (AP1).

Compressor Protection

e compressor contains a thermal overload switch tom protect it from abnormal conditions.

If temperature sensed by the overload sensor is over 239 F, the compressor will stop and the outdoor fan will stop a er 30

seconds. When the temperature is below 203 F, the overload protection will reset to normal state.

DC Buss Voltage Protection

e so ware will monitor the DC bus voltage.

If voltage on the DC Bus is below 150 or over 420v, the compressor will stop and the outdoor fan will stop in 30 seconds.

When the voltage on the DC bus returns to normal and the compressor has been o for 3 minutes, the compressor will

resume its operation.

21

Product Introduction

System Operation 9,000/12,000 btuh Models, cont.

Other Controls

1)On/O

e on-o state will change with each button press.

2)Mode Selection

Press the “Mode” button to change from Auto, Cool, Dry, Fan or Hesat Pump

3)Temperature Setting

Each time you press the “TEMP+” or “TEMP-” button the temperature setting will change by 1 F. e temperature range

is 60.8 F - 86 F. In Auto Mode this button will not function.

4)Time Switch

e unit will stop and start by setting the Timer on the remote controller.

5)Energy Savings Mode (Press Temp & Clock simultaneously, display will indicate “SE”)

In heating mode, refer to the Cold Air Prevention explained in the (3)Heating Mode process .

In cooling mode, the fan speed will adjust according to the fan speed curve below:

T

amb.

88 F

T

+ 3 F

preset

T

+ 1 F

preset

Fan Speed

Turbo

High Med. Low

22

Product Introduction

System Operation 9,000/12,000 btuh Models, cont.

Other Controls

6)Sleep Control

e Terra has 3 Sleep mode settings to improve comfort and energy savings.

Auto Mode and Fan Mode do not utilize the Sleep Mode Settings

Sleep Mode 1 (Gradual Cycle)

1. Cool or Dry Mode

a) A er 1 hour of operation the temperature setting will raise 2 F

b) A er 2 hours of operation the temperature setting will increase 4 F and stay at this setting until the

sleep mode in canceled

2. Heat Mode

a) A er 1 hour of operation the temperature setting will decrease 2 F

b) A er 2 hours of operation the temperature setting will decrease 4 F and stay at this setting until the

sleep mode in canceled

T

amb.

87.8 F

T

+ 5.4 F

preset

T

+ 1.8 F

preset

Fan Speed Super High High Med Low

23

Product Introduction

System Operation 9,000/12,000 btuh Models, cont.

Other Controls

Sleep Mode 2 (Adaptive Cycle)

1. Cool or Dry Mode (Initial setpoint between 61 F. - 74 F.)

a) A er 1 hour of operation the temperature setting will raise 2 F every hour

b) A er 3 hours of operation the temperature setting will raise 6 F above initial setpoint and stay at this

setting

c) A er 7 hours of operation, the setpoint will move to 4 F. above the initial setpoint and remain until the

sleep mode in canceled.

Cool or Dry Mode (Initial setpoint between 75 F. - 81 F.)

a) A er 1 hour of operation the temperature setting will raise 2 F every hour

b) A er 3 hours of operation the temperature setting will raise 4 F above initial setpoint and stay at this

setting

c) A er 7 hours of operation, the setpoint will move to 2 F. above the initial setpoint and remain until the

sleep mode in canceled.

Cool or Dry Mode (Initial setpoint between 82 F. - 85 F.)

a) A er 1 hour of operation the temperature setting will raise 2 F every hour

b) A er 3 hours of operation the temperature setting will raise 24 F above initial setpoint and stay at this

setting

c) A er 7 hours of operation, the setpoint will move back to the initial setpoint and remain until the

sleep mode in canceled.

