Gree GWH12KF-K3DNA6G, GWH12KF-K3DNA9G, GWH09KF-K3DNA6G, GWH09KF-K3DNA9G, GWH12KF-K3DNB2G Service Manual

...

GREE ELECTRIC APPLIANCES,INC.OF ZHUHAI

Change for Life

Service Manual

Models: GWH09KF-K3DNA5G

GWH09KF-K3DNA6G

GWH09KF-K3DNA9G

GWH09KF-K3DNB2G

GWH12KF-K3DNA5G

GWH12KF-K3DNA6G

GWH12KF-K3DNA9G

GWH12KF-K3DNB2G

GWH12KF-K3DNB3G

(Refrigerant R410A)

Service Manual

Table of Contents

Table of Contents

Part

Ⅰ

: Technical Information

.......................................................................1

1. Summary

......................................................................................................................1

2. Specications

..........................................................................................................2

2.1 Specication Sheet ...........................................................................................................2

2.2 Operation Characteristic Curve ........................................................................................6

2.3 Capacity Variation Ratio According to Temperature .........................................................6

2.4 Cooling and Heating Data Sheet in Rated Frequency .....................................................7

2.5 Noise Curve ......................................................................................................................7

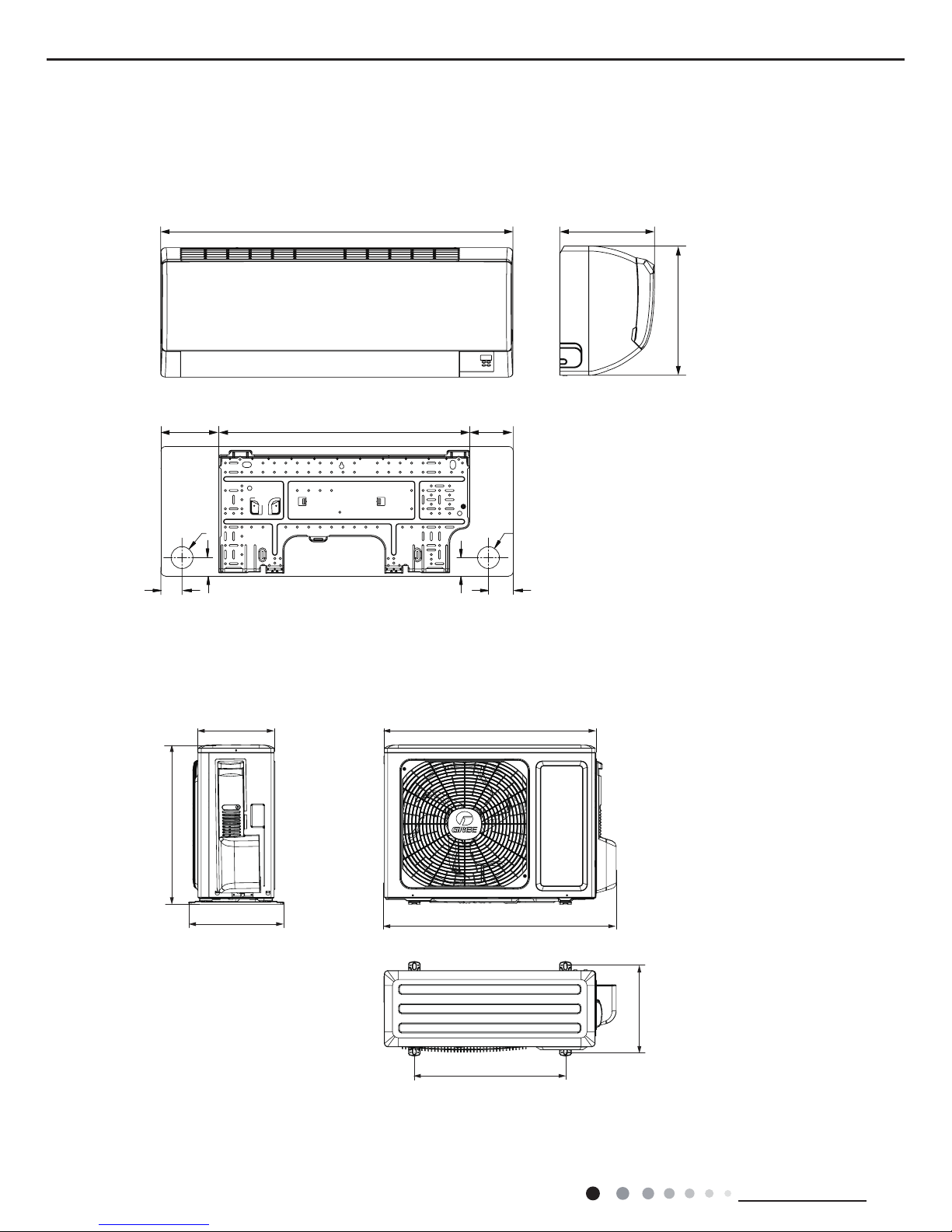

3. Outline Dimension Diagram

........................................................................8

3.1 Indoor Unit ........................................................................................................................8

3.2 Outdoor Unit .....................................................................................................................8

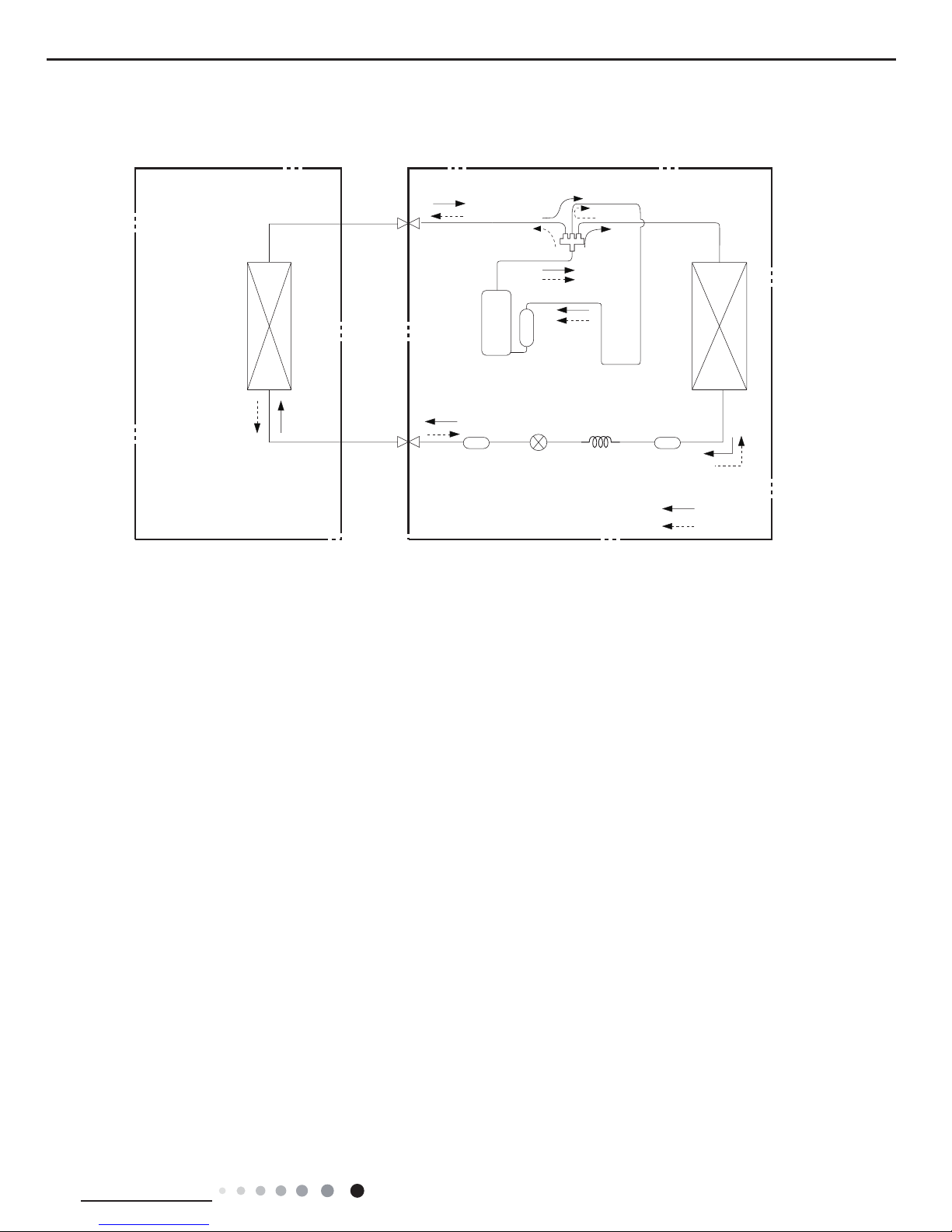

4. Refrigerant System Diagram

......................................................................9

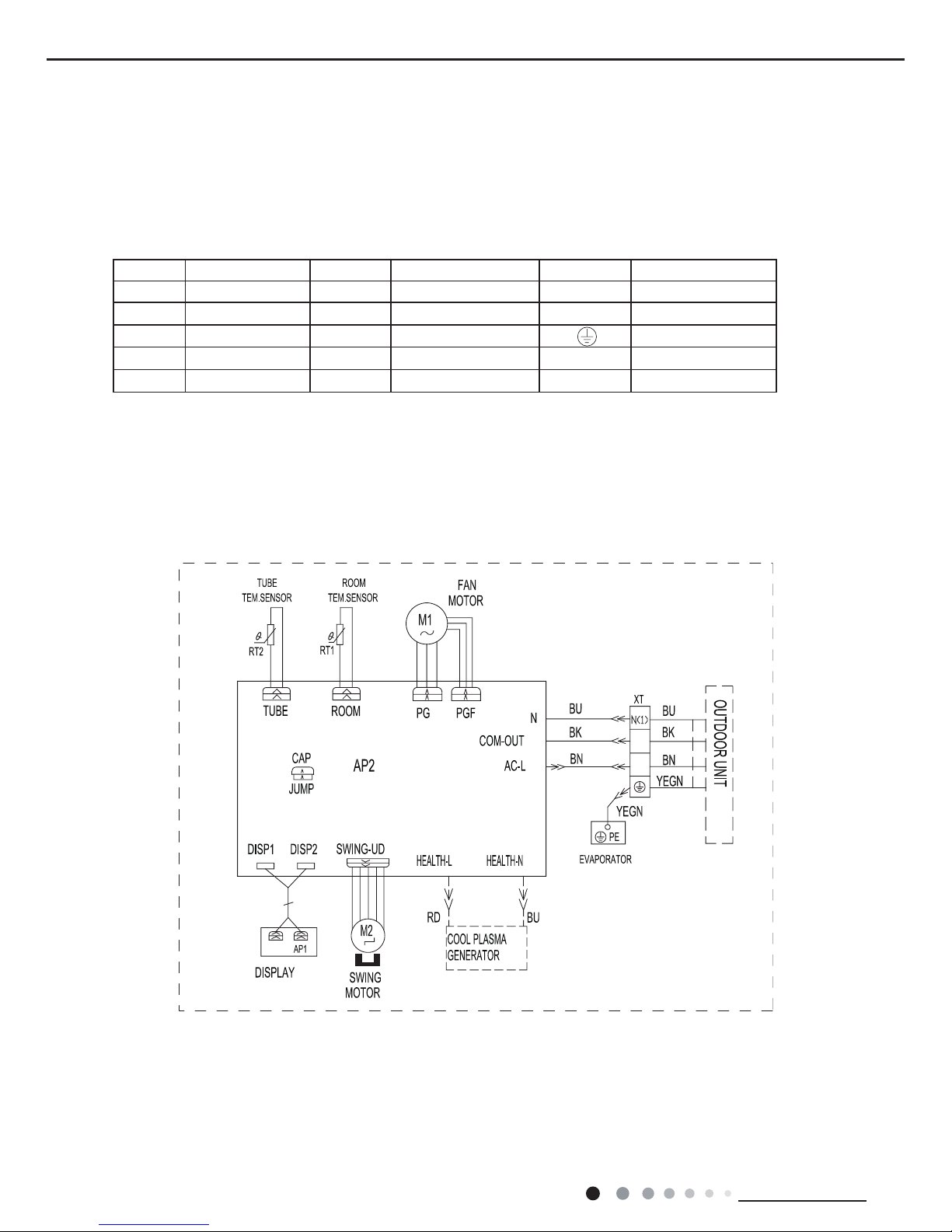

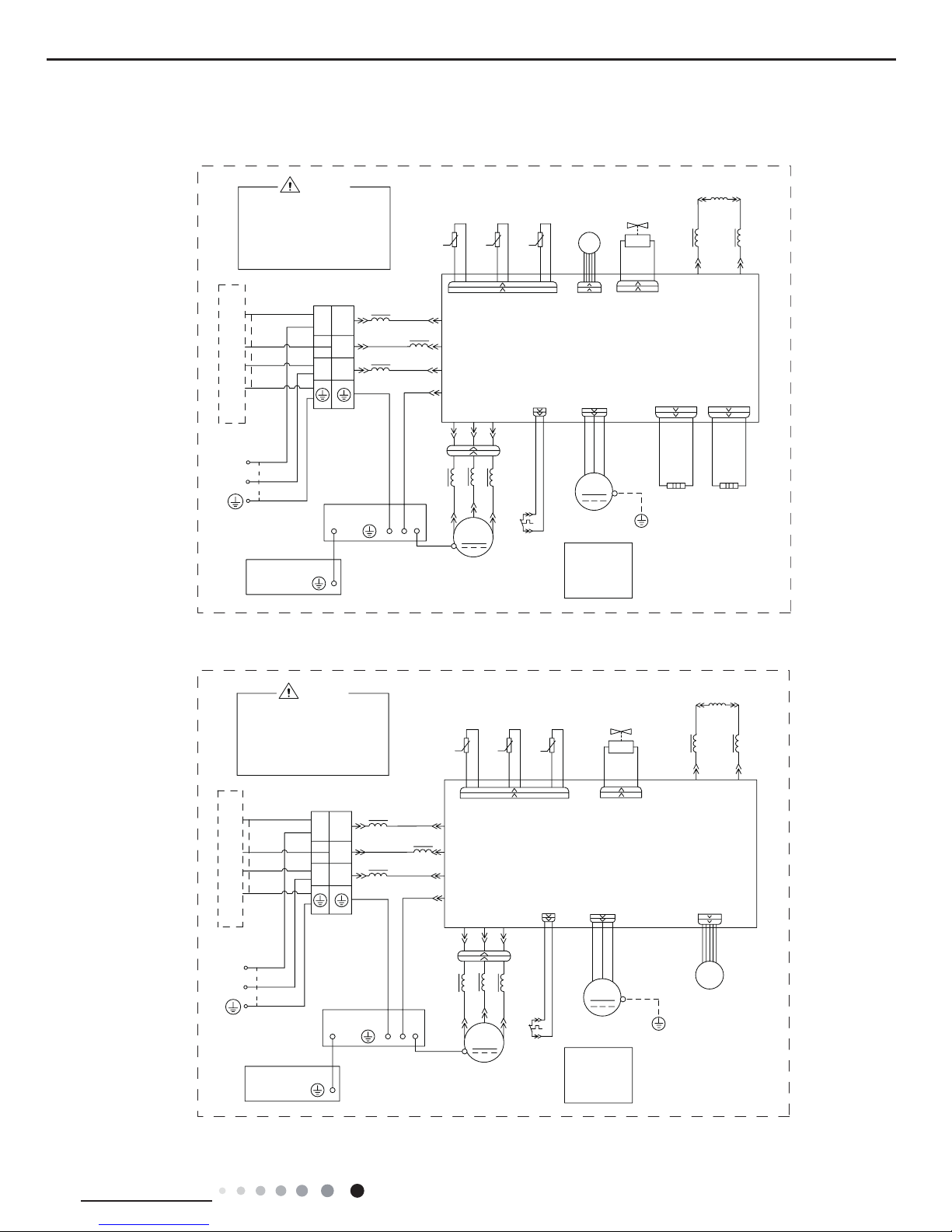

5. Electrical Part

.........................................................................................................10

5.1 Wiring Diagram ...............................................................................................................10

5.2 PCB Printed Diagram .....................................................................................................12

6. Function and Control

......................................................................................14

6.1 Remote Controller Introduction .....................................................................................14

6.2 Brief Description of Modes and Functions ......................................................................18

Part

Ⅱ

: Installation and Maintenance

.................................................22

7. Notes for Installation and Maintenance

..........................................22

8. Installation

................................................................................................................24

8.1 Installation Dimension Diagram ......................................................................................24

8.2 Installation Parts-checking ............................................................................................26

8.3 Selection of Installation Location ....................................................................................26

