Gree GWC12KF-K3DNA5A, GWC09KF-K3DNA5A, GWH12KF-K3DNA6A, GWH09KF-K3DNB1A, GWH12KF-K3DNB1A Service Manual

...

GREE ELECTRIC APPLIANCES,INC.OF ZHUHAI

Service Manual

MODEL:

(Refrigerant R410A)

GWC09KF-K3DNA5A GWC12KF-K3DNA5A

GWH09KF-K3DNA5A GWH12KF-K3DNA5A

GWH09KF-K3DNA6A GWH12KF-K3DNA6A

GWH09KF-K3DNB1A GWH12KF-K3DNB1A

Table of Contents

Summary and features..................................................................................1

Part 1 Safety Precautions

..........................................................................................2

Part 2 Specifications.....................................................................................................3

2.1 Unit Specifications..................................................................................................3

2.3 CapacityVariation Ratio AccordingtoTemperature...............................................11

2.2 Operation Characteristic Curve............................................................................11

2.4 Operation Date.....................................................................................................12

2.5 Noise criteria curve tables for both models..........................................................12

Part 3 Construction Views

......................................................................................13

3.1 Indoor Unit ...........................................................................................................13

3.2 Outdoor Unit ........................................................................................................14

Part 4 Refrigerant System Diagram

...................................................................15

5.1 Electrical Data......................................................................................................16

5.2 Electrical Wiring....................................................................................................16

5.3 Printed Circuit Board............................................................................................18

Part 5 Schematic Diagram

......................................................................................16

6.1 Remote Control Operations..................................................................................23

6.2 Changing Batteries and Notices ..........................................................................25

6.3 Description of Each Control Operation.................................................................26

6.4

.....................................................28

6.5 Frequency Control................................................................................................28

6.6 3-minutes Standby...............................................................................................28

6.7 Compressor Protection Function..........................................................................28

6.8 Discharge Pipe Control........................................................................................29

6.9 Input Current Control............................................................................................29

6.10 Freeze-up Protection Control.............................................................................29

6.11 Heating Peak-cut Control...................................................................................30

6.12 Defrost Control...................................................................................................30

6.13 Fan Control........................................................................................................31

Part 6 Function and Control

...................................................................................23

Troubleshooting of Temp Sensor Malfunction

Table of Contents

Part 8 Exploded Views and Parts List

..............................................................38

Part 9 Troubleshooting...............................................................................................53

9.1

Precautions Before Performing Inspection or Repair

...........................................53

9.2

Confirmation

.........................................................................................................53

9.3

Judgement by Flashing LED of Indoor/Outdoor Unit

...........................................53

9.4

How to Check Simply the Main Part

.....................................................................55

9.5

2-way, 3-way Valve Appearance

..........................................................................59

8.1 Indoor unit.............................................................................................................38

8.2 Outdoor unit..........................................................................................................45

Part10 Removal Procedure.......................................................................................66

10.1

Removal Procedure of Indoor Unit

.....................................................................66

10.2

Removal Procedure of Outdoor Unit

...................................................................80

Part 7 Installation Manual

........................................................................................32

7.3 Install Indoor Unit.................................................................................................32

7.2 Installation Position Selection..............................................................................32

7.1 Tools Required for Installation.............................................................................32

7.4 Install Outdoor Unit ..............................................................................................36

7.5 Test Operation......................................................................................................37

1

Summary and features

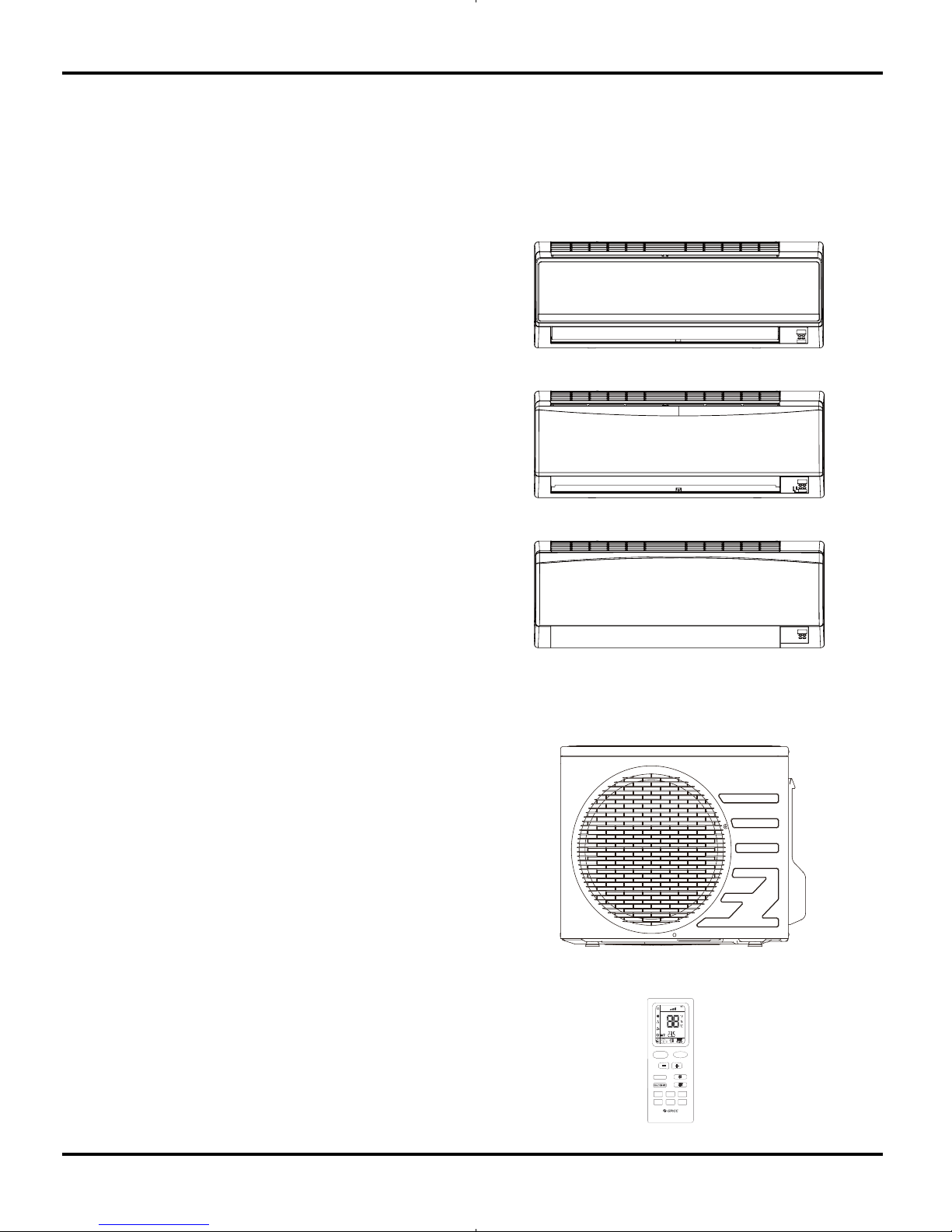

Indoor Unit

GWC09KF-K3DNA5A/I

GWH09KF-K3DNA5A/I

GWC12KF-K3DNA5A/I

GWH12KF-K3DNA5A/I

Outdoor Unit

GWC09KF-K3DNA5A/O

GWH09KF-K3DNA5A/O

GWC12KF-K3DNA5A/O

GWH12KF-K3DNA5A/O

Remote control window

YB1F2

Summary and features

GWH09KF-K3DNA6A/I

GWH12KF-K3DNA6A/I

FAN

AUTO

OPER

HEALTH

AIR

FILTER

TURBO

ON/OFF

X-FAN

HOUR

HUMIDITY

ON/OFF

MODE

FAN

X-FAN

TURBO

TEMP

TIMER

SLEEP

LIGHT

GWH09KF-K3DNB1A/I

GWH12KF-K3DNB1A/I

2

1.Safety Precautions

Safety Precautions

Important!

This air conditioning system meets strict safety and

operating standards. As the installer or service person,

it is an important part of your job to install or service the

system so it operates safely and efficiently.

Follow each installation or repair step exactly as shown.

Observe all local, state, and national electrical codes.

Pay close attention to all warning and caution notices

given in this manual.

To prevent injury to the user or other people and

property damage, the following instructions must

be followed.

About the pict

ures:

Erroneous handing gives a high possi-

bility to induce serious results such as

death or heavy injury.

Erroneous handing may induce serious

injury depending on the situation.

Do not supply power to the unit until all wiring and tubing

are completed or reconnected and checked.

Highly dangerous electrical voltages are used in this

system. Carefully refer to the wiring diagram and these

instructions when wiring. Improper connections and inad-

equate grounding can cause accidental injury or death.

Ground the unit following local electrical codes.

Connect all wiring tightly. Loose wiring may cause over-

heating at connection points and a possible fire hazard.

All electric work must be performed by licensed technician,

ac-

cording to local regulations and the instructions given in this

manual.

There is risk of fire, electric shock, explosion, or injury.

Ask your dealer or specialized subcontractor for installation or

repair work.

Make sure the ceiling/wall is strong enough to hold the

unit’s weight. The outdoor unit should be installed in a

location where air and noise emitted by the unit will not

disturb the neighbo

rs.

Properly insulate any tubing run inside a room to prevent

"sweating" that can cause dripping and water damage to

walls and floors.

The outdoor unit must be installed on stable, level surface,

in a place where there is no accumulation of snow, leaves

or rubbish.

The unit should be installed according to the instructions

in order to minimize the risk of damage from earthquakes,

typhoons or strong winds.

When the refrigerant touches the fire etc., it was decomposed

and a poisonous gas is generated.

Use only the specified refrigerant to charge the re

frigerant

circuit.

Do not mix it with any other refrigerant and do not allow air to

remain in the circuit.

Air enclosed in the circuit can cause high pressure resulting

in a rupture and other hazards.

After completing installation work, make sure that refriger-

ant gas has not leaked.

The limit density is made not to be exceeded even if the refrig-

erant leaks by any chance.

Turn the power off at the main power box (mains) before open-

ing the unit to check or repair electrical parts and wiring.

Keep your fingers and clothing away from any moving parts.

Clean up the site after you finish, remembering to check that

no metal scraps or bits of wiring have been left inside the unit

being serviced.

The unit must be properly earth connected.

Caution

Warning

Warning

Caution

Never install on the place where a combustible gas might

leak. The gas may ignite or explode when the gas leaks and

collects in surround of the unit.

When the unit is installed at telecommunication centers or

hospitals, take a proper provision against noise.

When installing at a watery place, provide an electric leak

breaker.

Do not wash the unit with water.

Be very careful about unit transportation. The unit should not

be carried by only one person if it is more than 20kg. It occasionally causes the damage of the unit and health to be impaired.

Do not touch the heat exchanger fins w

ith your hands.

Doing so may cut your hands.

Do not touch the compressor or refrigerant piping w

ithout

wearing glove on your hands. Touching directly such part can

cause a burn or frostbite as it becomes high or low temperature

according to the refrigerant state.

Do not operate the air conditioner without the air filter set

place. Dust may accumulate, and cause a failure.

At emergency (if you smell something burning), stop opera-

tion and turn the power source switch off.

3

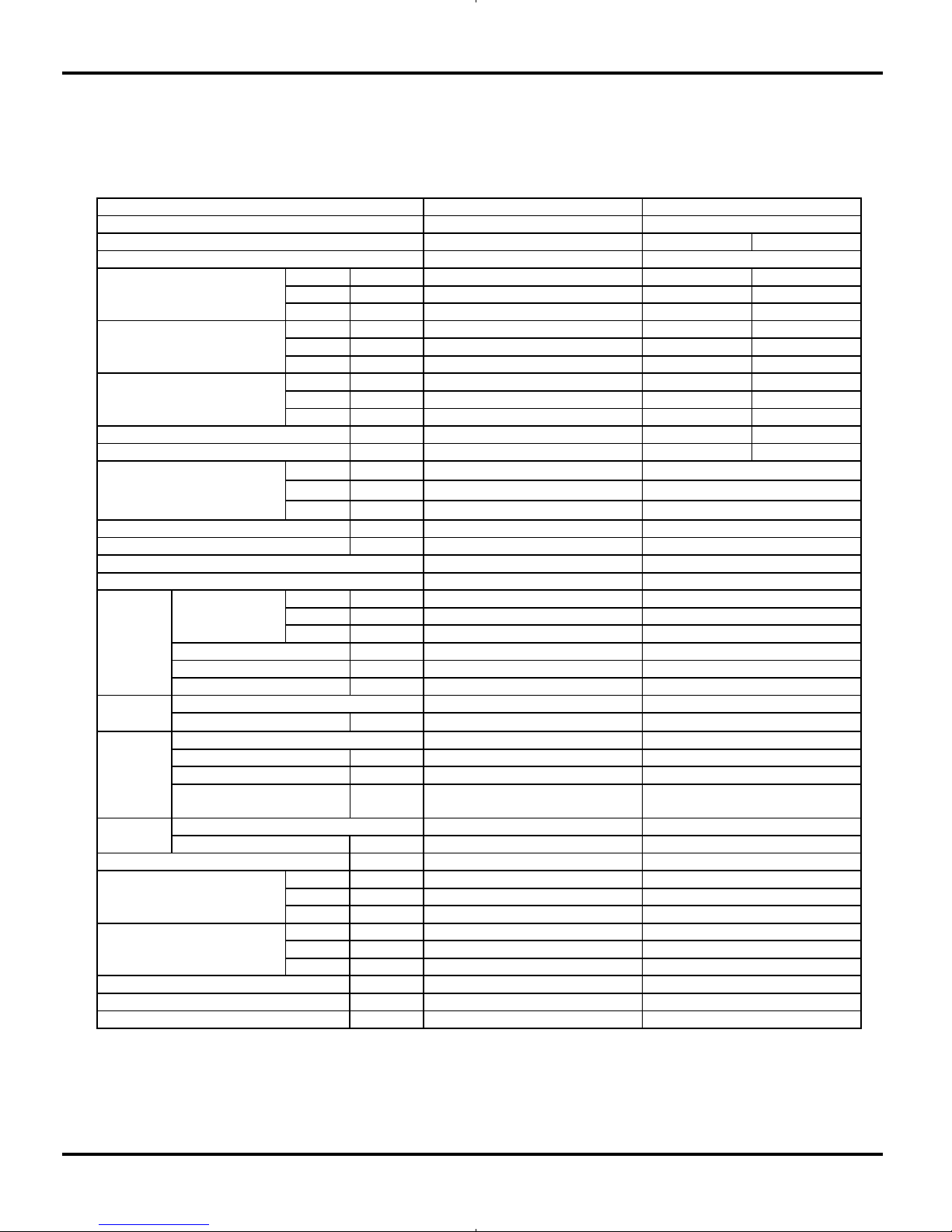

2.Specifications

Remarks:

Rated conditions are:

Cooling: Indoor air temperature 27°C D.B. / 19°C W.B.

Outdoor air temperature 35°C D.B. / 24°C W.B.

Heating: Indoor air temperature 20°C D.B.

Outdoor air temperature 7°C D.B. / 6°C W.B.

