Gree GWH09AB-A3DNA1B/O, GWH12AB-A3DNA1B, GWH12AB-A3DNA1B/I, GWH12AB-D3DNA1B/I, GWH12AB-A3DNA1B/O Service Manual

...

GREE ELECTRIC APPLIANCES,INC.OF ZHUHAI

Service Manual

MODEL:GWH09AB-A3DNA1B

GWH12AB-A3DNA1B

GWH12AB-D3DNA1B

(Refrigerant R410A)

Table of Contents

Summary and features

..................................................................................1

Part 1 Safety Precautions

..........................................................................................2

Part 2 Specifications

.....................................................................................................3

Part 3 Construction Views

........................................................................................7

3.1 Indoor Unit ........................................................................................................

.....7

3.2 Outdoor Unit ..........................................................................................................7

Part 4 Refrigerant System Diagram

.....................................................................8

5.1 Electrical Data........................................................................................................9

5.2 Electrical Wiring......................................................................................................9

Part 5 Schematic Diagram

........................................................................................9

6.1 Remote Control Operations..................................................................................15

6.2 Changing Batteries and Notices ..........................................................................17

6.3 Description of Each Control Operation.................................................................18

Part 6 Function and Control

...................................................................................15

Part 7 Installation Manual

........................................................................................23

7.2 Installation Drawing..............................................................................................25

7.3 Install Indoor Unit.................................................................................................26

7.4 Install Outdoor Unit ..............................................................................................28

7.5 Check After Installation and Operation Test.........................................................29

5.3 Printed Circuit Board...........................................................................................

..12

7.1 Notices for Installation...........................................................................................23

Table of Contents

Part 8 Exploded Views and Parts List

..............................................................30

Part 9 Troubleshooting

...............................................................................................40

9.1

Malfunction Analysis

.............................................................................................40

9.2

Flashing LED of Indoor/Outdoor Unit and Primary Judgement

............................44

9.3

How to Check Simply the Main Part

.....................................................................47

8.1 Indoor unit.............................................................................................................30

8.2 Outdoor unit..........................................................................................................34

Part10 Removal Procedure

.......................................................................................56

10.1

Removal Procedure of Indoor Unit

.....................................................................56

10.2

Removal Procedure of Outdoo

The pic. below is the actual panel and the vectorgraph in the manual is for reference only

.

r Unit

...................................................................59

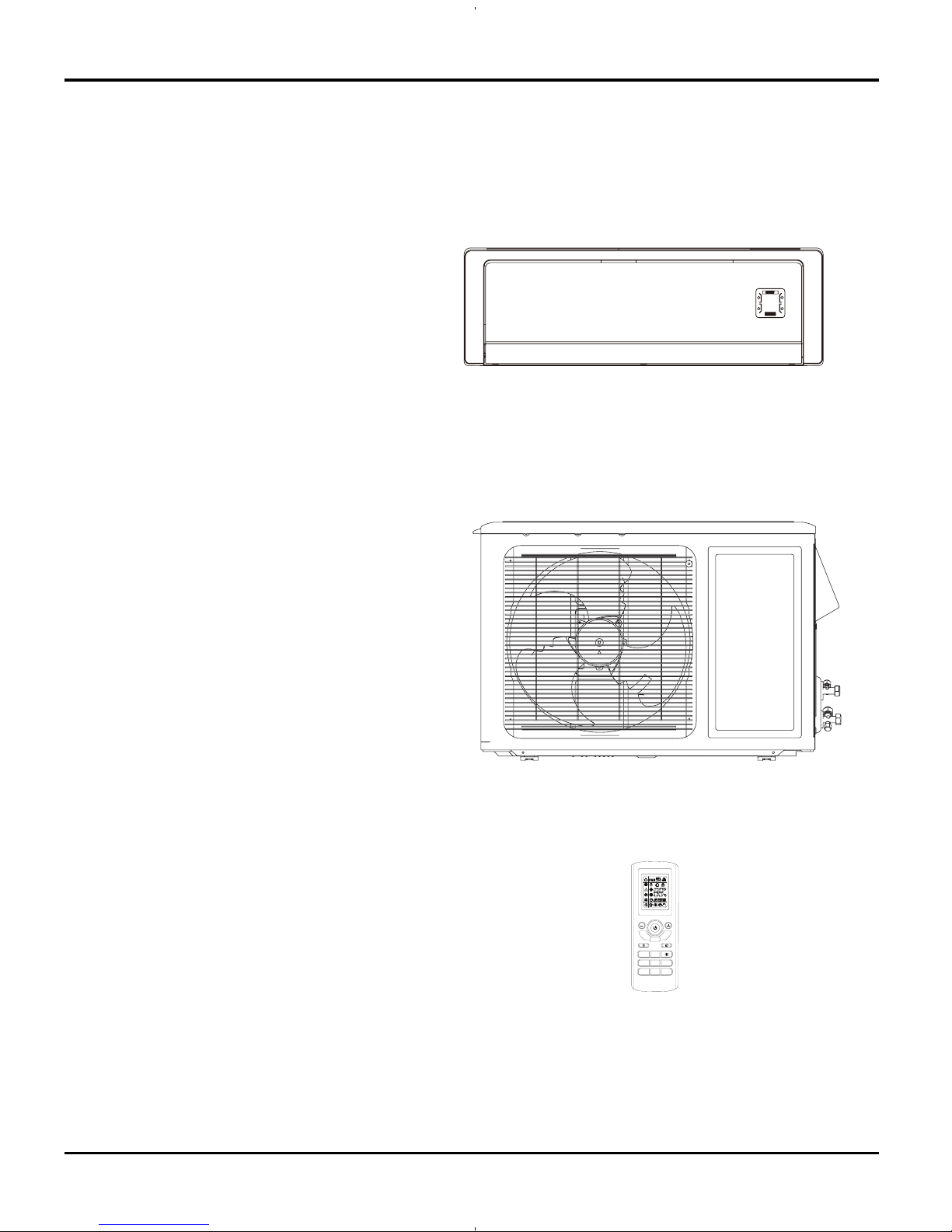

Summary and features

Indoor Unit

GWH09AB-A3DNA1B/I

GWH12AB-A3DNA1B/I

GWH12AB-D3DNA1B/I

Outdoor Unit

GWH09AB-A3DNA1B/O

GWH12AB-A3DNA1B/O

GWH12AB-D3DNA1B/O

Remote control window

YT1FF

Summary and features

FAN

MODE

IFEEL

CLOCK

TIMER

ON

X-FAN TEMP

TIMER

OFF

TURBO SLEEP LIGHT

1

1.Safety Precautions

Safety Precautions

Highly dangerous electrical voltages are used in this

system. Carefully refer to the wiring diagram and these

instructions when wiring. Improper connections inad-

equate grounding can cause accidental injury or death.

Ground the unit local electrical codes.

Connect all wiring tightly. Loose wiring may cause over-

heating at connection points and a possible fire hazard.

Make sure the ceiling/wall is strong enough to hold the

unit’s weight. The outdoor unit be installed in a

location where air and noise emitted by the unit will not

inside a room to prevent

"sweating" that can cause dripping

and

water

damage to

walls and floors.

The outdoor unit must be installed on stable, level surface,

where there is no accumulation of snow, leaves

or rubbish.

The unit should be installed according to the instructions

in order to minimize the risk of damage from earthquakes,

Keep your fingers and clothing away from any moving parts.

Caution

Never on the place where a combustible gas might

leak

When the unit is installed at telecommunication centers or

hospitals, take a proper provision against noise.

When installing at a watery place, provide an electric leak

Do not wash the unit with water.

Be very careful about unit transportation.The unit not

Do not touch the heat exchanger fins w th

Do not touch the compressor or refrigerant piping whithout

wearing glove

.

Do not operate the air conditioner without

air filter

.

i

Installing, starting up, and servicing air--conditioning equipment

can be hazardous due to system pressures, electrical components,

and equipment location (roofs, elevated structures, etc.).

Only trained, qualified installers and service mechanics should

install, start--up, and service this equipment.

Untrained personnel can perform basic maintenance functions such

as cleaning coils. All other operations should be performed by

trained service personnel.

When working on the equipment, observe precautions in the

literature and on tags, stickers, and labels attached to the

equipment.

Follow all safety codes. Wear safety glasses and work gloves. Keep

quenching cloth and fire extinguisher nearby when brazing. Use

care in handling, rigging, and setting bulky equipment.

Read these instructions thoroughly and follow all warnings or

cautions included in literature and attached to the unit. Consult

local building codes and current editions of the National Electrical

Code ( NEC ).

Recognize safety information. This is the safety--alert symbol

!

!

.

When you see this symbol on the unit and in instructions or

manuals, be alert to the potential for personal injury.Understand

these signal words: DANGER, WARNING, and CAUTION.

These words are used with the safety--alert symbol. DANGER

identifies the most serious hazards which will result in severe

personal injury or death. WARNING signifies hazards which

could result in personal injury or death. CAUTION is used to

identify unsafe practices which may result in minor personal injury

or product and property damage. NOTE is used to highlight

suggestions which will result in enhanced installation, reliability, or

operation.

or

according to

!

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury

or death.

Before installing, modifying, or servicing system, main

electrical disconnect switch must be in the OFF position.

There may be more than 1 disconnect switch. Lock out and

tag switch with a suitable warning label.

should

refrigerant or condensate line

running

Contact of refrigerant and fire generates poisonous gas.

Use specified refrigerant only.

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

Never use the system compressor as a vacuum pump.

CAUTION

!

Refrigerant and indoor coil should be evacuated using the

recommended deep vacuum method of 500 microns. The alternate

triple evacuation method may be used if the procedure outlined

below is followed. Always break a vacuum with dry nitrogen.

Clear the site after installation. Make sure no foreign objects

are left in the unit.

Always ensure effective grounding for the unit.

install

, or it may lead to fire or explosion.

should

Should any emergency occur, stop the unit and disconnect the

power immediately.

hurricanes or strong winds.

lines

ground fault breaker

.

be carried by only one person if it is more than 45lb

.

bare hands.

disturb the neighbors

.

