Gree GWH09RA-K3DNA1A, GWH12RB-K3DNA1A Service Manual

GREE ELECTRIC APPLIANCES,INC.OF ZHUHAI

Service Manual

MODEL: GWH09RA-K3DNA1A

GWH12RB-K3DNA1A

(Refrigerant R410A)

Table of Contents

Summary and features..................................................................................1

Part 1 Safety Precautions

..........................................................................................2

Part 2 Specifications.....................................................................................................3

2.1 Unit Specifications..................................................................................................3

2.3 CapacityVariation Ratio AccordingtoTemperature.................................................5

2.2 Operation Characteristic Curve..............................................................................5

2.4 Operation Data.......................................................................................................6

2.5 Noise criteria curve tables for both models............................................................6

Part 3 Construction Views

........................................................................................7

3.1 Indoor Unit .............................................................................................................7

3.2 Outdoor Unit ..........................................................................................................7

Part 4 Refrigerant System Diagram

.....................................................................9

5.1 Electrical Data......................................................................................................10

5.2 Electrical Wiring....................................................................................................10

5.3 Printed Circuit Board............................................................................................12

Part 5 Schematic Diagram

......................................................................................10

6.1 Remote Control Operations..................................................................................

15

6.2 Changing Batteries and Notices ..........................................................................

19

6.3 Description of Each Control Operation.................................................................20

Part 6 Function and Control

...................................................................................15

Part 7 Installation Manual

........................................................................................25

7.2 Installation Drawing..............................................................................................27

7.6 Installation and Maintenance of Healthy Filter......................................................31

7.3 Install Indoor Unit.................................................................................................28

7.4 Install Outdoor Unit ..............................................................................................29

7.5 Check After Installation and Test Operation.........................................................30

7.1 Notices for Installation...........................................................................................25

Table of Contents

Part 8 Exploded Views and Parts List

..............................................................32

Part 9 Troubleshooting

...............................................................................................38

9.1

Malfunction Analysis

.............................................................................................38

9.2 ................................................................................................42

9.3

How to Simply Check the Main Part

....................................................................45

8.1 Indoor unit.............................................................................................................32

8.2 Outdoor unit..........................................................................................................34

Part10 Removal Procedure

.......................................................................................55

10.1

Removal Procedure of Indoor Unit

.....................................................................55

10.2

Removal Procedure of Outdoor Unit

...................................................................60

Malfunction Code

1

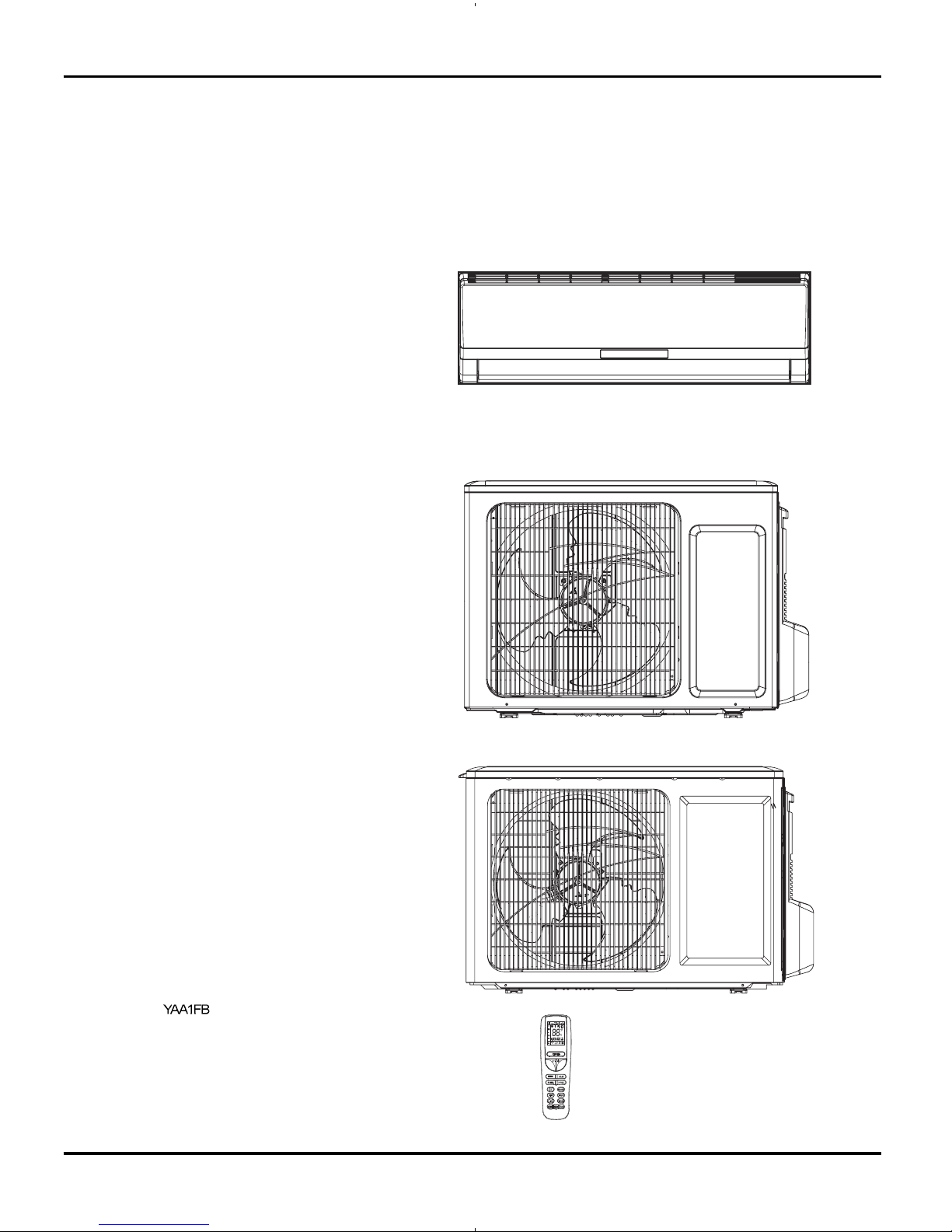

Summary and features

Indoor Unit

Outdoor Unit

Remote control

Summary and features

GWH09RA-K3DNA1A/I

GWH12RB-K3DNA1A/I

GWH12RB-K3DNA1A/O

GWH09RA-K3DNA1A/O

2

Safety Precautions

1.Safety Precautions

Caution

Warning

Warning

Caution

could result in

personal injury

or death.

Incorrect handling

result in

injury, or damage to product

or property.

Incorrect handling

may

minor

Recognize the following safety information:

Installing, starting up, and servicing air conditioner can be

hazardous due to system pressure, electrical components, and

equipment location, etc.

Only trained, qualified installers and service personnel are

allowed to install, start-up, and service this equipment.

Untrained personnel can perform basic maintenance functions

such as cleaning coils. All other operations should be

performed by trained service personnel.

When handling the equipment, observe precautions in the

manual and on tags, stickers, and labels attached to the

equipment. Follow all safety codes. Wear safety glasses and

work gloves. Keep quenching cloth and fire extinguisher nearby

when brazing.

Read the instructions thoroughly and follow all warnings or

cautions in literature and attached to the unit. Consult local

building codes and current editions of national as well as local

electrical codes.

All electric work must be performed by a licensed technician

according to local regulations and the instructions given in this

manual.

Never supply power to the unit unless all wiring and tubing

are completed, reconnected and checked.

This system adopts highly dangerous electrical voltage.

Incorrect connection or inadequate grounding can cause

personal injury or death. Stick to the wiring diagram and all

the instructions when wiring.

Have the unit adequately grounded in accordance with

local electrical codes.

Have all wiring connected tightly. Loose connection may

lead to overheating and a possible fire hazard.

All installation or repair work shall be performed by your dealer

or a specialized subcontractor as there is the risk of fire, electric

shock, explosion or injury.

Make sure the ceiling/wall is strong enough to bear the

weight of the unit.

Make sure the noise of the outdoor unit does not disturb

neighbors.

Properly insulate any tubing running inside the room to

prevent the water from damaging the wall.

Make sure the outdoor unit is installed on a stable, level

surface with no accumulation of snow, leaves, or trash

beside.

Follow all the installation instructions to minimize the risk

of damage from earthquakes, typhoons or strong winds.

Avoid contact between refrigerant and fire as it generates

poisonous gas.

Apply specified refrigerant only. Never have it mixed with

any other refrigerant. Never have air remain in the

refrigerant line as it may lead to rupture and other hazards.

Make sure no refrigerant gas is leaking out when

installation is completed.

Should there be refrigerant leakage, the density of

refrigerant in the air shall in no way exceed its limited

value , or it may lead to explosion .

Before installing, modifying, or servicing system, main

electrical disconnect switch must be in the OFF position.

There may be more than 1 disconnect switch. Lock out and

tag switch with a suitable warning label.

Keep your fingers and clothing away from any moving

parts.

Clear the site after installation. Make sure no foreign

objects are left in the unit.

Always ensure effective grounding for the unit.

Never install the unit in a place where a combustible gas

might leak, or it may lead to fire or explosion.

Make a proper provision against noise when the unit is

installed at a telecommunication center or hospital.

Provide an electric leak breaker when it is installed in a

watery place.

Never wash the unit with water.

Handle unit transportation with care. The unit should not be

carried by only one person if it is more than 20kg.

Never touch the heat exchanger fins with bare hands.

Never touch the compressor or refrigerant piping without

wearing glove.

Do not have the unit operate without air filter.

Should any emergency occur, stop the unit and disconnect

the power immediately.

3

Specifications

2.Specifications

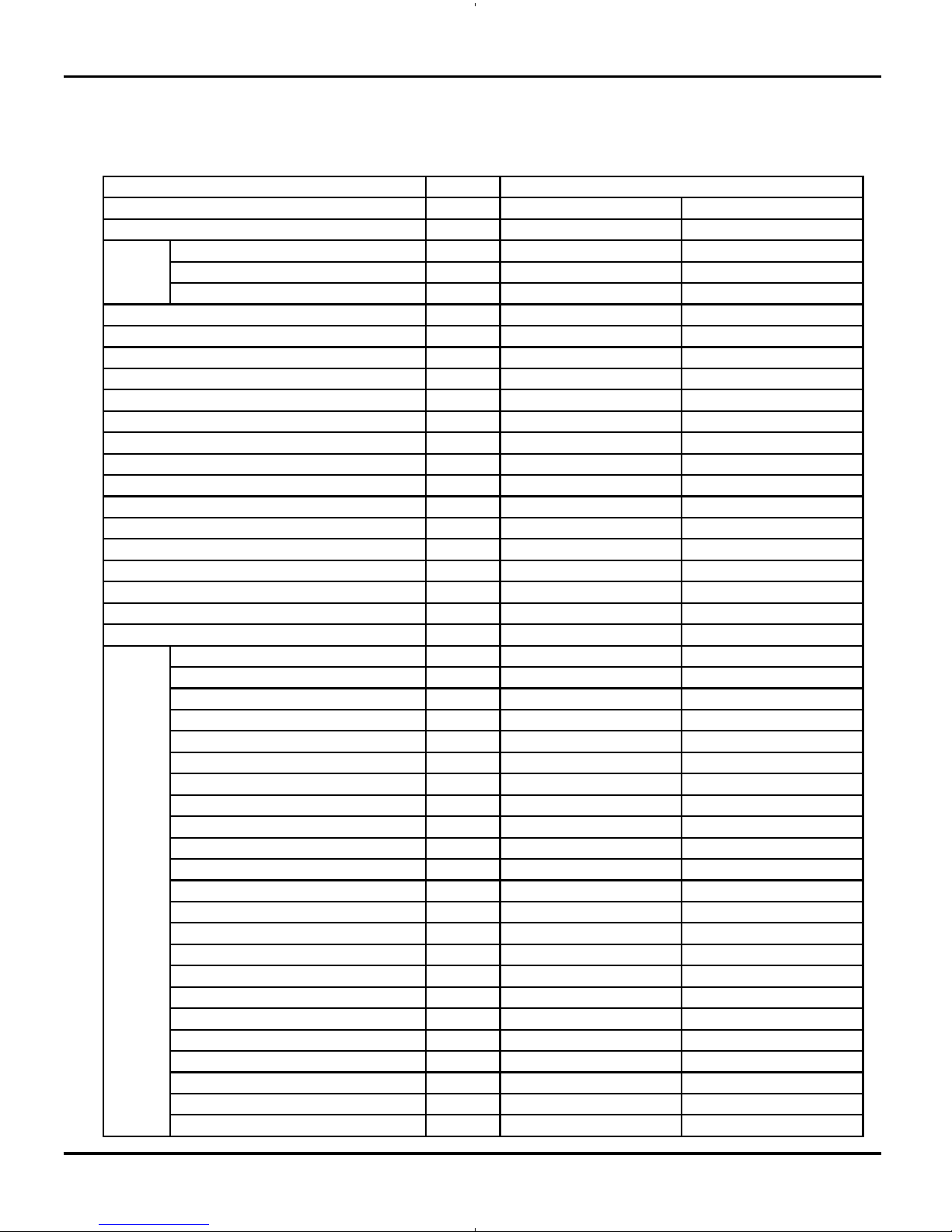

2.1 Unit Specifications

Unit

GWH09RA-K3DNA1A GWH12RB-K3DNA1A

CB14400020 CB14400030

Rated Voltage

V

220-240 220-240

Rated Frequency Hz 50 50

Phases 1 1

Indoor Indoor

W

2500(5003200) 3500(9504000)

