Gree GUD100W/NhA-T, GUD125W/NhA-T, GUD140W/NhA-T, GUD100W/NhA-X, GUD125W/NhA-X Service Manual

...

1

U-Match 5 SERIES UNIT SERVICE MANUAL

Capacity: 3.5KW~16.0KW

Rate Frequency: 50/60Hz

Operation Range: -20°C ~48℃

Foreword

Thank you for choosing Gree U-Match air conditioners. In order to correctly install and use our units, and for

the satisfactory operation effect, please read this manual carefully.

This manual specifies safe operation requirements from perspectives of product introduction, control,

troubleshooting and maintenance, as well as basic principles and implementation methods. Professional

operators must abide by relevant national (local) safety requirements and technical specifications set forth in this

manual during operations; otherwise, the air conditioning system may fail or be damaged, and personnel safety

accident may also occur.

Safety Notice

The air conditioner is charged with inflammable refrigerant R32.

Before using the air conditioner, please first read the instruction manual.

Before installing the air conditioner, please first read the instruction manual.

Before repairing the air conditioner, please first read the technical service manual.

Compared with common refrigerant, R32 is an environmental-friendly refrigerant that has no harm to the ozone layer and weak

greenhouse effect. Its GWP is 675. Because of its thermodynamic characteristics, R32 requires a smaller charging quantity to reach

high energy efficiency. It is inflammable and odourless, but may cause explosion under certain circumstances.

CONTENTS

1. SAFETY NOTICE ON MAINTENANCE ......................................................................................................... 1

2. SAFETY NOTICE ON OPERATION ............................................................................................................... 2

1. PRODUCT INTRODUCTION ............................................................................................................................ 3

1.1 Lists of Units ..................................................................................................................................................................... 3

1.1.1 List of ODUs ....................................................................................................................................................................... 3

1.1.2 List of IDUs ......................................................................................................................................................................... 4

1.2 Electrical Parameters ........................................................................................................................................................ 8

2. CONTROL ............................................................................................................................................................... 9

2.1 Operation Mode ............................................................................................................................................................... 9

2.1.1 Cooling Mode ..................................................................................................................................................................... 9

2.1.2 Heating Mode ................................................................................................................................................................... 10

2.2 Control Mode ................................................................................................................................................................. 10

2.2.1 Based Control ................................................................................................................................................................... 10

2.2.2 Special Control ................................................................................................................................................................. 11

2.2.3 Protection Control ............................................................................................................................................................ 12

2.3 Functions ....................................................................................................................................................................... 12

2.3.1 Setting of Filter Cleaning Reminder .............................................................................................................................. 12

2.3.2 Low-temperature Drying Function ................................................................................................................................. 13

2.3.3 Child-lock Function .......................................................................................................................................................... 13

2.3.4 Memory Function ............................................................................................................................................................. 13

2.3.5 Door Control Function ..................................................................................................................................................... 13

2.3.6 Switch between Fahrenheit and Degree Celsius ........................................................................................................ 14

2.3.7 Inquiry of Ambient Temperature ..................................................................................................................................... 14

2.3.8 Inquiry of Historical Malfunction ..................................................................................................................................... 14

2.3.9 Debugging Function ........................................................................................................................................................ 14

2.3.10 Connect to Interface of Centralized Control .............................................................................................................. 17

3. TROUBLESHOOTING ......................................................................................................................................19

3.1 Wiring Diagrams ............................................................................................................................................................. 19

3.1.1 Wiring Diagrams of ODUs .............................................................................................................................................. 19

3.1.2 Wiring Diagrams of IDUs ................................................................................................................................................ 23

3.2 PCB Layout ..................................................................................................................................................................... 26

3.2.1 Interface ............................................................................................................................................................................ 26

3.2.2 IPM,PFC Testing Method ................................................................................................................................................ 37

3.3 Error Code ...................................................................................................................................................................... 39

3.4 Troubleshooting ............................................................................................................................................................. 41

3.4.1 ―E1‖ Compressor High Pressure Protection ................................................................................................................ 41

3.4.2 ―E2‖ Indoor Anti-freezing Protection .............................................................................................................................. 42

3.4.3 ―E3‖ Compressor Low-pressure Protection, Refrigerant Shortage Protection, Refrigerant Recovery Mode ..... 43

3.4.4 ―E4‖ Compressor Air Discharge High-temperature Protection .................................................................................. 44

3.4.5 ―E6‖ Communication Error .............................................................................................................................................. 45

3.4.6 ―E8‖ Indoor Fan Error ...................................................................................................................................................... 46

3.4.7 ―E9‖ Water Overflow Protection ..................................................................................................................................... 47

3.4.8 ―F0‖ Indoor Ambient Temperature Sensor Error .......................................................................................................... 48

3.4.9 ―F1‖ Evaporator Temperature Sensor Error ................................................................................................................. 49

3.4.10 ―F2‖ Condenser Temperature Sensor Error ............................................................................................................... 50

3.4.11 ―F3‖ Outdoor Ambient Temperature Sensor Error ..................................................................................................... 51

3.4.12 ―F4‖ Discharge Temperature Sensor Error ................................................................................................................ 52

3.4.13 ―F5‖ Wired Control Temperature Sensor Error .......................................................................................................... 53

3.4.14 ―C5‖ IDU Jumper Cap Error ......................................................................................................................................... 54

3.4.15 ―EE‖ IDU or ODU Memory Chip Error ......................................................................................................................... 54

3.4.16 ―PF‖ Electric Box Sensor Error .................................................................................................................................... 55

3.4.17 ―H3‖ Compressor Overload Protection ....................................................................................................................... 56

3.4.18 ―H4‖ Overload ................................................................................................................................................................. 56

3.4.19 ―H5‖ IPM Protection ....................................................................................................................................................... 57

3.4.20 ―H6‖ DC Fan Error ......................................................................................................................................................... 58

3.4.21 ―H7‖ Driver Out-of-Step Protection .............................................................................................................................. 59

3.4.22 ―HC‖ PFC Protection ..................................................................................................................................................... 60

3.4.24 ―Lp‖ IDU and ODU Unmatched .................................................................................................................................... 62

3.4.25 ―U7‖ 4–Way Valve Switch-Over Error ......................................................................................................................... 63

3.4.26 ―P0‖ Driver Reset Protection ........................................................................................................................................ 63

3.4.27 ―P5‖ Over-Current Protection ....................................................................................................................................... 64

3.4.28 ―P6‖ Master Control and Driver Communication Error ............................................................................................. 65

3.4.29 ―P7‖ Driver Module Sensor Error ................................................................................................................................. 66

3.4.30 ―P8‖ Driver Module High Temperature Protection ..................................................................................................... 67

3.4.31 ―PA‖ AC Current Protection .......................................................................................................................................... 67

3.4.32 ―Pc‖ Driver Current Error .............................................................................................................................................. 68

3.4.33 ―Pd‖ Sensor Connection Protection ............................................................................................................................ 69

3.4.34 ―PL‖ Bus Low-Voltage Protection ................................................................................................................................ 69

3.4.35 ―PH‖ Bus High-Voltage Protection ............................................................................................................................... 70

3.4.37 ―ee‖ Drive Memory Chip Error ...................................................................................................................................... 71

3.4.38 ―c4‖ ODU Jumper Cap Error ........................................................................................................................................ 72

3.4.39 ―EL‖ Emergency Stop (Fire Alarm) .............................................................................................................................. 73

3.5 Failures Not Caused by Errors ......................................................................................................................................... 73

4. MAINTENANCE ..................................................................................................................................................75

4.1 System Diagram .............................................................................................................................................................. 75

4.2 Connection Pipe Vacuum Pumping .................................................................................................................................. 75

4.3 Refrigerant Charging ....................................................................................................................................................... 76

4.4 Maintenance of Major Components ................................................................................................................................ 78

4.5 Removal of Major Components....................................................................................................................................... 78

4.5.1 Removal of ODU Major Components ........................................................................................................................... 78

4.5.2 Removal of IDU Major Components ........................................................................................................................... 114

4.6 Explosive View and Lists of Parts ................................................................................................................................... 125

4.6.1 ODU Explosive View and Lists of Parts ...................................................................................................................... 125

4.6.2 IDU Explosive View and Lists of Parts ........................................................................................................................ 146

APPENDICES ........................................................................................................................................................ 180

1 Resistance/temperature lists of temperature sensors ........................................................................................................ 180

1.1 Voltage list of 15 kΩ temperature sensors (including ODU and IDU temperature sensors) .................................. 180

1.2 Voltage list of 20 kΩ pipeline temperature sensors (including temperature sensors for defroster, IDU and ODU

pipes) ......................................................................................................................................................................................... 182

1.3 Voltage list of 50 kΩ discharge temperature sensors (including discharge air temperature sensor) ................... 185

2. Temperature/Pressure List of Refrigerant ......................................................................................................................... 187

3. Refrigerant Notice/Concentration ....................................................................................................................................188

4. Operation Tools ............................................................................................................................................................... 189

GREE U-Match 5 SERIES UNIT SERVICE MANUAL

1

1. Safety Notice on Maintenance

PROHIBITED:

1. Do not pierce or burn.

2. Please note that refrigerant may be odorless.

3. The appliance shall be stored in a room without continuously operating ignition sources (For example: open

flames, an operating gas appliance or an operating electric heater).

4. Indoor unit adopts special joints that can’t be detached. The installation method is the same with the

common joints. However, because the joint can’t be detached, if it is badly connected and causes leakage,

it needs to be cut and replaced by a new one through welding.

5. Using unsuitable parts or tools may lead to electric shock or fire hazard.

6. If refrigerant leaks during maintenance, please ventilate the room immediately. Heavy leakage may lead to

breathing difficulty, severe injury or death.

7. Disconnect power before disassembling the appliance for maintenance.

8. The appliance should be maintained and cared by authorized technical personnel with necessary

qualifications.

WARNING:

1. If the working place is more than 2m's high, please wear a safety helmet, gloves and a safety belt.

2. Never mix any other substances except the specified refrigerant into the refrigerant circuit.

3. When re-locating the appliance, check whether the new location is strong enough to withstand the weight of

the appliance.

4. If there is refrigerant leak, please fix the leak before charging in the refrigerant. After refrigerant is charged,

check for refrigerant leaks. If you cannot spot the leak, stop the maintenance work. Please evacuate the

system and close the service valve to prevent refrigerant leaking into the room.

5. Prepare suitable tools and protectors.

6. If you need to carry out maintenance or check the electric circuit without cutting off the power, please be

careful not to touch the electrical parts.

NOTICE:

1. If the appliance is maintained at a humid place, it should be grounded to avoid electric shock.

2. Never repair the unit with wet hands. Operating the unit with wet hands may lead to electric shock.

3. If the unit is not correctly grounded, please check and fix it.

4. Before cleaning the unit, please disconnect power to prevent the inner fan from starting up and running at

high speed; otherwise personal injury may occur.

5. Measure the insulation resistance after maintenance. The resistance must be 1M or higher. Bad insulation

may lead to electric shock.

6. Welding and cutting work must be done in a well-ventilated place.

7. Gas appliances, heaters and other fire sources should be kept away from the installation and maintenance

site.

8. Maintenance should be done according to suggestions of the manufacturer.

9. Maintenance should be done only after the refrigerant is completely reclaimed from the unit.

GREE U-Match 5 SERIES UNIT SERVICE MANUAL

2

OBSERVED:

1. After the maintenance work is done, check the drainage of indoor unit.

2. Do not tilt the unit, otherwise, water may spill out from the unit and make the floor and furniture wet.

3. Disassembly of the unit, handling of the refrigerant, oil and accessories should all be done according to

applicable local rules and regulations.

2. Safety Notice on Operation

PROHIBITED:

1. Never try to modify the unit, otherwise, it may cause electric shock, overheat or fire hazard.

2. If the power cord or conducting wires are scratched, please replace them.

3. Never use connected or extended power cord or share the power socket with other appliances.

4. Prepare a specialized power circuit for the appliance.

WARNING:

1. If the power plug is dirty, please clean it before inserting it to the power socket. If the power plug is loose,

please tighten it up.

2. Do not damage the power cord. A damaged or refitted power cord may lead to electric shock or fire hazard.

3. Check frequently whether the appliance is in good condition.

NOTICE:

1. After changing the batteries of remote control, please discard them to avoid being swallowed by children.

2. When the unit is working, do not remove the fan cover.

3. Do not use organic solvents to wipe the controller operating panel.

4. Before cleaning the unit, cut off the power supply.

GREE U-Match 5 SERIES UNIT SERVICE MANUAL

3

1. Product Introduction

1.1 Lists of Units

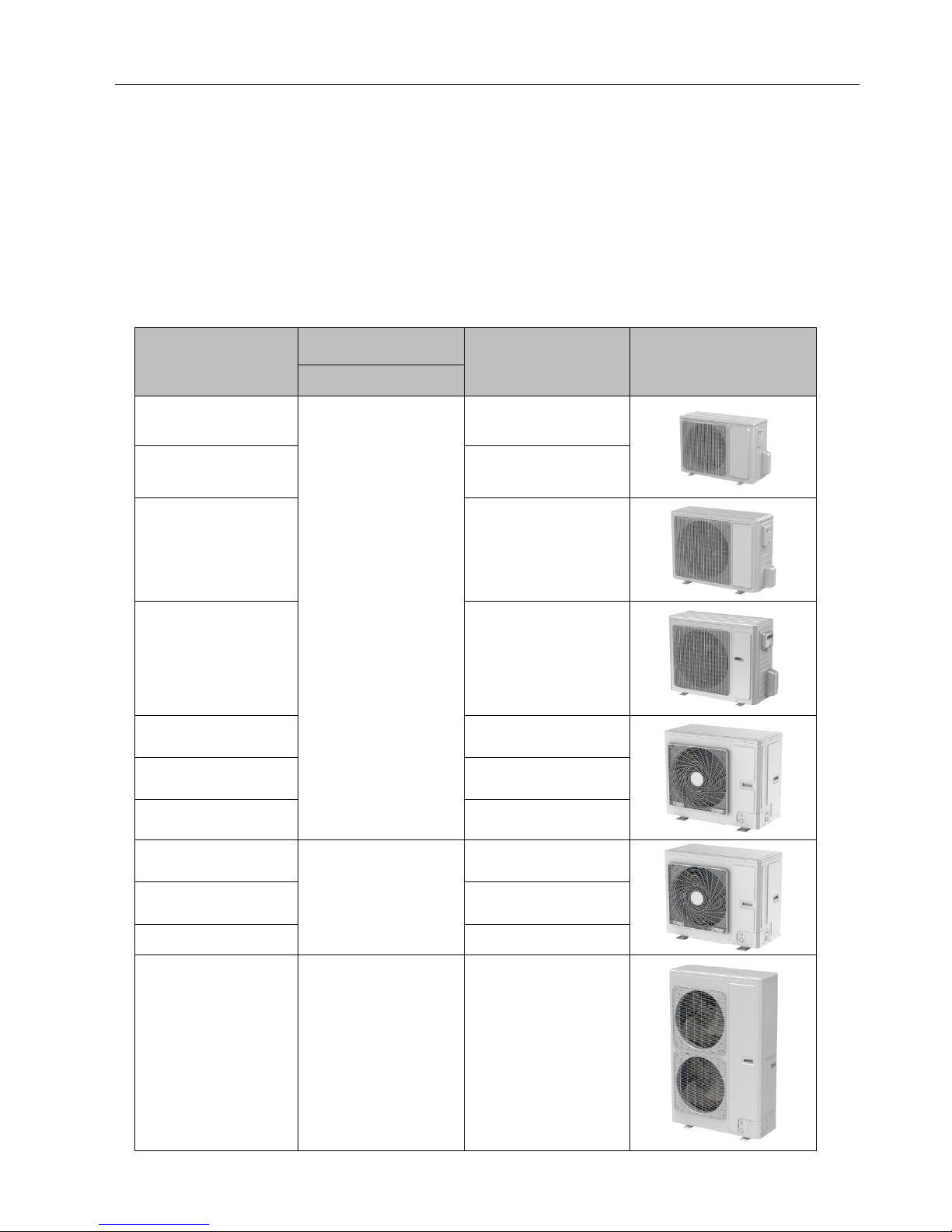

1.1.1 List of ODUs

Model

Power Supply

Finished Product Code

Appearance

V/Ph/Hz

GUD35W/NhA-T

220-240V 1N~50Hz

208-230V 1N~60Hz

CF090W1310

GUD50W/NhA-T

CF090W1210

GUD71W/NhA-T

CF090W1220

GUD85W/NhA-T

CF090W1230

GUD100W/NhA-T

CF090W1240

GUD125W/NhA-T

CF090W1260

GUD140W/NhA-T

CF090W1280

GUD100W/NhA-X

380-415V 3N~50Hz/60Hz

CF090W1250

GUD125W/NhA-X

CF090W1270

GUD140W/NhA-X

CF090W1290

GUD160W/NhA-X

380-415V 3N~50Hz/60Hz

CF090W1300

GREE U-Match 5 SERIES UNIT SERVICE MANUAL

4

Note: 1 Ton =12000Btu/h = 3.517kW

If one outdoor unit is to be connected with multiple indoor units, the indoor units must have the same cooling capacity and be of the

same type.

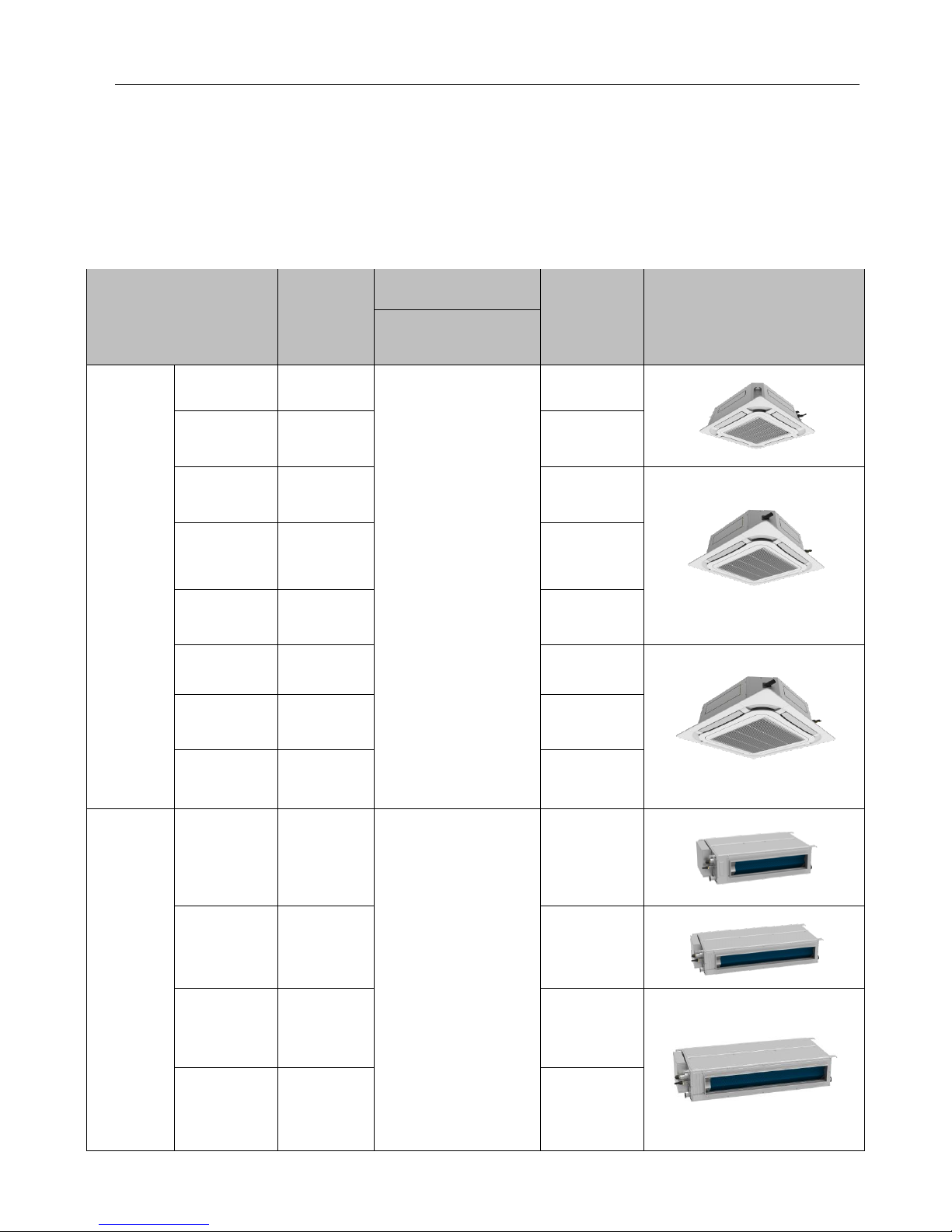

1.1.2 List of IDUs

Model

Rated

Cooling/

Hating

Capacity (kw)

Power Supply

Finished

Product Code

Appearance

V/Ph/Hz

Cassette

Type

GUD35T/A-T

-

220-240V 1N~50Hz

208-230V 1N~60Hz

-

GUD50T/A-T

5.0/5.5

ET010N1540

GUD71T/A-T

7.0/8.0

ET010N1420

GUD85T/A-T

8.5/8.8

ET010N1430

GUD100T/A-T

10.0/12.0

ET010N1440

GUD125T/A-T

12.1/13.5

ET010N1450

GUD140T/A-T

13.4/15.5

ET010N1460

GUD160T/A-T

14.5/17.0

ET010N1470

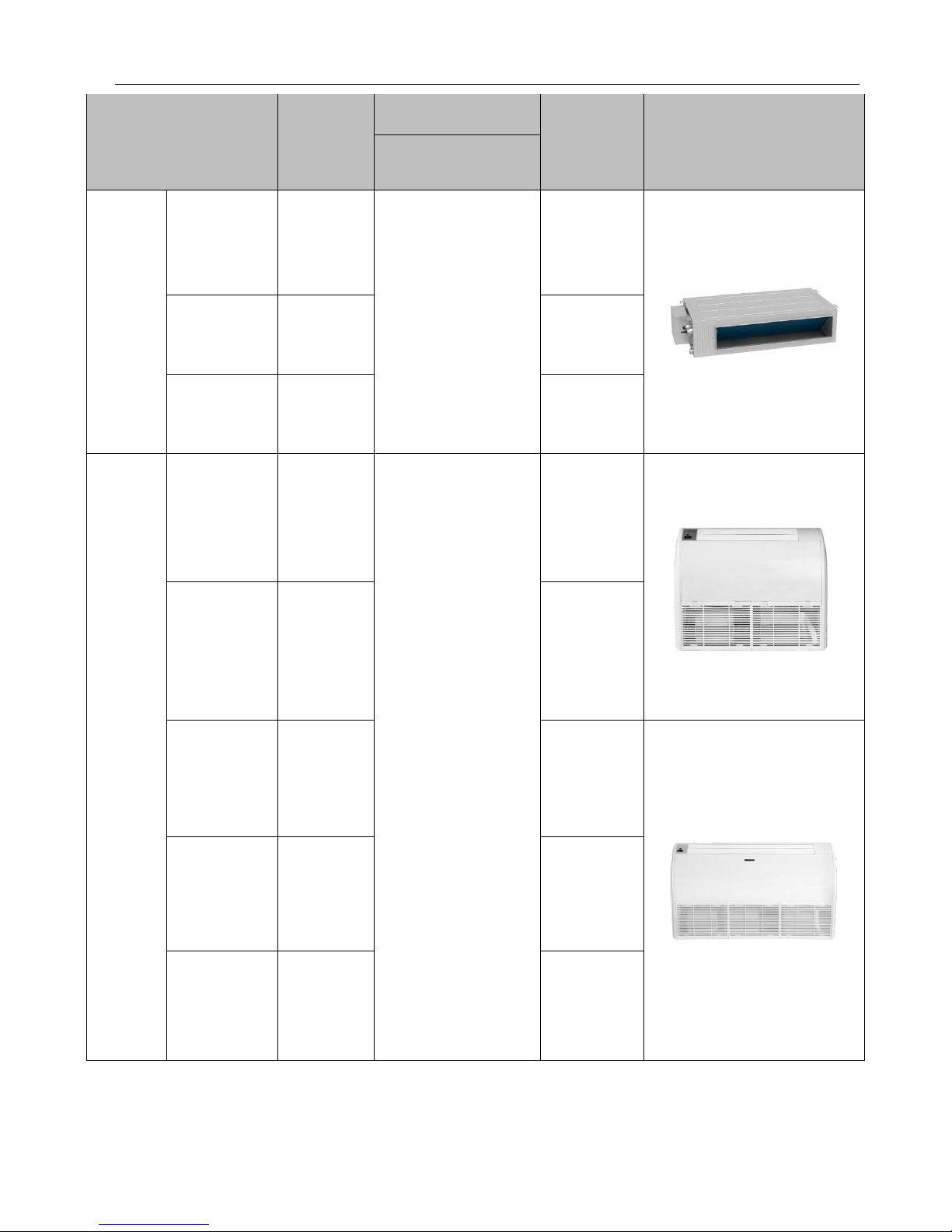

Duct Type

GUD35P/A-T

3.5/4.0

220-240V 1N~50Hz

208-230V 1N~60Hz

CF022N1650

GUD50P/A-T

5.0/5.5

CF022N1630

GUD71P/A-T

7.0/8.0

CF022N1620

GUD85P/A-T

8.5/8.8

CF022N1610

GREE U-Match 5 SERIES UNIT SERVICE MANUAL

5

Model

Rated

Cooling/

Hating

Capacity (kw)

Power Supply

Finished

Product Code

Appearance

V/Ph/Hz

Duct Type

GUD100PH/A-T

10.0/12.0

220-240V 1N~50Hz

208-230V 1N~60Hz

CF022N1590

GUD125PH/A-T

12.1/13.5

CF022N1570

GUD140PH/A-T

13.4/15.5

CF022N1550

GUD160PH/A-T

16.0/17.0

CF022N1530

GUD35PS/A-T

3.5/4.0

CF022N1640

GUD50PS/A-T

5.0/5.5

CF022N1620

GUD71PS/A-T

7.0/8.0

CF022N1660

GUD85PS/A-T

8.5/8.8

CF022N1600

GUD100PHS/A-T

10.0/12.0

CF022N1580

GREE U-Match 5 SERIES UNIT SERVICE MANUAL

6

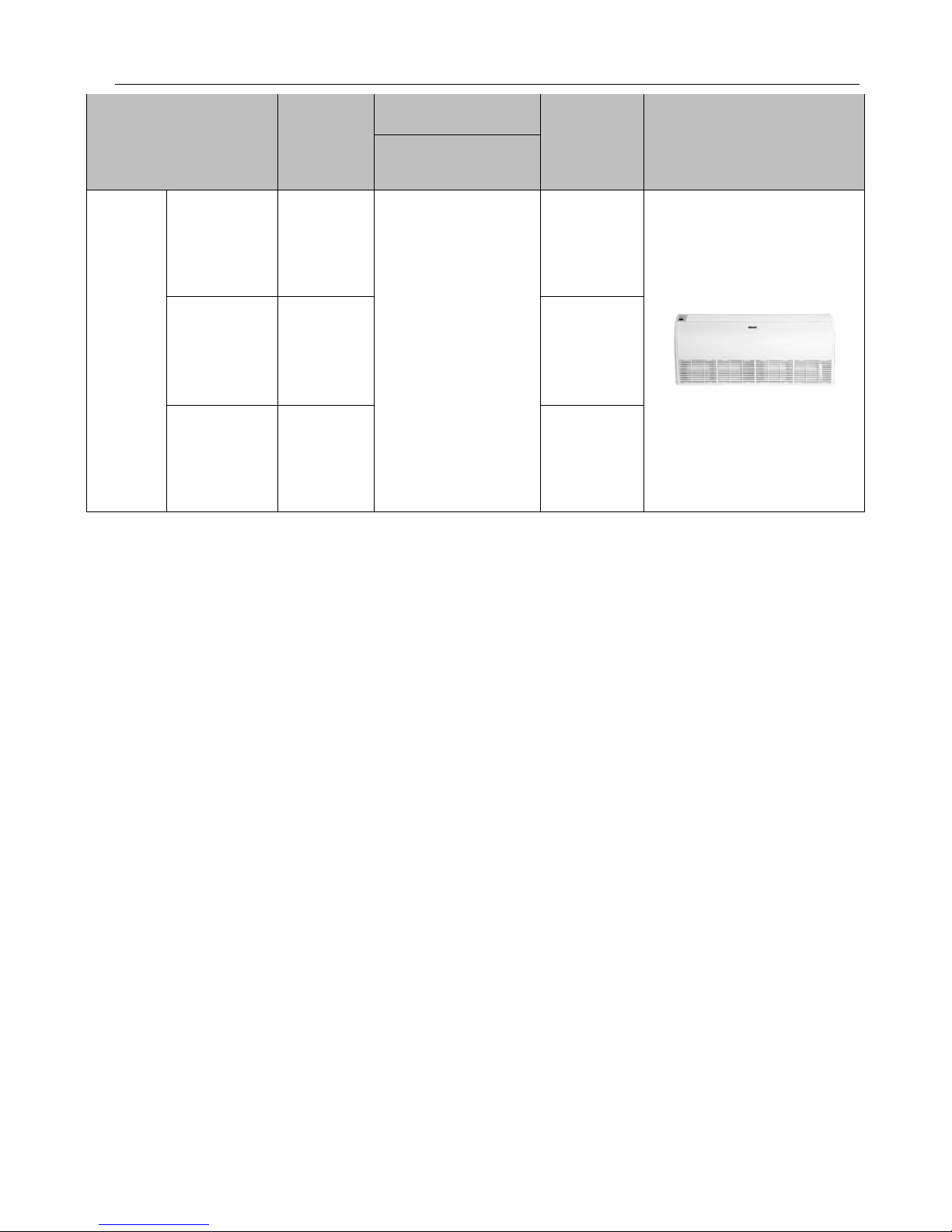

Model

Rated

Cooling/

Hating

Capacity (kw)