Properly insulate any

2

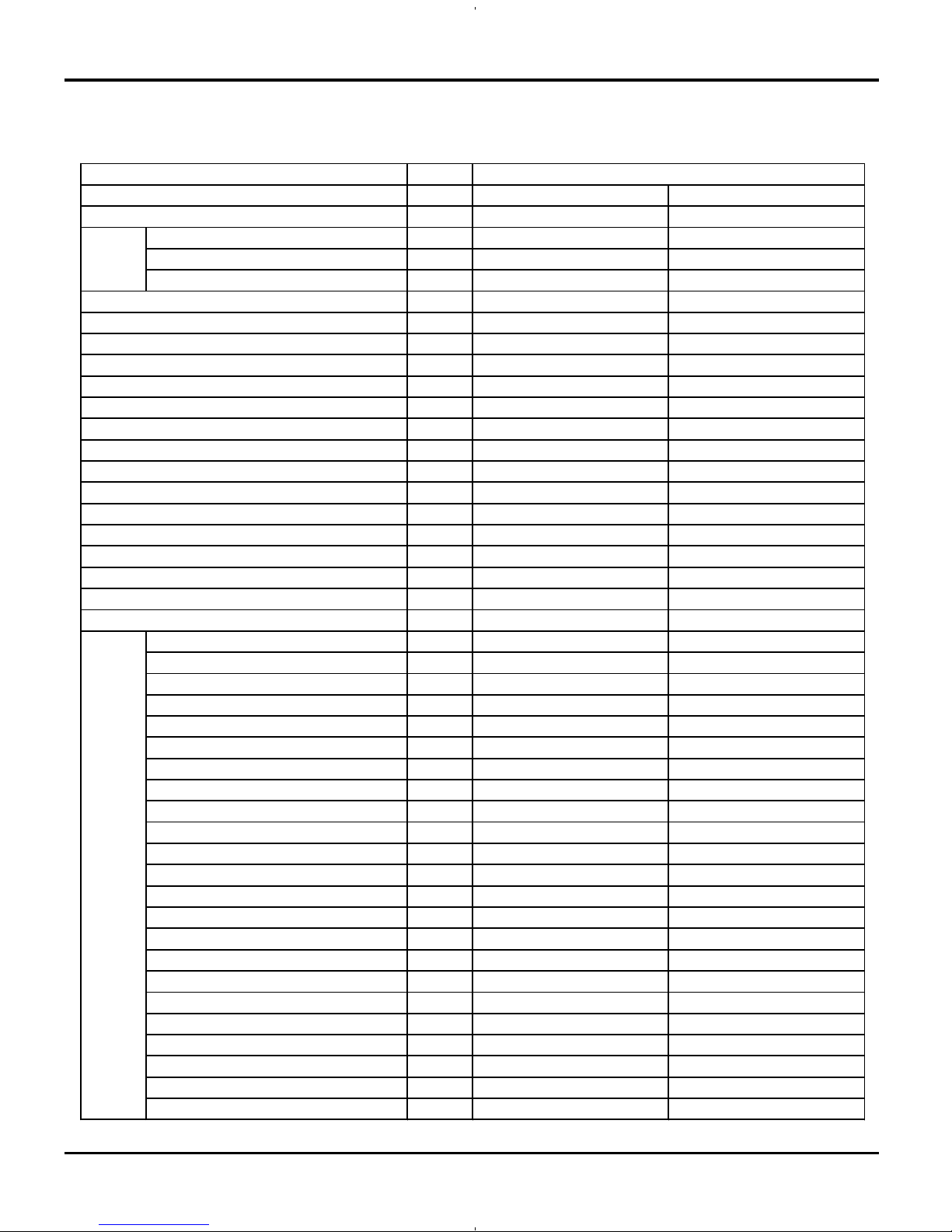

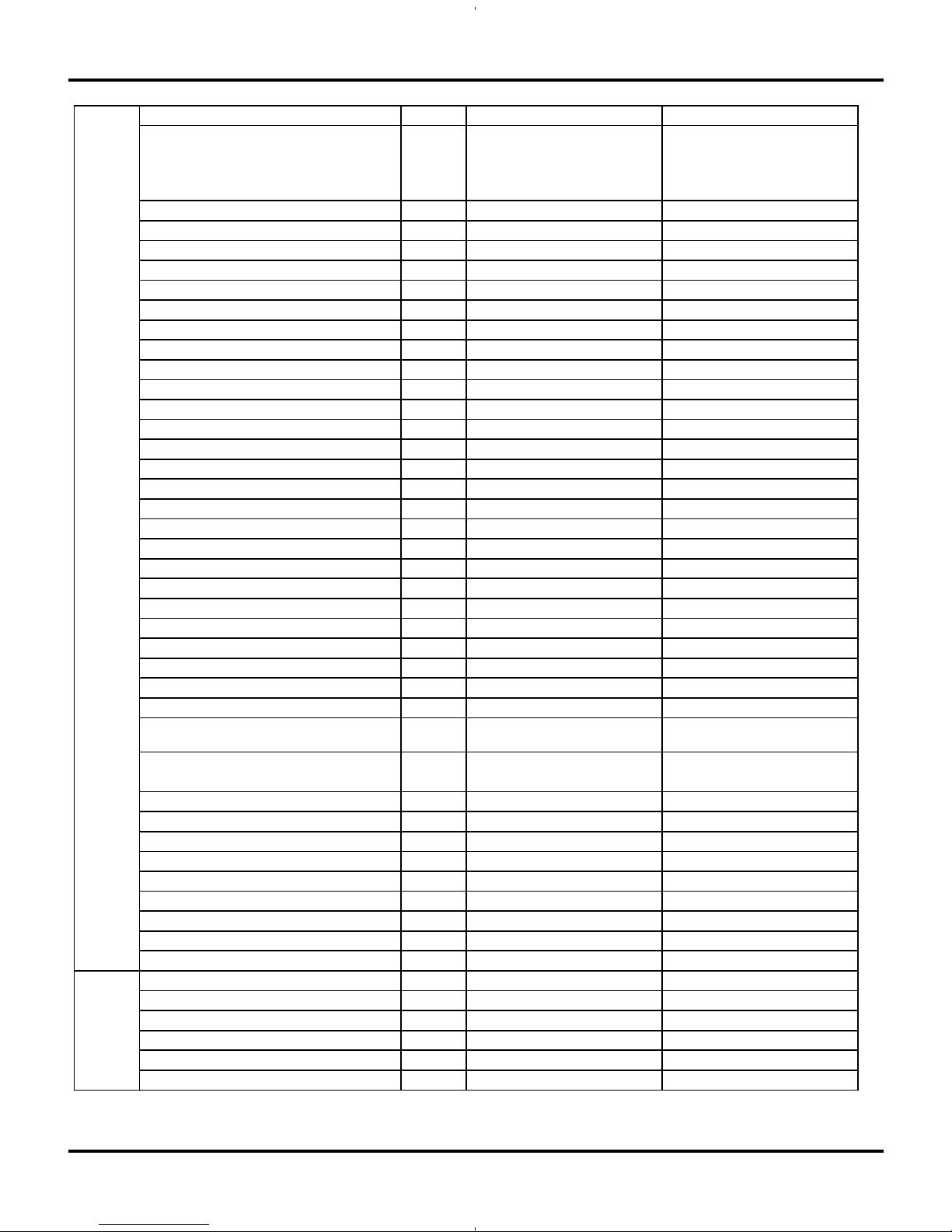

2.Specifications

Specifications

Unit

GWH09AB-A3DNA1B GWH12AB-A3DNA1B

CB11500550 CB11500570

Rated Voltage V

115 115

Rated Frequency Hz 60 60

Phases 1 1

Outdoor Outdoor

Btu/h 9000(400011950) 12000(450013000)

Btu/h 9500(341212500) 11700(320014000)

W630(1661180) 960(1601180)

W 680(2001230) 1140(4001250)

A 8.5 14.5

W 1100 1300

A10 12

CFM

300

300

gal./hr

0.32

0.37

BTU/W 14.3 12.5

W/W 4.04 3.34

W/W 23 2 2

W/W 9.8 8.9

sq.ft.

129-194 172-258

Model of indoor unit GWH09AB-A3DNA1B/I GWH12AB-A3DNA1B/I

Fan Type Cross-flow Cross-flow

Diameter Length(DXL) inch ĭ(3-3/8)X(26-3/10) ĭ(3-3/8)X(26-3/10)

Fan Motor Cooling Speed (SH/H/M/L/SL) r/min 1400/1150/1050/900/- 1500/1150/1050/900/-

Fan Motor Heating Speed (SH/H/M/L/SL) r/min 1450/1250/1150/1050/400 1450/1250/1150/1050/400

Output of Fan Motor W 10 10

Fan Motor RLA A / /

Fan Motor Capacitor ȝF/ /

Input of Heater W / /

Evaporator Form Aluminum Fin-copper Tube Aluminum Fin-copper Tube

Pipe Diameter inch

ĭ11/40

ĭ11/40

Row-fin Gap inch 2-1/17 2-1/17

Coil Length (LXDXW) inch

(25-7/8)X1X(11-2/9) (25-7/8)X1X(11-2/9)

Swing Motor Model MP28VB MP28VB

Output of Swing Motor W 2 2

Fus e A 3.15 3.15

Sound Pressure Level (SH/H/M/L/SL) dB (A) 42/38/30/28/- 42/38/30/28/-

Sound Power Level (SH/H/M/L/SL) dB (A) 52/48/40/38/- 52/48/40/38/-

Dimension (WXHXD) inch

34.3X11.1X7

34.3X11.1X7

Dimension of Carton Box (W/H/D) inch 36.8X14.7X10.2

36.8X14.7X10.2

Dimension of Package (W/H/D) inch

36.8X14.7X10.2 36.8

X14.7X10.2

Net Weight

lb.

26 26

Gross Weight lb. 33

33

ValueParam eter

Model

Product Code

Power

Supply

Power Supply Mode

l

Cooling Capacity (MinMax)

Heating Capacity (MinMax)

Cooling Power Input (MinMa x)

Heating Power Input (MinMa x)

Cooling Power Current

Heating Power Current

Rated Input

Rated Current

Air F l ow Volu me

Moisture Removal

Application Area

Indoor

Unit

EER

COP

SEER

HSPF

3

A 8 13

The above data is subject to change without notice. Please refer to the nameplate of the unit.

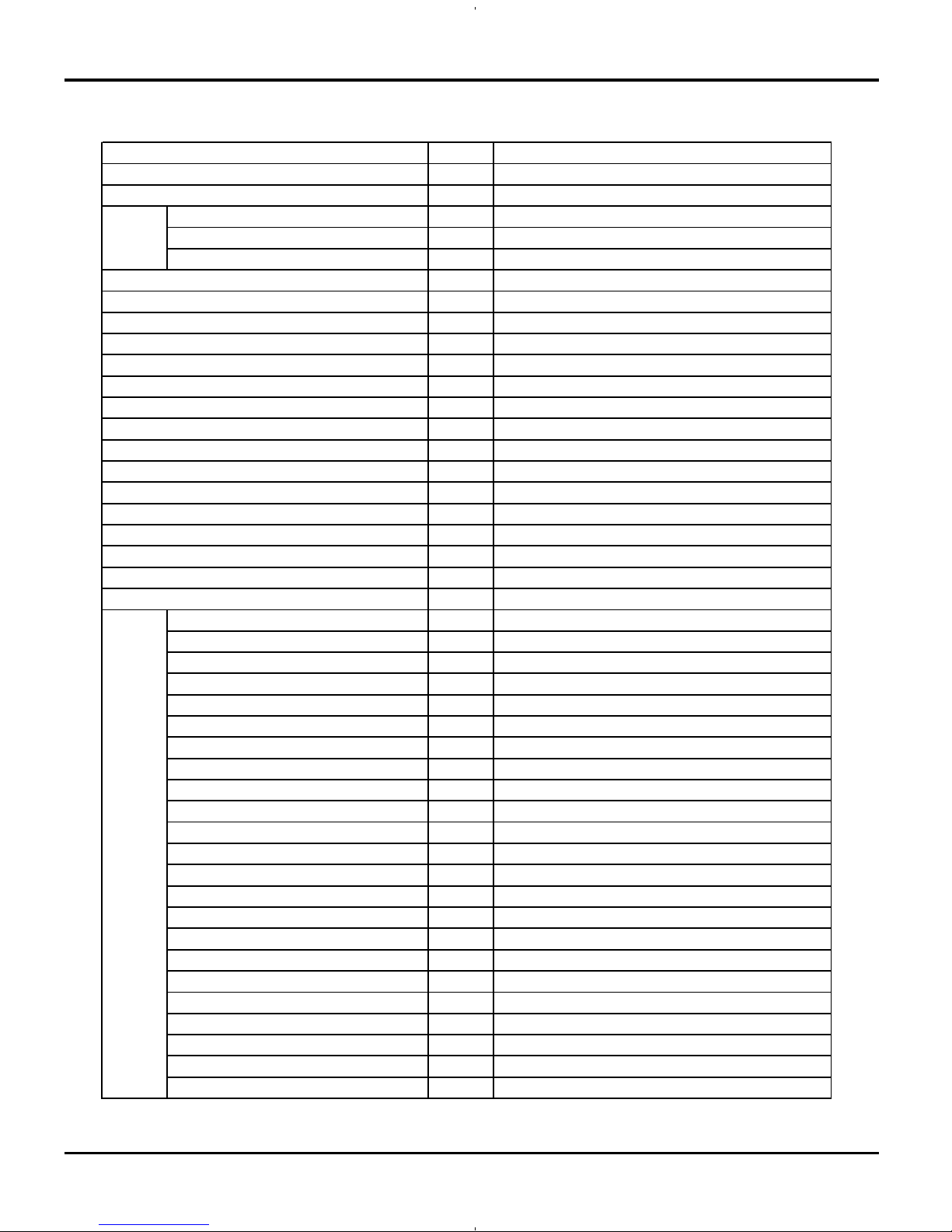

Specifications

Model of Outdoor Unit GWH09AB-A3DNA1B/O GWH12AB-A3DNA1B/O

Compressor Manufacturer/Trademark

CHINA

RESOURCES(SHENYANG)

SANYO COMPRESSOR CO.