W

2750(8003500) 3750(8804300)

W 623 (280-1200)

960(3501250)

W 669 (310-1350)

1010(3401360)

A 2.72 4.50

A 2.91 4.60

W 1350 1300

A 5.88 6.00

m

3

/h

600/500/400/300/- 600/500/400/300/-

L/h 0.8 1.4

W/W 4.01 3.64

W/W 4.11 3.71

W/W / /

W/W / /

m

2

12-18 16-24

Model of indoor unit GWH09RA-K3DNA1A/I GWH12RB-K3DNA1A/I

Fan Type Cross-flow Cross-flow

Diameter Length(DXL) mm ĭ92X645 ĭ92X645

Fan Motor Cooling Speed (SH/H/M/L/SL) r/min 1260/1070/900/730/- 1290/1070/900/690/-

Fan Motor Heating Speed (SH/H/M/L/SL) r/min 1280/1050/980/920/- 1280/1050/980/920/-

Output of Fan Motor W 20 20

Fan Motor RLA A 0.10 0.10

Fan Motor Capacitor ȝF1.0 1.0

Input of Heater W / /

Evaporator Form Aluminum Fin-copper Tube Aluminum Fin-copper Tube

Pipe Diameter mm ĭ7 ĭ7

Row-fin Gap mm 2-1.4 2-1.4

Coil Length (LXDXW) mm 690X24.8X266.7 690X24.8X266.7

Swing Motor Model MP24AA MP24AA

Output of Swing Motor W 2 2

Fuse A 3.15 3.15

Sound Pressure Level (SH/H/M/L/SL) dB (A) 41/38/35/32/- 42/39/36/33/-

Sound Power Level (SH/H/M/L/SL) dB (A) 51/48/45/42/- 52/49/46/43/-

Dimension (WXHXD) mm 845X275X180 845X275X180

Dimension of Carton Box (L/W /H) mm 923X264X356 923X264X356

Dimension of Package (L/W/H) mm 926X267X371 926X267X371

Net Weight kg 10 10

Gross Weight kg 13 13

Application Area

Indoor

Unit

EER

COP

SEER

HSPF

Rated Input

Rated Current

Air Flow Volume(SH/H/M/L/SL)

Dehumidifying Volume

Cooling Power Input (MinMax)

Heating Power Input (MinMax)

Cooling Power Current

Heating Power Current

Power

Supply

Power Supply Mode

Cooling Capacity (MinMax)

Heating Capacity (MinMax)

ValueParameter

Model

Product Code

4

Specifications

The above data is subject to change without notice. Please refer to the nameplate of the unit.

Model of Outdoor Unit GWH09RA-K3DNA1A/O GWH12RB-K3DNA1A/O

Compressor Manufacturer/Trademark

ZHUHAI LANDA

COMPRESSOR

CO.,LTD./GREE

PANASONIC W ANBAO

COMPERSSOR

(GUANGZHOU)

CO.LTD/PANASONIC

Compressor Model QXA-A086zC190 5RS102ZJA21

Compressor Oil FVC68D FV50S

Compressor Type Rotary Rotary

L.R.A. A 25.00 25.00

Compressor RLA A 12.00 4.47

Compressor Power Input W 940 985

Overload Protector INT11L-6233 1NT11L-5270

Throttling Method Capillary Capillary

Operation temp ºC

1630 1630

Ambient temp (cooling) ºC

1843 1843

Ambient temp (heating) ºC

-724 -724

Condenser Form Aluminum Fin-copper Tube Aluminum Fin-copper Tube

Pipe Diameter mm ĭ7 ĭ7.94

Rows-fin Gap mm 2-1.4 2-1.4

Coil Length (LXDXW) mm 695X38.1X508 870X38X580

Fan Motor Speed rpm 830 660/900

Output of Fan Motor W 30 30

Fan Motor RLA A 0.30 0.15

Fan Motor Capacitor ȝF/ /

Air Flow Volume of Outdoor Unit

m

3

/h

1600 1800

Fan Type Axial-flow Axial-flow

Fan Diameter mm ĭ400 ĭ400

Defrosting Method Automatic Defrosting Automatic Defrosting

Climate Type T1 T1

Isolation I I

Moisture Protection IP24 IP24

Permissible Excessive Operating Pressure

for the Discharge Side

MPa 3.8 3.8

Permissible Excessive Operating Pressure

for the Suction Side

MPa 1.2 1.2

Sound Pressure Level (H/M/L) dB (A) 50/-/- 52/-/-

Sound Power Level (H/M/L) dB (A) 60/-/- 62/-/-

Dimension (WXHXD) mm 776X540X320 848X540X320

Dimension of Carton Box (L/W /H) mm 848X360X580 878X360X580

Dimension of Package (L/W/H) mm 851X363X595 881X363X595

Net Weight kg 29 36

Gross Weight kg 33 39

Refrigerant R410A R410A

Refrigerant Charge kg 0.9 1.12

Length m 5 5

Gas Additional Charge g/m 30 50

Outer Diameter Liquid Pipe mm ĭ6 ĭ6

Outer Diameter Gas Pipe mm ĭ9.52 ĭ9.52

Max Distance Height m 10 10

Max Distance Length m 15 20

Outdoor

Unit

Connecti

on Pipe

5

Specifications

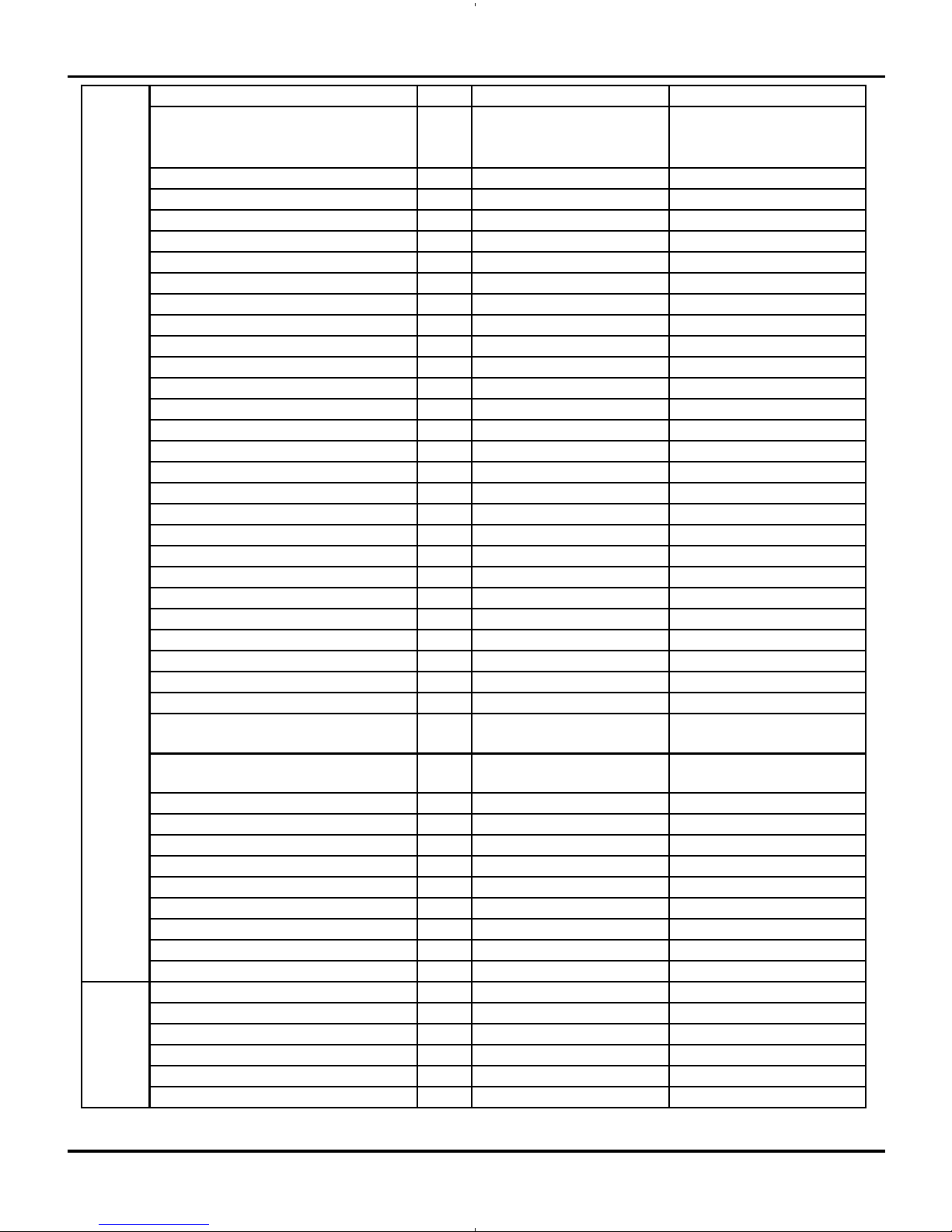

2.2 Operation Characteristic Curve

0

1

2

3

4

5

6

7

8

9

10

0 20 40 60 80 100 120

Condition

Indoor:DB 27

WB19

Indoor air flow: Turbo

Pipe length:5m

Voltage:230V

Compressor Speed(rps)

0

1

2

3

4

5

6

7

8

0 20 40 60 80 100 120

Condition

Indoor:DB 20

Indoor air flow:Turbo

Pipe length:5m

Voltage:230V

Compressor Speed(rps)

Cooling

Heating

Current(A)

Current(A)

2.3 Capacity Variation Ratio According to Temperature

50

60

70

80

90

100

110

32 33 34 35 36 37 38 39 40 41 42 43 44 45 46

Capacity ratio(%)

Condition

Indoor:DB27℃ WB19℃

Indoor air flow:

Turbo

Pipe length:5m

Outdoor temp. (°C)

0

20

40

60

80

100

120

-15 -10 -5 0 5 10

Capacity ratio(%)

Condition

Indoor:DB20℃

Indoor air flow:

Turbo

Pipe length:5m

Outdoor temp. (°C)

gnitaeHgnilooC

09K

12K

09K

12K

6

Specifications

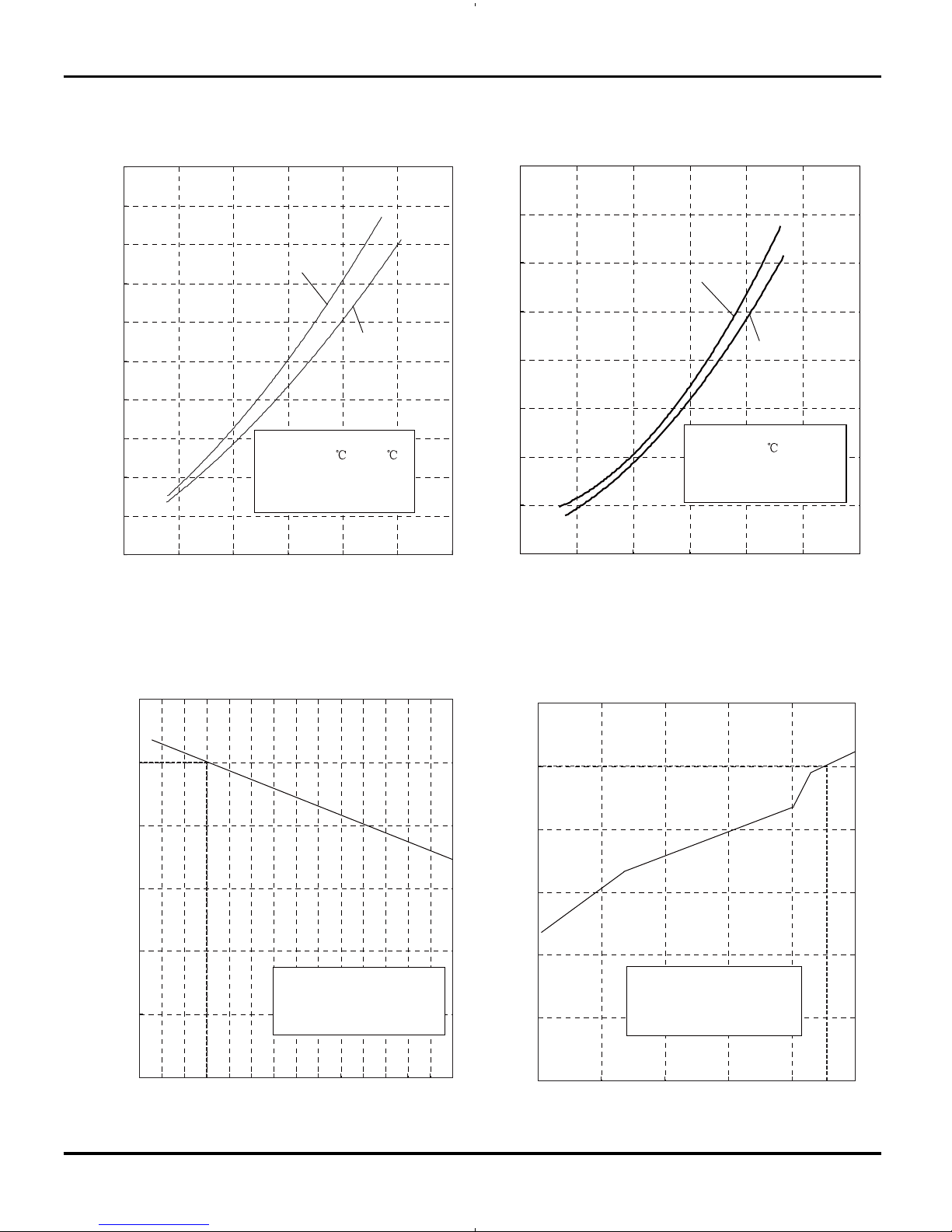

2.4 Operation Data

Cooling

Heating

NOTES :

(1)

(2) Measure surface temperature of heat exchanger pipe around center of heat exchanger path U bent.

(Thermistor themometer)

(3) Connecting piping condition : 5 m

Standard

pressure

Indoor Outdoor P (MPa) T1 (°C) T2 (°C)

09K Turbo 830 54

12K Turbo 900 60

Outdo or fan

mode

Compressor

revolution

(rps )

Temperature condition

(°C)

Model

name

Heat exchanger pipe temp.

Indoor fan

mode

in:75~85

out:37~43

35/2427/19 0.85~1.0

in:8~11

out:11~14

Standard

pressure

Indoor Outdoor P (MPa) T1 (°C) T2 (°C)

09K Turbo 830 62

12K Turbo 900 66

in:1~3

out:2~5

7/620/- 2.5~3.0

in:75~85

out:37~43

Outdoor fan

mode

Compressor

revolution

(rps )

Temperature condition

(°C)

Model

name

Heat exchanger pipe temp.

Indoor fan

mode

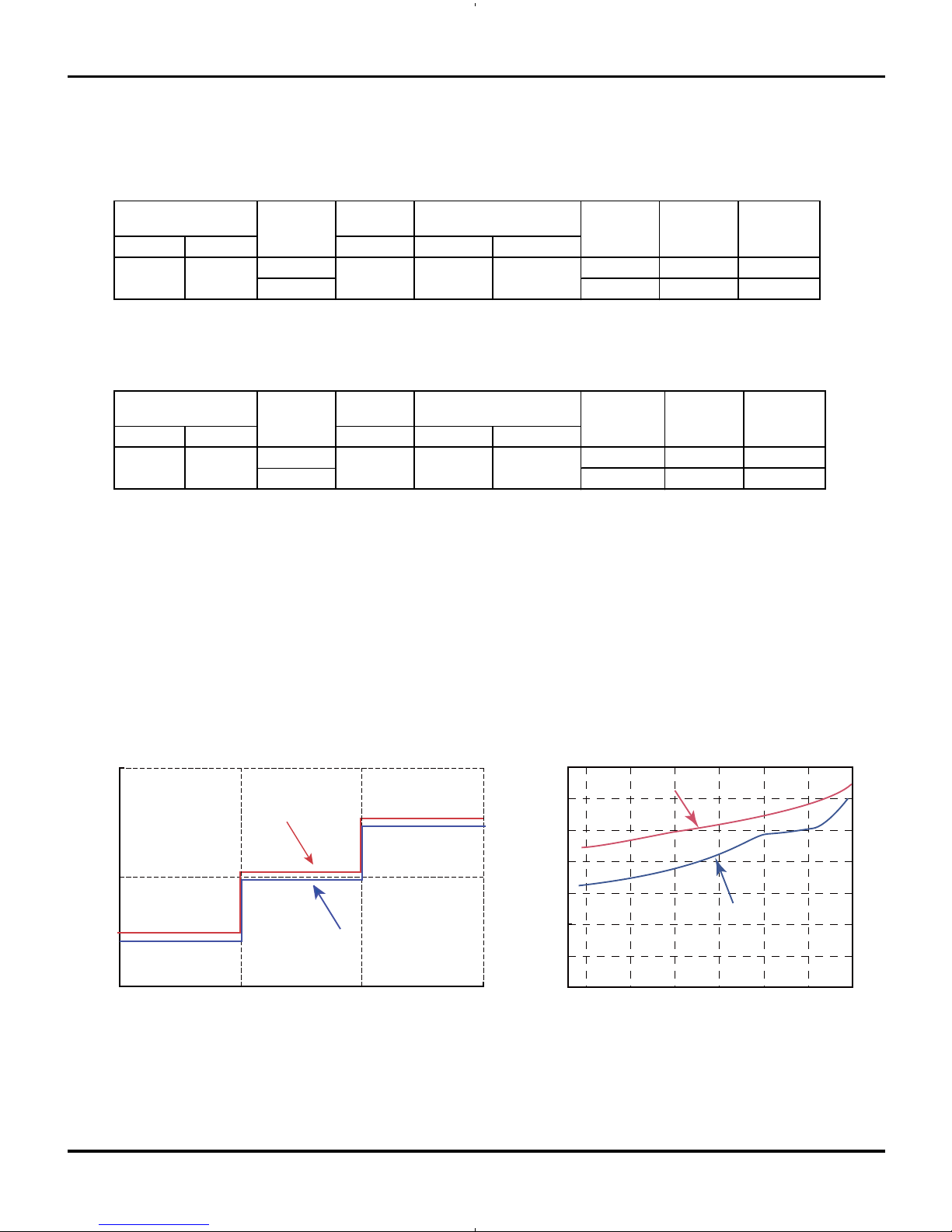

2.5 Noise Criteria Curve Tables for Both Models

40

30

20

Indoor side noise when blowing

Indoor fan motor rotating speed

Low Middle High

12K

40

42

44

46

48

50

52

54

20 4030 50 60 70 80

Compressor frequency(Hz)

Noise dB(A)

Noise dB(A)

Heating

Cooling

09K

T1: Inlet and outlet pipes temperatures of evaporator; T2: Inlet and outlet pipes temperatures of

condenser; P: Pressure of gas pipe which connects indoor unit to outdoor unit (on the gas

valve side).

