Gree GWH(12)KF-K3DNA6E/I, GWH(12)KF-K3DNB1E/I, GWH(07)KF-K3DNA6E/I, GWH(09)KF-K3DNB1E/I, GWH(07)KF-K3DNA8E/I Service Manual

...

GREE ELECTRIC APPLIANCES,INC.OF ZHUHAI

Change for Life

Service Manual

Models:

GWH(07)KF-K3DNA8E/I

GWH(07)KF-K3DNA6E/I

GWH(07)KF-K3DNB4E/I

GWH(07)KF-K3DNB1E/I

GWH(07)KF-K3DNA5E/I

GWH(07)KF-K3DNB2E/I

GWH(09)KF-K3DNA6E/I

GWH(09)KF-K3DNB1E/I

GWH(09)KF-K3DNA5E/I

GWH(09)KF-K3DNB2E/I

GWH(12)KF-K3DNA6E/I

GWH(12)KF-K3DNB4E/I

GWH(12)KF-K3DNB1E/I

GWH(12)KF-K3DNB2E/I

GWH(12)KF-K3DNA5E/I

GWH(18)KG-K3DNA6E/I

GWH(18)KG-K3DNB2E/I

GWH(18)KG-K3DNA8E/I

GWH(18)KG-K3DNB1E/I

GWH(18)KG-K3DNA5E/I

(Refrigerant R410A)

Service Manual

Table of Contents

Table of Contents

Part

Ⅰ

: Technical Information

................................................................................. 1

1. Summary

................................................................................................................................ 1

2. Specications

.................................................................................................................... 2

2.1 Specication Sheet

..............................................................................................................2

2.2 Noise Criteria Curve Tables for Both Models

................................................................. 4

3. Outline Dimension Diagram

.................................................................................. 5

4. Electrical Part

..................................................................................................................... 6

4.1 Wiring Diagram ...........................................................................................................................6

4.2 PCB Printed Diagram ................................................................................................................. 8

5. Function and Control

................................................................................................ 10

5.1 Remote Controller Introduction ...............................................................................................10

5.2 Brief Description of Modes and Functions ................................................................................14

Part

Ⅱ

: Installation and Maintenance

........................................................... 18

6. Notes for Installation and Maintenance

.................................................... 18

7. Installation

.......................................................................................................................... 20

7.1 Installation Dimension Diagram ................................................................................................ 20

7.2 Installation Parts-Checking ....................................................................................................... 22

7.3 Selection of Installation Location .............................................................................................. 22

7.4 Requirements Forelectric Connection ...................................................................................... 22

7.5 Installation of Indoor Unit .......................................................................................................... 22

7.6 Check after Installation and Test Operation ............................................................................. 25

8. Maintenance

...................................................................................................................... 26

8.1 Error Code ................................................................................................................................ 26

8.2 Troubleshooting ...................................................................................................................... 28

8.3 Maintenance Method for Normal Malfunction ........................................................................... 34

9. Exploded View and Parts List

........................................................................... 36

10. Removal Procedure

................................................................................................. 46

Service Manual

Table of Contents

Appendix:

................................................................................................................................... 52

Appendix 1: Reference Sheet of Celsius and Fahrenheit

...................................................... 52

Appendix 2: Conguration of Connection Pipe

........................................................................52

Appendix 3: Pipe Expanding Method

.........................................................................................53

Appendix 4: List of Resistance for Temperature Sensor

........................................................ 54

1

Technical Information

Service Manual

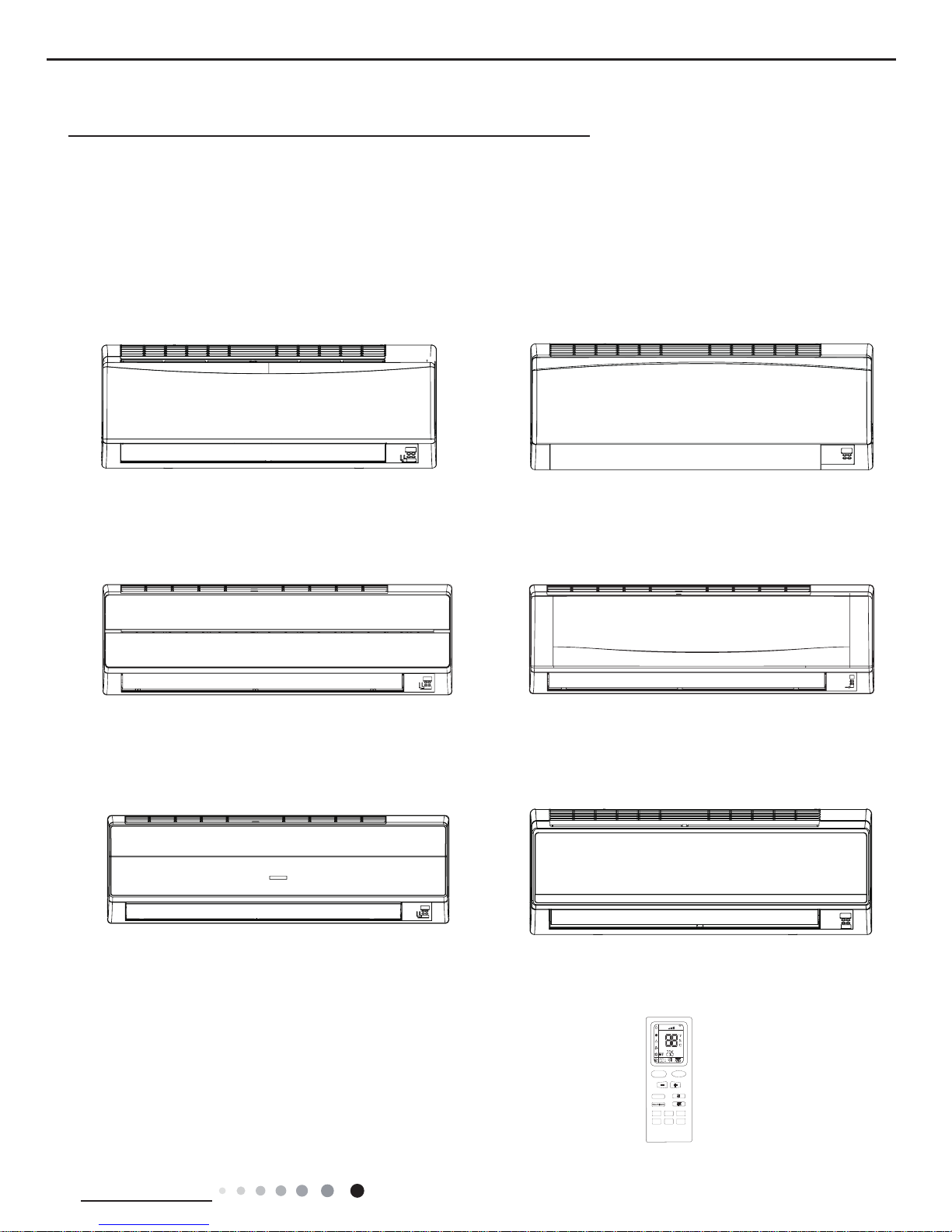

1. Summary

Indoor Unit:

GWH(07)KF-K3DNA6E/I

GWH(09)KF-K3DNA6E/I

GWH(12)KF-K3DNA6E/I

GWH(18)KG-K3DNA6E/I

GWH(07)KF-K3DNA8E/I

GWH(18)KG-K3DNA8E/I

GWH(07)KF-K3DNB4E/I

GWH(12)KF-K3DNB4E/I

GWH(07)KF-K3DNB2E/I

GWH(09)KF-K3DNB2E/I

GWH(12)KF-K3DNB2E/I

GWH(18)KG-K3DNB2E/I

GWH(12)KF-K3DNA5E/I

GWH(18)KG-K3DNA5E/I

GWH(07)KF-K3DNA5E/I

GWH(09)KF-K3DNA5E/I

Part

Ⅰ

: Technical Information

GWH(07)KF-K3DNB1E/I

GWH(09)KF-K3DNB1E/I

GWH(12)KF-K3DNB1E/I

GWH(18)KG-K3DNB1E/I

Remote Controller:

FAN

AUTO

OPER

HEALTH

AIR

FILTER

TURBO

ON/OFF

X-FAN

HOUR

HUMIDITY

ON/OFF

MODE

FAN

X-FAN

TURBO

TEMP

TIMER

SLEEP

LIGHT

YB1F2(XFAN)

2

Technical Information

Service Manual

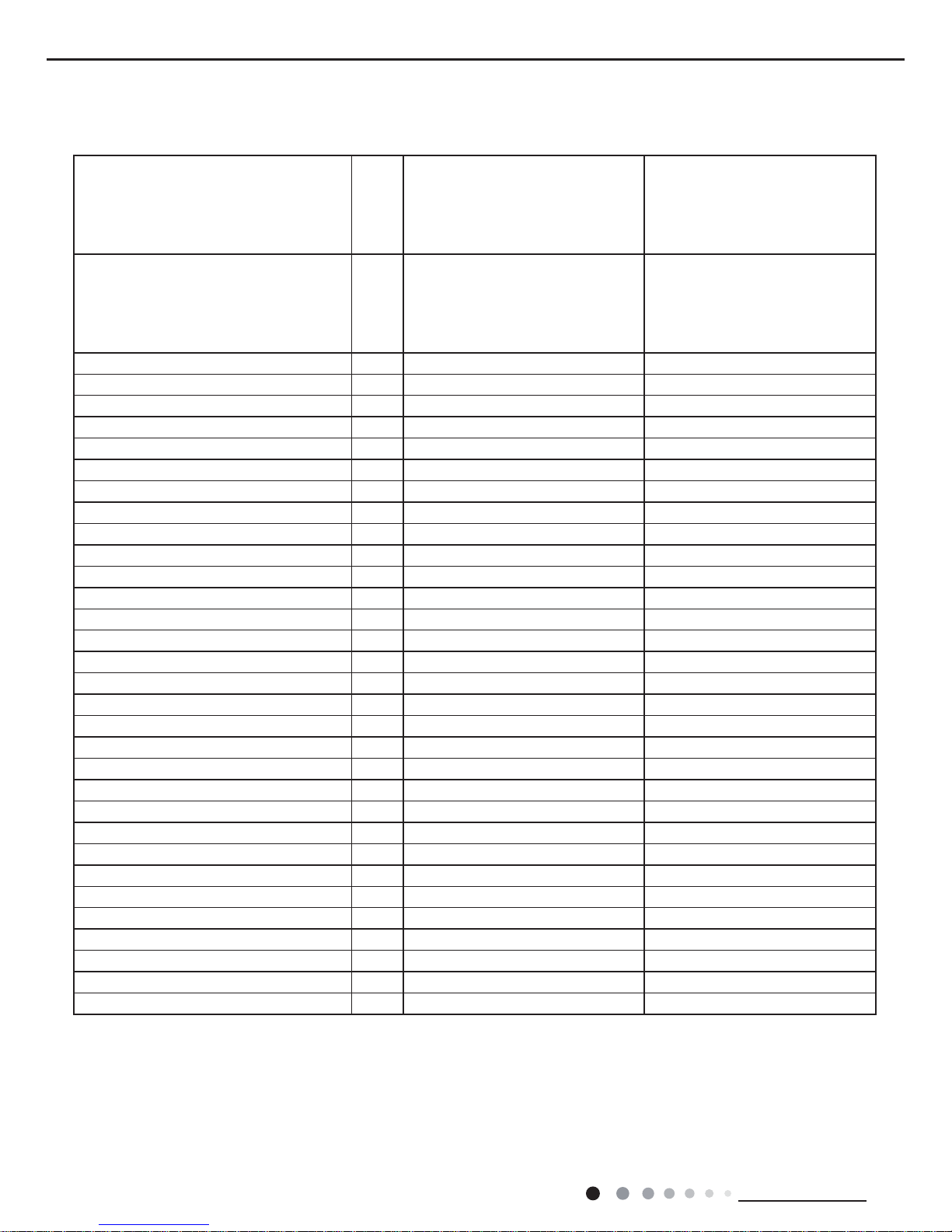

2. Specications

2.1 Specication Sheet

The above data is subject to change without notice. Please refer to the nameplate of the unit.