Cool or Dry Mode (Initial setpoint above 85 F.)

a) e original setpoint will be maintained for 7 hours, then a er 7 hours it will decrease by 1 F until the

sleep mode is canceled

2. Heat Mode (Initial setpoint 61 F.)

a) e unit will maintain this setpoint until Sleep Mode is canceled

Heat Mode (Initial setpoint between 62 F. - 68 F.)

a) A er 1 hour of operation the temperature setting will decrease 2 F and maintain this setpoint until

Sleep Mode is canceled

Heat Mode (Initial setpoint between 69 F. - 81 F.)

a) A er 1 hour of operation the temperature setting will decrease 2 F and maintain this setpoint until

Sleep Mode is canceled

Heat Mode (Initial setpoint between 82 F. - 86 F.)

a) A er 1 hour of operation the temperature setting will decrease 2 F every hour

b) A er 3 hours, the setpoint will be xed at 6 F below the initial setpoint and remain at this setpoint until

Sleep Mode is canceled

24

Product Introduction

System Operation 9,000/12,000 btuh Models, cont.

Other Controls

Sleep Mode 3 (Customized Cycle)

You will be required to enter 8 room setpoint values for 8 hours of runtime. e last room setpoint value will be maintained until Sleep Mode is canceled.

In Sleep Mode 3, press the “Turbo” button to enter setup mode. e remote controller will display “1:00” in the time location. Use the “+” and “-” buttons to select the desired room setpoint for the 1st hour of runtime, then press the “Turbo”

button to save the data.

e remote controller will display “2:00”. Once again, use the “+” and “-” buttons to select the desired room setpoint for the

second hour of run time. Press the “Turbo” button to save the data.

Repeat this procedure for the remaining hours (total of 8). A er all 8 settings have been saved, the remote controller will

automatically revert back to the standard time and temperature display.

At anytime, you may press the “ON/OFF”, “MODE”, “TIMER”, “SLEEP” or “TURBO” buttons to cancel the Sleep Mode 3

7)Indoor Fan Control

e indoor fan can be set to Ultra High, High, Med, Low and Auto with the remote controller.

In auto mode, the following speeds will be set:

Cooling Mode

a) T

b) T

c) T

ambient >= T

indoor

- 2 F < T

setpoint

ambient <= T

indoor

T

preset

T

+ 2 F

preset

indoor

+ 2 F, fan will run on high speed

setpoint

ambient < T

- 2 F, fan will run on low speed

setpoint

T

amb.

+ 2 F, fan will run on medium speed

setpoint

T

-2 F

preset

Fan Speed High Med. Low O

25

Product Introduction

System Operation 9,000/12,000 btuh Models, cont.

Other Controls

Fan Only “Auto” Mode

a) T

b) T

c) T

ambient > T

indoor

+ 2 F <= T

setpoint

ambient < 2 F of T

indoor

T

T

preset

preset

T

setpoint

+ 4 F

preset

-2 F

+ 4 F, fan will run on high speed

ambient <= T

indoor

setpoint,

T

amb.

setpoint

fan will run on low speed

+ 4 F, fan will run on medium speed

Fan Speed High Med. Low O

Dry Mode

e indoor fan will be set to low speed.

Heating Mode

a) T

b) T

c) T

ambient <= T

indoor

+ 1 F < T

setpoint

ambient >= T

indoor

T

T

preset

preset

T

indoor

+ 5 F

preset

+1 F

setpoint

setpoint

+ 1 F, fan will run on high speed

ambient < T

+ 2 F, fan will run on low speed

T

amb.

+ 5 F, fan will run on medium speed

setpoint

Fan Speed

26

O

Low

High Med.

Product Introduction

System Operation 9,000/12,000 btuh Models, cont.

Other Controls

8) Buzzer Control

e buzzer control will send a “Tone” when the air conditioner is powered-up or received information sent by the remote

control. You will also hear the tone when there is a button input or if the indoor unit doesn’t receive a signal from the remote controller in the Heat Mode.

9) Auto Button (Manual Override) - Located on indoor unit.

In the event the controller is missed placed or the batteries are defective, this will override the remote controller. If the controller is on, pressing this button will stop it, if it is

o , pressing the button will turn the controller on. When turning the controller on, the

swing and light will be on and the unit will run based on the remote controller setting.