LTD ./S ANYO

CHINA

RESOURCES(SHENYANG)

SANYO COMPRESSOR CO.

LTD ./S ANYO

Compressor Model C-6RZ110H1A C-6RZ110H1A

Compressor Oil FV50S FV50S

Compressor Type Rotary Rotary

L.R.A. A 33.00 33

Compressor RLA A 4.59 4.59

Compressor Power Input W 800 800

Overload Protector Int11l-3979 Int11l-3979

Throttling Method Electron expansion valve Electron expansion valve

Operation temp ºF 61

86 61

86

Ambient temp (cooling) ºF

41

115 41115

Ambient temp (heating) ºF

586

5

86

Condenser Form Aluminum Fin-copper Tube Aluminum Fin-copper Tube

Pipe Diameter inch ĭ3/8 ĭ3/8

Rows-fin Gap inch

2-1/18

2-1/18

Coil Length (LXDXW) inch (29-2/5)X(1-3/4)X20

(29-2/5)X(1-3/4)X

20

Fan Motor Speed rpm 830 830

Output of Fan Motor W 30 30

Fan Motor RLA A / /

Fan Motor Capacitor ȝF/ /

Air Flow Volume of Outdoor Unit

CFM

1059 1177

Fan Type Axial-flow Axial-flow

Fan Diameter inch ĭ(15-3/4)

ĭ

(15-3/4)

Defrosting Method Automatic Defrosting Automatic Defrosting

Clim ate Type T1 T1

Is ol ati on I I

Mois ture Protection IP24 IP24

Permissible Excessive Operating

Pressure for the Discharge Side

MPa 3 .8 3 .8

Permissible Excessive Operating

Pressure for the Suction Side

MPa 1 .2 1 .2

Sound Pressure Level (H/M/L) dB (A) 52/-/- 55/-/-

Sound Power Level (H/M/L) dB (A) 62/-/- 65/-/-

Dimension (WXHXD) inch

33.3X21.3X12.6

33.3X23.2X12.6

Dimension of Carton Box (W/H/D) inch 34.5X22.8X14.2 34.5X24.8X14.2

Dimension of Package (W/H/D) inch

34.5X22.8X14.2 34.5X24.8X14.2

Net Weight lb. 88 90

Gross Weight lb.

96

99

Refrigerant R410A R410A

Refrigerant Charge

oz. 47.6

47.6

Precharge line length

ft.

16

16

Gas Additional Charge lb./ft. 0.14 0.14

Outer Diameter Liquid Pipe inch ĭ1/4

ĭ1/4

Outer Diameter Gas Pipe inch ĭ3/8

ĭ1/2

Max Distance Height ft. 33 33

Max Distance Length ft. 66

66

Outdoor

Unit

Connecti

on Pipe

4

Specifications

Unit Value

GWH12AB-D3DNA1B

CB11500380

Rated Voltage V

208/230

Rated Frequency Hz 60

Phas es 1

Outdoor

Btu/h 12000(450013000)

Btu/h 13000(320014000)

W960(1601180)

W 1140(4001250)

A5

A5.5

W 1200

A6

CFM

330

gal./hr. 0.37

BTU/W 12.5

W/W 3.34

W/W 22

W/W 10.5

sq.ft.

172-258

Model of indoor unit GWH12AB-D3DNA1B/I

Fan Type Cross-flow

Diameter Length(DXL) inch

ĭ(3-3/8)X(26-3/10)

Fan Motor Cooling Speed (SH/H/M/L/SL) r/min 1500/1150/1050/900/-

Fan Motor Heating Speed (SH/H/M/L/SL) r/min 1450/1250/1150/1050/400

Output of Fan Mo tor W 10

Fan Motor RLA A /

Fan Motor Capacitor ȝF/

Input of Heater W /

Evaporator Form Aluminum Fin-copper Tube

Pipe Diameter inch ĭ11/40

Row-fin Gap inch 2-1/17

Coil Length (LXDXW) inch (25-7/8)X1X(11-2/9)

Sw in g Moto r Model MP2 8VB

Output of Swi ng Motor W 2

Fus e A 3.15

Sound Pressure Level (SH/H/M/L/SL) dB (A) 47/38/30/28/-

Sound Power Level (SH/H/M/L/SL) dB (A) 57/48/40/38/-

Dimension (WXHXD) inch 34.3X11.1X7

Dimension of Carton Box (W/H/D) inch 36.8X14.7X10.2

Dimension of Package (W/H/D) inch 36.8X14.7X10.2

Net Weight lb. 26

Gross Weight lb. 33

Indoor

Unit

EER

COP

SEER

HSPF

Rated Current

Air F l ow Volum e

Moisture Removal

Application Area

Heating Power Input (Min

Ma x)

Cooling Power Current

Heating Power Current

Rated Input

Power Supply Mode

l

Cooling Capacity (MinMa x)

Heating Capacity (MinMa x)

Cooling Power Input (MinMa x)

Param eter

Model

Product Code

Power

Supply

5

Specifications

Model of Outdoor Unit GWH12AB-D3DNA1B/O

Compressor Manufacturer/Trademark

CHINA RESOURCES(SHENYANG) SANYO

COMPRESSOR CO. LTD./SANYO

Compressor Model C-6RZ110H1A

Compressor Oil FV50S

Compressor Type Rotary

L.R.A. A 33.00

Compressor RLA A 4.59

Compressor Power Input W 800

Overload Protector Int11l-3979

Throttling Method Electron expansion valve

Operation temp ºF 61

86

Ambient temp (cooling) ºF

41115

Ambient temp (heating) ºF

5

86

Condenser Form Aluminum Fin-copper Tube

Pipe Diameter inch ĭ3/8

Rows-fin Gap inch 2-1/18

Coil Length (LXDXW) inch (29-2/5)X(1-3/4)X22

Fan Motor Speed rpm 830

Output of Fan Motor W 30

Fan Motor RLA A /

Fan Motor Capacitor ȝF/

Air Flow Volume of Outdoor Unit

CFM 1177

Fan Type Axial-flow

Fan Diameter inch ĭ(15-3/4)

Defrosting Method Automatic Defrosting

Climate Type T1

Isolation I

Moisture Protection IP24

Permissible Excessive Operating Pressure for the

Discharge Side

PSI

551

Permissible Excessive Operating Pressure for the

Suction Side

PSI

174

Sound Pressure Level (H/M/L) dB (A) 55/-/-

Sound Power Level (H/M/L) dB (A) 65/-/-

Dimension (WXHXD) inch 33.3X23.2X12.6

Dimension of Carton Box (W/H/D) inch 34.5X24.8X14.2

Dimension of Package (W/H/D) inch 34.5X24.8X14.2

Net Weight lb. 90

Gross Weight lb. 99

Refrigerant R410A

Refrigerant Charge

oz. 45.8

Precharge line length

ft.

16

Gas Additional Charge lb./ft. 0.14

Outer Diameter Liquid Pipe inch ĭ1/4

Outer Diameter Gas Pipe inch ĭ1/2

Max Distance Height ft. 33

Max Distance Length

ft. 66

Outdoor

Unit

Connecti

on Pipe

The above data is subject to change without notice. Please refer to the nameplate of the unit.

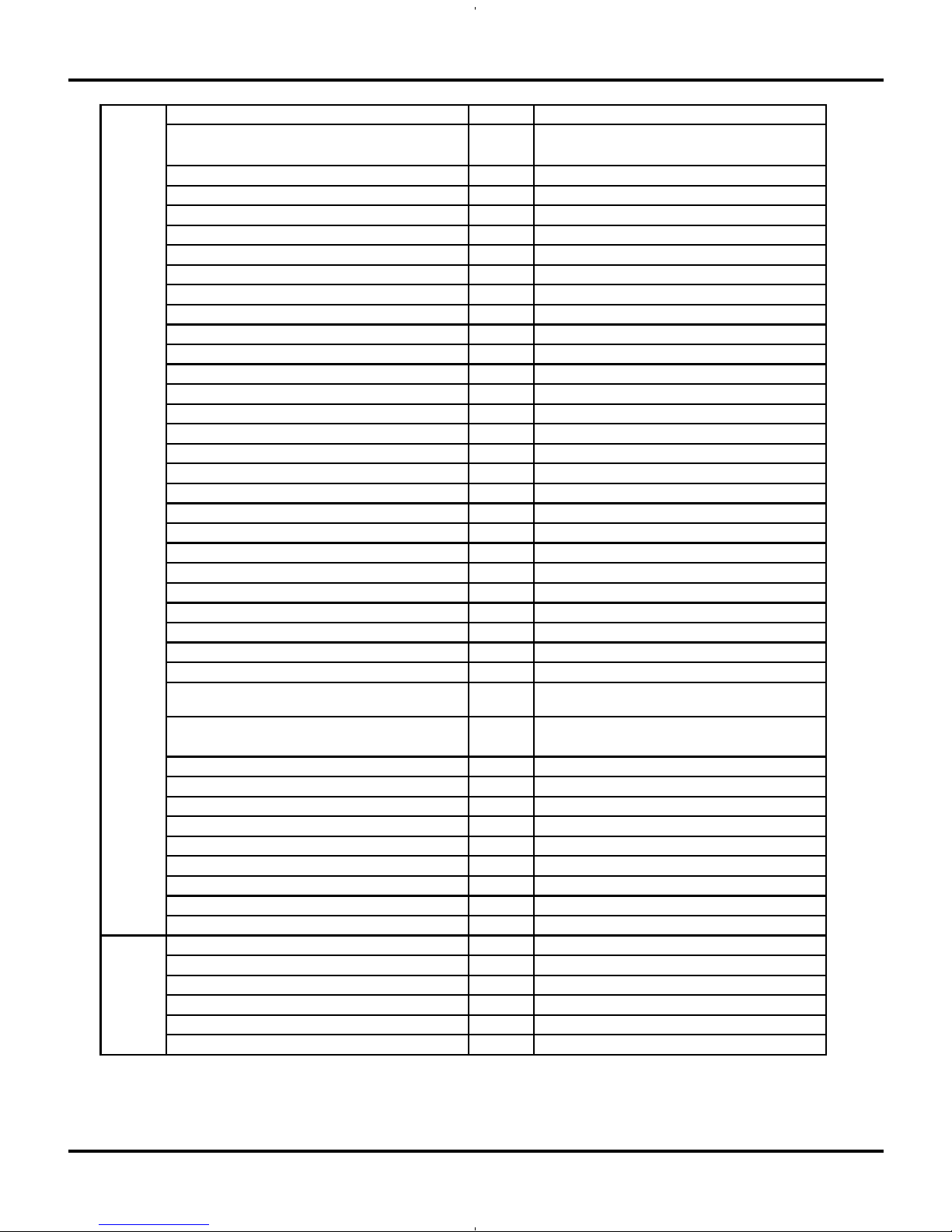

6

3. Construction Views

3.1 Indoor Unit (THE SAME DIMS FOR 9k12k)

Constrction views

Unit:inch

4

34-1/3

7

23-4/5

6-8/15

11-1/7

12K Unit:

3.2 Outdoor Unit

D

21-1/4

11-1/4

H

W

Model W H D

09K

33-3/8

21-1/4 12-3/5

12K 33-3/8 23-2/9 12-3/5

7

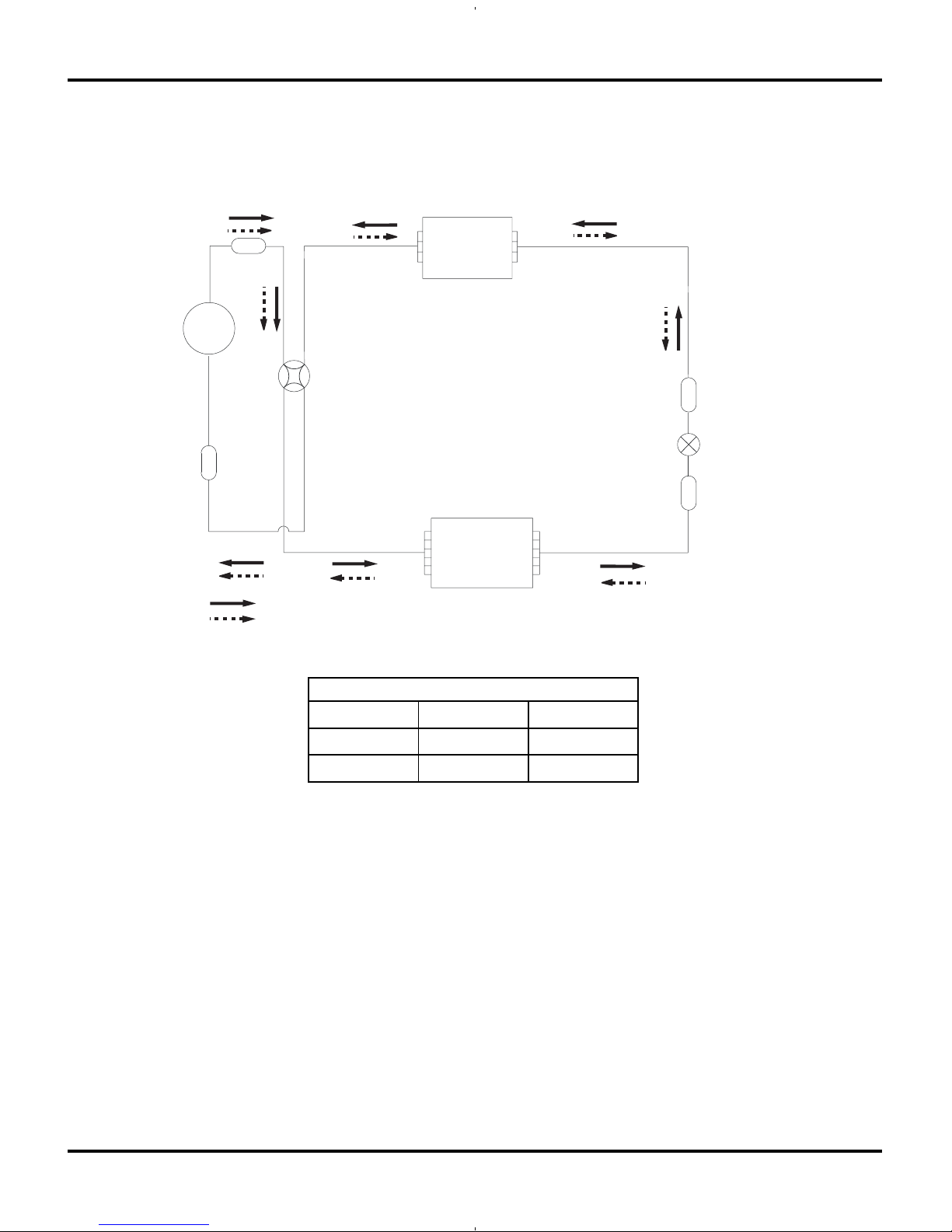

4. Refrigerant System Diagram

Refrigerant System Diagram

Strainer

Strainer

Muffler

4-Way valve

Expansion valve

Heat exchanger

( INDOOR )

Heat exchanger

( OUTDOOR )

rotalumucca-buS

rosserpmoC

Cooling

Heating

Refrigerant Pipe Diameter

Liquid Gas

09K

1/4ą 3/8ą

12K

1/4ą 1/2ą

8

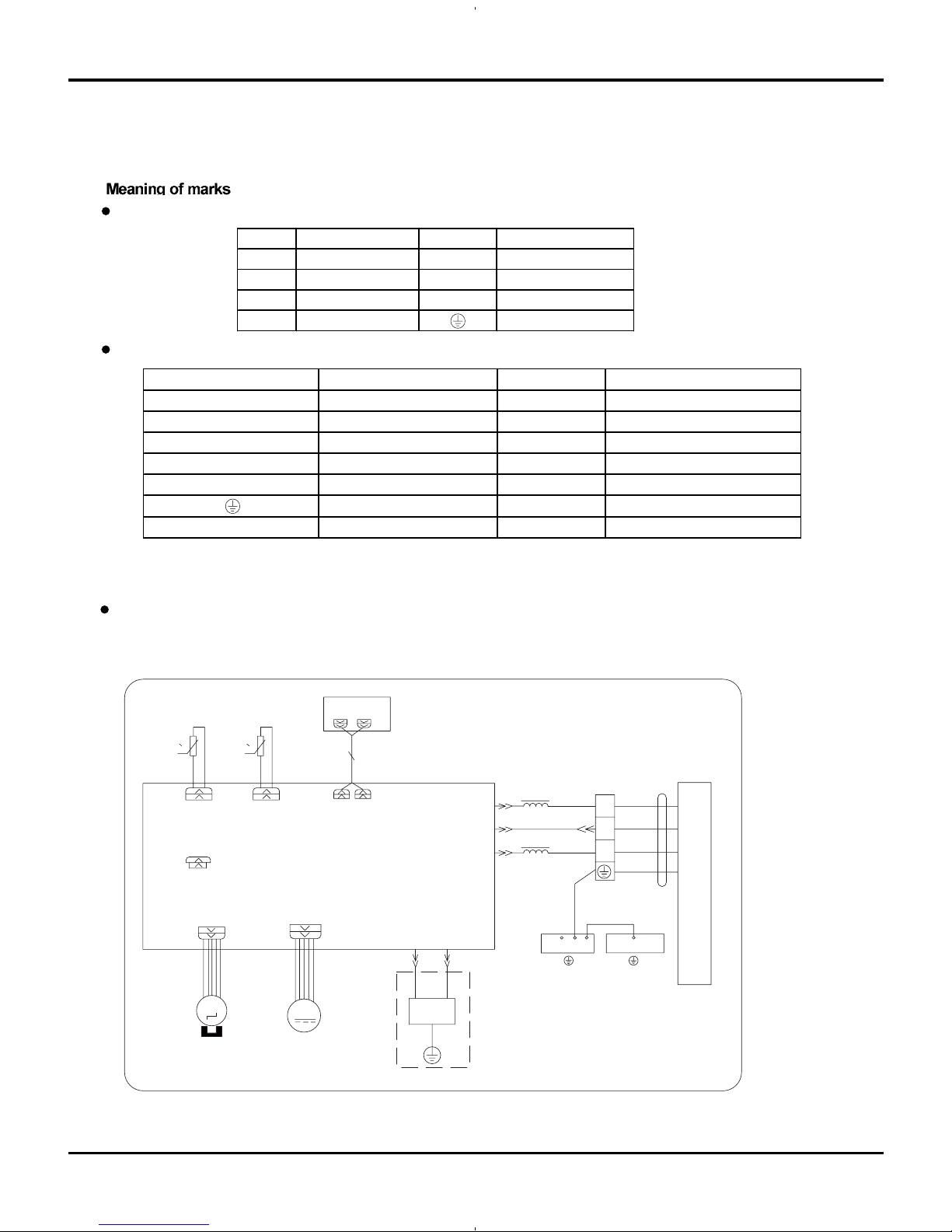

5. Schematic Diagram

5.1 Electrical Date

5.2 Electrical wiring

Outdoor Unit

Symbol Color s ymbol Symbol Color symbol

WH

WHITE

BN

BROWN

YE

YELL OW

BU

BLUE

RD

RED

BK

BLACK

YEGN

YELLOW GREEN Ground

Indoor Unit

Indoor Unit

Schematic Diagram

Symbol Parts name Symbol Color symbol

L1 L2

1OLQH)URQWOLQH

WH

WHITE

4YV

ZD\YDOY

YE

YELLOW

EKV

electric expansion valv

RD

RED

L reactor BN

SAT OVERLOAD BN BROWN

COMP

COMPRESSOR

BU

BLUE

Ground

BK

BLACK

YEGN

YELLOW GREEN

AP1 DISPLAY

EVAPORATOR

ELECTRIC BOX

W5

BK

N1

W2 YEGN

W1YEGN

COM-INNER

3

2

OUTDOOR UNIT

N(1)