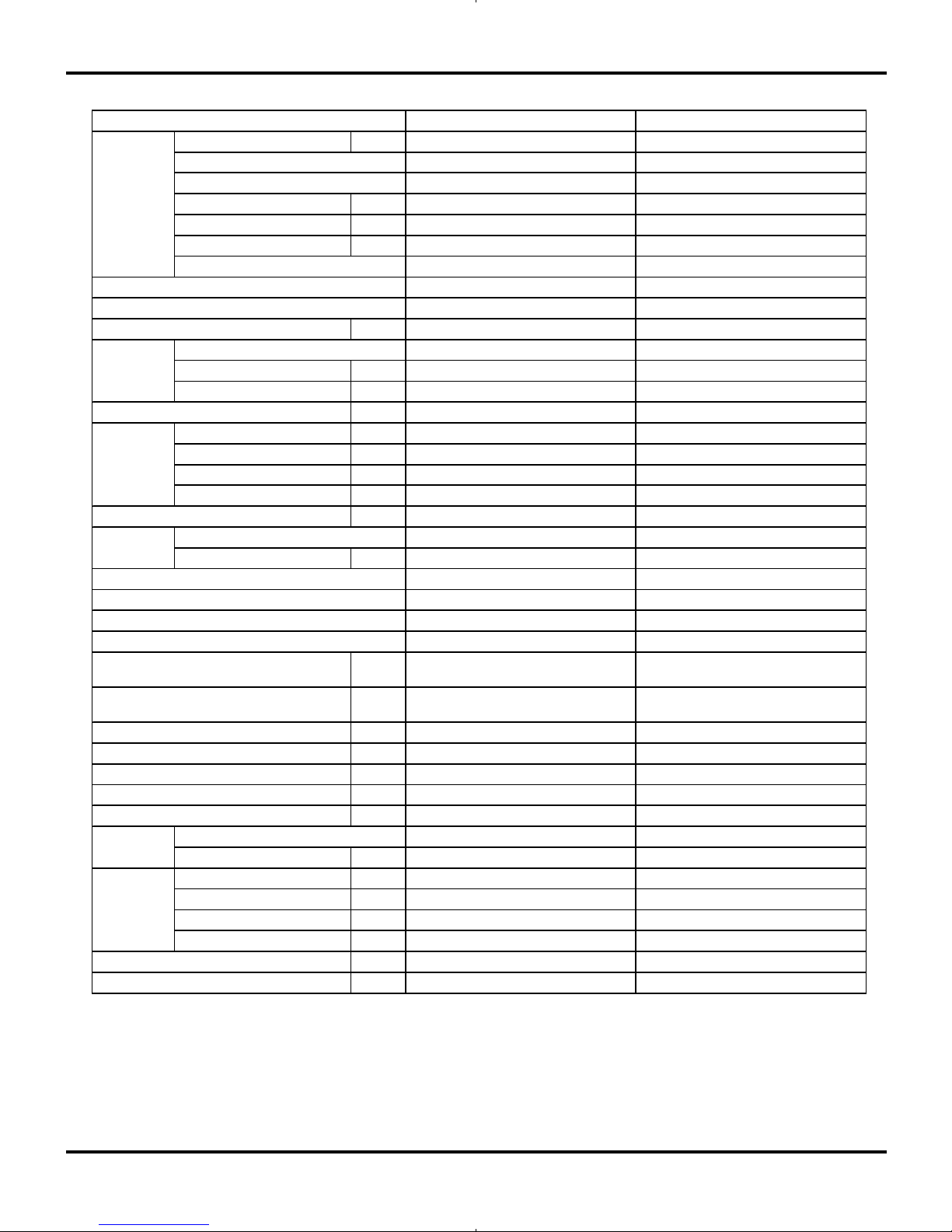

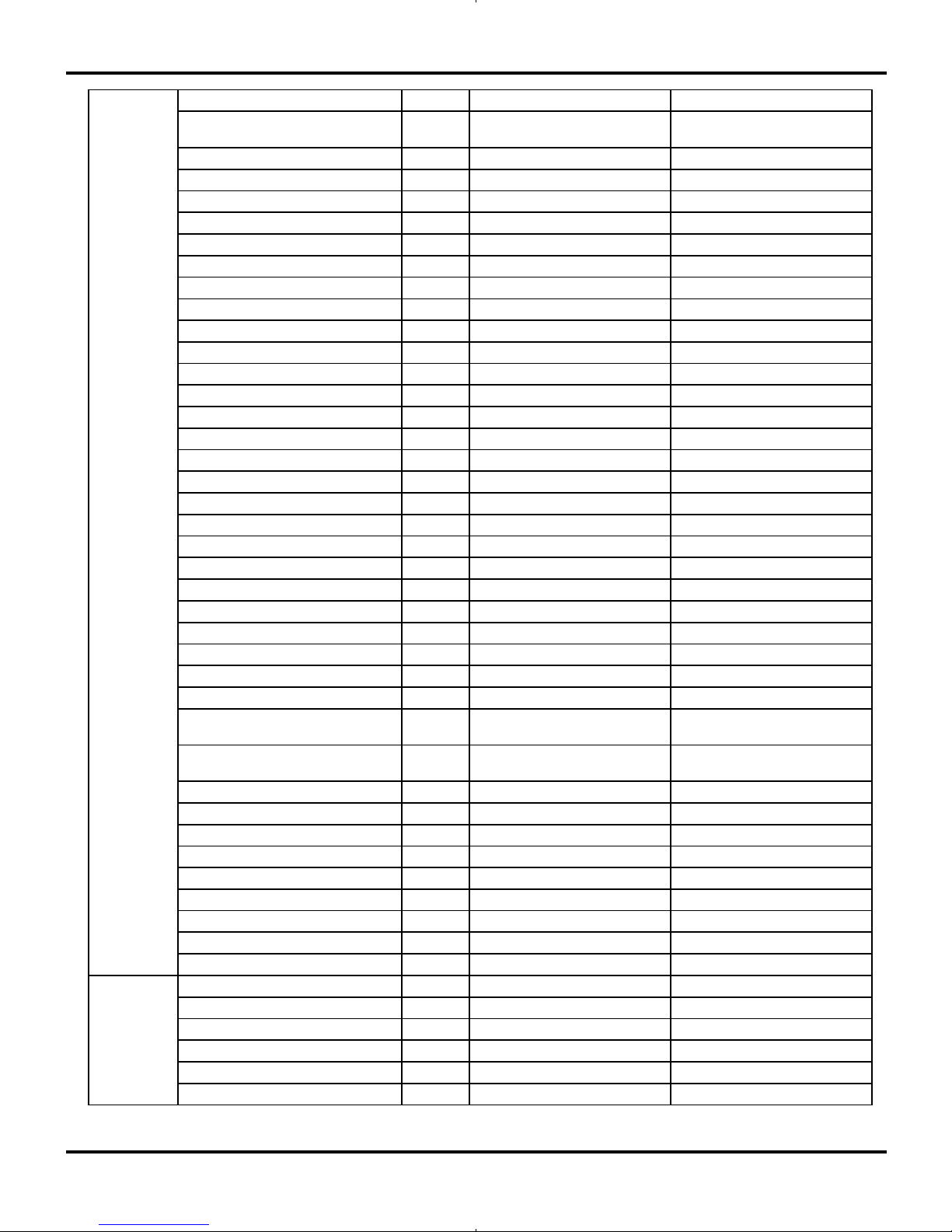

2.1 Unit Specifications

Models GWC09KF-K3DNA5A, GWH09KF-K3DNA5A

Specifications

COOLING HEATING

High Hz 78 98

Standard Hz 53 72

Low Hz 15 24

High W / Btu/h 3230 / 11000 4100 / 14000

Standard W / Btu/h 2650 / 9000 3520 / 12000

Low W / Btu/h 450 / 1500 450 / 1500

High W 1350 1450

Standard W 800 950

Low W 200 200

W 1420 1550

A6.36.8

H

m

3

/h

M

m

3

/h

L

m

3

/h

l/h

W/W

Hr/min

Mr/min

Lr/min

W

μF

A

mm

mm

mm

mm

W

A

HdB (A)

MdB (A)

LdB (A)

HdB (A)

MdB (A)

LdB (A)

mm

mm

kg

610X294X24

8/11

38

48

770X283X201

844X342X261

24

40

34

30

MP24 BA

1.5

PCB 3.15A

1.2

0.16

Cro ss flow fa n

Φ92X594

Aluminum fin-copper tube

7

2-1.4

8/11

GWH09KF-K3DNA5A

220-240V

~

600

0.8

3.3/3.7

A/A

GWH09KF-K3DN A5A/I

1100

10

844X342X261

24

40

34

38

48

30

770X283X201

1.2

700

1.5

PCB 3.15A

610X294X24

MP24 BA

0.16

Cross flow fan

Φ92X594

Aluminum fin-copper tube

A/A

GWC09KF-K3DNA5A/I

1100

10

900

GWC09KF-K3DNA5A

220-240V

~

600

0.8

1420

6.3

800

2650 / 9000

450 / 1500

COOLING

Model

Function

Rated Voltage

Rated Input

Frequency

(Inverter different Compress or

speed)

Total Capacity

(Inverter different Compress or

speed)

Power Input

(Inverter different Compress or

speed)

78

3230 / 11000

200

1350

53

15

Ai r F low Vol u m e

Rated Current

Fus e (A)

Dimension (WXHXD) ( mm)

Fan

Evaporator

Swing

Mo tor

Coil length (l)Xheigh

t

(H)Xcoil width (L)

Output

Type

Dimension of Package (LXWXH)

Net Weight /Gross Weight

Output

Capacitor

RLA

Diameter-Length

Pipe Diameter

Row-Fin Gap

Sound Pressure Level

Sound Power Level

700

Dehumidifying Volume

7

2-1.4

Energy Class

EER / C.O.P

Speed

Fan Motor

Indoor unit

3.3

CB14600050 CB14600051 CB14600060 CB14600063Product Code

Model

370

280

370

280

900

4

The above data is subject to change without notice. Please refer to the nameplate of the unit.

GWC09KF-K3DNA5A/O GWH09KF-K3DNA5A/O

Manufacturer/tradem ark DIT/daikin DIT/daiki n

1YC23AEXD 1YC23AEXD

L.R.A. (A) A 4 4

R LA( A) A 4 4

Power Input(W) W 600 600

CS-7SA CS-7SA

Capillary Capillary

Transducer starting Transducer starting

℃

10~48 -15~48

Aluminum fin-copper tube Aluminum fin-copper tube

Pipe Diameter mm 7 7

Rows-Fin Gap mm 1-1.4 1-1.4

mm 647X528X19.05 647X528X19.05

Speed rpm 930 930

Output of Fan Motor W 30 30

RLA A 0.236 0.236

Capacitor μF2 2

m

3

/h

1600 1600

AXial fan AXial fan

Diameter mm 370 370

/ Auto defrosting

T1 T1

II

IP24 IP24

Mp a 3 .8 3 .8

Mp a 1 .2 1 .2

dB (A) 51 51

dB (A) 61 61

mm 710X550X275 710X550X275

mm 771X348X592 771X348X592

kg 27/31 28/32

R410A R410A

Weight kg 0.74 0.74

Length (m) m

55

Gas additional charge g/m

15 20

Liquid Pipe Diameter mm

Φ6 Φ6

Gas Pipe Diameter mm

Φ9.52 Φ9.52

m10 10

m15 15

Starting Method

Type

Defrosting Method

Overload Protector

Air Flow Volume of Outdoor Unit

Outdoor Unit

Compressor

Fan

Fan Motor

Working Temp Range

Heat

EXchanger

Coil

Coil

Model

Coil length (l) X height (H) X coil width (L)

Thro ttlin g Method

Mois ture Protection

Permissible EXcessive Operating

Pressure for the Discharge Side

Permissible EXcessive Operating

Pressure for the Suction Side

Type

Climate Type

Isolation

Dimension (WXHXD)

Dimension of Package (LXWXH)

Sound Press ure Level

Sound Power Level

Net Weight /Gross Weight

Connection

Pipe

MaX. Interunit Piping Length

MaX. Interunit Height Difference

Refrigerant

Name of refrigerant

Specifications

Rotary type

Rotary type

5

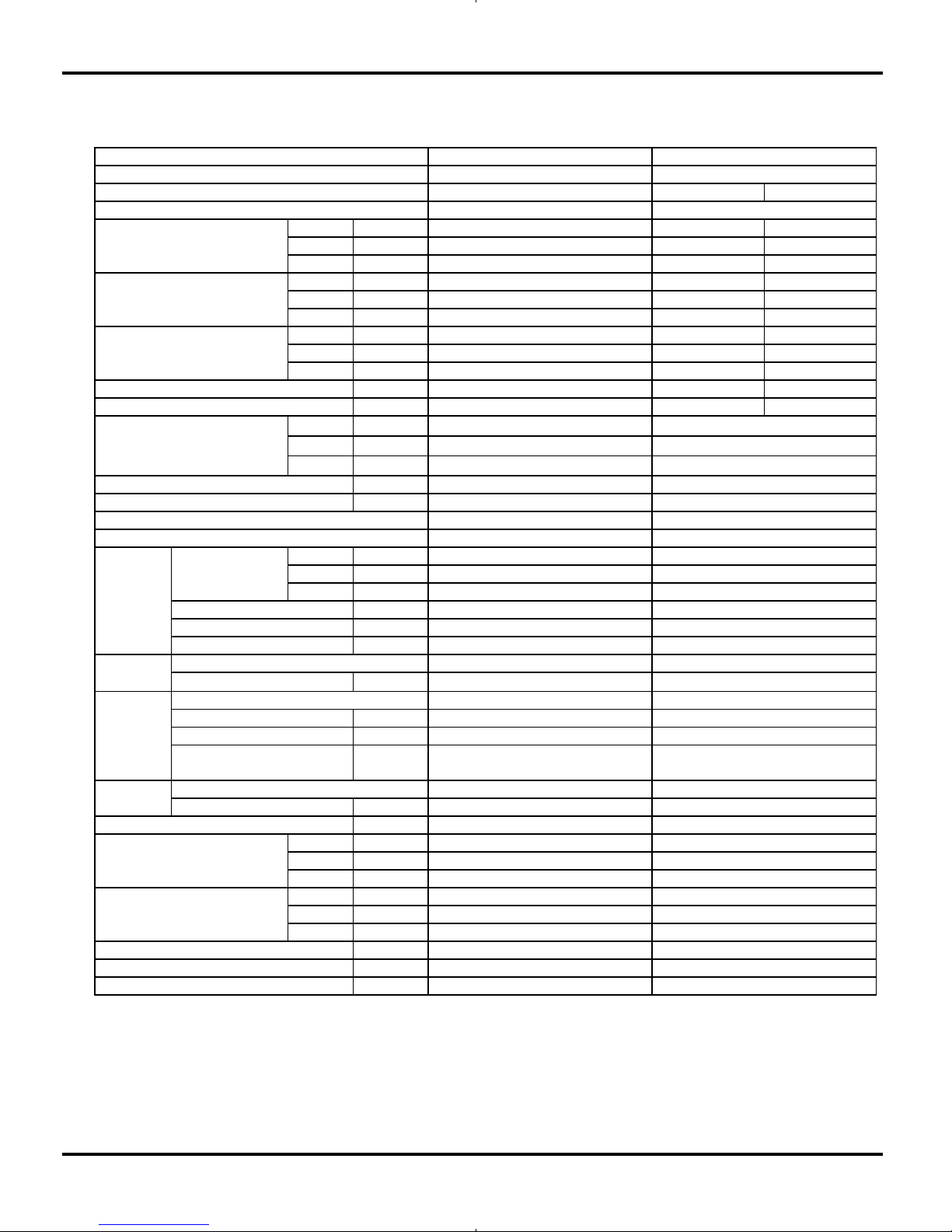

Remarks:

Rated conditions are:

Cooling: Indoor air temperature 27°C D.B. / 19°C W.B.

Outdoor air temperature 35°C D.B. / 24°C W.B.

Heating: Indoor air temperature 20°C D.B.

Outdoor air temperature 7°C D.B. / 6°C W.B.

