Gree GUHD18NK3FO, GUHD36NK3FO, GUHD30NK3FO, GUHD24NK3FO, GUHD36NM3FO Service Manual

...

T1/R410A/50Hz

(GC201509 -

І

)

U-MATCH

Ⅳ

SERIES DC INVERTER AIR

CONDITIONERS SERVICE MANUAL

CONTENTS

PRODUCT .......................................................................................................................................................................... 2

1 MODELS LIST .............................................................................................................................................................. 2

1.1 Outdoor Unit .......................................................................................................................................................... 2

1.2 Indoor Unit ............................................................................................................................................................ 3

2 NOMENCLATURE ....................................................................................................................................................... 4

2.1 Outdoor Unit .......................................................................................................................................................... 4

2.2 Intdoor Unit ........................................................................................................................................................... 4

3 PRODUCT DATA .......................................................................................................................................................... 5

3.1 Product Data of Indoor Unit................................................................................................................................... 5

3.2 Operation Range ................................................................................................................................................. 14

3.3 Electrical Data ..................................................................................................................................................... 14

4 PIPING DIAGRAM ...................................................................................................................................................... 15

CONTROL ......................................................................................................................................................................... 18

1 OPERATION FLOWCHART ....................................................................................................................................... 18

1.1 Cooling/Dry Operation ........................................................................................................................................ 18

1.2 Heating Operation ................................................................................................................................ ............... 19

2 WIRELESS REMOTE CONTROLLER ....................................................................................................................... 20

2.1 Operation and Display View ................................................................................................................................ 20

3 WIRED CONTROLLER .............................................................................................................................................. 22

3.1 Display View ....................................................................................................................................................... 22

3.2 Operation View ................................................................................................................................................... 25

4 OPERATION INSTRUCTION OF SPECIAL FUNCTIONS .......................................................................................... 28

4.1 Setting of Filter Clean Reminder Function .......................................................................................................... 28

4.2 Low Temperature Drying Function ...................................................................................................................... 30

4.3 Lock Function...................................................................................................................................................... 30

4.4 Memory Function ................................................................................................................................................ 30

4.5 Door Control Function/Human Sensitive Function .............................................................................................. 30

4.6 Switch between Fahrenheit and Centigrade ....................................................................................................... 30

4.7 Enquiry of Ambient Temperature ........................................................................................................................ 31

4.8 Enquiry of Historical Malfunction ......................................................................................................................... 31

4.9 Debugging Function ................................................................ ............................................................................ 31

5 INSTALLATION OF WIRED CONTROLLER .............................................................................................................. 34

5.1 Standard Accessories ......................................................................................................................................... 34

5.2 Installation Position and Requirement ................................................................................................................. 35

5.3 Installation of Wired Controller ............................................................................................................................ 35

5.4 Removal of Wired Controller ............................................................................................................................... 36

6 TROUBLESHOOTING ............................................................................................................................................... 36

6.1 Display of Error Code .......................................................................................................................................... 36

7 CENTRALIZED CONTROLLER ................................................................................................................................. 38

7.1 Smart Zone Controller ......................................................................................................................................... 38

7.2 Additional Special Functions ............................................................................................................................... 40

INSTALLATION ................................................................................................................................................................. 55

1 INDOOR UNIT INSTALLATION.................................................................................................................................. 55

1.1 Installation of Duct Type ...................................................................................................................................... 55

1.2 Installation of Floor Ceiling Type ......................................................................................................................... 64

1.3 Installation of Cassette Type ............................................................................................................................... 71

2 OUTDOOR UNIT INSTALLATION .............................................................................................................................. 80

2.1 Before Installation ............................................................................................................................................... 80

2.2 Installation Site .................................................................................................................................................... 80

2.3 Caution for Installation ........................................................................................................................................ 81

2.4 Dimension Data .................................................................................................................................................. 82

3 REFRIGERATION PIPING WORK ............................................................................................................................. 83

3.1 Refrigeration Piping Work Procedures and Caution in Connecting ..................................................................... 83

3.2 Specification of Connection Pipe ........................................................................................................................ 87

4 ELECTRIC WIRING WORK ....................................................................................................................................... 88

4.1 Wiring Precautions .............................................................................................................................................. 88

4.2 Electrical Wiring .................................................................................................................................................. 88

MAINTENANCE ................................................................................................................................................................ 94

1 TROUBLE TABLE ...................................................................................................................................................... 94

1.1Main Control Malfunction ..................................................................................................................................... 94

2 FLOW CHART OF TROUBLESHOOTING ................................................................................................................. 97

2.1 Troubleshooting Flow Chart of Main Control Malfunction .................................................................................... 97

2.2 Troubleshooting Flow Chart of Drive Malfunction .............................................................................................. 104

2.3 Interface ............................................................................................................................................................ 109

2.4 IPM, PFC Testing Method ................................................................................................................................. 114

3 WIRING DIADRAM ................................................................................................................................................... 118

3.1 Outdoor unit ...................................................................................................................................................... 118

3.2 Indoor unit ......................................................................................................................................................... 123

4 DISASSEMBLY AND ASSEMBLY PROCEDURE OF MAIN PARTS ......................................................................... 127

4.1 Outdoor Unit ...................................................................................................................................................... 127

4.2 Indoor Unit ........................................................................................................................................................ 133

5 EXPLODED VIEWS AND SPARE PART LIST .......................................................................................................... 146

5.1 Outdoor Unit ...................................................................................................................................................... 146

5.2 Indoor Unit ........................................................................................................................................................ 158

U-Match Series DC Inverter Service Manual

1

PRODUCT

U-Match Series DC Inverter Service Manual

2

PRODUCT

1 MODELS LIST

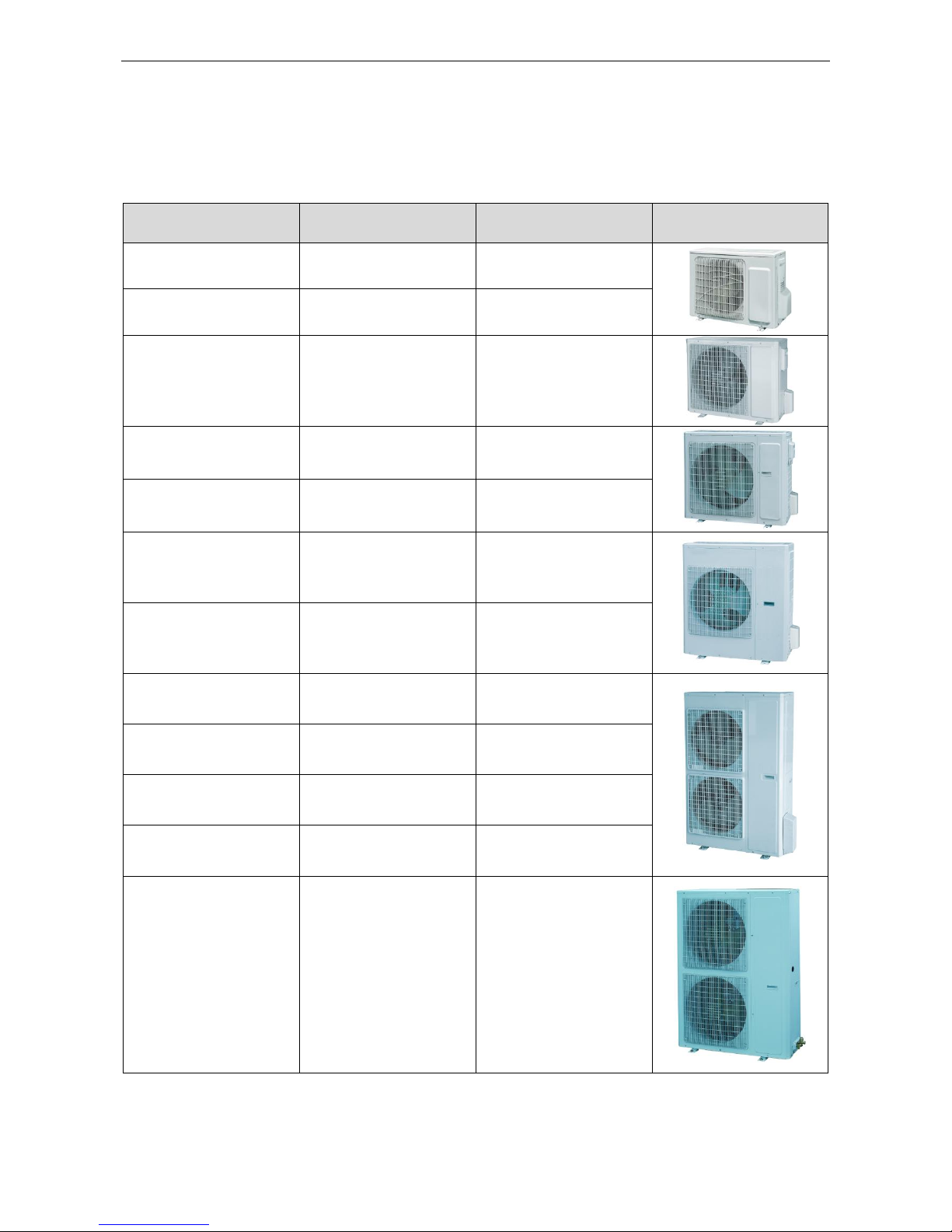

1.1 Outdoor Unit

Model Name

Product Code

Power Supply

(V, Ph, Hz)

Appearance

GUHD09NK3FO

CF090W0630

220-240V~ 50Hz

GUHD12NK3FO

CF090W0640

220-240V~ 50Hz

GUHD18NK3FO

CF090W0650

220-240V~ 50Hz

GUHD24NK3FO

CF090W0660

220-240V~ 50Hz

GUHD30NK3FO

CF090W0670

220-240V~ 50Hz

GUHD36NK3FO

CF090W0680

220-240V~ 50Hz

GUHD36NM3FO

CF090W0690

380-415V 3N~ 50Hz

GUHD42NK3FO

CF090W0700

220-240V~ 50Hz

GUHD42NM3FO

CF090W0710

380-415V~ 3N 50Hz

GUHD48NK3FO

CF090W0720

220-240V~ 50Hz

GUHD48NM3FO

CF090W0730

380-415V 3N~ 50Hz

GUHD60NM3FO

CF090W0740

380-415V 3N~ 50Hz

U-Match Series DC Inverter Service Manual

3

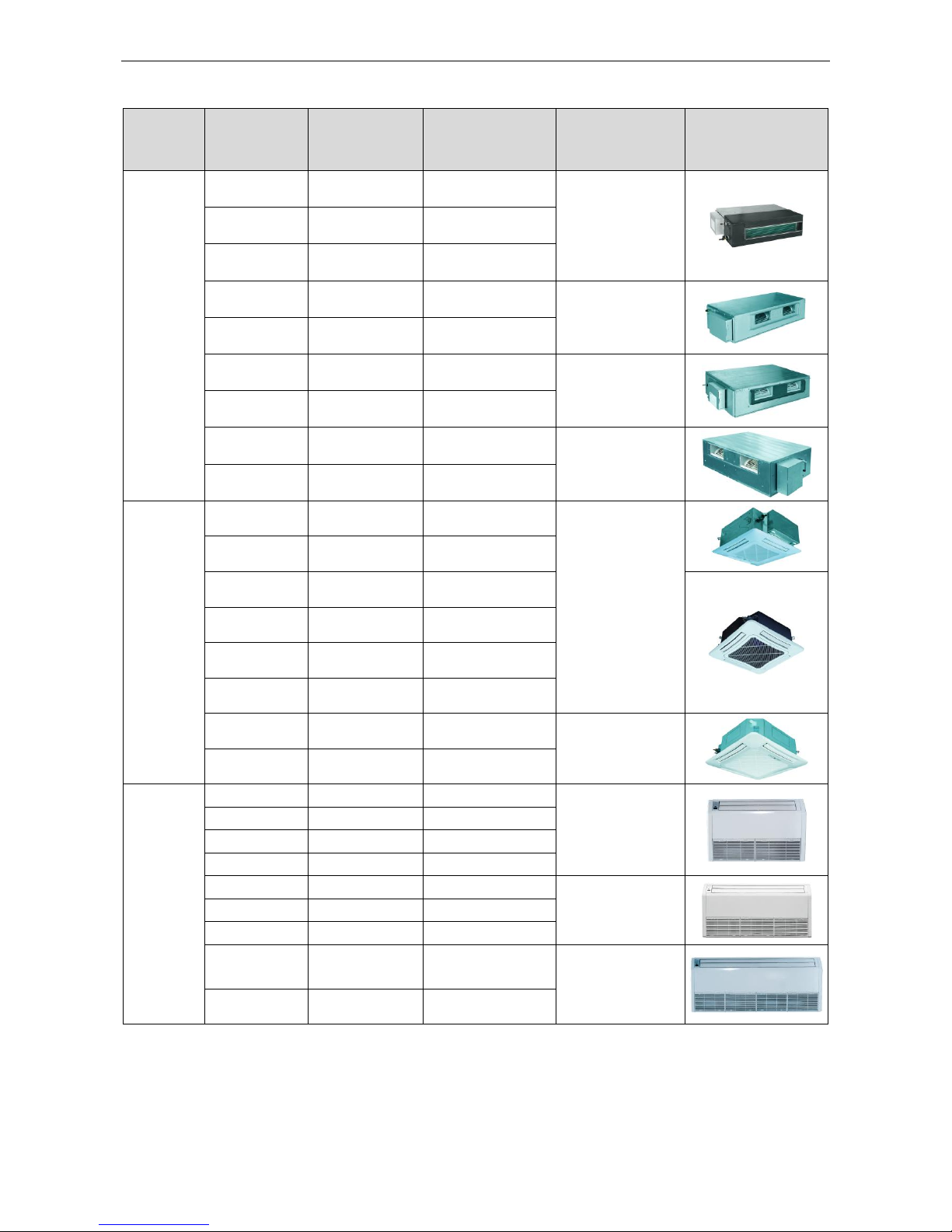

1.2 Indoor Unit

Type

Model Name

Product Code

Nominal Capacity

Cooling/Heating

(kW)

Power

Supply

(V, Ph, Hz)

Appearance

Duct

Type

GFH09K3FI

CF060N0420

2.7/2.9

220-240V~ 50Hz

GFH12K3FI

CF060N0430

3.5/3.8

GFH18K3FI

CF060N0440

5.0/5.6

GFH24K3FI

CF060N0450

7.0/8.0

220-240V~ 50Hz

GFH30K3FI

CF060N0460

8.3/9.2

GFH36K3FI

CF060N0470

10.0/12.0

220-240V~ 50Hz

GFH42K3FI

CF060N0480

11.5/13.5

GFH48K3FI

CF060N0490

14.0/15.5

220-240V~ 50Hz

GFH60K3FI

CF060N0500

16.0/17.5

Cassette

Type

GKH12K3FI

ET010N0670

3.5/3.8

220-240V~ 50Hz

GKH18K3FI

ET010N0680

5.0/5.5

GKH24K3FI

ET010N0690

7.0/8.0

GKH30K3FI

ET010N0740

8.3/9.2

GKH36K3FI

ET010N0700

10.0/12.0

GKH42K3FI

ET010N0710

11.0/12.5

GKH48K3FI

ET010N0720

14.0/16.0

220-240V~

50Hz

GKH60K3FI

ET010N0730

16.0/17.0

Ceiling

Type

GTH09K3FI

ED020N0650

2.7/2.9

220-240V~ 50Hz

GTH12K3FI

ED020N0660

3.5/3.8

GTH18K3FI

ED020N0670

5.0/5.6

GTH24K3FI

ED020N0680

7.0/8.0

GTH30K3FI

ED020N0690

8.5/9.2

220-240V~

50Hz

GTH36K3FI

ED020N0700

10.0/12.0

GTH42K3FI

ED020N0710

11.5/13.5

GTH48K3FI

ED020N0720

14.0/16.0

220-240V~

50Hz

GTH60K3FI

ED020N0730

16.0/17.0

Note:1 Ton =12000Btu/h = 3.517kW

Notes: The universal outdoor units means that the customer can choose any of three kind of indoor unit

to match the outdoor unit without any change with it.