8.4 Electric Connection Requirement ...................................................................................26

8.5 Installation of Indoor Unit ................................................................................................26

8.6 Installation of Outdoor Unit .............................................................................................29

8.7 Vacuum Pumping and Leak Detection ...........................................................................30

8.8 Check after Installation and Test Operation ...................................................................30

Service Manual

9. Maintenance

............................................................................................................31

9.1 Flashing LED of Indoor/Outdoor Unit and Primary Judgement ......................................31

9.2 Procedure of Troubleshooting ........................................................................................39

9.3 Maintenance Method for Normal Malfunction .................................................................54

10. Exploded View and Parts List

..............................................................56

10.1 Indoor Unit ....................................................................................................................56

10.2 Outdoor Unit .................................................................................................................62

11. Removal Procedure

.......................................................................................65

11.1 Removal Procedure of Indoor Unit ...............................................................................65

11.2 Removal Procedure of Outdoor Unit ............................................................................79

Appendix:

........................................................................................................................84

Appendix 1: Reference Sheet of Celsius and Fahrenheit ....................................................84

Appendix 2: Conguration of Connection Pipe .....................................................................84

Appendix 3: Pipe Expanding Method ...................................................................................85

Appendix 4: List of Resistance for Temperature Sensor ......................................................86

1

Technical Information

Service Manual

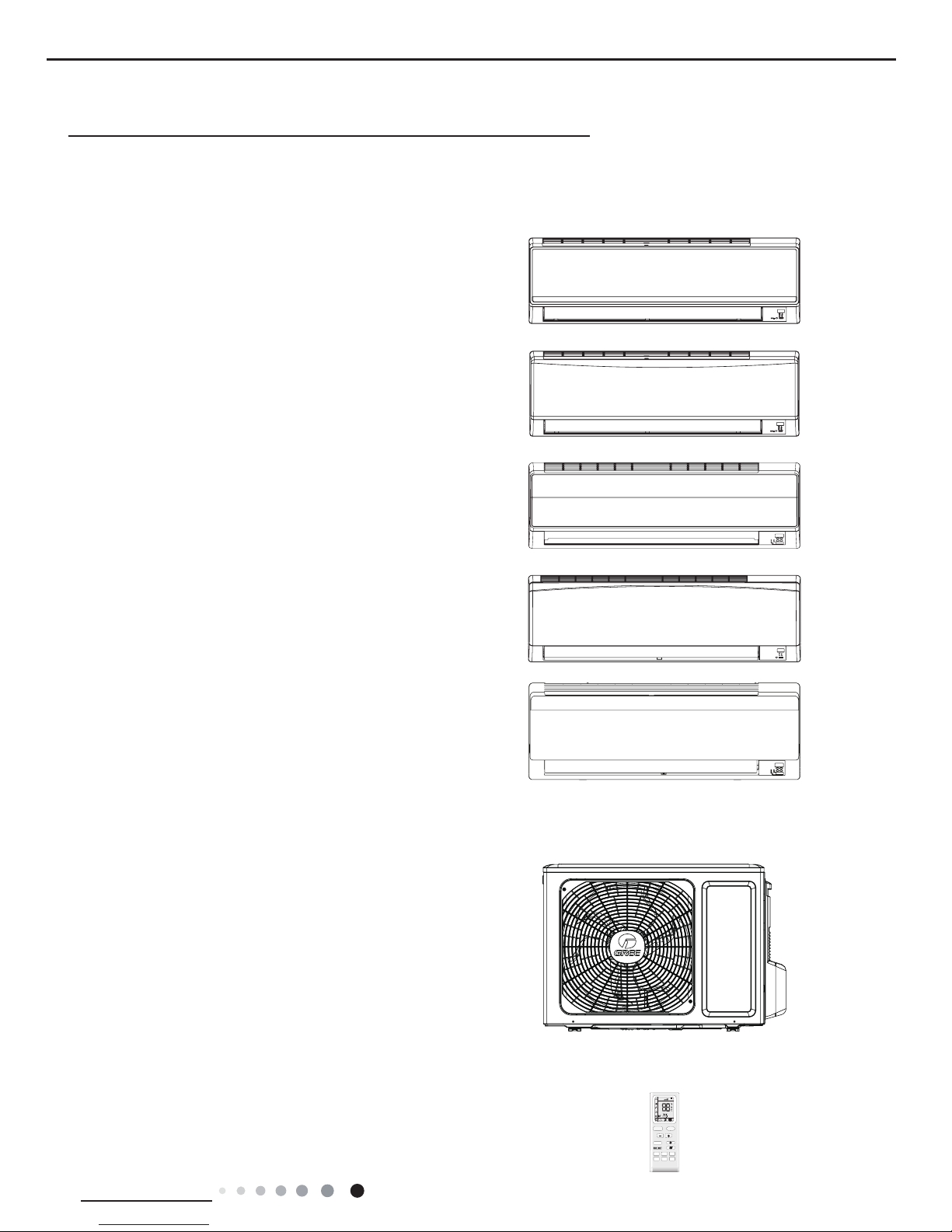

1. Summary

Part

Ⅰ

: Technical Information

Indoor Unit:

GWH09KF-K3DNA6G/I(Cold Plasma)

GWH12KF-K3DNA6G/I(Cold Plasma)

GWH09KF-K3DNA5G/I(Cold Plasma)

GWH12KF-K3DNA5G/I(Cold Plasma)

GWH09KF-K3DNB2G/I(Cold Plasma)

GWH12KF-K3DNB2G/I(Cold Plasma)

GWH09KF-K3DNA9G/I

GWH12KF-K3DNA9G/I

GWH12KF-K3DNB3G/I(Cold Plasma)

Outdoor Unit:

Remote Controller

:

GWH09KF-K3DNA6G/O

GWH12KF-K3DNA6G/O

YB1F2(XFAN)

FAN

AUTO

OPER

HEALTH

AIR

FILTER

TURBO

ON/OFF

X-FAN

HOUR

HUMIDITY

ON/OFF

MODE

FAN

X-FAN

TURBO

TEMP

TIMER

SLEEP

LIGHT

ON/OFF

2

Technical Information

Service Manual

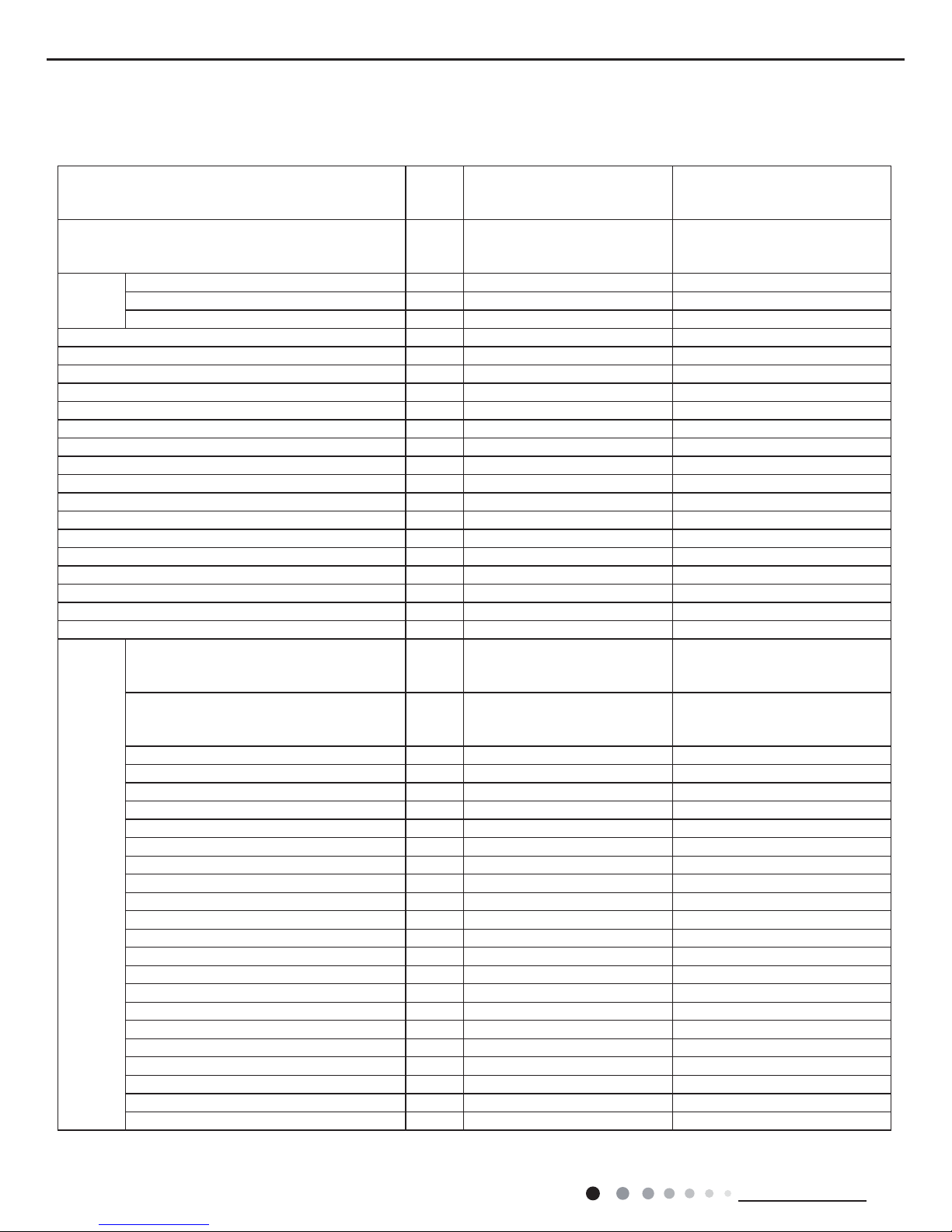

2. Specications

2.1 Specication Sheet

Model

GWH09KF-K3DNA6G(LCLH)

GWH09KF-K3DNB2G(LCLH)

GWH09KF-K3DNA5G(LCLH)

GWH12KF-K3DNA6G(LCLH)

GWH12KF-K3DNB2G(LCLH)

GWH12KF-K3DNA5G(LCLH)

Product Code

CB146036201

CB409002701

CB146037601

CB146036101

CB409002401

CB146037501

Power

Supply

Rated Voltage V~ 220-240 220-240

Rated Frequency Hz 50 50

Phases 1 1

Power Supply Mode Outdoor Outdoor

Cooling Capacity(Min~Max) W 2600(450~3230) 3500(450~3230)

Heating Capacity(Min~Max) W 2800(450~4100) 3800(450~4100)

Cooling Power Input(Min~Max) W 870(200~1420) 1150(200~1420)

Heating Power Input(Min~Max) W 900(200~1550) 1100(200~1550)

Cooling Current Input A 3.8 5.1

Heating Current Input A 4.0 4.9

Rated Input W 1550 1650

Rated Cooling Current A 6.3 6.9

Rated Heating Current A 6.9 7.3

Air Flow Volume (SH/H/M/L) m

3

/h 600/520/370/280 680/560/410/300

Dehumidifying Volume L/h 0.8 1.4

EER W/W 2.99 3.04

COP W/W 3.11 3.45

SEER 5.6 5.6

SCOP / /

Application Area m

2

12-18 16-24

Indoor

Unit

Indoor Unit Model

GWH09KF-K3DNA6G/I

GWH09KF-K3DNB2G/I

GWH09KF-K3DNA5G/I

GWH12KF-K3DNA6G/I

GWH12KF-K3DNB2G/I

GWH12KF-K3DNA5G/I

CB146N36200

CB409N02701

CB146N37600

CB146N36100

CB409N02400

CB146N37500

Indoor Unit Fan Type Cross-ow Cross-ow

Indoor Unit Fan Diameter Length(DXL) mm Ф92X596 Ф92X596

Cooling Speed (SH/H/M/L) r/min 1350/1100/900/700 1350/1150/950/750

Heating Speed (SH/H/M/L) r/min 1350/1140/980/820 1350/1190/1020/850

Indoor Unit Fan Motor Power Output W 10 10

Indoor Unit Fan Motor RLA A 0.18 0.18

Indoor Unit Fan Motor Capacitor μF 1.2 1.2

Evaporator Form Aluminum Fin-copper Tube Aluminum Fin-copper Tube

Evaporator Pipe Diameter mm Ф7 Ф7

Evaporator Row-n Gap mm 2-1.4 2-1.4

Evaporator Coil Length (LXDXW) mm 610X24X294 610X24X294

Swing Motor Model MP24BA MP24BA

Swing Motor Power Output W 1.5 1.5

Fuse Current A 3.15 3.15

Indoor Unit Sound Pressure Level (SH/H/M/L) dB (A) 41/38/30/24 42/39/31/25

Indoor Unit Sound Power Level (SH/H/M/L) dB (A) 55/52/44/38 56/53/45/39

Indoor Unit Dimension (WXHXD) mm 770X283X201 770X283X201

Indoor Unit Dimension of Carton Box (LXWXH) mm 844X342X261 844X342X261

Indoor Unit Dimension of Package (LXWXH) mm 847X345X276 847X345X276

Indoor Unit Net Weight kg 8 9

Indoor Unit Gross Weight kg 9.5 10.5

3

Technical Information

Service Manual

The above data is subject to change without notice; please refer to the nameplate of the unit.

Outdoor Unit

Outdoor Unit Model GWH09KF-K3DNA6G/O GWH12KF-K3DNA6G/O

Outdoor Unit Product Code CB146W36201 CB146W36101

Compressor Manufacturer

ZHUHAI LANDA

COMPRESSOR CO.,LTD.

ZHUHAI LANDA

COMPRESSOR CO.,LTD.

Compressor Model QXA-A091zE190A QXA-A091zE190A

Compressor Oil RB68EP RB68EP

Compressor Type Rotary Rotary

Compressor Locked Rotor Amp (L.R.A) A 20 20

Compressor Rated Load Amp (RLA) A 4.5 4.5

Compressor Power Input W 942 942

Compressor Overload Protector 1NT11L-6233 1NT11L-6233

Throttling Method Electron expansion valve Electron expansion valve

Set Temperature Range °C 16~30 16~30

Cooling Operation Ambient Temperature

Range

°C -15~43 -15~43

Heating Operation Ambient Temperature

Range

°C -20~24 -20~24

Condenser Form Aluminum Fin-copper Tube Aluminum Fin-copper Tube

Condenser Pipe Diameter mm Ф7 Ф7

Condenser Rows-n Gap mm 1-1.4 2-1.4

Condenser Coil Length (LXDXW) mm 710X19.05X508 710X38.1X506

Outdoor Unit Fan Motor Speed rpm 900 900

Outdoor Unit Fan Motor Power Output W 30 30

Outdoor Unit Fan Motor RLA A 0.36 0.36

Outdoor Unit Fan Motor Capacitor μF / /

Outdoor Unit Air Flow Volume m

3

/h 1600 1600

Outdoor Unit Fan Type Axial-ow Axial-ow

Outdoor Unit Fan Diameter mm Ф400 Ф400

Defrosting Method Automatic Defrosting Automatic Defrosting

Climate Type T1 T1

Isolation I I

Moisture Protection IP24 IP24

Permissible Excessive Operating Pressure

for the Discharge Side

MPa 4.3 4.3

Permissible Excessive Operating Pressure

for the Suction Side

MPa 2.5 2.5

Outdoor Unit Sound Pressure Level (H/M/L) dB (A) 51/-/- 53/-/Outdoor Unit Sound Power Level (H/M/L) dB (A) 62/-/- 63/-/Outdoor Unit Dimension (WXHXD) mm 776X540X320 776X540X320

Outdoor Unit Dimension of Carton Box

(LXWXH)

mm 848X360X580 848X360X580

Outdoor Unit Dimension of Package

(LXWXH)

mm 851X363X595 851X363X595

Outdoor Unit Net Weight kg 28 29

Outdoor Unit Gross Weight kg 31 32

Refrigerant R410A R410A

Refrigerant Charge kg 0.7 0.85

Connection

Pipe

Connection Pipe Length m 5

5

Connection Pipe Gas Additional Charge g/m 20

20

Outer Diameter of Liquid Pipe mm Ф6

Ф6

Outer Diameter of Gas Pipe mm Ф9.52

Ф9.52

Max Distance Height m 10

10

Max Distance Length m 15

20

Note: The connection pipe applies metric diameter.