Models GWC12KF-K3DNA5A, GWH12KF-K3DNA5A

Specifications

COOLING HEATING

High Hz 92 108

Standard Hz 72 78

Low Hz 15 24

High W / Btu/h 3960 / 13500 5130 / 17500

Standard W / Btu/h 3530 / 12000 4100 / 13990

Low W / Btu/h 600 / 2000 600 / 2000

High W 1450 1550

Standard W 1100 1135

Low W 220 220

W 1550 1650

A6.57.8

H

m

3

/h

M

m

3

/h

L

m

3

/h

l/h

W/W

Hr/min

Mr/min

Lr/min

W

μF

A

mm

mm

mm

mm

W

A

HdB (A)

MdB (A)

LdB (A)

HdB (A)

MdB (A)

LdB (A)

mm

mm

kg

CB14600070 CB14600072 CB14600080 CB14600083

Model

410

300

410

300

950

750

Dehumidifying Volum e

7

2-1.4

610X294X24

Energy Class

EER / C.O.P

Speed

Fan Motor

Indoor unit

3.21

Dimension of Package (LXWXH)

Net Weight /Gross W eight

Output

Capacitor

RLA

Diameter-Length

Pipe Diameter

Row-Fin Gap

Sound Pressure Level

Sound Power Level

Air Flow Volume

Rated Current

Fuse (A)

Dimension (W XHXD) ( mm)

Fan

Evaporator

Swing

Motor

Coil length (l)Xheight (H)Xcoil

width (L)

Output

Type

92

3960 / 13500

220

1450

72

15

Model

Function

Rated Voltage

Rated Input

Frequency

(Inverter different Compressor

speed)

Total Capacity

(Inverter different Compressor

speed)

Power Input

(Inverter different Compressor

speed)

Product Code

GWC12KF-K3DNA5A

220-240V

~

680

1.5

1550

6.5

1100

3530 / 12000

600 / 2000

COOLING

A/A

GWC12KF-K3DNA5A/I

1150

10

950

1.2

750

1.5

PCB 3.15A

MP24BA

0.16

Cross flow fan

Φ92X594

Aluminum fin-copper tube

39

49

31

770X283X201

844X342X261

25

41

35

9/12

GWH12KF-K3DNA5A

220-240V

~

680

1.5

3.21/3.61

A/A

GWH12KF-K3DNA5A/I

1150

10

MP24BA

1.5

PCB 3.15A

1.2

0.16

Cross flow fan

Φ92X594

Aluminum fin-copper tube

7

2-1.4

610X294X24

9/12

39

49

770X283X201

844X342X261

25

41

35

31

6

GWC12KF-K3DNA5A/O GWH12KF-K3DNA5A/O

Manufacturer/tradem ark DIT/daikin DIT/daiki n

1YC23AEXD 1YC23AEXD

L.R.A. (A) A 4 4

R LA( A) A 4 4

Power Input(W) W 600 600

CS-7SA CS-7SA

Capillary Capillary

Transducer starting Transducer starting

℃

10~48 -15~48

Aluminum fin-copper tube Aluminum fin-copper tube

Pipe Diameter mm 7 7

Rows-Fin Gap mm 2-1.4 2-1.4

mm 647X528X38.1 647X528X38.1

Speed rpm 930 930

Output of Fan Motor W 30 30

RLA A 0.236 0.236

Capacitor μF2 2

m

3

/h

1600 1600

Axial fan Axial fan

Diameter mm 370 370

/

Auto defrosting

T1 T1

II

IP24 IP24

Mp a 3 .8 3 .8

Mp a 1 .2 1 .2

dB (A) 53 53

dB (A) 63 63

mm 710X550X275 710X550X275

mm 771X348X592 771X348X592

kg 29/33 30/34

R410A R410A

Weight kg 1.0 1.0

Length (m) m

55

Gas additional charge g/m

15 20

Liquid Pipe Diameter mm

Φ6 Φ6

Gas Pipe Diameter mm

Φ9.52 Φ9.52

m10 10

m20 20

Net Weight /Gross Weight

Connection

Pipe

Max. Interunit Piping Length

Max. Interunit Height Difference

Refrigerant

Name of refrigerant

Dimension (WXHXD)

Dimension of Package (LXWXH)

Sound Press ure Level

Sound Power Level

Mois ture Protection

Permissible Excessive Operating

Pressure for the Discharge Side

Permissible Excessive Operating

Pressure for the Suction Side

Type-Piece

Climate Type

Isolation

Outdoor Unit

Compressor

Fan

Fan Motor

Working Temp Range

Heat

Exchanger

Coil

Coil

Model

Coil length (l) x height (H) x coil width (L)

Thro ttlin g Method

Starting Method

Type

Defrosting Method

Overload Protector

Air Flow Volume of Outdoor Unit

Specifications

The above data is subject to change without notice. Please refer to the nameplate of the unit.

Rotary type

Rotary type

7

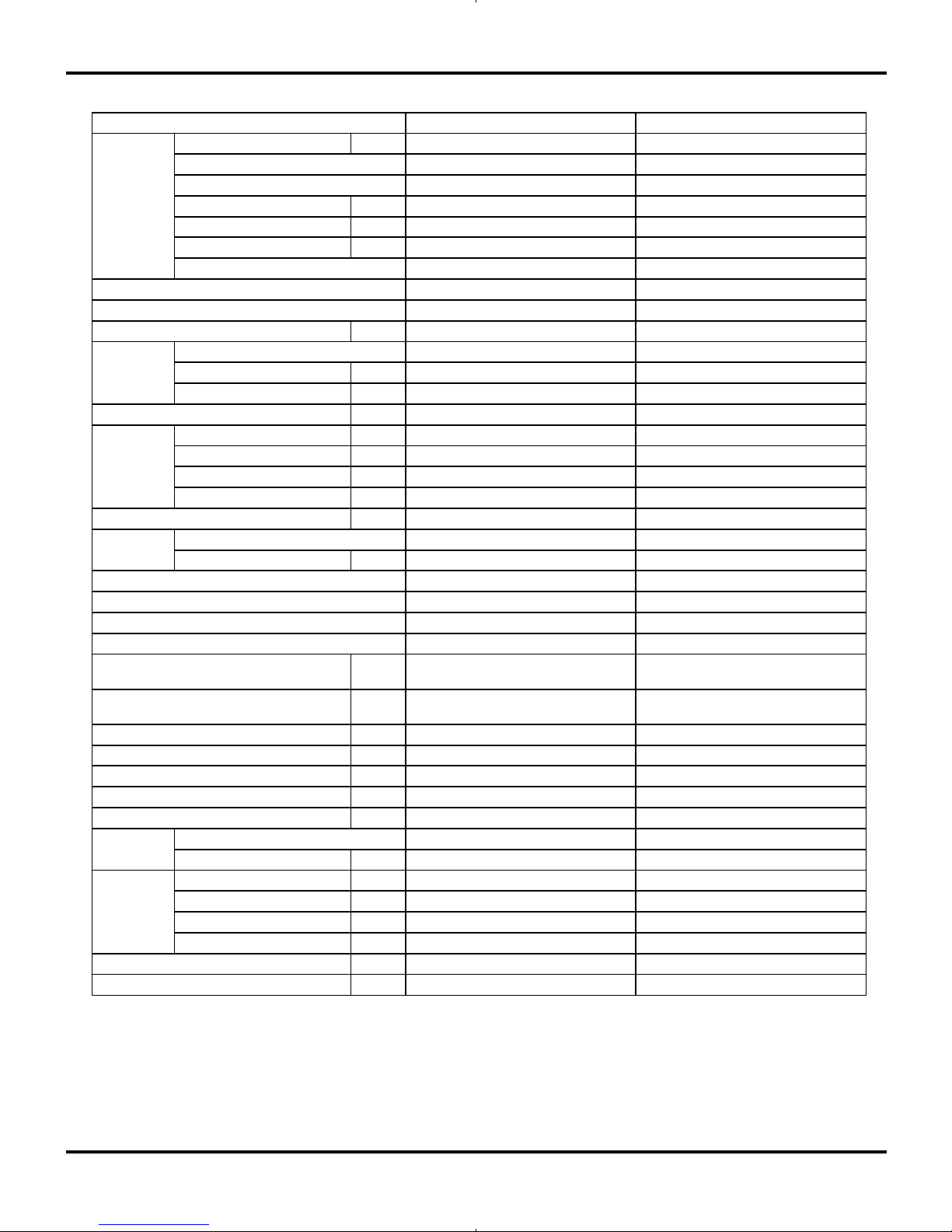

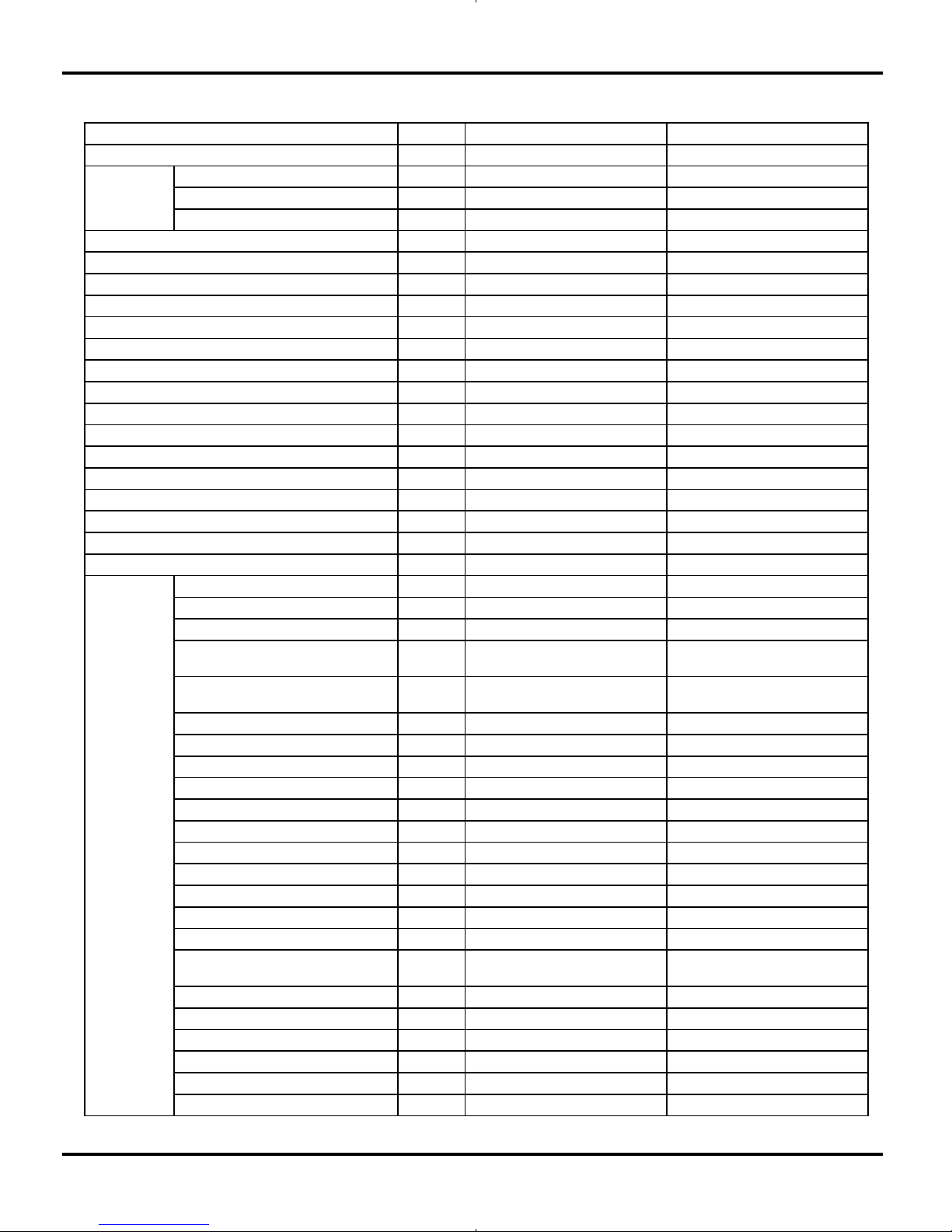

Models GWH09KF-K3DNA6A, GWH12KF-K3DNA6A

Specifications

GWH09KF-K3DNA6A GW H12KF-K3DNA6A

CB146

00110 CB14600120

Rated Voltage V

~

220-240 220-240

Rated Frequency Hz 50 50

Phases 1 1

Indoor Indoor

W 2650(450~3230) 3530(600~3960)

W 3520(450~4100) 4100(600~5130)

W 800(200~1350) 1100(220~1450)

W 950(200~1450) 1135(220~1550)

A 3.55 4.88

A 4.21 5.04

W 1550 1650

A 6.88 7.32

m

3

/h

600/520/370/280/- 680/560/410/300/-

L/h 1 1.2

W/W 3.3 3.21

W/W 3.7 3.61

W/W / /

W/W / /

m

2

12-18 16-24

Model of indoor unit GWH09KF-K3DNA6A/I GWH12KF-K3DNA6B/I

Fan Type Cross-flow Cross-flow

Diameter Length(DXL) mm Φ92X594 Φ92X594

Fan Motor Cooling Speed

(SH/H/M/L/SL)

r/min 1300/1100/900/700/- 1350/1150/950/750/-

Fan Motor Heating Speed

(SH/H/M/L/SL)

r/min 1300/1140/980/820/- 1350/1190/1020/850/-

Output of Fan Motor W 10 10

Fan Motor RLA A 0.16 0.16

Fan Motor Capacitor μF1.2 1.2

Input of Heater W 0 0

Evaporator Form Aluminum Fin-copper Tube Aluminum Fin-copper Tube

Pipe Diameter mm Φ7 Φ7

Row-fin Gap mm 2-1.4 2-1.4

Coil Length (LXDXW) mm 610X294X24 610X294X24

Swing Motor Model MP24BA MP24BA

Output of Swing Motor W 1.5

1.5

Fuse A PCB 3.15A

PCB 3.15A

Sound Pressure Level

(SH/H/M/L/SL)

dB (A) 41/38/30/24/- 42/39/31/25/-

Sound Power Level (SH/H/M/L/SL) dB (A) 51/48/40/34/- 52/49/41/35/-

Dimension (W XHXD) mm 770X283X201 770X283X201

Dimension of Carton Box (L/W/H) mm 841X339X246

841X339X246

Dimension of Package (L/W/H) mm 844X342X261

844X342X261

Net Weight kg 8 9

Gross Weight kg 11 12

SEER

HSPF

Application Area

Indoor Unit

Air Flow Volume(SH/H/M/L/SL)

Dehumidifying Volum e

EER

COP

Cooling Power Current

Heating Power Current

Rated Input

Rated Current

Cooling Capacity (Min~Max)

Heating Capacity (Min~Max)

Cooling Power Input (Min~Max)

Heating Power Input (Min~Max)

Model

Product Code

Power Supply

Power Supply Mode

8

Specifications

The above data is subject to change without notice. Please refer to the nameplate of the unit.