7

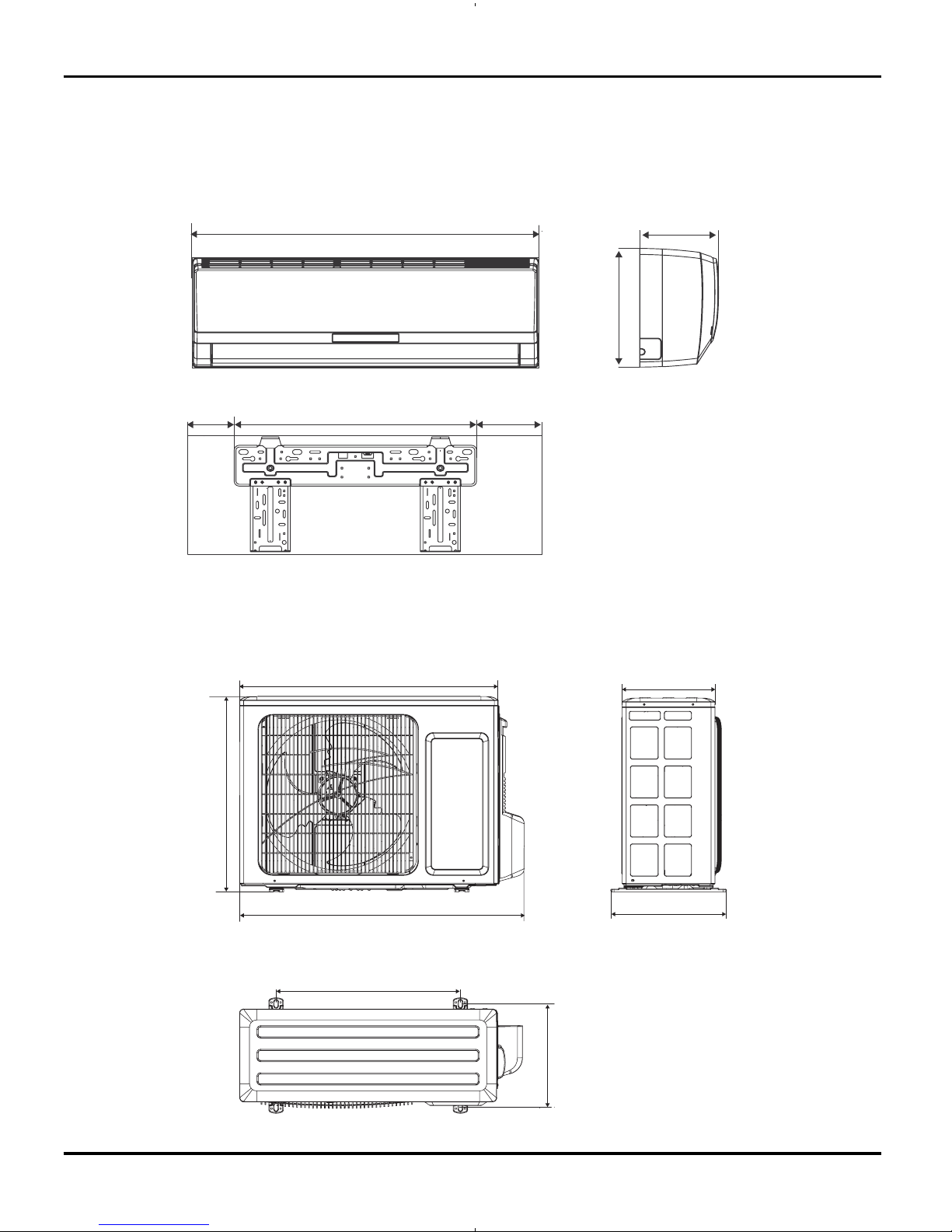

Constrction views

3. Construction Views

3.1 Indoor Unit

Unit:mm

845

130

542

173

180

275

3.2 Outdoor Unit

257

320

776

540

712

510

286

09K Unit

8

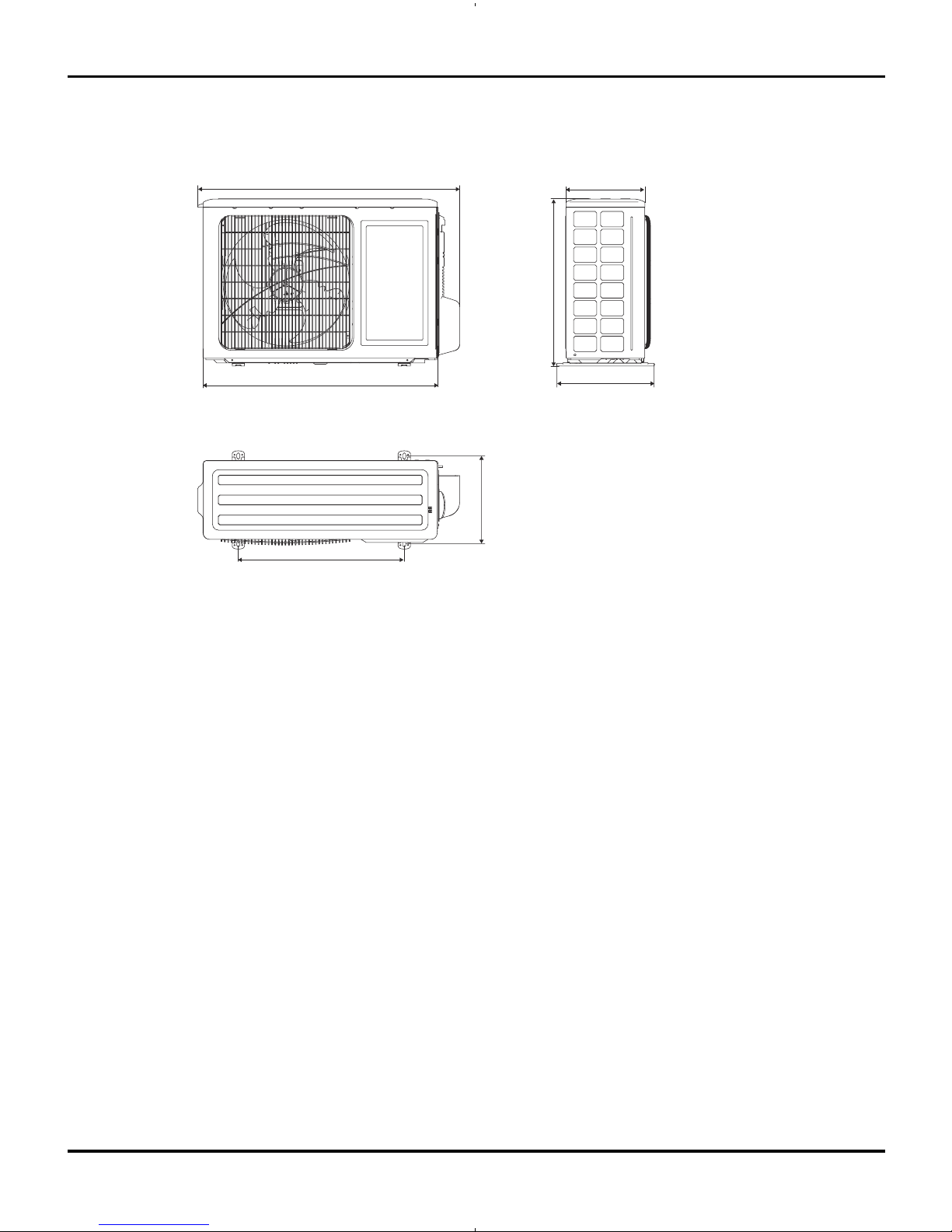

Constrction views

848

540

320

763

257

540

286

12K Unit

Unit:mm

9

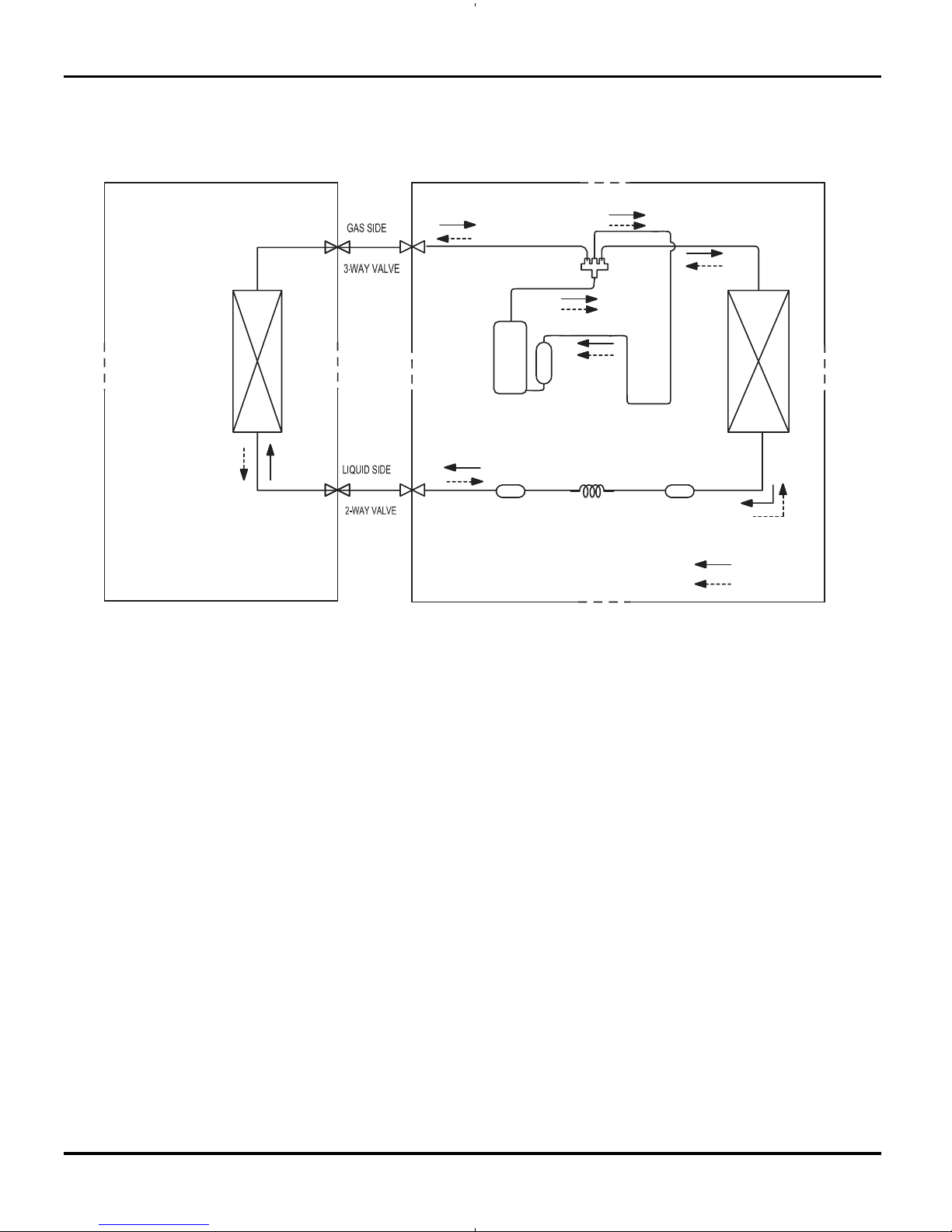

Refrigerant System Diagram

4. Refrigerant System Diagram

Refrigerant pipe diameter

Liquid : 1/4" (6 mm)

Gas : 3/8" (9.52mm)

TINU ROODTUOTINU ROODNI

HEAT

EXCHANGER

(EVAPORATOR)

COOLING

HEATING

HEAT

EXCHANGER

(EVAPORATOR)