4

Technical Information

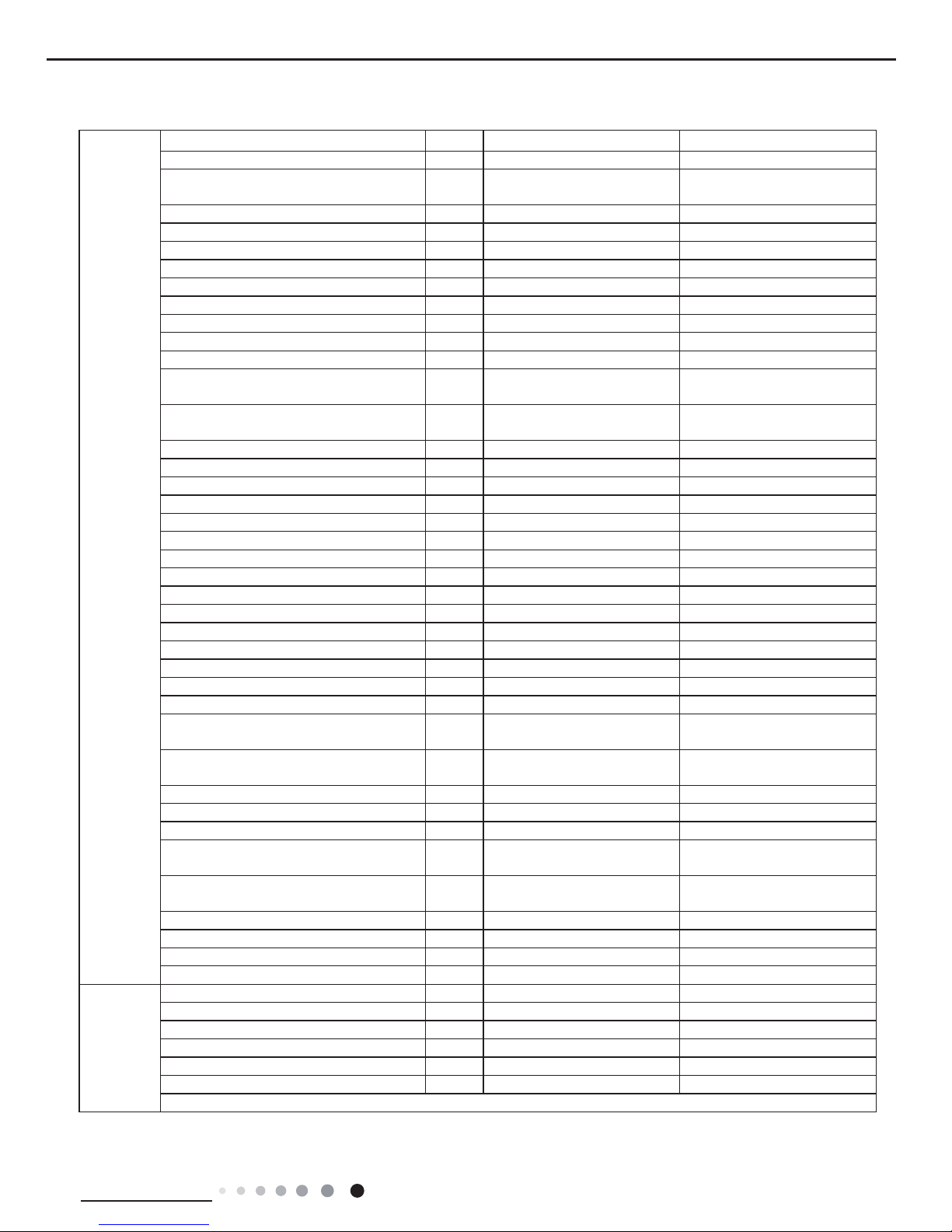

Service Manual

Model

GWH09KF-K3DNA6G(LC)

GWH09KF-K3DNA9G(LC)

GWH12KF-K3DNA6G(LC)

GWH12KF-K3DNA9G(LC)

GWH12KF-K3DNB3G(LC)

Product Code

CB146036200

CB146037000

CB146036100

CB146037100

CB146037800

Power

Supply

Rated Voltage V~ 220-240 220-240

Rated Frequency Hz 50 50

Phases 1 1

Power Supply Mode Outdoor Outdoor

Cooling Capacity(Min~Max) W 2600(450~3230) 3500(450~3230)

Heating Capacity(Min~Max) W 2800(450~4100) 3800(450~4100)

Cooling Power Input(Min~Max) W 870(200~1420) 1150(200~1420)

Heating Power Input(Min~Max) W 900(200~1550) 1100(200~1550)

Cooling Current Input A 3.8 5.1

Heating Current Input A 4.0 4.9

Rated Input W 1550 1650

Rated Cooling Current A 6.3 6.9

Rated Heating Current A 6.9 7.3

Air Flow Volume (SH/H/M/L) m

3

/h 600/520/370/280 680/560/410/300

Dehumidifying Volume L/h 0.8 1.4

EER W/W 2.99 3.04

COP W/W 3.11 3.45

SEER 5.6 5.6

SCOP / /

Application Area m

2

12-18 16-24

Indoor

Unit

Indoor Unit Model

GWH09KF-K3DNA6G/I

GWH09KF-K3DNA9G/I

GWH12KF-K3DNA6G/I

GWH12KF-K3DNA9G/I

GWH12KF-K3DNB3G/I

CB146N36200

CB146N37000

CB146N36100

CB146N37100

CB146N37800

Indoor Unit Fan Type Cross-ow Cross-ow

Indoor Unit Fan Diameter Length(DXL) mm Ф92X596 Ф92X596

Cooling Speed (SH/H/M/L) r/min 1350/1100/900/700 1350/1150/950/750

Heating Speed (SH/H/M/L) r/min 1350/1140/980/820 1350/1190/1020/850

Indoor Unit Fan Motor Power Output W 10 10

Indoor Unit Fan Motor RLA A 0.18 0.18

Indoor Unit Fan Motor Capacitor μF 1.2 1.2

Evaporator Form Aluminum Fin-copper Tube Aluminum Fin-copper Tube

Evaporator Pipe Diameter mm Ф7 Ф7

Evaporator Row-n Gap mm 2-1.4 2-1.4

Evaporator Coil Length (LXDXW) mm 610X24X294 610X24X294

Swing Motor Model MP24BA MP24BA

Swing Motor Power Output W 1.5 1.5

Fuse Current A 3.15 3.15

Indoor Unit Sound Pressure Level (SH/H/M/L) dB (A) 41/38/30/24 42/39/31/25

Indoor Unit Sound Power Level (SH/H/M/L) dB (A) 55/52/44/38 56/53/45/39

Indoor Unit Dimension (WXHXD) mm 770X283X201 770X283X201

Indoor Unit Dimension of Carton Box (LXWXH) mm 844X342X261 844X342X261

Indoor Unit Dimension of Package (LXWXH) mm 847X345X276 847X345X276

Indoor Unit Net Weight kg 8 9

Indoor Unit Gross Weight kg 9.5 10.5

5

Technical Information

Service Manual

The above data is subject to change without notice; please refer to the nameplate of the unit.

Outdoor Unit

Outdoor Unit Model GWH09KF-K3DNA6G/O GWH12KF-K3DNA6G/O

Outdoor Unit Product Code CB146W36200 CB146W36100

Compressor Manufacturer

ZHUHAI LANDA

COMPRESSOR CO.,LTD.

ZHUHAI LANDA

COMPRESSOR CO.,LTD.

Compressor Model QXA-A091zE190A QXA-A091zE190A

Compressor Oil RB68EP RB68EP

Compressor Type Rotary Rotary

Compressor Locked Rotor Amp (L.R.A) A 20 20

Compressor Rated Load Amp (RLA) A 4.5 4.5

Compressor Power Input W 942 942

Compressor Overload Protector 1NT11L-6233 1NT11L-6233

Throttling Method Electron expansion valve Electron expansion valve

Set Temperature Range °C 16~30 16~30

Cooling Operation Ambient Temperature

Range

°C -15~43 -15~43

Heating Operation Ambient Temperature

Range

°C -15~24 -15~24

Condenser Form Aluminum Fin-copper Tube Aluminum Fin-copper Tube

Condenser Pipe Diameter mm Ф7 Ф7

Condenser Rows-n Gap mm 1-1.4 2-1.4

Condenser Coil Length (LXDXW) mm 710X19.05X508 710X38.1X506

Outdoor Unit Fan Motor Speed rpm 900 900

Outdoor Unit Fan Motor Power Output W 30 30

Outdoor Unit Fan Motor RLA A 0.36 0.36

Outdoor Unit Fan Motor Capacitor μF / /

Outdoor Unit Air Flow Volume m

3

/h 1600 1600

Outdoor Unit Fan Type Axial-ow Axial-ow

Outdoor Unit Fan Diameter mm Ф400 Ф400

Defrosting Method Automatic Defrosting Automatic Defrosting

Climate Type T1 T1

Isolation I I

Moisture Protection IP24 IP24

Permissible Excessive Operating Pressure

for the Discharge Side

MPa 4.3 4.3

Permissible Excessive Operating Pressure

for the Suction Side

MPa 2.5 2.5

Outdoor Unit Sound Pressure Level (H/M/L) dB (A) 51/-/- 53/-/Outdoor Unit Sound Power Level (H/M/L) dB (A) 62/-/- 63/-/Outdoor Unit Dimension (WXHXD) mm 776X540X320 776X540X320

Outdoor Unit Dimension of Carton Box

(LXWXH)

mm 848X360X580 848X360X580

Outdoor Unit Dimension of Package

(LXWXH)

mm 851X363X595 851X363X595

Outdoor Unit Net Weight kg 28 29

Outdoor Unit Gross Weight kg 31 32

Refrigerant R410A R410A

Refrigerant Charge kg 0.7 0.85

Connection

Pipe

Connection Pipe Length m 5

5

Connection Pipe Gas Additional Charge g/m 20

20

Outer Diameter of Liquid Pipe mm Ф6

Ф6

Outer Diameter of Gas Pipe mm Ф9.52

Ф9.52

Max Distance Height m 10

10

Max Distance Length m 15

20

Note: The connection pipe applies metric diameter.

6

Technical Information

Service Manual

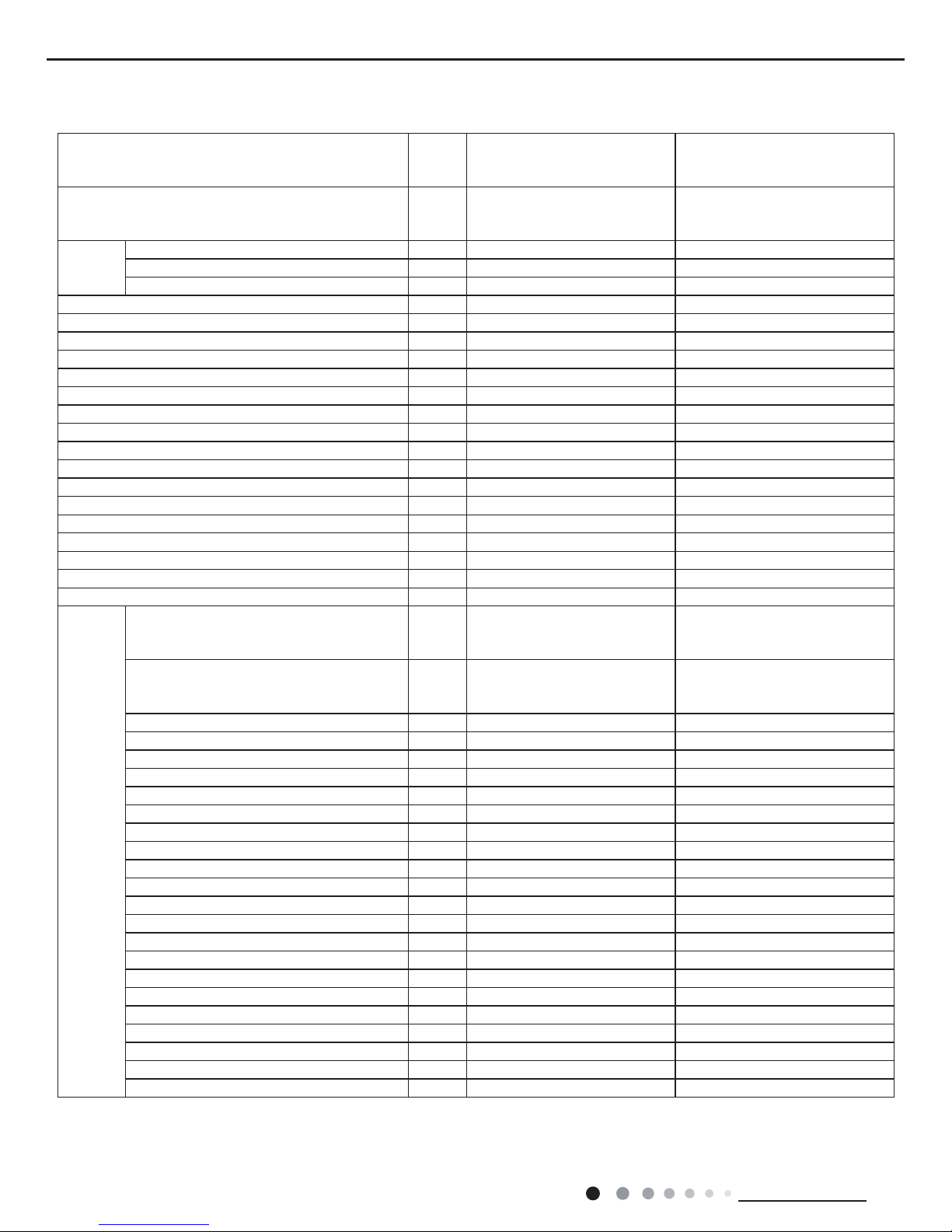

2.2 Operation Characteristic Curve

Cooling Heating

0 10 20 30 40 50 60 70 90 0 10 20 30 40 50 60 70 80 90 100 120110

80

11

10

9

8

7

6

5

4

3

2

1

0

11

10

9

8

7

6

5

4

3

2

1

0

220V

230V

240V

220V

230V

240V

Current (A)

Current (A)

Conditions

Indoor:DB27°C/WB19°C

Outdoor:DB35°C/WB24°C

Indoor air flow:Super High

Pipe length:5m

Conditions

Indoor:DB20°C/WB15°C

Outdoor:DB7°C/WB6°C

Indoor air flow:Super High

Pipe length:5m

Compressor speed (rps) Compressor speed (rps)

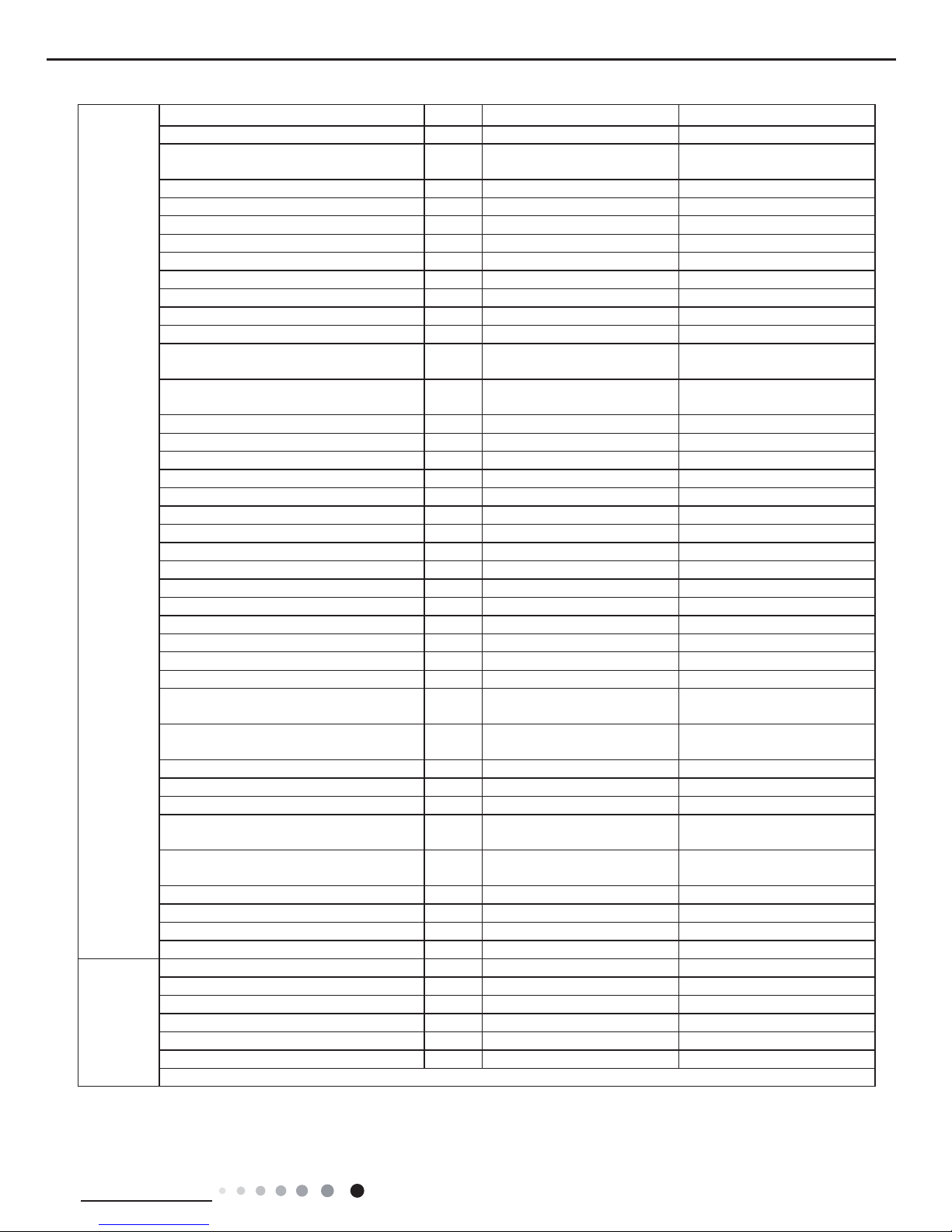

2.3 Capacity Variation Ratio According to Temperature

Capacity ratio(%)