Power Supply

Finished

Product Code

Appearance

V/Ph/Hz

Duct Type

GUD125PHS/A

-T

12.1/13.5

220-240V 1N~50Hz

208-230V 1N~60Hz

CF022N1560

GUD140PHS/A

-T

13.4/15.5

CF022N1540

GUD160PHS/A

-T

16.0/17.0

CF022N1520

Floor Ceiling

Type

GUD35ZD/A-T

3.5/4.0

220-240V 1N~50Hz

208-230V 1N~60Hz

ED020N1720

GUD50ZD/A-T

5.0/5.5

ED020N1730

GUD71ZD/A-T

7.0/8.0

ED020N1740

GUD85ZD/A-T

8.5/8.8

ED020N1750

GUD100ZD/A-T

10.0/12.0

ED020N1680

GREE U-Match 5 SERIES UNIT SERVICE MANUAL

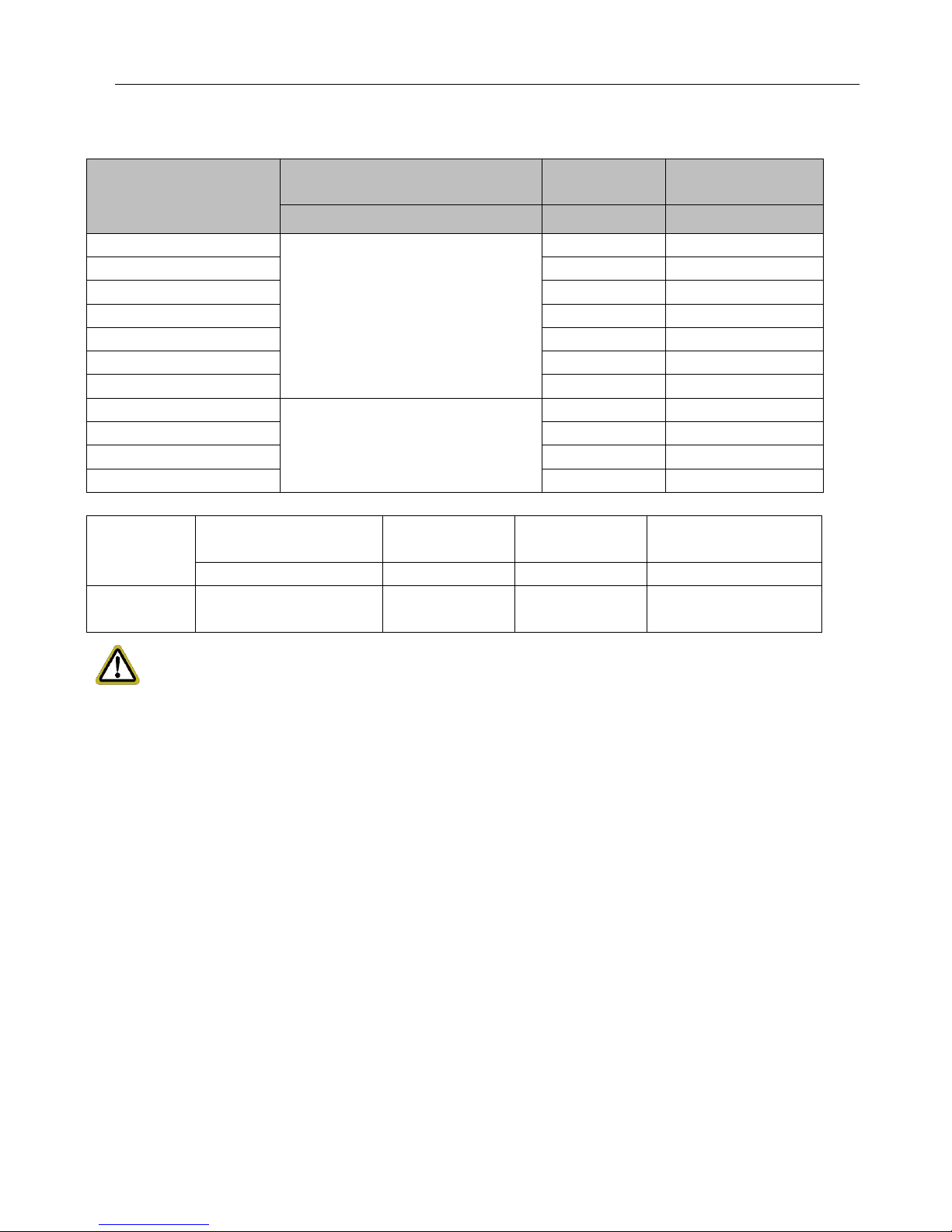

7

Model

Rated

Cooling/

Hating

Capacity (kw)

Power Supply

Finished

Product Code

Appearance

V/Ph/Hz

Floor

Ceiling

Type

GUD125ZD/A-T

12.1/13.5

220-240V 1N~50Hz

208-230V 1N~60Hz

ED020N1690

GUD140ZD/A-T

13.4/15.5

ED020N1700

GUD160ZD/A-T

16.0/17.0

ED020N1710

Note: The outdoor unit is generally suitable to any one of the three types of indoor units with no need of change (limited to cassette

type, duct type and floor ceiling type).

GREE U-Match 5 SERIES UNIT SERVICE MANUAL

8

1.2 Electrical Parameters

Model

Power supply

Circuit breaker

capacity

Min. sectional area of

power cord

V/Ph/Hz

A

mm2

GUD35W/NhA-T

220-240V 1N~50Hz

208-230V 1N~60Hz

16

1.5

GUD50W/NhA-T

16

1.5

GUD71W/NhA-T

20

2.5

GUD85W/NhA-T

25

2.5

GUD100W/NhA-T

32

4.0

GUD125W/NhA-T

32

4.0

GUD140W/NhA-T

40

6.0

GUD100W/NhA-X

380-415V 3N~50Hz/60Hz

16

1.5

GUD125W/NhA-X

16

1.5

GUD140W/NhA-X

16

1.5

GUD160W/NhA-X

16

1.5

Model

Power Supply

Fuse Capacity

Circuit Breaker

Capacity

Min. Sectional Area of

Power Cord

V/Ph/Hz

A A mm2

Indoor unit

220-240V 1N~50Hz

208-230V 1N~60Hz

3.15 6 1.0

NOTICE:

① Fuse is located on the main board.

② Install a circuit breaker at every power terminal near the units (indoor and outdoor units) with at least 3mm contact gap. The

units must be able to be plugged or unplugged.

③ Circuit breaker and power cord specifications listed in the above table are determined based on the maximum power input of

the units.

④ Specifications of power cords listed in the above table are applicable in a working condition where ambient temperature is 40℃

and multi-core copper cable (e.g. YJV copper cable, with insulated PE and PVC sheath) is protected by a conduit, and is

resistant to 90℃ in maximum (See IEC 60364-5-52). If working condition changes, please adjust the specifications according

to national standards.

⑤ Specifications of circuit breaker are based on a working condition where the working temperature is 40℃. If working condition

changes, please adjust the specifications according to national standards.

⑥ Adopt 2pc of 0.75mm² power cords to be the communication cords between indoor and outdoor units. The maximum length is

100m. Please select a proper length according to local conditions. Communication cords must not be twisted together. To be in

compliance with EN 55014, it is necessary to use 8 meters long wire.

⑦ Adopt 2pc of 0.75mm² power cords to be the communication cords between wired control and indoor unit. The maximum

length is 30m. Please select a proper length according to local conditions. Communication cords must not be twisted together.

To be in compliance with EN 55014, it is necessary to use 7.5 meters long wire.

⑧ The wire gauge of communication cord should not be less than 0.75mm². It‘s recommended to use 0.75mm² power cords as

the communication cords.