Strainer

Strainer

Capillary/EEV

Accumlator

Compressor

4-Way valve

10

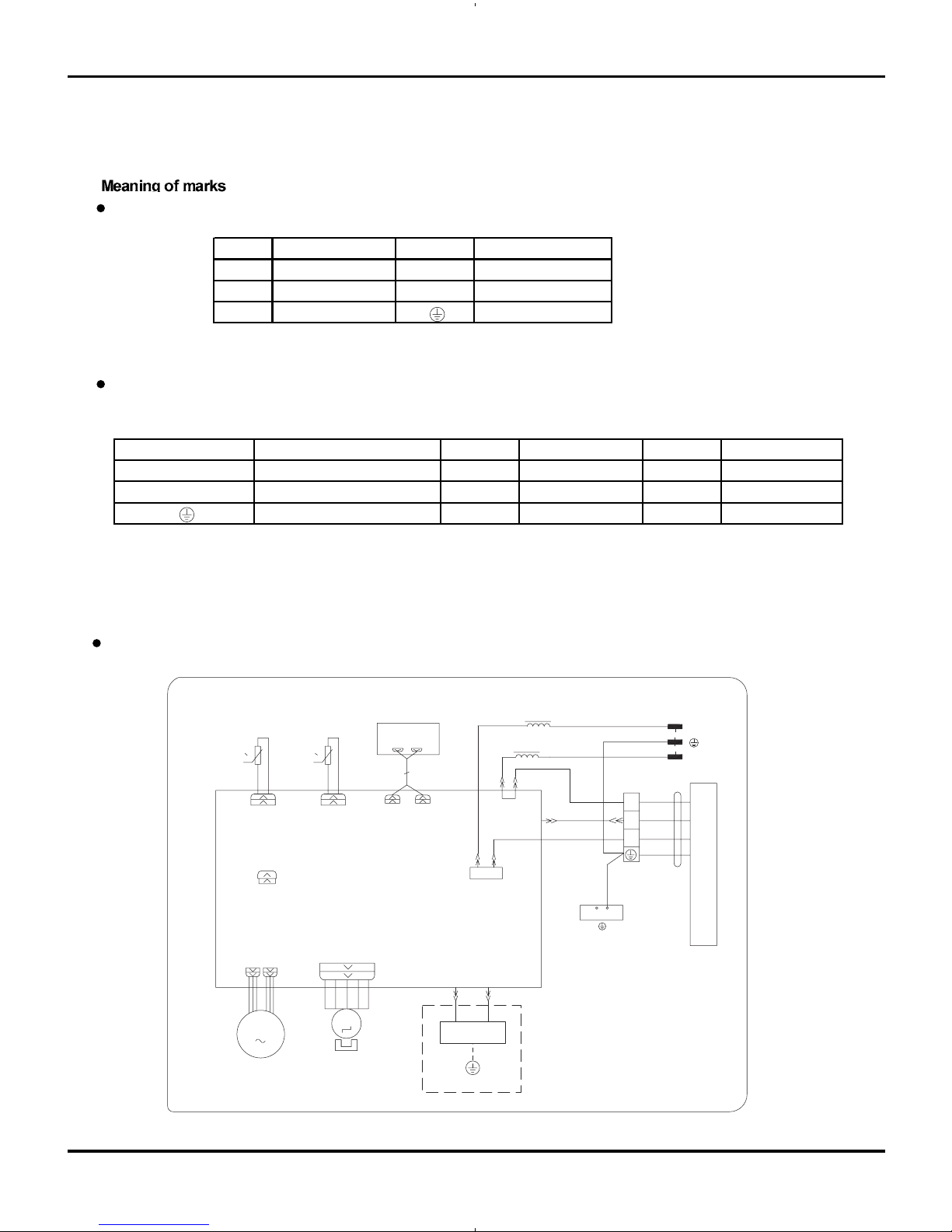

Schematic Diagram

5. Schematic Diagram

5.1 Electrical Data

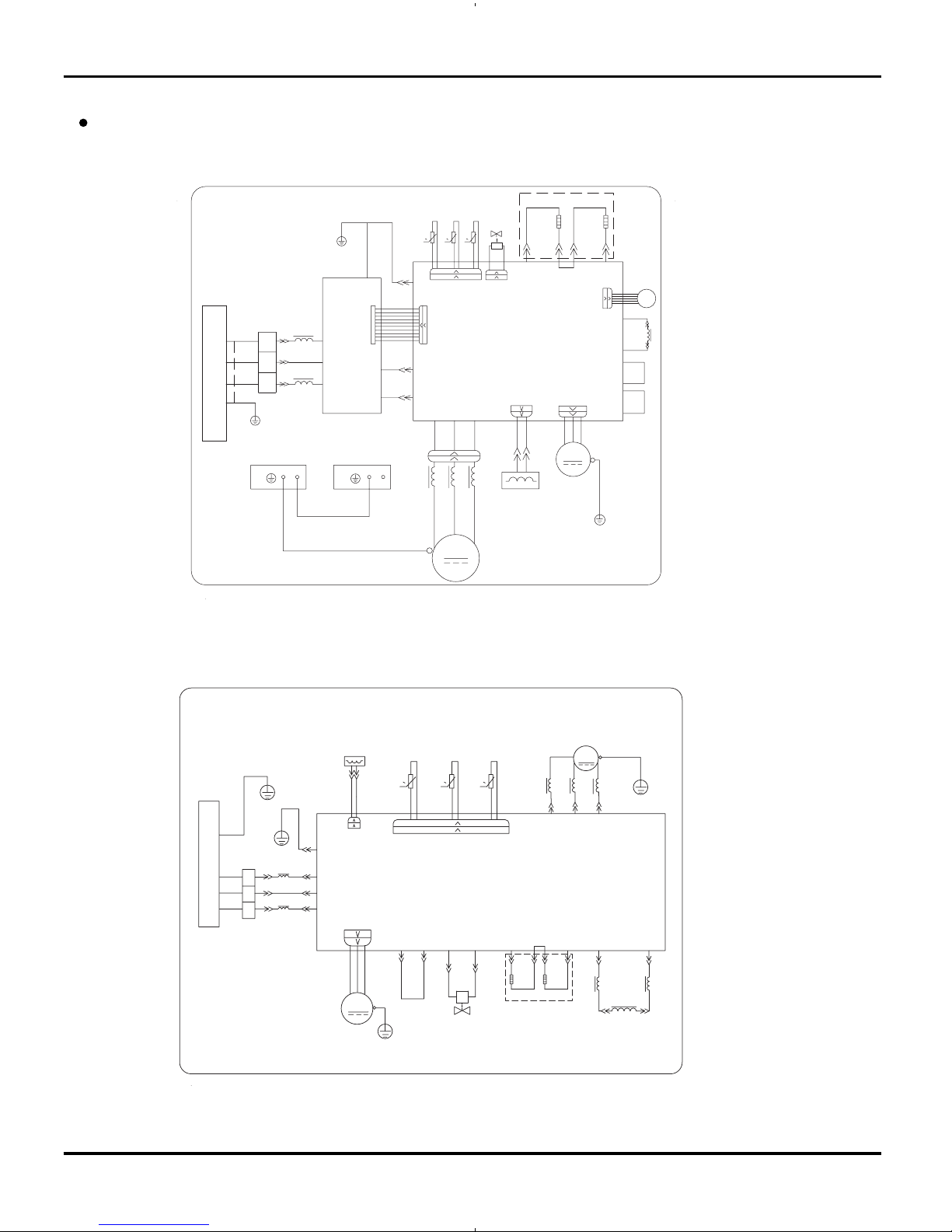

5.2 Electrical wiring

Outdoor Unit

Indoor Unit

Indoor Unit

L-OUT

L1

L1

00

RT1

RT2

M

JUMP

CAP

TEM.SENSOR

ROOM

TUBE

TEM.SENSOR

FAN MOTOR

SWING MOTOR(U.D)

AP2

SWING-UD

K4

TUBEROOM

AC-L

PG

PGF

DISP-1 DISP-2

CN2

CN1

AP1

DISPLAY

13

GENERATOR

COOL PLASMA

M

PE

XT1

W1BU

W3BN

N(1)

OUTDOOR UNIT

2

3

COM-OUT

W4YEGN

N

W2BK

BU

YEGN

BN

L

N

POWER

RD BU

YEGN

HEALTH-NHEALTH-L

PE

EVAPORATOR

Symbol Color symbol Symbol Color symbol

BN

BROWN

BU

BLUE

RD

RED

BK

BLACK

YEGN

YELLOW GREEN PROTECTIVE EARTH

Symbol Parts name Symbol Color symbol Symbol Color symbol

CT 1,2

OVERLOAD

YE

YELLOW

YEGN

YELLOW GREEN

COMP

COMPRESSOR

RD

RED

BU

BLUE

PROTECTIVE EARTH

BN

BROWN

BK

BLACK

11

Schematic Diagram

These circuit diagrams are subject to change without notice. Please refer to the one supplied with the unit.

Outdoor Unit

N(1)

XT

3

2

N

AC-L

PE

0

RT1

0

RT2

RT3

0

N1

AC-L1

L

COMP

PE

PE PE

YEGN

4YV

AP1

AP2

W1

W3

W5

W6

W9

W8

W11

W12

W13

W14 W15

W16

W17 W18

W19

W20

L1

L2

R

S

C

E

W23

CT1,2

COM-OUT

L1

W2

EKV

PE

PE

CN1

W7

YEGN

YEGN

YEGN

YEGN

YEGN

BU

BU

BU

BU

BU

BU

BN

BN

BN

BN

BK

BK

RD

RD

RD

YE

YE

I

N

D

O

O

R

U

N

I

T

COMP

TUBE

TEM.SENSOR

TEM.SENSOR

OUTROOM

EXHAUST

TEM.SENSOR

FAN

ELECTRIC BOX

MID.ISOLATION SHEET

L2 L2

RD

RD

HEATER

(COMP)

HEAT-N1

BN

W21

BU

W10

HEAT-L

HEAT-N2

(CHASSIS)

HEATER

LX1-1

LX1-2

AC-L2

AC-L3

AC-N1

AC-N2

CN1

OFAN

OVC-COMP

CN3

CN2

4V

E

AC-N

AC-L

UVW

M

EH1 EH2

09K Unit

12K Unit

YV4

0

RT3

RT2

0

RT1

0

TUBE

TEM.SENSOR

TEM.SENSOR

EXHUAST

OUTROOM

TEM.SENSOR

OG:ORANGE

BN:BROWN

BU:BLUE

BK:BLACK RD:RED

YE:YELLOW

WH:WHITE

YEGN:YELLOW GREEN

HEATER

(CHASSIS)(COMP)

HEATER

RD

RD

COMP

M

EH2EH1

YEGN

BU

PE

PE

W3

E

COMU

AC-L1

N1

OVC-COMP

XT1

N(1)