Model of Outdoor Unit GWH09KF-K3DNA5A/O GWH12KF-K3DNA5A/O

Compressor

Manufacturer/Trademark

Daikin Compressor Industries

/daikin

Daikin Compressor

Industries/daikin

Compressor Model 1YC23AEXD 1YC23AEXD

Compressor Oil DAPHEN FVC50K DAPHEN FVC50K

Compressor Type Rotary Rotary

L.R.A. A 4 4

Compressor RLA A 4 4

Compressor Power Input W 600W 600W

Overload Protector CS-7SA CS-7SA

Throttling Method Capillary Capillary

Operation temp

℃

16~30 16~30

Ambient temp (cooling)

℃

10~48 10~48

Ambient temp (heating)

℃

-15~24 -15~24

Condenser Form Aluminum Fin-copper Tube Aluminum Fin-copper Tube

Pipe Diameter mm Φ7 Φ7

Rows-fin Gap mm 1-1.4 2-1.4

Coil Length (LXDXW) mm 647X528X19.05 647X528X38.1

Fan Motor Speed rpm 930 930

Output of Fan Motor W 30 30

Fan Motor RLA A 0.236 0.236

Fan Motor Capacitor μF2 2

Air Flow Volume of Outdoor Unit

m

3

/h

1600 1600

Fan Type Axial-flow Axial-flow

Fan Diameter mm 370 370

Defrosting Method Automatic Defrosting Automatic Defrosting

Clim ate Type T1 T1

Isolation I I

Moisture Protection IP24 IP24

Permissible Excessive Operating

Pressure for the Discharge Side

MPa 3.8 3.8

Permissible Excessive Operating

Pressure for the Suction Side

MPa 1.2 1.2

Sound Pressure Level (H/M/L) dB (A) 51/-/- 53/-/-

Sound Power Level (H/M/L) dB (A) 61/-/- 63/-/-

Dimension (W XHXD) mm 658X550X275 658X550X275

Dimension of Carton Box (L/W/H) mm 768X345X577 768X345X577

Dimension of Package (L/W/H) mm 771X348X592 771X348X592

Net Weight kg 28 30

Gross Weight kg 32 34

Refrigerant R410A R410A

Refrigerant Charge kg 0.74 1

Length m 5 5

Gas Additional Charge g/m 30 20

Outer Diameter Liquid Pipe mm Φ6 Φ6

Outer Diameter Gas Pipe mm Φ9.52 Φ9.52

Max Distance Height m 10 10

Max Distance Length m 15 20

Outdoor Unit

Connection

Pipe

9

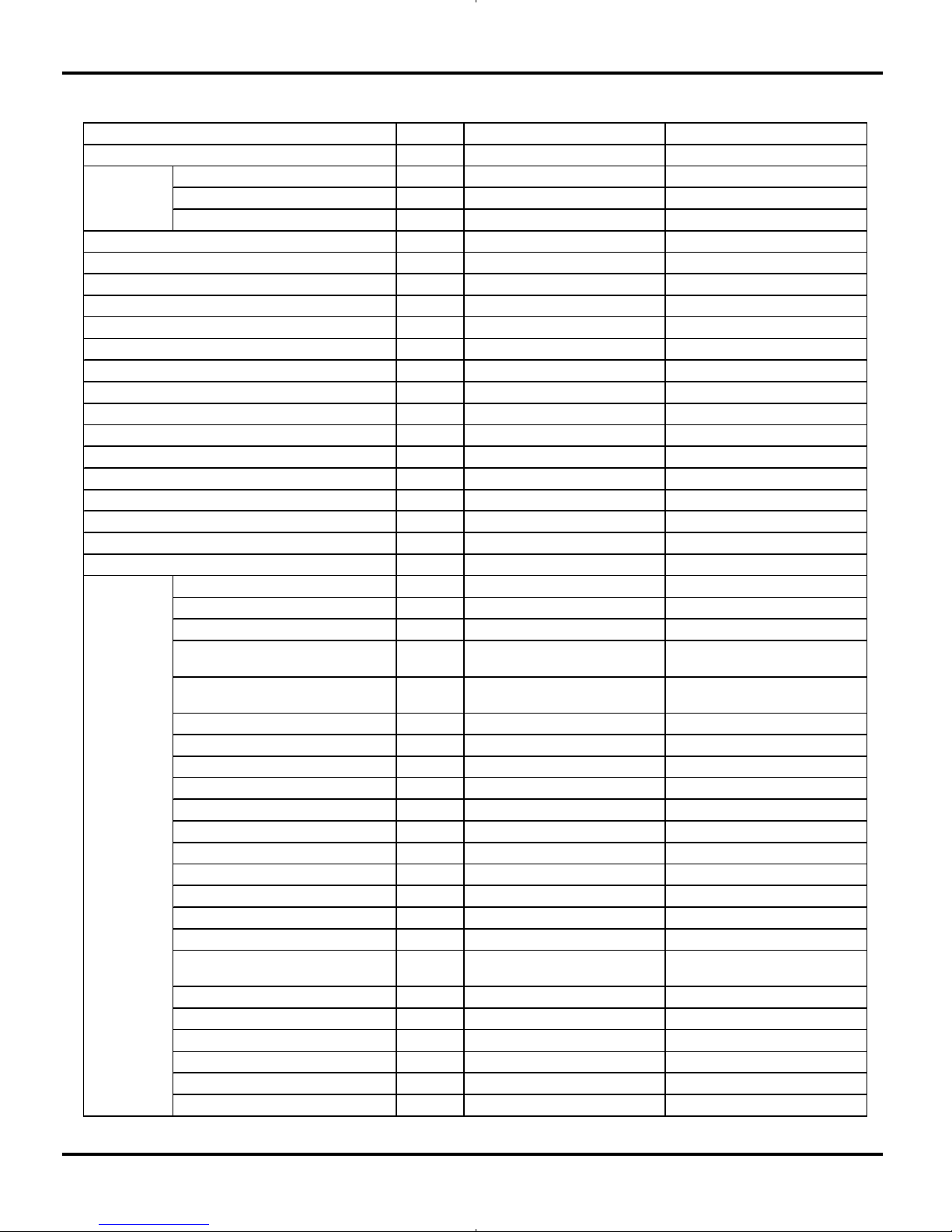

Specifications

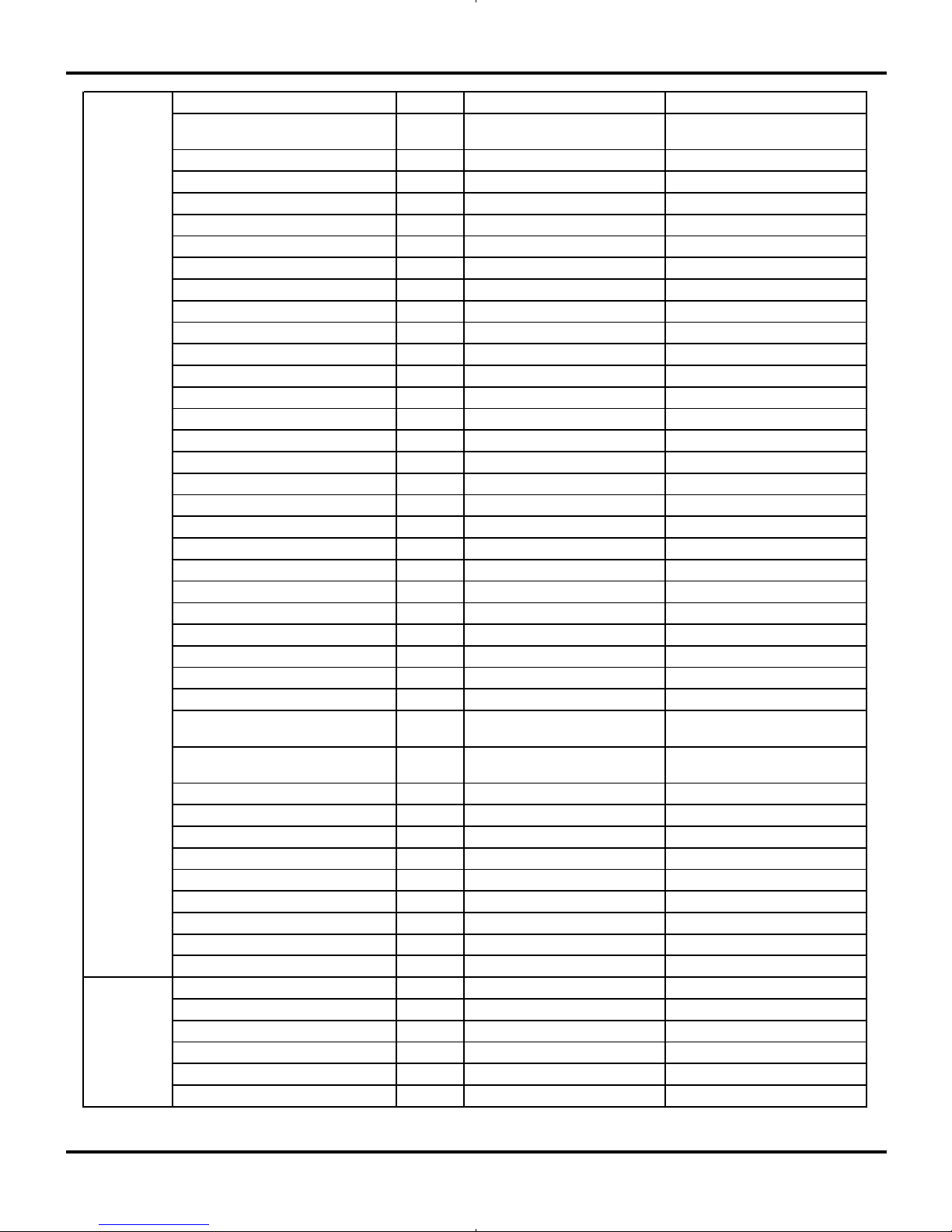

Models GWH09KF-K3DNB1A,GWH12KF-K3DNB1A

GWH09KF-K3DNB1A GW H12KF-K3DNB1A

CB14600760 CB14600770

Rated Voltage V

~

220-240 220-240

Rated Frequency Hz 50 50

Phases 1 1

Indoor Indoor

W 2650(450~3230) 3530(600~3960)

W 3520(450~4100) 4100(600~5130)

W 800(200~1350) 1100(220~1450)

W 950(200~1450) 1135(220~1550)

A 3.55 4.88

A 4.21 5.04

W 1550 1650

A 6.88 7.32

m

3

/h

600/520/370/280/- 680/560/410/300/-

L/h 1 1.2

W/W 3.3 3.21

W/W 3.7 3.61

W/W / /

W/W / /

m

2

12-18 16-24

Model of indoor unit GWH09KF-K3DNB1A/I GWH12KF-K3DNB1A/I

Fan Type Cross-flow Cross-flow

Diameter Length(DXL) mm Φ92X594 Φ92X594

Fan Motor Cooling Speed

(SH/H/M/L/SL)

r/min 1300/1100/900/700/- 1350/1150/950/750/-

Fan Motor Heating Speed

(SH/H/M/L/SL)

r/min 1300/1140/980/820/- 1350/1190/1020/850/-

Output of Fan Motor W 10 10

Fan Motor RLA A 0.16 0.16

Fan Motor Capacitor μF1.2 1.2

Input of Heater W 0 0

Evaporator Form Aluminum Fin-copper Tube Aluminum Fin-copper Tube

Pipe Diameter mm Φ7 Φ7

Row-fin Gap mm 2-1.4 2-1.4

Coil Length (LXDXW) mm 610X294X24 610X294X24

Swing Motor Model MP24BA MP24BA

Output of Swing Motor W 1.5

1.5

Fuse A PCB 3.15A

PCB 3.15A

Sound Pressure Level

(SH/H/M/L/SL)

dB (A) 41/38/30/24/- 42/39/31/25/-

Sound Power Level (SH/H/M/L/SL) dB (A) 51/48/40/34/- 52/49/41/35/-

Dimension (W XHXD) mm 770X283X201 770X283X201

Dimension of Carton Box (L/W/H) mm 844X342X261

844X342X261

Dimension of Package (L/W/H) mm 847X345X276

847X345X276

Net Weight kg 8 9

Gross Weight kg 11 12

Model

Product Code

Power Supply

Power Supply Mode

Cooling Capacity (Min~Max)

Heating Capacity (Min~Max)

Cooling Power Input (Min~Max)

Heating Power Input (Min~Max)

Cooling Power Current

Heating Power Current

Rated Input

Rated Current

Air Flow Volume(SH/H/M/L/SL)

Dehumidifying Volum e

EER

COP

SEER

HSPF

Application Area

Indoor Unit

10

Specifications

The above data is subject to change without notice. Please refer to the nameplate of the unit.

Model of Outdoor Unit GWH09KF-K3DNA5A/O GWH12KF-K3DNA5A/O

Compressor

Manufacturer/Trademark

Daikin Compressor Industries

/daikin

Daikin Compressor

Industries/daikin

Compressor Model 1YC23AEXD 1YC23AEXD

Compressor Oil DAPHEN FVC50K DAPHEN FVC50K

Compressor Type Rotary Rotary

L.R.A. A 4 4

Compressor RLA A 4 4

Compressor Power Input W 600W 600W

Overload Protector CS-7SA CS-7SA

Throttling Method Capillary Capillary

Operation temp

℃

16~30 16~30

Ambient temp (cooling)

℃

18~43 18~43

Ambient temp (heating)