U-Match Series DC Inverter Service Manual

4

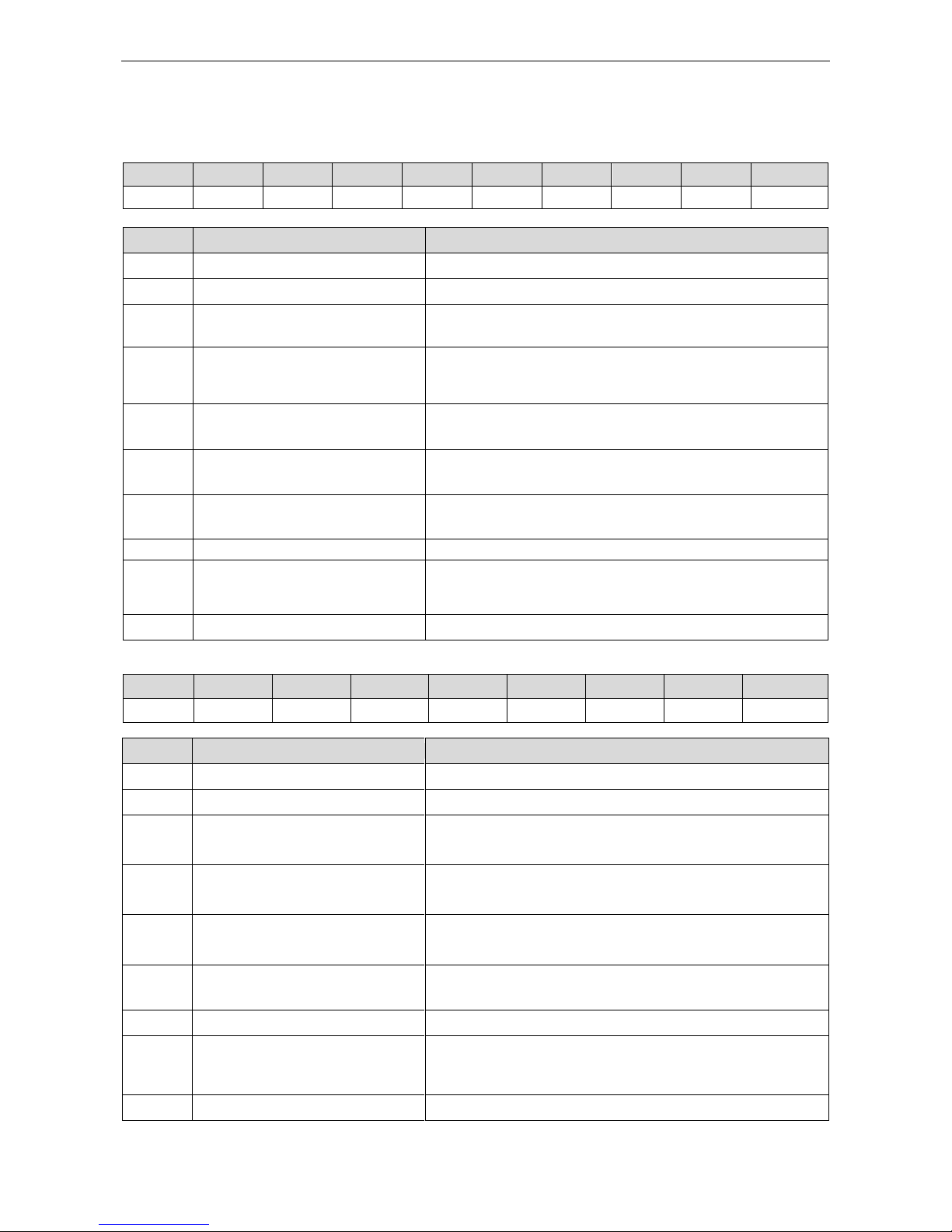

2 NOMENCLATURE

2.1 Outdoor Unit

G U H D 09 N K 3 F

O

1 2 3 4 5 6 7 8 9

10

NO.

Description

Options

1

Gree Electric Appliances Inc

Capital Letter :G 2 Unit Type

U=U-Match Outdoor Unit

3

Product Type

C=Cool Only

H=Heat Pump without Aux Electric Heaters

4

Compressor Power Supply

Type Code

N=Constant Frequency

D=DC Inverter

A=AC Inverter

5

Nominal Cooling Capacity

Nominal Cooling Capacity

=Number×1000Btu/h

6

Climate Type

N=Climate T1 Condition

T= Climate T3 Condition

7

Power Supply Code

K= 220-240V~ 50Hz

M=380-415V 3N~ 50Hz

8

Refrigerant

1 =R22; 2=R407C; 3=R410A

9

Design Code

Design Code: A, B, C, D……

Design Change Code=0 (default)

1,2,3......

10

Unit Code

O=Outdoor unit

2.2 Intdoor Unit

G F H

09 T K 3 F

I

1 2 3 4 5 6 7 8 9

NO.

Description

Options

1

Gree Electric Appliances Inc

Capital Letter :G

2

Unit Type

F=Duct Type; K=Cassette Type; T= Floor-ceiling Type

3

Product Type

C=Cool Only

H=Heat Pump without Aux Electric Heaters

4

Nominal Cooling Capacity

Nominal Cooling Capacity

=Number×1000Btu/h

5

Climate Type

Omit=Climate T1 Condition

T= Climate T3 Condition

6

Power Supply Code

K= 220-240V~ 50Hz

M=380-415V 3N~ 50Hz

7

Refrigerant

1 =R22; 2=R407C; 3=R410A

8

Design Code

Design Code: A, B, C, D……

Design Change Code=0 (default)

1,2,3......

9

Unit Code

I=indoor unite

U-Match Series DC Inverter Service Manual

5

3 PRODUCT DATA

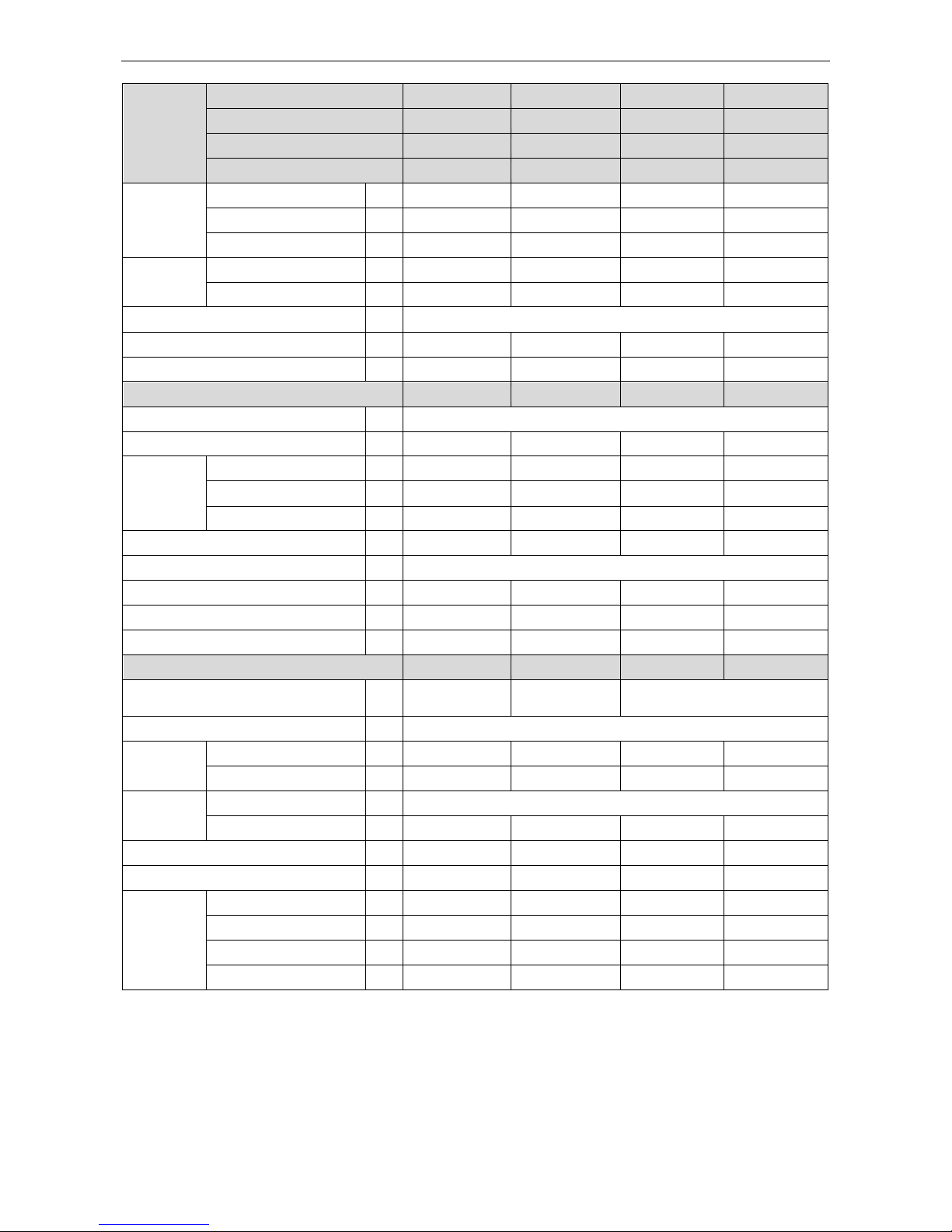

3.1 Product Data of Indoor Unit

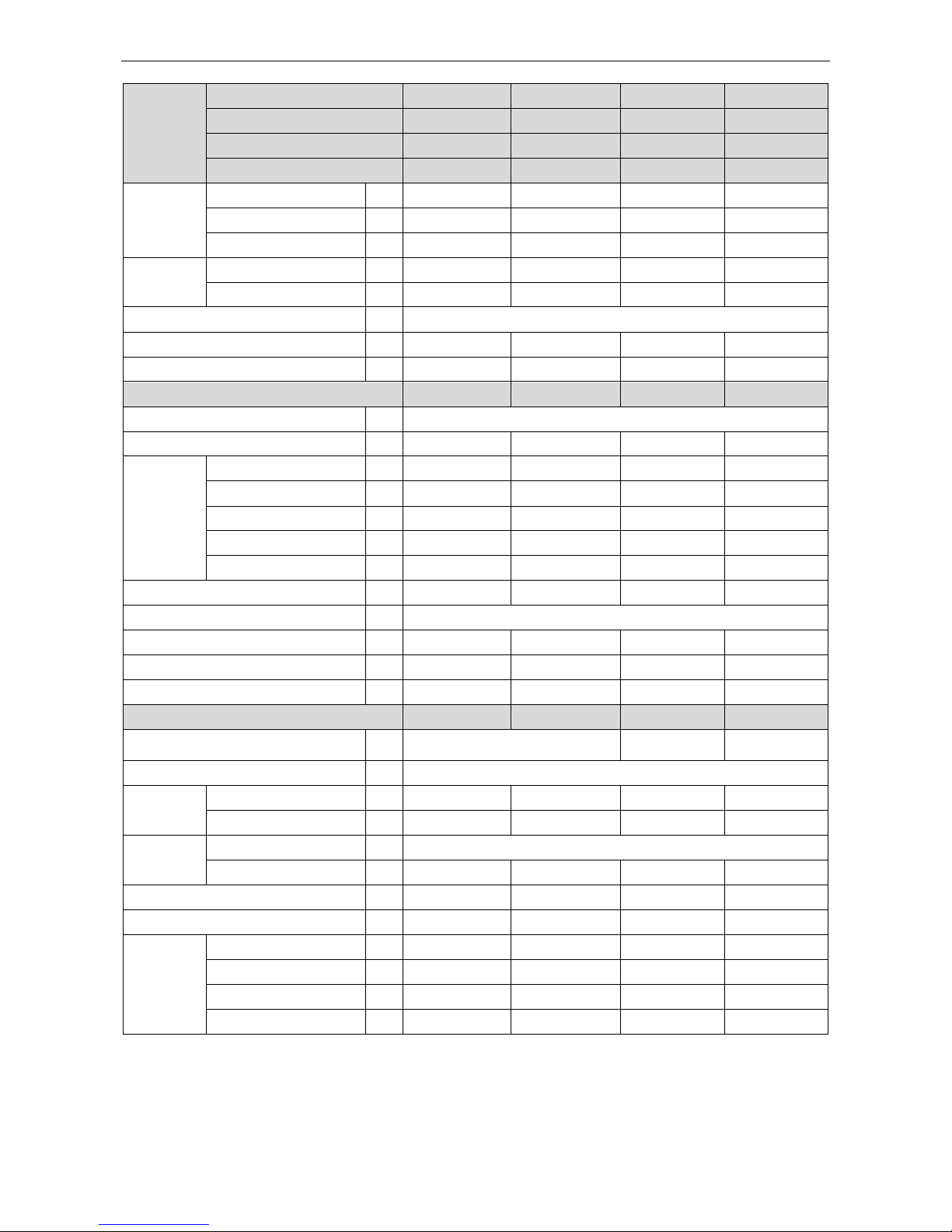

3.1.1 Duct Type

Model

Indoor unit

GFH09K3FI

GFH12K3FI

GFH18K3FI

GFH24K3FI

Product Code

CF060N0420

CF060N0430

CF060N0440

CF060N0450

Outdoor unit

GUHD09NK3FO

GUHD12NK3FO

GUHD18NK3FO

GUHD24NK3FO

Product Code

CF090W0630

CF090W0640

CF090W0650

CF090W0660

Capacity

Cooling Capacity

kW

2.7(0.80-3.40)

3.5(0.90-3.70)

5.0(1.60-5.50)

7.0(2.20-8.500)

Heating Capacity

kW

2.9(0.80-3.70)

3.8(0.90-4.10)

5.6(1.40-6.80)

8.0(2.40-9.50)

PdesignH

kW

2.8

3.0

4.5

7.0

Power Input

Cooling

kW

0.84(0.20-1.28)

1.17(0.20-1.40)

1.60(0.55-1.75)

2.18(0.85-2.50)

Heating

kW

0.80(0.20-1.20)

1.05(0.22-1.20)

1.58(0.50-1.90)

2.21(0.80-2.75)

Design load Average

SEER / SCOP

W/W

5.6/3.8

5.6/4.0

5.6/3.8

6.1/4.0

Energy Rate(Cooling / Heating)

A+/A

A+/A+

A+/A

A++/A+

Indoor Unit

GFH09K3FI

GFH12K3FI

GFH18K3FI

GFH24K3FI

Power Supply 220-240V~ 50Hz

Heat Exchange

Cross Fin Coil

Cross Fin Coil

Cross Fin Coil

Cross Fin Coil

Fan

Drive

direct

direct

direct

direct

Motor Output

kW

0.04×1

0.05×1

0.07×1

0.11×1

Air Flow

m3/h

650

750

1000

1400

Rated Ext. Static Pressure

Pa

25

25

25

25

Ext. Static Pressure Range

Pa

0~30

0~30

0~30

0~100

Sound Pressure Level(SS/H/M/L)

dB(A)

36/34/28/26

37/36/34/28

40/39/36/28

47/46/44/40

Air Filter Standard washable synthetic

Drain

mm

Φ20×1.2

Φ30×1.5

Φ30×1.5

Φ20×1.2

Outline Dimensions (W×H×D)

mm

925×250×665

1035×265×720

1035×265×720

1280×270×560

Net Weight

kg

27

33

33

34

Outdoor Unit

GUHD09NK3FO

GUHD12NK3FO

GUHD18NK3FO

GUHD24NK3FO

Power Supply 220-240V~ 50Hz

Heat Exchange Cross Fin Coil

Compressor

Type

Rotary

Rotary

Rotary

Rotary

Power Input

W

942

942

1440

2550

Refrigerant

Control Electronic Expansion Valve

Charge

kg

1.2

1.2

1.4

2.2

Outline Dimensions (W×H×D)

mm

850×540×320

850×540×320

955×700×395

980×790×425

Net Weight

kg

34

34

47

67

Piping

Connections

Liquid

Inch

Φ1/4

Φ1/4

Φ1/4

Φ3/8

Gas

Inch

Φ3/8

Φ3/8

Φ1/2

Φ5/8

Max. Length

m

20

20

20

30

Max. Height

m

15

15

15

15

U-Match Series DC Inverter Service Manual

6

Model

Indoor unit

GFH30K3FI

GFH36K3FI

GFH36K3FI

GFH42K3FI

Product Code

CF060N0460

CF060N0470

CF060N0470

CF060N0480

Outdoor unit

GUHD30NK3FO

GUHD36NK3FO

GUHD36NM3FO

GUHD42NK3FO

Product Code

CF090W0670

CF090W0680

CF090W0690

CF090W0700

Capacity

Cooling Capacity

kW

8.3(2.40-8.70)

10.0(3.20-11.50)

10.0(3.20-11.50)

11.5(3.60-12.50)

Heating Capacity

kW

9.2(2.40-9.90)

12.0(2.90-14.50)

12.0(2.90-14.50)

13.5(3.90-15.50)