2

3

L1

W2

W4

W1

L1

CT1,2

W12

RD

CN2

W9

BU

N3

N2

COMP

YEGN

E

U

W

V

L2 L2L2

W7

W6

W5

PE

W8

COMP-W

COMP-V

COMP-U

BU

RD

AP1

AC-L2

4V

OFAN1

PE

FAN

BK

BN

BU

BK

BN

YEGN

YE

T

I

N

U

R

O

O

D

N

I

L

L3L3

WH

OG

W10

W11

LX-1LX-2

HEAT-LHEAT-N1 HEAT-N2

12

Schematic Diagram

TOP VIEW

BOTTOM VIEW

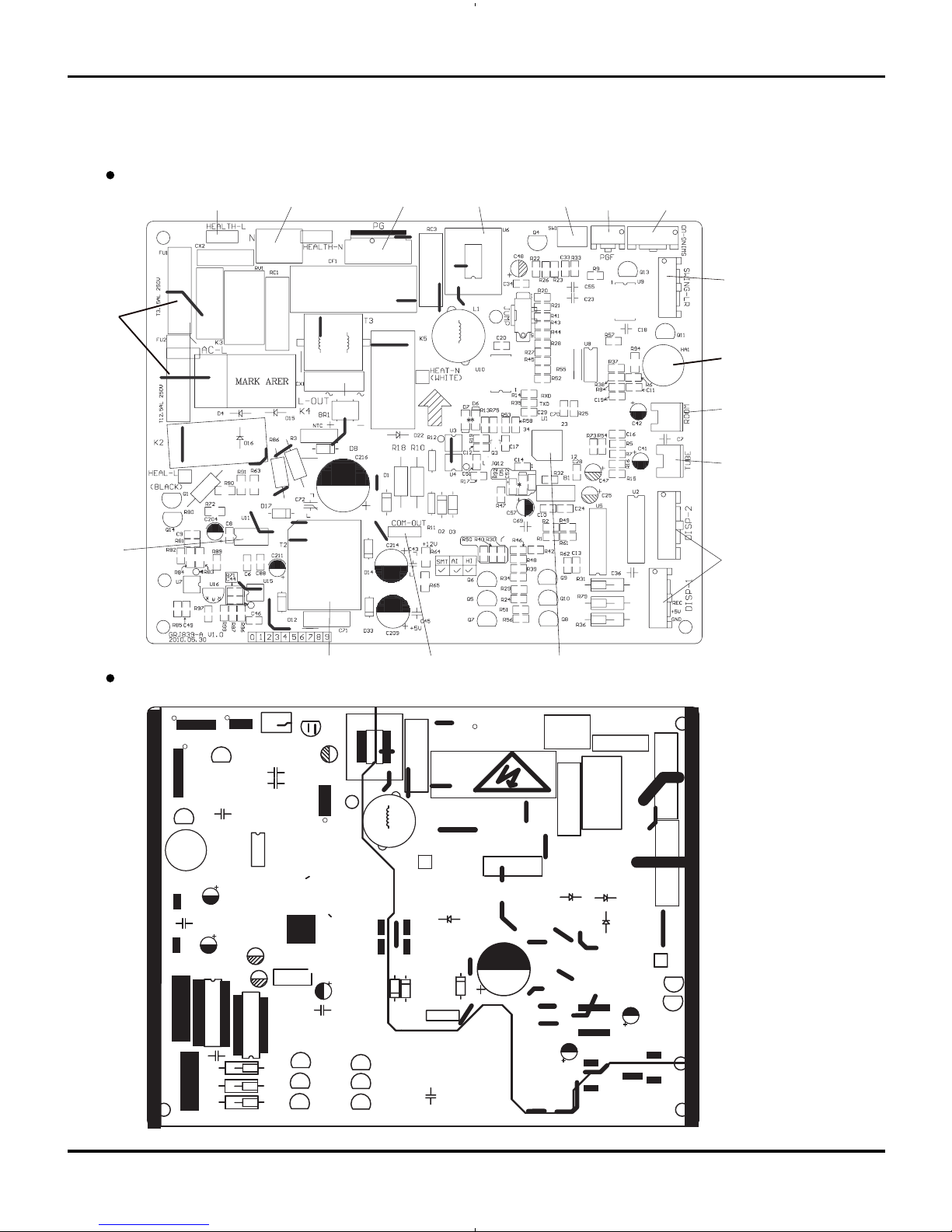

5.3 Printed Circuit Board

(1) Indoor unit

Live wire of health function

Port of neutral wire

Port of indoor fan

Solid-state relay

Auto button

Feedback of indoor fan

Port of motor for vertical swing

Port of motor for horizontal swing

Buzzer

Port of indoor ambient temp sensor

Port of indoor pipe temp sensor

Port of display

Main chip

Communication port

High-frequency transformer

Power of switch

Protective tube

13

Schematic Diagram

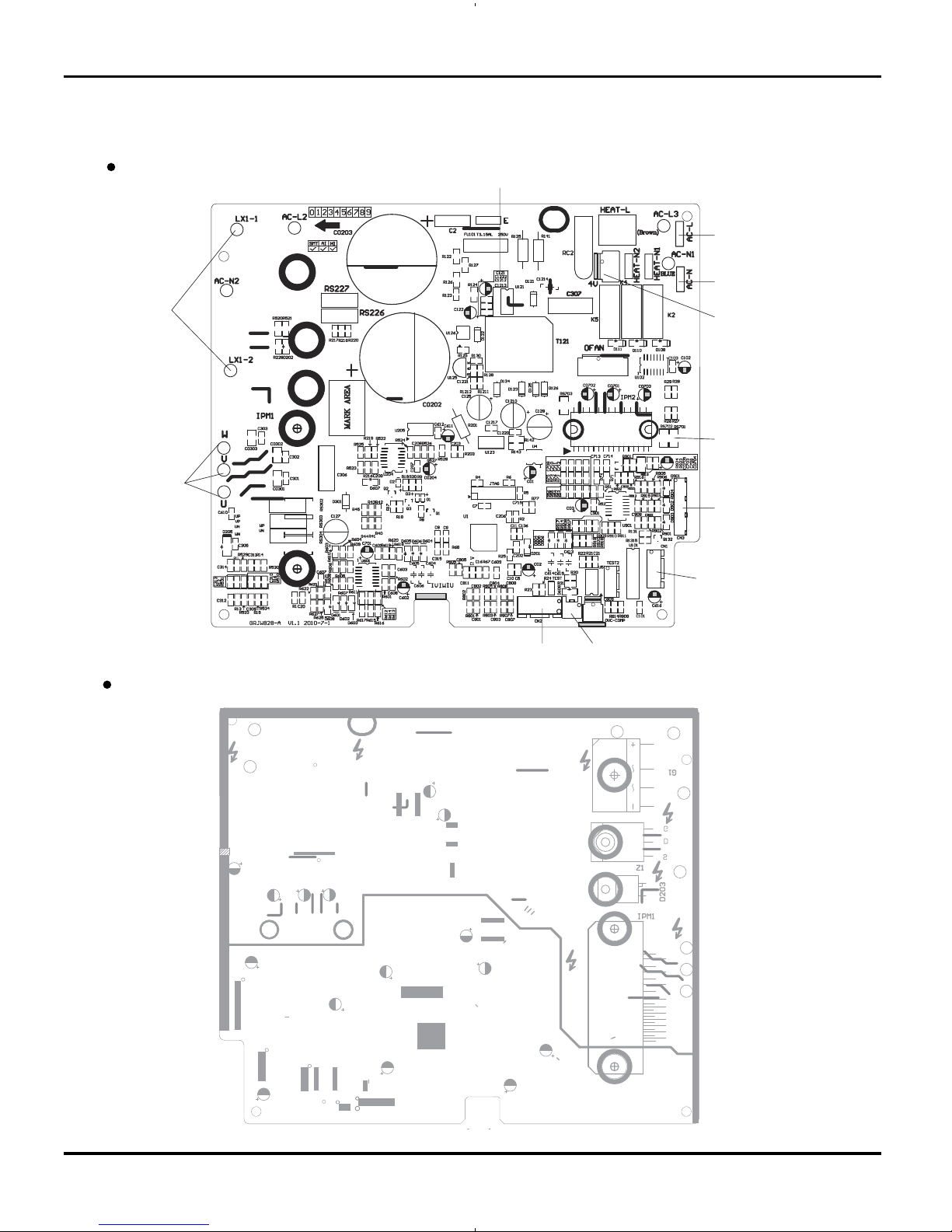

TOP VIEW

BOTTOM VIEW

(2) Outndoor unit

09K Unit

Power of switch

Neutral wire

Live wire

4-way valve

Port of fan

Communication port

Electronic expansion valve

OverloadTemp sensor

Port of compressor

Terminal of reactor

14

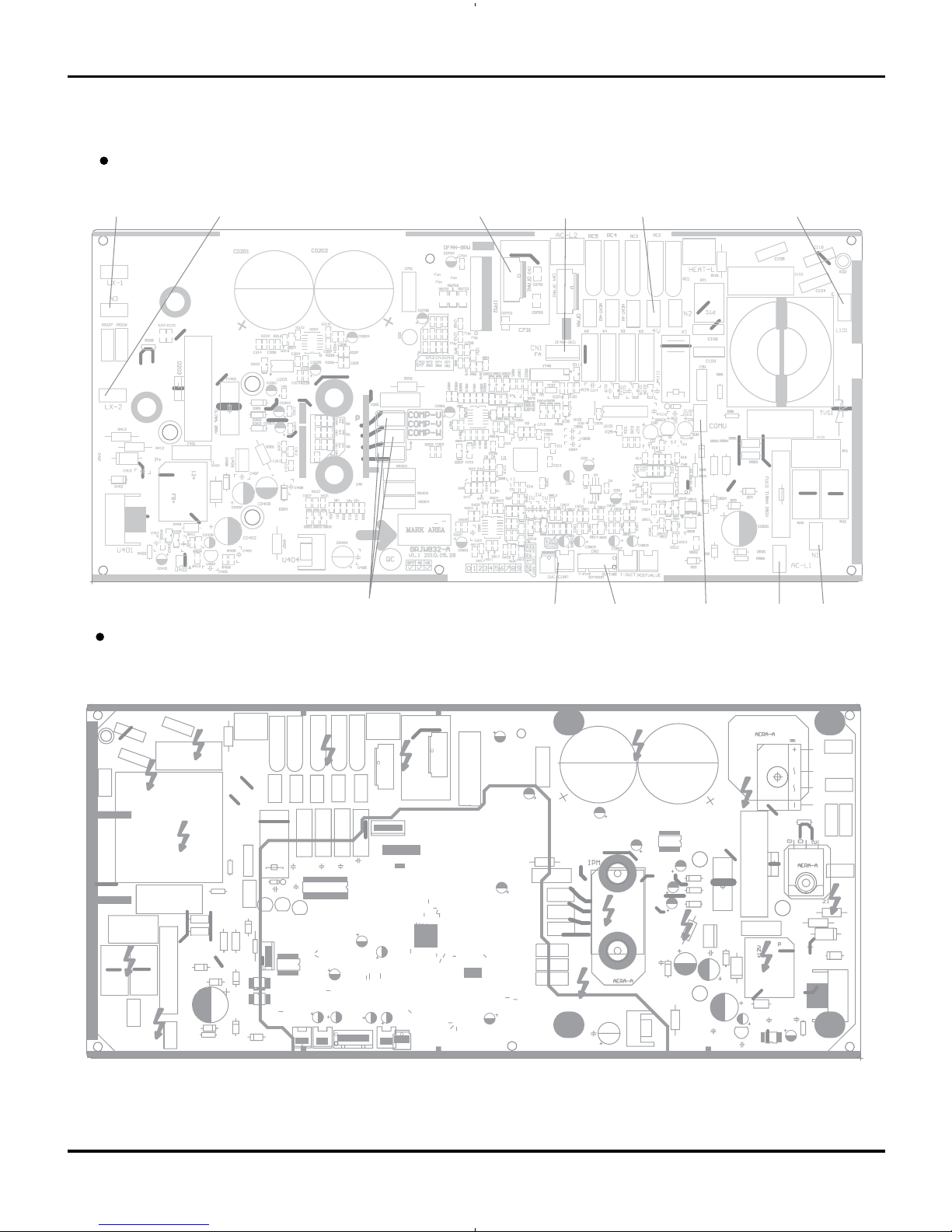

Schematic Diagram

TOP VIEW

BOTTOM VIEW

12K Unit

Port 1 of reactor

Port 2 of reactor

Outdoor fan

Electronic expansion valve

4-way valve

Ground wire

Neutral wireLive wire

Communication port

to indoor unit

Temp sensor

Overload protector

of compressor

Port of compressor

15

Function and Control

6. Function and Control

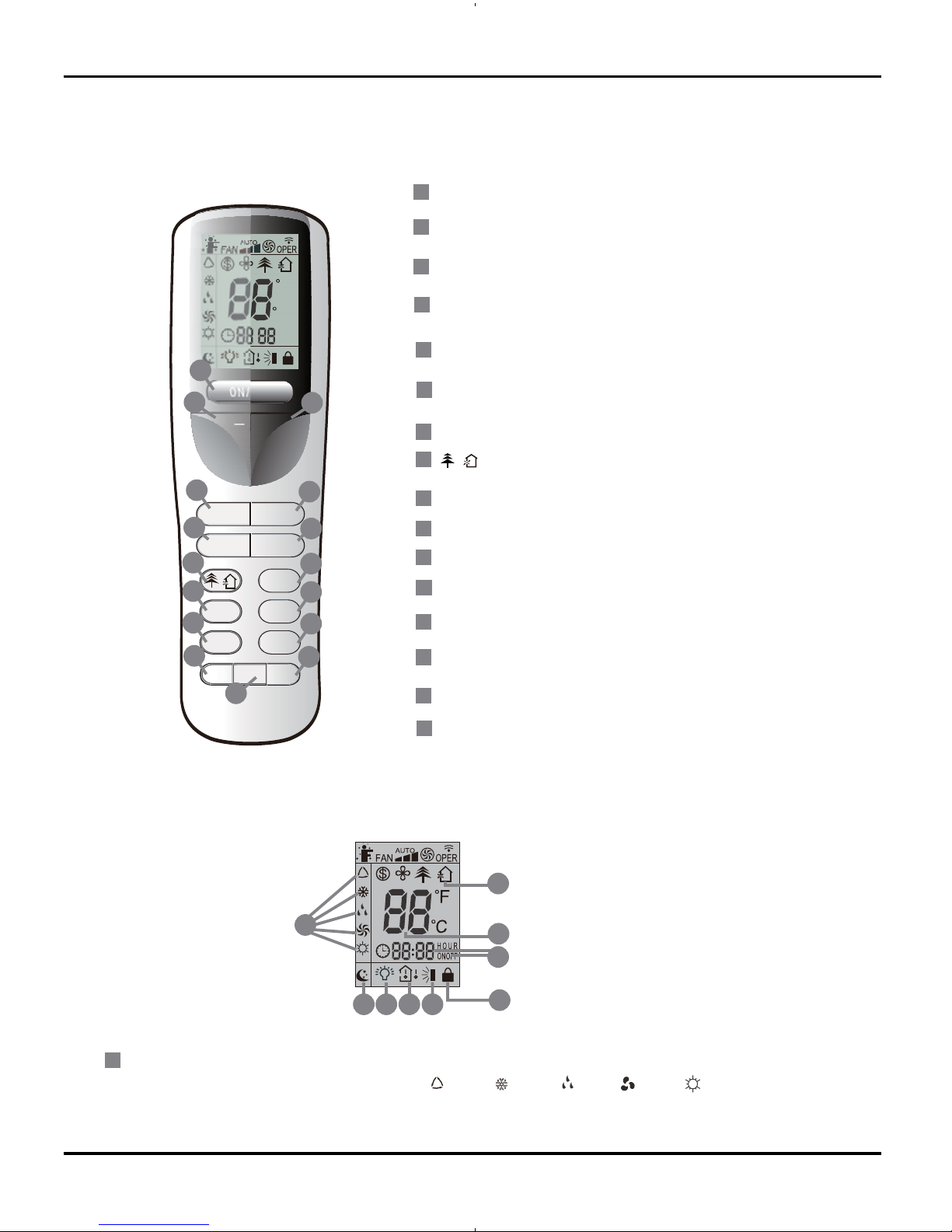

6.1 Remote Controller Description

ON OFF/

-+

MODE FAN

SWING I F E E L

SLEEP

TEMP

TIMER-ON

CLOCK

T -OFFIMER

TURBO LIGHT

/

X-FAN

F

C

:

HOUR

ONOFF

1

7

8

/

4

3

2

5

6

11

13

12

16

10

14

9

15

3

15

5

4

14

7

16

13

12

9

8

11

10

2

1

6

17

22

23

25

24

18 19 20 21

MODE icon:

17

If MODE button is pressed,current operation mode icon (AUTO), (COOL), (DRY), (FAN) or (HEAT only for heat

pump models) will show.