GREE U-Match 5 SERIES UNIT SERVICE MANUAL

9

2. Control

2.1 Operation Mode

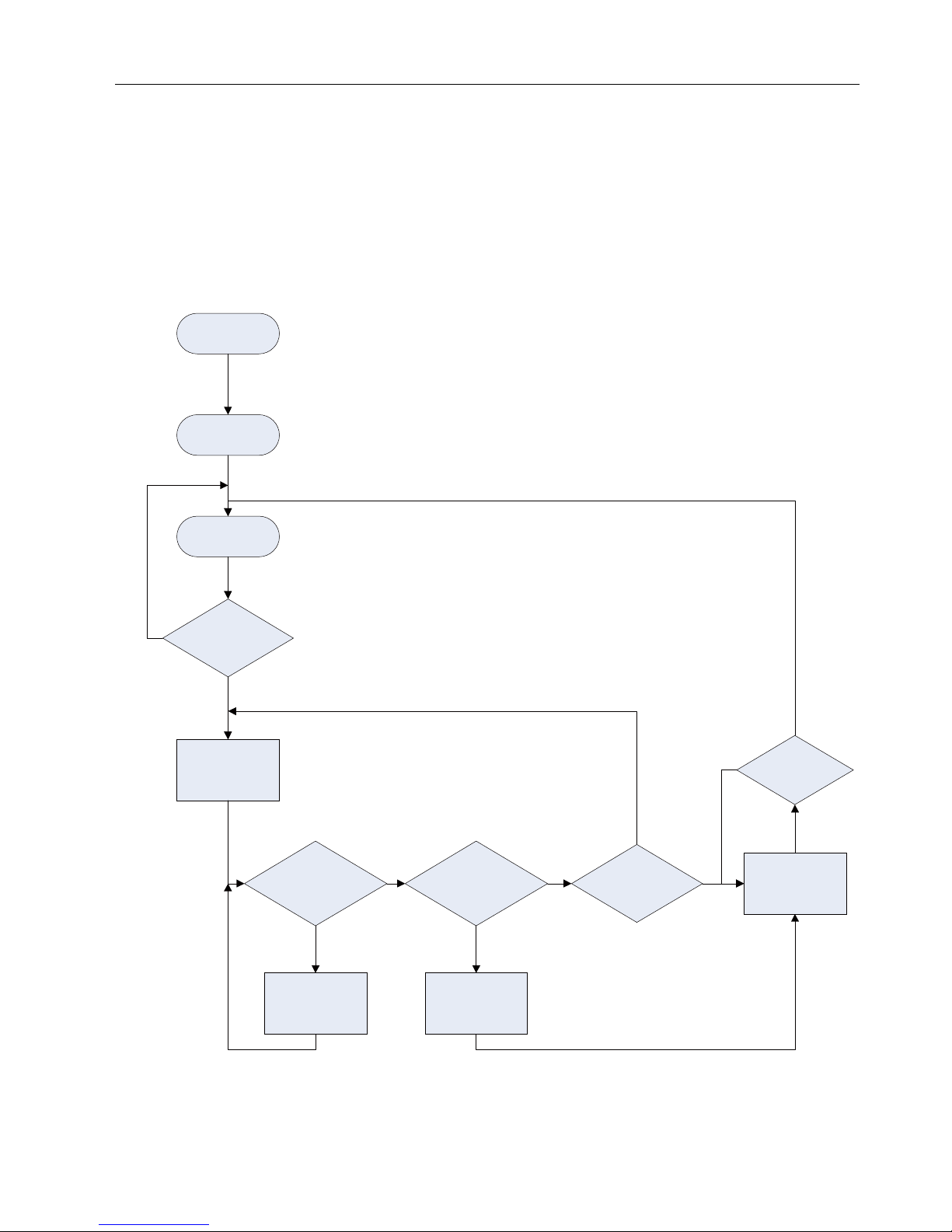

2.1.1 Cooling Mode

Power on

Cooling start

control

Indoor fan run

Satisfying open

Comp .condition

Comp. and

outdoor fan

run

Oil return IN

condition are met

Defrost IN

condition are met

Oil return

operation

Defrosting

operation

Temp of

indoor≤Set

temp

N

Y

N

N

Y Y

N

Comp. and

outdoor fan

stop

Y

Comp. stop

for 3 min

Y

N

GREE U-Match 5 SERIES UNIT SERVICE MANUAL

10

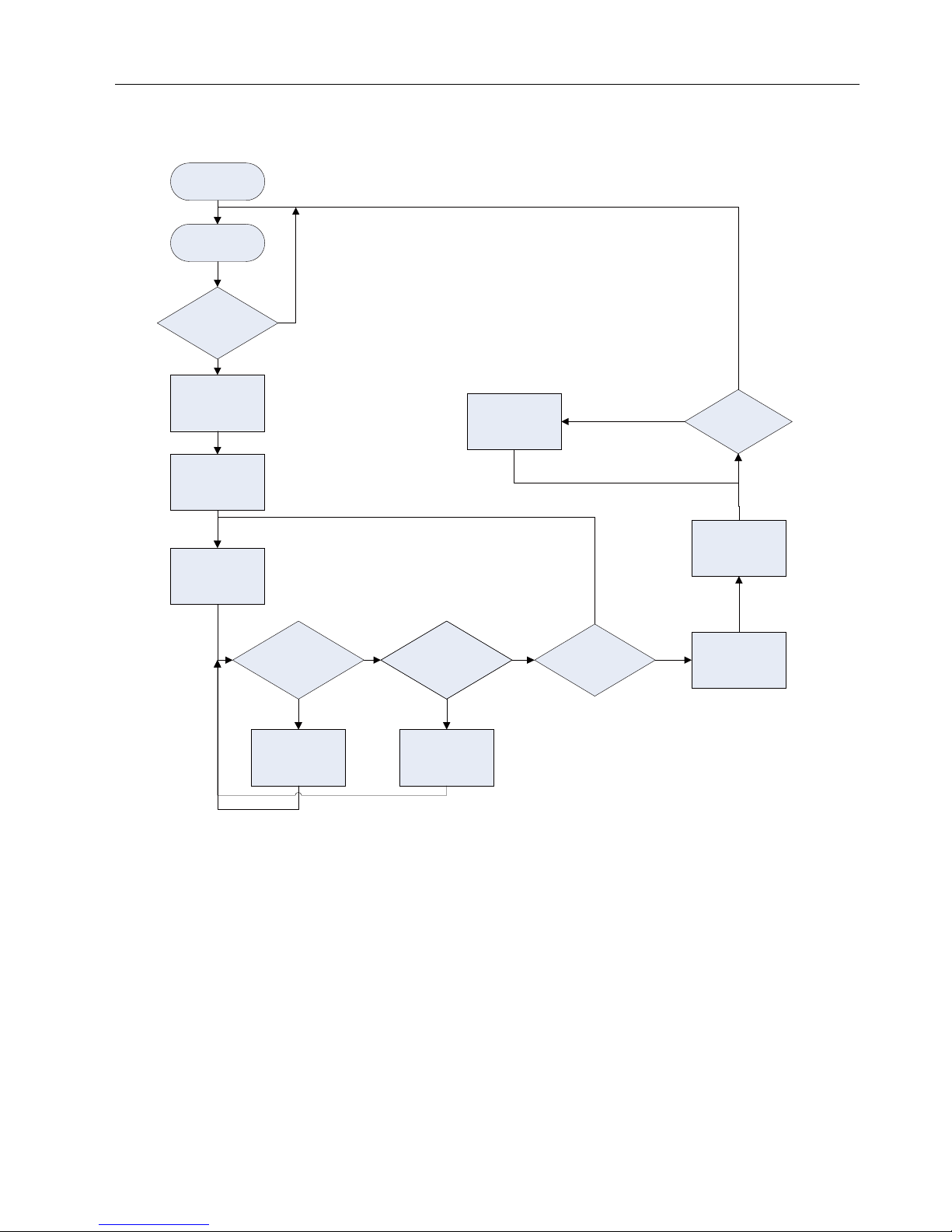

2.1.2 Heating Mode

Power on

Oil return IN

condition are met

Defrost IN

condition are met

Oil return

operation

Defrosting

operation

Temp of

indoor≤Set

temp

Y

N

Comp. and

outdoor fan

stop

Y

Comp. stop

for 3 min

Y

Y

Heating start

control

Satisfying open

Comp.condition

Comp. and

outdoor fan

run

Avoid cool

wind

indoor fan run

N

N

Y

N

N

indoor fan run

for 1 min

Comp. and

outdoor fan

stop

2.2 Control Mode

2.2.1 Based Control

2.2.1.1 Compressor Control

When cooling or heating mode is turned on, indoor fan will run for a while before the compressor starts. Under different modes,

the compressor can only be stopped after running for some time (special cases excluded). This is to protect the compressor from

frequent start or stop. Once the compressor is stopped, it must not be restarted right away. Please wait for a few minutes.

2.2.1.2 EXV Control

When the unit is first started, the electronic expansion valve will reset control. During the process, the expansion valve will

produce rattling sound. When cooling or heating mode is turned on, the valve will be open at a certain step before the compressor

starts.

GREE U-Match 5 SERIES UNIT SERVICE MANUAL

11

2.2.1.3 Outdoor Fan Control

This series air conditioner has two types of outdoor units: one with a single fan and the other with double fans. The outdoor fan

can run at the highest level 10 and the lowest level 1. By controlling the speed of outdoor fan, the unit can achieve cooling at low

temperature and heating at high temperature. In fan mode, outdoor fan will not work.

2.2.1.4 .4-way Valve Control

After heating mode is turned on for a while, 4-way valve will be energized to change the direction of refrigerant flow so that the

system can run in heating and the indoor unit will not blow cold air. Under other modes, the valve will not be energized.

To avoid the 4-way valve from incorrectly changing directions, when the unit stops in heating, due to a temperature point or

other protection reasons, the 4-way valve will continue to function temporarily and lose power after a while.

There must be adequate differential pressure for the 4-way valve to change directions.

2.2.2 Special Control

2.2.2.1 Defrosting Control

ODU defrosting control in heating: Defrosting will start when the temperature sensed by outdoor tube temperature sensor

reaches a preset value. During defrosting, the 4-way valve will switch to the cooling condition, and outdoor and indoor fans will both

stop. When the temperature sensed by outdoor tube temperature sensor reaches the preset value of defrosting stop, system will

quit defrosting. The 4-way valve will switch back to the heating condition, outdoor fan will start working first and indoor fan will

resume its previous fan speed after performing cold air prevention.

2.2.2.2 Oil Return Control

If the unit is running at low frequency for a long time, system will enable oil return control. This is to lead oil in the pipeline back

to the compressor so that the compressor will not be lack of oil. Generally, the oil return takes about 5min. The compressor running

frequency will be raised to the preset oil return frequency.

2.2.2.3 Refrigerant Recovery Control

Enabling method: Remote control and wired control both use the same enabling method. That is, within 5min after power is

connected, start cooling mode (turn on the unit) and set temperature at 16℃, then press “▲, ▼, ▲, ▼, ▲, ▼” (6 times of

pressing) in 5s to enter the refrigerant recovery mode. If it is successfully enabled, the indoor unit will display the corresponding

code E3.

After the refrigerant recovery mode is enabled, if remote control or wired control sends a signal or the refrigerant recovery

mode has been enabled for 10min, system will exit from refrigerant recovery. If outdoor unit is shut down because of malfunction,

refrigerant recovery will be stopped immediately.

Please note that refrigerant recovery mode cannot be enabled under the following conditions:

1. If temperature is shielded remotely, refrigerant recovery mode cannot be enabled. You need to first unlock the remote shield

against temperature.

2. If temperature is higher than 16 degrees under energy-saving mode, refrigerant recovery mode cannot be enabled. You

need to first turn off the energy-saving mode.

2.2.2.4 Forced Operation Control

This control is used to quickly check whether the unit can operate normally after installation. Wired control has to be used to

enable this control. For cassette type unit, you can enable the control through the light board.

Enabling method through the light board of cassette type unit: After the unit is installed and connected to power, press TEST

button on the light board to enter forced operation mode. Short-press TEST button (less than 2s), cooling mode will be activated.

Long-press TEST button (more than 2s), heating mode will be activated.

Enabling method through wired control:

Under power-on status,

Forced cooling: press the “▼” button continuously for 5s to enter the forced test mode;

Forced heating: press the“▲”button continuously for 5s to enter the forced test mode.

GREE U-Match 5 SERIES UNIT SERVICE MANUAL

12

During test mode, press any button to quit the test mode.

Note: Forced test mode can only be enabled when the unit is first turned on and not yet receives any remote control signal or

button control signal.

2.2.3 Protection Control

2.2.3.1 High Pressure Protection Control

System will enable high pressure protection control if the high pressure switch is detected open for continuously a little time.

Under high pressure protection, system will be shut down and display error code E1.

When high pressure protection occurs for the first time, system will restore operation if the high pressure switch is detected to

be reclosed for continuously a little time. When high pressure protection occurs for the second time in a certain time period, system

will not restore operation. You need to manually turn off the unit and clear the error before restarting up the unit. (If high pressure

protection occurs frequently, please send for professional personnel to repair.)

2.2.3.2 Low Pressure Protection Control

System will enable low pressure protection control if the low pressure switch is detected open for continuously a little time.

Under low pressure protection, system will be shut down and display error code E3. When low pressure protection occurs, system

will restore operation if the low pressure switch is detected to be reclosed within a few minutes after shutdown. If low pressure

protection occurs for several times in a period of time, system will not restore operation automatically. You need to manually turn off

the unit before restarting up the unit.

2.2.3.3 High Temperature Prevention Control

Under heating mode, system will enable high temperature prevention control if the temperature sensed by indoor tube

temperature sensor reaches a certain value. When high temperature prevention control is enabled, outdoor fan will slow down.

2.3 Functions

2.3.1 Setting of Filter Cleaning Reminder

When setting washing remind function, the timer area will display 2–bit number that means the pollution level, then press

“▲” and “▼” buttons to select, and press “SWING/ENTER” button to confirm the setting. Conversion relation between the

displayed pollution level and accumulative operating time are as the following list. After setting, when it reaches the washing time,

“CLEAN” icon will flash and remind, if you press “▲” and “▼” buttons to adjust the level, and press “SWING/ENTER”

button, then the accumulative time for filter washing remind will not be reset; if the time after adjustment is larger than the current

accumulative time, then “CLEAN” icon will stop flashing; if the time after adjustment is less than the current accumulative time,

then “CLEAN” icon will continue to flash.

The only method for cancelling the remind function is to press “FUNCTION” button to switch to “CLEAN” icon, and set

the timer area to be “00”, and then press “SWING/ENTER” button, then the accumulative time of filter washing remind is reset.

Pollution

Level

Accumulated

Operating

Time (hour)

Pollution

Level

Accumulated

Operating

Time (hour)

Pollution

Level

Accumulated

Operating

Time (hour)

10

5500

20

1400

30

100

11

6000

21

1800

31

200

12

6500

22

2200

32

300

13

7000

23

2600

33

400

GREE U-Match 5 SERIES UNIT SERVICE MANUAL

13

Pollution

Level

Accumulated

Operating

Time (hour)

Pollution

Level

Accumulated

Operating

Time (hour)

Pollution

Level

Accumulated

Operating

Time (hour)

14

7500

24

3000

34

500

15

8000

25

3400

35

600

16

8500

26

3800

36

700

17

9000

27

4200

37

800

18

9500

28

4600

38

900

19

10000

29

5000

39

1000

2.3.2 Low-temperature Drying Function

Under dry mode, when the setting temperature is 16°C, press “▼” button for twice, the setting temperature becomes

12°C, then the unit enters into low-temperature dry function.

When low-temperature dry function is turned on, directly press “▲” button or switch the mode can quit the function.

2.3.3 Child-lock Function

Without error, under ON or OFF status of unit, press “▲” and “▼” buttons simultaneously for 5 seconds can enter into

child-lock function, the liquid crystal screen will display “ ”; press “▲” and “▼” buttons simultaneously again for 5 seconds

can quit the child-lock function.

Under child-lock status, no response for pressing any buttons. The unit will memorize the child-lock status after power failure

and re-energizing the unit.

2.3.4 Memory Function

Under power-off status, press “MODE” and “▲” button simultaneously for 5 seconds can turn on or turn off memory

function. When memory function is set, “MEMORY”displays.

If memory function has not been set, when the unit is re-energized after power failure, the unit is power-off status. If the

memory function is set in wired controller, when the wired controller is re-energized after power failure, it will resume to the operating

status before power failure.

2.3.5 Door Control Function

When door control function is selected, the wired control will work when the room card is inserted and stop working when the

room card is pulled out. When door control function senses the room card is not inserted.

The setting method please refer to Debugging Function (2.3.9).

Note:

① . In long-distance monitoring or centralized control, no matter the room card is inserted or not, the ON/OFF of unit can be

controlled. If long-distance monitoring or centralized control information is received when the room card is not inserted.

When the card is reinserted, door control function is judged to be turned on. If long-distance monitoring or centralized

control information is received when the room card is inserted, it will keep the original status.

②. The unit can not be controlled by buttons when the card is not inserted.

GREE U-Match 5 SERIES UNIT SERVICE MANUAL

14

2.3.6 Switch between Fahrenheit and Degree Celsius

Under power-off status, press “MODE” and “▼” buttons simultaneously for 5 seconds, display board will switch between

degree Celsius and Fahrenheit.

2.3.7 Inquiry of Ambient Temperature

Under power-off or power-on status, press and hold “SWING/ENTER” button for 5 seconds to enter into ambient temperature

inquiry interface, then timer area displays the ambient temperature type 01 or 02, and ambient temperature area displays the

corresponding ambient temperature of corresponding type. In which, 01 refers to outdoor ambient temperature, 02 refers to indoor

ambient temperature. Press “MODE” button can switch between type 01 and 02. Press buttons other than “MODE” or when

the unit receives remote control signal, it will quit the inquiry status. If there is no any operation for 20 seconds, it will quit

automatically.

Note:

When the outdoor ambient temperature sensor detects the same temperature for 12 hours, it will shield the display of outdoor

ambient temperature sensor.

2.3.8 Inquiry of Historical Malfunction

Under off or on state of the unit, continuously press Function and ▼ buttons for 5s to view historical malfunction.

In enquiry state, set temperature displaying zone displays “00”. Press ▲ and ▼ buttons to view the 5 malfunctions

happened recently. The timer displaying position displays the specific error code. The 5th displayed malfunction is the last

malfunction.

2.3.9 Debugging Function

Under off state of the unit, press Function and Timer buttons at the same time for 5s to go to the debugging menu. Press Mode

button to adjust the setting items and press ▲ or ▼ button to set the actual value.

2.3.9.1 Setting ambient temperature sensor (dual ambient temperature sensors function)

Under debugging state, press Mode button to adjust to “00” in temperature displaying zone. Timer zone displays setting

state and press ▲ or ▼ button to adjust. There are 3 selections:

(1) The ambient temperature at air return is set as indoor ambient temperature (timer zone displays 01)

(2) The temperature at wired controller is set as indoor ambient temperature (timer zone displays 02)

(3) Select the temperature sensor at air return in cooling, dry and fan mode; select the temperature sensor at wired controller in

heating and auto mode.

2.3.9.2 Displaying setting of freeze protection error code

Under debugging state, press Mode button to adjust to “02” in temperature displaying zone. Timer zone displays setting

state and press ▲ or ▼ button to adjust. There are 2 selections:

(1) Displayed (LCD displays 01)

(2) Not displayed (LCD displays 02)

It is defaulted to be not displayed for export unit and be displayed for domestic unit.