PdesignH

kW

7.6

10.4

10.4

10.5

Power Input

Cooling

kW

2.67(0.85-2.70)

3.20(0.70-4.50)

3.20(0.70-4.50)

4.00(0.65-4.70)

Heating

kW

2.57(0.80-2.86)

3.40(0.70-4.60)

3.40(0.70-4.60)

3.90(0.76-4.75)

Design load Average

SEER / SCOP

W/W

6.1/4.0

5.6/4.0

5.1/4.0

5.6/3.8

Energy Rate(Cooling / Heating)

A++/A+

A+/A+

A/A+

A+/A

Indoor Unit

GFH30K3FI

GFH36K3FI

GFH36K3FI

GFH42K3FI

Power Supply 220-240V~ 50Hz

Heat Exchange

Cross Fin Coil

Cross Fin Coil

Cross Fin Coil

Cross Fin Coil

Fan

Drive

direct

direct

direct

direct

Motor Output

kW

0.11×1

0.23×1

0.23×1

0.23×1

Air Flow

m3/h

1400

2100

2100

2100

Rated Ext. Static Pressure

Pa

37

37

37

37

Ext. Static Pressure Range

Pa

0~100

0~150

0~150

0~150

Sound Pressure Level(SS/H/M/L)

dB(A)

47/46/44/40

53/52/48/44

53/52/48/44

53/52/48/44

Air Filter Standard washable synthetic

Drain Piping

mm

Φ20×1.2

Φ20×1.2

Φ20×1.2

Φ20×1.2

Outline Dimensions (W×H×D)

mm

1280×270×560

1225×290×775

1225×290×775

1225×290×775

Net Weight

kg

34

46

46

46

Outdoor Unit

GUHD30NK3FO

GUHD36NK3FO

GUHD36NM3FO

GUHD42NK3FO

Power Supply

220-240V~ 50Hz

380-415V 3N~

50Hz

220-240V~ 50Hz

Heat Exchange Cross Fin Coil

Compressor

Type

Rotary

Rotary

Rotary

Rotary

Power Input

W

2550

4150

4000

4150

Refrigerant

Control Electronic Expansion Valve

Charge

kg

2.4

3.5

3.5

3.7

Outline Dimensions (W×H×D)

mm

980×790×425

1105×1100×440

1105×1100×440

960×1350×410

Net Weight

kg

71

92

98

95

Piping

Connections

Liquid

Inch

Φ3/8

Φ3/8

Φ3/8

Φ3/8

Gas

Inch

Φ5/8

Φ5/8

Φ5/8

Φ5/8

Max. Length

m

30

30

30

50

Max. Height

m

15

15

15

30

U-Match Series DC Inverter Service Manual

7

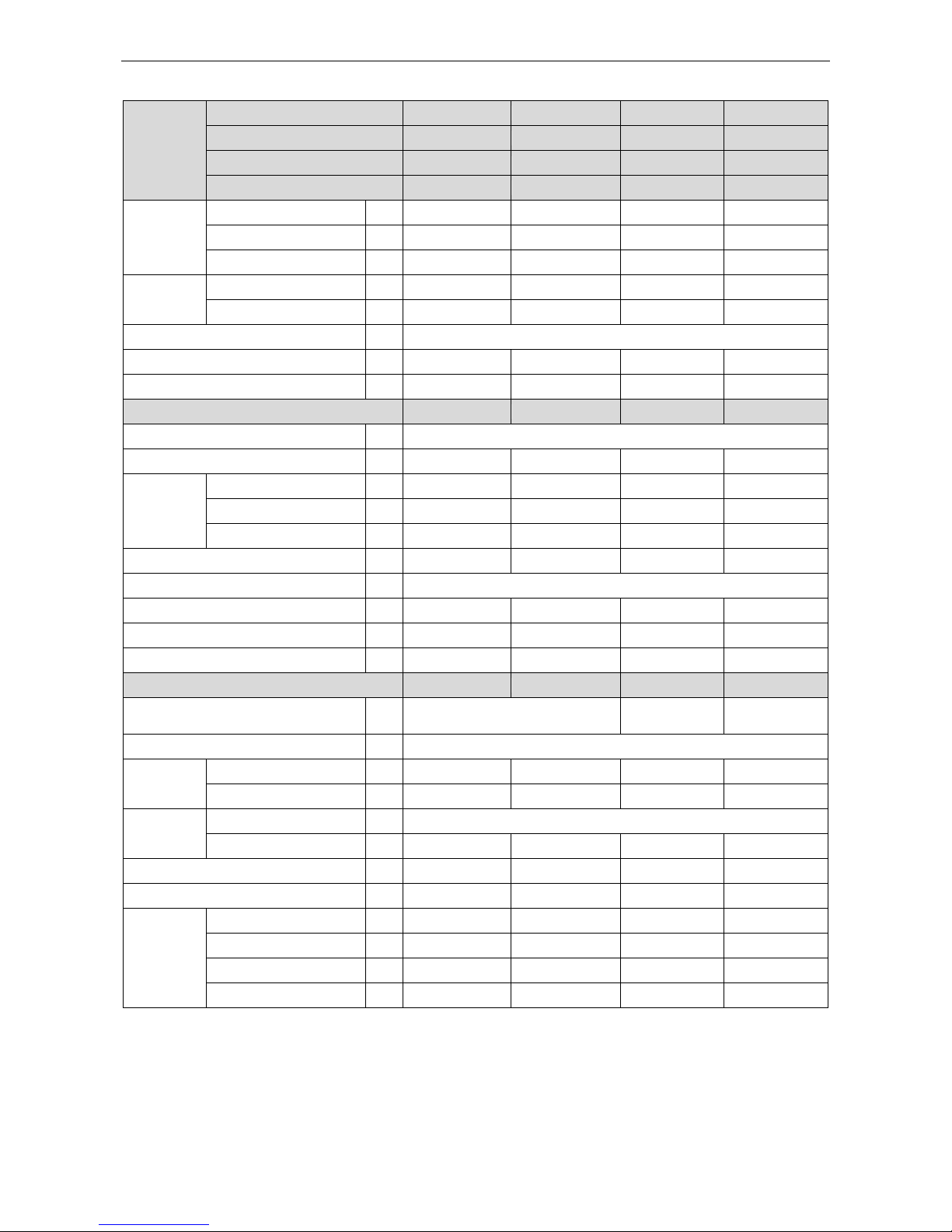

Model

Indoor unit

GFH42K3FI

GFH48K3FI

GFH48K3FI

GFH60K3FI

Product Code

CF060N0480

CF060N0490

CF060N0490

CF060N0500

Outdoor unit

GUHD42NM3FO

GUHD48NK3FO

GUHD48NM3FO

GUHD60NM3FO

Product Code

CF090W0710

CF090W0720

CF090W0730

CF090W0740

Capacity

Cooling Capacity

kW

11.5(3.60-12.50)

14.0(6.00-14.50)

14.0(6.00-14.50)

16.0(7.4~16.5)

Heating Capacity

kW

13.5(3.90-15.50)

15.5(5.20-17.00)

15.5(5.20-17.00)

16.5(6.2~18.5)

PdesignH

kW

10.5

11.8

11.8

12.5

Power Input

Cooling

kW

4.00(0.65-4.70)

4.70(1.40-5.60)

5.10(1.40-5.60)

5.60(1.20-6.90)

Heating

kW

3.90(0.76-4.75)

4.40(1.30-5.50)

4.50(1.30-5.50)

4.60(1.20-6.90)

Design load Average

SEER / SCOP

W/W

5.6/4.0

6.1/3.8

5.6/3.8

5.6/3.8

Energy Rate(Cooling / Heating)

A+/A+

A++/A

A+/A

A+/A

Indoor Unit

GFH42K3FI

GFH48K3FI

GFH48K3FI

GFH60K3FI

Power Supply 220-240V~ 50Hz

Heat Exchange

Cross Fin Coil

Cross Fin Coil

Cross Fin Coil

Cross Fin Coil

Fan

Drive

direct

direct

direct

direct

Motor Output

kW

0.23×1

0.25×1

0.25×1

0.28×1

Air Flow

m3/h

2100

2400

2400

3000

Rated Ext. Static Pressure

Pa

37

50

50

50

Ext. Static Pressure Range

Pa

0~150

0~150

0~150

0~150

Sound Pressure Level(SS/H/M/L)

dB(A)

53/52/48/44

55/53/49/45

55/53/49/45

57/56/54/49

Air Filter Standard washable synthetic

Drain Piping

mm

Φ20×1.2

Φ20×1.2

Φ20×1.2

Φ20×1.2

Outline Dimensions (W×H×D)

mm

1225×290×775

1340×350×750

1340×350×750

1340×350×750

Net Weight

kg

46

56

56

56

Outdoor Unit

GUHD42NM3FO

GUHD48NK3FO

GUHD48NM3FO

GUHD60NM3FO

Power Supply

380-415V 3N~

50Hz

220-240V~ 50Hz

380-415V 3N~ 50Hz

Heat Exchange Cross Fin Coil

Compressor

Type

Rotary

Rotary

Rotary

Rotary

Power Input

W

4000

4580

4580

4580

Refrigerant

Control Electronic Expansion Valve

Charge

kg

3.7

4.0

4.0

5.0

Outline Dimensions (W×H×D)

mm

960×1350×410

960×1350×410

960×1350×410

1085×1365×425

Net Weight

kg

108

105

114

126

Piping

Connections

Liquid

Inch

Φ3/8

Φ3/8

Φ3/8

Φ3/8

Gas

Inch

Φ5/8

Φ5/8

Φ5/8

Φ3/4

Max. Length

m

50

50

50

50

Max. Height

m

30

30

30

30

U-Match Series DC Inverter Service Manual

8

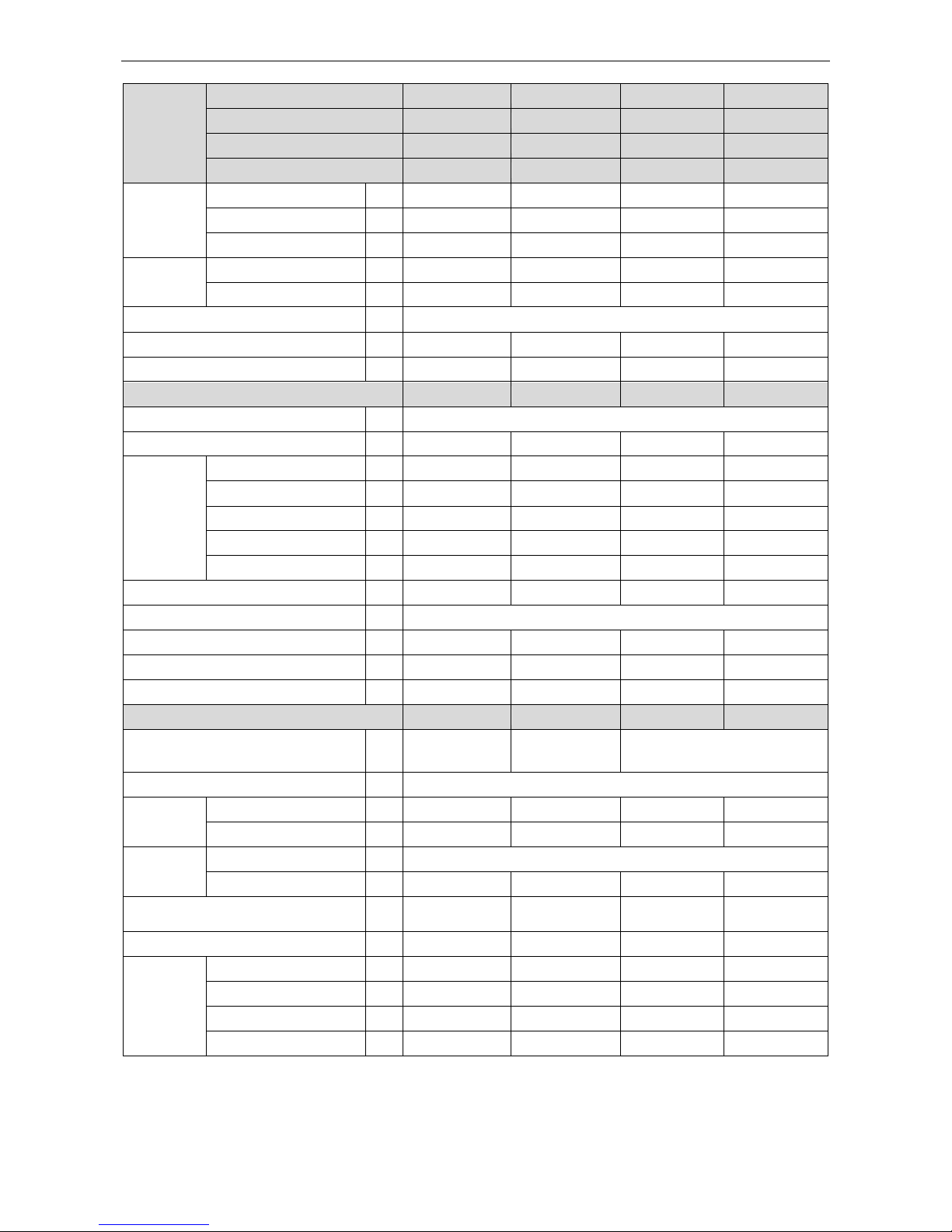

3.1.2 Cassette Type

Model

Indoor unit

GKH12K3FI

GKH18K3FI

GKH24K3FI

Product Code

ET010N0670

ET010N0680

ET010N0690

Outdoor unit

GUHD12NK3FO

GUHD18NK3FO

GUHD24NK3FO

Product Code

CF090W0640

CF090W0650

CF090W0660

Capacity

Cooling Capacity

kW

3.5(0.90-3.90)

5.0(1.60-5.80)

7.0(2.40-8.50)

Heating Capacity

kW

3.8(0.90-4.10)

5.5(1.40-6.50)

8.0(2.40-9.50)

PdesignH

kW

3.0

4.5

7.2

Power Input

Cooling

kW

1.09(0.30-1.40)

1.55(0.55-1.75)

2.18(0.85-2.50)

Heating

kW

1.05(0.22-1.20)

1.64(0.50-1.90)

2.21(0.80-2.75)

Design load Average

SEER / SCOP

W/W

5.6/4.0

5.6/3.8

6.1/4.0

Energy Rate(Cooling / Heating)

A+/A+

A+/A

A++/A+

Indoor Unit

GKH12K3FI

GKH18K3FI

GKH24K3FI

Power Supply

220-240V~50Hz

Heat Exchange

Cross Fin Coil

Cross Fin Coil

Cross Fin Coil

Fan

Drive

direct

direct

direct

Motor Output

kW

0.03×1

0.04×1

0.065×1

Air Flow

m3/h

700

760

1300

Sound Pressure Level(SS/H/M/L)

dB(A)