AP2

L

W3

BN

W4

BU

XT1

G

HEALTH-LHEALTH-N

YEGN

BURD

GG

FAN MOTOR

STEP MOTOR

ROOM TUBE

DISP3 DISP4

00

TEM.SENSOR

TUBE

ROOM

TEM.SENSOR

RT1 RT2

JUMP

L1

L1

COOL PLASMA

GENERATOR

M

M

SWING-UD CN1

(1) Models GWH09AB-A3DNA1B/I ,GWH12AB-A3DNA1B/I

9

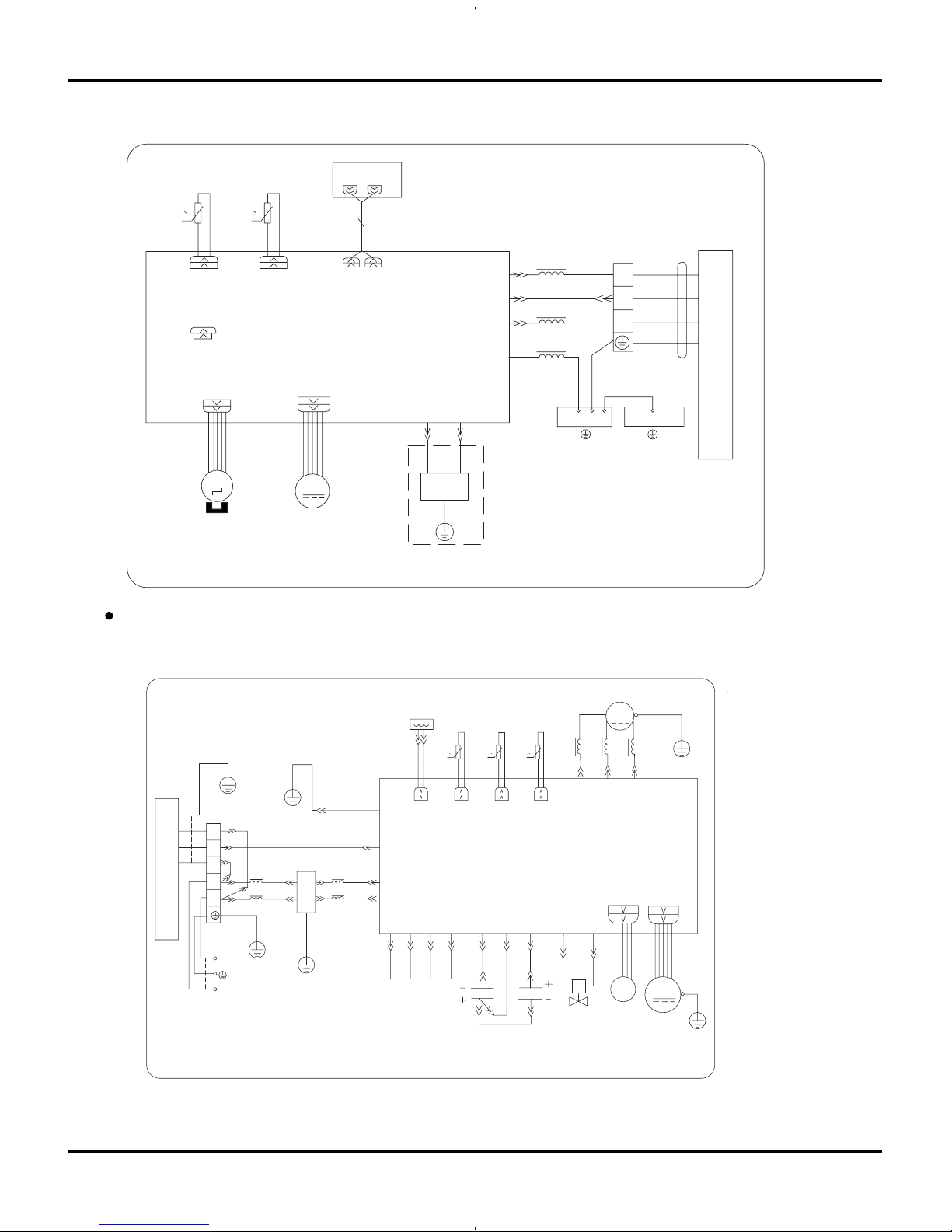

Outdoor Unit

Schematic Diagram

4YV

RT5

0

0

RT4

0

RT3

OUTROOM

EXHAUST

OUTTUBE

OFAN

E

OVERHEAT

R

E

C

S

U

V

W

CT1,2

AP1

W3YEGN

W10 RD

COMP

W8 YEGN

FAN MOTOR

W5 BU

W6 YE

W7 BK

AC-N1

AC-L1

4V

AC-N2

COMU

EKV

CN1

TEM.SENSOR

OUTROOM

EXHUAST

TEM.SENSOR

TEM.SENSOR

TUBE

W2 BU

W1 BN

W4 BK

G

G

I

N

D

O

O

R

U

N

I

T

W13 YEGN

POWER

N

L

L

N

N(1)

3

2

L2L2L2

L1

L1

G

G

G

W15 BU

W14 BN

W16 WH

W17 RD

G

L4

L4

W23 OGW20 BU

W22 WH

W21 BN

AC-L2 AC-L4AC-N5AC-N3 AC-N4 AC-L2AC-L3

W19 BU W24 RD

W18 YEGN

COMP

M

XT2

3

4

E

2

1

FILTER

C4

C3

2

1

2

1

(2) Model GWH12AB-D3DNA1B/I

AP1 DISPLAY

EVAPORATOR

ELECTRIC BOX

W5 BK

N1

W2 YEGN

W1 YEGN

COM-INNER

3

2

OUTDOOR UNIT

N(1)

AP2

L

W3 BN

W4 BU

XT1

G

HEALTH-L HEALTH-N

YEGN

BURD

GG

FAN MOTOR

STEP MOTOR

ROOM TUBE

DISP3 DISP4

00

TEM.SENSOR

TUBE

ROOM

TEM.SENSOR

RT1 RT2

JUMP

E

W6 YEGN

L1

L1

L1

COOL PLASMA

GENERATOR

M

M

SWING-UD CN1

(1) Models GWH09AB-A3DNA1B/O,GWH12AB-A3DNA1B/O

10

These circuit diagrams are subject to change without notice, please refer to the one supplied with the unit.

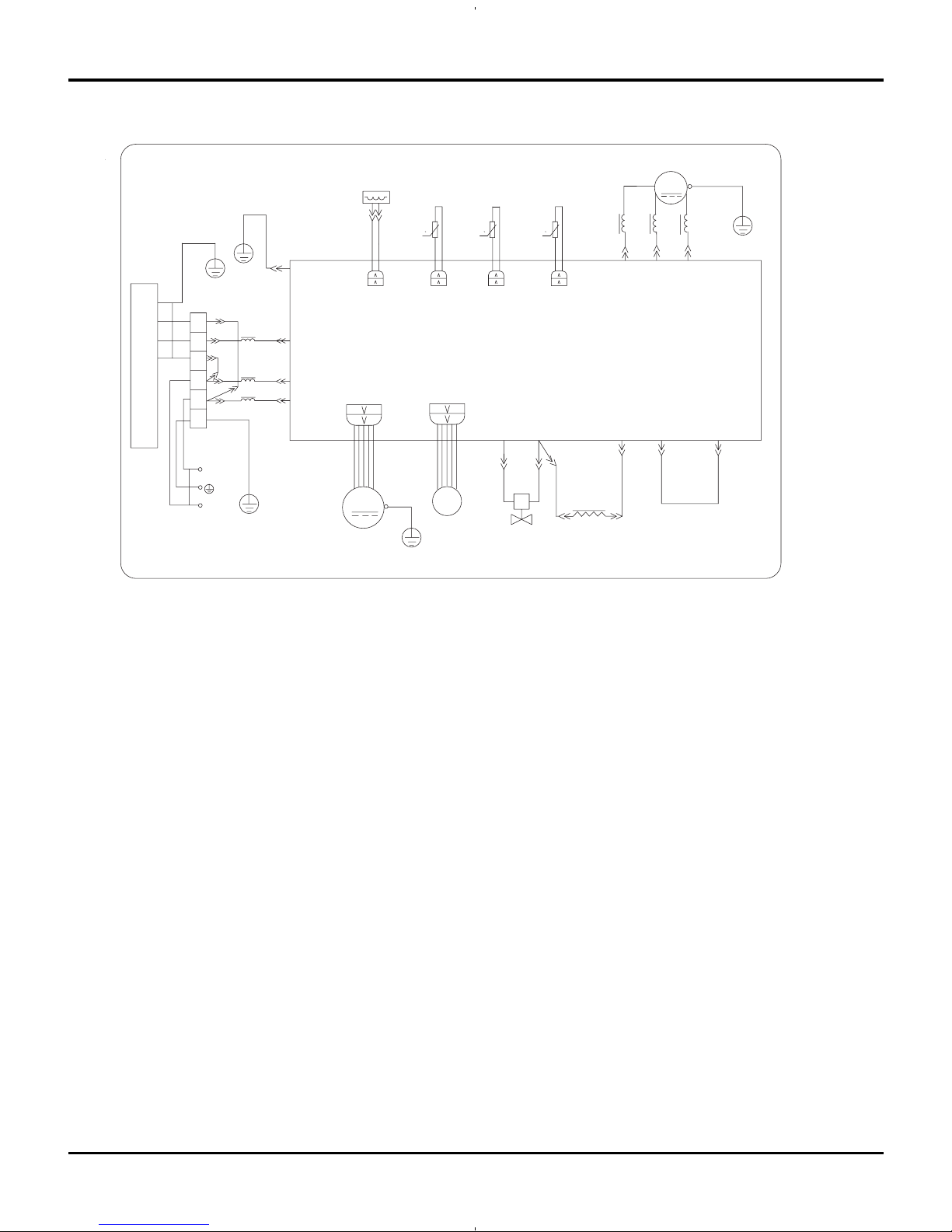

4YV

RT5

0

0

RT4

0

RT3

OUTROOM

EXHAUST

OUTTUBE

OFAN

E

OVERHEAT

R

E

C

S

U

V

W

CT1,2

AP1

W3 YEGN

W10 RD

COMP

W8 YEGN

FAN MOTOR

W5 BU

W6 YE

W7 BK

N1

AC-L1

4V

AC-L2

AC-L3

N2 N3

L

COMU

W 9 BU

W11 OG

W12 WH

EKV

CN1

TEM.SENSOR

OUTROOM

EXHUAST

TEM.SENSOR

TEM.SENSOR

TUBE

W2 BU

W1 BN

W4 BK

G

G

I

N

D

O

O

R

U

N

I

T

W

13 YEGN

POWER

L1

L

N

N(1)