Model

GWH(07)KF-K3DNA6E/I

GWH(07)KF-K3DNA8E/I

GWH(07)KF-K3DNB4E/I

GWH(07)KF-K3DNB1E/I

GWH(07)KF-K3DNA5E/I

GWH(07)KF-K3DNB2E/I

GWH(09)KF-K3DNA6E/I

GWH(09)KF-K3DNB1E/I

GWH(09)KF-K3DNA5E/I

GWH(09)KF-K3DNA6E/I

GWH(09)KF-K3DNB2E/I

Product Code

CB146N26201

CB146N32800

CB146N33300

CB146N30000

CB146N35500

CB409N01400

CB146N26301

CB146N30100

CB146N28301

CB146N26302

CB409N01100

Rated Voltage V~ 220-240 220-240

Rated Frequency Hz 50 50

Phases 1 1

Cooling Capacity KW 2.1 2.6

Heating Capacity KW 2.6 2.8

Air Flow Volume (SH/H/M/L) m3/h 550/520/370/280 600/520/370/280

Dehumidifying Volume L/h 0.6 0.8

Fan Type Cross-ow Cross-ow

Fan Diameter-height mm Φ92X594 Φ92X594

Fan Motor Speed (SH/H/M/L) Cool rpm 1350/1100/900/700 1350/1100/900/700

Fan Motor Speed (SH/H/M/L) Heat rpm 1350/1140/980/820 1350/1140/980/820

Fan Motor Power Output W 10 10

Fan motor running current A 0.16 0.16

Fan Motor Capacitor μF 1.2 1.2

Evaporator Material Aluminum Fin-copper Tube Aluminum Fin-copper Tube

Evaporator Pipe Diameter mm 7 7

Evaporator Number of Rows 2 2

Evaporator Fin Pitch mm 1.4 1.4

Evaporator Length(L) X Height(H) X Width(W) mm 610X25.4X294 610X25.4X294

Motor Model FN10V-PG FN10V-PG

Overload Protector 3.15 3.15

Motor Full Load Amp(FLA) A 0.16 0.16

Sound Pressure Level (SH/H/M/L) dB (A) 40/38/30/24 41/38/30/24

Sound Power Level (SH/H/M/L) dB (A) 50/48/40/34 51/48/40/34

Outline Dimension (WXHXD) mm 770X283X201 770X283X201

Package Carton Dimension (LXWXH) mm 844X342X261 844X342X261

Package Dimension (LXWXH) mm 847X345X276 847X345X276

Net Weight kg 8 8

Gross Weight kg 10 10

Liquid Pipe mm Φ6 Φ6

Gas Pipe(to Indoor Unit) mm Φ9.52 Φ9.52

3

Technical Information

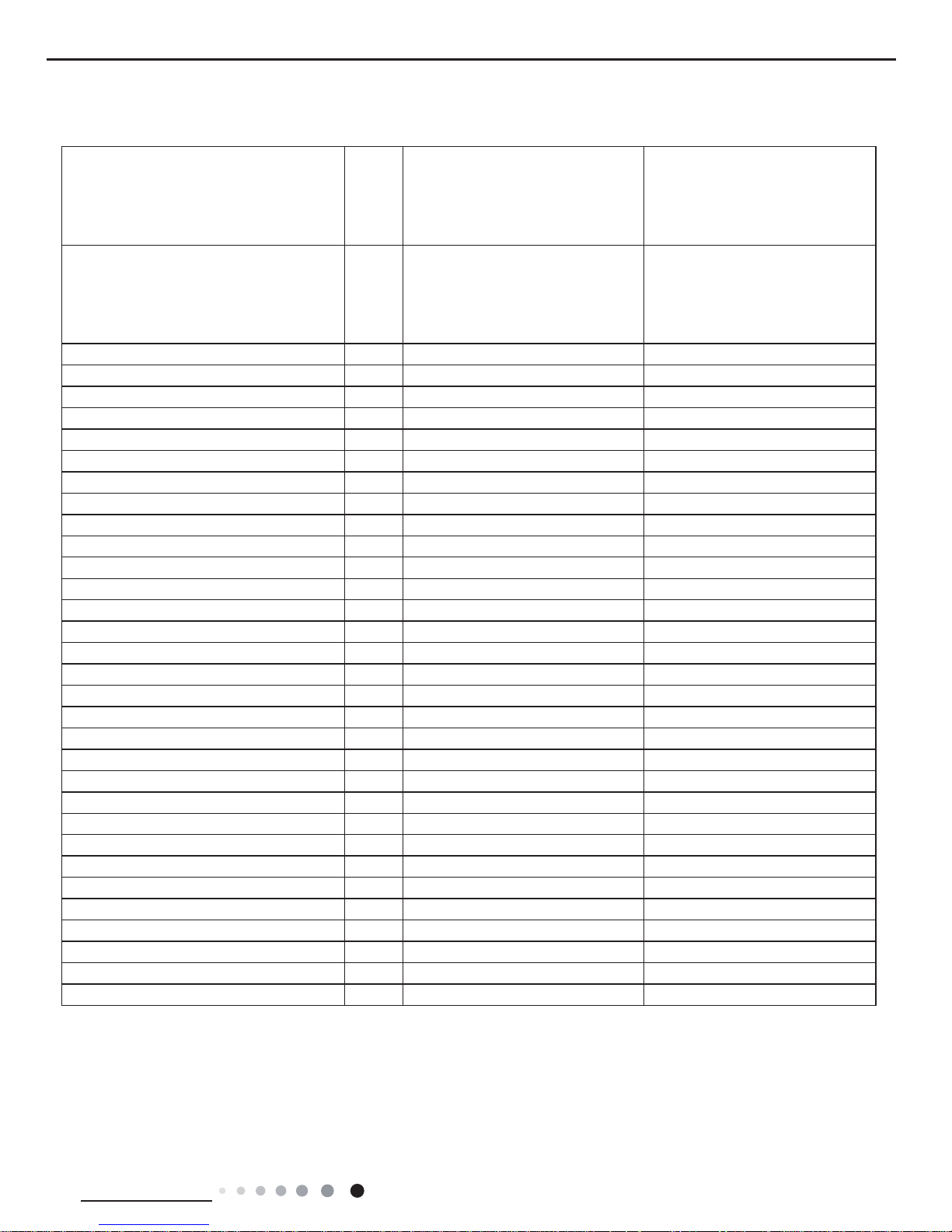

Service Manual

The above data is subject to change without notice. Please refer to the nameplate of the unit.

Model

GWH(12)KF-K3DNA6E/I

GWH(12)KF-K3DNB4E/I

GWH(12)KF-K3DNB1E/I

GWH(12)KF-K3DNA5E/I

GWH(12)KF-K3DNA6E/I

GWH(12)KF-K3DNB2E/I

GWH(18)KG-K3DNA6E/I

GWH(18)KG-K3DNB2E/I

GWH(18)KG-K3DNB1E/I

GWH(18)KG-K3DNA5E/I

Product Code

CB146N26401

CB146N33400

CB146N30500

CB146N33001

CB146N26402

CB409N00900

(CB146N32500/CB146N26501)