Outdoor temp. (°C)

Capacity ratio(%)

Outdoor temp. (°C)

Capacity ratio(%)

Capacity ratio(%)

Outdoor temp. (°C)

-20 -15 -10 -5 0 5 10

110

120

130

100

90

80

70

60

50

40

50

60

70

80

90

100

110

120

130

32 33 34 35 36 37 38 39 40 41 42 43 44 45 46

50

60

70

80

90

100

110

120

130

32 33 34 35 36 37 38 39 40 41 42 43 44 45 46

Conditions

Indoor:DB27°C/WB19°C

Indoor air flow:High

Pipe length:5m

Conditions

Indoor:DB27°C/WB19°C

Indoor air flow:High

Pipe length:5m

Condition

Indoor:DB20°C

/WB15°C

Indoor air flow:

High

Pipe length:5m

–15 –10 –5 5

110

100

90

80

70

60

50

40

0 7 10

Conditions

Indoor:DB20°C/WB15°C

Indoor air flow:Super High

Pipe length:5m

Outdoor temp.(°C)

Cooling

Heating operation ambient temperature range is -20°C~24°C

Heating operation ambient temperature range is -15°C~24°C

Cooling

Heating

Heating

7

Technical Information

Service Manual

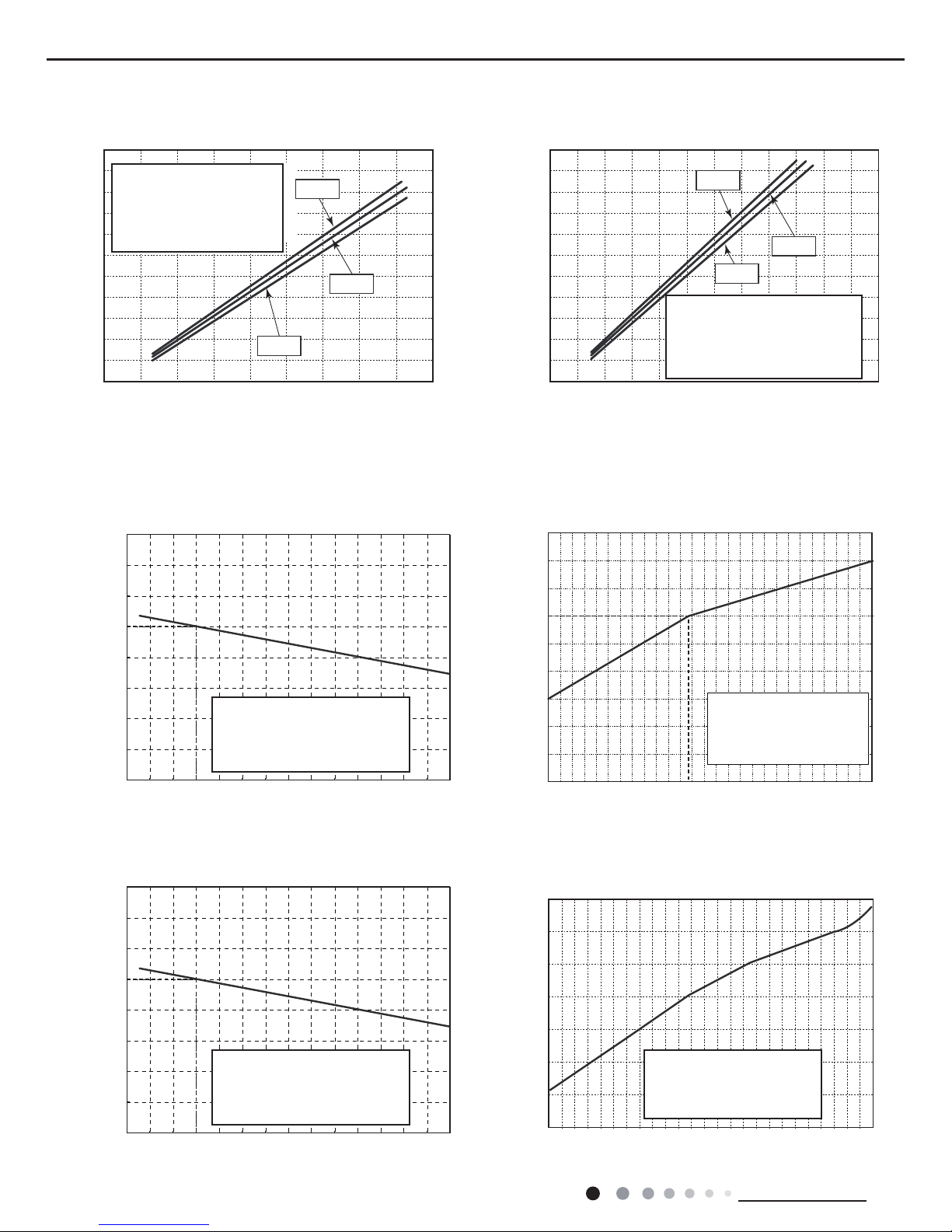

2.4 Cooling and Heating Data Sheet in Rated Frequency

Instruction:

T1: Inlet and outlet pipe temperature of evaporator

T2: Inlet and outlet pipe temperature of condenser

P: Pressure at the side of big valve

Connection pipe length:5 m.

Cooling:

Heating:

Rated cooling

condition(°C) (DB/WB)

Model

Pressure of gas pipe

connecting indoor

and outdoor unit

Inlet and outlet pipe

temperature of heat

exchanger

Fan speed

of indoor

unit

Fan speed

of outdoor

unit

Compressor

revolution (rps)

Indoor Outdoor P (MPa) T1 (°C) T2 (°C)

27/19 35/24

09K 0.9 to 1.1 12 to 14 75 to 37 Super High High 63

12K 0.8 to 1.0 10 to 12 85 to 43 Super High High 70

Rated heating

condition(°C) (DB/WB)

Model

Pressure of gas pipe

connecting indoor

and outdoor unit

Inlet and outlet pipe

temperature of heat

exchanger

Fan speed

of indoor

unit

Fan speed

of outdoor

unit

Compressor

revolution (rps)

Indoor Outdoor P (MPa) T1 (°C) T2 (°C)

20/15 7/6

09K 2.4 to 2.6 70 to 35 2 to 4 Super High High 69

12K 2.4 to 2.6 70 to 35 2 to 4 Super High High 72

2.5 Noise Curve

Indoor side noise when blowing Outdoor side noise when blowing

Indoor fan motor rotating speed

Compressor frequency(Hz)

Noise/dB(A)

50

60

30

40

20

Low

Middle

High

Super High

12K

09K

40

42

44

46

48

50

52

54

56

20 4030 50 60 70 80 90

Noise dB(A)

09&12K Cooling

09&12K Heating

8

Technical Information

Service Manual

3. Outline Dimension Diagram

3.1 Indoor Unit

Φ55

Φ55

41.3

41.3

54

54.5

120.5 548.5

770

201

283

103

3.2 Outdoor Unit

unit:mm

unit:mm

712

776

257

320

540

286

510

9

Technical Information

Service Manual

4. Refrigerant System Diagram

Indoor unit

Outdoor unit

COOLING

HEATING

4-Way valve

Discharge

Suction

Heat

exchanger

(evaporator)

Heat

exchanger

(condenser)

Valve

Valve

Liquid pipe

side

Gas pipe

side

Strainer

Electron

expansion

valve

Strainer

Capillary

Accumlator

Compressor

Connection pipe specication:

Liquid pipe:1/4" (6mm)

Gas pipe:3/8" (9.52mm)

10

Technical Information

Service Manual

5. Electrical Part

5.1 Wiring Diagram

● Indoor Unit

●Instruction

Symbol Symbol Color Symbol Symbol Color Symbol Name

WH White GN Green CAP Jumper cap

YE Yellow BN Brown COMP Compressor

RD Red BU Blue Grounding wire

YEGN Yellow/Green BK Black / /

VT Violet OG Orange / /

Note: Jumper cap is used to determine fan speed and the swing angle of horizontal lover for this model.

3

2

(optional)

11

Technical Information

Service Manual

● Outdoor Unit

(1)GWH09KF-K3DNA6G/O(CB146W36201), GWH12KF-K3DNA6G/O(CB146W36101)

(2)GWH09KF-K3DNA6G/O(CB146W36200), GWH12KF-K3DNA6G/O(CB146W36100)

These wiring diagrams are subject to change without notice; please refer to the one supplied with the unit.

/

5'

<(

%8

:$51,1*

PLQXWHVWRSUHYHQWWKHULVN

SRZHUHGRIIIRUOHVVWKDQ

UXQQLQJVWRSSLQJRUKDVEHHQ

WHUPLQDOZKHQWKHPDFKLQHLV

3OHDVHGRQWWRXFKDQ\

RIHOHFWULFVKRFN

97

97

%1

%8

%1

%.

%8

+($7+($7

+HDWHU

+HDWHU

%DQG

&RPS

%DQG

%RWWRP

(+

%/2&.

(;+$867

2875220

28778%(

(;3$16,21

9$/9(

<(*1

<(*1

<(*1

<(*1

<(*1

<(*1

3(

3(

<(*1

6+((7

%2;

0,',62/$7,21

(/(&75,&$/

;

5,1*

0$*1(7,&

N

N

N

5,1*

0$*1(7,&

5,1*

0$*1(7,&

5'

9$/9(

:$<

:$<

<9

(/(&7521,&

(.9

&1

(+

6(1625

57

57

57

7(03

6(1625

7(03

6(1625

7(03

%1

%8

/

5($&725

/

/

3(

&208

$&/

1

/

$30DLQ%RDUG

BU

BK

BN

8

9

:

6$7

29&&203

5'

3(

3(

0

)$1

2)$1

&1

1

/

32:(5

1

/

1

;7

7(50,1$/

29(5/2$5'

3527(&725

/;

/;

&203

&203

<(

5'

8

9

:

%8

/

3(

/

,1'22581,7

JURXQGRQO\

LURQVKHOOPRWRU

DSSOLHVWRWKH

0RWRU

127(

02725

/

/

3(

/

%8

:

9

8

5'

<(

&203

&203

/;

/;

3527(&725

29(5/2$5'

7(50,1$/

;7

/

1 1

32:(5

/

1

&1

2)$1

)$1

0

3(

3(

5'

29&&203

6$7

:

9

8

BN

BK

BU

$30DLQ%RDUG

/

1

$&/

&208

3(

/

/

5($&725

/

%8

%1

7(03

6(1625

7(03

6(1625

7(03

57

57

57

6(1625

&1

(.9

(/(&7521,&

<9

:$<

:$<

5'

0$*1(7,&

5,1*

0$*1(7,&

5,1*

N

N

N

0$*1(7,&

5,1*

;

(/(&75,&$/

0,',62/$7,21

%2;

6+((7

<(*1

3(

3(

<(*1

<(*1

<(*1

<(*1

<(*1

<(*1

9$/9(

(;3$16,219$/9(

28778%(

2875220

(;+$867

%/2&.

%8

%.

%1

%8

%1

97

97

RIHOHFWULFVKRFN

3OHDVHGRQWWRXFKDQ\

WHUPLQDOZKHQWKHPDFKLQHLV

UXQQLQJVWRSSLQJRUKDVEHHQ

SRZHUHGRIIIRUOHVVWKDQ

PLQXWHVWRSUHYHQWWKHULVN

:$51,1*

%8

<(

5'

,1'22581,7

127(

0RWRU

DSSOLHVWRWKH

LURQVKHOOPRWRU

JURXQGRQO\

02725

12

Technical Information

Service Manual

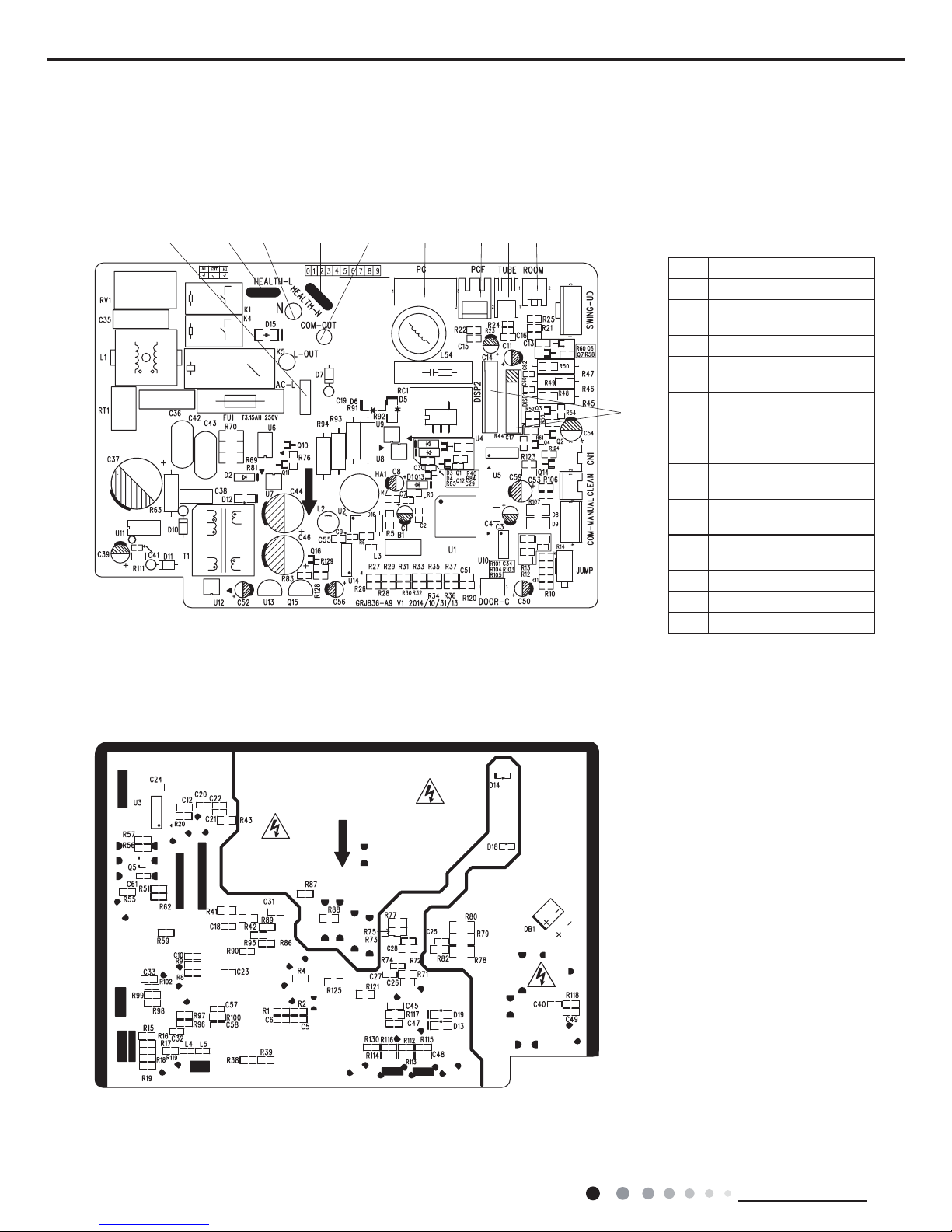

5.2 PCB Printed Diagram

Indoor Unit

●TOP VIEW

●BOTTOM VIEW

No.