3

2

L2L2L2

L1

L1

G

G

G

W15 BU

W14 BN

L1

L2

G

COMP

M

XT2

Schematic Diagram

(2) Models GWH09AB-A3DNA1B/O,GWH12AB-A3DNA1B/O

11

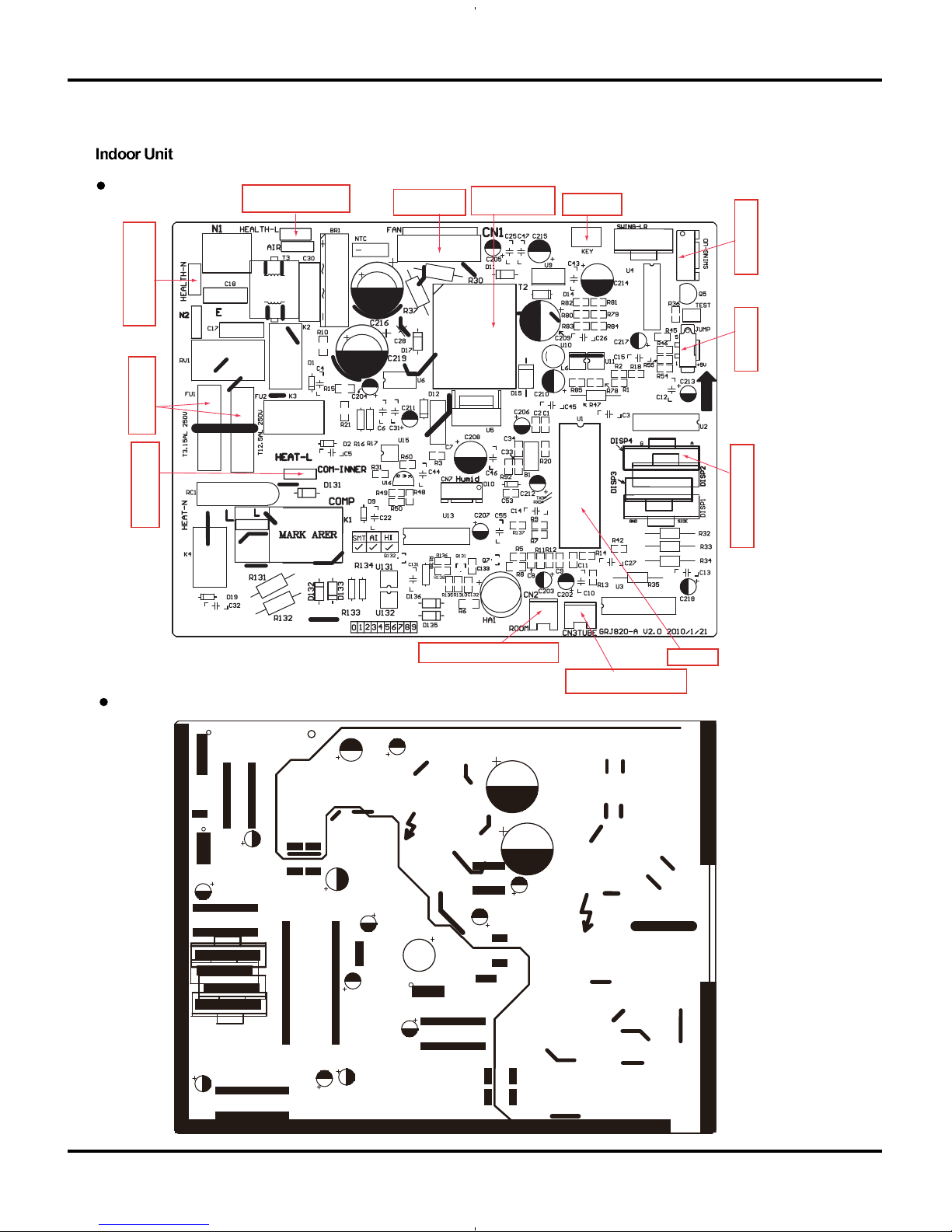

Interface for live wire

of healt h function

Interface of

indoor fan

Tra ns for mer wi th

high freq uency

Auto button

Vertical swing

Jumper cap

Interface for display

Main chip

Indoor pipe temp sensor

Indoor tambien temp sensor

Interface for

communication

Protective tube

Interface for null wire

of health function

5.3 Printed Circuit Board

TOP VIEW

BOTTOM VIEW

Schematic Diagram

12

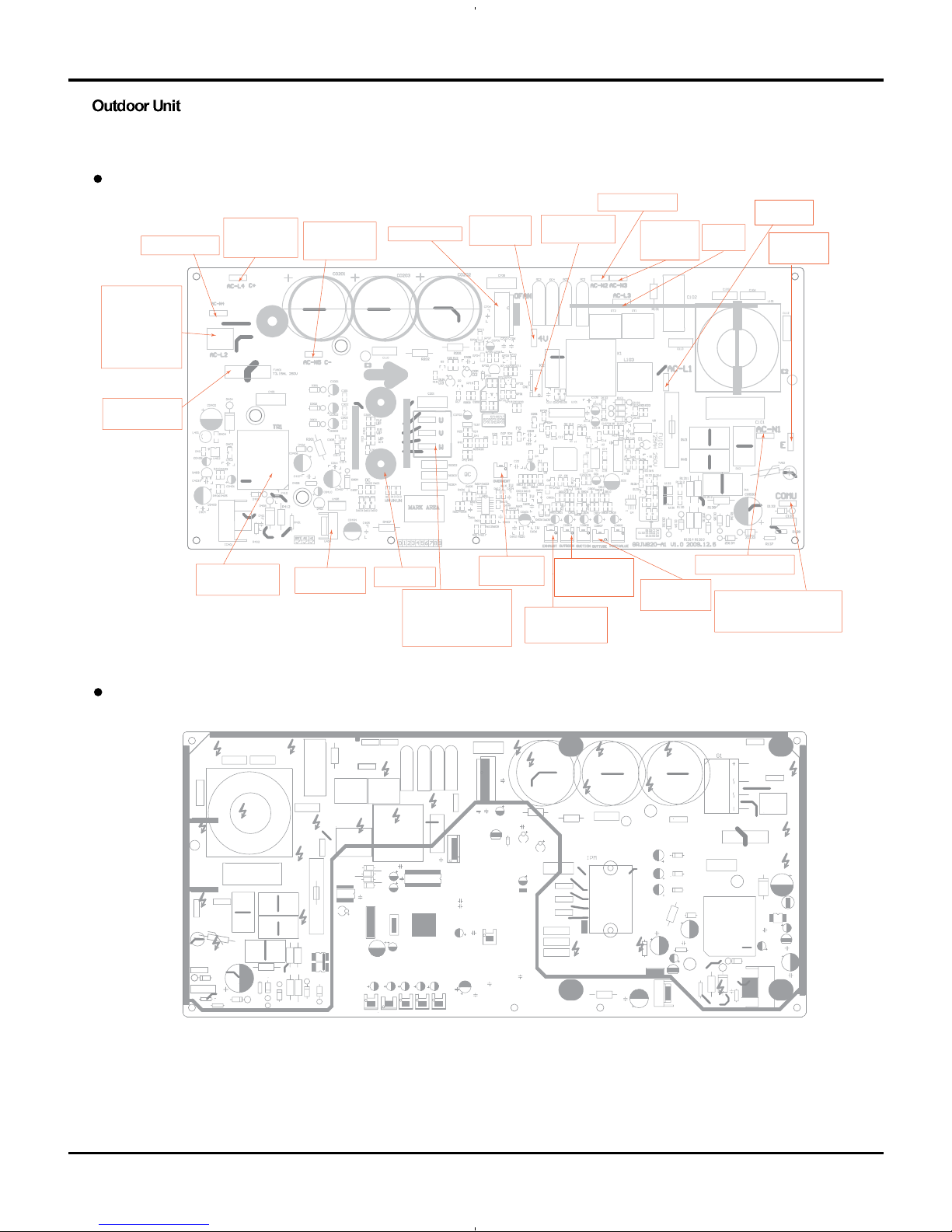

TOP VIEW

BOTTOM VIEW

(1) Models GWH09AB-A3DNA1B/O , GWH12AB-A3DNA1B/O

Schematic Diagram

Jumper null wire

Positive pole

of big capacitor

(brown wire)

Terminal for fan

Terminal for

4-way valve

Jumper null wire

Terminal for

null wire of

4-way valve

Jumper

live wire

Terminal for

live wire

Terminal for

ground wire

Terminal for communication

wire connecting to black

communication wire of IDU.

Terminal for null wire

Outdoor pipe

temp sensor

Outdoor ambient

temp se nsor

Compressor

discha rge temp

sensor

Overload

temp s ensor

Three-phase terminal

of compressor

Phase U-blue wire

Phase Y-yellow wire

Phase W-red wire

IPM module

Voltage

regulator 7805

Tra ns for mer with

high freq uency

Protective tube

for switch power

Jumper live wire,

joint terminal for

positive pole and

negative pole of

two capacitors(

orange wire)

Negative pole

of big capacitor

(blue wire)