CB409N01900

CB146N35400

CB146N32901

Rated Voltage V~ 220-240 220-240

Rated Frequency Hz 50 50

Phases 1 1

Cooling Capacity KW 3.5 5.3

Heating Capacity KW 3.8 5.8

Air Flow Volume (SH/H/M/L) m3/h 680/560/410/300 800/680/560/460

Dehumidifying Volume L/h 1.4 1.8

Fan Type Cross-ow Cross-ow

Fan Diameter-height mm Φ92X594 Φ98X710

Fan Motor Speed (SH/H/M/L) Cool rpm 1350/1150/950/750 1350/1100/950/800

Fan Motor Speed (SH/H/M/L) Heat rpm 1350/1190/1020/850 1400/1200/1050/900

Fan Motor Power Output W 10 20

Fan motor running current A 0.16 0.31

Fan Motor Capacitor μF 1.2 1.5

Evaporator Material Aluminum Fin-copper Tube Aluminum Fin-copper Tube

Evaporator Pipe Diameter mm 7 7

Evaporator Number of Rows 2 2

Evaporator Fin Pitch mm 1.4 1.4

Evaporator Length(L) X Height(H) X Width(W) mm 610X25.4X294 657X25.4X304.8

Motor Model FN10V-PG FN20V-PG

Overload Protector 3.15 3.15

Motor Full Load Amp(FLA) A 0.16 0.31

Sound Pressure Level (SH/H/M/L) dB (A) 42/39/31/25 45/40/37/32

Sound Power Level (SH/H/M/L) dB (A) 52/49/41/35 55/50/47/42

Outline Dimension (WXHXD) mm 770X283X201 865X305X215

Package Carton Dimension (LXWXH) mm 844X342X261 945X380X295

Package Dimension (LXWXH) mm 847X345X276 948X383X310

Net Weight kg 9 12

Gross Weight kg 11 15

Liquid Pipe mm Φ6 Φ6

Gas Pipe(to Indoor Unit) mm Φ9.52 Φ12

4

Technical Information

Service Manual

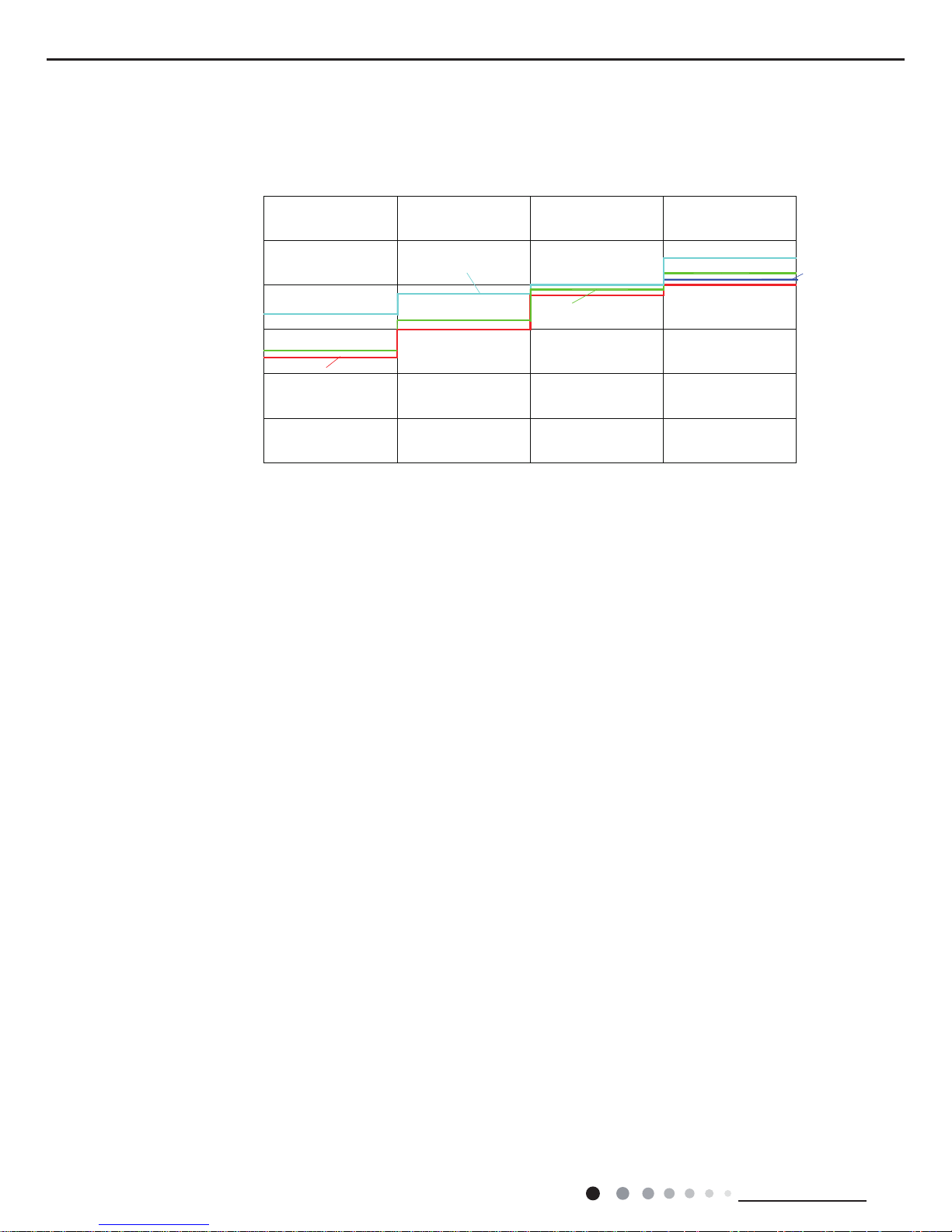

2.2 Noise Criteria Curve Tables for Both Models

0

10

Noice/dB(A)

20

30

40

50

60

Low Middle High Super High

Indoor Fan Motor Rotating Speed

7K

9K

12K

18K

5

Technical Information

Service Manual

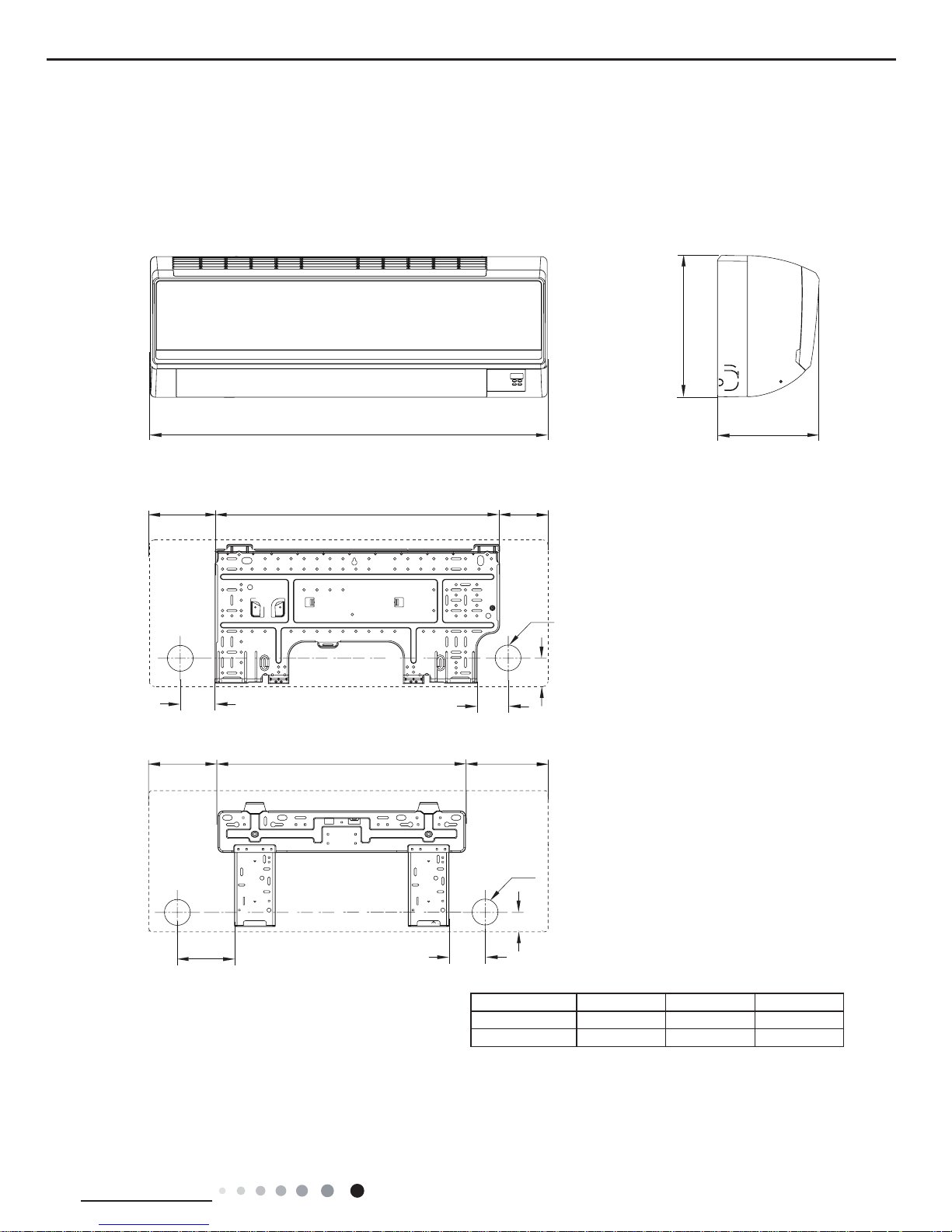

3. Outline Dimension Diagram

3.1 Indoor Unit

Modle W H D

07/09/12K 770 283 201

18K 865 305 215

W

120

66

93

150

542

161

71

173

548 102

2XΦ55

2XΦ55

H

41.3

40

D

07/09/12K:

18K:

Unit:mm

6

Technical Information

Service Manual

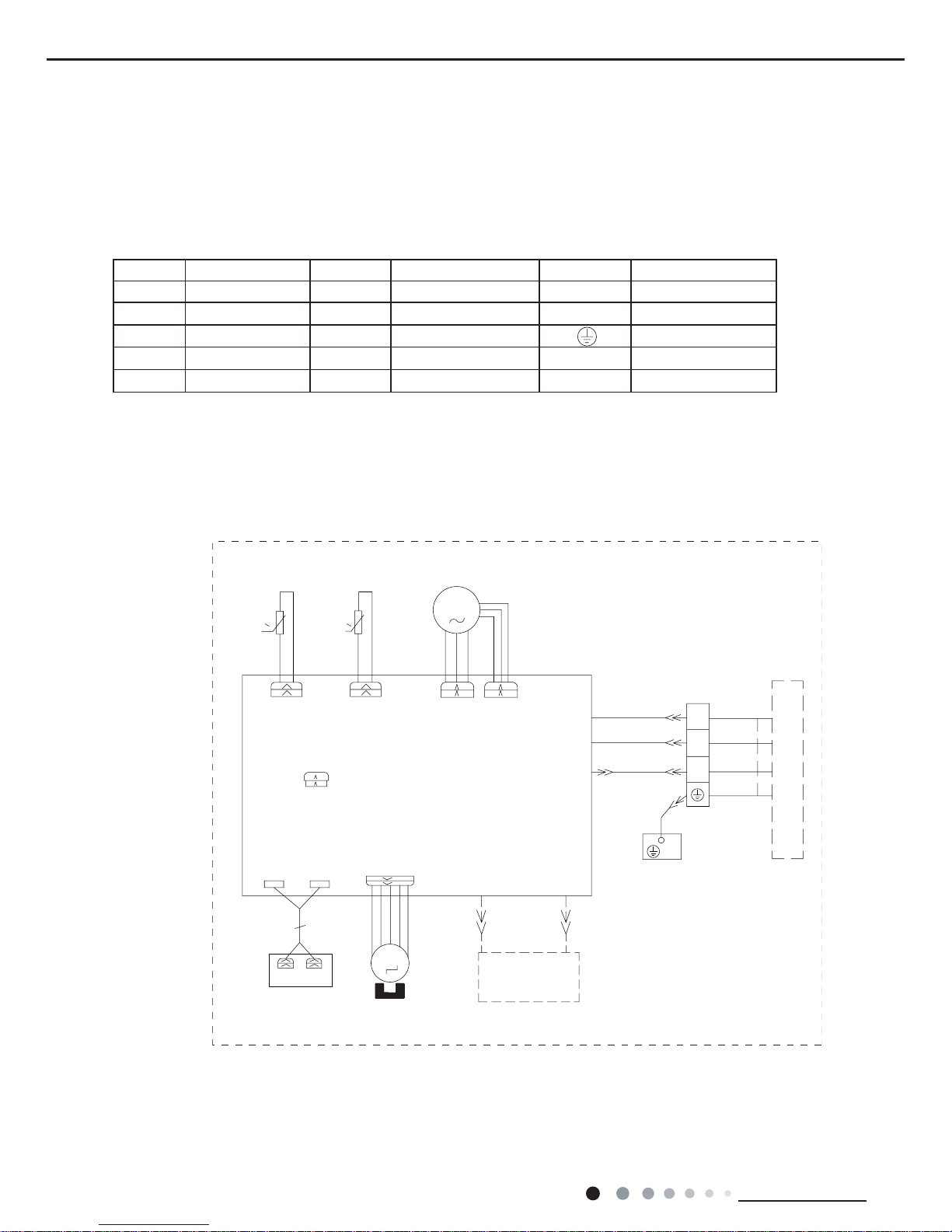

4. Electrical Part

4.1 Wiring Diagram

● Indoor Unit

●Instruction

Symbol Symbol Color Symbol Symbol Color Symbol Name

WH White GN Green CAP Jumper cap

YE Yellow BN Brown COMP Compressor

RD Red BU Blue Grounding wire

YEGN Yellow/Green BK Black / /

VT Violet OG Orange / /

Note: Jumper cap is used to determine fan speed and the swing angle of horizontal lover for this model.

0

TUBE

ROOM

N

M2

N(1)

XT

BU

3

YEGN

2

RT1

DISP1

0

RT2

BK

BN

PE

YEGN

COM-OUT

BK

BN

BU

AP1

AC-L

DISP2

SWING-UD

PGF

M1

PG

MOTOR

FAN

TEM.SENSOR

ROOM

TEM.SENSOR

TUBE

OUTDOOR UNIT

DISPLAY

SWING

MOTOR

EVAPORATOR

AP2

HEALTH-NHEALTH-L

COOL PLASMA

GENERATOR

BU

RD

(optional)

JUMP

CAP

07/09/12K

7

Technical Information

Service Manual

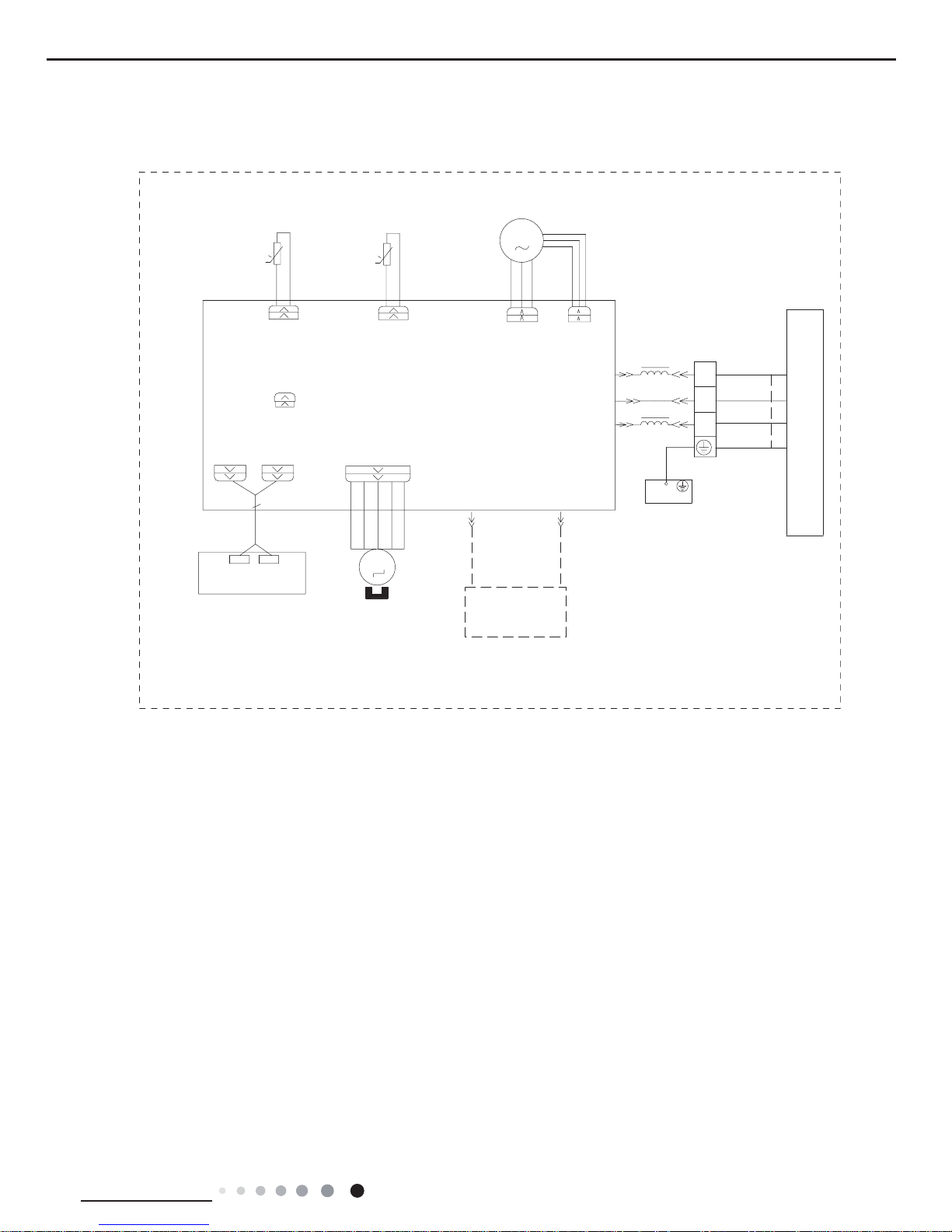

These wiring diagrams are subject to change without notice; please refer to the one supplied with the unit.