Name

1 Interface of live wire

2

Interface of live wire for

health function

3 Interface of neutral wire

4

Interface of neutral wire for

health function

5

Interface of neutral wire and

live wire communication

6

Control interface of PG

motor

7

Feedback interface of

indoor fan

8

Indoor tube temperature

sensor interface

9

Ambient temperature

sensor interface

10 Up & down swing

11 Interface of display

12 Jumper cap

1 2 3 4 5 6 7 8 9

10

11

12

13

Technical Information

Service Manual

1

2

3

4

5

6

7

8

9

10

11

121314

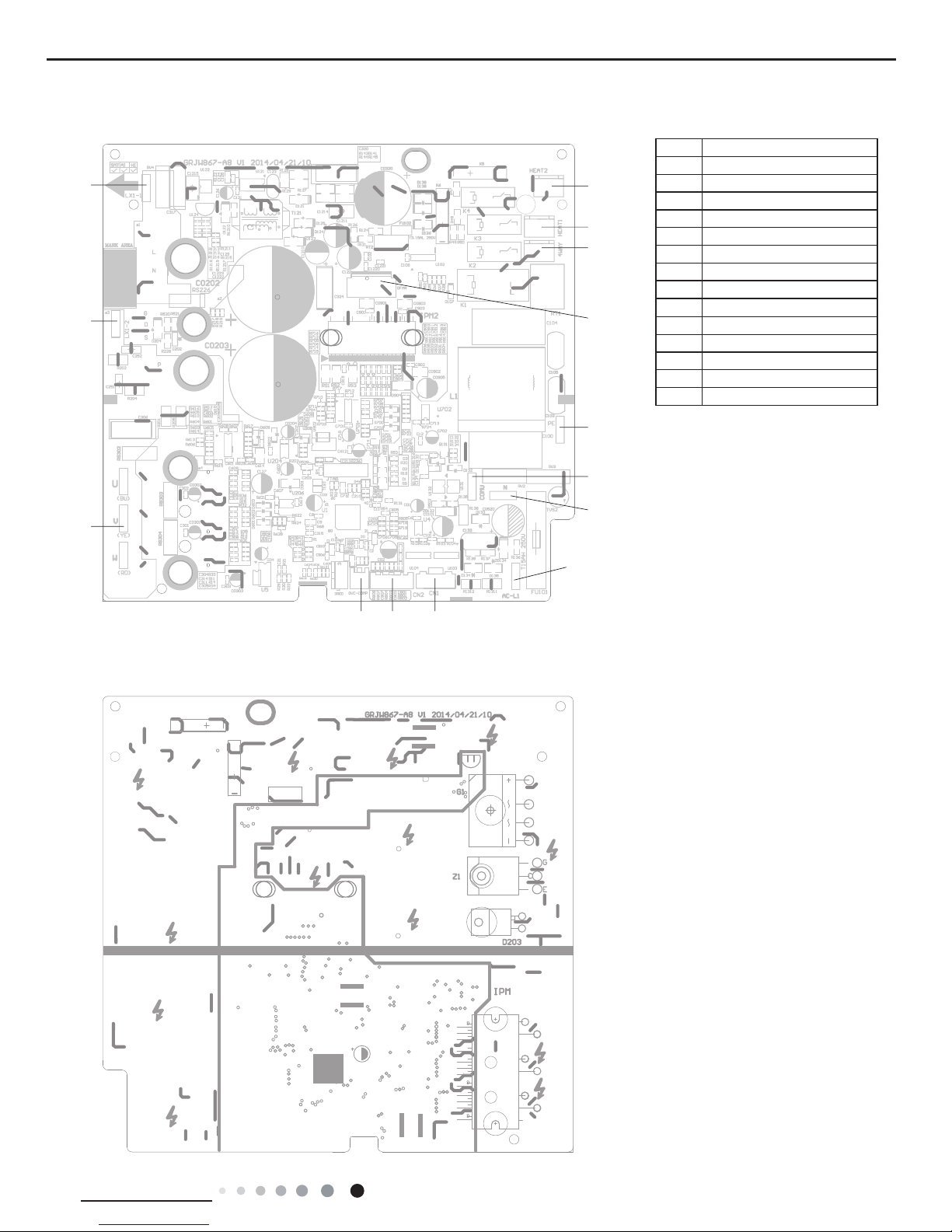

Outdoor Unit

●TOP VIEW

●BOTTOM VIEW

No. Name

1 Compressor

2 Reactor 2

3 Reactor 1

4 Chassis electric heating

5 Compressor electric heating

6 4-way valve

7 DC fan

8 Earthing wire

9

Communication wire

10 Neutral wire

11 Live wire

12 Electronic expansion valve

13 Temperature sensor

14 Overloard

14

Technical Information

Service Manual

6. Function and Control

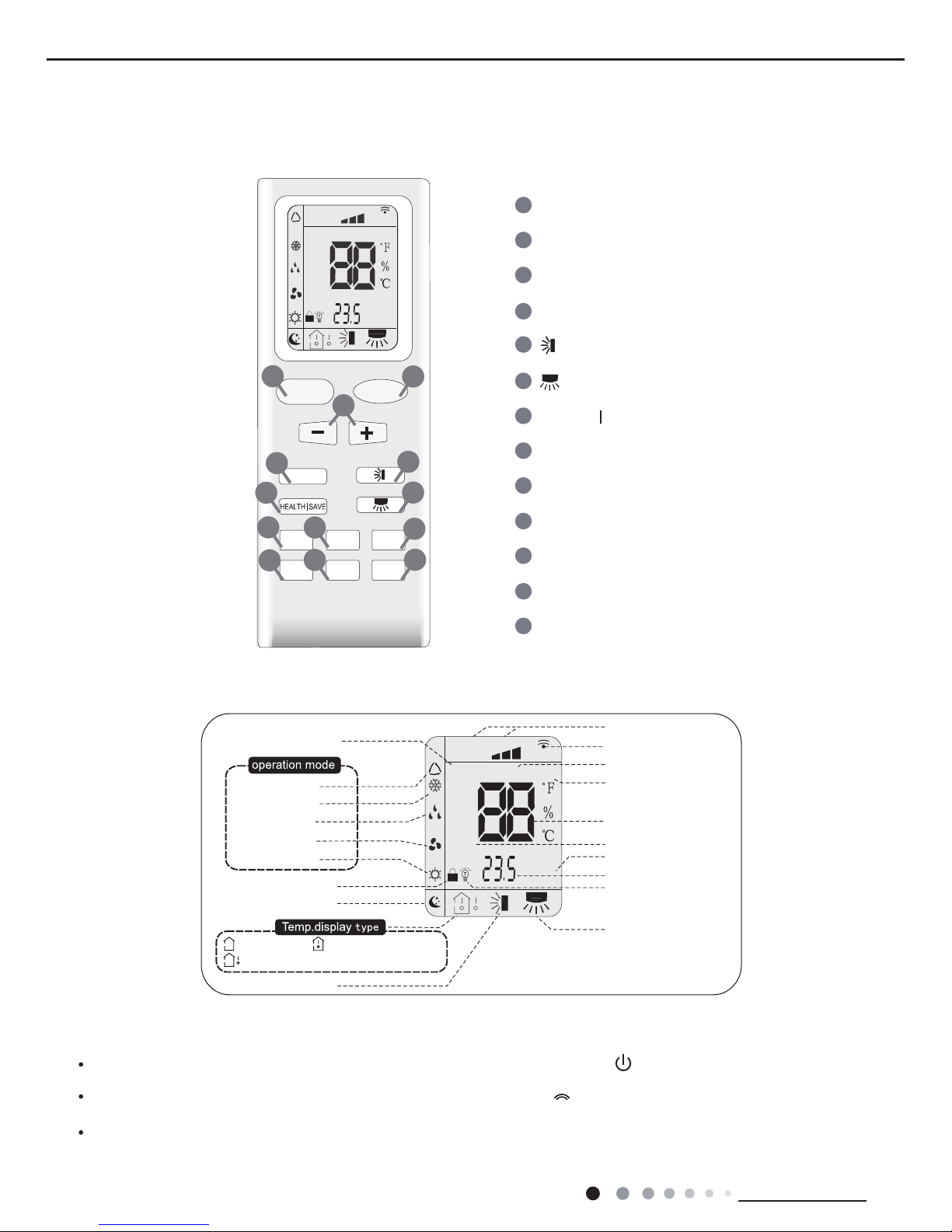

6.1 Remote Controller Introduction

Introduction for buttons on remote controller

Note:

After putting through power, air conditioner will give out a sound and operation indicator "

" is ON (red indicator). You can operate the air

conditioner through the remote controller.

At ON status, after each pressing button on remote controller, the signal icon "

" on remode controller will ash once. Air conditioner will

give out a sound, which indicates the signal has been sent to air conditioner.

At OFF status, display screen on remote controller displays set temperature. At on status, display screen on remote controller displays

the corresponding start up function’s icon.

Buttons on remote controller

Introduction for icons on display screen

ON/OFF Button

2

3

1

5

6

4

9

10

8

12

13

11

MODE Button

+/- Button

X-FAN Button

TEMP Button

TURBO Button

SLEEP Button

LIGHT Button

Button

HEALTH SAVE Button

7

Button

TIMER Button

FAN Button

FAN

AUTO

OPER

HEALTH

AIR

FILTER

TURBO

ON/OFF

X-FAN

HOUR

HUMIDITY

ON/OFF

MODE

FAN

X-FAN

TURBO

TEMP

TIMER

SLEEP

LIGHT

2

10

7

9

12

8

3

11

6

5

13

4

1

Child lock

Left&right swing

Sleep mode

Auto mode

Air mode

Cool mode

Heat mode

Fan mode

Dry mode

Up&down swing

:Indoor ambient temp.:Set temp.

:Outdoor ambient temp.

FAN

OPER

AUTO

HEALTH

AIR

FILTER

TURBO

ON/OFF

X-FAN

HOUR

HUMIDITY

TIMER ON/TIMER OFF

Set time

Light

Send signal

Health mode

X-fan

Set fan speed

Set temperature

Turbo mode

Temp. display type

Operation mode

15

Technical Information

Service Manual

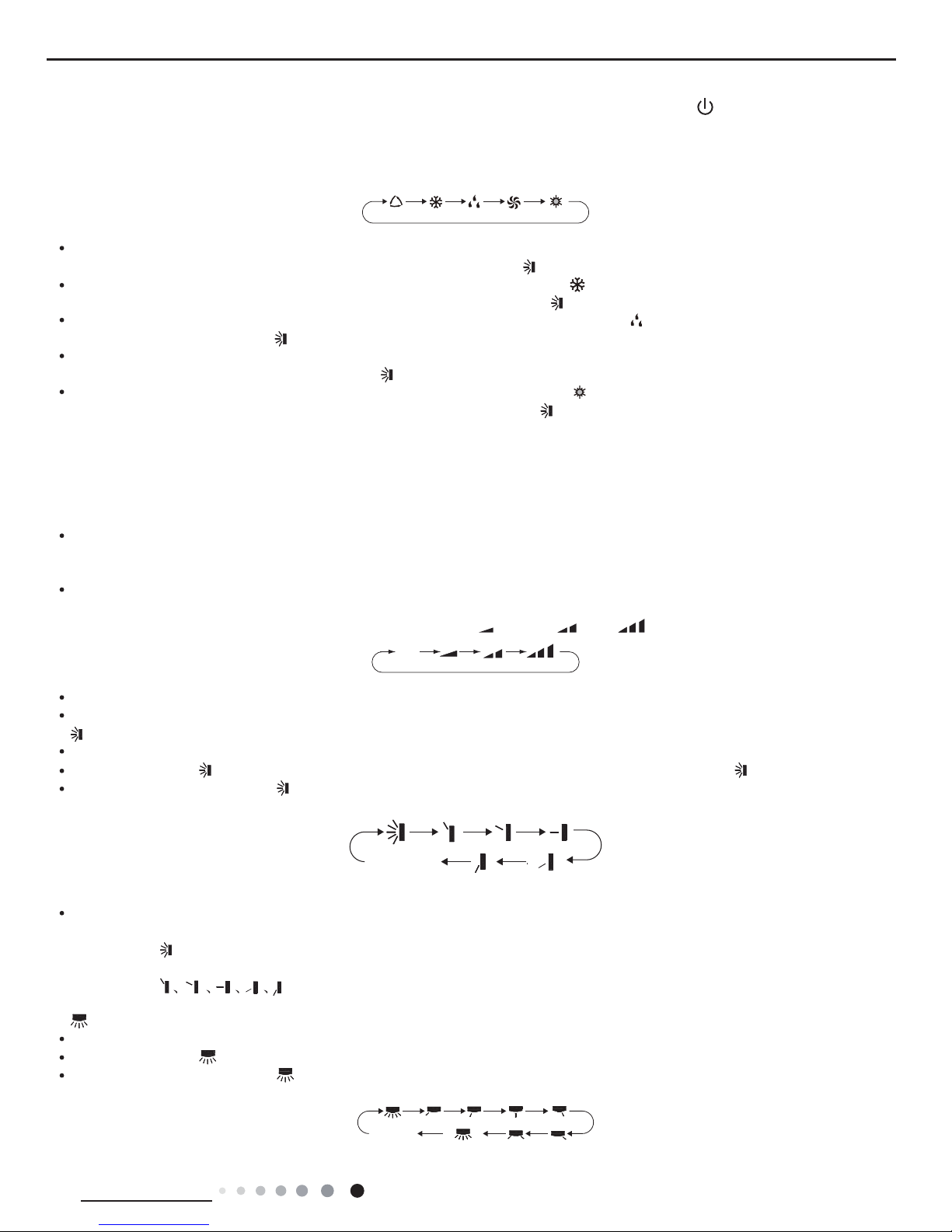

1.ON/OFF button

Press this button can turn on or turn off the air conditioner. After turning on the unit,operation indicator "

" on indoor unit is ON (green

indicator. Color may be differ-ent for different models)and indoor unit gives out a sound.

2.MODE button

Press this button can select your required operation mode.

AUTO COOL DRYF AN HEAT

After selecting auto mode, air conditioner will operate automatically according to ambient temperature. Set temperature can’t be adjusted

and also can’t be displayed. Press "FAN" button can adjust fan speed. Press "

" button can adjust swing angle.

After selecting cool mode, air conditioner operates under cool mode. Cool indicator "

" on indoor unit is ON. You can press "+" or "-"

button to adjust set temperature. Press "FAN" button can adjust fan speed. Press "

" button can adjus t swing angle.

After selecting dry mode, air conditioner operates under dry mode at low speed. Dry indicator "

" on indoor unit is ON. Under dry mode,

fan speed can’t be adjusted. Press "

" button to adjust swing angle.

After selecting fan mode, air conditioner operates only under fan mode, All mode indicators on indoor unit is OFF. Operation indicator is

ON. Press "FAN" button can adjust fan speed. Press "

" button to adjust swing angle.

After selecting heat mode, air conditioner operates under heat mode. Heat indicator "

" on indoor unit is ON. You can press "+" or "-"

button to adjust set temperature. Press "FAN" button to adjust fan speed. Press "

" button to adjust swing angle. (Cooling only unit can’t

receive the signal for heating mode.)

Note:

For preventing cold wind, after starting up heating mode, indoor fan will blow fan afterdelaying 1-5min. (Details time is decided by indoor

ambient temperature) Temperature setting range on remote controller: 16

o

C~30oC(61oF~86oF) . Fan speed setting range: auto, low speed,

medium speed and high speed.

3."+" or "-" button

After each pressing of "+" or "-" button, it can increase or decrease set temperature 1

o

C(1oF~2oF) . Hold "+" or "-" button, 2s later, set

temperature on remote controller will change quickly. After reaching to your required time, loosen the button. Temperature indicator on

indoor unit will also change accordingly. (Temperature can’t be adjusted under auto mode)

Under TIMER ON, TIMER OFF or Clock setting, you can press "+"or "-" button to adjust time. (Refer to TIMER button for details)

4.FAN button

Pressing this button can set fan speed circularly as: auto (AUTO), low(

), medium( ), high( ).

Note:

Under AUTO Speed,IDU fan motor will adjust the fan speed (high, medium or low speed) according to ambient temperature.

Fan speed under dry mode is low speed.

5.

button

Press this button to start or stop up & down swing function.The remote controller defaults to simple swing condition.

Press "+" button and "

" button at the same time at unit OFF to switch between simple swing and static swing; " " blinks for 2 seconds.

In static swing condition, pressing "

" button, the swing angle of up & down louver changes as below:

If the unit is turned off during swing operation,the louver will stop at present position.

Note:

When selecting "

" with remote controller, it’s auto swing. Horizontal louver of air conditioner will swing up&down automatically at the

maximum angle.

When selecting "

" with remote controller, it is the xed position swing. Horizontal louver of air conditioner will stop at

that position as shown by the icon to swing.

6.

button

Press this button to start or stop left & right swing function. The remote controller defaults to simple swing condition.