46/45/41/36

47/46/44/37

47/46/42/38

Air Filter

Standard washable synthetic

Drain Piping

mm

Φ25×1.5

Φ25×1.5

Φ25×1.5

Outline Dimensions (W×H×D)

mm

595×240×595

595×240×595

840×240×840

Net Weight

kg

20

20

26

Outdoor Unit

GUHD12NK3FO

GUHD18NK3FO

GUHD24NK3FO

Power Supply

220-240V~50Hz

Heat Exchange

Cross Fin Coil

Compressor

Type

Rotary

Rotary

Rotary

Power Input

W

942

1440

2550

Refrigerant

Control Electronic Expansion Valve

Charge

kg

1.2

1.4

2.2

Outline Dimensions (W×H×D)

mm

850×540×320

955×700×395

980×790×425

Net Weight

kg

34

47

67

Piping

Connections

Liquid

Inch

Φ1/4

Φ1/4

Φ3/8

Gas

Inch

Φ3/8

Φ1/2

Φ5/8

Max. Length

m

20

20

30

Max. Height

m

15

15

15

U-Match Series DC Inverter Service Manual

9

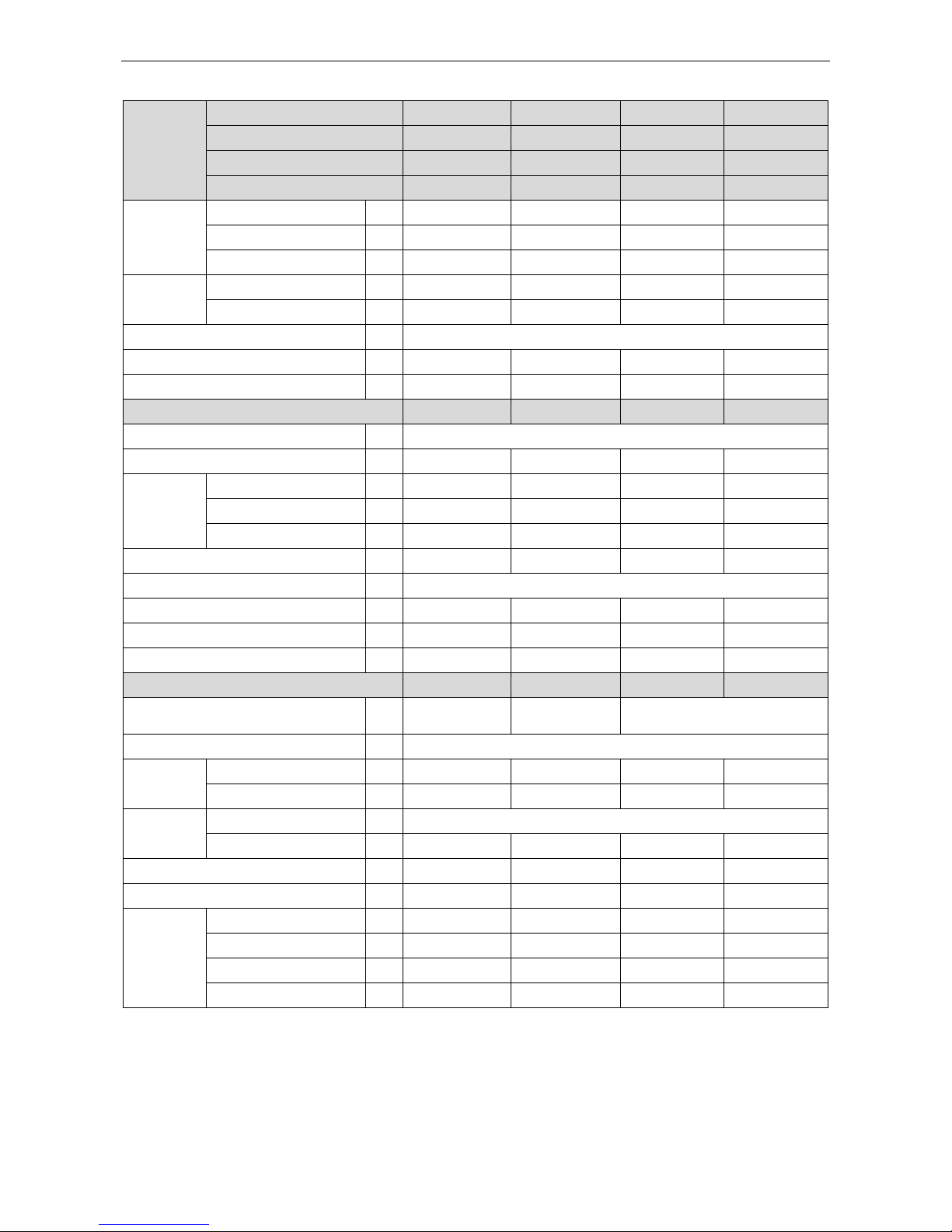

Model

Indoor unit

GKH30K3FI

GKH36K3FI

GKH36K3FI

GKH42K3FI

Product Code

ET010N0740

ET010N0700

ET010N0700

ET010N0710

Outdoor unit

GUHD30NK3FO

GUHD36NK3FO

GUHD36NM3FO

GUHD42NK3FO

Product Code

CF090W0670

CF090W0680

CF090W0690

CF090W0700

Capacity

Cooling Capacity

kW

8.3(2.60-9.20)

10.0(3.20-11.50)

10.0(3.20-11.50)

11.0(3.30-12.00)

Heating Capacity

kW

9.2(2.40-9.90)

12.0(2.90-14.50)

12.0(2.90-14.50)

12.5(3.60-15.00)

PdesignH

kW

7.6

10.4

10.4

9.5

Power Input

Cooling

kW

2.67(0.85-2.70)

3.20(0.75-4.50)

3.20(0.75-4.50)

3.90(0.53-4.65)

Heating

kW

2.57(0.80-2.86)

3.50(0.60-4.80)

3.50(0.60-4.80)

3.80(0.64-4.80)

Design load Average

SEER / SCOP

W/W

6.1/4.0

6.1/4.0

6.1/4.0

5.6/4.0

Energy Rate(Cooling / Heating)

A++/A+

A++/A+

A++/A+

A+/A+

Indoor Unit

GKH30K3FI

GKH36K3FI

GKH36K3FI

GKH42K3FI

Power Supply 220-240V~ 50Hz

Heat Exchange

Cross Fin Coil

Cross Fin Coil

Cross Fin Coil

Cross Fin Coil

Fan

Drive

direct

direct

direct

direct

Motor Output

kW

0.065×1

0.11×1

0.11×1

0.11×1

Air Flow

m3/h

1500

1860

1860

1860

Sound Pressure Level(SS/H/M/L)

dB(A)

49/48/45/40

51/49/46/43

51/49/46/43

51/49/46/43

Air Filter Standard washable synthetic

Drain Piping

mm

Φ25×1.5

Φ25×1.5

Φ25×1.5

Φ25×1.5

Outline Dimensions (W×H×D)

mm

840×320×840

840×320×840

840×320×840

840×320×840

Net Weight

kg

31

31

31

31

Outdoor Unit

GUHD30NK3FO

GUHD36NK3FO

GUHD36NM3FO

GUHD42NK3FO

Power Supply

220-240V~ 50Hz

380-415V 3N~

50Hz

220-240V~ 50Hz

Heat Exchange Cross Fin Coil

Compressor

Type

Rotary

Rotary

Rotary

Rotary

Power Input

W

2550

4150

4000

4150

Refrigerant

Control Electronic Expansion Valve

Charge

kg

2.4

3.5

3.5

3.7

Outline Dimensions (W×H×D)

mm

980×790×425

1105×1100×440

1105×1100×440

960×1350410

Net Weight

kg

71

92

98

95

Piping

Connections

Liquid

Inch

Φ3/8

Φ3/8

Φ3/8

Φ3/8

Gas

Inch

Φ5/8

Φ5/8

Φ5/8

Φ5/8

Max. Length

m

30

30

30

50

Max. Height

m

15

15

15

30

U-Match Series DC Inverter Service Manual

10

Model

Indoor unit

GKH42K3FI

GKH48K3FI

GKH48K3FI

GKH60K3FI

Product Code

ET010N0710

ET010N0720

ET010N0720

ET010N0730

Outdoor unit

GUHD42NM3FO

GUHD48NK3FO

GUHD48NM3FO

GUHD60NM3FO

Product Code

CF090W0710

CF090W0720

CF090W0730

CF090W0740

Capacity

Cooling Capacity

kW

11.0(3.30-12.00)

14.0(6.00-14.80)

14.0(6.00-14.80)

16.0(7.4~16.5)

Heating Capacity

kW

12.5(3.60-15.00)

16.0(5.20-18.00)

16.0(5.20-18.00)

16.5(6.2~18.5)

PdesignH

kW

9.5

12.0

12.0

12.5

Power Input

Cooling

kW

3.90(0.53-4.65)

4.60(1.30-5.50)

4.60(1.30-5.50)

5.70(1.20-6.90)

Heating

kW

3.80(0.64-4.80)

4.50(1.20-5.40)

4.50(1.20-5.40)

4.60(1.20-6.90)

Design load Average

SEER / SCOP

W/W

6.1/4.0

6.1/3.8

5.6/3.8

6.1/4.0

Energy Rate(Cooling / Heating)

A++/A+

A++/

A+/A

A++/A+

Indoor Unit

GKH42K3FI

GKH48K3FI

GKH48K3FI

GKH60K3FI

Power Supply 220-240V~ 50Hz

Heat Exchange

Cross Fin Coil

Cross Fin Coil

Cross Fin Coil

Cross Fin Coil

Fan

Drive

direct

direct

direct

direct

Motor Output

kW

0.11×1

0.15×1

0.15×1

0.17×1

Air Flow

m3/h

1860

2300

2300

2400

Sound Pressure Level(SS/H/M/L)

dB(A)

51/49/46/43

53/52/47/41

53/52/47/41

54/53/47/41

Air Filter Standard washable synthetic

Drain Piping

mm

Φ25×1.5

Φ25×1.5

Φ25×1.5

Φ25×1.5

Outline Dimensions (W×H×D)

mm

840×320×840

910×290×910

910×290×910

910×290×910

Net Weight

kg

31

43

43

43

Outdoor Unit

GUHD42NM3FO

GUHD48NK3FO

GUHD48NM3FO

GUHD60NM3FO

Power Supply

380-415V 3N~

50Hz

220-240V~ 50Hz

380-415V 3N~ 50Hz

Heat Exchange Cross Fin Coil

Compressor

Type

Rotary

Rotary

Rotary

Rotary

Power Input

W

4000

4580

4580

4580

Refrigerant

Control Electronic Expansion Valve

Charge

kg

3.7

4.0

4.0

5.0

Outline Dimensions (W×H×D)

mm

960×1350×410

960×1350×410

960×1350×410

1085×1365×425

Net Weight

kg

108

105

114

126

Piping

Connections

Liquid

Inch

Φ3/8

Φ3/8

Φ3/8

Φ3/8

Gas

Inch

Φ5/8

Φ5/8

Φ5/8

Φ3/4

Max. Length

m

50

50

50

50

Max. Height

m

30

30

30

30

U-Match Series DC Inverter Service Manual

11

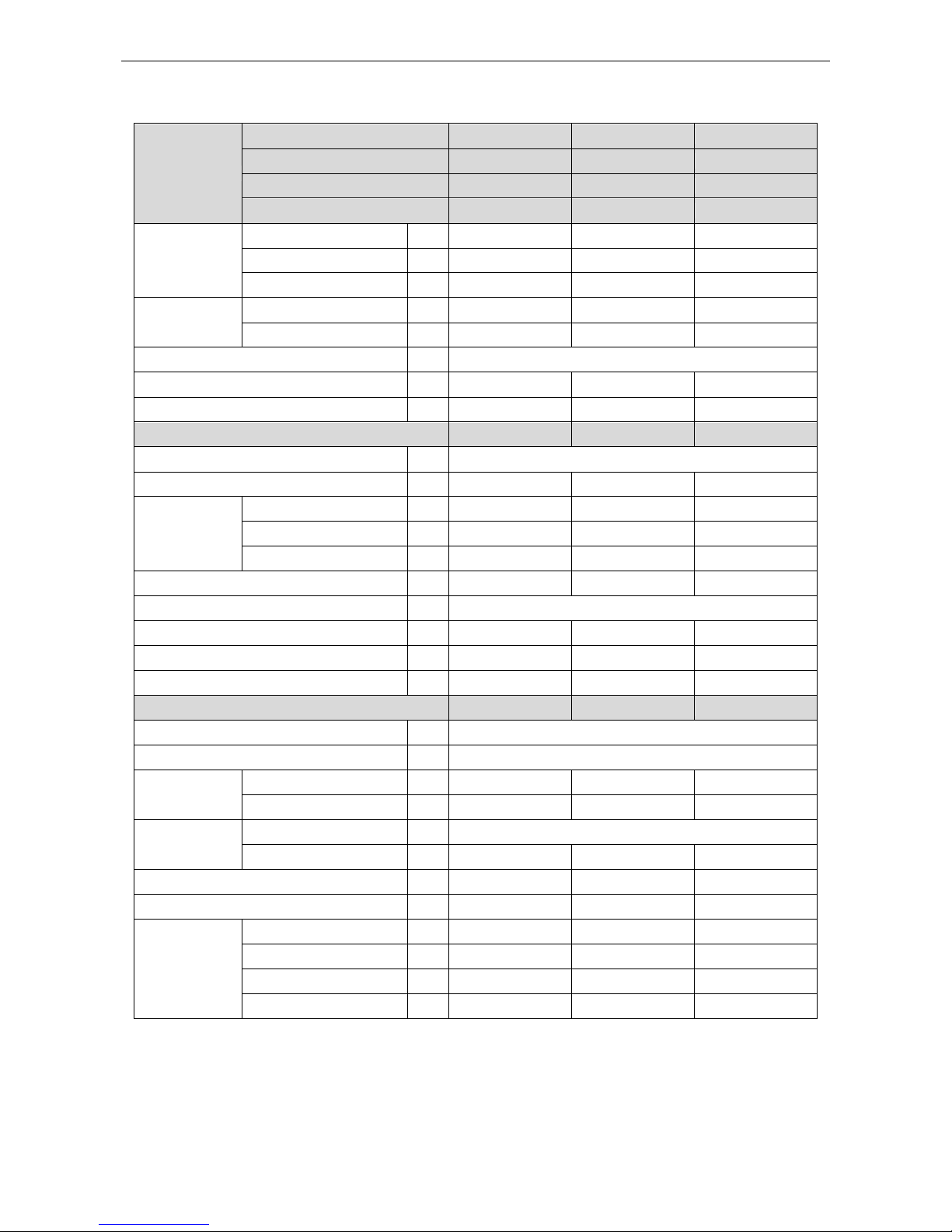

3.1.3 Floor-ceiling Type

Model

Indoor unit

GTH09K3FI

GTH12K3FI

GTH18K3FI

GTH24K3FI

Product Code

ED020N0650

ED020N0660

ED020N0670

ED020N0680

Outdoor unit

GUHD09NK3FO

GUHD12NK3FO

GUHD18NK3FO

GUHD24NK3FO

Product Code

CF090W0630

CF090W0640

CF090W0650

CF090W0660

Capacity

Cooling Capacity

kW

2.7(0.80-3.50)

3.5(0.90-3.90)

5.0(1.60-5.80)

7.0(2.40-8.20)

Heating Capacity

kW

2.9(0.80-3.80)

3.8(0.90-4.10)

5.6(1.40-6.80)

8.0(2.40-9.00)

PdesignH

kW

2.9

3.0

4.5

7.0

Power Input

Cooling

kW

0.84(0.20-1.28)

1.09(0.26-1.40)

1.55(0.55-1.75)

2.18(0.85-2.50)

Heating

kW

0.80(0.20-1.20)

1.05(0.22-1.20)

1.55(0.50-1.90)

2.21(0.80-2.75)

Design load Average

SEER / SCOP

W/W

6.1/3.8

6.1/4.0

6.1/4.0

5.6/4.0

Energy Rate(Cooling / Heating)

A++/A

A++/A+

A++/A+

A+/A+

Indoor Unit

GTH09K3FI

GTH12K3FI

GTH18K3FI

GTH24K3FI

Power Supply 220-240V~ 50Hz

Heat Exchange

Cross Fin Coil

Cross Fin Coil

Cross Fin Coil

Cross Fin Coil

Fan

Drive

direct

direct

direct

direct

Motor Output

kW

0.015×1

0.02×1

0.04×1

0.065×1

Air Flow

m3/h

600

700

1000

1200

Sound Pressure Level(SS/H/M/L)

dB(A)

31/29/26/24

35/33/30/27

44/42/38/32

49/48/46/40

Air Filter Standard washable synthetic

Drain Piping

mm

Φ17×1.75

Φ17×1.75

Φ17×1.75

Φ17×1.75

Outline Dimensions (W×H×D)

mm

1220×225×700

1220×225×700

1220×225×700

1220×225×700

Net Weight

kg

38

39

39

40

Outdoor Unit

GUHD09NK3FO

GUHD12NK3FO

GUHD18NK3FO

GUHD24NK3FO

Power Supply 220-240V~ 50Hz

Heat Exchange Cross Fin Coil

Compressor

Type

Rotary

Rotary

Rotary

Rotary

Power Input

W

942

942

1440

2550

Refrigerant

Control Electronic Expansion Valve

Charge

kg

1.2

1.2

1.4

2.2

Outline Dimensions (W×H×D)

mm

850×540×320

850×540×320

955×700×395

980×790×425

Net Weight

kg

34

34

47

67

Piping

Connections

Liquid

Inch

Φ1/4

Φ1/4

Φ1/4

Φ3/8

Gas

Inch

Φ3/8

Φ3/8

Φ1/2

Φ5/8

Max. Length

m

20

20

20

30

Max. Height

m

15

15

15

15

U-Match Series DC Inverter Service Manual

12

Model

Indoor unit

GTH30K3FI

GTH36K3FI

GTH36K3FI

GTH42K3FI

Product Code

ED020N0690

ED020N0700

ED020N0700

ED020N0710

Outdoor unit

GUHD30NK3FO

GUHD36NK3FO

GUHD36NM3FO

GUHD42NK3FO

Product Code

CF090W0670

CF090W0680

CF090W0690

CF090W0700

Capacity

Cooling Capacity

kW

8.5(2.60-9.20)