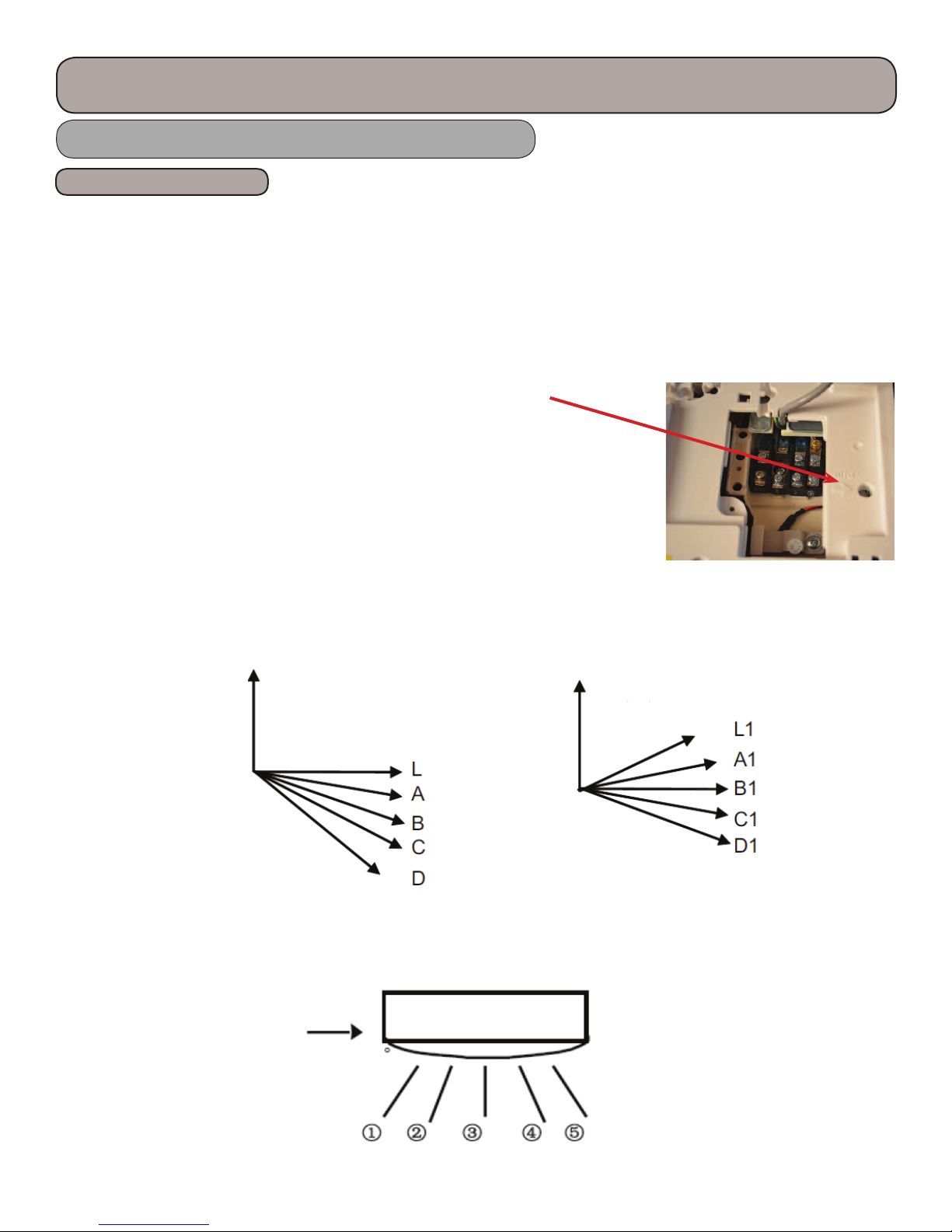

10) Swing Control

Vertical Swing

During power-up, the vertical swing motor will move the horizontal louver counter clockwise and close the air de ector.

In Heating and Auto/Heat mode, the air de ector will move to position “D” if no swing mode is set. In Cooling mode the

louver will move to L1. All other positions can be set by pressing the appropriate button to change the swing location.

Heating Angle Cooling Angle

Horizontal swing

During power-up, the vertical louver will be reset to the start position and then stop in the middle position. ere are 7

positions that the horizontal swing can be set including automatic swing and stopping between position 1 & 5.

0

0

0

0

27

Product Introduction

System Operation 9,000/12,000 btuh Models, cont.

Other Controls

11) Display

1. Operational and Mode Display

All the display patterns will display for a time when the power is on, the operation pattern will display in red under standby

status. When the unit is started by the remote controller, the indication pattern will light and display the current operation.

You can turn o the display by pressing the “Light” button on the remote controller.