2.3.9.3 Setting refrigerant lacking protection function

Under debugging state, press Mode button to adjust to “04” in temperature displaying zone. Timer zone displays setting

GREE U-Match 5 SERIES UNIT SERVICE MANUAL

15

state and press ▲ or ▼ button to adjust. There are 2 selections:

(1) With refrigerant lacking protection function (LCD displays 01)

(2) Without refrigerant lacking protection function (LCD displays 02)

2.3.9.4 Selecting blowing residual heating of indoor unit

Under debugging state, press Mode button to adjust to “05” in temperature displaying zone. Timer zone displays setting

state and press ▲ or ▼ button to adjust. There are 2 selections:

(1) Mode 1 (LCD displays 00)

(2) Mode 2 (LCD displays 01)

Note: Blowing residual heating of indoor unit

Mode 1: Unit stops when reaching temperature point and indoor fan motor does not stop in cooling mode; after unit stops when

reaching temperature point in heating mode, duct type unit and floor ceiling unit blow residual heat for 60s and then stop indoor unit,

while cassette type unit always operates in low fan speed and blows residual heat for 60s when there is malfunction.

Mode 2: After unit stops when reaching temperature point, the indoor fan motor stops operation with a 10s-delay no matter in

cooling mode or in heating mode.

2.3.9.5 Mode selecting of compressor electric heating belt

Under debugging state, press Mode button to adjust to “06” in temperature displaying zone. Timer zone displays setting

state and press ▲ or ▼ button to adjust. There are 2 selections:

(1) Mode 1 (LCD displays 00)

(2) Mode 2 (LCD displays 01)

Note:

Mode 1: Compressor electric heating belt starts when outdoor ambient temperature is below 35℃ and stops when outdoor

ambient temperature is above 37℃. When outdoor ambient temperature is within 35℃~ 37℃, the belt will keep its previous

operation state.

Mode 1: Compressor electric heating belt starts when outdoor ambient temperature is below -2℃ and stops when outdoor

ambient temperature is above 0℃. When outdoor ambient temperature is within -2℃~0℃, the belt will keep its previous operation

state.

2.3.9.6 Selecting low-power consumption mode

Under debugging state, press Mode button to adjust to “07” in temperature displaying zone. Timer zone displays setting

state and press ▲ or ▼ button to adjust. There are 2 selections:

(1) With low-power consumption mode (LCD displays 00)

(2) Without low-power consumption mode (LCD displays 01)

2.3.9.7 Selecting door control function

Under debugging state, press Mode button to adjust to “08” in temperature displaying zone. Timer zone displays setting

state and press ▲ or ▼ button to adjust. There are 2 selections:

(1) Without door control function (LCD displays 00)

(2) With door control function (LCD displays 01)

2.3.9.8 Selecting long-distance monitoring or centralized controller

Under debugging state, press Mode button to adjust to “10” in temperature displaying zone. Timer zone displays setting

state and press ▲ or ▼ button to adjust. There are 2 selections:

(1) Centralized controller (LCD displays 00)

(2) Long-distance monitoring (LCD displays 01)

2.3.9.9 Selecting fan mode of indoor fan motor

Under debugging state, press Mode button to adjust to “11” in temperature displaying zone. Timer zone displays setting state

and press ▲ or ▼ button to adjust.

a.There are 5 selections for low static pressure duct:

(1) P3 (LCD displays 03)

GREE U-Match 5 SERIES UNIT SERVICE MANUAL

16

(2) P4 (LCD displays 04)

(3) P5 (LCD displays 05)

(4) P6 (LCD displays 06)

(5) P7 (LCD displays 07)

Note: You can select P03, P04, P05, P06, P07 in fan mode of indoor fan motor, which means different fan mode combinations

are corresponding to different static pressure. Ex-factory defaulted mode is P05. You can set the mode through wired controller. S01,

S02, S03„„S12, S13 means the rotation speed of indoor unit is from low to high.

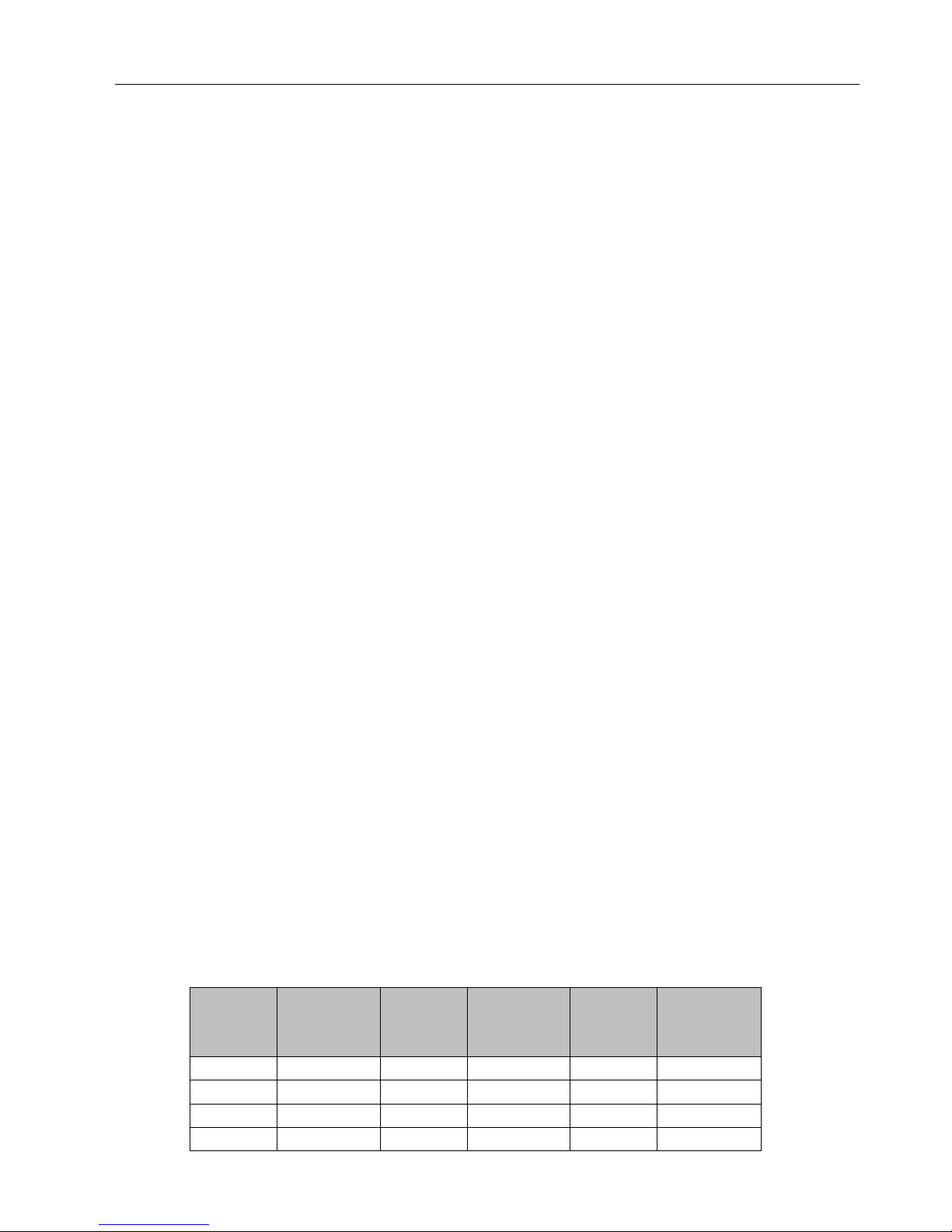

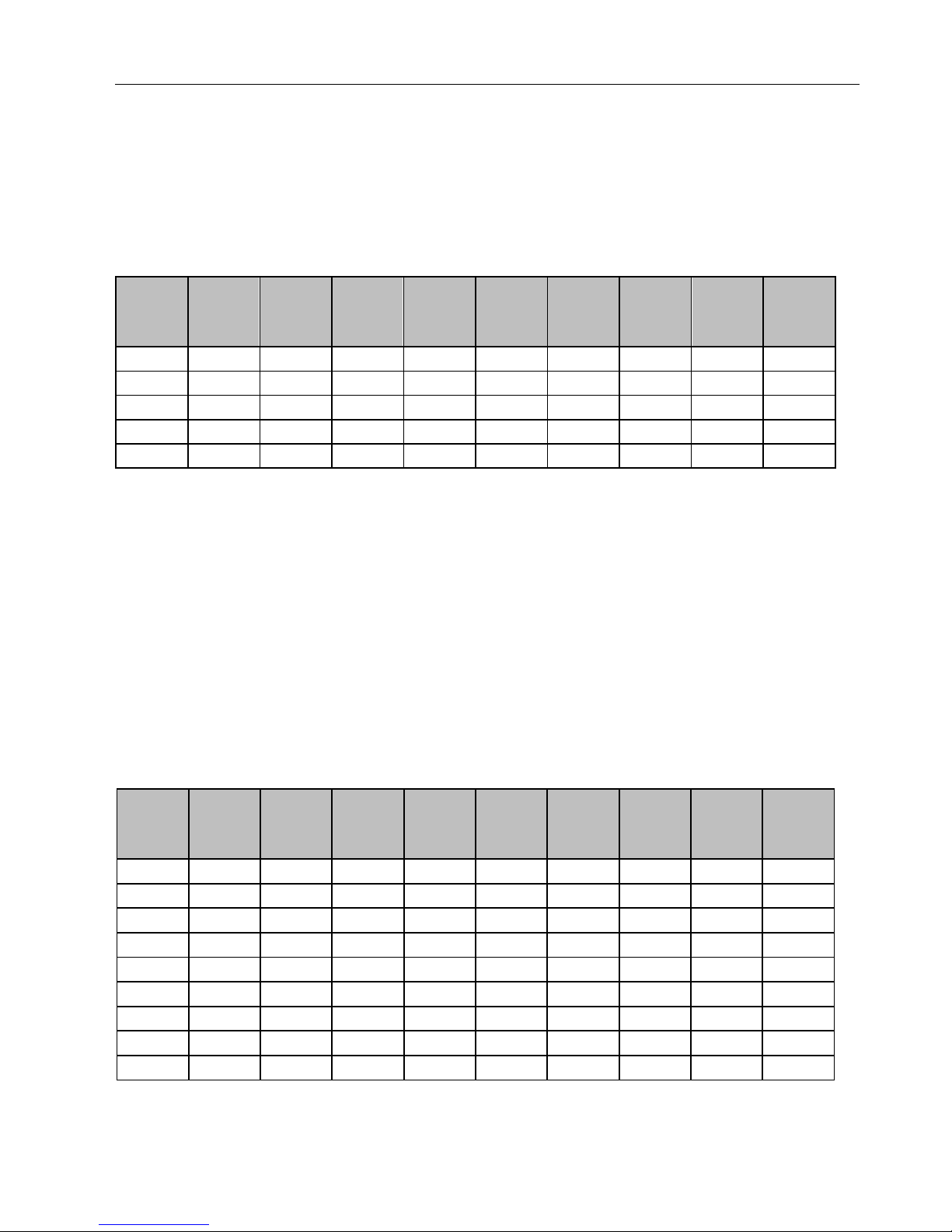

Combination relationship of P03, P04, P05, P06, P07

Static

pressure

selection

Super

high

speed

High

speed

Medium

high

speed

Medium

speed

Medium

low speed

Low

speed

Quiet

R1 speed

Quiet

R2 speed

Quiet

R3 speed

P03

S09

S08

S07

S06

S05

S04

S03

S02

S01

P04

S10

S09

S08

S07

S06

S05

S04

S03

S02

P05

S11

S10

S09

S08

S07

S06

S05

S04

S03

P06

S12

S11

S10

S09

S08

S07

S06

S05

S04

P07

S13

S12

S11

S10

S09

S08

S07

S06

S05

b.There are 9 selections for high static pressure duct:

(1) P1 (LCD displays 01)

(2) P2 (LCD displays 02)

(3) P3 (LCD displays 03)

(4) P4 (LCD displays 04)

(5) P5 (LCD displays 05)

(6) P6 (LCD displays 06)

(7) P7 (LCD displays 07)

(8) P8 (LCD displays 08)

(9) P9 (LCD displays 09)

Note: You can select P01, P02, P03, P04, P05, P06, P07, P08, P09 in fan mode of indoor fan motor, which means different fan

mode combinations are corresponding to different static pressure. Ex-factory defaulted mode is P05. You can set the mode through

wired controller. S01, S02, S03„„S12, S13 means the rotation speed of indoor unit is from low to high.