10.0(3.20-11.50)

10.0(3.20-11.50)

11.5(3.60-12.50)

Heating Capacity

kW

9.2(2.40-9.90)

12.0(2.90-14.50)

12.0(2.90-14.50)

13.5(3.90-15.50)

PdesignH

kW

7.6

10.4

10.4

10.5

Power Input

Cooling

kW

2.67(0.85-2.70)

3.20(0.80-4.60)

3.20(0.80-4.60)

3.90(0.60-4.70)

Heating

kW

2.57(0.80-2.86)

3.40(0.65-4.80)

3.40(0.65-4.80)

3.70(0.69-4.80)

Design load Average

SEER / SCOP

W/W

6.1/4.0

6.1/4.0

6.1/4.0

6.1/4.0

Energy Rate(Cooling / Heating)

A++/A+

A++/A+

A++/A+

A++/A+

Indoor Unit

GTH30K3FI

GTH36K3FI

GTH36K3FI

GTH42K3FI

Power Supply 220-240V~ 50Hz

Heat Exchange

Cross Fin Coil

Cross Fin Coil

Cross Fin Coil

Cross Fin Coil

Fan

Drive

direct

direct

direct

direct

Motor Output

kW

0.09×1

0.14×1

0.14×1

0.14×1

Air Flow

m3/h

1500

1900

1900

1900

Sound Pressure Level(SS/H/M/L)

dB(A)

49/46/44/38

54/53/51/46

54/53/51/46

55/54/52/47

Air Filter Standard washable synthetic

Drain Piping

mm

Φ17×1.75

Φ17×1.75

Φ17×1.75

Φ17×1.75

Outline Dimensions (W×H×D)

mm

1420×245×700

1420×245×700

1420×245×700

1420×245×700

Net Weight

kg

48

48

48

50

Outdoor Unit

GUHD30NK3FO

GUHD36NK3FO

GUHD36NM3FO

GUHD42NK3FO

Power Supply

220-240V~ 50Hz

380-415V 3N~

50Hz

220-240V~ 50Hz

Heat Exchange Cross Fin Coil

Compressor

Type

Rotary

Rotary

Rotary

Rotary

Power Input

W

2550

4150

4000

4150

Refrigerant

Control Electronic Expansion Valve

Charge

kg

2.4

3.4

3.5

3.7

Outline Dimensions (W×H×D)

mm

980×790×425

1105×1100×440

1105×1100×440

960×1350×410

Net Weight

kg

71

92

98

95

Piping

Connections

Liquid

Inch

Φ3/8

Φ3/8

Φ3/8

Φ3/8

Gas

Inch

Φ5/8

Φ5/8

Φ5/8

Φ5/8

Max. Length

m

30

30

30

50

Max. Height

m

15

15

15

30

U-Match Series DC Inverter Service Manual

13

Model

Indoor unit

GTH42K3FI

GTH48K3FI

GTH48K3FI

GTH60K3FI

Product Code

ED020N0710

ED020N0720

ED020N0720

ED020N0730

Outdoor unit

GUHD42NM3FO

GUHD48NK3FO

GUHD48NM3FO

GUHD60NM3FO

Product Code

CF090W0710

CF090W0720

CF090W0730

CF090W0740

Capacity

Cooling Capacity

kW

11.5(3.60-12.50)

14.0(6.00-14.80)

14.0(6.00-14.80)

16.0(7.4~16.5)

Heating Capacity

kW

13.5(3.90-15.50)

16.0(5.20-18.00)

16.0(5.20-18.00)

16.5(6.2~18.5)

PdesignH

kW

10.5

11.8

11.8

12.5

Power Input

Cooling

kW

3.90(0.60-4.70)

4.80(1.40-5.60)

4.80(1.40-5.60)

5.70(1.20-6.90)

Heating

kW

3.70(0.69-4.80)

4.30(1.30-5.50)

4.30(1.30-5.50)

4.60(1.20-6.90)

Design load Average

SEER / SCOP

W/W

5.6/4.0

5.6/3.8

5.6/4.0

5.1/4.0

Energy Rate(Cooling / Heating)

A+/A+

A+/A

A+/A+

A/A+

Indoor Unit

GTH42K3FI

GTH48K3FI

GTH48K3FI

GTH60K3FI

Power Supply 220-240V~ 50Hz

Heat Exchange

Cross Fin Coil

Cross Fin Coil

Cross Fin Coil

Cross Fin Coil

Fan

Drive

direct

direct

direct

direct

Motor Output

kW

0.14×1

0.19×1

0.19×1

0.20×1

Air Flow

m3/h

1900

2300

2300

2500

Sound Pressure Level(SS/H/M/L)

dB(A)

55/54/52/47

56/55/50/46

56/55/50/46

58/56/52/46

Air Filter Standard washable synthetic

Drain Piping

mm

Φ17×1.75

Φ17×1.75

Φ17×1.75

Φ17×1.75

Outline Dimensions (W×H×D)

mm

1420×245×700

1700×245×700

1700×245×700

1700×245×700

Net Weight

kg

50

59

59

59

Outdoor Unit

GUHD42NM3FO

GUHD48NK3FO

GUHD48NM3FO

GUHD60NM3FO

Power Supply

380-415V 3N~

50Hz

220-240V~ 50Hz

380-415V 3N~ 50Hz

Heat Exchange Cross Fin Coil

Compressor

Type

Rotary

Rotary

Rotary

Rotary

Power Input

W

4000

4580

4580

4580

Refrigerant

Control Electronic Expansion Valve

Charge

kg

3.7

4.0

4.0

5.0

Outline Dimensions (W×H×D)

mm

960×1350×410

960×1350×410

960×1350×410

1085×1365×425

Net Weight

kg

108

105

114

126

Piping

Connections

Liquid

Inch

Φ3/8

Φ3/8

Φ3/8

Φ3/8

Gas

Inch

Φ5/8

Φ5/8

Φ5/8

Φ3/4

Max. Length

m

50

50

50

50

Max. Height

m

30

30

30

30

U-Match Series DC Inverter Service Manual

14

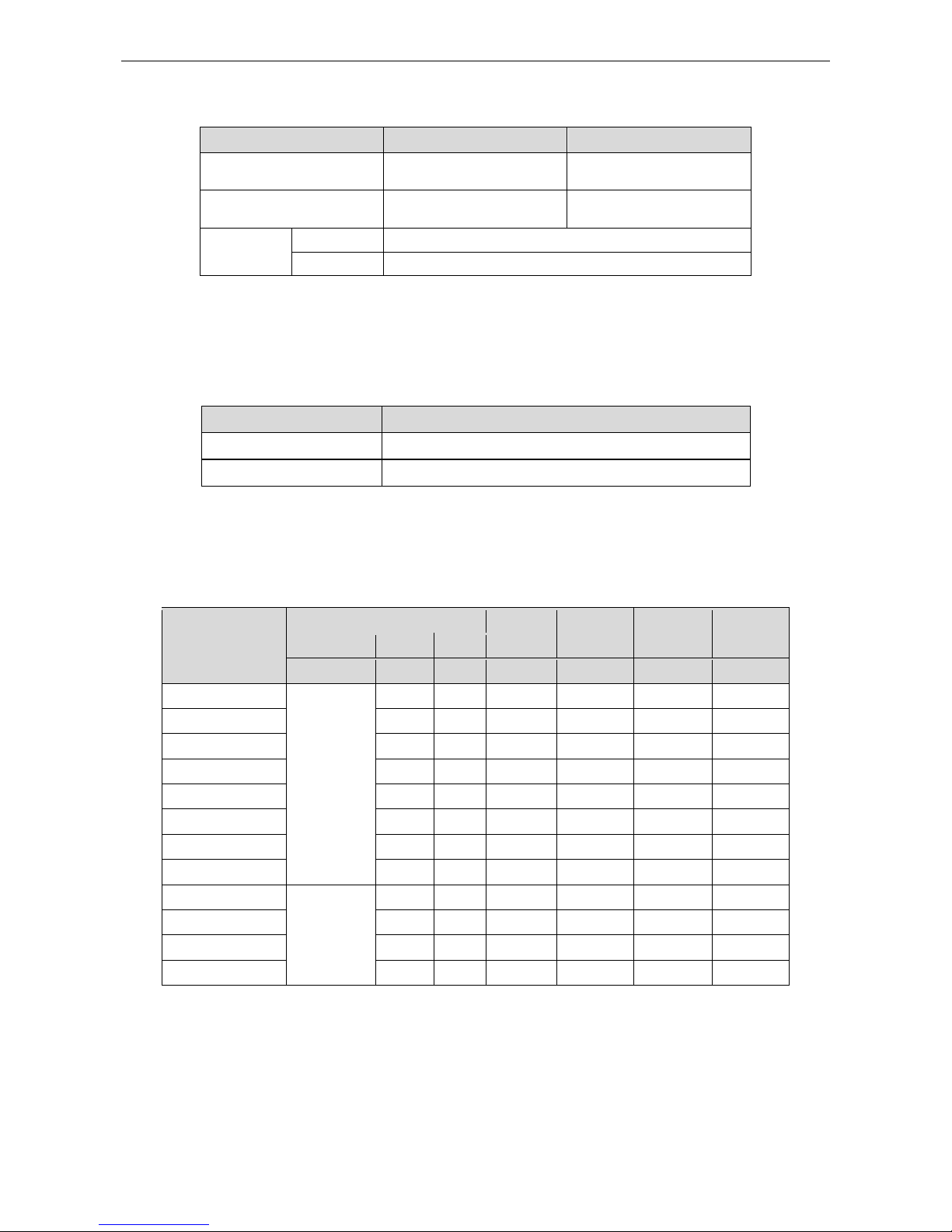

Note: Nominal capacities are based on the follow conditions.

Mode

Indoor

Outdoor

Cooling

DB:27(80.6)

WB:19(66.2)

DB:35(95)

WB:24(75.2)

Heating

DB:20(68)

WB:--(--)

DB:7(44.6)

WB:6(42.8)

Piping

Length

09k-42k

5m

48k-60k

7.5m

The air volume is measured at the relevant standard external static pressure.

Noise is tested in the semianechoic room, so it should be slightly higher in the actual operation due

to environmental change.