electronic

expansion valve

13

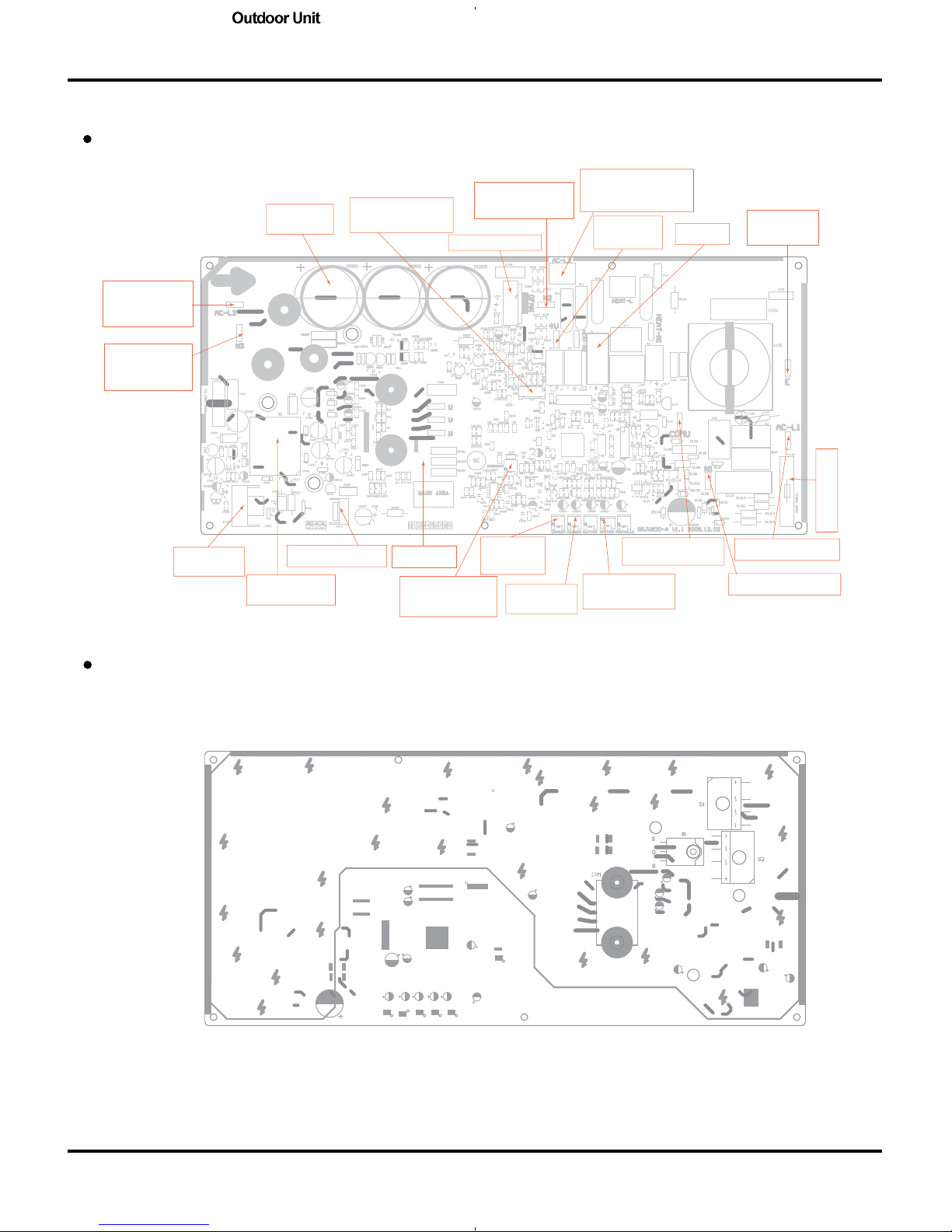

TOP VIEW

BOTTOM VIEW

Schematic Diagram

(2) Model GWH12AB-D3DNA1B/O

Electrolysis

condenser

electronic

expansion valve

Terminal for DC fan

Jumper terminal

for null wire,

connecting to N3

Terminal for live wire

connecting to reactor

and 4-way valve

Main relay

Terminal for

ground wire

Protective tube

Terminal for live wire

Terminal for null wire

Terminal for

communication wire

Outdoor pipe

temp sensor

Outdoor ambient

temp sensor

Compressor

discha rge

temp se nsor

Terminal for

overload protector

of compressor

IPM module

Voltage regulator7805

Transformer with

high freq uency

Chip for

switch power

Jumper terminal

for null wire,

connecting to N2

Terminal for live

wire, connecting

to reactor

Terminal for

4-way valve

14

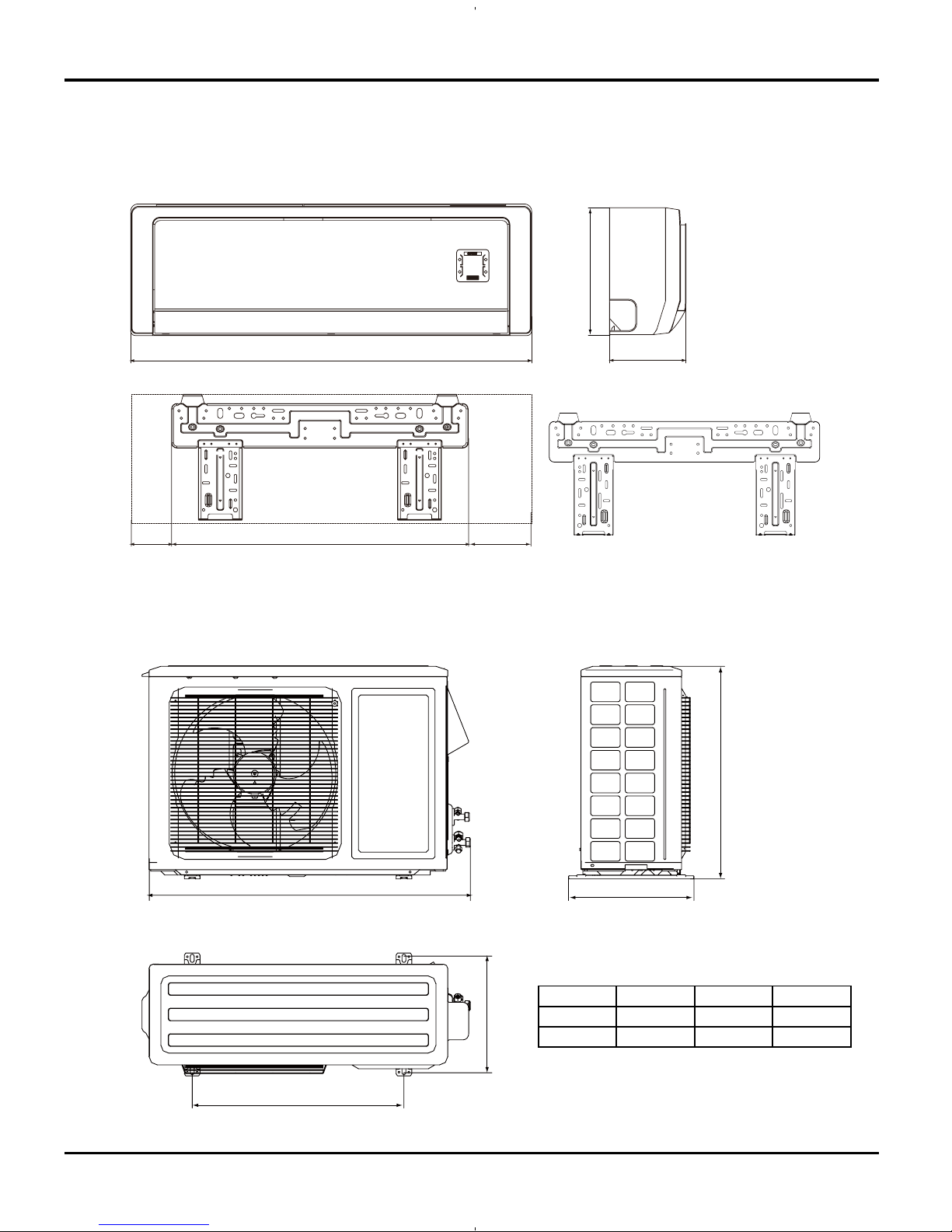

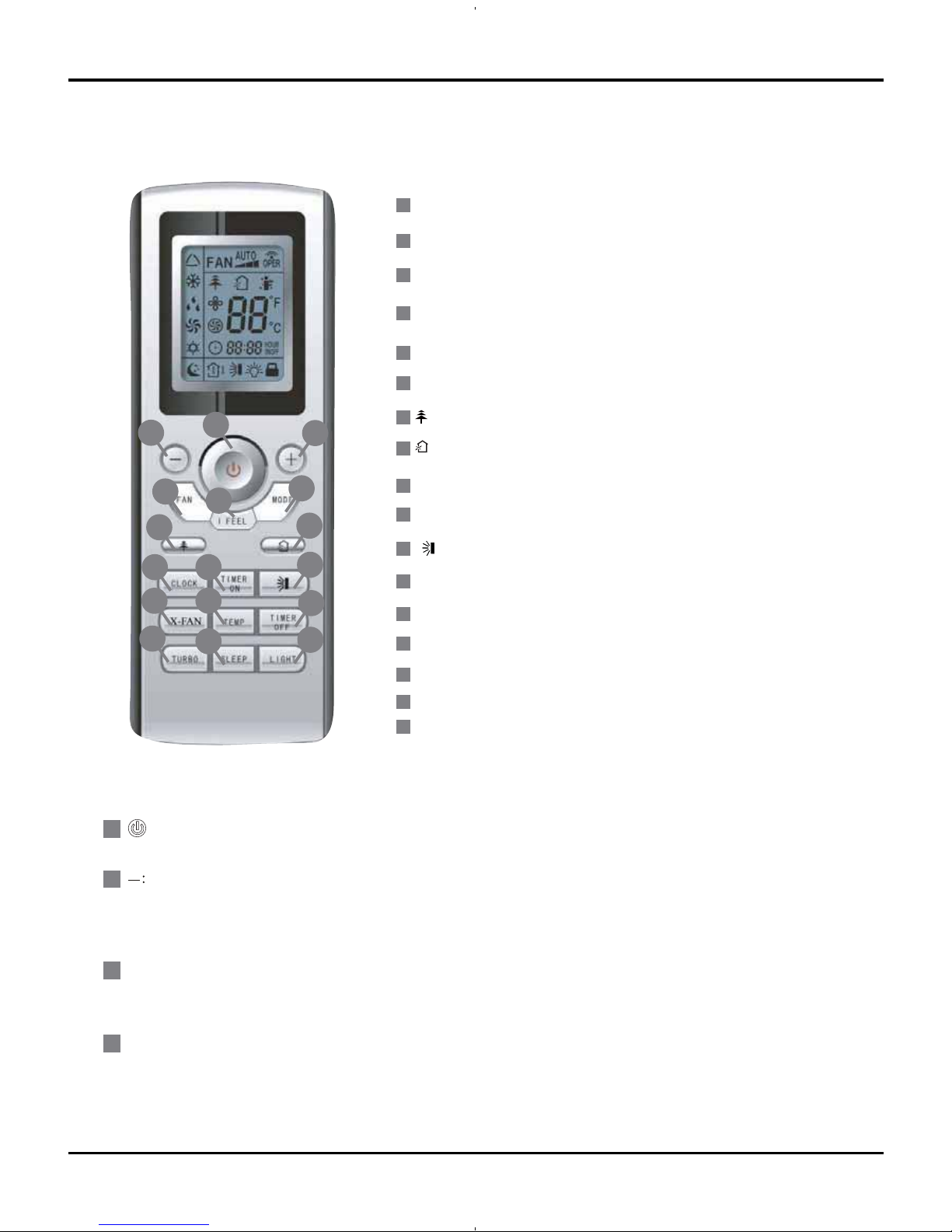

6. Function and Control

6.1 Remote Control Operations

Function and Control

Timer ON Button

TIMER OFF Button

Clock Button

X-FAN Button

Temperature Displaye Button

TURBO Button

Sleep Mode Button

Light Mode Button

ON/OFF Button

1

7

6

I FEEL Button

MODE Button

5

3

Setpoint Temperature DOWN Button

2

FAN Speed Button

4

11

10

14

9

12

13

15

16

17

8

3

14

9

10

13

16

12

5

4

15

11

8

17

7

2

1

6

+

:

FAN :

1

3

2

4

Press this button, the unit will be turned on, press it once more, the unit will be turned off.

To lower temperature set point. Press this button, sets temperature,when unit is on . Continuously press and hold this

button for more than 2 seconds,the corresponding contents will be changed rapidly,but in AUTO mode, set tempera-

ture is not adjustable.

.

To increase temperature set point. Press this button, the temperature can be set up, continuously press this button and

hold for two seconds, the relative contents can quickly change, but in AUTO mode, set temperature is not adjustable.

Setpoint Temperature UP Button

HEALTH function Button

AIR function Button

Press this button, Auto, Low, Middle, High speed can be circularly selected. After powered on, Auto fan speed is default.

Under Dehumidify mode, Low fan speed only can be set up.

(

X-FAN is the alternative expression of

BLOW for the purpose of understanding.)

15

Function and Control

CLOCK

:

9

8

7

I FEEL :

5

MODE

:

6

Press this button, I FEEL On and I FEEL Off can be selected.In the I FEEL function.

The unit will adjust temperature automatically according to the sensed temperature.

TIMER ON

:

11

10

X-FAN :

12

OFF

This is an universal use remote controller. If remote controller sends the following three kinds of status , or , the swing

status of main unit will be which indicates the guide louver swings up and down between that all five positions:

:

Press this button, Auto, Cool,Dry, Fan, Heat mode can be selected circularly. Auto mode is default while power on. Under Auto

mode, the temperature will not be displayed; In this mode, the unit will automatically select the suitable operation mode in accordance with the room temperature to make the room more comfortable for you.

AUTO

COOL

DRY

FAN

Note:Only for models with heating function.

HEAT

Press this button to set HEALTH function ON or OFF. After the unit is turned on, it defaults to HEALTH function ON.

Press this button to select AIR function ON or OFF.

Press this button, the clock can be set up,signal blink and display.Within 5 seconds, the value can be adjusted by pressing

+ or - button, if continuously press this button for 2 seconds above,in every 0.5 seconds, the value on ten place of Minute will

be increased 1. During blinking, repress the Clock button, signal will be constantly displayed and it denotes the setting succ-

eeded. After powered on, 12:00 is defaulted to display and signal will be displayed. If there is signal be displayed that

denotes the current time value is Clock value, otherwise is Timer value.

Timer On setting: Signal “ON” will blink and display, signal will conceal, the numerical section will become the timer on setting

status. During 5 seconds blink,by pressing + or - button to adjust the time value of numerical section, every press of that button, the value will be increased or decreased 1 minute. Hold pressing + or -button, 2 seconds later, it quickly change, the way

of change is:During the initial 2.5 seconds, ten numbers change in the one place of minute, thenthe one place is constant, ten

numbers change in the tens place of minute at 2.5 seconds speed and carry. During 5s blink, press the Timer button, the timer

setting succeeds. The Timer On has been set up, repress the timer On button, the Timer On will be canceled. Before setting the

Timer, please adjust the Clock to the current actual time.

Press this button, to set up swing angle, which circularly changes as below:

When the guide louver start to swing up and down, if turn off the Swing, the air guide louver will stop at current position.

Pressing X -FAN button in COOL or DRY mode,the icon is displayed and the indoor fan will continue operation for 10 minutes in

order to dry the indoor unit even you have turned off the unit.After energization, X-FAN OFF is defaulted. X-FAN is not available

in AUTO,FAN or HEAT mode.

Aut o

Low speed

Medium speed

High speed

(The function is not for the models mentioned in the manual.)

(The function is not for the models mentioned in the manual.)

16

Function and Control

ƾ

●

●

●

●

●

When replacing the batteries, do not use old or different types of batteries,otheerwise,

If the remote controller will not be used for a long time, please

it may cause malfunction.

remove batteries

to prevent batteries from leaking.

The operation should be performed in its receiving range.

It should be kept 1m away from the TV set or stereo sound sets.

If the remote controller does not operate normally, please take the

batteries out

and replace them after 30 seconds.If still not operating properly,

Notes:

replace the batteries.

Sketch map for

replacing batteries

18

19

SLEEP:

LIGHT:

16

17

Press this button, Sleep On and Sleep Off can be selected. After Sleep function set up, the unit will automatically select

the suitable operation mode to maintain the most comfortable temperature for you. This function is available in COOL ,

HEAT or DRY mode

TURBO:

15

Press this button to activate / deactivate the Turbo function which enables the unit to reach the preset temperature in

shortest time. Such as in COOL mode, the unit will blow strong cooling air at super high fan speed. In HEAT mode, the

unit will blow strong heating air at super high fan speed.