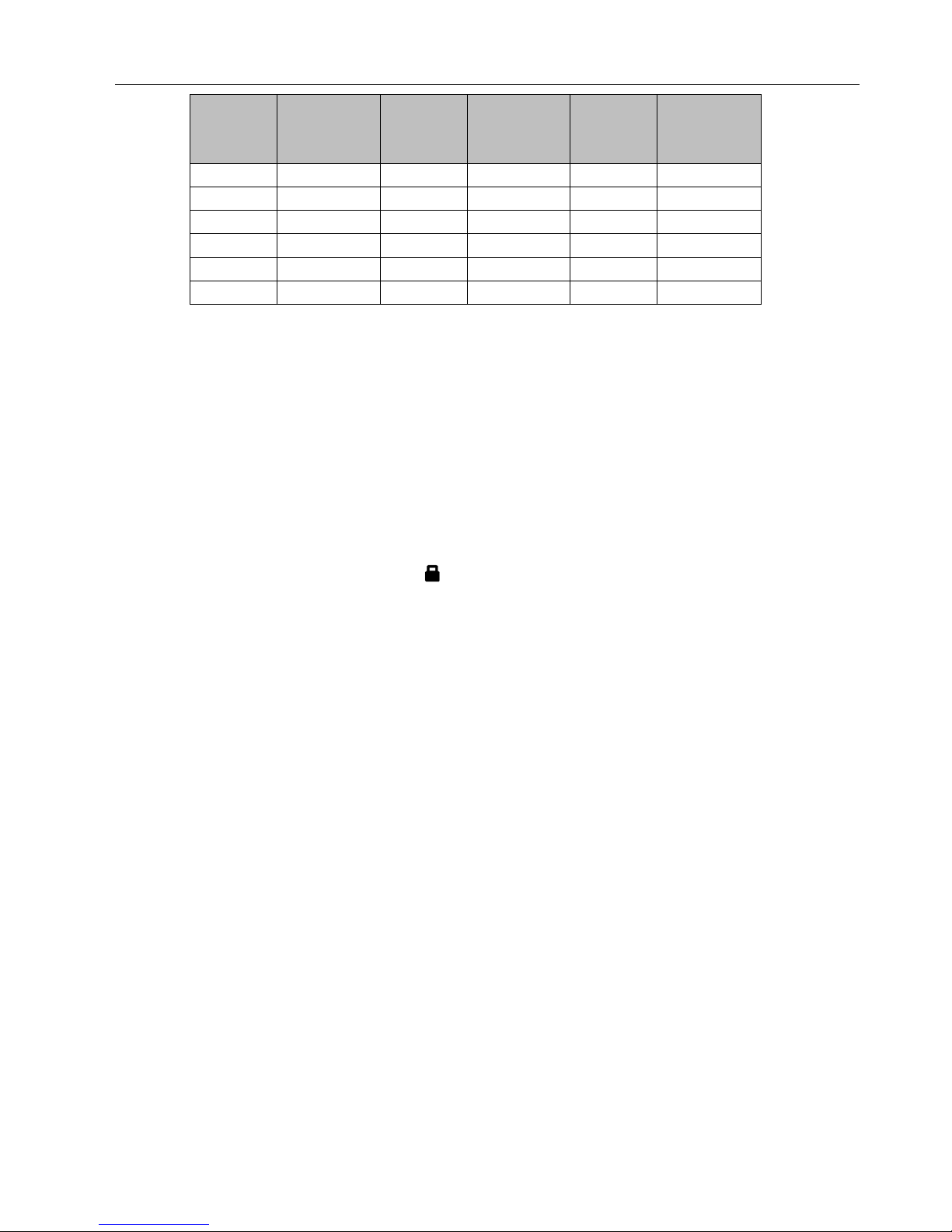

Combination relationship of P01, P02, P03, P04, P05, P06, P07, P08, P09

Static

pressure

selection

Super

high

speed

High

speed

Medium

high

speed

Medium

speed

Medium

low speed

Low

speed

Quiet

R1 speed

Quiet

R2 speed

Quiet

R3 speed

P1

S05

S03

S02

S02

S01

S01

S01

S01

S01

P2

S06

S04

S03

S03

S02

S02

S02

S02

S02

P3

S07

S05

S04

S04

S03

S03

S03

S03

S03

P4

S08

S06

S05

S05

S04

S04

S04

S04

S04

P5

S09

S07

S06

S06

S05

S05

S05

S05

S05

P6

S10

S08

S07

S07

S06

S06

S06

S06

S06

P7

S11

S09

S08

S08

S07

S07

S07

S07

S07

P8

S12

S10

S09

S09

S08

S08

S08

S08

S08

P9

S13

S11

S10

S10

S09

S09

S09

S09

S09

2.3.9.10 Selecting compensation of temperature sensor at air return

Under debugging state, press Mode button to adjust to “12” in temperature displaying zone. Timer zone displays setting

state and press ▲ or ▼ button to adjust. There are 16 selections:

GREE U-Match 5 SERIES UNIT SERVICE MANUAL

17

(1) Compensate 0℃ (LCD displays 00)

(2) Compensate 1℃ (LCD displays 01)

(3) Compensate 2℃ (LCD displays 02)

(4) Compensate 3℃ (LCD displays 03)

(5) Compensate 4℃ (LCD displays 04)

(6) Compensate 5℃ (LCD displays 05)

(7) Compensate 6℃ (LCD displays 06)

(8) Compensate 7℃ (LCD displays 07)

(9) Compensate 8℃ (LCD displays 08)

(10) Compensate 9℃ (LCD displays 09)

(11) Compensate 10℃ (LCD displays 10)

(12) Compensate 11℃ (LCD displays 11)

(13) Compensate 12℃ (LCD displays 12)

(14) Compensate 13℃ (LCD displays 13)

(15) Compensate 14℃ (LCD displays 14)

(16) Compensate 15℃ (LCD displays 15)

Note: Indoor ambient temperature compensation can be set through the wired control (E.g.: If 02 is selected, it indicates the

compensation temperature is 2℃. If the indoor ambient temperature detected by the temperature sensor at air return is 29℃, the

ambient temperature after compensation is 29℃-2℃=27℃).

After finishing setting, press Enter/Cancel button to save and exit setting. After entering this interface, the system will exit this

menu if there is no operation on the button within 20s. Normal off state interface will be displayed and present setting will not be

saved.

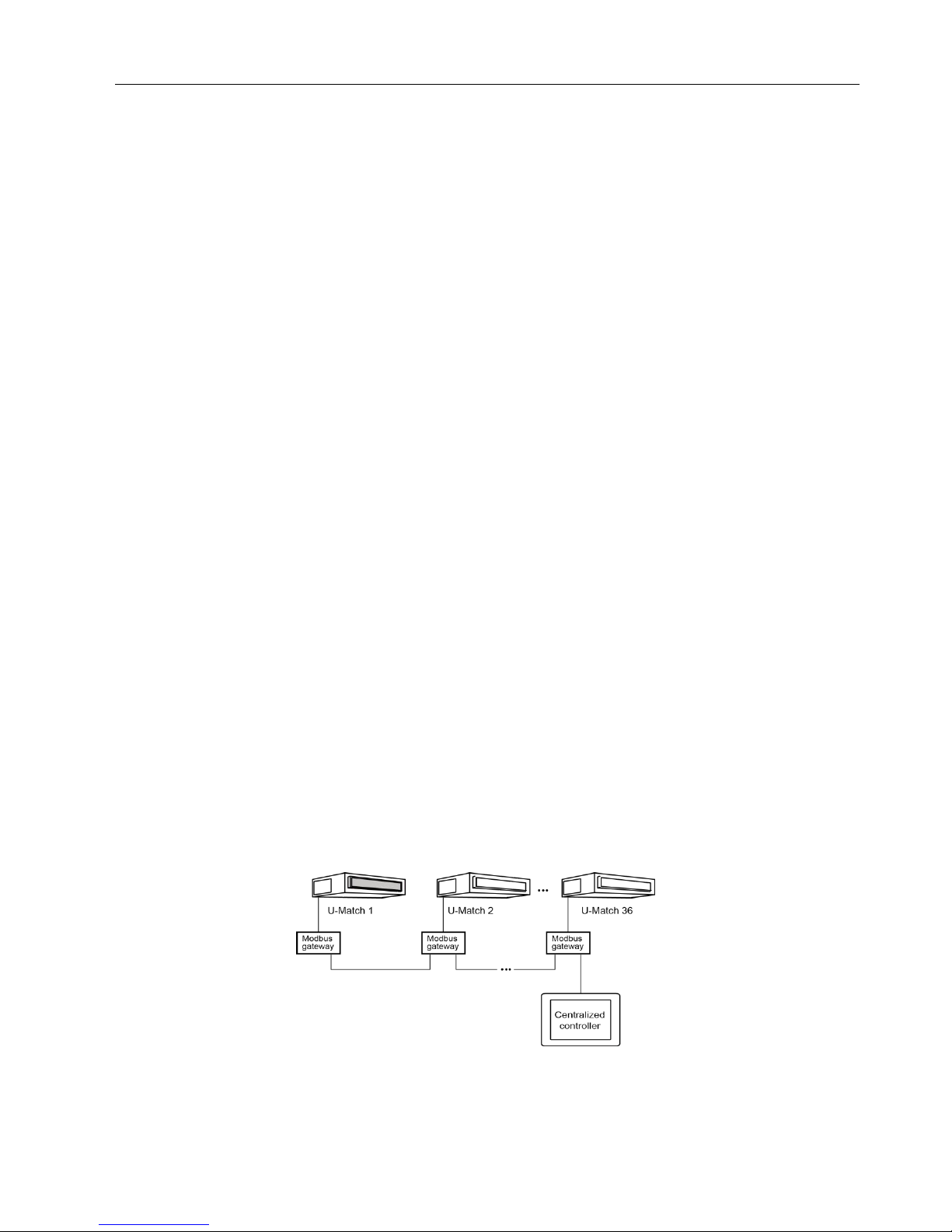

2.3.10 Connect to Interface of Centralized Control

The indoor unit is with the interface of centralized controller. When centralized controller is connected, centralized control of unit

can be realized when the wired controller is not connected;

(1) Interface instruction:

1) The printing of interface on the indoor unit PCB is COM_BMS, before connecting the centralized controller,a gateway model

ME50-00/EG(M) is required , The following figure shows an example;

2) Electrical characteristic: none;

3) Working principle: centralized control the communication of indoor mainboard and realize the unit control;

(2) Function instructions:

In order to achieve this function, set the address mode and address through wired controller. Please refer to Point 3 for the

setting method. The address mode is defaulted to be connecting to centralized controller mode and the defaulted address is 1;

GREE U-Match 5 SERIES UNIT SERVICE MANUAL

18

When the centralized controller is connected, centralized control of the unit can be realized to control unit ON/OFF, operation

mode, set fan speed/temperature and weekly timer.

(3) Setting method:

1) Centralized control for up to 16 indoor units.

Firstly, set the address mode of wired controller into centralized controller address mode. The setting method is:

Under off state of the unit, press Function and Timer buttons at the same time for 5s to go to the debugging menu. Press Mode

button to adjust to ―10‖ in temperature displaying zone. Timer zone displays setting state and press ▲ or ▼ button to adjust. There

are 2 selections:

a. Centralized controller address mode (LCD displays 00)

b. Long-distance control address mode (LCD displays 01)

Choose the first selection and then press Enter/Cancel button to save and exit setting. Now, the address of wired controller is

set to match the address of centralized controller. The unit will memorize this setting status. The setting value will be memorized

after power failure.

Address setting of each unit: when the address mode is set to be centralized controller address mode. The address setting

value range is 01~16. The setting method is:

Under off state of the unit, press Function and Mode buttons at the same time for 5s to enter setting interface of wired controller

address. LCD displays address sequence. Press ▲ or ▼ button to adjust the address sequence and then press Enter/Cancel

button to confirm. The setting value will be memorized after power failure.

When the address is set, the wired controller can be removed and connect the centralized controller to the indoor mainboard.

Then connect the required units to realize centralized control of these units;

Note:

① When centralized controller is to be connected, set the address mode into centralized controller address mode through wired

controller. Long-distance control address mode can not be set;

② The unit addresses in the same network must be different, otherwise, communication malfunction will occur and the unit can not

work normally;

③ When centralized controller is to be connected, the unit address range is 1-16. Only 16 sets of unit in maximum can be

connected

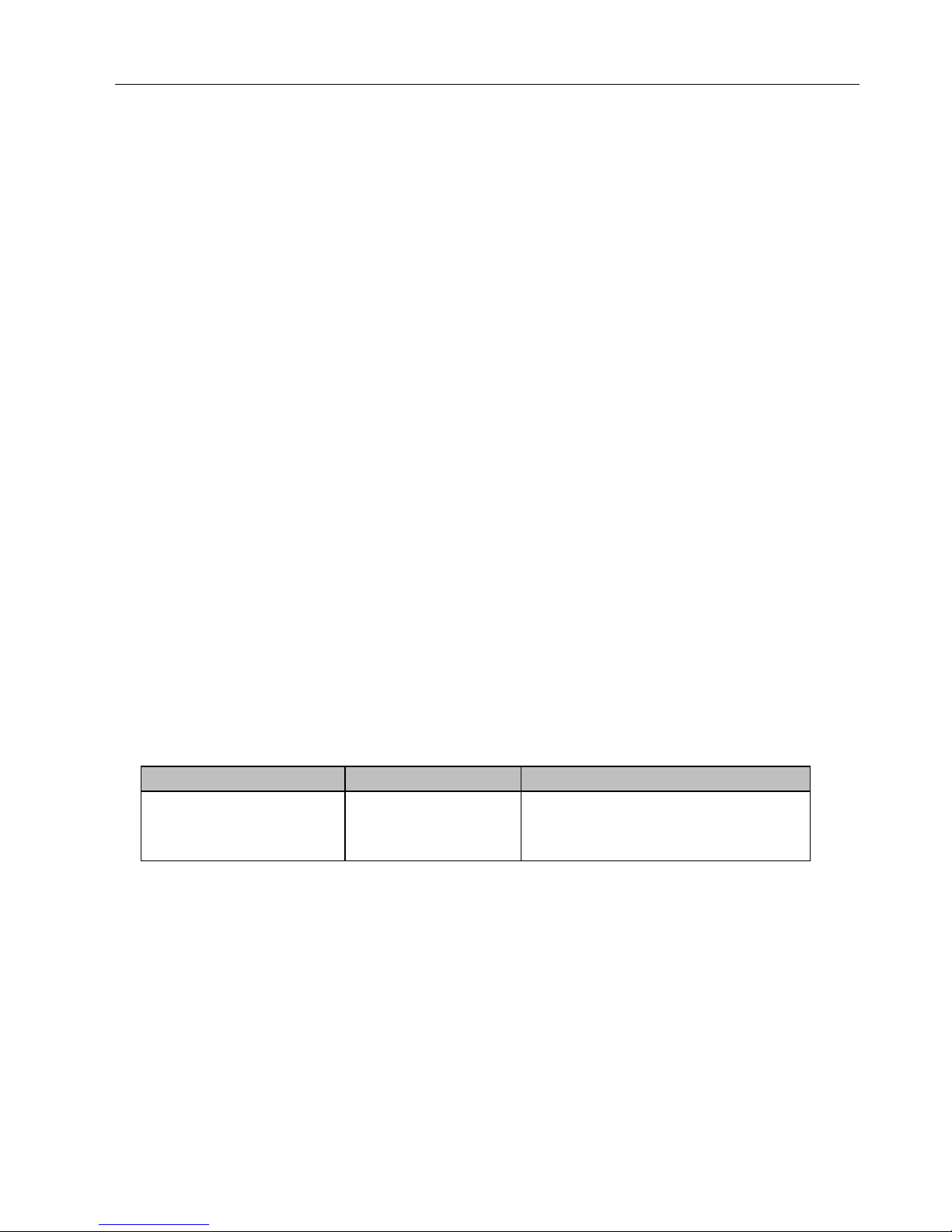

④ The code and model of wired controller is as below:

Name

Product code

Remark

Centralized controller

CE50-24/E

MC207025

Only 16 sets of unit in

maximum can be connected to this controller

2) Centralized control for up to 36 indoor units.