3.2 Operation Range

Mode

Range of Outdoor Temperature

Cooling

-15-48

Heating

-10-24

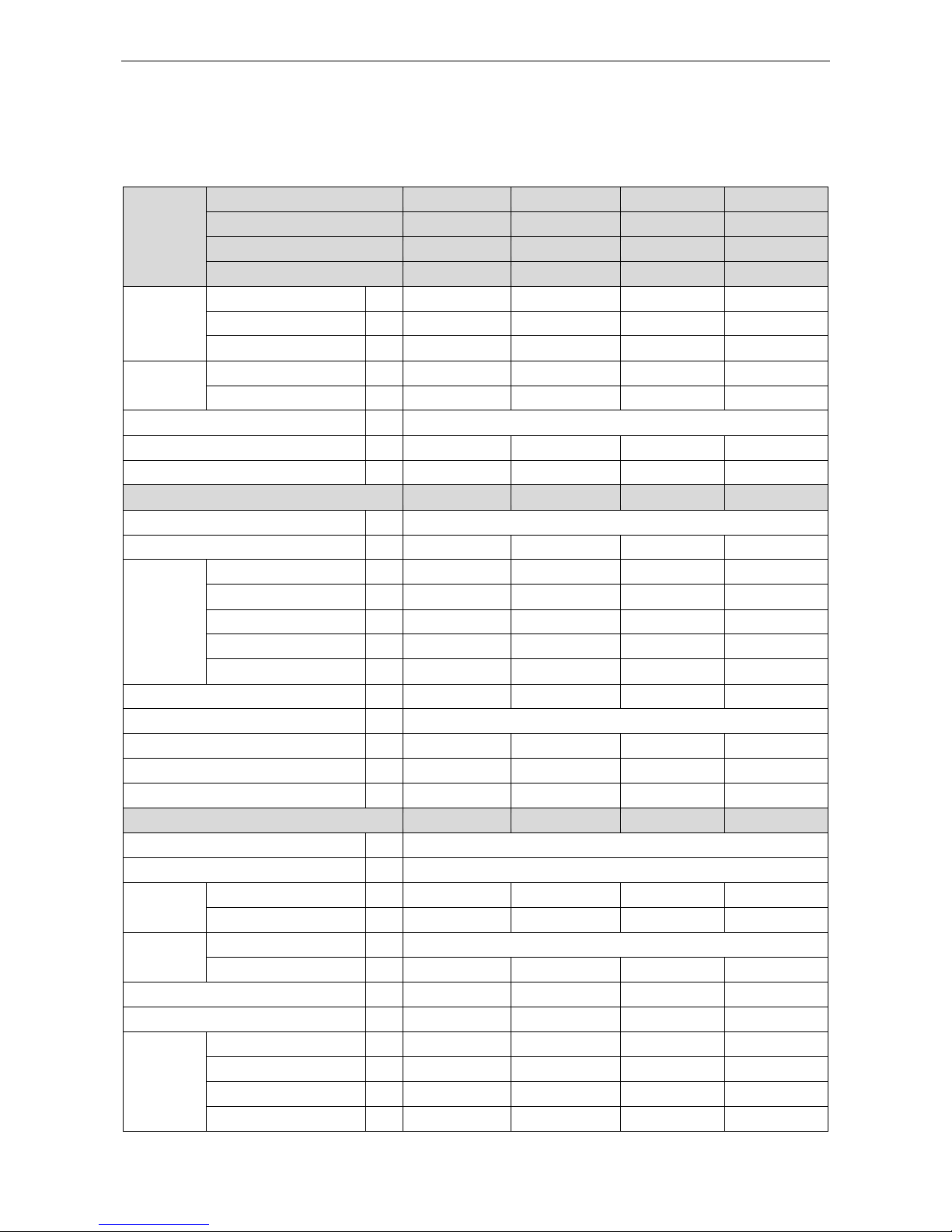

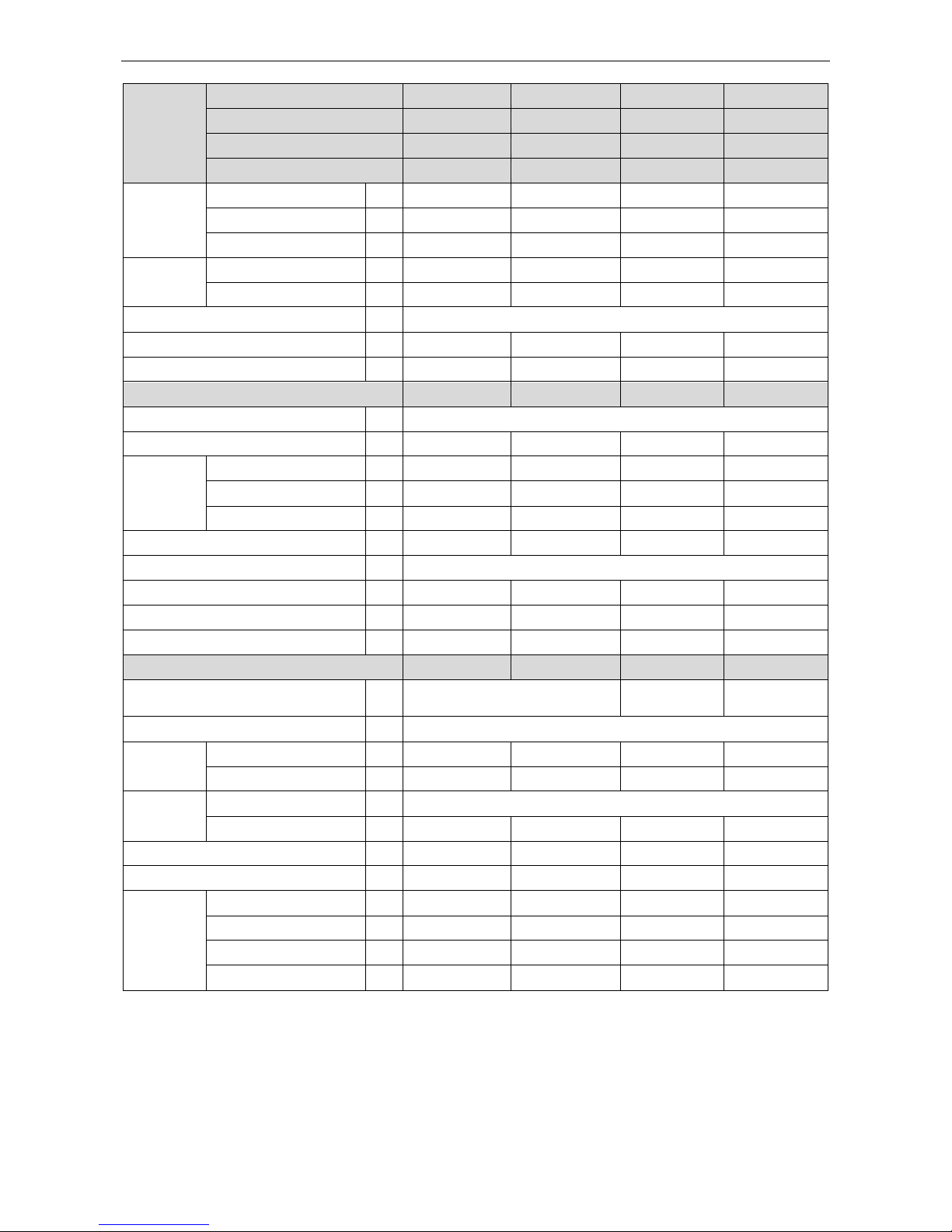

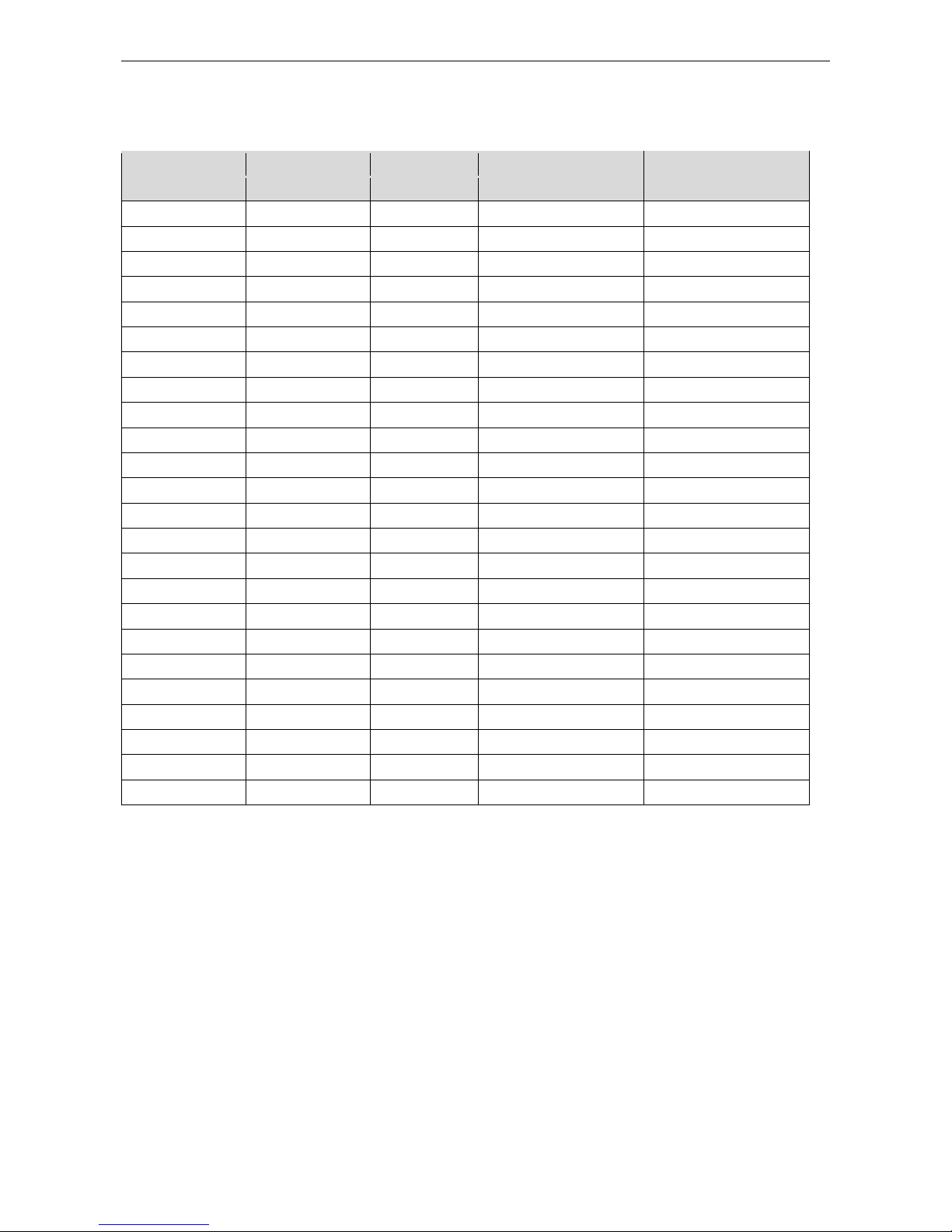

3.3 Electrical Data

3.3.1 Outdoor unit

Table 1-4-1 Electrical Data of Outdoor Unit

Model

Compressor

Fan Motor

Fuse

Capacity

Breaker

Capacity

Min. Power

Supply Cord

Power Supply

Qty.

RLA

FLA

V/Ph/Hz

− A A A A

mm2

GUHD09NK3FO

220-240,1,50

1

4.5

<1

3.15/5

10

1.0

GUHD12NK3FO

1

4.5

<1

3.15/5

10

1.0

GUHD18NK3FO

1

7.2

<1

5/15

16

1.5

GUHD24NK3FO

1

11.5

<1

5/30

20

2.5

GUHD30NK3FO

1

11.5

<1

5/30

20

2.5

GUHD36NK3FO

1

19

<1

5/30

32

4.0

GUHD42NK3FO

1

19

<1

5/30

32

4.0

GUHD48NK3FO

1

21

<1

3.15/5

40

6.0

GUHD36NM3FO

380-415,3,50

1

8

<1

5

16

1.5

GUHD42NM3FO

1

8

<1

5

16

1.5

GUHD48NM3FO

1

8

<1

5

16

1.5

GUHD60NM3FO

1

8

<1

5

16

1.5

U-Match Series DC Inverter Service Manual

15

3.3.2 Indoor unit

Table 1-4-2 Electrical Data of Indoor Unit

Model

Power Supply

Fan Motor FLA

Fuse/Breaker Capacity

Min. Power Supply Cord

V/Ph/Hz A A

mm2

GFH09K3FI

220-240,1,50

<1

5/6

1.0

GTH09K3FI

220-240,1,50

<1

5/6

1.0

GFH12K3FI

220-240,1,50

<1

5/6

1.0

GTH12K3FI

220-240,1,50

<1

5/6

1.0

GKH12K3FI

220-240,1,50

<1

5/6

1.0

GFH18K3FI

220-240,1,50

<1

5/6

1.0

GTH18K3FI

220-240,1,50

<1

5/6

1.0

GKH18K3FI

220-240,1,50

<1

5/6

1.0

GFH24K3FI

220-240,1,50

<1

5/6

1.0

GTH24K3FI

220-240,1,50

<1

5/6

1.0

GKH24K3FI

220-240,1,50

<1

5/6

1.0

GFH30K3FI

220-240,1,50

<1

5/6

1.0

GTH30K3FI

220-240,1,50

<1

5/6

1.0

GKH30K3FI

220-240,1,50

<1

5/6

1.0

GFH36K3FI

220-240,1,50

<1

5/6

1.0

GTH36K3FI

220-240,1,50

<1

5/6

1.0

GKH36K3FI

220-240,1,50

<1

5/6

1.0

GFH42K3FI

220-240,1,50

<1

5/6

1.0

GTH42K3FI

220-240,1,50

<1

5/6

1.0

GKH42K3FI

220-240,1,50

<1

5/6

1.0

GFH48K3FI

220-240,1,50

<1

5/6

1.0

GTH48K3FI

220-240,1,50

<1

5/6

1.0

GFH60K3FI

220-240,1,50

<1

5/6

1.0

GTH60K3FI

220-240,1,50

<1

5/6

1.0

Notes:

RLA: Rated load amperes

LRA: Locked rotor amperes

FLA: Full load current

①

Install the disconnect device with a contact gap of at least 3mm in all poles nearby the units

(Both indoor unit and outdoor unit).The appliance must be positioned so that the plug is

accessible.

②

The specifications of the breaker and power cable listed in the table above are determined based

on the maximum power (maximum amps) of the unit.

③

The specifications of the power cable listed in the table above are applied to the conduit-guarded

multi-wire copper cable (like, YJV copper cable, consisting of PE insulated wires and a PVC

cable jacket) used at 40°С and resistible to 90°С (see IEC 60364-5-52). If the working condition

U-Match Series DC Inverter Service Manual

16

changes, they should be modified according to the related national standard.

④

The specifications of the breaker listed in the table above are applied to the breaker with the

working temperature at 40°С. If the working condition changes, they should be modified

according to the related national standard.