℃

-15~24 -15~24

Condenser Form Aluminum Fin-copper Tube Aluminum Fin-copper Tube

Pipe Diameter mm Φ7 Φ7

Rows-fin Gap mm 1-1.4 2-1.4

Coil Length (LXDXW) mm 647X528X19.05 647X528X38.1

Fan Motor Speed rpm 930 930

Output of Fan Motor W 30 30

Fan Motor RLA A 0.236 0.236

Fan Motor Capacitor μF2 2

Air Flow Volume of Outdoor Unit

m

3

/h

1600 1600

Fan Type Axial-flow Axial-flow

Fan Diameter mm 370 370

Defrosting Method Automatic Defrosting Automatic Defrosting

Climate Type T1 T1

Isolation I I

Moisture Protection IP24 IP24

Permissible Excessive Operating

Pressure for the Discharge Side

MPa 3.8 3.8

Permissible Excessive Operating

Pressure for the Suction Side

MPa 1.2 1.2

Sound Pressure Level (H/M/L) dB (A) 51/-/- 53/-/-

Sound Power Level (H/M/L) dB (A) 61/-/- 63/-/-

Dimension (W XHXD) mm 710X318X550 710X318X550

Dimension of Carton Box (L/W/H) mm 771X348X592 771X348X592

Dimension of Package (L/W/H) mm 774X351X607 774X351X607

Net Weight kg 28 30

Gross Weight kg 32 34

Refrigerant R410A R410A

Refrigerant Charge kg 0.74 1

Length m 5 5

Gas Additional Charge g/m 30 20

Outer Diameter Liquid Pipe mm Φ6 Φ6

Outer Diameter Gas Pipe mm Φ9.52 Φ9.52

Max Distance Height m 10 10

Max Distance Length m 15 20

Outdoor Unit

Connection

Pipe

11

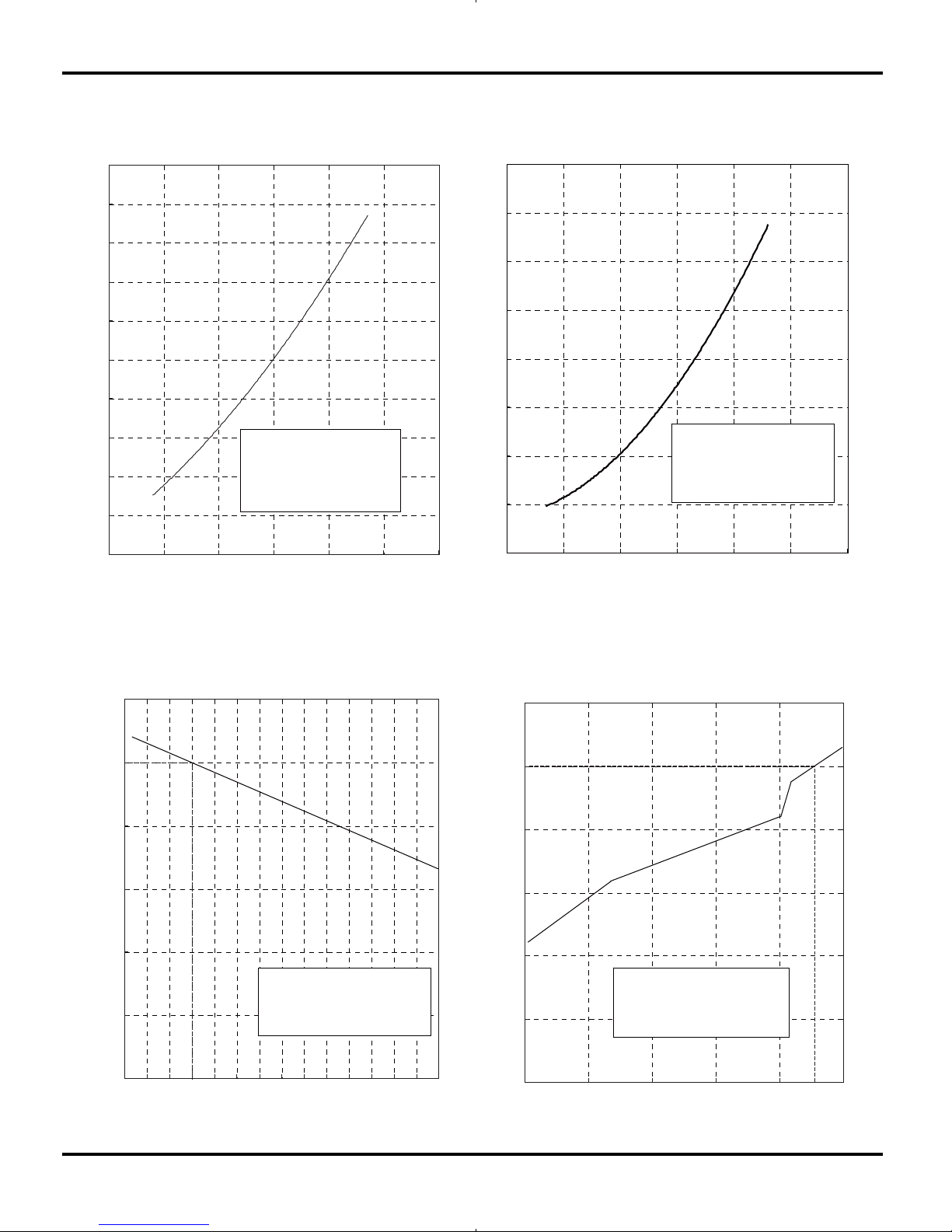

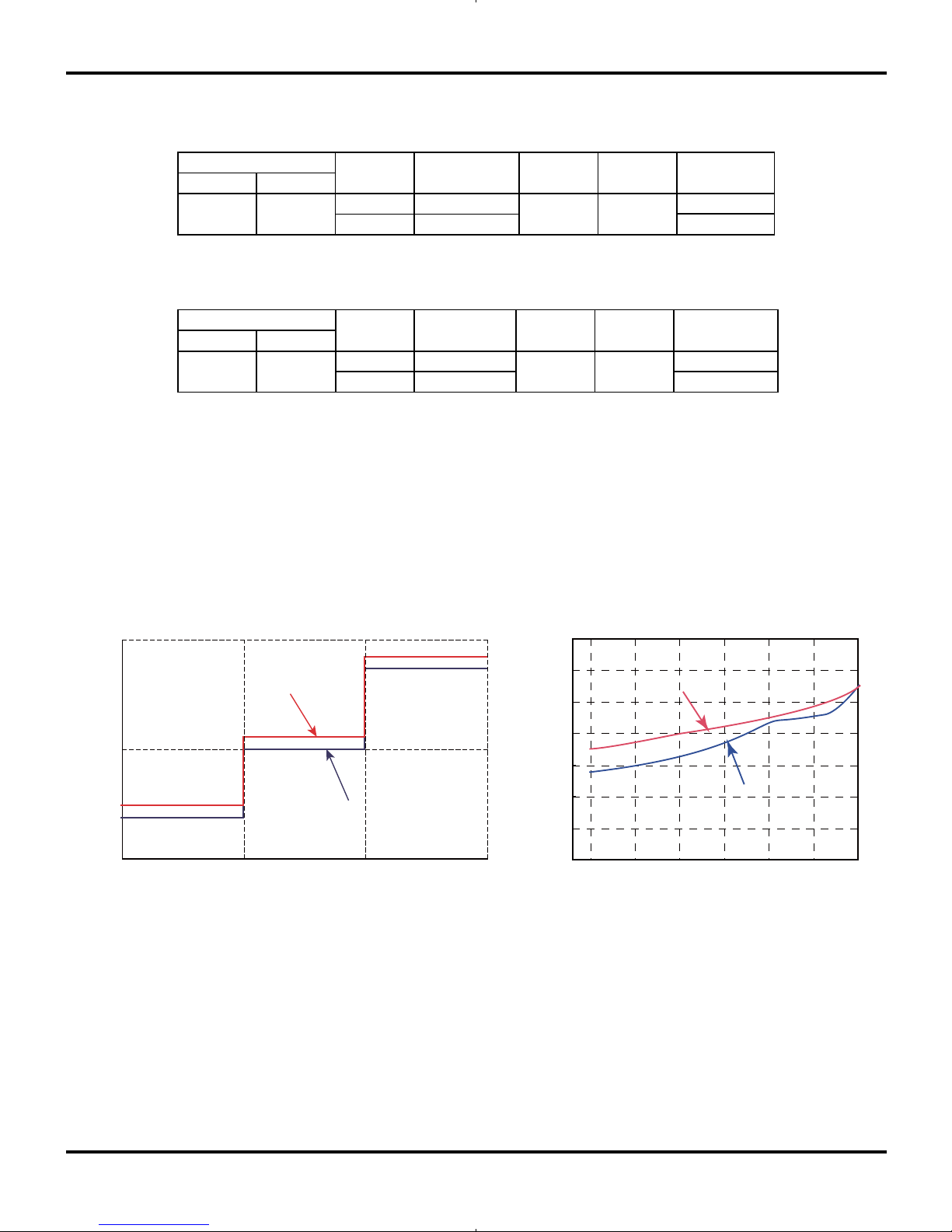

2.2 Operation Characteristic Curve

0

1

2

3

4

5

6

7

8

9

10

0 20 40 60 80 100 120

Condition

Indoor:DB 27ć WB19ć

Indoor air flow: Super High

Pipe length:5m

Voltage:230V

Compressor Speed(rps)

0

1

2

3

4

5

6

7

8

0 20 40 60 80 100 120

Condition

Indoor:DB 20ć

Indoor air flow: Super High

Pipe length:5m

Voltage:230V

Compressor Speed(rps)

Cooling

Heating

Current(A)

Current(A)

2.3 Capacity Variation Ratio According to Temperature

50

60

70

80

90

100

110

32 33 34 35 36 37 38 39 40 41 42 43 44 45 46

Capacity ratio(%)

Condition

Indoor:DB27℃ WB19℃

Indoor air flow: Super High

Pipe length:5m

Outdoor temp. (°C)

0

20

40

60

80

100

120

-15 -10 -5 0 5 10

Capacity ratio(%)

Condition

Indoor:DB20℃

Indoor air flow: Super High

Pipe length:5m

Outdoor temp. (°C)

Cooling Heating

Specifications

12

Cooling

Heating

NOTES :

(1) Measure surface temperature of heat exchanger pipe around center of heat exchanger path U

bent. (Thermistor themometer)

(2) Connecting piping condition : 5 m

2.4 Operation Date

Indoor Outdoor

09K 0.9 to 1.1 53

12K 0.8 to 1.0 72

Outdoor

Fan Mode

Compressor

Revolution(rps)

27/19 35/24 Super High 930rpm

Temp. Condition(℃)

Mode l

Standard

Pressure(Mpa)

Indoor Fan

Mode

Indoor Outdoor

09K 2 .3 to 2.5 72

12K 2 .4 to 2.6 78

Outdoor

Fan Mode

Compress or

Revolution(rps)

20/- 7/6 Super High 930rpm

Temp. Condition(℃)

Model

Standard

Pressure(Mpa)

Indoor Fan

Mode

Specifications

2.5 Noise Criteria Curve Tables for Both Models

40

30

20

Indoor side noise when blowing

Indoor fan motor rotating speed

Low Middle High

12K

09K

40

42

44

46

48

50

52

54

20 4030 50 60 70 80

Compressor frequency(Hz)

Noise dB(A)

Noise dB(A)