2. Indoor Unit Display

Depending on the settings on the remote controller, the Indoor Unit LED display may display the current temperature

setpoint and indoor ambient temperature. “H1” will be displayed during the defrost cycle.

12)Drying Function (XFan)

e indoor fan will run for 10 minutes a er the unit is turned o (cooling or dry modes only) to ensure that additional

moisture is removed from the coil.

13)Power-O Memory Function

Upon a power failure the mode of operation, swing function, light, set temperature and fan speed will retain memory. e

unit will restart when recovering from a power interruption to the memory saved before the interruption occurred. If the

power interruption occurs during a timed mode, the time le will not be remembered and will start to recount from the

beginning. ere will be a 3 minute compressor delay before resuming.

14)Outdoor Compressor and Condenser Heating Band Control

Under normal conditions, the control logic of the Electric Heating Bands will be as follows:

1. Control of Compressor Electric Heating Band

a) Conditions for startup: e compressor is o and outdoor ambient <= 23 F

b) Conditions for turning o : Compressor operating, Compressor o and outdoor ambient >= 28 F

c) Band will turn o if the outdoor ambient temperature sensor has a malfunction.

2. Control of Condenser Electric Heating Band

a) Condenser Band will be on if the Outdoor Ambient <= 34 F

b) During defrost operation, the heater band will operate 3 minutes a er the compressor starts operating. When

the compressor has operated for 3 minutes and the outdoor ambient >= 38 F, the band will be de-energized.

c) Electric band will be de-energized when the outdoor ambient >= 38 F

d) When 34 F < outdoor Ambient < 38 F, the electric heater band will keep it’s previous status.

If the outdoor sensor has a malfunction, the Electric Heating Band will be de-energized. It will have a 2 minute delay before it can be started again.

28

Product Introduction

System Operation 18,000/24,000 btuh Models

Basic Functions

e compressor should stay o for at least 3 minutes before starting the unit. e compressor circuit has a 3 minute delay if

the compressor is de-energized during a run cycle. If the compressor starts from a de-energized cycle, there will be no time

delay. e compressor has a minimum run time of 6 minutes regardless of room temperature.