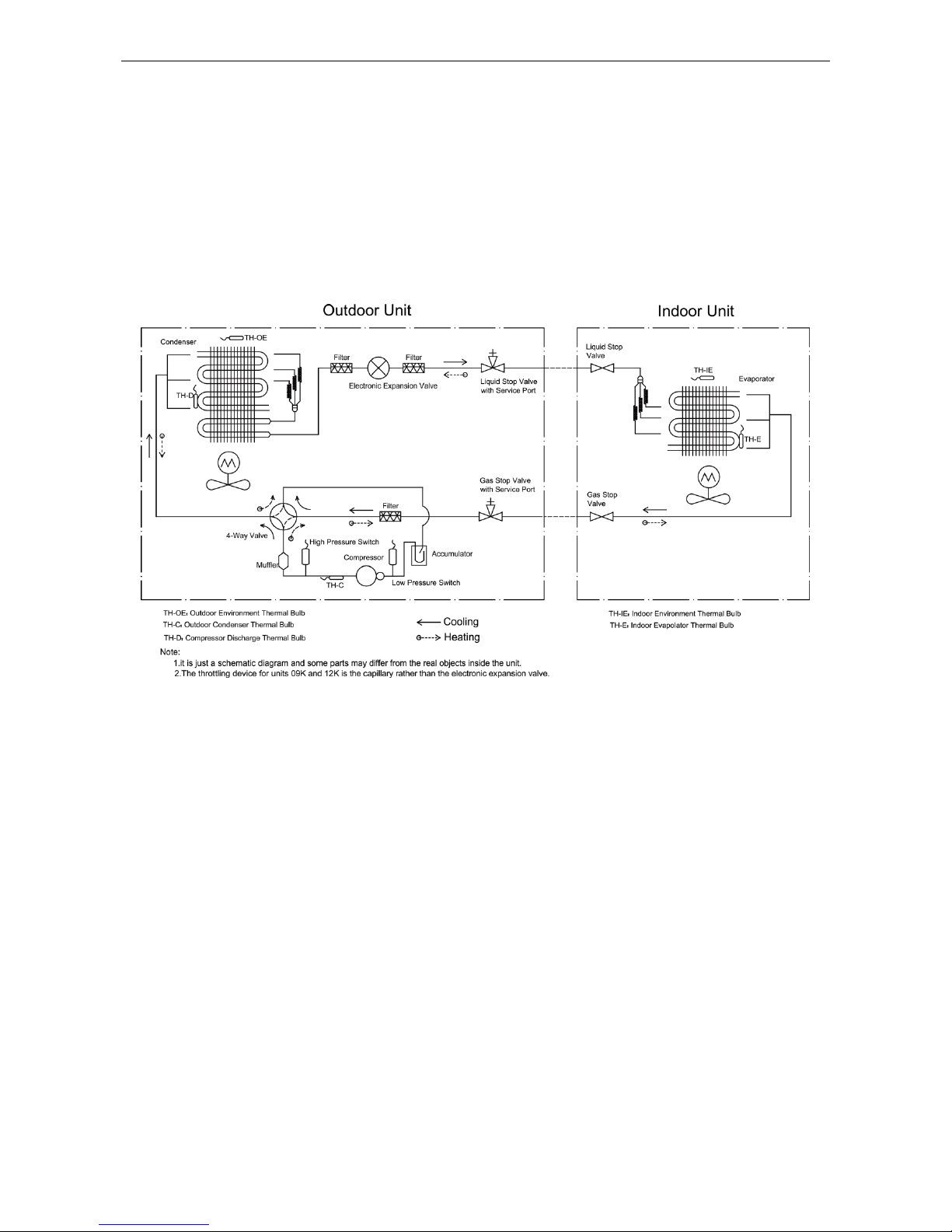

4 PIPING DIAGRAM

U-Match Series DC Inverter Service Manual

17

CONTROL

U-Match Series DC Inverter Service Manual

18

CONTROL

1 OPERATION FLOWCHART

1.1 Cooling/Dry Operation

U-Match Series DC Inverter Service Manual

19

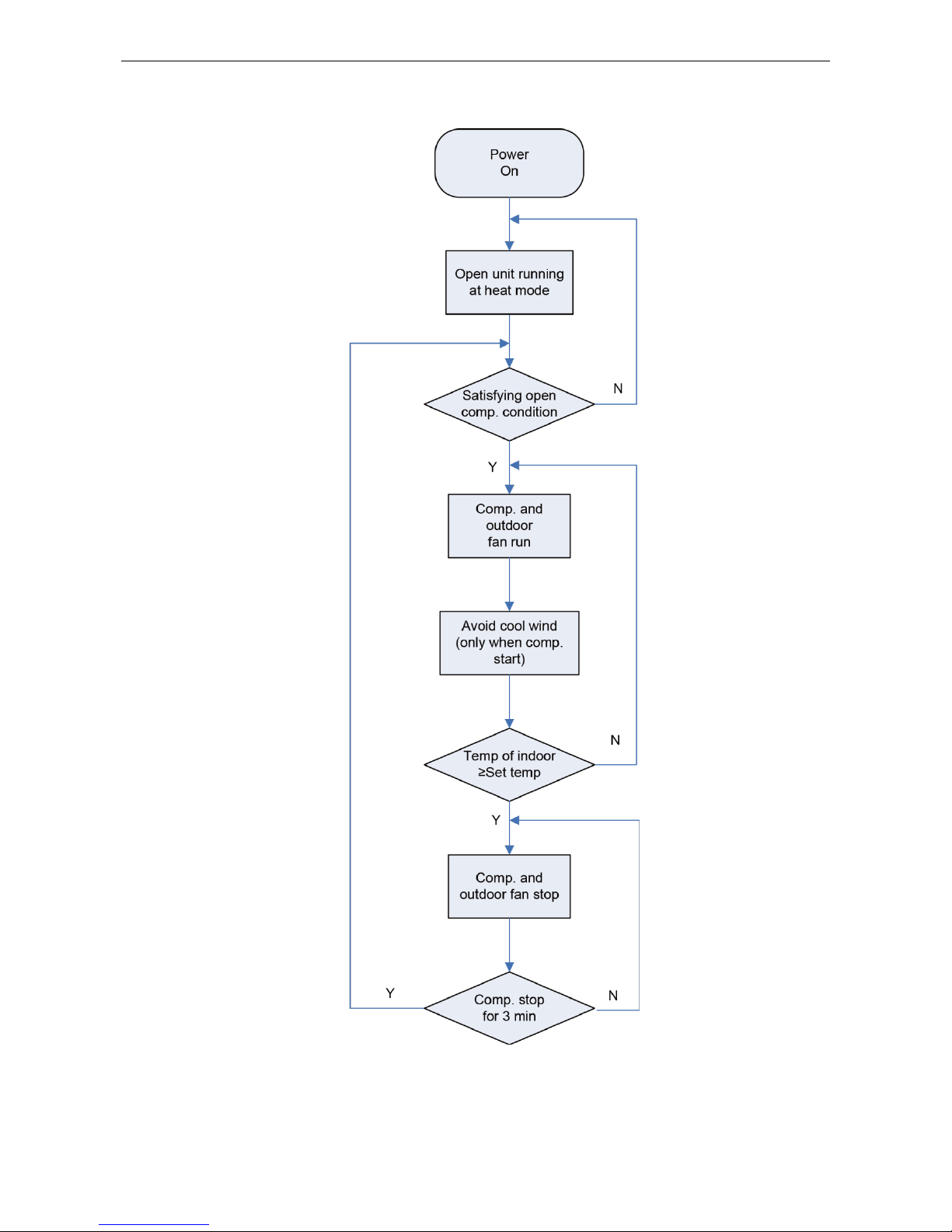

1.2 Heating Operation

U-Match Series DC Inverter Service Manual

20

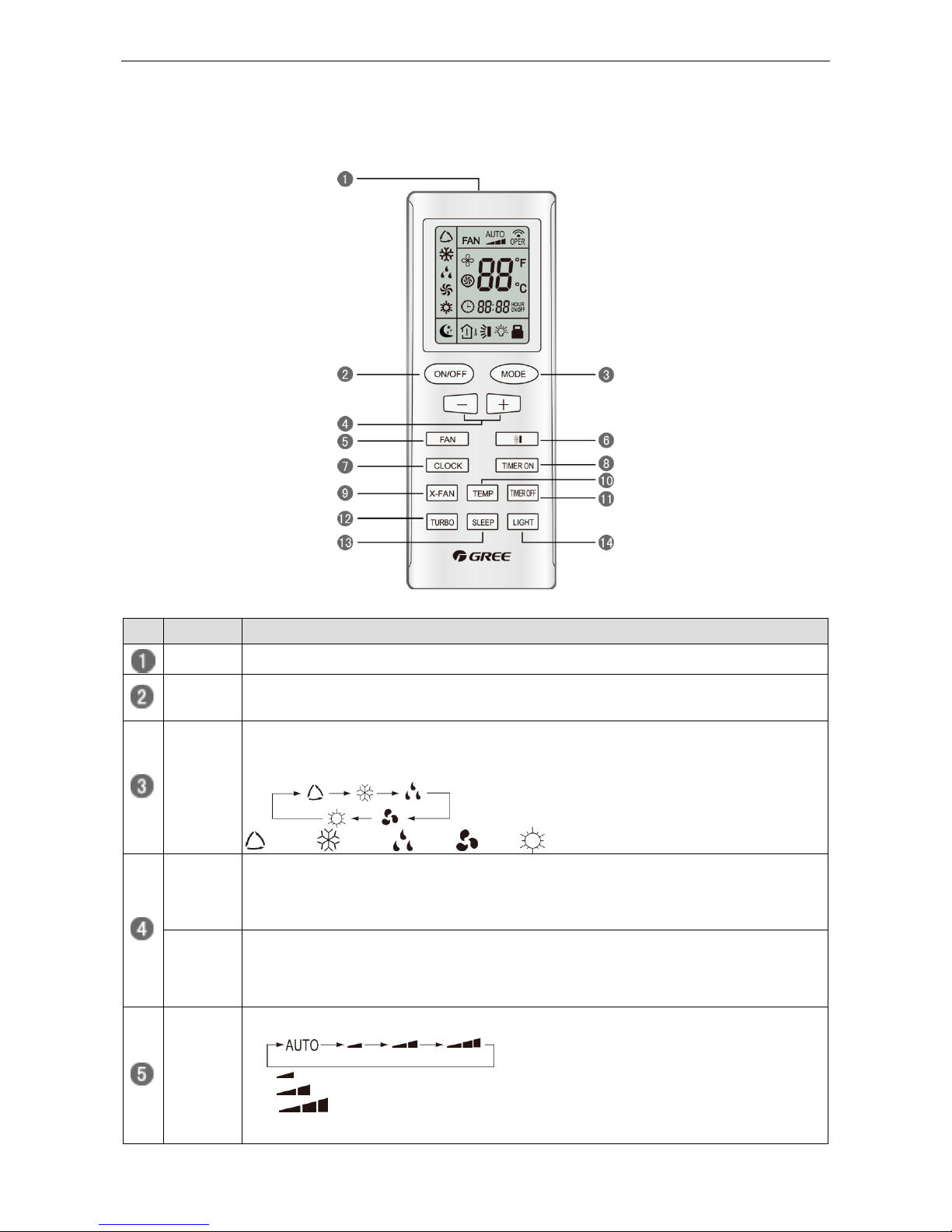

2 WIRELESS REMOTE CONTROLLER

2.1 Operation and Display View

Table 2-2-1 Operation instruction of wireless remote controller

No.

Name

Function Description

Signal

transmitter

Signal transmitter

ON/OFF

button

Press this button and the unit will be turned on; press it once more and the unit will be turned off.

When turning off the unit, the Sleep function will be canceled, but the presetting time is still

remained.

MODE

button

By pressing this button, Auto, Cool, Dry, Fan, Heat mode can be selected circularly. Auto

mode is default after power on. Under the Auto mode, the setting temperature will not be

displayed; Under the Heat mode, the initial value is 28°C (82°F); under other modes, the initial

value is 25°C (77°F).

AUTO; COOL; DRY; FAN; HEAT (only for cooling and heating unit)

- button

Preset temperature can be decreased by pressing this button. Pressing and holding this button

for more than 2 seconds can make the temperature changed quickly until release this button and

then transmit this order. The temperature adjustment is unavailable under the Auto mode, but

the order can be sent by pressing this button. Centigrade setting range: 16-30; Fahrenheit scale

setting range 61-86.

+ button

Preset temperature can be increased by pressing this button. Pressing and holding this button

for more than 2 seconds can make the temperature changed quickly until release the button and

then transmit this order. The temperature adjustment is unavailable under the Auto mode, but

the order can be sent by pressing this button. Centigrade setting range: 16-30; Fahrenheit scale

setting range 61-86.

FAN

button

By pressing this button, Auto, Low, Middle, High speed can be circularly selected. After power

on, Auto fan speed is default.

Low speed

Middle speed

High speed

Note: Under the DRY mode, the fan will be kept running at the low speed and the fan speed isn't

adjustable.

U-Match Series DC Inverter Service Manual

21

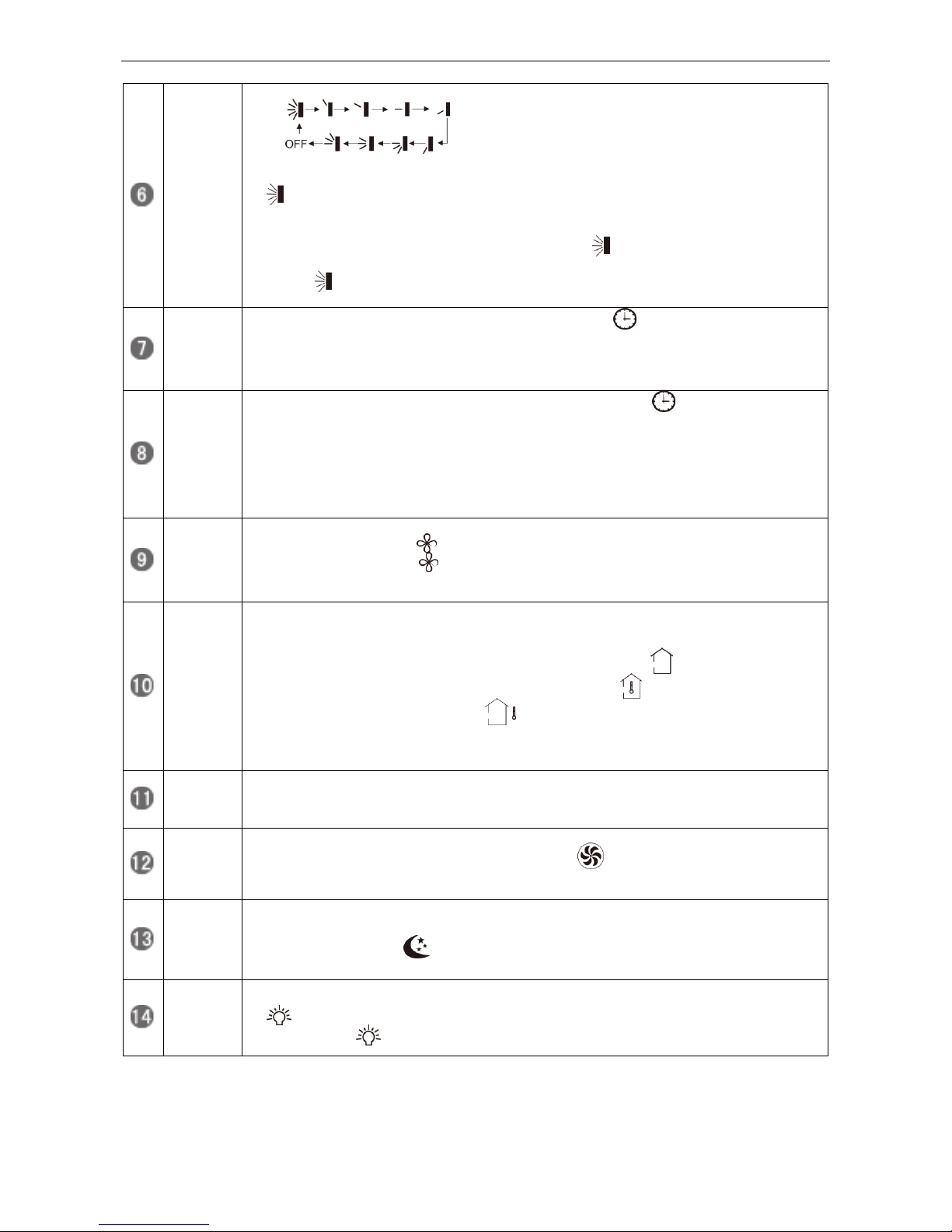

SWING

UP/DOW

N button

Press this button to set up the swing angle, which circularly changes as below:

When the guide louver starts to swing up and down, if SWING functions are canceled, the air

guide louver will stop and remains at the current position.

Indicates the guide louver swings up and down among those five directions.(Simplified

SWING function applicable for some Fan Coil Units: When the wireless remote controller is

energized initially with the unit under the OFF status, it should be set by pressing the + button

and the SWING button simultaneously, with the symbol blinking twice. Then, after the unit is

turned on, this function can be activated by pressing the SWING button, with the displayed

symbol indicating swing function is on and without this displayed symbol indicating swing

function is off.)

CLOCK

button

By pressing this button, the clock is allowed to be set, with blinking, and then press the +/-

button to adjust the clock within 5 seconds. If the +/-button is pressed down constantly for more

than 2 seconds, the clock setting will be increased or decreased 10 minutes every 0.5 seconds.

After that, another press on the CLOCK button accepts the setting. 12:00 is the default, when

the wireless remote controller is energized.

TIMER

ON button

When TIMER ON is activated, ON will blink while the symbol will disappear. Within 5

seconds it is allowed to set the ON time by pressing the +/- button. Each press will make the

time increase or decrease one minute. Besides, the time can also be set by pressing the +/button constantly. That is, in the early 2.5 seconds, the time will increase/decrease quickly per

single minute, and in the late 2.5, the time will increase/decrease per ten minutes. After the

desired time value is set, press TIENE ON again to conform the setting within five seconds. After

that, another press on TIMER ON will cancel the setting. Prior to this setting, the clock shall be

set to the actual time.

X-FAN

button

Pressing this button can activate or deactivate the X-FAN function. In Cool or Dry mode, by

pressing this button, if " " is displayed, it indicates the X-FAN function is activated. By

repressing this button, if " " disappears, it indicates the X-FAN function is deactivated. After

energization, X-FAN OFF is defaulted. If the unit is turned off, X-FAN can be deactivated but

can't be activated.

TEMP

button

By pressing this button it is allowed to select displaying the indoor setting temperature or the

indoor ambient temperature.

Indoor setting temperature is default after the indoor unit is energized initially.

By pressing the TEMP button, when the temperature symbol is displayed, the indoor

displayer will show the indoor setting temperature; when is displayed, it will show the

indoor ambient temperature; when is invalidation, If current displays indoor ambient

temperature, if received the other remote control signal, it will display presetting temperature, 5s

later, will back to display the ambient temperature. (This function is applicable to partial of

models)

TIMER

OFF

button

By pressing this button it is available to go to the TIMER OFF setting state with the same setting

method as that of the TIMER ON, in which case the OFF symbol blinks.

TURBO

button

In the Cool or Heat mode, pressing this button can activate or deactivate the TURBO function.

When the TURBO function is activated, its symbol will be displayed; when the running

mode or the fan speed is changed, this function will be canceled automatically. (This function is

applicable to partial of models).

SLEEP

button

By pressing this button, Sleep On and Sleep Off can be selected. After powered on, Sleep Off is

defaulted. Once the unit is turned off, the Sleep function is canceled. When Sleep is set to on,

the symbol of SLEEP will display. Under the Fan and Auto modes, this function is not

available.

LIGHT

button

Press this button to select LIGHT on or off in the displayer. When the LIGHT is set to on, the icon

will be displayed and the indicating light in the displayer will be on. When the LIGHT is set

to off, the icon will be disappeared and the indicating light in the displayer will be off.

U-Match Series DC Inverter Service Manual

22

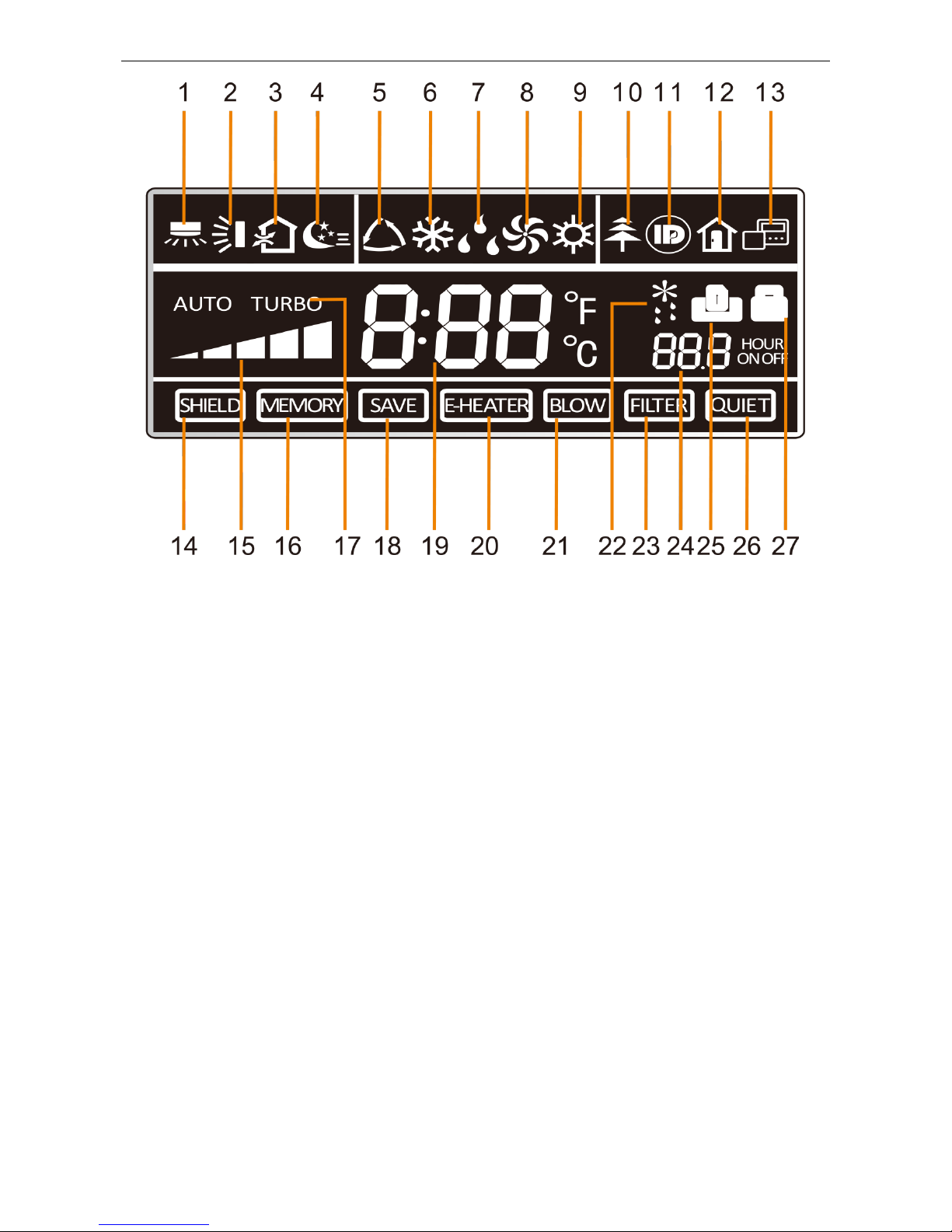

3 WIRED CONTROLLER

3.1 Display View

Figure 2-3-1 Appearance of wired controller

U-Match Series DC Inverter Service Manual

23

Figure 2-3-2 LCD display of wired controller

U-Match Series DC Inverter Service Manual

24

Table 2-3-1 Instruction to LCD Display

No.

Icons

Introduction

1 Left and right swing function

2 Up and down swing function

3 Air exchange function

4 Sleep function

5 Auto mode

6 COOL mode

7 DRY mode

8 FAN mode

9 HEAT mode

10 Health function

11 I-Demand function

12 Vacation function

13 Status display of master and slave wired controller

14

Shield function

The button operation, temperature setting, "On/Off" operation, "Mode" setting,

and "Save" setting are disabled.