AC-L

3BK

TEM.SENSOR

TEM.SENSOR

PE

BK

ROOM

TUBE

M2

SWING-UD

RT2

AP2

2BN

PG

4YEGN

0

M1

1BU

FAN

OUTDOOR UNIT

BN

2

YEGN

3

BU

XT

N(1)

TUBE

ROOM

0

RT1

SWING

MOTOR

COM-OUT

N

PGF

MOTOR

CAP

JUMP

DISP2

DISP1

AP1

RECEIVER AND

DISPLAY BOARD

BU

RD

HEALTH-N

HEALTH-L

GENERATOR

COOL PLASMA

NOTE:The parts with broken line is applicable

to the models with COOL PLASMA GENERATOR

EVAPORATOR

18K

8

Technical Information

Service Manual

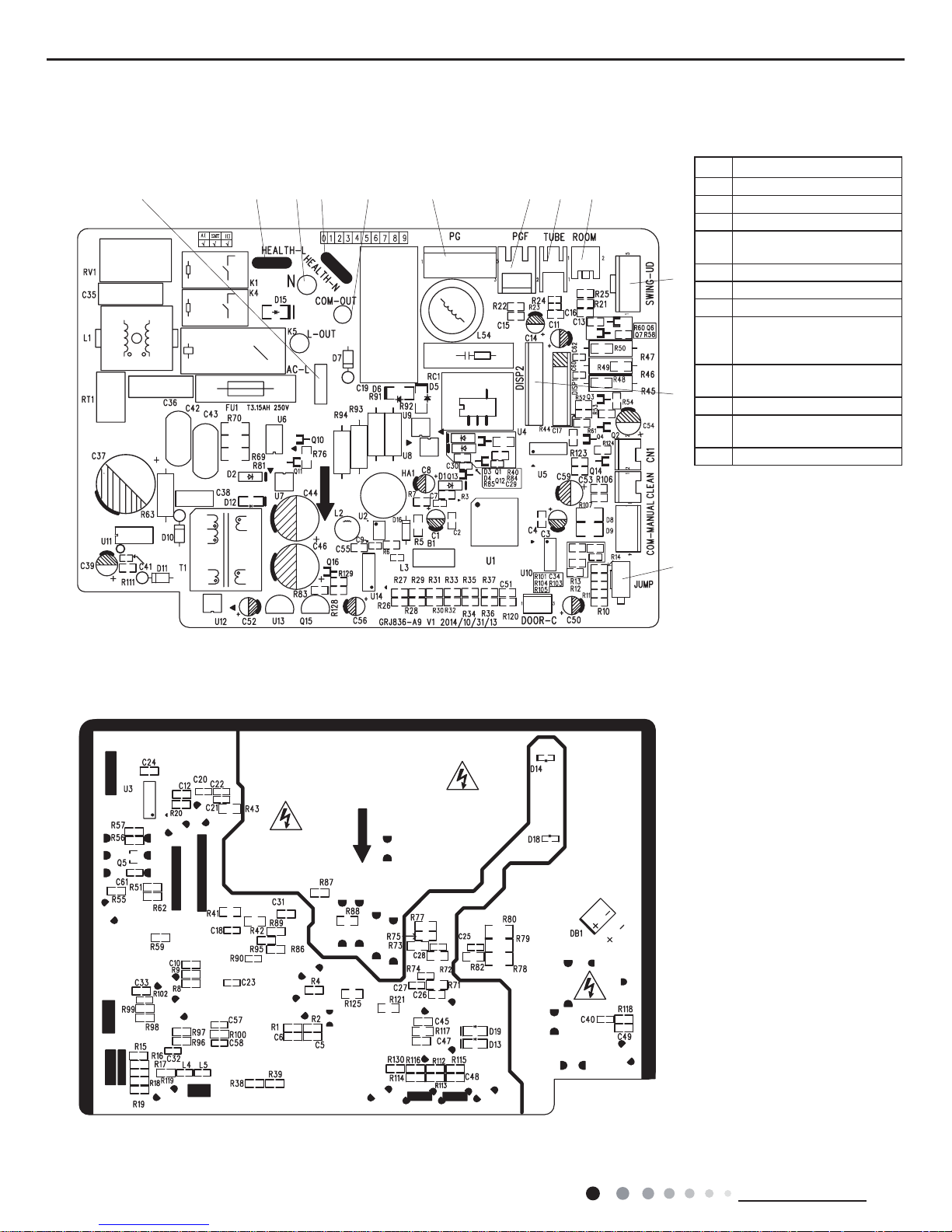

4.2 PCB Printed Diagram

● Top view

● Bottom view

(1) 07/09/12K

No. Name

1 Jumper cap

2 Display interface 1, 2

3 Up&down swing

4

Ambient temperature

sensor

5 Tube temperature sensor

6 PG feedback interface

7 PG motor interface

8

Communication interface

between live wire and

neutral wire

9

Neutral wire for healthy

function

10 Interface of neutral wire

11

Live wire for healthy

function

12 Interface of live wire

1

2

3

456

78

91011

12

9

Technical Information

Service Manual

● Top view

● Bottom view

(2) 18K

No. Name

1

Interface of health function

neutral wire

2 Interface of live wire

3 Neutral wire

4 Fuse

5 PG motor

6

Interface of health function

live wire

7

Communication interface

between indoor unit and

outdoor unit

8 Auto button

9 Up&down swing

10 PG feedback

11 Display interface

12 Jumper cap

13

Ambient temperature

sensor

14 Tube temperature sensor

1

2

3

4

5

6

7

8

9

10

11

12

13

14

10

Technical Information

Service Manual

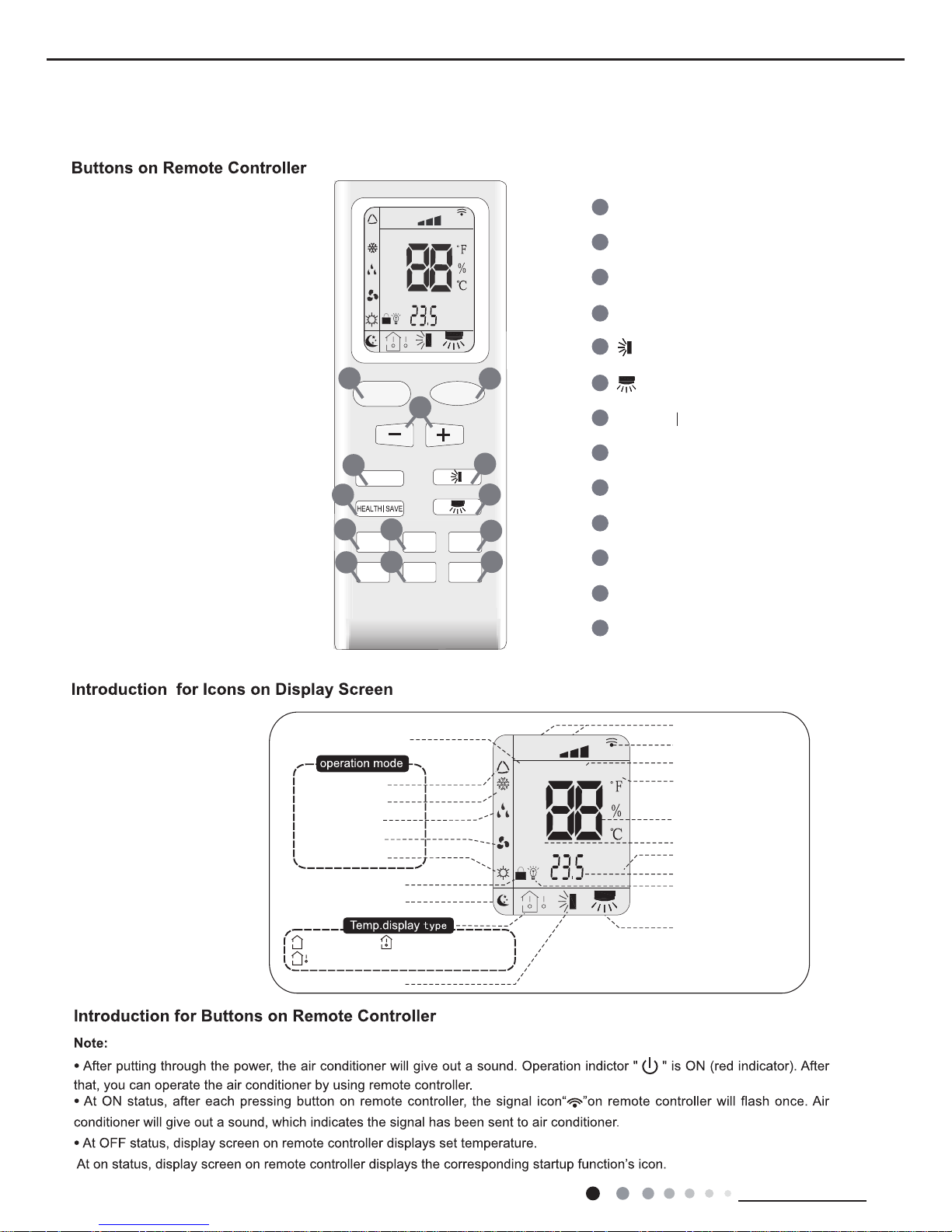

5. Function and Control

5.1 Remote Controller Introduction

ON/OFF Button