Heating

Cooling

13

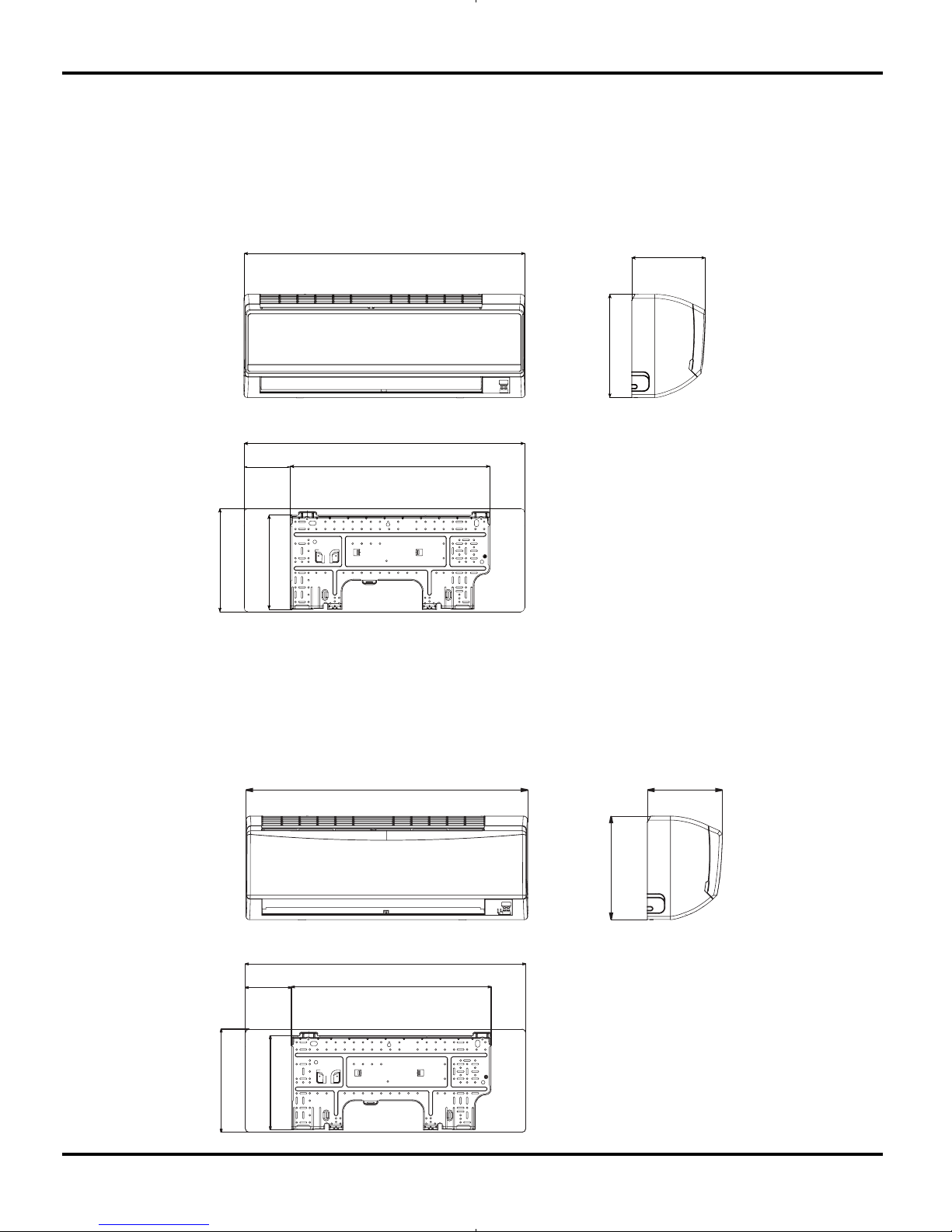

3. Construction Views

3.1 Indoor Unit

Constrction views

Models:GWC09KF-K3DNA5A/I,GWH09KF-K3DNA5A/I,GWC12KF-K3DNA5A/I,GWH12KF-K3DNA5A/I

Models:GWH09KF-K3DNA6A/I,GWH12KF-K3DNA6A/I

548.5

258.5

126.5

770

283

770

283

201

770

201

283

548.5

258.5

126.5

770

283

Unit:mm

14

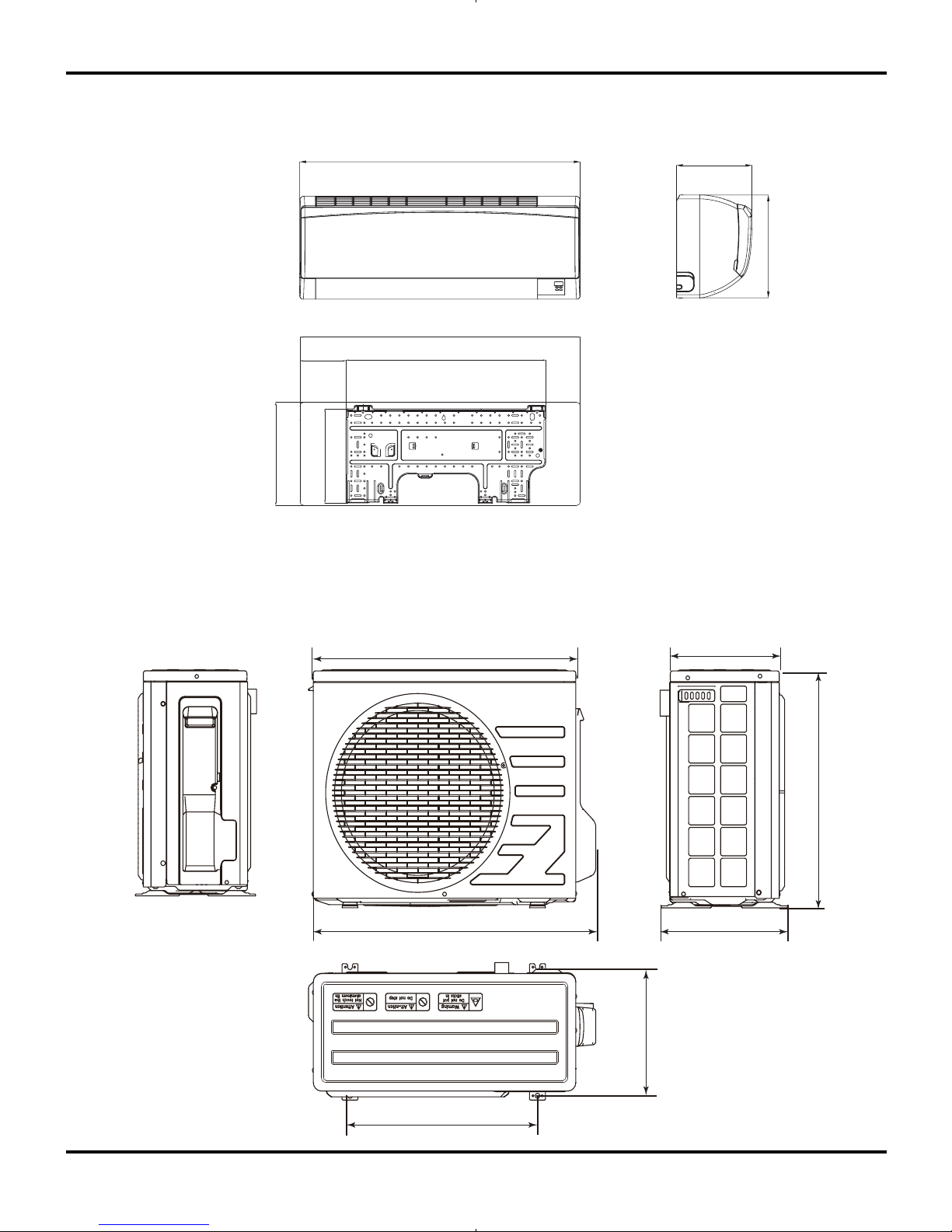

3.2 Outdoor Unit

Constrction views

710

658

275

550

318

470

299

Models:GWH09KF-K3DNB1A/I,GWH12KF-K3DNB1A/I

548.5

258.5

126.5

770

283

283

201

770

15

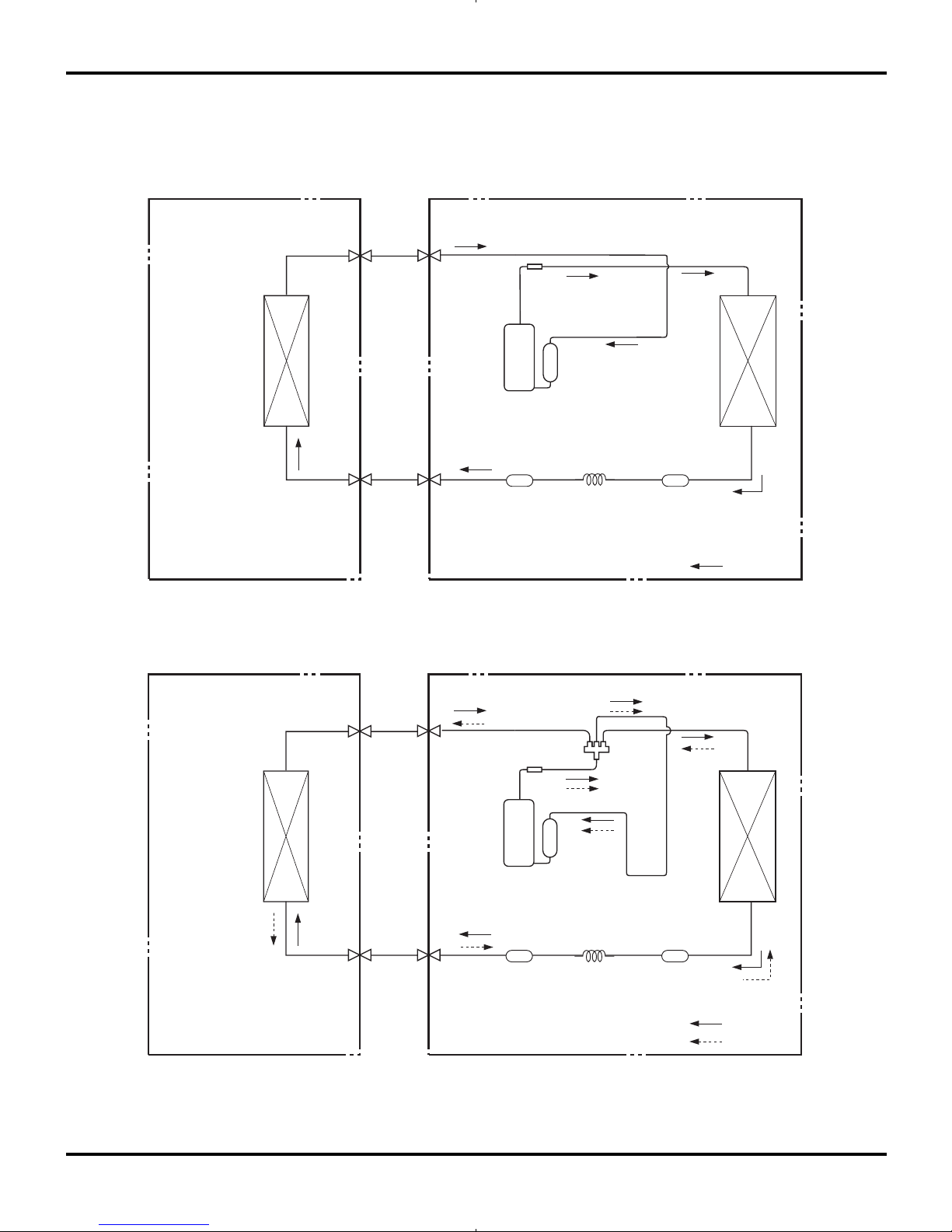

4. Refrigerant System Diagram

INDOOR UNIT OUTDOOR UNIT

HEAT

EXCHANGE

(EVAPORATOR)

HEAT

EXCHANGE

(CONDENSER)

COMPRESSOR

GAS SIDE

3-WAY VALVE

LIQUID SIDE

3-WAY VALVE

COOLING

HEATING

Accumlator

Discharge

Suction

Muffler

4-Way valve

CapillaryStrainer Strainer

Refrigerant pipe diameter

Liquid : 1/4" (6 mm)

Gas : 3/8" (9.52 mm)

INDOOR UNIT OUTDOOR UNIT

HEAT

EXCHANGE

(EVAPORATOR)

HEAT

EXCHANGE

(CONDENSER)

COMPRESSOR

GAS SIDE

3-WAY VALVE

LIQUID SIDE

2-WAY VALVE

COOLING

Accumlator

Discharge

Suction

Muffler

CapillaryStrainer Strainer

(1)Cooling Only Models

(2)Cooling & Heating Models

Refrigerant System Diagram

16

5. Schematic Diagram

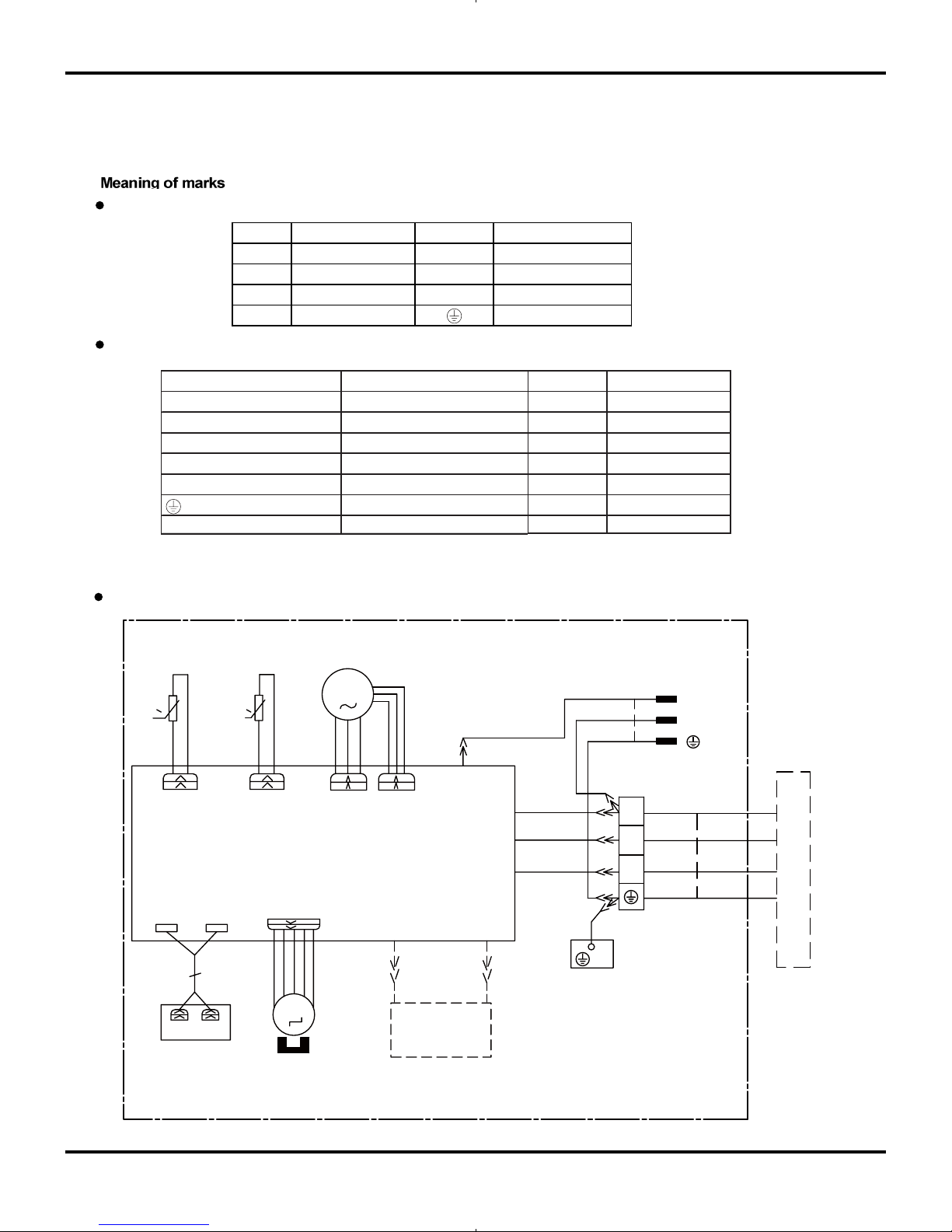

5.1 Electrical Data

5.2 Electrical wiring

Outdoor Unit

Symbol Color symbol Symbol Color symbol

WH

WHITE

BN

BROWN

YE

YELLOW

BU

BLUE

RD

RED

BK

BLACK

YEGN

YELLOW GREEN PROTECTIVE EARTH

Indoor Unit

Indoor Unit

Schematic Diagram

Symbol Parts name Symbol Color symbol

L1

REACTOR

WH

WHITE

PCB1~PCB2

PRINTED CIRCUIT BOARD

YE

YELLOW

S10/S11S40/S70/S80/S90

CONNECTOR

RD

RED

SAT

OVERLOAD

BN

BROWN

COMP

COMPRESSOR

BU

BLUE

PROTECTIVE EARTH

BK

BLACK

YEGN

YELLOW GREEN

ORANGE

OG

to the models with cold-plasma function.

NOTE:The part with broken line is applicable

GENERATOR

COOL PLASMA

HEALTH-L HEALTH-N

AP2

MOTOR

SWING

DISPLAY

OUTDOOR UNIT

TUBE

TEM.SENSOR

ROOM

TEM.SENSOR

FAN

MOTOR

PG

RD

BU

M1

PGF

SWING-UD

DISP2

L-OUT

AC-L

AP1

BU

BN

BK

COM-OUT

YEGN

PE

BN

BK

RT2

0

DISP1

RT1

2

YEGN

3

YEGN

N

BU

BU

XT

N(1)

L

BN

POWER

M2

N

ROOM

TUBE

0

EVAPORATOR

17

W

V

U

MOTOR

YEGN

X1

4YV

PE PE

PE

S40

PE

SAT

HA2

HA1

COMP.

S70

HR1

HR2

L1

HL3

HN3

HN2

HL2

S10 S11

S80S90

0

RT5

RT4

0

RT3

0

W

V

U

PCB2

E2

E1

AC1

S

AC2

PCB1

PE

2

3

XT

N(1)

WARNING

Please don't touch any terminal when the voltage of

prevent the risk of electrical shock!

terminal DC+ and DC- at PCB2 is higher than 30V to

INDOOR UNIT

M

YEGN

CLAPBOARD

SUB-ASSY

ELECTRICAL BOX

TEM.SENSOR

OUTTUBE OUTROOM

TEM.SENSOR

TEM.SENSOR

EXHAUST

OG

YEGN

YEGN

BURD YE

WH

YEGN

BU

BN

BU

BU

BK

BN

YEGN

WH

RD BU

OG

YE

FAN

YEGN

BU

BN

BK

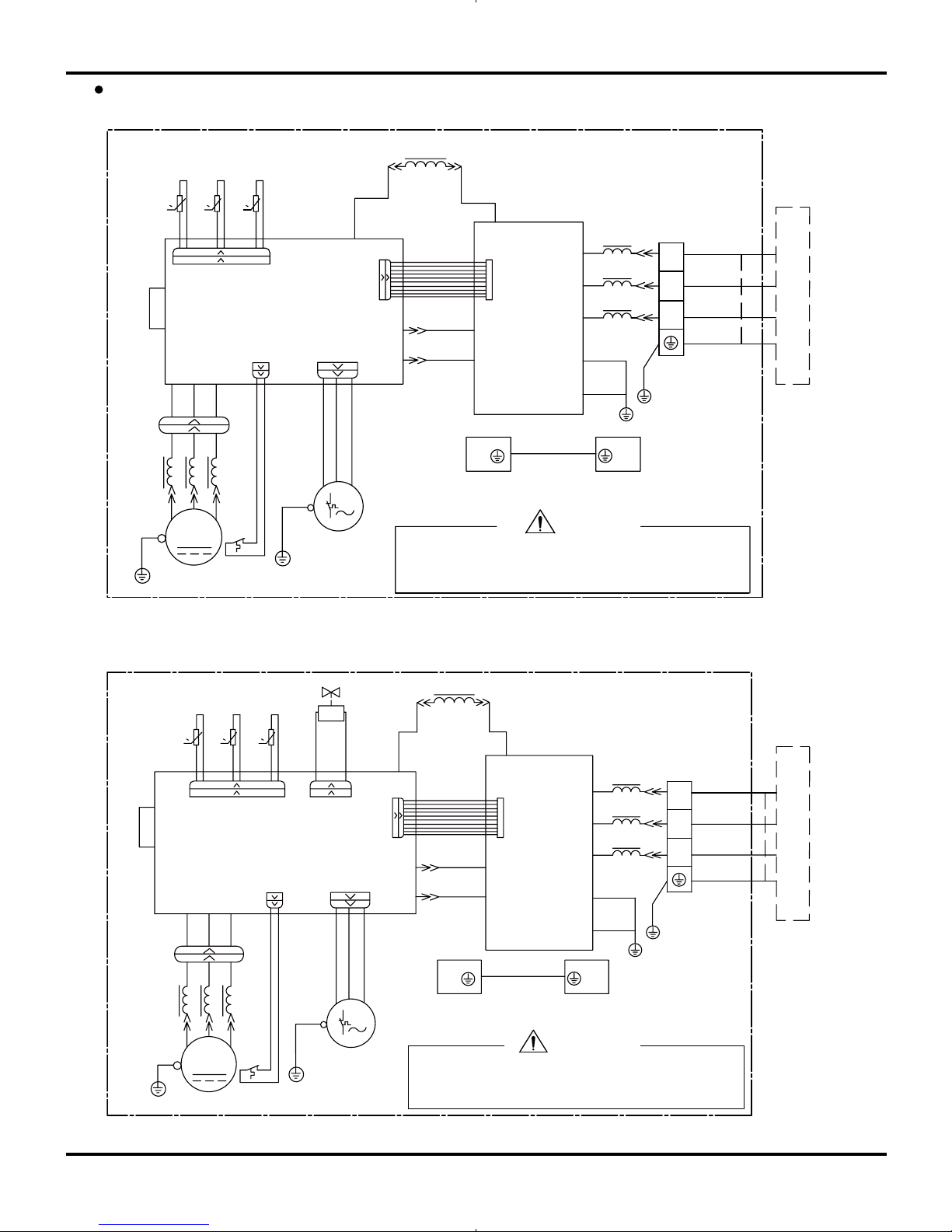

Outdoor Unit

Models GWC09KF-K3DNA5A/O ,GWC12KF-K3DNA5A/O

N(1)

XT

3

2

PE

PCB1

AC2

S

AC1

E1

E2

PCB2

U

V

W

0

RT3

0

RT4

RT5

0

S90

S11S10

HL2

HN2

HN3

HL3

L1

HR2

HR1

FAN

S70

COMP.