15 Fan speed

16

Memory function

The unit will resume the original setting state after power recovery.

17 Turbo function

18 Energy-saving function

19 Ambient/setting temperature

20 Electric heater

21 Blow function

22 Defrosting function

23 Filter cleaning

24 Timer Setting

25 Keycard control / Detected status sensed by human body

26 Quiet function

27 Lock function

U-Match Series DC Inverter Service Manual

25

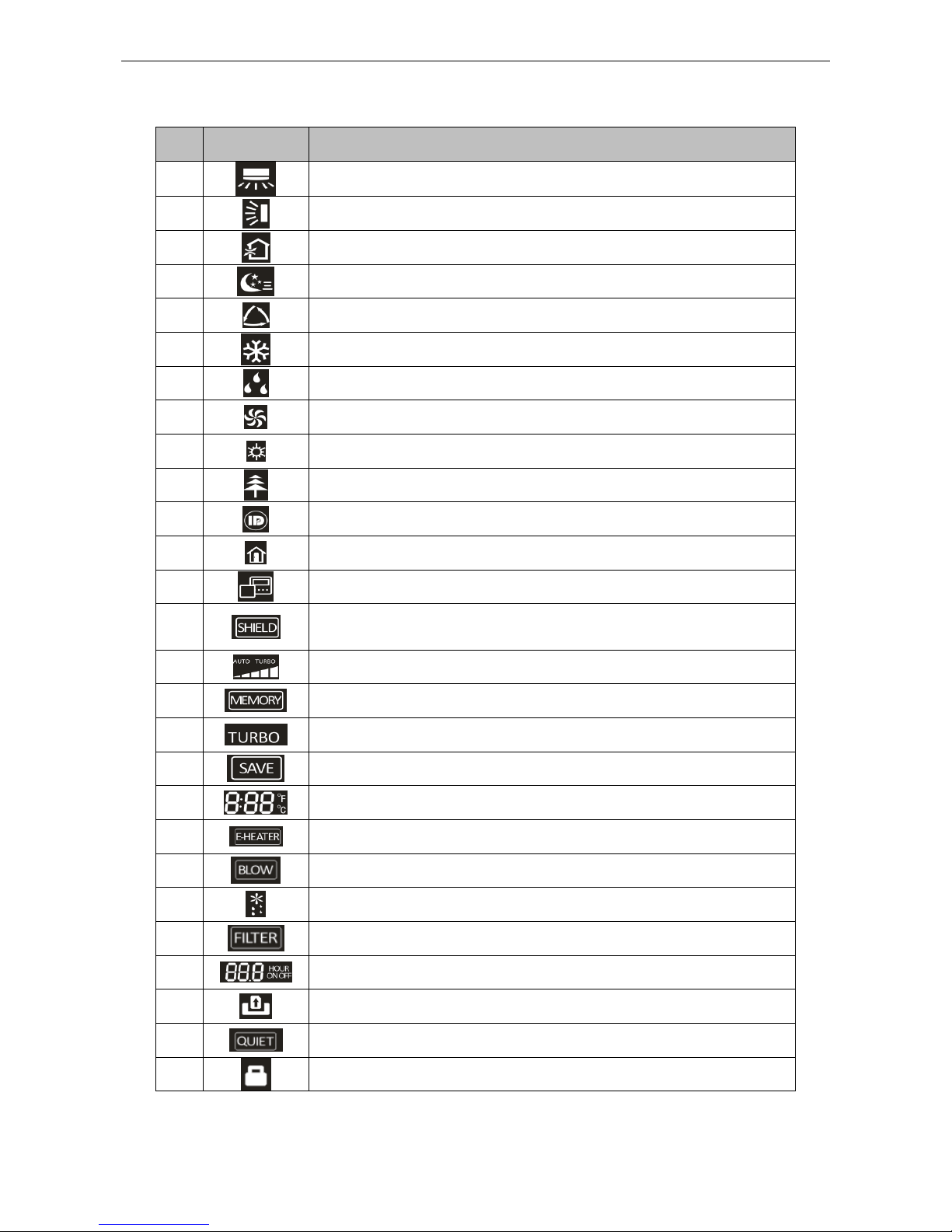

3.2 Operation View

3.2.1 Silk Screen of Buttons

Figure 2-3-3 Silk screen of buttons

3.3.2 Instruction to Function of Buttons

Table 2-3-2 Instruction to buttons of wired controller

No.

Description

Functions

1

Enter/Cancel

(1)Function selection and canceling;

(2)Press it for 5s to view the ambient temperature; press Mode button to

select viewing outdoor ambient temperature or indoor ambient temperature.

2

▲

(1) Running temperature setting range of indoor unit: 16-30℃;

(2) Timer setting range: 0.5-24hr;

(3) Setting of air function level;

(4) Setting of energy-saving temperature;

(5) Setting of cleaning class.

6

▼

3

Fan

Setting of high/medium high/medium/medium low/low/auto fan speed.

4

Mode

Setting of auto/cooling/heating/fan/dry mode of indoor unit.

5

Function

Switch over among these functions of swing/air/sleep/health/

I-Demand/out/turbo/save/e-heater/X-fan/clean/quiet.

7

Timer

Timer setting.

8

On/Off

Turn on/off indoor unit.

4 Mode and

2 ▲

Memory function

Press Mode and ▲ buttons at the same time for 5s under off state of the unit

to enter/cancel memory function (If memory function is set, indoor unit will

resume original setting state after power failure and then power recovery. If

not, indoor unit is defaulted to be off after power recovery. Ex-factory setting

of memory function is on).

2 ▲ and

6 ▼

Lock

Upon startup of the unit without malfunction or under off state of the unit,

press ▲ and ▼ buttons at the same time for 5s to enter lock state. In this

case, any other buttons won‟t respond when pressing. Repress ▲ and ▼

buttons for 5s to quit lock state.

4 Mode and

5 Function

Enquiry and

setting of address

of wired controller

Under off state of the unit, press Mode and Function buttons at the same time

for 5s to set the address. (More details please refer to project debugging)

5 Function and

7 Timer

Setting of project

parameters (More

details please

refer to the Notes)

Under off state of the unit, press Function and Timer buttons at the same time

for 5s to go to the debugging menu. Press Mode button to adjust the setting

items and press ▲ or ▼ buttons to set the actual value.

4 Mode and

6 ▼

Switch between

Fahrenheit and

Centigrade

Under off state of the unit, press Mode and ▼ buttons at the same time for 5s

to switch between Fahrenheit and Centigrade.

5 Function and

6 ▼

Viewing historical

malfunction

Continuously press Function and ▼ buttons for 5s to view historical

malfunction. Then press ▲ and ▼ buttons to adjust displayed contents. The

timer displaying position displays the sequence of malfunction and the

detailed error code. The 5th displayed malfunction is the last malfunction.

1 Enter/Cancel

and

4 Mode

Setting of master

and slave wired

controller

Under off state of the unit, press Enter/Cancel and Mode buttons at the same

time for 5s to set master and slave wired controller. Press ▲ or ▼ button to

adjust. (More details please refer to project debugging)

U-Match Series DC Inverter Service Manual

26

Notes:

The following functions can be set through Function and Timer buttons: setting of ambient

temperature sensor, selecting three speeds in high speed and three speeds in low speed of indoor fan

motor, display setting of freeze protection error code, setting of cold air prevention and hot air hot

prevention function, setting of refrigerant-lacking protection function, selecting of blowing residual heat of

indoor unit, selecting of compressor electric heater mode, selecting of low-power consumption mode,

selecting door control function, selecting human sensitive function, long-distance monitoring,

temperature compensation value at the air return port.

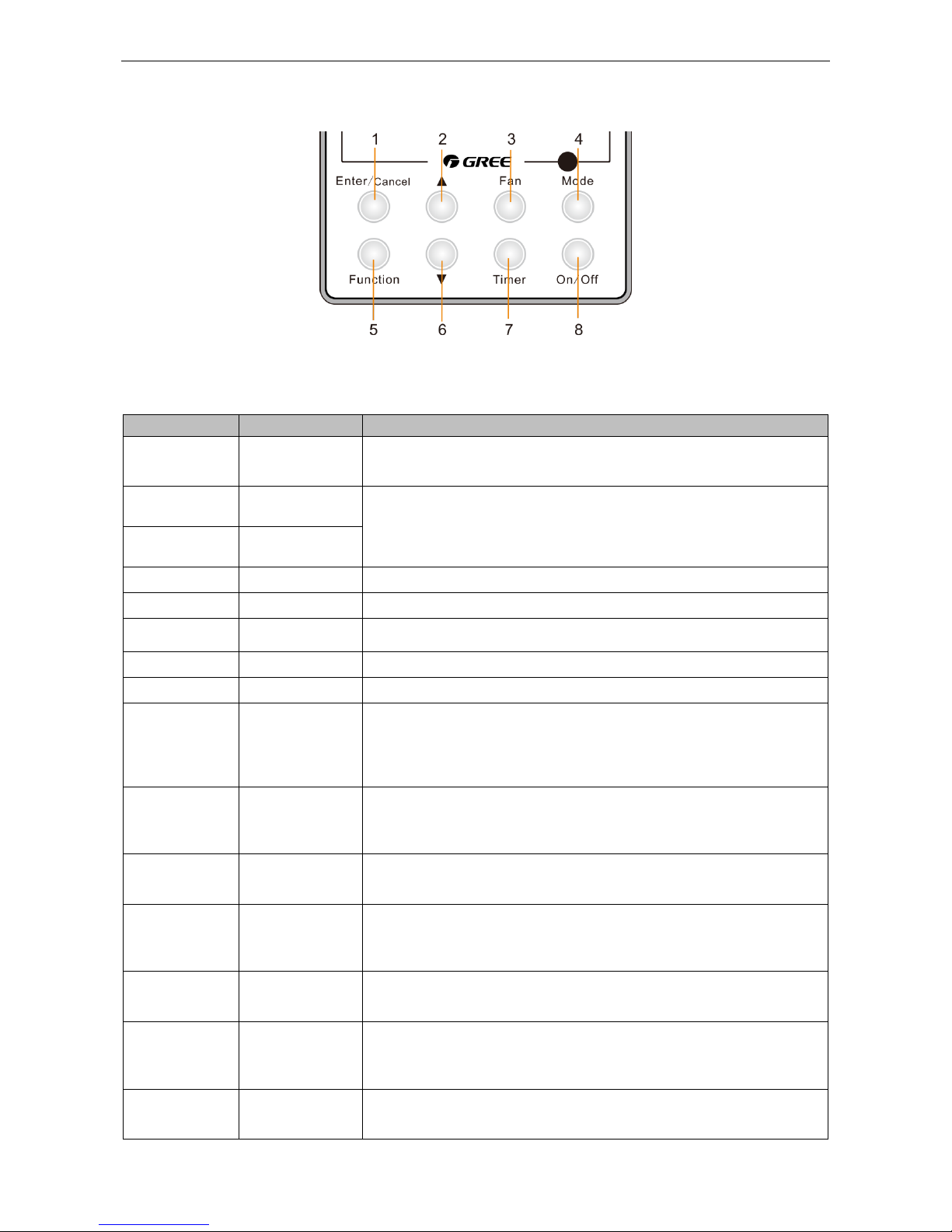

3.2.3 Setting of Wired Controller’s Address

3.2.3.1 Enquiry and Setting of Wired Controller’s Address

Under off state of the unit, press Function and Mode buttons at the same time for 5s to enter setting

interface of wired controller‟s address. In this case, LCD displays address number. Then press▲ or ▼

button to adjust address and then press Enter/Cancel button to confirm. The address setting is related to

the setting of Debugging Function 4.9.10. When the selection in 4.9.10 is 00, address of centralized

controller is to be set and the address setting range is 01~16; when the selection in 4.9.10 is 01, address

of long-distance monitor is to be set and the address setting range is 01~255.

Enquiry and setting of wired controller‟s address is shown as Figure 2-3-4 below:

Figure 2-3-4 Enquiry and setting of wired controller‟s address

U-Match Series DC Inverter Service Manual

27

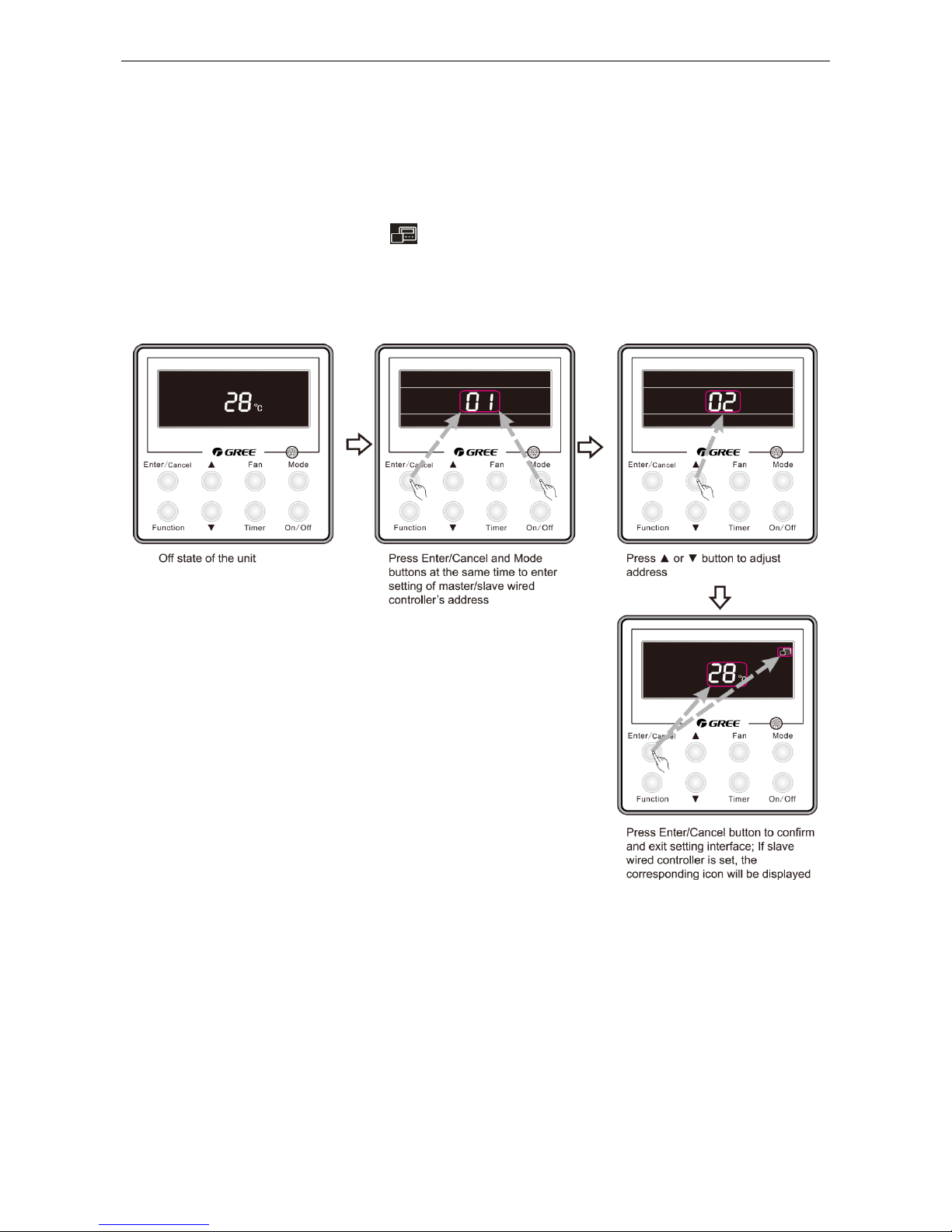

3.2.3.2 Setting of Master/Slave Wired Controller’s Address

Under off status of the unit, press Enter/Cancel and Mode buttons at the same time for 5s to go to

the enquiry and setting interface of master/slave wired controller. In this case, LCD displays wired

controller‟s address (01 for master wired controller and 02 for slave wired controller). Press ▲ or ▼

button to adjust address of master/slave wired controller and then press Enter/Cancel button to confirm.

If slave wired controller is set, the icon will be displayed.

Note: If there is only one wired controller, it only can be set as the master; if there are two wired

controllers, one should be the master and the other should be the slave.

Setting of master/slave wired controller‟s address is shown as Figure 2-3-5 below:

Figure 2-3-5 Enquiry and setting of master/slave wired controller‟s address

Loading...

Loading...