2

3

1

5

6

4

9

10

8

12

13

11

MODE Button

+/- Button

X-FAN Button

TEMP Button

TURBO Button

SLEEP Button

LIGHT Button

Button

HEALTH SAVE Button

7

Button

TIMER Button

FAN Button

FAN

AUTO

OPER

HEALTH

AIR

FILTER

TURBO

ON/OFF

X-FAN

HOUR

HUMIDITY

ON/OFF

MODE

FAN

X-FAN

TURBO

TEMP

TIMER

SLEEP

LIGHT

2

10

7

9

12

8

3

11

6

5

13

4

1

Child lock

Left&right swing

Sleep mode

Auto mode

Air mode

Cool mode

Heat mode

Fan mode

Dry mode

Up&down swing

:Indoor ambient temp.:Set temp.

:Outdoor ambient tep.

FAN

OPER

AUTO

HEALTH

AIR

FILTER

TURBO

ON/OFF

X-FAN

HOUR

HUMIDITY

TIMER ON/TIMER OFF

Set time

Light

Send signal

Sleep mode

X-fan

Set fan speed

Set temperature

Turbo mode

Temp. display type

Operation mode

11

Technical Information

Service Manual

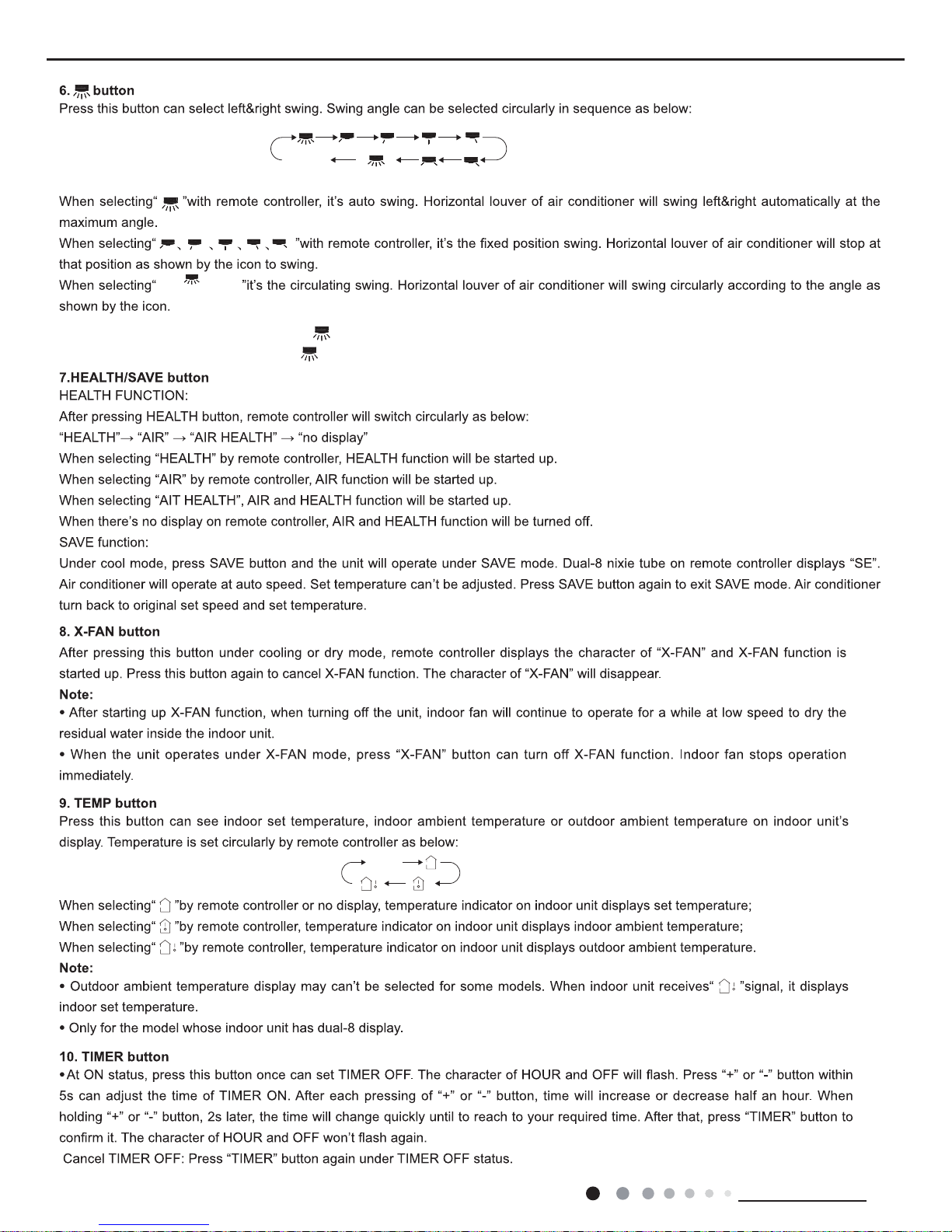

AUTO COOL DRY FAN HEAT

Auto

no display

(horizontal louvers

stops at current position)

high speed.

5.

Under unit off status, press “+” button and button simultaneously to switch between simple swing setting and fixed-angle swing setting.

During switching the two swing settings, icon will blink for 2s.

12

Technical Information

Service Manual

no display

no display

(swing angle is

displayed dynamically)

(horizontal louvers

stops at current position)

(swing angle is

displayed dynamically)

Under unit off status, press “+” button and button simultaneously to switch between simple swing setting and fixed-angle swing setting.

During switching the two swing settings, icon will blink for 2s.

(Note:Health function is not available for some models.)