Press "+" button and "

" button at the same time at unit OFF to switch between simple swing and static swing; blinks for 2 seconds.

In static swing condition, pressing "

" button, the swing angle of left & right louver changes as below:

AUTO

no display

(horizontal louvers

stops at current

position)

no display

(horizontal

louvers stops

at current

position)

(swing angle is

displayed

dynamically)

16

Technical Information

Service Manual

If the unit is turned off during swing operation,the louver will stop at present position.

When selecting "

" with remote controller, it is the xed position swing. Horizontal louver of air conditioner will stop at

that position as shown by the icon to swing.

When selecting "(

swing angle is displayed dynamically

)" it’s the circulating swing. Horizontal louver of air conditioner will swing circularly according to

the angle as shown by the icon.

Note:

There is no this function for the units. If press this key, the main unit will click, but it also runs under original status.

7.HEALTH/SAVE button

After pressing HEALTH button, remote controller will switch circularly as below: "HEALTH"→"AIR"→"AIR HEALTH"→"no display"

When selecting "HEALTH" by remote controller, HEALTH function will be started up.

When selecting "AIR" by remote controller, AIR function will be started up.

When selecting "AIT HEALTH", AIR and HEALTH function will be started up.

When there’s no display on remote controller, AIR and HEALTH function will be turned off.

AIR function is applicable for some models.

SAVE function:

Under cool mode, press SAVE button and the unit will operate under SAVE mode. Dual-8nixie tube on remote controller displays "SE".

Air conditioner will operate at auto speed. Set temperature can’t be adjusted. Press SAVE button again to exit SAVE mode. Air conditioner

turn back to original set speed and set temperature.

This function is applicable to partial of models.

8.X-FAN button

After pressing this button under cooling or dry mode, remote controller displays the character of "X-FAN" and X-FAN function is started up.

Press this button again to cancel X-FAN function. The character of "X-FAN" will disappear.

Note:

After starting up X-FAN function, when turning off the unit, indoor fan will continue to operate for a while at low speed to dry the residual

water inside the indoor unit.

When the unit operates under X-FAN mode, press "X-FAN" button can turn off X-FAN function. Indoor fan stops operation immediately.

9.TEMP button

Press this button can see indoor set temperature, indoor ambient temperature or outdoor ambient temperature on indoor unit’s display.

Temperature is set circularly by remote controller as below:

When selecting "

" by remote controller or no display, temperature indicator on indoor unit displays set temperature.

When selecting "

" by remote controller, temperature indicator on indoor unit displays indoor ambient temperature.

When selecting "

" by remote controller, temperature indicator on indoor unit displays outdoor ambient temperature.

Note:

Outdoor ambient temperature display may can’t be selected for some models. When indoor unit receives "

" signal, it displays indoor

set temperature.

Only for the model whose indoor unit has dual-8 display.

10.TIMER button

At ON status, press this button once can set TIMER OFF. The character of HOUR and OFF will ash.Press "+" or "-" button within 5s

can adjust the time of TEMER ON. After each pressing of "+" or "-" button, time will increase or decrease half an hour. When holding "+"

or "-" button, 2s later, the time will change quickly until to reach to your required time. After that, press "TIMER" button to conrm it. The

character of HOUR and OFF won't ash again.

Cancel TIMER OFF: Press "TIMER" button again under TIMER OFF status.

At OFF status, press this button once can set TIMER ON. Please refer to TIMER off for detailed operation.

Cancel TIMER ON: Press "TIMER" button again under TIMER ON status.

Note:

Time setting range: 0.5-24 hours.

Time interval between two operations can’t exceed 5s. Otherwise, remote controller will exit the setting status automatically.

11.TURBO button

When pressing this button under cooling or heating mode, air conditioner will enter into quick cooling or quick heating mode. The

character of "TURBO" is displayed on remote controller. Press this button again to exit turbo function and the character of "TURBO" will be

disappeared on remote controller.

12.SLEEP button

Press this button under cooling, heating mode can start up sleep function."

" icon will be displayed on remote controller. Press this button

again to cancel sleep function. "

" icon on remote controller will be displayed.

13.LIGHT button

Press this button can turn off the light for indoor unit’s display. "

" icon on remote controller will disappear. Press this button again to turn

on the light for indoor unit’s display. "

" icon on remote controller will be displayed.

no display

17

Technical Information

Service Manual

Function introduction for combination buttons

Child lock function

Press "+" and "-" buttons simultaneously can turn on or turn off child lock function. When child lock function is started up, "

" icon will be

displayed on remote controller. If operate remote controller "

" icon will ash three times, while remote controller won’t send signal.

Switchover function for temperature display

After turning off the unit by remote controller, press "-" button and "MODE" button simultaneously to switch between

o

C and °F.

Operation guide

1. After putting through the power, press "

" button on remote controller to turn on the air conditioner.

2. Press "

" button to select your required mode: AUTO, COOL, DRY, FAN, HEAT.

3. Press "+" or "-" button to set your required temperature. (Temperature can’t be adjusted under auto mode).

4. Press "

" button to set your required fan speed: auto, low, medium and high speed.

5. Press "

" button to select fan blowing angle.

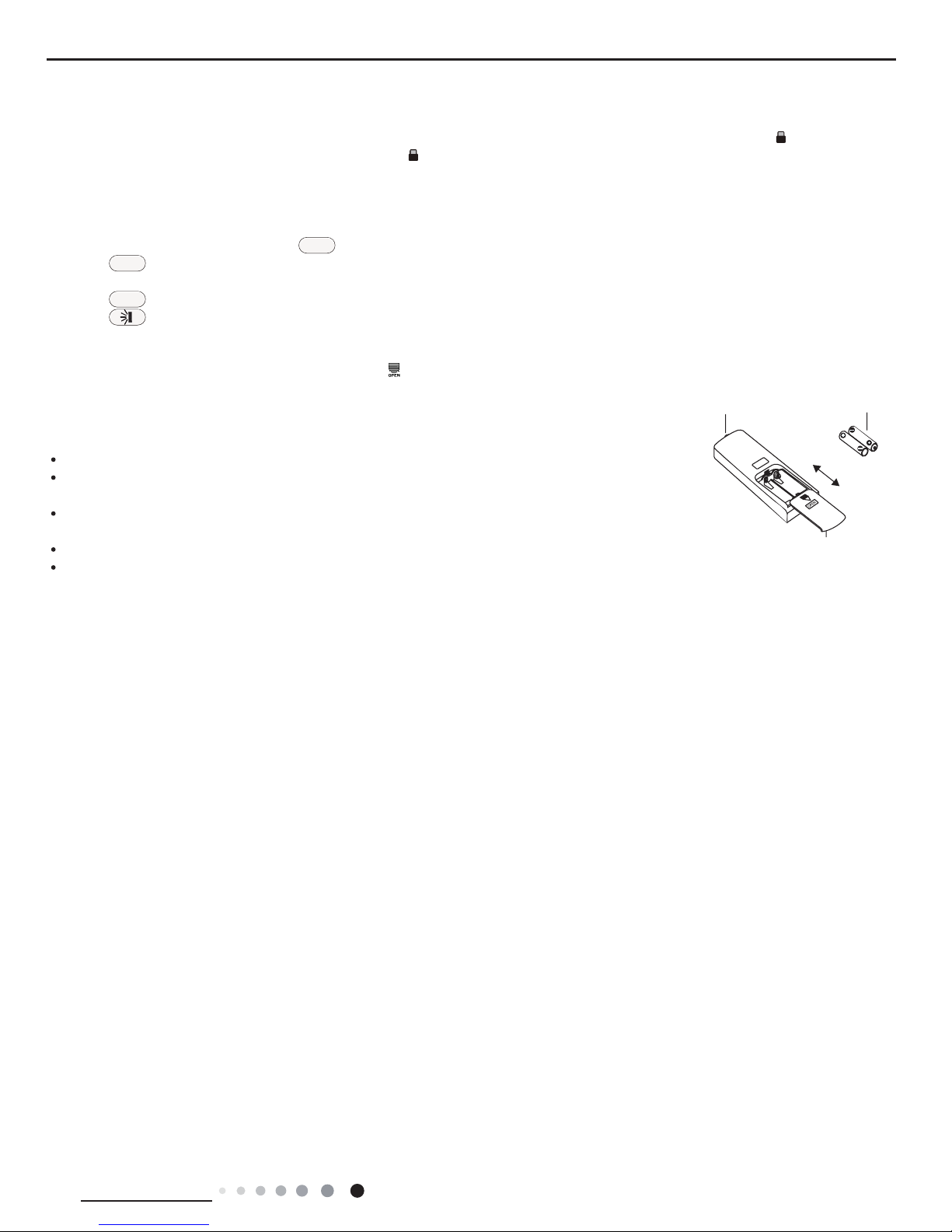

Replacement of batteries in remote controller

1. Press the back side of remote controller marked with "

", as shown in the g, and then push out the cover of battery box along the arrow

direction.

2. Replace two 7# (AAA 1.5V) dry batteries, and make sure the position of "+" polar and "-" polar are correct.

3. Reinstall the cover of battery box.

NOTICE

During operation, point the remote control signal sender at the receiving window on indoor unit.

The distance between signal sender and receiving window should be no more than 8m, and there should

be no obstacles between them.

Signal may be interfered easily in the room where there is uorescent lamp or wireless telephone; remote

controller should be close to indoor unit during operation.

Replace new batteries of the same model when replacement is required.

When you don’t use remote controller for a long time, please take out the batteries.

If the display on remote controller is fuzzy or there’s no display, please replace batteries.

ON/OFF

MODE

FAN

signal sender battery

Cover of battery box

remove

reinstall

18

Installation and Maintenance

Service Manual

6.2 Brief Description of Modes and Functions

1.Temperature Parameters

●Indoor preset temperature (Tpreset)

●Indoor ambient temperature (Tamb.)

2. Basic Functions

Once energized, in no case should the compressor be restarted within less than 3 minutes. In the situation that memory function is

available, for the rst energization, if the compressor is at stop before de-energization, the compressor will be started without a 3-minute

lag; if the compressor is in operation before de-energization, the compressor will be started with a 3-minute lag; and once started, the

compressor will not be stopped within 6 minutes regardless of changes in room temperature;

(1)COOL mode

①

The condition and process of cooling

If Tamb≥Tpreset COOL mode will act, the compressor and outdoor fan will run, and the indoor fan will run at the set speed.

If Tamb≤Tpreset-2°C, the compressor will stop, the outdoor fan will delay 30 seconds to stop, and the indoor fan will run at the set

speed. If Tpreset-2°C≤Tamb ≤Tpreset , the unit will keep running in the previous mode. In this mode, the reversal valve will not be

powered on and the temperature setting range is 16 ~30°C.

②

Protection function

●Overcurrent protection

If total current is high, the compressor will run in limited frequency. If total current is too high, the compressor will stop, the outdoor fan

will delay 30 seconds to stop, indoor unit will display E5 and outdoor yellow light will blink 5 times.

●Antifreezing protection

When the antifreezing protection is detected, the compressor will stop, the outdoor fan will stop after 30 seconds, and the indoor fan

and swing motor will keep running in the original mode. When antifreezing protection is eliminated and the compressor has stopped for

3 minutes, the compressor will resume running in the original mode.

(2) Dehumidifying mode

①

Working conditions and process of dehumidifying

If Tamb.>Tpreset, the unit will enter cooling and dehumidifying mode, in which case the compressor and the outdoor fan will operate

and the indoor fan will run at low speed.

If Tpreset -2°C≤Tamb.≤Tpreset, the compressor remains at its original operation state.

If Tamb.< Tpreset -2°C, the compressor will stop, the outdoor fan will stop with a time lag of 30s, and the indoor fan will operate at low

speed.

②

Protection function

Protection is the same as that under the cooling mode.

(3) HEAT mode

①

The condition and process of heating

If Tamb≤Tpreset+2°C, HEAT mode will act, the compressor, outdoor fan and reversal valve will run, the indoor fan will delay 3min to

stop at the latest.

If Tpreset +2°C≤Tamb≤Tpreset +5°C,the unit will keep running in the original mode.

If Tamb≥Tpreset +5°C, the compressor will stop, the outdoor fan will delay 30sec to stop and indoor fan will blow 60S at low speed, the

fan speed cannot be shifted within blow residual heat.

●In this mode, the temperature setting range is 16 ~30°C.

●The air conditioner will adjust the running frequency of the compressor automatically according to the change of ambient temperature.

●When the unit is turned off in HEAT mode, or switched to other mode from HEAT mode, the four-way valve will be powered off after

the compressor stops.

②

The condition and process of defrosting

When frost is detected in the condenser, the system will enter into defrosting state. When defrosting starts, the compressor and indoor

fan will stop, and the outdoor fan and four-way valve will delay 30 seconds to stop. The compressor will start after 15 seconds and

then defrosting will be started. When the compressor has run for 7 minutes or defrosting is nished, the compressor will stop. After 30

seconds the four-way valve opens and after another 60 seconds, the compressor and outdoor fan resume running. The indoor fan will

delay 3 minutes to run at the latest and heating indicator on indoor unit OFF 0.5s and ON 10s.

③

Protection function

●Anti-cold-wind protection

In HEAT mode, in order to prevent the indoor unit from blowing out cold wind, each time the compressor starts, the indoor fan will delay

3 minutes after the compressor to run at the latest and it can adjust fan speed automatically when temperature is low.

●Overcurrent protection

Overcurrent protection is the same with that in COOL mode.

●Cold air prevention

The unit is started under heating mode (the compressor is ON):

19

Installation and Maintenance

Service Manual

1.In the case of Tindoor amb. <24°C: if T≤tube40°C and the indoor fan is at stop state, the indoor fan will begin to run at low speed with

a time lag of 2 minutes. Within 2 minutes, if Ttube>40°C, the indoor fan also will run at low speed; and after1-minute operation at low

speed, the indoor fan will be converted tooperation at preset speed. Within 1-minute low speed operation or 2-minute non-operation, if

Ttube>42°C, the fan will run at present speed.

2.In the case of Tindoor amb.≥24°C: if Ttube≤42°C, the indoor fan will run at low speed, and afterone minute, the indoorfan will be

converted to preset speed. Within one-minute low speed operation, if Ttube>42°C, the indoor fan will beconvertedto preset speed.

Note:T

indoor amb.

indicated in 1 and 2 refers to, under initially heating mode, the indoor ambient temperature before the command to start

the compressor is performed according to the program, or after the unit is withdrawn from defrost, the indoor ambient temperature

before the defrost symbol is cleared.

●Total current up and frequency down protection

If the total current I

total

≤W, frequency rise will be allowed; if I

total

≥X, frequency rise will not be allowed; if I

total

≥Y, the compressor will run at

reduced frequency; and if I

total

≥Z, the compressor will stop and the outdoor fan will stop with a time lag of 30s.

(4) Fan Mode

Under the mode, the indoor fan will run at preset speed and the compressor, the outdoor fan, the four-way valve and the electric heater

will stop.

Under the mode, temperature can be set within a range of 16 - 30°C.

(5) AUTO Mode

①

The condition and process of auto

a. When Tamb.≥26°C the unit will operate at Cooling mode. In that case, the set temperature will be 25°C.

b. When Tamb.≤22°C the heat pump unit will operate at Heating mode. In that case, the set temperature will be 20°C; the cooling-only

unit will operate at Fan mode and the set temperature will be 25°C.

c. When 23°C≤Tamb.≤25°C the unit will keep its operation status but if it is rstly energized, the unit will operate at Fan mode.

d. When unit operates at Auto mode, the frequency of compressor will be the same as that in Cooling mode if the unit is coolingwhile it

will be the same as that in the Heating mode if the unit is heating.

②

Protection function

a.In cooling operation, protection is the same as that under the cooling mode;

b.In heating operation, protection is the same as that under the heating mode;

c.When ambient temperature changes, operation mode will be converted preferentially. Once started, the compressor will remain

unchanged for at least 6 minutes.

(6) Common Protection Functions and Fault Display under COOL, HEAT, DRY and AUTO Modes

①

Overload protection

Ttube: measured temperature of outdoor heat exchanger under cooling mode; and measured temperature of indoor heat exchanger

under heating mode.

1) Cooling overload

a. If T tube52, the unit will return to its original operation state.

b. If T tube55, frequency rise is not allowed.

c. If T tube58, the compressor will run at reduced frequency.

d. If T tube62, the compressor will stop and the indoor fan will run at preset speed.

2) Heating overload

a. If T tube52, the unit will return to its original operation state.

b. If T tube55, frequency rise is not allowed.

c. If T tube58, the compressor will run at reduced frequency.

d. If T tube62, the compressor will stop and the indoor fan will blow residue heat and then stop.

②

Exhaust temperature protection of compressor

If exhaust temperature 98, frequency is not allowed to rise.