HA1

HA2

SAT

PE

S40

PE

PEPE

X1

YEGN

MOTOR

U

V

W

BK

BN

BU

YEGN

YE

OG

CLAPBOARD

BURD

WH

YEGN

BN

BK

BU

BU

BN

BU

YEGN

WH

YERD BU

YEGN

YEGN

OG

EXHAUST

TEM.SENSOR

TEM.SENSOR

OUTROOMOUTTUBE

TEM.SENSOR

ELECTRICAL BOX

SUB-ASSY

YEGN

M

INDOOR UNIT

WARNING

Please don't touch any terminal when the voltage of

prevent the risk of electrical shock!

terminal DC+ and DC- at PCB2 is higher than 30V to

Models GWH09KF-K3DNA5A/O ,GWH12KF-K3DNA5A/O ,GWH09KF-K3DNA6A/O ,

GWH12KF-K3DNA6A/O , GWH09KF-K3DNB1A/O ,GWH12KF-K3DNB1A/O

Schematic Diagram

These circuit diagrams are subject to change without notice, please refer to the one supplied with the unit.

18

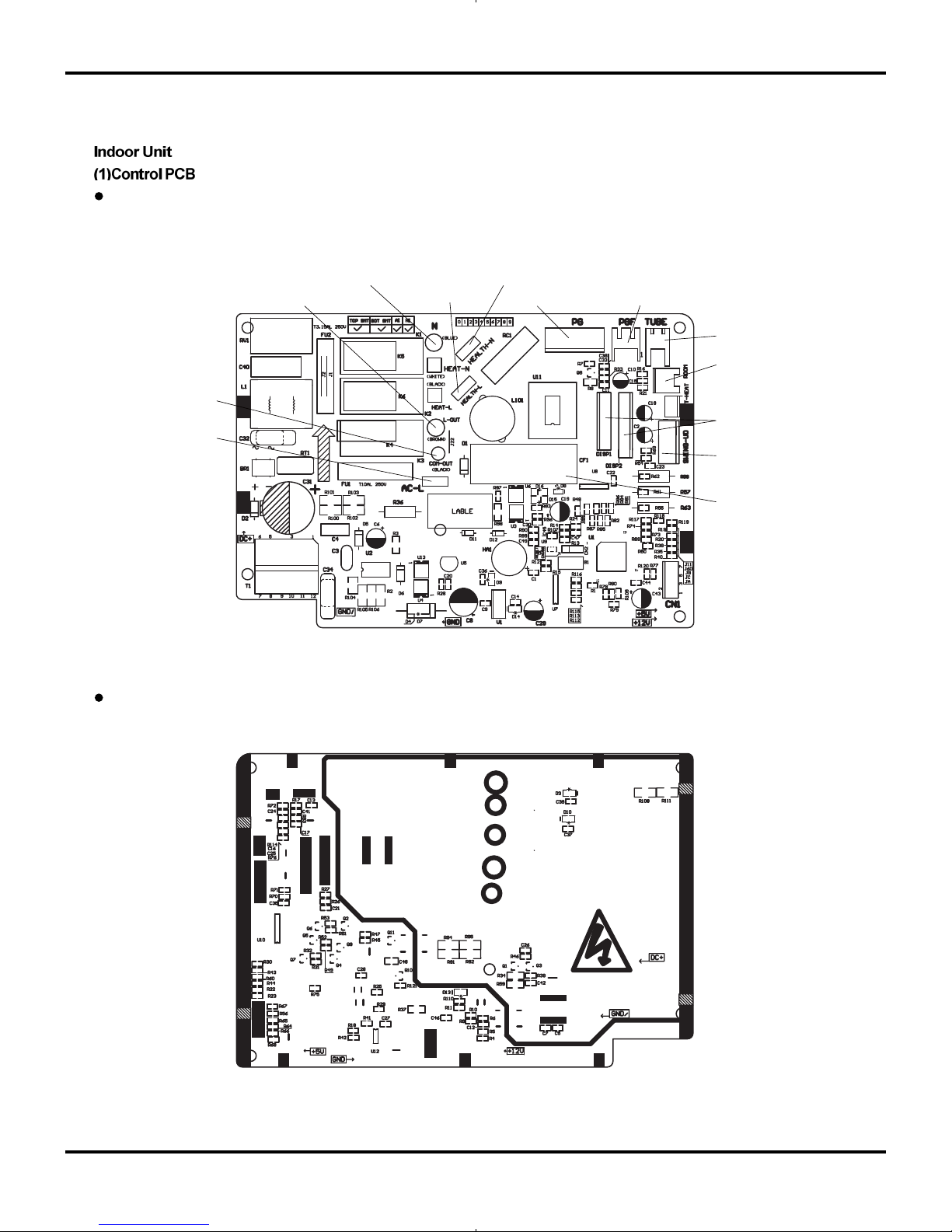

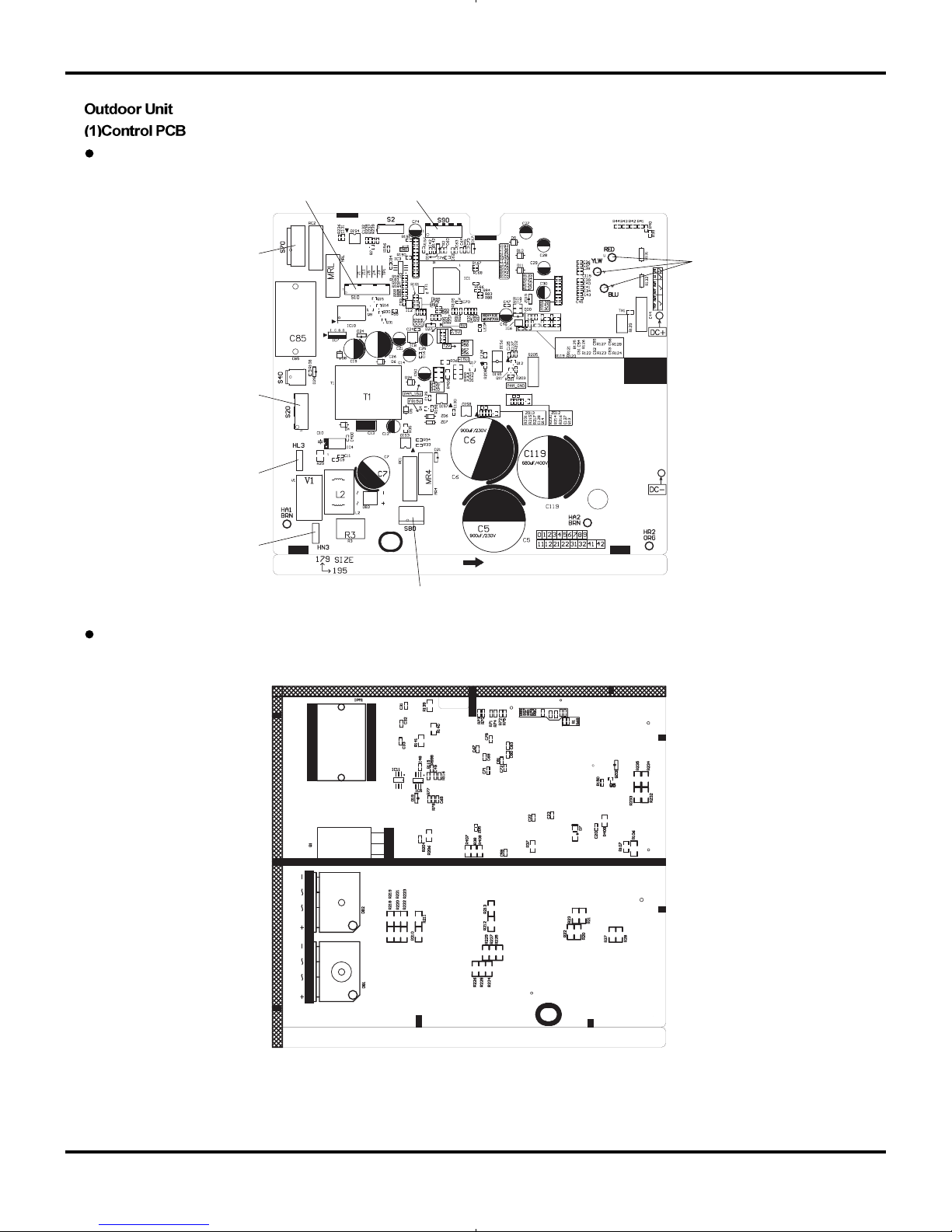

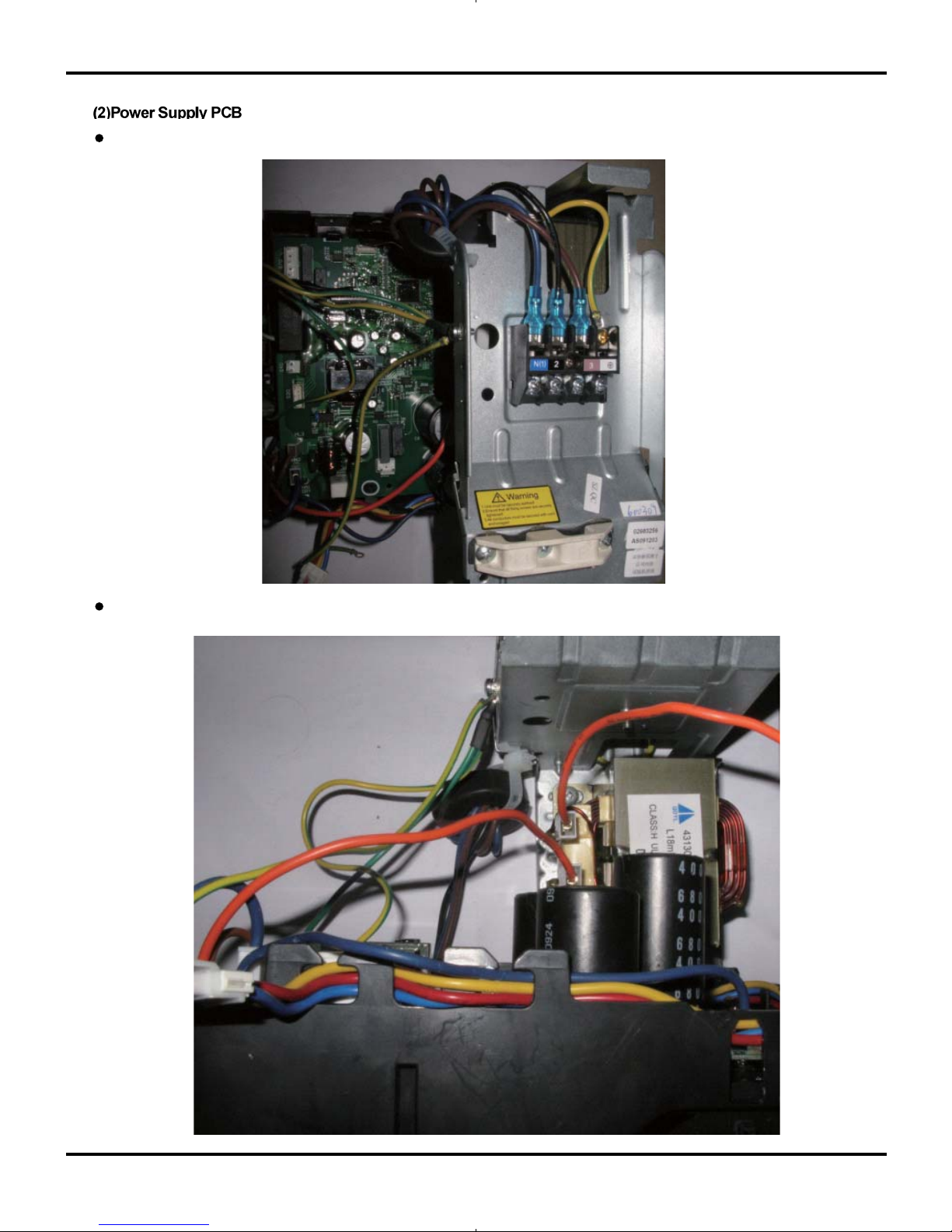

5.3 Printed Circuit Board

TOP VIEW

BOTTOM VIEW

Schematic Diagram

Interface of input live wire

Interface of input null wire

Interface of live wire

of cold-plasma

Interface of null wire of cold-plasma

Interface of indoor fan

Interface for feedback of indoor fan

Interface of pipe temp sensor

Interface of ambient temp sensor

Interface of communication wire

Interface of input live wire

Interface of motor

Interface of capacitor of fan

Interface of display device

19

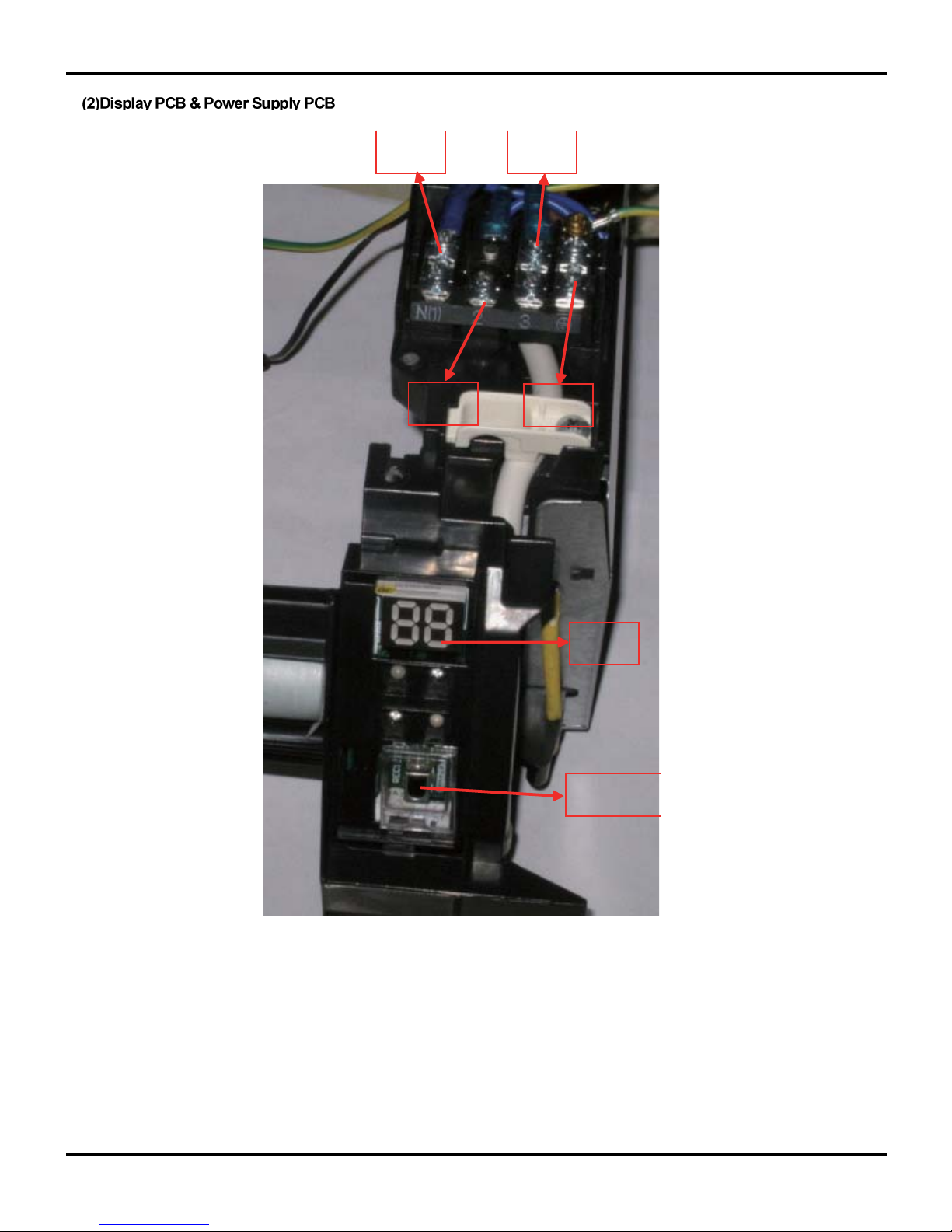

Schematic Diagram

null line live wire

communication

wire

ground wire

dispaly

board

infrared

receiver

20

TOP VIEW

BOTTOM VIEW

Schematic Diagram

Interface of mainboard and wave filter

Interface of temp sensor

Interface of compressor

Interface of outdoor fan

Interface of overload protector of compressor

Interface of live wire

Interface of null wire

Interface of 4-way valve

21

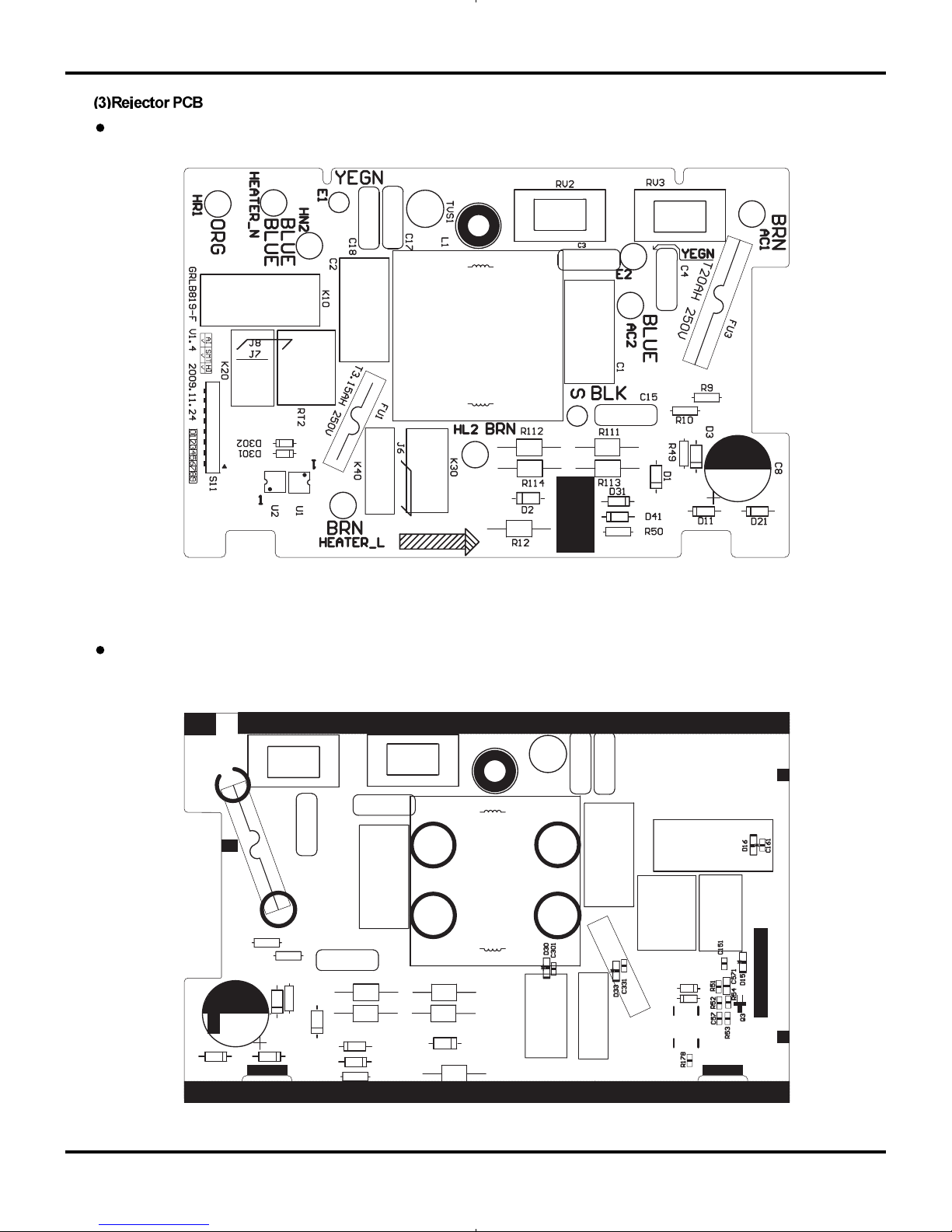

FRONT VIEW

BOTTOM VIEW

Schematic Diagram

22

TOP VIEW

Schematic Diagram

BOTTOM VIEW

23

6. Function and Control

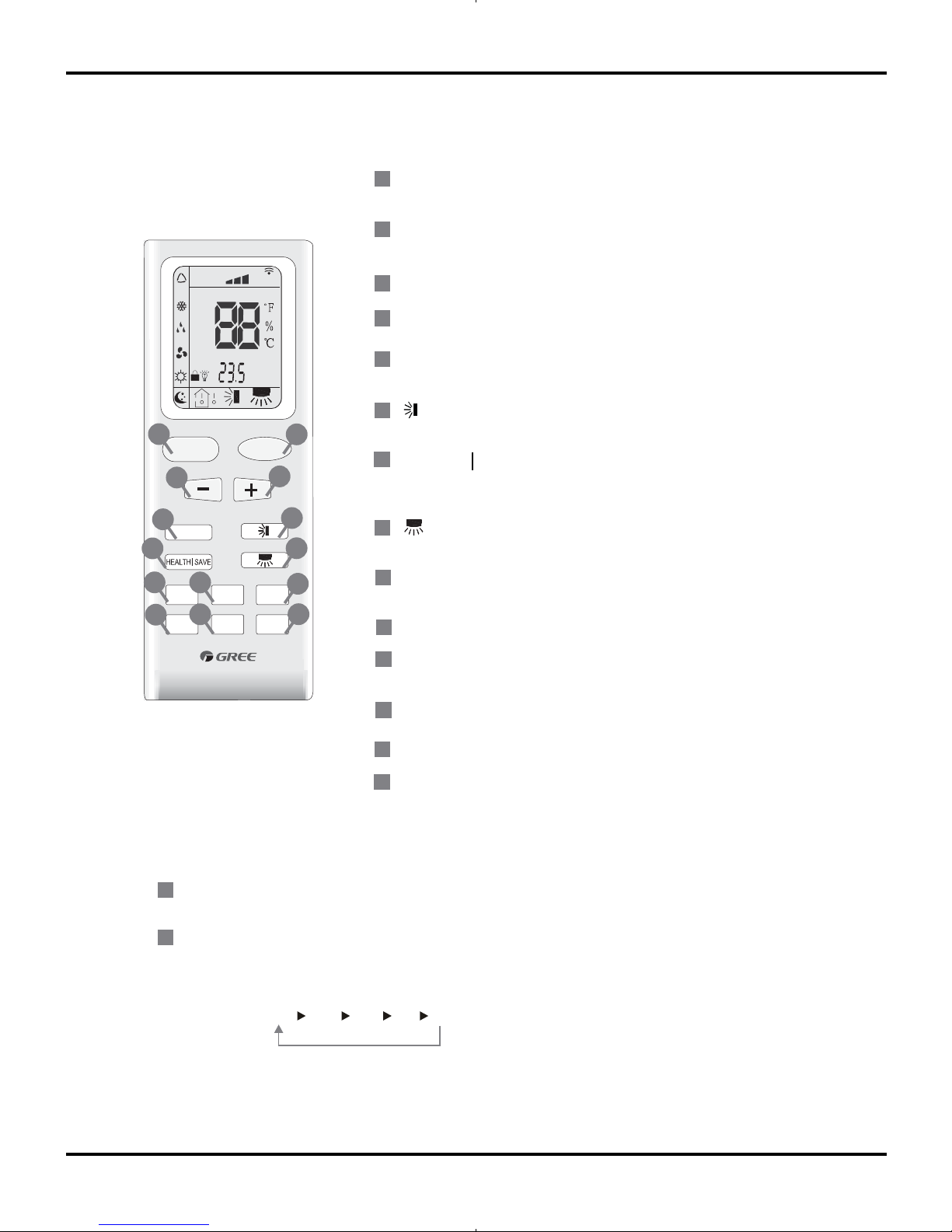

6.1 Remote Control Operations

Function and Control

Press this button to start or stop operation.

ON/OFF

MODE

+

-

Press it to select operation mode

(AUTO/COOL/DRY/FAN/HEAT).

: Press it to increase temperature setting.

: Press it to decrease temperature setting.

FA

HEALTH SAVE

N

Press it to set up &down swing angle.

TIMER

X-FAN

(X-FAN is the alternative expression of BLOW for the

purpose of understanding.)

Press it to select health mode on or off.

TEMP

TURBO

SLEEP

LIGHT

Press it to set fan speed.

Press it set auto-on timer/auto-off timer.

1

2

7

4

3

5

6

Press it to set left & right swing angle.

8

11

9

10

12

13

14

FAN

AUTO

OPER

HEALTH

AIR

FILTER

TURBO

ON/OFF

X-FAN

HOUR

HUMIDITY

ON/OFF

MODE

FAN

X-FAN

TURBO

TEMP

TIMER

SLEEP

LIGHT

2

11

7

10

13

9

43

12

8

6

14

5

1

Press it to turn on/off the light.

Remote controller description

ON/OFF :

MODE :

1

2

Press this button to start the unit operation .Press this button again to stop the unit operation.

Each time you press this button,a mode is selected in a sequence that goes from AUTO, COOL,DRY, FAN,

and HEAT

*,

as the following:

AUTO

COOL