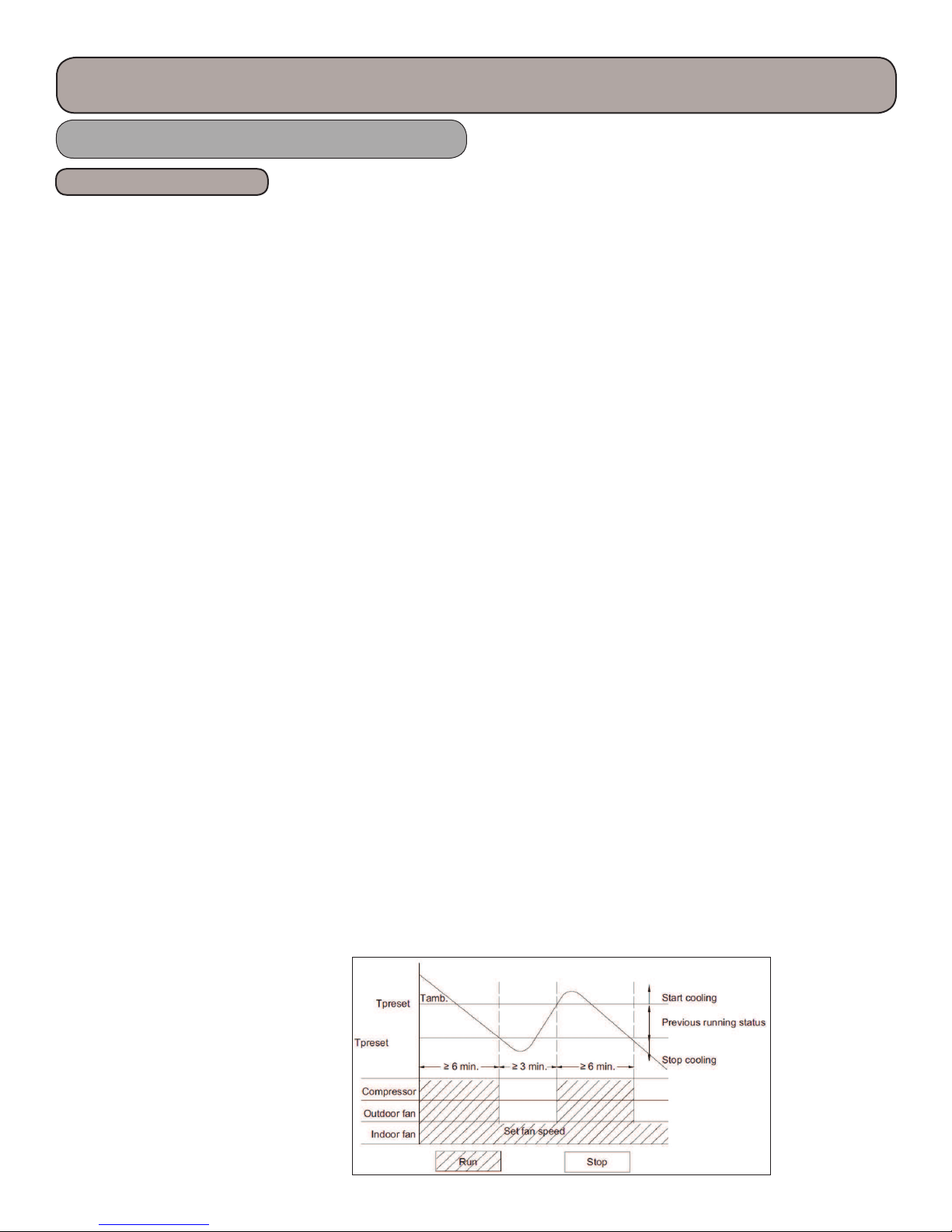

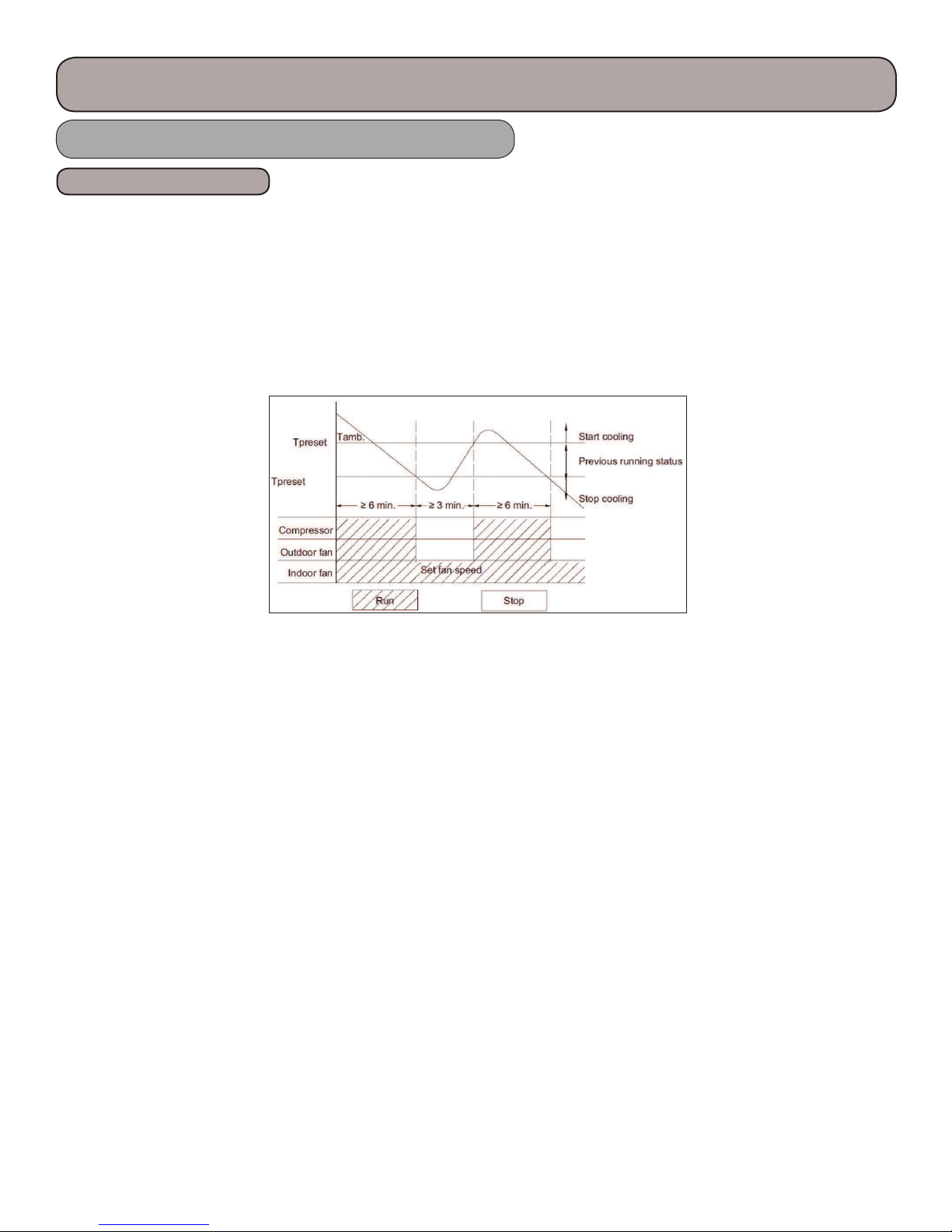

1) Cooling Mode

Cooling Process

When the indoor ambient rises 5 F above the preset temperature, the unit will start the cooling cycle. e outdoor fan and

compressor will start. e indoor fan will run continuously at the selected speed. e outdoor unit will monitor the appropriate temperatures and pressure and adjust the compressor speed and the EEV as required. If the indoor ambient is > 5

F then the preset temperature, the compressor speed will increase; < 5 F the compressor will begin reducing it’s speed. e

G10 technology will control compressor speed based on indoor load and compressor amperage. When the indoor temperature is satis ed, the compressor will stop, then 30 seconds later the outdoor fan will stop.

- 5.4 F

Evaporator Freeze Protection

e so ware will monitor the indoor evaporator coil for freezing.

In Cooling or Dry mode, if the Indoor tubes are < 32 F, for 3 consecutive minutes, the compressor will stop. e compressor will start when the tubes are above the calculated temperature limit. If the indoor tubes are < 43 F,

the compressor will adjust it’s speed as needed. If the unit has stopped 6 times repeatedly, the unit will stop and a fault code

will be displayed. e unit will need to be turned o , then back on to reset. As the compressor runs in normal mode, the

number of faults will be cleared, they may also be cleared by switching from fan mode to heat mode.

Overcurrent Protection

e so ware will monitor the compressor current to maintain it in a safety and operating range.

If the total current >= 17 amps, the compressor will stop and the indoor fan will stop a er 30 seconds. e system can

resume a er a 3 minute startup delay.

29

Product Introduction

System Operation 18,000/24,000 btuh Models, cont.

Basic Functions

2) Dry Mode

Drying Process

is feature will not take the place of a dehumidi er, it is intended to dry the ler and slightly cool the air. If the indoor

ambient temperature is greater than the preset temperature, the unit will enter the cooling and drying mode, in which

case the compressor will operate and the indoor fan will run at a low speed. When the indoor ambient temperature is at or

below the preset temperature, the unit will operate in it previous running state. When the indoor ambient drops to more

than 3.6 F below the preset temperature the compressor will stop running, then 30 seconds later the outdoor fan will stop,

the indoor fan will run at low speed.

-3.6 F

Overcurrent Protection (Same as Cooling Mode)