ON/OFF Button

Set point Temperature DOWN Button

Set point Temperature UP Button

MODE Button

FAN Speed Button

SWING Button;

I FEEL Button

Sleep Mode Button

Temperature Display Button

TIMER ON Button

Clock Button

TIMER OFF Button

TURBO Button

Light Mode Button

X-FAN Button

16

Function and Control

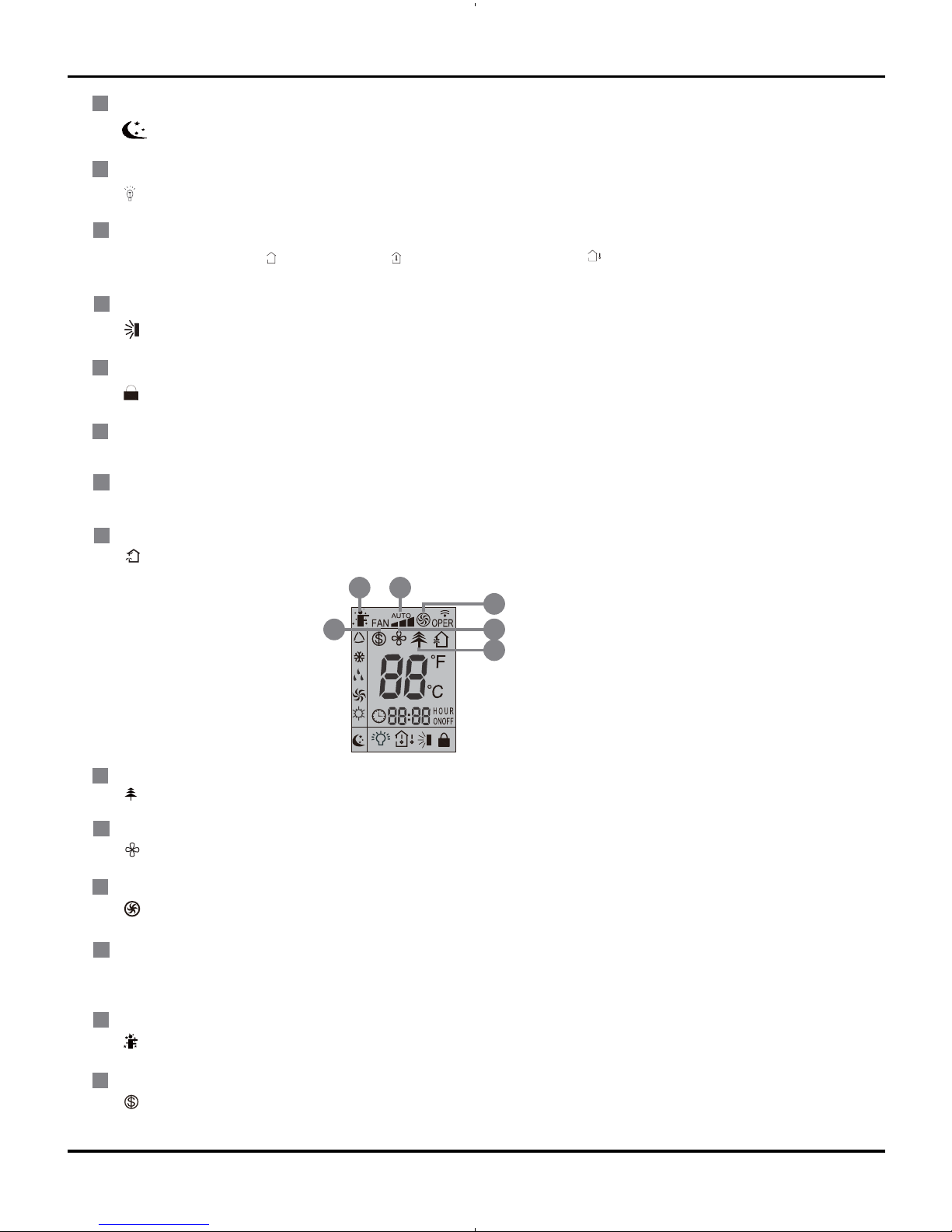

SLEEP icon :

18

is displayed by pressing the SLEEP button. Press this button again to clear the display.

LIGHT icon:

19

is displayed by pressing the LIGHT button. Press LIGHT button again to clear the display.

TEMP icon:

20

Pressing TEMP button, (set temperature), (intdoor ambient temperature), (outdoor ambient temperature) and blank

is displayed circularly.

21

Up & down swing icon:

is displayed when pressing theup & down swing down button.Press this button again to clear the display.

LOCK icon:

22

is displayed by pressing "+"and “-” buttons simultaneously. Press them again to clear the display.

SET TIME display:

23

After pressing TIMER button, HOURON or OFF will blink.This area will showthesettime.

DIGITAL display:

24

This area will show the set tempe-rature. In SAVE mode,"SE" will be displayed.

is displayed when pressing the AIR button.Press this button again to clear the display.

AIR icon:

25

2930

26

2731

28

HEALTH icon:

26

is displayed when pressing the HEALTH button.Press this button again to clear the display.

X-FAN icon:

27

is displayed when pressing the X-FAN button. Press this button again to clear the display.

TURBO icon:

28

is displayed when pressing the TURBO button.Press this button again to clear the display.

FAN SPEED display:

29

Press FAN button to select the desired fan speed setting(AUTO-Low-Med-High).Your selection will be displayed in the LCD

windows,except the AUTO fan speed.

I FEEL icon:

30

is displayed when pressing the I FEEL button.Press this button again to clear the display.

8ćHeating icon:

31

is displayed when Pressing “TEMP” and “CLOCK” simulta-neously in Heat mode.

17

Function and Control

Press this button toachieve the on and off of healthy and scavenging functionsin operation status. Press this button

for the firs ttime to start scavenging function; LCD displays“ ”. Press the button for the second time to start healthy

and scavenging functions simultaneously; LCD displays“ ” and“ ” . Press this button for the third time to quit

healthy and scavenging functions simultaneously. Press the button for the fourth time to start healthy function; LCD

display“ ”.Press this button again to repeat the operation above.

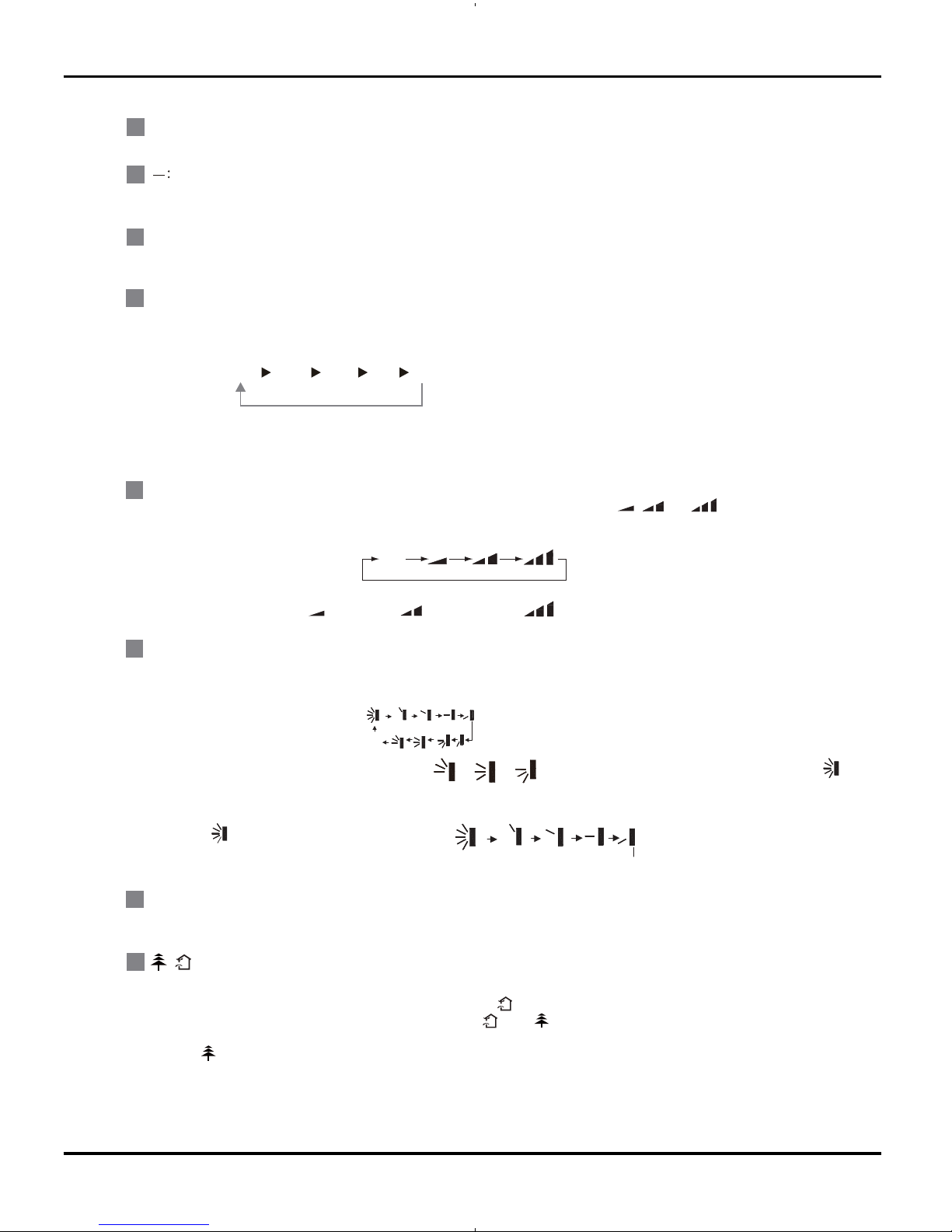

6

Press this button to set up &down swing angle, which circularly changes as below

:

OFF

This remote controller is universal . If any command , or is sent out,the unit will carry out the command as

indicates the guide louver swings as:

/

8

Press this button to turn on I FEEL function. The unit automatically adjust temperature according to the sensed temperature. Press this button again to cancel IFEEL function.

IFEEL:

SWING:

7

ON/OFF

:

MODE

:

+

:

This button is used for setting Fan Speed in the sequence that goes from AUTO,

to

then back to Auto.

,

,

,

FAN

:

1

4

3

2

5

Press this button to turn on the unit .Press this button again to turn off the unit.

Press this button to decrease set temperature. Holding it down above 2 seconds rapidly decreases set temperature.

In AUTO mode, set temperature is not adjustable.

Press this button to increase set temperature.Holding it down above 2 seconds rapidly increases set temperature.

In AUTO mode, set temperature is not adjustable.