DRY

FAN HEAT

*

*Note:Only for models with heating

function.

After energization, AUTO mode is defaulted. In AUTO mode, the set temperature will not be displayed on the

mode in accordance with the room temp

erature to make indoor room comfortable.

LCD, and the unit will automatically select the suitable operation

24

Function and Control

+

:

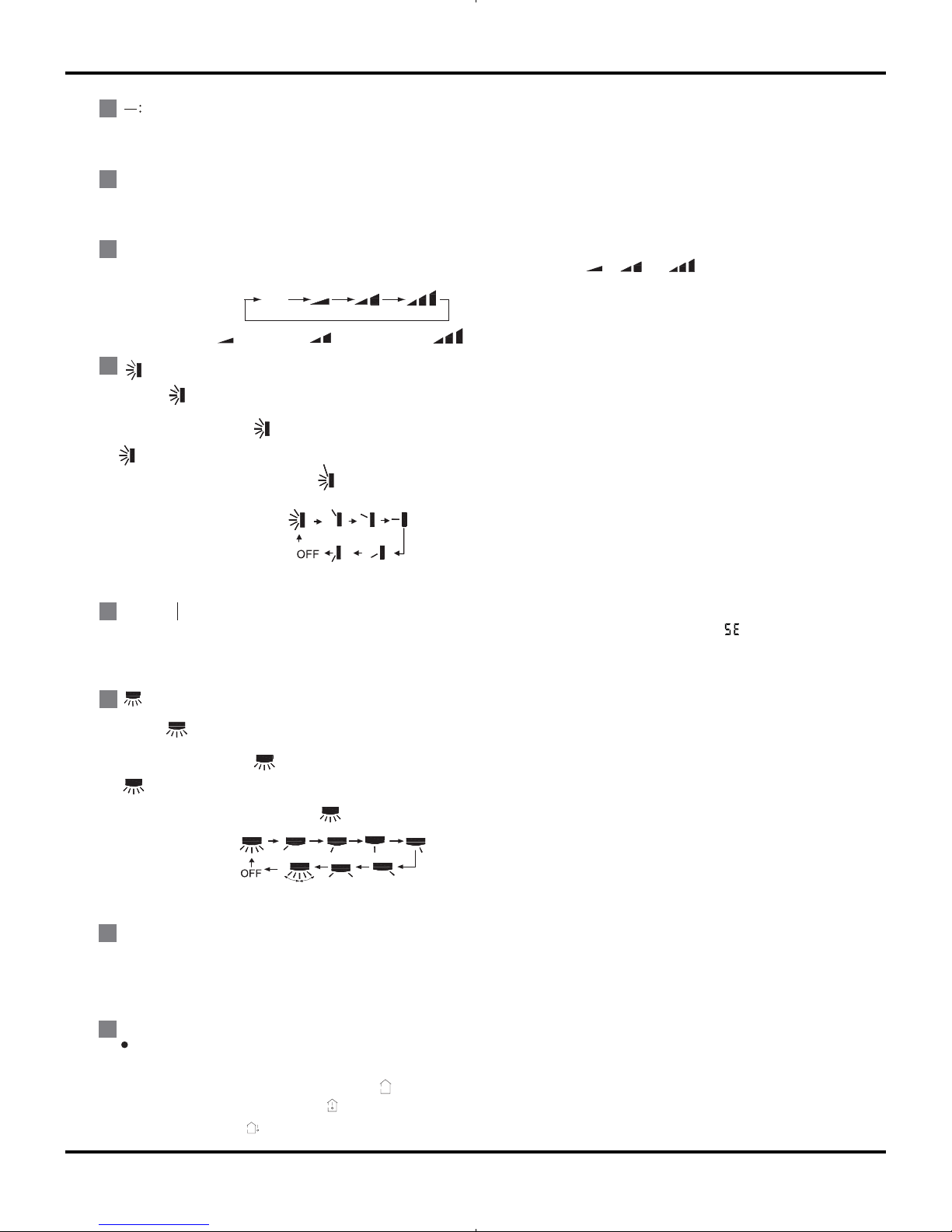

FAN :

4

3

5

Press this button to decrease set temperature.Holding it down above 2 seconds rapidly.decreases set temperature. In

Press this button to increase set temperature.Holding it down above 2 seconds rapidly increases set temperature. In

This button is used for setting fan speed in the sequence that goes from AUTO,

,

to

then back to Auto.

,

,

Aut o

Low speed

Medium speed

High speed

:

6

Press button to start or stop up & down swing function.The remote controller

defaults to simple swing condition.

Press + button and button at the same time at unit OFF to switch bet

ween simple swing and static swing,

blinking 2 seconds.

In static swing condition, press

If the unit is turned off during swing operation,the louver will stop at present position.

button, the swing angle of up & down louver changes as below:

●

●

●

●

AUTO mode, set temperature is not adjustable.

AUTO mode, set temperature is not adjustable.

HEALTH SAVE:

Press HEALTH part of this button to turn on or off HEALTH function.

7

X-FAN:

9

10

TEMP:

:

8

Pressing X-FAN button in COOL or DRY mode,the icon "X-FAN" is displayed and the indoor fan will continue operation

for 10 minutes in order to dry the indoor unit even though you have turned off the unit.

After energization, X-FAN OFF is defaulted. X-FAN is not available in AUTO,FAN or HEAT mode.

Pressing SAVE part of this button,

and the unit goes into SAVE operation mode. Press SAVE part of the button again to cancel SAVE function .During

SAVE operation, the tmperature and fan speed is not adjustable.

is displayed

Press + button and button at the same time at unit OFF to switch between simple swing and static swing,

Press button to start or stop left & right swing function.The remote controller defaults to simple swing condition.

blinking 2 seconds..

In static swing condition, press button, the swing angle of left & right louver

changes as below:

●

●

●

If the unit is turned off during swing operation,the louver will stop at present position.

●

Press this button to select set temperature or indoor ambient temp to be displayed by indoor unit. When there is no mark displayed

on remote controller, the current display will not change after the signal is received by indoor unit ( set temperature will be shown

when first energization of the unit); When “ ” is displayed on remote control, the set temp will be displayed after the signal

is received by indoor unit; When “ ” is displayed,the indoor ambient temp will be displayed after the signal is received by

indoor unit; When “ ” is displayed on remote control, the current display will not change after the signal is received by indoor

unit.

Loading...

Loading...