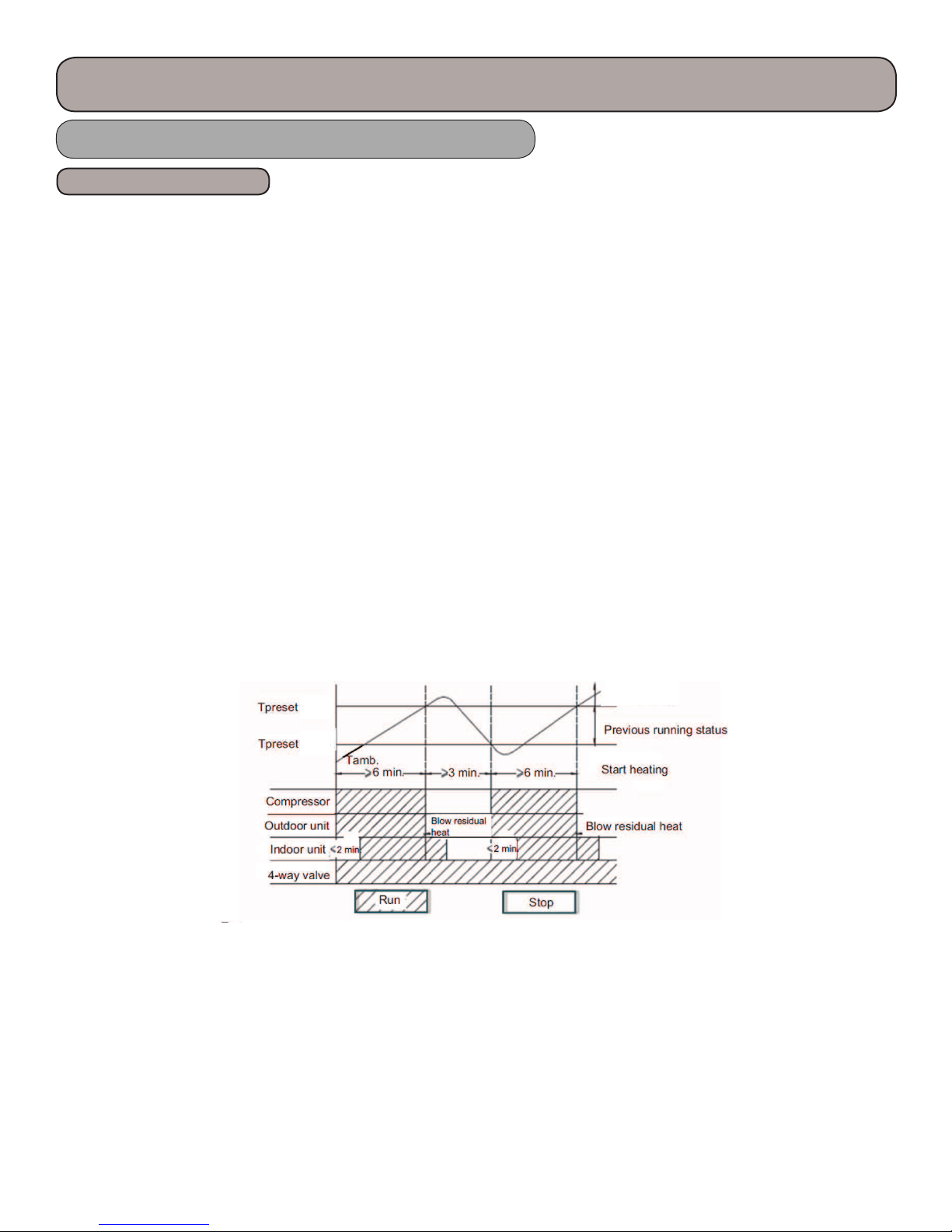

3)Heating Mode

Heating Process

When the indoor ambient drops 2 F below the preset temperature, the unit will start the heating cycle. e outdoor fan,

compressor and 4-way valve will operate. e indoor fan will operate in the “Cold Air Prevention” mode in which the

indoor fan will have a 2 minute delay a er the call for heating. e indoor evaporator coil temperature must reach 104 F

before the indoor fan will start, this will prevent cold air from discharging from the indoor coil. When the indoor evaporator coil temperature is > 104 F, the indoor fan will operate at low speed for 1 minute. With 1 minute of operation or 2

minutes of no fan operation and the indoor evaporator coil temperature is > 108 F, the indoor fan will operate at its preset

condition.

If the indoor ambient temperature is < 9 F and > 2 F of the preset temperature, the unit will run in its original mode of

operation.

If the compressor is running and the mode is changed from cooling to heating, the 4-way valve will be energized 2-3 minutes later.

If the indoor ambient temperature is >= 9 F than the preset temperature, the compressor will stop and the outdoor fan will

stop a er a 30 second delay. e indoor fan will continue to operate at its preset mode.

e G10 technology will determine compressor frequency based on ambient temperatures.

30

Loading...

Loading...