Firstly, set the address mode of wired controller into Long-distance control address mode. The setting method is:

Under off state of the unit, press Function and Timer buttons at the same time for 5s to go to the debugging menu. Press Mode

button to adjust to ―10‖ in temperature displaying zone. Timer zone displays setting state and press ▲ or ▼ button to adjust. There

are 2 selections:

a. Centralized controller address mode (LCD displays 00)

b. Long-distance control address mode (LCD displays 01)

Choose the second selection and then press Swing/Enter button to save and exit setting. Now, the address of wired controller is

set to match the address of centralized controller. The unit will memorize this setting status. The setting value will be memorized

after power failure.

Address setting of each unit: when the address mode is set to be Long-distance control address mode. The address setting

value range is 01~36. The setting method is:

Under off state of the unit, press Function and Mode buttons at the same time for 5s to enter setting interface of wired controller

GREE U-Match 5 SERIES UNIT SERVICE MANUAL

19

address. LCD displays address sequence. Press ▲ or ▼ button to adjust the address sequence and then press Swing/Enter button

to confirm. The setting value will be memorized after power failure.

When the address is set, the wired controller can be removed and connect the centralized controller to the indoor mainboard.

Then connect the required units to realize centralized control of these units;

Note:

① The unit addresses in the same network must be different, otherwise, communication malfunction will occur and the unit can

not work normally;

② When centralized controller is to be connected, the unit address range is 1-36. Only 36 sets of unit in maximum can be

connected

③ The code and model of wired controller is as below:

Name

Product code Remark

Centralized controller

CE52-24/F(C)

MC207052

Only 36 sets of unit in

maximum can be connected to this controller

3. Troubleshooting

3.1 Wiring Diagrams

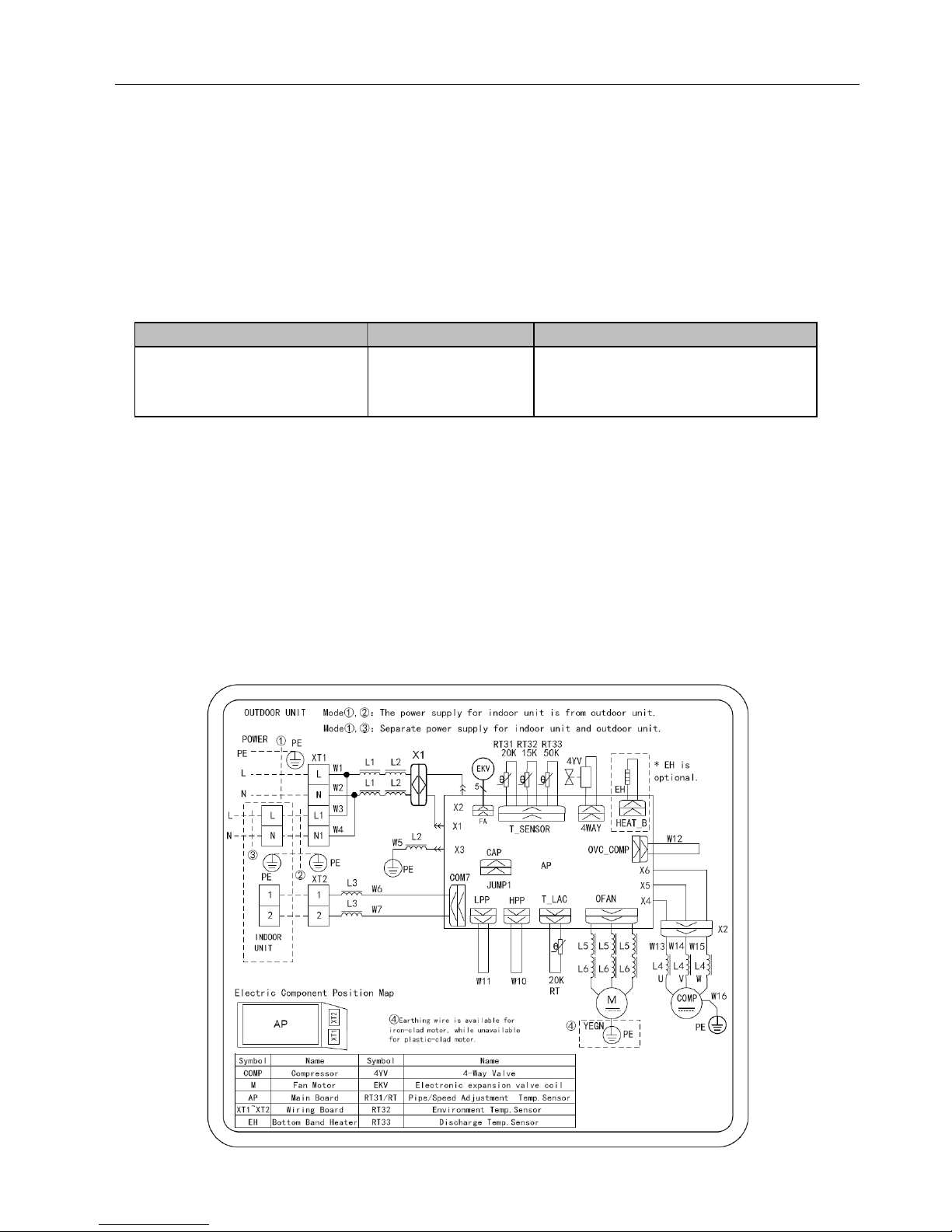

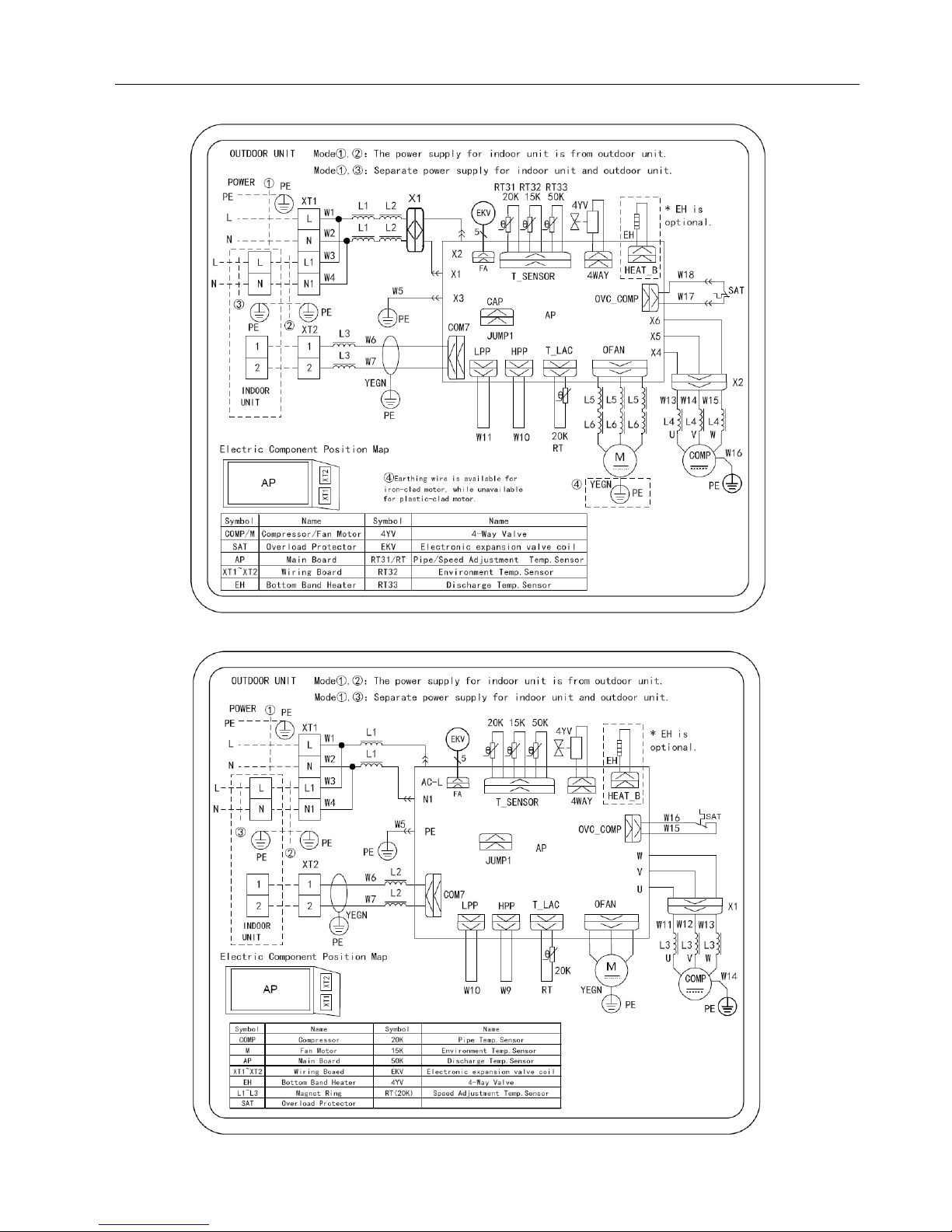

3.1.1 Wiring Diagrams of ODUs

Model:

GUD35W/NhA-T,

GREE U-Match 5 SERIES UNIT SERVICE MANUAL

20

Model:

GUD50W/NhA-T

Model: GUD71W/NhA-T, GUD85W/NhA-T

GREE U-Match 5 SERIES UNIT SERVICE MANUAL

21

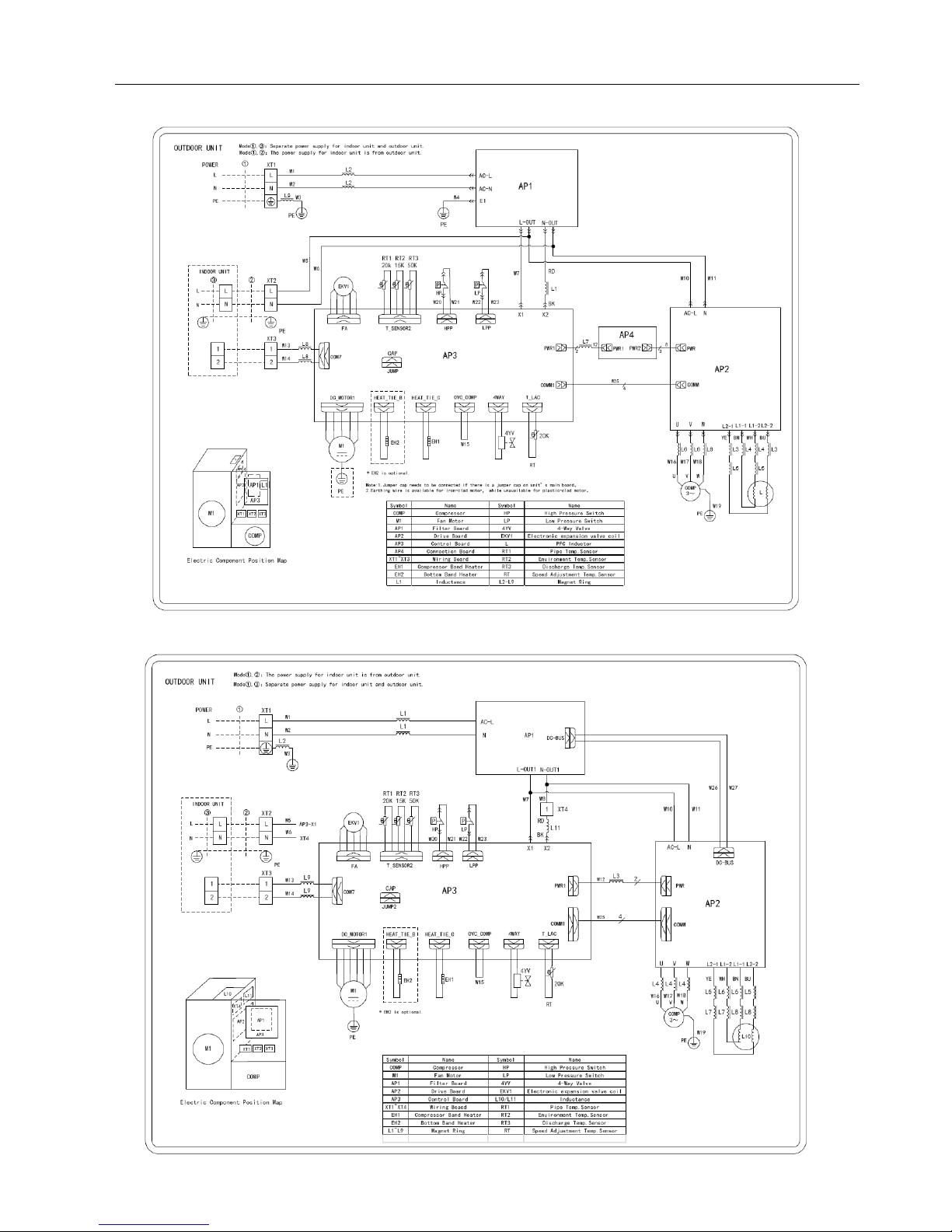

Model:GUD100W/NhA-T

Model:GUD125W/NhA-T, GUD140W/NhA-T

GREE U-Match 5 SERIES UNIT SERVICE MANUAL

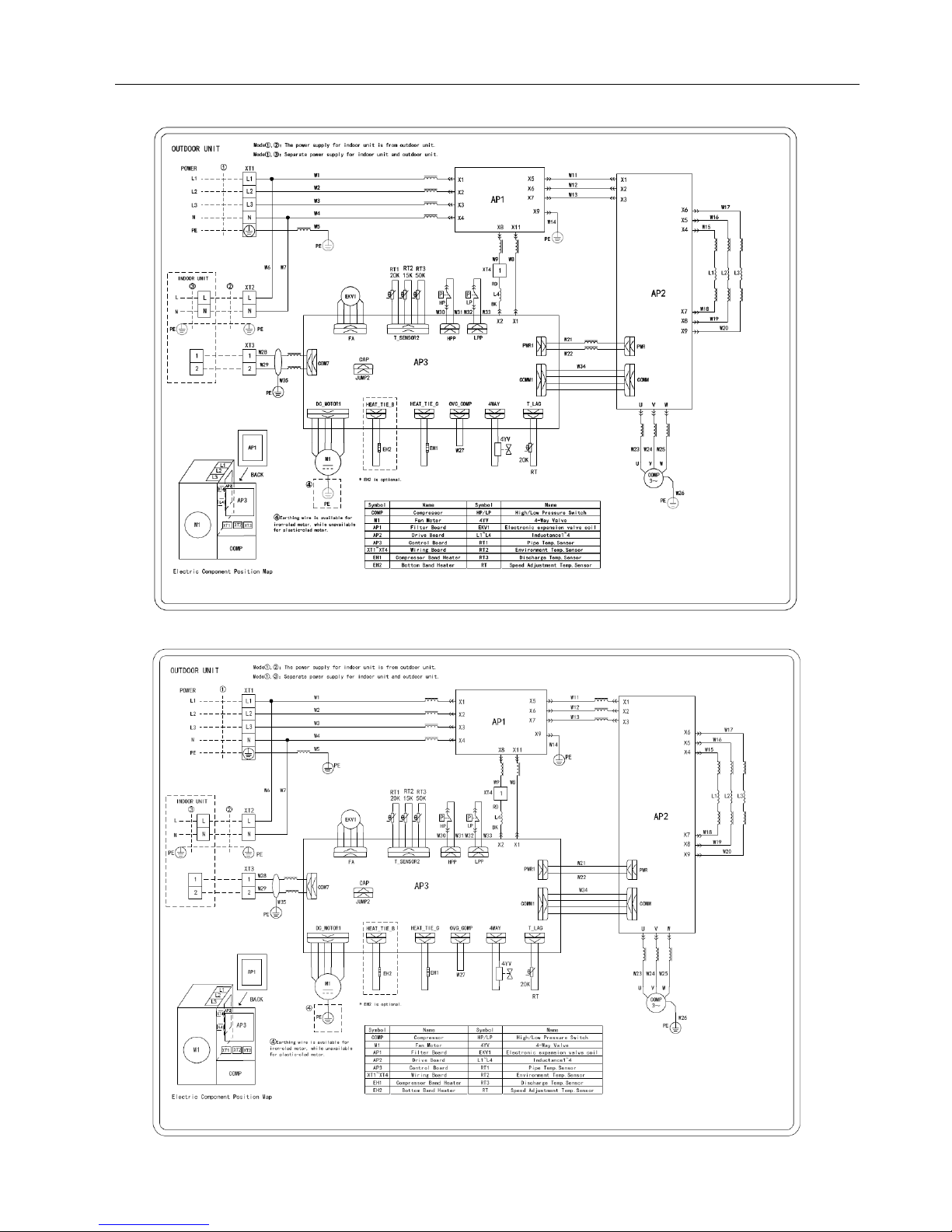

22

Model:GUD100W/NhA-X

GUD125W/NhA-X,GUD140W/NhA-X

GREE U-Match 5 SERIES UNIT SERVICE MANUAL

23

Model:GUD160W/NhA-X

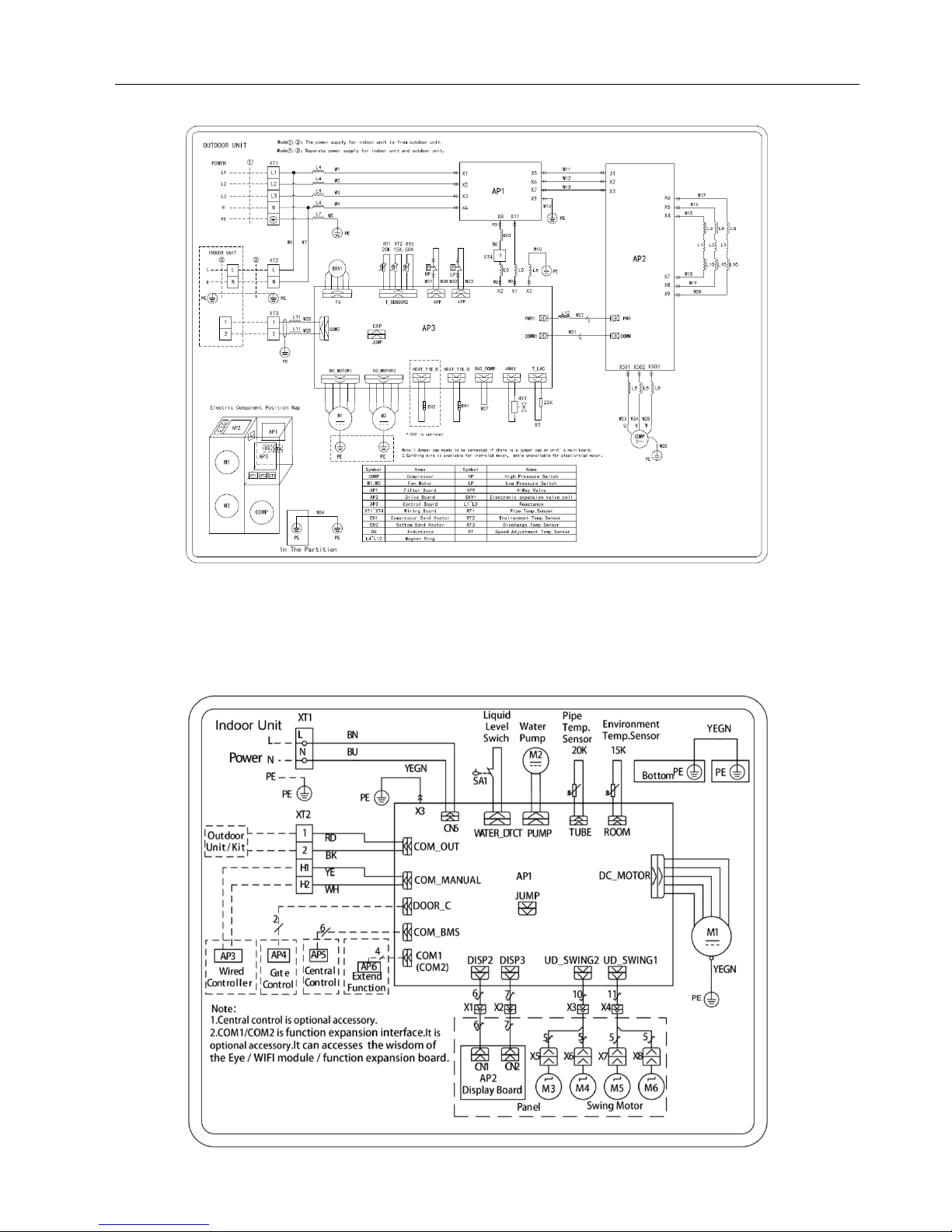

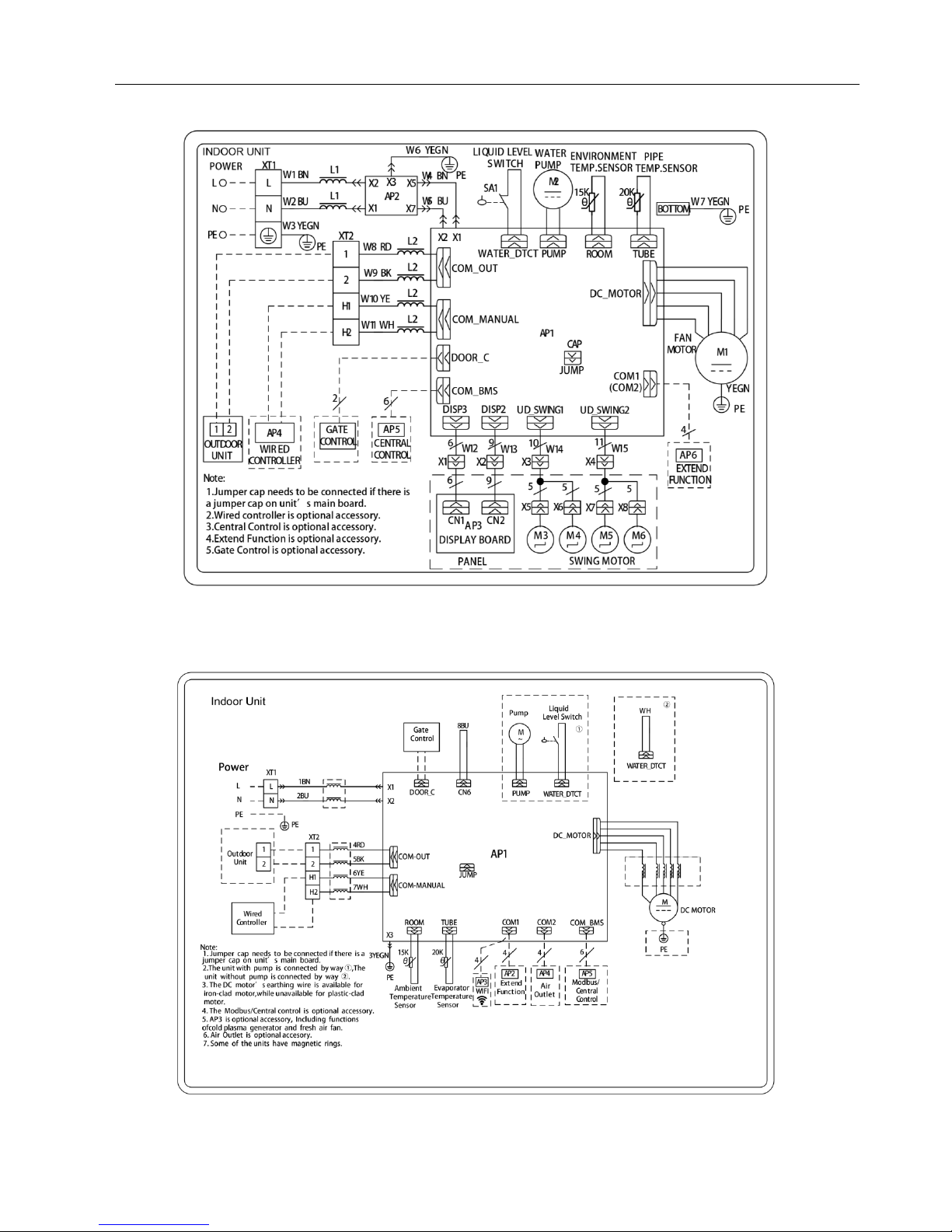

3.1.2 Wiring Diagrams of IDUs

Model: GUD35T/A-T, GUD50T/A-T

GREE U-Match 5 SERIES UNIT SERVICE MANUAL

24

Model: GUD71T/A-T, GUD85T/A-T, GUD100T/A-T, GUD125T/A-T, GUD140T/A-T, GUD160T/A-T

Duct Type

Model: GUD35P/A-T, GUD50P/A-T, GUD71P/A-T, GUD85P/A-T,

GUD35PS/A-T, GUD50PS/A-T, GUD71PS/A-T, GUD85PS/A-T

GREE U-Match 5 SERIES UNIT SERVICE MANUAL

25

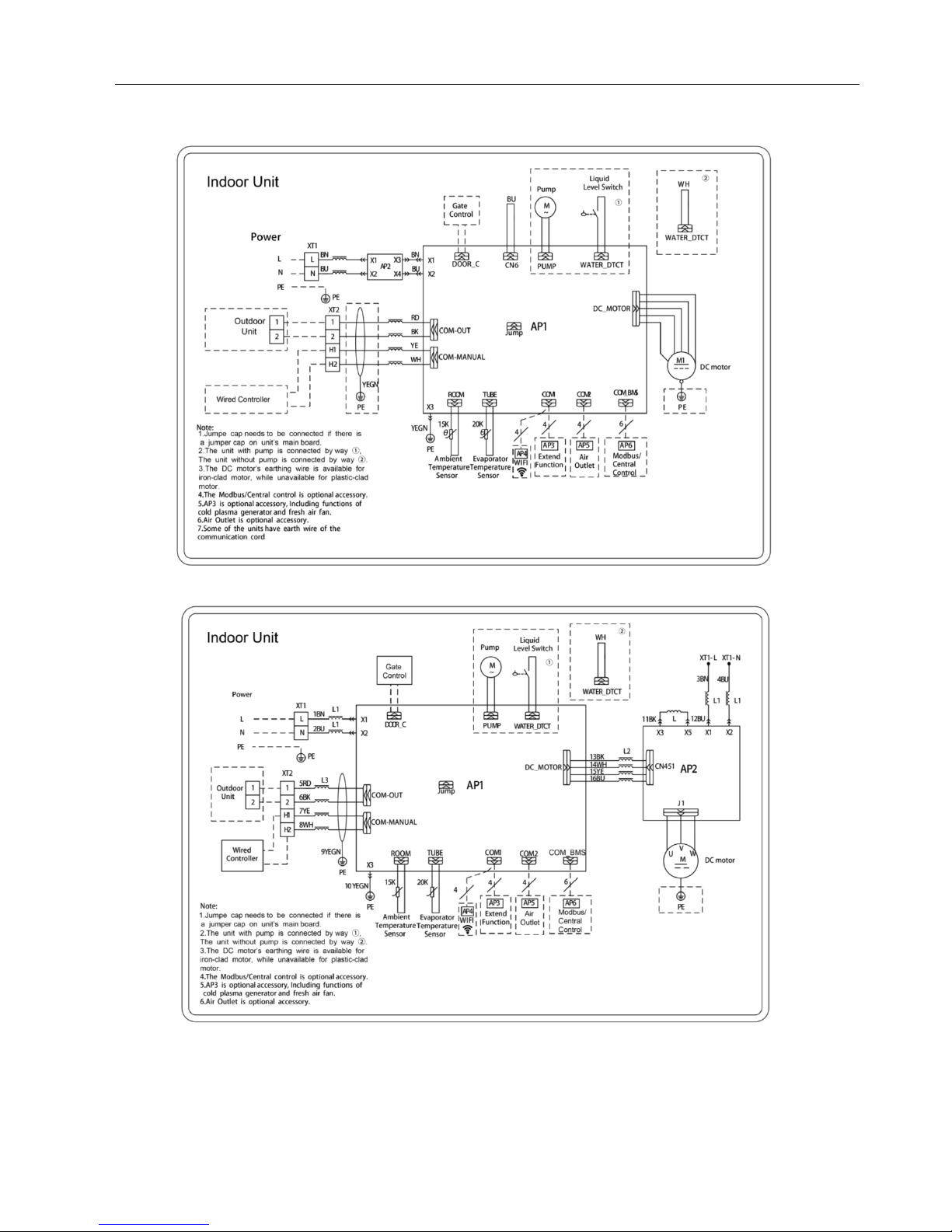

Model: GUD100PH/A-T, GUD125PH/A-T, GUD140PH/A-T

GUD100PHS/A-T, GUD125PHS/A-T, GUD140PHS/A-T

Model: GUD160PH/A-T, GUD160PHS/A-T

Loading...

Loading...