(This function is not applicable for some models)

Press this button to select LIGHT on or off in the displayer. When the LIGHT on is set,the icon will be displayed and

the indicator light in the displayer will be on. When the LIGHT off is set, the icon will be displayed and the indicator

light in thedisplayer will be off.

"+" and "–"button about lock:

Press "+ " and "-" buttons simultaneously to lock or unlock the keypad. If the remote controller is locked, is displayed .

In this case, pressing any button , blinks three times.

"MODE" and " - " buttons About switch between fahrenheit and celsius:

At unit OFF, press "MODE" and " - " buttons simultaneously to switch between ℉ and ℃.

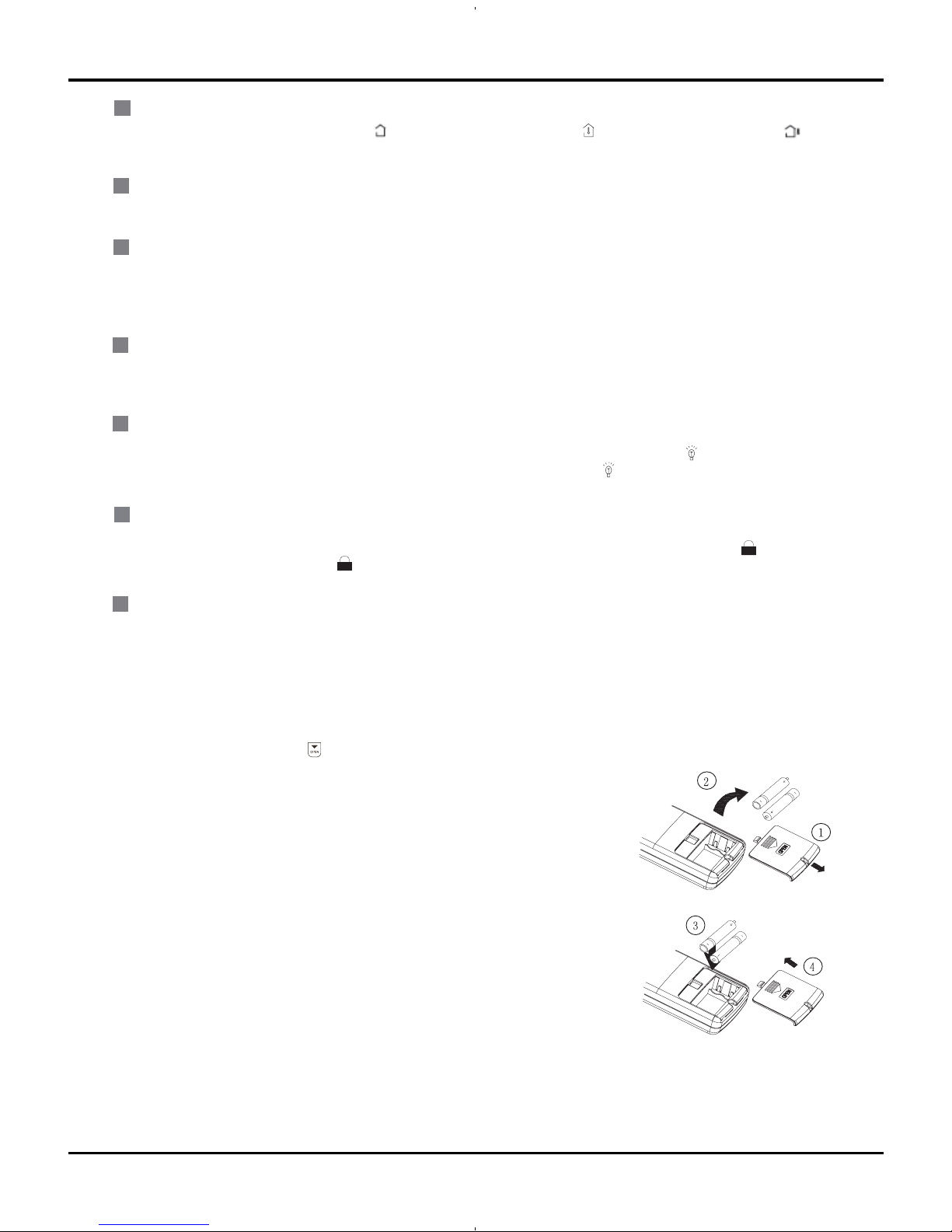

1.Slightly to press the place with , along the arrowhead direction to push the back

cover of wireless remote control. (As show in figure)

2. Take out the old batteries. (As show in figure)

3. Insert two new AAA1.5V dry batteries, and pay attention to the polarity.

(As show in figure)

4 .Attach the back cover of wireless remote control. (As show in figure)

TIMER OFF :

14

13

TEMP :

Once press this key to enter into TIMER OFF setup, in which case the TIMER OFF icon will blink.The method of setting

is the same as TIMER ON.

Press this button, could select displaying (the indoor setting temperature) , (indoor ambient temperature )or (

outdoor am-bient temperature) .The unit defaults not to display the icon. During operation of TEMP button, the set temperature is always displayed

6.2 Changing batteries and notices

17

6.3 Description of Each Control Operation

Function and Control

1. Temperature Parameters

Indoor preset temperature (Tpreset)

Indoor ambient temperature (T

amb.)

2. Basic Functions

Once energized, in no case should the compressor be restarted within less than 3 minutes. In the situation that memory function

is available, for the first energization, if the compressor is at stop before de-energization, the compressor will be started without

a 3-minute lag; if the compressor is in operation before de-energization, the compressor will be started with a 3-minute lag; and

once started, the compressor will not be stopped within 6 minutes regardless of changes in room temperature;

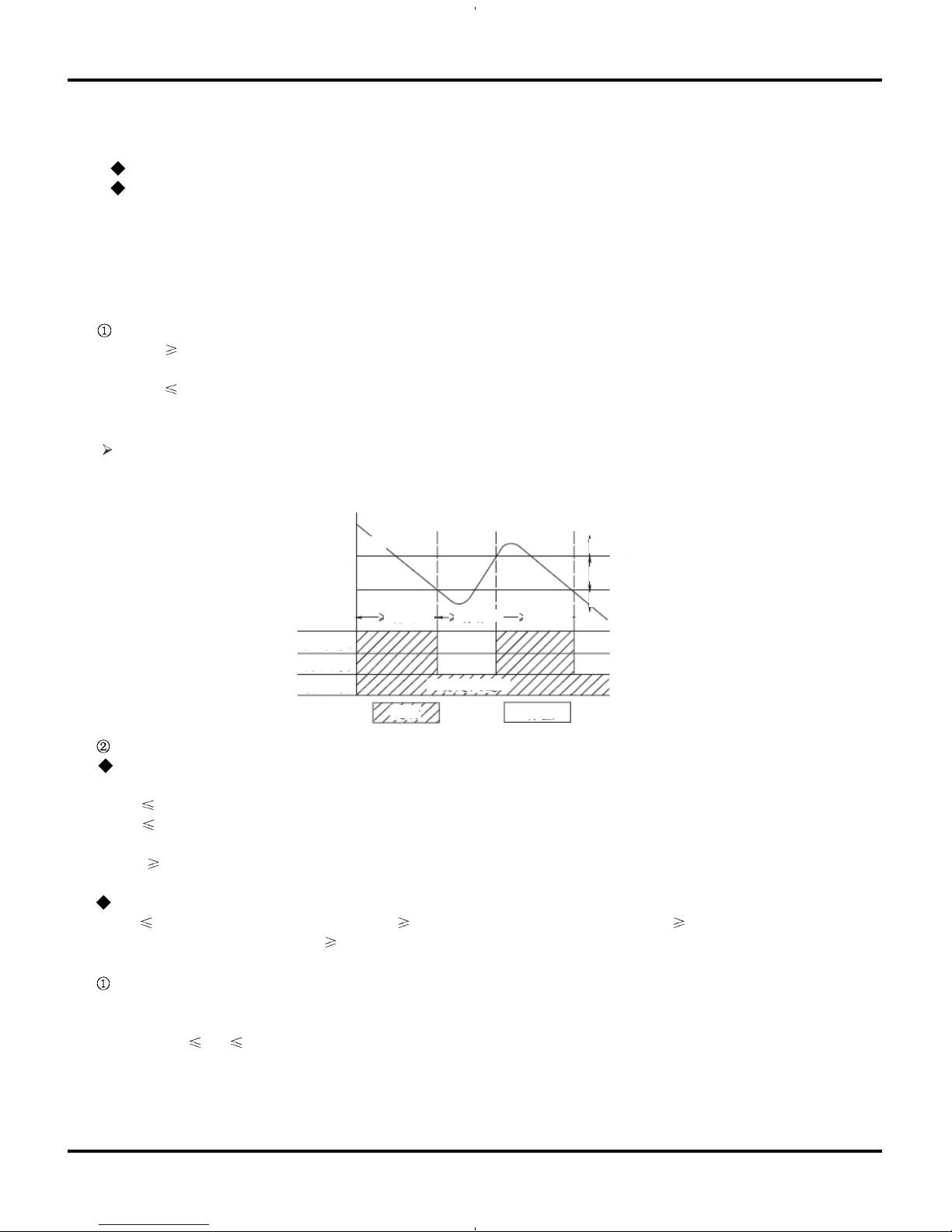

(1) Cooling Mode

Working conditions and process of cooling

When T

amb Tpreset, the unit will enter cooling operation, in which case the indoor fan, the outdoor fan and the compressor will

work and the indoor fan will run at preset speed.

When T

amb Tpreset -28.4 , the compressor will stop, the outdoor fan will stop with a time lag of 30s, and the indoor fan will run

at preset speed.

When T

preset -28.4 < Tamb.< Tpreset +33.8 , the unit will remain at its previous state.

Under this mode, the four-way valve will be de-energized and temperature can be set within a range from 61 to 86

If the compressor is shut down for some reason, the indoor fan and the swing device will operate at original state.

Start cooling

Stop cooling

Compressor

Original working state

Run

Stop

Outdoor fan

Indoor fan

T

preset

T

reset

28.4

T

amb

Preset fan speed

6 minutes

6 minutes

3 minutes

Protection

Antifreeze protection

Under cooling and dehumidifying mode, 6 minutes after the compressor is started:

If T

evap 35.6 , the compressor will operate at reduced frequency.

If T

evap 30.2 is detected for durative 3 minutes, the compressor will stop, and after 30 seconds, the outdoor fan will stop;

and under cooling mode, the indoor fan and the swing motor will remain at the original state.

If T

evap. 42.8 and the compressor has remained at OFF for at least 3 minutes, the compressor will resume its original

operation state.

Total current up and frequency down protection

If Itotal

A, frequency rise will be allowed; if Itotal B, frequency rise will not be allowed; ifItotal C, the compressor will

run at reduced frequency; and if Itotal

D, the compressor will stop and the outdoor fan will stop with a time lag of 30s.

(2) Dehumidifying Mode

Working conditions and process of dehumidifying

If T

amb>Tpreset, the unit will enter cooling and dehumidifying mode, in which case the compressor and the outdoor fan will

operate and the indoor fan will run at low speed.

If T

preset 28.4 Tamb Tpreset, the compressor remains at its original operation state.

If T

amb.< Tpreset 28.4 , the compressor will stop, the outdoor fan will stop with a time lag of 30s, and the indoor fan will

operate at low speed.

ºF

ºF

ºF

ºF

ºF

ºF

ºF

ºF

ºF

ºF

18

Loading...

Loading...