13

Technical Information

Service Manual

Signal sender

Battery

Cover of

battery box

Remove

Reinstall

14

Technical Information

Service Manual

5.2 Brief Description of Modes and Functions

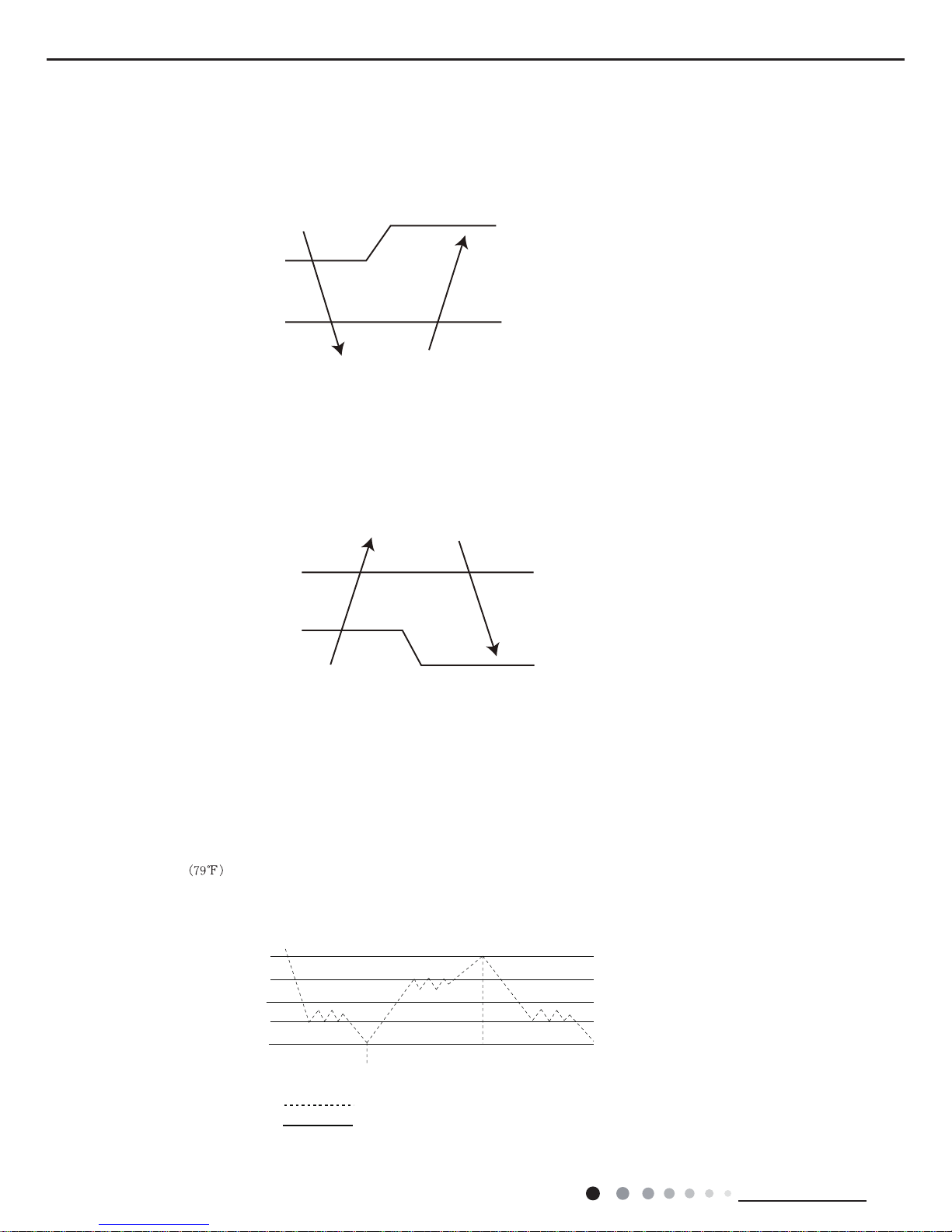

A

B

C

B

C

A

1.Cooling Only

(1) Under this mode, fan and swing run at preset status, the temperature setting range is 16-30ć.

(2) Under malfunction for outdoor unit and protection stop, the indoor unit runs with the original status, and display malfunction.

(3) The indoor fan stops when the modes conflict with each other.

2. Dry Mode

(1) Under this mode, the indoor fan runs with low speed, and swing runs at preset status, the temperature setting range is 16-30

(2) Under malfunction for outdoor unit and protection stop, the indoor unit runs with the original status, and display malfunction.

3. Heating Mode

(1) Under this mode, the temperature setting range is 16-30ć.

(2) Working condition and Process of Heating

When the unit is ON and in heating mode, indoor fan starts cold air prevention operation; when the unit is off and the

indoor fan stopped before, it blows residual heat.

(3) Protection Function. The compressor stops as the malfunction (including any temperature sensor malfunction) in

heating mode, the indoor fan runs with blowing residual heat

(4) Defrosting and Oil Return

Once defrosting singnal of outdoor unit is received,Heating indicator on indoor unit OFF 0.5s and ON 10s.

ć.

4. Working Methods of Auto Mode

(1) When Tamb.≥26ć

, it operates in Cool mode.

(2) For heat pump unit, when Tamb.≤22ć, it operates in Heat mode.

(3) When 22ć< Tamb.< 26ć, it operates in auto fan mode upon initial startup of the unit. When changing to auto mode from

other modes, it will keep the previous operation mode (when it enter Dry mode, it operates in auto fan mode.).

5. Fan Mode

Only indoor fan operates in Fan mode. Under auto fan speed, it runs in cooling auto fan mode.

I. Basic Operation Mode

1. Cool; 2.Dry; 3.Heat; 4.Auto; 5.Fan

II. Basic Functions

indoor temperature---target temperature

target temperature---indoor temperature

With compressor capacity supplied

With no compressor capacity supplied

Cooling

operation

Heating

operation

Cooling

operation

15

Technical Information

Service Manual

1. Buzzer

The buzzer will give out a beep when the controller is energized, receiving signal from remote controller and auto button.

2. Auto Button

Press this button once, it will operate in Auto mode, and indoor fan operates in Auto fan mode and swing. When the unit is on,

pressing this button will turn off the unit.

3. Auto Fan

a. Auto fan speed under heating mode

When Tinddor amb. ≤Tpreset+1℃, indoor fan operates at high speed;

When Tpreset+1℃<T inddor amb.<Tpreset+3℃, indoor fan operates at medium speed;

When T inddor amb.≥Tpreset+3℃, indoor fan operates at low speed.

b. Auto fan speed under cooling or fan mode

WhenT amb.≥Tpreset+3℃, indoor fan operates at high speed;

When Tpreset+1<T amb.<Tpreset+3℃, indoor fan operates at medium speed;

WhenT amb.≤Tpreset+1℃, indoor fan operates at low speed.

c. Auto fan speed under drying mode is low speed.

During auto fan speed, there’s should be at least 3min and 30s operation time when switching between high speed, medium

speed and low speed.

4. Sleep

5. Timer Function

(1) General Timer:

1.1 Time On: if Timer On is set when the system is,the controller will operate in the original setting mode after reaching the

timer on time. The timer interval is 0.5h, and the setting range is 0.5-24h.

1.2 Timer Off: Timer Off can be set when the unit is on. The unit will be off when timer off time is reahced. The timer

interval is 0.5h, and the setting range is 0.5-24h.

(2) Clock Timer:

2.1 Timer On: If Timer On is set when the system runs, it will continue to run; if Timer On is set when the system is off, the

system will start to run in the original setting mode when timer on time is reached.

2.2 Timer Off: If timer off is set when the system is off, the system keeps stand-by status; if timer off is set when the system

is on, the system stops when reaching timer off time.

III. Other Control

Sleep mode is only valid under cooling mode and heating mode;

Cooling mode: Basing on the set temperature of remote controller, after turning on the sleep function for a few hours, set

temperature will increase properly and automatically according to human body’s comfort.

Heating mode: Basing on the set temperature of remote controller, after turning on the sleep function for a few hours, set

temperature will decrease properly and automatically according to human body’s comfort.

2.3 Timer Change

Timer On and Timer OFF can be set via remote ON/OFF button. Timer time can be reset and the system will operate according to

the latest setting.

When the unit is on and Timer On and Timer Off are both set, the system will operate according to the set state. When the timer off

time is reached, the system will stop.

When the system stops, and Timer On and Timer Off are both set, the system will remain stop until timer on time is reached. After

that, the unit will operate according to the set mode everyday when the timer on time is reached. When the timer off time is reached,

the system will stop. If timer on time is the same as timer off time, the system will stop.

6. Memory Function

Memory contents: mode, up& down swing, light, set temperature, set fan speed, general timer (but clock timer). After power failure, if

the unit is reenergized, it will operate according to memory contents. If Timer function is not set in the last remote control, the system

will operate according to the last remote control.

If general timer function is set in the last remote control and power failure occurs before timer time is reached, the unit will operate

according to the timer function set in the last remote control. Timer time is calculated after the unit is re-energized.

If general timer function is set in the last remote control and power failure occurs after timer time is reached, the system will operate

according to the memory content before power failure. Timer operation is not memorized.

Loading...

Loading...