If exhaust temperature 103, the compressor will run at reduced frequency.

If exhaust temperature 110, the compressor will stop.

If exhaust temperature 90 and the compressor has stayed at stop for at least 3 minutes, the compressor will resume its operation.

③

Communication fault

If the unit fails to receive correct signals for durative 3 minutes, communication fault can be justied and the whole system will stop.

④

Module protection

Under module protection mode, the compressor will stop. When the compressor remains at stop for at least 3 minutes, the compressor

will resume its operation. If module protection occurs six times in succession, the compressor will not be started again.

⑤

Overload protection

If temperature sensed by the overload sensor is over 115, the compressor will stop and the outdoor fan will stop with a time lag of 30

seconds.

⑥

If temperature is below 95, the overload protection will be relieved. If voltage on the DC bus is below 150V or over 420V, the

compressor will stop and the outdoor fan will stop with a time lag of 30 seconds. When voltage on the DC bus returns to its normal

value and the compressor has stayed at stop for at least 3 minutes, the compressor will resume its operation.

20

Installation and Maintenance

Service Manual

3. Other Controls

(1) ON/OFF

Press the remote button ON/OFF: the on-off state will be changed once each time you press the button.

(2) Mode Selection

Press the remote button MODE, then select and show in the following ways: AUTO, COOL, DRY, FAN, HEAT, AUTO.

(3) Temperature Setting Option Button

Each time you press the remote button TEMP+ or TEMP-, the setting temperature will be up or down by 1°C. Regulating Range:

16~30°C, the button is useless under the AUTO mode.

(4) Time Switch

You should start and stop the machine according to the setting time by remote control.

(5) SLEEP State Control

①

Cooling mode

a. When initial temperature setting is 16~23°C, after turning on sleep function, temperature will increase 1°C every one hour. After

temperature is increased by 3°C, the unit will keep this temperature. After operation for 7 hours, temperature will decrease

1°C. After that, the unit will operate at this temperature all the time.

b. When initial temperature setting is 24~27°C, after turning on sleep function, temperature will increase 1°C every one hour. After

temperature is increased by 2°C, the unit will keep this temperature. After operation for 7 hours, temperature will decrease

1°C. After that, the unit will operate at this temperature all the time.

c. When initial temperature setting is 28~29°C, after turning on sleep function, temperature will increase 1°C every one hour. After

temperature is increased by 1°C, the unit will keep this temperature. After operation for 7 hours, temperature will decrease

1°C. After that, the unit will operate at this temperature all the time. When the initial temperature setting is 30°C, the unit will

operate under this temperature. After operation for 7 hours, temperature will decrease 1°C. After that, the unit will operate at this

temperature all the time.

②

Heating mode:

a. When initial temperature setting is 16°C, the unit operate under this temperature all the time.

b. When initial temperature setting is 17~20°C, after turning on sleep function, temperature will decrease 1°C every one hour. After

temperature is increased by 1°C, the unit will keep this temperature.

c. When initial temperature setting is 21~27°C, after turning on sleep function, temperature will decrease 1°C every one hour.

After temperature is increased by 2°C, the unit will keep this temperature.

d. When initial temperature setting is 28~30°C, after turning on sleep function, temperature will decrease 1°C every one hour. After

temperature is increased by 3°C, the unit will keep this temperature.

(6) Indoor Fan Control

Speed of indoor fan can be set as Turbo, High, Med., Low by remote control. In that case, fan will operate at super high, high, medium,

or low speed accordingly. The fan speed can also be set at Auto, which is as follows:

①

In heating mode: in auto heating or heating mode, the auto fan speed is as follows:

a. Tamb.≤Tpreset+1°C: indoor fan will operate at high speed;

b. Tpreset+1°C<Tamb.<Tpreset + 3°C: indoor fan will operate at med. speed;

c. Tamb.≥Tpreset + 3°C: indoor fan will operate at low speed; At least 210 seconds of operation shall be maintained for switchover

between high and low speeds, med. and low speeds, and high and low speeds.

②

In cooling mode, in auto cooling or cooling mode, the auto fan speed is as follows:

a. Tamb.≥Tpreset+2°C: indoor fan will operate at high speed.

b. Tpreset <Tamb.<Tpreset + 2°C: indoor fan will operate at med. speed;

c. Tamb.≤Tpreset: indoor fan will operate at low speed. At least 210 seconds of operation shall be maintained for switchover between

high and low speeds, med. and low speeds, and high and low speeds.

(7) Buzzer Control

The buzzer will send a “Di” sound when the air conditioner is powered up or received the information sent by the remote control or there

is a button input, the single tube cooler doesnt receive the remote control ON signal under the mode of heating mode.

(8) Auto button

If the controller is on, it will stop by pressing the button, and if the controller is off, it will be automatic running state by pressing the

button, swing on and light on, and the main unit will run based on the remote control if there is remote control order.

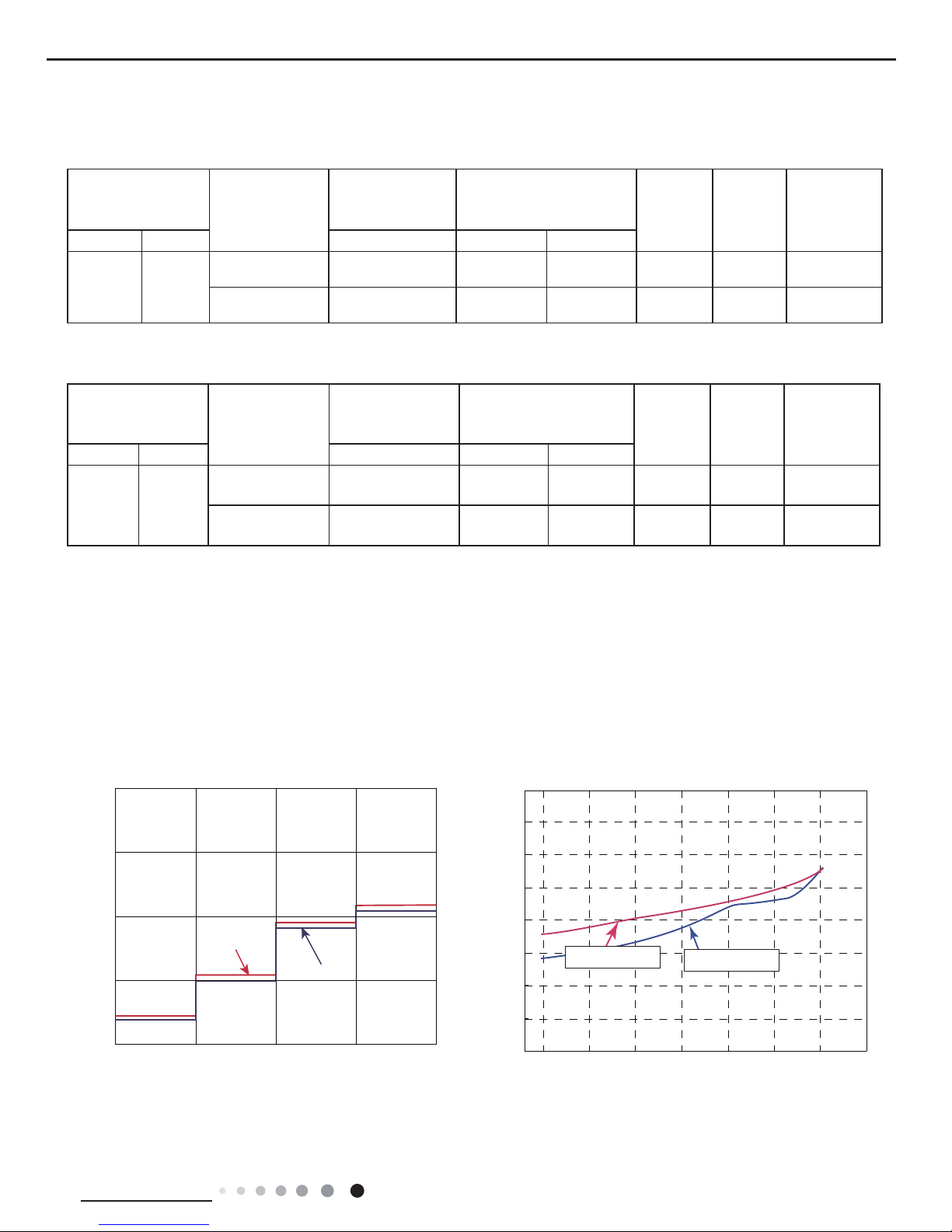

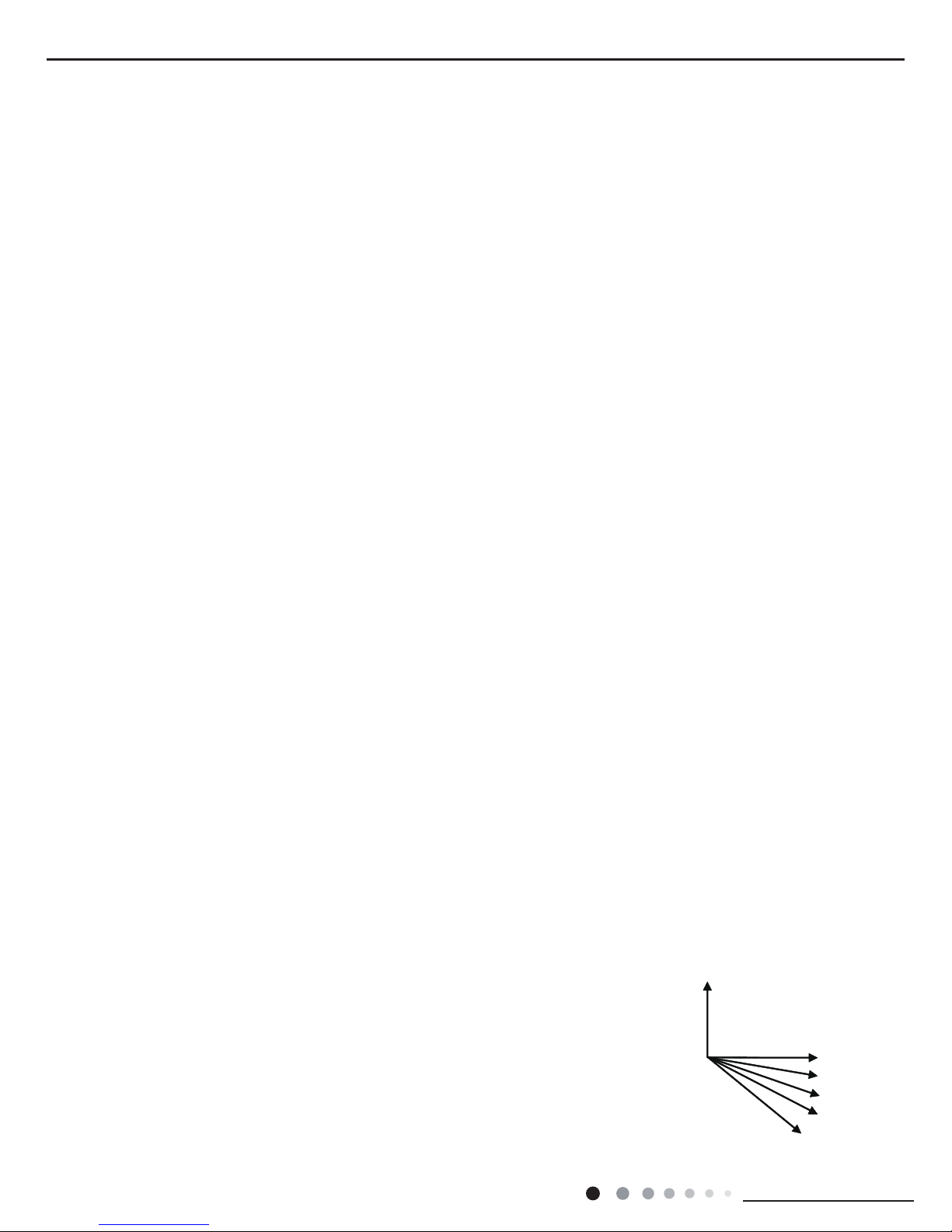

(9) Up-and-Down Swinging Control

When power on, the up-and-down motor will rstly move the air deector to o counter-clockwise,

close the air outlet. After starting the machine, if you dont set the swinging function, heating mode

and auto-heating mode, the up-and-down air deector will move to D clockwise; under other modes,

the up-and-down air deector will move to L1. If you set the swinging function when you start the

machine, then the wind blade will swing between L and D. The air deector has 7 swinging states:

Location L, Location A, Location B, Location C, Location D, Location L to Location D, stop at any

location between L-D (the included angle between L~D is the same). The air deector will be closed

at 0 Location, and the swinging is effectual only on condition that setting the swinging order and the

A

L

B

C

D

O(0

R

)

O(0 )

L1

A1

B1

C1

D1

cooling angle

R

21

Installation and Maintenance

Service Manual

inner fan is running. The indoor fan and compressor may get the power when air deector is on the default location.

(10) Display(NOTE:Nixie tube is not available for A8 panel.)

①

Operation pattern and mode pattern display

All the display patterns will display for a time when the power on, the operation indication pattern will display in red under standby

status. When the machine is start by remote control, the indication pattern will light and display the current operation mode (the mode

light includes: Cooling, heating and dehumidify). If you close the light key, all the display patterns will close.

②

Double-8 display

According to the different setting of remote control, the nixie light may display the current temperature (the temperature scope is

from 16 to 30°C) and indoor ambient temperature. The heating and air supply temperature will display 25°C under auto-mode, the

temperature will display 20°C under the heating mode, and under defrosting status, heating indicator on indoor unit OFF 0.5s and ON

10s.(If you set the fahrenheit temperature display, the nixie light will display according to fahrenheit temperature)

(11) Protection function and failure display

E2: Freeze-proong protection E4: Exhausting protection E5: Overcurrent protection E6: Communication failure

F1: Indoor ambient sensor start and short circuit (continuously measured failure in 5S)

F2: Indoor evaporator sensor start and short circuit (continuously measured failure in 5S)

F3: Outdoor ambient sensor start and short circuit (continuously measured failure in 30S)

F4: Outdoor condenser sensor start and short circuit (continuously measured failure in 30S, and dont measure within 10 minutes

after defrosted)

F5: Outdoor exhausting sensor start and short circuit (continuously measured failure in 30S after the compressor operated 3 minutes)

H3: Overload protection of compressor H5: Module protection PH: High-voltage protection PL: Low-voltage protection

P1: Nominal cooling and heating P2: Maximum cooling and heating P3: Medium cooling and heating

P0: Minimum cooling and heating

(12) Drying Function

You may start or stop the drying function under the modes of cooling and dehumidify at the starting status (The modes of automatism,

heating and air supply do not have drying function). When you start the drying function, after stop the machine by pressing the switch

button, you should keep running the inner fans for 2 minutes under low air damper (The swing will operate as the least status within 2

minutes, and other load is stopped), then stop the entire machine;When you stop the drying function, press the switch button will stop

the machine directly.

When you start the drying function, operating the drying button will stop the inner fans and close the guide louver.

(13) Power-failure memory function

What will be memorized includes modes, up and down wind blow, light, preset temperature, preset wind speed, general timing (no

memory for moment timing), and Fahrenheit /Celsius degree. When the unit is powered on again after power failure, operation

continues according to memorized content. If timing is not set by the last remote control command, the system will memorize the last

remote control command and operate in the mode specied in the last remote control command. If timing is set by the last remote

control command and power failure happens before the preset time, the system, as powered on again, will memorize the timing

function set by the last remote control command. Timing will be re-counted from the time at which the system is powered again. If

timing is set by the last remote control command and timing of start or stop is reached before power failure, the system, as powered

on again, will memorize operation state before power failure and will not perform timing action. Moment timing is out the range of

memory.

(14) Refrigerant recycling function (applicable when changing installation location or in maintenance)

1. Enter refrigerant recycling function

Within 5min after energizing (unit ON or OFF status is ok), continuously press LIGHT button for 3 times within 3s to enter refrigerant

recycling mode; Fo is displayed and refrigerant recycling function is started. At this moment, the maintenance people closes liquid

valve. After 5min, stick the thimble of maintenance valve with a tool. If there is no refrigerant spraying out, close the gas valve

immediately and then turn off the unit to remove the connection pipe.

2. Exit refrigerant recycling function

After entering refrigerant recycling mode, when receive any remote control signal or enter refrigerant recycling mode for 25min, the

unit will exit refrigerant recycling mode automatically If the unit is in standby mode before refrigerant recycling, it will be still in standby

mode after nishing refrigerant recycling; if the unit is in ON status before refrigerant recycling, it will still run in original operation

mode.