Aut o

Low speed

Medium speed

High speed

Each time you press this button,a mode is selected in a sequence that goes from AUTO, COOL,DRY,FAN,,and

HEAT

*

, as the following:

AUTO

COO L

DRY

FAN H EAT

*

*Note:Only for models with heating function.

After energization, AUTO mode is defaulted. In AUTO mode, the set temperature will not

be displayed on the LCD,

and the unit will automatically select the suitable operation mode in accordance with the room temperature to make

indoor room comfortable.

18

Function and Control

LIGHT:

15

Press LIGHT button to turn on the display's light and press this button again to turn off the display 's light. If the light is turned

on , is displayed. If the light is turned off, disappears.

SLEEP:

9

Press this button to go into the SLEEP operation mode. Press it again to cancel this function. This function is available

in COOL , HEAT (Only for models with heating function) or DRY mode to maintain the most comfortable temperature

for you.

Pressing TEMP button, (set temperature), (indoor ambient temperature) and (outdoor ambient temperatur)

and blank is displayed circularly . The unit defaults not to display the icon. During operation of TEMP button, the set temperature is always displayed.

Note: Outdoor ambient temperature is only displayed for some models.

CLOCK :

12

TIMERO N :

TIMEROFF:

11

13

TURBO:

10

14

TEMP:

Press this button to initiate the auto-ON timer. To cancel the auto-timer program, simply press this button again.

Press CLOCK button, blinking. Within 5 seconds, pressing + or - button adjusts the pressent time. Holding down either

button above 2 seconds increases or decreases the time by 1 minute every 0.5 second and then by 10 minutes every 0.5

second. During blinking after setting, press CLOCK button again to confirm the setting,and then will be constantly displayed.

After press of this button, disappears and "ON "blinks. 00:00 is displayed for ON time setting. Within 5 seconds, press

+ or - button to adjust the time value. Every press of either button changes the time setting by 1 minute. Holding down either

button rapidly changes the time setting by 1 minute and then 10 minutes. Within 5 Seconds after setting, press TIMER ON

button to confirm.

X-FAN:

16

Pressing X-FAN button in COOL or DRY mode,the icon is displayed and the indoor fan will continue operation for 10 minutes in order to dry the indoor unit even though you have turned off the unit.

After energization, X-FAN OFF is defaulted. X-FAN is not available in AUTO,FAN or HEAT mode.

Press this button to activate / deactivate the Turbo function which enables the unit to reach the preset temperature in the

shortest time. In COOL mode, the unit will blow strong cooling air at super high fan speed. In HEAT mode, the unit will blow

strong heating air at super high fan speed.

Press this button to initiate the auto-off timer. To cancel the auto-timer program, simply press the button again.TIMER OFF

setting is the same as TIMER ON.

Press "+ " and "- " buttons simultaneously

to lock or unlock the keypad. If the remote controller is locked,

is

displayed

. In this case, pressing any button, blinks three times.

At unit OFF, press "MODE

"

and

" - "

buttons simultaneously to switch between and .

Combination of "+" and "-" buttons : About lock

17

Combination of "MODE " and "-" buttons :

18

About switch between Fahrenheit and centigrade

Press “TEMP” and “CLOCK” simultaneously in COOL mode to start energy-saving function.

Nixie tube on the remote controller

displays “SE”. Repeat the operation to quit the function.

Combination of " TEMP " and "CLOCK" buttons : About Energy-saving Function

19

19

Function and Control

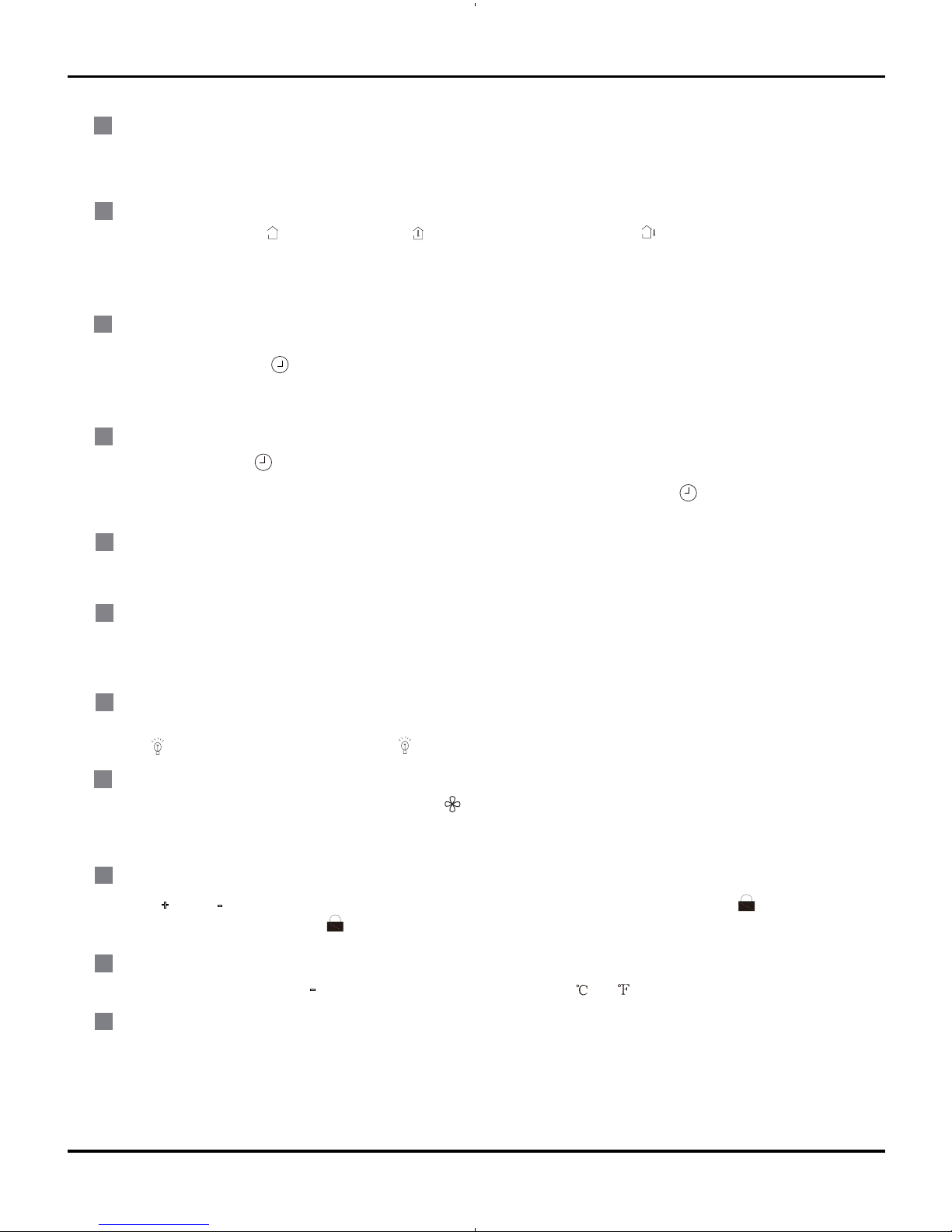

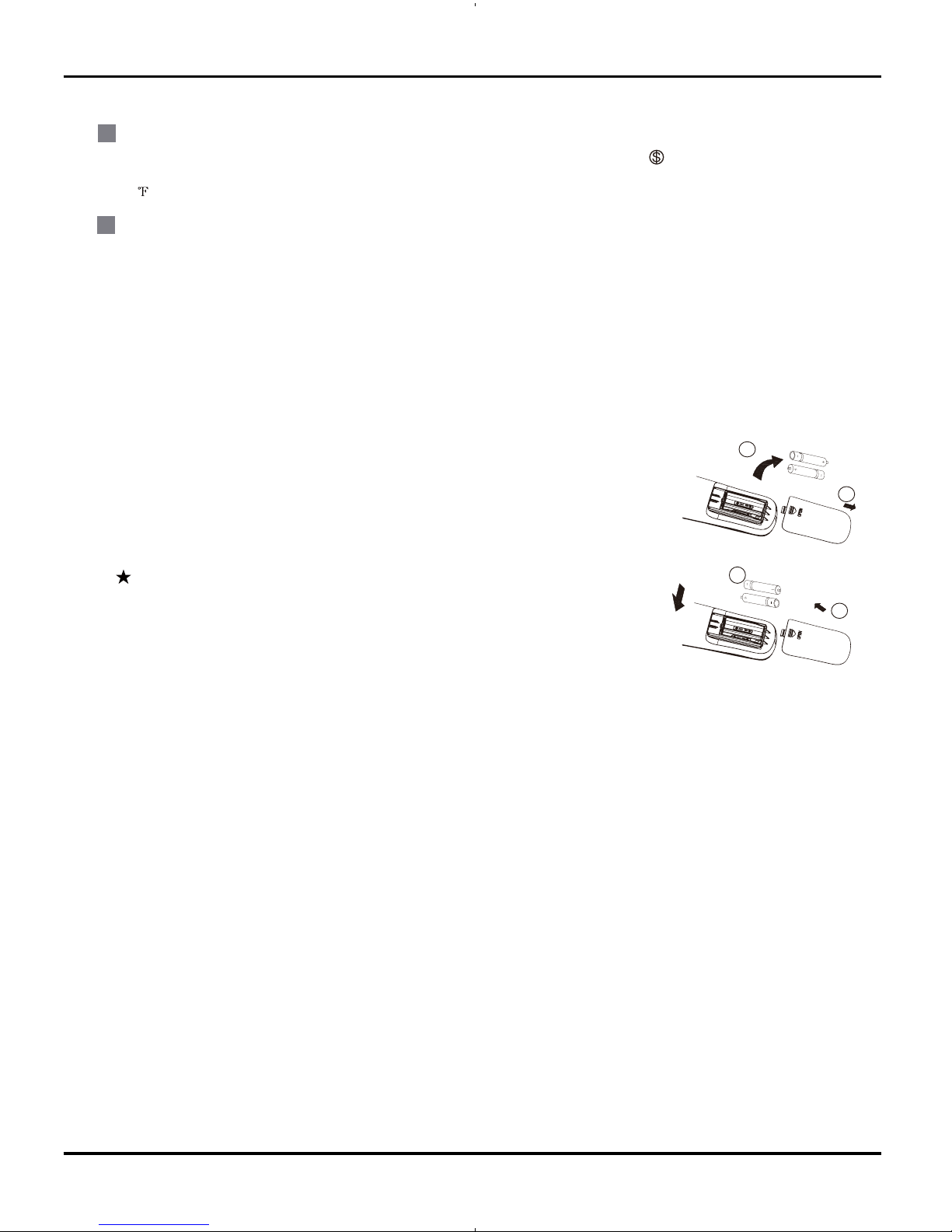

1.Remove the battery cover plate from the rear of the remote controller.

(As shown in the figure)

2.Take out the used batteries.

3.Insert two new AAA1.5V dry batteries, and pay attention to the polarity.

4. Reinstall the battery cover plate.

When replacing the batteries, do not use used or different types of batteries,

If the remote controller will not be used for a long time, please

otherwise, it may cause malfunction.

remove batteries to prevent batteries from leaking.

The operation should be performed in its receiving range.

It should be kept 1m away from the TV set or stereo sound sets.

If the remote controller does not operate normally, please take the

batteries out and reinsert them after 30 seconds.If it still can't operate properly,

Notes:

replace the batteries.

Sketch map for

replacing batteries

About Back-lighting Function

21

in HEAT mode to start

The unit lights for 4s when energizing for the first time, and 3s for later press.

8 Heating Function Nixie tube on the remote controller displays and a selected temperature of

.

“ ”

“8 ”

(46 if Fahrenheit is adopted). Repeat the operation to quit the function.

Combination of " TEMP " and "CLOCK" buttons : About 8 Heating Function Press “TEMP” and “CLOCK” simultaneously

20

℃

℃

℃

1

2

3

4

6.2 Changing batteries and notices

Loading...

Loading...