(15) Compulsive Defrosting Function

1. Start up compulsory defrosting function

Under ON status, set heating mode with remote controller and adjust the temperature to 16°C. Press “+, -, +, -, +,-” button

successively within 5s and the complete unit will enter into compulsory defrosting status. Meanwhile, heating indicator on indoor unit

will ON 10s and OFF 0.5s successively. (Note: If complete unit has malfunction or stops operation due to protection, compulsory

defrosting function can be started up after malfunction or protection is resumed.

2. Exit compulsory defrosting mode

After compulsory defrosting is started up, the complete unit will exit defrosting operation according to the actual defrosting result, and

the complete unit will resume normal heating operation.

22

Installation and Maintenance

Service Manual

1. Select the installation location according to the requirement of this manual.(See the requirements in installation

part)

2. Handle unit transportation with care; the unit should not

be carried by only one person if it is more than 20kg.

3. When installing the indoor unit and outdoor unit, a sufcient xing bolt must be installed; make sure the installation

support is rm.

4. Ware safety belt if the height of working is above 2m.

5. Use equipped components or appointed components during installation.

6. Make sure no foreign objects are left in the unit after nishing installation.

Electrical Safety Precautions:

7. Notes for Installation and Maintenance

Safety Precautions:

Important!

Please read the safety precautions carefully before

installation and maintenance.

The following contents are very important for installation

and maintenance.

Please follow the instructions below.

●The installation or maintenance must accord with the

instructions.

●Comply with all national electrical codes and local

electrical codes.

●Pay attention to the warnings and cautions in this

manual.

●All installation and maintenance shall be performed by

distributor or qualied person.

●All electric work must be performed by a licensed

technician according to local regulations and the

instructions given in this manual.

●Be caution during installation and maintenance. Prohibit

incorrect operation to prevent electric shock, casualty and

other accidents.

1. Cut off the power supply of air conditioner before

checking and maintenance.

2. The air condition must apply specialized circuit and

prohibit share the same circuit with other appliances.

3. The air conditioner should be installed in suitable

location and ensure the power plug is touchable.

4. Make sure each wiring terminal is connected rmly

during installation and maintenance.

5. Have the unit adequately grounded. The grounding

wire can’t be used for other purposes.

6. Must apply protective accessories such as protective

boards, cable-cross loop and wire clip.

7. The live wire, neutral wire and grounding wire of

power supply must be corresponding to the live wire,

neutral wire and grounding wire of the air conditioner.

8. The power cord and power connection wires can’t be

pressed by hard objects.

9. If power cord or connection wire is broken, it must be

replaced by a qualied person.

1. Avoid contact between refrigerant and re as it generates

poisonous gas; Prohibit prolong the connection pipe by

welding.

2. Apply specied refrigerant only. Never have it mixed with

any other refrigerant. Never have air remain in the refrigerant

line as it may lead to rupture or other hazards.

3. Make sure no refrigerant gas is leaking out when

installation is completed.

4. If there is refrigerant leakage, please take sufcient

measure to minimize the density of refrigerant.

5. Never touch the refrigerant piping or compressor without

wearing glove to avoid scald or frostbite.

Warnings

Refrigerant Safety Precautions:

Improper installation may lead to re hazard, explosion,

electric shock or injury.

Installation Safety Precautions:

Part

Ⅱ

: Installation and Maintenance

10. If the power cord or connection wire is not long enough,

please get the specialized power cord or connection wire

from the manufacture or distributor. Prohibit prolong the wire

by yourself.

11. For the air conditioner without plug, an air switch must

be installed in the circuit. The air switch should be all-pole

parting and the contact parting distance should be more than

3mm.

12. Make sure all wires and pipes are connected properly and

the valves are opened before energizing.

13. Check if there is electric leakage on the unit body. If yes,

please eliminate the electric leakage.

14. Replace the fuse with a new one of the same specication

if it is burnt down; don’t replace it with a cooper wire or

conducting wire.

15. If the unit is to be installed in a humid place, the circuit

breaker must be installed.

23

Installation and Maintenance

Service Manual

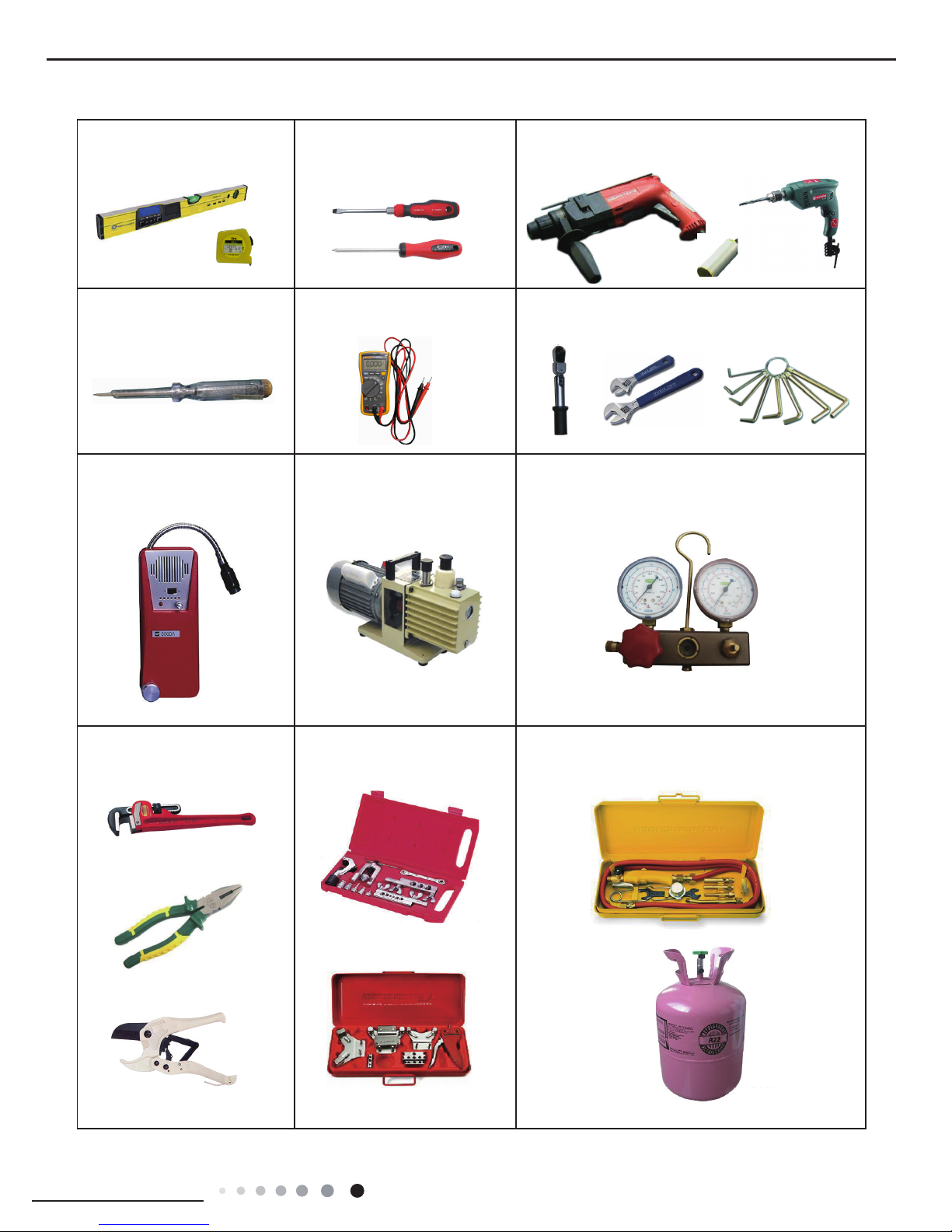

Main Tools for Installation and Maintenance

1. Level meter, measuring tape

4. Electroprobe

7. Electronic leakage detector

10. Pipe pliers, pipe cutter

2. Screw driver

5. Universal meter

8. Vacuum pump

11. Pipe expander, pipe bender

3. Impact drill, drill head, electric drill

6. Torque wrench, open-end wrench, inner

hexagon spanner

9. Pressure meter

12. Soldering appliance, refrigerant container

24

Installation and Maintenance

Service Manual

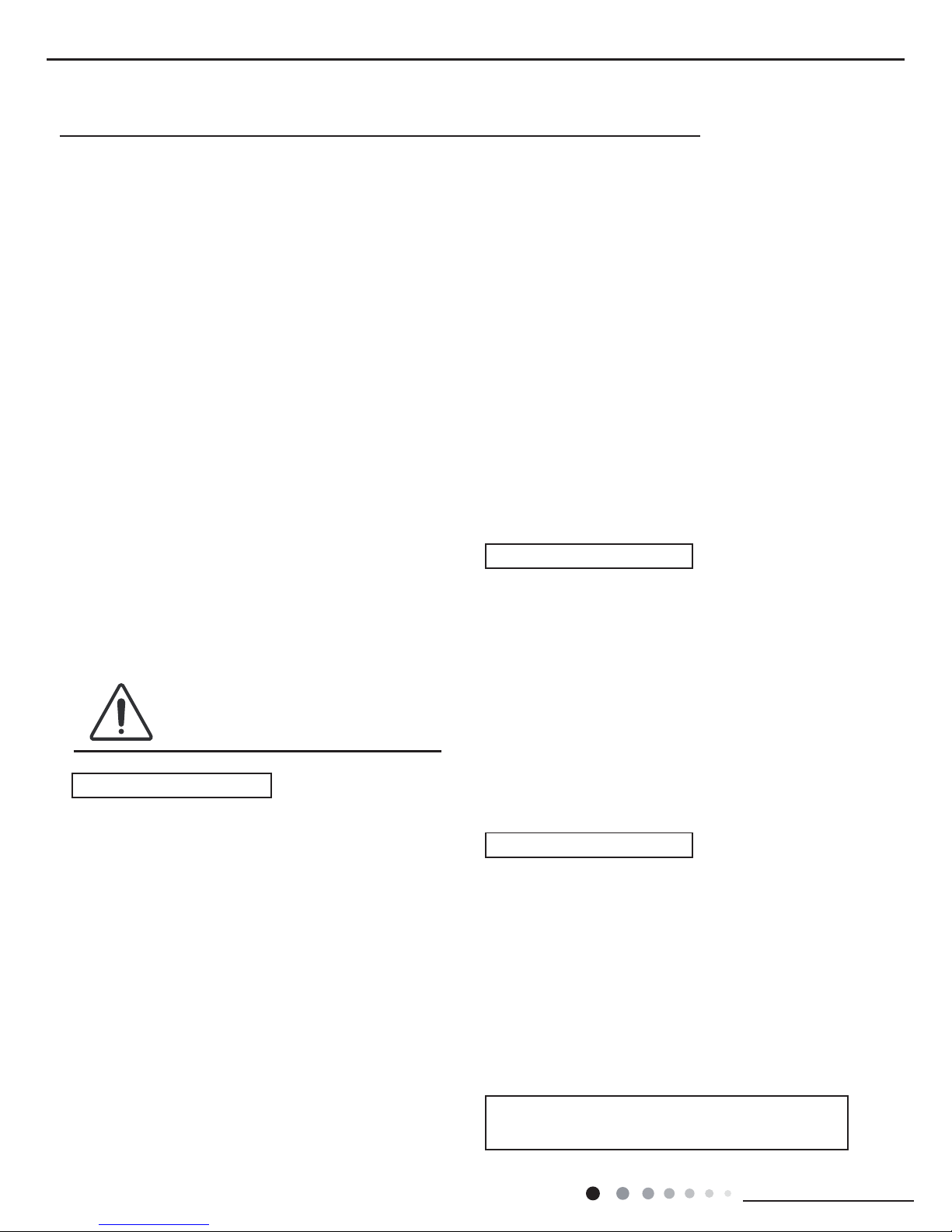

8. Installation

8.1 Installation Dimension Diagram

Drainage pipe

At least 250cm

At least 15cm

At least 50cm

At least 50cm

At least

30cm

At least 300cm

At least 200cm

Space to the oor

Space to the obstruction

Space to the obstruction

Space to the

obstruction

Space to the ceiling

Space to the obstruction

Space to the obstruction

At least 30cm

At least 15cm

At least 15cm

Space to the wall

Space to the wall

Space to the wall

25

Installation and Maintenance

Service Manual

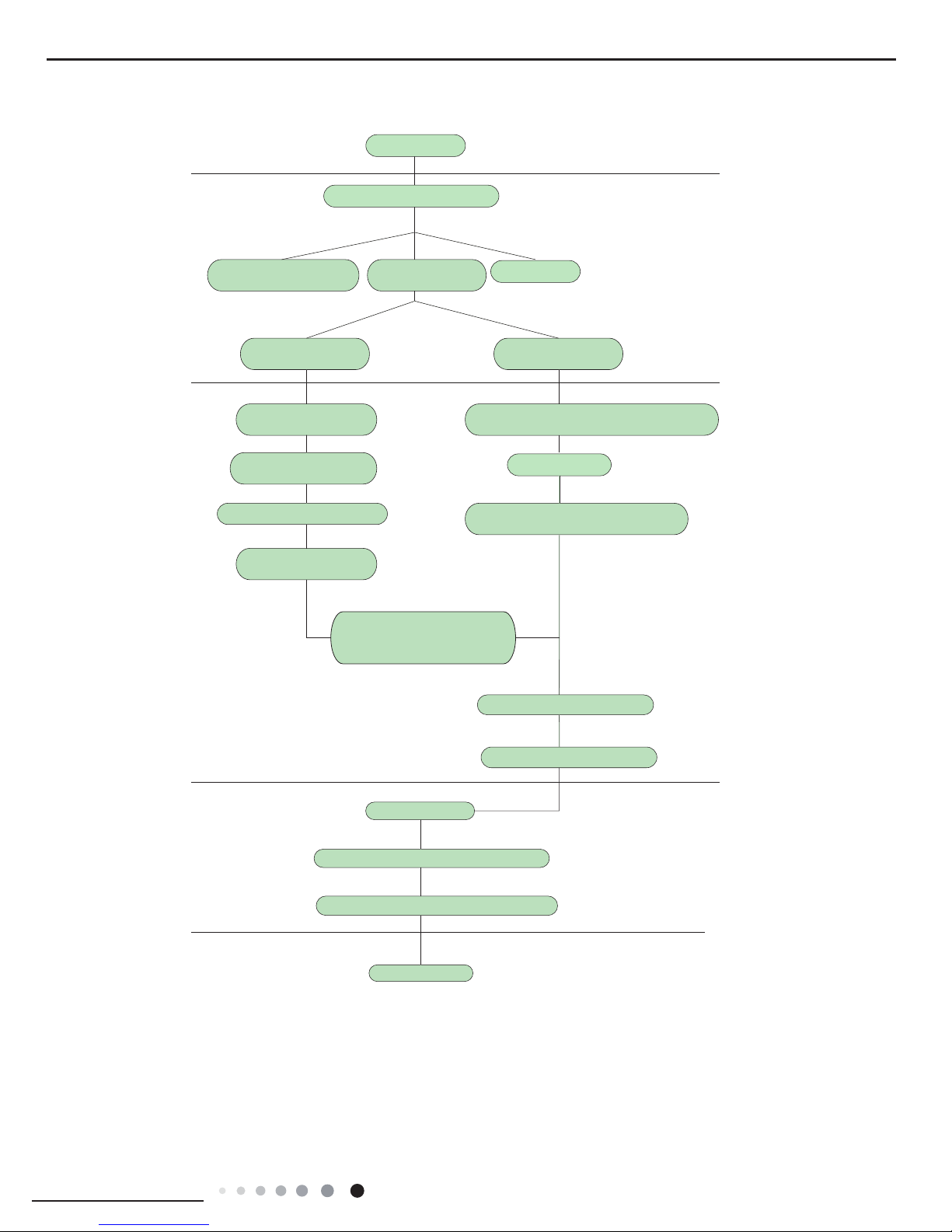

Preparation before installation

Prepare tools

Read the requirements

for electric connection

select installation

location

Select indoor unit

installation location

Install wall-mounting

frame, drill wall holes

Connect pipes of indoor

unit and drainage pipe

Connect wires of indoor unit

Connect wires of outdoor unit

Bind up pipes and

hang the indoor unit

Make the bound pipes pass

through the wall hole and then

connect outdoor unit

Neaten the pipes

Vacuum pumping and leakage detection

Check after installation and test operation

Finish installation

Note: this flow is only for reference; please find the more detailed installation steps in this section.

Select outdoor unit

installation location

Install the support of outdoor unit

(select it according to the actual situation)

Install drainage joint of outdoor unit

(only for cooling and heating unit)

Connect pipes of outdoor unit

Start installation

Fix outdoor unit

Installation procedures

Loading...

Loading...